Page 1

4/2001

V

)

Vortex flowmeter

Installation and

Operating

Instructions

FM 1091(I

Page 2

Contents

Part A System installation and start-up

1. Description 4

2. Installation in the pipe line 4 – 6

2.1 General

2.2 Sandwich type to DIN 19205 / ANSI 6

2.3 Flanged type to DIN 2501 / ANSI B16.5 (SCH-40) 6

2.4 Temperature / Pressure Measurement for

External Density Compensation 6

3. Electrical connection 7-8

3.1 Installation location and cable diameter 7

3.2 Connection to power

3.3 Outputs

3.3.1 Abbreviations 7

3.3.2 Current (analog) output I 7

3.3.3 Connection between VFS1000 (I) F and VFC 091 F 8

3.3.4 Pulse Output P 8

4. Start-up 8

Part B Signal converter VFC 091

5 Operation of the signal converter 9

5.1 General 9

5.1.1 Starting up signal converter 9

5. I.2 Measurement mode 9

5.1.3 Programming or menu mode 9

5.1.4 Error handling 9

5.2 Operating and check elements 10

5.3 Program organization and programming chart 11

5.3.1 Menu levels 11

5.3.2 Programming chart 12

5.3.3 Description of keys 12

5.4 Programming and function of keys 14+15

5.5 Error Messages 16

5.5.1 Error Messages in Measurement mode 16

5.5.2 Error Messages in Programming mode 16

2

Page 3

6. Description of programme functions 7-23

6.1 Numerical order description 7-20

6.2 Functional order description 20

6.2.1 Physical units 20

6.2.2 Numerical format 21

6.2.3 Display 21

6.2.4 Flow range and meter size 21

6.2.5 Primary information 22

6.2.6 Application information 22

6.2.7 Internal Electronic Totalizer 22

6.2.8 Current (analog) output I 22

6.2.9 Pulse. output P 22-23

6.2.10 Coding desired for entry into programming mode 23

6.2.11 Behaviour of outputs during programming 23

6.2.12 HART® Programmability 23

6.2.13 Functions through HHC 24

6.2.14 Generic Online Menu Tree 25

Part C Functional checks and Trouble shooting hints

7. Functional checks 26

7.1 Primary head functional checks 26

7.1. Vortex Sensor 26

7.2 Signal converter functional checks 26

7.2.1 Self diagnostics 26

7.2.2 Display check 26

7.2.3 Current output check 26

7.2.4 Pulse output check 26

7.2.5 Frequency measurement check 26

8. Trouble shooting hints 27

Part D VFM 1091 (I) Ex

9. Description of the system 28

9.1 Temperature class 28

9.2 Electrical connection 28

10. Field connection diagram 29

11. Nameplate & Certificates of VFM 1091(I) Ex 29-30

Part E Technical data 31-50

3

Page 4

Part A system installation and start-up

1. Description

KRONHE MARSHALL vortex flowmeters operate on the Karman

vortex street principle to measure volumetric flow rate of gases /steam

and liquids. VFM 1091 computes normalized volumetric and mass flow

rates from operating & normalized density values supplied through

operator interface.

Items included with shipment for Compact flowmeter

• Compact Vortex flowmeter and operating instructions

• Installation and Operating Instructions

• Mounting bolts, washers, nuts

• Programming chart indicating factory configuration setting

• Optional upstream and downstream pipes

• Gaskets between primary head & pipeline

Items included with shipment for field mounted

Flowmeter

• Field mounted sensor VFS 1091 F

• Pipe/Wall mounted separated signal converter VFC 091F

• Connecting Cable (10m) between VFS 1091 F & VFC 091F

• Installation and Operating Instructions

• Mounting bolts, washers, nuts

• Programming chart indicating factory setting.

Provided by customer

• All cables for electrical connections.

2. Installation in the pipeline

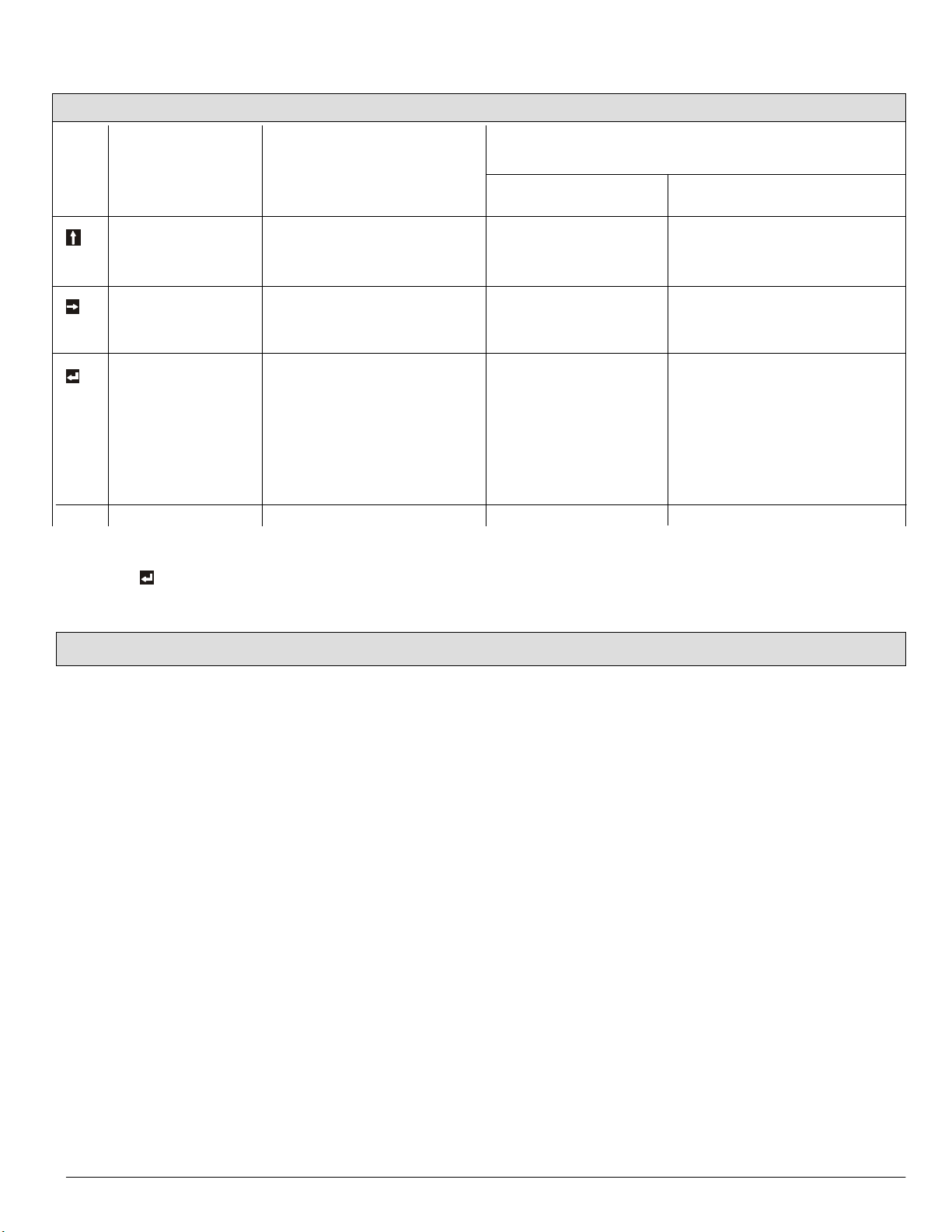

2.Difference between inside diameters of primary head and

pipeline

DΝ Meter size of primary head in millimeters or Inches

Φ Inside diameter of primary head in millimeters Max.

∆Φ allowable difference between inside

diameters of primary head and pipeline

SIZE φ ∆φ SIZE φ ∆φ

DN

(mm)

mm

(inch)

10S 8.9

(0.35)

10 12.6

(0.50)

15 14.9

(0.59)

20 20.9

(0.82)

25 28.5

(1.12)

40 43.1

(1.70)

50 54.5

(2.15)

80 82.5

(3.25)

100 107.1

(4.22)

150 159.3

(6.27)

200 206.5

(8.13) 1 (0.039)

mm

(inch)

0.4

(0.016)

0.4

(0.016)

0.4

(0.016)

0.4

(0.016)

0.4

(0.016)

0.4

(0.016)

0.6

(0.024)

0.6

(0.024)

0.6

(0.024)

0.8

(0.031)

DN

(inch)

3/8"S 8.9

mm

(inch)

(0.35)

3/8" 12.6

(0.50)

1/2" 14.9

(0.59)

3/4" 20.9

(0.82)

1" 26.7

(1.05)

1/5" 40.9

(1.61)

2" 52.6

(2.07)

3" 78

(3.07)

4" 102.4

(4.03)

6" 154.2

(6.07)

8" 202.7

(7.98) 1 (0.039)

mm

(inch)

(0.016)

(0.016)

(0.016)

(0.016)

(0.016)

(0.016)

(0.024)

(0.024)

(0.024)

(0.031)

Ensure that the bore of upstream and down-stream pipes are smooth

and without deposits or scaling of welding beads.

