Page 1

GR

Installation and

Operating Instructions

TTP 200/300/400

©

KROHNE 12/2003 7.02278.21.00

Subject to change without notice.

Variable area flowmeters

Vor tex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Page 2

Contents

Safety information..........................................................................................................................3

Items includes with supply............................................................................................................3

Product liability and warranty.......................................................................................................3

CE / EMC / Standards/ Approvals .................................................................................................3

1

Installation...........................................................................................................................4

1.1 Mechanical installation..........................................................................................................4

1.2 Process connections.............................................................................................................4

Electrical connection..........................................................................................................5

2

2.1 External signal converter ......................................................................................................5

2.2 With integrated signal converter............................................................................................6

2.3 Start-up ................................................................................................................................. 6

2.4 Operator control ....................................................................................................................6

3

Fault diagnosis and corrective action...............................................................................7

4

Technical data ..................................................................................................................... 8

4.1 Technical data.......................................................................................................................8

4.2 Dimensions ...........................................................................................................................9

4.2.1 TTP 200 ................................................................................................................................ 9

4.2.2 TTP 300 ................................................................................................................................ 9

4.2.3 TTP 400 .............................................................................................................................. 10

Ordering code ...................................................................................................................11

5

5.1 Ordering code .....................................................................................................................11

5.2 Spare parts .........................................................................................................................12

5.3 Accessories ........................................................................................................................12

6

Product description .......................................................................................................... 13

6.1 Applications ........................................................................................................................13

6.2 Functional principle ............................................................................................................. 13

6.3 Construction........................................................................................................................ 13

6.3.1 Pt100 resistance performance and wiring methods ............................................................13

6.3.2 Pt100 tips and response times............................................................................................ 14

6.4 Features.............................................................................................................................. 14

If you need to return a device for testing or repair to KROHNE...............................................15

2 Installation and Operating Instructions TTP x00

Page 3

Safety information

Please read this manual carefully, and also take note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well as prevailing safety regulations and accidents

prevention rules. For safety and warranty reasons, any internal work on the instruments, apart

from that involved in normal installation and electrical connection, must be carried out only by

qualified KROHNE personnel.

Items includes with supply

• Measuring instrument

• Hygienic adapter

• Installation and operating instructions

Product liability and warranty

Responsibility for suitability and intended use of these instruments rests solely with the operator.

Improper installation and operation of the instruments may lead to loss warranty.

In addition, the “General conditions of sale” forming the basis of the purchase contract are

applicable.

If instruments need to be returned to KROHNE, please note the information given on the last-butone page of these instructions.

KROHNE regrets that it cannot repair or check your instruments unless accompanied by a fully

completed Service and Repair sheet.

CE / EMC / Standards/ Approvals

The product bears the CE marking on account of compliance with and application of the following

standards:

EMCG (89/336/EEC)

EN 50081-1 EN 55022 Class B

EN 61000-6-2 EN 61000-4-2 ESD 4/8 kV

EN 61000-4-3 HF radiated 10 V/m

EN 61000-4-4 Burst 4 kV

EN 61000-4-5 Surge 1 kV sym., 2 kV unsym.

EN 61000-4-6 HF cable 10 V

Installation and Operating Instructions TTP x00 3

Page 4

1 Installation

1.1 Mechanical installation

• Use only the recommended sleeves or adapters. If other systems are used, no guarantee can

be given for proper functioning or leak-tightness.

• Do not use Teflon or paper gaskets for the hygienic process connections featuring a conical

seal.

• The tightening torque for the sleeve should be between 10 and 20 Nm.

1.2 Process connections

The hygienic weldable process sleeves are easy to weld into tanks and pipes. The marking points

to the centre of the future position of the cable gland or M12 connector. This form of assembly

allows installation in conformity with standards of hygiene (to EHEDG, FDA).

Various hygienic adapter sleeves (see Accessories) are available for fitting to other process

connections.

