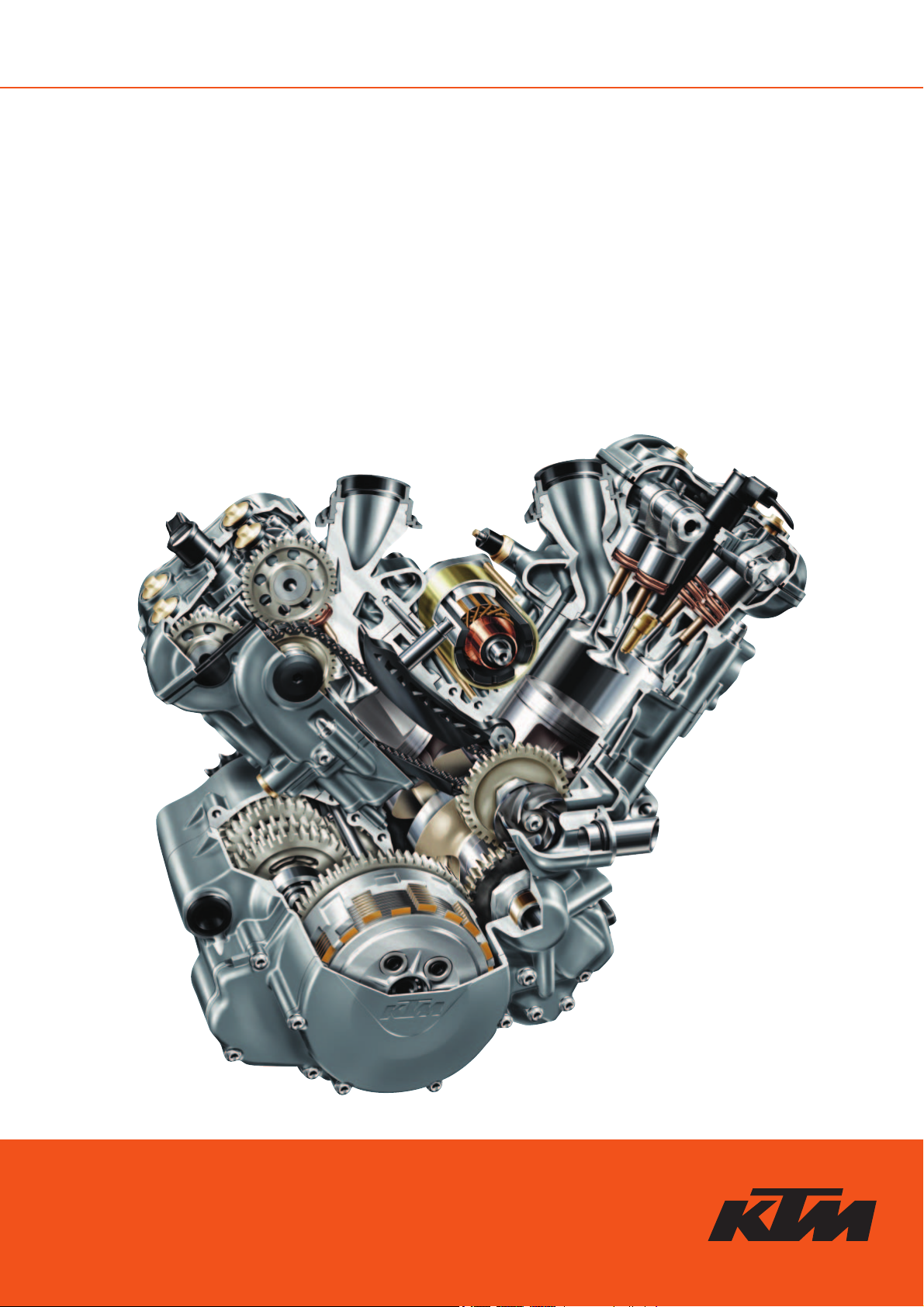

KTM 990 Super Duke, 950 SUPERMOTO, 950 SUPER ENDURO Repair manual

950/990 ADVENTURE

990 SUPER DUKE

950 SUPERMOTO

950 SUPER ENDURO

REPARATURANLEITUNG

MANUALE DI RIPARAZIONE

MANUEL DE RÉPARATION

MANUAL DE REPARACIÓN

ART.NR.: 3.206.044-E

REPAIRMANUAL2003-2007

REPAIRMANUAL2003-2007

950/990 ADVENTURE

990 SUPER DUKE

950 SUPERMOTO

950 SUPER ENDURO

KTM Group Partner

1 SERVICE-INFORMATIONS

2 GENERAL INFORMATION

3 REMOVING AND REFITTING ENGINE

4 DISASSEMBLING ENGINE

5 SERVICING INDIVIDUAL COMPONENTS

6 ASSEMBLING ENGINE

7 ELECTRICAL / INJECTION

8 FUEL SYSTEM

9 TROUBLE SHOOTING

10 CHASSIS

11 TECHNICAL SPECIFICATIONS

12 PERIODIC MAINTENANCE SCHEDULE

13 WIRING DIAGRAMS

14

15

16

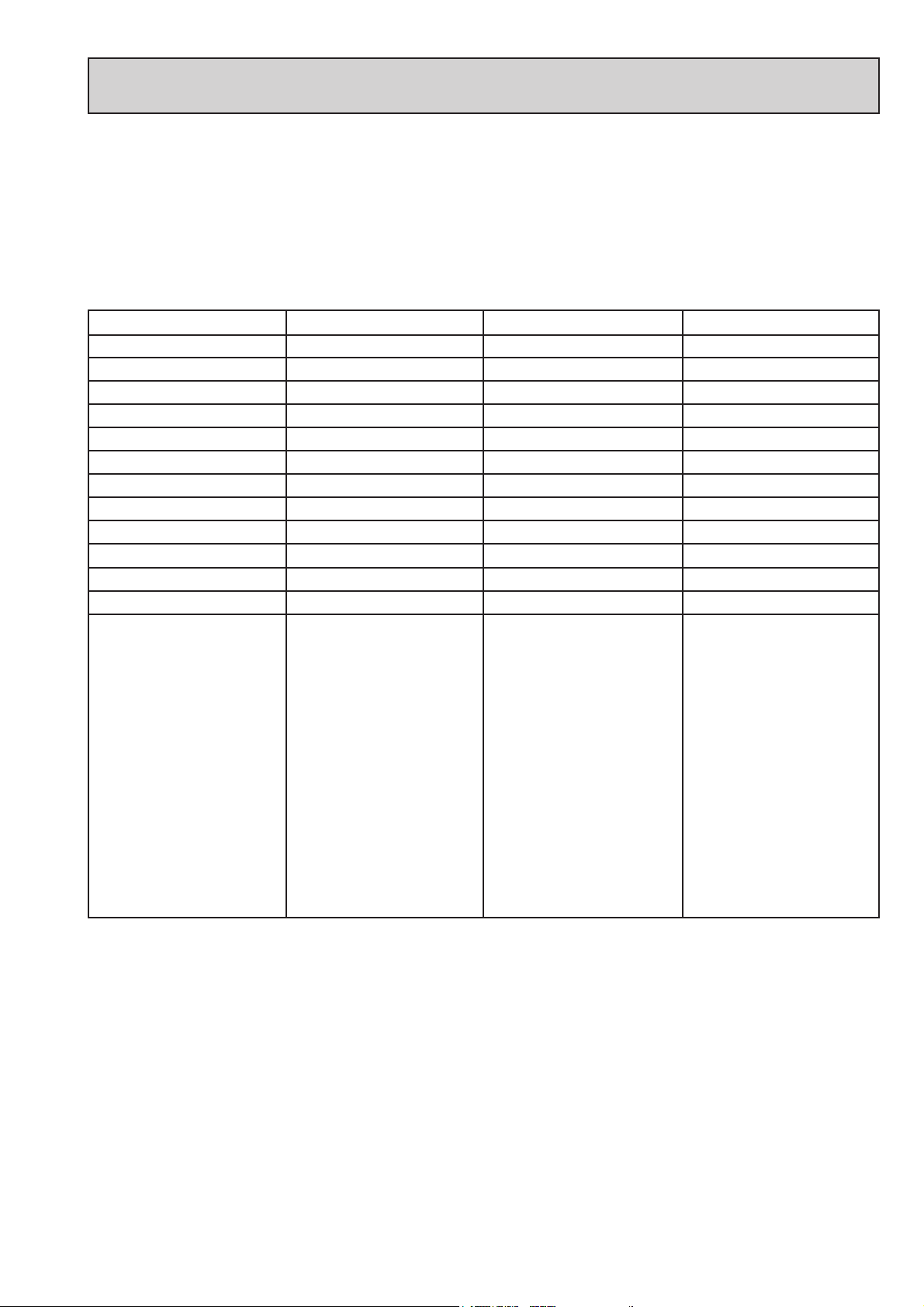

Remove page (s) Replace by page (s) Insert page (s) after page

5-2 to 5-5 5-2 to 5-5

11-1 11-1

11-6 to 11-13 11-6 to 11-13

11-18 to 11-19 11-18 to 11-19

13-1 to 13-6 13-1 to 13-6

13-35 to 13-44 13-35 to 13-44

13-63 to 13-72 13-63 to 13-72

13-89 to 13-98 13-89 to 13-98

13-117 to 13-125 13-117 to 13-125

IMPORTANT INFORMATION/UPDATING INSTRUCTIONS

To be able to continue using the existing loose-leaf repair instructions, simply print the

following pages and insert them in the existing repair instructions:

1,3,7,9,13,71-74,211-218,223,224,253-258,287-296,315-324,341-350,369-378

KTM REPAIR MANUAL IN LOOSE-LEAF FORM

STORING THE REPAIR MANUAL IN THE BINDER

– Put the index into the binder.

