Page 1

Two-wire transmitter with ProfiBus-PA® interface

© KROHNE 11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en

Page 2

Copyright

Copyright

CopyrightCopyright

All rights reserved. Any duplication of this documentation or extracts thereof by any means is

prohibited without prior written consent from KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2010 by

KROHNE Messtechnik GmbH • Ludwig-Krohne-Straße 5 • 47058 Duisburg

Tel. +49 (203) 301-0

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

2

Page 3

1111 Safety information

2222 Device description

3333 Installation

4444 Electrical connections

5555 Operation

6666 Technical data

7777 Service

Safety information ................................

Safety informationSafety information

1.1 Intended use ......................................................................................................... 4

1.2 Product liability and guarantee ............................................................................ 4

1.3 Certifications ........................................................................................................ 5

1.3.1 Certifications, PC connection cable, Type A ................................................................5

1.4 Manufacturer's safety instructions ...................................................................... 5

1.4.1 Notes about the documentation ...................................................................................5

1.4.2 Symbol conventions ......................................................................................................6

Device description ................................

Device descriptionDevice description

Installation ................................

InstallationInstallation

3.1 TT 60 C installation ............................................................................................... 8

3.2 TT 60 R installation..............................................................................................10

Electrical connections ................................

Electrical connectionsElectrical connections

4.1 Safety instructions...............................................................................................11

4.2 Connections .........................................................................................................12

4.3 ProfiBus connection ............................................................................................13

4.3.1 Shielding and grounding .............................................................................................13

4.3.2 Cable parameters for areas with potentially explosive atmospheres .....................14

4.3.3 Terminator...................................................................................................................15

4.3.4 ProfiBus architecture .................................................................................................15

4.4 TT 60 C connection diagram................................................................................16

4.5 TT 60 C connection diagram ...........................................................................17

4.6 TT 60 R connection diagram................................................................................18

Operation................................

OperationOperation

5.1 Connection using the KROHNE PC configuration set..........................................19

5.2 General ................................................................................................................20

5.2.1 Smart Sense ................................................................................................................21

5.2.2 Monitoring of sensor aging.........................................................................................21

Technical data ................................

Technical dataTechnical data

6.1 TT 60 C specifications..........................................................................................22

6.1.1 Technical data .............................................................................................................22

6.1.2 TT 60 C dimensions .....................................................................................................23

6.1.3 Data inputs and outputs..............................................................................................23

6.1.4 Ambient temperature data for areas with potentially explosive atmospheres.......23

6.2 TT 60 C specifications .................................................................................... 24

6.2.1 Technical data .............................................................................................................24

6.2.2 TT 60 C dimensions .............................................................................................25

6.2.3 Data inputs and outputs..............................................................................................25

6.2.4 Ambient temperature data for areas with potentially explosive atmospheres,......25

6.3 TT 60 R specifications..........................................................................................26

6.3.1 Technical data .............................................................................................................26

6.3.2 TT 60 R dimensions .....................................................................................................27

Service................................

ServiceService

7.1 Ordering information...........................................................................................28

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

...............................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

....................................................

................................................................

....................................................

................................................................

...............................8888

..............................................................

............................................

................................................................

................................19

................................................................

........................................................

................................................................

....................................

................................................................

....................4444

........................................

....................7777

........................................

............11

........................

........................22

................................................

11

1111

19

1919

22

2222

....28

28

........

2828

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

3

Page 4

1 Safety information

1.1 Intended use

The TT 60 C is a two-wire universal transmitter with ProfiBus-PA® interface for temperature

and other measurement applications. It is intended for installation in a B connection head or

larger according to DIN 43729.

The TT 60 C is optionally available in an intrinsically safe version for installation in areas with

potentially explosive atmospheres. These devices are labeled with the Ex symbol .

The TT 60 R is an intelligent, two-wire universal transmitter with ProfiBus-PA® interface for

temperature and other measurement applications.

It is only intended for installation on a top-hat rail according to DIN EN 50022.

ATTENTION!

ATTENTION!

ATTENTION!ATTENTION!

Responsibility for the use of the measurement devices with regard to suitability, intended use

and area of application lies solely with the user.

The manufacturer shall not be liable for damage resulting from improper use or use for other

than the intended purpose.

1.2 Product liability and guarantee

Use for other than the intended purpose or improper installation and operation may lead to loss

of the guarantee. The guarantee shall likewise be void if the device is damaged or its function

otherwise impaired.