0.4

0.4

0.4

0.4

0.4

0.4

0.6

0.6

0.6

0.8

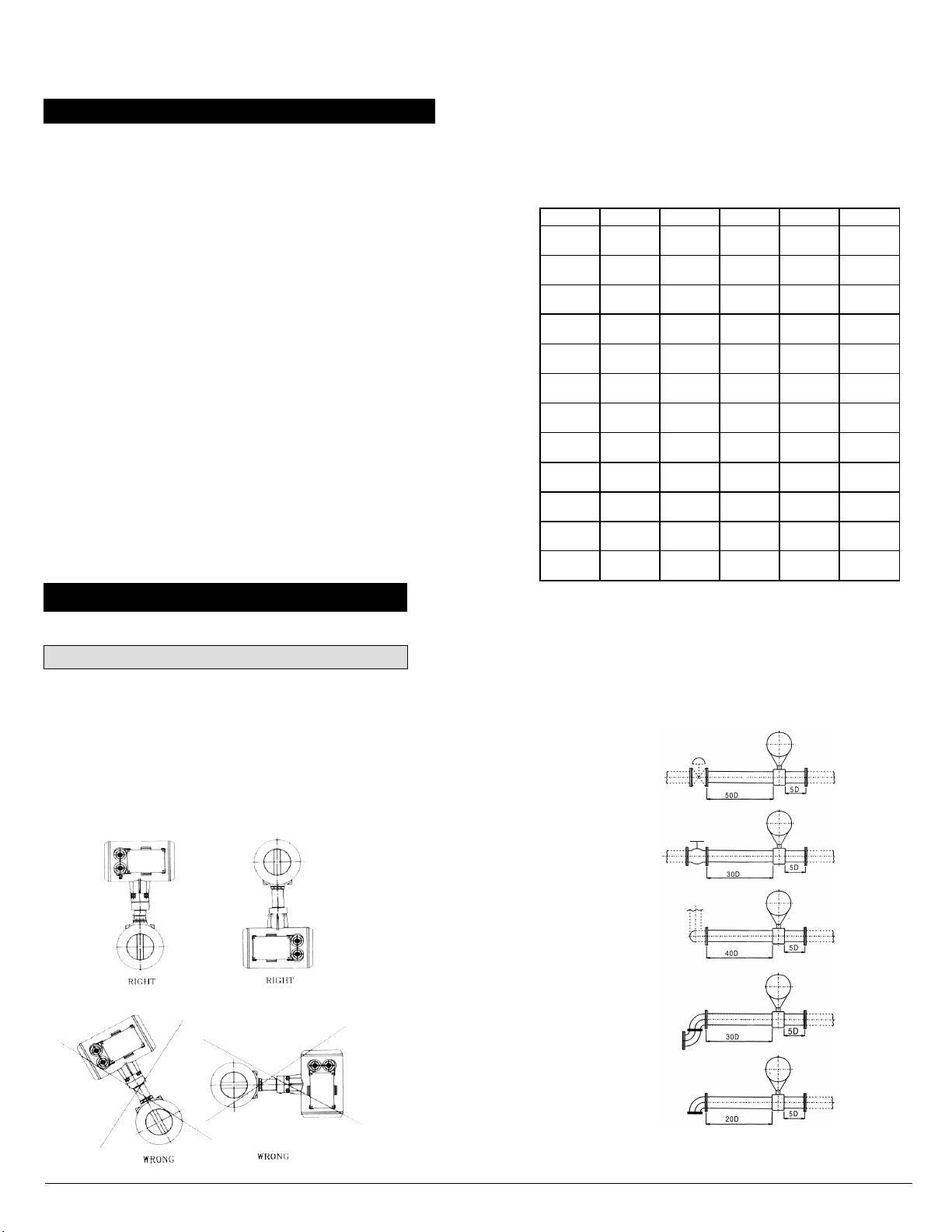

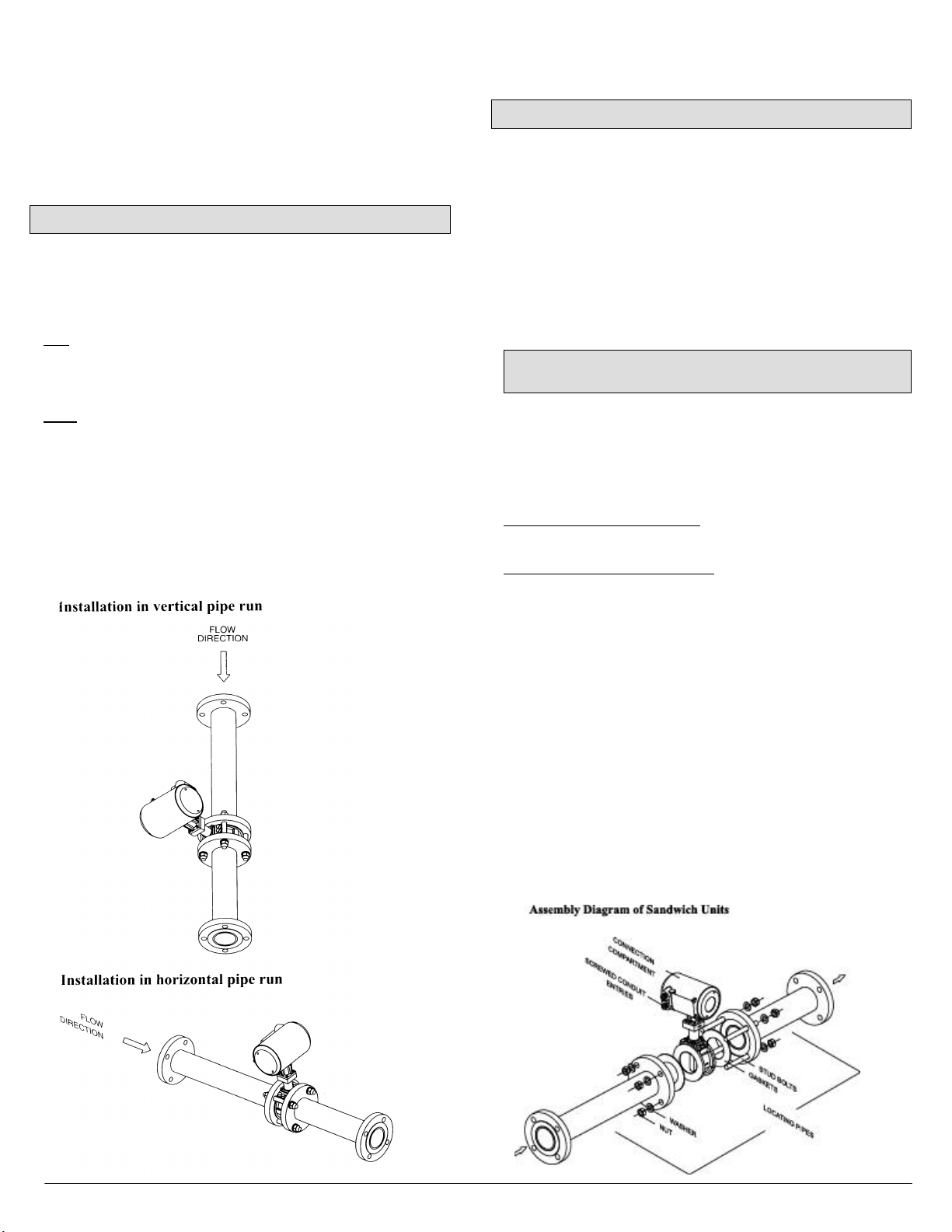

2.1 General

1. Flow direction and meter position -

• Flow must always be in the direction of the arrow, bluff side of

vortex-shedding body facing incoming flow i.e. upstream side.

• Vertical pipe run: upward flow direction

• Horizontal pipe run: see below

3. Straight, unimpeded inlet and outlet runs

D = Meter size (Nominal Dia. DN)

CONTROL VALVE

BALL/GATE VALVE

(FULLY OPEN)

0

2 X 90

BENDS

3-DIMENSIONAL

(SAME FOR 3 X 90

0

2 X 90

BENDS

0

90

BENDS

OR “T” PIEC

0

BENDS)

4

Page 5

EXPANDER

REDUCER

Flexible pipes or bellows may be used before the upstream and after the

downstream in case the vibrations are too high. Pipe vibration limit is

0.2 g peak to peak up to 8-500 Hz crossover frequency. (which equals

0.75 mm)

FLOW STRAIGHTENER

SPACIAL FLOW STRAIGHTENER

With flow straightener the inlet pipe length may be halved e.g. for a

control valve the inlet length is 25D instead of 50D. The minimum inlet

pipe length including flow straightener must always be 12 D.

The small sizes (below 1" or DN 25) come with upstream &

downstream pipelines & flange connections to suit customer's flanges.

4. Pipe vibration

Caused, for example, by the action of pumps, valves, etc., will falsify

measurements particularly at low flow velocities. Support the pipeline

on both sides of the flowmeter; in the direction perpendicular to both

the pipeline & bluffbody axis.

SANDWICH VERSION

5. Pipeline along a wall

Where possible, the distance between the pipe centerline and wall

should be greater than 0.5 m (20”). If it is less, first connect all cables

to terminals in the connection compartment (power supply and outputs)

and run them via an intermediate connection box (see also Section 3)

before installing the flowmeter.

Do not lag (Thermally insulate) the meter body.

6. Orientation

• Turn the Display board through ±90 or 180 to obtain horizontal

positioning of the display.

• Turn the signal converter housing through ±900 or 1800 should that

be more suitable for the location of the installation.

7. State of Medium

• Ensure single-phase flow. Liquid droplets in gas / vapour, solid

particles in gas/liquid & gas bubbles in liquid are not permitted.

In Liquid application e.g. water; to prevent cavitation, minimum D/S

pressure is given by the relation:

Pds (bar_g) >= (2.9* DP)+ (1.3 * Ps) - 1.013

where DP= pr.drop of VFM in Bar from sizing

program.

Ps= Sat.pr.in Bar at op.temp

FLANGED VERSION

Page 6

• In case of steam or compressed gas, a moisture separator may be used

compensation

50D upstream of the meter if the dryness fraction is less than 95%.

• For gases, a filter or strainer may be used to remove solid particles.

This is specially important for meter sizes below 1".

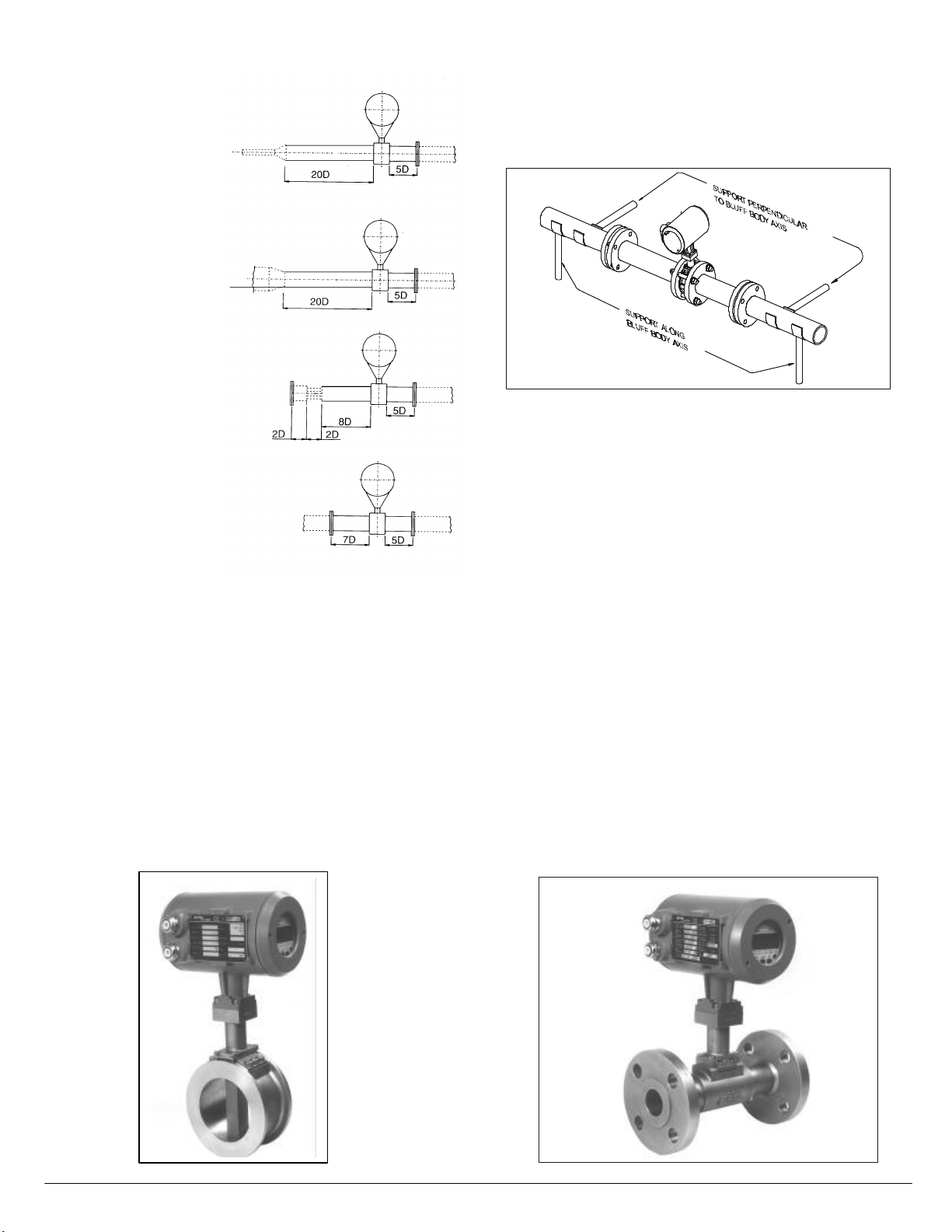

2.2 Sandwich type to DIN 19205 / ANSI

• Meter sizes DN25, 40, 50, 80, 100 and 150 (1" to 6")

• Pipe flanges

(Pressure Ratings

DIN: DN25/PN40, 100; DN40/PN40, 100;

DN50/PN40, 64, 100; DN80/PN40, 64, 100;

DN100/PN16, 40, 64 and DN150 / PN16, 40.

ANSI: 1" to 6” / #150, 300 SORF)

• Gaskets inside diameter must be greater than the inside diameter of the

Primary head, e.g. Use flat gaskets to DIN 2690, Gaskets must not

project into the effective pipe cross sectional area. washers, nuts and

bolts are

2.3 Flanged type to DIN 2501 / ANSI B 16.5(SCH-40)

• Meter sizes DN10S, 10, 15, 20, 25, 40, 50, 80, 100, 150

and 200 (3/8"S to 8")

• Pipe flanges

(Pressure ratings

DIN: DN25/PN40, 100, DN40/PN40, 100; DN50/PN40, 64, 100;

DN80/ PN40, 64, 100, DN 100 /PN16, 40, 64; DN150/PN16,

PN40, DN200/PN10, 16 and

ANSI: 1/2” to 8" / # 150, 300 SORF)

• Gaskets are supplied by us with flanged unit.

• check flange connection for leak-tightness after

flowmeter installation.

2.4 Temperature / Pressure measurement for External density

To measure the temperature and pressure of the medium for either mass

flow/normalized f1ow computation using external flow computer or

measure operating density using external pressure and temperature

measurement (e.g. to feed the density value in the VFM off-line mass

or normalized flow computation) suitable measuring points should

• Bolts, nuts and washers are supplied with meter, check flange

connection for leak-tightness after flowmeter installation.

Installation upstream of f1owmeter

Min. distance: 20*DN (DN = meter size)

Installation downstream of flowmeter

Min. distance: 5*DN (DN = meter size)

Allowance must be made for the pressure drop in the flowmeter as

correction value for operating conditions prevailing upstream of the

flowmeter.

Page 7

3. Electrical Connection

3.1 Installation Location & Cable diameter

Location

• Do not expose the compact flowmeter to direct sunlight Install a

sunshade if necessary.

• Do not expose to intense vibration. If necessary support the pipeline

to the left right of the flowmeter.

• The rotating design of the housing makes it easier to connect the two

cables for power and outputs to the terminals in the rear terminal

box.

Cable diameter

• To conform to protection category requirements, observe

• the following recommendations :

• Cable diameter: 8 to 13 mm (0.31" to 0.51")

• Enlarge the inside diameter of the Screwed conduit entry by

removing the appropriate onion ring(s) from the seal, only if cables

have extremely tight fit.

• Fit blanking plug PG16 and apply sealant to unused cable entries.

• Do not kink cables at conduit entries

• Provide water drip point (U bend in cable).

Conduit Installation, general wiring considerations

When electrical codes require conduit, it must be installed in such a

manner that the meter connection compartment remains at all dry

times.

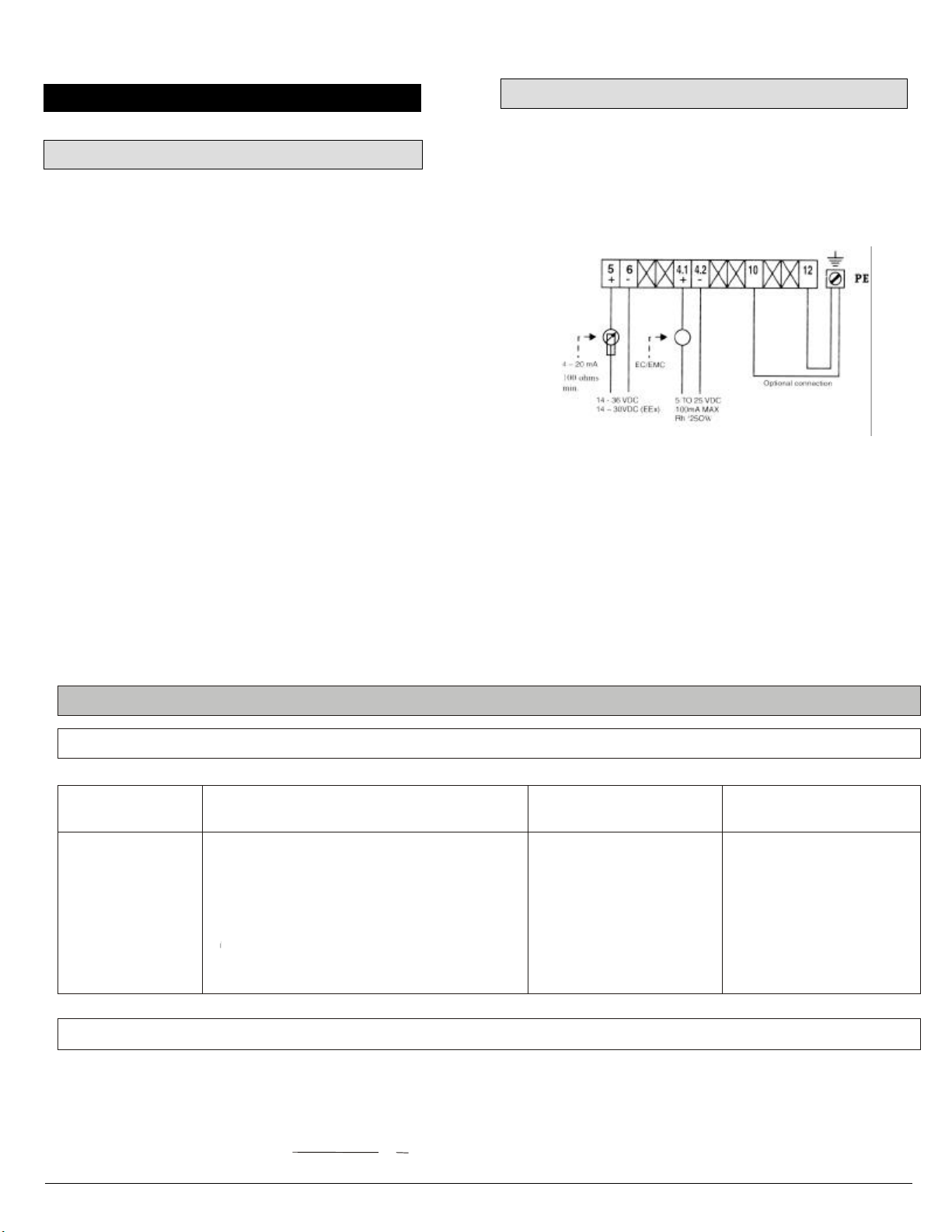

3.2 Connection to loop power supply

• In case of functional extra low voltages (24VDC) protective

separation in conformity with VDE 400 part 410, or equivalent

national standard, must be ensured.

