KROHNE UFM 530 HT Specifications

Technical Datasheet

Technical Datasheet

UFM 530 HT

UFM 530 HT

UFM 530 HTUFM 530 HT

• Accurate, repeatable and long-lasting performance

• Efficient bundle waveguide technology

• Flow measurement even under harsh process conditions

Technical DatasheetTechnical Datasheet

© KROHNE 02/2010 - 4000210602 - TD UFM 530 HT R02 en

CONTENTS

UFM 530 HT

1 Product features 3

1.1 Robust solution for high temperature liquids ................................................................. 3

1.2 Measuring principle.......................................................................................................... 5

2 Technical data 6

2.1 Technical data................................................................................................................... 6

2.2 Dimensions and weight .................................................................................................. 10

2.2.1 Flow sensors......................................................................................................................... 10

2.2.2 UFC 030 signal converter...................................................................................................... 12

3 Installation 13

3.1 Intended use ................................................................................................................... 13

3.2 Mounting......................................................................................................................... 13

3.2.1 Mounting position of the flow sensor ................................................................................... 13

3.2.2 Mounting location of the flow sensor ................................................................................... 13

3.2.3 Insulation............................................................................................................................... 16

3.2.4 Pipe flanges........................................................................................................................... 16

3.2.5 Pipes with cathodic protection ............................................................................................. 17

4 Electrical connections 18

4.1 Power supply of the converter ....................................................................................... 18

4.2 Connection of signal cables ........................................................................................... 20

4.3 Electrical connections of the signal inputs and outputs ............................................... 21

4.3.1 Non Ex versions .................................................................................................................... 21

4.3.2 Ex versions ............................................................................................................................ 24

2

www.krohne.com 02/2010 - 4000210602 - TD UFM 530 HT R02 en

UFM 530 HT

1.1 Robust solution for high temperature liquids

UFM 530 HT

UFM 530 HT is a dual beam ultrasonic flow meter for crudes and a broad range of refined

UFM 530 HTUFM 530 HT

products, that are processed under extreme conditions (high temperature / high pressure).

Also for accurate flow measurement of synthetic heat transfer oil at extreme high temperatures

(500 °C) and rapidly changing temperatures, the UFM 530 HT offers a unique solution. The UFM

530 HT with its robust industrial construction performs with minimum operational – and

maintenance costs, due to a solid fully welded construction without any moving parts and hence

no wear.

UFM 530 HT

UFM 530 HT is a combination of a UFS 500 HT flow sensor and a UFC 030 signal converter. The

UFM 530 HTUFM 530 HT

UFC 030 signal converter is installed separately from the high temperature UFS 500 HT flow

sensor.

PRODUCT FEATURES 1

www.krohne.com02/2010 - 4000210602 - TD UFM 530 HT R02 en

3

1 PRODUCT FEATURES

Highlights

Highlights

HighlightsHighlights

• Major measurement even at temperatuers up to 500 °C

• Excellent long term stability and reliability

• No moving or intruding parts

• Robust construction, resistant to corrosive and abrasive products

• Dual parallel paths for Reynolds independency

• Wide selection of materials, sizes and pressure classes

Industries

Industries

IndustriesIndustries

Petrochemical - refineries:

• Vacuum distillation unit (VDU)

• Topping unit (atmospheric installations)

• Visbreaking unit

• Coker unit

Renewable energy - concentrated solar power (CSP):

• Solar field heat transfer circuit

• Thermal salt tanks

• Power block

UFM 530 HT

Applications

Applications

ApplicationsApplications

• Furnace flow measurement

• Recycled product

• Reduced crude

• Vacuum residues

• Long residues

• Heavy bottom products

• Synthetic heat transfer fluids (HTF)

