Page 1

Version November 1996

CORIMASS P and E Series

Software Version P2.20

Installation a nd

Operating

Instructions

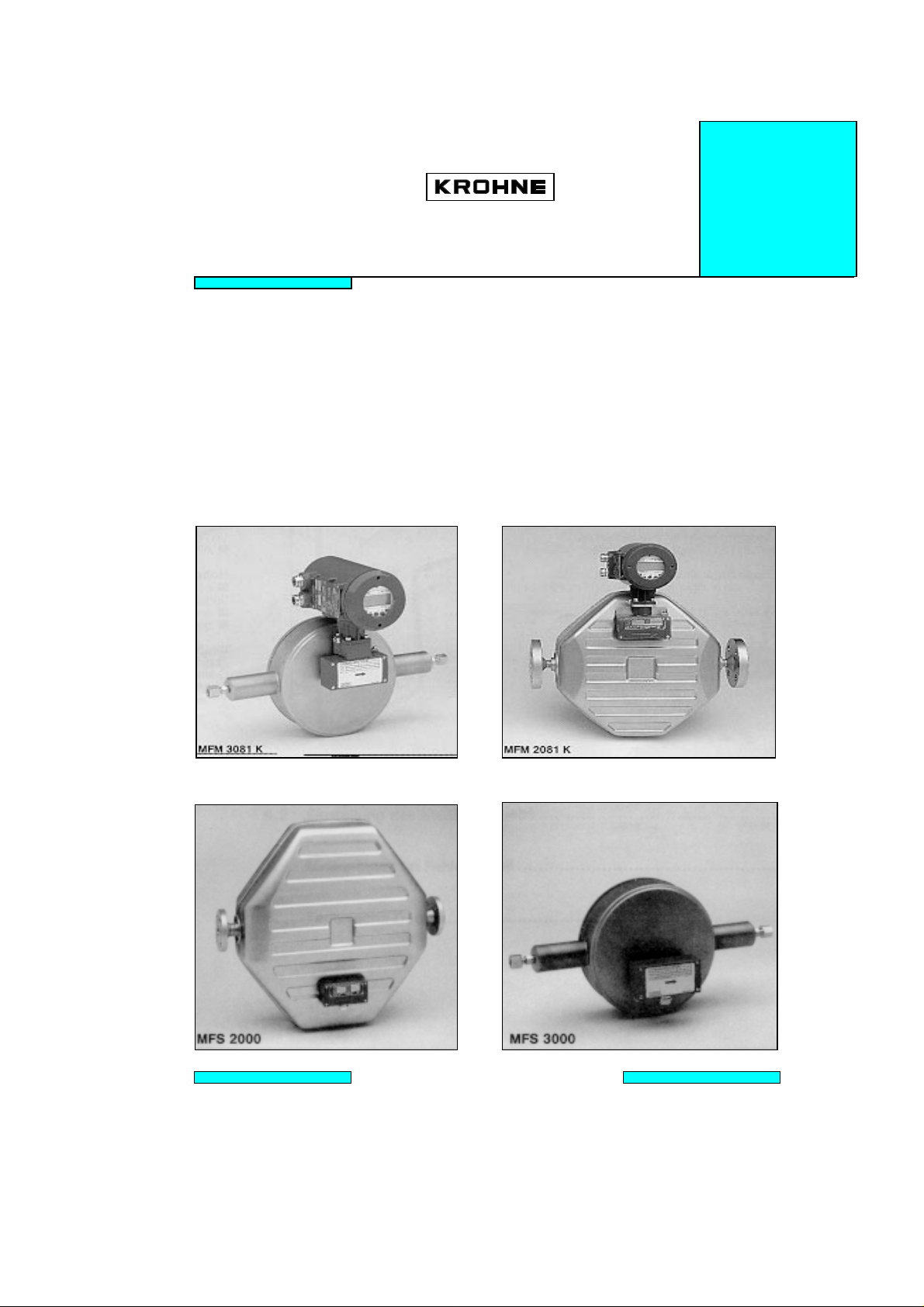

MFM 2081 K and F

MFM 3081 K and F

Page 2

How to use these installation and operating instr uct i ons

For easy reference these Instructions are divided into four parts.

Only Part A (page 3) is needed for install at ion and initial start-up.

All CORI MASS mass flowmeters of the P- and E-Series are fact or y set t o y our order

specifications.

Part A

Part B

Part C

Part D

The CORIMASS mass fl owmeter MFM 2081 and MFM 3081 is designed for the direct

measurement of mass f l ow rat e, product density and pr oduct temperature, and also indirectl y

enables measurement of parameters such as total m ass, concentrat ion of dissolved

substances and the volume flow.

For use in hazardous areas, special codes and regulations are applicabl e which are specified

in the special “Ex installati on and operati ng instructions“ (s uppl ied only with hazardous-duty

equipment).

Responsibility as to suitability and intended use of our instrum ents rests solely wit h t he

purchaser.

Improper inst allation and operation of t he fl owmeters may lead to loss of warranty.

Install f lowmeter in the pipeline (Sect. 1), connect up (Sect. 2) and power the

flowmeter (Sect. 3).

The system is operati onal

Operator control and f unctions of the MFC 081 Signal Converter.

Service and functional checks.

Technical data and dim ensions.

Product liability and warranty

In addition, t he “general conditions of sale“ for ming the basis of the purchase agreement

are applicable.

If you need to return CORI MASS f lowmeters to KROHNE, pl ease complete the form on t h e

last page of thi s manual and return it wi t h t he m eter to be repaired. Krohne regr et s t hat it

cannot repair or check your fl owmeter unless accompanied by this compl et e d f or m.

CE / EMC St andar ds / Approvals

• The Corimass MFM 2081 and MFM 3081 with the MFC 081 signal converter meet the

requirements of the EU-EMC Direct i ves and bear the CE symbol.

• The Corimass MFM 2081 and MFM 3081 K -Ex are approved as hazardous duty equipment

to the harmonised European Standards and to Factor y Mutual (FM) (pending). Further

details are given in the “Ex” supplementary instructi ons pr ovi ded only wit h hazardous-dut y

equipment.

Technical data subject t o change wi t hout not ice

2

Page 3

Contents

Part A: Installation and Start-up 4 - 28

1. Instrument Descr i pt i on 5

1.1 The Corimass Measuring System 5

1.2 Mass Flow Sensor 6

1.2.1 Measuring Principle 6

1.2.2 Transducer MFS 2000 (P-Series) 6

1.2.3 MFS 3000 Transducer (E-Series) 7

2. Installation 8

2.1 General Principles 8

2.2 Installation Guidelines 9

2.2.1 Location of Corimass Transducer 9

2.2.2 Requirements of the piping system 12

2.2.3 Special remarks on the MFS 3000 15

3. Electrical Inst al lation 17

3.1 Location and Connecting Cables 17

3.2 Connection to Power 17

3.3 Inputs and Outputs 18

4. Start-up 20

4.1 Factory Set Parameters 20

4.2 Initial St ar t-up 20

4.3 Installat ion Factor 21

4.4 Zero Point Adjustment 21

4.5 Programming the Converter with a Bar Magnet 22

4.6 Installat ion of the Converter MFC 081 F 22

4.7 Connection of Remote Mounted Version 23

4.8 Connection Diagram of Compact Version 28

Part B: MFC 081 Signal Converter - Software Version P2.20 29 - 76

5. Operation of t he Si gnal Convert e r 29

5.1 Operating and Check Elements 29

5.2 Krohne Operating Concept 30

5.3 Key Functions 31

5.3.1 How to enter programming mode 32

5.3.2 How to terminate programming mode 32

5.4 Table of Programmable Functions 35

5.5 Reset / Quit Menu - Totalizer Reset and Status Indication Acknowledgement 45

5.6 Status Messages 47

5.7 Menu Variations for Systems with O t her Out put O ptions 48

6. Description of Funct i ons 49

6.1 Zero Point Adjustment 49

6.2 Low Flow Cutoff 51

6.3 Time Constant 51

6.4 Programming the Display for Measurement Values 52

6.5 Programming Numeric Data 55

6.6 Setting the Current Output 56

6.7 Setting the Frequency / Pulse Output 59

6.8 Setting the Process Alarm Output 63

6.9 Setting the Control Input 65

6.10 Setting the System Control 66

6.11 Standby Function 67

3

Page 4

6.12 Density Calibration Adjust ment 69

6.12.1 Water as the reference liquid 69

6.12.2 Process fluid as the reference liquid 69

6.13 Density - Special functions 71

6.13.1 Density - Special functions 71

6.13.2 Referred density (option) 72

6.13.3 Fixed density (option) 72

6.14 User Data 73

6.14.1 Programming the display language 73

6.14.2 Password protection of m enus 73

6.14.3 Custody transfer protection code 74

6.14.4 Primar y head type and tube parameters (CF 1 - 9) 76

6.14.5 Location 76

Part C: Special O pt i ons, Functional Checks, Service and O r der Numbers 77 - 96

7. Special Options 77

7.1 Use in Hazardous Areas 77

7.2 Converter with Non-standard Output O pt ions 77

7.3 Concentration Measurement and Special Density Options 77

7.4 Converter with Smart / HART Communication O pt ion 77

7.5 Converter with RS 485 Communi cat i on O ption 78

7.6 Custody Transfer Option 78

8. Functional Checks 78

8.1 Test Functions 78

8.1.1 Testing the display 78

8.1.2 Testing current output 79

8.1.3 Testing pulse output 79

8.1.4 Testing alarm out put 81

8.1.5 Testing control input 81

8.1.6 Viewing temperature 82

8.1.7 Viewing primar y head signal condi tions 82

9. Service and Troubleshooting 83

9.1 Threads and “O” Ring of the Converter Housing Lid 83

9.2 Replacing the Converter Electronics 83

9.3 Change of Operating Voltage and Power Fuse F9 84

9.3.1 Replacement of power fuse F9 84

9.3.2 Changing the operating voltage 84

9.4 Turning the Display Circuit Board 85

9.5 Turning the Signal Converter Housing 85

9.6 Troubleshooting 86

9.7 Fault Finding 89

9.8 Checking the Primary Head 92

9.9 Status W ar ni ngs 93

10. Order Numbers 96

Part D: Technical Data and Dimensions 97 - 103

11. Technical Data 97

11.1 Primar y Head 97

11.2 MFC 081 Signal Converter 99

11.3 Measuring Accuracy / Error limits 100

11.4 Dimensions and weights 101

11.4.1 Compact Systems - MFS 3081 K / MFS 2081 K 101

11.4.2 Remote Systems - MFS 3081 F / MFS 2081 F 102

4

Page 5

Part A Installation and Start up

1. Instrument Descr i pt i on

1.1 The CORIMASS M easur ing System

The CORIMASS Measuring Sys tem uses the Cori o lis principle for measuring the mas s flow

rate of fluids wit h hi gh accur acy.