• Hazardous area application will require the connection of

protective Earth.

• Connection to power, VFM 1091 K

• Current and frequency outputs are galvanically isolated when the

optional ground above is not used and can therefore be

simultaneously connected to a receiver instrument which is

grounded or separately connected to two receiver instruments.

• Ensure that 24V, 4-20 mA loop is grounded at one point only (i.e.

either at the input of the signal converter or at the input of the

indicator, or at the output of the Power Supply). Do not ground the

loop at more than one point.

3.3 Outputs

3.3.l Abbreviations

Abbreviation Stands for

EC

EMC

P

P

100%

Q

0%

Q

100%

Electronic counter

Electro-mechanical counter

Pulse output

Pulses for Q =100% flow rate

0% flow rate

Full-scale range, 100%. flow rate.

3.3.2 Current (analog) output I

• The current output is galvanically isolated from Pulse output P.

• Max. load at terminals 5/6

U – 12 V

max. load in Kohms

R =

B

B

20mA

<1200 ohms

Programming

via Fct. No....

-

-

1.3.X

1.3.2

1.1.2

1.1.2+1.3.2

Description

see Sect....

3.2+3.3.4

3.2

6.1+6.2.9

6.2.9

6.1

6.1+6.2.9

7

Page 8

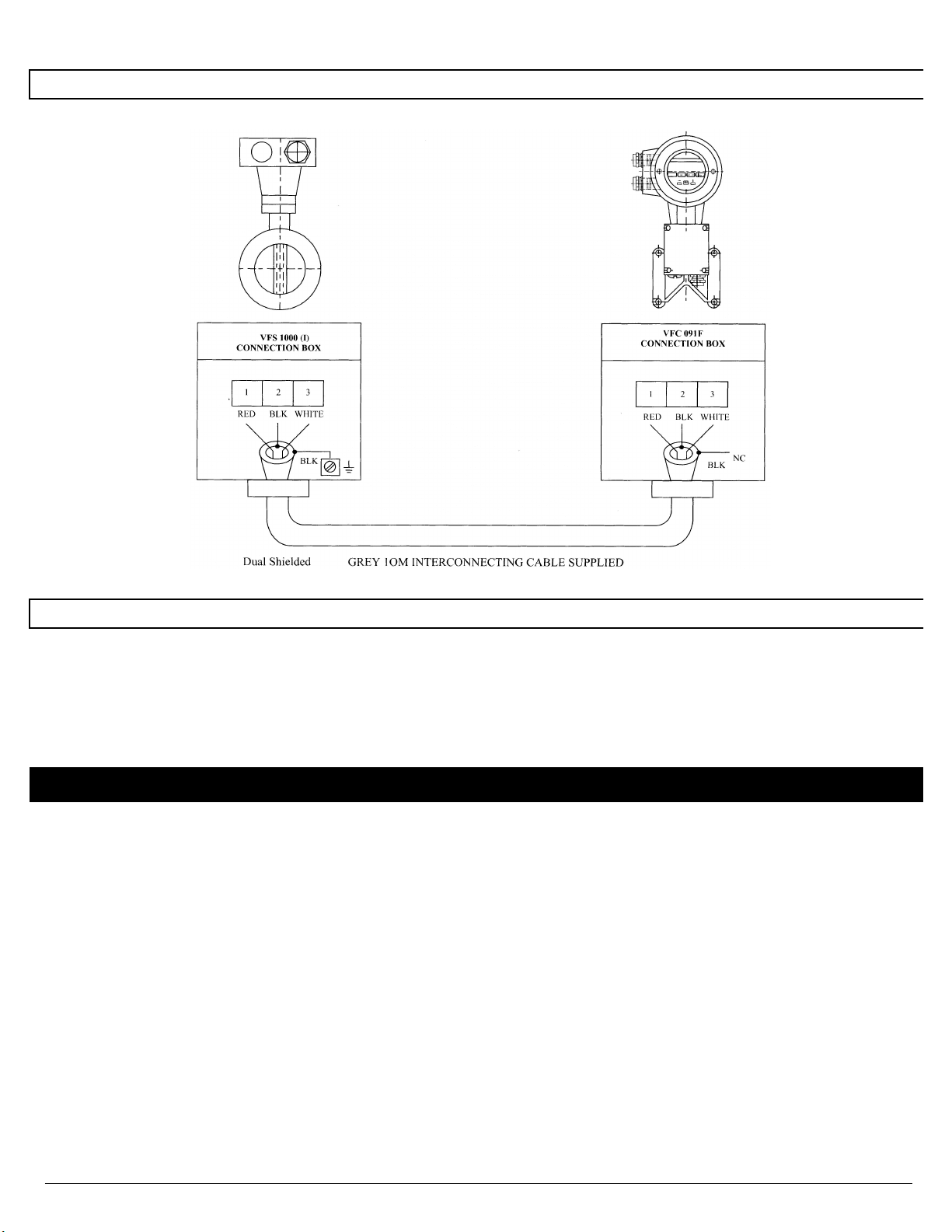

3.3.3 Connection between VFS1091 & VFC 091F

3.3.4 Pulse out put

• The pulse output is galvanically isolated from the 4-20mA current output and may be optionally grounded.

• All functions and operating data are programmable; see Section 5, 6.1 6.2.9

• Factory-set data and functions are listed in the enclosed report on settings. This can also be used to record any changes made to the operating

parameters.

• Passive frequency output, open collector for connection of active electronic counters EC or switchgear, input voltage 5 to 25V, load current max.

100 mA, min load resistance RL 250, selectable pulse width duty cycle or 250 mSec

4. Start-up

• Check that the system has been correctly installed as described in Sect. 1, 2 and 3.

• Before initial start-up check that the following details on the nameplate agree with the data specified in the report of settings for the signal

converter. If not, reprogramming will be necessary.

Meter size Fct3.1.1, Sect. 6.1, 6.2.5.

K-Factor Fct 3.1.2, Sect. 6.1, 6.2.5.

• The flowmeter is ready for service 15 minutes (waiting time) after switching on the power source. Increase flow velocity slowly and steadily.

• Avoid abrupt changes in pressure in the pipeline.

• If the process medium is steam, condensate may form initially and cause faulty measurements when the system is started up for the first time.

• When powered, the signal converter normally operates in the measurement mode. The power-on sequence to measurement mode is as follows:

“TEST” is displayed for approx. 3 seconds followed by

“VFM 1091 ” the instrument type followed by

“Ver x.xx” the software version of the instrument.

Then instrument operates in measurement mode where it displays the parameter being measured Or FATAL ERROR if there are one or more

critical errors detected (For description on errors refer Sect. 5.5.)

8

Page 9

Part B Signal Converter VFC 091

5. Opening of the signal converter

5.1 General

5.1.1 Starting up signal converter

When power is switched ON to signal converter it displays TEST, VFM, 1091 & Ver.x.x.x and then goes to measurement mode. In this initial

sequence VFM 1091 (I) carries out self-diagnostics to check its own functiona1elements and loads the configuration data from non-volatile

memory. If any error(s) are detected in power on diagnostics converter displays

to carry normal measurements. The first measured parameter displayed is the one being displayed when power supply was removed last time.

5.1.2 Measurement Mode

In measurement mode, the parameters that converter measures/computes are shown on display in the appropriate units. (See Sect. 5.2 for display

details). As per the configuration, display can be either in non- cyclic/cyclic mode. In non cyclic mode of display, use key to see the next

parameter on display. In cyclic mode display shows all parameters one after another, wherein each parameter is displayed for about 6 seconds.

While in the measurement mode, the flow and the current values can be monitored using the HART

values, the communicator also displays the minimum and maximum values of flow values, which are programmed into the device.

5.1.3 Programming or menu mode

All the configuration/settings/test functions are grouped in the form of menu having a tree structure (see Sect. 5.3.1 for details) and are accessible

in the programming mode. Operator can view or alter the present settings, data values by the use of functions available in this mode. VFC091

implements all the universal commands and relevant common practice commands of HART

parameters using HART

All changes made in programming mode are stored in non-volatile memory and have appropriate effect on the operation of signal converter. While

being programmed (i.e. while in the menu), the instrument will stop making further measurements and the current O/P will be frozen to the last

value, pulse O/P will also stop. The changes made using the HART

data to the device. After data is received, VFC091 updates the configuration n with thenewly received data. During the updation period, the

measurement is interrupted. (The updation time is less than half second).

5.1.4 Error handling

®

Communicator. These are mainly flow-related parameters.

®

communicator are stored in the communicator till you request to "Send" the

FATAL. ERROR since instrument has critical error(s) and is not able

®

Communicator. Other than flow and current

®

this enables you to program some of the main

Converter can detect errors during power-on diagnostics as well as when in normal measurement mode. Errors are put into two main categories

viz. fatal errors and non-fatal errors. Fatal errors cause measurement to stop since they are serious in nature. Non-fatal errors do not affect

functionality of the converter.

If one or more errors are present, display (in measurement mode) starts blinking. If programmed so, error information is shown on display interleaved

between display of two parameters.

9

Page 10

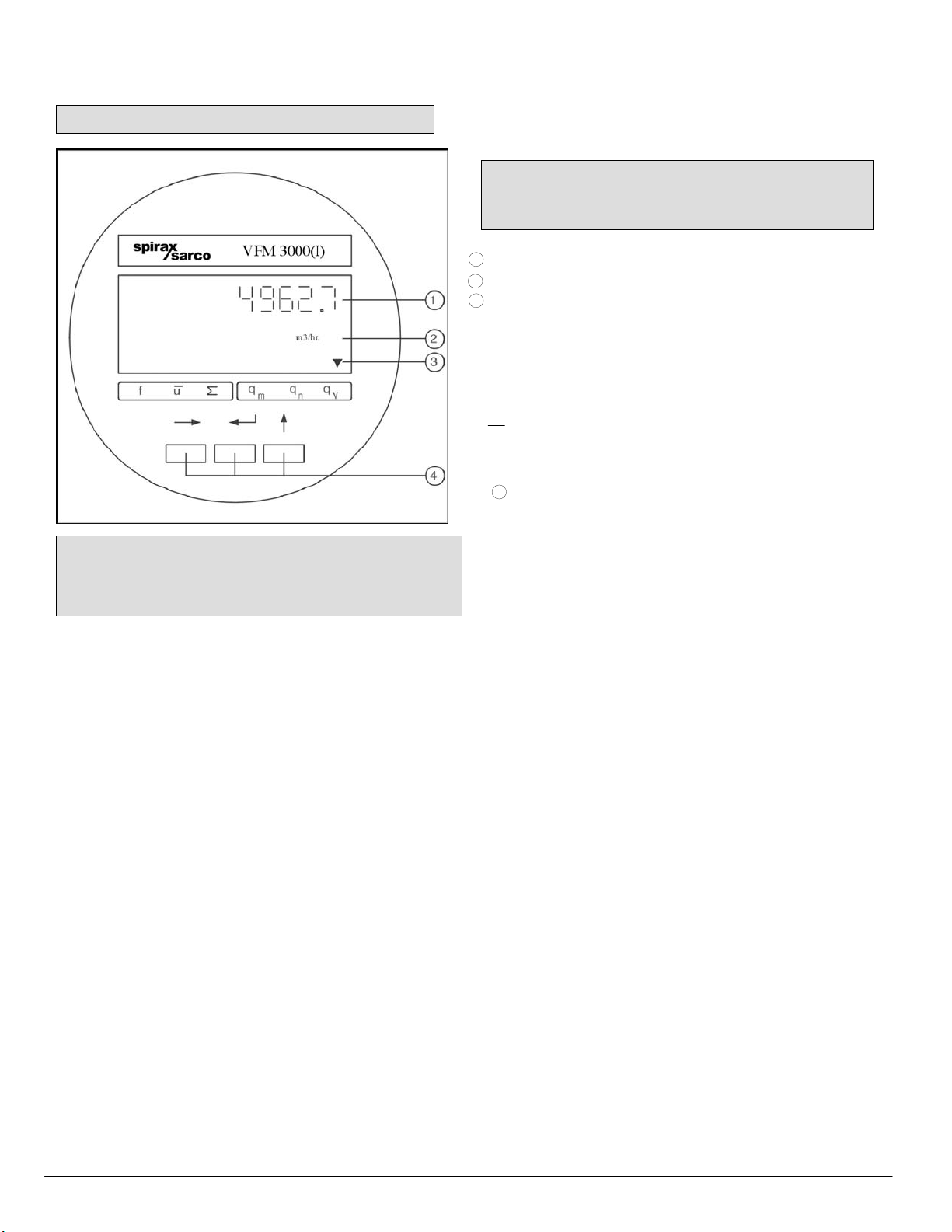

5.2 Operating & check elements

Caution

To avoid damage to electronics, be certain that the area around the

meter is dry before removing electronics compartment cover.

