Page 1

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications engineering

Engineering systems & solutions

GR

©

KROHNE 09/98 1.2M87E1099876

Installation and

operating instructions

VFM 3100 F - T

VFM 3100 W- T

Vortex Flowmeter

Page 2

3.2. No Output Troubleshooting 27

3.3. Module Test Procedure 28

3.4. Preamplifier Test Procedure 28

3.4.1. Extended Temperature Range Sensor 28

3.4.2. Standard Temperature Range Sensor 28

3.5. Sensor Test Procedure 29

3.5.1. Standard Temperature Range Sensor 29

3.5.2. Extended Temperature Range Sensor 29

4. Maintenance 29

4.1. Introduction 29

4.1.1. Vortex Generation and Shedding 29

4.1.2. Vortex Sensing 29

4.1.3. Amplification, Conditioning and Processing 29

4.2. Electronic Module 30

4.2.1. Electronic Module Removal 30

4.3. Electronic Module Replacement 33

4.4. Preamplifier 34

4.4.1. Preamplifier Removal 34

4.4.2. Replacing the Preamplifier 35

4.5. Post-Assembly Dielectric Test 37

4.6. Sensor Replacement with Integral Electronic Module 37

4.6.1. Disassembly 37

4.6.2. Replacing the Sensor 38

4.7. Sensor Replacement with Remote Electronic Module 41

4.7.1. Disassembly 41

4.7.2. Assembly 42

5. Determining Special Measuring Units 43

6. Isolation Valves 43

6.1. Replacing the Sensor 43

6.2. Replacing or Installing an Isolation Valve 44

7. HART Configuration Instructions 45

7.1. Introduction 45

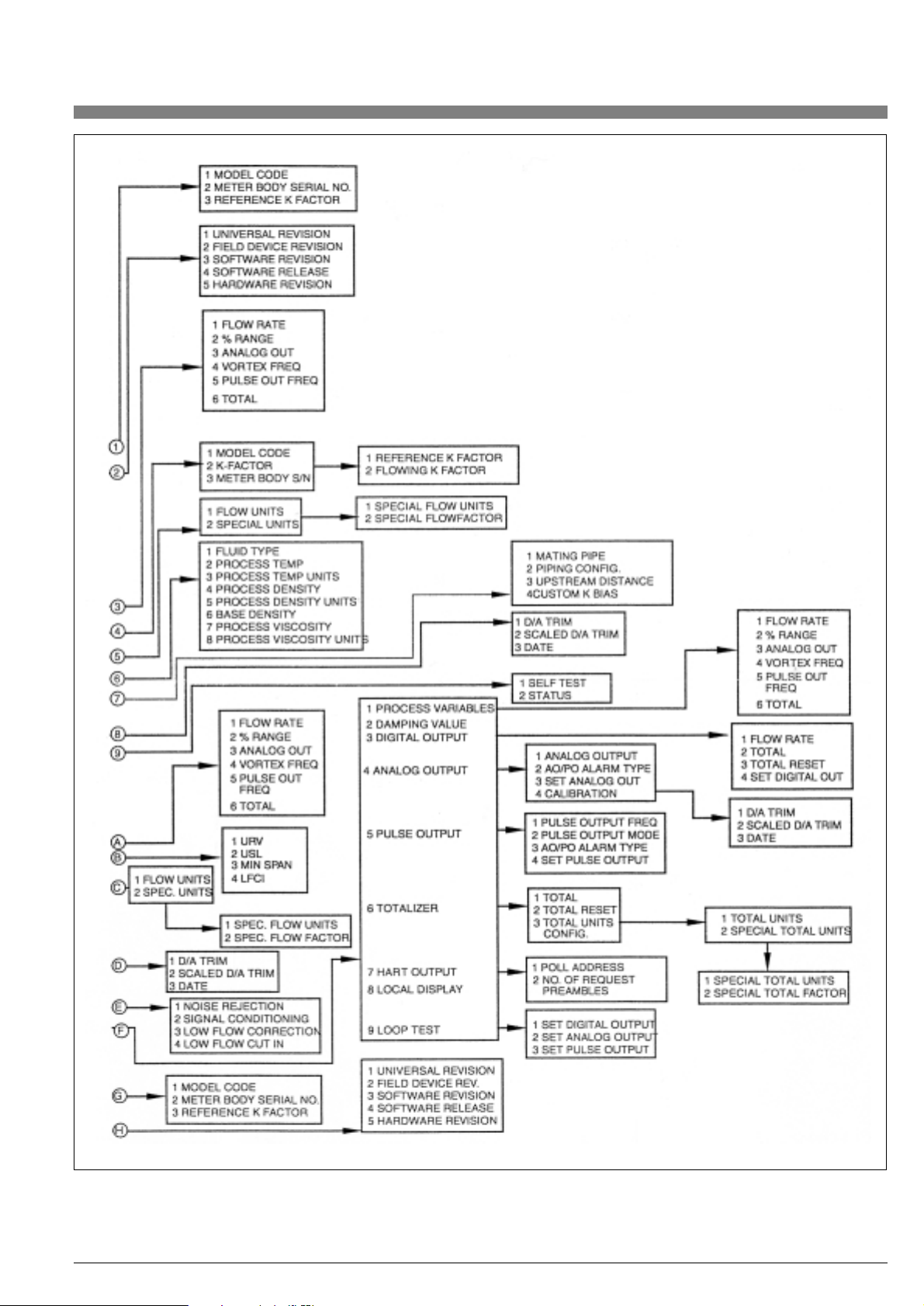

7.2. HART Menu Structure 45

8. Local Configuration Instructions 49

8.1. Introduction 49

8.2. Using the Local Configurator 49

8.2.1. Measurements (MEASURE) 49

8.2.2. Display Bar Indicator 49

8.2.3. Moving inside the Menu System 49

8.2.4. Viewing Data (DISPLAY) 50

8.2.5. Answering a Question 50

2

1. Installation 6

1.1. Introduction 6

1.1.1. Description 6

1.1.2. Fundamental Installation Requirements 6

1.1.3. Standard Specifications 7

1.1.4. Electrical Safety Specifications 8

1.1.5. Unpacking 8

1.1.6. VFM 3100 Identification 8

1.2. Mechanical Installation 9

1.2.1. Piping Considerations 9

1.2.2. Installation Position 10

1.2.3. Ambient Temperature 10

1.2.4. Vibration 10

1.2.5. Installation Procedure 12

1.2.6. Repositioning the Electrical Housing 12

1.2.7. VFM 3100 with Remote Electronic Module 13

1.3. Field Termination 19

1.3.1. Conduit Connections 19

2. Operating the VFM 3100 22

2.1. Introduction 22

2.2. Passwords 22

2.3. Configuration Database 22

2.4. Changing the Configuration (Configuration Menu) 23

2.4.1. Identification Parameters 23

2.4.2. Transmitter Options 23

2.4.3. Process Fluid Parameters 25

2.4.4. Application Parameters 25

2.4.5. Output Options 25

2.5. Preconfiguring the VFM 3100 26

2.6. Displaying the Configuration Database 26

2.7. Adjusting the VFM 3100 26

2.7.1. mA Calibration (D/A Trim) 26

2.7.2. Total Reset 26

2.7.3. Low Flow Cut-In 26

2.7.4. Upper Range Value 26

2.8. Reading the Measurements 26

2.9. Testing the VFM 3100 and Loop (Test Menu) 26

2.9.1. Self-Test 26

2.9.2. Loop Test or Loop Calibration 26

2.10. Electronic Module Replacement 26

3. Troubleshooting 27

3.1. General Troubleshooting 27

3.1.1. VFM 3100 Has Incorrect Output 27

3.1.2. VFM 3100 Output Indicates Flow When

There Is No Flow 27

3.1.3. VFM 3100 Output Indicates Higher

Flow Rate with Decreasing Flow 27

3.1.4. Fluctuating Output 27

Contents

Page 3

8.2.6. Entering the Password 50

8.2.7. Activating an Edit, Pick-List or

User Function Menu Block 50

8.2.8. Editing Numbers and Strings 50

8.2.9. Picking from a List 50

8.2.10. mA Calibration

(TEST/CAL 4 mA or CAL 20 mA) 50

8.2.11. Transmitter Status 50

8.2.12. Changing the Password 50

8.3. Local Configurator Menu Tree 51

8.3.1. Reading the Menu Tree 51

8.4. Local Configurator Menu (1 through 8) 51

9. Configuration Database 59

9.1. Flowtube Parameters 59

9.2. Identification Parameters 59

9.3. Transmitter Options 60