– Put the front page of the repair manual (210x297 mm) into the transparent pocket provided for this purpose on the outside of

the binder.

– Put the spine label (170x45 mm) into the transparent pocket provided for this purpose on the spine of the binder.

– Put the summary list of contents (150x297 mm) into the transparent pocket provided for this purpose on the inside of the

binder or insert this page on the beginning of the manual.

– Then insert the individual chapters of the manual between the sheets of the index according to the page number printed in

the right bottom corner of each page.

Example: page no. 3-5; 3 = chapter 3; 5 = page 5

All pages with a page number that begins with the digit 3, for example, must be put under the index heading „Chapter 3“.

– Index sheets that have not been marked with a certain chapter are for your personal convenience. The respective headings can

be entered in the list of contents.

EXPLANATION

- UPDATING

Edition: 02/2007

3.206.009-E Repair Manual LC8

Basicversion Modelyear 2003

4/2003

3.206.016-E Updating of Rep.Manual 3.206.009-E

Modelyear 2004

(Engine number with first digit “4“)

11/2003

3.206.025-E Updating of Rep.Manual 3.206.009-E

Modelyear 2005

(Engine number with first digit “5“)

01/2005

3.206.035-E Updating of Rep.Manual 3.206.009-E

Modelyear 2005/06

(Engine number with first digit “5“ and “6”)

01/2006

3.206.044-E Updating of Rep.Manual 3.206.009-E

Modelyear 2007

(Engine number with first digit “7“)

02/2007

technical details, technical data,

technical specifications, wiring diagrams

INTRODUCTION

This repair manual offers extensiv repair-instructions and is an up-to-date version that describes

the latest models of the series. However, the right to modifications in the interest of technical

improvement is reserved without updating the current issue of this manual.

A description of general working modes common in work shops has not been included. Safety

rules common in the work shop have also not been listed. We take it for granted that the repairs

are made by qualified profesionally trained mechanics.

Read through the repair manual before beginning with the repair work.

WARNING

STRICT COMPLIANCE WITH THESE INSTRUCTIONS IS

ESSENTIAL TO AVOID DANGER TO LIFE AND LIMB.

!

CAUTION

!

NON-COMPLIANCE WITH THESE INSTRUCTIONS CAN LEAD TO

DAMAGE OF MOTORCYCLE COMPONENTS OR RENDER MOTORCYCLES

UNFIT FOR TRAFFIC !

„NOTE” POINTS OUT USEFUL TIPS.

Use only ORIGINAL KTM SPARE PARTS when replacing parts.

The KTM high performance engine is only able to meet user expectations if the maintenance work

is performed regularly and professionally.

In accordance with the international quality management ISO 9001 standard, KTM uses quality

assurance processes that lead to the highest possible product quality.

KTM Sportmotorcycle AG reserves the right to modify any equipment, technical specifications,

colors, materials, services offered and rendered, and the like so as to adapt them to local

conditions without previous announcement and without giving reasons, or to cancel any of the

above items without substituting them with others. It shall be acceptable to stop manufacturing a

certain model without previous announcement. In the event of such modifications, please ask your

local KTM dealer for information.

KTM Sportmotorcycle AG

5230 Mattighofen, Austria

All design and assembly modification rights reserved.

C

by KTM SPORTMOTORCYCLE AG, AUSTRIA All rights reserved

REPLY FAX FOR REPAIR MANUALS

Item no. of repair manual Page Current text Correct text

Additional suggestions, requests or comments on our Repair Manuals (in German or English):

Name mechanic/shop foreman Company/work shop

We have made every effort to make our repair manuals as accurate as possible but it is always possible

for a mistake or two to creep in.

To keep improving the quality of our repair manuals, we request mechanics and shop foremen to assist us

as follows:

If you find any errors or inaccuracies in one of our repair manual – whether these are technical errors,

incorrect or unclear repair procedures, tool problems, missing technical data or torques, inaccurate or

incorrect translations or wording, etc. – please enter the error(s) in the table below and fax the completed

form to us at 0043/7742/6000/5349.

NOTE to table:

– Enter the complete item no. for the repair manual in column 1 (e.g.: 3.206.044-E).

You will find the number on the cover page or in the left margin on each right page of the manual.

– Enter the corresponding page number in the repair manual (e.g.: 5-7) in column 2.

– Enter the current text (inaccurate or incomplete) in column 3 by quoting or describing the respective

passage of the text. If your text deviates from the text contained in the repair manual, please write

your text in German or English if possible.

– Enter the correct text in column 4.

Your corrections will be reviewed and incorporated in the next issue of our repair manual.

GENERAL INFORMATION

Repair manual KTM LC8 Art.-No. 3.206.044-E

OIL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

AIR INTAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

SLS-SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

ABS-SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

SPECIAL TOOLS – ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

SPECIAL TOOLS – CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

BLEEDING THE CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

RESETTING THE CONTROL UNIT AFTER REPLACING/REPAIRING THE ENGINE . . .2-11

ADJUSTING THE THROTTLE CABLE FOR MODELS WITH FUEL INJECTION . . . . . . .2-12

ECU-SOFTWARE UPDATE/MAPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

BLEEDING THE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . .SEE CHAPTER 12

CHECKING THE OIL PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

INDEX

2-1

2

2-2

Repair manual KTM LC8 Art.-No. 3.206.044-E

1

5

6

7

8

9

bk

bm

bn

bo

bp

bq

br

bs

bt

ck

cn

cm

cl

bl

8

2

3

4

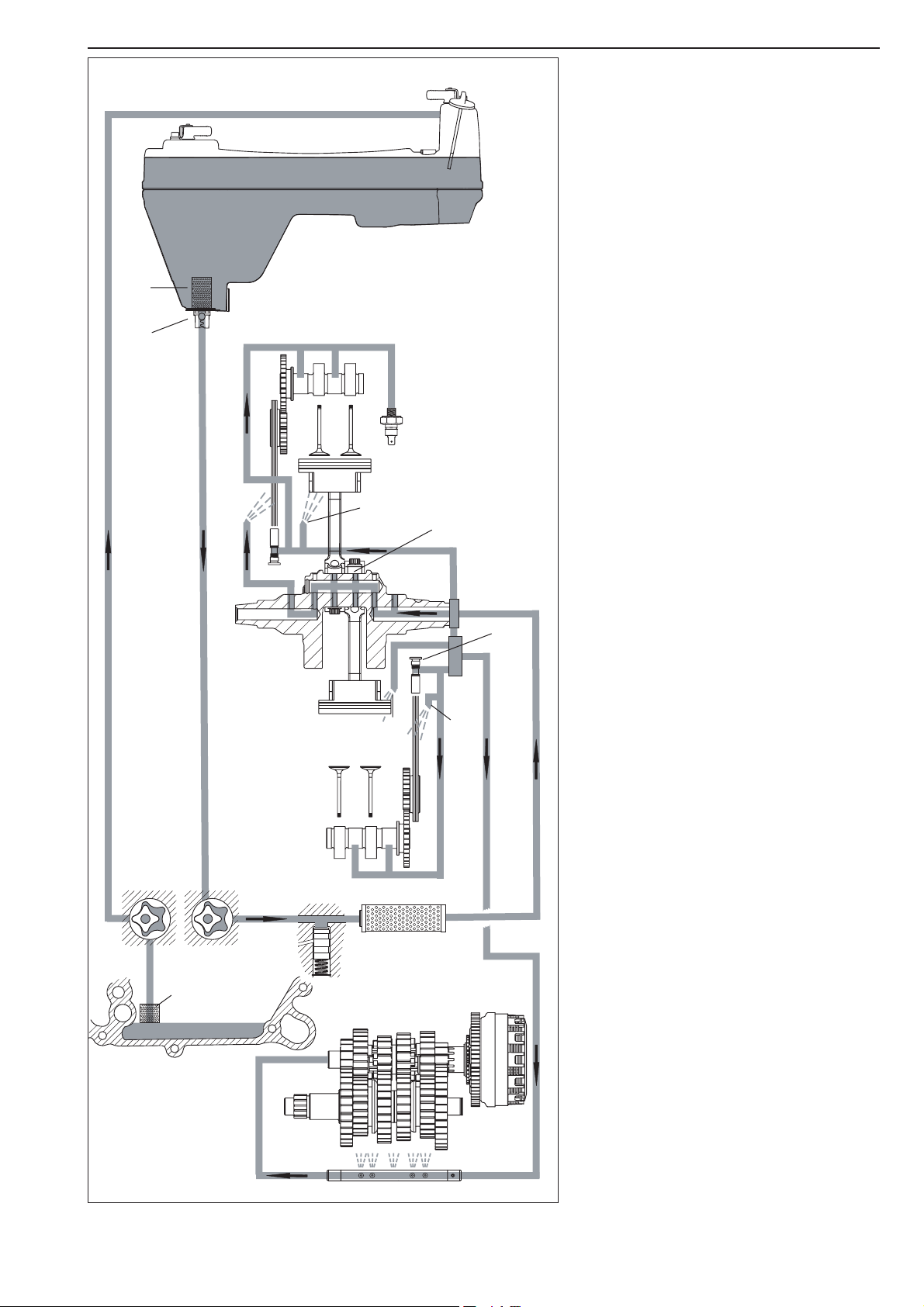

Oil system

Pressure pump 1 draws engine oil from oil tank

2 through oil filter 3 and the oil return valve

4 and pumps it past the pressure relief valve 5

through the oil filter 6 into the annular groove

7.

