Page 1

Handbook

Handbook

UFM 530 HT

UFM 530 HT

UFM 530 HTUFM 530 HT

HandbookHandbook

Inline ultrasonic flowmeter for high-temperature liquids

Hardware version: 2134721100-200

Software μP2: 90-05

© KROHNE 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2013 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 3

UFM 530 HT

CONTENTS

1 Safety instructions 5

1.1 Software history ............................................................................................................... 5

1.2 Intended use ..................................................................................................................... 5

1.3 Certifications .................................................................................................................... 5

1.3.1 CE-certification .......................................................................................................................5

1.4 Safety instructions from the manufacturer ..................................................................... 6

1.4.1 Copyright and data protection ................................................................................................ 6

1.4.2 Disclaimer ............................................................................................................................... 6

1.4.3 Product liability and warranty ................................................................................................ 7

1.4.4 Information concerning the documentation........................................................................... 7

1.4.5 Warnings and symbols used................................................................................................... 8

1.5 Safety instructions for the operator................................................................................. 8

2 Device description 9

2.1 Scope of delivery............................................................................................................... 9

2.2 Device description .......................................................................................................... 10

2.3 Nameplates .................................................................................................................... 10

2.4 Example nameplate........................................................................................................ 11

3 Installation 12

3.1 General notes on installation ......................................................................................... 12

3.2 Storage ........................................................................................................................... 12

3.3 Transport ........................................................................................................................ 12

3.4 Inlet and outlet ............................................................................................................... 13

3.5 Mounting......................................................................................................................... 14

3.5.1 Mounting position of the flow sensor ................................................................................... 14

3.5.2 Mounting location of the flow sensor ................................................................................... 14

3.5.3 Insulation............................................................................................................................... 17

3.5.4 Pipe flanges........................................................................................................................... 17

3.5.5 Pipes with cathodic protection ............................................................................................. 18

4 Electrical connections 19

4.1 Safety instructions.......................................................................................................... 19

4.2 Power supply of the converter ....................................................................................... 19

4.3 Connection of signal cables ........................................................................................... 21

4.4 Electrical connections of the signal inputs and outputs ............................................... 22

4.4.1 Non Ex versions .................................................................................................................... 22

4.4.2 Ex versions ............................................................................................................................ 25

4.5 Connection diagram examples ...................................................................................... 29

4.5.1 Current output ...................................................................................................................... 29

4.5.2 Pulse output .......................................................................................................................... 30

4.5.3 Digital input........................................................................................................................... 31

4.5.4 Analog input .......................................................................................................................... 32

5 Start-up 33

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

3

Page 4

CONTENTS

UFM 530 HT

5.1 Start-up procedure.........................................................................................................33

6 Operation 34

6.1 Signal converter: front panel and operating keys ......................................................... 34

6.2 Available versions........................................................................................................... 35

6.3 Signal converter: menu structure.................................................................................. 36

6.4 Important menu functions in detail................................................................................ 49

6.4.1 Error/totalizer (Menu 0.00.00) .............................................................................................. 49

6.4.2 View error messages / reset error messages (menu 0.00.01 and 0.00.02)......................... 51

6.4.3 Full-scale value for 100% volume and flow rate units (menu 3.01.01)................................ 51

6.4.4 Low-flow cut-off, cut-off "on"/"off" value (menu 3.01.05...3.01.07)..................................... 51

6.4.5 Direction of current output (menu 3.04.02).......................................................................... 52

6.4.6 User-defined unit for volume flow rate and totalizer (menu 3.07.05...3.07.07)................... 52

6.4.7 Plausibility filter (menu 3.07.09...3.07.11) ............................................................................ 53

7 Service 54

7.1 Electronics exchange ..................................................................................................... 54

7.1.1 Exchange of the electronics unit .......................................................................................... 54

7.1.2 Replacing the mains fuse ..................................................................................................... 56

7.2 Maintenance ................................................................................................................... 57

7.2.1 Admonitions for replacement of flow sensor in separate systems ..................................... 57

7.3 Cleaning.......................................................................................................................... 57

7.4 Spare parts availability...................................................................................................58

7.5 Availability of services .................................................................................................... 58

7.6 Returning the device to the manufacturer..................................................................... 58

7.6.1 General information.............................................................................................................. 58

7.6.2 Form (for copying) to accompany a returned device............................................................ 59

7.7 Disposal .......................................................................................................................... 59

8 Technical data 60

8.1 Measuring principle........................................................................................................60

8.2 Technical data................................................................................................................. 61

8.3 Dimensions and weight .................................................................................................. 65

8.3.1 Flow sensors......................................................................................................................... 65

8.3.2 UFC 030 signal converter...................................................................................................... 67

9 Notes 68

4

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 5

UFM 530 HT

1.1 Software history

Release date Hardware Software Documentation

1990-05 2134721100-200 μP2: 90-05 MA UFM 530 HT R01

1.2 Intended use

CAUTION!

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

SAFETY INSTRUCTIONS 1

microcontroller: 01.13

DSP: 10.20

This product is designed for the measurement of liquids with high temperatures

up to 500°C / 932°F (Ex hazardous areas are limited to 440°C / 824°F).

1.3 Certifications

1.3.1 CE-certification

The device fulfils the statutory requirements of the following EC directives:

• Electromagnetic compatibility directive (EMC directive 2004/108/EC).

• Low voltage directive (73/23/EEC), product is designed in accordance with EN IEC 61010-1

first and second edition (safety requirements for electrical equipment for measurement,

control and laboratory use part 1).

• Pressure equipment directive (Module H of 97/23/EC, full quality assurance).

• ATEX directive (94/9/EC)

DANGER!

Local safety regulations shall be observed in combination with the measures special to this

product to avoid dangerous situations.

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

5

Page 6

1 SAFETY INSTRUCTIONS

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

UFM 530 HT

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

6

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 7

UFM 530 HT

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

7

Page 8

1 SAFETY INSTRUCTIONS

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

UFM 530 HT

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.5 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

8

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 9

UFM 530 HT

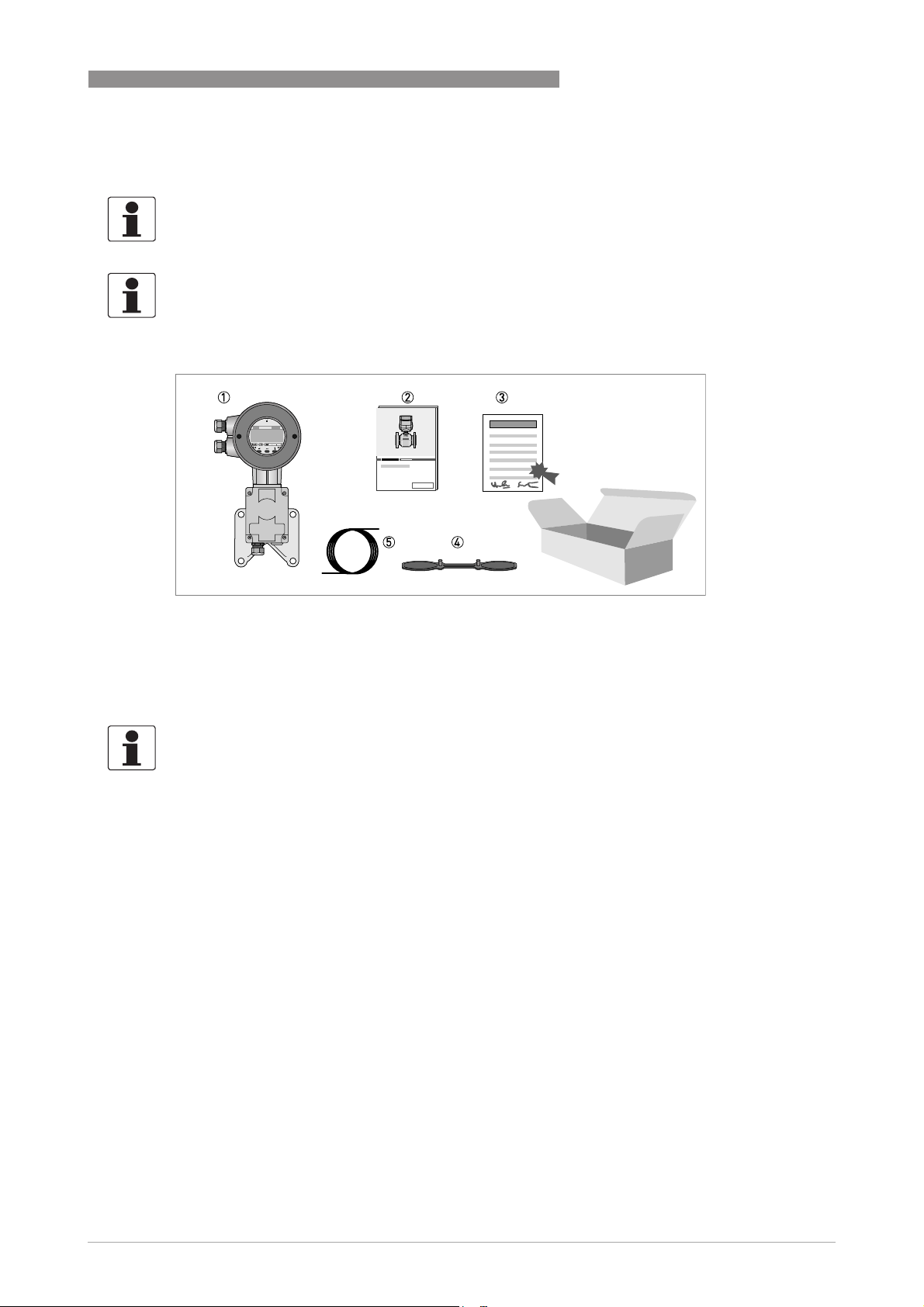

2.1 Scope of delivery

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

DEVICE DESCRIPTION 2

Figure 2-1: Standard scope of delivery, independent from the sensor version illustrated below

1 Signal converter UFC 030 in ordered version

2 Product documentation

3 Factory calibration report

4 Special wrench for opening the converter housing

5 Signal cable

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

9

Page 10

2 DEVICE DESCRIPTION

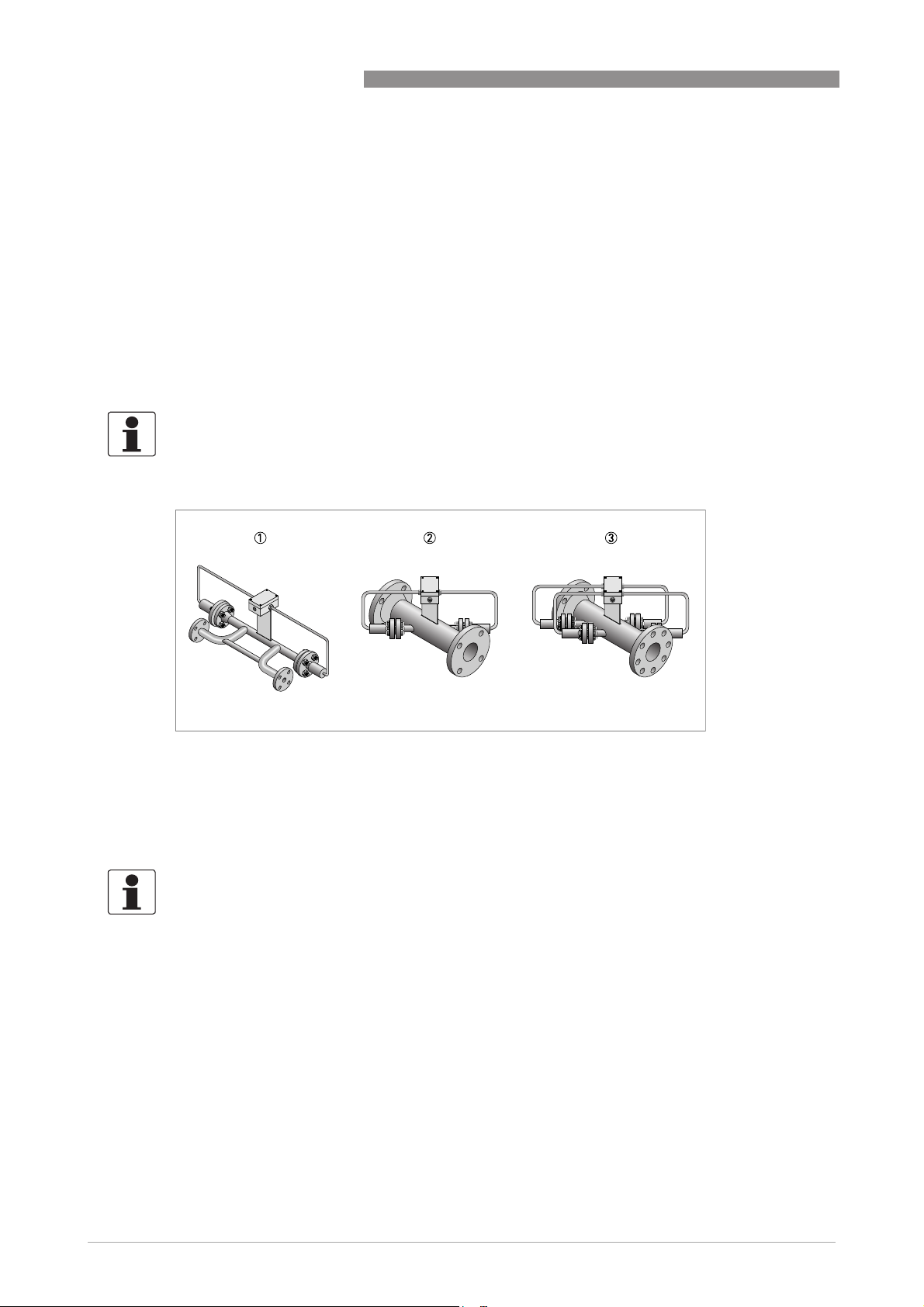

2.2 Device description

The UFM 530 HT is a bi-directional flowmeter (the arrow on the flowmeter indicates the positive

direction). It consists of a UFS 500 HT flow sensor and an UFC 030 signal converter.

