Page 1

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications engineering

Engineering systems & solutions

GR

©

KROHNE 07/2000 D 31 IF10 02 D

Addition to the installation and

operating instructions

CORIMASS E + P Class

MFM 3081 K/F

MFM 2081 K/F

Ex-Version

Page 2

These instructions should be used in conjunction with the Standard Installation and

Operating Instructions for the MFM 2081/3081 K/F. If you require a copy, please contact

your nearest KROHNE Office or representative.

Product liability and warranty

The CORIMASS mass flowmeter MFM 2081/3081 K/F is designed for the direct

measurement of mass flow rate, product density and product temperature, and also

indirectly enables measurement of parameters such as total mass, concentration of

dissolved substances and the volume flow.

For use in hazardous areas, special codes and regulations are applicable which are

specified in the special ”Ex installation and operating instructions” (supplied only with

hazardous-duty equipment).

Responsibility as to suitability and intended use of our instruments rests solely with the

purchaser.

Improper installation and operation of the flowmeters may lead to loss of warranty.

In addition, the ”general conditions of sale” forming the basis of the purchase agreement

are applicable.

If you need to return CORIMASS flowmeters to KROHNE, please complete the form on the

last page of the Installation and Operating manual and return it with the meter to be

repaired. KROHNE regrets that it cannot repair or check your flowmeter unless accompanied

by this completed form.

Content

1 Description....................................................................................................3

1.1 Description of the Transducer............................................................................4

1.2 Description of the Converter..............................................................................4

1.3 Installation of MFM 2081 / MFM 3081 EEx........................................................5

2 Electrical installation...................................................................................6

2.1 Location and connecting cables ........................................................................6

2.2 Electrical Connection on converter without intrinsically safe outputs.....................6

2.3 Electrical connection on converter with intrinsically safe outputs..........................9

2 Additional Instruction for Ex version MFM 2081 / 3081

Page 3

1 Description

The mass flowmeter MFM 2081/3081 K EEx and MFM 2081/3081 F EEx consists of two

main components:

The Signal Converter, which calculates and displays the measured values and the

transducer which supplies the converter with the analog signals.

A Cable Seal, which is screwed into the converter housing, leads the electric signals from

the transducer to the converter. The signal cable between the transducer and converter is

intrinsically safe.

In the separate version MFM 20381/3081 F EEx the transducer MFS 2000/3000 EEx and

the converter MFC 081 F EEx are connected to each other via a shielded multi-conductor

cable. The maximum cable length is 50 m.

The converter housing of the compact version MFM 2081/3081 K EEx is permanently

screwed onto the transducer and must not be removed at any time.

Cenelec Approvals

PTB approves the conformity of the mass flow meter according to the harmonized European

Standards:

EN50018 "d" - Pressure tight housing

for the electronics housing and the terminal compartment

EN50019

EN50020

"e" - Increased safety

for the standard termination compartment

"i" - Intrinsically Safe

"b" for the Zener barriers and all electrical circuits inside the transducer

"a" for the converter outputs

The following approvals are valid:

Compact P and E meters, including intrinsically safe

EEx de [ib] IIC T6...T3

EEx d [ib] IIC T6-T3

EEx de [ia/ib] IIC T6-T3

EEx d [ia/ib] IIC T6-T3

Converter, remote mounted version, including intrinsically safe

EEx de [ib] IIC T6-T3

EEx d [ib] IIC T6-T3

EEx de [ia/ib] IIC T6-T3

EEx d [ia/ib] IIC T6-T3

P meter, remote mounted version

EEx ib IIC T6-T3 MFS 2000 F PTB Ex 98.D.2038 X

E meter, remote mounted version

EEx ib IIC T6-T3 MFS 3000 F PTB Ex 98.D.2039 X

Additional Instruction for Ex version MFM 2081 / 3081 3

MFM 2081 K

MFM 3081 K

MFM 2081 Ki

MFM 3081 Ki

MFC 081 F

MFC 081 Fi

PTB Ex 96.D.2037 X

PTB Ex 98.D.2037 X

Page 4

US-American Approvals

FM Class I, II & III Div. 1

Group A,B,C,D,E,F,G

FM Class I, II & III Div. 2

Group A,B,C,D,E,F,G

1.1 Description of the Transducer

The transducer MFS 2000-EEx and MFS 3000-EEx are intrinsically safe units and contains

three separated safe circuits. These are:

