Page 1

Technical Datasheet

Technical Datasheet

DK46 - DK800

DK46 - DK800

DK46 - DK800DK46 - DK800

Technical DatasheetTechnical Datasheet

Variable area flowmeter

• Local indication without auxiliary power supply

• Adaptable to meet customers' requirements

• Replaceable mounting parts that are easily assembled

© KROHNE 07/2009 - 4000193403 TD DK46_800-R04 en

Page 2

CONTENTS

DK46 - DK800

1 Product features 3

1.1 DK46 - DK800 variable-area flowmeter........................................................................... 3

1.2 Options and variants......................................................................................................... 5

1.3 Operating principle........................................................................................................... 7

2 Technical data 8

2.1 Technical data................................................................................................................... 8

2.2 Dimensions and weights ................................................................................................ 11

2.3 Measuring ranges...........................................................................................................13

2.4 Differential pressure regulators .................................................................................... 16

3 Installation 19

3.1 Intended use ................................................................................................................... 19

3.2 Installation conditions ....................................................................................................19

3.2.1 Installation in the piping ....................................................................................................... 19

4 Electrical connections 20

4.1 Limit switch .................................................................................................................... 20

5 Order form 21

6 Notes 22

2

www.krohne.com 07/2009 - 4000193403 TD DK46_800-R04 en

Page 3

DK46 - DK800

1.1 DK46 - DK800 variable-area flowmeter

The DK46...DK800 flowmeters are suitable for measuring the volume flow rate of liquids and

gases.

PRODUCT FEATURES 1

DK46 accuracy 4,0%

DK800 accuracy 2,5%

DK47 accuracy 2,5%

DK48 accuracy 1,0%

www.krohne.com07/2009 - 4000193403 TD DK46_800-R04 en

3

Page 4

1 PRODUCT FEATURES

Highlights

• Simple installation and start-up

• Compact design

• Low maintenance

• Limit switches are optional

• All variants come with high quality needle valves

• No wearing parts

• Fragment protection

Industries

• Chemical

• Heating, cooling, and air conditioning

• Iron, steel and metal

• Oil & Gas

• Pharmaceutical

• Analytical technology

• Mechanical engineering

• Paper and pulp

• Water

DK46 - DK800

Applications

• Fine metering

• Gas chromatography

• Minimum level monitoring and control

• In connection with a differential pressure regulator: Ensures constant flow rate in the case of

variable inlet or outlet pressures

4

www.krohne.com 07/2009 - 4000193403 TD DK46_800-R04 en

Page 5

DK46 - DK800

1.2 Options and variants

DK devices with limit switches

PRODUCT FEATURES 1

The DK devices can be provided with max. two

limit switches, NAMUR or 3-wire open

collector.

DK with differential pressure regulators

Differential pressure regulators are used to

provide constant flow rates in the case of

variable inlet or outlet pressures.

www.krohne.com07/2009 - 4000193403 TD DK46_800-R04 en

5

Page 6

1 PRODUCT FEATURES

Instrument designation

DK46 - DK800

Instruments with head 1 and foot pieces 2

made from:

Stainless steel = DK…/R

Brass = DK…/N

PVDF = DK…/PV

6

www.krohne.com 07/2009 - 4000193403 TD DK46_800-R04 en

Page 7

DK46 - DK800

1.3 Operating principle

The flowmeter operates on the float measuring principle

The measuring unit consists of a glass cone in which a float can move freely up and down. The

medium flows through the flowmeter from bottom to top.

The float adjusts itself so that the buoyancy force AAAA, acting on it, the form drag WWWW and its weight GGGG

are in equilibrium: G = A + W

G = A + W.

G = A + WG = A + W

PRODUCT FEATURES 1

Figure 1-1: Operating principle

The height of the float is read on the scale of the measuring glass and indicates the flow rate.