When using thi s measuring principl e, it is possible to measure the mass flow rate directl y,

independent of any other parameters of the fluid, such as density, temperature, pressure,

viscosity, conduct i vity and flow profi l e. Hom ogeneously distr i but ed sm all solid particles

(slurries) and gas bubbles have no noticeable effect on the measuring accuracy.

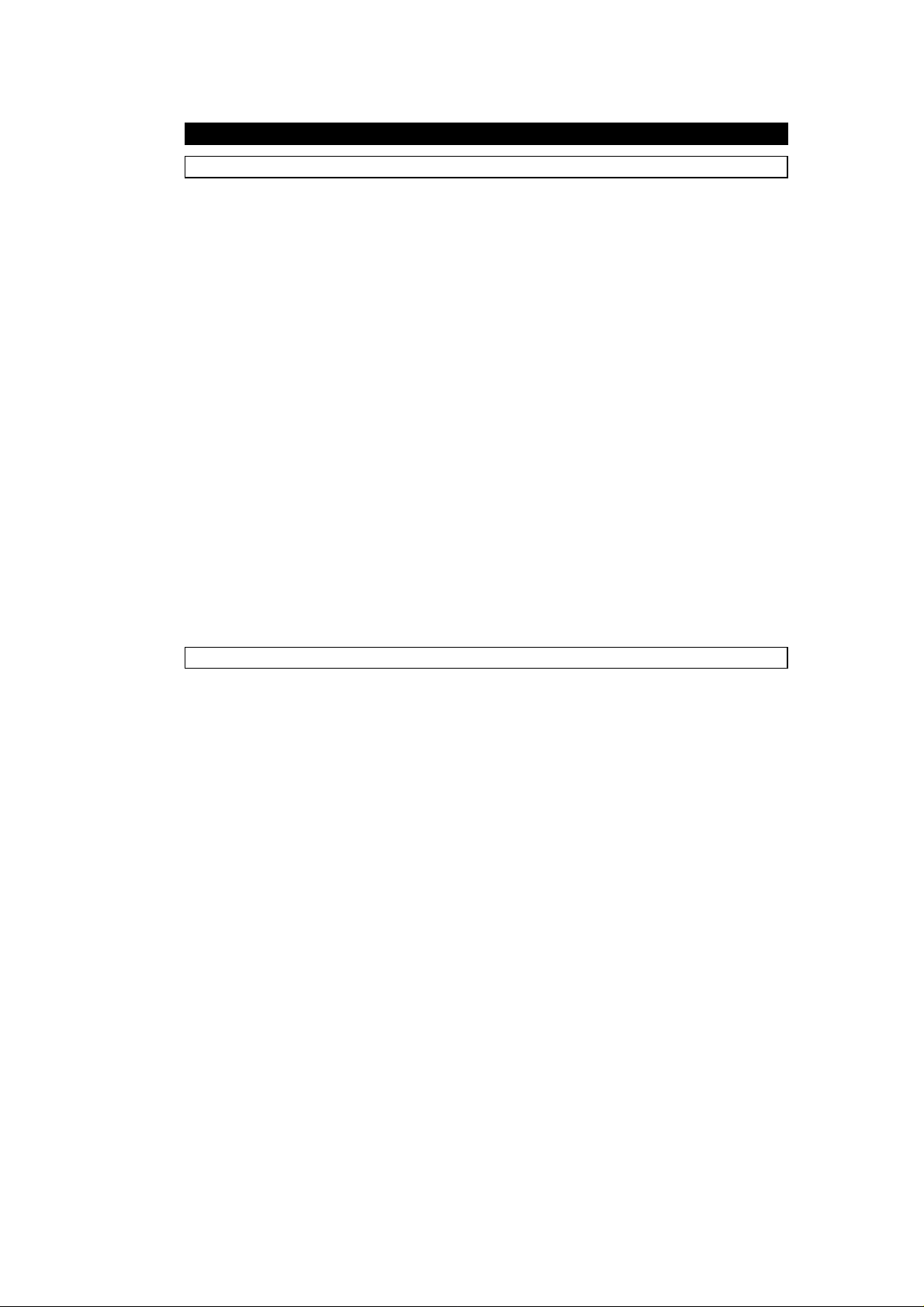

The CORIMASS mass flow rate system i s of modular type design, com pr ising a transducer

and a converter. In the compact version MFM 2081 K / MFM 3081 K the converter is mount ed

directly to the transducer; in t he separate version MFM 2081 / MFM 3081 the transducer MFS

2000 / MFS 3000 and the converter MFC 081 F are connected to each other via a shielded

multi-conductor cable (figur e 1). The MFM 2081 is also referred to as “P-Series,” and the

MFM 3081 is also referred to as “E-Series”. The measurement values of mass flow rate, total

mass and density are available.

Additional to t he standard syst em f or special r equirements the following models are available:

− tr ansducer wit h electri c or liquid heating

− tr ansducer with secondary containment or pressure relief

− hazardous duty model:

EEx ib II B or EEx ib II C (no electric heating!) ar e appli ed

− FM Class I, II, III, Div. 1 and Div. 2, Groups B-G ( pending)

Compact Version Separate Version

MFM 2081 K MFM 2081 F

Transducer MFS 2000 plus Converter MFC 081 F

Shielded multi-conduct or cabl e

Fig. 1 The CORIMASS Measuring System

5

Page 6

1.2 Mass Flow Sensor

1.2.1 Measuring Pr i nci ple

Coriolis for ces occur in r ot at ing systems when accompanying bodies are moved toward or

away from the rotat ional axis. This is illustrated by the following simple set-up: a pipe tube

rotates with a constant angular veloci t y ar ound t he axis A - B (fi gur e 2). The flui d par t icles

flow with the velocity v through t he loop. Between the points C and D they move away from

the axis and therefore have to be accelerated from a smaller to a lar ger tangential veloci t y.

Respectively, the fluid particles have to decelerate reducing their tangential velocity between

points E and F. The opposing coriol i s f or ces acti ng upon t he two dif f erent parts of t he pipe

loop are directly proporti onal to the product of the mass and the velocity of the fluid. They

cause the pipe loop to deform (DD’, EE’ and FF’ respectively) with r espect to a r otating loop

filled with a flowing fluid.

Fig. 2 Coriolis force in a rotating pipe loop

Rotation does not necessarily mean the completion of f ull circular or bi t s. Short circular

segments suffice. In the event of oscillation, the deformation of the pipe loop sides oscillates,

too. The total change in the moti on of t he pipe loop caused by the mass flow can be detected

via inductive sensors. A signal di r ectly r elated the mass f l ow rat e of the fluid flowing through

the pipe loop is then generated after appropriate signal processing.

1.2.2 Transducer MFS 2000 (P-Seri es)

For greater sized mass flow meters it has proven to be of advantage for the fluid t o f low

through two parall el measuring loops, which oscillate in opposite directions and with a phase

difference of 180°. This symmetrical arr angem ent of t he loops and the sti f f ness of the bridge

(i.e. the pipe loop supports) suppress most disturbances caused by external equipment.

Figure 3 displays an optimised transducer of the MFS 2000 series designed for mass fl ow

measurement.

Fig. 3: Transducer MFS 2000 without housing

6

Page 7

The use of flow dividers with optimised flow properties combined with the application of

measuring tubes with a large tube cross-section ensures mini mum loss of pr essure. The

danger of cavitation i n t he specified m easuri ng r ange is eliminated.

The use of thick-walled measuring tubes with a large cross-section exercises a further positive

effect. Due to the increase in the vibrating mass, the measuring system is less sensitive to

gas bubbles in the measured medium.

1.2.3 MFS 3000 Transducer (E- Ser i es)

The CORIMASS MFS 3000 series is comprised of precision transducers f or the measurement

of small fluid and gas mass f low rates with the range of 0.006 kg./mi n. t o 33. 3 kg. /min. ( 0. 013

lb./min. to 73.16 lb./min.).

In contrast to the CORIMASS P-seri es of instr u ments, t h e CORIMASS E-series is d esi g n ed as

a single-tube system with the inherent advantages of a single flow path (see Fig. 4).

Fig. 4: MFS 3000 Transducer without housing

Due to its low-frequency tuned reference platform, t he MFS 3000 is largely insensiti ve to

interference. The unit is characterised by a rugged transducer loop, which permits optional

measurements up to operating pressure levels of as much as 300 bar (4352 psig) depending

on model.

A further advantage of the E-series is its ease of maintenance and servicing.