MFM 2081 K/F

MFM 3081 K/F

MFM 2081 K/F

MFM 3081 K/F

J.I.4B8A1.AX

J.I.4B7A7.AX

• ?Driver Circuit

• ?Sensor Circuit

• ?PT100 Circuit

The cables of these circuits are fed through the transducer housing via a special seal. There

are various transducer sizes available with different end connection options. Although

standard and EEx transducers appear the same, in fact the EEx version has a longer

converter mount (neck) and also contains specific clamping diodes fitted across the driver

coil. Therefore, it is essential to avoid using a standard converter with EEx transducer and

vice versa.

In order to fulfil the Ex certification requirements, it is absolutely necessary to comply with

the technical data. The maximum allowed process temperatures are:

MFS 3000 / E meter 200°C

MFS 2000 / P meter 200°C

MFS 2000 / P meter high temperature option, 60ºC

environmental temperature

MFS 2000 / P meter high temperature option, 55ºC

environmental temperature

1.2 Description of the Converter

The Ex converter is available in two different versions:

The ‘de’ version

The electronics are placed in a pressure tight section of the converter housing, protection

class ‘d’, while the termination compartment is not pressure tight. The converter housing

may be fitted with different cable glands such as NPT, PG16 or NPF glands for the mains

supply and the input/output cables. The protection class of the termination compartment

in ‘e’.

The ‘d’ version

The electronics as well as the termination compartment are placed in a pressure tight

housing. The termination compartment is not fitted with any gland for the mains supply or

the input/output cables. The customer is responsible for fitting an Ex approved cable gland

into the PG16 thread of the housing. There are various suppliers for such cable glands on

the market. The protection class of the termination compartment is ‘d’.

4 Additional Instruction for Ex version MFM 2081 / 3081

240°C

255°C

Page 5

For both cases the required waiting time between switching off the electronics and opening

the housing has to be considered. The waiting time is mentioned on the data plate of the

system and amounts to 25 minutes for T6 and 10 minutes for T5.

The Ex protection of the system is not valid if the electronics housing is not closed securely.

Make sure after opening the converter housing, to close it fully with the enclosed wrench.

The programming of the converter may also be performed with a closed lid by using the

supplied magnet. Three magnet sensors are assembled on the display board, which allow

the user to operate the converter without touching the display itself.

KROHNE MFC 081

Fig. 1: Converter

After opening the converter housing as described above, one of the following operations

may be performed by the local KROHNE service engineer :

• Replace supply fuse F9

• Changing electronics

• Changing supply voltage setting

• Changing EPROM’s

These operations are to be performed in an identical manner to the standard converter.

(Please refer to the standard operation manual). Make sure the correct mains fuse (right

value, ceramic body, 1500A breaking capacity) and the corresponding fuse label on the

fuse housing is used. Fuses and labels may be ordered from KROHNE.

Using wrong fuses violates the Ex approval and may damage the system. The earthing

metal sheet of the electronic must be fastened firmly with the screw onto the converter

housing!

The converter should be ‘high pot’ tested according to a specific procedure. Therefore, it is

not permitted to change output modules or any other hardware components (except the list

mentioned above by the local service engineer) without repeating the ‘high pot’ test.

Please contact KROHNE for advice.

1.3 Installation of MFM 2081 / MFM 3081 EEx

In order to get the highest possible accuracy, the user is advised to carry out the pipework

installation as described in the standard manual.