The operating elements are accessible after removing the cover of

the electronics section using the special wrench supplied.

Caution

Do not damage screw thread, never allow dirt to accumulate,

and make sure it is well greased at all times.

1

Display, 1st line

2

Display, 2nd line

3

Display, 3rd line

q v Volumetric flow rate

q n Normalised volumetric flow rate

q m Massflow rate

S Totalizer value

u Velocity of medium

F Vortex frequency

4

Keys for Programming the Signal Converter, refer

To Sect.5.4 for function of keys.

10

Page 11

F

F

F

F

F

F

F

F

F

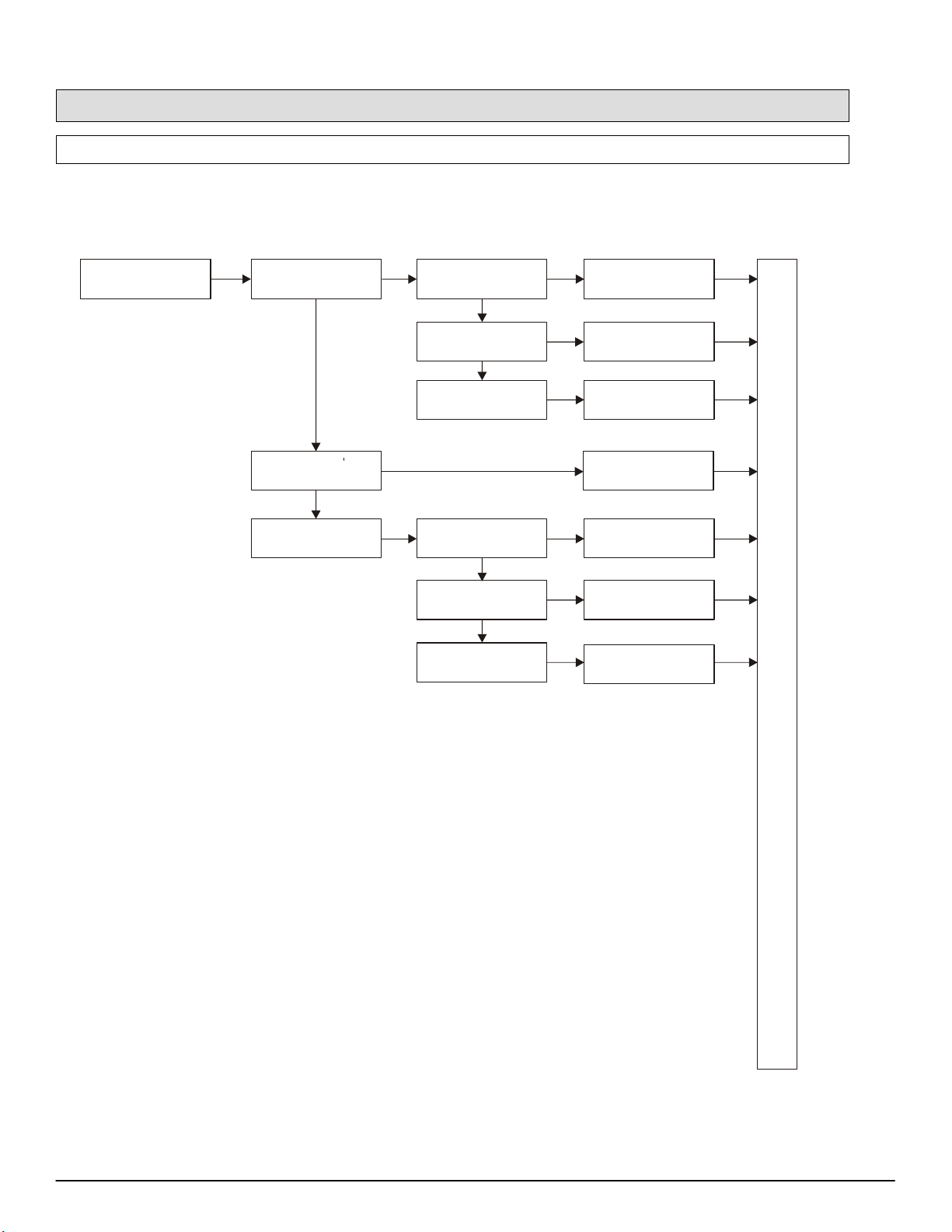

5.3 Program organization & programming chart

5.3.1 Menu levels

The program for the signal converter consists of 5 levels. The 1

st

line of display will identify the menu levels during programming

Actual Display

Fct 1.0

OPERATION

Fct

2.0

TEST

Fct 3.0

INSTALL.

Fct 1.1.0

BASIS PARAM

Fct 1.2.0

DISPLAY

Fct 1.3.0

PULS O/P.

Fct 3.1.0

BASIS PARAM

ct 3.2.0

USER DATA

ct 3.3.0

APPLICAT

ct 1.1.1-1.1.4

ct 1.2.1-1.2.6

ct 1.3.1-1.3.3

ct 2.1-2.3

ct 3.1.1-3.1.2

ct 3.2.1-3.2.3

ct 3.3.1-3.3.4

A

C

C

E

S

S

T

O

S

E

T

T

I

N

G

S

O

R

D

A

T

A

P

O

S

S

I

B

L

E

A

T

T

H

I

S

L

E

V

E

L

O

N

L

Y

Measuring

mode level

Main

menu

Submenu

level

Function

level

Data

level

level

11

Page 12

12

Page 13

13

Page 14

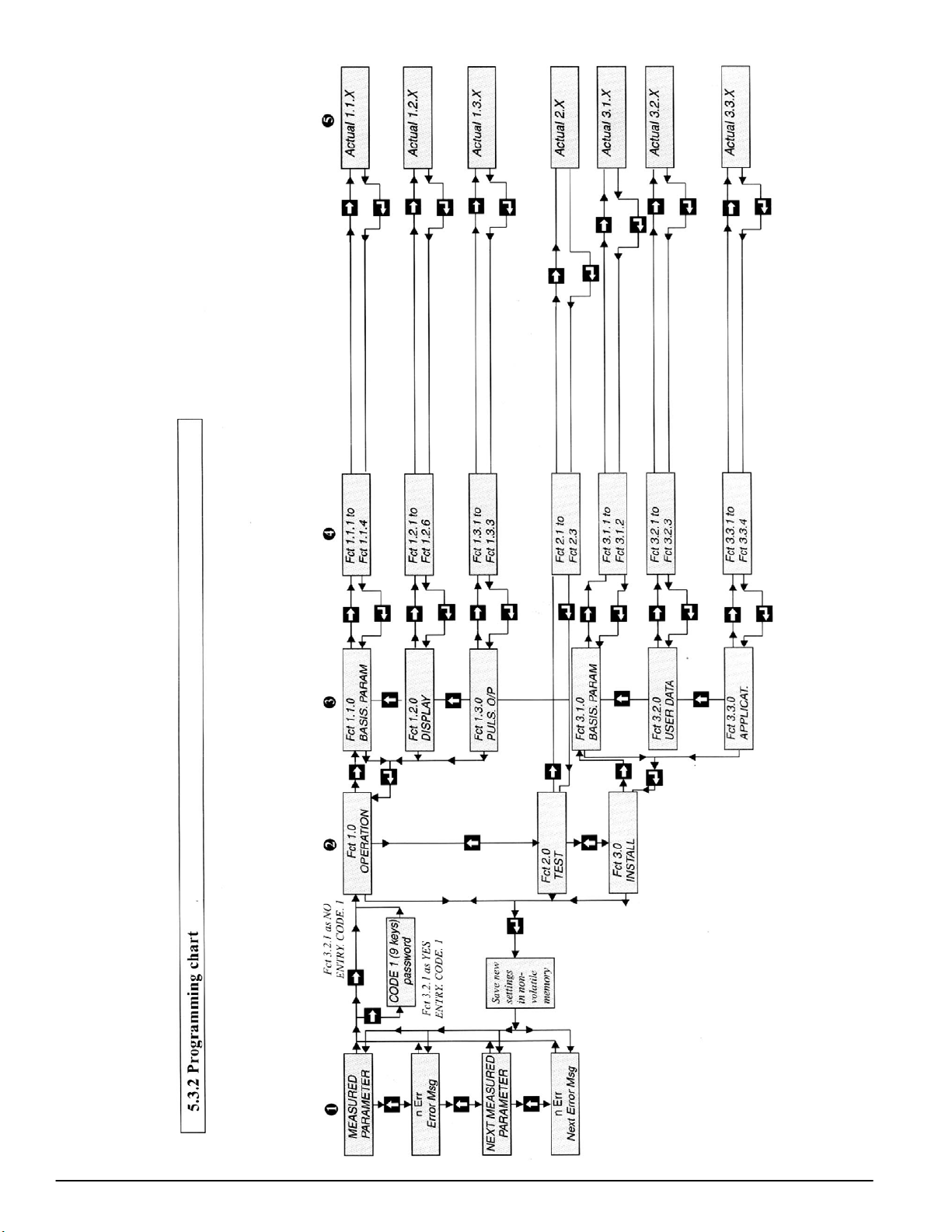

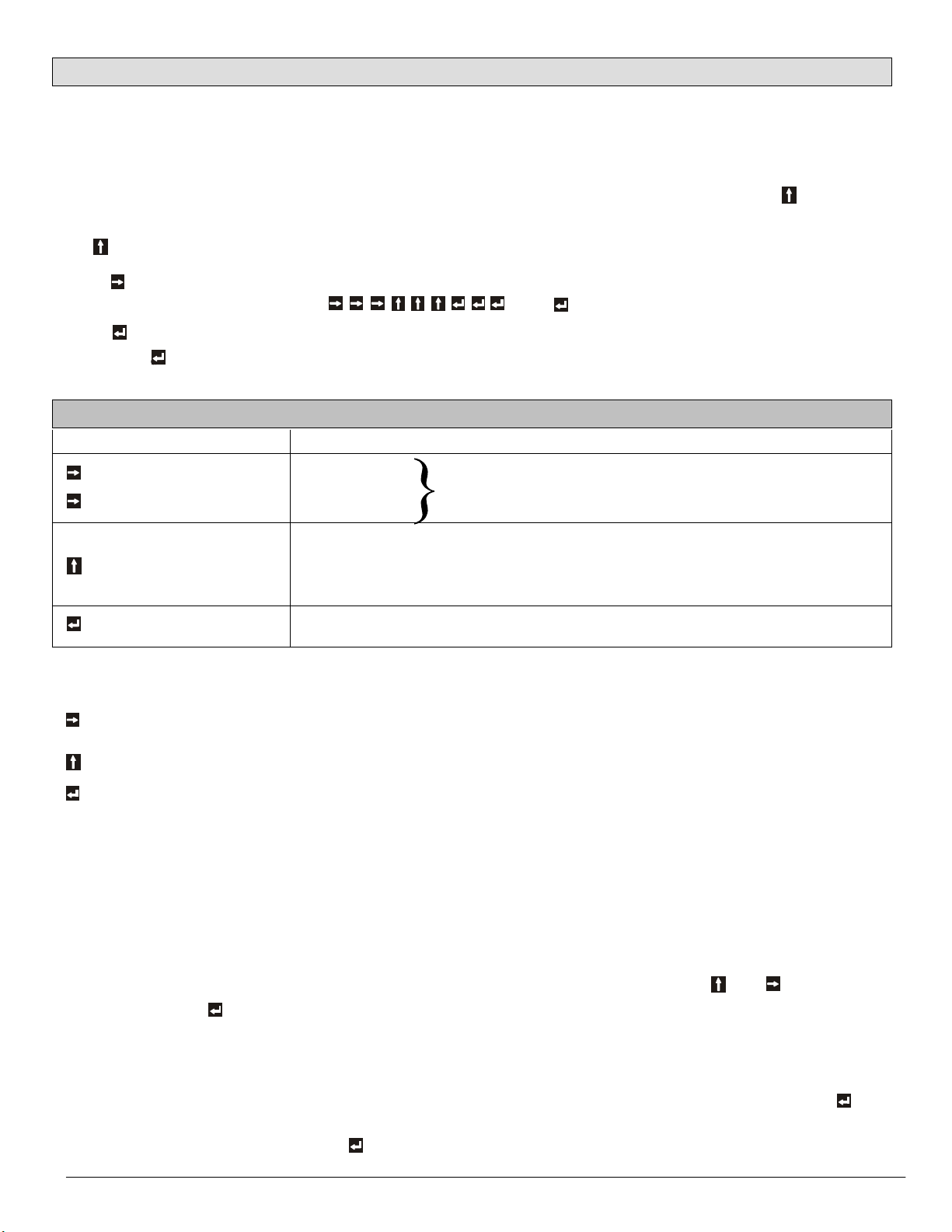

5.4 Program organization & function keys

Function of keys in measurement mode:

After power-on, the signal converter enters the normal measuring mode. Display shows the actual measured value of the parameter, units and

arrow markers to identify parameter. A steady (non-blinking) display indicates that there are no errors in measuring mode. Use key to get the

next parameter on display. If display is in cyclic mode (Fct 1.2.6 CYCLE DISP as YES) the next parameter is displayed after every 6 seconds

and key has no function.