The main bearing

8, the conrod bearings 9

and the spraying nozzle bk (front timing chain)

are supplied with oil through holes in the

crankshaft. An oil duct leads to spraying nozzle

bl (piston cooling), the timing chain tensioner

bm, the camshaft bn and the oil pressure switch

bo in the front cylinder.

Another oil duct leads from the annular groove

to a distributor groove

bp in the clutch cover.

From there an oil duct leads to the spraying

nozzle

bq (piston cooling). Another oil duct

supplies the timing chain tensioner

br, the

spraying nozzle

bs (timing chain) and the

camshaft

bt on the rear cylinder with oil.

Another oil duct leads to the oil injection tube

ck which lubricates the transmission gears. Oil

is conducted to the pushrod and to the clutch

through the injection tube, another oil duct and

the reducing jet.

The suction pump

cl draws the oil from the oil

sump

cn through the screen cm into the oil tank

2.

NOTE: each piston is lubricated and cooled by 2

jets starting with the 2005 model.

2-3

1

3

3

2

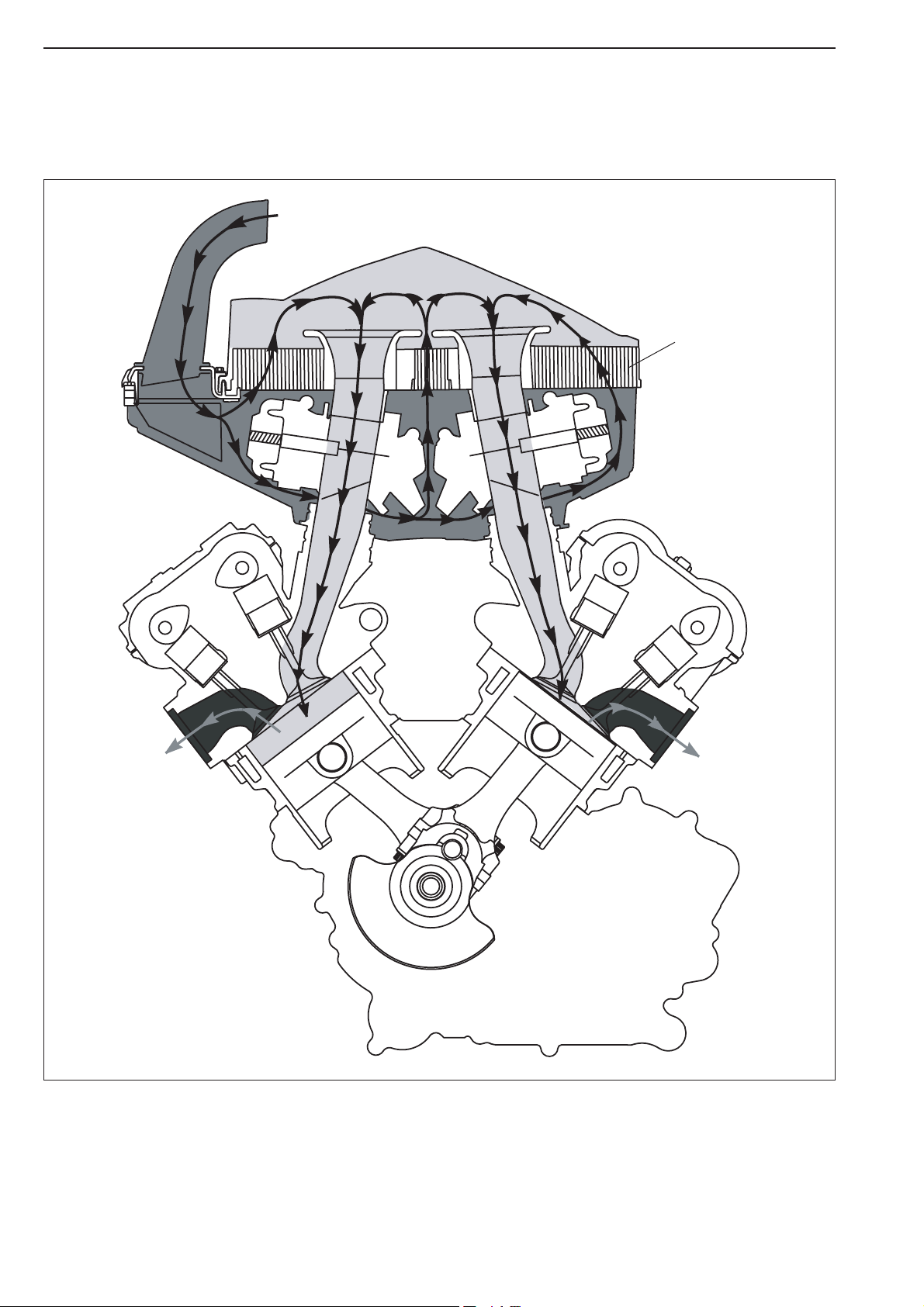

Intake system

Fresh air is drawn into the filter box through the intake snorkel 1, past the carburetors 2 and through the air filter 3.

The cleaned air is conducted to the combustion chamber through the carburetors and intake ports.

The diagram for the injection engine is similar; the air flows to the intake ports through the throttle body instead of through the

carburetor.

2-4

Repair manual KTM LC8 Art.-No. 3.206.044-E

1

2

3

3

4

4

4

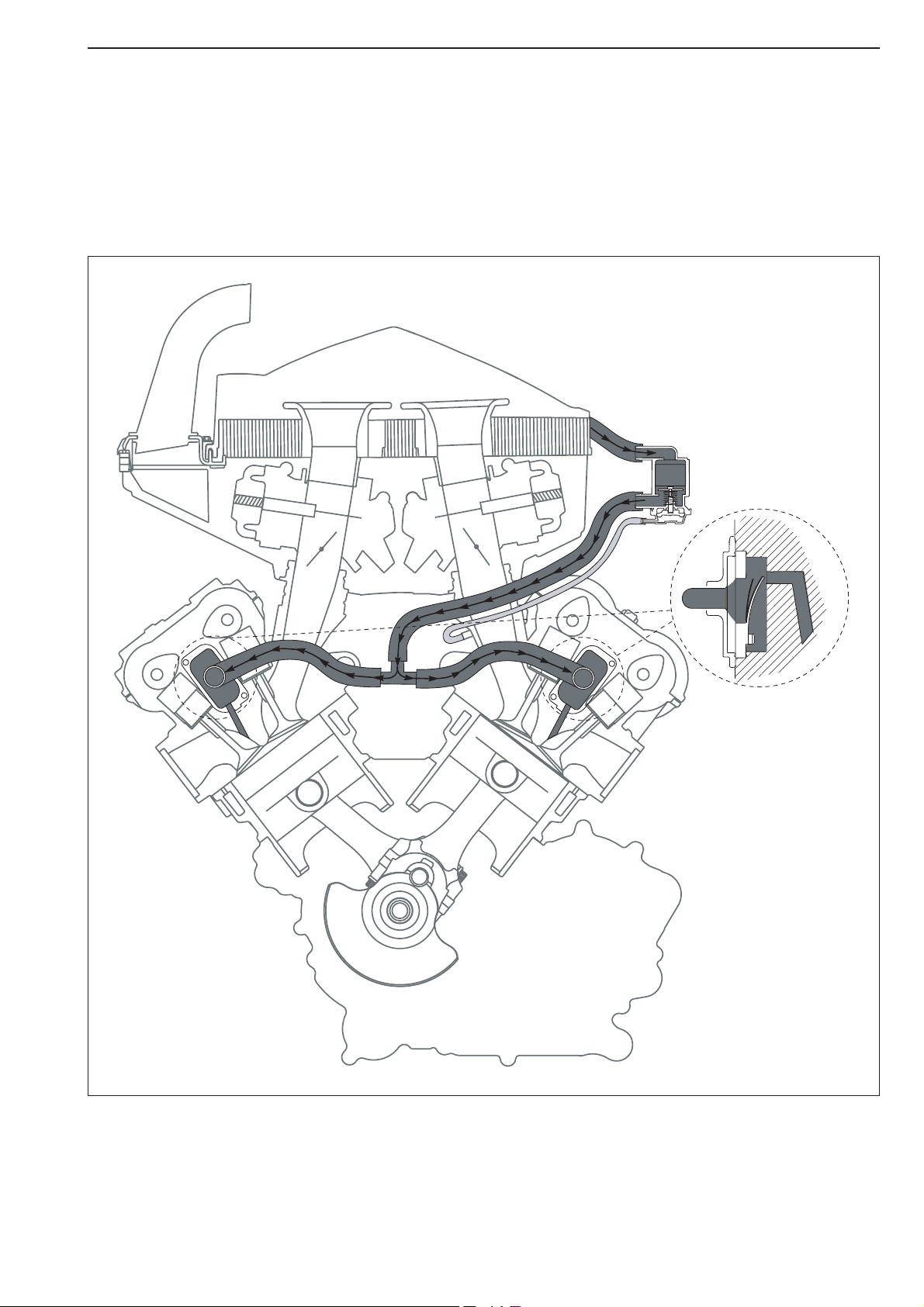

Secondary air system

The secondary air system supplies fresh air to the emissions in the exhaust port, resulting in the afterburning (oxidation) of the

emissions. A line leads from the filter box

1 to the control valve 2 which opens as soon as the throttle valves 3 are opened.

