Page 1

c

7025282200 www.krohne.com

KROHNE 11/2007

GR

Installation and

Operating Instructions

SDA

Flap-type flowmeter

for liquid measurements

Note In case of instruments which are explosion prote

please observe the supplementary installation and operating

instructions:

SDA/... Kat. II2G with electr. internals Id. Nr. 702529##00

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Page 2

Table of Contents

Product liability and warranty ...............................................................................................................3

1 General............................................................................................................................................4

1.1 Description code ..........................................................................................................................4

1.2 Marking ........................................................................................................................................4

1.3 Key for Pressure Equipment Directive.........................................................................................5

1.4 Functional principle......................................................................................................................5

2 Installation and Start-up................................................................................................................6

2.1 Prerequisite for the installation ....................................................................................................6

2.3 Preparation of the pipeline...........................................................................................................6

2.4 Observance of the IP degree (NEMA Type) of protection........................................................... 6

3 Flow table........................................................................................................................................7

4 Materials..........................................................................................................................................7

5 Technical Data................................................................................................................................8

6 Measuring temperatures ...............................................................................................................8

7 Dimensions.....................................................................................................................................9

8 Indicator part..................................................................................................................................10

8.1 Contact inserts.............................................................................................................................10

8.1.1 Electrical connection....................................................................................................................10

8.1.2 Limit setting..................................................................................................................................12

8.1.3 Switch contact definition ..............................................................................................................12

8.1.4 Technical data of limit switches ...................................................................................................13

8.2 Electrical signal output ESK.........................................................................................................14

8.2.1 Electrical connection....................................................................................................................14

8.2.2 HART

TM

communication with the ESK .........................................................................................14

8.2.3 Technical data of ESK II ..............................................................................................................15

9 Service ............................................................................................................................................15

9.1 Contact insert...............................................................................................................................15

9.2 Installing an ESK .........................................................................................................................15

10 Maintenance ...................................................................................................................................16

Information on returning instruments..................................................................................................17

Form for returning the instrument........................................................................................................20

Page 3

Product liability and warranty

The flowmeter is suitable for measuring the volume flow of liquids.

Special regulations apply for use in explosion-hazardous areas. (Refer to the section on the scope of delivery.)

Responsibility for the suitability and usage to the intended purpose of these flowmeters rests solely with the operator.

Improper installation or improper operation of the flowmeters may lead to the loss of warranty. In addition, the "General

conditions of sale" which form the basis of the purchase contract are applicable.

The calculation of the pressurized parts is effected with allowance for corrosion, erosion through abrasion or cavitation.

If the flowmeter needs to be returned to KROHNE Messtechnik, please note the information at the end of these

installation and operating instructions.

Scope of delivery

● Installation and operating instructions Ident. No.: 702124##00

● Supply without installation accessories (screw bolts, flange seal and cabling)

Special certificates (supplied to order only)

● Test certificate to EN 10204:

● Pressure test, paint penetration test, irradiation test, leak test,

ultrasonic test, heIium leakage test,

● Cleaning pursuant to works regulations

● Calibration certificate

Page 4

1 General

1.1 Description code

The description code consists of the following elements: *)

1 2 3 4

1 Series measuring unit SDA

2 Display part series

M9 : Standard indicator

M9S : with added corrosion prevention

M9R : Stainless steel housing

3 Electrical signal output

ESK : Analog signal output

4 Limit switch

K1 : One limit switch

K2 : Two limit switches

*) Positions which are not used in the description code are not required.