The top edge of the float marks the reading line for flow values.

www.krohne.com07/2009 - 4000193403 TD DK46_800-R04 en

7

Page 8

2 TECHNICAL DATA

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local representative.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

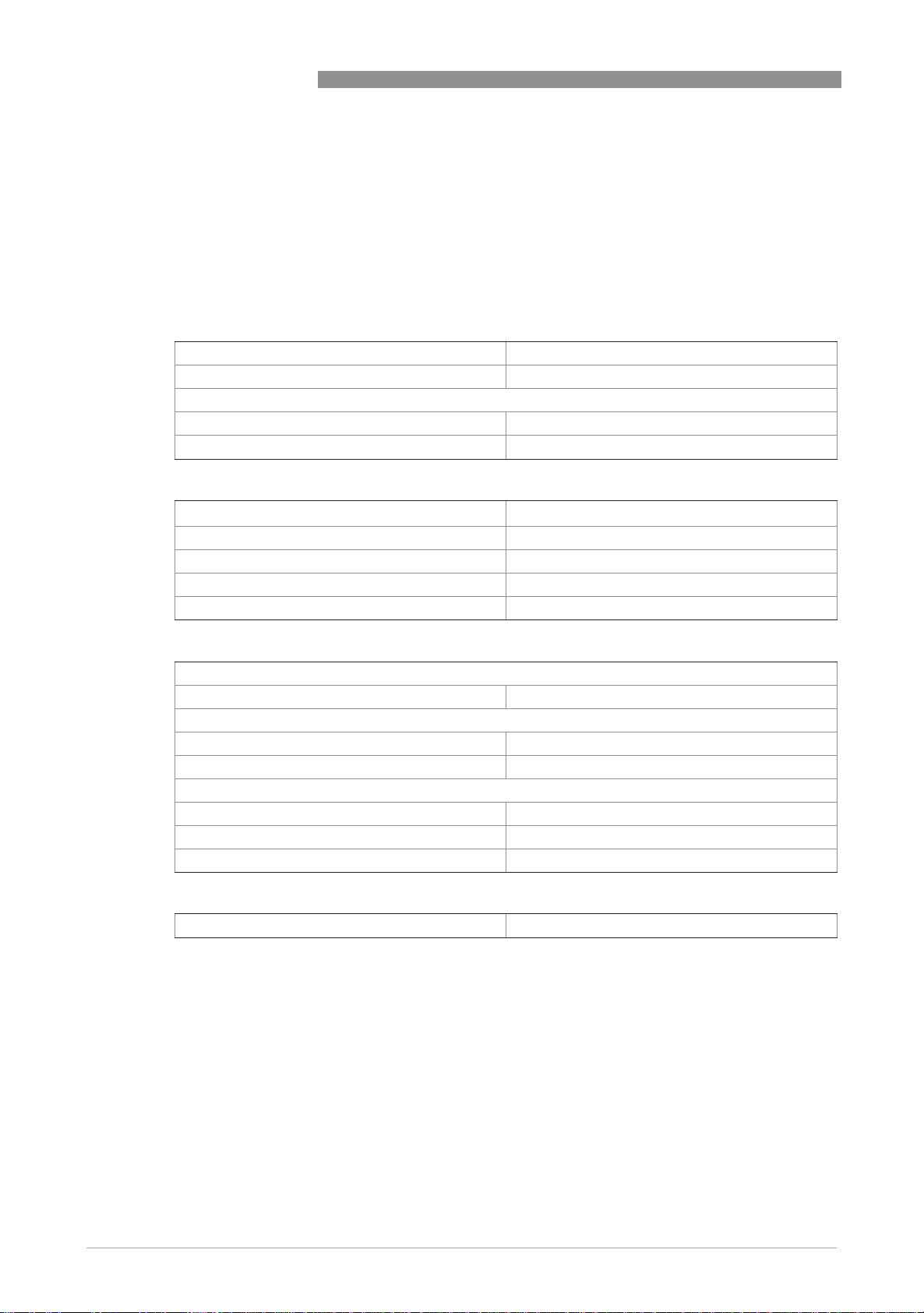

Measuring system

Application range Flow measurement of liquids and gases

Operating method / measuring principle Variable area measuring principle

Measurement

Primary measured value Float position

Secondary measured value Operating and standard volumetric flow

Measuring accuracy

Directive VDI / VDE 3513, sheet 2 (qG = 50%)