The line continues to the reed valves

4 in the cylinder heads which are actuated by the pressure pulsation in the exhaust

system. As a result, cleansed fresh air arrives in the exhaust port. The oxygen content in the air and the high exhaust gas

temperature cause the emissions to oxidize.

If the throttle valves are closed and the engine goes into an overrun condition, the underpressure in the intake port will rise and

the control valve will close. This prevents exhaust backfire (combustion of the unburned fuel/air mixture).

The secondary air system operates in a similar manner in models equipped with an injection engine; a solenoid valve controlled

by the control unit is used instead of the control valve.

2-5

1

1

2

2

3

4

5

6

7

2

2

3

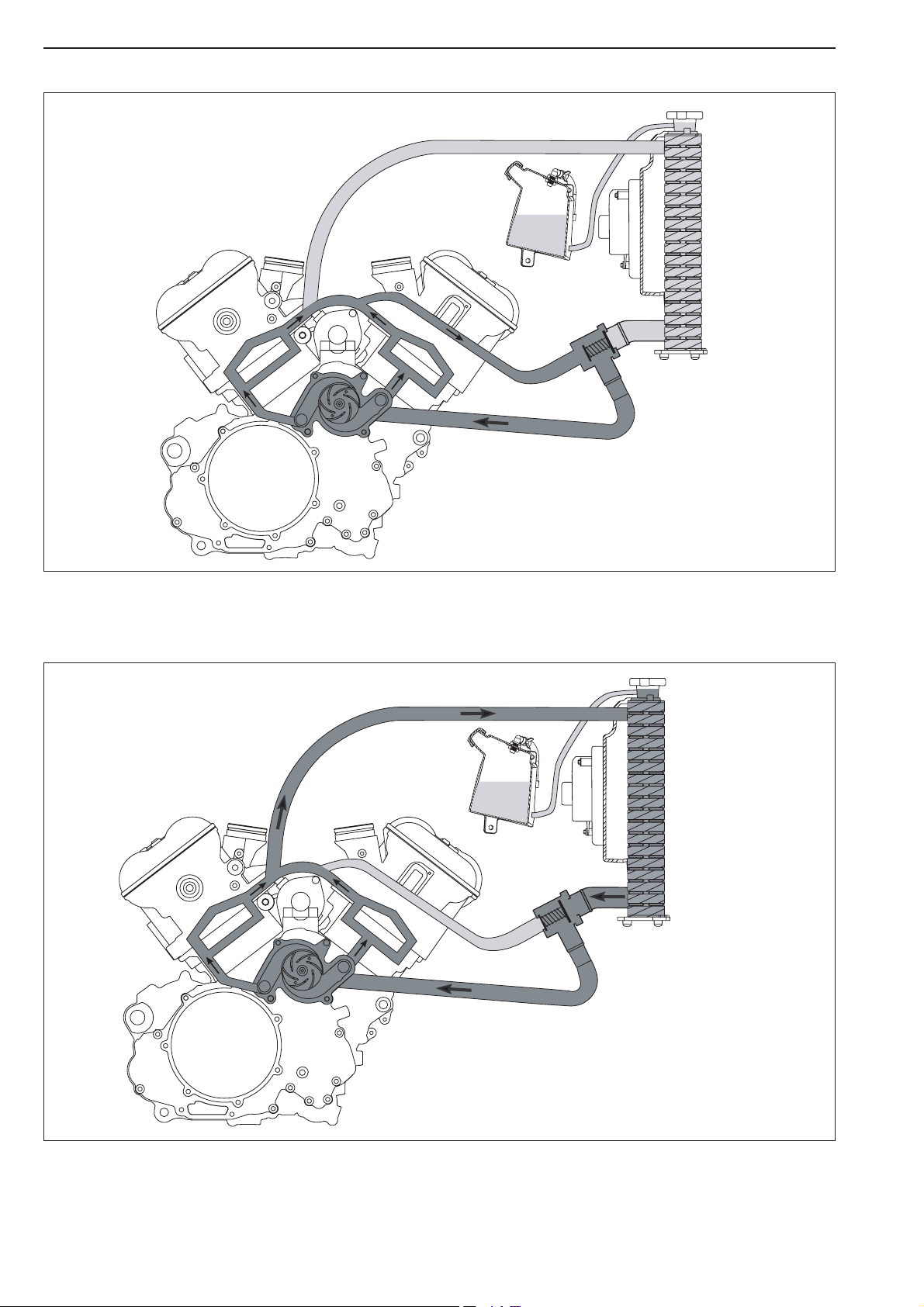

Closed thermostat

The thermostat is closed if the temperature of the cooling liquid drops below 75° C. The water pump 1 pumps the cooling liquid

through the cylinder and cylinder heads

2 and the thermostat 3.

Open thermostat

The thermostat 3 opens at 75° C. The water pump 1 pumps the cooling liquid through the cylinder and cylinder heads 2, the

aluminum cooler

4 and the thermostat. The pressure in the cooling system (max. 1.4 bar) is regulated by a valve in the radiator

cap

5. The cooling liquid level in the compensating tank 6 must be between the MIN and MAX marks when the engine is cold.

The fan

7 switches on at 102° C.

Cooling system

2-6

Repair manual KTM LC8 Art.-No. 3.206.044-E

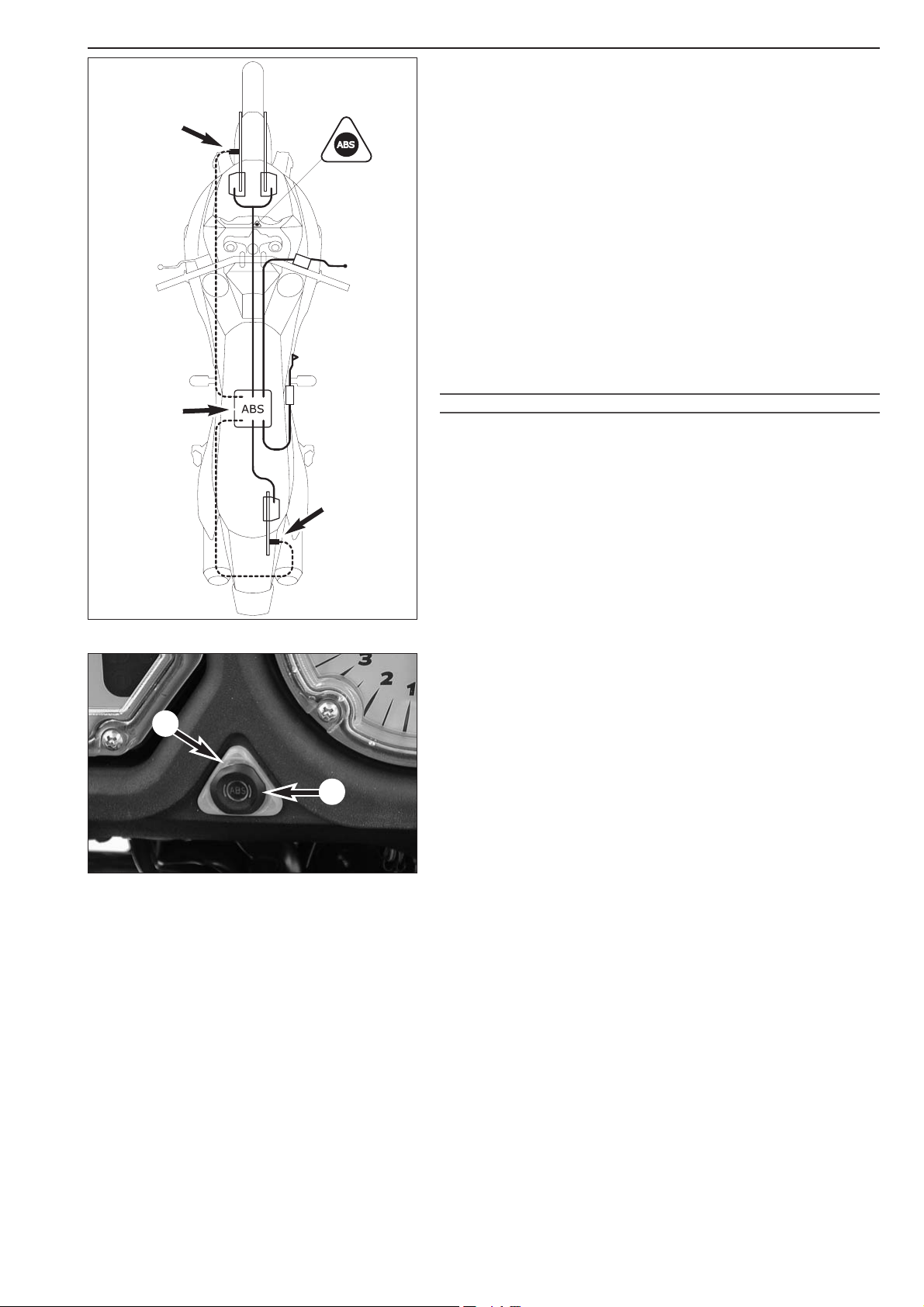

ABS (antilock brake system)

The ABS is a safety system that prevents the wheels from locking when

driving straight ahead without the influence of lateral forces. The ABS

unit

1, consisting of a hydraulic unit, an electronic control unit and the

electric pump motor, is located under the seat. Sensors

2 on the front

and rear wheel send pulses to the control unit to indicate how fast the

wheel is turning.

