Page 1

KROHNE 01/94 7.30718.32.00

©

GR

Installation and

operating instructions

UFM 600 T

ALTOSONIC

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications engineering

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Page 2

All rights reserved. No part of this publication may be copied or published

by means of printing, photocopying, microfilm or otherwise without prior

written consent of KROHNE Altometer.

This restriction also applies to the corresponding drawings and diagrams.

KROHNE Altometer has the right to change the parts or specifications at

any time whitout prior or direct notice to the client. The contents of this

publication are subject to change without notice.

This publication is to be used for the standard version only. Thus KROHNE

Altometer cannot held responsible for any damage resulting from the

incorrect application of this publication to the version actually delivered to

you.

For additional information regarding configuration, maintenance and repair,

contact the technical department of your supplier.

This publication has been written with great care. However, KROHNE

Altometer cannot be held responsible, either for any errors occuring in this

publication or their consequences.

PM 04.97.Rev.3

Page 3

ALTOSONIC

A INTRODUCTION ................................................................6

B SYSTEM DESCRIPTION ................................................. 8

B.1 Measuring Principle ........................................................... 8

B.2 Measuring System............................................................. 10

B.3 Equipment......................................................................... 12

B.4 Controls and Connections ................................................. 14

B.5 Transducers and Mountings ............................................. 16

B.6 Display and Data Storage .................................................. 17

B.7 Direct Output..................................................................... 18

B.8 Power Supply.................................................................... 18

C OPERATION .................................................................... 20

C.1 Initial Set-Up...................................................................... 20

C.1.1 Installation of mounting rails............................................... 21

C.1.2 Programming the application parameters .......................... 24

C.1.3 Installation of the transducers ............................................ 26

C.1.4 Zero set / zero point calibration ......................................... 28

C.2 Start Up Menu................................................................... 30

C.2.1 Enter start up menu........................................................... 30

C.2.2 Application Functions ........................................................ 30

C.2.3 Plausibility check ............................................................... 34

C.3 Error Detection .................................................................. 35

C.3.1 Low signal marker function................................................ 35

C.3.2 Error messages ................................................................. 36

C.4 Data Collection.................................................................. 38

C.4.1 Data collection procedure.................................................. 38

C.4.2 Transfer to PC (data and parameters)................................ 40

C.4.3 Parameter handling ........................................................... 41

C.5 Quit / Reset Menu ............................................................. 42

C.6 Direct Output Ports ........................................................... 44

C.6.1 General ............................................................................. 44

C.6.2 Output hold ....................................................................... 44

C.6.3 Current output................................................................... 44

C.6.4 Frequency output .............................................................. 44

C.6.5 Connection diagrams .......................................................45a

C.7 Trouble Shooting............................................................... 46

UFM 600 T

2

Contents

Page 4

D PROGRAMMING MODE................................................. 48

D.1 General ............................................................................. 48

D.2 How to Program................................................................ 49

D.3 List of Functions ................................................................ 52

D.4 Main Menu: 3.0.0 INSTALLATION .................................... 54

D.5 Main Menu: 2.0.0 TEST..................................................... 72

D.6 Parameter errors ............................................................... 74

E MAINTENANCE............................................................... 76

E.1 Fuse .................................................................................. 76

F TECHNICAL DATA.......................................................... 78

F.1 General ............................................................................. 78

F.2 Transducers & Clamp-on Set ............................................ 79

F.3 Signal Converter ................................................................ 80

APPENDIX 1 : Pipe Material Sonic Velocities .................. 84

APPENDIX 2 : Sonic Velocities of Liquids ....................... 85

APPENDIX 3 : Sonic Velocity Calculation........................ 86

APPENDIX 4 : Exponential Notation.................................87

APPENDIX 5 : Default Settings + Example of

Output Parameters .................................. 88

APPENDIX 6 : Spare Parts ............................................. 90

3

A

B

C

D

E

F

Page 5

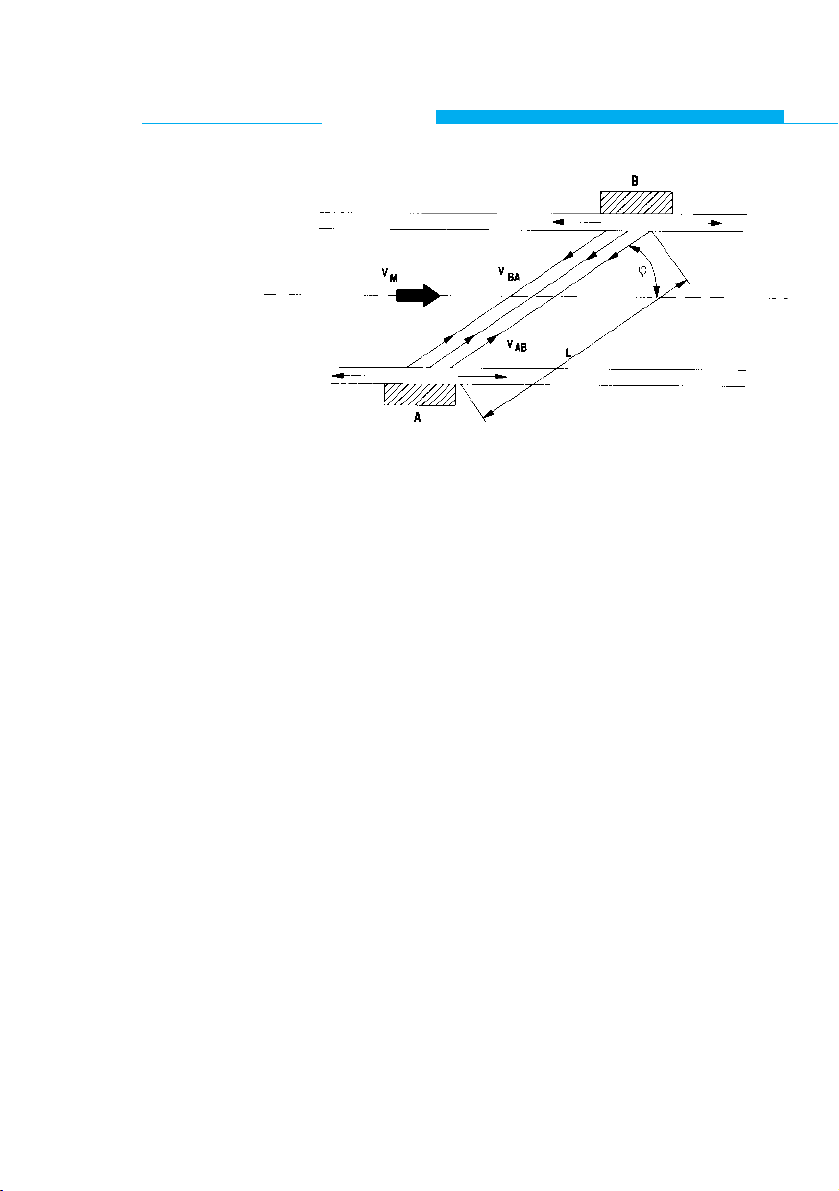

Fig. B.1 : Measuring principle........................................................... 8

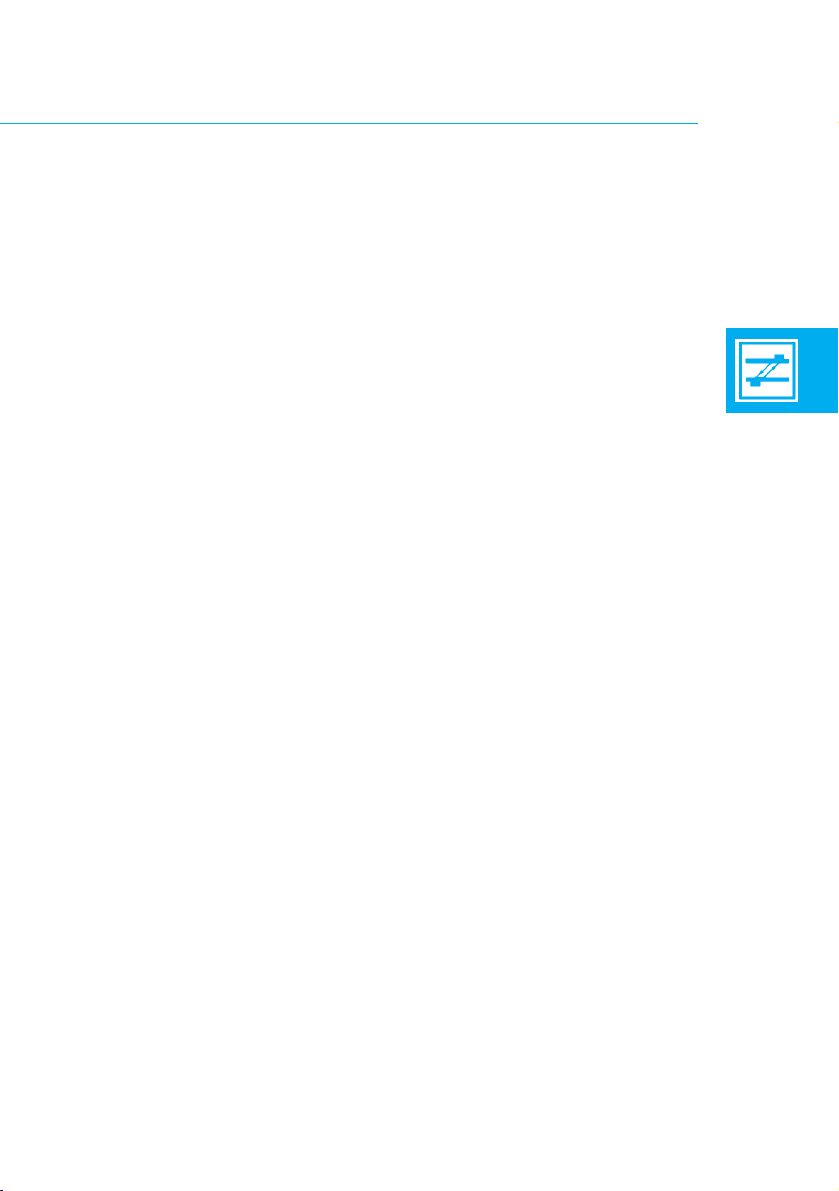

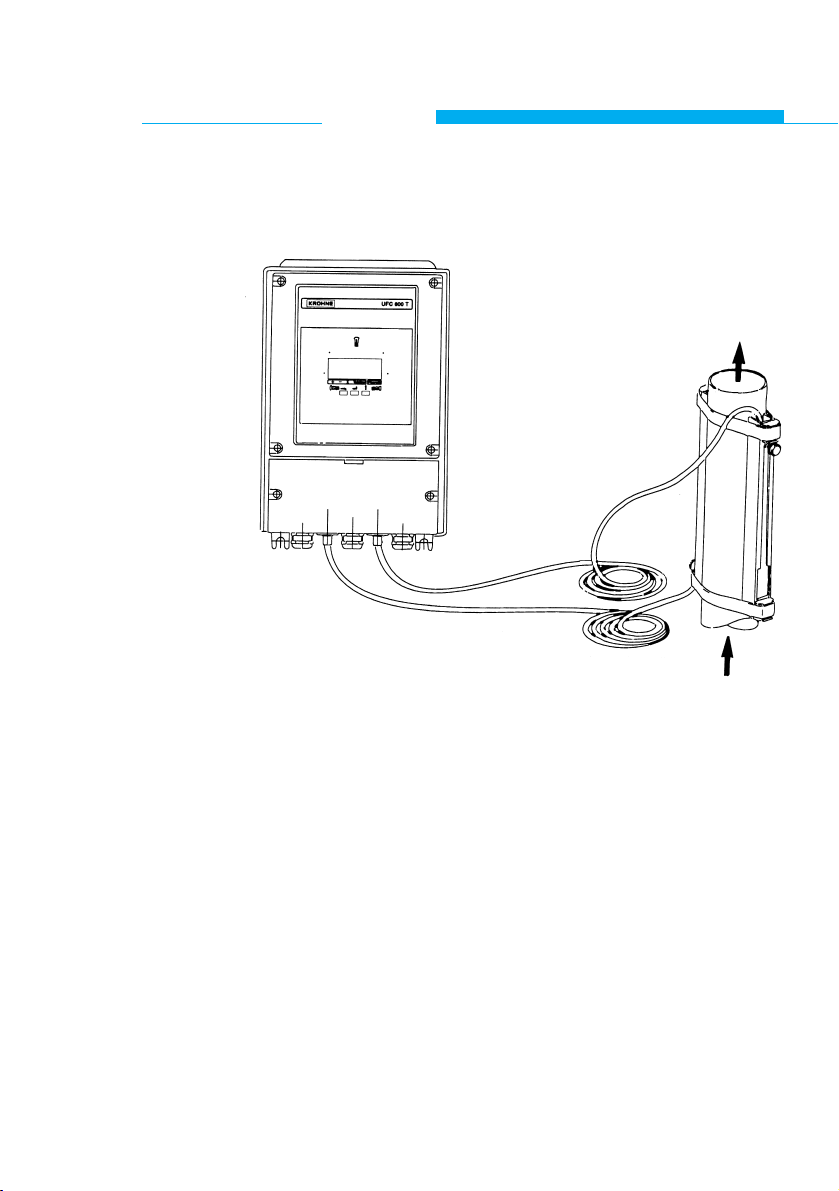

Fig. B.2 : System diagram................................................................ 11