Additional Instruction for Ex version MFM 2081 / 3081 5

Page 6

Further requirements / differences are listed below:

• ?The ideal installation factor of an EEx unit is much higher than of a standard system due

to Zener barriers and clamping diodes the EEx system consumes more power during

running. The high installation factor does not mean a lower accuracy.

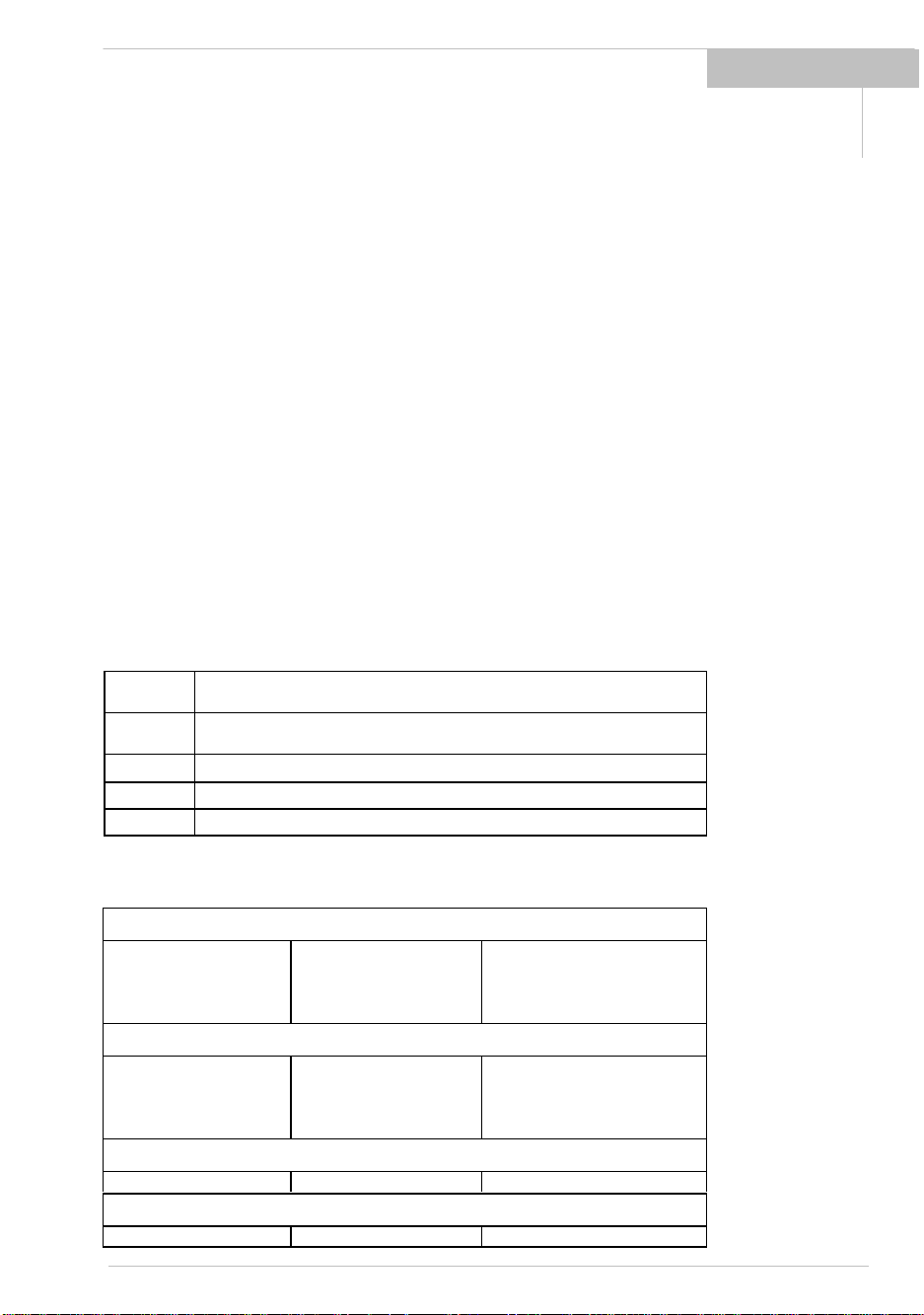

• The installation factor should have a value as indicated in the following table.