Use the key to go to the programming mode If Fct.3.2.1 ENTRY. CODE.1 is YES then converter will ask for the Code 1 password. Password

is the following sequence of 9 key operations Press key to go back to normal display.

Use the key results in prompt for Code 2 password. Code 2 password is predefined and reserved for Khrone Marshall service person.

Operator should not use key at normal display. If used by accident then give any arbitrary key sequence to code 2 prompt until display gets

back to normal.

Using keys in measuring mode

KEY FUNCTION

Without

Followed by 9 keys Coding, dependent on programming Fct.3.2.1. Go to programming mode.

With

Displaying next parameter measured or next error message

(Fct.1.2.5 as YES for error message)

if in non cyclic mode (Fct.1.2.6 as NO) In cyclic mode the key has no function

Reserved for use by Khrone Marshall

Functions of keys in programming mode:

Programming and other functions are grouped in a menu having tree structure. To navigate in the menu tree use keys as follows.

To go into the branch i.e., from main menu level to submenu level or submenu level to function level. If you go were already at function

level then that function will be executed.

Selects other options/branches at the same level.

Takes you one level back. If you were already at main menu level then this key takes you back to measurement mode.

Programming functions involve one or more of the following types of data.

1. Selecting an option from option list – Initially present option is displayed in second line of displayed and display blinks to indicate that there

are other choices. Use the key to scroll through all options one by one. Using will cause that option to be selected and also completes

selection process.

2. Entering a numeric value-You can enter +ve or –ve number in floating point with exponent notation.

-9

Rang : 0.0001 x 10

to 9.9999 x 10 9

Format: d.dddd E-d

e.g 1.2345 E-3, 1.2345E6

Method of entry: Initially present value is displayed in the first line display. A flashing digit will change by using key. Select next digit

position in sequence and terminates entry of the number.

Note:

a) Digits cycle through 0-9 values. A sign fields cycles as “ “ and “ – “ for exponent negative

b) When you enter a value beyond its limit then you get message d.ddddEd (MIN. VALUE) or d.ddddEd (MAX VALUE). Press after

you have noted limit and then correct value to be in valid limits.

c) If you don’t want to change value press at the beginning itself !

14

Page 15

Using keys in programming mode

Key Main menu level Submenu Data level

Function level

Option/Units Numerical values / strings

Select main menu Select submenu or function select next Change flashing digit or

Proposal Character Proposal

Enter displayed Enter displayed submenu Shift flashing digit or

Main menu (execute) function character position

Quit programming Return to main menu Select displayed Enter the displayed numerical

Mode and go back or submenu proposal and return value or alphanumerical

To measurement to function level if no string. Then return to

Mode further data entry is function level if no further

required by the required by that function

function

Newly entered data will be saved in non-volatile memory and accepted by measuring program only after termination of programming mode as

described below.

Pressing the key at main menu level quits the programming mode. Before exiting programming mode, device updates the configuration

according to the changes done in the menu.

Programming using HART® based communicator

While in the measuring mode the communicator displays the measured values of flow, the computed current output value and Qmax, Qmin

values programmed into the device. Using the communicator, you can see / modify many of the device parameters. For details of using HART®

Communicator please refer the HART

reference. Please refer 6.2.12 for details of HART® programmability.

®

Communicator manual. The Generic Online Menu of the communicator is given in 6.2.14 for your quick

15

Page 16

5.5 Error messages

5.5.1 Error messages in Measurement mode

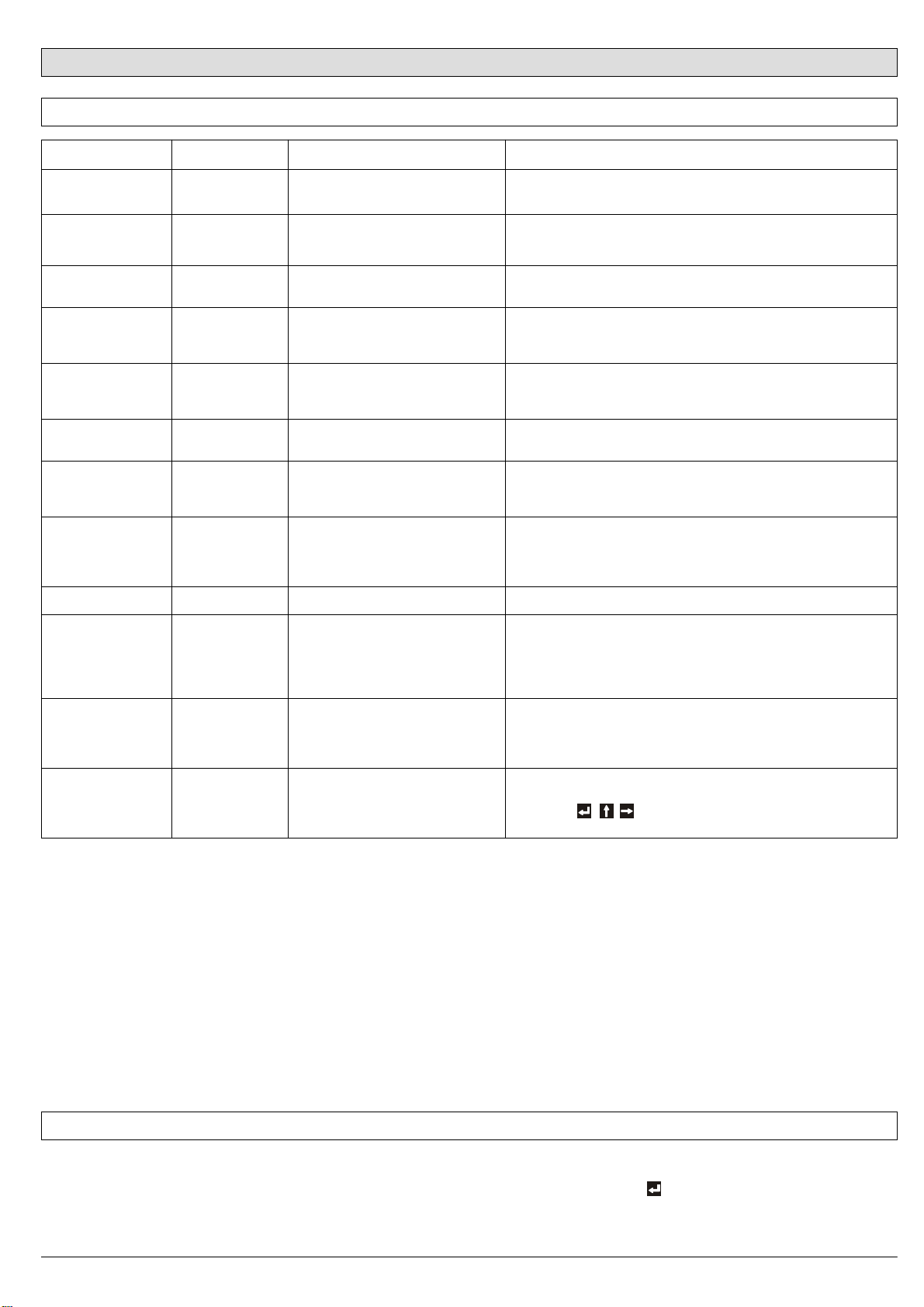

Error message Type Description Corrective action required

INTL ERR. nn * Internal error in Switch off the power and try again. If the problem

converter operation persists contact KHRONE MARSHALL service.

NO SIGNAL N No signal from No flow through the primary or Vortex sensor problem.

the vortex sensor If sensor problem, contact KHRONE MARSHALL service.

LOW FREQ N Vortex frequency Check Flow rate>q min else call KHRONE MARSHALL

Service.

too low

HIGH FREQ N Vortex frequency Check Flow rate<q max else call KHRONE MARSHALL

Service.

too high

LOW FLOW N Flow rate lower

than minimum flow Converter will continue to display actual flow rate. However

rate q min accuracy of measurement may suffer.

HIGH FLOW N Actual flow rate Corrective action depends on application process. If flow

higher than q max rate exceeds too much further it may damage entire instrument

physically!

INV. CONFIG F Configuration date Check entire configuration again. If error persists-call

in non-volatile memory KHRONE MARSHALL service.

is not valid.

UC FAIL F Micro-Controller failure Contact KHRONE MARSHALL Service.

LCDC FAIL F LCD Controller IC (s) has Contact KHRONE MARSHALL Service.

failed (This error is

applicable to users having

display option)

KEY FAIL F Failure of Keys Contact KHRONE MARSHALL Service.

(applicable to instrument

which have display option)

NOVRAM FAIL F Non Volatile Memory Contact KHRONE MARSHALL Service.

has failed

LINE INTER N Supply interrupted Press keys to reset this error.

· This text is displayed for Fatal Errors. The nature of error is beyond the scope of user (failure of IC or other hardware inside converter electronics

etc.). All that can be done is to switch OFF power and then try again. If error message continues, call KHRONE MARSHALL service. internal

error nn = internal error number.

· Type N indicates non-fatal errors whereas F indicates fatal errors.

· Measurement stops if any Fatal error is encountered. This means that device makes flow rate equal to zero,

· Current output to minimum value 4m A & pulse output OFF.

· When errors are displayed during the measuring mode, 'n Err" (n = number) will appear in the 1st line. n gives the number of momentarily

occurring errors that are displayed alternately with the actual measured value.

· Error messages disappear when their cause disappears

5.5.2 Error Messages in Programming mode

Error in programming mode can only occur while entering any numerical value. When you enter numerical value outside possible limits you get

message " n.nnn E n" in 1st line and MIN. VALUE or MAX VALVE or in the 2nd line ("MIN VALUE" if entered value is less than lower limit and

“MAX VALVE “ if higher limit is crossed). Note the message indicating permissible limit then press the key to continue.

16

Page 17

b

d

/

r

M

H

e

d

e

n

H

y

b

H

w

y

w

H

6. m function

6.1 Numerical order description

This section describes all the functions which can be programmed locally.

Some of the parameters of the device can be programmed using the

HART

with their corresponding Generic Online Menu (GOM) steps for HHC275.

For more details of GOM refer to 6.2.12 and 6.2.14. Program functions are

given in numeric

order as follows:

Description of progra

.

®

ased communicator (For example HHC 275). These are given

· Function number & title

· Description of the function

Limits – Applicable limits for numerical input

Fct. 1.0 OPERATION

This is the first main menu level. Submenus and their functions groupe

under (1.x.x functions) control the operation of the instrument in the

following areas:

- flow range to measure.

- display settings of measured values, units, errors etc.

- pulse output programming.

Fct. 1.1.0 BASIC.PARAM

This submenu groups functions that:

- Set basic flow measurement type ( volumetric / normalized-volumetric

mass flow measurement)

- Flow range (minimum & maximum flow) to measure time constant fo

flow rate.

Fct. 1.1.1 MEAS.INST. measuring instrument type

Set instrument to measure volumetric or normalized volumetric or mass

flow rate as per the options –

• VOLUME • NORM. VOLUME • MASS

Usually, this function is initially used only once. If you need to change the

basic measurement type later-on, you should check/reprogram all flow rate

and totalizer related functions such as -

FLOW UNITS, TOTAL. UNITS, RANGE P, TOTAL. VALUE

ART: GOM 1,3,2

Fct. 1.1.2 MAX. FLOW maximum flow rate

Enter the maximum flow rate desired. Max. flow should be within th

measuring range for the given primary data (3.l.x functions) an

application data (3.3.x functions).

After setting the Qmax value, set range P value Fct. 1.3.2 to ensure that th

Pulse output function works normally. The current output range (4-20mA)

corresponds to 0% flow (Q 0%) and 100% flow (Q

value of Q

If the flowrate exceeds the MAX FLOW an error condition (HIGH FLOW)

is generated

is entered at the MAX. FLOW Function.

100%

AX FLOW, MIN. FLOW,

) respectively. The

100%

The following units are available to choose from depending o

programming of. Fct. 1.1.1 MEAS. INST.

for volumetric flow –

• m3/hr • m3/min • UK Gal/Sec

•

Litre/hr • Litre/min • Litre/Sec

• ft3/hr •

•

cft/hr • cft/min • cft/Sec

•

cuft/hr • cuft/min • cuft/Sec

•

US Gal/hr • US Gal/min • US Gal/Sec

UK Gal/hr • UK Gal/min • UK Gal/Sec

•

for normalized volumetric flow –

• Norm.m3/hr • Norm.m3/min • Norm.m3/Sec

• Norm.L/hr • Norm.L/min • Norm.L/Sec

• Sft3/hr • Sft3/min • Sft3/Sec

• Scft/hr • Scft/min • Scft/Sec

for mass flow -

• kg/hr • kg/min • kg/Sec

• T/hr • T/min • T/Sec

• Lb/hr • Lb/min • Lb/Sec

LIMITS 1 to 1 x 10

ART : GOM 1,3,3

Fct. 1.1.3 MIN. FLOW minimum flow rate.

Enter the minimum flow rate in the same units as for max. flow above.

Min. flow should be within the measuring range for the given primar

data (3.1.X functions) and application data (3.3.X functions). If flow is

elow min.flow then an error condition (LOW FLOW) will be

generated. Note that this value should not be zero for vortex

flowmeters. This value is normally set to the minimum flowrate

(determined from sizing) for the size of primary used.

LIMITS –Greater than zero to (0.5*max flow.) Higher limit is 50%

of the value entered Fct. 2.1.2 MAX FLOW,

ft3/min • ft3/Sec

ART: GOM 1,3,3

Fct. 1.1.4 TIMECONST. time constant for flow rate

Enter a low-pass filter time constant in seconds to be applied to flo

rate. A value of zero indicates that low-pass filter is not be applied.