The signal converter is installed separately from the high-temperature flow sensor.

The flow sensor is designed for process temperatures between -25...+500°C / -13...+932°F (Ex

hazardous areas are limited to -25...+440°C / -13...+824°F) and is manufactured from

316 stainless steel. Depending on the diameter it uses single beam or dual beam technology. All

coax cables are protected with metal tubes. On top of the flow sensor a connection box is

mounted.

INFORMATION!

Other diameters, pressure classes, materials or customized designs are available on request.

UFM 530 HT

Figure 2-2: Available sensor versions

1 Building construction "single beam" (DN25...40)

2 Building construction "single beam" (DN50...80)

3 Building construction "dual beam" (≥DN100)

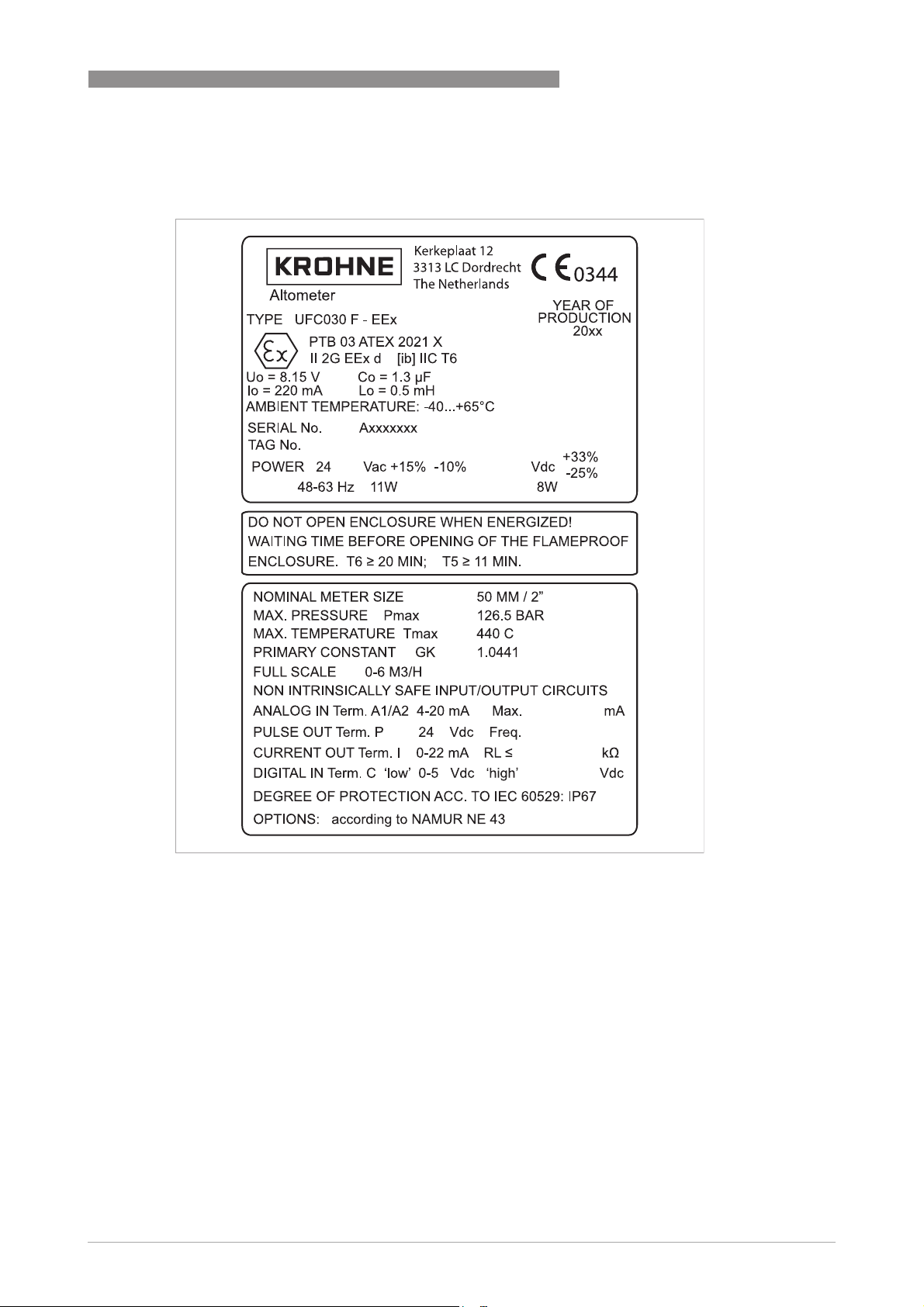

2.3 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

10

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 11

UFM 530 HT

2.4 Example nameplate

DEVICE DESCRIPTION 2

Figure 2-3: Example of nameplate

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

11

Page 12

3 INSTALLATION

3.1 General notes on installation

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

• Store the device in a dry, dust-free location.

• Avoid continuous direct sunlight.

• Store the device in its original packaging.

• Storage temperature: -50...+70°C / -58...+158°F

UFM 530 HT

3.3 Transport

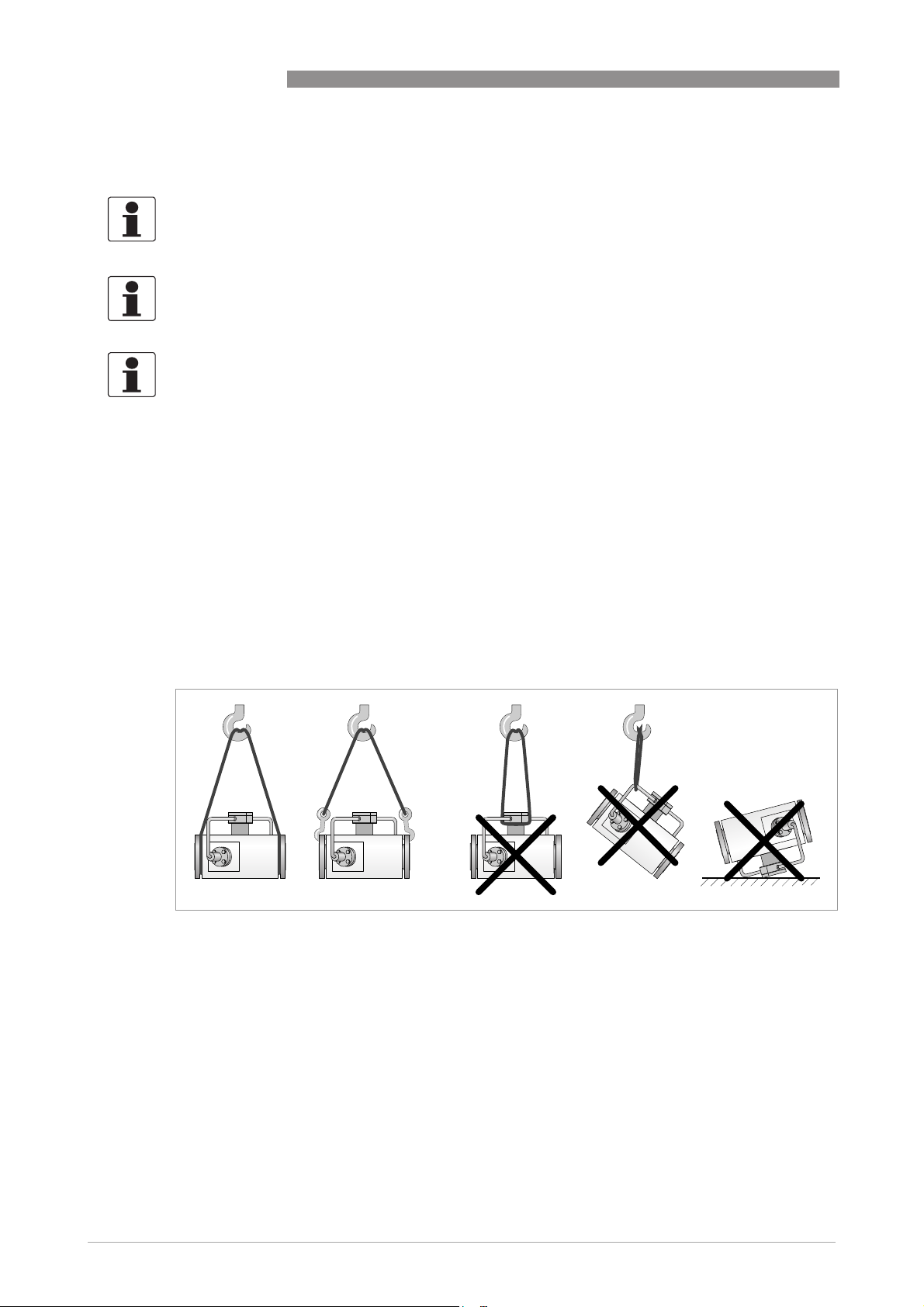

Figure 3-1: Correct lifting with the help of straps or crane hooks.

12

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 13

UFM 530 HT

3.4 Inlet and outlet

INFORMATION!

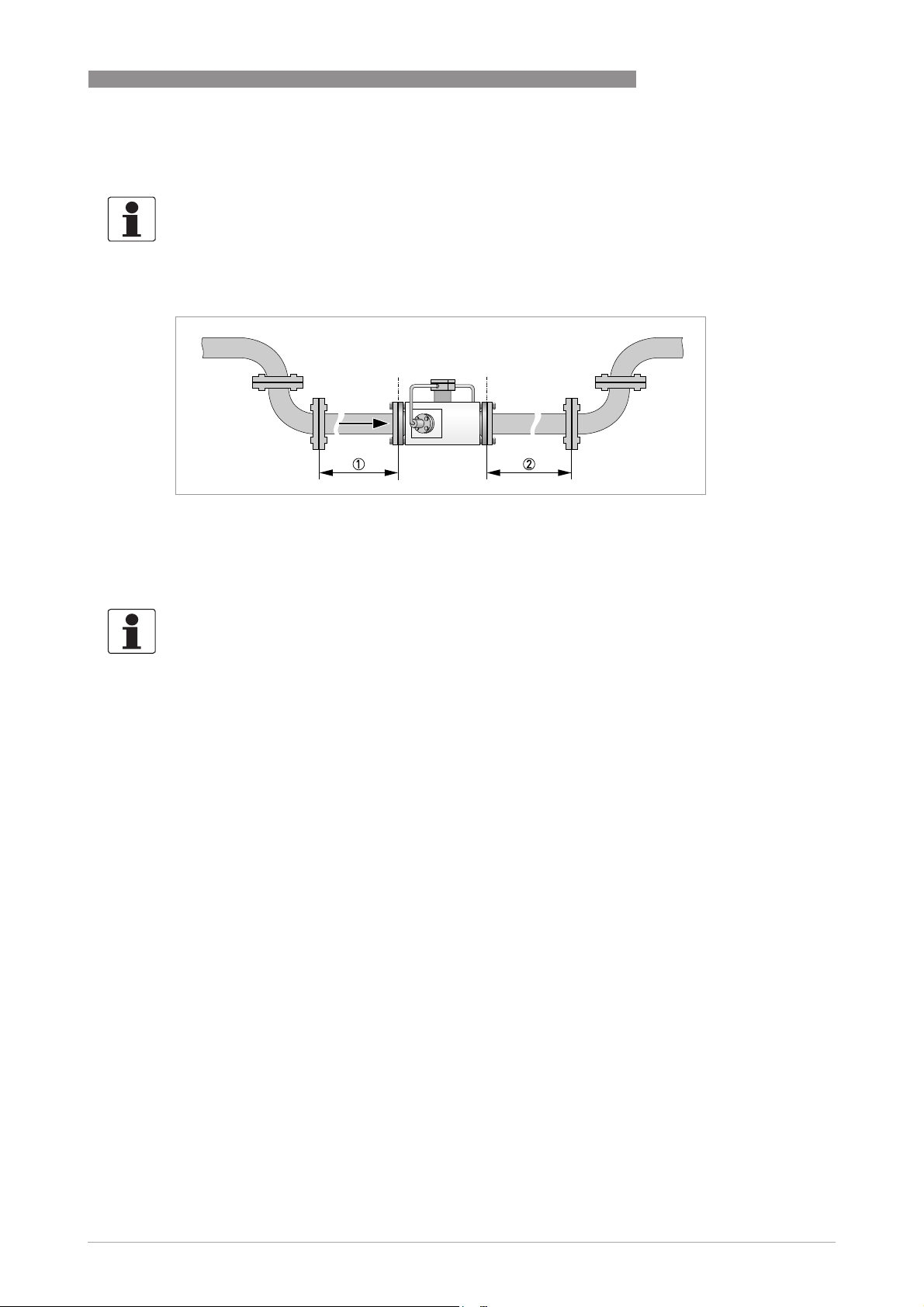

To avoid measuring errors and to get proper measuring results an inlet section upstream and an

outlet section downstream is necessary. Regard the following illustration and table and regard

the information for different fluid products:

