KTM 400 LC4, 660 LC4 2003, 660 LC4 '98-03 Service Manual

REPAIR MANUAL

REPARATURANLEITUNG

MANUALE DI RIPARAZIONE

MANUEL DE RÉPARATION

MANUAL DE REPARACIÓN

ART.NR.: 3.206.006-E

KTM Group Partner

400-660LC42003

400-660LC4

REPAIR

MANUAL

1 SERVICE-INFORMATIONS

2 GENERAL INFORMATION

3 REMOVING AND REFITTING ENGINE

4 DISASSEMBLING THE ENGINE

5

SERVICING ON INDIVIDUAL COMPONENTS

6 ASSEMBLING THE ENGINE

7 ELECTRICAL

8 FUEL SYSTEM

9 TROUBLE SHOOTING

10 TECHNICAL SPECIFICATIONS

11 PERIODIC MAINTENANCE SCHEDULE

12 WIRING DIAGRAMS

13

14

15

16

Remove page (s) Replace by page (s) Insert page (s) after page

2-1C to 2-3C 2-1D to 2-3D 2-5D

2-5C to 2-11C 2-6D to 2-13D

3-3 3-3D

4-1A 4-1D

4-5 to 4-16 4-5D to 4-17D

5-1A to 5-2A 5-1D to 5-2D

5-12 5-12D

5-14B to 5-17 5-14D to 5-17D

5-21 / 5-25 5-21D / 5-25D

6-1A to 6-2 6-1D to 6-2D

6-5C to 6-19C 6-5D to 6-21D

7-1 to 7-49C 7-1D to 7-51D

8-1C to 8-37C 8-1D to 8-49D

9-1 9-1D

10-1.1C 10-2D 10-62D to 10-72D

11-1C 11-1D 11-22D to 11-27D

12-2C 12-2D 12-57D to 12-66D

IMPORTANT INFORMATION/UPDATING INSTRUCTIONS

To be able to continue using the existing loose-leaf repair instructions, simply print the

following pages and insert them in the existing repair instructions:

15-18, 20-28, 32, 35, 40-54, 64, 66-69, 73, 77, 79-81, 84-207, 219, 280-291,

314-319, 323, 378-387

KTM REPAIR MANUAL IN LOOSE-LEAF FORM

STORING THE REPAIR MANUAL IN THE BINDER

– Put the index into the binder.

– Put the front page of the repair manual (210x297 mm) into the transparent pocket provided

for this purpose on the outside of the binder.

– Put the spine label (170x45 mm) into the transparent pocket provided for this purpose on the

spine of the binder.

– Put the summary list of contents (150x297 mm) into the transparent pocket provided for this

purpose on the inside of the binder or insert this page on the beginning of the manual.

– Then insert the individual chapters of the manual between the sheets of the index according to

the page number printed in the right bottom corner of each page.

Example: page no. 3-5 3 = chapter 3 5 = page 5

All pages with a page number that begins with the digit 3, for example, must be put under the

index heading „Chapter 3“.

– Index sheets that have not been marked with a certain chapter are for your personal convenience.

T

he respective headings can be entered in the list of contents.

Repair manual KTM LC4 Art.-Nr. 3.206.006 -E

EXPLANATION - UPDATING

Edition 4/2003

3.205.49-E Repair Manual LC4 6/1998

Basicversion Modelyear 1998

(Engine number with first digit „8“)

3.205.73-E Updating of Rep.Manual LC4 7/1999

Modelyear 1999

(Engine number with first digit „9“)

3.205.89-E Updating of Rep.Manual LC4 9/2000

Modelyear 2000/2001

(Engine number with first digit „0“ and „1“)

3.210.30-E Updating of Rep.Manual LC4 12/2001

Modelljahr 2002

(Engine number with first digit „2“)

3.206.006-E Updating of Rep.Manual LC4 4/2003

Modelljahr 2003

(Engine number with first digit „3“)

Modification / Updating:

Special tools, hydraulic clutch, Keihin carburator,

technical details model 2003, technical specification,

Maintenance schedule and wiring diagrams for modell 2003

INTRODUCTION

This repair manual offers extensiv repair-instructions and is an up-to-date version that describes the

latest models of the series. However, the right to modifications in the interest of technical

improvement is reserved without updating the current issue of this manual.

A description of general working modes common in work shops has not been included. Safety rules

common in the work shop have also not been listed. We take it for granted that the repairs are

made by qualified profesionally trained mechanics.

Read through the repair manual before beginning with the repair work.

WARNING

STRICT COMPLIANCE WITH THESE INSTRUCTIONS IS

ESSENTIAL TO AVOID DANGER TO LIFE AND LIMB.

!

CAUTION

!

NON-COMPLIANCE WITH THESE INSTRUCTIONS CAN LEAD

TO DAMAGE OF MOTORCYCLE COMPONENTS OR RENDER

MOTORCYCLES UNFIT FOR TRAFFIC !

„NOTE” POINTS OUT USEFUL TIPS.

Use only ORIGINAL KTM SPARE PARTS when replacing parts.

The KTM high performance engine is only able to meet user expectations if the maintenance work

is performed regularly and professionally.

KTM Austria’s certificate of achievement for its quality system ISO 9001 is the beginning of an

ongoing total reengineered quality plan for a brighter tomorrow.

KTM Sportmotorcycle AG

5230 Mattighofen, Austria

All design and assembly modification rights reserved.

