Page 1

OPTISYS TUR 1050

Handbook

Compact measuring system for turbidity

© KROHNE 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2012 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 3

OPTISYS TUR 1050

CONTENTS

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 Certification ...................................................................................................................... 5

1.2.1 CE ............................................................................................................................................ 5

1.2.2 ETL .......................................................................................................................................... 5

1.2.3 US EPA 180.1........................................................................................................................... 5

1.2.4 ISO 7027 and DIN 27027.......................................................................................................... 5

1.3 Safety instructions from the manufacturer ..................................................................... 6

1.3.1 Copyright and data protection ................................................................................................ 6

1.3.2 Disclaimer ............................................................................................................................... 6

1.3.3 Product liability and warranty ................................................................................................ 7

1.3.4 Information concerning the documentation........................................................................... 7

1.3.5 Warnings and symbols used................................................................................................... 8

1.4 Safety instructions for the operator................................................................................. 8

2 Device description 9

2.1 Scope of delivery............................................................................................................... 9

2.2 Device description .......................................................................................................... 10

2.3 Nameplates .................................................................................................................... 12

3 Installation 14

3.1 Notes on installation ......................................................................................................14

3.2 Storage and transport .................................................................................................... 14

3.3 Requirements of the device............................................................................................ 14

3.4 Installation order............................................................................................................ 15

3.4.1 Placing the desiccant pouch and the humidity indicator ..................................................... 15

3.4.2 Selecting site and mounting ................................................................................................. 16

3.4.3 Mounting ............................................................................................................................... 18

3.4.4 Connecting the hoses............................................................................................................ 19

3.4.5 Drain vent .............................................................................................................................. 20

3.4.6 Inserting and fixing the ultrasonic cuvette with flow-through holder ................................. 21

4 Electrical connections 22

4.1 Safety instructions.......................................................................................................... 22

4.2 Description of board and bulkheads .............................................................................. 22

4.3 Circuit breaker and specifications of power supply ...................................................... 23

4.4 Cable specifications........................................................................................................ 23

4.5 Installation order of the electrical connections............................................................. 23

4.5.1 Connecting the cables in the junction box power assembly ................................................ 24

4.5.2 Alarms terminal (signal output) ........................................................................................... 25

4.5.3 RS 485 or 4...20 mA signal output.........................................................................................25

4.5.4 Connecting the sensor interconnect cable........................................................................... 26

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

3

Page 4

CONTENTS

OPTISYS TUR 1050

5 Operation 27

5.1 Start-up........................................................................................................................... 27

5.2 Display and operating keys ............................................................................................ 28

5.3 Normal operation ...........................................................................................................28

5.4 Getting access with activated security access function ................................................ 29

5.5 Menu topology ................................................................................................................ 30

5.6 Calibration mode (main menu) ...................................................................................... 30

5.6.1 Calibration liquids................................................................................................................. 31

5.6.2 Calibration procedure (physical), inclusive indexing ........................................................... 31

5.6.3 Calibration procedure (offset calibration)............................................................................ 33

5.6.4 Calibration error ................................................................................................................... 35

5.7 Configuration mode (main menu) .................................................................................. 35

5.7.1 Selecting the output.............................................................................................................. 36

5.7.2 Setting the 4...20 mA output inclusive error level................................................................ 37

5.7.3 Configuring the RS 485 port.................................................................................................. 38

5.7.4 Configuring the alarm relays................................................................................................ 39

5.7.5 Offset calibration................................................................................................................... 41

5.7.6 Enabling or disabling the security access............................................................................ 41

5.7.7 Extended settings.................................................................................................................. 41

5.8 Restoring the factory settings........................................................................................ 47

5.9 Faults: reasons and remedies ....................................................................................... 47

6 Service 50

6.1 Service admonitions ....................................................................................................... 50

6.2 Maintenance ................................................................................................................... 50

6.2.1 Replacing or cleaning cuvette .............................................................................................. 50

6.2.2 Replacing desiccant pouch and humidity indicator.............................................................. 51

6.2.3 Replacing the source lamp................................................................................................... 51

6.3 Availability of services .................................................................................................... 52

6.4 Spare parts availability...................................................................................................52

6.5 Spare or accessory parts ............................................................................................... 52

6.6 Returning the device to the manufacturer..................................................................... 53

6.6.1 General information.............................................................................................................. 53

6.6.2 Form (for copying) to accompany a returned device............................................................ 54

6.7 Disposal .......................................................................................................................... 54

7 Technical data 55

7.1 Measuring principle........................................................................................................55

7.2 Technical data table .......................................................................................................56

7.3 Dimensions and weight .................................................................................................. 58

8 Notes 59

4

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 5

OPTISYS TUR 1050

1.1 Intended use

The OPTISYS TUR 1050 series consists of a white light (WL) version and an infrared (IR) version.

Both versions are designed to measure online the turbidity of water. Furthermore the two

following different measuring ranges are available: 0.02...100 NTU/FNU or 0.02...1000 NTU/FNU

1.2 Certification

1.2.1 CE

CE marking

The device fulfils the statutory requirements of the following EC directives:

• Electromagnetic compatibility (EMC) in accordance with:

EN 61326-1:2006: Emission standard and immunity for industrial environments.

• Low Voltage Directive:

Safety requirements for electrical equipment for measurement, control and laboratory use in

accordance with EN 61010-1:2001, Edition 2.0.

SAFETY INSTRUCTIONS 1

The manufacturer certifies successful testing of the product by applying the CE marking.

1.2.2 ETL

The manufacturer tested the device and it fulfils the following ETL requirements:

• ETL: tested to UL 61010B-1, 1st Edition, January 24th, 2003.

• ETLc: tested to CS C22.2#1010.1-92.

1.2.3 US EPA 180.1

The white light version meets the design criteria specified by the US EPA 180.1 on turbidity

measurement.

1.2.4 ISO 7027 and DIN 27027

The infrared version meets the design criteria specified in ISO 7027 and DIN 27027 for the

measurement of the turbidity of a sample.

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

5

Page 6

1 SAFETY INSTRUCTIONS

1.3 Safety instructions from the manufacturer

1.3.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

OPTISYS TUR 1050

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.3.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

6

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 7

OPTISYS TUR 1050

1.3.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.3.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

7

Page 8

1 SAFETY INSTRUCTIONS

1.3.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

OPTISYS TUR 1050

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

This symbol refers to all important consequences of the previous actions.

1.4 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

8

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 9

OPTISYS TUR 1050

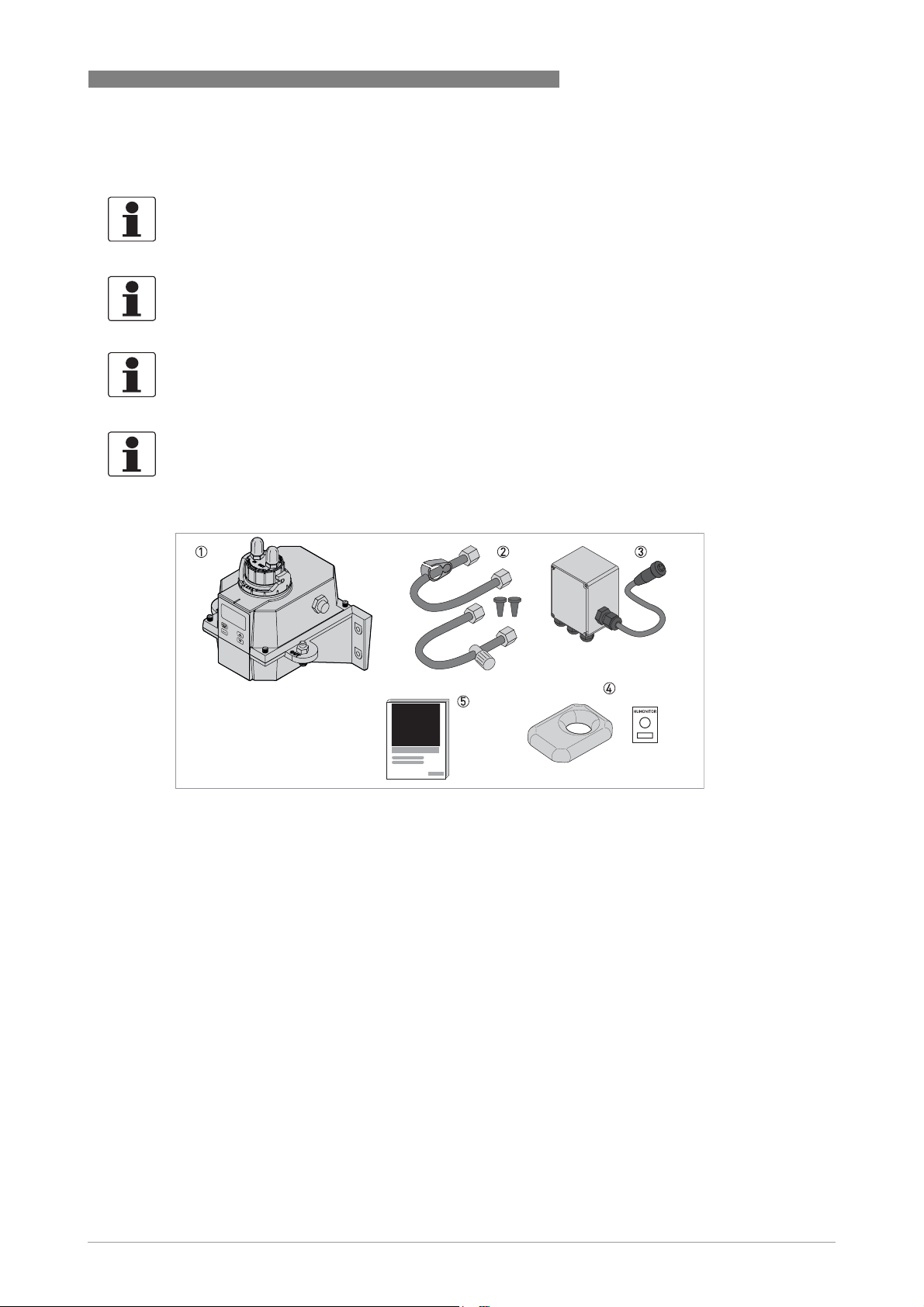

2.1 Scope of delivery

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

DEVICE DESCRIPTION 2

Figure 2-1: Scope of delivery

1 Electronic device with flow-through assembly and ultrasonic cuvette

2 Tubing kit (drain vent, shut-off clamp, backpressure valve, connection tubes with fittings for

ultrasonic cuvette assembly)