KROHNE Messtechnik GmbH hereby guarantees that the product will be free of material and

workmanship defects for a period of five (5) years from the date of delivery ("limited

guarantee"). This limited guarantee refers to repairs or exchanges, and is only valid for the first

end user of the product.

The "General conditions of sale" forming the basis of the purchase contract are also applicable.

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

4

Page 5

1.3 Certifications

Approval Demko 06 ATEX 141336X

Approval Demko 06 ATEX 141336X

Approval Demko 06 ATEX 141336XApproval Demko 06 ATEX 141336X

TT 60 C:

TT 60 C: CE

TT 60 C: TT 60 C:

TT 60 C Ex:

TT 60 C Ex: CE 0102

TT 60 C Ex: TT 60 C Ex:

IMPORTANT NOTE

IMPORTANT NOTE!

IMPORTANT NOTEIMPORTANT NOTE

See also the ATEX certificate "Special conditions for safe use".

The measuring device complies with the statutory requirements of the following EC directives:

The manufacturer's declaration can be viewed on the Internet at

http://www.krohne.com/html/dlc/index.shtml.

KROHNE Messtechnik GmbH certifies successful testing of the product by applying the CE

mark.

CE II 3G EEx nL I

CE CE

CE 0102 II 1G Ex ia IIC

CE 0102CE 0102

II 3G EEx nL IIC

II 3G EEx nL I II 3G EEx nL I

II 1G Ex ia IIC

II 1G Ex ia IIC II 1G Ex ia IIC

IC

ICIC

1.3.1 Certifications, PC connection cable, Type A

Approval Demko 06 ATEX 141337X

1.4 Manufacturer's safety instructions

The measuring device has been built and tested in accordance with the current state of the art,

and complies with the relevant safety standards.

However, dangers may arise from improper use or use for other than the intended purpose. For

this reason, observe all of the safety instructions in this document carefully.

1.4.1 Notes about the documentation

In addition to the safety rules and industrial safety regulations in this documentation, national

and regional safety rules and industrial safety regulations must also be observed.

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

5

Page 6

1.4.2 Symbol conventions

For greater clarity, the following symbols are used in this documentation:

DANGER!, WARNING!, ATTENTION!, CAUTION!

DANGER!, WARNING!, ATTENTION!, CAUTION!

DANGER!, WARNING!, ATTENTION!, CAUTION!DANGER!, WARNING!, ATTENTION!, CAUTION!

This symbol indicates general dangers.

All warnings must always be observed. Even partial failure on your part to observe them can

lead to serious damage to health, damage to the device or to the user's system components.

DANGER!

DANGER!

DANGER!DANGER!

This symbol is used to identify dangers when working with electric current.

Work on the device's electrical and electronic components may only be performed by qualified

personnel with the appropriate training.

DANGER!

DANGER!

DANGER!DANGER!

This symbol indicates dangers in areas with potentially explosive atmospheres, for example

those which may arise during installation and operation of explosion-proof devices.

Special regulations apply for use in areas with potentially explosive atmospheres; these must

always be observed in order to ensure safe use in such areas. Installation, set-up, operation

and maintenance of the device may only be performed by qualified persons with training in

explosion protection.

Important note!, Note!, Information!

Important note!, Note!, Information!

Important note!, Note!, Information!Important note!, Note!, Information!

This symbol identifies important notes and information for working with the device.

Legal note!

Legal note!

Legal note!Legal note!

This symbol identifies references to legal and normative regulations.

Action

Action

ActionAction

This symbol identifies all instructions for actions; the actions must be performed by the user

in the specified sequence.

Effect

Effect

EffectEffect

This symbol identifies all of the important effects of the previous actions.

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

6

Page 7

2 Device description

The KROHNE TT 60 C/R is two-wire universal transmitter with ProfiBus-PA® interface for

o Temperature measurements with resistance thermometers

o Temperature measurements with thermocouples

o Temperature differential measurements with resistance thermometers

o Measurements with potentiometers

o Voltage measurements in a range from -10...1000 mV

The transmitter supports two input signals, thus allowing differential, average and redundant

measurements and monitoring of sensor aging.

The TT 60 C is optionally available for areas with potentially explosive atmospheres.

The two-wire universal transmitter TT 60 C is designed for installation in a B connection head

according to DIN 43729 or larger.