C

by KTM SPORTMOTORCYCLE AG, AUSTRIA All rights reserved

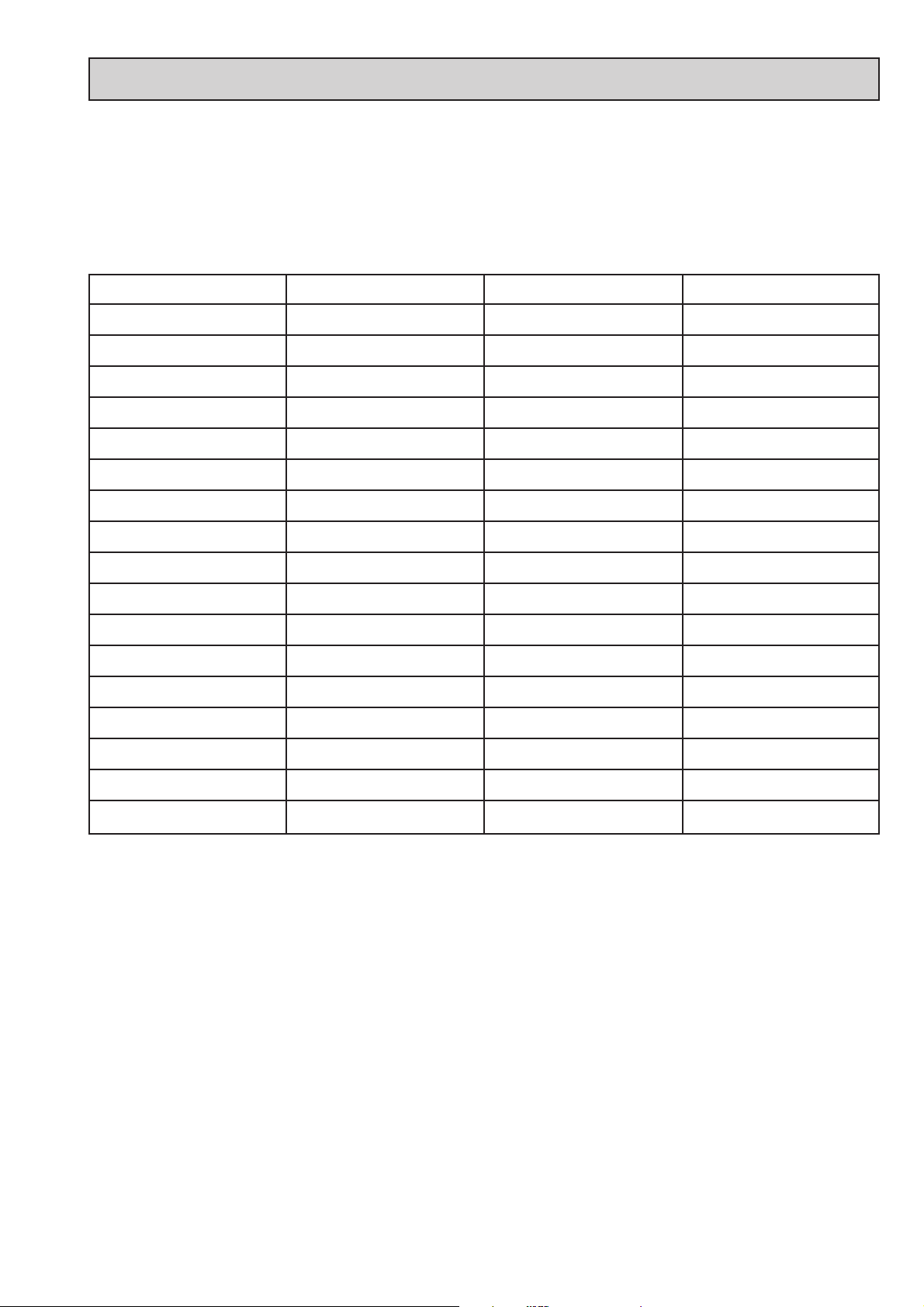

REPLY FAX FOR REPAIR MANUALS

We have made every effort to make our repair manuals as accurate as possible but it is always possible for

a mistake or two to creep in.

To keep improving the quality of our repair manuals, we request mechanics and shop foremen to assist us

as follows:

If you find any errors or inaccuracies in one of our repair manual – whether these are technical errors,

incorrect or unclear repair procedures, tool problems, missing technical data or torques, inaccurate or

incorrect translations or wording, etc. – please enter the error(s) in the table below and fax the completed

form to us at 0043/7742/6000/5349.

NOTE to table:

– Enter the complete item no. for the repair manual in column 1 (e.g.: 3.210.66-E).

You will find the number on the cover page or in the left margin on each right page of the manual.

– Enter the corresponding page number in the repair manual (e.g.: 5-7c) in column 2.

– Enter the current text (inaccurate or incomplete) in column 3 by quoting or describing the respective

passage of the text. If your text deviates from the text contained in the repair manual, please write

your text in German or English if possible.

– Enter the correct text in column 4.

Your corrections will be reviewed and incorporated in the next issue of our repair manual.

Item no. of repair manual Page Current text Correct text

Additional suggestions, requests or comments on our Repair Manuals (in German or English):

Name mechanic/shop foreman Company/work shop

MODELS WITHOUT FRAME OIL

CHANGING THE ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

CHANGING THE OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

CHANGING THE MICROFILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

OIL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

OIL CIRCUIT 660 SMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

MODELS WITH FRAME OIL

CHANGING THE ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

CHANGING THE FINE SCREEN FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

CHANGING THE OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

OIL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

SECONDARY AIR SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

EPC-SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

BLEEDING OF THE HYDRAULIC CLUTCH . . . . . . . . . . . . . . . . . . . . . . . .2-13

Repair manual KTM LC4 Art.-Nr. 3.206.006 -E

GENERAL INFORMATION

INDEX

2-1D

2

Repair manual KTM LC4 Art.-Nr. 3.206.006 -E

2-2D

Changing the engine oil (models without frame oil)

NOTE: The engine oil change is to be carried out when the engine is

still warm.

WARNING

A

N ENGINE HAVING BEEN RUN WARM, AND THE ENGINE OIL IN IT ARE VERY HOT -

DO NOT BURN YOURSELF

.

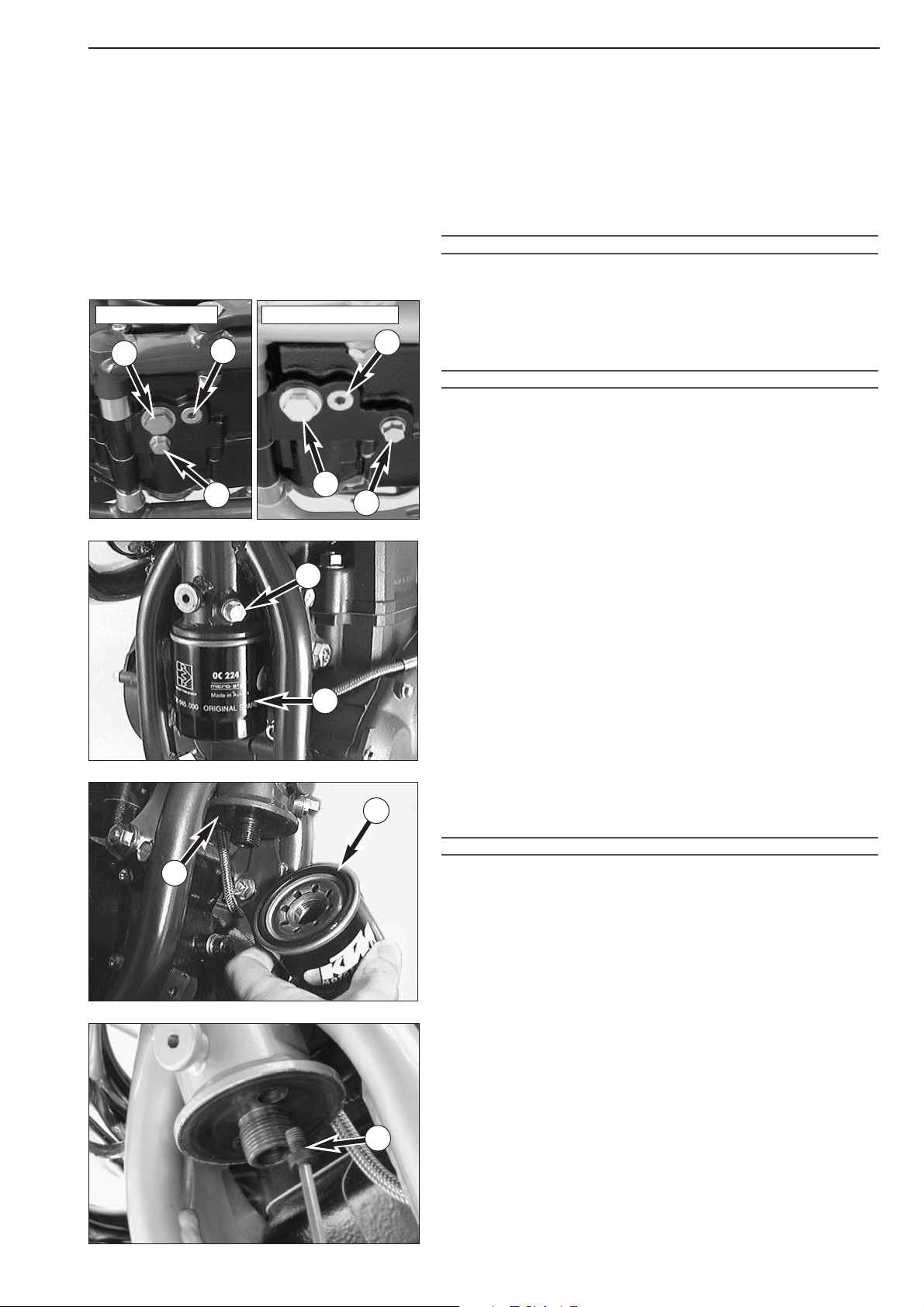

– Place the motorbike on a horizontal surface. Remove the two plugs

(

1 and 2), and drain oil into a container.

NOTE: A third plug was installed in the 660 SMC model. Tightening

torque: 20 Nm

!

CAUTION

!