Meter Size Installation factor

MFM 2081 K/F

MFM 2081 K/F Ex

MFM 3081 K/F

MFM 3081 K/F Ex

< 50

< 100

< 20

< 60

The correct operation of the Zener barriers inside the converter are only guaranteed with a

robust and safe connection of the converter housing with potential earth (potential

compensation PA). Please use the outer earthing connector at the square flange of the

converter housing for earthing.

In case the converter housing has a pressure tight termination compartment, make sure the

connected cable glands / adapters have an Ex certification.

2 Electrical installation

2.1 Location and connecting cables

Location

Do not expose the compact flow meter to direct sunlight. Install a sunshade if necessary.

Connecting cables

To conform to protection category requirements, observe the following recommendations:

• Fit blanking plug PG 16 and apply sealant to unused cable entries.

• In case if the terminal area is EEd, please use approved blanking plug.

• Do not kink cables directly at cable entries.

• Provide water drip point (U bend in cable).

• Do not connect rigid conduit to cable entries.

• If cables are a tight fit, enlarge inside diameter of cable gland by removing the

appropriate ring(s) from the seal.

2.2 Electrical Connection on converter without intrinsically safe

outputs

Please ensure that the information about power given on the dataplate corresponds to the

locally available mains voltage.

• Note information given on the instrument dataplate (voltage, frequency)!

• Electrical connection in conformity with IEC 364 or equivalent national standard.

• Special regulations apply to installation in hazardous areas. Please refer to separate

"Ex" installation instructions.

6 Additional Instruction for Ex version MFM 2081 / 3081

Page 7

• The PE protective ground conductor must be connected to the separate U-clamp

terminal in the terminal box of the signal converter.

• Do not cross or loop the cables in the terminal box of the signal converter. Use

separate (PG or NPT) cable glands for power and output cables.

• Ensure that the screw thread of the round cover on the terminal box is well greased at

all times.

NOTE: The grease used must be non-corrosive to aluminium; it must be resin- and acidfree.

• Protect sealing ring from damage.

5 6 4 4.1 4.2 11 12

N L AC

Output- - + DC

Connection PE

s. table

Fig. 2: Power and signal connections for MFC 081 K/F without intrinsically safe outputs

The tables below show the possible input output connection for the converter. The exact

configuration depends on which optional output modules were fitted in the factory.

Table of input/output connections

Nr. Option 1 (Current, pulse, alarm

and input)

Common (-) Common (-)

5

Current output (+) Current output 1 (+)

6

Control input Control input

4

Pulse output Current output 2 (+)

4.1

Status output (active) Status output (passive)

4.2

* The inputs/outputs share a common signal ground which is galvanically isolated from the

ground (PE)

In addition, the signal may need protection from external interferences. The use of screened

cables and a filter capacitor next to any counter is recommended (Fig. 3).

It is possible to connect the pulse output without an external voltage supply. However to do

this the function of the status output must be sacrificed. (Fig. 4)

If the alarm output is used to power the pulse signal then the following settings must be

made in the menus:

(i) Fct. 3.5.1 ALARM FUNCTION must be set to OFF.

(ii) Fct. 3.5.2 ALARM ACTIVE LEVEL must be set to ACTIVE LOW.