The two-wire universal transmitter TT 60 R is designed for installation on a top-hat rail

according to DIN EN 50022 .

The output of all versions of the TT 60 complies with the latest ProfiBus PA® standard for

temperature measuring transducers, i.e. Profile 3.0, Class A and B.

The transmitter can be configured using ProfiBus-PA® or an IBM-compatible PC. Configuration

of the transmitter using an IBM-compatible PC requires the "ProfiSoft" software.

The Windows-based "ProfiSoft" software can be used to access all functions of the transmitter.

The current software version is available for downloading on our website

http://www.krohne.com/html/dlc/index.shtml.

You can find configuration instructions in the "ProfiSoft" reference manual.

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

7

Page 8

3 Installation

3.1 TT 60 C installation

TT 60 C / TT 60 C are intended for installation in DIN B connection heads or larger. The

large ∅ 7 mm / 0.28 inch center hole (see Chapter 6.1.2) facilitates the electrical connection and

installation.

ATTENTION!

ATTENTION!

ATTENTION!ATTENTION!

The TT 60 C may only be installed in a light metal housing whose magnesium component

(Mg) does not exceed 6%.

For applications in a safe area, a housing according to IP 54 is recommended.

ATTENTION!

ATTENTION!

ATTENTION!ATTENTION!

The TT 60 C may only be installed in areas with potentially explosive atmospheres Zone 2 and in

safe areas. If it is installed in Zone 2, a housing with at least IP 54 must be used.

In areas with potentially explosive atmospheres Zone 0 and Zone 1, the TT 60 C

must be

used.

The transmitter must be supplied with power by an intrinsically safe power supply unit or Zener

barrier outside of the potentially explosive zone.

ATTENTION!

ATTENTION!

ATTENTION!ATTENTION!

The TT 60 C must be installed in a housing with the protection rating IP 20 or better.

Figure 1: Connection head installation kit VI70ADA00017

1

Screw M4

2

Spring

3

Lock washer

4

Measuring sensor

5

Protection tube

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

8

Page 9

IMPORTANT NOTE!

Ambient temperature considerations

The temperature transmitter TT 60 C has been developed for the ambient temperature range

from -40…+ 85°C (-40…+185°F). Please also note that the ambient temperature is also

dependent on the temperature category in Sections 6.1.4 and 6.2.4, Ex data of the ambient

temperature.

The process temperature is also transferred to the transmitter housing via the protective tube.

If the process temperature is close to or exceeds the maximum specified process temperature,

then the temperature in the transmitter housing can rise above the maximum permissible

ambient temperature.

Always check that the ambient temperature where the transmitter is installed is always within

the permissible range. One way to decrease heat transfer via the protective tube is to make the

protective tube longer or in general to install the transmitter farther away from the heat source.

The same safety measures can be taken if the temperature is below the specified minimum

temperature.

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

9

Page 10

3.2 TT 60 R installation

The TT 60 R transmitter is intended for installation on a top-hat rail according to DIN EN 50022.

AT

ATTENTION!

TENTION!

ATAT

TENTION!TENTION!

The TT 60 R may not be installed for measurements in areas with potentially explosive

atmospheres.

For measurements in areas with potentially explosive atmospheres, the TT 60 C

used.