The KTM 990 Adventure ABS operates with two independent brake

circuits (front and rear wheel brake). During normal service the brake

system works just like a conventional brake without the ABS. The ABS

control phase sets in when the control unit detects that one of the

wheels is starting to lock. It releases the pressure in the respective

brake circuit and prevents the wheel from locking. You can feel the

control function as a slight pulsing in the brake lever.

The ABS warning lamp

3 must light up when the ignition is switched

on and go out at a speed of approx. 5 KPH after you drive off. If it stays

on or lights up while driving, the ABS is defective.

The ABS can be switched off with the ABS button

4.

!

CAUTION

!

–D

O NOT MOUNT WHEELS WITH A DIFFERENT RIM DIAMETER. THE ABS

FUNCTION CAN NO LONGER BE GUARANTEED

.

–T

HE ABS IS DESIGNED TO BE USED WITH THE TIRES AUTHORIZED BY KTM.

T

HE ABS FUNCTION CANNOT BE GUARANTEED IF OTHER TIRES ARE USED.

–M

AXIMUM

ABS CONTROL CAN NO LONGER BE GUARANTEED IF THE TIRE

PRESSURE IS INCORRECT

.

–T

HE ABS SYSTEM IS DESIGNED FOR THE 990 ADVENTURE MODEL AND MAY

NOT BE INSTALLED IN THE 990 ADVENTURE S

SINCE THE 990 ADVENTURE S

MODEL HAS A DIFFERENT CENTER OF GRAVITY; 990 ADVENTURE S

FORKS/SHOCK ABSORBERS MAY NOT BE MOUNTED ON 990 ADVENTURE MODELS

WITH

ABS.

–A

LL OTHER MODIFICATIONS THAT DISPLACE THE MOTORCYCLE'S CENTER OF

GRAVITY

(E.G. LOWERING) JEOPARDIZE THE PROPER FUNCTIONING OF THE ABS

SYSTEM.

ABS warning lamp

The ABS warning lamp 3 must light up when the ignition is switched

on and go out at a speed of approx. 5 KPH after you drive off. If it stays

on or lights up while driving, the ABS is defective. The ABS is no longer

active and the wheels can lock when braking.

NOTE:

– The brake system will still function but ABS control will no longer be

active.

– The ABS warning lamp can also light up if there is a large deviation

between the speed of the front and rear wheel in extreme driving

situations, e.g. during a wheelie or if the rear wheel slips when

accelerating on loose ground. The ABS will no longer be active and

the wheels can lock when braking. To activate the ABS again, stop

and switch the ignition off/on. If the warning lamp goes off again at a

speed of approx. 5 KPH after you drive off, the ABS is active and

fully operative.

ABS button

The ABS button 4 switches off the ABS. To switch off the ABS, stop

the motorcycle and press the ABS button for at least 3 seconds with the

engine running. Let go of the ABS button as soon as the ABS warning

lamp starts blinking fast. The ABS warning lamp will blink slowly to

indicate that the ABS is switched off.

To switch the ABS on again, stop and switch off the ignition. The ABS

will be active again when you switch on the ignition.

See the KTM ABS training documents for a detailed description of the

ABS system.

1

2

2

3

4

2-7

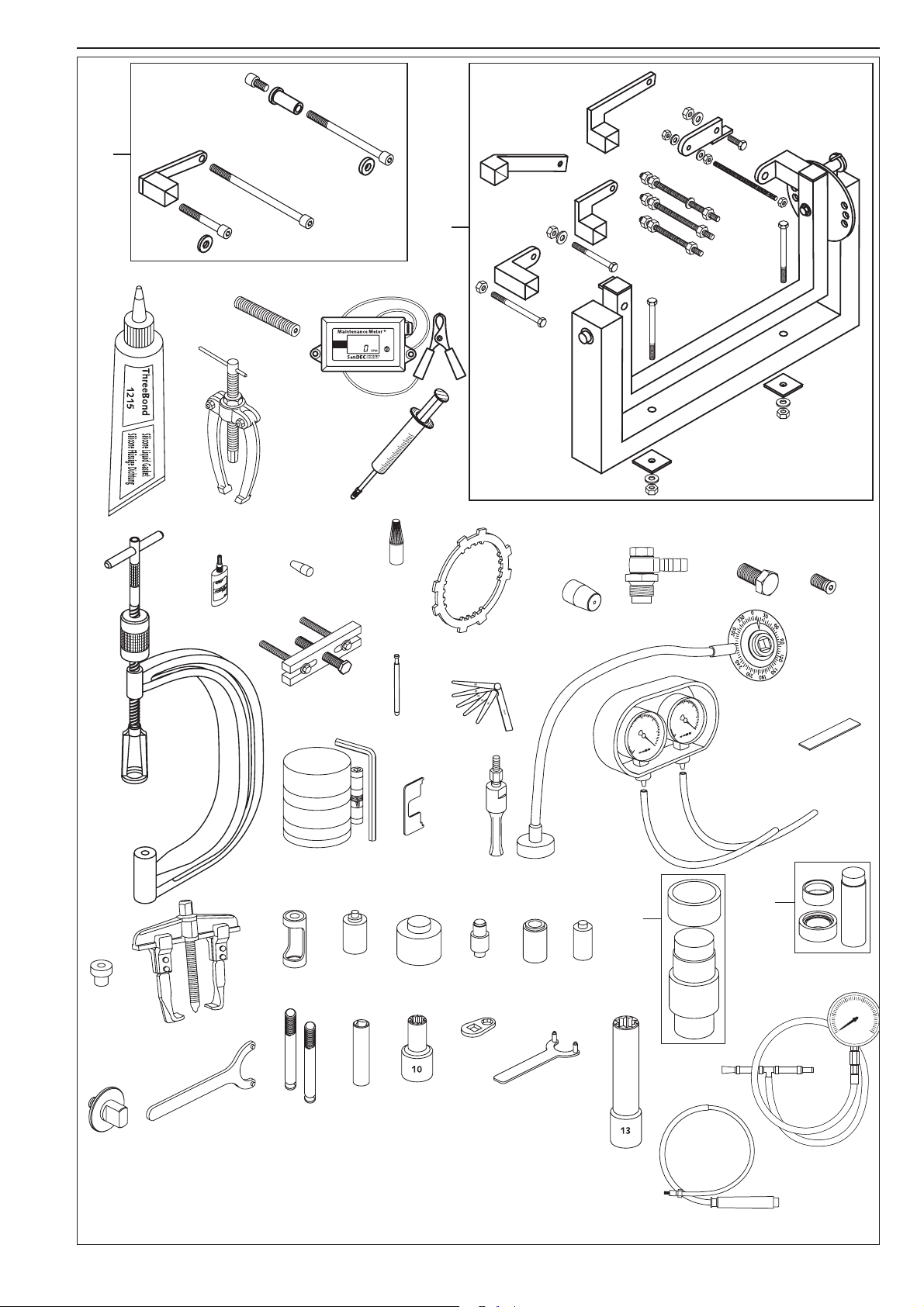

SPECIAL TOOLS – ENGINE

FIG PART NO DESCRIPTION

1 309098 Seal Three-Bond

2 0113 080802 Crankshaft locking bolt

3 151.12.017.000 Gear puller

4 451.29.075.000 Tachometer

5 503.29.050.000 Bleeding syringe for hydraulic clutch

6 560.12.001.000 Universal-engine work stand

7 584.29.059.000 Loctite 648 green 20 ml

8 585.29.005.000 Protection sleeve for shaft seal ring of water pump

9 590.29.019.000 Valve spring mounter

10 590.29.021.044 Puller

11 590.29.026.006 Limit plug gauge 6,05 mm

12 590.29.041.000 Feeler gauge for valve clearance

13 6 899 785 Loctite 243 blu 10 ml

14 600.29.002.000 Engine holder for engine work stand

15 600.29.003.000 Clutch holder

16 600.29.005.000 Protection sleeve for shaft seal ring of output shaft

17 600.29.006.000 Oil pressure adapter

18 600.29.009.000 Magneto extractor

19 600.29.009.010 Pressure screw for magneto extractor up to the 2004 model

600.29.009.110 Pressure screw for rotor extractor from the 2005 model

20 600.29.010.000 Degree wheel

21 600.29.011.000 Carburator synchronisation tool

22 600.29.012.000 Plastigauge-measuring strips

23 600.29.015.000 Piston ring mounting tool

24 600.29.016.000 Setting gauge for float level

25 600.29.018.000 Internal gear puller 28 mm

26 600.29.031.000 Protection sleeve for crankshaft (for pulling of the primary gear)