DK46 4.0%

DK47 2.5%

DK48 1.0%

DK800 2.5%

DK46 - DK800

Operating conditions

Temperature

Temperature

TemperatureTemperature

Max. operating temperature TS -5..+100°C / +23...+212°F

Pressure

Pressure

PressurePressure

Operating pressure PS Pressure Equipment Directive 97/23/EC

Test pressure PT Pressure Equipment Directive 97/23/EC

Max. permitted operating gauge pressure PS at TS = 100°C / 212°F:

DK…/R (stainless steel top and bottom fittings ) 10 bar / 145 psig 1

DK…/N (brass top and bottom fittings ) 10 bar / 145 psig 1

DK…/PV (PVDF top and bottom fittings ) 4 bar / 58 psig

Installation conditions

Inlet and outlet None

1 higher pressures upon request

8

www.krohne.com 07/2009 - 4000193403 TD DK46_800-R04 en

Page 9

DK46 - DK800

Materials

1 top and bottom fittings made of PVDF not on DK48

TECHNICAL DATA 2

Top fitting, bottom fitting CrNi steel 1.4404 / 316 L, nickel-plated brass, PVDF 1

Top fitting, bottom fitting (optional)

Hastelloy

Measuring tube Borosilicate glass

Float (ball) CrNi steel 1.4401 / 316

Float options

Glass, POM, titanium, Hastelloy® C4

Float DK48 (AIII) CrNi steel 1.4571 / 316 Ti, Aluminium, PEEK

Metering unit CrNi steel 1.4571 / 316 Ti

Valve spindle CrNi steel 1.4404 / 316 L

Gaskets (standard) PTFE / FPM

Gaskets (optional) PTFE / FFKM, PTFE / EPDM

Gaskets (optional) EPDM, FFKM

Protective cover Polycarbonate

®

Temperatures

Max. temperature of medium T

Max. T

Min. temperature of medium T

Max. ambient temperature T

Max. T

Min. ambient temperature T

Other temperatures on request.

with limit switches +65°C +149°F

m

with limit switches +65°C +149°F

amb.

amb.

amb.

m

m

+100°C +212°F

-5°C +23°F

+100°C +212°F

-20°C -4°F

www.krohne.com07/2009 - 4000193403 TD DK46_800-R04 en

9

Page 10

2 TECHNICAL DATA

Technical Data Limit Switches

Terminal connection Connection box M16x1.5

Cable diameter 5...10 mm

Limit switch I7R2010-NL I7R2015-NL I7R2010-N I7R2015-N RB15-14-E2

Ring diameter 10 mm 15 mm 10 mm 15 mm 15 mm

Switching function bistable bistable monostable monostable bistable

NAMUR yes yes yes yes no

Connection technology 2-wire 2-wire 2-wire 2-wire 3-wire

Nominal voltage U

Current consumption 1mA passage ↓ 1 3 mA - ball outside

Current consumption 3mA passage ↑ 1 1 mA - ball in the limit

Operating voltage U

Operating current I 0…100 mA

No load current I 20 mA

Output Ua - passage ↓ ≤ 1 VDC 2

Output Ua - passage ↑ ≥ U

1 For devices with the valve at the top (at the outlet) and devices with outlet pressure regulators, the function is inverted!

2 For devices with the valve at the top in the output and devices with outlet pressure regulators, the function is inverted!

0

ext.

RC10-14-N3 RC15-14-N3 RC10-14-N0 RC15-14-N0

8 VDC 8 VDC 8 VDC 8 VDC

switch

DK46 - DK800

10…30 VDC

– 3 VDC 2

b

Field of application for limit switches

DK46, DK47, DK800 DK48

Ball Ring diameter Cone no. Ring diameter

Ø 4 mm / 0.158" 10 mm G 13.11 -

Ø 6 mm / 0.236" 15 mm G 14.06 -

Ø 8 mm / 0.315" - G 14.08 -

G 15.07 10 mm

G 15.09 10 mm

G 15.12 10 mm

G 16.08 10 mm

G 16.12 10 mm

G 17.08 15 mm

G 17.12 15 mm

G 18.06 -

G 18.08 -

G 18.12 -

The limit switches with ring diameters of 15mm as max. contact can only be used up to 60 l/h -

15.8 gph water or 2400 l/h - 89,3 scfh air (outer diameter of the measuring glass).