THE SCREW PLUG A MUST NOT BE REMOVED

, THIS IS PART OF THE BY

-PASS VALVE.

– Clean the plugs thoroughly with a fireproof solvent and compressed

air, in order to remove the metal abrasion.

– After all the oil has drained through, clean raised and flat faces and

install plugs with seals. Tighten plug

1 with 30 Nm (22 ft.lb) and

plug

2 with 20 Nm (15ft.lb).

– Remove the oil dipstick at the clutch cover, pour in engine oil and

replace the oil dipstick.

Oil capacity (up to model 2002) : 1.40 l

Oil capacity (from model 2003 on) : 1.50 l

Changing the oil filter

Replace the oil filter when changing the engine oil.

–Press the foot brake pedal and place a screwdriver or similar between

foot brake pedal and stopper roll so that the oil filter cover is more

accessible.

– Remove banjo bolt

3 and the three bolts 4.

– Remove oil filter cover

5 and oil filter.

– Clean filter housing, oil filter cover and sealing surfaces. Check oil

duct in oil filter cover if clogged.

–Press the new O-ring

6 into the groove of the filter cover (if

necessary fix with grease). Mount a new oil filter

7 on the

connection piece of the oil filter cover an mount the whole unit.

NOTE: From model 2001 onwards the gasket

8 is mounted with a

changed filter cover

5. If the new gasket 8 should be used on older

engines, the filter cover must be flat regrinded or renewed (see

Technical Info Nr. 0201/30/01).

– Mount three bolts and tighten with 5 Nm (4 ft.lb).

– Mount hollow bolt with seal rings and tighten with 15 Nm

(11 ft.lb).

1

1

A

A

2

up to Modell 2001

from Modell 2002 on

2

3

4

5

6

7

8

3

4

5

2-3D

Changing the microfilter

Replace the microfilter while changing the engine oil.

–To do so, remove bolts

1 and take off the microfilter cover 2.

– Remove the microfilter, clean its parts and check the O-ring on the

microfilter cover for signs of damage.

– Insert a new microfilter into the filter housing, tilt the motorcycle

sideways and fill the microfilter housing with engine oil.

– Slightly grease the O-ring and mount the microfilter cover. Then put

the motorcycle back on its stand.

– It is necessary to bleed the microfilter so that all lubricating points

can be quickly supplied with engine oil.

–To do this, fill with oil and remove the jet screw from the oil line on

the clutch cover.

– Start the engine and close off the bore on the clutch cover with a

rag.

– Allow the engine to run at idle until oil runs out of the oil line

3.

–Turn off the engine. Mount the jet screw, using two new seal rings.

–Torque the jet screw to 10 Nm and check for leaks.

– Start the engine and let it idle for 1 - 2 minutes.

!

CAUTION

!

DO NOT REV UP THE ENGINE IMMEDIATELY AFTER AN OIL CHANGE ! KEEP IN MIND

THAT IT TAKES SOME TIME UNTIL ALL LUBRICATING POINTS ARE PROPERLY PROVIDED

WITH ENGINE OIL

.

– Allow the engine to run until warm. Then, turn off the engine, and

place the motorbike on a flat, level surface in an upright position

(center stand). Wait for 5 minutes. Unscrew and remove the oil

dipstick, and wipe it clean with a cloth.

– Screw the dipstick in all the way and remove it again. The oil level

should be between the two marks on the oil dipstick, however, it

must never rise above the MAX mark. Otherwise, engine oil would

get into the air filter box by way of the engine venting system. Add

engine oil, if necessary.

–Finally, check oil system and engine for leaks.

!

CAUTION

!

–ONLY USE HIGH

-QUALITY OILS MEETING OR SURPASSING THE QUALITY

REQUIREMENTS OF

JASO T903 MA (FOR SPECIFICATIONS SEE CONTAINERS).

–I

NSUFFICIENT OIL OR POOR QUALITY OIL RESULTS IN PREMATURE WEAR OF THE

ENGINE

.

–Y

OU MAY USE EITHER MINERAL OILS OR SYNTHETIC OILS FULFILLING THE ABOVE

CRITERIA

.

NOTE: Dispose of used oil properly !

Under no circumstances may used oil be disposed of in the sewage

system or in the open countryside.

1 liter oil contaminates 1.000.000 liter water.