• Molten salt

4

www.krohne.com 02/2010 - 4000210602 - TD UFM 530 HT R02 en

UFM 530 HT

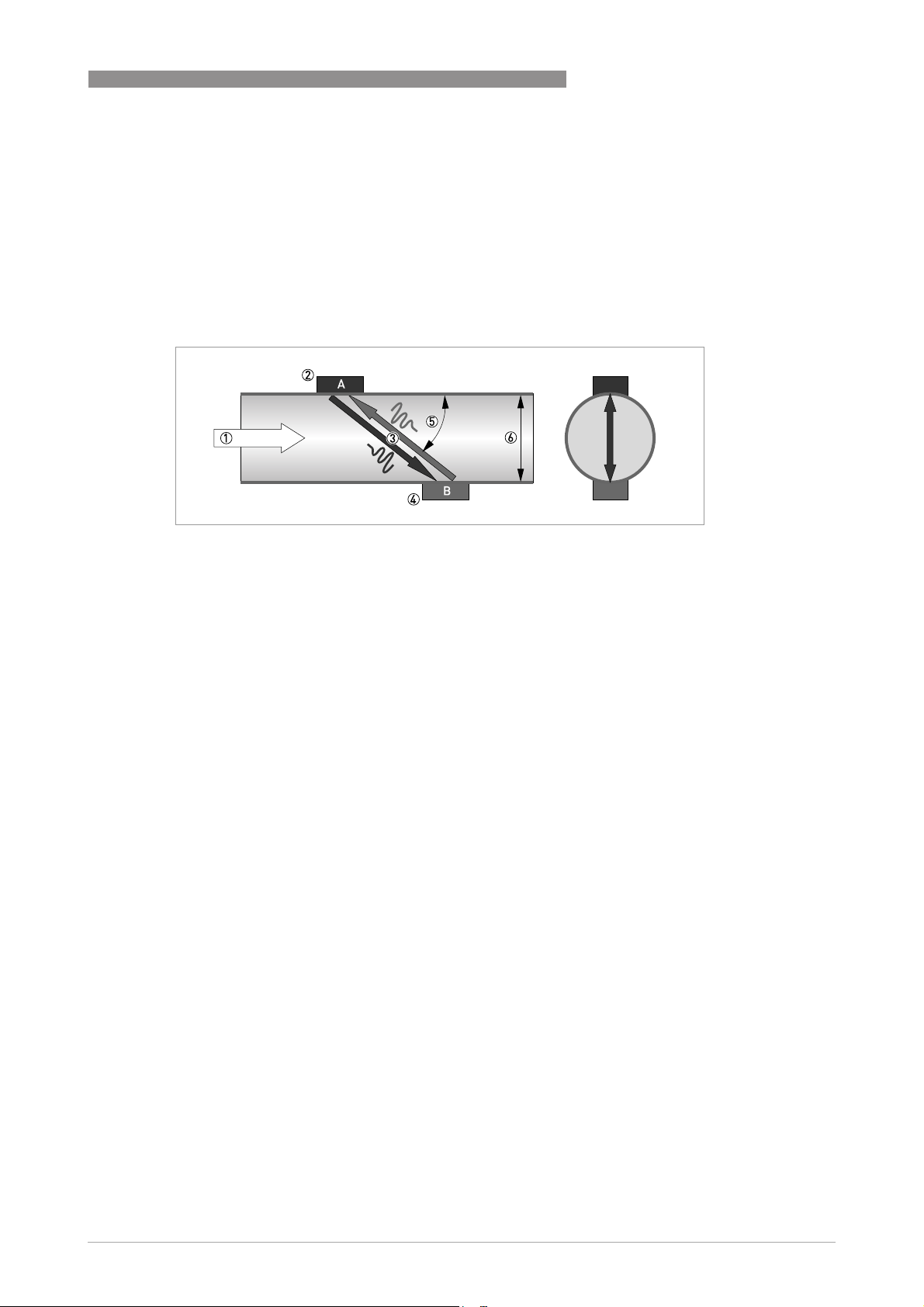

1.2 Measuring principle

• Like canoes crossing a river, acoustic signals are transmitted and received along a diagonal

measuring path.

• A sound wave going downstream with the flow travels faster than a sound wave going

upstream against the flow.

• The difference in transit time is directly proportional to the mean flow velocity of the medium.