With this function it is possible to compromise between a stead

indication (on display/current output) and response time (to flo

changes)

LIMITS – 0 TO 20 SECONDS

ART : GOM 1,3,6

Fct. 1.2.0 DISPLAY

This submenu group the display function which

- Allow selection of units for all measured parameters

- Select what parameters to include in display cycle

- Select display mode (cyclic/non-cyclic) and error messages to/not to

appear in display cycle

17

Page 18

t

I

N

H

y

e

f

a

n

p

r

t

Fct. 1.2.1 FLOW UNITS for display

Select a unit in which flow rate is to be displayed from the following lis

of the available units, depending on programming of Fct.1.1.1 MEAS.

NST.

For volumetric flow -

• m3/hr • m3/min • m3/Sec

• Litre/hr • Litre/min • Litre/Sec

3

• ft

/hr • ft3/min • ft3/Sec

• cft/hr • cft/min • cft/Sec

• cuft/hr • cuft/min • cuftSec

• US Gal/hr • US Gal/min • US Gal/Sec

• UK Gal/hr • UK Gal/min • UK Gal/Sec

• % MAX. FLOW

for normalized volumetric flow -

• Norm.m3/hr • Norm. m3/min • Norm. m3/Sec

• Norm.L/hr • Norm.L/min • Norm.L/Sec

• Sft3/hr • Sft3/min • Sft3/Sec

• Scft/hr • Scft/min • Scft/Sec

• %MAX.FLOW

or mass flow -

• kg/hr • kg/min • kg/Sec

• T/hr • T/min • T/Sec

• Lb/hr • Lb/min • Lb/Sec

• % MAX.FLOW

ote that the list is same as for Fct. 1.1.2 except for an additional unit %

MAX. FLOW (to display flow rate as a percentage of max flow).

ART: GOM 1,3,2

Fct.1.2.2 TOTAL UNITS totalizes unit for display. Totalized flow ma

be displayed in one of the following units.

For volumetric flow -

• m3 • Litre • ft3

• cft • Cuft • US Gal

• UK Gal NO DISPLAY

For normalized volumetric flow –

• Norm. m3 • Norm. L • sft3

• scft • NO DISPLAY

for mass flow –

• kg • T • Lb

• NO DISPLAY

Use NO DISPLAY to exclude totaliser from display cycle.

Fct.. 1.2.3 VELO.UNITS velocity unit for display

You can choose from

• m/Sec • ft/Sec • NO DISPLAY

Select NO DISPLAY if you don't want this parameter to be displayed.

Fct. 1.2.4 FREQ UNITS frequency unit for displays

You can choose from

• Hz • kHz • NO DISPLAY

Select NO DISPLAY if you don't want this parameter to b

displayed.

Fct. 1.2.5 ERROR MSG. display of error messages.

If you want error messages to appear between display o

parameters in normal measuring mode, choose YES otherwise

select NO.

Fct. 1.2.6 CYCLE DISP. Cyclic/non-cyclic display.

YES. means display will cycle automatically. This means

measured parameter is shown in selected units for about 6

seconds and then the next parameter in the display cycle is show

for 6 seconds and so on. NO (non-cyclic display) means the

arameter is continuously shown on the display (to see othe

parameters or to change setting use

error messages in between changeover from one parameter to

next if error(s) are present and Fct. 1.2.5 ERROR MSG. is YES

Fct. 1.3.0 PULSE O/P

This submenu groups Pulse output related functions.

Fct. 1.3.1 FUNCTION P Pulse output

Choose YES to make Pulse output active as per

functions Fct. 1.3.2 to Fct. 1.3.3.NO makes Pulse

output inactive (0 Hz).

Fct. 1.3.2 RANGE P Pulse output range value

Enter a value here for the number of pulses required per uni

volume/mass. This must always be set after max flow value Fct.

1.1.2. is set.

Example –

For a value of 0.1 Kg, 10 pulses per Kg = 1 pulse per 0.1 Kg.

Pulse output programming is independent of max. flow. The

various options of units for are given below. RANGE P are given

below.

for volumetric flow –

• PULSE/m3 • PULS/litre • PULS/ft3

• PULS/cft • PULS/cuft • PULS/US.Gal

• PULS/UK.Gal

for normalized volumetric flow –

• PUL./Norm.m3 • PULS/Norm.L • PULS/Sft3

• PULS/Scft

for mass flow –

• PULS/kg • PULS/t • PULS/Lb

LIMITS - (0 TO 0.5 Hz) / Q

where Q

is flowrate in Volume or Mass units per second

100%

100%

the key). You may see

pulse/unit volume or mass,

18

Page 19

u

N

t

e

d

r

y

t

t

O

w

H

t

d

r

t

d

h

n

N

d

Fct 1.3.3 P. WIDTH.LIM pulse width

You can limit the duration of active pulse width of the Pulse output. Yo

can choose -

• YES • NO

YES limits the pulse width to 250 mSec

O keeps the Pulse output at 50% duty cycle.

This function helps to minimize the overheating of

totalizer coils.

Fct. 2.0 TEST

This second main menu level groups test functions for display, curren

output and Pulse output. There are no sub-menus under 2.0. Since these

are test functions, when executed they have an immediate effect on th

signal converter for the duration the test function is executed. When

using all the other menu functions, the changes made are store

temporarily and have no effect on the operation of signal converte

unless you quit menu.

Fct. 2.1 TESTDISP. display test

All segments of the display are flashed together. You can press

at any time to terminate display test.

Fct. 2.2 TEST I current ouput test

Caution: during this test current output will change to set test values so

you should take appropriate action depending on your current outpu

application

Place current meter in series with current loop. Then enter integer value

of current output desired.

Entering a value will cause that current to flow so that you can check i

with a meter. Select CONT YES to test other current value or CONT N

to end. When you exit the menu, normal current value depending on flo

rate and programming of current output functions will be restored.

LIMITS - 4 to 20 mA.

ART: GOM 1,2,2

Fac. 2.3 TEST P Pulse output test

Caution: during this test frequency output will change to set test values

so you should take appropriate action depending on your pulse outpu

application

Connect voltmeter to pulse output. With supply & load connecte

select –

• Pulse OFF

• Pulse ON

ke

Selecting Pulse ON/OFF will cause the output to change accordingly so

that you can check it on the meter. Select CONT. YES to test further o

CONT. NO to end. When you exit the menu normal pulse outpu

depending on flow rate and programming of pulse output functions will

be restored.

Fct. 3.0 INSTALL

This is a main menu level whose submenus and their functions

cover all installation-related functions which include:

- Primary data (nominal diameter, k-factor).

- User data (password, totaliser setting etc.)

- Application data (medium, density operating and normal an

amplifier gain)

Fct. 3.1.0 BASIS. PARAM

This submenu functions allow user to enter the vortex

primary sensor data viz. nominal diameter and k- factor

Fct. 3.1.1 NOMINAL.DIA nominal diameter

Select from the options which DIN/ANSI size primary is used wit

the instrument. Options to choose from are –

• DN 10s • DN 10 • DN 15 • DN 20

• DN 25 • DN 40 • DN 50 • DN 80

• DN 100 • DN 150 • DN 200 • ANSI 3/8"s

•ANSI 3/8" • ANSI 1/2" • ANSI 3/4" • ANSI 1"

• ANSI 1.5" • ANSI 2" • ANSI 3" • ANSI 4"

• ANSI 6" • ANSI 8"

Fct. 3.1.2 K-FACTOR k-factor of the primary

Enter the primary constant k-factor value. This value is stamped o

the instrument label and in units of pulses/m3

LIMITS – Limits depend on nominal- dia

OM.DIA LOW LIM HIGH LIM

DN 10S/ANSI 3/8"S 1370000 1530000

DN 10/ANSI 3/8" 490000 543000

DN 15/ANSI 1/2" 290000 330000

DN 20/ANSI 3/4" 107000 120000

DN 25/ANSI 1" 42000 66000

DN 40/ANSI 1.5" 12300 18700

DN 50/ANSI 2" 6065 8800

DN 80/ANSI 3" 1740 2730

DN 100/ANSI 4" 775 1200

DN 150/ANSI 6" 240 350

DN 200/ANSI 8" 104 163

Fct. 3.2.0 USER DATA

This is submenu level. 3.2.x functions allow enabling of passwor

code 1, enabling and resetting of built-in electronic totalizer.

Fct. 3.2.1 ENTRY.CODE.1 enable code 1 password

Select YES if password should be checked to access the menu. Use

password to prevent configuration changes by an unauthorized

person. Answering NO means password is not required to enter

menu.

Fct. 3.2.2 TOT. RESET totalizer reset

This function on can be used to reset the totalizer (to zero) Two

options are presented

• YES • NO

To reset totalizer - Select YES

To keep totalizer value unchanged – Select NO.

19

Page 20

Fct. 3.2.3 TOT ON/OFF TOT. ON/OFF

n

e

–

–

–

f

Select option TOT. ON to start/restart totalizer and select optio

TOT.OFF to stop totalizer. Stopping totalizer means flow will not be

accumulated till the time totalizer is turned on again.

Fct. 3.3.0 APPLICAT.

This submenu groups functions which allow you to view/enter the

application data. These functions give the following information to th

instrument.

process medium

operating and normalised density values

amplifier gain

Fct.3.3.1 FLUID fluid type

Select whether process medium is steam or gas or liquid.

• GAS/ STEAM • LIQUID

Fct. 3.3.2 DENS. OPR. density at operating P&T Enter the density o

medium at operating pressure and temperature conditions. The value can be

entered in one of the following units –

• Kg/m3 • Kg /Litre • Lb/F

• Lb/cft3

LIMITS - 0.05 TO 2000Kg/m

Fct. 3.3.3 DENS. NORM density at normal P&T

Enter the density of medium at normal pressure and temp conditions. The

value can be entered in one of the following units –

• Kg /m3 • Kg /Litre • Lb/ft

• Lb/cft3

LIMITS – 0.05 to 2000Kg/m 3

Fct. 3.3.4 GAIN Gain Setting

The gain of the preamplifier can be changed to change the sensitivity of the

meter. The values that can be selected are

• 1 • 5 • 11 • 23

The factory set value is 5 for LIQUID and 11 for GAS / STEAM

6.2. Functional order description.21

6.2.1 Physical units

FLOW RATE UNITS

Refer to functions-

Fct 1.1.2 MAX. FLOW maximum flow rate

Fct. 1.1.3 MIN. FLOW minimum flow rate

Fct. 1.2.1 FLOW UNITS for display

Units for flow ratefor volumetric flow-

• m3/hr • m3/min • m3/Sec

• Litre/hr • Litre/min • Litre/Sec

3

• ft

/hr • ft3/min • ft3/Sec

• cft/hr • cft/min • cft/Sec

• cuft/hr • cuft/min • cuft/Sec

• US GAL/hr • US GAL/min • US GAL/Sec

• UK GAL/hr • UK GAL/min • UK GAL/Sec

• % MAX FLOW (only for Fct 1.2.1 FLOWUNITS )

for normalized volumetric flow-

• Norm.m3/hr • Norm.m3/min • Norm.m3/Sec

• Norm,L/hr • Norm,L/min • Norm,L/Sec

• Sft3/hr • Sft3/min • Sft3/Sec

• Scft/hr • Scft/min • Scft/Sec

• % MAX FLOW (only for Fct 1.2.1 FLOWUNITS )

for mass flow

• Kg/hr • Kg/min • Kg/Sec

• T/hr • T/min • T/Sec

• Lb/hr • Lb/min • Lb/Sec

• % MAX FLOW (only for Fct 1.2.1 FLOWUNITS )

TOTALIZER UNITS

Refer to functionsFct. 1.2.2 TOTAL.UNITS totalizer unit for display

units for totalizer-

• M3 • Litre • ft3

• cft • cuft • US Gal

• UK Gal

VELOCITY UNITS

Refer to functionsFct. 1.2.3 VELO.UNITS velocity unit for display

Units for velocity-

• m.sec • ft/Sec

PULSE OUTPUT UNITS

Refer to functionsFct. 1.2.3 RANGE P Pulse output range value

Units for RANGE P-

For volumetric flow -

• PULSE/m3 • PULS/Litre • PULS/Ft3

• PULS/cFt • PULS/cuFt • PULS/US Gal

• PULS/UK.Gal

for normalized volumetric flow -

• PULS/Norm.m3 • PULS/Norm.L • PULS/Sft3

• PULS/Scft

for mass flow-

• PULS/KG • PULS/T • PULS/Lb

DENSITY UNITS

Refer to functions-

Fct. 3.3.2 DENS.OPR. Density at operating P&T

Fct. 3.3.3 DENS.NORM. density at normal P&T

Units for density-

• Kg/m3 • Kg/Litre • Lb/ ft3

• Lb/cft

20

Page 21

6.2.2 Numerical format

• Display of numerical values

Real (i.e. fractional) values are displayed in the first line of the display consisting of 8 digits. Number is displayed in floating point format as far

as possible, otherwise an exponent notation is used. See examples below.

Floating format: 1234. 56.

Exponent format: 1.234E-10

In most practical applications, it is very rare that parameters need be displayed in exponent format.

The number of significant figures displayed is 6.

• Input of numerical values

Entry of numerical values is in the following format n.nnnnEn

Examp les: 1.2345 E + 3

Programming: refer to section 5.4

6.2.3 Display

Organization - display consists of the following 3 fields.

Field 1: Numeric (8 digit, 7 segment) used primarily for showing numeric values.

Field 2: Alphanumeric (10 characters, 14 segments) used for showing units, messages etc.

Field 3: Consists of [a] 6 markers at the bottom of display which are used to identify the parameter being

and [b] key-field at the top left of the display which is used to acknowledge the keys.

Programming – Measurement mode setting are as follows.

Ø To allow selection of units for all measured parameters.

Refer to Sect. 6.1 Fct. 1.2.1 to 1.2.4

Ø Select what parameters to include in display cycle.

Refer to Sect. 6.1 Fct. 1.2.2 to 1.2.5

Ø Select display mode (cyclic / non-cyclic) and error messages to / not to appear in display cycle.

Refer to Sect. 6.1 Fct. 1.2.5 to1.2.6

Measurement mode - Display shows measured parameter(s) in its selected unit. The marker identifies the parameter being displayed.