3

1

1

2

0°C

32°F

10W/50

5W/40

JASO T903 MA

TEMPERATURE

2-4D

Repair manual KTM LC4 Art.-Nr. 3.206.006 -E

8

7

1

2

3

4

5

6

9

10

11

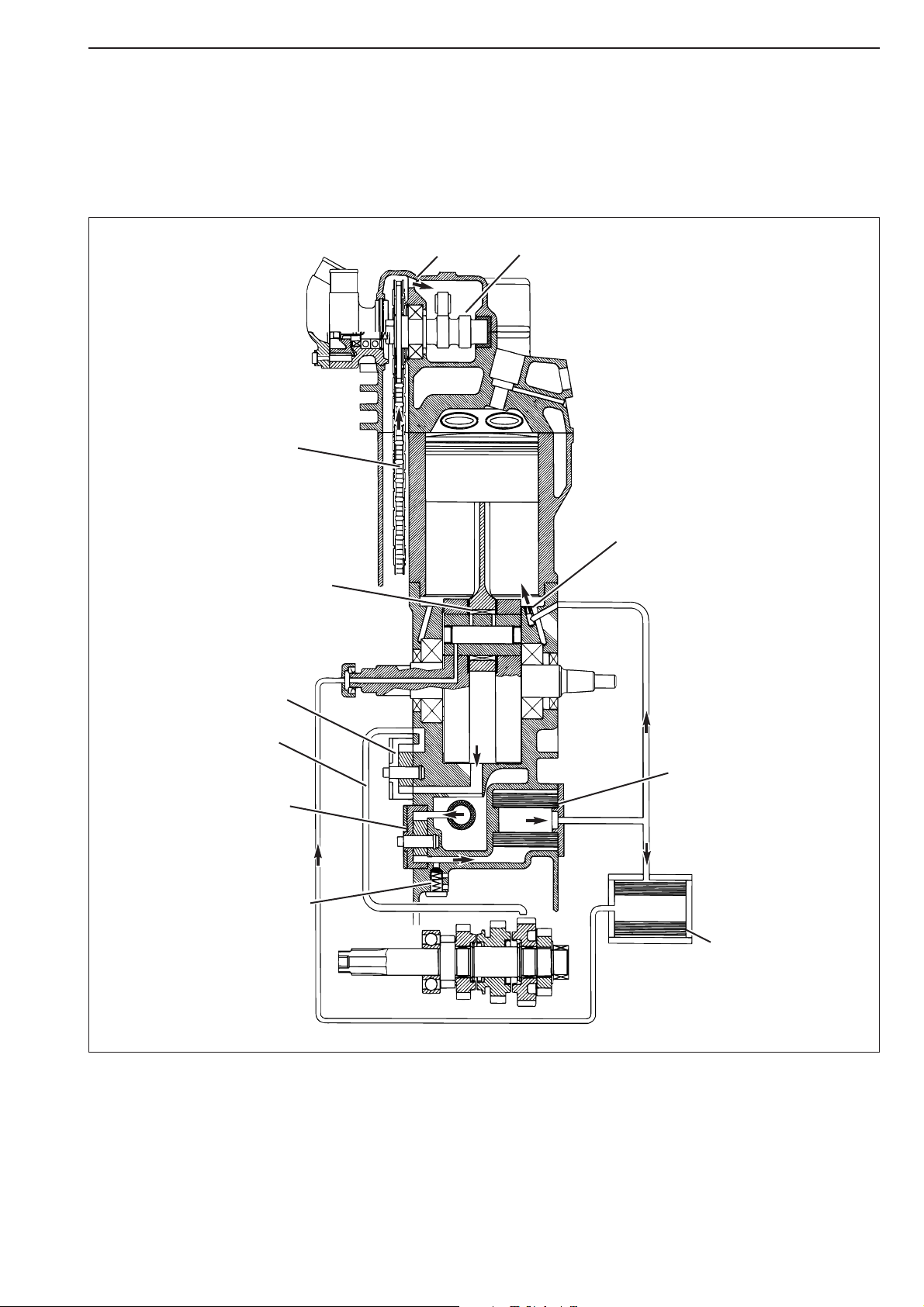

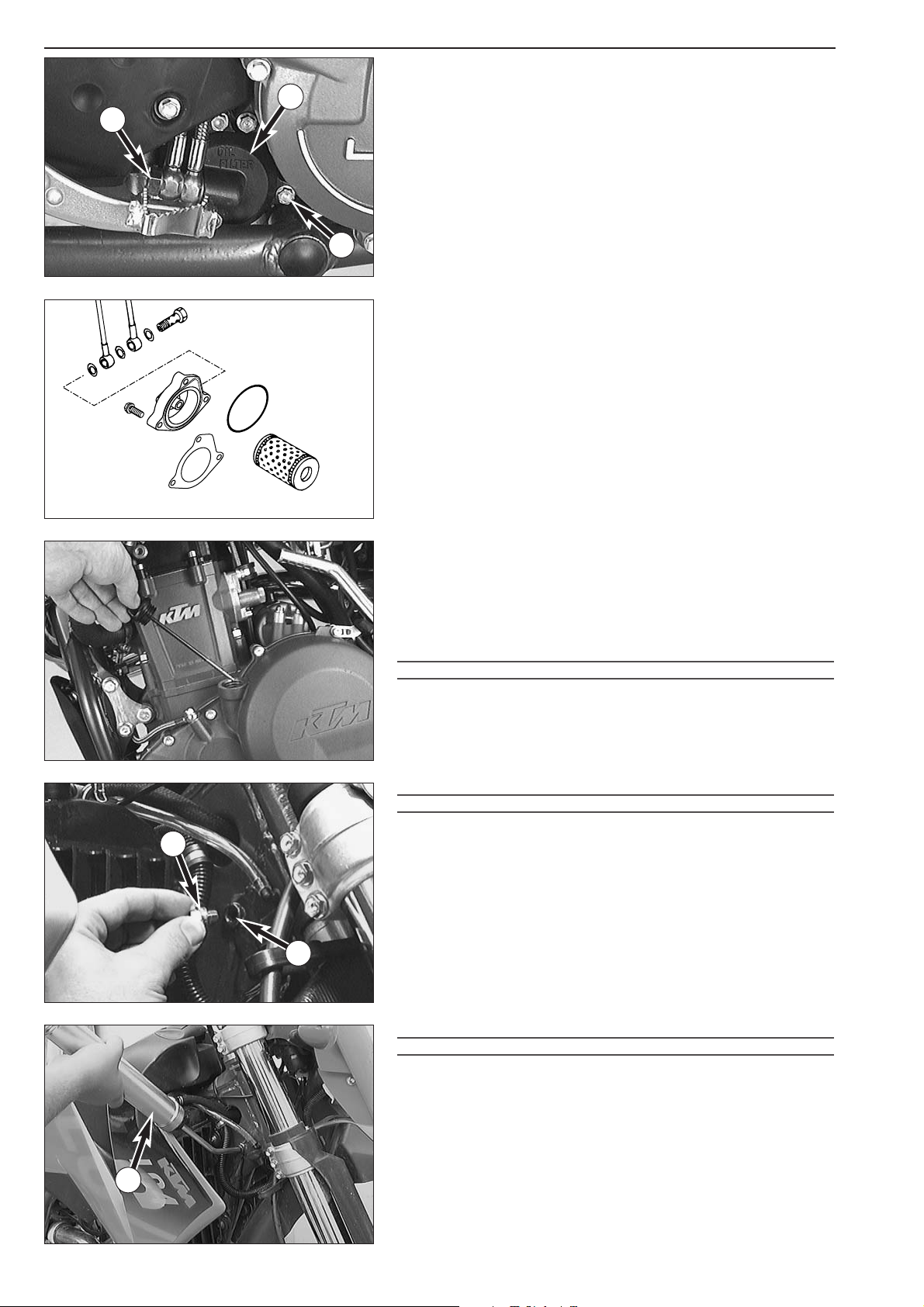

Oil circuit

The oil pump 1 pumps the engine oil past the by-pass valve 2 through the oil filter 3. After the oil filter, an oil lead branches

off to a jet

4 which sprays engine oil onto the piston pin bearing and piston head. The second oil lead takes the main flow of oil

to the microfilter

5, which filters out even the finest impurities. The cleaned engine oil is pumped through the oil lead and the

clutch cover into the crankshaft to the connecting rod bearing 6 and drips into the crankcase. An additional oil pump 7 sucks

the engine oil out of the crankcase and pumps it through the oil line

8 to the gear wheels of the 4th and 5th gear. Via the gear

wheels, the engine oil reaches the oil sump. The timing chain

9 runs through the oil sump and transports the engine oil upwards

to the cylinder head. Through the bore

bk the oil reaches the camshaft bl and the valves.