PRODUCT FEATURES 1

Figure 1-1: Measuring principle

1 Flow velocity

2 Transducer A

3 Acoustic path

4 Transducer B

5 Angle (between flow vector and acoustic path vector)

6 Diameter

www.krohne.com02/2010 - 4000210602 - TD UFM 530 HT R02 en

5

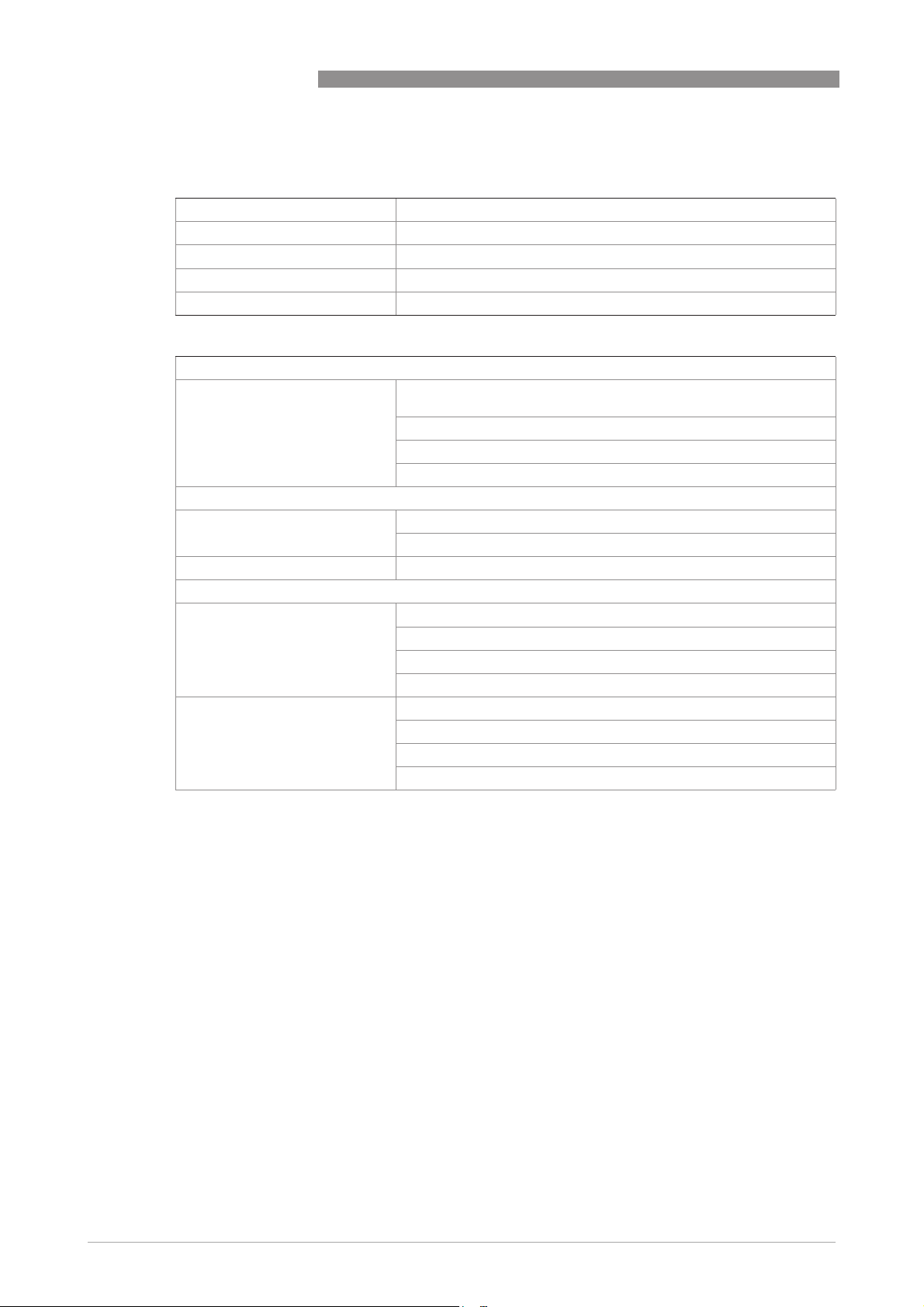

2 TECHNICAL DATA

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local representative.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