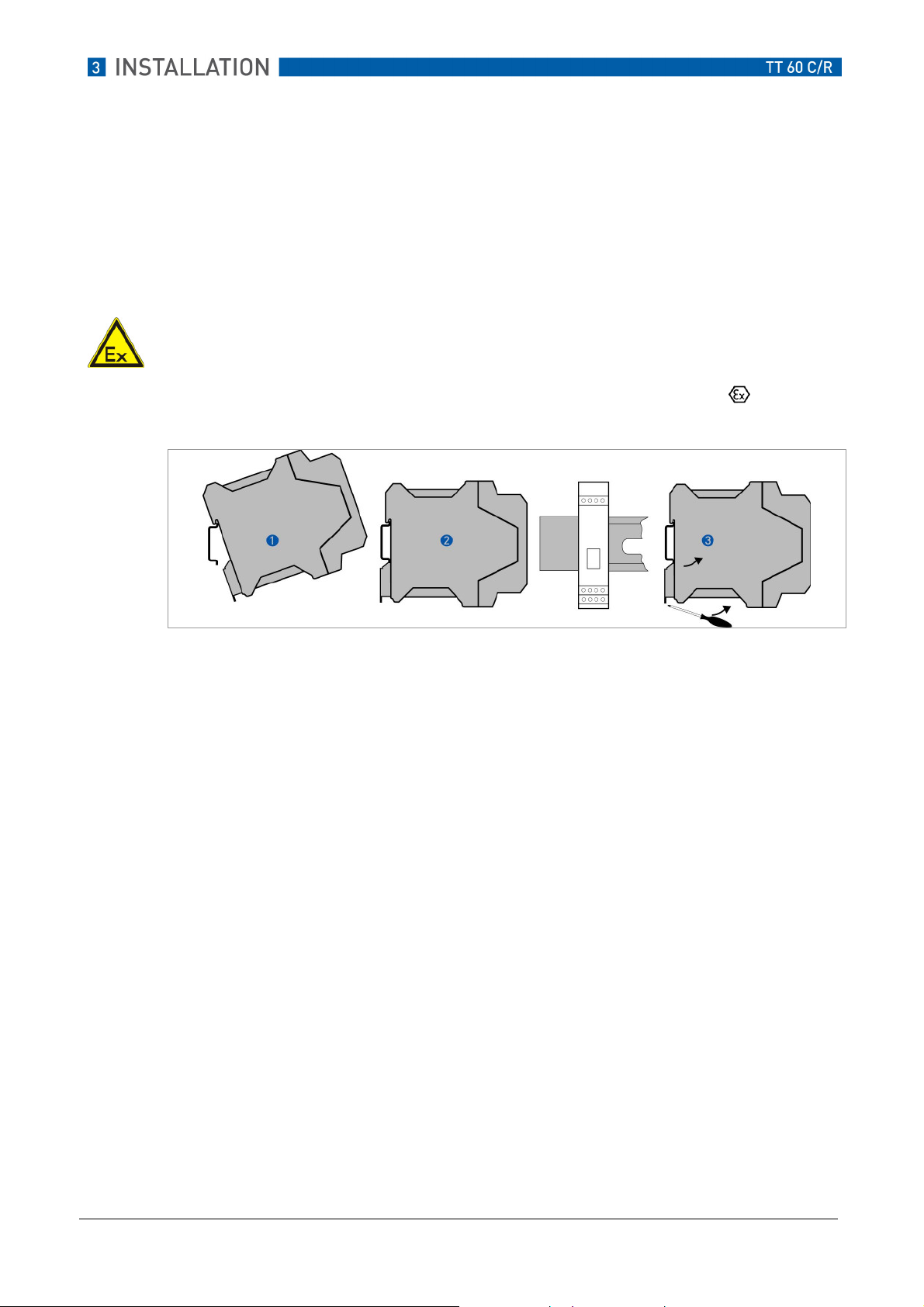

Figure 2: TT 60 R rail installation

1

Hook the upper groove of the transmitter onto the rail.

2

Press the transmitter downwards until the snap fastener engages on the rail.

To remove, press the snap fastener downwards using a screwdriver. Carefully pull the

3

transmitter forwards.

must be

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

10

Page 11

4 Electrical connections

4.1 Safety instructions

ATTENTION!

ATTENTION!

ATTENTION!ATTENTION!

Only trained and qualified personnel may carry out any work on the device. Always observe the

regional industrial safety and other safety regulations.

ATTENTION!

ATTENTION!

ATTENTION!ATTENTION!

Any work on the electrical connections may only be carried out in the de-energized state.

Observe the voltage specifications on the rating plate!

Observe the national regulations for electrical installations!

The transmitter is protected against polarity reversal.

polarity of the supply voltage is switched.

ATTENTION!

ATTENTION!

ATTENTION!ATTENTION!

When connecting devices with an Ex certificate, observe the corresponding chapters and the

instructions in this manual.

No damage will occur to the device if the

The TT 60 C

equipment" in standard EN 50020:2002, section 5.4

may only be connected to sensors that meet the requirements for "simple

.

The transmitter must be supplied with power by an intrinsically safe power supply unit or Zener

barrier outside of the potentially explosive zone.

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

11

Page 12

4.2 Connections

The input and output signals and the power supply must be connected in accordance with the

following illustrations. The in-head transmitter is easy to install with the KROHNE connection

head installation kit (see order information chapter 7.1). To avoid measuring errors, all cables

must be connected properly and the screws tightened correctly.