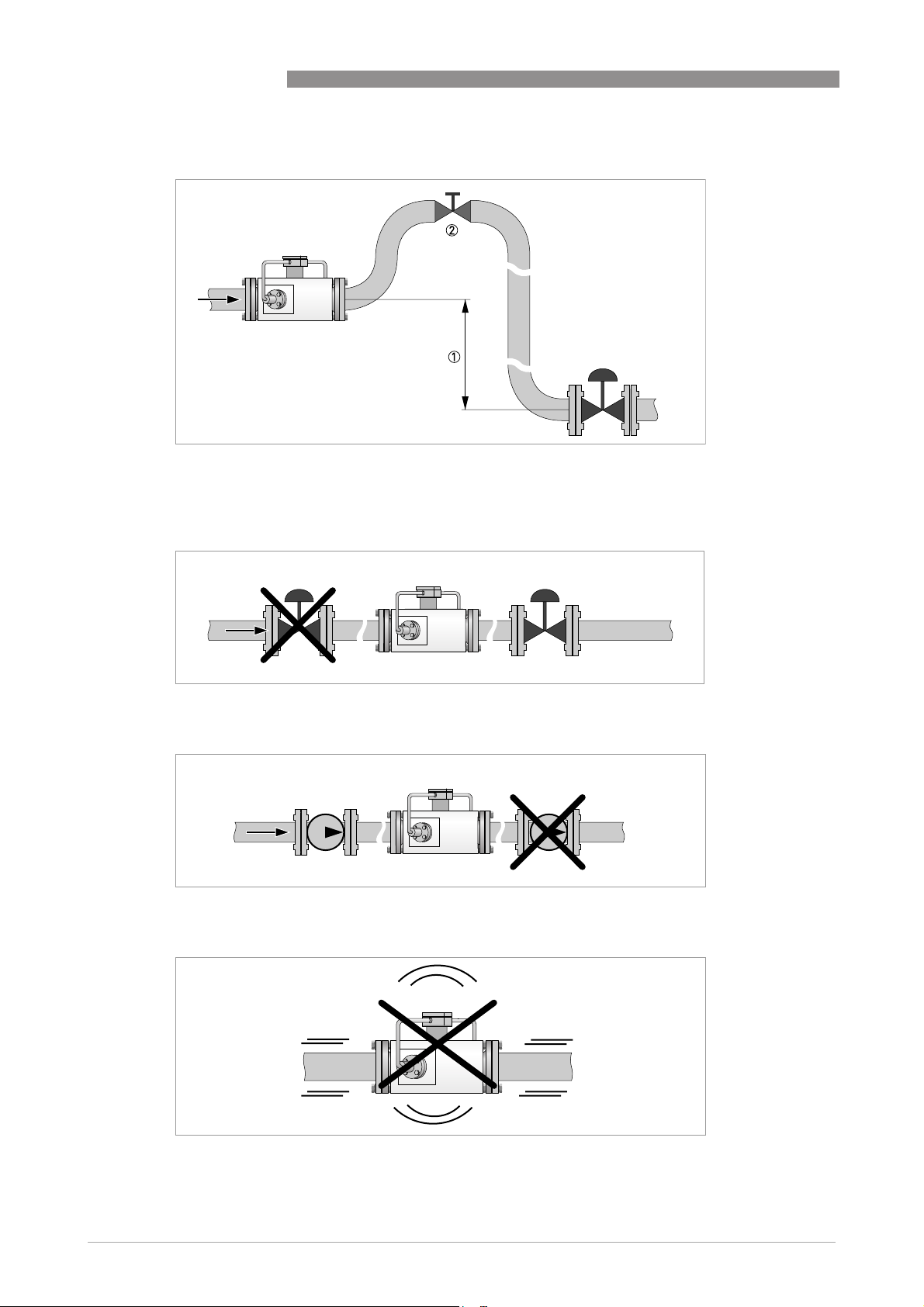

Figure 3-2: Recommended straight inlet and outlet

1 DN25...80: ≥ 50 DN

DN100...300: ≥ 15 DN

2 DN25...80: ≥ 10 DN

DN100...300: ≥ 5DN

INSTALLATION 3

INFORMATION!

Different fluid products

Different fluid products

Different fluid productsDifferent fluid products

To mix different fluid products, install the flow meter upstream of mixing point or at minimum

distance of 30 DN downstream of the mixing point.

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

13

Page 14

3 INSTALLATION

3.5 Mounting

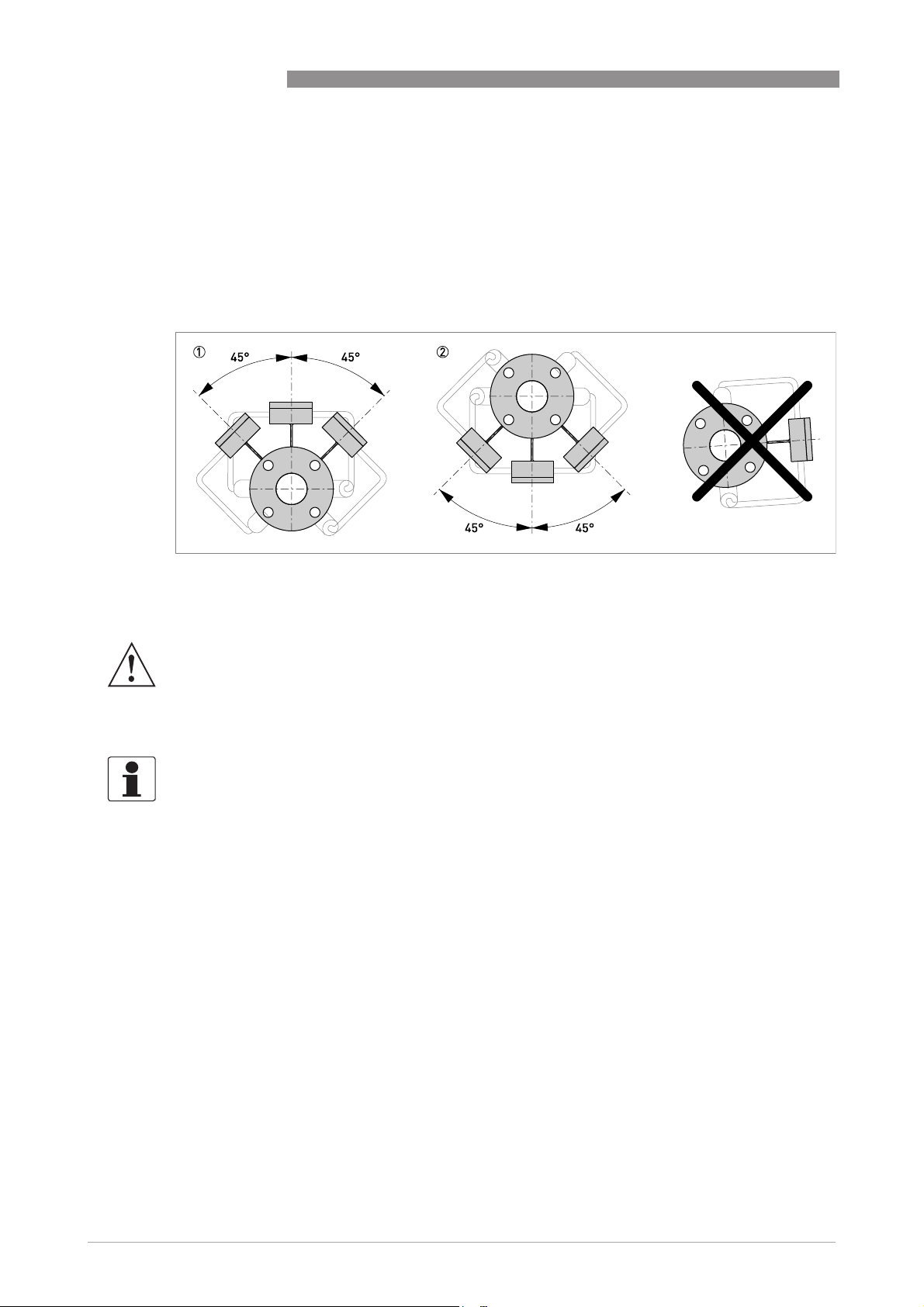

3.5.1 Mounting position of the flow sensor

Installation of the flow sensor is allowed in horizontal, slightly ascending and vertical pipe

sections with up going flow direction (see next section). If installed in a horizontal or slightly

ascending pipeline, the connection box of the flow sensor has to be up or down.

UFM 530 HT

Figure 3-3: Allowed position of the flow sensor (up and down)

WARNING!

Do not unscrew the flanged transducer construction. This will cause direct contact with the high

temperature liquid running through the flow sensor.

3.5.2 Mounting location of the flow sensor

INFORMATION!

For proper flow measurement the measuring tube must be completely filled at all times. When

the sensors become non-wetted, a loss of signal message will be displayed. There is no damage

when this occurs.

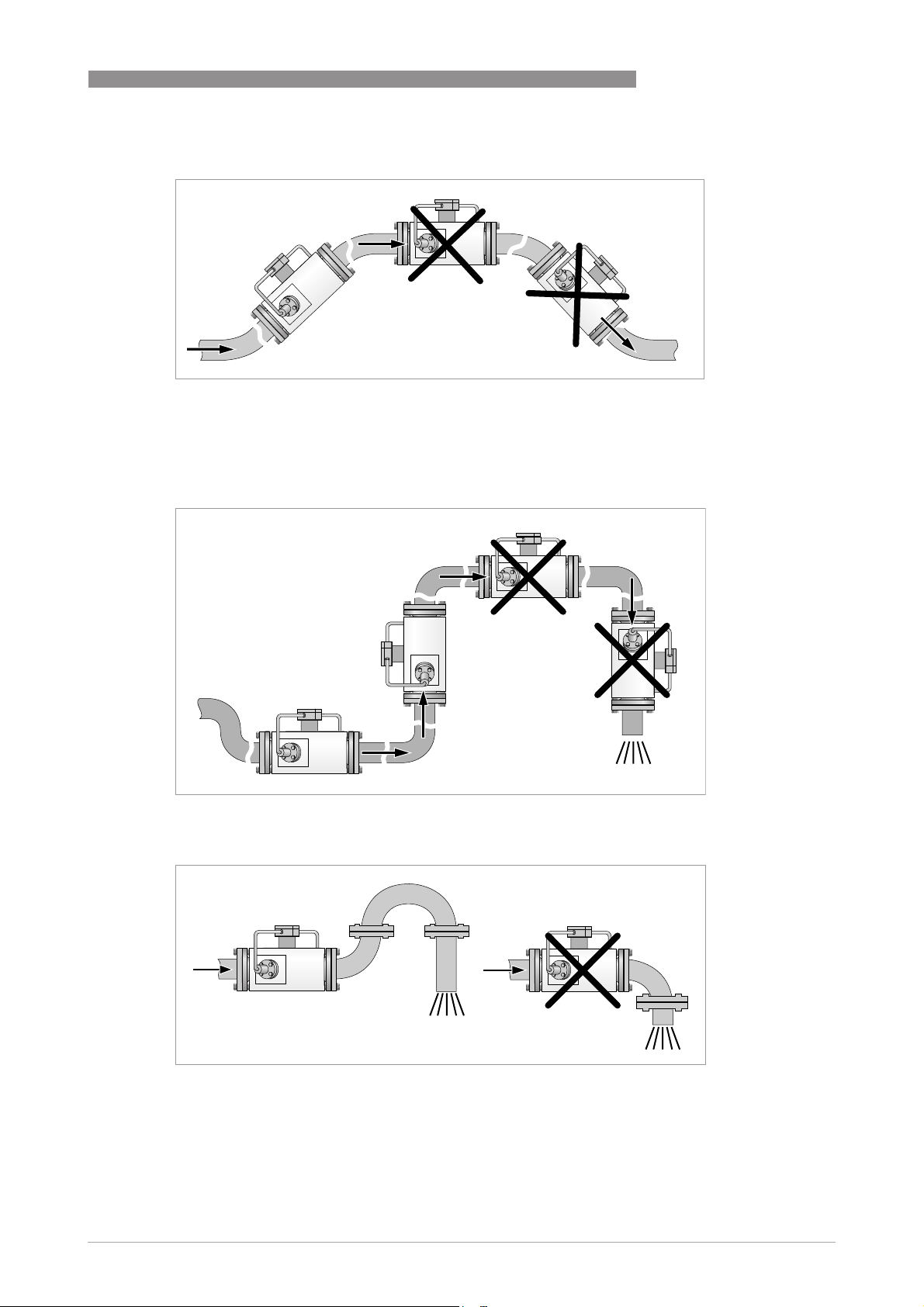

Observe the following precautions to avoid measuring errors or malfunctioning of the flow meter

due to gas or air inclusions or an empty pipe.

Since gas will collect at the highest point of a pipe, installation of the flowmeter at that location

should always be avoided. In long horizontal pipes the flow meter has to be installed in a slightly

ascending pipe section. If not possible, ensure adequate velocity to prevent air, gas or vapour

from collecting in the upper part of the flow tube.

14

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 15

UFM 530 HT

INSTALLATION 3

Figure 3-4: Avoid locations where gas can be present.

Also installation in a down going pipe should be avoided since a completely filled pipe may not be

guaranteed due to cascading effects. Additionally flow profile distortion is possible.

Figure 3-5: Avoid locations where gas can be present

Figure 3-6: Ensure you have a completely filled pipe.