• Process connection G1/2“h is the hygienic standard connection with conical seal.

• For installation in small-diameter pipelines it is recommended to use the hygienic M12 system

(from DN 15).

• When using a sliding sleeve, please use the threadless variant. The clamp cone forms a

hygienic seal with the protective tube.

• A standard G1/2“ connection is available for applications with no hygiene requirements (e.g.

cooling water).

4 Installation and Operating Instructions TTP x00

Page 5

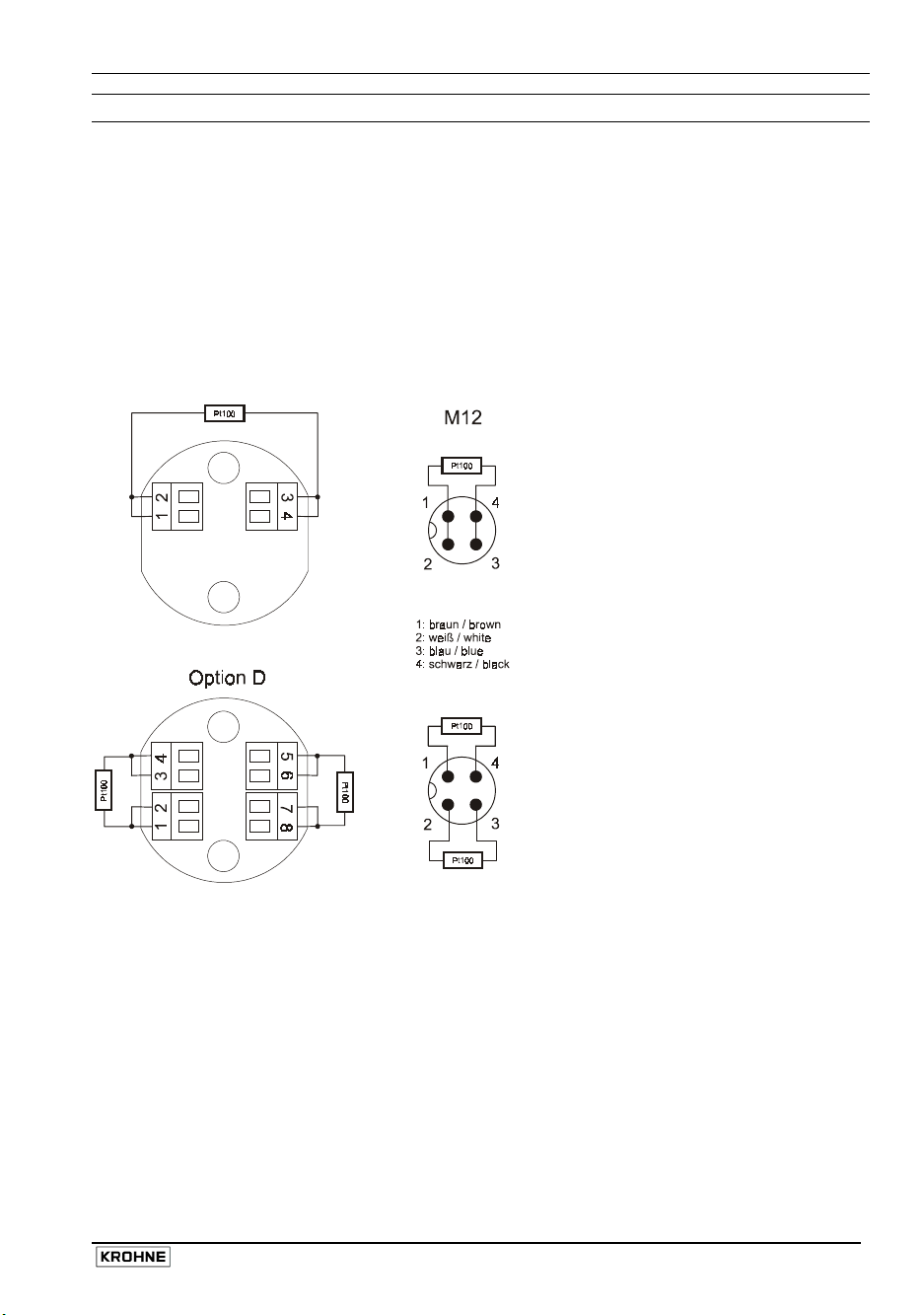

2 Electrical connection

2.1 External signal converter

Terminals 1, 2 and 3, 4 are used for connecting up the Pt100 sensor. You can, as required,

connect up in 2-, 3- or 4-wire technology.

• The 2-wire connection should not be used when particularly high accuracy is required and

where the connecting cables are of longish length.

• When using a 3-wire connection, make sure that all wires have the same cross-sectional area.

The same options are available for the double Pt100, but if connection is made with an M12

connector then only the 2-wire connection may be used.

Installation and Operating Instructions TTP x00 5

Page 6

2.2 With integrated signal converter

Terminals 1 and 2 are used for the infeed via a 4...20 mA current loop. As supply voltage, at least

8 V must be available at the module. Do not use any voltage supply higher than 28 V. The pin

assignment for the M12 connector is shown in the connection diagram. Please pay regard to the

respectively valid wiring regulations.

2.3 Start-up

• Check the leak-tightness at the sleeve.

• Make sure that the cable gland is tight or, as the case may be, the M12 plug connector is

properly screwed down.

• After powering the unit, check for correct functioning.

2.4 Operator control

External signal converter

Refer to the directions supplied with the evaluator. Set the measuring range and type of