2-5D

8

7

1

2

3

4

4

5

6

9

10

11

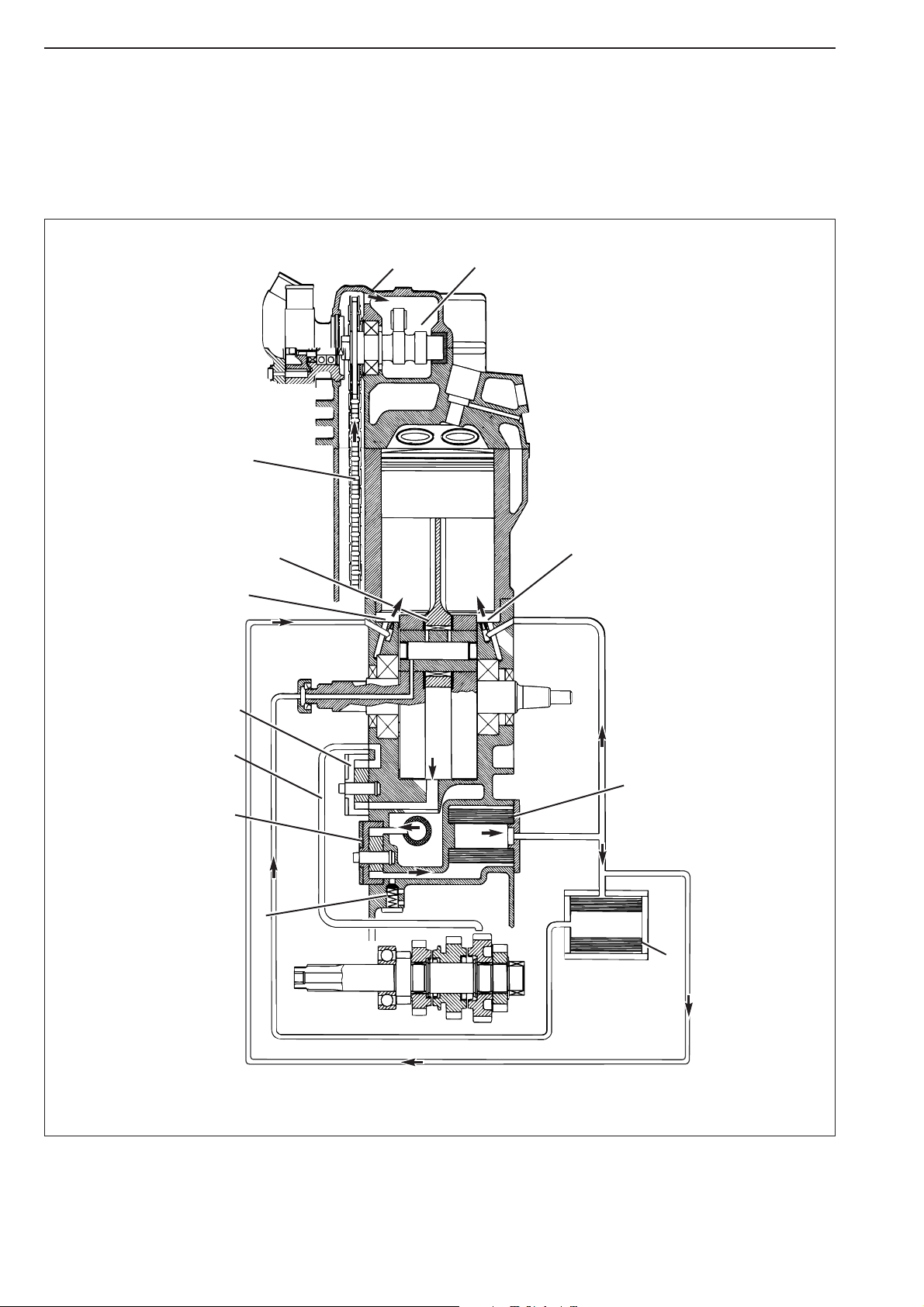

Oil circuit 660 SMC

The oil pump 1 pumps the engine oil past the by-pass valve 2 through the oil filter 3. After the oil filter, an oil lead branches

off to a jet

4 which sprays engine oil onto the piston pin bearing and piston head. The second oil lead takes the main flow of oil

to the second jet

4 and the microfilter 5, which filters out even the finest impurities. The cleaned engine oil is pumped through

the oil lead and the clutch cover into the crankshaft to the connecting rod bearing

6 and drips into the crankcase. An additional

oil pump

7 sucks the engine oil out of the crankcase and pumps it through the oil line 8 to the gear wheels of the 4th and 5th

gear. Via the gear wheels, the engine oil reaches the oil sump. The timing chain

9 runs through the oil sump and transports the

engine oil upwards to the cylinder head. Through the bore

bk the oil reaches the camshaft bl and the valves.

2-6D

Repair manual KTM LC4 Art.-Nr. 3.206.006 -E

Changing the engine oil (models with frame oil)

NOTE: For improved cooling of the engine oil, the front tube of the

frame was integrated into the oil circuit.Thus, when you change the oil,

you also have to drain the engine oil from the front tube and bleed the

oil system.

If the oil system is not bled at all or bled insufficiently, the bearings of

the engine will not get enough lubrication, which in turn may result in

engine failure.

The engine oil change is to be carried out when the engine is still warm.

WARNING

AN ENGINE HAVING BEEN RUN WARM, AND THE ENGINE OIL IN IT ARE VERY HOT -

DO NOT BURN YOURSELF

.

– Place the motorcycle on a horizontal surface. When working on a

motorcycle with engine guard, remove the latter before commencing

to change the engine oil.

– Remove the two plugs

1 and 2, and drain oil into a container.

!

CAUTION

!

PLUG A MUST NOT BE REMOVED,

THIS IS PART OF THE BY

-PASS VALVE

.

Changing the fine screen filter

Replace the fine screen 3 filter when changing the engine oil.

– Loosen the three bolts and remove the cover.

– Undo the spin-on filter

3 with the corresponding special tool, twist

it off manually and let the engine oil out of the front pipe of the

frame.

– Unscrew plug

4 at the lower end of the front pipe and drain oil (up

to model 2000).

– Clean sealing surfaces on the front pipe

5, fill new fine screen filter

with engine oil, and oil rubber gasket

6. Replace fine screen filter

and screw it back in place, your bare hand will do.

!

CAUTION

!

USE ONLY ORIGINAL KTM FINE SCREEN FILTERS. USING ANOTHER FILTER BRAND CAN

RESULT IN DAMAGE TO THE ENGINE

!

–From model 2001 onwards the drain plug 7 of the frame oil is

located in the oil filter flange, draining is only possible after removing

the oil filter.

– Clean all 3 plugs thoroughly with a fireproof solvent and compressed

air, in order to remove the metal abrasion.

– After all the oil has drained through, clean sealing areas and install

plugs with gaskets. Tighten plug

1 with 30 Nm (23 ft.lb), plug 2

with 20 Nm and plug 4 with 10 Nm (up to model 2000). Drain plug

of frame oil (model 2001 onwards) is to be mounted without a

gasket and tightened to 10 Nm (7 lb.ft).

1

1

A

A

2

up to Modell 2001

from Modell 2002 on

2

5

3

4

6

7

2-7D

Changing the oil filter

Replace the oil filter when changing the engine oil.

–Press the foot brake pedal and place a screwdriver or similar between

foot brake pedal and stopper roll so that the oil filter cover is more

accessible.

– Remove banjo bolt

1 and the three bolts 2.

– Remove oil filter cover

3 and oil filter.

– Clean filter housing, oil filter cover and sealing surfaces. Check oil

duct in oil filter cover if clogged.

–Press the new O-ring

4 into the groove of the filter cover (if

necessary fix with grease). Mount a new oil filter

5 on the

connection piece of the oil filter cover an mount the whole unit.

NOTE: From model 2001 onwards the gasket

6 is mounted with a

changed filter cover

3. If the new gasket 6 should be used on older

engines, the filter cover must be flat regrinded or renewed (see

Technical Info Nr. 0201/30/01).

– Mount three bolts and tighten with 5 Nm (4 ft.lb).

– Mount banjo bolt with seal rings and tighten with 15 Nm

(11 ft.lb).

– Remove the oil dipstick at the clutch cover, pour in engine oil and

replace the oil dipstick.

Oil quantity (engine only) : 1.40 liter

!

CAUTION

!

IF THE ENGINE OIL HAS BEEN DRAINED FROM THE FRONT PIPE OF THE FRAME

, YOU

MUST BLEED THE OIL SYSTEM

!

– Remove the plug

7 next to the steering head and use a lubricating

syringe

8 (see special tools) to fill the front pipe with approx. 0.6 l

engine oil. Add oil until it begins to emerge at bore

B.

– Mount the plug, using a new seal ring.

!

CAUTION

!

DO NOT REV UP THE ENGINE IMMEDIATELY AFTER AN OIL CHANGE. KEEP IN MIND

THAT IT TAKES SOME TIME UNTIL ALL LUBRICATING POINTS ARE PROPERLY PROVIDED

WITH ENGINE OIL

.

– Allow the engine to run until warm. Then, turn off the engine, and

place the motorbike on a flat, level surface in an upright position

(center stand). Wait for 5 minutes. Unscrew and remove the oil

dipstick, and wipe it clean with a cloth.

– Screw the dipstick in all the way and remove it again. The oil level

should be between the two marks on the oil dipstick, however, it

must never rise above the MAX mark. Otherwise, engine oil would

get into the air filter box by way of the engine venting system. Add

engine oil, if necessary.

–Finally, check oil system and engine for leaks.

!

CAUTION

!

–ONLY USE HIGH-QUALITY OILS MEETING OR SURPASSING THE QUALITY

REQUIREMENTS OF

JASO T903 MA (FOR SPECIFICATIONS SEE CONTAINERS).

–I

NSUFFICIENT OIL OR POOR QUALITY OIL RESULTS IN PREMATURE WEAR OF THE

ENGINE

.

–Y

OU MAY USE EITHER MINERAL OILS OR SYNTHETIC OILS FULFILLING THE ABOVE

CRITERIA

.

NOTE: Dispose of used oil properly !

Under no circumstances may used oil be disposed of in the sewage

system or in the open countryside !

1 liter oil contaminates 1.000.000 liter water !