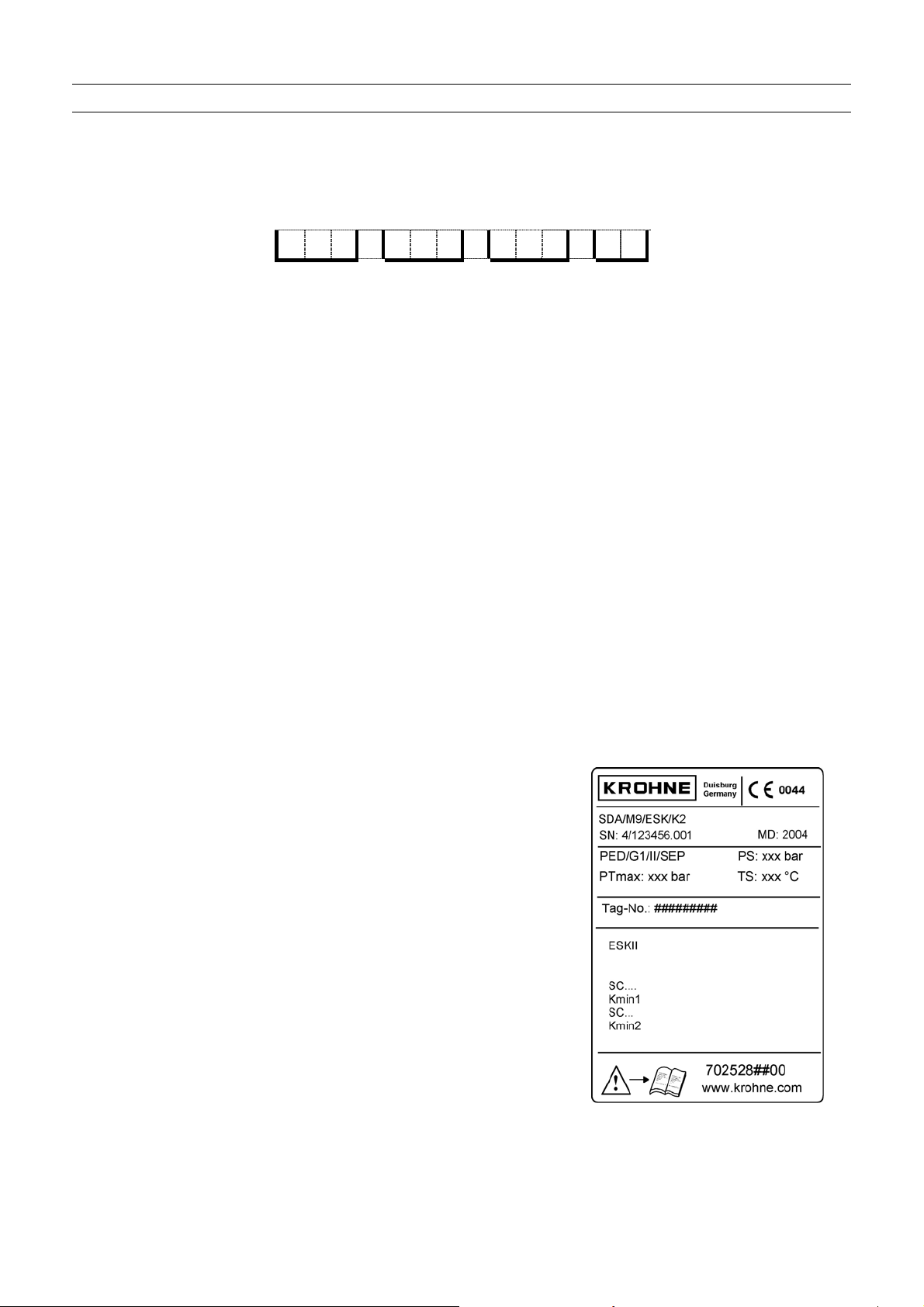

1.2 Marking

The type marking of the complete instrument is carried out at the display part by means of the rating plates shown

here (also refer to the description code).

Example:

MD: Year of manufacturing

PS: Max. permissible operating pressure

at max. permissible operating temperature TS

PT max: Maximum pressure tested

TS: Max. operating temperature

PED: Directive for Pressure Equipment

Tag No : Measuring point tag

0044: Identification number of the supervising office for

EC Directive for Pressure Equipment 97/23/EC

SN: Serial number

SO: Sales order / item

KO: KROHNE order

Vxxxx…: Product configurator code

AC: Article code

Page 5

1.3 Key for Pressure Equipment Directiv e

PED / / /

1 2 3 4 5

1 Pressure Equipment Directive

2 Fluid

G Gases, liquefied gases, gases dissolved under pressure, vapors and those liquids

whose vapor pressure lies more than 0.5 bars over the normal atmospheric pressure