9.4. Process Fluid Parameters 60

9.5. Application Parameters 61

9.6. Output Options 61

3

Page 4

4

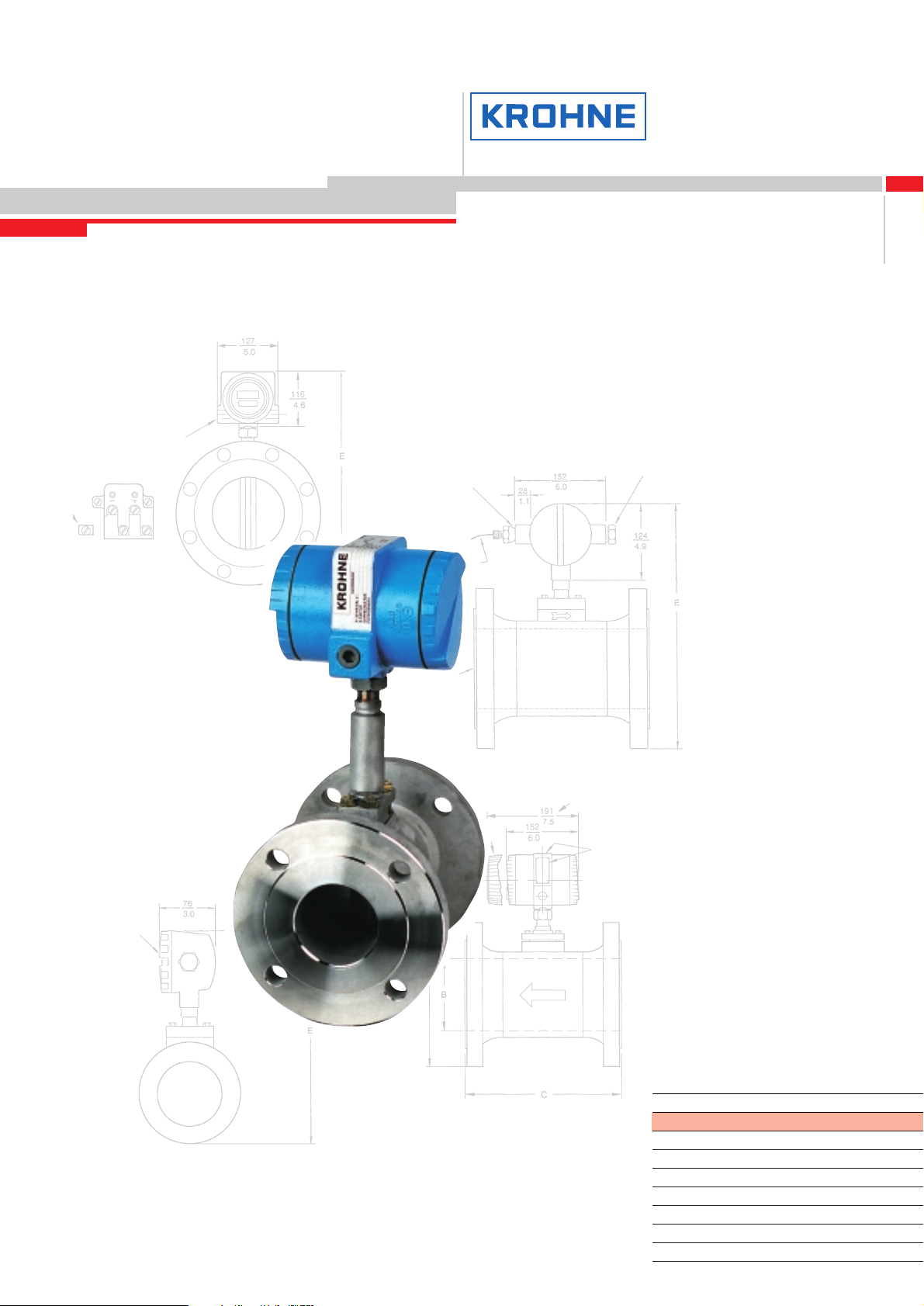

1 VFM 3100 F-T Flange Body 6

2 VFM 3100 W-T Sandwich Body 6

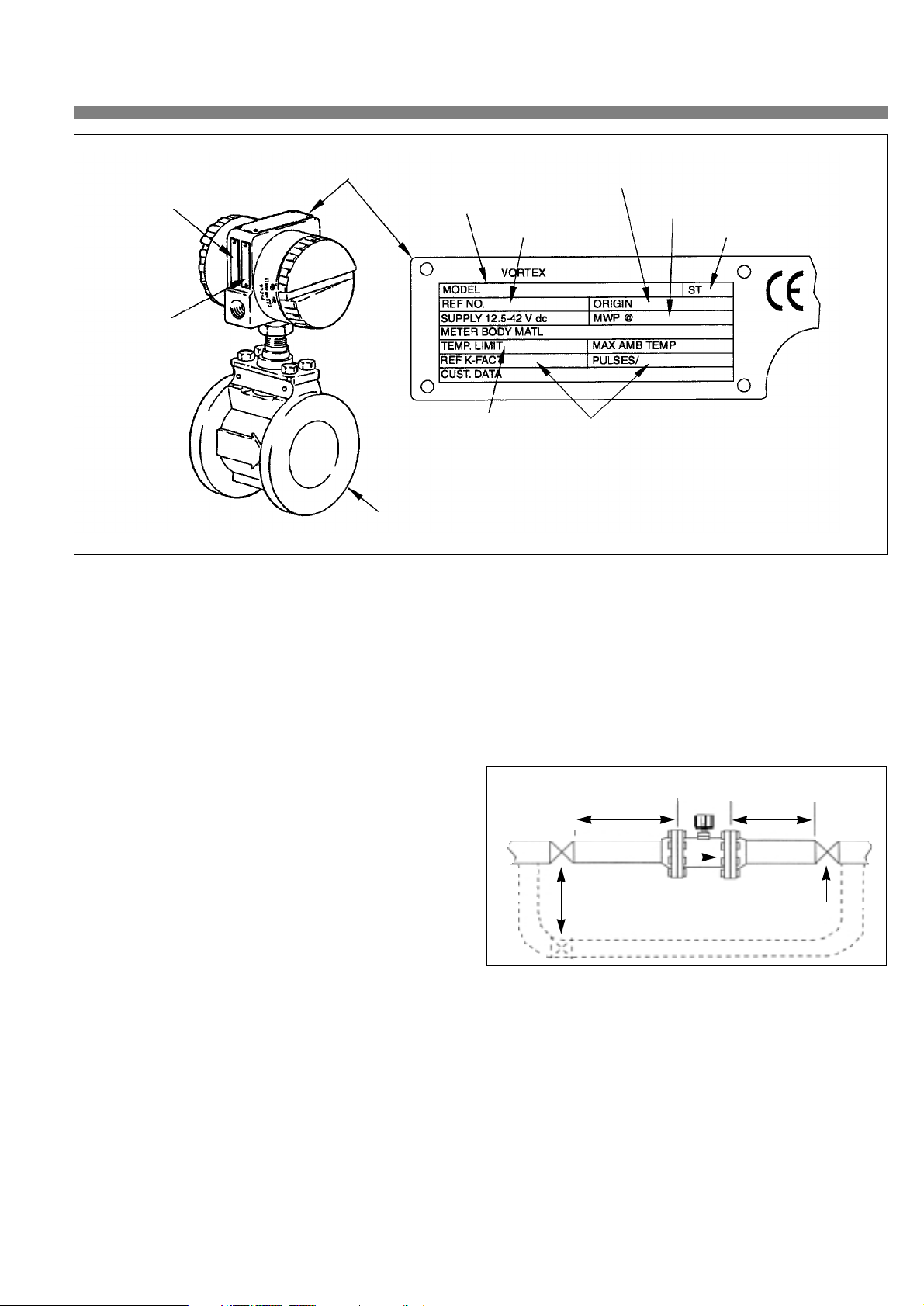

3 VFM 3100 Identification 9

4 Typical Piping Configuration 9

5 Pressure and Temperature Tap Locations 10

6 VFM 3100 F Installation 12

7 VFM 3100 W Centering (using Spacers OR Sleeves) 12

8 Repositioning the Electrical Housing 13

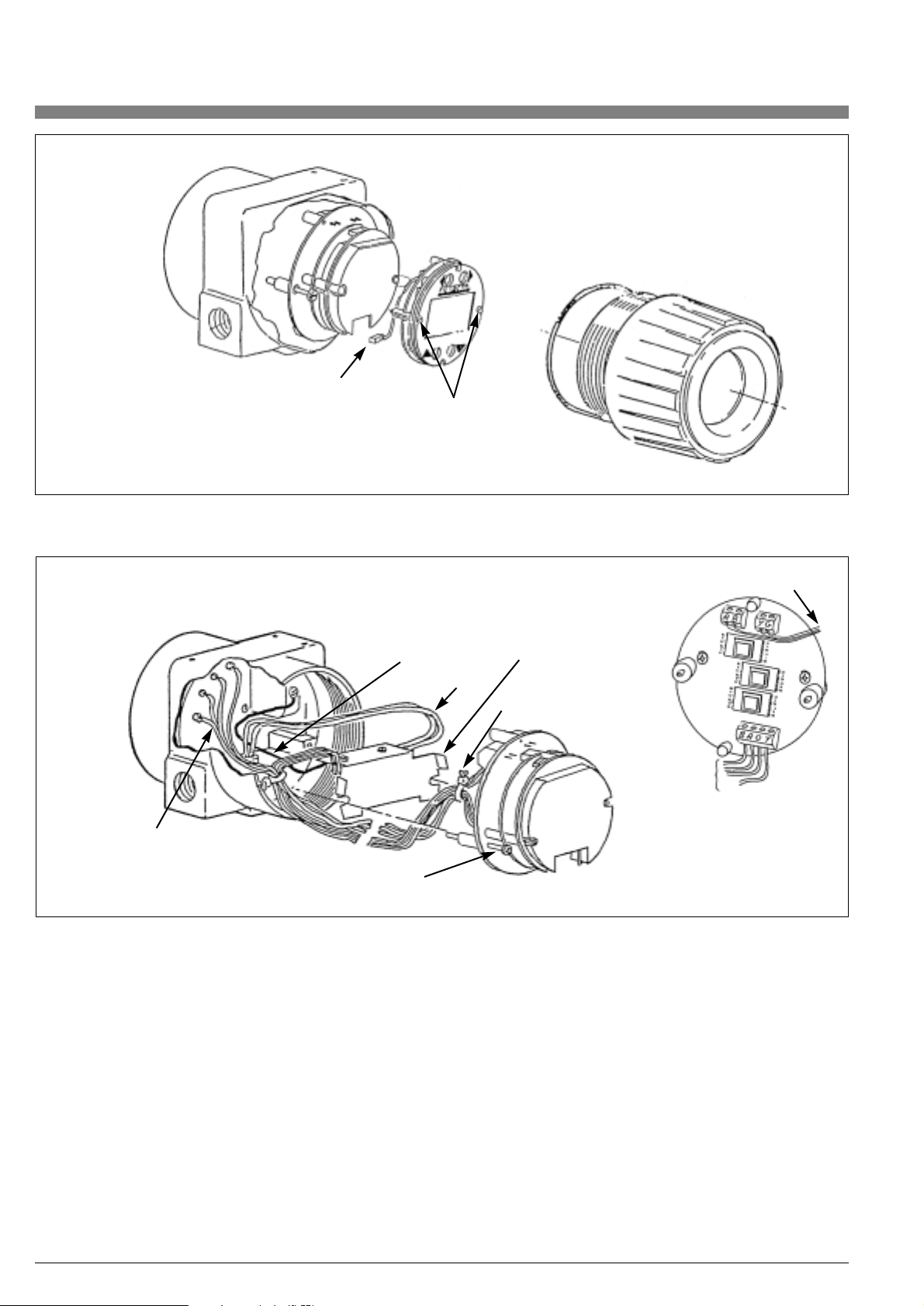

9 Overall View of Remote Mounted VFM 3100 16

10 Electronics Housing 19

11 Installation Wiring - 4-20 mA Output (Two-wire) 20

12 Load Requirements 20

13 Installation Wiring - Pulse Output (Three-wire) 21

14 Installation Wiring (Four-wire) 21

15 Normal Vortex Frequency Waveform 29

16 VFM 3100 Block Diagram 30

17 Electronic Module Connections -

Standard Temperature

Range (Integral Mount) 31

18 Electronic Module Connections - Extended

Temperature Range 31

19 Electronic Module with Display Connections 32

20 Electronic Module Connections -

CENELEC Certified Extended and Standard

Temperature Range 32

21 Electronic Module - CENELEC Certified Flameproof 33

22 Preamplifier Assembly - Integral Mount

Extended Temperature Range 34

23 Preamplifier Assembly - Remote Mount Assembly 34

24 Preamplifier - Remote Mounted VFM 3100

(CENELEC Certified Flameproof) 35

25 Preamplifier Assembly 36

26 Preamplifier - Remote Mounted VFM 3100 37

27 Connections for Post-Assembly Dielectric Test 37

28 VFM 3100 Assembly 38

29 O-Ring/Sensor/Flow Dam 39

30 Electrical Housing/Mechanical Connector 39

31 VFM 3100 Assembly 39

32 Connector Bolt Torquing Sequence 40

33 Connector Bolt Torquing Sequence 40

34 Flowtube/Junction Box –

Standard Temperature Range 41

35 Flowtube/Junction Box -

Extended Temperature Range 41

36 VFM 3100 Assembly/Junction Box 42

37 Sensor/Mechanical Connector/Junction Box 42

38 Isolation Valve 44

39 Dual Manifold 45

40 HART On-Line Menu Structure 46

41 Fast-Key Function/Variable Chart 48

42 Local Configurator Menu 51

Figures

Page 5

1 Standard Specifications 7

2 Electrical Safety Specifications 8

3 VFM 3100 Mounting Arrangements 11

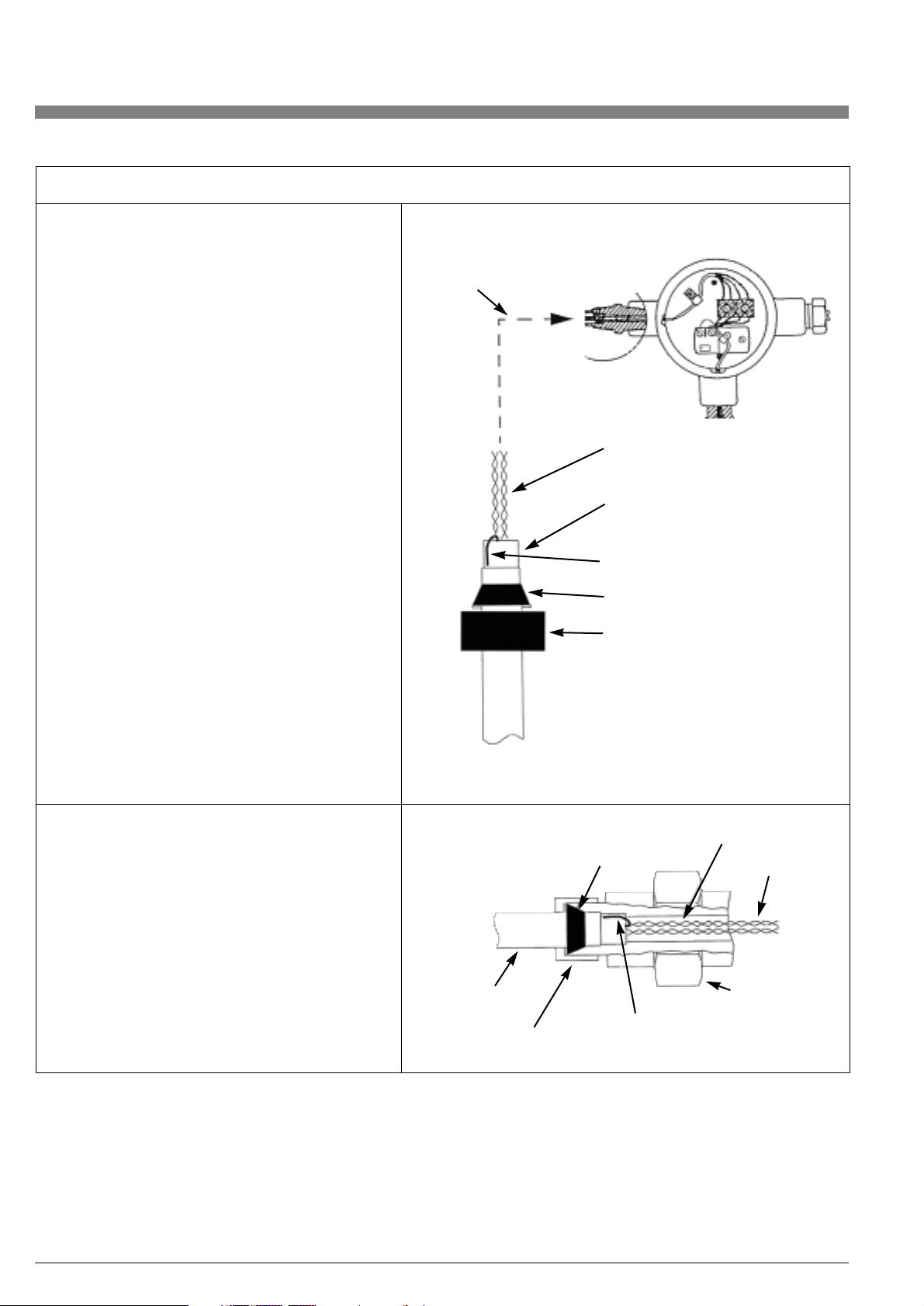

4 Preparation of Remote Signal Cable 14

5 Preparation of Remote Signal Cable (Electronics End) 15

6 Connection of Remote Signal Cable 17

7 Connection of Remote Signal Cable (Electronics End) 18

8 Configuration Database 22

9 User Information 22

10 Electronic Module Terminal Block Connections 30

11 Maximum Test Pressure 40

12 Menu Tree Functional Overview 49

13 Configuration Database 59

5

Tables

Page 6

6

1. Installation

1.1 Introduction

1.1.1 Description

The VFM 3100 F/W-T (Figures 1 and 2) measure fluid (liquid, gas, or

steam) flow rates using the principle of vortex shedding.

Fluid flowing through the VFM 3100 body passes a specially shaped

vortex shedder that causes vortices to form and shed alternately

from the sides of the shedder at a rate proportional to the flow rate of

the fluid. These shedding vortices create an alternating differential

pressure that is sensed by a detector located above the shedder. A

pulsed voltage is generated by the detector with a frequency that is

synchronous with the vortex shedding frequency. This voltage is then

conditioned by the electronic module to produce either a pulse rate

signal or an analog (4 to 20 mA dc) signal.

1.1.2 Fundamental Installation Requirements

Meters shall be installed to meet all applicable local installation regulations, such as hazardous location requirements, electrical wiring

codes, and mechanical piping codes. Persons involved in the installation should be trained in these code requirements in order to ensure that the installation takes maximum advantage of the safety features designed into the VFM 3100.