7

Page 8

2. Installation

2.1 General Princi pl es

The MFS 2000 and MFS 3000 CORIMASS mass flowmeters are capable of providing hi gh

accuracy and excellent repeatability. The narrow band pass digital filtering, the dual parallel

tubes of the P-Series and the tuned reference platform of the E-Series provide exceptional

immunity to external vibratory di st ur bances from process equipment in the area. Furthermore,

the power of the CORIMASS with its dual driver design perm its unsurpassed performance on

certain types of slurries and on li qui ds wi t h gas bubbles. Both designs are self-draining when

installed vertically.*

As with all Cori o lis mass flo wmeters, th e CORIMASS is an act ive device with its own energy

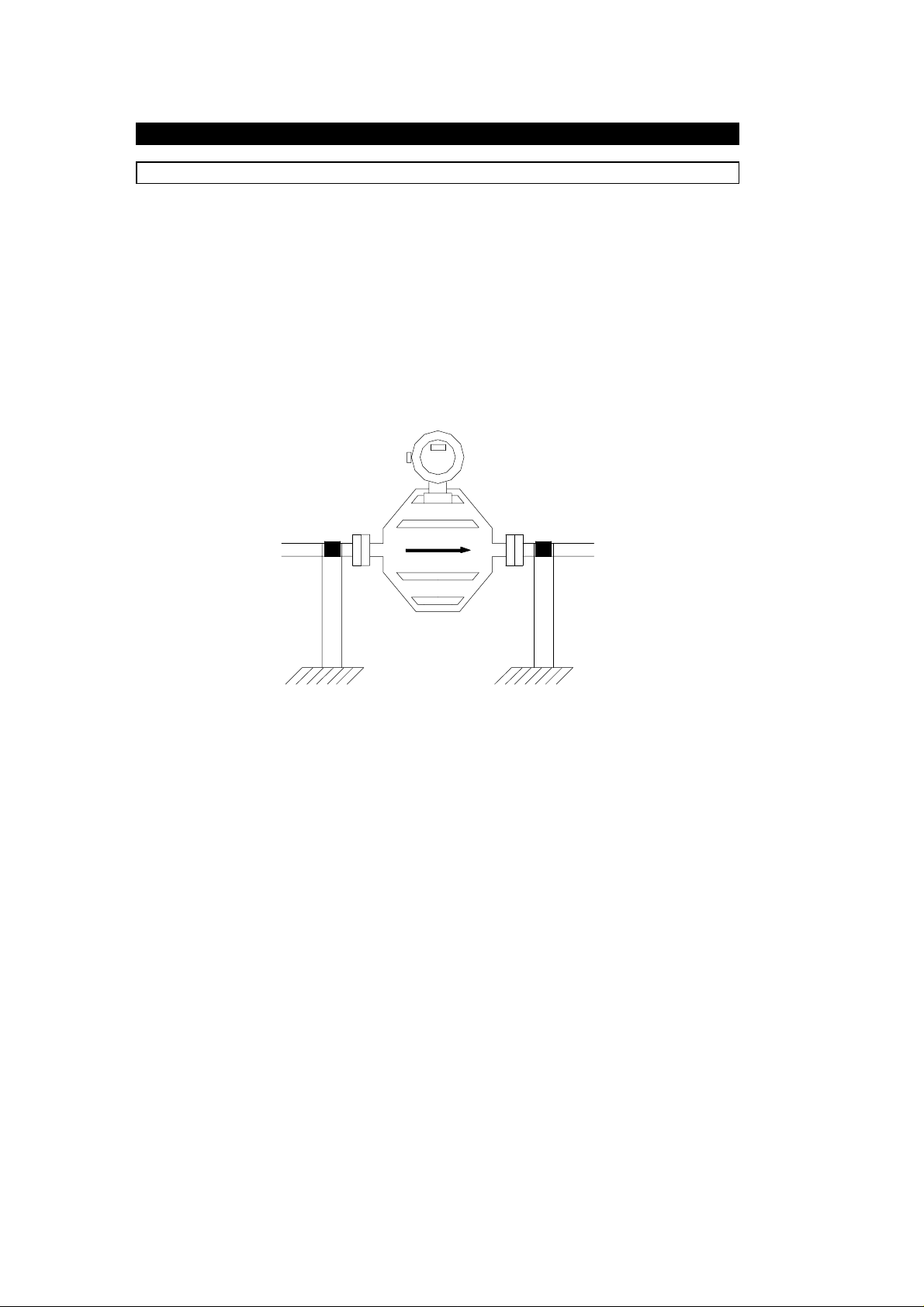

source. The MFS 2000 mass flow sensor should be mounted into and by a rigid suppor t i ng

piping system to avoid reflected resonant energy from adjacent piping and mounting st r uct ur es

in order to take advantage of the high degree of precision built int o t he instr ument (fig. 5) . A

possible exception is mentioned in Section 2.2.2.

Fig. 5 Basic inst a lla tion requirement

MFS 2000: rigid, stress free supporting of the tra nsducer

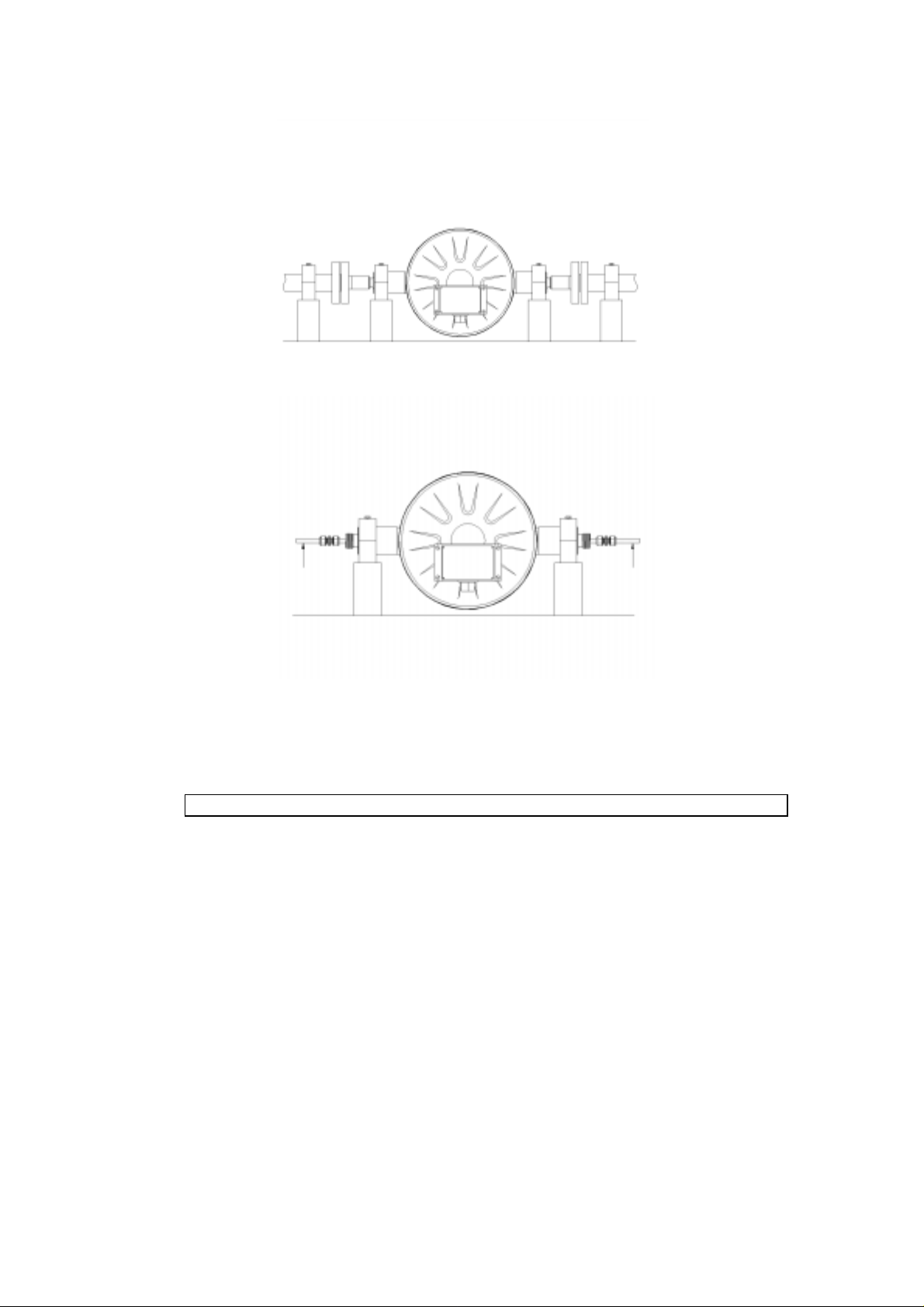

The MFS 3000 transducer should be mounted by using two metallic clamps (supplied with the

flowmeter), which are secured to a rigid mounting surface, as shown. For optimum

performance these clamps should be positi oned near the outboard ends of the transducer

support tubes. They should also be well aligned to prevent undue stress on the MFS 3000

transducer housing when the clamps are secured. Adjacent piping should be rigidly support ed

and aligned with the transducer to avoid excess loading on the transducer process

connections(See Fig. 6). For connection to tubing, pr ocess tubi ng shoul d also be secured at

appropriate locati ons ( indicated by arrows in Fig. 6) t o minimize vibration.

* Note: 1.5E requires aproximately 7° anti-clockwise rotation f r om vertical.

8

Page 9

Fig. 6: Installation MFS 3000

A good installation is the basis for the high measurement accuracy of the unit.

The following instal lation guidelines are practical to implem ent, par t iculary if pl anned before

the CORIMASS is first installed.