B

1

2

3

4

5

6

3

1

2

7

8

2-8D

Repair manual KTM LC4 Art.-Nr. 3.206.006 -E

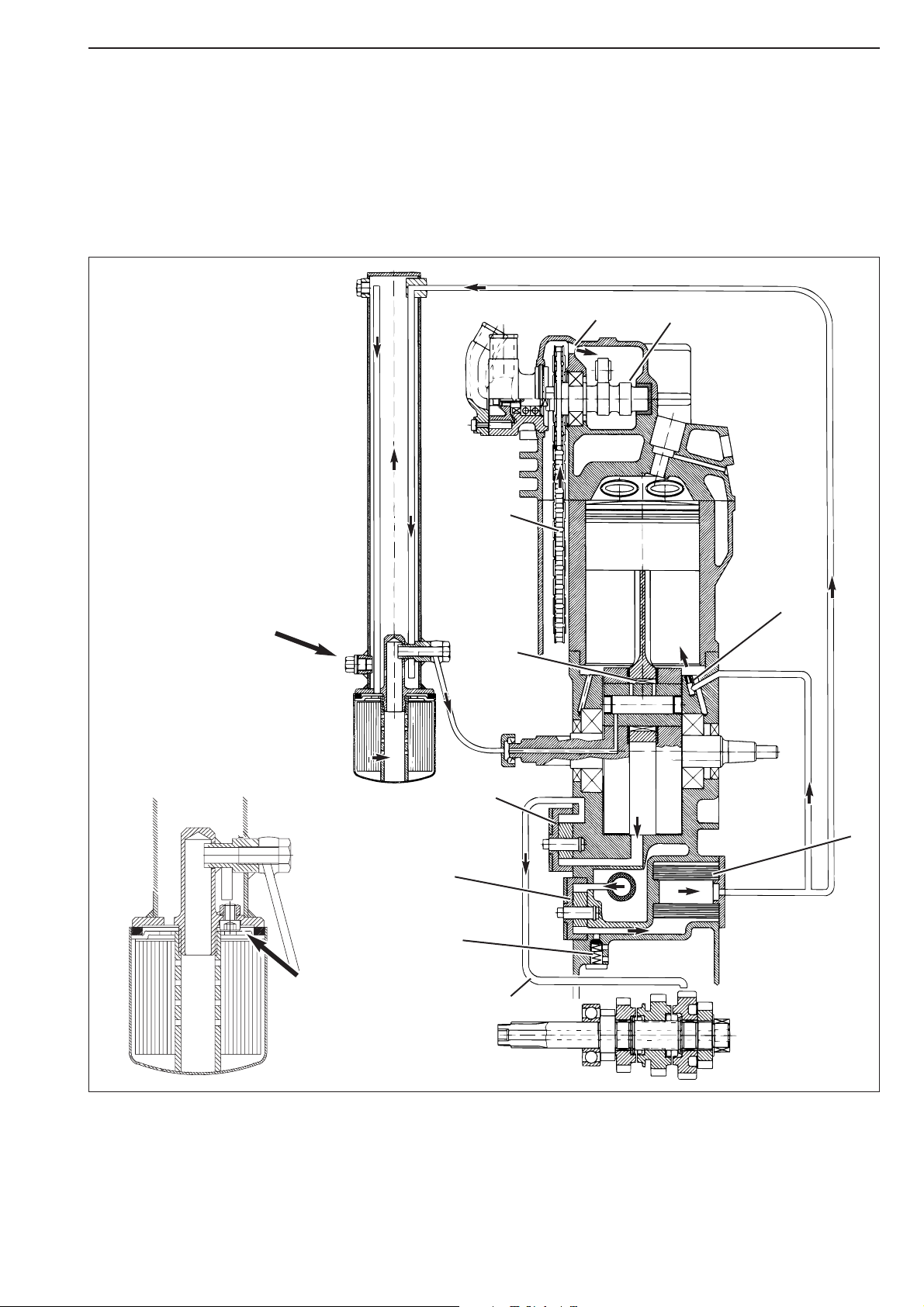

Oil circuit

The oil pump 1 pumps the engine oil past the by-pass valve 2 through the oil filter 3. After the oil filter, an oil line branches off

to a jet

4 which sprays engine oil onto the piston pin bearing and piston head. The second oil line takes the main flow of oil into

the front pipe of the frame

5, where the engine oil is cooled down. Afterwards the engine oil runs through the fine screen filter

6, which filters out even the finest impurities. The cleaned engine oil is pumped through the oil line and the clutch cover into the

crankshaft to the conrod bearing

7 and drips into the crankcase. An additional oil pump 8 sucks the engine oil out of the

crankcase and pumps it through the oil line

9 to the gear wheels of the 4th and 5th gear. Via the gear wheels, the engine oil

reaches the oil sump. The timing chain

bk runs through the oil sump and transports the engine oil upwards to the cylinder head.

Through the bore hole

bl the oil reaches the camshaft bm and the valves.

8

7

5

6

9

10

12

11

1

2

3

4

Drain plug - frame oil

up to Model 2000

Drain plug - frame oil

Model 2001 onwards

2-9D

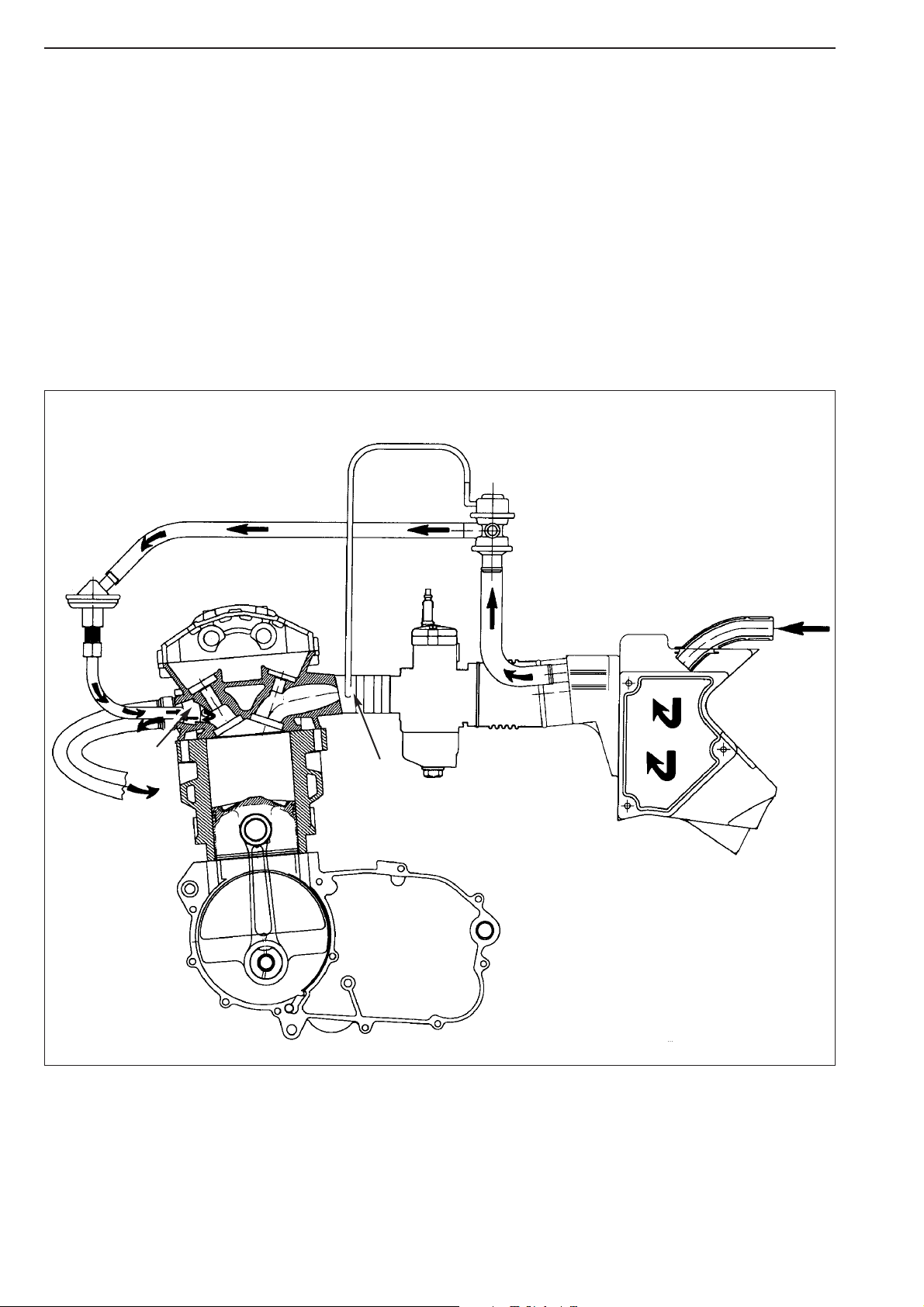

Functional characteristics of the secondary air system (SLS)