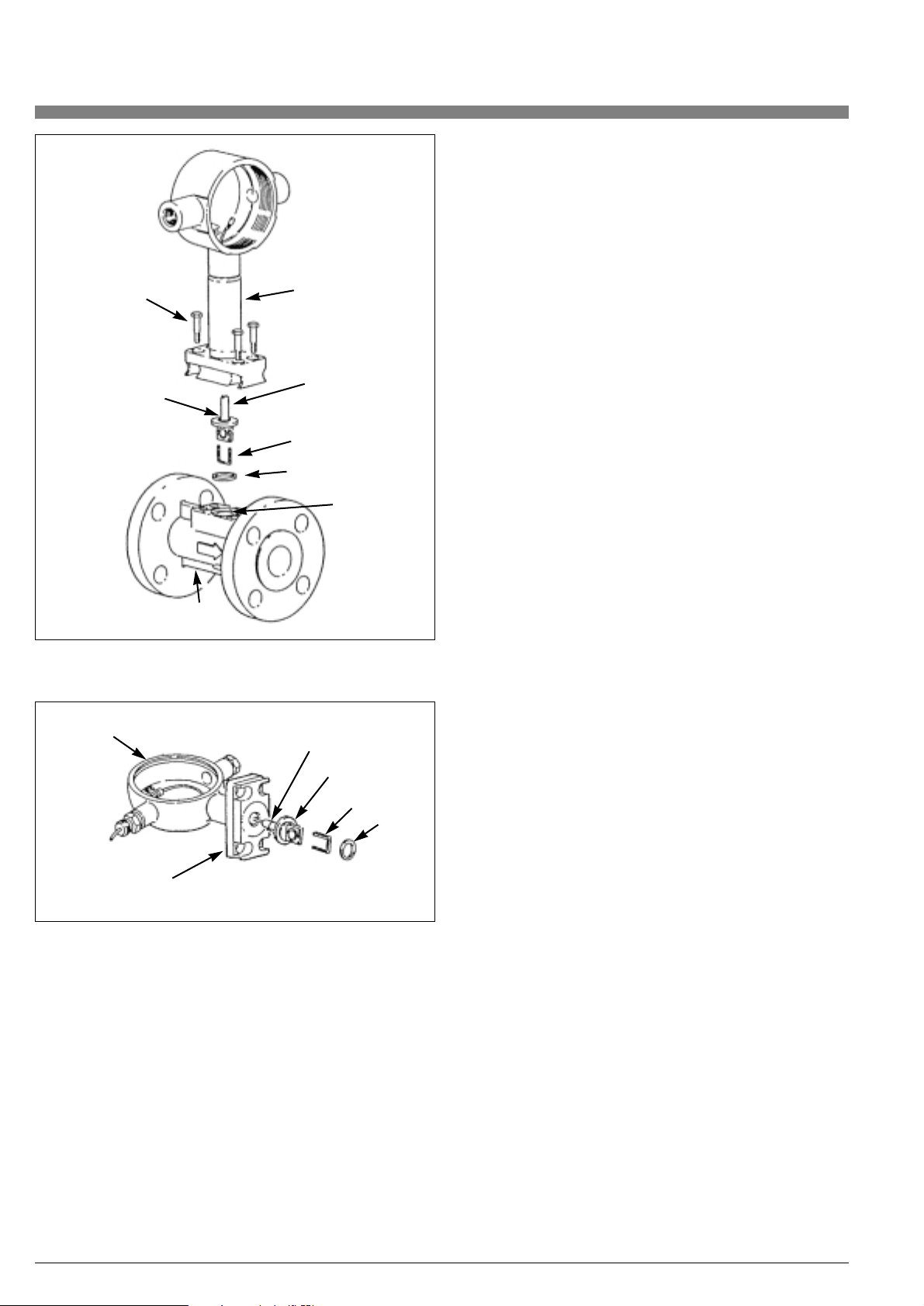

Figure 2. VFM 3100 W-T Sandwich Body

Figure 1. VFM 3100 F-T Flange Body

Page 7

1.1.3. Standard Specifications

Table 1.

7

Item Specification

Process Temperature Limits -20 and +430 °C (0 and 800 °F)

(a)

Ambient Temperature Limits -40 and +85 °C (-40 and +185°F)

Power Supply Requirements:

Supply Voltage Limits 12,5 and 42 V dc

Supply Current 22 mA dc

Product Safety Specification Refer to instrument data plate for type of certification and

observe aplicable wiring requirements. Electrical certifications

and conditions of certification are listed on page 8.

Flow Rate Requirements Rd = 5000 minimum: Automatic compensation for the

non-linear behavior of vortex shedding in the Rd range

5000 to 20000 is built into the VFM 3100.

This compensation requires the user to input values

for the flowing density and viscosity.

Static Pressure Limits Full vacuum to pressure rating of mating flanges

with maximum operative limit of 10 MPa (1500 psi:

100 bar or kg/(cm

2

) at 24°C (75°F).

VFM 3100 Output

Analog 4 to 20 mA dc into a maximum of 1450 ohms depending

on power supply (refer to graph in Figure 12).

Digital (HART) Digital signal conveyed at a 1200 baud transmission rate.

HART protocol.

Scaled Pulse Isolated 2 wire „contact closure”. Pulse rate

(0 to 100 Hz) proportional to volumetric flow rate.

Scaled Pulse Output Specifications • Isolated 2-wire contact-closure

• Applied voltage limits:

12.5 Vdc minimum

42.0 Vdc maximum

• Maximum „ON” state voltage drop: 0.5 Vdc

• Maximum „ON” state current: 250 mA

• Update rate: 4 Hz

• Maximum „OFF” state leakage current:

0.10 mA @ 12.5 Vdc

0.25 mA @ 24.0 Vdc

0.42 mA @ 42.0 Vdc

• 250 mA short circuit protected

• Reserve polarity protected

Signal Output Combinations 2-Wire Hook-Up

4-20 mA and HART (1200 baud)

3-Wire Hook-Up

4 to 20 mA, HART (1200 baud) and Scaled Pulse

4-Wire Hook-Up

4 to 20 mA, HART (1200 baud) and Scaled Pulse

(a) Maximum temperature limit is a function of sensor type.

Page 8

8

After removing the flowtube from its shipping carton, inspect it for

visible damage. If any damage is observed, notify the carrier immediately and request an inspection report. Obtain a signed copy of the

report form the carrier. The calibration certificate and any other documentation shipped with the VFM 3100 should be separated from the

packing material and held for future reference. Re-install any flange

covers or protective material to safeguard the VFM 3100 until it is installed.

Packing material should be disposed of in accordance with local

regulations. All packing material is non-hazardous and is generally

acceptable to landfills.

1.1.6. VFM 3100 Identification

The model code is stamped on the data plate as shown in Figure 3

and is digitally readable from the configuration menu.

The Standard Temperature Range sensor is made of 316 stainless

steel and is filled with silicone oil, maximum temperature 200 °C

(400 °F). An optional fill is Fluorolube, maximum temperature 90 °C

(200 °F). The Extended Temperature Range sensor is made of 316

stainless steel and is unfilled, maximum temperature 430 °C (800 °F).

Both standard and high temperature sensors are available made

from Hastelloy.

1.1.4. Electrical Safety Specifications

Table 2.

CSA

intrinsically safe for Class I, Division I,

Groups A, B, C, D; Class II, Division I,

Groups E, F, G: and Class III, Division I

CSA explosionproof for Class I, Division I,

Groups C and D; dust-ignitionproof for Class II

and III, Division I, Groups E, F,

and G; and Class III, Division I.

Suitable for Class I, Division 2,

Groups A, B, C, D; class II, Division 2,

Groups F, G; and Class III, Division 2.

FM intrinsically safe for Class I, II and III,

Division 1, Group A, B, C, D, E, F, and G;

nonincendive Class I, II and III, Division 2,

Groups A, B, C, D, F, and G.

FM explosionproof for Class I, Division 1, Groups C

and D; dust-ignitionproof for Class II and III, Division 1,

Groups E, F, and G; nonincendive Class I, II and III,

Division 2, Groups A, B, C, D, F, and G.

CENELEC intrinsically safe for EEX ib,

Gas Group IIC, Zone 1.

CENELEC flameproof for EEx d (ib), Gas, Group IIC,

Zone 1

Testing Laboratory, Type of Protection,

and Area Classification

Temperature Class T3C at 85°C and

T4A at 40°C maximum ambient.

Limited to Gas Groups C and D when

connected to 33 V, 185 Ω Zener

barrier.

Temperature Class T5.

Temperature Class T3C at 85°C and

T4A at 40°C maximum ambient.

Temperature Class T5.

Temperature Class T4 at 0.8 W.

Temperature Class T5 at 0.5 W.

Temperature Class T6 at 0.3 W.

Temperature Class T6.

Application Conditions

NOTE: These transmitters have been designed to meet the electrical safety descriptions listed in the table above. For detailed information or status of testing laboratory approvals/ certifications,

contact KROHNE.

1.1.5. Unpacking

The VFM 3100 is built to be durable, but it is part of a calibrated

precision system and should be handled as such.

NOTE: VFM 3100 may (depending on pressure rating of flanges

with which they will be used) have a set of centering spacers included. Do not discard these centering spacers. They must be used

to install the VFM 3100 properly.

VFM 3100 with remote-mounted electronics are rugged two-piece

units. A remote cable connection is assembled to the VFM 3100

junction box and electronics housing. The cable may be cut to the

required length per instructions beginning on page 13. Do not allow

the weight of either the flowtube or electronics housing to be supported by the remote cable.

Remove the flowtube from the shipping carton using care to avoid

dropping or otherwise subjecting it to impact, particularly at the

flange or wafer faces. Never put anything through the flowtube for

lifting purposes as damage to the shedder bar may occur.

Page 9

9

Data Label

Certification Label

Measuring

Range Label

Model Code

Serial No.

Productioncode

Maximum Pressure

Style Letter

Temp Limit per

Sensor Option

Complete VFM 3100

Calibration

Factor

Figure 3. VFM 3100 Identification

1.2. Mechanical Installation

There are two mounting arrangements: integral and remote. The

following sections deal with both the integral and remote VFM 3100

arrangements.

1.2.1. Piping Considerations

Effects of Piping on VFM 3100 Performance

The flange size of the adjoining pipe must be the same nominal size

as the VFM 3100. Flanges with a smooth bore, similar to weld neck

flanges, are preferred.

Normal performance data is based on the use of Schedule 40 piping

upstream and downstream of the VFM 3100. If this is not the case,

the actual schedule must be selected from a picklist during configuration and the distance to the disturbance in pipe diameters entered.

This enables the VFM 3100 to automatically compensate for any induced flow effects.

In addition, the bore of the pipe (flange) and VFM 3100 must be

aligned (see "Installation Procedure" on page 12), and the flange

gaskets installed such that they do not protrude into the flow stream.

NOTE: 1. VFM 3100 mounted near pump discharge or suction lines

may be exposed to oscillatory flow that may affect vortex shedding

or product pipe vibration. Also, VFM 3100 mounted near the discharge of a liquid positive displacement pump or near oscillating

control valves may experience severe flow fluctuations that could damage the sensor. To avoid these adverse situations, install the VFM

3100 at least 20 feet or 40 pipe diameters, whichever is larger, from

the disturbance in question.

2. It is good piping practive that the internal surface of the pipe shall

be free from mill scale, pits, holes, reaming scores, rifling, bumps, or

other irregularities for four pipe diameters upstream and two pipe

diameters downstream of the VFM 3100.

Consideration for VFM 3100 Repair

When installing the VFM 3100, consider VFM 3100 repair. The

VFM 3100 should be accessible for servicing. If the flow cannot be

interrupted to replace a sensor, then an isolation manifold should be

mounted on the VFM 3100 before it is installed.

An acceptable and recommended practice is to install bypass

piping so that the entire VFM 3100 may be removed for servicing

(see Figure 4).

Liquid Control Installations

It is recommended for liquid flow that the VFM 3100 be mounted

upstream at least 5 pipe diameters from the control valve and in

vertical installations in the upward flowing leg. This will help to maintain a full pipe and ensure that there is sufficient back pressure to

prevent flashing or cavitation.

30 Pipe Diameters

recommended

5 Pipe Diameters

recommended

Shutoff Valves

Figure 4. Typical Piping Configuration

Page 10

Gas Control Installations

For gas control installations, there are choices for VFM 3100 location

that should be considered. For maximum rangeability, locate the

VFM 3100 30 or more pipe diameters downstream from a control

valve. This will assure maximum velocity at the VFM 3100 and produce the most efficient signal from the sensor.

When the flow is more stable, the VFM 3100 may be mounted a minimum of 5 pipe diameters upstream of the control valve. Pressure

fluctuations often are less on the upstream side of a control valve.

This should be considered as a means to provide the most accurate

density when a flow computer is not used.

The VFM 3100 electronics automatically calculates the effect of upstream piping on K-factor when installation piping data is entered by

user.

Steam Control Installations

For steam control installations, it is recommended that the VFM 3100

be mounted 30 pipe diameters or more downstream of the control

valve. This is particularly useful when measuring saturated steam to

ensure that there is a minimum amount of condensate present at the

VFM 3100.

Pressure and Temperature Taps

NOTE: The inside of the pipe at the pressure and temperature taps

must be free of burrs and obstructions.

Pressure Taps -- For density measurement (when required),

locate the tap 3-1/2 to 4-1/2 pipe diameters DOWNSTREAM

of the VFM 3100. See Figure 5.

NOTE: On a gas installation, the pressure tap should be located on

the top of the pipe. On a liquid installation, the pressure tap (if required) should be located on the side of the pipe. On a steam installation, the pressure tap should be located on the top when the pressure

measuring device (typically a pressure transmitter) is above the

pipeline, and on the side when the measuring device is below the

pipeline. With vertical piping, the pressure tap may be located anywhere around the circumference of the pipeline.

Temperature Taps -- For temperature measurement (when required), locate the tap 5 to 6 pipe diameters DOWNSTREAM of

the VFM 3100. The smallest possible probe is recommended to

reduce flow disturbance. See Figure 5.

10

1.2.2. Installation Position

For optimal performance the locations of the sensor and integral

electronics relative to the piping must be considered. Factors that

influence this decision include process fluid type, ambient temperature, and vibration.