10

www.krohne.com 07/2009 - 4000193403 TD DK46_800-R04 en

Page 11

DK46 - DK800

2.2 Dimensions and weights

Dimensions

TECHNICAL DATA 2

Device a b

d f approx.

± 0.25

[mm] ["] [mm] ["] [mm] ["] [mm] ["]

DK46 111 4.37 90 3.55 45 1.77 82 3,2

DKR46 136 5,36 90 3,55 - - 125 4,92

DK800 146 5.75 125 4.92 80 3.15 82 3,2

DK47 196 7.72 175 6.89 130 5.12 82 3,2

DK48 346 13.6 325 12.8 280 11.0 82 3,2

c = 4,3 mm / 0,169"

e = 33 mm / 1,3"

f ca. 82 mm / 3,2"

g = 28 mm / 1,1"

Dimensions of panel cutout and faceplate

Device a c

[mm] ["] [mm] ["]

DK46 128 5.04 145 5.71

DK800 163 6.42 180 7.09

DK47 213 8.39 230 9.06

DK48 363 14.3 380 15.0

b = 32 mm / 1.26" d = 40 mm / 1.58"

e = 27.5 mm / 1.08"

www.krohne.com07/2009 - 4000193403 TD DK46_800-R04 en

11

Page 12

2 TECHNICAL DATA

Weights

Weight 0.4 0.88 0.5 1.1 0.6 1.3 0.7 1.5

Weights with regulator 2.1 4.6 2.2 4.9 2.3 5.1 2.4 5.3

Process connection

Standard ¼" NPT internal thread

Options G¼, Ermeto 6 or 8, tube connection 6 mm or 8 mm, Dilo, Gyrolok, Swagelok 1

1 other connection upon request

DK46 - DK800

DK46 DK800 DK47 DK48

[kg] [lbs] [kg] [lbs] [kg] [lbs] [kg] [lbs]

12

www.krohne.com 07/2009 - 4000193403 TD DK46_800-R04 en

Page 13

DK46 - DK800

2.3 Measuring ranges

Measuring span 10 : 1

Flow values 100%

Ball Ø DK46 DK47 DK800 DK(R)46 DK47 DK800

[mm] ["] [l/h] [gph] [l/h] [gph] [l/h] [gph] [l/h] [scfh] [l/h] [scfh] [l/h] [scfh]

4 0.158 2.5 0.65 - - 2.5 0.65 5 0,22 - - 5 0,18

6 0.236 5 1.3 5 1.3 5 1.3 100 3,8 250 9,5 100 3,8

60 1 16 1 60 16 60 16 1200145 1 - - 1000 38

TECHNICAL DATA 2

Water Air

- - - - - - 8 0,3 - - 8 0,3

- - - - - - 16 0,6 16 0,6 16 0,6

- - - - - - 40 1,5 40 1,5 40 1,5

- - - - - - 60 2,2 100 3,8 60 2,2

12 3.0 12 3.0 12 3.0 250 9,5 500 19 250 9,5

25 6.5 25 6.5 25 6.5 500 19 800 30 500 19

40 11 40 11 40 11 800 30 - - 800 30

100125 1 100 25 100 25 - - - - 1800 65

- - - - 120 30 - - - - 2400 90

- - - - 160 42 - - - - 3000 110

- - - - - - - - - - 4000 140

- - - - - - - - - - 5000 180

8 0.315 120130 1 - - - - - - - - - -

160142 1 - - - - - - - - - -

1 not for DKR46

Reference condition:

Water 20°C / 68°F

Air 20°C / 68°F - 1.2 bar abs. / 17.4 psi (in normal state)