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

15

Page 16

3 INSTALLATION

Figure 3-7: Air vent

1 Level difference > 5 m / 16 ft

2 Install an air vent.

UFM 530 HT

Figure 3-8: Install control valve downstream of the flow meter.

Figure 3-9: Install pump upstream of flowmeter.

16

Figure 3-10: Avoid installation in vibrating pipelines.

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 17

UFM 530 HT

3.5.3 Insulation

WARNING!

Complete insulation of the UFS 500 HT flow sensor is prohibited. Insulation is allowed up to the

first flange of each transducer.

WARNING!

The connection box and the flanged transducers require adequate cooling by ambient air and

must be protected against heat radiation by surrounding equipment.

INSTALLATION 3

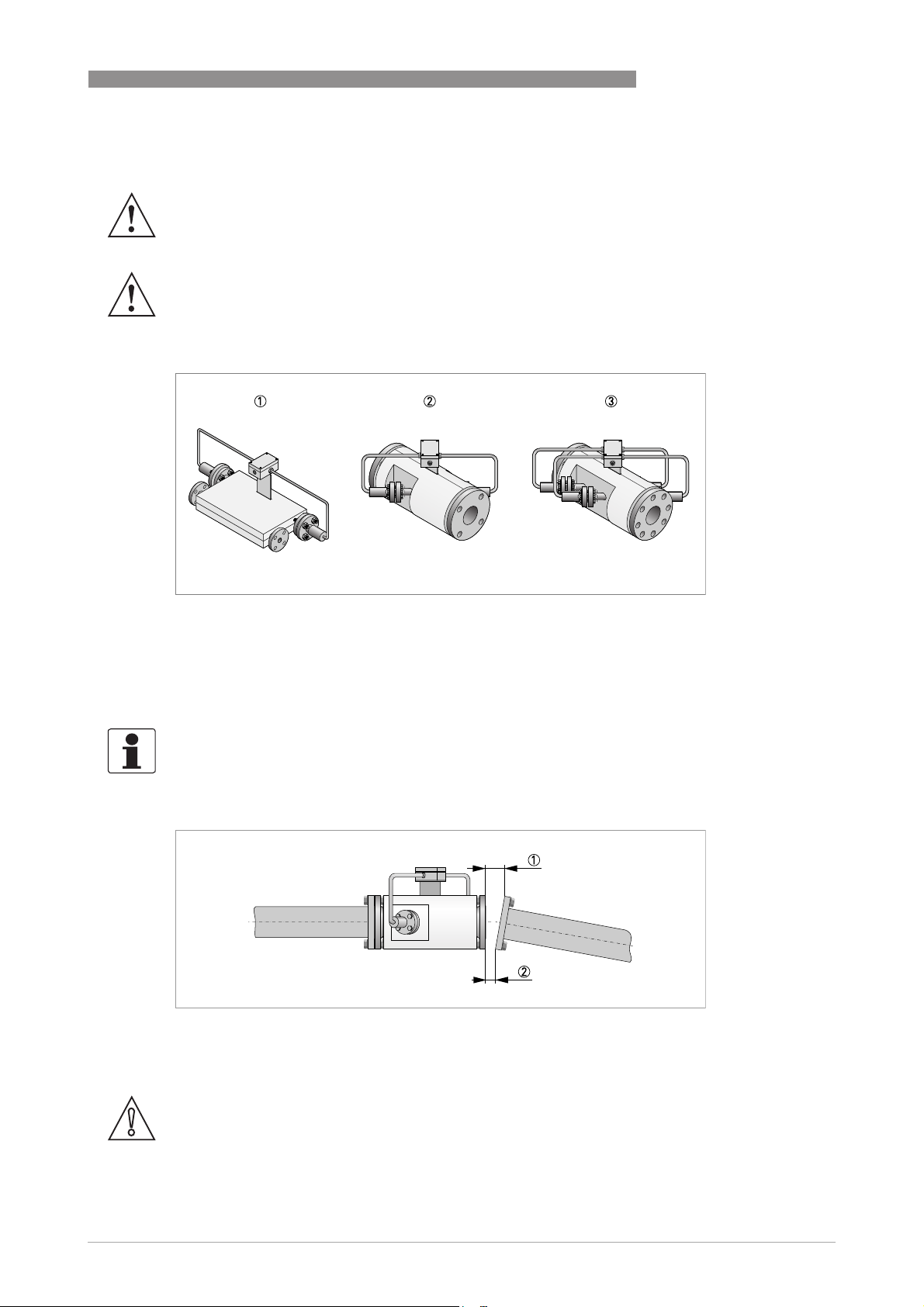

Figure 3-11: Approved insulations.

1 Building construction "single beam" for DN25...40

2 Building construction "single beam" for DN50...80

3 Building construction "dual beam" for ≥ DN100

3.5.4 Pipe flanges

INFORMATION!

Refer to dimensional drawings for flange spacing and in addition allowance for thickness of

gaskets.

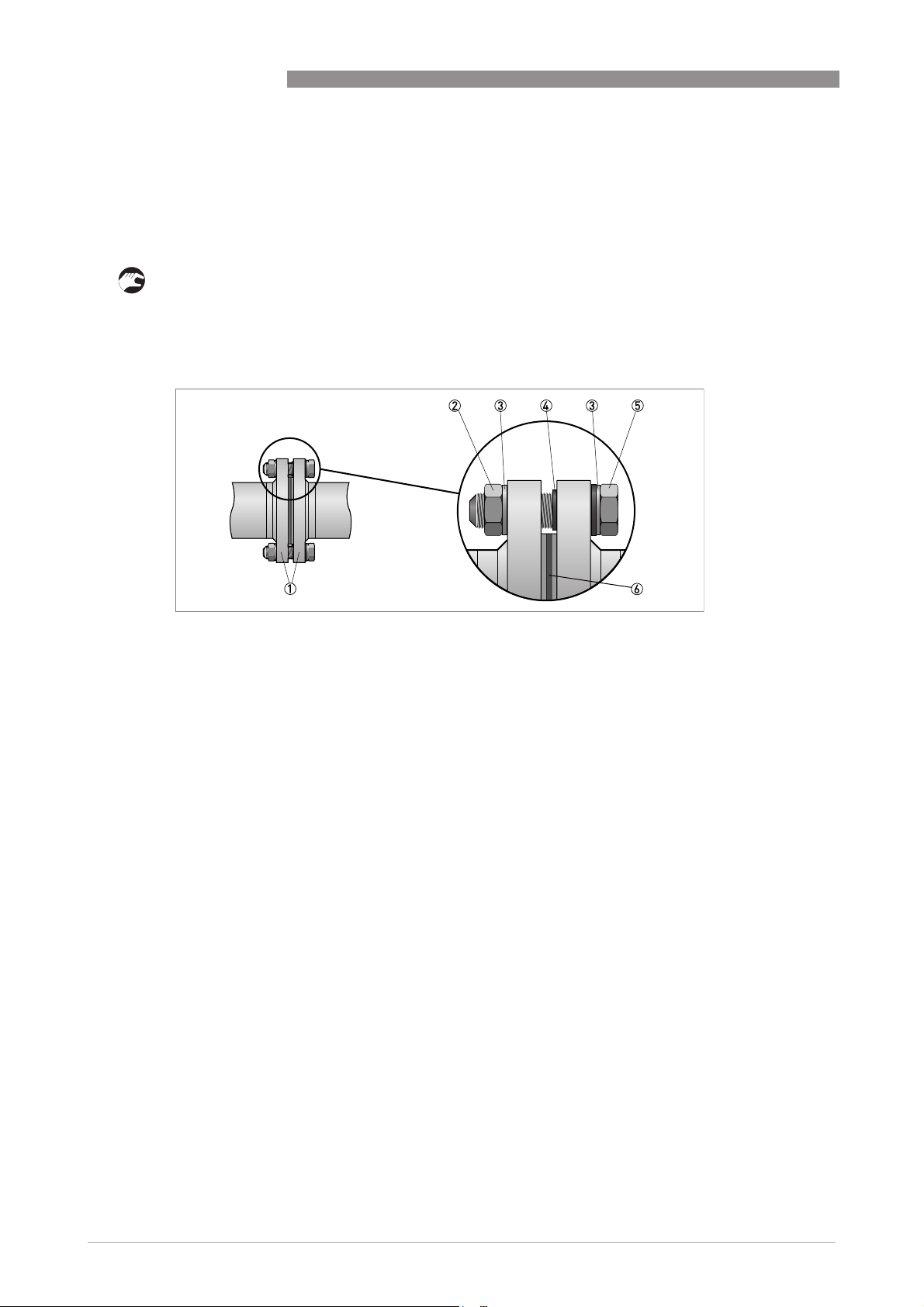

Figure 3-12: Maximum deviation between flanges

1 L

max

2 L

min

CAUTION!

Max. permissible deviation of pipe flange faces:

- L

L

max

≤ 0.5 mm / 0.02"

min

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

17

Page 18

3 INSTALLATION

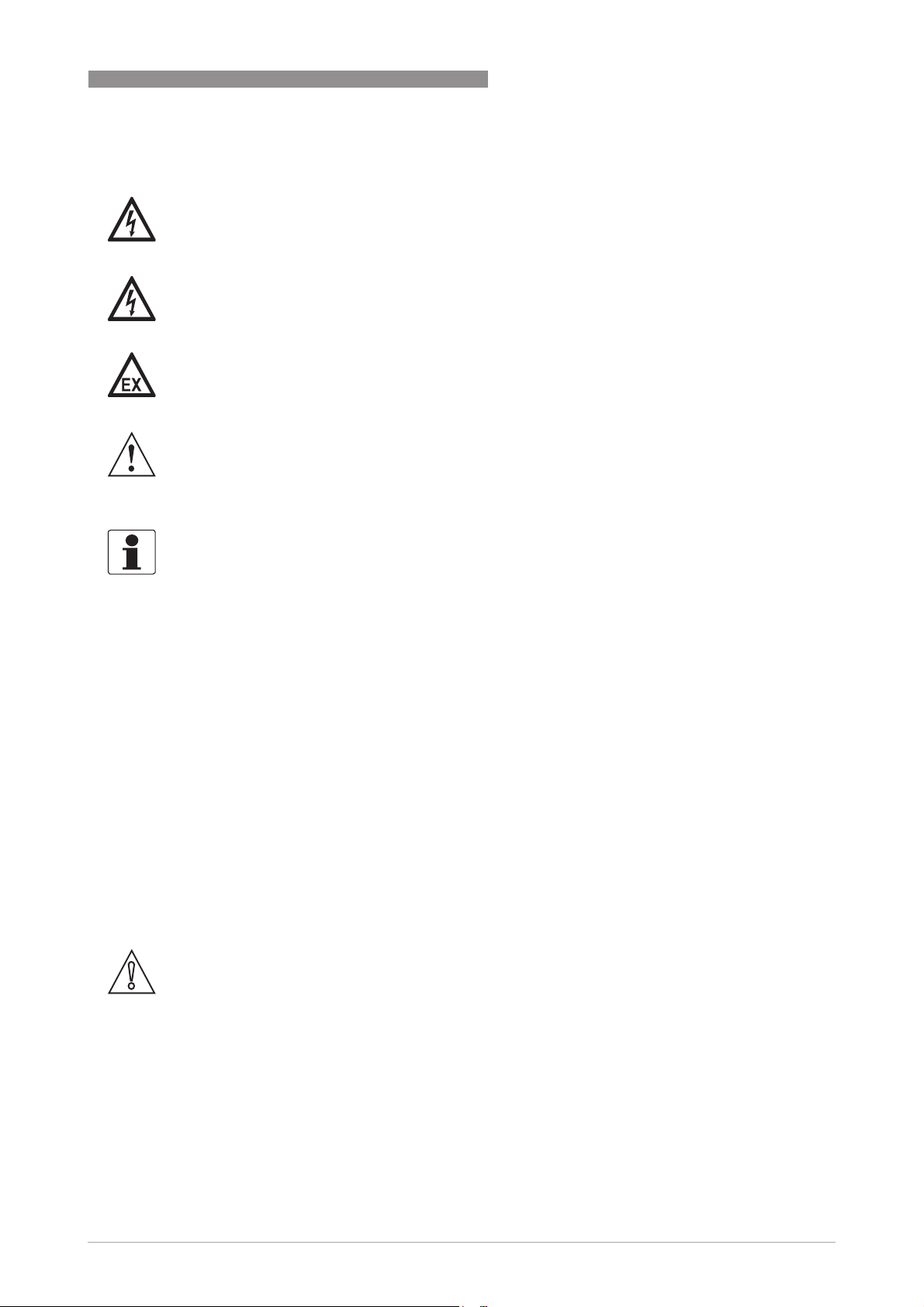

3.5.5 Pipes with cathodic protection

Pipes with electric corrosion protection are generally insulated inside and outside so that the

fluid has no conductive connection to the ground. The flow meter must be insulated from the

pipe. Observe the following instructions when installing the flow meter:

• The pipe flanges must be connected to each other using a copper cable (L), but must not be

connected to the flowmeter.

• The bolts for the flange connections and the gaskets must be insulated. Use sleeves and

washers that are made of insulating material (these must be provided by customer).

UFM 530 HT

Figure 3-13: Cathodic protection

1 Flanges (left one: of flow sensor, right one: of pipe)

2 Nut

3 Washer

4 Insulating sleeve

5 Bolt

6 Gasket

18

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 19

UFM 530 HT

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

ELECTRICAL CONNECTIONS 4

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Power supply of the converter

Environmental conditions

The flowmeter is designed to operate safe under the following conditions. Observe them before

the connection to the mains supply voltage is established:

• Indoor and outdoor use, usable up to protection category IP67 according to IEC 60529

(Note: IP67 is only warranted when using suitable cabling with the cable glands and covers

mounted as specified).