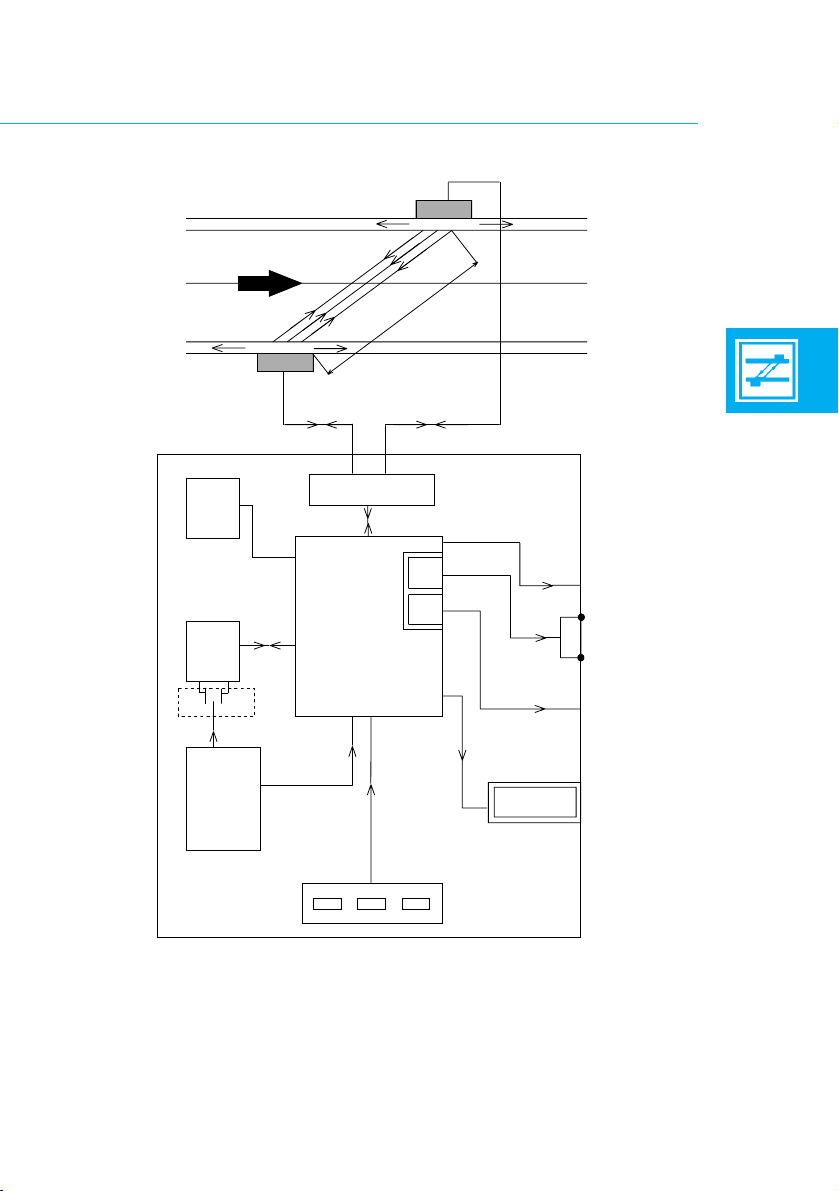

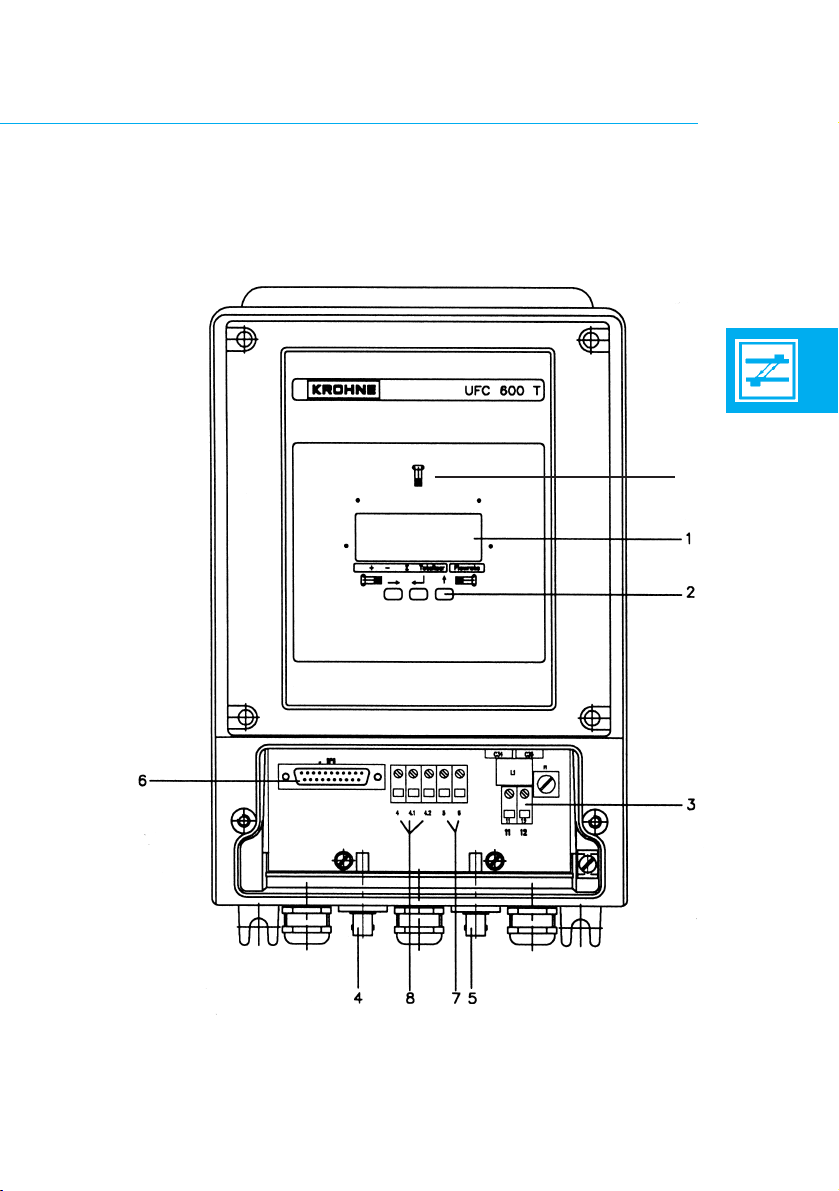

Fig. B.3 : UFM 600 T with all equipment displayed........................... 13

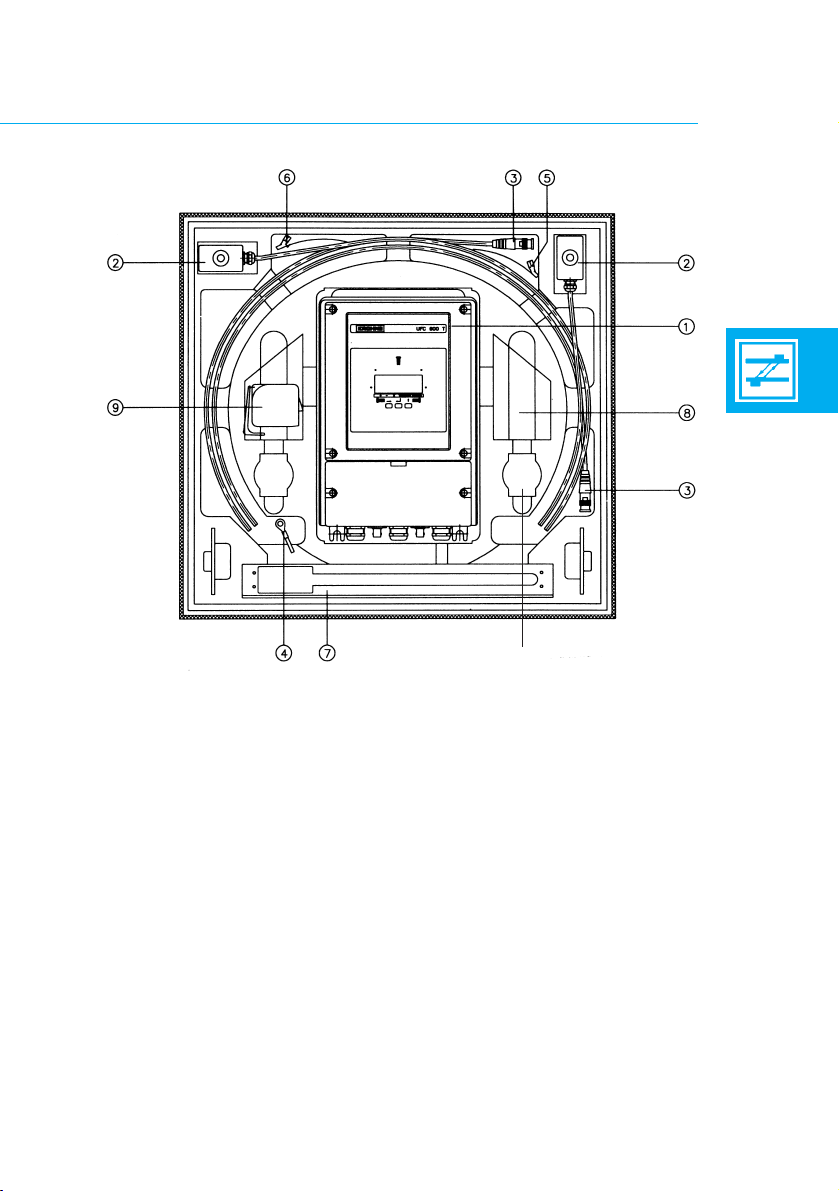

Fig. B.4 : UFC 600 T converter ........................................................ 15

Fig. B.5 : Transducers and unit ........................................................ 16

Fig. C.1 : Mounting rail ..................................................................... 22

Fig. C.2 : Mounting rails fitted on the pipe ........................................ 22

Fig. C.3 : Mounting positions............................................................ 23

Fig. C.4 : Position of transducer and cable....................................... 26

Fig. C.5 : Upstream and downstream connections........................... 27

Fig. D.1 : Entering the programming mode....................................... 49

Fig. D.2 : Low flow cutoff ................................................................. 55

Fig. D.3 : Bi-directional flow (I).......................................................... 61

Fig. D.4 : Flow direction indication (I) ................................................ 61

Fig. D.5 : Positive flow (I) .................................................................. 61

Fig. D.6 : Negative flow and output (I)............................................... 61

Fig. D.7 : Bi-directional flow (F)......................................................... 63

Fig. D.8 : Flow direction indication (F) ............................................... 63

Fig. D.9 : Positive flow (F) ................................................................. 64

(I) current output

(F) frequency output

4

ALTOSONIC

List of illustrations

UFM 600 T

Page 6

5

Page 7

System Description

The Altosonic UFM 600 T is an ultrasonic flowmeter which can easily be

clamped on existing pipelines with inner diameters between 50 mm and

3000 mm (2" to 120") and pipe wall thicknesses up to 40 mm.

Measurement is performed obstructionless, without changing the existing

pipework and without any headloss.

The UFM 600 T is an economical solution for all kinds of flow measurements of liquids containing no or little solid particles or gas.

Examples are: cooling water, waste water, oil, acids, bases etc.