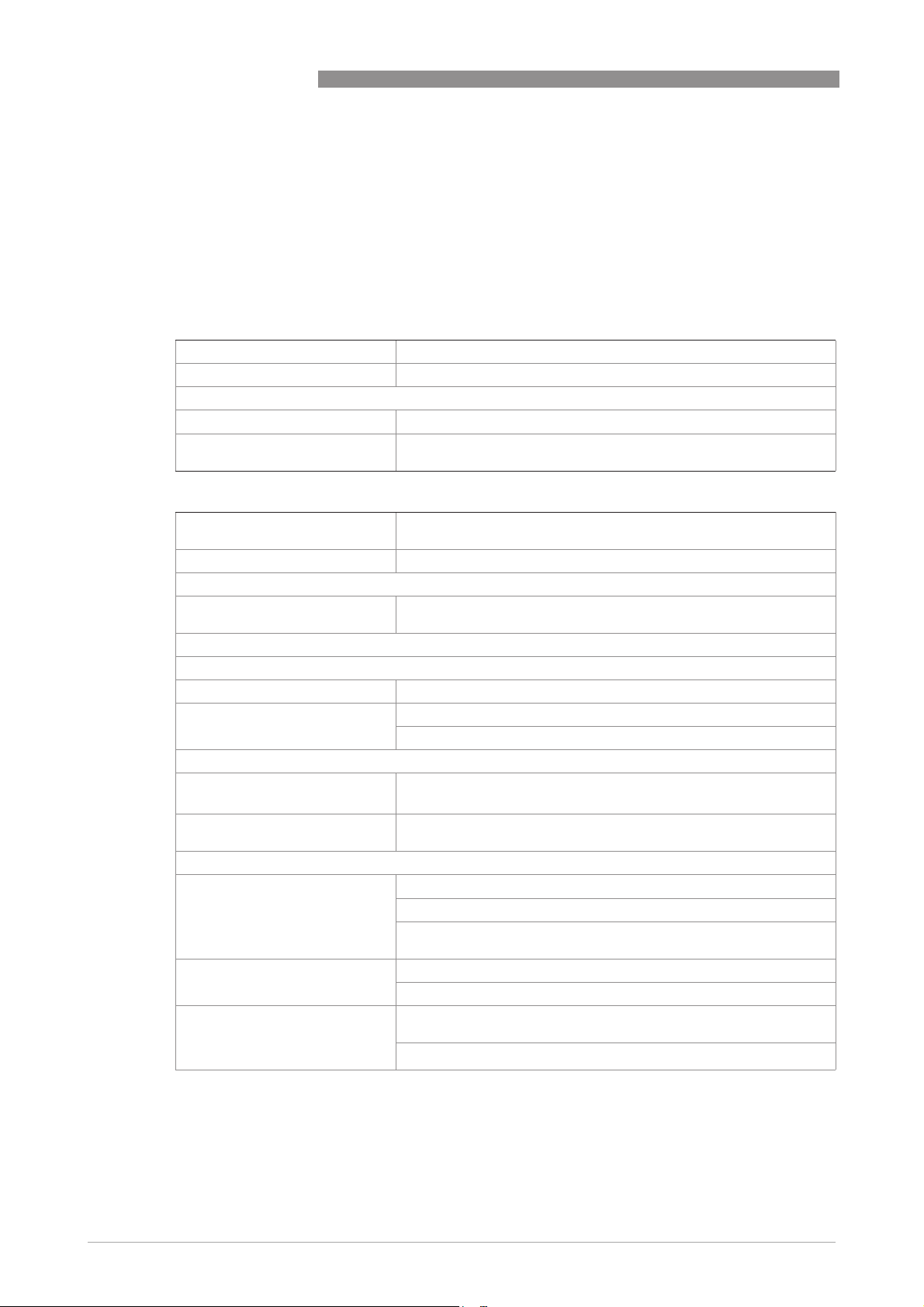

Measuring system

Measuring principle Ultrasonic transit time.