2.2 Installation Guidelines

2.2.1 Location of CORI MASS Transducer

Please ensure the following install at ion guidelines are adhered to as they are

necessary

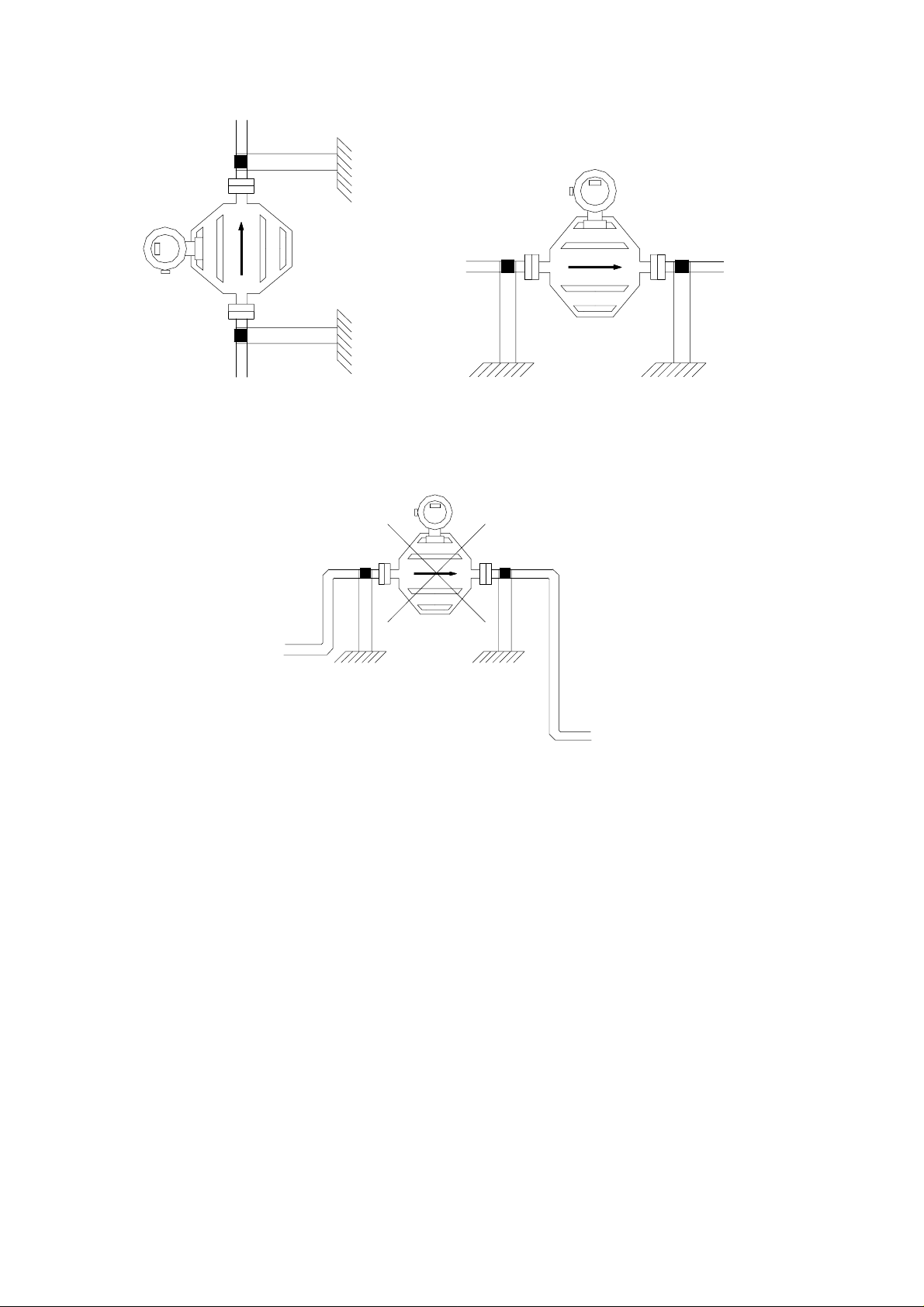

The transducer can be installed in any position. However, when installed in a vertical position

the transducer is self-draini ng and allows gas bubbles to be readily purged from f lowmeter

during flowing conditions (see Fig. 7a and 7b).

for good measurement results and trouble-free start-up.

absolutely

9

Page 10

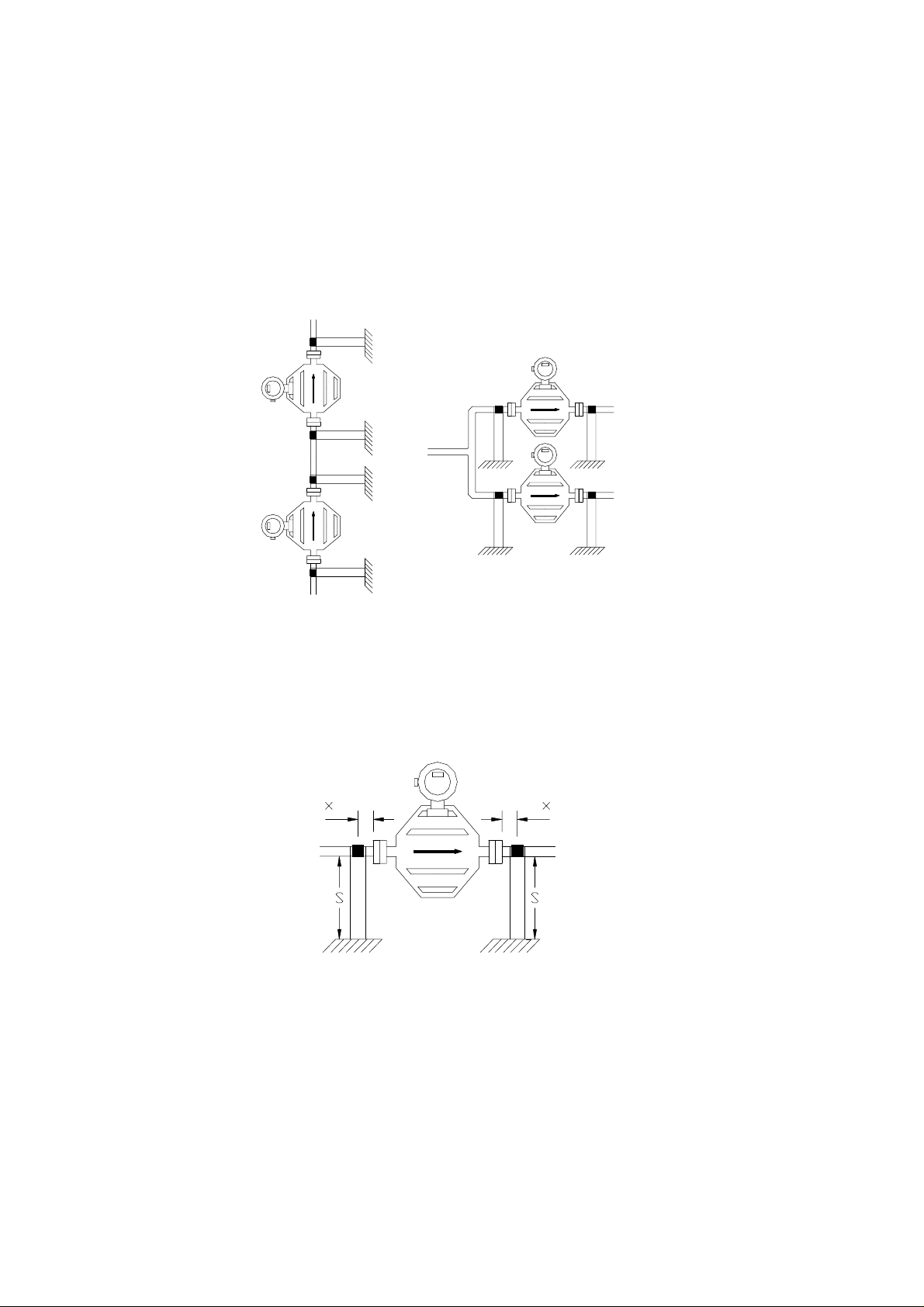

Fig. 7a Vertical installation Fig. 7b Horizontal installation

Highest positi on in Pipeline

Avoid mounti ng t he transducer in t hi s position as gas bubbles may col l ect and rem ai n in

measuring system causi ng i ncor r ect measurements (see Fig. 8).

Fig. 8 Avoid highest position in pipeline

10

Page 11

Falling Pipeline

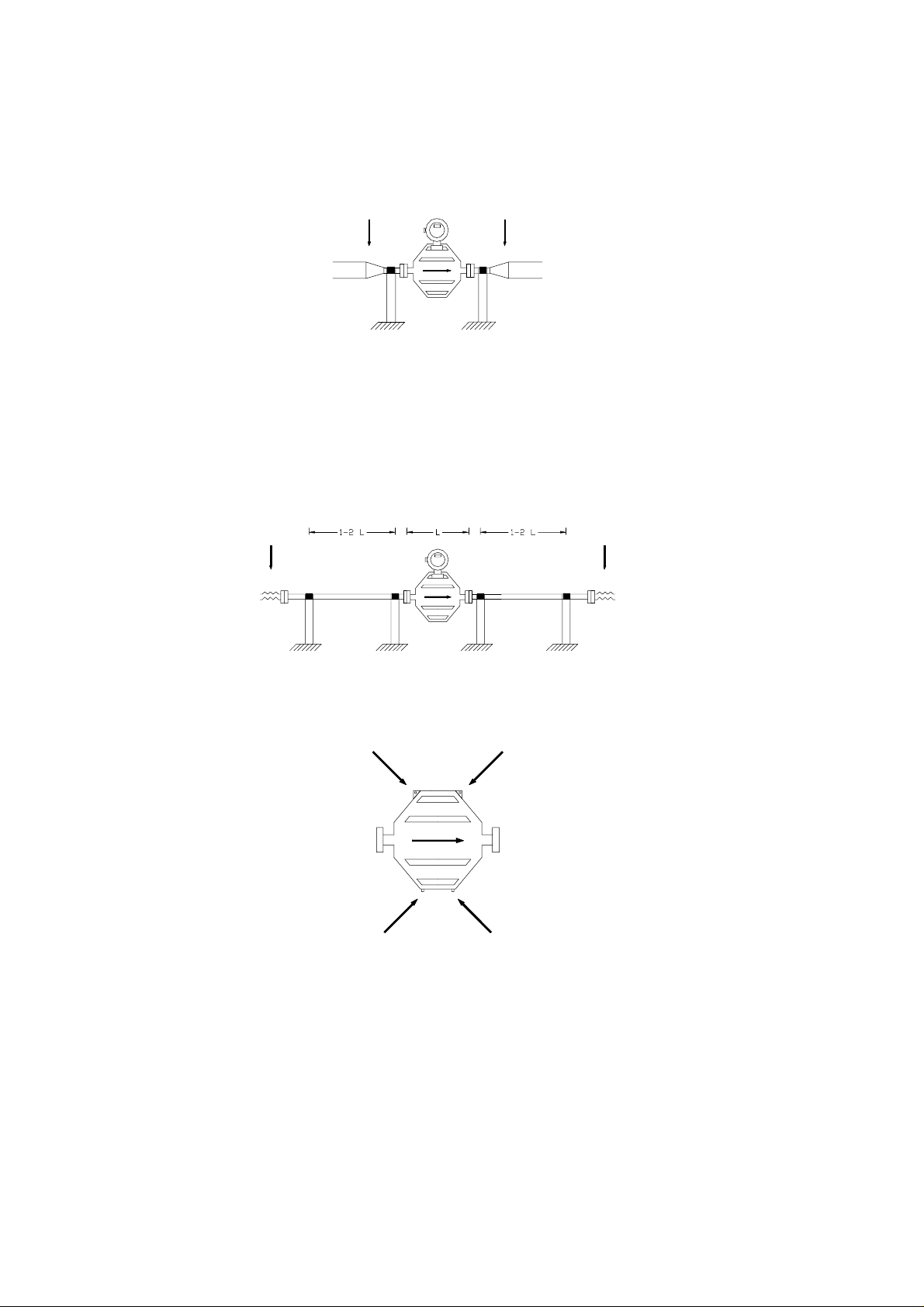

Long downstream pipelines (> 3m ) should be avoided due to degassing of the medium .