6

ALTOSONIC

Introduction

UFM 600 T

little bows welded

on the tube

Mounting strap

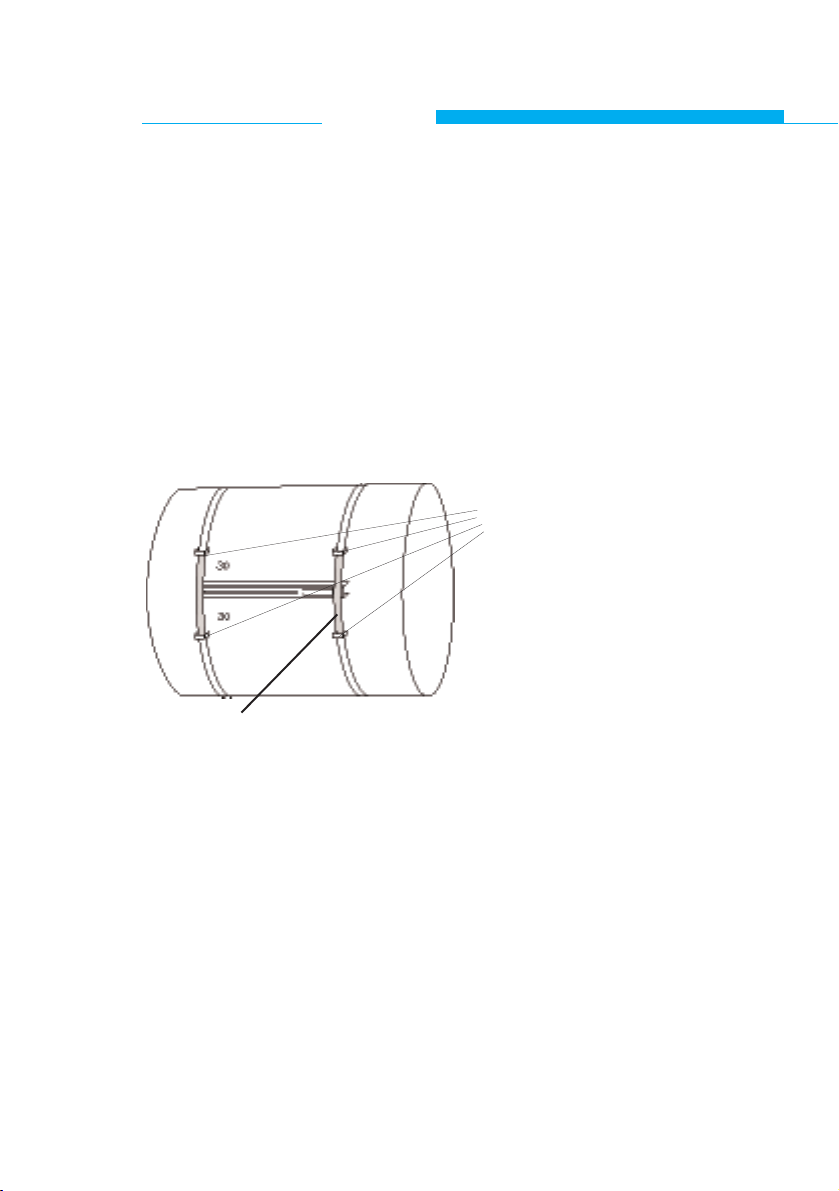

At mounting on diameters > DN 1600, we recommend to weld 4 little

bows on the tube as indicated in the sketch.

See also Chap. C.1.1.

Page 8

7

Page 9

B.1 Measuring Principle

Fig. B.1 : Measuring principle

A sound wave that is sent in the direction of the flow through

a medium will travel faster than one that is sent in the opposite direction.

This principle is used in the ultrasonic transit time flowmeter.

Two ultrasound transmitters/receivers are fitted on opposite

sides of the pipe section as shown in Fig. B.1.

Initially transducer A transmits an ultrasonic sound signal that

will be received by transducer B. The time lapse tABbetween

transmission and reception is measured.

Then the functions of both probes are reversed and the transit time tBAin the opposite direction is measured.

From tABand t

BA

the actual flow can be calculated taking into

account the following factors:

- pipe diameter

- wall thickness

- lining thickness, if applicable

- sonic velocity in the liquid

- sonic velocity in the pipe material

- sonic velocity in the pipe lining material, if applicable

Measurements are taken continuously.

NOTE: Each transducer transmits and receives ultrasound signals.

8

ALTOSONIC

System Description

UFM 600 T

Page 10

9

Page 11

B.2 Measuring System

A microprocessor controls the transducers via an analog/

digital interface and calculates the actual flow.

The control program is stored in EPROM memory.

Parameters for the application and processing the data are

entered via the keyboard.

A liquid crystal display is used for the indication of all

measuring data.

All data collected in the field can be stored in RAM memory

and transferred to an IBM compatible PC via an RS 232 output; the same applies to the parameter settings.

Both current and frequency output signals are available for

auxiliary readout and/or control purposes.

Figure B.2 shows a diagram of the flowsystem.

10

ALTOSONIC

System Description

UFM 600 T

Page 12

Fig. B.2 : System diagram

11

EEPROM

(µP1)

SENSOR

FLOW

SENSOR

UP DOWN

SIGNAL

PROCESSOR

RAM

POWER

SUPPLY

MICRO

PROCESSOR

(µP2)

KEYBOARD

RS 232 OUTPUT

CURRENT OUTPUT*

FREQUENCY*

OUTPUT

DISPLAY

*) galvanically insulated

Page 13

B.3 Equipment

The UFM 600 T flowmeter is fitted in a sturdy case.

Figure B.3 shows the UFM 600 T with all items

displayed:

1. UFC 600 T signal converter (1x)

2. RS 600 clamp on transducer (2x)

3. Shielded cable (coax) (2x)

4. Grounding cable (1x)

5. Small mounting strap (2x)

6. Large mounting strap (4x)

7. Mounting rail (2x)

8. Acoustic coupling grease (1x)

9. Measuring tape (5m) (1x)

- Manual and data sheets

- 3,5" diskette

10. Magnet bar (1x)

12

ALTOSONIC

System Description

UFM 600 T

Page 14

Fig. B.3 : UFM 600 T with all equipment displayed

13

➉

Page 15

B.4 Controls and Connections

Figure B.4 shows the controls and connections of the

flowmeter unit.

1 Liquid crystal display

2 Keyboard (3 keys)

3 Power supply (term. 11,12)

4 Connector for upstream transducer

5 Connector for downstream transducer

6 RS 232 output for PC

7 mA-Output (term. 5, 6)

8 Frequency output (term. 4,.4.1, 4.2)

9 Hall contacts

14

ALTOSONIC

System description

UFM 600 T

Page 16

Fig. B.4 : UFC 600 T converter

15

9

Page 17

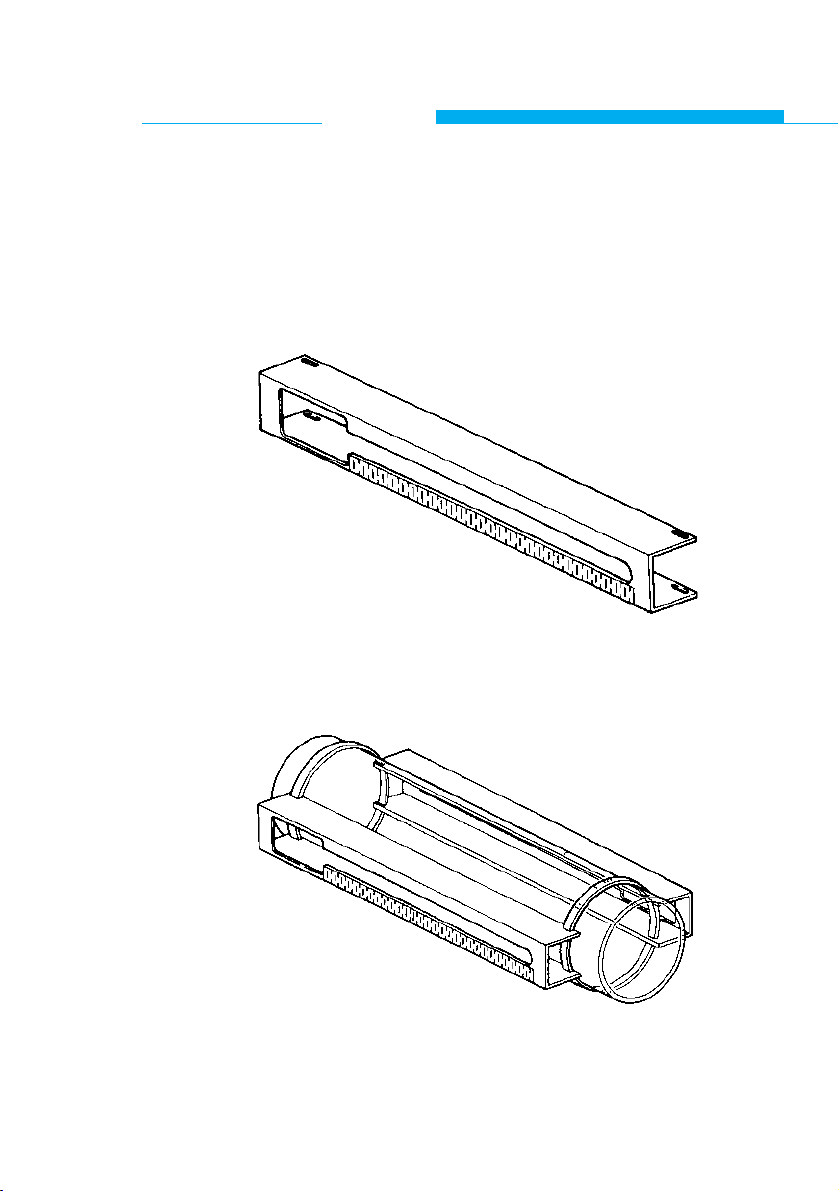

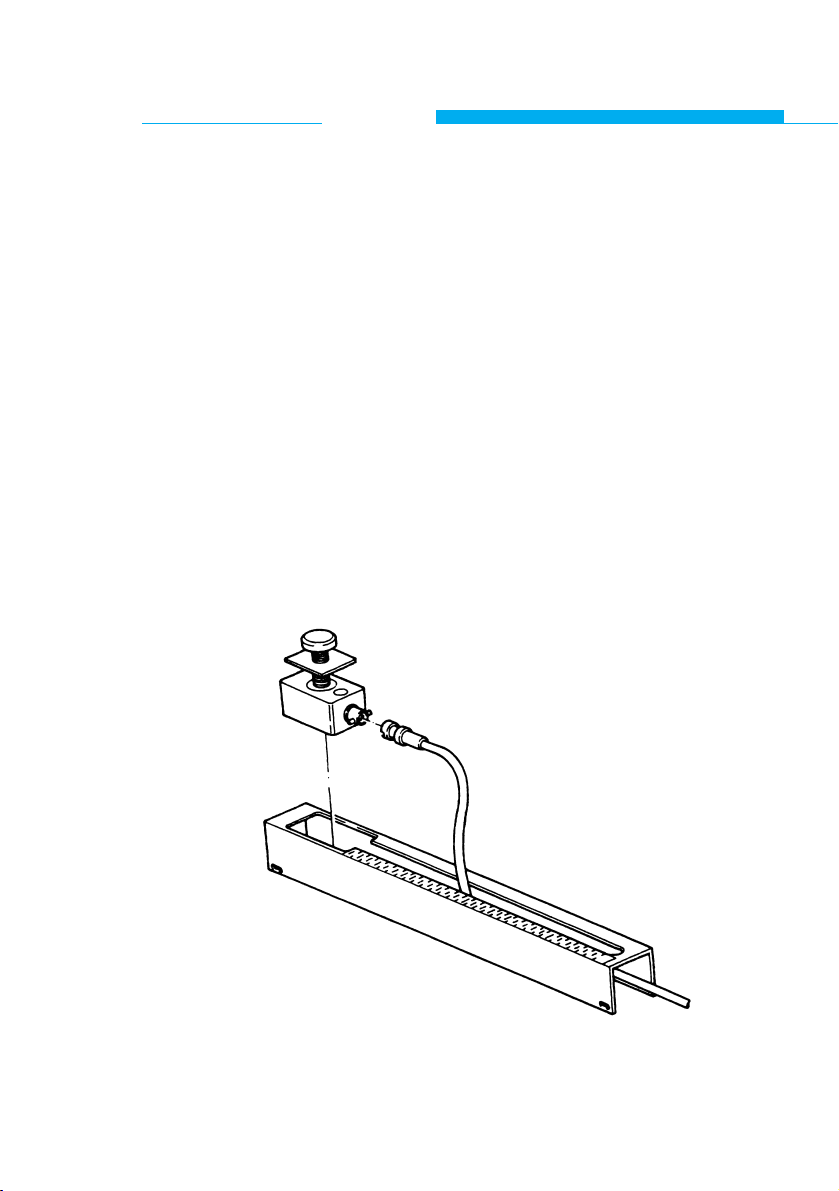

B.5 Transducers and Mountings (see Fig. B.5)

Fig. B.5 : Transducers, signal converter and auxillary items

Two mounting rails are clamped against the pipe wall by two

straps.

The transducers can slide inside the mounting rails to obtain

the correct distance between them. The transducers are then

tightened firmly against the pipe wall.

Coupling grease is used between the transducers and the

pipe wall to provide a good transfer of the ultrasound signal

through the pipe material.