3 Junction box power assembly

4 Desiccant pack (desiccant pouch with humidity indicator)

5 Documentation

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

9

Page 10

2 DEVICE DESCRIPTION

2.2 Device description

Front view of the complete device

OPTISYS TUR 1050

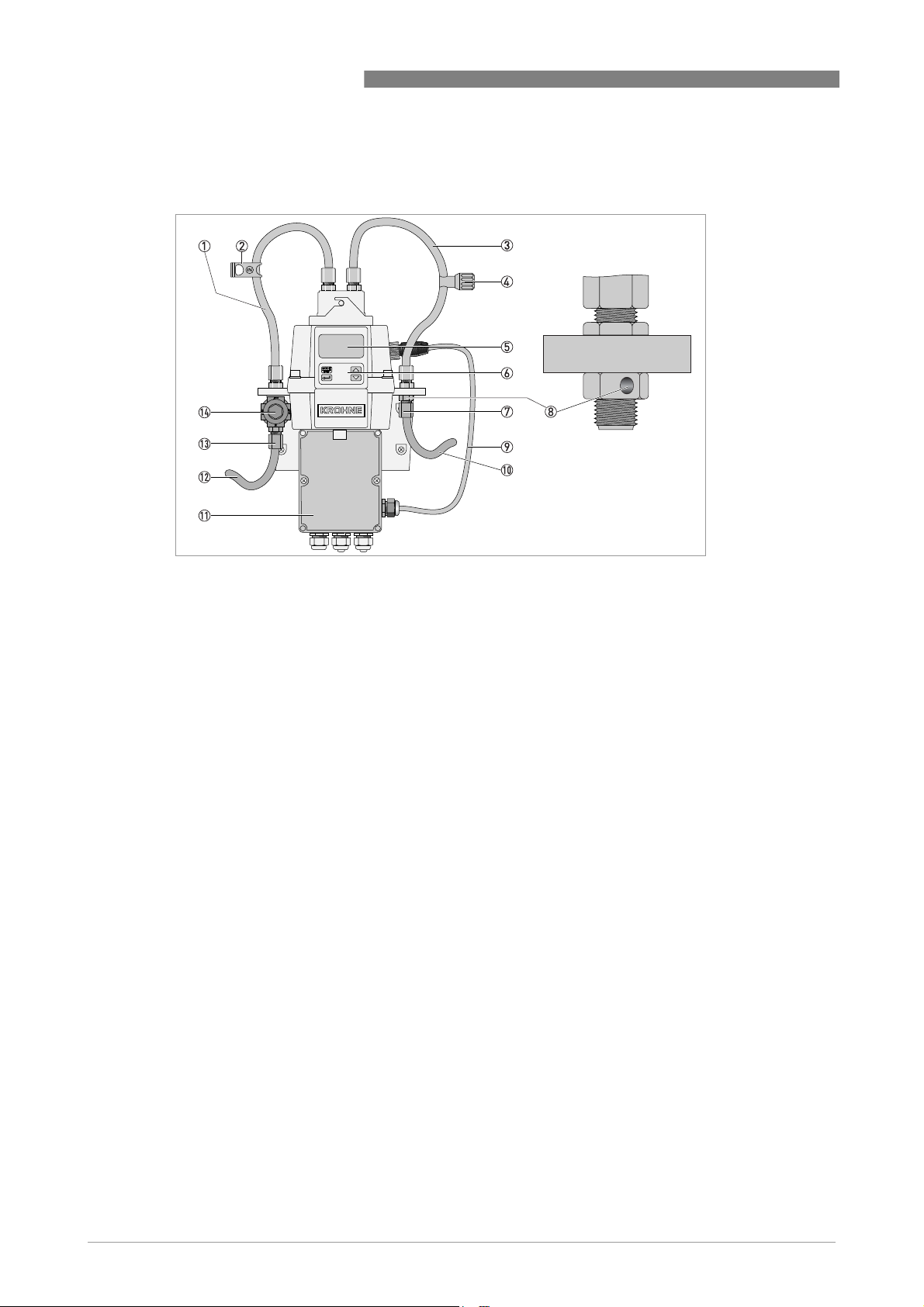

Figure 2-2: Description of the complete device

1 Intake tubing

2 Shut-off clamp (stops the intake flow during cuvette cleanings and replacements)

3 Drain tubing

4 Backpressure valve (allows adjustment of the amount of back pressure, which helps to control the flow rate and elim-

inate small bubbles)

5 Display (LCD)

6 Operation keys

7 Drain hose connection (inner Ø: 4.75 mm / 0.19", outer Ø: 8 mm / 0.31"), the hose has to lead to a suitable drain site

8 Drain vent hole

9 Sensor interconnect cable

10 Drain hose

11 Junction box power assembly

12 Intake hose

13 Intake hose connection (inner Ø: 4.75 mm / 0.19",outer Ø: 8 mm / 0.31"), has to supply the sensor with a dependable

sample flow

14 Pressure regulator

10

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 11

OPTISYS TUR 1050

Ultrasonic cuvette with flow-through holder

Figure 2-3: Description of ultrasonic cuvette with flow-through holder

1 Intake tubing

2 Drain tubing

3 Bolt

4 Ultrasonic cuvette

5 Bottom plate with ultrasonic transducer (at the bottom side)

DEVICE DESCRIPTION 2

The device is available with a white light source or an infrared light source. There are no visible

differences between these versions. Both versions provide the possibility of ultrasonic cleaning.

Every device has a pressure regulator for the incoming flow which reduces pressures up to

14 bar / 203 psi down to 1 bar / 15 psi.

Dehumidification system

The device is equipped with a continuous dehumidification system that works with the help of a

replaceable desiccant pouch in the electronic device. While the system heat is used to warm the

air, a fan inside the device continuously circulates this heated and by the desiccant pouch

dehumidified air around the optical well and the electronic device. This features eliminates the

need for a dry purge line.

The device monitors the replaceable desiccant pouch condition continuously. The lower line of

the display shows the message "DESC" in the event that you have to replace a saturated

desiccant pouch that may cause problems.

Liquid crystal display (LCD)

For a better readability in low light or no light conditions the LCD is backlight. The backlight

always stays on, but the brightness is adjustable.

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

11

Page 12

2 DEVICE DESCRIPTION

RS 485 interface

In addition to the Modbus communication the device can operate in two other RS 485 modes:

• Online: the device operates as a small SCADA system (Supervisory Control and Data

Acquisition) with an optional software package (to get this package contact the manufacturer

or your local sales office). This system allows the connection of up to 255 devices for data

logging which all have to be an OPTISYS TUR 1050. Furthermore this system offers a direct

interface with common database and spreadsheet software.

• Simple: the device can provide basic communications with the help of simple programs.

Examples for such programs are Hilgraeve hyperterminal (included in most Microsoft

Windows packages) or Visual Basic.

Ultrasonic cleaning

This feature helps to clean the ultrasonic cuvette continuously. The system works by sending an

ultrasonic frequency through spring connections in the upper part of the device to a piezo

transducer at the bottom of the ultrasonic cuvette.

The ultrasonic cleaning can increase the time between cleanings significantly. However it cannot

substitute the manual cleaning entirely.