• Maximum altitude: up to 2000 m above see level.

• Maximum relative humidity: up to 80%.

• Operation ambient temperature range: -40...+65°C.

• Storage temperature range: -40...+70°C.

CAUTION!

Never allow dirt to accumulate on the gasket of the rear (blind) cover. A dirty gasket has to be

cleaned, a damaged gasket must be replaced immediately.

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

19

Page 20

4 ELECTRICAL CONNECTIONS

Before the cables can be fastened to the power supply terminal, the rear (blind) cover has to be

removed.

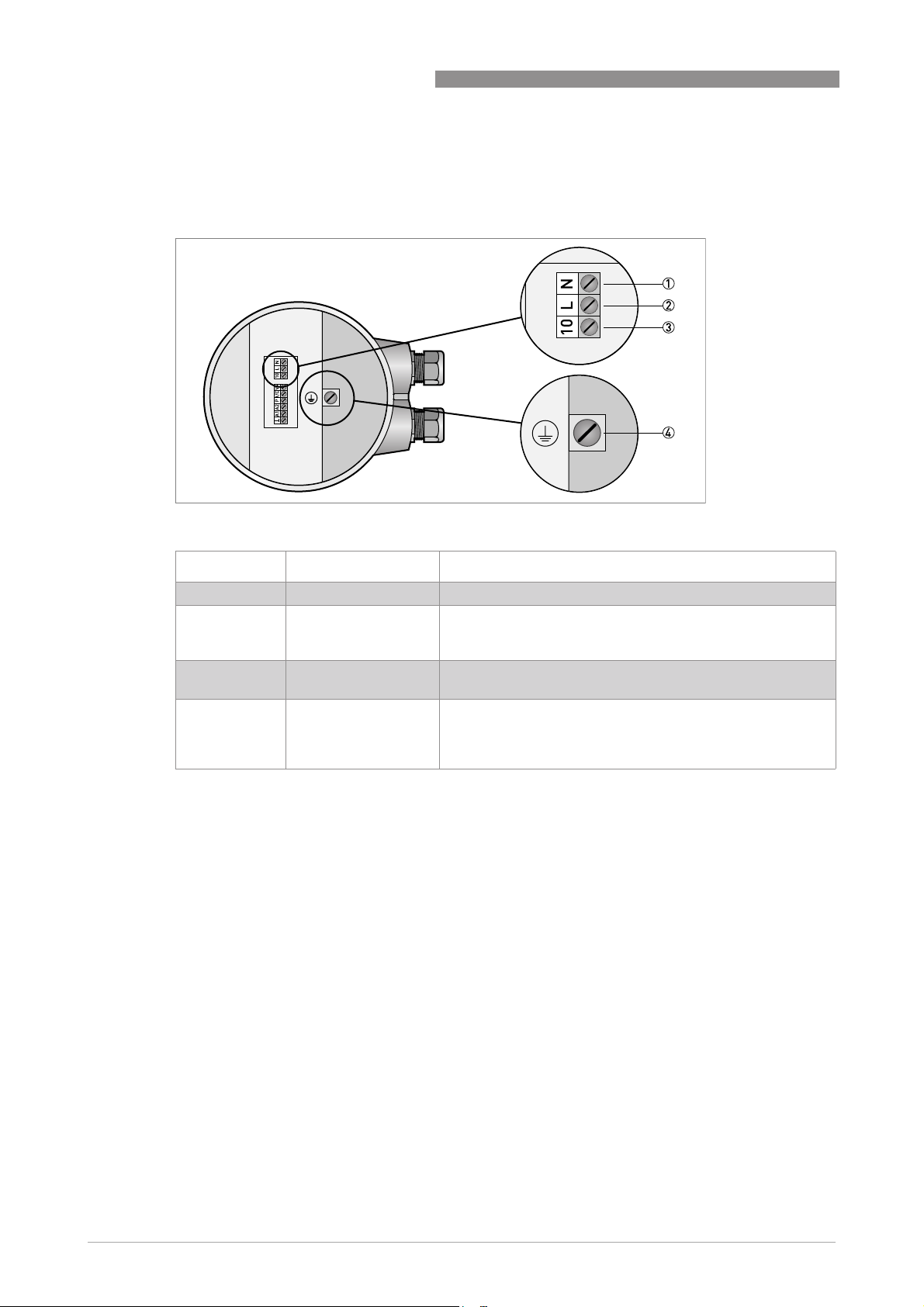

Figure 4-1: Terminals for power supply

UFM 530 HT

Item number Function Specification

1 Neutral power supply.

2 Life power supply. Mains voltage AC supply: 100 VAC < U < 240 VAC (-15%, +10%),

SELV AC/DC supply: 24 VDC (-25%, +33%), 24 VAC (-10%,

+15%).

3 Reserved ground

connection.

4 Protective ground

connection (PE),

Functional ground

connection (FE).

Not for protective earthing.

Protective conductor clamp terminal. Conductors up to

4mm2(11 AWG) need to be connected to this terminal.

20

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 21

UFM 530 HT

4.3 Connection of signal cables

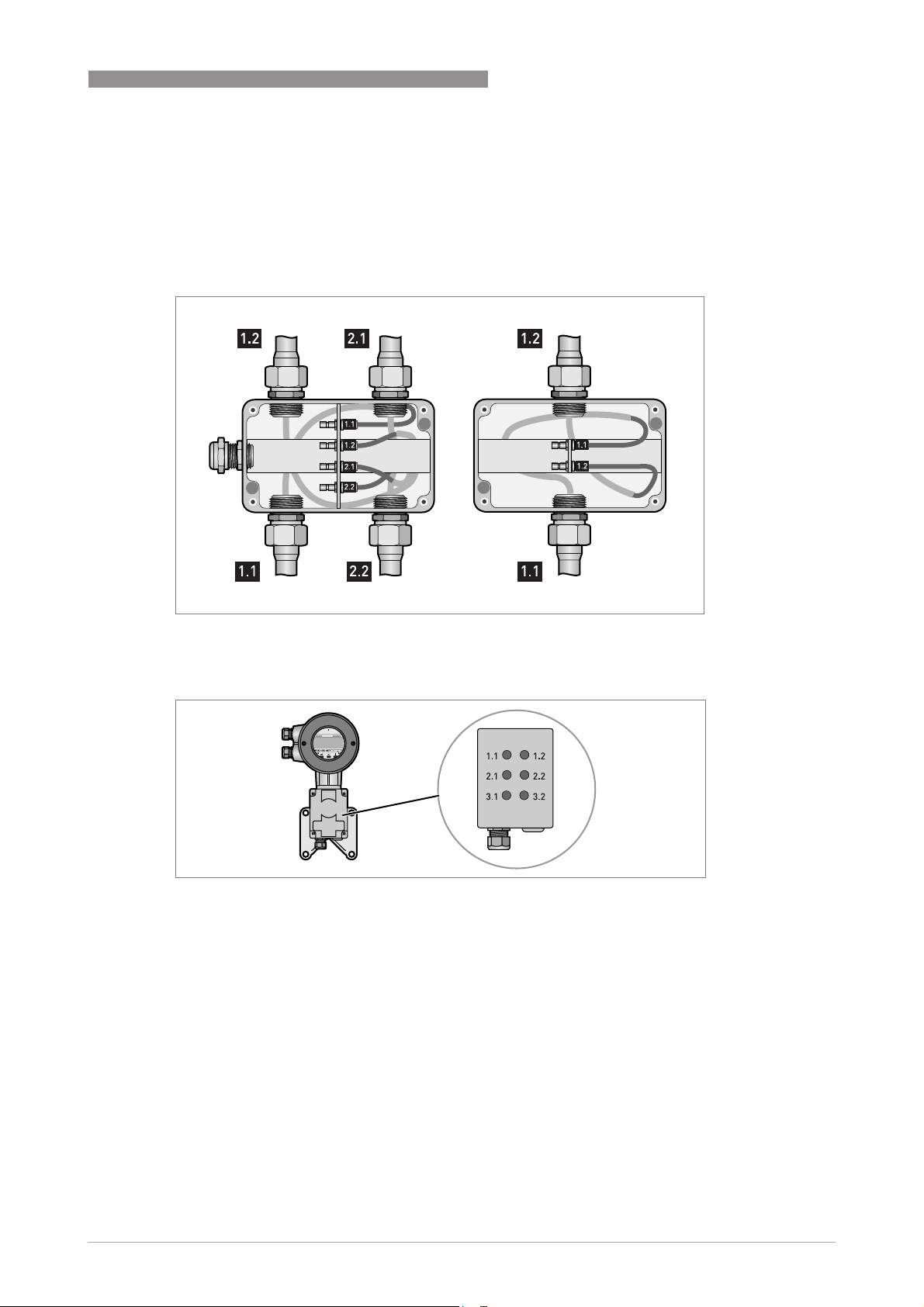

Connect the signal cable from the connection box of the UFS 500 HT sensor to the UFC 030

signal converter according to underneath drawings for the single beam and dual beam

construction.

ELECTRICAL CONNECTIONS 4

Figure 4-2: Connection of the sensor cables for dual beam (left) and

single beam (right) building construction (sensor side)

Figure 4-3: Connection of the sensor cables, converter side

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

21

Page 22

4 ELECTRICAL CONNECTIONS

4.4 Electrical connections of the signal inputs and outputs

CAUTION!

For wiring of the signal inputs and outputs it is advised to use unshielded twisted pairs.

CAUTION!

Please observe instrument polarity: current (I) is always flowing towards I, C, P, A1, A2 terminals

(current sink).

The signal inputs and outputs terminals are located in the converter terminal box. It is

accessible after removing the rear (blind) cover of the converter. There are versions for non Ex

and for Ex applications.

4.4.1 Non Ex versions

Non Ex standard version

UFM 530 HT

Figure 4-4: Terminals for standard instrument.

Terminal Function Specification

1 DC power supply from converter for active

2 Combined current output (I) and digital

3 Pulse / frequency output. I

4 Analog input 2, for temperature or

5 Analog input 1, for temperature

6 Common ground -

wiring of inputs and outputs.

input (C). Current output (I) includes

®

-Communication.

HART

pressure measurement.

measurement.

22 VDC at full load, 24 VDC maximum,

I ≤ 100 mA.

Current output (I): I ≤ 22 mA,

≤ 680 Ω, U

R

load

Digital input (C): low = 0...5 VDC,

high = 15...32 VDC (will be switched off

when current output activated).

= 150 mA, U

max

maximal frequency = 2 kHz.

0(4)...20 mA, Ri= 58,2 Ω, fuse = 50 mA.

0(4)...20 mA, Ri= 58,2 Ω, fuse = 50 mA.

max

max

= 15 VDC.

CAUTION!

Never use the active and passive mode at the same terminal simultaneously.

®

If HART

-Communication is used, do not connect the pulse/frequency output P in active mode.

=32VDC/ 24VAC,

22

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 23

UFM 530 HT

ELECTRICAL CONNECTIONS 4

INFORMATION!

The electrical input and output signals can be connected either in active or in passive mode. In

active mode DC supply voltage is provided from the terminal V+. In passive mode supply voltage

is provided from an external source.

Non Ex version with Profibus PA

Figure 4-5: Terminals for instrument with Profibus PA (non Ex).

Terminal Function Specification

1 Communication connection - For Fieldbus communication

2 Communication connection + For Fieldbus communication

3 Combined current output (I), digital

input (C) and Pulse / frequency output.

Current output (I) includes HART

Communication.

4 Analog input 2, for temperature or

pressure measurement.

5 Analog input 1, for temperature

measurement.

6 Common ground

®

-

Current output (I): I ≤ 22 mA,

R

≤ 680 Ω, U

load

Digital input (C): low = 0...5 VDC,

high = 15...32 VDC (will be switched off

when current output activated).

Pulse output: I

U

= 32 VDC / 24 VAC, maximal

max

frequency = 2 kHz.

0(4)...20 mA, Ri= 58,2 Ω, fuse = 50 mA.

0(4)...20 mA, Ri= 58,2 Ω, fuse = 50 mA.

max

= 150 mA,

max

= 15 VDC.

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

23

Page 24

4 ELECTRICAL CONNECTIONS

Non Ex HiPower version

Figure 4-6: Terminals for non Ex HiPower instrument.

Terminal Function Specification

UFM 530 HT

1 DC power supply from converter for active

wiring of inputs and outputs.

2 Combined current output (I) and digital

input (C). Current output (I) includes

®

HART

-Communication.

22 VDC at full load, 24 VDC maximum,

I ≤ 100 mA.

Current output (I): I ≤ 22 mA,

R

≤ 680 Ω, U

load

max

= 15 VDC.

Digital input (C): low = 0...5 VDC,

high = 15...32 VDC (will be switched off

when current output activated).

3 Pulse / frequency output. I

= 150 mA, U

max

=32VDC/ 24VAC,

max

maximal frequency = 2 kHz.

4 Analog input 2, for temperature or

0(4)...20 mA, Ri= 58,2 Ω, fuse = 50 mA.

pressure measurement.

5 Analog input 1, for temperature

0(4)...20 mA, Ri= 58,2 Ω, fuse = 50 mA.

measurement.

6 Common ground -

24

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 25

UFM 530 HT

4.4.2 Ex versions

WARNING!