Figure 3: Installation diagram, TT 60 C/R

1

Pt100, Pt1000, Ni100, Ni1000, "SmartSense", 2-wire connection

2

Pt100, Pt1000, Ni100, Ni1000, "SmartSense", 3-wire connection

3

Pt100, Pt1000, Ni100, Ni1000, "SmartSense", 4-wire connection

4

Pt100, redundant sensor elements

5

Potentiometer, 2-wire connection

6

1) SmartSense wire

Potentiometer, 3-wire connection

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

12

Page 13

Figure 4: Installation diagram, TT 60 C/R

1

Potentiometer, 4-wire connection

2

Thermocouple

3

Thermocouple, redundant sensor elements

4

Thermocouple, with remote reference junction compensation

5

Voltage

6

1) SmartSense wire

Voltage, redundant

4.3 ProfiBus connection

4.3.1 Shielding and grounding

In environments subject to electrical interference, shielded and twisted wires enable precise

measurement results.

The electrical wiring of the data bus must be installed properly and shielded in order to enable

precise measurement results.

IMPORTANT NOTE!

IMPORTANT NOTE!

IMPORTANT NOTE!IMPORTANT NOTE!

If you use non-shielded wires, they must not be laid near power cables or electrical loads.

In order to ensure the electromagnetic compatibility of the entire measuring system, all

components must be shielded and grounded.

The shields and grounds must provide complete protection against interference.

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

13

Page 14

CAUTION!

CAUTION!

CAUTION!CAUTION!

EN 61158-2 stipulates that all data bus interfaces must be isolated from the local ground.

The ProfiBus must not be grounded.

Figure 5: Circuit schematic, ProfiBus shielding and grounding

1

Power supply

2

Supply cable

3

Connection box

4

Connection cable to field device

5

Field device

6

Equipotential bonding

4.3.2 Cable parameters for areas with potentially explosive atmospheres

Resistance Values

Cable resistance 15...150 Ω/km

Cable inductance 0.4...1 mH/km

Cable capacitance 45...200 nF/km

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

14

Page 15

4.3.3 Terminator

The ProfiBus cable must be terminated at both ends.

The terminator consists of a capacitor and a film resistor connected in series.

Values

4.3.4 ProfiBus architecture

Figure 6: Typical ProfiBus architecture

ProfiBus DP components

1

DP/PA segment coupler with 3 and 4

2

Signal coupler

3

Power supply

4

Connection box

5

PA segment

6

Bus terminator

7

Field devices

8

The illustration above shows a typical ProfiBus architecture. Field devices with low power

consumption (e.g. pressure and temperature transmitters) are fed via the two-wire bus. Signal

transmission is likewise via the bus.

In the case of installations in areas without potentially explosive atmospheres, up to 32 devices

can be connected per segment, depending on the power rating of the segment coupler.

In the case of installations in areas with potentially explosive atmospheres, normally 10 devices

can be connected per segment.

(T)

R = 100 Ω ± 2%

C = 1 µF ± 20%

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

15

Page 16

4.4 TT 60 C connection diagram

ATTENTION!

ATTENTION!

ATTENTION!ATTENTION!

The TT 60 C may only be operated in areas with potentially explosive atmospheres Zone 2 and in

safe areas.

Figure 7: TT 60 C connection diagram

1

Input

2

ProfiBus PA® terminator

3

ProfiBus PA® output, bus lines

Bus feed unit / segment coupler

4

(in the case of applications in areas with potentially explosive atmospheres, certified

devices must be used)

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

16

Page 17

4.5 TT 60 C connection diagram

ATTENTION!

ATTENTION!

ATTENTION!ATTENTION!

The transmitter may be operated in areas with potentially explosive atmospheres if the voltage

supply is ensured by means of an appropriate power supply unit or a Zener barrier!

Figure 8: TT 60 C connection diagram

1

Input

2

ProfiBus PA® terminator

3

ProfiBus PA® output, bus lines

4

Certified bus feed unit / segment coupler

5

Safe area

6

Area with potentially explosive atmosphere

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

17

Page 18

4.6 TT 60 R connection diagram

ATTENTION!

ATTENTION!

ATTENTION!ATTENTION!

Neither install the transmitter in an area with a potentially explosive atmosphere, nor connect it

to a sensor in an area with a potentially explosive atmosphere!