If long downstream pi peli nes are unavoidable instal l an additional vent valve as shown in

Figure 9, unless there is under all operating conditions suf f icient back pressure to avoid

flashing of l iquid to vapor.

Fig. 9 Avoid long downstream pipelines after the transducer

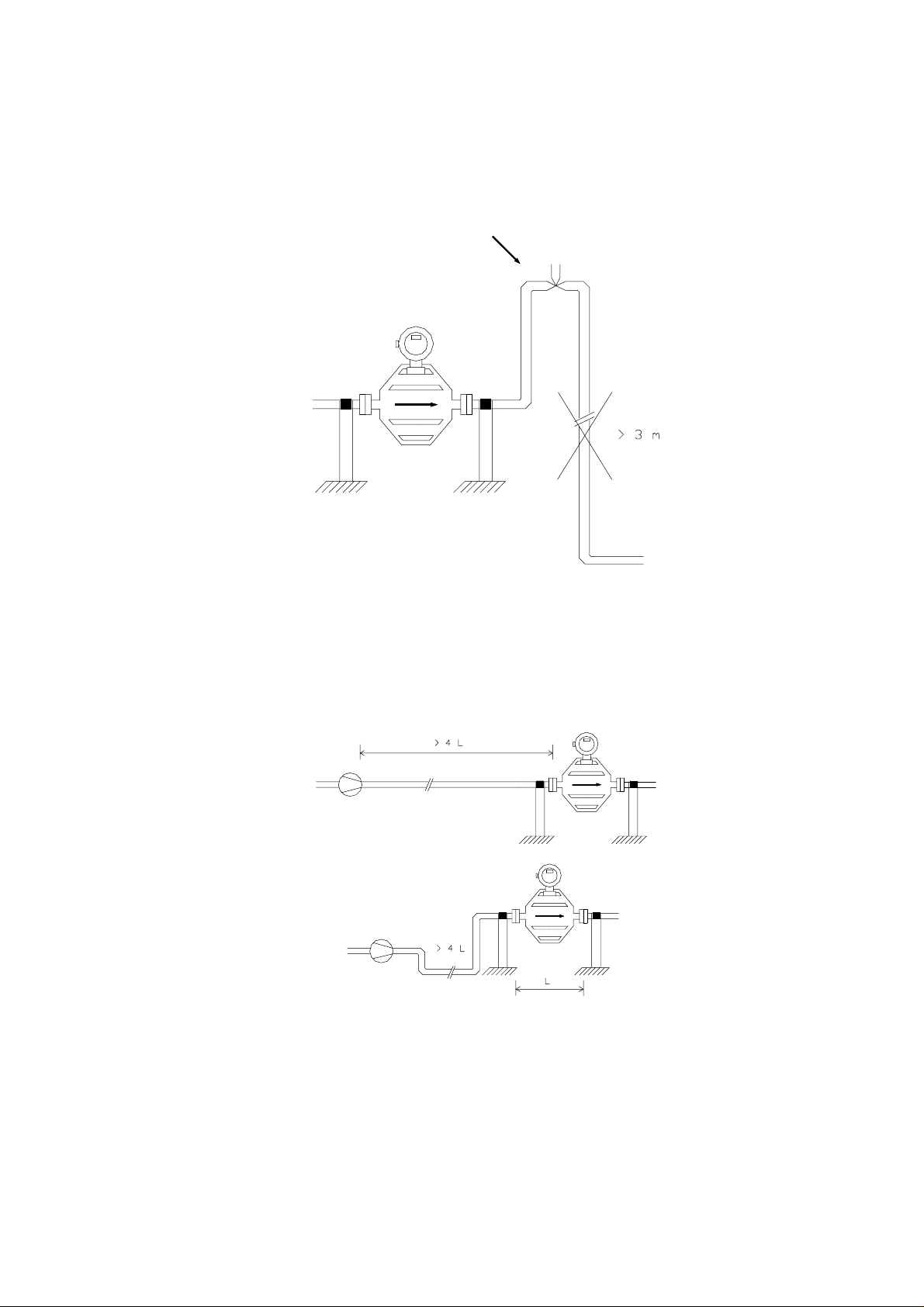

Pumps

Pumps should be install ed at least 4 × L fr om the transducer.

Where pumps cause excessive vibration, de-coupling by flexible hose may be necessary.

Install as shown i n Fi gur e 10.

Fig. 10 Minimum distance from delivery pump 4 ×L

11

Page 12

Additional Devi ces

Control valves, inspection gl asses, etc., shoul d be instal led at least 1 × L from the transducer

flange.

De-coupled pairs of Tr ansducer s

Transducers of the same size (or operating frequencies within 3 Hz) should not be installed in

close proximity (< 4 L) in the same pipeline or connected via a mutual mount ing frame unless

they have been specially frequency de-coupled by the manufacturer (see Fig. 11).

The first 5 digit s of t he RB (shown on the Data Plate and on the Calibrati on Certi f icate) give

the operating frequency of the transducer with water.

Fig. 11 Mounting of matched transducers serial or parallel

2.2.2 Requirement s of t he Pi pi ng System

Fixing

The mounting supports must be kept as short and as rigid as pract i cal to prevent excitation of

resonant vibrations by the transducer (see Fig. 12). Addit ional cross bracing is necessary

when the maximum support length s

is exceeded (see Fig. 13).

m

Fig. 12 Mount ing with rigid suppor ts

12

Page 13

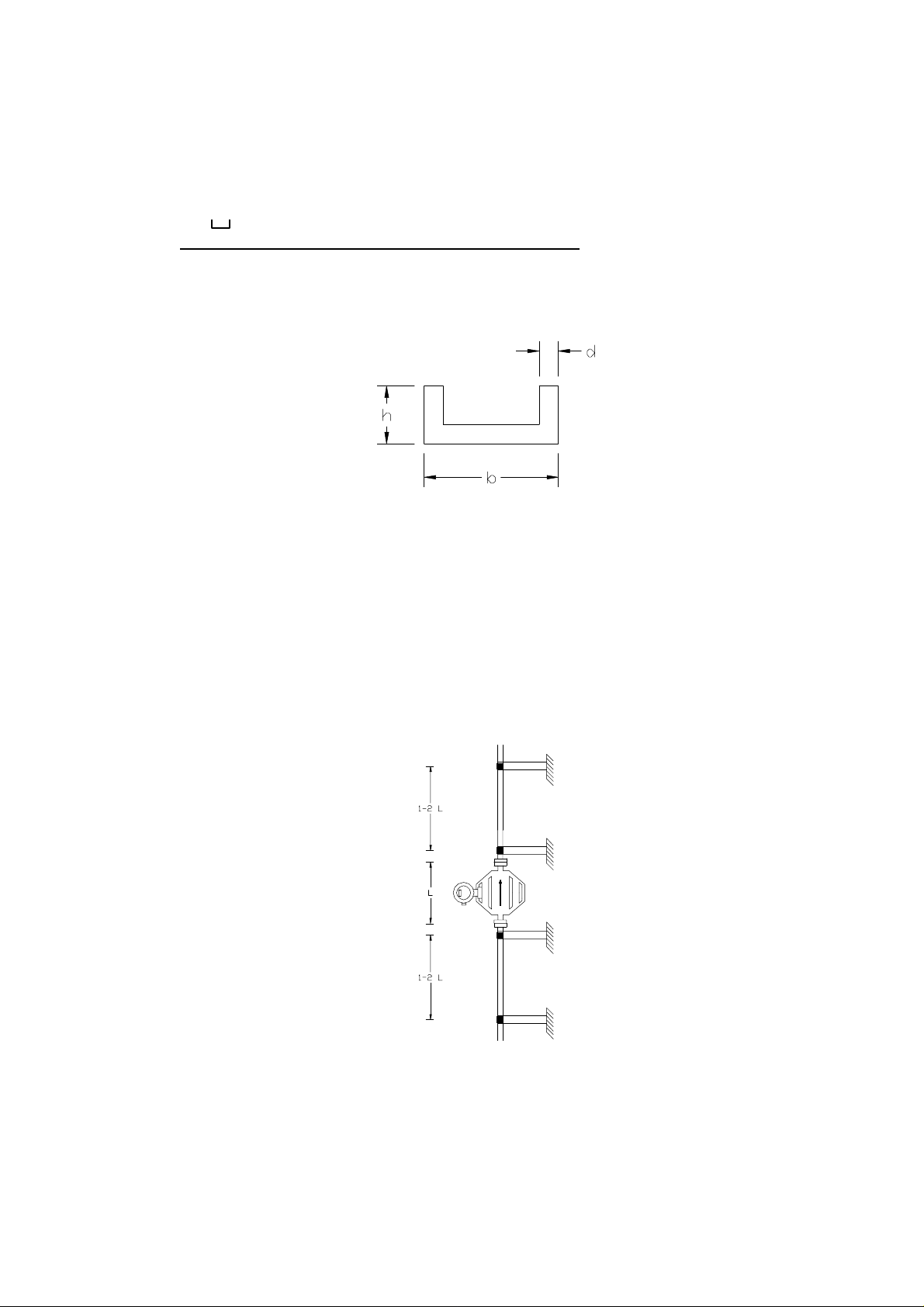

As an example the table indicates maximum support length for U-shape profile and the various

transducer sizes.

Dimensions and maximum lengths s

of U-shape supports. The chosen material dimensions

m

are examples for adjusting support dimensions to transducer size.

profile

b

mm (in)hmm (in)dmm (in)

s

m

mm (in)

e.g. for

60 P

300 P

800 P

1500 P

60 (2.4)

80 (3.1)

120 (4.7)

160 (6.3)

30 (1.2)

45 (1.8)

55 (2.2)

65 (2.6)

6 (.24)

6 (.24)

7 (.28)

7.5 (.30)

1260 (49.6)

1490 (58.7)

1810 (71.3)

2090 (82.3)

Fig. 13 U-profile

The pipe clamp on the supports should have a large surface area contact with t he support and

process pipe. No rubber, plastic or other material should be installed between the clamp and

process pipe. The transducer should be supported and clamped free of tension on either side

of the flanges as illustrated. The clamps should be equidistant and as close to the flanges as

possible.

Do not mount supports on f lang es or on the housing .

Process pipes on either side of the transducer should be axially aligned, and fl anges should be

parallel face to face within 0.4 mm (.016 in). the installat ion dimension (L) acr oss t he

transducer flanges must be mat ched to the process pipe flanges within ± 2 mm (.079 in).