The transducers are connected to the control unit by means

of two shielded cables.

16

ALTOSONIC

System description

UFM 600 T

Page 18

B.6 Display and Data Storage

Display:

The following display options are available:

- Actual flow rate and direction.

- Total positive and negative flow volume since the

start of the measuring session.

- Absolute flow volume since the start of the

measuring session.

- Transit time of the acoustic signal.

- Error messages.

- Back lit function of the display.

Since the display shows only one read out at a time, they can

be viewed sequentially.

Collect data:

At a programmable interval, all flow information selected

to be displayed can be stored and sent to a PC via the

RS 232 output. Also the parameter settings can be send to a

PC.

17

Page 19

B.7 Direct Output

Both current and frequency output signals are available for

control purposes. These can be either analog signals or just

flow direction indicator signals.

To avoid adverse effects on equipment connected to the

flowmeter a signal hold function can be activated; this is

important if the flowmeter is being used as part of a control

loop. When you terminate the measuring session the last

output signal can be maintained.

B.8 Power Supply

The flowmeter can be delivered in two versions for different

power sources:

- AC Power supply 85 - 264 VAC

- DC power supply 18 - 32 VDC

When the unit is switched off, the data stored in the volatile

memory is maintained by a backup battery on the microprocessor board.

This battery is capable of supporting the RAM for at least

5 years.

18

ALTOSONIC

System description

UFM 600 T

Page 20

19

Page 21

C.1 Initial Set-Up

The main steps of the installation procedure of the flowmeter

are:

1 Install the mounting rails on the pipe.

2 Program the application parameters through the

Start Up Menu, up to the point where the

microprocessor calculates the transducer distance.

3 Install the transducers in the mounting rails, according

to the microprocessor calculated distance.

4 If applicable perform a zero point calibration.

20

ALTOSONIC

Operation

UFM 600 T

Page 22

C.1.1 Installation of mounting rails

Mounting Considerations:

The pipe section on which the transducers will be clamped

must always be completely filled with liquid, even if there is

no flow.

The transducers can be fitted on both horizontal and vertical

pipe sections (or any other elevation).

On horizontal pipes the transducers should be fitted such

that the ultrasonic pulse travels approximately horizontally

through the pipe since gas/vapour at the top of the pipe or

any contamination at the bottom can cause an obstruction to

the ultrasonic pulses.

The solid or gas content of the liquid must not exceed 1 percent by volume.

Note that, due to cavitation, bubbles can appear behind

valves, pumps etc., so the transducers should not be

installed too closely to these positions.

The absolute minimum distances are given in the table

below.

Highly distorted flow profiles may require significantly longer

straight upstream lengths.

Upstream straight length

- when mounted behind a pump ≥ 15 x DN

- when mounted behind a fully opened valve ≥ 10 x DN

- when mounted behind one or more elbows ≥ 10 x DN

- when mounted behind a reduction α/2,7° ≥ 5 x DN

Downstream straight length ≥ 5 x DN

(DN: Nominal Diameter)

21

Page 23

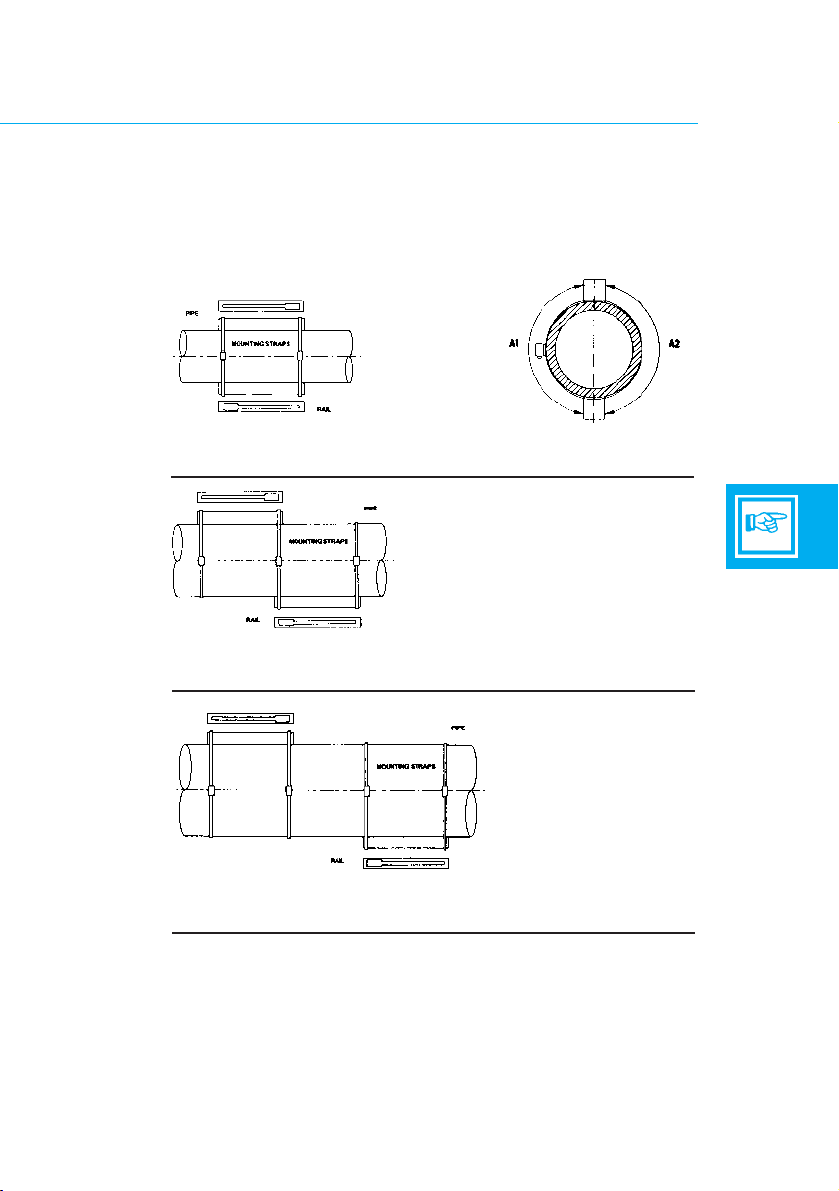

Mounting Procedure:

a Severe rust or thick coatings have to be removed from

the pipe where the transducers will be installed.

b Slide the securing straps through the slots on both

ends of each mounting rail (see fig. C.1).

Fig. C.1 : Mounting rail

c Attach the rails on opposite sides of the pipe such that

the large slots point in opposite directions (see fig. C.2).

Fig. C.2 : Mounting rails fitted on the pipe

22

ALTOSONIC

Operation

UFM 600 T

Page 24

d Use the supplied tape measure to ensure that the rails

are fitted diametrically opposite each other

(see fig. C.3-1a. ).

Distance A1 must equal distance A2. Secure the rails by

tightening the straps.

Fig. C.3 : Mounting positions

23

1.

3.

1a.

Mounting position if calculated transducer distance does

not exceed 350 mm (14")

Mounting position if calculated transducer distance is

between 350 mm (14") and 700 mm (28")

2.

Mounting position if calculated transducer distance does

exceed ≥ 700 mm (28")

Page 25

C.1.2 Programming the application parameters

After the flowmeter has been switched on it will start in the

measuring mode.

Pressing twice the key enters the Start Up Menu.

In this menu the application related parameters can be programmed.

All functions are described in section C.2.

Push Button Functions

The flowmeter can be programmed by means of the three

keys located below the liquid crystal display.

By pushing the left-hand key 'ARROW RIGHT' the

parameter shown on the display will be activated

and the desired value can be entered or an option

can be selected.

After pushing the key in the middle 'ENTER' the

programmed information will be stored and the

program advances to the next parameter.

For entering numbers or letters the 'ARROW UP'

key must be used; this will increment the ASCII

value of the blinking character (next higher number or next letter in the alphabet).

If a selection from a table must be made the

'ARROW UP' key can be used to display the next

option in the table. After using the 'ARROW UP'

key without actually programming a parameter the

next parameter will be displayed.

24

ALTOSONIC

Operation

UFM 600 T

Page 26

Input of values

Input of values outside the range, indicated at the function

descriptions, will result in a flashing error message; the minimum or maximum value allowed is displayed above the error

message.

After pressing any key the function is active again and the

correct value can be entered.

Start Up Menu

Enter all application parameters in the Start Up Menu; see

section C.2 for full details. Continue until the transducer distance is on display. Now the transducers can be installed.

25

Page 27

C.1.3 Installation of the transducers

Since the required transducer distance "S" is known now the

transducers can be positioned in the rails:

1 Turn the transducer securing screw completely counter

clockwise until the transducer positioning plate touches

the top of the transducer housing.

2 Feed the coax cables through both mounting rails.

3 Cover the bottom of both transducers with a thick layer of

the sonic coupling grease.

4 Connect each transducer to a coax cable and slide the

transducers into the rails (fig. C.4.) While inserting the

transducers, care must be taken not to touch the pipe

wall with the transducers before the proper position is

obtained, otherwise the coupling grease will be wiped off

the transducers and the result will be a bad sonic coupling between the transducers and the pipe wall.

Fig. C.4 : Position of transducer and cable

26

ALTOSONIC

Operation

UFM 600 T

Page 28

27

NOTE: - The cable connections at the transducers must always

point away from each other (fig. C.5).

- Make sure that the transducers are not placed over a

welding seam.

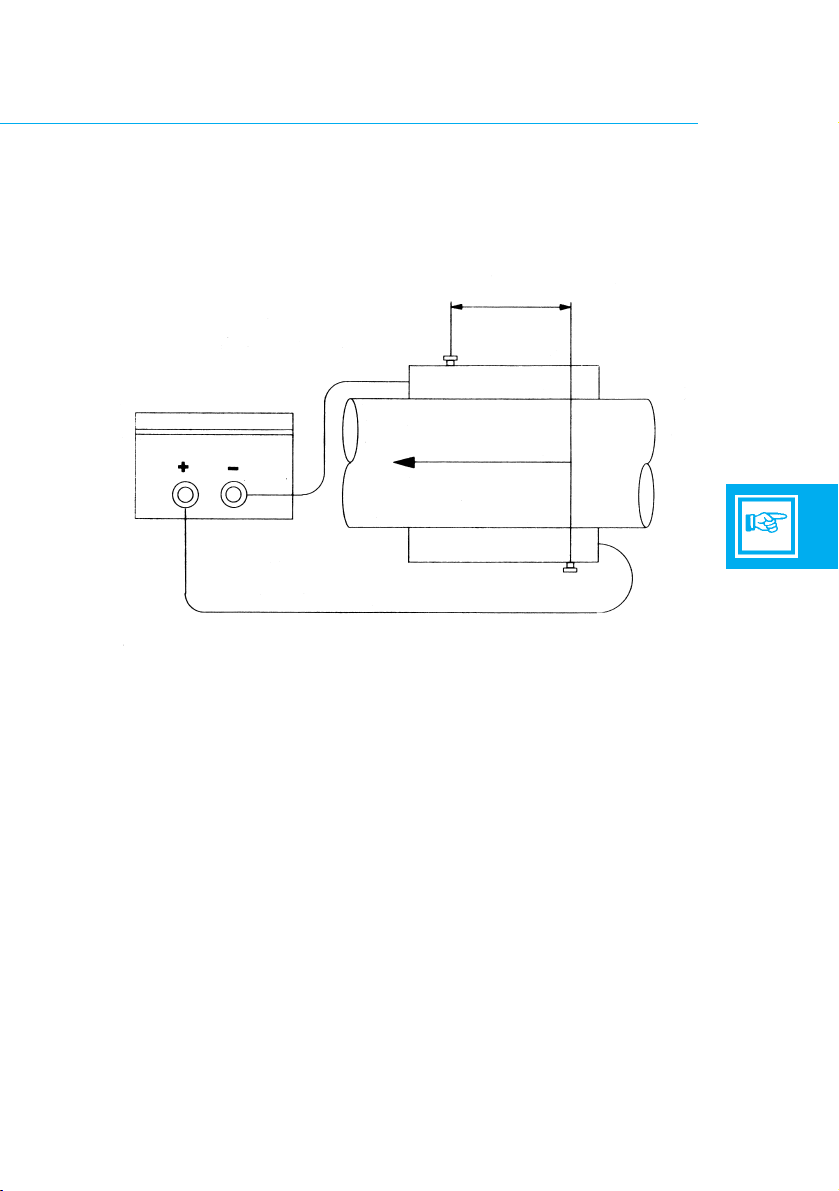

Fig. C.5 : Upstream and downstream connection

5 Use the cm scale on the mounting rails to position

the transducers at the proper distance from each other

and hand tighten the securing screws.

6 Check using the indication of the low signal marker (see

C 3.1) whether the unit is functioning properly.