27 600.29.033.000 Puller for primary gear

28 600.29.041.000 Valve spring mounter insert

29 600.29.043.010 Pressing tool for seal of clutch release shaft

30 600.29.043.020 Pressing tool for seal of output shaft

31 600.29.043.030 Pressing tool for seal and bearing of shifting shaft

32 600.29.043.040 Pressing tool for seal of water pump

33 600.29.043.050 Pressing tool for seal of balancer shaft

600.29.043.060 Pressing tool for bearing of water pump

34 600.29.044.050 Pressing tool for main bearings (In/out)

35 600.29.046.028 Pressing tool for supporting bearing (In)

36 600.29.050.000 Pretensioning tool - lower part

37 600.29.051.000 Pretensioning tool - hook wrench

38 600.29.058.000 Puller for spreader components

39 600.29.073.000 Spark plug wrench 16 mm

40 600.29.075.000 Special nut for conrod

41 600.29.081.000 Special tool for cylinder head nuts

42 600.29.082.000 Holder for water pump wheel

43 600.29.083.000 Special nut for cylinder head nuts

44 610.29.094.000 EFi-tool for pressure check

45 625.29.093.000 Intermediate adapter for ignition cable

2-8

Repair manual KTM LC8 Art.-No. 3.206.044-E

648

LOCTITE

243

1

2

3

4

5

8

9

bk

6

bl

bm

bn

bo

bp

bq

br

bs

bt

cl

cm

cn

co

cp

cq

cr

cs

ct

dk

dl

dm

dn

do

dp

dq

dr

ck

ds

dt

ek

el

23

14

05BAR

em

7

en

eo

ep

2-9

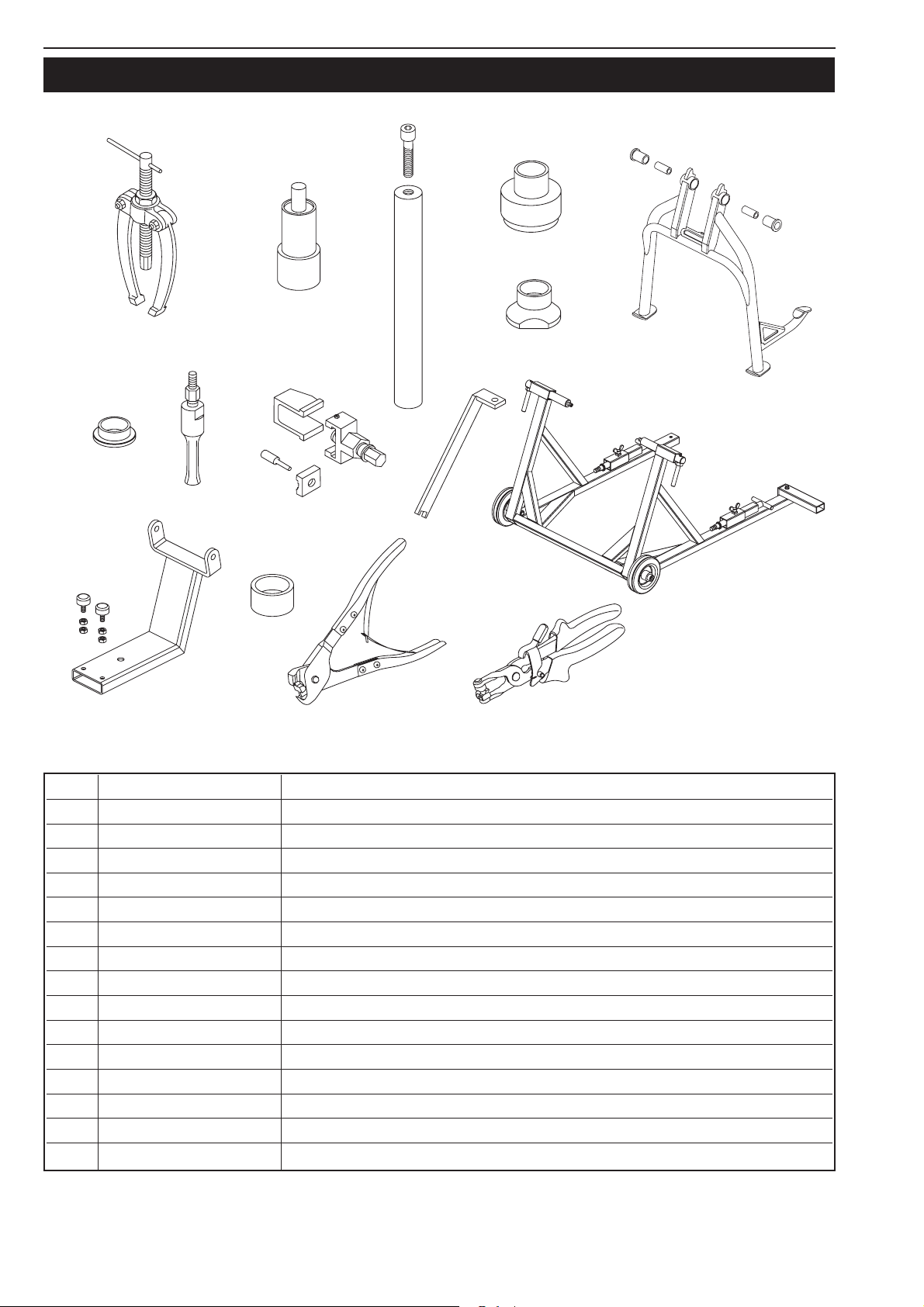

SPECIALTOOLS – CHASSIS

FIG PART NO DESCRIPTION

1 151.12.017.000 Gear puller

2 584.29.086.000 Pressing tool for swing arm bearing

3 584.29.089.000 Chassis tool holder

4 584.29.091.000 Press-in tool for

bearing seat / rear wheel bearing

5 584.29.092.000

Knock-out tool for bearing seat

6 600.03.022.000 Center stand

7 600.10.013.000 Sleeve for pressing tool for swim arm bearing

8 600.29.018.000 Internal gear puller 28 mm

9 600.29.020.000 Chain rivet tool

10 600.29.055.000 Center stand lock

11 600.29.055.100 Floor jack attachment

12 600.29.056.000 Anvil dolly (for 584.29.086.000)

13 600.29.057.000 Pliers for Öttiker clamps

14 600.29.057.100 Pliers for spring-loaded band-type clamp

15 625.29.055.000 Assembly stand 950 Supermoto/990 Super Duke

6

4

3

1

7

bl

2

5

8

9

bk

bp

bm

bn

bo

2-10

Repair manual KTM LC8 Art.-No. 3.206.044-E

Checking the oil level of the hydraulic clutch - 950/990

Adventure/

950 Supermoto

To check the oil level in the master cylinder of the clutch remove the

cover. For this purpose, remove bolts and cover together with the

rubber boot

1. The oil level in the horizontal-standing master cylinder

should be 4 mm below the upper edge. If necessary add SAE 10

biodegradable hydraulic oil (e.g. Motorex Kupplungs-Fluid 75).

!

CAUTION

!

O

NLY USE

SAE 10 BIODEGRADABLE HYDRAULIC OIL TO REFILL THE MASTER

CYLINDER

. NEVER USE BRAKE FLUID NOR MIX BIODEGRADABLE HYDRAULIC OILS

WITH MINERAL OILS

!

Checking the oil level of the hydraulic clutch - 990 Super Duke

The oil level in the horizontal-standing master cylinder should be

between the "MIN" and "MAX" marks.

If necessary, add SAE 10 biodegradable hydraulic oil (Motorex

Kupplungsfluid 75).

!

CAUTION

!

O

NLY USE SAE 10 BIODEGRADABLE HYDRAULIC OIL TO FILL THE MASTER

CYLINDER

. DO NOT USE BRAKE FLUID AND DO NOT MIX WITH HYDRAULIC MINERAL

OIL

.

Bleeding of the hydraulic clutch

For bleeding, the cover of the master cylinder of the clutch needs to be

removed. For this purpose, remove bolts and take off cover together

with rubber bellows

1. At the slave cylinder of the clutch, remove the

bleeder nipple. At its place, mount the bleeder syringe

2 which is

filled with biodegradable hydraulic oil (e.g. Motorex Kupplungs-Fluid

75).

Refill oil, until oil is discharged from the bore

A of the master cylinder

in a bubble-free state. Make sure that the oil does not overflow.

!

CAUTION

!

H

AVING COMPLETED THE BLEEDING PROCEDURE, YOU HAVE TO VERIFY THAT THE OIL

LEVEL IN THE MASTER CYLINDER IS CORRECT

. FOR FILLING OF THE MASTER

CYLINDER

, USE SAE 10 BIODEGRADABLE HYDRAULIC OIL ONLY (EX. MOTOREX

KUPPLUNGS-FLUID 75); NEVER USE BRAKE FLUID NOR MIX BIODEGRADABLE

HYDRAULIC OILS WITH MINERAL OILS

.