Process Fluid

When using:

Saturated Steam: The electronics housing should be below the

VFM 3100 body, so that the sensor cavity remains filled with condensate.

NOTE: A VFM3100 used on steam should be located downstream

of a control valve.See "Steam Control Installations."

Superheated Steam: The electronics housing should be below the

VFM 3100 body when the steam has less than 10 °F (5.6 °C) superheat. The housing should be above the VFM 3100 body when the

superheat is more than 10 °F and no condensate will be forming on

the sensor. An isolation valve may be used in superheated steam

applications with adequate insulation.

Gas: The electronics housing may be above or below the VFM 3100

body. The normal recommended position of the electronics housing

is above the VFM 3100 body.

Liquid: For a liquid with solid particles, the electronics housing

should be above the VFM 3100 body. Care should be taken so that

entrapped air does not accumulate in the sensor cavity. For a clean

liquid, the electronics housing may be mounted below the VFM 3100

body. Care must be taken if there is any sediment or fine dirt, that the

particles do not accumulate in the sensor cavity. A VFM 3100 used

on liquid should be mounted upstream from a control valve.

VFM 3100 may also be mounted with the electronics housing positioned to the side. This ensures escape of entrapped air and minimizes sediment accumulation.

The above considerations are summarized in Table 3 for single and

dual measurement VFM 3100 with and without isolation valves.

1.2.3. Ambient Temperature

Ambient temperature limits must be observed per specifications.

However, if the electronic housing is above the ambient temperature

limit (85 °C, 185 °F), the VFM 3100 may be mounted with the electronic housing located to the side to aid the cooling of the electronic

module. The bottom conduit connection shoud be used (the top one

plugged) to avoid possible accumulation of condensate at the terminal block.

1.2.4. Vibration

The vortex shedder axis should be oriented to reduce or, in some cases virtually eliminate, vibration influence. Positioning VFM3100 so

that vibrations are parallel to sensor diaphragms will minimize effect

of vibrations.

Pressure Tap

Temperature Tap

Direction of Flow

Figure 5. Pressure and Temperature Tap Locations

Page 11

11

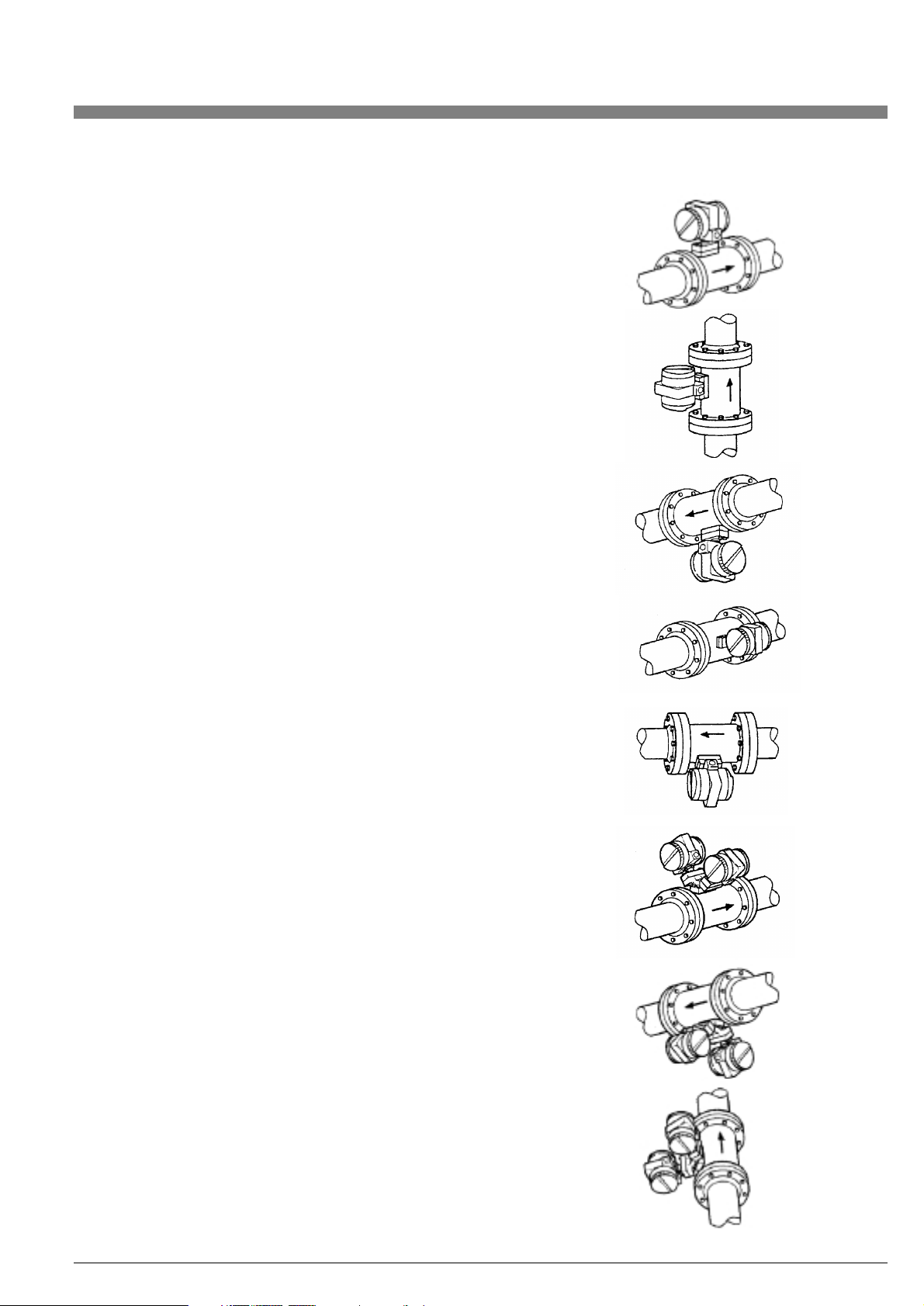

Table 3. VFM 3100 Mounting Arrangements

Single Measurement (with and without isolation valves)

Housing Above Pipe

GAS Recommended mounting.

STEAM Recommended for super-heated steam with adequate

insulation. Not recommended for saturated steam.

LIQUID Adequate self-purging. Recommended mounting.

Isolation Valve may cause temporary start-up error

due to entrapped air.

Vertical Pipe

GAS Recommended mounting.

STEAM Recommended for super-heated steam with adequate

insulation. Not recommended for saturated steam.

LIQUID Adequate self-purging. Recommended mounting.

Housing Below Pipe

GAS Recommended for clean applications only.

STEAM Not recommended for super-heated steam.

Recommended for saturated steam.

LIQUID Recommended when self-purging is important.

Housing Beside Horizontal Pipe

GAS Recommended mounting.

STEAM Not recommended for saturated steam. Recommended

for superheated steam provided the pipe is adequately

insulated.

LIQUID Adequate self-purging, recommended mounting.

Housing to the Side and Below Horizontal Pipe

Note: Requires flanges with eight or more bolts

GAS Not recommended

STEAM Not recommended

LIQUID Recommended.

Dual Measurement (with or without isolation valves)

Housing Above Pipe

GAS Recommended mounting.

STEAM Recommended for super-heated steam with adequate

insulation. Not recommended for saturated steam.

LIQUID Not self-purging. May cause errors at startup.

Not recommended for batch operations.

Vertical Pipe

GAS Recommended mounting.

STEAM Recommended for super-heated steam with adequate

insulation. Not recommended for saturated steam.

LIQUID Adequate self-purging. Recommended mounting.

Housing Below Pipe

GAS Not recommended.

STEAM Not recommended for super-heated steam.

Recommended for saturated steam.

LIQUID Self-purging. Recommended for batch operations.

Page 12

12

1.2.5. Installation Procedure

VFM 3100 F–Flanged Body

• Gaskets are required and must be supplied by the user.

Select a gasket material suitable for the process.

• Insert gaskets between body of VFM 3100 and adjacent

flanges. See Figure 6. Position gaskets so that ID of each

gasket is centered on ID of VFM 3100 and adjacent piping.

CAUTION:

• Verify that the ID of the gaskets is larger than that of the VFM

3100 bore and pipe and that they do not protrude into the

VFM 3100 entrance or exit. Accuracy of the measurement will

be affected.

• Gaskets will not prevent flanges from being wetted by process

fluids.

NOTE: When installing new flanges in the process piping and the

VFM 3100 is used as a gauge to set the flanges, the inside diameter

of the VFM 3100 must be protected from weld splatter. It is recommended that a solid sheet of gasketing be installed at each end of the

VFM 3100 during welding. Remove this sheet and install flange gasket after welding. Remove any splatter in either the pipe or the VFM

3100 as this could affect VFM 3100 accuracy.

• Visually inspect for concentricity of mating flanges.

• Tighten bolts in accordance with conventional flange bolt

tightening practice (i.e., incremental and alternate tightening

of bolts).

VFM 3100 W– Sandwich Body

For optimal performance, the sandwich body VFM 3100 should be

centered with respect to the adjoining pipe. Normally, this requires

the use of centering fixtures that are supplied with the VFM 3100.

NOTE: Centering fixtures are not required for meters with ANSI

Class 150 flanges.

Two types of centering fixtures are presently in use; the older centering sleeves and the newer hex-nut spacers. The VFM 3100 may

come with either type of fixture. Most meter sizes have two centering

fixtures (two sets in the case of the hex-nut spaceres), but some larger sizes may have twice this number, two for each side.

• See Figure 7. Insert the first stud through the downstream

flange at one of the lower holes, through the centering sleeves

or two hex-nut spacers, and then through the upstream flange.

Place the nuts on both ends of the stud but do not tighten.

• Using the remaining centering sleeve or hex-nut spacers,

repeat Step 1 at the lower hole adjacent to the first.

• Set the VFM 3100 between the flanges. For centering with the

hex-nut spacers, rotate spacers to the thickness that centers

the VFM 3100.

NOTE: By rotating the hex-nut spacers to the correct thickness, you

can center the VFM 3100 to any type of flange.

• Gaskets are required and must be supplied by the user.

Select a gasket material suitable for the process fluid.

• Insert gaskets between body of VFM 3100 and adjacent

flanges. Position gaskets so that ID of each gasket is centered

on ID of VFM 3100 and adjacent piping.

CAUTION: Verify that the ID of the gaskets is larger than that of

the VFM 3100 bore and pipe and that they do not protrude into the

VFM 3100 entrance or exit.

NOTE: If welding of flanges to the process piping is required, protect

the VFM 3100 from weld splatter, which could affect VFM 3100

accuracy. It is recommended that a solid sheet of gasketing be installed at each end of the VFM 3100 during welding. Remove this sheet

and install flange gasket after welding.

• Visually inspect for concentricity of mating flanges.

• Install the rest of the studs and nuts and tighten the nuts in

accordance with conventional flange bolt tightening practice

(i.e., incremental and alternate tightening of bolts).

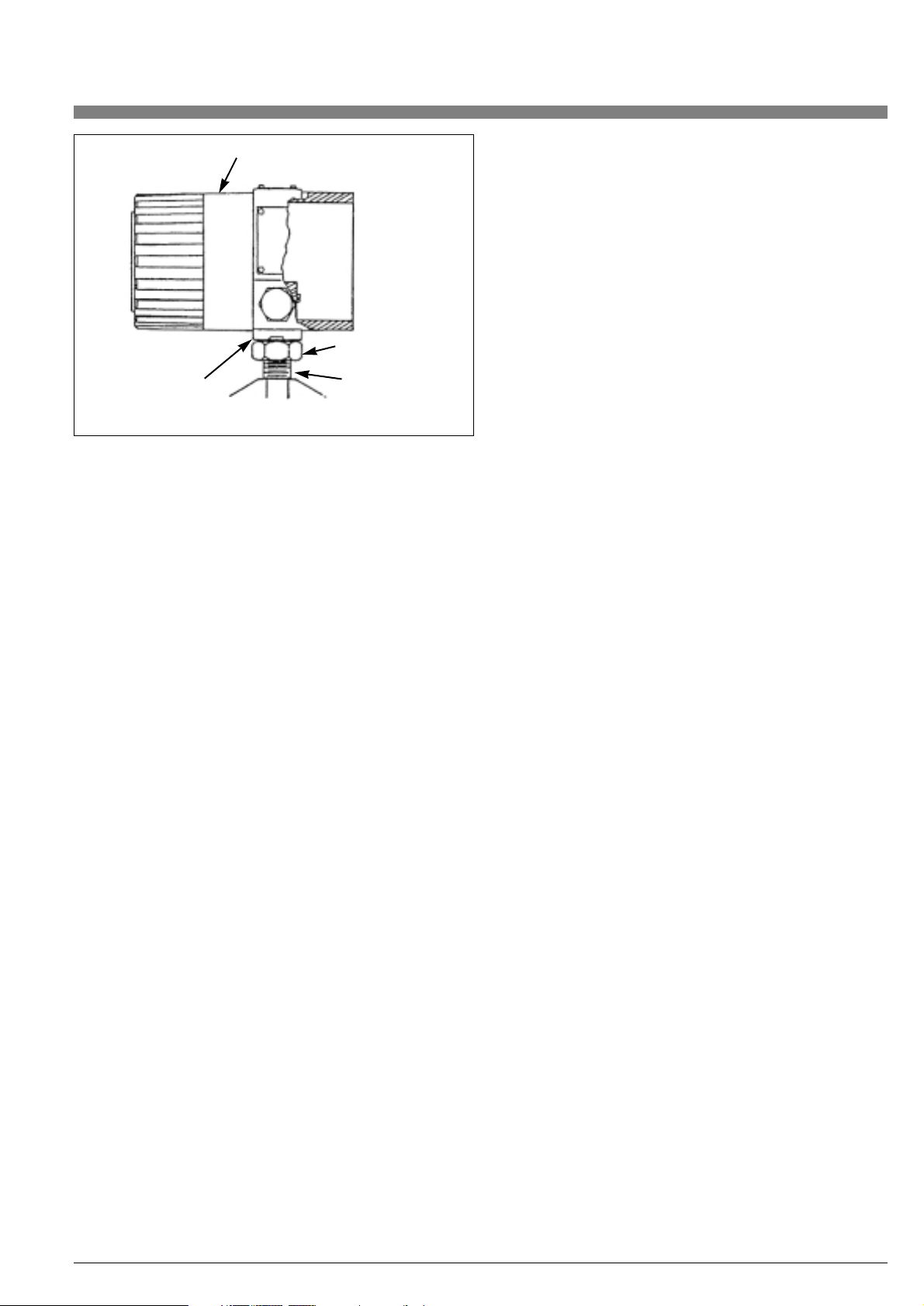

1.2.6. Repositioning the Electrical Housing

The VFM 3100 housing may be repositioned up to a maximum of

270°C from its original position by rotating the electrical housing.