Continue with Zero Set function (C.1.4.)

NOTE: REMOVAL OF THE TRANSDUCERS FROM

PIPE WALL

When removing the transducers from the pipe wall, especially

after they have been in place for a long period, care should

be taken:

• Not to damage the tranducers by pulling strongly at the

securing screw.

• Therefore, to remove a tranducer, it must be removed in

a slicing motion. Do not just pull it straight off the pipe all !!

sensor distance S

FLOWDIRECTION

Page 29

C.1.4 Zero set / Zero point calibration

Zero Set

After leaving the transducer distance function the ZERO SET

function can be activated.

The flowmeter is functioning now without displaying any flow

readings. Only the low signal marker (see C.3.1) gives an

indication of the signal quality based on the factory set

default zero point calibration.

The low signal marker will indicate if a zero point calibration is

feasible.

A zero point calibration is strongly advised as this will

improve the overall accuracy.

If no zero point calibration is to be executed, this function

can be skipped.

See also section C.3, Error Detection, for the accuracy to be

expected.

28

ALTOSONIC

Operation

UFM 600 T

Page 30

Zero Point Calibration

Before performing the zero point calibration ensure that:

- The unit is functioning properly (see low signal marker).

- There is no flow at the location where the transducers are

installed and the pipe section is completely filled with liquid.

Now activate the Start Up Menu and enter the ZERO SET

function:

- With DEFAULT or MEASURED will be visible

- Use to select between DEFAULT or MEASURED

- If DEFAULT is selected press to set the preprogrammed

DEFAULT zero point

- If MEASURED is selected press

- Now CALIB. NO will be visible.

- Use to select YES and press

- The microprocessor now performs an input signal test.

- On the top line the zero point correction in % is displayed.

- If the correction is near 0% the calibration was successful;

select STORE YES and press to save the zero point calibration.

If no reliable signal is detected the error message BAD ZERO

is displayed and the calibration should be abandoned; in

order to restart the zero point calibration procedure. The data

collection can be started now or other parameters can be

entered through the programming mode (chapter D).

NOTE: MEASURED zero point is selected if there is no flow.

DEFAULT zero point should be selected if the flow cannot

been stopped.

29

Page 31

C.2 Start Up Menu

C.2.1 Enter start up menu

The Start Up Menu is activated by pressing the key twice

from the measuring mode or pressing the key once from

the main menu 1.0.0.

C.2.2 Application Functions

The functions in which the application parameters can be

programmed always appear on the display in the same order

as described below:

To enter a next function, the key must be pressed.

DIAMETER

Program the outer pipe diameter.

The diameter can be entered either in mm or in inches.

Range:

2.0000 E 0 mm ≤ DIAMETER ≤ 4.0000 E 3 mm

7.8740 E-2 inch ≤ DIAMETER ≤ 1.5748 E 2 inch

PIPEWALL

Program the pipe wall thickness.

The wall thickness can be entered either in mm or in inches.

Range:

1.0000 E-1 mm ≤ PIPEWALL ≤ 5.0000 E 1 mm

3.9370 E-3 inch ≤ PIPEWALL ≤ 1.9685 E 0 inch

30

ALTOSONIC

Operation

UFM 600 T

Page 32

PIPE MAT.

Program the sonic velocity of the pipe material.

The following 5 options are preprogrammed (or will reappear

after running 3.5.8 DEFAULT SET, see chapter D):

STEEL : 3.1700 E 3 m/s

ST. STEEL : 3.1200 E 3 m/s

IRON : 2.1200 E 3 m/s

PVC : 2.1200 E 3 m/s

Other : 1.5000 E 3 m/s

All five option positions can be reprogrammed completely

according to the user´s requirements (names and sonic

velocities).

The sonic velocity can only be programmed in m/s.

Range:

1.5000 E 3 m/s ≤ Sonic velocity ≤ 4.7500 E 3 m/s

See appendix 1 for sonic velocities of the most frequently

used pipe materials.

LINING

Select YES or NO depending on whether or not the pipe is

provided with a lining.

When NO is selected the parameters LINING THICKNESS

and LINING MATERIAL can not be programmed.

LINING TH.

(does not appear on display when lining = "NO" )

The lining thickness can be entered either in mm or in inches.

Range:

1.0000 E-1 mm ≤ LINING THICKNESS ≤ 5.0000 E 1 mm

3.9370 E-3 inch ≤ LINING THICKNESS ≤ 1.9685 E 0 inch

31

Page 33

LINING MAT.

(does not appear on display when lining = "NO")

Program the sonic velocity of the lining material.

The following 5 options are preprogrammed (or will reappear

after running 3.5.8 DEFAULT SET, see chapter D):

PVC : 2.1200 E 3 m/s

Other 1 : 1.0000 E 3 m/s

Other 2 : 1.0000 E 3 m/s

Other 3 : 1.0000 E 3 m/s

Other 4 : 1.0000 E 3 m/s

The sonic velocity can only be programmed in m/s.

Range:

3.0000 E 2 m/s ≤ Sonic velocity ≤ 4.7500 E 3 m/s

See appendix 1 for sonic velocities of some lining materials

used frequently.

All five option positions can be reprogrammed completely

according to the user's requirements (names and sonic

velocities).

LIQUID

Program the sonic velocity of the liquid inside the pipe.

The following 5 options are preprogrammed (or will reappear

after running 3.5.8 DEFAULT SET, see chapter D):

WATER : 1.5000 E 3 m/s

Other 1 : 1.0000 E 3 m/s

Other 2 : 1.0000 E 3 m/s

Other 3 : 1.0000 E 3 m/s

Other 4 : 1.0000 E 3 m/s

The sonic velocity can only be programmed in m/s.

Range:

1.0000 E 2 m/s ≤ Sonic velocity ≤ 2.5000 E 3 m/s

See appendix 2 for sonic velocities of frequently encountered

liquids.

All five option positions can be reprogrammed completely

32

ALTOSONIC

Operation

UFM 600 T

Page 34

according to the user´s requirements (names and sonic

velocities).

NOTE: If the sonic velocity is not known it can be estimated by using

the sonic velocity calculation, see appendix 3.

FULL SCALE

Select the flow rate units and program the full scale value.

A selection can be made out of 9 preprogrammed units and

one unit can be specified by the user (see function 3.5.3,

3.5.4 and 3.5.5 in chapter D).

Unit Range

m3/Sec 9.4240 E-7 ≤ F.S. ≤ 1.5080 E 2

m3/min 5.6533 E-7 ≤ F.S. ≤ 9.0481 E 3

m3/hr 3.3926 E-3 ≤ F.S. ≤ 5.4288 E 5

Liter/Sec 9.4240 E-4 ≤ F.S. ≤ 1.5080 E 5

Liter/min 5.6544 E-2 ≤ F.S. ≤ 9.0481 E 6

Liter/hr 3.3926 E 0 ≤ F.S. ≤ 5.4288 E 8

US G/Sec 2.4896 E-4 ≤ F.S. ≤ 3.9837 E 4

US G/min 1.4937 E-2 ≤ F.S. ≤ 2.3902 E 6

US G/hr 8.9624 E-1 ≤ F.S. ≤ 1.4341 E 8

...../...... 9.4240 E-7 ≤ F.S. ≤ 1.5080 E 2

(user defined unit)

LOCATION

The name of a measuring site or tag number can be programmed here. When function 3.6.5 is activated (see chapter

D) the location name will be recorded in the header of each

data block that is stored.

SENS. DIST.

After the previous parameters in the Start Up Menu have

been programmed, the microprocessor will calculate, either

in mm or inches as chosen for under diameter, the desired

distance between the two transducers, measured along the

pipe axis. Enter this function to read the result on the display.

33

Page 35

ZERO SET :

Zero point calibration.

Select between the factory set default value for the zero point

or perform a zero point calibration for the actual situation.

See paragraph C.1.4 for the precise conditions and instructions for a calibration.

C.2.3 Plausibility check

After any changes are made to the parameter settings the

microprocessor will perform a plausibility check on the

changed settings, before the measuring mode can be activated. If no "impossibilities" in the configuration are detected

the microprocessor asks for confirmation before the new settings are stored.

If discrepancies in the parameters entered are found the

microprocessor will display the message "PARAMERROR"

which prevents you from storing parameters that are incorrect; the options available to correct the configuration are

described in section D.6.

The next function which will appear is again, the first function

of this Start Up Menu: "DIAMETER".

The Start Up Menu is left by pressing the key once from

any function name in the Start Up Menu. When doing this,

the Main Menu will be entered (function 1.0.0.)

34

ALTOSONIC

Operation

UFM 600 T

Page 36

C.3 Error Detection

C.3.1 Low signal marker function

The condition of the input signal from the transducers is indicated by a marker in the top left hand corner of the display.

The marker consists of four arrows divided over 360 degrees.

The microprocessor calculates the percentage of the

measurements that is inconsistent.

Marker indications:

> 80 % of measurements inconsistent

The flowmeter will

not function.

40 % of measurements inconsistent

20 % of measurements inconsistent

The flowmeter will

function, though

not optimally.

10 % of measurements inconsistent

No inconsistent readings detected Optimal functioning

flowmeter.

35

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

.

.

.

.

.

.

.

.

.

.

Page 37

C.3.2 Error messages

If the microprocessor produces an error message a * sign

appears at the lower left hand side of the display.

Enter the QUIT / RESET mode to view the error message(s)

(see chapter C.5).

It depends on the settings of the Installation functions 3.2.4

and 3.2.6, whether the error messages will be displayed in

between the flow data.

List of Error Messages:

SIGN LOST : Transducer disconnected

TOTALIZER : Overflow of the totalizer.

FREQ.OUTP. F: Overflow of the frequency signal; full

scale value is too small

CUR. OUTP. I : Overflow of the current signal; full

scale value is too small

CAL. DATA : The transducer calibration is

distorted; contact your supplier

EE1 EE2 : Error detected during memory check;

switch unit off and on; if message still

reappears after two attempts, contact

your supplier

EEPROM2 : See EE1 EE2

ROM : Checksum error detected during

memory test; contact your supplier

RAM : Error detected during verification of

parameter settings stored previously;

use function 3.5.8 DEFAULT SET and

switch off and on; if message

reappears contact your supplier.

36

ALTOSONIC

Operation

UFM 600 T

Page 38

37

STORE: A total number of 350 data blocks are

been stored. Rest capacity 40 data

blocks till data storage is full.

FATAL ERROR: Check sum error detected; contact

your supplier.

PARAMERROR: This message will not appear during

measurement; at the end of both the

start up menu and the programming

mode a parameter check is performed before the measuring mode

can be entered (see section D.6).

Page 39

C.4 Data Collection

C.4.1 Data collection procedure

Sampling Rate / Data Storage Capacity

A total number of 390 data blocks can be stored.

This number is independent of the amount of information that

is programmed to be on display and/or stored.

It is very important to determine a useful combination of the

measuring period and the data sampling rate.

If the flow rate shows only minor fluctuations or fluctuations

are not relevant a low sampling rate can be programmed.

Thus a long measuring period can be achieved or more than

one data collecting interval can be realized before the data

has to be transferred to a PC.

If the flow rate fluctuations are important the sampling rate

should not be too low. Otherwise, relevant information might

not be recorded.

NOTE: When all 390 data blocks are occupied no further data will be

stored. The flowmeter will continue to operate normally.

WARNING IS GIVEN WHEN THE DATA STORAGE IS FILLED

WITH 350 DATA BLOCKS (See chapter C.3.2. Error

Messages)

Reset Data

If a new measurement series is started (previous flow data

can be discarded) the data blocks can be cleared; two

RESET DATA functions are available:

1 use the function 3.6.6, RESET DATA, in the programming

mode

2 enter the QUIT/RESET menu (see section C.5.)from the

measuring mode and select the RESET DATA option.

Reset Totalizers

If applicable the totalizers must be reset at the beginning of a

measuring series. Enter the QUIT/RESET menu from the

measuring mode and select the totalizer(s) that have to be

reset (see section C.5)

38

ALTOSONIC

Operation

UFM 600 T

Page 40

Preparation for new measurements

Providing any previous flow data can be discarded, a data

collection session can be started as follows:

1 Select the STORE or BOTH option of function 3.6.3 in the

programming mode

2 Clear the RAM by means of one of the two ways to Reset

Data

3 Start the measuring mode

4 If applicable reset the totalizers

Preparations for continued measurements

It is advisable not to activate the STORE option of function

3.6.3 in the programming mode until the actual measuring

period is to be started; otherwise unnecessary data blocks

are being stored and storage space is lost.

After installing the transducers it is advisable to run in the

measuring mode for some time during which the data is only

sent to the display (function 3.6.3 OFF).