Measuring range data for floats made of CrNi steel

Other flow ranges on request

Conversion to other media or operating data (pressure, temperature, density, viscosity) takes

place using the calculation method in accordance with VDI /VDE Directive 3513.

www.krohne.com07/2009 - 4000193403 TD DK46_800-R04 en

13

Page 14

2 TECHNICAL DATA

Measuring ranges DK48

Measuring span 10 : 1

Flow values 100%

Material Stainless Steel Hardrubber Aluminium Stainless Steel

Cone no. [l/h] [gph] [l/h] [scfh] [l/h] [scfh] [l/h] [scfh]

G 13.11 1 0.4 0.1 - - 7 0.25 16 0.6

G 14.06 0.6 0.16 - - 12 0.45 25 0.95

G 14.08 1 0.25 - - 20 0.75 40 1.5

G 15.07 1.6 0.4 - - 30 1.1 60 2.2

G 15.09 2.5 0.65 - - 40 1.5 90 3.5

G 15.12 4 1.0 - - 60 2.2 140 5.0

G 16.08 6 1.6 - - 100 3.7 200 7.5

G 16.12 10 2.5 - - 160 6.0 300 11

G 17.08 16 4.0 - - 250 9.0 500 19

G 17.12 25 6.5 - - 400 15 800 30

G 18.06 40 10 400 15 600 22 1200 45

G 18.08 63 16 600 22 1000 37 2000 75

G 18.12 100 25 1000 37 1600 60 3000 110

1 reduced accuracy : 2.5%

DK46 - DK800

Water Air

Reference condition:

Water 20°C / 68°F

Air 20°C / 68°F - 1.013 bar abs. / 14.7 psi (in normal state)

Measuring range data for floats made of CrNi steel

Other flow ranges on request

Conversion to other media or operating data (pressure, temperature, density, viscosity) takes

place using the calculation method in accordance with VDI /VDE Directive 3513.

14

www.krohne.com 07/2009 - 4000193403 TD DK46_800-R04 en

Page 15

DK46 - DK800

Valves

TECHNICAL DATA 2

Max. flowrate Valve characteristic

value

Valve spindle Water Air Kv Cv

Ø [mm] Ø [inches] [l/h] [gph] [l/h] [scfh]

1 0.039 5 1.3 100 3,7 0.018 0,02

2.5 0.98 50 13 1000 37 0.15 0,17

4.5 0.177 160 42 4300 160 0.48 0,55

[m3/h]

[gpm]

Valve characteristics

Spindle Ø 1.0mm - 0,039" Spindle Ø 2.5mm - 0,098"

Spindle Ø 4.5mm - 0,177"

1 Flow, air

2 Flow, water

3 Spindle revolution n

www.krohne.com07/2009 - 4000193403 TD DK46_800-R04 en

15

Page 16

2 TECHNICAL DATA

2.4 Differential pressure regulators

Differential pressure regulators are used to guarantee constant flow during fluctuating inlet and

outlet pressure. Minimum pressures are required to operate the regulators (see regulator

characteristics).

Differential pressure regulators are not equivalent to pressure reducing valves!

Differential pressure regulators are not equivalent to pressure reducing valves!

Differential pressure regulators are not equivalent to pressure reducing valves!Differential pressure regulators are not equivalent to pressure reducing valves!

1111 Inlet pressure regulators, type RE, NRE

Inlet pressure regulators, type RE, NRE

Inlet pressure regulators, type RE, NRE Inlet pressure regulators, type RE, NRE

The regulators keep the flow rate constant in the case of a variable inlet pressure and a constant

outlet pressure.

DK46 - DK800

Example - inlet pressure

regulator RE1000:

Current flow rate: 1000 l/h air

Outlet pressure p2 constant: 1.013 bar abs.

The flow rate in the meter remains constant with a fluctuating inlet pressure greater than 0.5

bar.

2222 Outlet pressure regulator, type RA, NRA

Outlet pressure regulator, type RA, NRA

Outlet pressure regulator, type RA, NRA Outlet pressure regulator, type RA, NRA

The regulators keep the flow rate constant in the case of a constant inlet pressure and a variable

outlet pressure. There must be a pressure differential between the inlet and the outlet pressure

for the outlet pressure regulator to function. The inlet pressure p1 must always be greater than

the outlet pressure p2.