OPTISYS TUR 1050

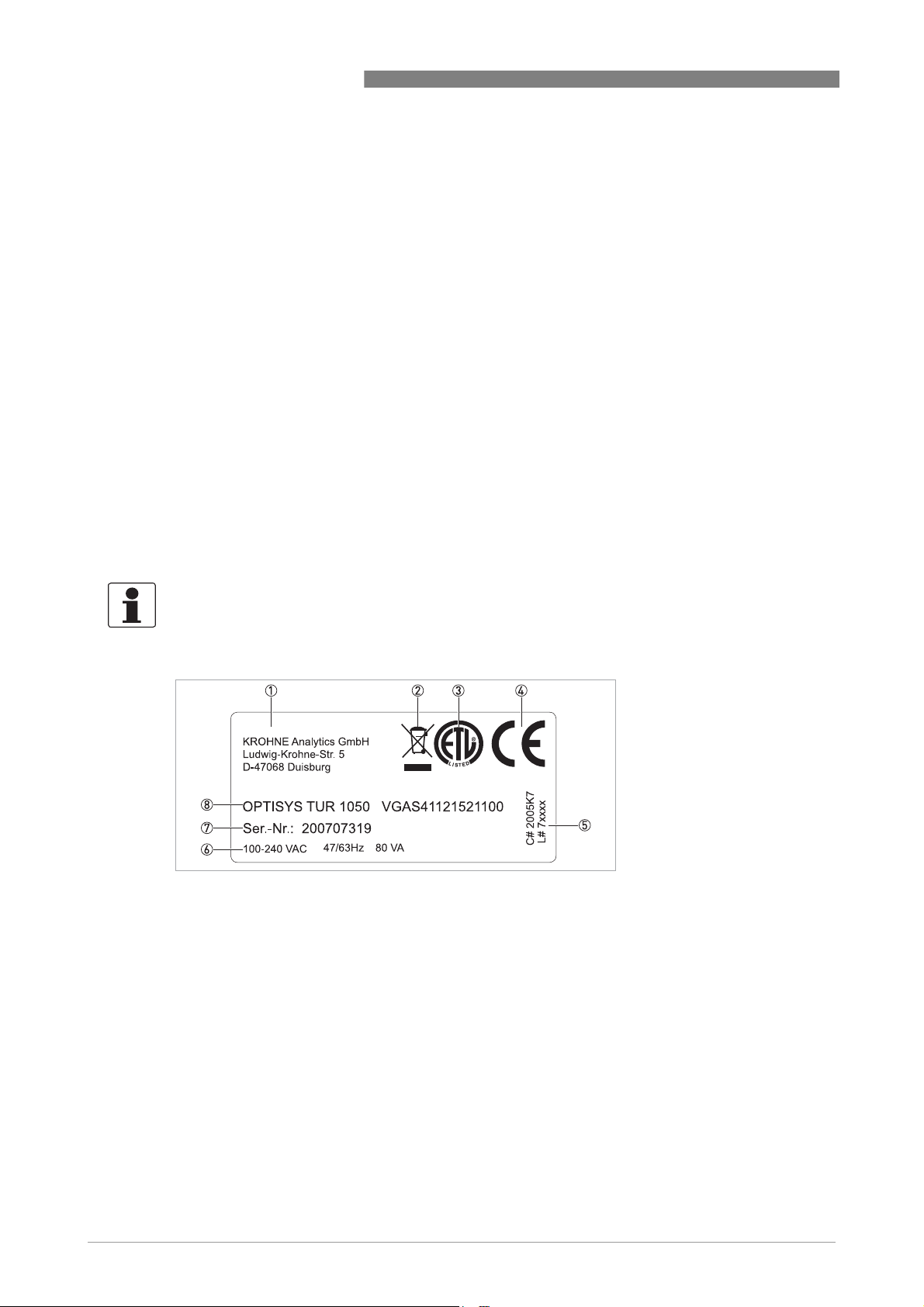

2.3 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

Infrared version

Figure 2-4: Example for nameplate for infrared version

1 Manufacturer and address

2 WEEE waste bin symbol

3 ETL symbol

4 CE symbol

5 Logistics numbers

6 Electrical data

7 Serial number

8 Device designation and order code

12

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 13

OPTISYS TUR 1050

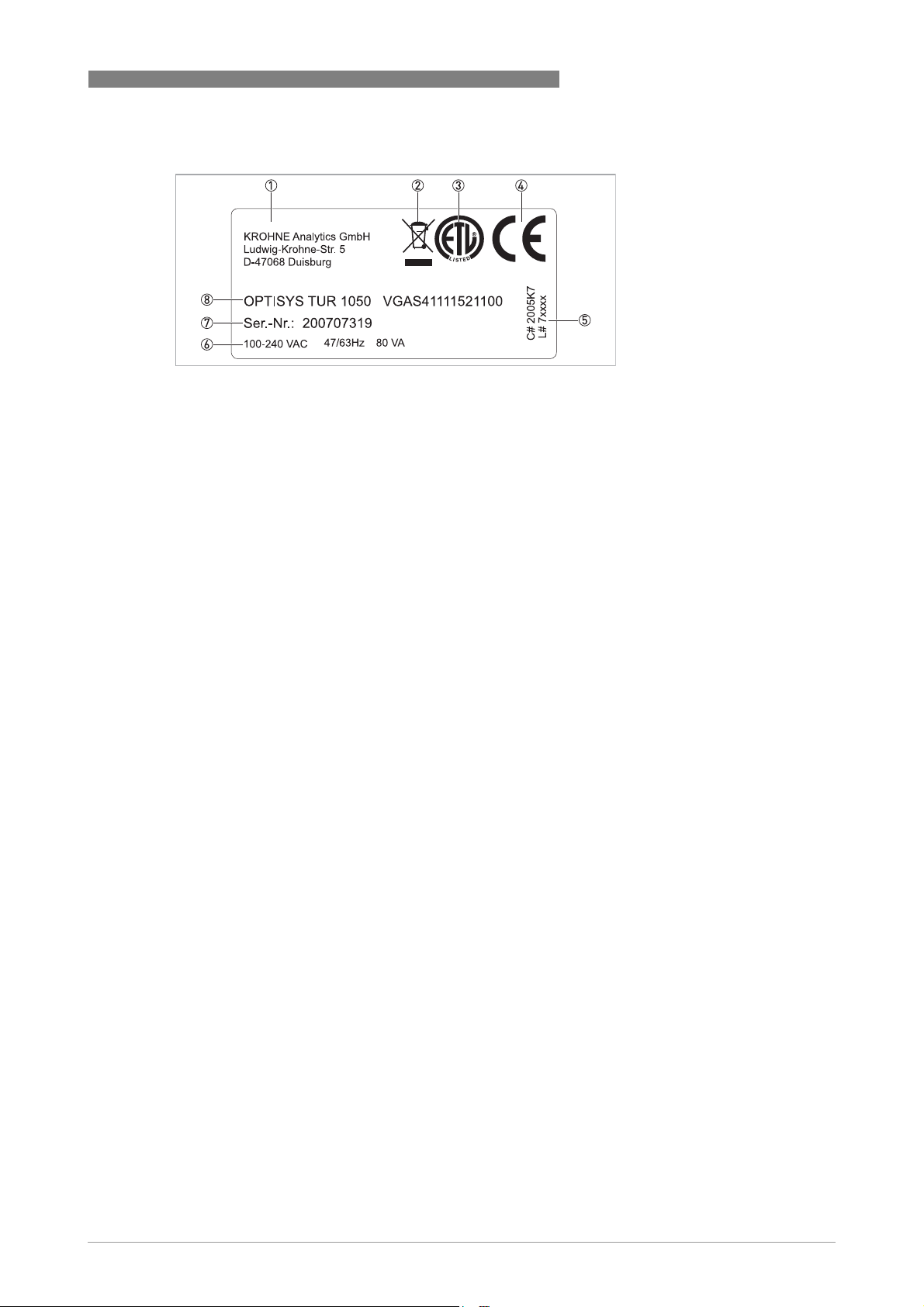

White light version

Figure 2-5: Example for nameplate for white light version

1 Manufacturer and address

2 WEEE waste bin symbol

3 ETL symbol

4 CE symbol

5 Logistics numbers

6 Electrical data

7 Serial number

8 Device designation and order code

DEVICE DESCRIPTION 2

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

13

Page 14

3 INSTALLATION

3.1 Notes on installation

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage and transport

• Store and transport the device in a dry, dust-free environment.

• Store and transport the device in an environment with a temperature between -20...+60°C/

-4...+176°F.

• The original packing is designed to protect the equipment. It has to be used if the device is

transported or sent back to the manufacturer.

OPTISYS TUR 1050

3.3 Requirements of the device

The device was designed to require very low input pressure. Though the device offers a wide

pressure range, as it has an integrated pressure regulator:

• Input pressure range: 0.07...14 bar / 1...200 psi (built in regulator set at 1 bar / 15 psi)

• Maximum allowable flow rate of the cuvette: 0.1...1 l/min / 0.026...0.26 gal/min

• Maximum fluid temperature: +50°C / +122°F

14

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 15

OPTISYS TUR 1050

3.4 Installation order

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

To install the device in the correct way, follow the order of the following sections and their

instructions.

3.4.1 Placing the desiccant pouch and the humidity indicator

CAUTION!

A missing or saturated desiccant pouch affects not only the performance of the whole device, but

can also destroy the internal electronics!

If the seal at the device base does not fit properly or is defective, the lifetime of the desiccant

decreases. Therefore assure the following items:

•

Do not start-up the device with a desiccant pouch missing, replace a saturated pouch!

•

Replace the desiccant pouch when the display shows the message "DESC".

•

Inspect the enclosure seal each time you replace the desiccant.

•

If the seal is not properly seated or damaged, reseat or replace it!

INSTALLATION 3

Execute the following steps to insert or replace the desiccant pouch and the humidity indicator

®

(Humonitor

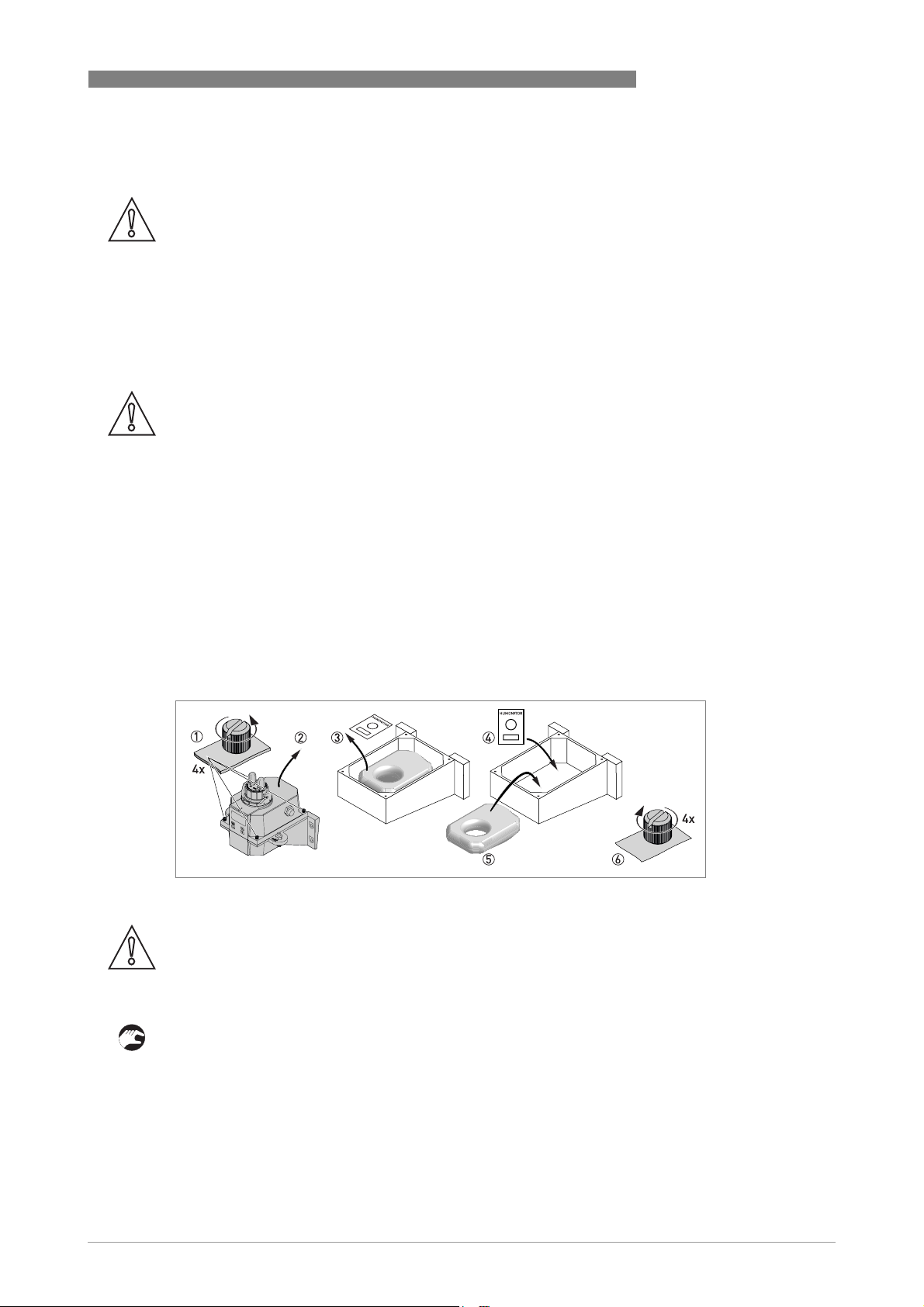

Figure 3-1: Desiccant pack (desiccant pouch with humidity indicator)

card) or to inspect the seal:

CAUTION!