1

Input

2

ProfiBus PA® terminator

3

ProfiBus PA® output, bus lines

Bus feed unit / segment

4

coupler

Figure 9: TT 60 R connection diagram

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

18

Page 19

5 Operation

5.1 Connection using the KROHNE PC configuration set

ATTENTION!

ATTENTION!

ATTENTION!ATTENTION!

No PC may be connected to a transmitter in areas with potentially explosive atmospheres.

If you wish to configure the transmitter with the PC, this must be done outside of the area with a

potentially explosive atmosphere or by means of communication via ProfiBus.

If the transmitter is configured with the PC, a configuration cable and an adapter from the

configuration set (order number see Chapter 7.1) must be used as the connection between the

PC and the transmitter.

An ATEX certified cable must be used for transmitters bearing the symbol.

TT 60 C X X

TT 60 C

TT 60 R X X

Type A Type C

X X

Table 1: PC connection cable

Type A

Cable

Type C

Adapter

Figure 10: PC connection cable

Order number Comment

Type A (cable) VI70IPRX0002 ATEX certified

Type C (adapter) VI70IPRP0001 --

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

19

Page 20

5.2 General

IMPORTANT NOTE

IMPORTANT NOTE!

IMPORTANT NOTEIMPORTANT NOTE

The TT 60 is shipped ex works with a standard configuration.

Standard settings:

Standard settings:

Standard settings:Standard settings:

Address 126

Input signal Pt100, 4-wire

Output signal °C

Filter 0 s

Sensor monitoring Off

All models of the TT 60 series have a ProfiBus PA®-interface. The transmitters can be

configured using

With a PC, configuration can be carried out before the device is integrated into the ProfiBus.

Configuration using a PC requires a connection to a serial interface and the "ProfiSoft"

software.

The current version of the software is available for download on our website

http://www.krohne.com/html/dlc/index.shtml.

You can find configuration instructions in the "ProfiSoft" reference manual.

o ProfiBus PA®o an IBM compatible PC.

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

20

Page 21

5.2.1 Smart Sense

If the appropriate measuring sensors are provided (an additional wire in the sensor), the

transmitter can continuously monitor the insulation resistance of the sensor, including the

connection wires. This function (Smart Sense) is possible for resistance thermometers and

thermocouples. If the insulation resistance is too low, the measured result will be incorrect and

a message will be generated via ProfiBus.

This function requires configuration with the "ProfiSoft" software via a PC or via the ProfiBus.

5.2.2 Monitoring of sensor aging

If a resistance thermometer or a thermocouple with two sensors is used, the TT 60 can be used

to monitor the aging of the sensor. The transmitter compares the measured values of the two

sensors. Aging is indicated if the differential between the measured values is too great. In this

case a message is generated via the ProfiBus. For further information, see the "Profisoft"

manual.

Action

Action

ActionAction

To protect the PC connections, they must be closed off using the supplied protection caps

after configuration has been completed.

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

21

Page 22

6 Technical data

6.1 TT 60 C specifications

6.1.1 Technical data

Designation

Input

Input Pt10, Pt50, Pt100, Pt200,

InputInput

Ni50, Ni100, Ni120, Ni1000 -200... +250°C

Designation Value

DesignationDesignation

Value

ValueValue

-200...+850°C

Pt500, Pt1000

Potentiometer

0...4000 Ω

Thermocouples Types: B, C, D, E, G, J, K, L, N, R, S,

T, U

Voltage -10...+1000 mV

Redundan

Redundant channels and

RedundanRedundan

arithmetic functions

arithmetic functions

arithmetic functionsarithmetic functions

t channels and

t channels and t channels and

Differential channel 1 - channel 2 or

channel 2 - channel 1

Average value 0.5 x (channel 1 + channel 2)

Average value with

redundancy

0.5 x (channel 1 + channel 2),

channel 1 or channel 2 if the other

channel fails

Minimum value Min (channel 1, channel 2)

Maximum value Max (channel 1, channel 2)