When the exhaust valve is open, the hot exhaust gases flow through the exhaust port 1 at a very high speed. As a consequence

of the flow conditions in the exhaust port and due to the influence exerted by the entire exhaust system on the escaping gases,

the pressure in the exhaust port drops temporarily (underpressure).

During these cyclic underpressure phases, the secondary air valve

2 opens, thus adding oxygen of the air to the hot exhaust

gases through pipe

3.

At higher engine speeds, the secondary air valve interrupts the oxygen supply to prevent overheating of the catalytic converter.

Additionally, the secondary air valve prevents the exhaust gases from flowing back into the air filter box

4.

When the motorcycle is pushed (high underpressure in the intake port) the control valve (ASV)

5 interrupts the air flow into the

exhaust port to prevent exhaust detonations.

The control valve is controlled via a control pipe

6. This control pipe transmits the underpressure from the intake port 7 to the

control valve.

During normal operation (slight underpressure in the intake port), the control valve is open.

The reaction between the oxygen of the air and the harmful components of the exhaust gases (CO - carbon monoxide, HC hydrocarbon) reduces the content of harmful substances by approximately 50%. The use of a catalytic converter, in combination

with the SLS, allows an additional significant reduction of pollutant emissions.

6

5

7

3

2

1

4

Repair manual KTM LC4 Art.-Nr. 3.206.006 -E

2-10D

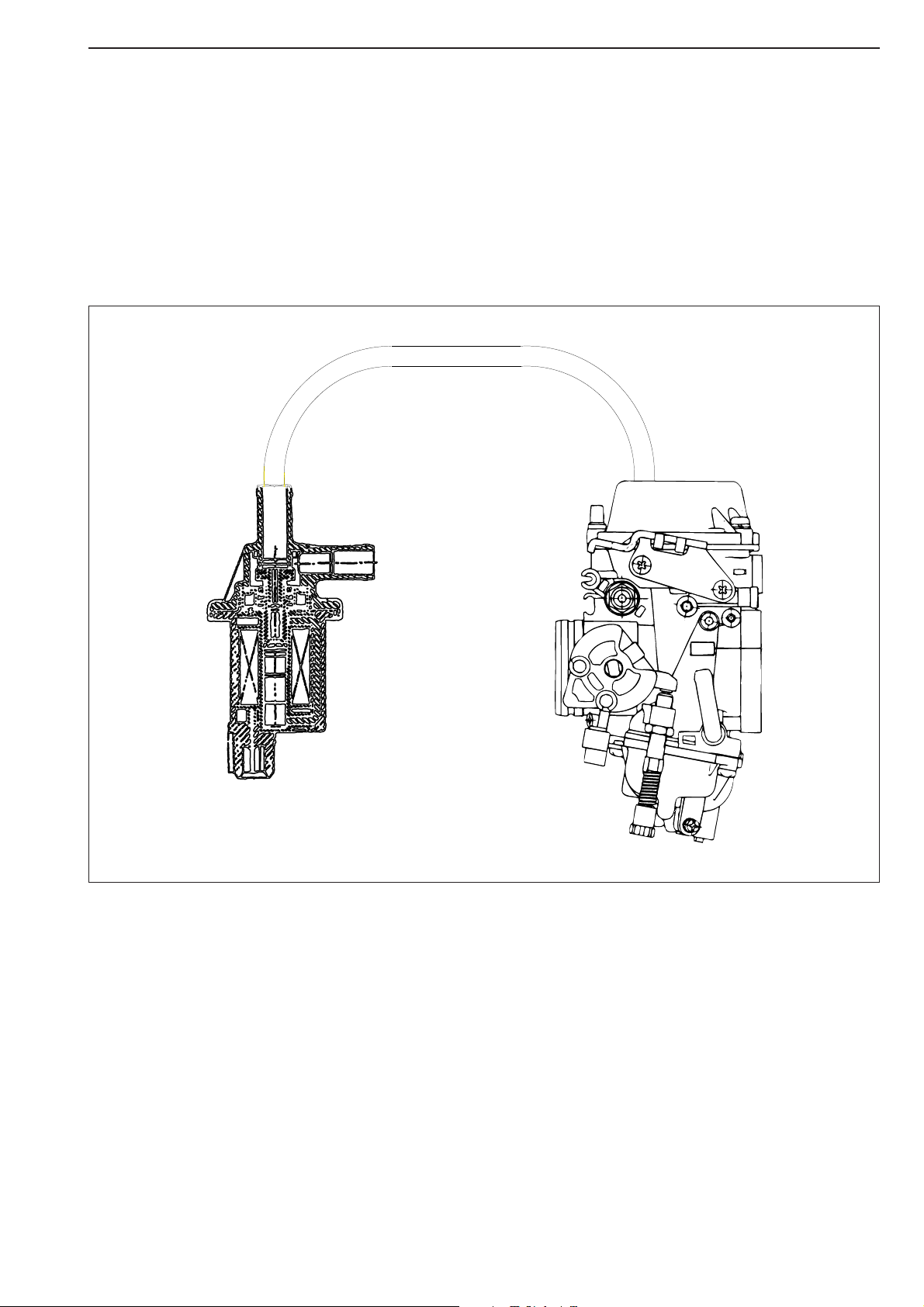

Electronic Power Control System (EPC)

Main components of the EPC system:

– Constant-pressure carburetor

– Control device

– Solenoid valve

– 2 contact screws at the engine

– Micro-switch (at carburetor)

FUNCTIONAL CHARACTERISTICS:

The EPC system is not activated during normal operation of the motorcycle.

It is, however, activated as soon as the throttle is fully opened at a speed of 45 - 55 km/h while the second or third gear are

engaged.

The EPC control device opens the solenoid valve, directing an appropriate flow of fresh air onto the upper side of the slide

membrane of the constant-pressure carburetor, thus reducing the opening speed of the slide. This mechanism significantly reduces

the exhaust gas emissions of the vehicle.