The desiccant degrades prematurely after removing the protective packaging. Therefore do not

open the packaging before usage, install the desiccant pouch quickly and close the device as

soon as possible.

• Move the lock ring counterclockwise and pull out the ultrasonic cuvette with flow-through

holder (detailed information on page 21).

• Unscrew the four corner thumbscrews of the electronic device manually according to 1 in the

following drawing (if the screws are too tight, use a screwdriver for slotted grub screws).

• Remove the upper half of the electronic device 2.

• Prior to installing the desiccant pouch for the first time, remove the shipping support (plastic

tube with a red flag reaching outside) within the upper part of the device; after removing you

can discard the tube.

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

15

Page 16

3 INSTALLATION

• If you want to replace the desiccant pouch and the humidity indicator, take them out at first 3.

• Take the shrink packed desiccant pouch and the humidity indicator out of the protective

packaging.

• Put the humidity indicator on the bottom of the lower part of the electronic device and lay the

desiccant pouch on it 4 and 5.

• Inspect the seal and reseat or replace it if necessary.

• Reassemble everything in reverse order 6.

• To expedite the recognition of the new desiccant, reset the powered device by disconnecting

the sensor interconnect cable for two seconds and reconnecting it.

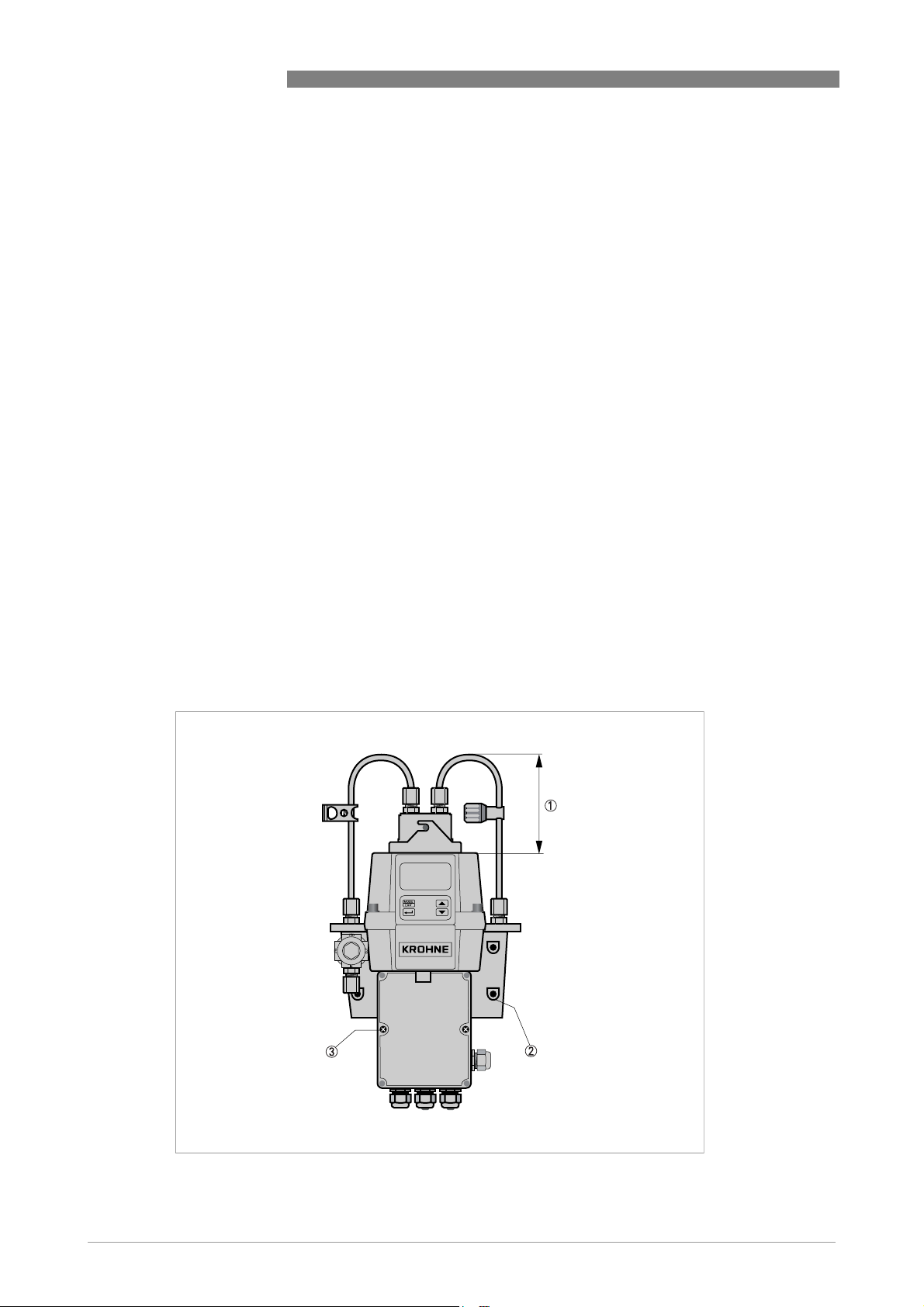

3.4.2 Selecting site and mounting

The preferred way of mounting of the device is wall mounting. If this is not possible, you can

mount the device on any suitable level surface. Irrespective of this possibilities always note the

following guidelines:

• Choose a location that is easily accessible for operation and service and that is as close as

possible to the sampling point to ensure a quick response time (maximum distance:

3m/10ft)

• Leave at least 20 cm / 8" of free space above the device for easy service (e.g. removal of the

flow head and insertion of calibration cuvettes), see position number 1 in the following

drawing.

• Ensure that the front display rests at eye level.

• Refer to chapter "Dimensions" for the device dimensions.

• Use screws M6 / 1/4" to fix the electronic device 2 and M4 / 3/16" to fix the junction box

power assembly 3.

OPTISYS TUR 1050

16

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 17

OPTISYS TUR 1050

INFORMATION!

The design of the device recommends that the junction box power assembly cradles in a hutch

below the electronic device. Therefore the correct procedure is to fix the junction box power

assembly first and then mount the electronic device on top of it.

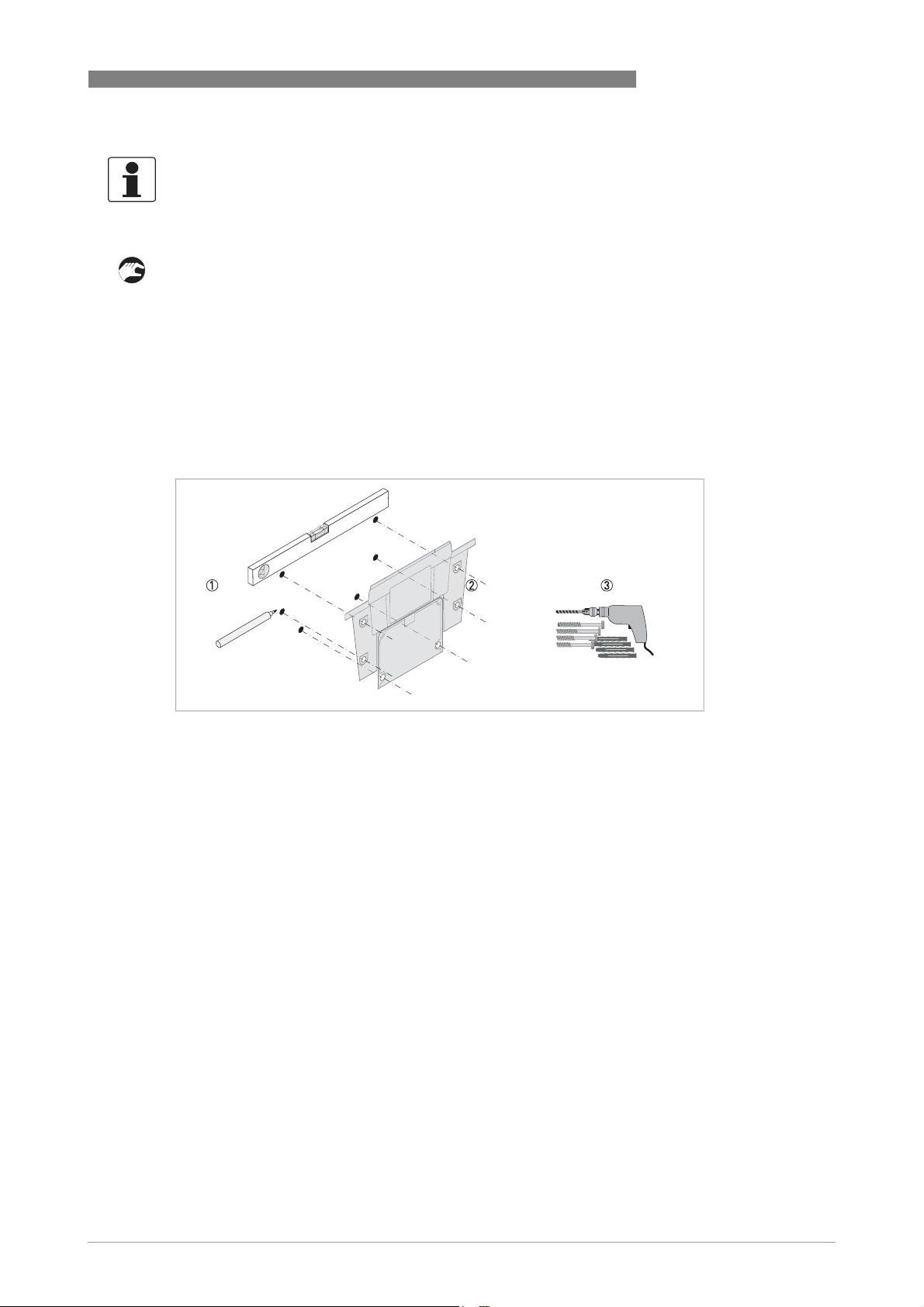

Mounting procedure

• Take a water-level, a pencil and ruler and use the dimensions in the following drawing to mark

the six mounting hole locations on the mounting surface.