(1013 mbars) at the maximum permissible temperature

L Liquids whose vapor pressure lies a maximum of 0.5 bars above the atmospheric

pressure at the maximum permissible temperature

3 Fluid group

1 Group 1: Explosion-hazardous, highly flammable, readily flammable, flammable

(when the maximum permissible temperature lies above the flash point),

highly toxic, toxic, fire stimulating

2 Group 2: All the fluids not specified in Group 1

4 Category

3.3 In accordance with Article 3.3 of Directive 97/23/EC

I Category I to 97/23/EC

II Category II to 97/23/EC

III Category III to 97/23/EC

5 Conformity evaluation process

SEP Solid engineering practice

A Module A internal process inspection

A1 Module A1 internal process inspection with supervision of the acceptance

H Module H Comprehensive quality assurance

The PED key marking is contained on the rating plate of the instrument.

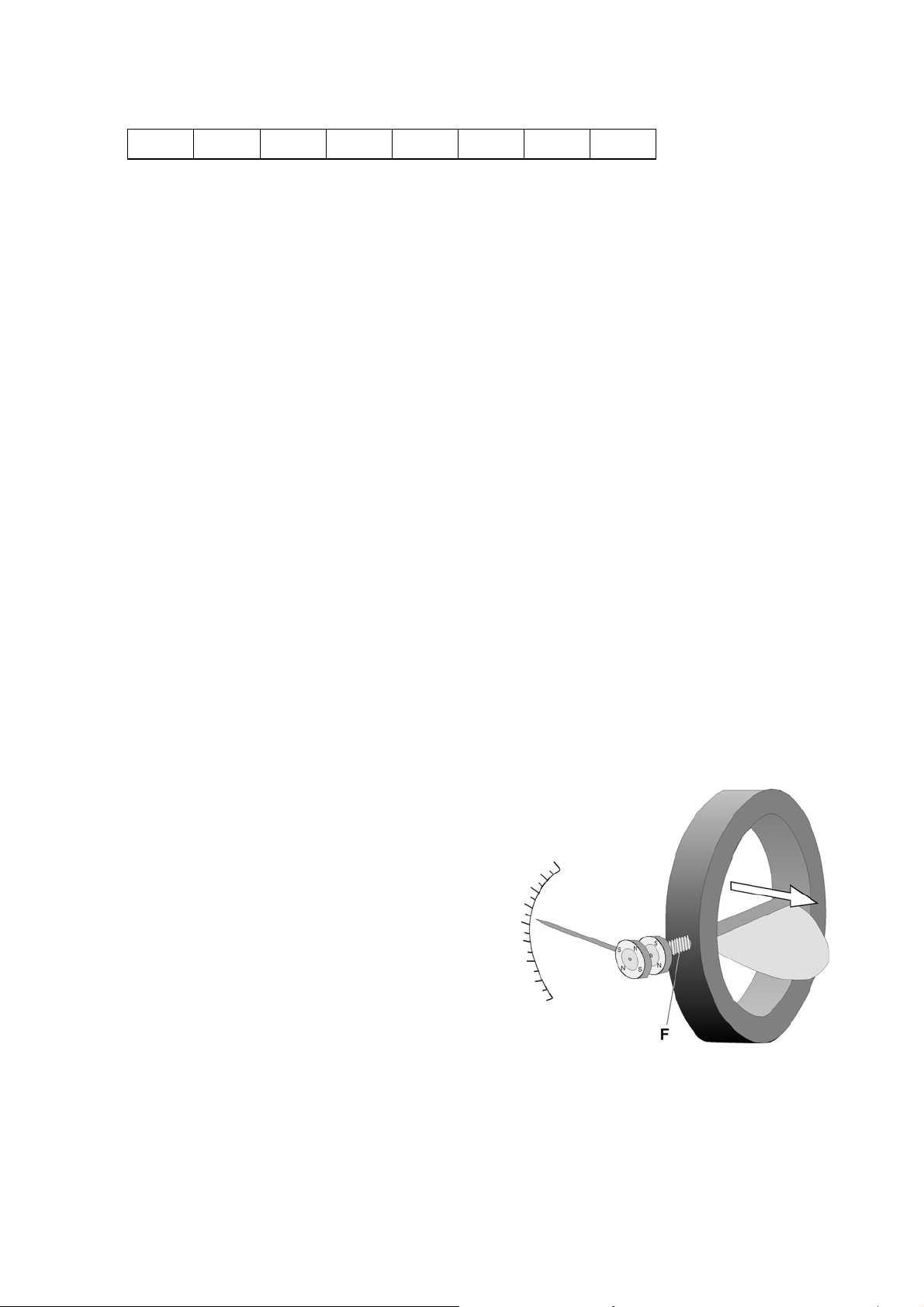

1.4 Functional principle

A half-round plate, or flap, is fastened across the

direction of flow to a springmounted rotating spindle

in a ring that is inserted between flanges in a pipeline.

As the flow rate increases, the flap rotates counter

to the restoring force F of the spring in the direction

of flow.

The ensuing angle of rotation, depending on the

volume rate of flow, is transmitted via a magnetic

coupling to the indicator part.

Page 6

s

s

r

2 Installation and Start-up

2.1 Prerequisite for the installation

The operating pressure of the plant may not exceed the value indicated on the rating plate.

Ensure that the parts coming into contact with the medium are compatible with the material.

The ambient and medium temperatures may not exceed certain maximum values.