connection at the unit.

With integrated signal converter

You can program the measuring range with the programming adapter, available as an accessory,

and the associated PC software. Refer to the operating instructions supplied with the

programming adapter.

6 Installation and Operating Instructions TTP x00

Page 7

3 Fault diagnosis and corrective action

In the event of a fault or maloperation, please go through the various faults listed in the table. Do

not attempt to disassemble the device.

Should you fail to locate the fault, please contact our Technical Service.

Fault Cause Action/elimination

With Pt100 connection

Incorrect display

Terminal assignment is

incorrect

Cable break Measure continuity Error display

Short-circuit Check wiring

With integrated signal converter

Incorrect current signal

Supply voltage at module

< 8 V

Incorrect measuring range Correct the programming

Cable break Check continuity of cables No current signal

Supply polarity incorrect Reverse terminals 1, 2

Current signal > 23 mA Short-circuit Check wiring

Check terminal assignment

Load impedance too high,

voltage too low

Installation and Operating Instructions TTP x00 7

Page 8

4 Technical data

4.1 Technical data

Connection head Stainless steel V2A 1.4305

Cable gland M16 (only TTP 200/400) Electrical connection

M12 connector

Type of protection IP 67

Ambient temperature –20...+60 °C

Process connections

Protective tube Dia. 6 mm x 1 mm; V4A 1.4571

Positioned lengths (mm) 20, 50, 100, 150, 250 (others on request)

Sensor element Pt100 DIN EN 60751 Cl. A (dual type also possible)

Response time t90 Dia. 6 mm: 7 s; dia. 4 mm: 6 s; dia. 3 mm: 1.5 s

Process temperature range –20...+170 °C

Operating pressure Max. 16 bar

With direct Pt100 connection

Output Screw terminals for 2-, 3-, 4-wire connection

With integrated head transmitter

Supply voltage 8...28 V DC (from current loop)