1

2

A

2-11

Resetting the control unit after replacing/repairing the engine

NOTE: the control unit must be reset after replacing the engine or after

engine repair if replacing a piston, cylinder or cylinder head.

The engine may have a poor idle behavior if the control unit is not

reset.

– Connect the KTM diagnostics tool, turn the ignition switch on and

start the program.

– Select "Extend"

1.

– Select "Device operation"

2.

– Enter your password.

– Select "All reference reset operation"

3 and move to the right

window with the arrow

4.

– Acknowledge with "Execute"

5 to "Reset" the control unit.

– Wait until the "Reset" process is completed, exit the program, turn

the ignition switch off and disconnect the KTM diagnostics tool.

– Allow the vehicle to idle for 15 minutes. Do not open the throttle

during this time, observe the coolant temperature, stop if the engine

is likely to overheat.

1

2

3

4

5

2-12

Repair manual KTM LC8 Art.-No. 3.206.044-E

Adjusting the throttle cable for models with fuel injection

NOTE: to adjust the throttle cable clearance, the throttle valves must

be closed. To close, retract the idle speed control stepper motor all the

way using the KTM diagnostics tool.

If this step is omitted, the throttle cable clearance cannot be correctly

adjusted.

– Connect the KTM diagnostics tool, turn the ignition switch on and

start the program.

– Select "Extend"

1.

– Select "Device operation"

2.

– Enter your password.

– Select "Idle speed control stepper motor"

3 and move to the right

window with the arrow

4.

– Acknowledge with "Execute"

5. The idle speed control stepper

motor will be completely retracted and the throttle valves completely

closed.

– Remove the left side cover on the air filter box and check whether

the throttle valves are completely closed.

– Switch the ignition switch off and adjust the throttle cable clearance

as follows:

– Loosen the counter nut

6, turn the adjusting screw 7 as needed

and tighten the counter nut again.

NOTE:

– You should be able to feel 3-5 mm play in the throttle grip when you

start to turn it.

– Make sure the throttle grip returns to the neutral position

automatically when released.

– Turn the ignition switch on again, exit the program, turn the ignition

switch off and disconnect the KTM diagnostics tool.

To check whether the setting is correct, start the engine, steer left and

right all the way to the stop. The idle speed should not change.

1

2

3

4

5

6

7

2-13

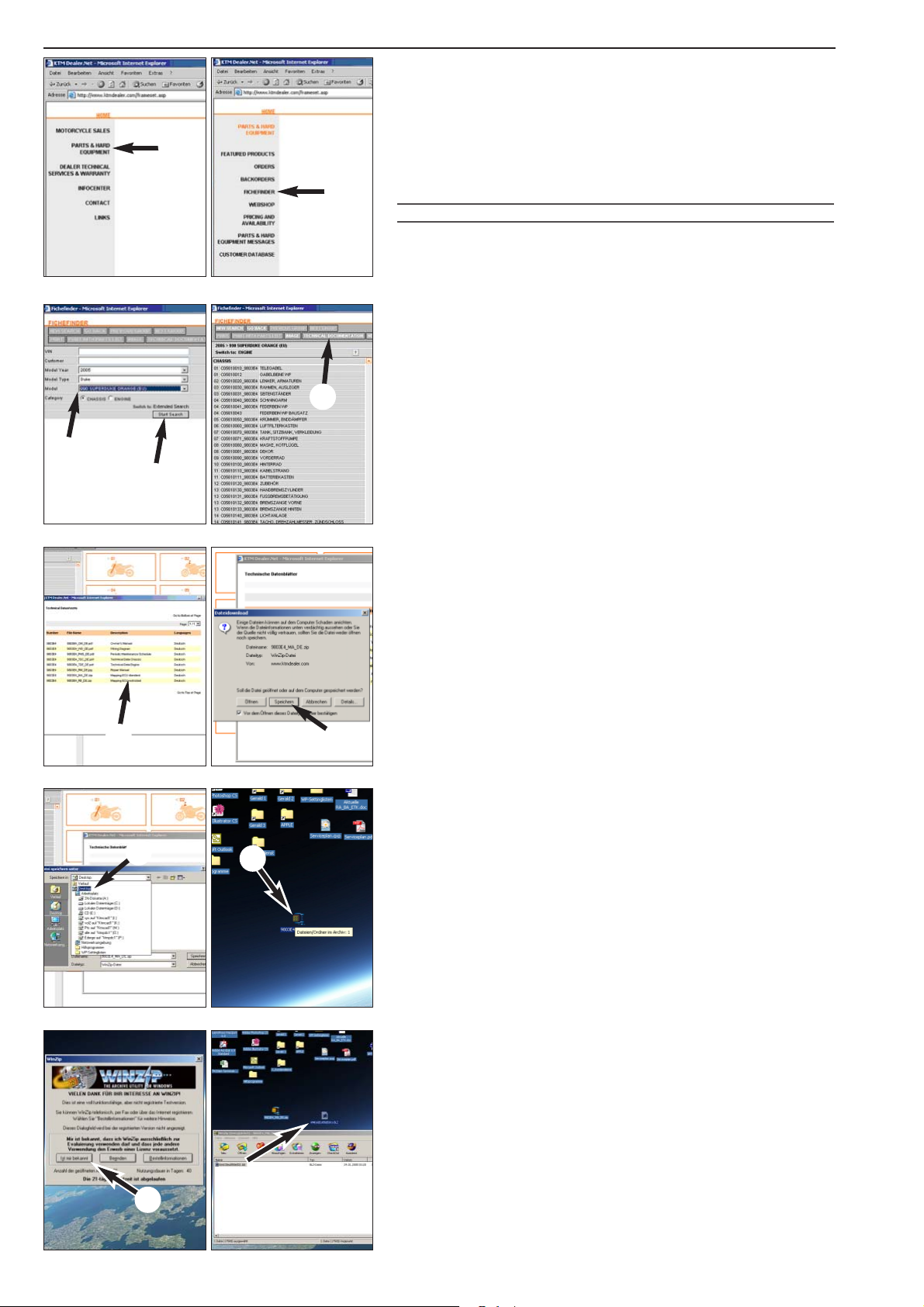

ECU software update/mapping

NOTE:

– ECU software update or mapping means that the software for the

injection system control unit has been modified. The software can

be downloaded from KTM's dealer.net site; the software is

transferred to the control unit via the KTM diagnostics tool (FAN).

– Some exhaust systems require new "mapping". If these exhaust

systems are replaced by the production system again, the "mapping"

will need to be reverted to the original version.

!

CAUTION

!

D

O NOT USE THE MODIFIED MAPPING WITH PRODUCTION EXHAUST SYSTEMS. THIS

CAN LEAD TO ENGINE DAMAGE AND YOU WILL RUN THE RISK OF BURNING

/INJURING

YOURSELF

.

Downloading the software:

– Log into dealer.net.

– Select "Parts and Hard Equipment"

1.

– Select "Fichefinder"

2.

– Select the model year, model type and model

3 and click "Start

search"

4.

– Select "Technical documentation"

5.

– Select the required mapping

6.

– Click "Save"

7.

– Select the storage location 8.

NOTE:

– Save the file onto your "Desktop" to make it easier to locate.

– This can take a little time, depending on your Internet connection

and the size of the mapping file.

– The downloaded file is compressed and needs to be extracted with

"winzip".

– Double click the downloaded file

9.

– Click "I agree" in the "winzip" window

bk.

– Mark the extracted file with the cursor and drag to your "Desktop".