WARNING: Stops are incorporated in the housing design. Do not

remove the stops as further rotation from the 270°C maximum may

cause damage to the sensor wires. Additionally this may violate safety code requirements for explosion-proof thread engagement in

hazardous locations.

• Unscrew housing locknut to bottom of thread. See figure 8.

• Square locking plate should slip down on shaft. If it does not,

pry out with scewdriver.

• Rotate electrical housing to desired position.

See Warning on page 12.

• Note recess on bottom of electrical housing into which the

locking plate fits. Screw the locking nut hand tight making sure

locking plate fits into recess on bottom of electrical housing.

• Secure the locknut firmly using a wrench.

Gasket

Gasket

VFM 3100

Gasket

Gasket

Install centering

fixtures on

adjacent lower

studs of flange

VFM 3100

2 hex-nut spacers

per side (not required

with class 150)

Hex-nut alignment device

(not required with class 150)

Centering sleeve

(not required with

class 150)

Figure 6. VFM 3100 F Installation

Figure 7. VFM 3100 W Centering (using Spacers OR Sleeves)

Larger meters

have 2 centering

fixtures per side

Page 13

1.2.7. VFM 3100 with Remote Electronic Module

The purpose of the remote electronic module is to allow for separation of the VFM 3100 body and the electronics housing.

This VFM 3100 consists of:

• An electronics housing mounted to a pipe or wall mounting

bracket with up to 15 m (50 ft) of interconnecting cable attached.

• A VFM 3100 body with junction box. The junction box contains

a preamplifier assembly. Refer to Figure 9.

• 1/2 NPT conduit connections are provided on both the housing

and the junction box.

NOTES:

• Mount the VFM 3100 so that the junction box is serviceable.

• The cable is prewired to the junction box to ensure proper

grounding of the shield. It is recommended not to disconnect

the cable from the junction box.

• If the cable must be disconnected, make sure the end labeled

"VFM 3100 End" is positioned at the junction box end.

• If the cable is to be shortened, refer to Table 2 for re-dressing

cable ends.

Installing the Remote Electronics

WARNING: For optimum VFM 3100 performance, the remote signal

cable must be prepared and connected following the procedures

outlined below.

To install the remote electronics as shipped, execute the following

procedure:

• Mount the VFM 3100 as described in the preceding section. Be

sure to mount the VFM 3100 so that the junction box is serviceable.

• Mount the housing. The bracket assembly supplied with the housing may be mounted directly to a wall or to a 2-inch pipe stand.

• Mount the housing close enough to the VFM 3100 so that the

supplied cable will reach between the VFM 3100 and the housing.

To install remote electronics that must be separated, disconnect the

remote signal cable at housing end as described below.

It is not recommended that you disconnect the VFM 3100 end

(junction-box end).

• Remove electronic compartment threaded cover.

• Unscrew the two captive screws, one on each side of the

electronic module.

• Pull out electronic module far enough to disconnect the

remote signal cable.

• Disconnect the four remote signal wires from the four position

terminal block on rear of the electronic module. See Figure 9.

• Unscrew knurled nut, pull it back onto cable jacket, also pull

rubber bushing onto the cable jacket. Leave these parts on the

cable jacket as they will be used when reconnecting the cable.

• Mount the VFM 3100 as described in the preceding section. Be

sure to mount the VFM 3100 so that the junction box is serviceable.

• Mount the housing close enough to the VFM 3100 so that the

supplied cable will reach between the VFM 3100 and electronic

housing.

• Mount the electronic housing. The bracket assembly supplied

with the housing may be mounted directly to a wall or a 2-inch

pipe stand.

Interconnection Wiring for Remote Electronics

Installation without Conduit:

If the VFM 3100 and electronic housing were NOT separated during

installation, the interconnection wiring is complete.

NOTE: Oxygen cleaned meters are shipped separated.

If Housing End Is Disconnected:

If the VFM 3100 and electronic housing were separated during installation, follow the procedures below for interconnection wiring.

• Make sure the knurled nut and rubber bushing are on the cable

jacket. Orient the cable so that the end labeled "VFM 3100 End"

is positioned at the VFM 3100 junction box and the "Electronics

End" is positioned at the remote electronics housing.

• If the pre-dressed cable does not look as shown in Table 6, prepare it following the instructions for dressing electronic housing

end of remote signal cable in Table 6 on page 17.

• Take the prepared cable, taking care not to damage the copper

braid, and push it into the connector at bottom of the electronic

housing, as shown in Step 1 of Table 6 on page 17 until it comes

to a stop.

• Ensure that the remote signal cable is pushed in all the way, until

the outer jacket bottoms out inside the connector. Push the

rubber bushing into position, until it sits snug inside the connector, as shown in Step 2 of Table 6 on page 17.

• Tighten the knurled nut on the connector to create a compression

fit for a good seal.

• Inside the electronic housing, connect the four remote signal wires to the color coded 4-position terminal block on the rear of the

electronic module. See Figure 9 on Page 16.

• Ensure that the remote signal and loop power wires are tucked

under the electronic module. Taking care not to pinch the wires,

place the module in housing over mounting screws. Tighten the

two captive mounting screws.

• Replace threaded housing cover tightly. This will prevent moisture

or other contaminants from entering the compartment.

13

Electrical housing

with digital display/configurator

Locknut

Connector

Locking plate

Figure 8. Repositioning the Electrical Housing

Page 14

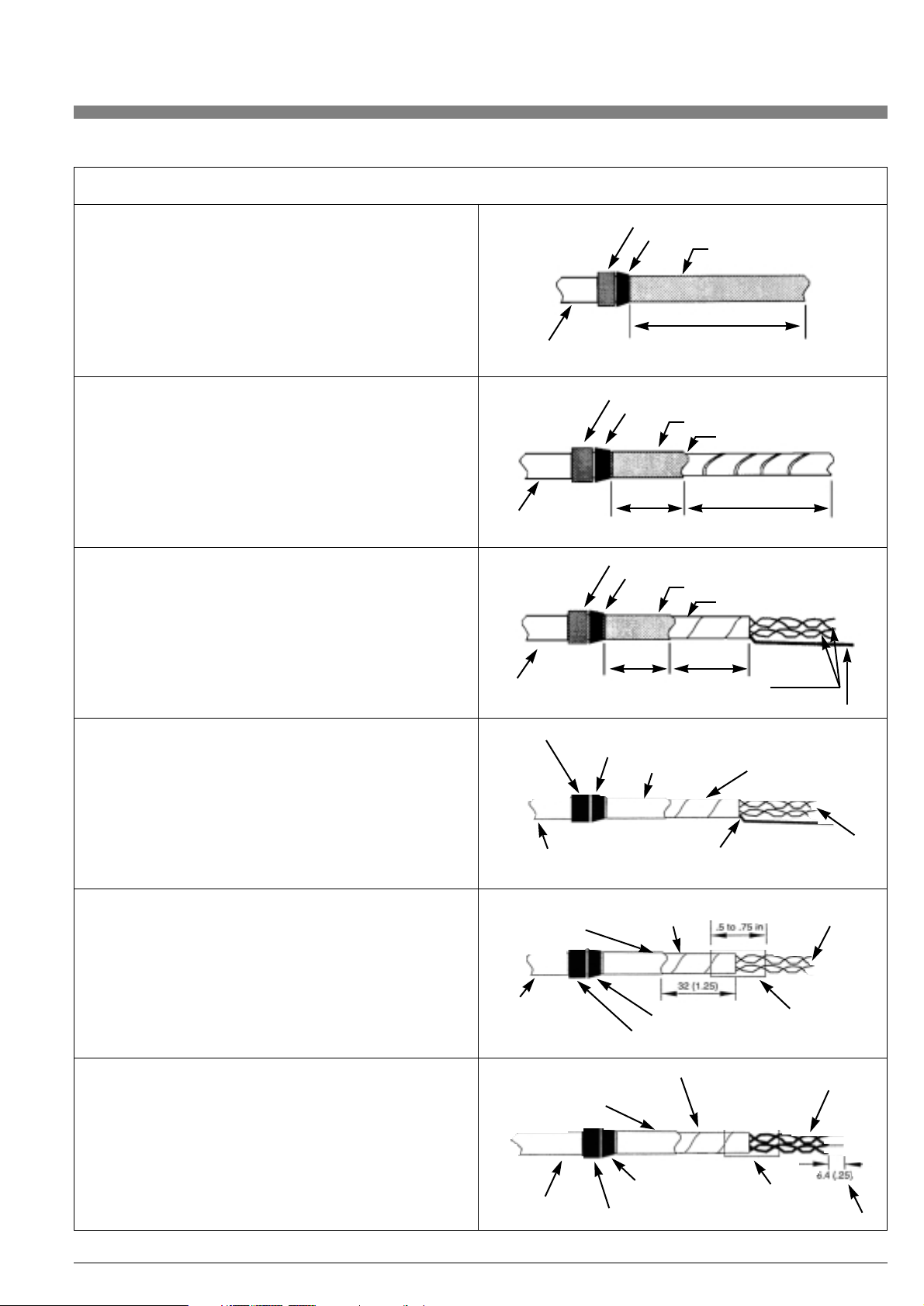

For installations where the provided pre-dressed remote signal cable

is not used, both ends of the cable being used must be prepared per

the instructions in Tables 4 and 5 of document. The cable must be

connected at both ends per instructions on Tables 6 and 7 on Pages

14

17 and 18. Terminate wires at J-Box following Figure 9 on Page 16.

At housing end, wires should be terminated at 4-position terminal

block on rear of electronic module as shown in Figure 9.

1. Slide the knurled nut and then the rubber bushing onto

outer jacket of cable as shown at right. Next, remove outer

polyethylene jacket of cable to dimension shown.

2. Cut and remove braided copper shield to dimension shown

at right. This will expose the barrier (plastic) tape and foil

mylar that encloses the conductors.

3. Cut and remove the barrier tape, foil mylar and fillers to

dimension shown at right. This will expose two twisted

pairs of conductors (brown-yellow, orange-red) and an

uninsulated drain wire. The barrier tape under the copper

braid prevents the drain wire from shorting to the copper

braid shield.

4. Trim the uninsulated drain wire to dimension shown at right.

To expose bare conductors for termination, cut and strip

ends of the two twisted pairs to dimension shown.

5. Fold drain wire back onto the copper braid as shown at

right. Label outer cable jacket „VFM 3100 End” to avoid

confusion during installatin. Cable is now ready for

installation.

VFM 3100 End (Junction Box End) Procedures

Knurled nut

Outer polyethylene

jacket

Outer polyethylene

jacket

Rubber bushing

191 mm (7.5 in)

Copper braid

Knurled nut

Rubber bushing

25 (1.0) 165 mm (6.5 in)

Copper braid

Barrier tape and

foil mylar

Outer polyethylene

jacket

Knurled nut

Rubber bushing

Copper braid

Barrier tape and

foil mylar

Knurled nut

Outer polyethylene

jacket

Label cable

jacket

Rubber bushing

Copper braid

Barrier tape and foil mylar

25 (1.0) 165 mm (6.5 in)

Two twisted pairs

Uninsulated drain wire

Outer polyethylene

jacket

Knurled nut

Rubber bushing

Copper braid

do not tape

6.4 mm (.25)

cut and strip

4 places

25 (1.0) 165 mm (6.5 in)

25 (1.0)

Two twisted pairs

Uninsulated drain wire

Bare conductor (4 places)