The electrical input and output signals must be connected in passive mode. The supply voltage

must be provided from an external source.

Ex standard version

Figure 4-7: Terminals for Ex standard instrument

ELECTRICAL CONNECTIONS 4

Terminal Function Specification

1 Neutral mains power supply 100...240 VAC, 24 VAC or 24 VDC

2 Live mains power supply 100...240 VAC, 24 VAC or 24 VDC

3 Combined current output (I) and digital

4 Pulse / frequency output I

5 Analog input 2, for temperature or

6 Analog input 1, for temperature

7 Common ground

input (C). Current output (I) includes

®

-Communication.

HART

pressure measurement.

measurement.

Current output (I): I ≤ 22 mA,

≤ 680 Ω, U

R

load

Digital input (C): low = 0...5 VDC,

high = 15...32 VDC (will be switched off

when current output activated).

= 150 mA, U

max

maximal frequency = 2 kHz.

0(4)...20 mA, Ri= 58,2 Ω, fuse = 50 mA.

0(4)...20 mA, Ri= 58,2 Ω, fuse = 50 mA.

= 15 VDC.

max

=32VDC/ 24VAC,

max

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

25

Page 26

4 ELECTRICAL CONNECTIONS

Ex NAMUR version

Figure 4-8: Terminals for Ex instrument with NAMUR

Terminal Function Specification

1 Neutral mains power supply 100...240 VAC, 24 VAC or 24 VDC

2 Live mains power supply 100...240 VAC, 24 VAC or 24 VDC

3 Combined current output (I) and digital

input (C). Current output (I) includes

®

HART

-Communication.

4 Pulse / frequency output I

5 Ground for pulse output

6 Analog input 1, for temperature

7 Common ground

measurement.

UFM 530 HT

Current output (I): I ≤ 22 mA,

R

≤ 680 Ω, U

load

Digital input (C): low = 0...5 VDC,

high = 15...32 VDC (will be switched off

when current output activated).

= 150 mA, U

max

maximal frequency = 2 kHz.

0(4)...20 mA, Ri= 58,2 Ω, fuse = 50 mA.

= 15 VDC.

max

=32VDC/ 24VAC,

max

INFORMATION!

The current output of the UFC 030 F-EEx can be set according to NAMUR NE43. The current

output will go either to 3.6 or 21.5 mA in case of failure indication.

26

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 27

UFM 530 HT

ELECTRICAL CONNECTIONS 4

The following Ex-i Modis versions have two Modis modules, providing intrinsically safe input /

output circuits. Modis versions don't have analogue inputs A1 / A2.

Ex-i (Modis) version

Figure 4-9: Terminals for instrument with Ex-i (Modis)

Terminal Function Specification

1 Neutral mains power supply 100...240 VAC, 24 VAC or 24 VDC

2 Live mains power supply 100...240 VAC, 24 VAC or 24 VDC

3 Ground for pulse, frequency or status

output

4 Pulse, frequency or status output I

5 Current output Current output (I): I ≤ 22 mA,

6 Ground for current output

= 150 mA, U

max

maximal frequency = 2 kHz.

R

≤ 680 Ω, U

load

=32VDC/ 24VAC,

max

= 15 VDC.

max

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

27

Page 28

4 ELECTRICAL CONNECTIONS

Ex-i (Modis) version with Profibus PA

Figure 4-10: Terminals for Ex-i (Modis) version with Profibus PA

Terminal Function Specification

1 Neutral mains power supply 100...240 VAC, 24 VAC or 24 VDC

2 Live mains power supply 100...240 VAC, 24 VAC or 24 VDC

3 Profibus communication -

4 Profibus communication +

5 Current output Current output (I): I ≤ 22 mA,

6 Ground for current output

R

load

≤ 680 Ω, U

max

UFM 530 HT

= 15 VDC.

28

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 29

UFM 530 HT

4.5 Connection diagram examples

INFORMATION!

The connection diagrams on the next pages are valid for most versions. However, not all

versions have the same connection possibilities. Versions that don't have the V+ terminal (for

instance Ex versions) can only be connected in a passive way, e.g. by using an external power

supply.

4.5.1 Current output

Current output active

• V+: 22 VDC at full load, 24 VDC maximum, I ≤ 100 mA

≤ 680 Ω

• R

L

• I < 22 mA

• U

= 15 VDC

max

ELECTRICAL CONNECTIONS 4

Figure 4-11: Current output (active)

Current output passive

• U

• I ≥ 22 mA (for supply)

• For Ex-i modis versions: I = 4..20 mA

• For Ex-i modis versions: R

Figure 4-12: Current output (passive)

= 15...24 VDC

ext

(For Ex-i modis versions: U

= 8,1...30 VDC)

ext

≤ (U

L

- 8) / 0,022

ext

INFORMATION!

Ex-i modis versions do not have an "I/C" terminal. Use the "I" terminal instead.

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

29

Page 30

4 ELECTRICAL CONNECTIONS

4.5.2 Pulse output

Pulse output active

• V+: 22 VDC at full load, 24 VDC maximum, I ≤ 100 mA

• Ri ≥ 470 Ω

• frequency ≤ 2 kHz

Figure 4-13: Pulse output (active)

UFM 530 HT

Pulse output passive

• U

• I ≤ 150 mA

• Ri ≥ 470 Ω

• frequency ≤ 2 kHz

Figure 4-14: Pulse output (passive)

≤ 32 VDC or U ≤ 24 VAC

ext

(For Ex-i modis versions: U

= 6...30 VDC)

ext

(For Ex-i modis versions: I ≤ 110 mA)

INFORMATION!

Ex-i modis versions have different terminal codings.

30

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 31

UFM 530 HT

Figure 4-15: Pulse output (passive) for Ex-i Modis

4.5.3 Digital input

INFORMATION!

The digital input will be switched off when the current output is activated.

Digital input active

• V+: 22 VDC at full load; 24 VDC maximum, I ≤ 100 mA

• Low = 0...5 VDC

• High = 15...32 VDC

ELECTRICAL CONNECTIONS 4

Figure 4-16: Digital input (active)

Digital input passive

• U

• I ≥ 1.5 mA

• Low = 0...5 VDC

• High = 15...32 VDC

= 15...30 VDC

ext

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

31

Page 32

4 ELECTRICAL CONNECTIONS

Figure 4-17: Digital input (passive)

4.5.4 Analog input

Analog input

• 0 (4)...20 mA

• Ri = 58.2 Ω

• Fuse 50 mA

UFM 530 HT

Figure 4-18: Analog input

32

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 33

UFM 530 HT

5.1 Start-up procedure

DANGER!

Hazardous voltages are present within this product during normal operation. Do not operate it

with the covers removed!

When powered, "start-up" is shown at the display for a short time. After that the normal

measuring mode starts.

INFORMATION!

The flowmeter is programmed at the factory according to your order. No changes are necessary.

START-UP 5

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

33

Page 34

6 OPERATION

6.1 Signal converter: front panel and operating keys

The front panel and its operating keys are accessible after removing the front cover of the

electronics section (use the special wrench for it). If it is not allowed to open the housing, for

instance in hazardous areas, you can program the converter with the magnetic pin.

CAUTION!

When removing the cover, do not damage the screw thread and the gasket, never allow dirt to

accumulate and make sure that they are well greased using Teflon. A damaged gasket must be

replaced immediately!

UFM 530 HT

1 Magnetic sensors to program the signal converter by means of a hand-held bar magnet (optional) without having to

remove the front cover (left sensor is equivalent to the "→" ke y, r igh t se nso r to "↑" key and sensor at the top to "^" key.

2 Compass needles.

3 Measured value ("E" stands for "Exponent").

4 Unit of measured value.

5 Indication of actual displayed value.

6 Operating keys (→, ^, ↑) for programming the signal converter.

Function of operating keys depending on selected mode

Key / symbol Measuring mode Menu mode Data level

→ Go to the parameter setting

mode. If access CODE 1 is

activated, CODE 1 must be

entered first.

^ Go to the error/totalizer

reset mode (via CODE 2).

↑ Cycle through measured

values.

Go to the next, lower menu

level.

Return to the previous

(higher) menu level or

leave the menu mode.

Cycle through menu

options within actual menu

level.

Go to the next character or

change line (only when two

lines are displayed).

Accept entered value.

Raise active digit.

34

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 35

UFM 530 HT

6.2 Available versions

INFORMATION!

The flowmeter is programmed at the factory according to your order. No changes are necessary.

All standard UFC 030 signal converters can be programmed in menu 3.02.01.

1. Standard version

1. Standard version

1. Standard version1. Standard version

2. CORR T: on-site interchangeable to "standard".

2. CORR T: on-site interchangeable to "standard".

2. CORR T: on-site interchangeable to "standard".2. CORR T: on-site interchangeable to "standard".

Temperature correction via analogue input 1 (temp range -50... +150°C) ; with this version the

outputs are non-Ex-I.

3. CORR T+P: on-site interchangeable to "standard".

3. CORR T+P: on-site interchangeable to "standard".

3. CORR T+P: on-site interchangeable to "standard".3. CORR T+P: on-site interchangeable to "standard".

Temperature correction via analogue input 1, pressure correction via analogue input 2 (press

range 0...100 bar) ; with this version the outputs are Ex-I.

Corrected volume calculation can be done based on temperature correction or temperature and pressure correction.

The volume correction factor is based on API 2540; chapter 11.1 for the temperature correction

and chapter 11.2 for the pressure correction.

For liquid oil products the volume correction factors can be estimated as 0.1% per degree

Celsius and 0.01% per bar as a rule of thumb. Therefore for normal industrial processes these

corrections are hardly ever applied.

OPERATION 6

4. HEAT: on-site interchangeable to "standard".

4. HEAT: on-site interchangeable to "standard".

4. HEAT: on-site interchangeable to "standard".4. HEAT: on-site interchangeable to "standard".

The UFC 030 signal converter is programmed for energy measurement, based on temperature

measurements connected via analogue inputs A1 and A2 (temperature range: -50...+150°C);

with this version the outputs are non-Ex-I. The following settings are needed:

No. of menu Display text Setting/description and functions

3.02.02 INP1 4mA minimum value of temperature sensor 1 on inlet

3.02.03 INP1 20mA maximum value of temperature sensor 1 on inlet

3.02.04 INP1 4mA minimum value of temperature sensor 2 on outlet

3.02.05 INP1 20mA maximum value of temperature sensor 2 on outlet

3.02.12 full scale xxx (unit yyy)

3.03.02 function

totalizer

3.03.05 unit for total

energy

3.05.01 function pulse

output

3.05.10 pulse/unit select unit

select direction

select unit

CORR FLOW

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

35

Page 36

6 OPERATION

5. BATCH: on-site interchangeable to "standard".

5. BATCH: on-site interchangeable to "standard".

5. BATCH: on-site interchangeable to "standard".5. BATCH: on-site interchangeable to "standard".

The following settings are needed:

No. of menu Display text Setting/description and functions

UFM 530 HT

3.04.01 FUNCTION

3.05.01 FUNCTION

3.06.01 FUNCTION

3.02.13 BATCH VOL xxx(unit yyy)

6. MODIS: setting can not be changed.

6. MODIS: setting can not be changed.

6. MODIS: setting can not be changed.6. MODIS: setting can not be changed.

(current

output)

(pulse output)

(digital output)

OFF

BATCH

BATCH

The analogue inputs 1 and 2 are not available in this version.

The Ex-I 1 version has a current output (incl. HART

The Ex-I 2 version has a current output (incl. HART

INFORMATION!

Depending on the programming of function 3.03.07 the additional or selectable indications can

be manually selected by pressing ↑ key, or they are alternating with the display of the measured

value(s). The corrected volume flow indication or volume flow totalizer indication is marked with

the letter "C" at the left of the display's second (middle) line. The batch totalizer indication is

marked with the letter "B".

6.3 Signal converter: menu structure

INFORMATION!

Since the UFC 030 converter can be equipped with different options, the availability of certain

options depends on the function of the converter.

®

) and a pulse output.

®

) and a Profibus PA output.

The menu structure consists of five user accessible parts. They are described on the following

pages.

Error / totalizer menu

No. of menu Display text Setting/description and functions

0.00.01 VIEW ERR View error messages list.

0.00.02 RST ERR Reset error messages:

1) NO RESET: keep error messages list.

2) RESET: reset error messages list.

0.00.03 RST TOTAL Reset display totalizer(s). Note: all totalizer values are reset!

Only availabe when function 3.07.08 is set to YES. Available options:

1) RESET ALL: reset all totalizer values.

2) NO RESET: keep totalizer values.

36

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 37

UFM 530 HT

OPERATION 6

INFORMATION!

The functions in this menu are a subset of menu 3.00.00. They are selected in this menu as most

commonly used functions for a quick installation. Note: parameters set in these functions are

automatically set in both menus!

Operation menu

No. of menu Display text Setting/description and functions

1.01.00, FLOW

1.01.01 FULL SCALE Full-scale value for 100% volume flow rate.

1.01.02 ZERO VALUE Zero value.

1.01.03 ZERO CAL Zero calibration.

1.01.04 MASTER TC Master time constant.

1.01.05 LF CUTOFF Low-flow cut-off.

1.01.06 CUTOFF ON Cut-off active.

1.01.07 CUTOFF OFF Cut-off de-active.

1.02.00, DISPLAY

1.02.01 DISP FLOW Display of flow.

1.02.02 FUNCT TOT Function of totalizer.

1.02.03 TOTAL VOL Display of totalizer.

1.03.00, PULSE OUTP (Pulse output)

1.03.01 PULSE RATE Pulse frequency value for 100% scale.

1.03.02 PULSE/UNIT Pulse value per volume flow unit.

1.03.03 PULSE/UNIT Pulse value per energy unit.

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

37

Page 38

6 OPERATION

Test functions menu

No. of menu Display text Setting/description and functions

This menu is for testing the display, the in- and outputs and for information on hard- and software

numbers.