Output 4...20 mA

Accuracy ± 0.1% of full-scale range

Threaded socket G1/2“h; V4A 1.4571

Threaded socket M12h; V4A 1.4571

Push-in connection via protective tube dia. 6 mm

Threaded socket G1/2; V4A 1.4571

8 Installation and Operating Instructions TTP x00

Page 9

4.2 Dimensions

4.2.1 TTP 200

4.2.2 TTP 300

Dimensions in mm

Installation and Operating Instructions TTP x00 9

Page 10

4.2.3 TTP 400

Dimensions in mm

10 Installation and Operating Instructions TTP x00

Page 11

5 Ordering code

5.1 Ordering code

Identification Key Temperature Sensor

VGP 2 4 1

TTP 200 (M 16)

TTP 300 (M 12)

2

Insertion length

1

2

3

20 mm

50 mm

100 mm

Electrical Connection

Screwed cable gland M 16 (for TTP 200 only)

1

Plug M 12

2

Sensor tips

1

2

3

150 mm

4

250 mm

5

Sensor tip 6 mm

Sensor tip 4 mm

Sensor tip 3 mm

Signal output

PT 100 resistor

1

TTP 200 4-20mA, measuring range -10 …+40 °C

2

3

4

5

TTP 300 4-20mA, measuring range -10 …+40 °C

2

3

4

5

4-20mA, freely programmable on site

6

TTP 200 4-20mA, measuring range 15 ... +100°F

A

B

C

D

TTP 300 4-20mA, measuring range 15 ... +100°F

A

B

C

D

4-20mA Customer specific measuring range

K

Options

Without

0

Accessories

0

1

4-20mA, measuring range -10 …+50 °C

4-20mA, measuring range -10 …+100 °C

4-20mA, measuring range -10 …+150 °C

4-20mA, measuring range -10 …+50 °C

4-20mA, measuring range -10 …+100 °C

4-20mA, measuring range -10 …+150 °C

4-20mA, measuring range 32 ... +120°F

4-20mA, measuring range 32 ... +210°F

4-20mA, measuring range 32 ... +300°F

4-20mA, measuring range 32 ... +120°F

4-20mA, measuring range 32 ... +210°F

4-20mA, measuring range 32 ... +300°F

Without

Adapter + Software for programming

Certificates

Without

0

VGP2 4 Order designation

Installation and Operating Instructions TTP x00 11

Page 12

5.2 Spare parts

Should a replaceable part of the sensor be lost or damaged, replacements can be ordered on the

basis of the appropriate part number.

Designation Part No.

Housing lid KMD.008.055.100

Cable gland M16 KVV.M16.010.008

Connector insert M12, 4-pin KVV.100.004.000

5.3 Accessories

Designation Type

System G1/2"h TTP 200

System G1/2"h TEF 020 HWN 200

Varivent flange version N HVF 250

Sanitary pipe assembly kit DN 25 HMT 225

Sanitary pipe assembly kit DN 50 HMT 250

Tri-Clamp flange DN 32, DN 40, 2" HTC 250

Process pipe (T-piece with sleeve) HWT 2X0 (DN 25 … DN 100)

System M12h TTP 300

Weldable sleeve, with collar HWN 310

Varivent flange version N HVF 350

Sanitary pipe assembly kit DN 25 HMT 325

Sanitary pipe assembly kit DN 50 HMT 350

Tri-Clamp flange DN 32, DN 40, 2" HTC 350

Process pipe (T-piece with sleeve) HWT 3X0 (DN 15 … DN 100)

Clamp/screw joint system TTP 400

Clamp screw adapter HLC 306

12 Installation and Operating Instructions TTP x00

Page 13

6 Product description

6.1 Applications

The screw-in temperature sensors of the series “with connection head“ are designed to measure

the temperature in all processes where high accuracy and ease of handling are what count. The

various mounting systems and adapters available enable the optimum choice to be made for your

application.

6.2 Functional principle

All temperature sensors of this series feature a Pt100 chip as the sensor element. A platinum

meander applied to a ceramic substrate is trimmed such that its electrical resistance at 0°C is

exactly 100 ohms. This resistance increases by 0.38 ohm for each 1 Kelvin temperature rise. The

exact resistance performance is described in the DIN EN 60751 standard. For our temperature

sensors we use without exception the high accuracy class “A“.