Two twisted pairs

Uninsulated drain wire

VFM 3100

end

Table 4. Preparation of Remote Signal Cable

Page 15

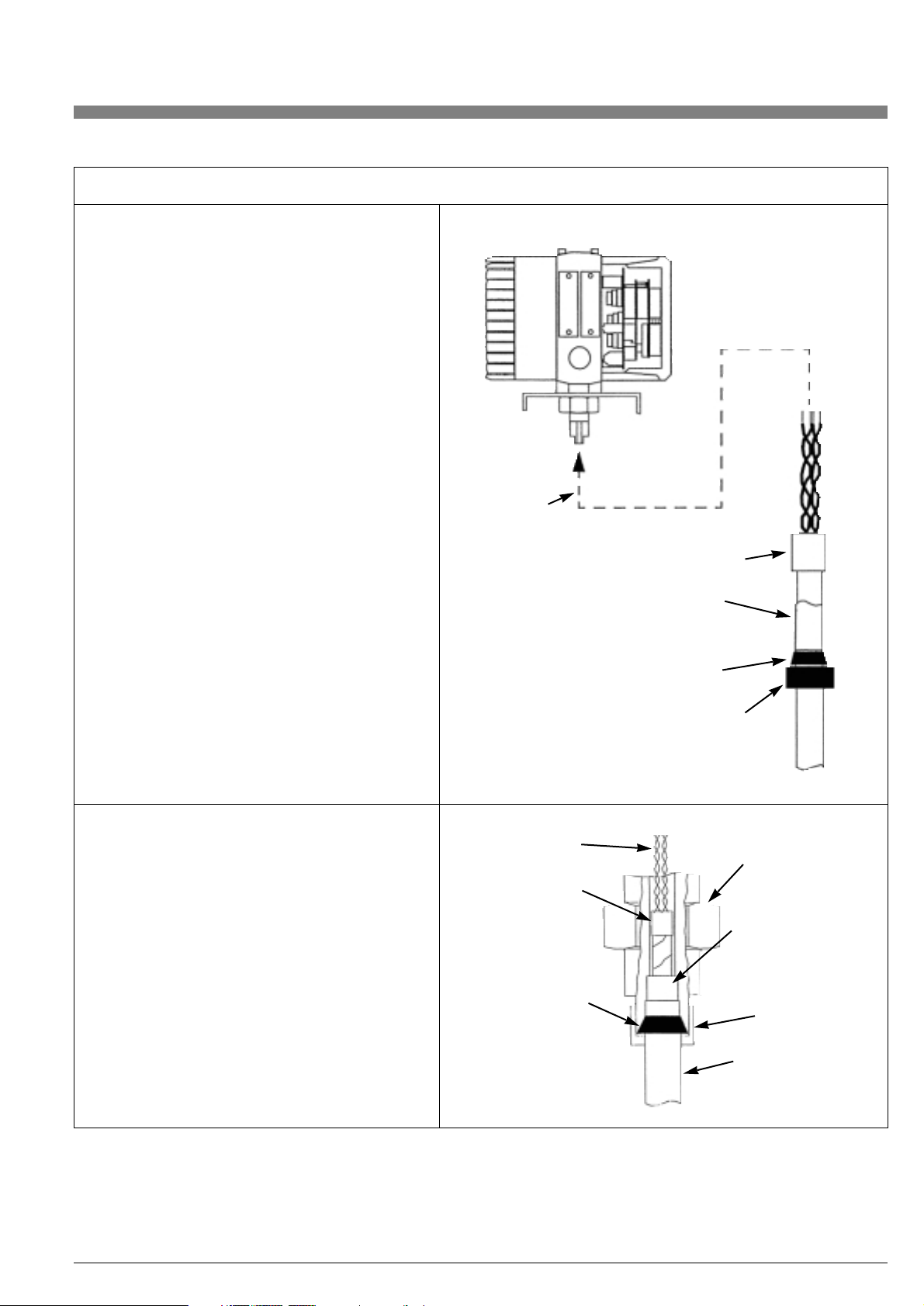

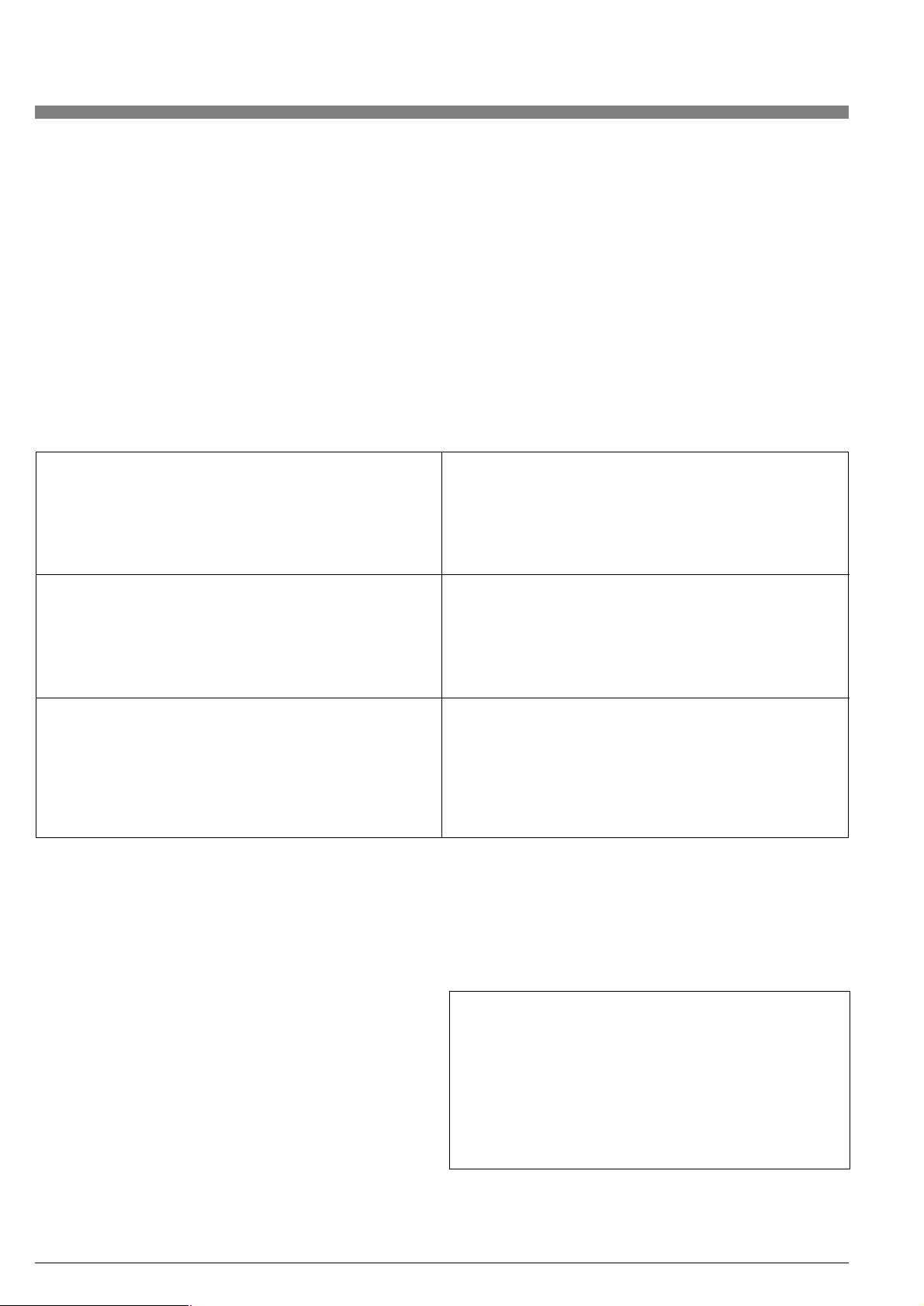

Table 5. Preparation of Remote Signal Cable (Electronics End)

15

1. Slide the knurled nut and then the rubber bushing onto

outer jacket of cable as shown at right. Next, remove outer

polyethylene jacket of cable to dimension shown.

2. Cut and remove braided copper shield to dimension shown

at right. This will expose the barrier (plastic) tape and foil

mylar that encloses the conductors.

3. Cut and remove the barrier tape, foil mylar and fillers to

dimension shown at right. This will expose two twisted

pairs of conductors (brown-yellow, orange-red) and an

uninsulated drain wire. The barrier tape under the copper

braid prevents the drain wire from shorting to the copper

braid shield.

Electronics End (Electronic Housing End) Procedures

Outer polyethylene

jacket

Outer polyethylene

jacket

Outer polyethylene

jacket

203 mm (8.0 in)

Knurled nut

Rubber bushing

Copper braid

178 mm (7.0 in)25 (1.0)

Knurled nut

Rubber bushing

Copper braid

Barrier tape and foil mylar

Knurled nut

Rubber bushing

Copper braid

Barrier tape and foil mylar

Two twisted pairs

Uninsulated drain wire

25 (1.0) 40 (1.5)

4. Cut off drain wire at end of barrier tape and foil mylar as

shown ar right. It is not used at this end.

5. Apply shrink tubing or electrical tape to end of barrier tape

and foil mylar at location shown at right. Note that the shrink

tube or tape covers end of barrier tape and mylar as well as

a portion of the 2 twisted pairs of wires. This will prevent the

barrier tape and foil mylar from unwrapping.

6. Cut and strip ends of the two twisted pairs to dimension

shown at right. Label outer cable jacket ”Electronic End”

to avoid confusion during installation. Cable is now ready

for installation.

Knurled nut

Copper braid

Barrier tape and foil

mylar

cut off

here

Two twisted pairs

Outer polyethylene

jacket

Knurled nut

Knurled nut

Rubber bushing

Rubber

bushing

Shrink tube or

electrical tape

cut and strip 4 places

Copper braid

do not tape

Copper braid

do not tape

Label cable

jacket

Electronic

end

Barrier tape

and foil mylar

Barrier tape and foil mylar

Shrink tube or

electrical tape

Two twisted pairs

Outer polyethylene

jacket

Two twisted pairs

Rubber bushing

Page 16

16

Electronic module

(see detail „A”)

See table 7 for details

of this connection

Disconnect

this end when

installing.

See table 5

for dressing of

cable at this end.

Outside braid makes contact to

housing. Braid is compressed for a

good electrical connection.

See table 6 and 7.

1/2 inch conduit may be connected

directly to connectors via 3-piece

union/coupler.

Cable must be pushed into stainless steel

fittings when installing compression nuts

to ensure that the braid is properly seated

for a good electrical connection (both ends).

See tables 6 and 7.

See table 5 for

dressing of cable

at this end.

VFM 3100 body.

External earth (ground)

connection screw –

cenelec flameproof only.

Pre-assembled and dressed

junction box

Braided shield and drain wire must

be in contact at this end of cable.

Note: do not disassemble to install.

Remote

cable

Output

signal

wires

brown

red

orange

yellow

Detail “A”

Figure 9. Overall View of Remote Mounted VFM 3100

Page 17

17

1. Take electronics end of prepared remote signal

cable and align it as shown at right. Ready for

assembly.

2. As shown in the diagrams at right, push the

prepared cable assembly into the remote

connector. Push until the cable bottoms out

(cannot be pushed in any furher). Push rubber

bushing into position and tighten the knurled

nut onto the remote connector to create a

good compression fit.

Electronics End (Electronic Housing End) Procedures

Push cable

assembly into

connector

Shrink tube or tape

Prepared remote

signal cable

(electronics end)

refer to table 3

Rubber bushing

Knurled nut

Electronics

end

Electronics

end

2 twisted pairs

Remote

connector

Compression fit of

copper braid in contact

with connector for

shielding

Knurled nut

Remote signal cable

Shrink tube or

electrical tape

Rubber bushing

Table 6. Connection of Remote Signal Cable

Page 18

18

1. Take VFM 3100 end of prepared remote signal

cable and align it as shown at right. Ready for

assembly.

2. As shown in the diagrams at right, making

sure that the drain wire is folded back against

the copper braid, push the cable assembly

into the remote connector. Push until the cable

bottoms out (cannot be pushed in any further).

Push rubber bushing into position and tighten

the knurled nut onto the remote connector to

create a good compression fit.

VFM 3100 End (Junction Box End) Procedures

VFM 3100

end

Push cable assembly

into connector

2 twisted pairs

Prepared remote

signal cable (VFM 3100 end)

refer to table 2

Drain wire folded back

Rubber bushing

Knurled nut

Knurled nut

Remote

signal cable

VFM 3100

end

Rubber bushing

Shrink tube or

electrical tape

2 twisted pairs

Junction box

connector

Compression fit of drain wire

and copper braid in contact

with connector for shielding

Table 7. Connection of Remote Signal Cable (Electronics End)

Page 19

19

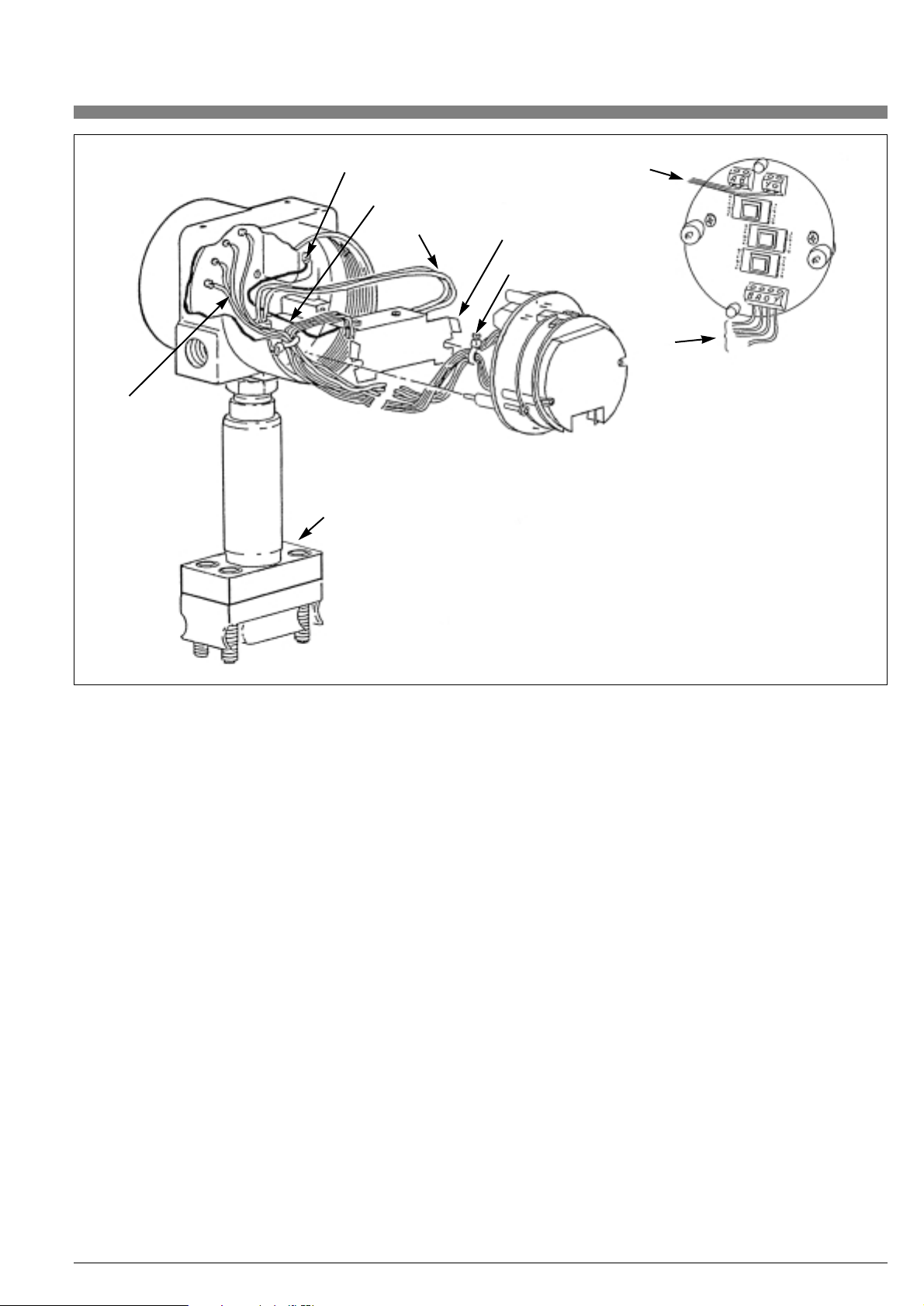

Installation with Conduit:

• The junction box is pre-wired. A conduit box or conduit may be

mounted directly to the 1/2 NPT connection at the remote housing. A box or a standard 3-piece union/coupler may be mounted

directly over the knurled nut. Do not disassemble pre-wired

connection at junction box.