The readings can be checked and adjustments made (e.g.

adjust full scale value) to ensure that the suitable data is collected.

The actual measuring period with data storage (and the RAM

partially filled) can then be started as follows:

1 Select the STORE or BOTH option of function 3.6.3 in the

programming mode

2 Leave the programming mode and enter the measuring

mode via the DIAMETER prompt of the Start Up menu

3 If applicable, reset the totalizers

39

Page 41

C.4.2 Transfer to PC (data and parameters)

Software

The floppy disk provided contains programs for the transfer

and conversion of the measuring data:

- GETFLOW.EXE

Function : Transfer measuring data and/or

parameter settings to the PC

The information will be stored in ASCII

format.

Syntax : GETFLOW <com> <file>

<com> : the number of the serial

port on the PC.

<file> : file name for the data to

be stored.

- FLOW2CEL.EXE

Function : Convert the ASCII data for processing

by Harvard Graphics, VP Planner or

Lotus 1,2,3.

Syntax : FLOW2CEL <input file> <output file>

<Language>

WITH Language:

E = English

D = Deutsch

F = Francais

N = Nederlands

NOTE: Both programs show their syntax if they are run without or

with false extensions.

- README _ E.DOC

If applicable this file offers an update on the software information.

40

ALTOSONIC

Operation

UFM 600 T

Page 42

Data transfer

For the transfer of information from the flowmeter to the PC

proceed as follows:

- Connect the RS 232 cable to the flowmeter and the serial

in/output port of the PC (com1 or com2).

- Enter the programming mode of the flowmeter and

activate the function 3.6.1 or 3.6.2 for either the output of

the parameter settings or the measuring data; see that

the selection is on YES

- Run program GETFLOW on the PC

For example if the Com1 port is connected and the data

has to be stored in file FLOW.DAT then type:

GETFLOW 1 FLOW.DAT

The message WAITING FOR DATA will appear.

- Now press on the flowmeter within 3 seconds.

- The data is transmitted to the PC and stored in the file

indicated using the ASCII format.

Data conversion

After all flow information is stored in an ASCII file use program FLOW2CEL to convert the data to a format that can be

adapted for presentation purposes.

Run program FLOW2CEL on the PC and follow the instructions displayed.

See README _ E.DOC for any additional information.

C.4.3 Terminal programs

Standard terminal programs (e.g. MS Windows® terminal)

can be used to receive data from the UFC 600 T signal

converter by using a straight RS 232 cable with 25 pins

female D-connector.

Settings must be: BAUDRATE 2400

DATA BITS 7

STOP BITS 1

PARITY NONE

41

Page 43

C.5 Quit / Reset Menu

The measuring mode can be exited with the code as

described below to enter the Quit/Reset Menu.

In this menu two functions can be used:

ERRORLIST:

Show the list of errors indicated by the * sign at the left-hand

side of the display.

When the error messages are not programmed to appear on

a regular display (function 3.2.4 and 3.6.4) the only way to

recognize an error (apart from the low signal marker) is by the

* sign at the left-hand side of the display.

Enter the error list with the key; the number of errors and

the first error message will be visible. Use the key to display the other error(s); eventually the ERR.ACQUIT function

will appear.

ERR.ACQUIT function:

After curing the cause of the error(s) enter the ERR.ACQUIT

function by using the key and select YES with key to

reset the error message and error marker *.

Even if the cause of an error is cured the error message and

the error marker will not disappear until they are cleared by

the ERR.ACQUIT function.

Use the key to leave the function.

Use the key to return to the measuring mode.

* Note that these error messages differ from those included

in the data block that is stored and sent to the RS 232

output at regular intervals (function 3.2.4 and 3.6.4) :

at the end of the next complete data collection interval

following the elimination of the errors these messages will

have disappeared automatically.

42

ALTOSONIC

Operation

UFM 600 T

Page 44

RESET:

In this submenu three reset options are available:

TOTAL + : Reset + totalizer.

TOTAL - : Reset - totalizer.

RESET DATA : Reset all data blocks.

In each option YES or NO must be selected.

The reset option is to be used to obtain a clear start of a data

sampling session.

Use the key to return to the measuring mode.

CODE:

The code to exit the measuring mode and to enter the

Quit/Reset mode is:

Although the code is rather simple it prevents the collected

data from being wiped out unintentionally.

If within 3 or 4 seconds the proper code has not been

entered the measuring mode is resumed without having been

interrupted.

43

Page 45

C.6 Direct Output Ports (Analog (mA) output and frequency /

pulse output)

C.6.1 General

The options available for these direct output ports are described further in section D.4 main menu: 3.0.0 INSTALLATION.

Refer to the technical specifications if any equipment is to be

connected to the current and/or frequency output. (see

C.6.3, C.6.4 and chapter F)

C.6.2 Output hold

It is advisable to activate the output hold function (3.5.2)

when the flowmeter is being used as part of a control loop.

NOTE: This hold function also affects the outputs in case of mal-

function (signal lost).

C.6.3 Current output

Specification:

Range : 0 to 20 mA, or 4 to 20 mA or I

0% to...;I 100% programmable

Load : 14 [V]

RL[kohms] <

I 100% [mA]

(e.g. 0.7 kohms at 20 mA,

2.8 kohms at 5 mA).

C.6.4 Frequency output

Specification:

Pulse rate for Q=100%: 10 to 36 000 000 pulses per hour

0.167 to 600 000 pulses per

minute

0.0028 to 10 000 pulses per

second (=Hz)

optionally in pulses per liter, m3or

US gallons

44

ALTOSONIC

Operation

UFM 600 T

Page 46

Active output short-circuit-proof

Terminals 4.1/4.2 : for electromechanical (EMC) or

electronic (EC) totalizers

Terminals 4/4.1/4.2: for electronic (EC) totalizers

Amplitude : approx. 27 V

Load rating see Table "pulse width"

Passive output

Terminals 4/4.1 : open collector for connection of

active electronic totalizers (EC)

or switchgear

Input voltage : 5 to 30 V

Load current : max. 100 mA

Pulse width is automatically choosen, depending on actual out

frequency.

Frequency f at Q=100% Pulse width Load rating of active output

Load current Load

0.0028 Hz < f ≤ 1 Hz 500 ms ≤ 150 mA ≥ 180 Ohm

approx.

50% duty

1 Hz < f ≤ 10 Hz cycle (1:1) ≤ 25 mA ≥ 1 k Ohm

50% duty

10 Hz < f≤ 1000 Hz cycle (1:1) ≤ 25 mA ≥ 1 k Ohm

1000 Hz < f≤ 2547 Hz 160 µs ≤ 25 mA ≥ 1 k Ohm

2547 Hz < f≤10000 Hz 50 µs ≤ 25 mA ≥ 1 k Ohm

45

Page 47

C.6.5 Connection Diagrams

45a

ALTOSONIC

Operation

UFM 600 T

I:

(term.5/6)

F

actie:

EC (term.4/4.1/4.2)

F

passive

EC (term.4/4.1)

F

active

EMC/EC(term.4.1/4.2)

4 4.1

4.2

5+6

-

40V4.1

4.2

27V

5+6

-

EMZ

EZ

40V4.1

4.2

27V

5+6

-

4 4.1

4.2

5+6

-

EZ

EZ

R1

R2

U: 5-30V

I

max

: 100mA

I

U

Page 48

45b

Page 49

C.7 Trouble Shooting

1 The flowmeter does not respond after connection to

the main power supply (no display or output messages).

- Check fuse.

2 The error marker * appears on the display

- Leave the measuring mode and enter the Quit/Reset

menu

(press ; see section C.5).

Cure the cause if necessary, and select

ERR.ACQUIT to reset the error marker.

3 Low signal marker: 3 or 4 markers on.

Cause Solution

Incorrect transducer Reposition transducers (see sec-

tion position C.1.3) using sufficient

coupling grease and check the

transducer distance afterwards.

Poor sonic coupling Check the pipe wall surface;

between pipewall and remove any rust, dirt and/or thick

transducer surface layers of paint or coating.

Apply sufficient grease on the

transducers and make sure not to

wipe off any grease from the transducers while they are being reinstalled.

Pipe is not completely Fill the pipe completely or select a

filled pipe section that is always com-

pletely filled with liquid.

Broken signal cable Use a multimeter to check the

condition of the cables and the

connectors. See your supplier for

46

ALTOSONIC

Operation

UFM 600 T

Page 50

replacements. If 3 or 4 markers

remain the selection of a different location on the pipe wall is recommended; some irregularities at

the interior of the pipe might have

caused poor signal reception.

5 Low signal marker: 1 or 2 markers on.

Cause Solution

Small deviation of the Adjust one transducer approx.

transducer distance from ± 5 mm. until the markers disthe correct value appear; do this very carefully so as

not to disturb the sonic coupling

grease layer between the transducer and the pipe wall.

47

Page 51

D.1 General

In the main menu, two Sub Menus can be activated:

Sub Menu 2 "TEST":

Four function tests can be executed:

- Display test

- Microprocessor test

- Current output test

- Frequency output test

Sub Menu 3"INSTALLATION":

Enter all parameters that determine the initial settings of the

flowmeter and the way the data is processed.

All functions available in both of these menus are listed in

section D.3 and described further in sections D.4 and D.5.

48

ALTOSONIC

Programming mode

UFM 600 T

Page 52

D.2 How to Program

Push button functions:

move the menu pointer one step to the right to

activate the submenu displayed.

either move the menu pointer to the left to leave a

submenu or store entered data and leave the submenu.

will increment the ASCII value of the blinking character by one; either the next higher number or the

next letter in the alphabet. Pushing this button in

the measuring mode, the display will be illuminated

for one hour.

Entering the Start Up Menu:

The Start Up Menu is entered by pressing twice the key

from the measuring mode or from the main menu 1.0.0. by

pressing the key once. The Start Up Menu is left by pressing the key (once to return to main menu 1.0.0, four to

return to measuring mode)

Entering the main menu:

The main menu mode is entered from measuring mode or

the Start Up Menu:

From measuring mode press to enter the main menu.

From Start Up Menu press to enter the main menu.

49

Page 53

Menu selection:

By entering the main menu, the submenu Start Up 1.0.0. will

be on display; use the key to select the submenus TEST

2.0.0. or INSTALL 3.0.0.

If the Start Up Menu is to be selected, press key when

1.0.0. is displayed.

Function selection:

Use the key to select a function from the chosen submenu.

Activate the selected function by pressing the key.

Enter numbers, characters and select units:

If applicable within a function, numbers, characters or units

can be selected at the position which shows a blinking sign

by using the key.

This position is selected by using the key.

The set up of the function is completed by pressing ; the

data is stored and the menu pointer returns to the active

submenu.

Leave Submenu:

Press to return to the main menu.

Ending the programming session:

Ending a programming session can be done by pressing

3 times while one of the submenus (1.0.0, 2.0.0 or 3.0.0.) is

active.

The programmed parameters will be saved directly without a

request whether the changes should be set.

After saving the parameters the microprocessor will go

directly to the measuring mode.

50

ALTOSONIC

Programming mode

UFM 600 T

Page 54

If any discrepancies are detected the error message

PARAMERROR is displayed and a separate menu is activated in which the parameters concerned can be corrected (see

section D.6).

NOTE: To save the programmed parameters in the Start Up menu

(fct. 1.0.0) press three times.

The signal converter is equipped with magnetic sensors (hall

contacts). This allows setting of the signal converter by

means of a hand-held bar magnet. Function of sensors without removing the front cover is the same as the corresponding keys.

Hold the bar magnet by the black rubber cap. Apply blue

end of the magnet (north pole) to the glass pane above the

magnetic sensors.

51

Page 55

D.3 List of Functions

2.00 TEST

2.1.0 DISPLAY

2.1.1 DISP.TEST

2.2.0 PROCESSOR

2.2.1 8048 TEST

2.3.0 CURR. OUTP.

2.3.1 TEST I

2.4.0 FREQ. OUTP.

2.4.1 TEST F

3.0.0 INSTALLATION

3.1.0 FLOW DATA (Submenu) Set flow parameters.

3.1.1 PRIM. CORR.(Function)

3.1.2 TRAN. RANGE

3.1.3 LF. CUTOFF

3.1.4 CUTOFF ON

3.1.5 CUTOFF OFF

3.2.0 DISPLAY Set output functions,

3.2.1 DISP.FLOW L.C.Display and define the

3.2.2 DISP.TOTAL contents of the data

3.2.3 UNIT TOTAL blocks.

3.2.4 ERROR MSG.

3.2.5 DISP TRAN. T.

3.2.6 CYCL. DISP.

3.3.0 CURR. OUTP. Set up analog output.

3.3.1 FUNCTION I

3.3.2 I 0 PCT.

3.3.3 I 100 PCT.

3.3.4 I MAX.

3.3.5 T- CONST I

52

ALTOSONIC

Programming mode

UFM 600 T

Page 56

3.4.0 FREQ OUTP. Set up frequency/pulse output.

3.4.1 FUNCTION F

3.4.2 PULSOUTP.

3.4.3 PULSRATE PULS/UNIT

3.4.4 T- CONST. F

3.5.0 SPEC. FCT. Set special functions.

3.5.1 LANGUAGE

3.5.2 OUTP. HOLD

3.5.3 UNIT TEXT

3.5.4 FACT. QUANT.

3.5.5 FACT. TIME

3.5.6 SET DATE

3.5.7 SET TIME

3.5.8 DEF.SET

3.5.9 SOFTW.V - NR.

3.6.0 COMM.DATA Set Store/RS 232 output.

3.6.1 OUTP. PARAM

3.6.2 OUTP. DATA

3.6.3 SEL. COMM.

3.6.4 INTERVAL

3.6.5 LOCAT.

3.6.6 RESET DATA

NOTE: The function names used in the description of the functions

are presented in the same way as on the L.C. display.