Example - outlet pressure

regulator NRA 800

Current flow rate: 800 l/h air

Inlet pressure constant: 6 bar

The flow rate in the meter remains constant with a fluctuating outlet pressure of 0 ... 5.5 bar.

Regulator characteristics

1 Inlet pressure regulators, type RE and NRE 2 Outlet pressure regulators, type RA and

NRA

16

www.krohne.com 07/2009 - 4000193403 TD DK46_800-R04 en

Page 17

DK46 - DK800

Control range inlet pressure regulator 1

Control ranges outlet pressure regulator 2

TECHNICAL DATA 2

Max. flowrate

Water Air Min. inlet pressure

[l/h] [gph] [l/h] [scfh] Δ p1 [bar] Δ p1 [psig]

RE-1000 ...40 ...10.6 ...1000 ...37,2 0.5 0.007

RE-4000 ...80 ...21.1 ...2000 ...74,4 1 0.015

...100 ...26.4 …3000 ...112 1.5 0.022

...160 ...42.3 ...4000 ...149 2 0.029

NRE-100 ...2.5 ...0.66 ...100 ...3,72 0.1 0.001

NRE-800 - - …250 ...9,3 0.1 0.001

- - …800 ...29,8 0.2 0.003

...25 ...6.60 - - 0.4 0.006

Max. flowrate

Water Air Min. pressure diff.

[l/h] [gph] [l/h] [scfh] [bar] [psig]

RA-1000 ...40 ...10.6 ...1000 ...37,2 0.5 0.007

RA-4000 ...100 ...26.4 …2000 ...74,4 1 0.015

- - ...3000 ...112 1.5 0.022

...160 ...42.3 ...4000 ...149 2 0.029

NRA-800 ...1 ...0.264 ...250 ...9,3 0.1 0.001

- - ...500 ...18,6 0.2 0.003

- - …800 ...29,8 0.2 0.003

...25 ...6.60 - - 0.4 0.006

Technical data, differential pressure regulator

Standard connection ¼" NPT

Optional Serto, Ermeto 6 or 8, tube nozzle 6 mm or 8 mm,Dilo, Gyrolok, Swagelok,

Max. operating gauge

pressure PS

Product temperature TS = 100 °C / 212 °F 3

Material CrNi steel 1.4404

Gasket PTFE 4

Membrane PTFE filled with carbon / graphite

O-ring FPM 4

1 other connections on request

2 higher pressures on request

3 higher temperatures on request

4 other materials on request

G¼ 1

10 bar / 145 psig

4 bar / 58 psig for DK.../PV 2

www.krohne.com07/2009 - 4000193403 TD DK46_800-R04 en

17

Page 18

2 TECHNICAL DATA

Dimensions with the differential pressure regulator

DK46 - DK800

a

b c d e f

approx.

[mm] ["] [mm] ["] [mm] ["] [mm] ["] [mm] ["] [mm] ["]

DK46 210 8.27 163 6.42 70 2.76 19 0.75 39 1.54 90 3.55

DK47 210 8.27 233 9.18 70 2.76 19 0.75 39 1.54 90 3.55

DK48 210 8.27 383 15.1 70 2.76 19 0.75 39 1.54 90 3.55

DK800 210 8.27 183 7.21 70 2.76 19 0.75 39 1.54 90 3.55

1 DK with inlet pressure regulator 2 DK with outlet pressure regulator

approx.

18

www.krohne.com 07/2009 - 4000193403 TD DK46_800-R04 en

Page 19

DK46 - DK800

3.1 Intended use

The variable area flowmeters are suitable for measuring gases, vapors and liquids.

These flowmeters are particularly suitable for measuring:

• Liquids

• Hydrocarbons

• Water

• Chemicals with low corrosiveness

• Industrial gases

In case of instruments which are used in explosive endangered areas please consider the

supplementary installation and operating instructions mentioned in the Ex-manual.