Parameter is displayed continuously in non-cyclic mode. [refer sect. 6.1 Fct. 1.2.6 ]. To select other parameter(s) of the display cycle, if any,

use

key. In cyclic mode, all the parameters selected in the display cycle are displayed in sequence one after another every 6 seconds.

Programming mode- Numeric line indicates menu/function level such as Fct.1.0 [current menu level digit "1" blinks] and alphanumeric line

indicates menu/function title such as OPERATION.

Error indications - Blinking display in measurement mode indicates that error(s) are present. Error messages are displayed interleaved between

changing from one display parameter to other, if Fct. 1.2.5 ERROR.MSG is YES. For description of error message refer Sect. 5.5.

Testing of display – Use Fct. 2.1 TEST DISP for display test. All segments of the display are flashed. You can press

terminate display test.

key at any time to

6.2.4 Flow range and meter

Flow rate (min. flow to max. flow) which the flowmeter will be able to measure depends on the primary data (3.1.x functions) and application

data (3.3.x functions). Thus, the flow range specified under the Fct. 1.1.2 MAX FLOW and Fct. 1.1.3 MIN. FLOW must be within the measuring

range. Flow range for any given application is determined by sizing the meter for that application. If flow rate exceeds max. flow an error

condition (HIGH FLOW) is generated. When the flow rate falls below the min. flow an error condition is generated. Vortex sensor signal l is

weak at this condition LOW FLOW and if flow rate reduces further, vortex signal related errors such as NO SIGNAL, LOW FREQ. will occur.

21

Page 22

6.2.5 Primary information

Primary data gives VFC 091 the basic information about the vortex primary sensor. Use Fct. 3.1.1 NOMINAL.DIA for specification of the

nominal DIN/ANSI size and Fct. 3.1.2 K-FACTOR for the calibration factor of the primary.

6.2.6 Application information

This is the data of process medium, it’s operating conditions and physical properties. It consists of

- process medium Fct. 3.3.1 FLUID

- operating and normal density conditions. Refer Fct. 3.3.2DENS. OPR and Fct. 3.3.3DENS NORM This is required only if Fct. 1.1.1. MEAS

INST. Is NORM. VOLUME or MASS.

6.2.7 Internal Electronic Totalizer

- The internal electronic totalizer counts volume, normalized- volume or mass. Totalizer value is saved in the non-volatile memory upon

power failure. Totalizer can be displayed in the units desired as per the programming of Fct. 1.2.2 TOTAL. UNITS. Totalizer counting is

interrupted for the duration of power failure. Counting may optionally be stopped and thereafter restarted by the use of Fct. 3.2.3 TOT.

ON/OFF. Totaliser counting is also interrupted when in programming mode (in Menu)

- Resetting [to 0] of the totalizer is possible by using Fct. 3.2.2 TOT. RESET.

6.2.8 Current (analog) output I

Current (Analog) Output I – The current output gives an analog representation of the flow-rate. An output of 20mA always corresponds to Q

& 4mA to Q 0 %The current output between Q

CHARACTERISTICS OF CURRENT OUTPUT I

TESTING OF CURRENT OUTPUT I

Fct. 2.2 TEST I can be used to check current output. Integer values between 4 and 20mA are possible to be monitored on a current meter. During

the test, current output changes to the test values(s). The normal current value is restored automatically [as per programming of current output]

when the measurement mode is resumed.

I

20mA

4mA

Q

% 0

and Qmin is 4mA.

0 %

Q

min

Q

Q

100 %

100 %

6.2.9 Pulse output P

Programming of Pulse output value is provided by 1.3.x functions.

Fct. 1.3.1 FUNCTION P Pulse output

Choose YES -to make Pulse output active as per functions Fct. 1.3.1 to Fct.1.3.3 NO makes Pulse output inactive (0 Hz). When Pulse output

function is not required choose the option NO.

22

Page 23

Fct. 1.3.2 RANGE P Pulse output range value

Pulse output is 0 Hz for 0 flow rate and a value (P

) equal to Q

100%

* RANGE P value.

100%

Example of pulses/unit volume or mass

Full scale setting, Q

: 1000 Litre/hr (set via Fct. 1.1.2)

100%

RANGE P : 1PULS/Litre (set via Fct. 1.3.2)

at 1000 litres per hour : 1000 pulses per hour would be the pulse output.

For limits on programming of RANGE P refer to Sect. 6.

Fct.1.3.3 PULS. WIDTH pulse width

This is used to limit the active duration of the Pulse output, to 250mSec and thereforc

reduce the overheating of external electromechanical totalizers coil.

For details refer to Sect. 6.

TESTING OF PULSE OUTPUT P

Fct.2.3 TEST P can be used to check Pulse output. The Pulse output may be set to ON or OFF state. This may be monitored with the help of a

voltmeter connected across the pulse output which is wired to a power supply & load in series. The normal pulse output function is restored

automatically [as per programming of Pulse output] when the measurement mode is resumed.

6.2.10 Coding desired for entry into programming mode

Fct. 3.2.1 ENTRY. CODE.1 set to YES for enabling Code l.

The entry code consists of 9 keystrokes of the 3 keys as follows

6.2.11 Behavior of outputs during programming

Programming of the VFM 1091(I) is "off-line" meaning that the instrument stops making measurements when it is in the programming mode. This

means VFM 1091(I) will keep totaliser value and Current/Pulse output as per the last value output before entering the programming mode.

6.2.12 Hart programmability

VFM 1091(I) supports all the Universal commands and the Common practice commands which are applicable to the meter.

The HART

Generic On-line Menu (GOM) step of HART

®

compatibility of VFM 1091(I) program functions is tabulated below. For functions which are HART® programmable, corresponding

®

Communicator is also given. Details of Generic On- line menu is given in 6.2.14.

PROGRAMMING FUNCTION HART HHC MENU

PROGRAMMABILITY

FST 1.0 OPERATION

FCT. 1.1.0 BASIS.PARAM

FCT. 1.1.1 MEAS.INST YES GOM 1,2,3

FCT.1.1.2 MAX. FLOW YES GOM 1,3,2

FCT 1.1.3 MIN. FLOW YES GOM 1,3,3

FCT. 1.1.4 TIME CONST YES GOM 1,3,6

FCT. 1.2.0 DISPLAY

FCT 1.2.1 FLOW UNITS YES GOM 1,3,2

FCT 1.2.2 TOTAL UNITS

TO

FCT. 1.2.6 CYCLE DISP NO

FCT 1.3.1.0 PULS.OUTP NO

FCT. 1.3.1 FUNCTION P

TO

FCT. 1.3.3 PULS. WIDTH NO

FCT 2.0 TEST

FCT. 2.1 TEST DISP NO

FCT 2.2 TEST 1 YES GOM 1,2,2

FCT 2.3 TEST P. NO

FCT 1.1. MEAS.INST YES

FCT 3.0 INSTALL NO **

Notes:

* GOM 1,3,2 is used to set the primary sensor unit. When primary sensor unit is changed, device automatically updates the MEAS.INST. As an

example, if the unit is changed to Kg/hr, then MEAS.INST will be set to MASS.

** Fct 3.0 install menu contains the device specific set up.

23

Page 24

6.2.13 Functions through HHC

The special functions which are accessible only through HART

®

communicator include Device Information and

Multidrop Operation

DEVICE INFORMATION

This is used to identify the devices in the field. This is stored in the device and shown to you on request but has no effect

on the functionality of the flowmeter. None of these parameters are used for computational purpose during the

measurement.

Manufacturer : This is a factory-programmed name. For VFM1091 (I) the manufacturer is KHRONE

MARSHALL.

Tag : The maximum number of characters allowed for tag is eight. Tag can be

effectively used to distinguish between different flowmeters in the field.

Descriptor : This parameter provides 16 characters which can be used to store more

descriptive data of a flowmeter.

Message : This provides 32 characters. This may be used for identification or display

of other important information regarding the flowmeter.

Revision Numbers: These are factory programmed and cannot be changed by the user.

Universal Rev - Gives the HART

®

Universal command revision which the flow

meter should conform to.

Transmitter Rev - Gives the revision for the device specific VFC091 model.

Software Rev - Gives the internal software revision.

Hardware Rev - Gives the revision number for the hardware.

Final Assembly - Refers to the factory set value of the electronic assembly.

Device ID - Gives unique identifier for transmitter.

MULTIDROP CONFIGURATION

In multidrop configuration, upto 15 flow meters can be connected to a single communications transmission line. If the

device is configured for multidrop operation, the current output is parked to the minimum value (4mA) and the

communication occurs digitally between the flowmeters and the control system. Since the speed of communication for

HART

®

is not fast enough for control applications, update rate should be considered before multidroping the flowmeters.

The other factors like the number of different models used the transmission line specifications, safety considerations etc.

should also be taken into account. In multidrop mode, the control system/communicator identifies each of the devices by

means of the polling address which can be programmed into the device.

POLL ADDRESS

This gives the identification number for the flowmeter in multidrop mode. The value of the number should be between 1

and 15. Please note that the flowmeter should be in loop mode while entering the poll address. Use Generic Online Menu

1,4, 3, 4, 1 to change the polling address of the meter.

MODEM

RS232

R

PC HHC P/U VFM4000

MULTI-DROP CONFI GURATION

24

Page 25

6.2.14 Generic On-line Menu Tree

1.Process variables

1.Present variable

2.Percent Range

3.Analog Output

2.Diagnostics and

Service

3.Basic Setup

1.Test device

2.Loop Test

3.Calibration

4.D/A Trim

1.Tag

2.PV Snsr unit

3.Range Values

4.Device Info

5.Xfer fnctn

6.PV Damp

1.Sensors

1.Self test

1.Apply values

2.Enter Values

1.Model

2.Tag

3.Date

4.Descriptor

5.Message

6.PV snsr s/n

7.Final asmbly #

8.Revision

1.Process variables

2.PV Snsr Unit

3.Sensor Info

1.Univ. Rev.

2.Fld. Dev. Rev

3.Softw. Rev.

1.PV LSL

2.PV USL

3.PV Min span

Generic Online Menu

1.Device setup

2.PV

3.AO

4.LRV

5.URV

4.Detailed Setup

5.Review

2.Signal condition

3.Output condition

4.Device

1.PV Damp

2.PV URV

3.PV LRV

4.Xfer Fnctn

5.PV% range

1.Analog Output

2.HART

®

output

1.Model

2.Tag

3.Date

4.Descriptor

5.Message

6.PV snsr s/n

7.Final asmbly #

8.Revision

1.A/O 1

2.A/O alrm typ

Looptest

3.

4.D/A trim

ScaledD/Atrim

5.

1.Poll Address

2.Number of

request

preambles

1.Univ. Rev.

2.Fld. Dev. Rev

3.Softw. Rev.

25

Page 26

Part C Function Checks and Trouble shooting hints

7. Functional checks

This section describes some functional checks, which can be

performed without using any special equipment. It must be

noted that these checks are very preliminary and do not check

all the functions of the primary head or the signal converter.

7. 1 Primary head functional checks

7.2 Vortex Sensor

To perform preliminary testing of the vortex piezo sensor, the

signal cable of the piezo sensor should be disconnected from

the signal converter electronics. To do this

Always switch-off power source before commencing

work.

l. Use the special wrench to remove cover from

the electronic compartment. Ensure that screw

threads of electronic compartment cover are

well greased at all times.

Preamplifier

flat cable from

CPU to Preamp

board

A

Power

supply

board

D

Flat

cable to

D

display

board

CPU board

Z

A

2. Remove screws A and turn display board to one side.

3. Remove the piezo cable from the preamplifier board at

location Z by its (and not by pulling cable itself!)

4. Do the following tests on the sensor cable

Capacitance between centre pin and each outer pin

Resistance between center pin and each outer pin

>200M ohm. Also resistance between each sensor

wire pin and earth should be >200 M ohm. Also short out

all three pins & measure resistance between these pins &

Earth. This should be > 200 M W

5. Reassemble converter.

7. 2 Signal converter functional checks

7. 2 .1 Self diagnostics

On power-on VFC 091 carries out diagnostic

checks wherein the instrument checks its functional elements

as far as possible. Diagnostic failure result

in fatal errors and are indication of a hardware fault

within electronics. Usually it is necessary to replace

electronics in such cases.

7. 2 .2 Display check

Display functionality can be checked by the use of

Fct 2.1 TESTDISP.

This function flashes all the segments of the display.

7. 2 .3 Current output check

Fct.2.2 TEST I can be used to test current output function of

VFC 091. With this function it is possible to generate

following test values- between 4 and 20mA

(integer values only)

Current output electronics is factory calibrated and

should be within +/- 0.02mA. Otherwise re-calibration of

current output is necessary by KHRONE MARSHALL

service person.

7. 2 .4 Pulse output check

Fct. 2.2 TEST P is meant for checking the pulse output

function with a power supply (24VDC) connected through a

load of lk/1W to pulse output terminals 4.1 & 4.2, and the

output level (high or low) monitored with a voltmeter.

7. 2 .5 Frequency measurement check

Disconnect the sensor cable from the electronics as indicated

in section 7.1.1 and feed a signal (sine or square wave) to the

sensor connector Z on the preamplifier board. The signal

should be fed between the center pin and one of the outer pins

of the connector Z. The value of frequency fed should be

indicated on the display when frequency measurement is

enabled. This can also be checked with the help of the VS1 or

VS2 Vortex Simulator in place of the signal source. The

amplitude of the signal l should be 50mVp-p and the

frequency between 2Hz and a value

equal to Qmax (m/hr) x K-factor (Pulses/m) max

3600

26

Page 27

8. Trouble shooting hints

p

It is assumed in this section that flowmeter has already been

installed. (for installation details refer Sect. 2+3)

Following are some trouble shooting hints.

SYMPTOMS: Display is blank.

· DC Supply voltage (between term. 5/6) is not

available (voltage range 12-36 Vd.c).