Application range (Non) conductive fluids.

Measured value

Measured value

Measured valueMeasured value

Primary measured value Transit time.

Secondary measured value Volume flow rate, totalised volume, velocity of sound (VoS), signal

Design

Measuring range 0.5...20 m/s / 1.7...66 ft/s

Signal converter

Signal converter

Signal converterSignal converter

Wall-mounted housing (W) remote version

Measuring sensor

Measuring sensor

Measuring sensorMeasuring sensor

UFS 500 HT is available in the following pipe diameters and building constructions:

DN25...80 / 0.98...3/15" Single beam construction.

DN100...300 / 3.94...11.81" Dual beam construction.

Options

Options

OptionsOptions

Inputs / outputs

Counters 2 internal counters with a max. of 8 counter places (e.g. for counting

Display and user interface

Display and user interface

Display and user interfaceDisplay and user interface

Graphic display 3-Line local display with backlight

Operator input elements 3 keys for operator control of the signal converter

Remote control All DTM's and drivers are available at the internet homepage of the

UFM 530 HT

strength, flow direction.

The measurement system consists of a measuring sensor and a

signal converter. It is only available as separate version.

UFC 030 F

Larger diameters on request.

Current (incl. HART®), pulse, frequency and/or status output, limit

switch and/or control input (depending on the I/O version)

volume and/or mass units)

Display turnable in 90° steps

The readability of the display could be reduced at ambient

temperatures below -25°C / -13°F

Magnetic pin for operator control of the signal converter (optional)

manufacturer

PACTware® including Device Type Manager (DTM)