The operator shall bear sole responsibility for the use of the flowmeters with regard to

suitability, intended use and corrosion resistance of the materials used to the process product.

The manufacturer shall not be liable for any damage resulting from improper use or use for

other than the intended purpose.

Do not use any abrasive or highly viscous process products.

INSTALLATION 3

3.2 Installation conditions

3.2.1 Installation in the piping

When installing the device in the piping, the following points must be observed:

•

The variable area flowmeter must be installed vertically (measuring principle). Flow direction

from bottom to top. For installation recommendations please refer also to VDI/VDE 3513

Sheet 3.

•

Before connecting, blow or flush out the pipes leading to the device.

•

Pipes for gas flow need to be dried before the device is installed.

•

Use connectors suitable for the particular device version.

•

Align the pipes axially with the connections on the measuring device so they are free of

stresses.

•

If necessary, support the piping to reduce vibrations being transmitted to the measuring

device.

•

Do not lay signal cables directly next to cables for the power supply.

www.krohne.com07/2009 - 4000193403 TD DK46_800-R04 en

19

Page 20

4 ELECTRICAL CONNECTIONS

4.1 Limit switch

The flowmeters can be equipped with a maximum of two limit switches. The switching function of

the limit switch can be designed as monostable or bistable.

Monostable function:

Monostable function: Switching pulse as float passes through switching point, independent of

Monostable function: Monostable function:

direction of movement.

Bistable function:

Bistable function: Stable changeover as float passes through switching point.

Bistable function: Bistable function:

DK46 - DK800

Example

Float above limit: Output "High"

(bistable):

Float below limit: Output "Low"

For switching patterns and electrical connection values of different limit switches, see Technical Data - Limit Switches

Electrical connection limit switches - 2-wire NAMUR

1 Lower limit switch to terminal 1

2 Upper limit switch to terminal 2

The terminal box includes an EMC filter unit.

Electrical connection limit switches - 2-wire NAMUR no terminal box

20

1 Limit switch (no terminal box)

2 Blue cable -

3 Brown cable +

4 External EMC filter

5 Receiver device

When connecting to an EMC filter, the ground terminal must be connected to the back rail of the

flowmeter.

Electrical connection limit switch - 3-wire (transistor)

bn - brown: supply voltage +

bk - black - switch

bu - blue: supply voltage -

www.krohne.com 07/2009 - 4000193403 TD DK46_800-R04 en

Page 21

DK46 - DK800

Please provide us with the missing information so that we can be of help to you as quickly as

possible.

Then please fax this page to the appropriate sales associate. We will then contact you as soon as

possible.

Device data

1 1 limit switch

2 2 limit switches

ORDER FORM 5

Connection type: 1/4" NPT (other)

Connection: horizontal vertical

Pressure rating:

Device DK46 DK47 DK48 DK800

Options: K1 1

K2 2

Differential pressure regulator: Intlet pressure regulator Outlet pressure regulator

Approval: Without ATEX

K1 1

K2 2

K1 1

K2 2

K1 1

K2 2

Rating data

Product:

Operating pressure: Absolute pressure Overpressure

Rated pressure:

Operating temperature:

Rated temperature:

Density: Standard density Operating density

Viscosity:

Measuring range:

Comments:

Contact data

Company:

Contact person:

Telephone number:

Fax number:

E-mail:

www.krohne.com07/2009 - 4000193403 TD DK46_800-R04 en

21

Page 22

6 NOTES

DK46 - DK800

22

www.krohne.com 07/2009 - 4000193403 TD DK46_800-R04 en

Page 23

DK46 - DK800

NOTES 6

www.krohne.com07/2009 - 4000193403 TD DK46_800-R04 en

23

Page 24

K

K

K

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Measuring systems for the oil and gas industry

• Measuring systems for sea-going tankers

© KROHNE 07/2009 - 4000193403 TD DK46_800-R04 en - Subject to change without notice.

Head Office KROHNE Messtechnik GmbH & Co. KG

Ludwig-Krohne-Str. 5

D-47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...