· Supply connected with reverse polarity

Important: Ensure that the screw threads of the covers on

the electronics and connection compartments are well

greased at all times

· Electronics faulty

SYMPTOM: Current output is not proper.

· Check current output electronics (refer Sect.7.2.3)

· Check that current output loop resistance is less

than Rmax specified by Section 3.3.2

SYMPTOM: Pulse output is incorrect

· Check the Pulse output electronics (refer Sect.7.2.4)

· Check programming of pulse output. (Functions

Fct1.3.x )

· Check that pulse output is not overloaded. For load

ratings of pulse output refer Sect.3.3.3.

SYMPTOM: Non zero flow indicated when no

actual flow in the pipe.

· Mains interference due to improper earthing.

The protective earth PE terminal should be

properly grounded.

SYMPTOM: Flow indicated responds to changes in flow

but indicated value does not correspond to actual flow

rate.

· Check programming of Fct.3.1.2 K-Factor which should be

same as on the nameplate.

· Meter not properly centered on the pipeline. The axis of

meter bore should be aligned with that of pipe.

· Gaskets at the meter are protruding into pipe bore.

Gaskets must not project into effective cross-

section of the pipe.

· Irregularities on the surface of the pipe bore.

The pipe bore should be free from irregularities

at the welded joints, dirt, deposits and excessive

surface roughness.

· Vortex signal is falsified due to a biBi-phase media are not permitted. Use a moisture

separator for wet steam applications to remove

moisture droplets from the steam. Use suitable

filters in gas applications to remove solid

particles from the flowing gas.

· Incorrect angular position of the meter

Refer to Sect.2.1 (1) for allowable mounting positions.

· Insufficient upstream / downstream pipe lengths.

Check that upstream / downstream pipe lengths are of

correct minimum length as given in Sect.2. 1(3).

· Check the flow direction & direction of arrow on

the primary!

· Excessive mechanical vibration in the pipe.

If so, support the pipeline near the flowmeter

perpendicular to both the axis of pipe and the axis

of bluff body.

SYMPTOM: Flowrate indicated is 0.0 even with flow in

the pipe.

· Vortex sensor cable disconnected or not properly

connected.

· Flow sensor faulty – some checks are given in

Sect.7.1.1

· Electronics faulty (preamplifier)

· Fct. 3.3.4 Gain too low: Set gain to value of 5 or greater &

check.

SYMPTOM: Fatal error INV. CONFIG (invalid

configuration)

· Configuration data in the non-volatile memory is

inadvertently corrupted. Go to the programming

mode and recheck (reprogram, if necessary) all

the settings. If error persists contact Forbes Marshall service.

SYMPTOM: Display contrast is progressively Fading.

· Never expose display directly to the sunlight!

Install a sunshade if necessary.

hase medium.

27

Page 28

Part D VFM 1091 (I) Ex

9. Description of the system

VFM 1091 (I) Ex is a two wire loop powered flow transmitter

designed with electronic circuits incorporating Intrinsic safety

features.

EEx [ib] IIC T2.... T6

Applicable standards: EN 50014 & EN 50020

9.1 Temperature class

The temperature class of the equipment operated in hazardous

area is determined by the process or medium temperature.

The relationship between the maximum process temperature

and the temperature class is approved by PTB and stated as

shown the following table.

85 °C

100 °C

135 °C

200 °C

220 °C

T6

T5

T4

T3

T2

9.2 Electrical connection

VFM 1091 (I) Ex has two isolated Intrinsically safe circuits

1. Loop power / Current output circuit

2. Pulse output circuit

The entity parameters for both these circuits are approved by

PTB and stated as: -

Ui= 30 V

Ii = 100 mA

Pi = 0.8 W

Li <

mH

Ci <

20 nF

The loop power supply connections from safe area to the flow

meter in hazardous area must be routed through a suitable

Zener Barrier placed in safe area or the instrument should be

powered through an Intrinsically safe power supply.

Note: On the current output lines, HART

superimposed as an option. In such case compatible Barrier

needs to be chosen which will pass the HART

®

signal is

®

signal for

detection and processing in safe area.

The Hazardous and safe area connections are illustrated in

diagram

The meter is provided with two cable entries in the terminal

compartment of enclosure. Each cable entry must be used to

insert cable to route loop power and pulse output circuit.

Refer the schematic where the positions of the cable entries

and cable routing is indicated.

28

Page 29

x

10. Field connections diagram

HHCHHC

VFM 1091 (I) E

4-20 mA

Hazardous Area

11. Name plate & certificates VFM 1091 (I) Ex.

4-20 mA

Load

14 - 30V DC

29

Page 30

Certificate number of VFM 1091 (I) Ex.

FM, CSA, PTB approvals are pending

30

Page 31

31

Page 32

32

Page 33

33

Page 34

Range limit Calculation for Gases

To obtain the operating density rx at the operating temperature and pressure the following

equation is used

x = r n x Px x Tn

r

Pn Tx

r x , r n = density of the gas at normal & operating conditions respectively.

Pn, Px = pressure of the gas in absolute units at normal operating conditions respectively.

Tn, T x = temperature of the gas in Kelvin at normal & operating conditions respectively.

To obtain operating volumetric flow from normalized volumetric flow and vice-versa the following

equation is used:

Qn = Qx x Px

x Tn

Pn Tx

where: Qn & Qx are normalized and operating volumetric flow rates respectively the ratio of compressibility

factors is assumed to be equal to 1.

The following operating data of the process medium must be known in order to calculate the measuring

range

· Density r x of product at flowing conditions, in kg/m3

· Dynamic (absolute) viscosity of medium at flowing conditions, in mPA *s (or in centipoise)

· Maximum volumetric flowrate Q

· Minimum volumetric flowrate Q

max in m3/hr.

min in m3/hr.

· Refer to page 4 for dimension of meter inside diameter.

The following limits apply to operation

· Reynolds number at min flow, Re > 20000 for linear measurements.

· Minimum detectable flow velocity Vmin (See Page 36 Diagram IV)

· Maximum flow velocity

Vmax =135.7306/

(r op)...For sizes DN25 to 200(1”to 8”)

= 83.87146/

(r op)...For sizes DN10S to 20(3/8”S to 3/4”)

In both the cases,Vmax is clamped at 75m/s. For densities,at and above 50kg/m3, Vmin is fixed to 0.94192 m/s for all sizes

· Calculating Reynolds number

Re = 353. 67 Q min * (m3/h) * (kg/m3)

Ø(mm)* h(mPa *s)

· Calculating maximum flow

Q (m3/hr) = 1 * Vmin(m/s) * Ø2 (mm)2 mm

353.67

· Calculating maximum flow

Q (m3/hr) = 1 * Vmax(m/s) * Ø2 (mm)2 mm

353.67

Range limit Calculation for Saturated Vapour

In the same way as for gases, use the above equations to establish the range limits for the

volume flowrate. Refer to vapour tables for the appropriate density, and calculate the volume

flowrate from the mass flowrate. Check the range limits if operating parameters change.

34

Page 35

Primary head VFS 1000 (I)

Versions and meter sizes Pressure ratings see “Dimensions” Table

Sandwich design to ... DIN 19205 DN 25 to 150

ANSI 1” to 6”

Flange connections to ...DIN 2501 DN 10S to 200

ANSI B 16.5 3/8”S TO 8”

Groove joint to... DIN 2515 DN 25 TO 150

(Optional) ANSI 1” to 6”

Process and ambient temperature see Diagram III

Materials

SR.NO. DESCRIPTION MATERIAL REMARKS

Housing

1

2. Vortex shedding body Unalloyed Titanium (No.3.7035) as standard

a. upto 180 deg C(356deg.F) Viton O ring Non steam applications

4. Bluff body metal seal C ring Inconel Ni plated Once used metal C ring shoul d

Seals

3.

b. upto 220deg C(428deg.F) Kalrez 4079 O ring Non steam applications

c. upto 240deg C(464deg.F) Parofluor O ring Steam applications

5. Gaskets GASKET, STYLE AF-139, NON

Max. allowable operating pressure (primary head) 40 bar (580 psig), optionally upto 100 bar (1450 psig)

Hazardous Duty Versions: FM, CSA, PTB approvals pending.

Error limits

Measuring error (in linear range) ± 1 % of measured value for DN 25 (1”) & above

Repeatability (in measuring range) ± 0.5 % of measured value

Temperature Error - 0.025 % of measured value per 10Kelvin (50

Pressure loss D p

at normal conditions

for air[1.013 bar (14.7psig)/0

o

for water [20

C (68o F) / r n = 998.2 kg/m (63.32 lbs/ft)] see Diagram II DP = Pressure loss in Pa

at operating conditions C = A constant

for gases and liquid DP= C * Q

for saturated steam DP = C * Qm2 Qm = Flow rate in kg/hr

(Note operating limits given in DIN 2501 and ANSI B 16.5)

Stainless Steel, A351 CF3M (316L) Upto size DN100/4''

Stainless Steel, A351 CF8 (304) From DN150/6'' to DN200/8''

not be used again. Tightening

torques for new seals are

mM6 = 1.5kg -

M8 = 2 kg - m

M10 = 5.5 kg - m

ASBESTOS Any one as per application

GASKET, STYLE AF-160, NON

ASBESTOS

GASKET, TEFLON (PTFE)

± 2 % of measured value for DN 10S (3/8”S) to DN 20 (3/4”)

o

c(32oF) / r n= 1.29 kg/m(0.081 lbs/ft)] see Diagram I

v2 * r

(values: see Table)

op

Qv = Flow rate in m/hr

r op r

=operating density in kg/m

op

o

F) variation

35

Page 36

Diagram I Diagram II

Pressure loss p for air 1.013 bar / 0oC (32oF) / n = 1.29 kg/m3 Pressure loss p for water 20oC / rn = 998.2 kg/m3

(14.69 psig/0

p (psig) p(mbr) p (psig) p(mbr)

1.45

1.02

0.73

0.44

.29

.15

.10

0.073

0.044

0.029

0.015

0.010

0.0 073

0.0044

0.0029

0.0015

1

62 1

Table for diagrams I + II and constantC Table for Diagrams I+II and constant C

Curve Meter size Constant C Curve Meter size Constant C

A DN 10 S / 3/8”S 13.7 G DN50 / 2” 7.80 x 10

B DN 10 / 3/8” 3.42 H DN80 / 3” 1.90 x 10

C DN 15 / 1/2” 1.75 I DN100 / 4” 5.30 x 10

D DN 20 / 3/4” 0.45 J DN150 / 6” 1.60 x 10

E DN 25 / 1” 1.50 x 10

F DN 40 / 1-1/2” 3.30 x 10

o

C/rn = 0.081 lbs/ft) (680oF/n = 62317 lbs/ft)

14.50

10.15

7.25

4.35

2.90

1.45

1.02

0.73

0.44

0.29

0.15

0.10

0.07

0.044

0.029

0.015

0

2357123571023 57

2

44 1

235

2

B C D E F G H I

A

7

10

357

23 5

10

7

23 57

235

100

2

100 1000

7

1000

357

2

J

357

m/h

US GPM

357

2

100

7

5

K

3

2

10

7

5

3

2

1

7

5

3

2

0.1

10000

3

10000

-1

K DN200 / 8” 5.90 x 10-5

-2

357

A B C D E F G H I J K

100

10

23 57

357

2

100 1000

2357

m/h

US GPM

357

2

3

1000

-3

-3

-4

-4

7

5

3

2

100

7

5

3

2

10

7

5

3

2

1000

Signal converter VFC 091

Full-scale rangeprogrammable in litres, m3, US gallons, kgs, tonnes, lbs or standard flow rate per second minute or hour

Power supply U

Current output (term, 5/6) 4 - 20 mA, DC, 2-wire

Load RB = U

20 mA

Ambient temperature TB see Diagram III

Local display 3-field LCD

Display functions actual flowrate and sum totalizer (8-digit), each programmable for continuous or sequential display

of measured parameters and error messages

Display units Engineering units or % of full scale

Actual flowrate liters, m

Totalizer liters, m

Display :

1st field (top) 8-digit, 7- segment display and sign, symbols for key acknowledgement

2nd field (middle) 10 character, 14 segment text display

3rd field (bottom) 6 markers

Mass flow measurement (off-line) operating and standard density programmable

14-36 V Dc with 100 ohms min in series

B

EEx (ib) 14 - 30 V DC

- 12 V

B

3

, US gallons, kgs, tonnes, lbs or standard flow rate per second, minute or hour

3

, US gallons, kgs, tonnes, lbs, ft3

t to identify current display

R (ohms)

B

1200

900

14

EEx

18.5

30 36

Standard

U

(V)

B

36

Page 37

Housing

Material Die-cast aluminium

Protection Category (EN 60529 / IEC 529) IP 65 & 67 (better than NEMA 4 and 4X)

Frequency output (passive) scalable pulse output, max, load current 100 mA DC

Max. pulse rate : 0.5 Hz

Accuracy

Linearity +/- 0.1 % of full scale range

Power influence +/-0.005 % of full-scale range per 1% variation in voltage supply

Temperature coefficient 100ppm of full-scale range per 1

0

C

Field mount converter Signal cable length up to 10 m (30 ft) maximum

Diagram III

Curve Meter size

A DN 10 S/ ½” S

B DN 10 S/ ½”

C DN 15 / ½”

D DN 20 / ½”

37

Page 38

Dimensions and weight

VHF 1091 (I) F

Primary head flanged versions same as for VFM 1091 (I) K versions

38

Page 39

b + 100 mm Note the operating limits to DIN 2401 and ANSI 16 5

Dimension ‘a’ without gaskets between flowmeter and pipe flanges. Gaskets not included with flowmeter. High temperature version with "raised" signal convertor housing: dimensions

Dimensions and weights

• Flange connections to DIN 2501 and ANSI B16.5 (Schedule 40), • Sandwich design to DIN 19205 and ANSI • Groove joint to DIN 2512 and ANSI, dimensions on request

39

Page 40

Dimensions and weights