Note: Do not use the drawing on the following page directly as mounting template as the

printed dimensions there differ from reality!

• Drill six holes into the mounting surface and insert six screw anchors into them.

• Use screws M4 / 3/16" to fix the junction box power assembly at first.

• Put the electronic device on top of the junction box power assembly and use screws M6 / 1/4"

to fix it.

INSTALLATION 3

Figure 3-2: Mounting filed terminal box

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

17

Page 18

3 INSTALLATION

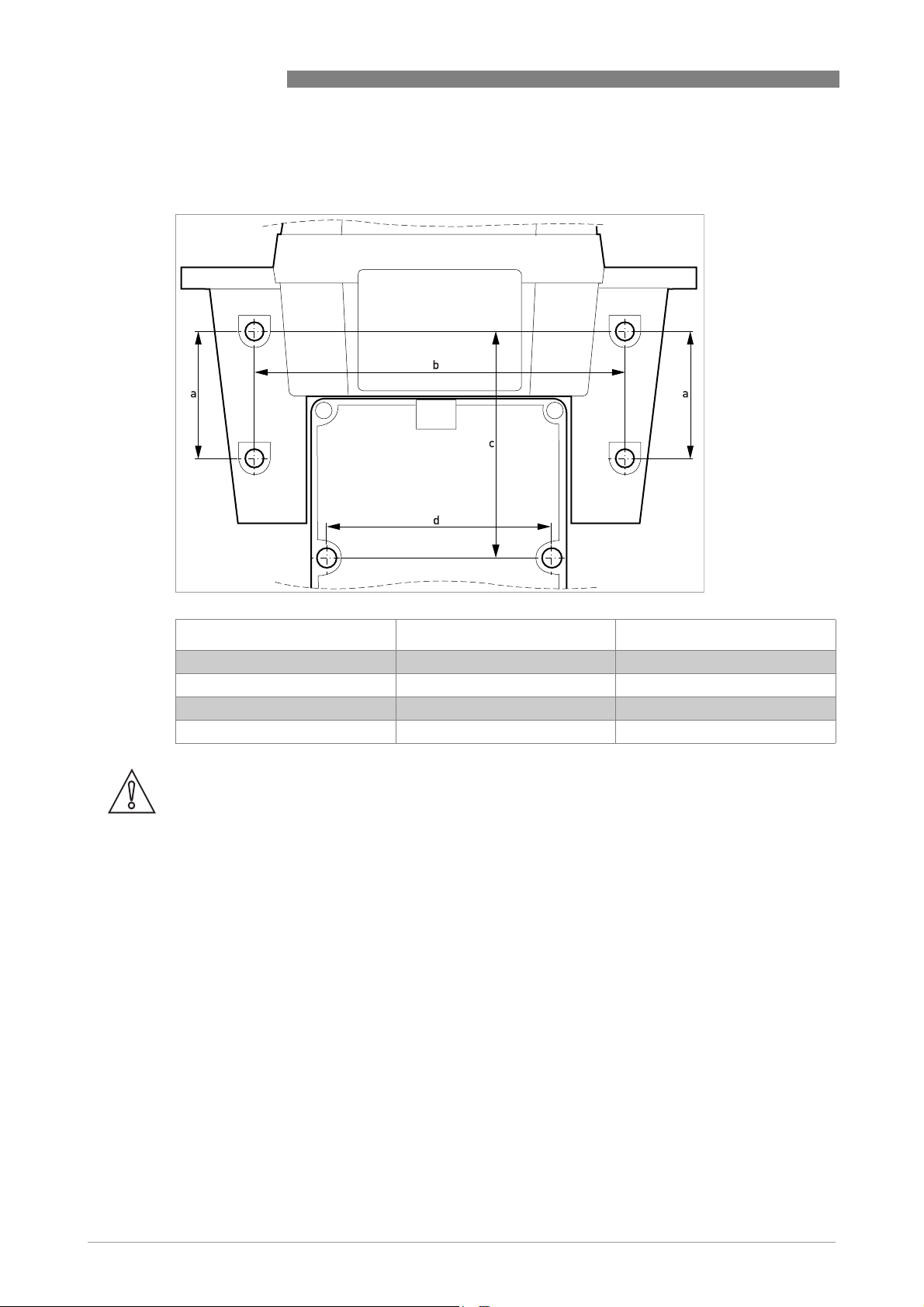

3.4.3 Mounting

OPTISYS TUR 1050

[mm] ["]

a 51 2.0

b 147 5.79

c 90 3.54

d 87 3.43

CAUTION!

Please do not use this directly as mounting template as the printed dimensions here differ from

reality!

18

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 19

OPTISYS TUR 1050

3.4.4 Connecting the hoses

The scope of delivery contains two tubings with fittings (intake tubing, drain tubing) for the

connection between the flow-through holder and the flow intake and flow drain. The intake

tubing has a shut-off clamp and the drain tubing has a backpressure valve. Connect the hoses

according to the following drawing:

CAUTION!

Do not connect the sensor interconnect cable with the upper part of the device now and regard

the installation order in the chapter "Electrical connections"! The reason is that you will have to

do the internal wiring at first and the connection of the sensor interconnect cable afterwards, the

reverse order could damage the device!

INSTALLATION 3

Figure 3-3: Connecting the hoses

1 Intake tubing with shut-off clamp

2 Drain hose with backpressure valve

3 Sensor interconnect cable

The hose for the connection between the sampling point and the device as well as the hose for

the flow drain do not belong to the scope of delivery. For this purpose use hoses with the

following specifications:

• Inner diameter: 4.75 mm / 3/16".

• Outer diameter: 8 mm / 5/16".

• Flexible and opaque hose material to prevent algae growth if direct sunlight can reach the

hose.

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

19

Page 20

3 INSTALLATION

Assemble the plumbing and connect the hoses according to the following drawing:

Figure 3-4: Procedure to assemble the plumbing and connect the hoses

• Slip the coupling nut over the hose 1

• Insert spreading ring into the hose 2

• Fix the nut on the thread of the pressure regulator 3

• Intake hose connection 4

• Drain hose connection 5

OPTISYS TUR 1050

INFORMATION!

To prevent that the drain water causes any damages, assure that the drain hose leads to a

suitable drain site.

3.4.5 Drain vent

CAUTION!

The manufacturer accepts no responsibility for damage caused by the introduction of vapours,

fluids or other materials into the device process stream which are not compatible with the

device

introducing any media into the device process stream!

The device has a drain vent in the "Out" bulkhead fitting. The drain vent allows atmospheric

equalization, thus helping to alleviate bubble formation in the cuvette.

INFORMATION!

During initial flow minor leakage may occur at the drain vent. This will subside once the normal

flow is established.

In some pressurised systems there may occur a continuous leakage at the drain vent hole.

Therefore the scope of delivery contains a seal screw that you can insert into the vent hole and

tighten.

’

s wetted materials. Always note the list of wetted parts in the technical data table before

20

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 21

OPTISYS TUR 1050

INSTALLATION 3

3.4.6 Inserting and fixing the ultrasonic cuvette with flow-through holder

CAUTION!

Never insert a cuvette with visible moisture or water on the glass or the transducer into the

upper part of the device, because this could destroy or damage the electronics or the

transducer! Always clean and dry the cuvette with a soft cloth just before inserting it. The

dehumidification system cannot remove large droplets of water, only residual moisture!

Figure 3-5: Procedure for inserting and fixing the ultrasonic cuvette with flow-through holder

INFORMATION!

The device can only detect a new cuvette if it works in the normal operation mode ("AUTO"). If the

device operates correctly after inserting a new cuvette, "AUTO" will flash on the display.

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

21

Page 22

4 ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

OPTISYS TUR 1050

4.2 Description of board and bulkheads

Figure 4-1: Description of board and bulkheads

1 Power supply terminal block

2 Alarms relay

3 4...20 mA/RS 485 terminal block

4 Power cable strain relief

5 4...20 mA/RS 485 cable bulkhead

6 Alarm cable bulkhead

7 Power cable bulkhead

8 Holes for strain relief strap

9 Sensor interconnect cable

22

All of the electrical connections to the device run via the junction box power assembly. For

shipment the manufacturer inserts plugs into the alarm and the 4...20 mA/RS 485 cable

bulkhead to waterproof the device.

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 23

OPTISYS TUR 1050

ELECTRICAL CONNECTIONS 4

4.3 Circuit breaker and specifications of power supply

DANGER!

The manufacturer strongly recommends to place a circuit breaker prior to the power

connection. Use this circuit breaker to de-energise all cables before starting any installation or

service work, otherwise a perilous electric shock can happen.

CAUTION!

The device has a switching power supply which demands 100...240 VAC and 47...63 Hz. To avoid

damage or destruction of the device always assure that the power supply meets this

specifications!

INFORMATION!

The power cord does not belong to the scope of delivery.

4.4 Cable specifications

• The power cable bulkheads accept the following cable diameter range: 5.8...10 mm /

0.23...0.39".

• All terminals accept wires in the range of 14...28 AWG.

• Stripping of insulation to a length of 6 mm / ¼".

4.5 Installation order of the electrical connections

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

CAUTION!

To prevent damage or destruction of all devices, always regard the following items:

•

Ensure that the meter itself and all devices that should be connected to the outputs are

de-energised before establishing a cable connection!

•

Before fixing a cable, look on the labels on the board and especially regard polarities!

To establish the electrical connections in the correct way, follow the order of the following

sections and their instructions.