Option 2* (2x current, not

galvanically isolated)

Additional Instruction for Ex version MFM 2081 / 3081 7

Page 8

(Max. 24 V DC)

V

ext

≥ 150 mA

R

ext

Fig. 3: Preferred connections to an external counter with separate power supply

(Example). For correct wiring see tables of input/output connections

(>1200 Ohm)

Fig. 4: Connection without external voltage source (Example). For correct wiring see tables

of input/output connections

Additional input/output options

No. Option 4* Option 5* Option 6

(Current and RS 485) (Current and Modbus) (1 Current, 1 Dual phase pulse

output and input)

5 Common (-) Common (-) Common (-)

6 Current output 1 (+) Current output 1 (+) Current output 1 (+)

4 TX/RX TX/RX Control Input

4.1 TX/RX TX/RX Pulse Output A

4.2 +5V +5V

Pulse Output B

No. Option C Option D Option E Option F

(2 Current, Pulse and

Input)

(3 Current and Pulse) (3 Current and Input) (3 Current and Alarm)

5 Common (-) Common (-) Common (-) Common (-)

Current output (+) Current output 1 (+) Current output 1 (+) Current output 1 (+)

6

Current output 2 (+) Current output 2 (+) Current output 2 (+) Current output 2 (+)

4

Control Input Current output 3

4.1

(+)

Pulsee Output Pulsee output Control Input Status output

4.2

The pulse output and status outputs are passive outputs.

Current output 3

(+)

Current output 3

(+)

(passive)

*Refer to separate RS 485 or Modbus manual"

8 Additional Instruction for Ex version MFM 2081 / 3081

Page 9

2.3 Electrical connection on converter with intrinsically safe

outputs

Please ensure that the instrument power supply information given on the data plate

corresponds to the locally available power supply to be used.

• Note information given on the instrument data plate (voltage,frequency)!

• Electrical connection in conformity with IEC 364 or equivalent standard.

• The PE ground conductor must be connected to the seperate U-clamp terminal in the

terminal box of the signal converter.

• Do not cross or loop the cables in the back of the converter. Please use seperate cable

entries (PG or NPT) for power and signal cables.

Ensure that the screw thread of the round cover on the terminal box is well greased at

all times.

• NOTE: The grease used must be non corrosive to aluminium; typically it must be resin-

and acid free.

• Protect the sealing ring from damage.

11 12

- + DC

Coding of the

Outputs acc. PE

to following table

Fig. 5: Power and signal connections for MFC 081 K/F with intrinsically safe outputs

Coding of Outputs

Term. No. Variant G

(1 Current, 1 Pulse

intrins.safe)

I 1 Current output (+) Current output (+) Current output (+)

I 1 Current output (-) Current output (-) Current output (-)

B Current output (+) Status output. (+) Control input(+)

B Pulse output (-) Status output. (-) Control input(-)

Term. No. Variant L

(2 Current, intrins safe)

I 1 Current output 1 (+) I 1 Current output 1 (+)

I 1 Current output 1 (-) I 1 Current output 1 (-)

I 2 Current output 2 (+) D Bus

I 2 Current output 2 (-) D Bus

Additional Instruction for Ex version MFM 2081 / 3081 9

Variant H

(1 Current, 1 Status output

intrins.safe)

Term. No. Variant M

Variant K

(1 Current, 1 Control input,

intrins.safe)

1Current, 1 Bus intrins.safe)

Page 10

Please

note,that the power supply terminals are

behind a lid. To connect, shift lid upwards,

connect power and close lid again.

2.3.1 Technical information of the Intrinsically safe outputs

Variant G,H K,L

type of protection intrinsically safe EEx ia IIC resp. EEx ib IIC to connect with intrinsically

safe circuits with following maximum values:

Ui ≤ 30 V Ci = 5 nF

I i ≤ 250 mA Li = 0

Pi ≤ 1.0 W

Variant M

type of protection intrinsically safe EEx ia IIC resp. EEx ib IIC to connect with intrinsically

safe fieldbus with following maximum values (FISCO):

Ui ≤ 30 V Ci = 5 nF

I i ≤ 300 mA Li = 0

Pi ≤ 4.2 W

10 Additional Instruction for Ex version MFM 2081 / 3081

Loading...

Loading...