6.3 Construction

The various weldable process sleeves are made of stainless steel to allow installation in

conformity with hygiene requirements. Various evaluation modules are available for evaluation of

the Pt100 signal (see Accessories). A signal converter integrated into the stainless steel

connection head provides a 4...20-mA standardised signal locally, which can be transmitted noisefree direct to the analogue input of an SPC or PLC. It is also possible to install a transmitter for

Profibus PA.

The Pt100 sensor is housed in a rugged 6 mm protective tube of variable length and made of

V4A. Due to the special type of thermal coupling, our temperature sensors achieve very fast

response times. Tapered sensor tips are also available for even higher requirements.

6.3.1 Pt100 resistance performance and wiring methods

Installation and Operating Instructions TTP x00 13

Page 14

6.3.2 Pt100 tips and response times

Tube 6 mm (S 6) Tube 4 mm (S 4) Tube 3 mm (S 3)

Halftime: T50 < 3.0 sec. Halftime: T50 < 2.5 sec. Halftime: T50 < 0.6 sec.

90% - time: T

< 7.0 sec. 90% - time: T90 < 6.0 sec. 90% - time: T90 < 1.5 sec.

90

Tube

Pt100 Chip

6.4 Features

• Sensors for hygienic installation, no elastomers

• Compact design, optionally with head transmitter

• For direct connection to an SPC or PLC (with integrated head transmitter)

• High accuracy (DIN EN 60751 Class A)

• Very fast response times

• Optimised flow geometry

• Food-compatible materials

• No maintenance requirement

• Installation in pipelines DN 15 and higher

• Defined position of the cable connection

• Hygienic adapter sleeves for other process connections

14 Installation and Operating Instructions TTP x00

Page 15

If you need to return a device for testing or repair to KROHNE

Your instrument has been carefully

manufactured and tested. If installed and

operated in accordance with these operating

instructions, your instrument will rarely present

any problems. Should you nevertheless need

to return an instrument for checkout or repair,

please pay strict attention to the following

points:

Due to statutory regulations concerning

protection of the environment and

safeguarding the health and safety of our

personnel, KROHNE may only handle, test

and repair returned instruments that have

been in contact with liquids if it is possible to

do so without risk to personnel and

environment.

This means that KROHNE can only service

your instrument if it is accompanied by a

certificate in line with the following model

confirming that the instrument is safe to

handle.

S P E C I M E N certificate

Company: ……………………………………….. Address: ……………………………………………

Department: …………………………………….. Name: ………………………………………………

Tel. No.: ………………………………………….

The enclosed instrument

Type: …………………………………………………………………………………………………………

KROHNE Order No. or Series No ………………………………………………………………………...

has been operated with the following liquid: ……………………………………………………………..

Because this liquid is

water-endangering * / toxic * / caustic * / flammable *

we have

– checked that all cavities in the instrument are free from such substances *

– flushed out and neutralized all cavities in the flowmeter *

(* delete if not applicable)

We confirm that there is no risk to man or environment through any residual liquid contained in the

instrument.

Date: ………………………….. Signature: ……………………………………………………………..

Company stamp:

Installation and Operating Instructions TTP x00 15

If the instrument has been operated with toxic,

caustic, flammable or water-endangering liquids,

you are kindly requested

• to check and ensure, if necessary by rinsing

or neutralizing, that all cavities in the

instrument are free from such dangerous

substances.

(Directions on how you can find out whether

the primary head has to be opened and then

flushed out or neutralized are obtainable from

KROHNE on request.)

• to enclose a certificate with the instrument

confirming that the instrument is safe to

handle and stating the liquid used.

KROHNE regret that they cannot service your

instrument unless it is accompanied by such a

certificate.

Loading...

Loading...