Sensor break function

Sensor break function On / Off

Sensor break functionSensor break function

Output

Output ProfiBus-PA ®

OutputOutput

Ambient temperat

Ambient temperature

Ambient temperatAmbient temperat

Galvanic isolation

Galvanic isolation 1500 VAC, 1 min

Galvanic isolationGalvanic isolation

Power supply

Power supply

Power supplyPower supply

Power consumption

Power consumption 11 mA

Power consumptionPower consumption

ure -40...+85°C

ureure

9...32 VDC

Typical accuracy

Typical accuracy Pt100 0.1°C

Typical accuracyTypical accuracy

Connection head

Connection head DIN B or larger

Connection headConnection head

Table 2: TT 60 C specifications

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

22

Page 23

6.1.2 TT 60 C dimensions

Dimension [mm] Dimension [inch]

1

2

3

4

44 1.73

27 1.06

7 0.28

33 1.30

Figure 11: TT 60 C dimensions

6.1.3 Data inputs and outputs

Bus connection

Bus connection

Bus connection Bus connection

(terminals 6+7)

(terminals 6+7)

(terminals 6+7)(terminals 6+7)

Ui:= V

Ii: = I

Pi: = P

30 VDC U0 = Voc 30 VDC Ui: = V

max

not limited I0 = Isc 0.4 mA Ii: = I

max

not limited P0 = Pt 6.5 mW Pi: = P

max

Sensor connection

Sensor connection

Sensor connectionSensor connection

(terminals 1

(terminals 1----5)

(terminals 1(terminals 1

5)

5)5)

Communic

Communications connection

CommunicCommunic

ations connection

ations connectionations connection

8.0 VDC

max

450 mA

max

800 mW

max

Ci: 1 nF C0 = Ca 1000 nF Ci: 10 nF

Li 10 µH L0 = La 750 mH Li 1 µH

Table 3: TT 60 C input/output electrical data

6.1.4 Ambient temperature data for areas with potentially explosive atmospheres, TT 60 C

Temperature class

Temperature class Ambient temperature

Temperature classTemperature class

Ambient temperature

Ambient temperatureAmbient temperature

T6

T5

T4

Tabelle 4: Temperature data, TT 60 C

-40°C ≤ Ta ≤ +75°C

-40°C ≤ Ta ≤ +85°C

-40°C ≤ Ta ≤ +85°C

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

23

Page 24

6.2 TT 60 C specifications

6.2.1 Technical data

Designation

Input

Input Pt10, Pt50, Pt100, Pt200,

InputInput

Ni50, Ni100, Ni120, Ni1000 -200...+250°C

Designation Value

DesignationDesignation

Value

ValueValue

-200...+850°C

Pt500, Pt1000

Potentiometer

0...4000 Ω

Thermocouples Types: B, C, D, E, G, J, K, L, N, R, S,

T, U

Voltage -10...+1000 mV

Redundant channels and

Redundant channels and

Redundant channels and Redundant channels and

arithmetic functions

arithmetic functions

arithmetic functionsarithmetic functions

Differential channel 1 - channel 2 or

channel 2 - channel 1

Average value 0.5 x (channel 1 + channel 2)

Average value with

redundancy

0.5 x (channel 1 + channel 2),

channel 1 or channel 2 if the other

channel fails

Minimum value Min (channel 1, channel 2)

Maximum value Max (channel 1, channel 2)

Sensor break function

Sensor break function On / Off

Sensor break functionSensor break function

Output

Output ProfiBus-PA ®

OutputOutput

Ambi

Ambient temperature

ent temperature -40...+85°C

AmbiAmbi

ent temperatureent temperature

Galvanic isolation

Galvanic isolation 1500 VAC, 1 min

Galvanic isolationGalvanic isolation

Power supply

Power supply

Power supplyPower supply

Power consumption

Power consumption 11 mA

Power consumptionPower consumption

9...17.5 VDC

Typical accuracy

Typical accuracy Pt100 0.1°C

Typical accuracyTypical accuracy

Connection head

Connection head DIN B or larger

Connection headConnection head

Table 5: TT 60 C specifications

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

24

Page 25

6.2.2 TT 60 C dimensions

Dimension [mm]

1

2

3

4

Dimension [mm] Dimension [inch]

Dimension [mm]Dimension [mm]

Dimension [inch]

Dimension [inch]Dimension [inch]

44 1.73

27 1.06

7 0.28

33 1.06

Figure 12: TT 60 C dimensions

6.2.3 Data inputs and outputs

Bus connection

Bus connection

Bus connection Bus connection

(terminals 6+7)

(terminals 6+7)

(terminals 6+7)(terminals 6+7)