For long pipe runs additi onal pipe supports must be installed 1 to 2 transducer lengths (L)

apart (fig. 14).

Fig. 14 Dist ance of a dditiona l supports

13

Page 14

Reduction in Process Pipe

Use standard reducing connectors on process pipes when they are larger than transducer

connection (fig. 15).

Fixing instructi ons mentioned previously must be foll owed.

Fig. 15 Use of reducing connectors

Flexible Hoses

Generally flexible hoses should be avoided. In applications where vibration is excessive,

flexible hoses can be used to de-couple the process from t he transducer.

Some applicati ons dem and t he use of flexible hoses and therefore the installation should

comply wit h t he diagr am (fig. 16) .

If in any doubt about t he use of flexible hoses contact KROHNE prior to instal l ation.

Fig. 16 Use of flexible hoses

Transport supports

not

Transport supports f itted to larger meters are

pipeline (fig. 17).

to be used for fixing the transducer in the

Fig. 17: Do not use t ransport supports for mounti ng

14

Page 15

Requirement for Zero Adjustment

A shut-off valve should be installed downstream of the transducer.

Tight shut-off is im por t ant ( f ig. 18).

Fig. 18 Shut-off valve downstream of the transducer

For best zero adjustment the meter can be installed in a by-pass arrangement as shown in the

diagram ( f ig. 19).

All peripheral devices can be active under operating conditi ons and t he process flow m ust not

be shut off.

Fig. 19 By-pass installation for best Zero Adjustment

2.2.3 Special rem ar ks on t he MFS 3000

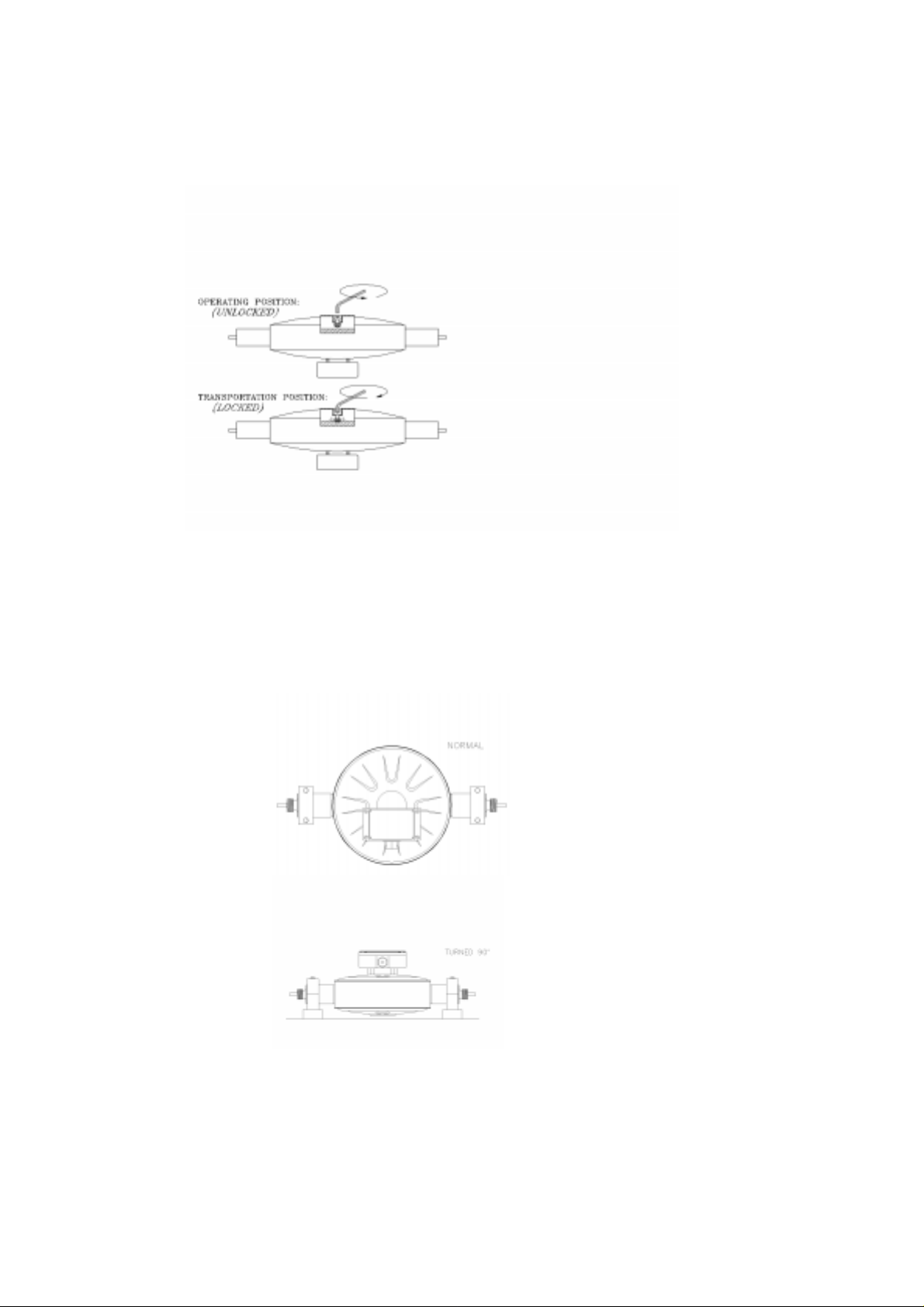

In order to guarantee the perfect function of the CORIMASS transducer MFS 3000 (even after

poor transport condi t i ons) , the transducer is provided with a “Transport Safety Device”. The

“Transport Safety Device” must be inactive for operation and active for t r anspor t ation as

follows:

Comm issioning:

Before commissioning, the “Transport Safety Device” must be made

recessed Allen Screw (on reverse side of the instrument) anti - clockwise against the

mechanical stop wit h a 6 mm All en Key. In the case of the MFS 3000 - 30E two “Transport

Safety Devices” are used, and both must be made inactive prior to commissioning

(see Fig. 20).

inactive

by turning the

15

Page 16

Transport:

active

Before packing the unit for transport t he “Transport Safety Device(s)” m ust be m ade

turning clockwise against t he m echanical st op ( see Fig. 20).

Note: Models MFS 3000 - 0.3 E, 1.5 E, and 10 E are depicted above. Model MFS 3000 - 30 E

has two transport locks ( not shown) on t he sam e side of the instrument as the single transport

lock shown.

by

Fig. 20 Location “Transport Safety Device”

Flexible pipes or hoses can easily be connected at the permanently inst al led transducer.

When instal ling in a horizontal posi t ion, the transducer can also be turned 90° and mounted

flat, as shown in Figure 21.

Fig. 21: Mounting variations for horizontal installation

16

Page 17

Caution:

If the M FS 3000 tr ansducer s ar e oper at ed in the flow directi on cont r ar y to that i ndicated

by the arrow on the rating plate, the transducer constant G K may change by 0.15%

3. Electrical inst al lation

3.1 Location and connecting cabl es

Location

Do not expose the compact flow meter to direct sunlight. Inst all a sunshade if necessary.

Connecting cables

To conform t o protection category requirements, observe the following recommendations:

– Fit blanki ng plug PG 16 or 1/2” NPT and apply sealant to unused cable entries.

– Do not kink cables directly at cable entries.

– Provide water drip point ( U bend in cable).

– Do not connect rigid conduit t o cable entries. Use flexible conduit when required. Make

sure conduit drains away from connection to converter and transducer.

– If cables are a tight f it, enlarge inside diameter of cabl e gland by rem oving the appropriate

ring(s) fr om the seal.

3.2 Connection to power

Please ensure that the informat ion about power given on the

dataplate corresponds to the locally avai l able mains voltage.

– Note informat ion given on the instrument dataplat e (volt age, fr equency)!

– Electri cal connect ion in conformi ty with IEC 364 or equivalent national standard.

– Special regulations apply t o i nst allation in hazardous areas. Please refer to separate "Ex"

installation instructions.

– The PE protective ground conductor must be connected to the separate U-clamp

terminal i n the terminal box of the signal converter.

– Do not cross or loop the cables in t he t er minal box of t he signal converter. Use separate

(PG or NPT) cable glands for power and output cables.

– Ensure that the screw thread of the round cover on the term i nal box is well greased at

all times.

NOTE: The grease used must be non-corrosive to alumi nium; typi cally it m ust be resinand acid-free.

– Protect sealing ring from damage.

– See Figure 22 for the arrangement of power connections.