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

23

Page 24

4 ELECTRICAL CONNECTIONS

4.5.1 Connecting the cables in the junction box power assembly

DANGER!

The device involves a line voltage that could endanger life! Only qualified electricians are allowed

to perform the electrical installation of the device. Always note all local and government

recommendations and methods for installation of electrical connections to and between the

device and other peripheral devices.

DANGER!

The manufacturer accepts no responsibility that the device is watertight again after the electrical

installation. Assure the water tightness after the terminal box was wired for operation. If any of

the bulkheads does not tighten a cable or plug properly this jeopardises the ratings of the device

and may cause a perilous electric shock.

Connection procedure

• Open the terminal box with a screwdriver.

• Remove the plugs in the cable bulkheads if you want to conduct a cable through them.

• Strip all needed wires to a length of 6 mm / ¼".

• Fix the cable on the terminal like in the following drawing 1 to 5.

• Use the strain relief strap to reduce the tension on the power terminals 6.

• Close the terminal box and assure that it is properly sealed.

OPTISYS TUR 1050

24

Figure 4-2: Connecting the cables in the junction box power assembly

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 25

OPTISYS TUR 1050

4.5.2 Alarms terminal (signal output)

The terminals "ALARM 1" and "ALARM 2" are mechanical relays rated at 240 VAC and 2 A. The

abbreviations on the board and below the terminal have the following meanings:

• NO: Normally open

• NC: Normally closed

• C: Common

As the configuration of the alarms is fail-safe, the normal state is a power supplied device and

non-active alarms. For detailed information concerning the configuration of the alarms refer to

Configuring the alarm relays

on page 39.

4.5.3 RS 485 or 4...20 mA signal output

INFORMATION!

The installation of the 4...20 mA isolator will render the RS 485 non-operational. Shifting

between the 4...20 mA (analog) and the RS 485 (digital) output mode works with the help of the

software, for further information refer to Selecting the output on page 36

ELECTRICAL CONNECTIONS 4

.

INFORMATION!

Transformer isolated outputs are available as a factory installed option.

The 4...20 mA output is energised by a 15 VDC power source and can drive recorder loads up to

600 Ω. It is isolated from line power and earth ground.

The RS 485 half-duplex digital interface (2-wire) operates with differential levels that are

unsusceptible to electrical interferences. This is why the usage of cable lengths up to

900 m / 2950 ft is possible. Independent of the output mode (analog or digital) always note the

following items:

• For ease of connecting, remove the plug in terminal block (the labels of the connections are

beneath this block).

• Do not run 4...20 mA or RS 485 cables in the same conduit as power as this could lead to

signal interferences.

• When using the RS 485 interface, equip the last device on each bus with a 120 Ω terminating

resistor to eliminate signal reflection on the line.

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

25

Page 26

4 ELECTRICAL CONNECTIONS

The electrical connection is independent of the output mode (analog or digital) and works as

follows:

Figure 4-3: Signal output connection

OPTISYS TUR 1050

RS485/4...20 mA

4.5.4 Connecting the sensor interconnect cable

CAUTION!

Always connect the sensor interconnect cable with the upper part of the device last of all! The

reason is that if you connect the sensor interconnect cable before the internal wiring, energising

the device with power could destroy or damage the device!

Figure 4-4: Connecting cable

26

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 27

OPTISYS TUR 1050

5.1 Start-up

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

Before start-up assure the following adjustments:

• The drain vent is open for gravity-feed and open-drain systems. In pressurised systems it has

• The back pressure valve is completely open.

• The hose connected with drain connection of the device leads to a suitable drain site.

• For continuous measurement the intake hose has to supply the sensor with a dependable

Start-up procedure

• Check that the circuit breaker is not in a position where it de-energises the device.

• Switch on the power supply.

• Wait until the device has completed its warm-up (1 hour during the initial start-up and

typically 45 minutes during all following start-ups), at the same time the fully automatic

drying process takes place.

i After the warm-up the display shows the measured turbidity, if a continuous process

OPERATION 5

to be plugged with a seal screw (the manufacturer ships the device with the seal screw in the

drain vent).

sample flow.

stream is flowing through the cuvette; refer to

the equivalent signal is provided on the analog 4...20 mA output or the digital RS 485 output,

depending on the options selected.

Normal operation

on page 28. In addition,

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

27

Page 28

5 OPERATION

5.2 Display and operating keys

Figure 5-1: Description of the display and operating keys

1 Indication of the turbidity levels and user guidance in the customer setting routine

2 Indication of an active access code and operation in offset mode

3 Indication of error messages and user guidance

4 Button to move up or increase

5 Button to move down or decrease

6 Button to enter the option or mode that is chosen

7 Button to cycle between the three operation modes

8 Mode arrows that indicate the current of the three operation modes: AUTO (normal operation), CAL (calibration) or

CONFIG (configuration)

OPTISYS TUR 1050

5.3 Normal operation

The device can report the turbidity of the process water in Nephelometric Turbidity Units (NTU)

or Formazin Nephelometric Units (FNU). Readings above 100 NTU/FNU or 1000 NTU/FNU

(depending on the specific device measuring range) are outside the range of this device.

During normal operation, the display shows an arrow beside "AUTO" in the upper left corner.

Simultaneously the lower row displays the current scale and the upper row the measured

reading. The following drawing is an example for a display during normal operation:

28

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 29

OPTISYS TUR 1050

5.4 Getting access with activated security access function

The device has a security access function that you can enable and disable in the configuration

mode (for more information refer to

the enabled function the following screen appears any time you press the button MODE/EXIT:

INFORMATION!

The only valid security code is 333, it cannot be changed.

Execute the following steps to get access to the menus CAL or CONFIG with an activated security

access:

Enabling or disabling the security access

OPERATION 5

on page 41). With

• If you have not already pressed the button MODE/EXIT, press it now (in the normal measuring

mode: 1x=CAL, 2x=CONFIG).

i You see the display like in the drawing above with the first number of the access code in the

upper row flashing.

• Use the buttons ↑ or ↓ to select the first number of the code (i.e. "3").

• Press the button ^ to accept the first number of the code.

i Now the second number of the code is flashing.

• Repeat the previous steps with the second and third number (always enter "3"), always

confirm the chosen number with the ^ button.

i If you have entered the valid code, the device directly goes to calibration or configuration

main menu. If you have entered a wrong code, it returns to the normal measuring mode

("AUTO").

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

29

Page 30

5 OPERATION

5.5 Menu topology

The device has three operation modes:

• Auto (AUTO): normal measuring mode

• Calibration (CAL): mode for physical calibration

• Configuration (CONFIG) mode for customer-specific adjustments and offset calibration

You can enter the calibration mode and the configuration mode with the help of the

correspondent main menus. Each main menu has a set of submenus.

Entering, navigating within and leaving a main menu:

• Press the button MODE/EXIT until the arrow on the left side of the display appears in front of

the abbreviation of the desired main menu (in the normal measuring mode: 1 x = CAL,

2x=CONFIG).

i You are now in one of the two main menus.

• You can move through the submenu items by pressing ^, in the submenu you can choose the

different options.

• You can always leave the submenu level and go back to the normal operation mode by

pressing the button MODE/EXIT.

OPTISYS TUR 1050

INFORMATION!

Note that you can change settings, i.e. values and options, with the help of ↑ or ↓ upwards and

downward. But you can only move through the menus in one direction. If you want to go back, you

have to leave the main menu by pressing MODE/EXIT and enter it again as described above.

5.6 Calibration mode (main menu)

The manufacturer calibrates and tests every device before it leaves the factory. Therefore you

can use the device directly out of the box. Under normal conditions the manufacturer

recommends a recalibration every three months. Also be aware of the following device

properties:

INFORMATION!

•

During calibration the fan inside the device does not run to extend the life of the desiccant;

the fan turns on again during each calibration countdown, after returning to the normal

operation mode ("AUTO") or after 5 minutes, whichever comes first.

•

While in calibration or configuration mode, the device has a time-out function; it

automatically returns the device to the normal operation mode ("AUTO") after a 15 minute

period of inactivity.

•

While in the calibration or configuration mode, the relay contacts hold at the last valid

condition and will not change state.

30

CAUTION!

The desiccant pouch may become prematurely saturated if the measurement chamber is

permanently uncovered; therefore keep the chamber covered during calibration and replace the

ultrasonic cuvette immediately thereafter.

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 31

OPTISYS TUR 1050

5.6.1 Calibration liquids

If you want to use the device over the entire measuring range (0.02...100 NTU/FNU or

0.02...1000 NTU/FNU), a complete calibration with three different calibration liquids is

necessary. If you require a device accuracy below 10 NTU/FNU (i.e. with potable water), you can

do the calibration with only two liquids (for this purpose the first calibration step can be

bypassed).

INFORMATION!

Always note the following items to achieve the best calibration results:

•

Use three calibration liquids with turbidities of 0.02, 10.0 and 100 or 1000 NTU/FNU if you

want to achieve the full-scale accuracy stated in this document.

•

You can use formazin as a primary calibration liquid. Though the manufacturer recommends

the own calibration kit as a primary option because this liquids are more stable than formazin

and have a minimum shelf life of twelve months (the manufacturer's calibration kit is

purchasable as accessory part).

•

Check the expiration dates of the liquids prior to calibration to ensure that they have not

expired.

OPERATION 5

If you want to calibrate the device with formazin, always use a fresh stock suspension. The

reason is that diluted formazin is unstable and this can distort the calibration.

For EPA compliant calibration results the agency recommends that a calibration of online

devices takes place with primary calibration liquids at least every three months.

5.6.2 Calibration procedure (physical), inclusive indexing

To achieve the highest possible accuracy, the manufacturer recommends to index all calibration

cuvettes. Furthermore indexing a calibration cuvette accounts for normal scratches and

aberrations in the cuvette glass when performing a calibration. The manufacturer supplies all

his optionally available calibration cuvettes with indexing rings (see below).

Execute the following steps to make a physical calibration inclusive indexing the calibration

cuvettes:

• Press the button MODE/EXIT once to switch into the calibration mode.

i The arrow in the display appears beside "CAL", the lower display line shows alternating

"100" (turbidity value of the first calibration liquid in NTU/FNU) and ^, the upper line shows

the real-time reading.