53

Page 57

D.4 Sub Menu: 3.0.0 INSTALLATION

3.1.0 FLOW DATA : set flow parameters

3.1.1 PRIM. CORR. : Primary Correction

This function allows the user to correct the primary constant

that is calculated by the microprocessor. Corrections on the

primary constant are useful in the case of for example poor

installation conditions or comparison to a reference flowmeter.

The primary constant will be multiplied by the number displayed; 1.0000 E0 means no correction and 1.1000 E0 indicates a correction of + 10%.

Range: 0.0000 E0 ≤ Prim. Corr.≤ 2.0000 E0

3.1.2 TRAN. RANGE : Transit (time) Range

Use this function only if the transit time of the acoustic signal

(the time elapsed between transmission and reception) is

used as output on either the current or the frequency output

(see Fct. 3.3.1 and 3.4.1).

The transit time value that corresponds to 100% output is

programmed.

Range: 2.0000 E1 ≤ Tran. Range ≤ 1.0000 E5 µsec

Current output example:

If 200 µsec is entered and the 0 - 20 mA output is being

used then an actual transit time of 150 µsec provides a 15

mA output signal. Likewise, if a 4 - 20 mA output is being

used, a 16 mA signal would be the analog output.

Frequency output example:

If 200 µsec is entered and the pulse rate at full flow is programmed to be 10000 Hz then an actual transit time of

120 µsec is indicated by a 6000 Hz signal.

54

ALTOSONIC

Programming mode

UFM 600 T

Page 58

3.1.3 L.F. CUTOFF : Low Flow Cutoff

To avoid erroneous measurements at low flow rates the Low

Flow Cutoff can be used ( see Fig. D.2).

Fig. D.2 : Low flow cutoff

If the flow rate drops below the "Cutoff On" level all outputs

will be switched off and if the flow rate exceeds the"Cutoff

Off" level the outputs will be activated again.

The "Cutoff On" level must be lower than the "Cutoff Off"

level otherwise a PARAMERROR message appears at the

parameter check (see section D.6).

After entering the function either YES or NO can be selected.

If YES is selected functions 3.1.4 and 3.1.5 become active.

If NO is chosen the low flow cutoff becomes inactive and

functions 3.1.4 and 3.1.5 will not appear on the display.

55

ACTUAL

FLOW

FLOW

METER

OUTPUT

OUTPUT INACTIVE

(flow=0%)

TIME

CUTOFF OFF LEVEL

CUTOFF ON LEVEL

TIME

Page 59

3.1.4 CUTOFF ON : (only if at 3.1.3 YES was

entered)

Program the flow rate level below which all outputs will be

switched off.

Enter the value in % of the full scale.

Range: 1- 20

NOTE: This value must be lower than the Cutoff Off value !!

3.1.5 CUTOFF OFF : (only if at 3.1.3 YES was

entered)

Program the flow rate level at which all outputs become

active again.

Enter value in % of full scale.

Range: 1- 20

56

ALTOSONIC

Programming mode

UFM 600 T

Page 60

3.2.0 DISPLAY : set output functions

L.C.display

NOTE: All functions that are programmed to be on display can also

be saved as programmed in function 3.6.3 SEL.COMM.

3.2.1 DISP. FLOW : Display Flow rate

Determine whether the flow rate should be displayed and if

so, in what sort of units; select a display option using the

key and press to store:

NO DISPLAY :

m3/Sec :

m3/min :

m3/hr :

Liter/Sec :

Liter/min :

Liter/hr :

US G/Sec : U.S. Gallon per second

US G/min :

US G/hr :

——-/—- : reserved for user defined unit

PERCENT : percentage of full scale as entered

in Start Up menu

3.2.2 DISP. TOTAL : Display Totalisator

outputs

Select which totalizer outputs should be displayed by using

the key and press to store:

NO DISPLAY : (function 3.2.3 will not appear)

+ TOTAL : Totalizer for positive flow

- TOTAL : Totalizer for negative flow

+/- TOTAL : Totalizers for both positive and

negative flow

SUM TOTAL : [+ TOTAL]- [- TOTAL]

ALL TOTAL : All three totalizer options are active

57

Page 61

3.2.3 UNIT TOTAL : unit for totalizers

(only if a totalizer has been set in 3.2.2)

Select unit for the totalizers using the key and press

to store:

m3 :

Liter :

US G :

------- : User defined unit

3.2.4 ERROR MSG. : Display Error Messages

Determine whether error messages should be displayed and

if so, what type of error messages; select a message option

using the key and press to store:

NO MESSAGE :

US ERROR : Only display of errors

related to the measurement itself

TOT. ERROR : Display of totalizer

errors only

ALL ERROR :

3.2.5 DISP. TRAN. T : Display Transit Time

The transit time is the time lapse between transmission of the

acoustic signal by one transducer and the reception of the

signal by the opposite transducer.

Select display of the transit time; choose either YES or NO

using the key and press to store.

58

ALTOSONIC

Programming mode

UFM 600 T

Page 62

3.2.6 CYCL. DISPL. : Cyclic Display

The cyclic display option can be used to automatically

change the function of the display, if more than one variable

is programmed to be displayed.

Only one variable can be shown on the display at a time.

With this option active the display sequences from one variable to the next every 5 seconds.

If the error messages are programmed to be displayed, these

appear in between the successive variables, if applicable.

For the totalizers and the flow rate, the actual function of the

display is indicated by an arrow symbol at the bottom of

the display.

If NO is selected the successive display of the variables is obtained by using the key.

59

▼

Page 63

3.3.0 CURR. OUTP.I : set up analog current

output

3.3.1 FUNCTION I : Program the analog

current output

Select an output option using the key and press

to store:

2 DIR : Enables flow measurement in 2 direc-

tions(+ and -) without change of

polarity in the output signal (Fig. D.3)

TRAN. TIME : Output signal is proportional to

the measured transit time of the

acoustic signal.

NOTE: this function requires:

- current setting at zero flow, Fct. 3.3.2

- current setting at full flow, Fct. 3.3.3

- transit time at full flow, Fct. 3.1.2

(see example in description of Fct. 3.1.2)

NO SIGNAL : Output signal indicates "signal loss".

OFF : No current output.

F/R IND. I : Output signal as flow direction

indication, 0% at + flow direction

and 100% at -flow direction

(fig. D.4).

1 DIR : Flow measurement in 1 direction

(+) only. (Fig. D.5)

I < I 0 PCT : Allows the output signal to drop

below the programmed value for

0% flow at negative (-) flow

direction. If 10 mA is programmed for

0% flow (Fct.3.3.2) and 20 mA for

100% (Fct. 3.3.3) then the output will

60

ALTOSONIC

Programming mode

UFM 600 T

Page 64

Fig. D.3 : Bi-directional flow (I) Fig. D.4 : Flow direction indication (I)

or signal loss indication (I)

Fig.D.5 : Positive flow (I) Fig. D.6 : Negative flow and output (I)

61

be 0 mA at - 100% flow (fig. D.6)

Signal lost

Signal received

Page 65

3.3.2 [I 0 PCT] : Program current output

at 0 %flow

Range: 00 mA ≤ [I 0 PCT] ≤ 16 mA

NOTE: This value must be lower than the [I 100 PCT] value !!

If this is not the case, a PARAMERROR message will appear

during the parameter check procedure.

3.3.3 [I 100 PCT] : Program current output

at100% flow.

Range: 04 mA ≤ [I 100 PCT] ≤ 20 mA

[I 100 PCT] must exceed [I 0 PCT] by at least 4 mA; if this is

not the case, a PARAMERROR message appears during the

parameter check (see section D.4).

3.3.4 [I MAX] : Program maximum out

put current

The maximum output level can be limited to protect accessory equipment.

Range: 04 mA ≤ I MAX ≤ 22 mA

[I MAX] must be equal to or greater than [I 100 PCT]; if this is

not the case, a PARAMERROR message appears during the

parameter check (see section D.4).

3.3.5 T - CONST.I : Time constant of cur-

rent output

To flatten out sudden fluctuations in the current output signal

a first order filter is included.

Program the time constant for the current output:

Range: 4.0000 E-2 ≤ T - CONST. ≤ 3.6000 E 3

Recommended initial value : 2 to 5 sec.

ATTENTION: Time constant also affects readings on

LC-display.

62

ALTOSONIC

Programming mode

UFM 600 T

Page 66

3.4.0 FREQ. OUTP. F : set up frequency /

pulse output

3.4.1 FUNCTION F : Program the analog fre-

quency output

Select an output option using the key and press

to store:

2 DIR : Enables flow measurement in 2 direc-

tions (fig. D.7).

TRAN. TIME : Output signal is proportional to the

measured transit time of the acoustic

signal.

NOTE: This function requires:

- PULSRATE setting, Fct. 3.4.2

- PULSRATE at full flow, Fct. 3.4.3

- Transit time at full flow, Fct. 3.1.2

(see example in description of Fct. 3.1.2)

NO SIGNAL : Output signal indicates "signal loss".

OFF : No frequency output.

F/R IND. F : Output signal as flow direction indica-

tion, 0% at + flow direction and

100% at - flow direction (Fig. D.8).

1 DIR : Flow measurement in 1 direction (+)

only (Fig. D.9).

Fig. D.7 : Bi-directional flow(F) Fig. D.8: Flow direction indication(F)

63

signal received

signal lost

only (Fig. D.9).

Page 67

Fig.D.9: Positive flow (F)

3.4.2 PULSOUTP. : Frequency output mode

Select one of the two frequency output modes using the

key and press to store:

PULSE/UNIT : Pulses per unit of volu-

me.

PULSRATE : Pulses per unit of time

at full scale flow.

Example of PULSE/UNIT :

Pulse value : 10 pulses per m3 (set

via Fct.3.4.3)

After 60 m3 have passed : Output: 600 pulses

since start.

Example PULSRATE :

Full scale setting : 1000 liters per second

(set via Start Up Menu)

Pulse rate full scale flow : 1000 pulses per second

(set via Fct. 3.4.3)

At 600 liters per second : Output: 600 Hz signal.

64

ALTOSONIC

Programming mode

UFM 600 T

Page 68

or signal lost indication (F)

3.4.3 PULS/UNIT - PULSRATE

(pulse/unit or pulse rate depends on selection in 3.4.2)

PULSE/UNIT : Program number of pul-

ses per unit of volume:

Pulse per volumetric unit: Range (maximum):

PulS/m3 9.9990 E 8

PulS/Liter 9.9990 E 5

PulS/US G 3.7850 E 6

PULSRATE : Program pulses per unit

of time at full scale flow:

Pulse rate unit: Range:

Min. Max.

PulSe/Sec 2.7778 E-3 1.0000 E 4

PulSe/min 1.6667 E-1 6.0000 E 5

PulSe/hr 1.0000 E 1 3.6000 E 7

3.4.4 T - CONST. F : Time constant of fre-

quency output

(see 3.3.5 T- CONST.I)

Program one of the two options for the time constant of the

frequency output:

T<F> = T<I> : Equal to the time con-

stant of the current output (see 3.3.5).

T<F> = 40 msec

65

Page 69

3.5.0 SPEC. FCT. : set special functions

3.5.1 LANGUAGE : Display language

Select a language option using the key and press

to store:

GB/USA : English

D : German

F : French

NL : Dutch

3.5.2 OUTP. HOLD : Hold outputs during

programming

If the flowmeter is not in the measuring mode no flow data is

available and all output levels will normally drop to zero.

With this function active all outputs maintain their last value

before the measuring mode was exited.

This feature should be utilized at the user's discretion.

Caution should be observed, if the signal is used in a control

loop since the controller may have to be switched to "manual". In all cases, responsible personnel should be notified that

the output is on "hold".