17

Page 18

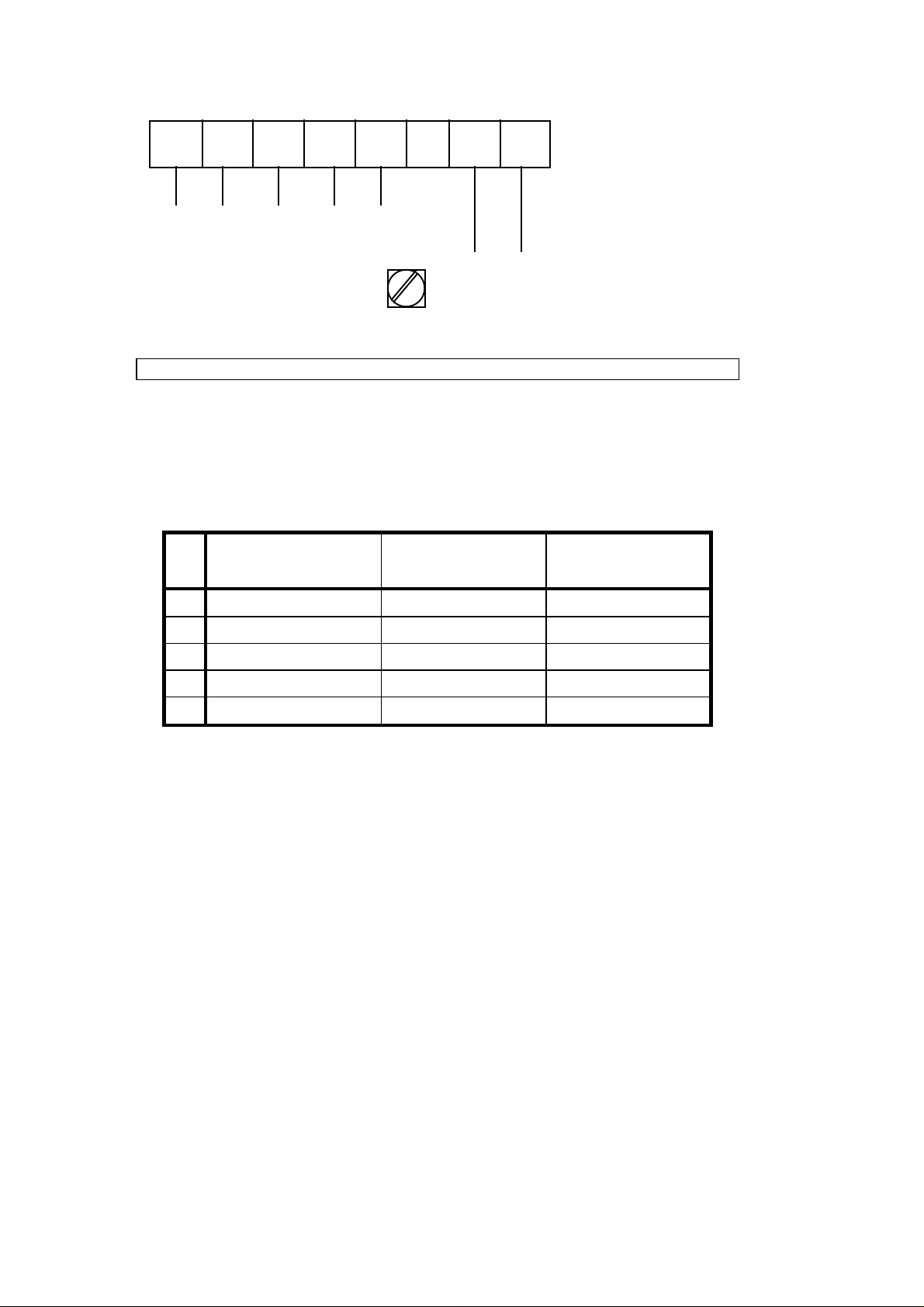

5 6 4 4.1 4.2 11 12

}

Output

Connections

see Section 3.3

Figure 22: Power and signal connections for MFC 081 K / F

3.3 Inputs and outputs

The table below shows the input/output connection for the converter. The exact configuration

depends on which optional output m odul es were fitted in the factor y. The output opt ions listed

include presently available and planned options. See Figure 22 for the arrangement of

converter connections.

specifically ordered.

Table of input/ out put connections

No. Option 1

(Current, pulse, alarm

and input )

5 Common ( - ) Common ( - ) Current output 1 (-)

6 Current output (+) Current output 1 (+) Current output 1 (+)

}

N L AC

- + DC

PE

Option 1 is nor mally supplied unless one of the other options i s

Option 2

(2 current,NGI)

*

Option 3

(2 current,GI)

**

4 Control input Control input. Current output 2 (-)

4.1 Pulse output Current output 2 (+) Current output 2 (+)

4.2 Alarm output ( active) Alarm output (passive) not used

* The inputs/outputs share a common signal ground which i s galvanically isolated from

ground (PE).

** Both current output s ar e galvani cal ly isolated from ground and each other.

For the standard converter, the pulse output is passive and requires an external voltage source

for operation. In addition, the signal may need protection from external electrical i nt erference.

The use of screened cables and a filter capacitor next to any counter is recomm ended. (Fig.

23)

It is possibl e to connect the pulse output without using an external voltage supply. However to

do this the function of the alarm output must be sacrificed. (Fig. 24) .

If the alarm out put is used to power the pulse signal, then the following settings

in the menus.

(i) Fct. 3.5.1 ALARM FUNCTI ON must be set to OFF

(ii) Fct . 3.5.2 ALARM ACTI VE LEVEL must be set to ACTIVE LOW.

18

must

be made

Page 19

ext (Max. 24 V DC

)

V

ext

R

4.2

4.1

4

6

5

Pulse Output

Common

Screened Cable

OV

Fig. 23: Connection with external voltage source

(> 800 ohm)

ext

R

4.2

4.1

4

6

5

Pulse Output

Common

Screened Cable

OV

Fig. 24: Connection using converter internal voltage source

Additional i nput /output options

ext

V

ext >

R

0.15

88888888

+

COUNTER

_

ext

C

(10 - 100nF if required)

88888888

+

COUNTER

_

ext

C

(10 - 100nF if required)

No. Option 4

(2 current,

pulse and

input)

5 Common

(-)

6 Current

output (+)

4 Current

output 2 (+)

4.1 Control

Input

4.2 Pulse

Output

Option 5

(3 current

and

pulse)

Common

(-)

Current

output 1 (+)

Current

output 2 (+)

Current

output 3

(+)

Pulse

output

Option 6

(3 current

and

input)

Common

(-)

Current

output 1 (+)

Current

output 2 (+)

Current

output 3

(+)

Control

Input

Option 7

(3 current

and

alarm

Common

(-)

Current

output 1 (+)

Current

output 2 (+)

Current

output 3

(+)

Alarm

output

(passive)

* Refer to separate RS 485 manual

** Refer to separate manual f or t hi s out put opt ion.

*

Option B

(Current

and

RS485)

Option C

(1 Current,

1 Dual

phase pulse

output and

input)

Common

(-)

Current

output 1 (+)

Common

(-)

Current

output 1 (+)

TX/RX Control

Input

TX/RX Pulse

Output A

+5V Pulse

Output B

**

19

Page 20

4. Start-up

4.1 Factory Set Parameter s

The mass flowmeter leaves the factory ready to be used. All process data has been

programmed according to the customer order. See factory program ming sheet delivered with

the flowmeter.

When no process details were supplied at the time of order, the mass flowmeter is

programmed to a standard default set of values and functions.

The current and pulse outputs treat all flows as posi t i ve. The actual flow and quantity is

thereby measured independent of the flow direction. The indicator will indicate a “ – “ or “ + “

in front of the flow rate.

These factory-set settings for current and pulse may cause an error under the following

conditions: When the pump is stopped and a reverse flow is present, which is lar ger than the

low flow cut-of f or when total i zing shoul d be indi cat ed for bot h f low directions.

To avoid these possible problems:

a) Set flow mode (Fct. 3.1. 8) t o eit her fl ow > 0 or Flow < 0, so that back flows are ignor ed.

or

b) Increase Low Flow cut-off (Fct. 3.1.7) so that small back flows are ignored.

or

c) Set the alarm output (Fct. 3. 5. 1) to DIRECTION so that external equipment can

differentiate between positive and negative flows.

4.2 Initial St art-up

• Please check that the power supply corresponds to the informati on suppl ied on the data

plate.

• Switch on t he power supply.

• On swi t ch- on, t he signal converter fi r st car r ies out a self-test. The following sequence is

displayed:

TEST

10 E PX.XX

Primary Head Software Version

STARTUP

Mass flow will be displayed following a brief settling phase for the primar y head.

A minimum warm-up time of 30 minutes is recom mended to ensure

stable measurement operation.

• For st able and accurate mass flow results the following should be checked:

a) The quality of the mechanical i nst al lation. See Sect. 2.

b) A good zero point calibration should be done. See Sect. 4.4. Further information

regarding zero point calibration can be found in Sect. 5.

20

Page 21

4.3 Installation factor

The extensive self-diagnosis functions of t he MFM 2081 and MFM 3081 also include a socalled installat ion factor. This f act or indicates whether the flow meter has been correctly

installed in the pipeline. The install at i on factor should be checked during the initial start - up

phase. The installation fact or can be checked by way of the keystroke combination described

in Section 5.

If correctly installed, the value of the installation factor when the primary head is full of water

should be as per the table below. If the figure is higher, the specified accuracy of the flow

meter cannot be guaranteed. Please check the installation again on t he basis of t he installation

inform at i on ( Sect. 2) . I f necessary adjust cl amping with the meter displ ayi ng t he installation

factor to obtain optimum performance.

Primary Type Installation

Factor

MFM 2081 K/ F < 50

MFM 2081 K/ F

< 100

Ex

MFM 3081 K/ F < 20

MFM 3081 K/ F

< 60

Ex

4.4 Zero point adjust ment

After installation adjust the zero point. To do this, the primary head must be completely filled

with the liquid pr oduct wi t hout gas or air inclusions. This is best obtained by allowing t he

liquid product t o flow through the primary head for approx. 2 minutes at a throughput rate of

greater than 50% of rated flow. Subsequently ensure that flow comes to a complete stop in the

primar y head (see fig 10, Section 2.2. 2) f or setting the zero without interruption to pr oduct

flow, use a bypass setup as shown in fig. 11 (Section 2.2. 2) .

Now initiate zero adjustment from measuring mode as described in Section 6.1.

Under certain conditions, it may not be possible to adjust the zero point:

– If the medium is in motion. Shut-off valves not tightly closed.

– If there are gaseous inclusions in the primary head. Flush t he primary head and repeat the

calibration.

– If resonant oscillations of the piping are interfering with the primary head. Check the

clamping of the instrument.

– If there are active warning(s) in the status message list. ( See section 5.6)

In such cases, the zero point adjustment procedure is automatically aborted and the following

message is displayed for a short ti me:

ZERO.ERROR

Then the converter returns to the start of the Zero Set function 1.1.1:

Further information on zero point adjustment is given in Section 5.

The CORIMASS MFM 2081 and MFM 3081 are ready to operate after zero has been adjusted.

All param eters have been factory-set in keeping with the data specified in your order. Detailed

inform at i on for further setting of the signal converter will be found in Part B of the operating

instructions.

21

Page 22

4.5 Programming the converter wit h a bar magnet

• The converter can be programm ed by means of the m agnetic sensors mounted on the

face plate without removing t he front lid (see Fig. 25).

• To do this, a bar magnet (standar d supply) is used to activate the sensors by holding the

magnet close to the glass window of the housing lid.

• These sensors then duplicate the functions of the push buttons.

MFC 081

Fig. 25: Magnetic sensor locations on MFC 081 face plate

CAUTION:

For previous software versions P2.14 to P2.18, the maximum connecting cable length between

transducer (primary head) and MFC 081 F signal converter is 5 meters (16.25 feet). Previous

software version R2.18 and this version, P2. 20, permit longer cable lengths up to 100 meters

(328 feet), unless limi t ed by CE and/or hazardous location requirements. Also note that

software versions R2.18 and P2.20 have hardware changes in the MFC 081 converter, as

compared to converters incorporati ng earlier software versions.