SOLENOID VALVE

2-11D

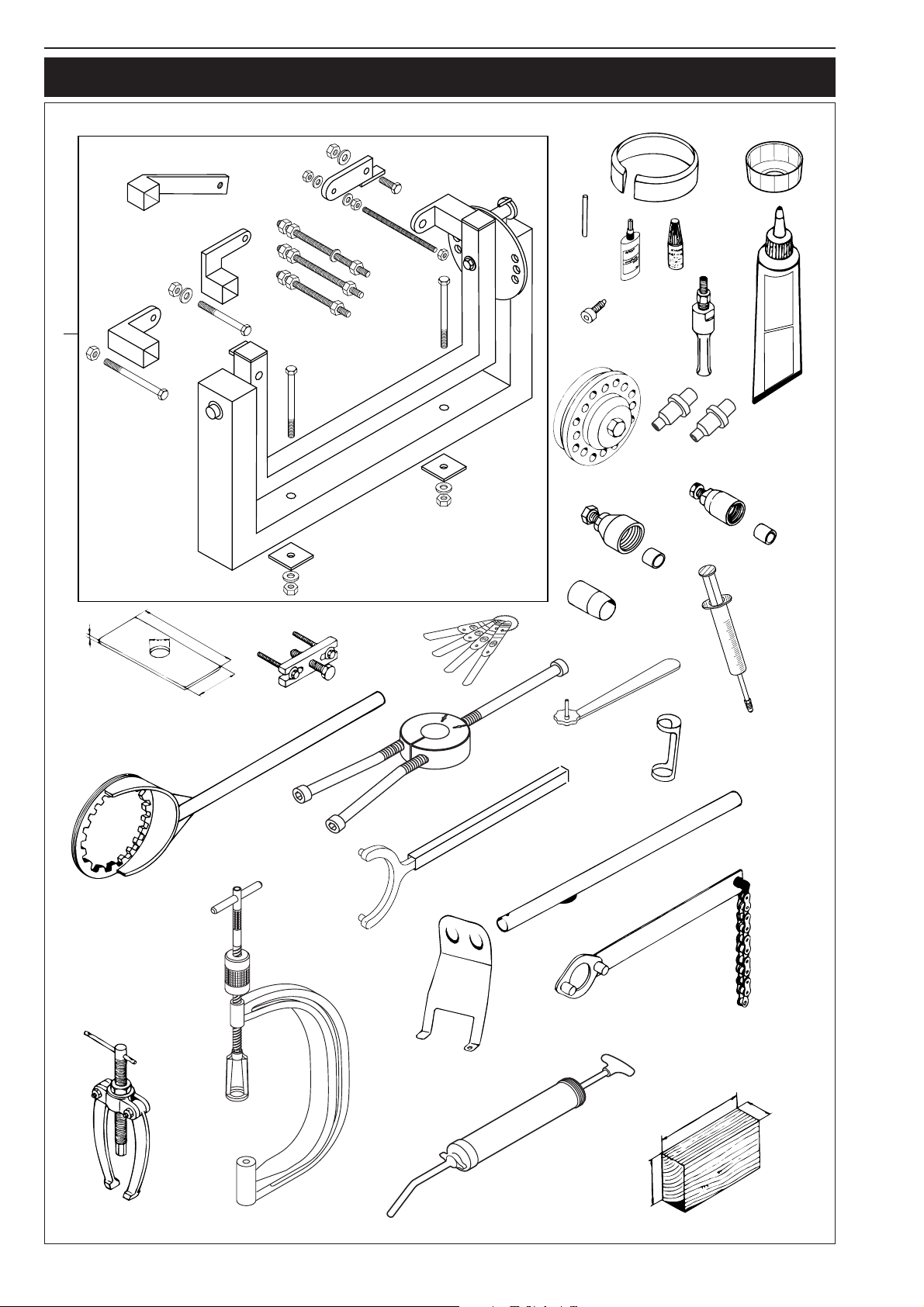

SPECIAL TOOLS

6

39

26

11

648

12

20

16

1

ThreeBond

1215

18

Silicone Liquid Gasket

Silicone Flüssige Dichtung

23

4#

4

5#

5

5

27

150

7

10

3

49

14

70

15

19

9

2

17

8

22

8#

130

35

48

65

Repair manual KTM LC4 Art.-Nr. 3.206.006 -E

2-12D

FIG. PART NO. DESCRIPTION

1 560.12.001.000 Universal engine work stand

2 583.29.003.000 Clutch holder

3 580.12.005.025 Mounting sleeve for crankshaft seal ring Ø 25 mm

4 584.29.009.000 Magneto extractor (Kokusan)

4# 580.12.009.000 Magneto extractor (SEM)

5 510.12.016.000 Protection cover for crankshaft (SEM)

5# 584.29.031.000 Protection cover for crankshaft (Kokusan)

6 580.12.015.089 Piston ringspanner Ø 89 mm

580.12.015.095 Piston ringspanner Ø 95 mm

580.12.015.100 Piston ringspanner Ø 100 mm

580.12.015.101 Piston ringspanner Ø 101 mm

585.29.015.102 Piston ringspanner Ø 102 mm

7 590.29.021.044 Extractor for primary gear and clutch hub

8 580.12.019.000 Valve mounting set

8# 590.29.019.000 Valve mounting set

9 6.276.470 Valve spring-push insert

10 590.29.041.000 Feeler gauge for valve clearance

11 6.899.785 Loctite 243 blue 6 ml

12 584.29.059.000 Loctite 648 red 20 ml

14 590.29.034.000 Wrench for mixture regulating screw

15 151.12.017.000 Gear puller

16 151.12.018.000 Internal bearing puller 12 - 16 mm

16 151.12.018.100 Internal bearing puller 18 - 23 mm

17 584.29.012.000 Flywheel holding spanner (Kokusan)

18 3090.98 Seal (Three-Bond)

19 584.29.037.040 Mounting tool inner ring NJ207 (all versions of LC4)

19 584.29.037.043 Mounting tool inner ring NJ306 (LC4-E)

20 580.30.080.000 Crankshaft locking bolt

22 510.12.012.000 Chain sprocket holder

23 546.29.027.000 Clutch rivetting tool

26 580.29.026.007 Limit plug gauge Ø 7,05 mm

39 583.29.039.000 Oil filter wrench

48 584.29.048.000 Syringe for pipe oil

49 503.29.050.000 Bleeding syringe for hydraulic clutch

2-13D

Checking the oil level of the hydraulic clutch

To check the oil level in the master cylinder of the clutch remove the

cover. For this purpose, remove screws

1 and cover 2 together

with the rubber boot

3. The oil level in the horizontal-standing

master cylinder should be 4 mm below the upper edge.

If necessary, fill up with biodegradable hydraulic oil SAE 10 (f.ex.

Motorex Kupplungs-Fluid 75).

!

CAUTION

!

– KTM

USES BIODEGRADABLE HYDRAULIC OIL FOR THE HYDRAULIC CLUTCH

CONTROL

. NEVER MIX BIODEGRADABLE HYDRAULIC OILS WITH MINERAL OILS

.

–A

LWAYS USE BIODEGRADABLE HYDRAULIC OIL SAE 10 TO FILL UP THE MASTER

CYLINDER

. NEVER REFILL WITH MINERAL HYDRAULIC OIL OR BRAKE FLUID.

Bleeding of the hydraulic clutch

To bleed, the cover of the master cylinder of the clutch needs to be

removed. For this purpose, remove screws

1 and take off cover 2

together with rubber bellows 3. At the slave cylinder of the clutch,

remove the bleeder nipple

4. In its place, mount the bleeder syringe 5

which is filled with SAE 10 hydraulic oil. Refill oil until oil is discharged

from the bore

6 of the master cylinder in a bubble-free state. Make

sure that the oil does not overflow. The bleeder syringe can be

purchased from your KTM dealer.

Having completed the bleeding procedure, you have to verify that the

oil level in the master cylinder is correct. If necessary, fill up with

biodegradable hydraulic oil SAE 10 (f.ex. Motorex Kupplungs-Fluid

75).

!

CAUTION

!

– KTM

USES BIODEGRADABLE HYDRAULIC OIL FOR THE HYDRAULIC CLUTCH

CONTROL

. N

EVER MIX BIODEGRADABLE HYDRAULIC OILS WITH MINERAL OILS

.

–A

LWAYS USE BIODEGRADABLE HYDRAULIC OIL SAE 10 TO FILL UP THE MASTER

CYLINDER

. NEVER REFILL WITH MINERAL HYDRAULIC OIL OR BRAKE FLUID.

2

1

3

4

6

5

Repair manual KTM LC4 Art.-Nr. 3.206.006 -E

REMOVING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

REFITTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

REMOVING AND REFITTING ENGINE

INDEX

3-1D

3

Loading...

Loading...