Select YES or NO using the key and press to

store.

3.5.3 UNIT TEXT

With this function the name of the user defined unit can be

programmed, e.g. Barrels/day.

The format of the unit is preprogrammed: -------/-----.

With both and keys the text (capital and numbers)

can be programmed. Use to store.

66

ALTOSONIC

Programming mode

UFM 600 T

Page 70

3.5.4 FACT. QUANT.

If a user defined unit is applied the quantity factor has to be

programmed.

This must be the conversion ratio into m3.

In the example with Barrels/Day (see 3.5.3) the quantity unit

Barrel has to be converted into m3 (1 Barrel = 1.5898 E-1

m3).

3.5.5 FACT. TIME

If a user defined unit is applied the time factor has to be programmed.

This must be the conversion ratio into seconds.

In the example with Barrels/Day (see 3.5.3) the time unit Day

has to be converted into seconds (1 Day = 8.6400 E 4 seconds).

3.5.6 SET DATE

Program the correct date in this function.

The actual date is included in the header of each data block

that is stored.

On entering this function the date can be programmed in

(mm-dd-yy) notation.

Programming the actual date is similar to that of numbers.

3.5.7 SET TIME

Program the correct time in this function.

The actual time is included in the header of each data block

that is stored.

Programming is similar to numbers.

67

Page 71

3.5.8 DEFAULT SET

If this function is used all parameters will be reprogrammed

to default settings (see Appendix 5).

(NOTE: factory settings are not affected by this function)

NOTE: The Date, Time and Location data will be lost, too !!

This function should only be used to restart programming if

the cause of a PARAMERROR can not be found; it offers a

start with no error messages as far as the parameters are

concerned.

3.5.9 SOFTW. V. NR.

This function can be entered to view the number of the current software version.

No action can be taken here.

68

ALTOSONIC

Programming mode

UFM 600 T

Page 72

3.6.0 COMM. DATA : set RS 232 output /

store

3.6.1 OUTP. PARAM.

With this function all programmed parameters can be sent to

a PC via the RS 232 output.

NOTE: No error message is given if a communication error (no

RS 232 response) occurs!

Select YES and press to start the output.

3.6.2 OUTP. DATA

With this function all collected data stored in the RAM can be

sent to a PC via the RS 232 output.

NOTE: No error message is given if a communication error (no

RS 232 response) occurs!

Select YES and press to start the output.

3.6.3 SEL. COMM.

With this function the output medium can be selected to

which the data is sent as programmed in 3.2.0 and 3.6.4.;

the intervals are programmed in 3.6.4.

The options are:

OFF : No output at all (only on LCD).

BOTH : Data is stored in the RAM as well as

sent to the RS 232 output.

OUTPUT : Data is send to the RS 232 output

only.

STORE : Data is stored in the RAM only.

For settings of the PC terminal program see: C 4.3.

69

Page 73

3.6.4 INTERVAL (not visible if SEL. COMM is OFF)

Program the interval between successive data collections as

programmed in 3.6.3.

Range: 01 - 60 min

3.6.5 LOCATION : Location

If this function is activated the location, as programmed in the

Start Up Menu, is recorded in the header of each data block

that is stored or sent to RS 232.

Select YES or NO using the key and press to store.

3.6.6 RESET DATA

If STORE is programmed in function 3.6.3 all data blocks are

stored in the internal RAM.

With this function the RAM can be cleared, to be able to store

new data (up to 390 blocks).

NOTE: the parameter settings are not affected by this function.

Select YES or NO using the key and press to store.

70

ALTOSONIC

Programming mode

UFM 600 T

Page 74

71

Page 75

D.5 Sub Menu : 2.0.0 TEST

2.1.0 DISPLAY

2.1.1 DISPLAY TEST

All individual segments of the liquid crystal display are

activated in a sequence ending in a flashing display of all

segments.

No action can be taken.

Select YES and press to start the test.

2.2.0 PROCESSOR

The microprocessor performs a self test.

No action can be taken.

Select YES and press to start the test.

If the test does not end with the message NO ERROR

contact your dealer.

Press to exit the function.

2.3.0 CURR. OUTP. I

2.3.1 TEST

To check the functioning of both the analog output and the

externally connected instruments and wiring, the analog output can be set to 7 specific values:

0, 4, 8, 12, 16, 20 and 22 mA

The value shown on the display should match the indication

on the instrument connected to the current output.

Press to start the test and use the

key to select output current.

Press to exit the function.

72

ALTOSONIC

Programming mode

UFM 600 T

Page 76

2.4.0 FREQ. OUTPUT

2.4.1 TEST

To check the functioning of both the frequency output and

the externally connected instruments and wiring, the frequency output can be set to 5 specific values:

1, 10, 100, 1000 and 10000 Hz

The value shown on the display should match the indication

on the instrument connected to the frequency output.

Press to start the test and use the

key to select output frequency.

Press to exit the function.

73

Page 77

D.6 Parameter errors

If discrepancies in the parameters entered are found the

microprocessor will display the message "PARAMERROR"

thus preventing you from storing parameters that are incorrect.

The PARAMERROR menu can appear at the end of both the

Start Up menu and the Installation Menu.

A third main menu is available now:

Fct. 4.0.0 PARAM.ERROR

In this menu only one submenu is available at a time; only the

submenu that applies to the discrepancy to be corrected will

be displayed.

List of possible submenus and functions within PARAMERROR:

4.0.0 PARAMERROR Discrepancy:

4.1.0 V RANGE The combination of the diameter, wall and lining thickness and the full

scale flow rate is not feasible.

4.1.1 DIAMETER

4.1.2 PIPEWALL

4.1.3 LINING TH.

4.1.4 FULL SCALE

4.2.0 I RANGE [I 100 PCT] does not exceed

[I 0 PCT] by at least 4 mA

4.2.1 I 0 PCT

4.2.2 I 100 PCT

4.3.0 I MAX mA [I MAX] is not equal to or greater

than [I 100 PCT]

4.3.1 I 100 PCT

4.3.2 I MAX

4.4.0 CUTOFF CUTOFF ON exceeds CUTOFF OFF

74

ALTOSONIC

Programming mode

UFM 600 T

Page 78

4.4.1 L.F. CUTOFF

4.4.2 CUTOFF ON

4.4.3 CUTOFF OFF

4.5.0 F>10KHZ Output frequency is too high,

must be less than 10kHz

4.5.1 FULL SCALE

4.5.2 PULSOUTP.

4.5.3 PULSRATE

4.5.4 PULS/UNIT

4.6.0 APPL.DATA Programmed sonic velocities are not

within the specified range

4.6.1 PIPE MAT.

4.6.2 LIQUID

4.6.3 LINING MAT.

4.7.0 FREQ.OUTPUT The combination of F-Function and

Pulsoutput is not feasible

4.7.1 FUNCTION F

4.7.2 PULSOUTP.

Activate the submenus and functions as described in section

D.2.

After the correct parameter values have been entered the

PARAMERROR menu can be exited by pressing the key

7 times; the parameters are checked and saved and the program stops at the beginning of the Start Up menu.

NOTE: Instead of activating the PARAMERROR menu the

INSTALLATION or TEST menus can be entered by using the

key.

75

Page 79

E.1 Mains Fuse

The mains fuse is located in the connection compartment.

NOTE: ONLY USE FUSES AS INDICATED NEXT TO THE FUSE

FITTING TO PREVENT SERIOUS DAMAGE TO THE

ELECTRONIC EQUIPMENT (see Spare Parts).

If the fuse is blown regularly, contact your dealer.

76

ALTOSONIC

Maintenance

UFM 600 T

Page 80

77

Page 81

F.1 General

Measuring beam 1

Diameter range 50 ... ≥ 3000 mm (2” ... ≥120”)

Pipe wall thickness ≤ 40 mm ( ≤ 1.6”)

Pipe wall materials metal, plastics, ceramics,

asbestos-cement with or without

firmly attached linings or coatings

Fluids any clean homogeneous liquid

with a gaseous or solid particle

content ≤1% by volume

Fluid temp. -25 to +120 °C (-13 to 248 °F)

Error limits 1 to 3%, depending on application

Reproducibility up to 0.2%

Time constant 0.04 to 3600 s

Outputs current, frequency/pulse and RS

232 for data transfer to PC

Display for indication of all measuring data,

calculated transducer distance,

error messages and transit time

Measured values volumetric flow rate, total flow,

transit time and flow direction (for-

ward/reverse)

Cable length:

Standard 5 m (15 ft)

Optional > 5 m...≤ 300 m( >15 ft...≤ 900 ft)

78

ALTOSONIC

Technical Data

UFM 600 T

Page 82

F.2 Transducers & Clamp-on Set

Transducers single beam; 2x RS 600

Diameters A single clamp-on set suitable for

50 mm (2”) to 2000 mm (80”)

pipes, incorporating 2 rails with

cm-scale and straps

Materials:

Transducer housing nickel plated brass with plastic

contact surface.

Rails aluminium, anodized

Protection category IP 65 (transducers with BNC connec-(standard): tors) acc. DIN 40050 / IEC 144

(option): IP 68 (cables fix connected to the

transducers)

Ambient temp. -25 to 60 °C

Process liquid temp. -25 to 120 °C

NOTE: High temperature sensor cable optional available.

79

Page 83

F.3 Signal Converter

Version UFC 600 T

Outputs fully programmable

galvanically insulated

- analog 0 to 20 mA, or 4 to 20 mA, or

I[0%] to I[100%] programmable.

load ≤ 100 Ohm

- frequency/pulse

pulse rate 0.0028 Hz.(= 10 pulses/hour) to

10000 Hz. or pulses per liter, m3,

US gallon, or per user defined unit

Low flow cut off programmable

in : 1 to 19%

out: 2 to 20%

80

ALTOSONIC

Technical Data

UFM 600 T

Page 84

Local display: back-lit LCD

Display functions actual flow rate, forward-, reverse-

and sum-totalizers (7 digit), transition time and error messages;

each programmable for continuous or sequential display

Display units

actual flow liters, m3, or US gallons per sec-

ond, minute or hour and one free

programmable unit

totalizers liters, m3, or US gallons and one

freely

programmable unit; min. one year

overflow time

Display language English, French, German, Dutch;

other languages on request

Display arrangement 8 digit , 7 element numerical and

sign display,

1st line symbols for push-button acknow-

ledgement

2nd line 10 character 14 segment text dis-

play.

3rd line 4 markers to identify the actual

display function

functions location, actual flow rate (and

direction), totalizer, time, transittime and error messages

81

Page 85

Power supply

AC power supply: 85 - 264 VAC

DC power supply: 18 - 32 VDC

Power consumption ≤ 10 VA AC

≤ 8 W DC

Housing Cast aluminium

82

ALTOSONIC

Technical Data

UFM 600 T

Page 86

Ambient temp. -25 to +50 °C (-13 to 122°F)

Protection

category IP 65, acc. to IEC 529

(equivalent to NEMA 4x)

Full scale value (Din= inner pipe diameter)

lower limit (V

100% min

. = 0.5 m/s)

Q

100%min

[m3/h] = ( Din [mm]/100 )

2

*

14.2

Q

100%min

[m3/h] = ( Din [inch] )

2

*

0.9

Q

100%min

[USGPM] = ( Din [inch])

2

*

3.9

upper limit

(V

100%max

= 17.1 m/s)

Q

100%max

[m3/h] = (Din [mm] )

2

*

0.05

Q

100%max

[m3/h] = (Din [inch] )

2

*

31.25

Q

100%max

[USGPM] = (Din [inch] )

2

*

138

Reynolds

number Re > 10.000

Repeatability 0.2

R = [%]

V

m*Di

R = repeatability in %

V

m

= flow velocity [m/s]

D

i

= inner pipe diameter [m]

83

Page 87

APPENDIX 1 : Pipe Material Sonic Velocities

ALTOSONIC

Appendix

84

MATERIAL NAME SONIC VELOCITY

Carbon Steel c ≤ 0.3% 3064 m/s

Carbon Steel c > 0.3% 3173 m/s

Carbon-Moly Steel 3173 m/s

Cr-Mo-Steel Cr ≤ 3% 3173 m/s

Cr-Mo-Steel 5% ≤ Cr ≤ 9% 3040 m/s

Chromium Steel (stainless) 3177 m/s

Austenitic St. Steel (general) 3120 m/s

St. Steel 304 3120 m/s

St. Steel 310 3120 m/s

St. Steel 316 3120 m/s

St. Steel 321 3120 m/s

St. Steel 347 3120 m/s

Grey Cast Iron 2125 m/s

Monel 67 Ni- 30 Cu 2810 m/s

Monel 66 Ni- 29 Cu- Al 2823 m/s

Alloy 706 (90 Cu - 10 Ni) 2334 m/s