2.01.00, DISPLAY

2.01.01 DISPLAY Test display, lights all pixels (end with ^ key).

2.02.00, OUTPUTS

2.02.01 CURRENT Test current output (0, 4, 12, 20 and 22 mA).

2.02.02 PULSE Test pulse/frequency output (1, 10, 100, 1000 and 2000 Hz).

2.03.00, INPUTS

2.03.01 AN INP 1 Test analog input 1.

2.03.02 AN INP 2 Test analog input 2.

2.03.03 DIG INPUT Test digital input. Measure level at digital input.

2.03.04 SENSOR Sensor status: good, open, short

UFM 530 HT

Use ↑ key to go to next value. Displayed value directly present at

current output. End with ^ key.

Use ↑ key to advance. Displayed value directly present at pulse

output. End with ^ key.

Measure current at analog input 1.

End with ^ key.

Measure current at analog input 2.

End with ^ key.

End with ^ key.

2.04.00, DEV INFO (Device information)

2.04.01 MANUFACT Display manufacturer.

2.04.02 MODEL NO Display model number.

2.04.03 SERIAL NO Display serial number.

2.04.04 UP2 HW NO Display μP2 hardware number.

2.04.05 UP2 SW NO Display μP2 software number.

2.04.06 FRNT HW NO Display front end hardware number.

2.04.07 DSP HW NO Display D.S.P. hardware number.

2.04.08 DSP SW NO Display D.S.P. software number.

2.04.09 TIME COUNT Display time counter.

38

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 39

UFM 530 HT

OPERATION 6

Installation menu

No. of menu Display text Setting/description and functions

3.01.00, FLOW (Volume flow parameters)

3.01.01 FULL SCALE Full-scale value for 100% volume and flow rate units (see

3.01.02 ZERO VALUE Although zero calibrated at the factory the flow sensor might still give

3.01.03 ZERO CAL Zero calibration (see function 1.01.03). Note: Carry out only at "zero"

3.01.04 MASTER TC The master time constant apply for the display and the current and

3.01.05 LF CUTOFF Low-flow cut-off for display and outputs.

3.01.06 CUTOFF ON Cut off "active" value.

3.01.07 CUTOFF OFF Cut off "de-active" value. Note: value "off" must be greater than value

3.01.08 METER SIZE The nominal diameter of the measuring tube. See the flow sensor

3.01.09 GK VALUE At the factory, each flow sensor is calibrated and supplied with a

3.01.10 FLOW DIR The forward flow direction is indicated with an arrow on the flow

function 1.01.01). The selection of units may be limited to SI units

only.

Available units: m3/s, m3/min, m3/hr, L/s, L/min, L/hr,

US.Gal/s, US.Gal/min, US.Gal/hr, bbls/hr, bbls/day or free user

configurable unit, set by using function 3.07.05...3.07.07).

an offset flow reading, at "zero" flow in the pipeline. Available

settings:

1) FIXED: factory zero setting.

2) MEASURED: value measured with function 3.01.03 (ZERO CAL).

flow and with completely filled measuring tube!

Duration approximately 15s with display

indicating "BUSY":

1) STORE NO: preserve old zero value.

2) STORE YES: store new zero value.

pulse outputs. It does not apply for totalisation and for the current

output in F/R setting. If required, a different time constant value can

be set for the pulse/frequency output under Function 3.05.06.

Range: 0.02...99.99 s.

1) NO: fixed tripping points (ON = 0.1%, OFF = 0.2%).

2) YES: see function 3.01.06 and 3.01.07.

Range: 1 through 19% of Q

"on"!

Range: 2 through 20% of Q

nameplate. Selection of size from meter size table:

25...3000 mm / 1...120".

calibration constant (GK). This constant can be found on the flow

sensor nameplate and must equal the value on the flow sensor

nameplate.

Range: 0.02...20.

sensor. Available settings:

1) POSITIVE: If the actual flow is in the direction of the arrow then the

flow is in the positive direction and the converter will have a positive

flow reading.

2) NEGATIVE: reversed reading of the converter, useful when the

process flow direction is changed so the flow sensor will not need to

be reversed.

100%

100%

.

.

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

39

Page 40

6 OPERATION

No. of menu Display text Setting/description and functions

3.01.11 MIN VOS Minimum velocity of sound (VOS). Value used for I0% or P0% when

3.01.12 MAX VOS Maximum velocity of sound.Value used for I

3.02.00, VERSION

3.02.01 FUNCTION Function of converter. This is factory pre-set and can only be changed

3.02.02 INP1 4 mA 4 mA reference for analog input 1, 4 mA temperature reference.

3.02.03 INP1 20 mA 20 mA reference for analog input 1, 20 mA temperature reference.

3.02.04 INP2 4 mA 4 mA reference for analog input 2, 4 mA temperature reference.

3.02.05 INP2 20 mA 20 mA reference for analog input 2, 20 mA temperature reference.

3.02.06 INP2 4 mA 4 mA reference for analog input 2, 4 mA pressure reference.

3.02.07 INP2 20 mA 20 mA reference for analog input 2, 20 mA pressure reference.

3.02.08 K0 Product constant K0.

UFM 530 HT

function "VOS" selected in function 3.04.01 or 3.05.01.

Units: m/s or feet/s,

range: 0...4999 m/s (0...16.400 feet/s).

or P

function "VOS" selected in function 3.04.01 or 3.05.01. Note:

maximum value must be greater than minimum value!

Units: m/s or feet/s,

range: 1...4999 m/s (0...16.400 feet/s).

to standard from any setting:

1) STANDARD.

2) CORR T: temperature correction of the measured flow via analog

input 1.

3) CORR T + P: temperature and pressure correction of the measured

flow via analog input 1 (pressure) and analog input 2 (temperature).

4) HEAT: reserved for measurement of heat power and heat energy

totalisation.

5) BATCH: batch volume.

6) MODIS: Cannot be altered.

Unit: °Cor°F, range: -50...+150°C / -58...302°F.

Unit: °Cor°F, range: -50...+150°C / -58...302°F.

Unit: °Cor°F, range: -50...+150°C / -58...302°F.

Unit: °Cor°F, range: -50...+150°C / -58...302°F.

Unit: bar(a) or psi(a), range: 0...100 bar(a).

Unit: bar(a) or psi(a), range: 0...100 bar(a).

100%

100%

when

40

Range: 10-9...109.

3.02.09 K1 Product constant K1.

Range: 10-9...109.

3.02.10 K2 Product constant K2.

Range: 10-9...109.

3.02.11 DENSITY 15 Product density at T = 15°C/ 59°F.

Range: 500...2000 kg/m3.

3.02.12 FULL SCALE Heat measurement. Full scale setting and unit for heat power.

Available units: GJ/s, GJ/hr, MJ/s, MJ/hr, GCal/s, GCal/hr, MCal/s,

MCal/hr.

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 41

UFM 530 HT

OPERATION 6

No. of menu Display text Setting/description and functions

3.02.13 BATCH VOL Batch volume total size and units.

Availabe units: m3, Liter, US-Gallon, Barrel or user definable unit.

Range: 0.025...100000 m3.

3.03.00, DISPLAY.

3.03.01 DISP FLOW Display of flow. Available options:

1) RATE: full-scale units (flow is shown with the unit as set in function

3.01.01).

2) PERCENT: flow is shown as a percentage (0...100%) of the full

scale value.

3) NO DISPLAY: no flow is shown.

3.03.02 FUNCT TOT Function of totalizer. Two totalizers (counters) are available. The

3.03.03 DISP TOTAL Display of totalizer. A totalizer can be selected here for displaying:

3.03.04 TOTAL VOL Unit for volume totalizer. Note: the maximal value of the totalizer is

totalizer values are incremented and stored once a second. The

following settings are available:

1) ACT FLOW: actual flow units, used for counting the total volume in

the totalizer (for each direction one totalizer is available, the sum of

the two can also be displayed).

2) CORR FLOW: the corrected flow is used for counting the total

volume in the totalizers.

3) POS BOTH: both the actual and the corrected flow are used for

counting the total volume in the totalizers. Note: both are only

counted in the positive direction!

1) TOTAL OFF: both totalizers are switched off, counting stops.

2) FORWARD: forward volume units.

3) REVERSE: reverse volume units.

4) BOTH: both totalizers, alternating.

5) SUM: sum of both totalizers.

6) BOTH + SUM: both totalizers und their sums show alternating.

7) NO DISPLAY: totalizers are not displayed but totalizers count.

3

99999999 x 10 m

and will roll over to 0 at overrun!

Available units: X10 m3, US-Gallon, m3, barrel, liter.

3.03.05 TOTAL ENER Unit for the heat energy totalizer. Note: the maximal value of the

totalizer is 99999999 x 10 GJ and will roll over to 0 at overrun!

Available units: X10 GJ, GJ, MJ, GCal., MCal.

3.03.06 VOS Unit for velocity of sound. Available options:

1) NO DISPLAY: no display of the velocity of sound.

2) m/s, feet/s.

3.03.07 CYCL DISP If more than one measured value are to be displayed (e.g. flow rate

and totalizer), each value can be selected manually by pressing the

↑ key, or the values can be alternately displayed each five seconds by

turning the cyclic display function on.

3.03.08 ERROR MSG Display error messages

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

41

Page 42

6 OPERATION

No. of menu Display text Setting/description and functions

UFM 530 HT

3.03.10 AN INPUT Enabling or disabling the display of the analog inputs. Note: this

3.03.11 SIGN LEVEL This function enables or disables the display of the signal level from

function is only available for converter function CORR T and

CORR T+P (see function 3.02.01)!

The display of the values represented by the current signal coming

from the temperature and pressure transducers. Available settings:

1) NO

2) YES

the sensors. For each measuring path this level is displayed as a gain

value 0...80 dBV at the input amplifier. Available options:

1) NO

2) YES

42

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 43

UFM 530 HT

OPERATION 6

3.04.00, CURR OUTP (Current output)

3.04.01 FUNCTION The current output can be programmed for the following functions:

1) OFF: switched off, current output steady at current value for 0 %

scale.

2) ACT FLOW: proportional with the actual volume flow.

3) CORR FLOW: proportional with the corrected volume flow. Note:

this function ist only available if the converter function is set to

CORR T or CORR T+P (see function 3.02.01)!

4) F/R IND: forward/reverse indication of actual flow.

100 pct mA value for forward flow, 0 pct mA value for reverse flow.

5) VOS: proportional with the velocity of sound (range is defined in

function 3.01.11 and 3.01.12).

6) GAIN: sensor signal gain, range is 0...100 dBV.

7) AN INP 1: proportional with the signal on analog input 1. Note: this

function is only available if the converter function is set to CORR T or

CORR T+P!

8) AN INP 2: proportional with the signal on analog input 2. Note: this

function is only available if the converter function is set to CORR T or

CORR T+P!

3.04.02 DIRECTION Direction of current output, only available when ACT FLOW or

3.04.03 RANGE Range of current output (Note: maximum reading is 22 mA!):

3.04.04 0pct Setting of mA for 0% of the range.

3.04.05 100 pct Setting of mA for 100% of the range. Note: value must be at least

3.04.06 LIMIT Limitation of current output. While default is 22 mA it can be switched

3.04.07 ERR INDIC Only available for NAMUR devices. Options:

CORR FLOW is selected in function 3.04.01. In this case there are the

following options:

1) FORWARD: the current output will only be active when the flow is

in the forward flow direction as defined in function 3.01.10.

2) BOTH: the current output will be active when the flow is in the

forward ord reverse flow direction, indicating both in the same range.

3) F/R SPEC: forward and reverse flow measurement indicated in

different range. Use this function to indicate the reverse flow in the

range from 0 mA through 0 pct mA. Note: when the flow goes from

the forward direction to the negative direction, the current output will

pass the "0 pct" mA value down to 0 mA, where it stops!

1) OTHER: user defined span.

2) 0...20/22 mA: 0...100 pct / limit.

3) 4...20/22 mA: 0...100 pct / limit.

Range: 0...16 mA (default: 4 mA).

4 mA greater than current value for 0% scale!

Range: 4...20 mA (default: 20 mA).

to 20 mA when safety system reserve higher currents as fault codes.

Range: 20...22 mA.

1) I

=3.6mA.

ERR

2) I

= 21.5 mA.

ERR

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

43

Page 44

6 OPERATION

3.05.00, PULSE OUTP (Pulse output)

3.05.01 FUNCTION Function of pulse output with the following options:

3.05.02 DIRECTION Direction of pulse output, only availabe when ACT FLOW or

3.05.03 DIG OUTPUT Function of digital output, only available when DIG OUTPUT is

3.05.04 TRIP PNT 1 First trip point.

3.05.05 TRIP PNT 2 Second trip point.

3.05.06 TIME CONST Time constant of pulse output (Note: the time constant setting only

UFM 530 HT

1) OFF: switched off, contact closed.

2) ACT FLOW: proportional with the actual volume flow.

3) CORR FLOW: proportional with the corrected volume flow.

4) F/R IND: forward/reverse flow indication. Contact closed for

forward flow, contact open for reverse flow .

5) VOS: proportinal with the velocity of sound (range defined in

function 3.01.11 and 3.01.12).