Ui:= V

Ii: = I

Pi: = P

17.5 VDC U0 = Voc 17.5 VDC Ui: = V

max

380 mA I0 = Isc 56 mA Ii: = I

max

5.32 W P0 = Pt 244 mW Pi: = P

max

Sensor connection

Sensor connection

Sensor connectionSensor connection

(term

(terminals 1

(term(term

inals 1----5)

inals 1inals 1

5)

5)5)

Communications connection

Communications connection

Communications connectionCommunications connection

8.0 VDC

max

450 mA

max

800 mW

max

Ci: 1 nF C0 = Ca 166 nF Ci: 10 nF

Li 10 µH L0 = La 6 mH Li 1 µH

Table 6: TT 60 C input/output electrical data

6.2.4 Ambient temperature data for areas with potentially explosive atmospheres, TT 60 C

Temperature class

Temperature class Ambient temperature

Temperature classTemperature class

Ambient temperature

Ambient temperatureAmbient temperature

T6

T5

T4

Table 7: TT 60 C temperature data

-40°C ≤ Ta ≤ +45°C

-40°C ≤ Ta ≤ +60°C

-40°C ≤ Ta ≤ +85°C

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

25

Page 26

6.3 TT 60 R specifications

6.3.1 Technical data

Designation

Input

Input Pt10, Pt50, Pt100, Pt200,

InputInput

Ni50, Ni100, Ni120, Ni1000 -200...+250°C

Designation Value

DesignationDesignation

Value

ValueValue

-200...+850°C

Pt500, Pt1000

Potentiometer

0...4000 Ω

Thermocouples Types: B, C, D, E, G, J, K, L, N, R, S,

T, U

Voltage -10...+1000 mV

Redundant channels and

Redundant channels and

Redundant channels and Redundant channels and

arithmetic functions

arithmetic functions

arithmetic functionsarithmetic functions

Differential channel 1 - channel 2 or

channel 2 - channel 1

Average value 0.5 x (channel 1 + channel 2)

Average value with

redundancy

0.5 x (channel 1 + channel 2),

channel 1 or channel 2 if the other

channel fails

Minimum value Min (channel 1, channel 2)

Maximum value Max (channel 1, channel 2)

Sensor break function

Sensor break function On / Off

Sensor break functionSensor break function

Output

Output ProfiBus-PA ®

OutputOutput

Ambient temperature

Ambient temperature -20.. +70°C

Ambient temperatureAmbient temperature

Galvanic isolation

Galvanic isolation 1500 VAC, 1 min

Galvanic isolationGalvanic isolation

Power supply

Power supply

Power supplyPower supply

Power consumption

Power consumption 11 mA

Power consumptionPower consumption

9...32 VDC

Typical accuracy

Typical accuracy Pt100 0.1°C

Typical accuracyTypical accuracy

Installation

Installation Rail according to EN 50020, 35 mm

InstallationInstallation

Table 8: TT 60 R specifications

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

26

Page 27

6.3.2 TT 60 R dimensions

Figure 13: TT 60 R dimensions

Dimension [mm]

Dimension [mm]

Dimension [mm]Dimension [mm]

1

2

3

115 4.53

100 3.93

22.5 0.88

Dimension [inch]

Dimension [inch]

Dimension [inch]Dimension [inch]

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

27

Page 28

7 Service

7.1 Ordering information

Product

Product Order No.

ProductProduct

TT 60 C VIP04H000010000

Order No.

Order No.Order No.

TT 60 C ATEX

VIP04HX00010000

TT 60 R VIP04L000010000

Software and cables

Software and cables

Software and cablesSoftware and cables

PC configuration set VI70CFG00092

ATEX cable for PC connection

VI70IPRX0002

(contained in the configuration set VI70CFG00092)

Adapter cable (4-pole)

VI70IPRP0001

(contained in the configuration set VI70CFG00092)

Accessories

Accessories

AccessoriesAccessories

Field housing for floor installation VI70ADA00008

Field housing for DIN rail installation VI70ADA00009

Connection head installation kit VI70ADA00017

Rail installation clip VI70ADA00013

Display LCD-W12 VI70LCDW1201

Configuration ex works VI70CAL00001

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

28

Page 29

For your notes:

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

29

Page 30

For your notes:

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

30

Page 31

For your notes:

11/2010 – 4000754401 – MA OPTITEMP TT60CR R01 en www.krohne.com

31

Page 32

Loading...

Loading...