6

www.krohne.com 02/2010 - 4000210602 - TD UFM 530 HT R02 en

UFM 530 HT

TECHNICAL DATA 2

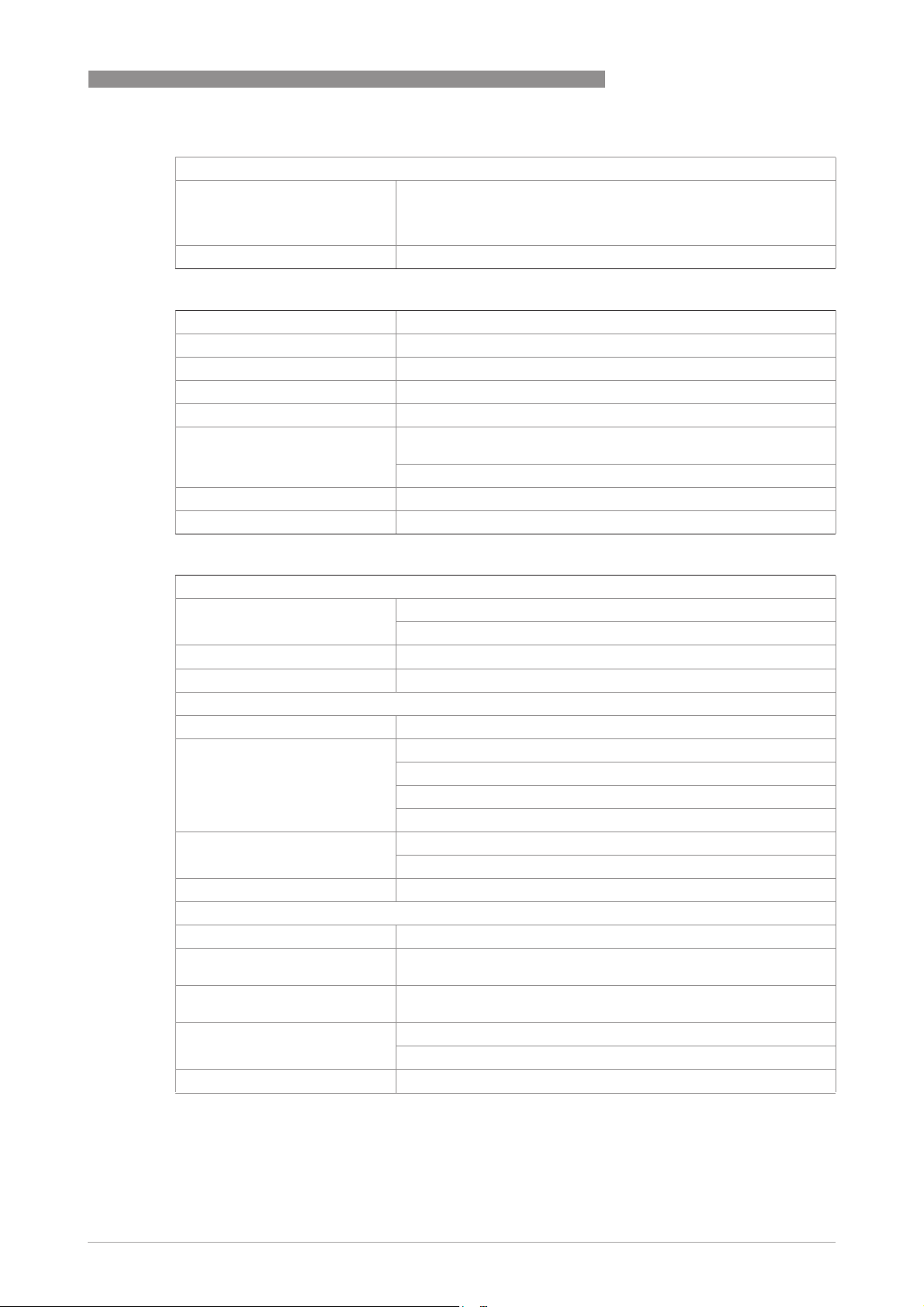

Display functions

Display functions

Display functionsDisplay functions

Menu Display of volume flow, mass flow, flow speed, velocity of sound, gain,

Language of display texts English, French, German

Measuring accuracy

Reference conditions

Reference conditions

Reference conditionsReference conditions

Medium Water

Temperature 20°C

Pressure 1 bar

Inlet section in DN 10 DN

Maximum measuring error

Maximum measuring error ±1% of the measured value for Re > 5000 and v = 1...20 m/s

Maximum measuring errorMaximum measuring error

Repeatability

Repeatability ±0.3%

RepeatabilityRepeatability

Calibration

Calibration 2-point, water, under reference conditions.

CalibrationCalibration

signal to noise ratio, diagnosis value, forward, reverse and

counters,warning and diagnosis information, setting parameters via

operating menu

(3.28...65.62 ft/s), temperature influence: 0.1% / 10 K.

±1cm/sat v<1m/s(±0,39"(satv<3,28ft/s)

Operating conditions

Temperature

Temperature

TemperatureTemperature

Process Standard versions: -25...+500°C / -13...+932°F

Ex versions: -25...+440°C / -13...+824°F

Ambient (signal converter) -40...+65°C / -40...+149°F

Storage (signal converter) -40...+70°C / -40...+158°F

Pressure

Pressure

PressurePressure

Ambient Atmospheric

EN 1092-1 DN25...80: PN40

DN100...150: PN16

DN200...300: PN10

Higher pressure ratings on request.

ASME B16.5 1...12": 150 lbs

Higher pressure ratings on request.

JIS 10K

Medium properties

Medium properties

Medium propertiesMedium properties

Physical condition Liquids.

Permissible gas content (by

volume)

Permissible solid particle

content (by volume)

Viscosity <100 cSt

Recommended flow velocity 0.5...20 m/s / 1.7...66 ft/s

<2%

<5%

Higher viscosities on request

www.krohne.com02/2010 - 4000210602 - TD UFM 530 HT R02 en

7

2 TECHNICAL DATA

Installation conditions

Minimum inlet run DN25...80 / ASME 0.98...3.15": 50 DN

Minimum outlet run DN25...80 / ASME 0.98...3.15": 10 DN

Dimensions and weights See chapter "Dimensions and weights".