• Run remote cable to the remote electronic module housing via

conduit. If required, prepare cable as shown in Table 5. Feed it into

the housing following Steps in the procedure for "Interconnection

Wiring for Remote Electronics" on page 13 and Table 6 on page 17.

• Mount conduit box or conduit to the 1/2 NPT connector directly

or via a 3 piece union/coupler, if necessary. Make connection to

the 1/2 NPT connector after the knurled nut has been tightened

to provide a compression fit for the cable. Refer to Table 6 on

page 17.

• At this point, follow Steps in the procedure for "Installation

Without Conduit" on page 13.

CENELEC Flameproof Version:

• The junction box side of the remote confirguration is pre-wired.

Add flameproof cable gland or E-Y fitting and conduit directly

to the special Foxboro adapter or via an approved CSA/UL 3piece union/coupler, if necessary. For this reason, the second

conduit plug is fitted with a grounding screw (see Figure 9).

NOTE: CENELEC certification requires that an infallible physical

earth (PE) connection be made to the junction box.

• Run the remote cable to the remote electronic module housing

via cable trays or conduit.

• Place knurled nut and rubber bushing over the cable as shown

in Table 5 on page 15.

• Prepare the remote cable as shown in Table 5.

• Remove the locked electronic module component cover from

remote electronic module housing. Unscrew captive mounting

screws and remove the electronic module without disconnecting

loop power wiring.

• Feed prepared remote cable into the electronics housing through

connector at bottom of housing. Push it in until the outer jacket

bottoms out inside the connector. See Table 6.

• Ensure that the cable is pushed in all the way and then push the

rubber bushing into position. Tighten the knurled nut to create a

compression fit. See Table 6.

• Inside the remote electronics housing, connect the four wires of

the remote cable to the 4-position terminal block on the rear of

the electronic module.

Follow the color-coded label. See Figure 9 on Page 16.

• Ensure that the excess remote cable and loop power wires are

tucked in under the electronics module. Without pinching, place

the module back into the housing and tighten the mounting

screws.

• Replace the housing cover tightly to prevent moisture and other

contaminants from entering and then lock it in place.

1.3. Field Termination

The following section addresses Wiring, conduit, and Earth (Ground)

Connection details.

1.3.1. Conduit Connections

NOTE: The wiring installation shall be in accordance with the local or

national regulations applicable to the specific site and classification

of the area.

The electronics housing has an electronic module compartment and

a field terminal compartment. It also provides 1/2 NPT conduit openings for access from either side of the VFM 3100 and for ease in

wiring to the field terminals. See Figure 10.

NOTE: One conduit opening contains a threaded plug. Do not discard this plug.

Remove the field terminal compartment cover (shown in Figure 10)

to make electrical connections. Keep the electronic module compartment cover closed to ensure protection for the electronic module

and to prevent moisture and atmospheric contaminants from entering the compartment.

There are three wiring combinations that depend on how the

VFM 3100 is to be used.

2-Wire Hook-up

4 to 20 mA and HART (1200 baud)

3-Wire Hook-up

4 to 20 mA, HART (1200 baud) and Scaled Pulse

4-Wire Hook-up

4 to 20 mA, HART (1200 baud) and Scaled Pulse

Two-Wire Hook-up

A dc power supply must be used with each transmitter and receiver

wiring loop to supply power for the mA signal. The dc power supply

may be either a separate signal unit, a multiple unit supplying power

to several transmitters, or built into the receiver. Connect the supply

and receiver loop wiring (0.50 mm2 or 20 AWG typical) to the

terminals in the field-terminal compartment of the transmitter,

as shown in Figure 11.

Electronic module

compartment

Electrical conduit

opening

Field terminal

compartment

Figure 10. Electronics Housing

Page 20

20

Twisted pair wiring should be used to prevent electrical noise from

interfering with the dc current output signal. In some instances,

shielded cable may be necessary. Earthing (grounding) of the shield

should be installed at one point only (at the power supply). Do not

earth (ground) the shield at the transmitter.

Transmitter connection polarities are indicated on the terminal block.

If the loop is to contain additional instruments, install them between

the negative terminal of the transmitter and the positive terminal

of the receiver, as shown in Figure 11.

Power Supply and External Load

The required loop power supply voltage is based on the total loop

resistance. To determine the total loop resistance, add the series

resistance of each component in the loop (do not include transmitter). The required power supply voltage can be determined from

Figure 12.

The transmitter will function with an output load less than 250 ohms,

provided that a configurator is not connected to it. Connecting a

configurator to a loop with less than 250 ohms may cause communication problems.

As an example, for a transmitter with a loop resistance of 500 ohms,

referring to Figure 12, the minimum power supply voltage is 22 V dc,

while the maximum power supply voltage is 42 V dc. Conversely,

given a power supply voltage of 24 V dc, the allowable loop resistance is from 200 to 565 ohms.

NOTES:

• The power supply must be capable of supplying 22 mA.

• Power supply ripple must not allow the instantaneous voltage

to drop below 12.5 V dc at the transmitter.

• The recommended minimum load is 250 ohms.

Case ground

terminal (earth)

Power

supply

Receiver

Additional

receivers

in loop.

250 ohm min load

required for

communication

Hart communicator.

Connect to loop to configure transmitter.

Two 1/2 NPT conduit connections are provided

(on opposite sides). Insert plug in connection

not used.

Terminal block

Figure 11. Installation Wiring -4-20 mA Output (Two-wire)

Figure 12. Load Requirements

Recommended supply voltage

and load limits

VDC

24

30

32

Load (OHMS)

250 and 565

250 and 860

250 and 960

Operating area

See note below

Supply voltage, V dc

Output load,

Min.

Load

Page 21

A dc power supply must be used with each transmitter and receiver

wiring loop to supply power for the transmitter. The dc power supply

may be either a separate signal unit, a multiple unit supplying power

to several transmitters, or built into the receiver.

Connect the supply and receiver loop wiring for pulse out (0.50 mm

2 or 20 AWG typical) to the terminals in the field-terminal compartment of the transmitter, as shown in Figure 13. To use this type of

3-wire hookup, the blue and green terminals on the back of the

module must be shorted.

A resistor is required to produce a voltage drop for proper operation

of the counter. A 680 ... 2 W resistor is recommended for most coun-

ters.The pulse signal can cause interference to signals in adjacent

signal cables. In some instances, shielded cable may be necessary.

Earth grounding of the shield should be at one point only (at the power supply). Do not ground the shield at the transmitter. Transmitter

connection polarities are indicated on the terminal block.

Power Supply and Load

The power supply voltage must be between 12.5 and 42 V dc. The

pulse "OFF" state current is a maximum of 0.42 mA at 42 V dc. In the

"ON" state, the pulse output is short circuit protected for 250 mA.

Four-Wire Hook-up

Two separate loops are required when using the scaled pulse output

in the four-wire hook-up arrangement. Each loop requires its own

power supply. Refer to Figure 14.

Select the resistor so that the current through the contact closure

does not exceed 250 mA.

Wiring may be run in conduit or in wireways. The wiring must meet all

applicable local standards such as hazardous location requirements

and electrical wiring codes. Signal wires should not be run in the

same conduit as power wires. Shielded twisted pair wiring is recommended.

21

Three-Wire Hook-up (See Figure 13)

Scaled Pulse Output

This wiring is primarily used to retrofit VFM3100 transmitters that

were wired as pulse only transmitters for totalization. This wiring is

typically for retrofitting existing installations. Configure the transmitter

for pulse output. Refer to the section on changing the configuration

beginning on page 23.

For new installations, a four-wire hook-up is recommended

for scaled pulse operation to improve communication integrity.

Red (+)

Output signal wires

Back of module

electronics side

Yellow (P)

Terminal block

Case ground

terminal

(earth)

250 OHM min.

load required for

communication

Hart communicator. Connect to loop

to configure transmitter.

Power

supply

Counter

680 OHM

Blue (-)

Shorting wire across

B and G

Sensor/preamplifier wires

Figure 13. Installation Wiring – Pulse Output (Three-wire)

Case ground

terminal (earth)

Terminal block

4-20 mA loop

680 Ω

Power

supply

Counter

Scaled pulse loop

Figure 14. Installation Wiring (Four-wire)

Page 22

22

2. Operating the VFM 3100

2.1 Introduction

Communication with the VFM 3100 is carried out using the HART

Model 275 Communicator or the optional Local Digital Display/Configurator. General instructions for using the HART Configurator can

be found in MAN 4250, HART Communicator Product Manual.

Vortex-specific instructions for using the HART configurator will be

found in chapter 8 of this document. Complete instructions for using

the Local Configurator will be found in chapter 9.

Note: For proper communication with VFM 3100, the HART

configurator must contain the DD for the KROHNE VFM 3100.

This DD is available from KROHNE, or any other authorized HART

Foundation source.

2.2 Passwords

The transmitter itself has no password. Rather, security measures,

i.e., the ability to access functions such as calibration, configuration,

and testing, are associated with the configurators used to communicate with the transmitter. The HART Communicator has no security

measure other than access to the device itself. The Local Digital Display/Configurator requires a password that is user definable. See

chapter 9.

2.3 Configuration Database

In order to function, the transmitter requires specific embedded

information, termed the “configuration database”. The parameters in

this database are listed in Table 8, and defined in chapter 9.

Each VFM 3100 is shipped from the factory with an operating configuration database; however, the VFM 3100 will not provide an accurate measurement if the configuration does not fit the application.

Be sure to check the configuration of each VFM 3100 prior

to start-up!

Flowtube Parameters

Model Code

Meter Body Serial Number

Reference K-Factor

Identification Parameters

Ta g

Descriptor

Date

Message

Polling Address

Transmitter Options

Flow Units

Total Units

Noise Rejection

Signal Conditioning

Low Flow Correction

Low Flow Cut-In

Process Fluid Parameters

Fluid Type

Process Temperature

Process Density

Base Density

Process Viscosity

Application Parameters

Mating Pipe

Piping Configuration

Upstream Distance

Custom K-factor Bias

Upper Range Value

Output Options

Damping Value

Pulse Output

AO/PO Alarm Type

Table 8. Configuration Database

Ta g

Fluid Type

Flow Units

Total Units

Process Temperature (value and units)

Process Density (value and units)

Base Density (if applicable; value)

Process Viscosity (if applicable; value and units)

Upper Range Value

Table 9. User Information

In all cases, the factory configuration includes the VFM 3100 Model

Code, Meter Body Serial Number, and Reference K-Factor.

It also includes the User Information in Table 9, if supplied with

the purchase order.

Page 23

23

Item Metric U.S.

Tag blank blank

Flow Units l/min USgpm

Total Units l USgal

Fluid Type Liquid (water) Liquid (water)

Process Temperature 20°C 70°F

Process Density 998,2 kg/m

3

62.301 lb/ft

3

Base Density 999.2 kg/m

3

62.374 lb/ft

3

Flowing Viscosity 1.002 cP 0.9753 cP

Upper Range Value Upper Range Limit for VFM 3100 Size Upper Range Limit for VFM 3100 Size

The units of this default configuration database, i.e., Metric or U.S.,

are established by the units of the Reference K-Factor.

NOTE: These defaults are not recommended for general operation.

If no other process information is available, entering “Liquid”, “Gas”,

or “Steam” as fluid type will establish default data bases as listed on

page 24.

Be sure to read the explanation of each parameter in “Configuration

Database” on page 22 prior to changing the configuration.

The remaining itemg in the database will have the following default

values:

* If the process density and viscosity are provided, the Low Flow

Correction will be set to On.

NOTE: These default values should be changed to match the

specific application. Before making any changes, be sure to read

the explanation of each parameter in “Configuration Database”

on page 22.

2.4. Changing the Configuration

(Configuration Menu)

Using the HART Communicator or the Local Digital Display/Configurator, any parameter in the configuration database can be

changed to fit the application by entering the Device Setup or Configuration Menu. The specific details for doing this depend on the

configurator, and are described in chapter 7 or 8. Some general information is presented below.

If the User Information in Table 9 is not supplied with the purchase

order, the transmitter is shipped with the following default set:

Descriptor blank

Date blank

Message blank

Polling Address 0

Noise Rejection On

Signal Conditioning On

Low Flow Correction* Off

Low Flow Cut-In (3rd level above minimum)

Mating Pipe Schedule 40

Piping Configuration Straight

Upstream Distance 30 Pipe Diameters

Custom K-factor Bias 0.0%

Damping Value 2.0 sec

Pulse Output Off

AO/PO Alarm Type Upscale

Flow Units Default units may be changed as desired.

Total Units Default units may be changed as desired.

Noise Rejection Keep default value On.

Signal Conditioning Keep default value On.

Low Flow Correction Should be changed to On if the low end of

the operating range is below a Reynolds

Number of 20,000.

NOTE: If On is selected, actual values of

the process density and process viscosity

must be entered into the database!