3

4

5

6

7

8

9

bk

1

2

2-14

Art.-No. 3.206.044-E

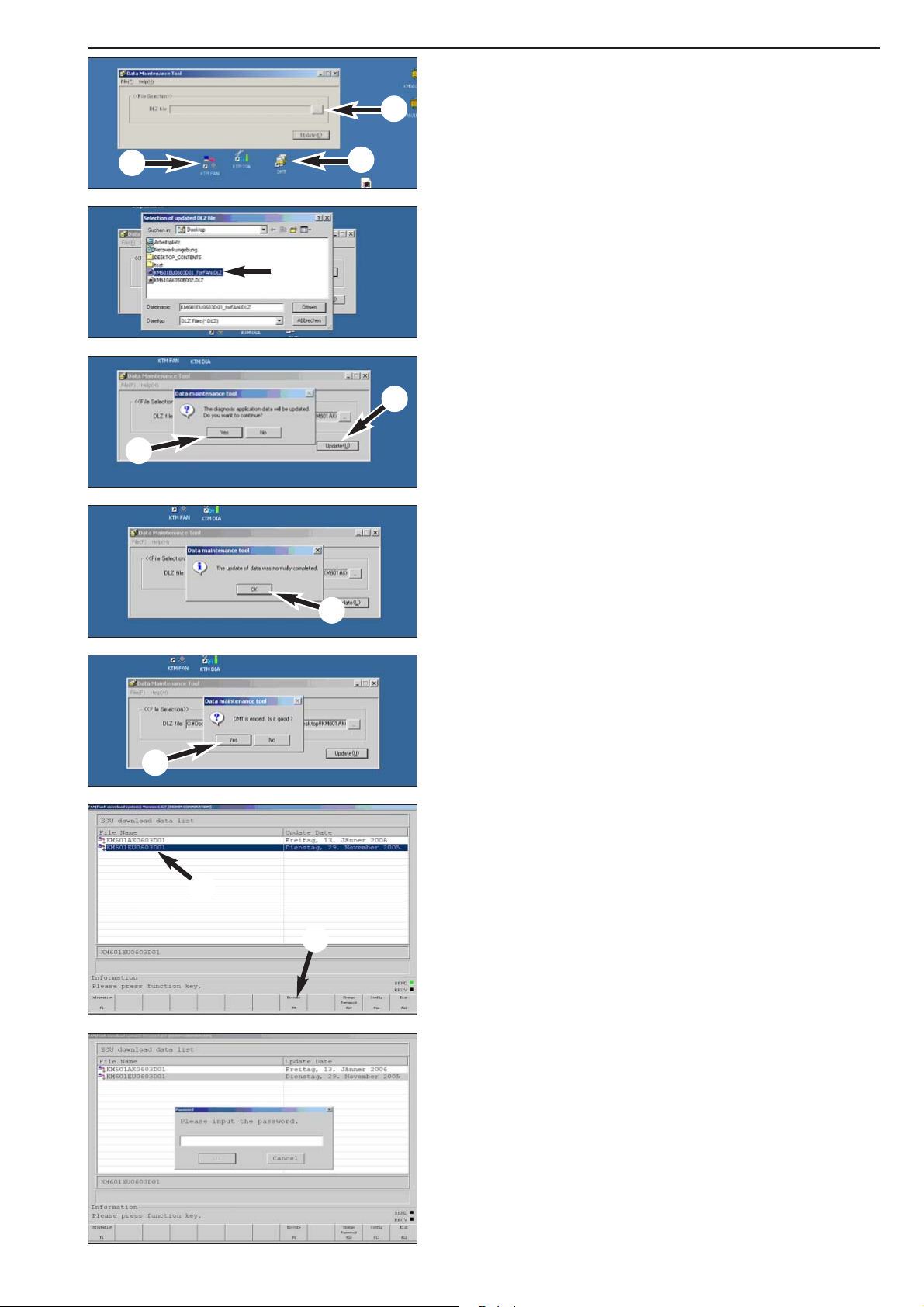

Starting the DMT (Data Maintenance Tool):

– Double click "DMT"

1 to start the DMT program.

NOTE:

– If the DMT is not installed yet, install with the KTM diagnostics tool

CD.

– If the program is already installed but the DMT icon does not appear

on your screen, start the program under "Start" (in the task bar at

the bottom of the screen) by clicking "Programs".

– Click the field in the DMT window with the 3 dots

2.

– Select the storage location of the downloaded mapping file in the

selection window ("Desktop")

3.

– Click "update" in the DMT window

4.

– Confirm "update" selection with "Yes"

5.

– End "update" with "OK"

6.

– Confirm that you are ending the "update" with "YES"

7.

Starting the FAN (Flash Download System):

– Double click on "FAN"

8 to start the FAN program.

NOTE:

– If the FAN is not installed yet, install with the KTM diagnostics tool

CD.

– If the program is already installed but the DMT icon does not appear

on your screen, start the program under "Start" (in the task bar at

the bottom of the screen) by clicking "Programs".

– Connect the motorcycle to the diagnostics adapter, switch on the

ignition.

– Click the mapping file

9 to be transferred to the ECU and confirm

with "Execute".

– Enter the password (Adapter number) and click "OK" to confirm.

Reparaturanleitung KTM LC8

1

2

3

4

5

6

7

8

9

bk

2-15

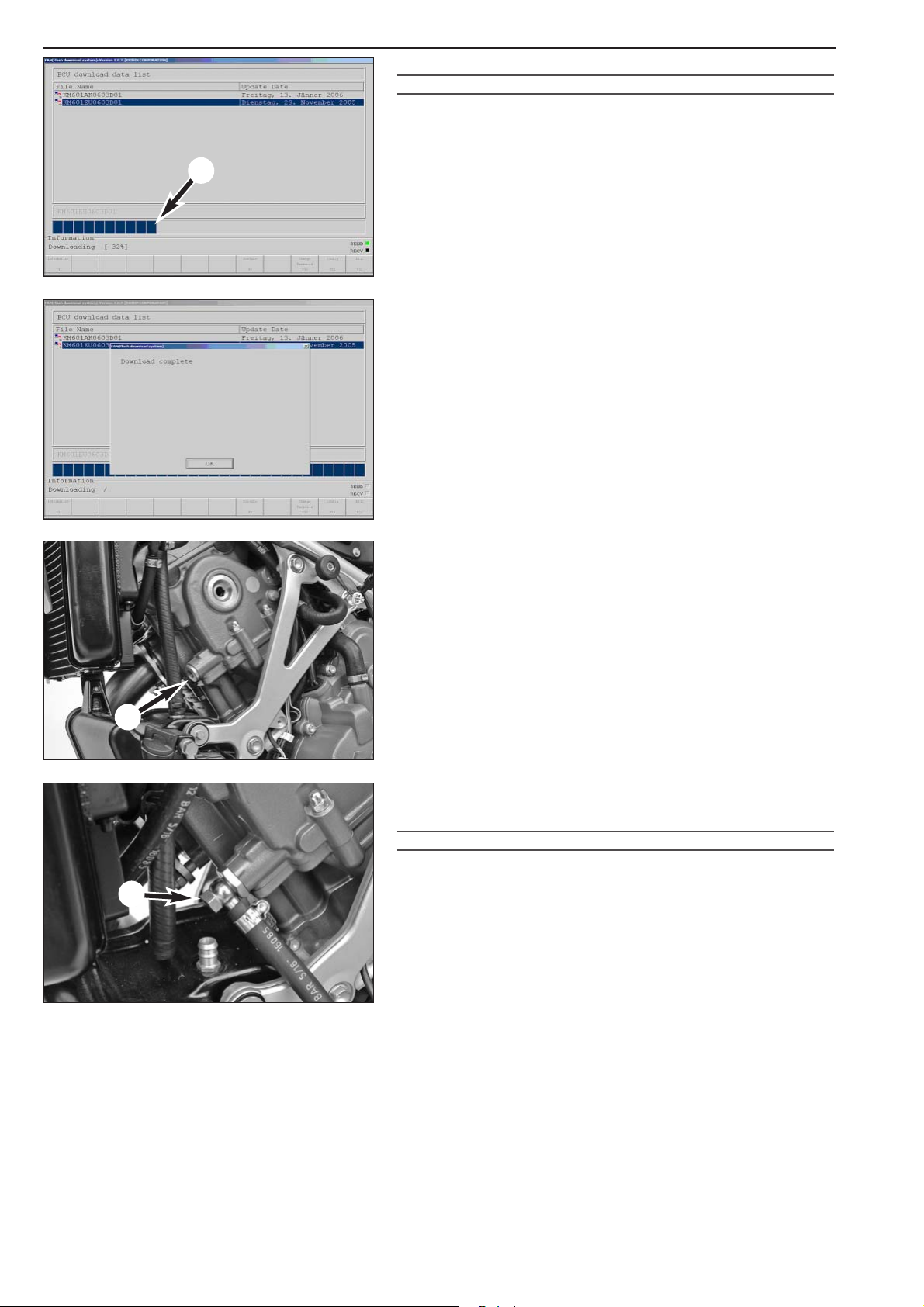

– The mapping file will be transferred to the ECU.

!

CAUTION

!

D

O NOT SWITCH OFF THE IGNITION OR DISCONNECT THE DIAGNOSTICS CABLE WHILE

THE FILE IS BEING TRANSFERRED

("FLASHING"). THIS CAN DAMAGE THE ECU.

NOTE:

– All of the indicator lamps in the digital speedometer will light up

while the file is being transferred.

– The bar

1 will show download progress.

– Click "OK" to confirm when the operation is completed.

– End the program, switch off the ignition and disconnect the

diagnostics cable.

– Start the engine and allow to idle for 15 minutes.

NOTE: the engine must run in idle for 15 minutes after each mapping

operation (Mapping initializing). Do not accelerate during this time,

observe the coolant temperature and abort if the engine threatens to

overheat.

Checking the oil pressure

– Remove the plug from the timing chain tensioner 2.

– Screw on the oil pressure adapter

3 600.29.006.000 and tighten.

– Connect the EFI pressure gauge 610.29.094.000 (without the T-

fitting) to the oil pressure adapter, tighten the banjo bolt.

!

CAUTION

!

–C

ONNECT ALL LOOSENED OIL AND FUEL LINES AGAIN BEFORE STARTING THE

ENGINE

.

–C

HECK THE OIL LEVEL AND CORRECT IF NECESSARY.

– Allow the engine to warm up and check the oil pressure with the

engine at operating temperature:

min. 0.8 bar at 1500 rpm

min. 2.4 bar - max. 3.5 bar at 6000 rpm

NOTE: the engine is at operating temperature when the engine oil in

the oil tank is approx. 100ºC.

– Remove the special tools again, screw the plug in the timing chain

with a new gasket and tighten to 20 Nm.

2

1

3

Loading...

Loading...