Materials

Sensor

Sensor

SensorSensor

Sensor material Measuring tube (DN25...300 / 0,98...11,81"): Stainless steel

Process connections

Process connections

Process connectionsProcess connections

Flange DN25...300 / 0,98...11,81": stainless steel 1.4404 (AISI 316L).

Finish (measuring tube) No paint.

Converter

Converter

ConverterConverter

Housing material Standard

Finish Standard

UFM 530 HT

DN100...300 / ASME 3.94...11.81": 15 DN

DN100...300 / ASME 3.94...11.81": 5 DN

1.4404 (AISI 316L).

Bundle wave guides: Stainless steel 1.4404 (AISI 316L).

Connection box: Die-cast aluminium (polyurethane coating).

Others materials on request

Others materials on request

Standard

StandardStandard

Die-cast aluminum (polyurethane coated).

Option

Option

OptionOption

Stainless steel 1.4404 (AISI 316L).

Standard

StandardStandard

Silver paint.

Optional

Optional

OptionalOptional

Offshore paint system, silver.

8

www.krohne.com 02/2010 - 4000210602 - TD UFM 530 HT R02 en

UFM 530 HT

TECHNICAL DATA 2

Electrical connections

Description of used abbreviations

Description of used abbreviations Q= XXX

Description of used abbreviationsDescription of used abbreviations

Galvanic insulation

Galvanic insulation All inputs/outputs are standard isolated from the power supply.

Galvanic insulationGalvanic insulation

Power supply

Power supply

Power supplyPower supply

Voltage 100...240 VAC (+10% / -15%), 48...63 Hz.

Power consumption AC: 10 VA

Cable entries (to power supply

and sensor)

Cable length Standard

Current output

Current output

Current outputCurrent output

Function/output data Measurement of volume flow rate, velocity of sound, signal strength,

Settings

Operating data/Connection Active mode: U

Pulse output

Pulse output

Pulse outputPulse output

Function/output data Measurement of volume flow rate, actual volume, velocity of sound,

Settings Calculated mass flow rate.

Operating data/Connection Active mode: U

Analog inputs

Analog inputs

Analog inputsAnalog inputs

Function/output data Inputs for calculated (or user defined) mass flow rate.

Settings For both inputs (A1 and A2): 4...20 mA.

Operating data/Connection Active mode: I

Digital input

Digital input

Digital inputDigital input

Function/output data Reset totalised volume, reset errors, force outputs to zero.

Settings On/off

Operating data/Connection Active mode: U

XXX; I

XXXXXX

= external voltage; U

U

ext

= maximal current; Uin= XXX

max

= maximal internal voltage.

int, max

XXX; U

XXXXXX

= internal voltage;

int

24 VAC (20...27 V), 24 VDC (18...32 V).

DC: 8 W

Standard

Standard

StandardStandard

M20 x 1.5

Optional

Optional

OptionalOptional

½" NPT or PF ½

Standard

StandardStandard

5 m / 16.40 ft

Optional

Optional

OptionalOptional

10...30 m / 32.81...98.43 ft

flow direction.

Q = 0%: 0...16 mA (HART versions: 4...16mA, in steps of 1 mA, limit

20...22 mA).

Q = 100%: 4...20 mA.

= 24 VDC, maximal load: 680 Ω.

int

Passive mode: U

≤ 24 VDC, maximal load: 680 Ω.

ext

signal strength, flow direction.

Pulse or frequency: 0...2000 Hz, status: on/off.

Passive mode: U

max

Passive mode: I

Passive mode: U

= 24 VDC, I

int

= 19...32 VDC, I

ext

= 22 mA, maximal load: 58 Ω.

= 22 mA, maximal load: 58 Ω.

max

≤ 24 VDC.

max

≤ 24 VDC.

max

max

=50mA.

=150mA.

max

www.krohne.com02/2010 - 4000210602 - TD UFM 530 HT R02 en

9

Loading...

Loading...