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

31

Page 32

5 OPERATION

• Remove the ultrasonic cuvette and insert the 100 NTU/FNU or 1000 NTU/FNU calibration

cuvette according to the following drawing (if you do not need the full-scale accuracy, press ↓

alternatively to bypass this calibration step and go directly to the 10 NTU/FNU calibration

step).

• If you need the 100 NTU/FNU or 1000 NTU/FNU calibration step, slowly rotate the calibration

cuvette one complete revolution (i.e. 360°), observe the measured turbidity on the display

during rotation and locate the position with the lowest measured turbidity.

• After one complete rotation return the cuvette to the position with the lowest measured

turbidity.

• Pull the indexing ring over the cap of the calibration cuvette according to the following

drawing, the ring should face directly forward.

i The cuvette is indexed now. When using it in future, insert it so that the pointer of the

indexing ring faces directly forward. For fine adjustment slowly rotate the calibration

cuvette about 5° clockwise and counterclockwise to find the lowest measured turbidity.

OPTISYS TUR 1050

32

• After finding out the lowest measured value of the 100 NTU/FNU or 1000 NTU/FNU calibration

cuvette and indexing it, press ^ to accept the 100 NTU/FNU or 1000 FNU/NTU calibration.

i The lower line of the display counts down the progress of the calibration step, afterwards

the device requests the next calibration step by showing 10 and ^ alternating.

• If the display does not show 10 and ^ alternating, press ↑ or ↓ until the display does so.

• Insert the 10 NTU/FNU calibration cuvette (contrary to the 100 NTU/FNU or 1000 NTU/FNU

calibration step you cannot leave out this step and the 0.02 NTU/FNU step).

• Repeat the procedure above and finally press ^ to accept the 10 NTU/FNU calibration.

i The lower line of the display counts down the progress of the calibration step, afterwards

the device requests the next calibration step by showing 0.02 and ^ alternating.

• Repeat the procedure above and finally press ^ to accept the 0.02 NTU/FNU calibration.

i The lower line of the display counts down the progress of the calibration step, afterwards

the device returns to the normal operation mode ("AUTO").

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 33

OPTISYS TUR 1050

5.6.3 Calibration procedure (offset calibration)

Under certain circumstances an offset calibration is more suitable than a physical calibration as

described in the previous chapter. This might be the case if the process application contains a

number of devices so that a regular physical calibration is not possible.

INFORMATION!

Be aware that an offset calibration does not offer the accuracy of a physical calibration. An offset

calibration makes the device accurate only at turbidity levels in the immediate vicinity of the grab

sample's value and not in the full measuring range!

The maximum offset value is ±1 NTU/FNU. If the deviation goes beyond this value, a physical

calibration is necessary. An offset calibration always starts with a comparison of samples:

• Collect a grab sample of the process water with the optional grab sample cuvette.

• Measure the turbidity with the help of the device.

• Take a second grab sample and measure its turbidity using a turbiditymeter for laboratory use

(the manufacturer's service department can give you examples of suitable devices).

• Compare the turbidity values of both samples. If they are very close, then an offset calibration

is not required and you can stop the procedure at this step.

OPERATION 5

If both samples differ substantially (but less than 1 NTU/FNU), continue with the actual offset

calibration. The following steps make the turbidity reading of the device agree with the value of

turbidity meter for laboratory use:

• In the normal measuring mode (AUTO), press the button MODE/EXIT twice.

i The device switches in the configuration mode and the arrow in the display appears in front

of "CONFIG".

• Press ^ several times until "OFST" appears in the lower row of the display.

i While the lower row shows"OFST", the upper row indicates the status of the offset function

("ON" or "OFF", default setting is "OFF")

• Change the status of the offset function by pressing ↓ or ↑, see following drawing.

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

33

Page 34

5 OPERATION

• Press ^ to accept the new operational status.

i The display now shows the set offset value (default setting is 0.00).

• Select the desired offset value by pressing ↑ or ↓ (regard the example below).

• Press ^ to accept the chosen offset value.

i The offset calibration is complete and the device goes to the next submenu in the

configuration main menu.

• If you want to return to the normal measuring mode, press MODE/EXIT.

INFORMATION!

Whenever the measurement rests upon an offset value, the information "OFFSET" appears in the

lower right corner of the display (even in the normal operation mode).

OPTISYS TUR 1050

Example of finding out the offset value

The correct offset value is the difference between the value measured with the turbidity meter

for laboratory use and the value measured with the actual meter. After you have entered an

offset value, the meter adds or subtracts this value from its own measured value (depending on

the algebraic sign of the difference).

If the actual meter measures 0.28 NTU/FNU in the grab sample and the meter for laboratory use

measures 0.04 NTU in the same sample, than the correct offset value is -0.24. After entering the

offset value the device subtracts 0.24 from its own measured value of 0.28 NTU/FNU and

displays a measuring result of 0.04 NTU/FNU.

34

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 35

OPTISYS TUR 1050

5.6.4 Calibration error

If the following information is shown on the display, the internal diagnostic function has

determined an error during the calibration procedure:

The reason for this error message is that either the calibration liquids were bad or they were

inserted in the wrong order. You may find a remedy with the following options:

• Check of the calibration liquids (e.g. the expiration date), afterwards restoring the factory

calibration or performing a recalibration.

• To recalibrate execute a calibration as described in the previous sections.

• To restore the factory calibration refer to

Restoring the factory settings

OPERATION 5

on page 47.

INFORMATION!

If the device reports a calibration error, you cannot use it for measuring purposes without

performing a recalibration or restoring the factory settings.

5.7 Configuration mode (main menu)

The device has the ability to customise it according to your specific needs any time during normal

operation with the help of the configuration mode. Be aware of the following device properties:

INFORMATION!

•

While in calibration or configuration mode, the device has a time-out function; it

automatically returns the device to the normal operation mode ("AUTO") after a 15 minute

period of inactivity.

•

While in the calibration or configuration mode, the relay contacts hold at the last valid

condition and will not change state.

•

You can leave the configuration mode at any time and menu by pressing the button

MODE/EXIT. The device automatically saves all changes.

•

The order of the following sections and subsections represents the menu topology.

As described in the section "Menu topology", you have to press the button MODE/EXIT twice to

switch to the configuration mode. Thereafter you are always in the first submenu, i.e. "Selecting

the output".

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

35

Page 36

5 OPERATION

5.7.1 Selecting the output

After switching to the configuration mode, the first submenu is always the selection of the

output. At first you see the following display:

AUTO

CAL

CONFIG

• Select the desired output by using ↓ or ↑ (options: 4-20 for the 4...20 mA output, 485 for the

RS 485 output, OFF if you do not need outputs) or leave the setting.

The displays for the two possible outputs look like the following drawings:

OPTISYS TUR 1050

AUTO

CAL

CONFIG

• Accept your selection by pressing ^.

i If you chose or leave the setting "OFF", the device switches to the submenu "Error level"; if

you chose or leave one of the outputs, the device switches to a submenu for the settings of

the chosen output (see one of the next two sections).

36

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 37

OPTISYS TUR 1050

5.7.2 Setting the 4...20 mA output inclusive error level

If you selected or left the 4...20 mA output in the previous step (for detailed information refer to

Selecting the output

see the following display:

AUTO

CAL

CONFIG

Your task is now to set the lower and the upper turbidity limits:

• Use the buttons ↑ and ↓ to define the lower turbidity limit which is assigned to the 4 mA output

level or leave the setting.

• Accept your selection by pressing ^.

i The device switches to the next menu item, i.e. the setting of the upper limit.

on page 36), the device automatically switches to this submenu. At first you

OPERATION 5

AUTO

CAL

CONFIG

• Use the buttons ↑ and ↓ to define the upper turbidity limit which is assigned to the

20 mA output level or leave the setting.

• Accept your selection by pressing ^.

i The device switches to the last menu item of this submenu, i.e. "Error level".

AUTO

CAL

CONFIG

In case of an error the 4...20 mA output can be used to indicate the problem. That means the

device can set the current either to 4.00 mA, 2.00 mA, 0 mA or to "OFF" ("OFF" is the default

setting and effects that the 4...20 mA output is unaffected by any error condition):

• Use the buttons ↑ or ↓ to choose the desired setting for the error level or leave the setting.

• Accept your selection by pressing ^.

i The device switches to the submenu "Configuring the alarm relays".

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

37

Page 38

5 OPERATION

5.7.3 Configuring the RS 485 port

INFORMATION!

The default communication parameters of the RS 485 port are: 8 bits, no parity and 1 stop bit.

OPTISYS TUR 1050

If you selected the RS 485 output (for detailed information refer to

Selecting the output

on page

36), the device automatically switches to this submenu. It allows to configure the RS 485 output

and starts with the baud rate:

• Use the buttons ↑ and ↓ to select one of the predefined baud rates or leave the setting

(options: 1200, 2400, 4800, 9600 or 19200 baud).

• Accept your selection by pressing ^.

i The device switches to the next menu item, i.e. the setting of the device address.

• Use the buttons ↑ and ↓ to select the desired device address or leave the setting (options:

1...255).

• Accept your selection by pressing ^.

i The device switches to the last menu item of this submenu, i.e. "Modbus mode".

AUTO

CAL

CONFIG

• Use the buttons ↑ and ↓ to select the options "RTU" or "ASCII" or leave the setting.

• Accept your selection by pressing ^.

i The device switches to the submenu "Configuring the alarm relays".

INFORMATION!

For further information concerning the Modbus mode contact the manufacturer.

38

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 39

OPTISYS TUR 1050

5.7.4 Configuring the alarm relays

The device has two alarm relays that operate as two independent programmable alarms. To fully

program each alarm, you have to input the work mode of the alarm function, the alarm set point

and the delay time for the alarm.

Work mode of the alarm function

• HI: the relay changes state when the measured turbidity level is higher than the programmed

alarm level for the chosen alarm delay time.

• LO: the relay changes state when the measured turbidity level is lower than the programmed

alarm level for the chosen alarm delay time.

• OFF: this option completely deactivates the alarm functions.

• ERROR: the relay changes state when an internal error occurs.

Alarm set point

This is the level at which an alarm activates. You can adjust the alarm set point to any valid

turbidity level over the range of the device in steps of 0.01 NTU/FNU.