6) DIG OUTPUT: digital output.

7) BATCH OUTP: batch output indication, only available for the batchversion. Contact closes at start of the batch and opens when the

batch is reached.

8) GAIN: gain of sensor amplifier, proportional with the signal level.

Range: 0...100 dBV.

9) AN INP 1: proportional with the signal on analog input 1, only

available for the converter functions CORR T and CORR T+P.

11) AN INP 2: proportional with the signal on analog input 2, only

available for the converter functions CORR T and CORR T+P.

CORR FLOW is selected in function 3.05.01.

1) FORWARD: the pulse output will only be active when the flow is in

the forward flow direction as defined in function 3.01.10.

2) BOTH: the pulse output will be active in both flow directions

(forward and reverse), indicating both in the same range.

selected in function 3.05.01. The pulse output now acts as a digital

output and can be programmed for the following functions:

1) PATH ERR: measuring path error indication (contact open).

2) TOTAL ERR: totalizer error indication (contact open).

3) ALL ERR: indication of all errors (contact open).

4) AN INP ERR: analog input error indication (contact open).

5) OVERRANGE: overrange indication (contact open).

6) TRIP POINT: status output trips if actual flow (Q) goes over a set

limit (an hysteresis is build in). Set points can be set using function

3.05.04 and 3.05.05.

Range: 0...120% of Q

Range: 0...120% of Q

applies to actual flow and corrected flow!):

1) 25 ms (lowest value).

2) MASTER TC: time constant has the value set in function 3.01.04.

100%

100%

.

.

44

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 45

UFM 530 HT

OPERATION 6

3.05.07 OUTPUT Unit of pulse output:

1) PULSE RATE (frequency): pulses per unit time, setting by entering

a frequency at 100% volume flow rate.

2) PULSE/UNIT (totalizer pulse output): pulses per unit volume ,

setting by entering a value for the number of pulses for each volume

or energy unit. Each pulse has a fixed volume (i.e. 1 pulse per

0.1 liter). This is the best method of remote totalizing, as pulses

simply need to be counted.

3.05.08 PULSE RATE Pulse rate (frequency) value for 100% scale. If function 3.05.07 is set

3.05.09 PULSE/UNIT Pulse value per volume unit for totalisation. Note: Check that the

3.05.10 PULSE/UNIT Pulse value per heat energy unit for totalisation. If function 3.05.07 is

3.05.11 PULS WIDTH For frequencies ≤10 Hz the following pulse widths can be applied:

to PULSE RATE, the following units can be chosen using this function:

pulse/s, pulse/hr, pulse/min.

Range: 10 pulses/h...2000 pulses/s, default setting: 1000 Hz.

maximum flow span will not cause the number of pulses generated

per second to exceed the maximum of 2000 Hz!

If function 3.05.07 is set to PULSE/UNIT, the unit and number of

pulses per unit can be set for the flow measurement using this

function. Available options: pulse/m

3

, pulse/l , pulse/US-Gallon,

pulse/bbl, free user definable unit.

Default setting: 1, maximum number of pulses per unit: 7870000.

set to PULSE/UNIT, the unit and number of pulses per unit can be set

for the heat power measurement using this function. Available

options: pulse/MJ, pulse/GCal, pulse/MCal, pulse/GJ.

Default setting: 1, maximum number of pulses per unit: 1000000.

1) 25 ms for P

2) 50 ms for P

3) 100 ms for P

4) 200 ms for P

5) 500 ms for P

100%

100%

100%

100%

100%

<10Hz.

<10Hz.

<5Hz.

<2.5Hz.

<1Hz.

For frequencies 10...1000 Hz: 50% duty cycle, 1000...2000 Hz: 70/30%

duty cycle (Note: pulse width may vary 5 ms, pulse period may vary

25 ms!)

3.06.00, DIG INPUT (Digital input)

3.06.01 FUNCTION Function of digital input. The digital input terminal is the same as the

current output terminal. Therefore, when a digital input function is

selected, the function of the current output needs to be set to OFF

and the current output range has to be set to 0...20 mA. The following

options are available for the digital input:

1) OFF: switched off, no function.

2) RST TOTAL: reset display totalizer(s), independent of the

programming of function 3.07.08.

3) RST ERROR: reset error messages.

4) FORCE ZERO: force display and outputs to their "zero" values.

5) BATCH: start (input high) or stop (input low) a batch, only available

for the batch-version.

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

45

Page 46

6 OPERATION

3.07.00, USER DATA

3.07.01 LANGUAGE Language for display texts:

3.07.02 ENTRY CODE Entry code for setting mode:

3.07.03 CODE 1 Press any 9-keystroke combination and then press the same

3.07.04 LOCATION Tag name setting. Free settable tag for identification, maximum

3.07.05 UNIT TEXT Text for user-defined unit. Definition: volume/time.

3.07.06 UNIT VOL

UFM 530 HT

1) GB/USA: English.

2) D: German.

3) F: French.

1) NO: entry with → key only.

2) YES: entry with → key and code 1, factory set on 9 x key.

combination again. Each keystroke is acknowledged by "?" in the

display. If both combinations are equal, "CODE OK" appears and the

new code can be stored. Otherwise "WRONG CODE" appears and the

desired code has to be entered again.

10 characters.

Characters assignable to each place: A...Z, blank character, 0...9.

Factory setting: KROHNE.

Characters assignable to each place: A...Z, blank character, 0...9.

Note: fraction bar "/" in 5th place is unalterable!

Factory setting: XXXX/YYY.

User-defined unit volume. Quantity of user-defined volume per m3.

Range: 10-5...107, factory setting: 1.

3.07.07 UNIT TIME User-defined unit time. Amount of user-defined time in seconds.

Range: 10-5...107, factory setting: 1.

3.07.08 RST ENABLE Enable the reset of the display totalizer(s). Note: this function doesn't

3.07.09 ERR LIMIT Error limit in % of measured value for plausibility filter on the sensor

3.07.10 CNT DECR Counter decrement setting for plausibility filter.

3.07.11 CNT LIMIT Counter limit for plausibility filter. When "0" is set, the plausibility

affect the ability to reset the display totalizer(s) using the digital

input! Available options:

1) NO: totalizer reset disabled.

2) YES: totalizer reset enabled.

paths.

filter will become inactive.

Range: 0...1000, factory setting: 0.

46

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 47

UFM 530 HT

OPERATION 6

3.09.00, COMMUNICATION

3.09.01 PROTOCOL Communication protocol:

1) OFF: no communication.

2) HART: HART® (standard available).

3) PROFIB PA: PROFIBUS PA (optional available).

3.09.02 HART ADDR

3.09.03 PP/FF ADDR PROFIBUS PA address.

INFORMATION!

In the next part, multiple error messages are shown. Details about the specific functions are

described earlier in the "Installation menu".

Parameter error menu

HART® address.

Range: 00...16.

Range: 000...126.

No. of menu Display text Setting/description and functions

4.01.00, FLOW VELOC

Volume flow velocity (v) value incorrect. The flow speed is calculated from the full scale volume flow and

the meter size. Note: ensure condition 0.5 m/s ≤ v ≤ 20 m/s (1.64 feet/s ≤ 65.62 feet/s) is met!

4.01.01 FULL SCALE Full-scale value for 100% volume flow rate.

4.01.02 METER SIZE Meter size.

4.02.00, CURR OUTP (Current output)

Current output range incorrect. Setting for 100% is compared with setting for 0%. Note: ensure condition

100 pct-0 pct ≥ 4mA is met!

4.02.01 RANGE Range of current output.

4.02.02 0pct Current value for 0% scale.

4.02.03 100 pct Current value for 100% scale.

4.03.00, LF CUTOFF (Low-flow cut-off)

Low-flow cut-off range incorrect. If low flow cut-off is set to "on", the value for CUTOFF-OFF is compared

with the value of CUTOFF-ON on. Note: ensure condition CUTOFF-OFF – CUTOFF-ON ≥ 1% is met!

4.03.01 LF CUTOFF Low-flow cut-off.

4.03.02 CUTOFF ON Cutoff "on" value.

4.03.03 CUTOFF OFF Cutoff "off" value.

4.04.00, ENERGY

Full scale value for heat energy rate (E) incorrect. The fullscale value is compared with the maximum

value that can be measured and should meet the condition E

maximum value that can be measured is at maximum flow and 200°C temperature difference!

4.04.01 HEAT FS Full-scale value for 100% heat energy rate.

max<Efullscale<Emax

/1000. Note: the

4.05.00, PULSE/VOS (Pulse/Velocity of sound)

Unit of pulse output for velocity of sound function incorrect. Note: ensure that "PULSE RATE" is selected

for "VOS"!

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

47

Page 48

6 OPERATION

No. of menu Display text Setting/description and functions

4.05.01 PULS FUNCT Function of pulse output.

4.05.02 PULSE OUTP Unit of pulse output.

4.06.00, VOS (Velocity of sound)

Velocity of sound range incorrect. Note: ensure condition MAX VOS - MIN VOS ≥ 1 m/s (3.28 feet/s) is met!

4.06.01 MIN VOS Minimum velocity of sound.

4.06.02 MAX VOS Maximum velocity of sound.

4.07.00, PULSE OUTP (Pulse output)

Pulse output frequency value (f) incorrect. The maximum frequency is calculated from the PULSE/UNIT

setting and the maximum value of the measured value. Note: ensure condition

1pulse/hr≤ f ≤ 2000 pulse/s is met!

4.07.01 PULSE/UNIT Pulse value for volume flow rate unit.

4.07.02 PULSE/UNIT Pulse value for heat power rate unit.

4.08.00, PULS WIDTH

Pulse output pulse width incorrect. Note: ensure condition pulse width ≤ 0.5 x pulse period time is met!

4.08.01 PULS WIDTH Pulse width for frequencies ≤ 10 Hz.

UFM 530 HT

4.09.00, HART

Current output range for HART® incorrect. If HART® is activated, the minimum possible current should

be 4 mA. Note: ensure condition CURR 0 pct ≥ 4mA is met!

4.09.01 CURR RANGE Range of current output.

4.09.02 CURR = PCT Current value for 0% scale.

4.10.00, INP/OUTP (Input/Output)

The digital input (C) and current output (I) are not allowed to be switched on simultaneously. If the

Profibus option is activated, only one of the following input/output functions can be used: digital input (C),

current output (I), pulse output (P). The current output is deactivated by setting the function of current

output to "off" and setting the range of current output to 0...20 mA.

4.10.01 INP FUNCT Function of digital input.

4.10.02 CURR FUNCT Function of current output.

4.10.03 CURR RANGE Range of current output.

4.10.04 PULS FUNCT Range of pulse output.

4.13.00, EPROM

EPROM checksum error. Resetting device is necessary.

48

www.krohne.com 12/2013 - 4002393201- HB UFM 530 HT R02 en

Page 49

UFM 530 HT

6.4 Important menu functions in detail

INFORMATION!

Since the UFC 030 converter can be equipped with different options, the availability of certain

options depends on the function of the converter.

In this chapter the different functions of the menu structure are described in more depth.

6.4.1 Error/totalizer (Menu 0.00.00)

This menu is accessible from the measuring mode by pressing the ^ key to enter "CODE 2" and

afterwards pressing the key ↑ and and then →.

INFORMATION!

Only when function 3.03.08 is set to YES, errors occurring during process flow measurement are

represented with flashing display lines and/or a compass field!

Depending on the programming of function 3.03.07, the error messages alternate with the

display of the measured value(s) every five seconds or they can be manually selected by pressing

the ↑ key.

OPERATION 6

1 Compass needle, indicating measuring path error(s): depending on the version of the sensor triangle a appears when

there is no measured value from path 2 and triangle b from path 1; triangle c appears when there is too much noise

on the measuring path(s) for proper measurement.

2 Flashing bar, indicating "new" errors, i.e. not yet acknowledged.

3 Flashing line with description of error message(s).

4 Flashing line with number of errors that have occurred.

The following list gives an alphabetical overview of error messages that can occur during

process flow measurement and what to do:

www.krohne.com12/2013 - 4002393201- HB UFM 530 HT R02 en

49

Page 50

6 OPERATION

UFM 530 HT

Error

Description of error message What to do

message

ADC AN INP Analog input internal error (A1or A2). Switch off the flowmeter and switch it on

COMMUNIC Communication device internal error. Reset the error and wait for one minute. If

CURR > MAX Current output overflow (> 22 mA). Check flow velocity.

DSP Digital signal processor (DSP) internal

EE MENU Menu parameters corrupted. Contact your local representative.

EE SERVICE Service parameters internal error. Contact your local representative.

EMPTY PIPE Measuring tube not completely filled,

FLOW > MAX Measuring range overflow

FRONT END Front end internal error. Only checked at power-up. Switch off the

INP1 < MIN Analog input 1 too low (<3.6 mA). Check analog input 1 connection.

INP1 > MAX Analog input 2 too high (>22 mA). Reduce analog input 1 current.

INP2 < MIN Analog input 2 too low (<3.6 mA). Check analog input 2 connection.

INP2 > MAX Analog input 2 too high (>22 mA). Reduce analog input 2 current.

RESTART Flow meter restarted. Reset errors.

UNRELIABLE Flow data disturbed, same as triangle 4 in

OPEN CIRC Sensor X not connected or damaged

PATH 1 Measuring path 1 error. Check flow conditions.

PATH 2 Measuring path 2 error. Check flow conditions.

PULS > MAX Pulse output overflow (>120%). Check flow velocity.