In order to prevent distortions the connecting flanges have to face each other axially and in parallel.

2.3 Preparation of the pipeline

Generally comply with the maximum pressure and maximum temperature levels allowable

for the SDA at the measuring point in your plant. The direction of flow must be the same as that

indicated by the flow arrow on the device.

Drain the pipelines before installing the device.

Use gaskets made of rubber or SIL; for plastics devices, use only gaskets made of rubber with

a Shore hardness A of approx. 65°.

The gaskets should not project into the pipeline and the flow meter must be in line with the pipe

axis, otherwise measurements would be falsified and/or the device could jam.

Incorporating the indicator part in the equipotential bonding system in the hazardous area:

The indicator part must be earthed. This can be done e.g. using a wire jumper between the

flange on the indicator part and a pipe flange on the main pipeline with cable lugs appropriate

for the bolted connection (not included with the flow meter!).

Incorporating the indicator in the lightning protection system (if necessary). The Operator is

responsible for checking and determining the scope!

2.4 Observance of the IP degree (NEMA Ty pe) of protection

The following instructions are to be observed in order to observe the IP degree (Nema Type) of electrical built-

in parts:

● After the connecting cable has been introduced, tighten the outlet nut.

● All the cable glands which are not used remain closed with blanking plugs.

● Do not kink lines directly at the cable gland.

● Provide a drain bend

● The feed lines may not be subjected to mechanical strains. Refer to the description

of the electrical supplementary components for this device.

Cable glands / screwed glands:

Thread Material Line diameter Degree of protect Remark

M 16x1.5 PA 5 - 10 mm IP 68 - 5 bars Standard

M 20x1.5 PA 8 - 13 mm IP 68 - 5 bars

M 16x1.5 Nickel-plated bras

M 20x1,5 Nickel-plated bras

5 - 9 mm IP 68 - 5 bars

10 - 14 mm IP 68 - 10 ba

* Degree of protection is limited here to the cable screwed gland

Page 7

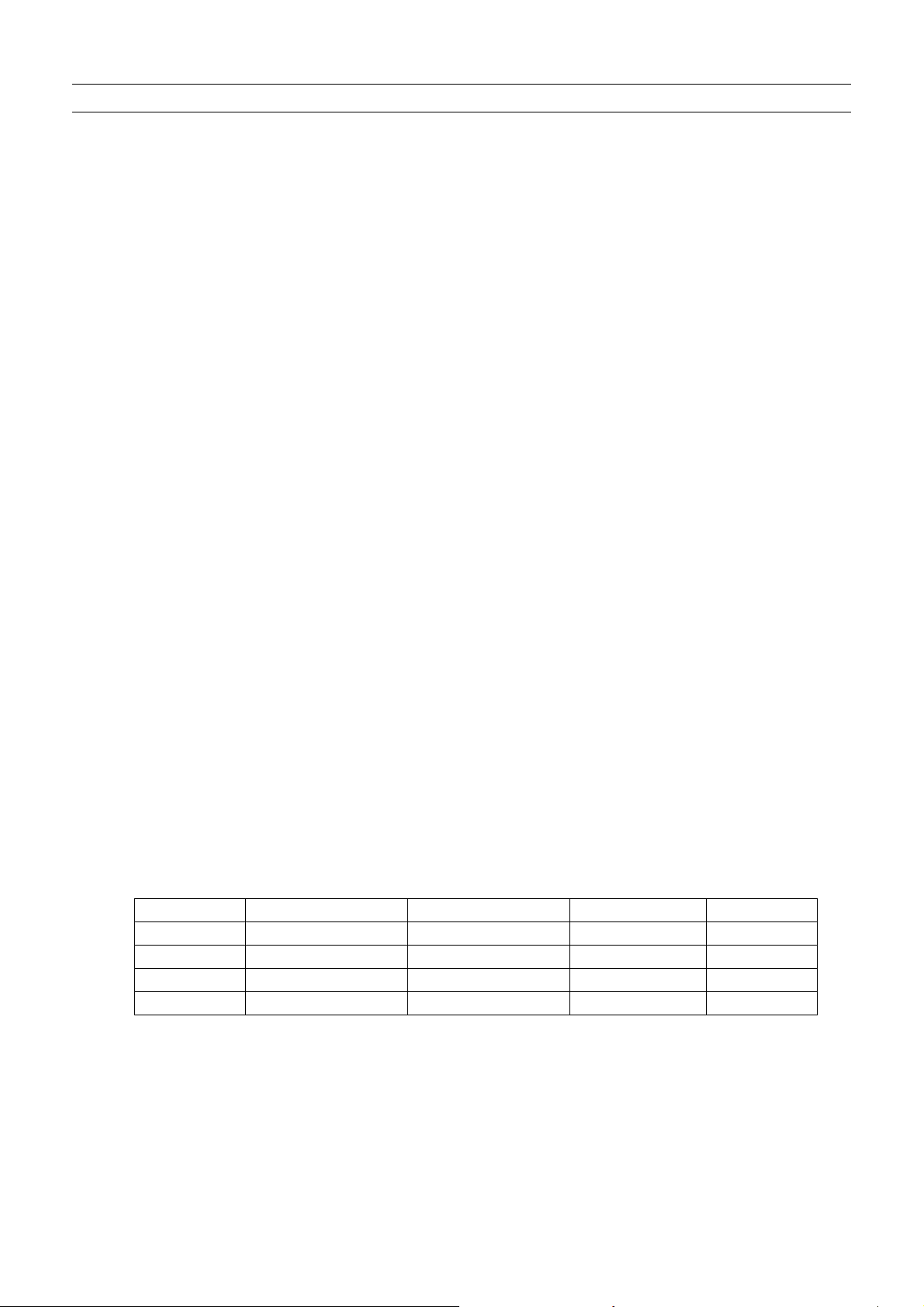

3 Flow table

Reference conditions: Water at 20°C

The turn-down range amounts to 10 : 1

The specified pressure losses apply for water and air at the maximum flow rate.

Nominal size Flow Water

DN Inch m3/h US GPH

25 1 6 - 12 1585 - 3170

32 1 1/4" 8 - 15 2113 - 3962

40 1 1/2" 6 - 25 1585 - 6604

50 2" 5 - 30 1320 - 7925

65 2 1/2" 20 - 80 5283 - 21133

80 3" 40 - 80 10566 - 21133

100 4" 40 - 120 10566 - 31700

125 5" 65 - 150 17171 - 39625

150 6" 80 - 225 21133 - 59438

200 8" 150 - 350 39625 - 92460

250 10" 150 - 350 39625 - 92460

300 12" 250 - 750 66043 - 198129

4 Materials

Ring

Corrosion protection for steel version

Scale casing

Pointer

Scale

Pane

Steel

Stainless steel 1.4571

PVC (up to DN300)

PP (up to DN300)

PVDF (up to DN300)