OPERATION 5

Alarm delay times

The alarm delay time prevents activating the alarm when the measured turbidity level exceeds

or falls below the alarm set point just for a short time. There are two options:

• Delay on: with this option you can define a time period; the turbidity level must exceed the

alarm set point for this time period before the alarm starts. Example: if you selected an alarm

set point of 50 NTU/FNU and an alarm delay time of 5 seconds, then the measured turbidity

must exceed 50 NTU/FNU for at least 5 seconds to start the alarm.

• Delay off: similar to the option "Delay on" you can define a time period; the turbidity level

must not fall below the alarm set point for this time period before the alarm stops. Example:

if you selected an alarm set point of 50 NTU/FNU and an alarm delay time of 5 seconds, then

the measured turbidity must fall below 50 NTU/FNU for at least 5 seconds to stop the alarm.

If you have completed all settings for the output as described in the previous sections, the device

moves to the submenu for the alarm configuration. At first you see the following display:

AUTO

CAL

CONFIG

• Use the buttons ↑ and ↓ to select the desired work mode (HI, LO, OFF, ERROR) or leave the

setting.

• Accept your selection by pressing ^.

i If you chose "OFF" or "ERROR", a prompt appears to set up the alarm for the second relay

(see below in this section). If you chose one of the other options, a prompt appears to set up

the alarm set point.

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

39

Page 40

5 OPERATION

AUTO

CAL

CONFIG

• Use the buttons ↑ and ↓ to select the desired alarm set point in the upper row or leave the

setting.

• Accept your selection by pressing ^.

i A prompt appears to set up the alarm delay times starting with "Delay on". Thus an arrow

pointing upward appears to the right of "DLY" in the lower row while the upper row shows

the preset number of seconds.

OPTISYS TUR 1050

• Use the buttons ↑ and ↓ to select the desired number of seconds for the time after which the

alarm has to be "on" (options: 1...30) or leave the setting.

• Accept your selection by pressing ^.

i The desired number of seconds for the time after which the alarm has to be "on" is set. The

display switches to the input of the value for "Delay off". Thus an arrow pointing downward

appears to the right of "DLY" in the lower row while the upper row again shows the preset

number of seconds.

• Use the buttons ↑ and ↓ to select the desired number of seconds for the time after which the

alarm has to be "OFF" or leave the setting.

• Accept your selection by pressing ^.

i The desired number of seconds for the time after which the alarm has to be "on" is set. The

display switches back to the selection of the desired work mode, but this time for the

second alarm relay.

• Repeat the procedure described in this section for the second alarm relay, starting again with

the work mode.

40

If you choose another work mode than "OFF" for the second alarm relay, you have to go through

the described procedure of defining the set point and the delay times for this relay. After defining

"Delay off" for the second alarm relay and pressing ^, the device switches to the next submenu

(i. e. enabling or disabling the security access). The same happens if you choose the work mode

"OFF" for the second alarm relay and press ^.

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 41

OPTISYS TUR 1050

5.7.5 Offset calibration

The offset calibration is a submenu item in the configuration mode. That means despite of its

function, it is not accessible via the calibration mode. For detailed information concerning the

offset calibration procedure refer to

Calibration procedure (offset calibration)

5.7.6 Enabling or disabling the security access

With an enabled security access the user has to enter a valid code to get to any mode other than

normal operation (AUTO).

INFORMATION!

The only valid security code is 333, it cannot be changed.

Execute the following steps to change the setting of the function:

• Use the buttons ↑ or ↓ to enable (upper row: ON) or disable (upper row: OFF) the security

access or leave the setting

i If you enabled the security access, the security key icon will be visible and flashing on the

display in all working modes of the device (AUTO, CAL, CONFIG) and their submenus.

OPERATION 5

on page 33.

• Accept your selection by pressing ^.

i The device switches to the last submenu of the configuration mode ("Extended settings").

For further information refer to

29.

5.7.7 Extended settings

"Extended settings" is the last submenu of the configuration mode. A couple of settings are

grouped together in this submenu to prevent them form being adjusted by mistake. The default

setting is "OFF", as shown in the following drawing:

AUTO

CAL

CONFIG

Getting access with activated security access function

on page

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

41

Page 42

5 OPERATION

You can leave the default setting or, if the setting is "ON", disable the extended settings again by

pressing ↑ or ↓.

INFORMATION!

If you disable the extended settings, i.e. choose the setting "OFF", the device stores all

adjustments for every menu item of the extended settings submenu. The manufacturer

recommends to disable the extended settings again after all adjustments to prevent adjustments

by mistake.

Any time you press ^ while the extended settings are disabled, the device switches back to the

normal measuring mode and saves all settings. If you enabled the extended settings with the

buttons ↑ or ↓ (i.e. "ON" appears in the upper row of the display) and press ^, the device

switches to the first menu item of the extended settings submenu (speed of response). The

procedure of changing a setting and switching to the next item is the same for every item of the

extended settings:

Changing a setting and switching to the next item

• Use the buttons ↑ or ↓ to change the setting.

• Accept your selection by pressing ^.

i The device switches to the next item of the extended settings. Pressing ^ after reaching the

last item (i.e. the 20 mA adjustment) will switch the device back to the normal measuring

mode (AUTO), all settings are saved.

OPTISYS TUR 1050

Speed of response

With the help of this function you can adjust the speed of response for both the displayed

NTU/FNU value and the output values (i.e. of the RS 485 or the 4...20 mA output). The default

setting is 10, the adjustable range is 1...100.

Note that the displayed speed of response in the upper row of the display is a relative number

and not the real speed of response in seconds. You can calculate the approximate response time

in seconds by multiplying the number in the upper row by 5.

Select the slowest speed of response (i.e. the highest number) if you want to avoid disturbances

of the reading by air and other anomalies. Select the fastest speed (i.e. the lowest number) if you

need to monitor rapid changes.

42

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 43

OPTISYS TUR 1050

Resolution of the measured value

The device can display from one up to four digits to the right of the decimal place. The default

setting are two decimal places. Four digits right to the decimal point are only possible for

measuring results below 10 NTU/FNU. Each decade upwards decreases the digits right to the

decimal place by one.

If the last or the last two digits right of the decimal place are not stable, you can reduce the

resolution (i.e. the amount of digits right to the decimal place) to hide these digits and get a

stable reading.

Display backlight brightness

OPERATION 5

The display backlight brightness is of particular interest if multiple devices are located in the

same area. If all of them should have the same clearness of display, then you might have to

adjust the backlight brightness of particular devices. The default setting is 8, ten levels are

available.

Setting the units

The most common unit of the measured value and the default setting is NTU (Nephelometric

Turbidity Units), but FNU (Formazin Nephelometric Units) is also available.

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

43

Page 44

5 OPERATION

Ultrasonic cleaning

With the help of this function you turn the ultrasonic cleaning on or off (default is "On").

RS 485 parameters

The RS 485 parameters are only adjustable and so appear if the RS 485 interface is enabled (for

detailed information refer to

parameters "BITS", "PRTY" (parity) and "STOP" (stop bit). After choosing a setting for the

ultrasonic cleaning in the previous step you see the following display at first:

Selecting the output

OPTISYS TUR 1050

on page 36). In this case you can change the

• Use ↑ or ↓ to select the desired number of bits or leave the setting, accept your selection by

pressing ^.

• Use ↑ or ↓ to select the desired parity or leave the setting, accept your selection by

pressing ^.

• Use ↑ or ↓ to select the desired number of bits or leave the setting, accept your selection by

pressing ^.

i The device switches to the next item of the extended settings (desiccant alarm).

44

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 45

OPTISYS TUR 1050

In the communication mode "Simple" the following information is exchanged between the

master computer and the device:

Enquiries of master computer Answer of device

Byte 1: attention character ":" in ASCII or 3A Hex The same attention character ":" in ASCII or 3A Hex

Byte 2: address of the device being enquired Address of the device

Byte 3/4: CR/LF or 0D 0A in Hex 3: Measured value

Example (master requesting a report from address

No. 1): 1 CRLF

Desiccant alarm

The device can output a humidity alarm if the detected humidity could cause condensation. The

default setting of the humidity alarm is "OFF", like in the following drawing:

OPERATION 5

4: Unit (NTU or FNU)

Example (response of the device set to address

No. 1): 001 0.0249 NTU

If you enabled the desiccant alarm and the humidity detector determines a problematic value,

the device activates the alarms and sets the 4...20 mA output to the selected error level. In the

normal measuring mode you see the measured value in the upper row and "DESC" in the lower

row:

AUTO

CAL

CONFIG

www.krohne.com11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

45

Page 46

5 OPERATION

4 mA and 20 mA adjustment

If you enabled the 4...20 mA output (for detailed information refer to

36) you can adjust the 4 mA and the 20 mA output separately (if the 4...20 mA output is disabled

this item does not appear in the extended settings). This means that you can increase or

decrease the current output slightly until you see exactly 4 mA or 20 mA at your multimeter or

control system. This settings will be slightly different on each device as the manufacturer sets

them to 4.00 mA and 20 mA before shipping. The limits are:

• 4mA: ± 0.2 mA or ± 200 counts

• 20 mA: ± 1mA or ± 1000 counts

After accepting your selection for the desiccant alarm by pressing ^ and while the 4...20 mA

output is enabled, you see the following display:

AUTO

CAL

CONFIG

OPTISYS TUR 1050

Selecting the output

on page

• Use ↑ or ↓ to make your adjustment.

• Press ^ to switch to the adjustment of the 20 mA output:

AUTO

CAL

CONFIG

After accepting the adjustment for the 20 mA output by pressing ^ the device switches back to

the normal measuring mode (AUTO). All settings are saved.

46

www.krohne.com 11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

Page 47

OPTISYS TUR 1050

5.8 Restoring the factory settings

INFORMATION!

The restore function affects not only the configuration settings, but also the calibration settings.

Executing this functions means that both return to the default which was defined by the

manufacturer. Furthermore the device works with reduced accuracy!

INFORMATION!

Be aware that if the reason for restoring the factory settings was a hardware defect (e.g. a

sensor lamp with a low output), the original problem still exists thereafter. Before an accurate