Low Flow Cut-In The default value for the Low Flow Cut-In

is the third level above the minimum. After

installing the VFM 3100, this level can be

changed such that under no-flow conditions the flow output is zero.

(See the following section “Adjusting the

VFM 3100” on page 26.)

NOTE: The HART protocol allows the connection of up to 15 HART

devices on a single twisted pair of wires, or over leased telephone

lines, a concept known as ‘multidropping’. In a multidrop installation,

each transmitter is identified by a unique address (1-15) referred to

as the polling address. In the multidrop mode, i.e., if the polling

address is non-zero, the analog output is set to a fixed value of 4 mA.

For a non-multidrop installation, i.e., a single transmitter loop, the

polling address of the transmitter should be left in its default value (0)

if the analog output is intended to indicate flow (4-20 mA). In a

multidrop installation the polling address of each transmitter must

be set to a unique integral value of 1 through 15. This can be done

before or after installation with the local configurator. If using the

HART Communicator, the polling address of each transmitter must

be set individually prior to installing in a multidrop environment.

2.4.2. Transmitter Option

Tag Default tag may be changed as desired.

Descriptor Default descriptor may be changed as desired.

Date Default date may be changed as desired.

Message Default message may be changed as desired.

Polling Address Default address may be changed as desired.

(See note below).

2.4.1. Identification Parameters

Page 24

24

NOTE: If the User Information is not supplied with the purchase order,

the following default data for a LIQUID will reside in the database.

Parameter Metric U.S.

Tag blank blank

Flow Units Nm3/hr SCF/hr

Total Units Nm

3

SCF

Fluid Type Gas (Air) Gas (Air)

Process Temperature 20 ˚C 70 ˚F

Process Density 9.546 kg/m

3

0.5858 lb/ft

3

Base Density 1.293 kg/m

3

0.07634 lb/ft

3

Process Viscosity 0.0185 cP 0.0186 cP

Upper Range Value Upper Range Limit for VFM 3100 Size Upper Range Limit for VFM 3100 Size

Parameter Metric U.S.

Tag blank blank

Flow Units kg/hr lb/hr

Total Units kg/hr lb/hr

Fluid Type Steam (saturated) Steam (saturated)

Process Temperature 175 ˚C 350 ˚F

Process Density 4.618 kg/m

3

0.2992 lb/ft

3

Base Density (N/A) 0.5977 kg/m

3

0.03730 lb/ft

3

Process Viscosity 0.0149cP 0.0150 cP

Upper Range Value Upper Range Limit for VFM 3100 Size Upper Range Limit for VFM 3100 Size

If the process fluid is not LIQUID, changing the fluid type to GAS

or STEAM will automatically bring up the appropriate default set

shown below.

Parameter Metric U.S.

Tag blank blank

Flow Units l/min USgpm

Total Units l USgal

Fluid Type Liquid (water) Liquid (water)

Process Temperature 20 ˚C 70 ˚F

Process Density 998,2 kg/m

3

62.301 lb/ft

3

Base Density 999.2 kg/m

3

62.374 lb/ft

3

Process Viscosity 1.002 cP 0.9753 cP

Upper Range Value Upper Range Limit for VFM 3100 Size Upper Range Limit for VFM 3100 Size

Page 25

As mentioned previously, the units of the default configuration database, i.e., US or Metric, are established by the units of the Reference

K-Factor.

These defaults are not recommended for general operation and

should be used only when no other information is known about the

process other than the fluid type. Be sure to read the explanation of

each parameter in chapter 9.Configuration Database, prior to changing the configuration.

2.4.3. Process Fluid Parameters

NOTE: The VFM 3100 uses the above three parameters to correct

internally for the effects of upstream piping and disturbances on the

Flowing K-Factor. Other known bias corrections can be entered

under Custom K-Factor Bias.

25

Fluid Type Selecting the fluid type establishes an appropriate default data-

base which can be modified to fit the application.

Process Temperature For accurate flow measurement, the actual value in the selected

units must be entered.

Process Density For optimal performance and accurate mass flow measurement,

the actual value in the selected units must be entered.

Base Density For accurate standard volume flow measurement, the proper

value must be entered in the same units as Process Density.

Process Viscosity For accurate flow measurement at low flow, the actual value in

the selected units must be entered. It is essential that the process viscosity be entered if the Low Flow Correction option is On.

Mating Pipe Select upstream mating pipe schedule.

Piping Configuration Select upstream piping configuration.

Upstream Distance Enter distance to first upstream flow disturbance in pipe

diameters.

Custom K-factor Bias To compensate for additional known biases in the flow

measurement system, enter the value, with sign, in percent.

Upper Range Value Enter desired maximum flowrate.

2.4.4. Application Parameters

2.4.5 Output Options

Damping Value Enter desired time in seconds.

Pulse Output Select desired output.

AO/PO Alarm Type Select desired fail condition. Applies only to 4 to 20 mA and Pulse

outputs.

Page 26

26

2.5. Preconfiguring the VFM 3100

With the HART Communicator, the database can be generated offline and then downloaded to the transmitter. The procedure for building the database consists of entering the appropriate information

as it is requested.

NOTE: The password for the local display configurator cannot be

configured from the HART Communicator.

2.6. Displaying the Configuration Database

HART Communicator (Review Menu).

The parameters in the configuration database can be viewed without

entering the Setup Menu. This is done via the Review Menu.

Local Configurator (Display Menu).

The parameters in the configuration database can be viewed without

entering the Configuration Menu. This is done via the Display Menu.

2.7. Adjusting the VFM 3100

The following four adjustments can be made to the VFM 3100:

mA Calibration (D/A Trim)

Total Reset

Low Flow Cut-In

Upper Range Value

These appear in various places in the structures

(refer to chapter 7 and 8).

2.7.1. mA Calibration (D/A Trim)

This function allows the 4 to 20 mA output of the transmitter to be

calibrated or matched to the calibration of the receiving device.

NOTE: The transmitter has been accurately calibrated at the factory.

Recalibration of the output is normally not required unless it is being

adjusted to match the calibration of the receiving device

2.7.2. Total Reset

This function allows the flow total to be reset to zero

2.7.3. Low Flow Cut-In

The low flow cut-in parameter allows the user to set the level above

which the VFM 3100 begins to measure flow, i.e., the lower range limit of the VFM 3100. This process can be carried out automatically if

the flow is turned off. Otherwise, manual selection from the following

pick-list of eight levels can be made:

Auto, (LO), (L1), (L2), (L3), (L4), (L5), (L6), (L7)

For convenience, these levels are displayed as estimated flow rates

in the selected flow units. The value of these flow rates depend on

the specific application parameters.

With the HART configurator the current value is displayed, and you

can elect to decrease or increase the level by one. If the level does

not change when this is done, the minimum or maximum level has

been reached, respectively. In the case of the local configurator you

can select the desired level from the displayed pick-list.

If Automatic mode is selected, the VFM 3100 chooses the lowest

level at which no signal is detected over a 20 second time interval.

You may wish to increase or decrease this setting. For instance, noise signals could be occurring at an interval greater than 20 seconds

and possibly not be detected during the automatic selection process. Repeating the auto-selection process helps to avoid this possibility.

2.7.4. Upper Range Value

This parameter sets the desired maximum flowrate of the VFM 3100.

2.8. Reading the Measurements

The Process Variable Menu (HART) or the Measurement Menu (Local) provides periodically updated values of the flow rate, vortex frequency (frequency in), scaled pulse frequency (frequency out), and

flow total. The fllow rate and total are presented in units of volume or

mass as configured, the frequencies in Hz. Due to the limited size of

the local display only one parameter is displayed at a time. It is possible to configure the device to display in succession two, three, or four

of the variables, as selected from a pick-list.

2.9. Testing the VFM 3100 and Loop

(Test Menu)

Entering the Diag/Service Menu for the HART Communicator or Test

Menu for the Local Configurator allows the following two test procedures to be activated:

• Self-Test

• Loop Test or Loop Calibration

2.9.1. Self-Test

This selection checks transmitter operation by injecting, near the

front end of the electronics, an internally generated periodic signal of

known frequency. The frequency of this signal is in turn measured

and checked against the injected signal.

2.9.2. Loop Test or Loop Calibration

This selection allows the transmitter to be used as a signal source to

check and/or calibrate other instruments in the control loop, such as

indicators, controllers, and recorders. The mA, scaled pulse, and digital output signals can be adjusted to any value within the range limits of the VFM 3100.

2.10. Electronic Module Replacement

If an Electronic Module is shipped as a replacement, the correct flowtube parameters will not reside in its configuration database. For proper operation of the VFM 3100, the correct values must be entered.

If the configuration database from the original VFM 3100 was saved

to a file, this file, containing the correct flowtube parameters, can be

downloaded to the new transmitter. If this is not the case, they must

be entered manually from the VFM 3100 tag.

In the latter case, enter the following data first when configuring the

VFM 3100!

• Model Code: Enter alphanumeric Model Code from VFM 3100

body tag (first 14 characters).

NOTE: If a Model Code beginning with the letter 'E' is entered via the

local configurator, a prompt screen will be displayed requesting that

the VFM 3100 configuration be selected from the following list:

- Single Measurement

- Dual Measurement

- Single Measurement with Isolation Valve

- Dual Measurement with Isolation Valve

This capability is NOT available with the HART configurator; hence,

the local configurator must be used to enter the flowtube parameters

if the Model Code begins with the letter ‘E’.

If the Model Code does not begin with an 'E', the above information

is read directly from the Model Code.

Page 27

• VFM 3100 Body Serial Number: Enter alphanumeric Serial Number from VFM 3100 tag.

NOTE: Although the VFM 3100 will operate properly without this information, it is convenient to enter it at this point.

• Reference K-Factor: Enter numeric value from VFM 3100 body tag

NOTE: It is not necessary to enter the units of the Reference

K-Factor. The units, i.e., US (pulses/ft3) or Metric (pulses/liter), are

determined internally by the VFM 3100, based on the nominal size of

the VFM 3100 (contained in the Model Code) and the entered numeric value of the Reference K-Factor.

3. Troubleshooting

3.1. General Troubleshooting

To maximize the usefulness of this chapter, read this General Troubleshooting section first. Then, follow the applicable procedural steps in

the order presented. Persons performing troubleshooting procedures should be suitably trained and qualified for those procedures.

NOTE: If applicable, remove transmitter under test from multidrop

environment.

3.1.1. VFM 3100 Has Incorrect Output

Check the configuration. Be sure the VFM 3100 has been configured

correctly.

Incorrect 4 to 20 mA Output

• Be sure the upper range value is correct.

• Check that the correct flow units are specified.

• Check that the VFM 3100 is not in the multidrop mode by

verifying that the polling address is zero. In the multidrop mode

the mA output is fixed at a constant 4 mA.

• Check that the VFM 3100 is not in one of the application

default modes.

a. For liquid the default mode is water.

For many situations this may be adequate.

b. For steam the default is 125 psig saturated steam.

There may be significant error at other pressures.

c. For gas the default mode is 100 psig air. Other gases and other

conditions require the correct configuration for density and

base density.

Incorrect Digital Output

• Check that the correct flow units are specified.

• For custom flow units check that the conversion factor is

correct.

Refer to “Determining Special Measuring Units” on page 43

to calculate the conversion factor.

• Check to be sure that the VFM 3100 is not in one of the appli-

cation default modes.

Incorrect Pulse Output

• Verify that correct flow units are used. Check the pulse reso-

lution factor.

• The scaled pulse output can only be used with a receiver that

does not calculate period, such as a counter.

3.1.2. VFM 3100 Output Indicates Flow When There Is No Flow

In some installations, the VFM 3100 can indicate flow when the line is

shut down. This could be the effect of a leaking valve, sloshing fluid,

or noise sources such as pump-induced pipe vibration. To eliminate

these false signals, try the following:

NOTE: Remote mounted VFM 3100 with standard temperature range sensors may have noisy signals if the slide switch on the preamplifier is in EXT position. Be sure the switch is in the correct position to

match the sensor.

• Be sure there is no flow.

• Be sure the noise rejection feature is set to ON.

• If damping is ON and set to greater than zero, the noise spikes

that exceed the low flow cut-in will appear as decaying signals

less than the low flow cut-in.

• Adjust the low flow cut-in level to produce zero output.

This level can be automatically set or manually adjusted via the

configurator.

• Check that transmitter and power supply are properly earthed

(grounded). This is particularly important for remote installations.

Refer to “Field Termination” on page 19 and “Interconnection

Wiring for Remote Electronics” on page 13.

• For remote VFM 3100, verify that signal cable has been properly

terminated.

3.1.3. VFM 3100 Output Indicates Higher Flow Rate with

Decreasing Flow

• Be sure the noise rejection feature is set to On.

• Adjust the low flow cut-in level to produce zero output.

This can be done with automatic or manual adjustment.

3.1.4. Fluctuating Output

• Verify that the signal conditioning feature is On.

• Fluctuations may be a true picture of the actual flow.

• A small offset of 1 to 2% with rapid fluctuations may be caused

by gaskets protruding into the flow stream.

3.2. No Output Troubleshooting

NOTE: VFM 3100 with extended temperature range sensors will

have reduced output if the slide switch on the preamplifier is in STD

position. Be sure the switch is in the correct position to match the

sensor.

• Be sure there is flow.

• Check the power supply. The voltage across the + and terminals must be between 12.5 and 42 volts dc.

a. If voltage is zero, check for blown fuse in power supply.

b. If voltage is low, but not zero, the VFM 3100 may be loading

the power supply. Remove the field terminal cover. Disconnect

the + and - leads and measure the voltage from the power

supply. If the voltage returns to normal, the circuit is good to

this point. Reconnect power to the + and - terminals.

c. Remove the electronic module compartment cover. Loosen

the mounting screws and remove the electronic module from

the housing. Measure the following voltages on the B-R-O-Y

terminal block. They should be:

Red to Yellow: +2.6 +0.2 Volts dc

Orange to Yellow: +2.6 +0.2 Volts dc