Epoxy, stove enamelled, colour: blue, RAL 5017

Aluminium, painted

Aluminium, painted

Aluminium, coated

Float glass

Page 8

5 Technical Data

Flow range min

max

Accuracy

Turndown ratio

Nominal sizes

Max. Operating pressure Standard

Option

0,5 ... 6 m3/h Water

150 ... 1500 m

3

/h Water

5% FS

min. 1 : 10

DN25 ... DN300

PN 6/10

PN 16/25/40

Mounting length Standard

Special spring

Connection Standard

Option

50 mm

60mm

Mounting between welding neck flanges to DIN 2501

ASME, JIS

Degree of protection, indicator part IP 67

6 Measuring temperatures

Type of Steel, stainless steel

PVC

PP

PVDF

- 70° C ... + 200° C

0° C ... + 20° C /10bar - 0° C ... + 40° C /6bar

0° C ... + 20° C /10bar - 0° C ... + 80° C /1,5bar

-40° C ... + 20° C /10bar - -40° C ... + 140° C / 2bar

Page 9

7 Dimensions

DN

d4 [mm] A [mm]

25 68 232,5

32

78 236,0

40 88 240,0

50 102 245,0

65 122 252,5

80 138 260,0

100 158 270,0

125 188 282,5

150 212 295,0

200 268 320,0

250 320 345,0

300 370 370,0

350 430 395,0

400 482 420,0

500 585 485,0

600 685 530,0

Standard ring C = 50mm (Option: 60mm)

Page 10

8 Indicator part

8.1 Contact inserts

The flowmeter SDA can be equipped with a maximum of two electronic limit

switches.

The limit switch functions with a slot-type initiator which is

operated inductively through the semicircular metal vane

belonging to the measuring pointer. The switching points

are set through the contact pointer. The setting of the

contact pointer serves at the same time for the optical display of the

set limit.

Contact types: 1 Limit switch

SC3,5-N0-Y 2-wire technology (NAMUR) 2 Contact pointer

SJ3,5-SN 2-wire technology safety-oriented 3 Connecting plug

SJ3,5-S1N 2-wire technology safety-oriented (inverted) 4 Connecting terminal

SB 3.5-E2 3-wire technology 5 Terminal socket

8.1.1 Electrical connection

The housing cover of the M9 display has to be removed in order to connect the contact insert. The connecting

terminals (4) have a pluggable design and can be removed in order to connect the lines. The built-in contact types are

listed in the rating plate of the display.

Electrical connection of the limit switches in 2-wire technology

Connection assignment for

SC3,5-N0-Y

SJ3,5-SN

SJ3,5-S1N

Contact MIN MAX

Connector color black gray

Labeling 1 2 3 4 5 6

2-wire technology - + - +

Electrical connection of the limit switches in 3-wire technology

Connection assignment for

SB3,5-E2

Contact MIN MAX

Connector color black gray

Labeling 1 2 3 4 5 6

3-wire technology + DC - + DC -

Connection diagram 3-wire technology

Page 11

Connection diagram 2-wire technology

NAMUR Safety-oriented *

SC3,5-N0-Y SJ3,5-SN and SJ3,5-S1N

Inputs Input

Terminals Terminal

in the in the

display display

Output I Output II Power Output III II Output I Power

LED yellow output LED green power LED yellow

Relay output

Switch S1 LED red LB/LK

Effective direction I LED red

Switch S2 LB/LK recognition

Switch S3 Effective direction II

LB/LK recognition LED green

Power

LB : Line break * Safety-oriented isolating switching amplifiers

LK : Line short-circuit are only single-channel!

Page 12

8.1.2 Limit setting

The setting is carried out directly via the contact pointer (2): Scale opening

- Slide the scale away

- Loosen the locking screw (1) slightly

- Slide the scale back to the latching point

- Set the contact pointer (2) to the desired switching point

- After setting, the contact pointer (2) is to be fastened

hand-screwed again with the locking screw (1) (max. 40 Ncm).

- Screw on the housing cover.

.

8.1.3 Switch contact definition

MIN contact

If the pointer vane (1) enters the slot, an alarm is triggered. If the

pointer vane lies outside the slot initiator, a wire break also causes

the alarm to be triggered.

No wire break recognition at SB3,5-E2

Option: Implementation as a maximum contact

In the alarm status the vane lies outside the slot.

Wire break recognition is not available here.

MAX contact

If the pointer vane (1) enters the slot (and thus dampens this initiator),

an alarm is triggered. If the pointer vane lies outside the slot initiator,

a wire break also causes the alarm to be triggered.

No wire break recognition at SB3,5-E2

Option: Implementation as a minimum contact

In the alarm status the vane lies outside the slot.

Wire break recognition is not available here.

Page 13

Definition of Min1 and Min2 / Max1 and Max2

Min1

Min2

Max1

Max2

8.1.4 Technical data of limit switches

current consumption

with the shown

pointer position

SC3,5-N0 ≤1 mA

SJ3,5-S1N ≤1 mA

current consumption

with the shown

pointer position

SJ3,5-S1N ≥3 mA

SC3,5-N0 ≥3 mA

SC3,5-N0-Y SJ3,5-SN SJ3,5-S1N SB3,5-E2

2-wire 2-wire 2-wire 3-wire

NAMUR NAMUR NAMUR

Switching element function NC contact NC contact NO contact NO contact PNP

Nominal voltage U0 8 V 8V 8V 10 to 30 V

Power consumption:

Pointer vane not detected

Pointer vane detected

≥ 3 mA ≥ 3 mA ≤ 1 mA ≤ 0.3 V

≤ 1 mA ≤ 1 mA ≥ 3 mA

Ub - 3 V

Continuous current - - - max. 100 mA

No-load current I0 - - -

≤ 15 mA

An isolating switching amplifier, e.g. Pepperl + Fuchs Series KF .. -SR2 ..., is required in order to

operate the SC3,5-N0-Y limit switch (refer to the chapter on the spare part list).

SJ3,5-SN and SJ3,5-S1N limit switches safety-oriented are connected to a safety-oriented isolating

switching amplifier, e.g. Pepperl + Fuchs K… –SH- ... (large S on the front)

Page 14

8.2 Electrical signal output ESK

8.2.1 Electrical connection

The connecting terminals of the M9 display have a pluggable design and can be removed in order to

connect the lines.

8.2.2 HART

HART

When HART

measured value transfer (4...20mA)

Exception at Multidrop operation. In Multidrop operation a maximum of 15 instruments with HART

TM

communication with the ESK

TM

communication is not compellingly required in order to operate the ESK.

TM

communication is carried out with the ESK, this does not by any means impair analog

TM

function can be operated in parallel, whereby their current outputs are switched inactive (approx. 4 mA).

If a HART

the resistor which is connected in series (R

TM

communicator (type Fisher Rosemount, Model 275) or a PC with HART

) has to exceed 250 Ohms.

ext.

TM

modem PC is used,

In this type of operation the auxiliary power must amount to at least 18 V. The communicator or the PC is

connected as shown in the drawing above.

It can be operated optionally via the connecting terminals of the ESK (2) or via an external resistance (1)

connected in series. The counter cannot be read out or operated by means of HART

TM

communication!

Page 15

8.2.3 Technical data of ESK II

Auxiliary power 12 (18 * ) to 30 V DC

Measurement signal 4.00 to 20.00 mA for 0 to 100 % flow value

> 20.8 mA for alarm status

Auxiliary power influence < 0.1%

Dependency on external resistance < 0.1%

Temperature influence < 5 μA / K

Max. external resistance / load 0 (250 * ) to 800 Ohms

* These values are to be observed as minimum values during HART

TM

communication.

9 Service

9.1 Contact insert

Bring the contact pointers (1) together in the center

Loosen the locking screw (2) of the contact pointers

Slide the contact insert into the third rail until the semicircle (3)

encloses the pointer support.

The connecting terminals of the contact insert have a pluggable

design and can be removed in order to connect the lines.

9.2 Installing an ESK

Assembly is based on the plug-in technique.

Insert the push-in lugs of the ESK under the

two studs of the baseplate (1).

Using slight pressure, press the ESK on to

the spring bolt (2) until it locks home and is securely

fastened.

Page 16

10 Maintenance

The flowmeter is also to be inspected for soiling, corrosive erosion and mechanical wear or damage to the measuring

tube and the display in the context of the routine operational maintenance of the installation and the pipelines. We

recommend at least annual inspections. In order to clean the instrument remove it from the pipeline.

Note

Pressurized lines have to be relieved before the measuring unit is removed.

Corresponding safety precautions with regard to residual liquids in the measuring unit in case of instruments which are

used to measure aggressive media.

New seals must always be used when remounting the measuring unit in the pipeline.

Electrostatic charges are to be avoided when the surfaces (e.g. viewing window) are cleaned!

Maintenance

The device is normally maintenance-free. Should it become soiled, it will need

to be removed from the pipeline for cleaning. Devices fitted with contacts

must be disconnected from supply and de-energized.

To dismantle the device you will need the following tools:

2x open-jawed spanner, jaw span 13mm

1x open-jawed spanner, jaw span 7mm

1x screwdriver 4x 0.6mm

1x socket spanner, size 7mm up to DN 100 or

1x socket spanner, size 8mm, up to DN 250 or

1x socket spanner, size 10mm, for DN 300 and higher.

Required spares: 2x gasket

If necessary, wear personal protective gear (safety goggles,

protective gloves, conductive footwear).

Depressurize the pipe.

Caution: Slacken screws/bolts only when the system has been deenergized, the pipe depressurized and free of fluid product.

Drain the pipes.

Remove the device from the pipeline in the reverse order

Detach the dial gauge with magnet casing from the neck of the

device by removing the four M8 screws (Item 1 or 2).

Unscrew the fastening screws (3) between spindle and flap (4).

Pull the spindle together with the magnet casing and the spring

assembly (5) out of the device.

Clean all mechanical parts with appropriate cleaning agents. If

necessary, clean the indicator part with a damp cloth that has been

rinsed in soap suds and wrung out.

Reassemble in the reverse order, paying special attention to the

position of the flap. The bearing marked with a centre punch must

point towards the spring. Do not change the original orientation of

the flap (maintaining the direction of rotation appropriate to the

indicator part ). The flap requires a minimum of 1 mm clearance on

both sides (risk of jamming and sparking).

Hazardous areas: Do not on any account remove the labelling on

the scale casing containing information on explosion protection.

Page 17

Information on returning instruments

Your instrument has been manufactured carefully and

tested several times. If installed and operated in

accordance with these instructions your instrument will

rarely present any problems. Should you nevertheless

need to return an instrument for checking or repair, please

pay strict attention to the following points:

Due to statutory regulations concerning protection of the

environment and safeguarding the health and safety of

our personnel, KROHNE may only handle, test and repair

returned instruments that have been in contact with liquids

if it is possible to do so without risk to personnel and

environment.

This means that KROHNE can only service your device if

it is accompanied by a certificate in line with the following

model confirming that the device is safe to handle.

If the instrument has been operated with toxic, caustic,

flammable or water-endangering liquids, you are kindly

requested:

- To check and ensure, if necessary by rinsing

or neutralizing, that all the cavities in

the instrument are free from such dangerous

substances. (Directions on how you can find out whether

the primary head has to

be opened and flushed out and neutralized

are obtainable from KROHNE on request.)

- To enclose a certificate with the device confirming that

the device is safe to handle and

stating the liquid used.

KROHNE regret that we cannot service your device

unless it is accompanied by such a certificate and thank

you for your understanding.

Page 18

Page 19

SDA Installation and operating instructions 19

Page 20

Form for returning the instrument

Company: ..................................................... Address: .......................................................................

Department: .................................................. Name: ..........................................................................

Tel. No.: ........................................................ Fax. No.: ......................................................................

The enclosed instrument

Type:...............................................................................................................................................................

KROHNE Order No. or Series No.: ................................................................................................................

has been operated with the following process liquid: .....................................................................................

Because this process liquid is water-endangering * / toxic * / caustic * / flammable *

we have

- Checked that all cavities in the instrument are free from such substances *

- Flushed out and neutralized all cavities in the instrument *

(* delete where not applicable)

We confirm that there is no risk to man or environment through any residual liquid contained in the instrument.

Date: ............................................................. Signature.......................................................................

Company stamp:

SDA Installation and operating instructions 20

Loading...

Loading...