4.6 Installat i on of the Converter MFC 081 F

In the compact version the converter is mount ed directly onto the transducer.

In the separate version MFC 081 F (remote mounted) it has to be noticed that t he readability

of the display depends on the lighting and the viewing angle. It should, t herefore, be installed

at eye-level and in good lighting conditi ons but not exposed to direct sunlight. Refer to Section

D for dimensions of t he MFC 081 converter.

Because of the rotatable housing it is easy to connect the wires for the power supply and the

input and outputs.

The installation of t he power supply wiring must compl y wi t h local Electrical Codes.

22

Page 23

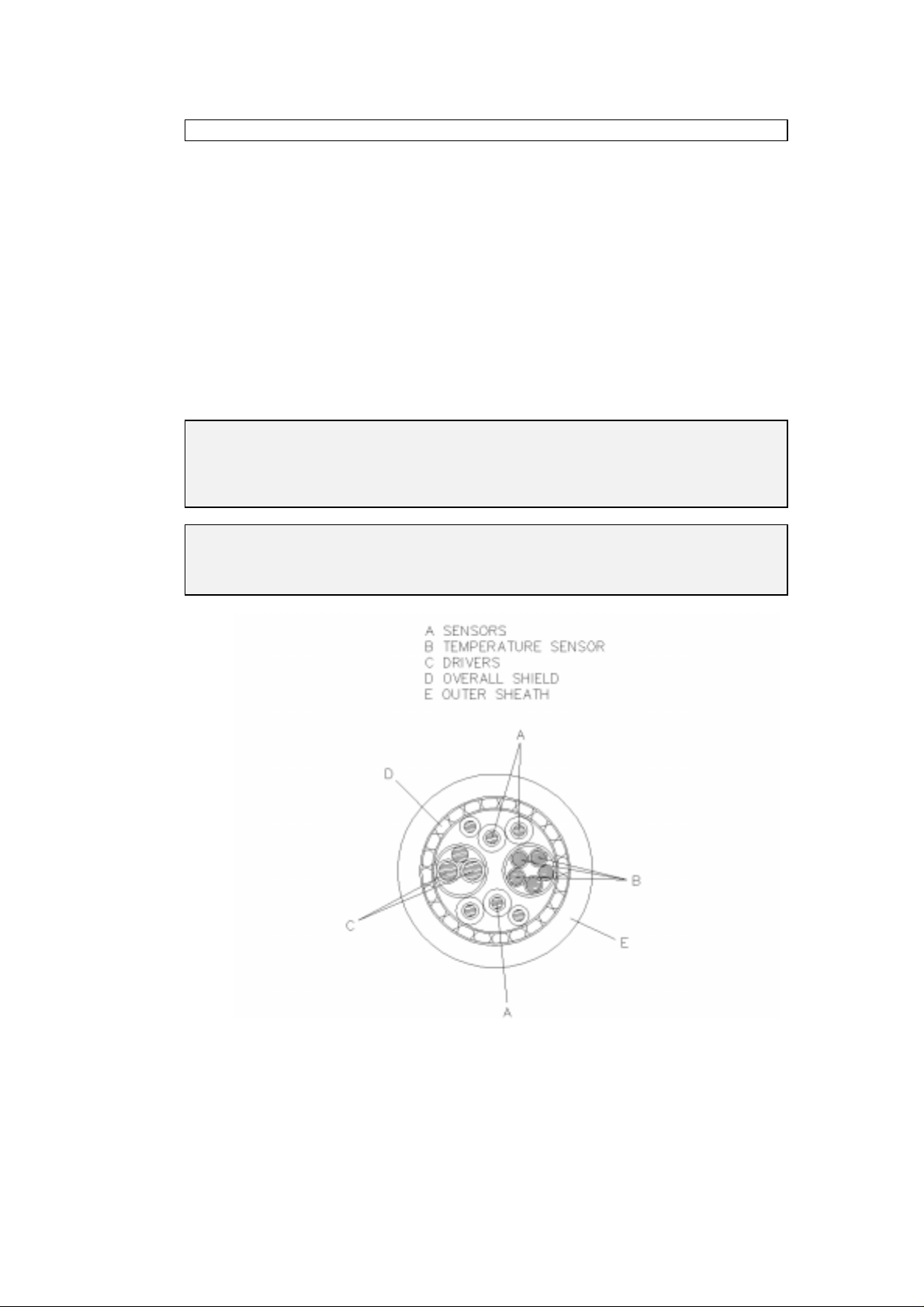

4.7 Connection of Rem ot e Mounted Version

The BTS 12L signal cable is specifically for CORIMASS remote mount ed versions and must be

used to assure proper operation. This cable must be connected as described below. The color

of the outer sheath is black for all st andar d instruments. For instruments located in hazardous

areas, the cable sheath may be blue or black depending upon the specific electrical

classificat i on and the approval agency (PTB, FM, etc.). Figure 26 shows a cross-section of the

BTS 12 L cable. Please note that not all conductors are used in the MFM 2081 / 3081 F

application. Figures 27 through 30 depict the connection of this cabl e to the transducer and

converter.

Minimum bend radius of cable should be 24 cm (10 inches). The cable must be fixed carefully

in the vicinity of t he transducer to avoi d r esonant vibr at ions of the cable. Also, all screws in

the terminal boxes and covers should be securely fastened.

Maximum cable length is dependant upon software version and may also be li mited by CE

requirements or local requirements for hazardous locat ions.

CAUTION:

When blue cable is required for hazardous duty instal l at ions, it is an essential part of t he

approval. For other cables the hazardous duty protection appr oval is not vali d.

Furthermore the ground terminals located on the transducers should be connected to the

potential com pensator f or t he hazardous area.

CAUTION:

For applicati ons where CE approval is required, the supplied signal cabl e fit tings must be

properly install ed to provi de less than 1 m illiohm contact resistance between the cable overall

shield and the fitti ng body.

Fig. 26: BTS 12 L Signal cable cross-section

23

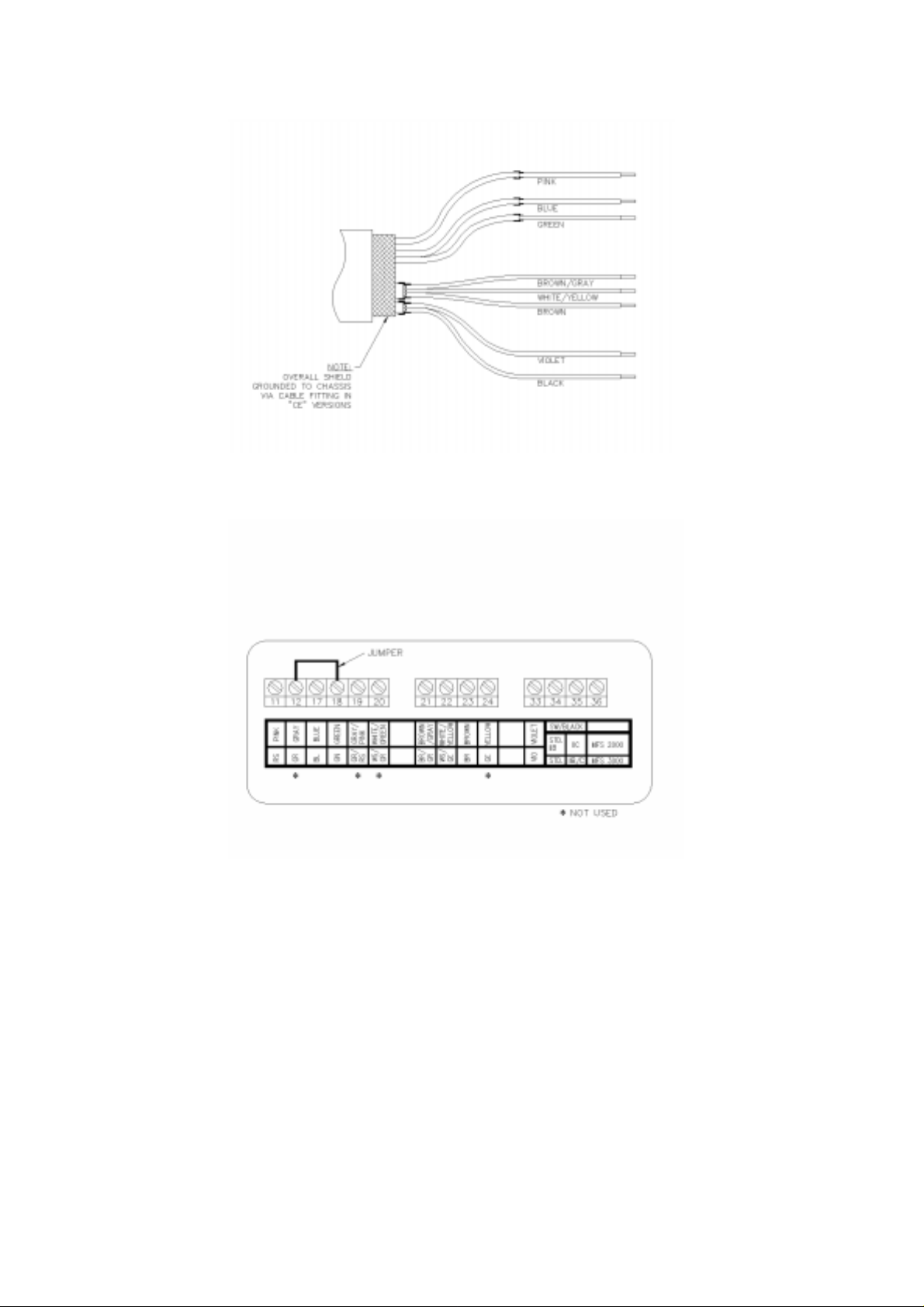

Page 24

Note: On the transducer cable end individual shields are not connected and should not

protrude from under the shrink t ubing.

Fig. 27: Signal cable terminations - transducer end

For MFM 2081 F, the black wire should be connected to terminal 34 for standard and EEx ib II

B applications, or t o 35 for EEx ib II C applicati ons

For MFM 3081 F, the black wire should be connected to terminal 34 for standard applications,

or to termi nal 35 for EEx ib II C applicat ions

Fig. 28: Transducer terminal box connections

24

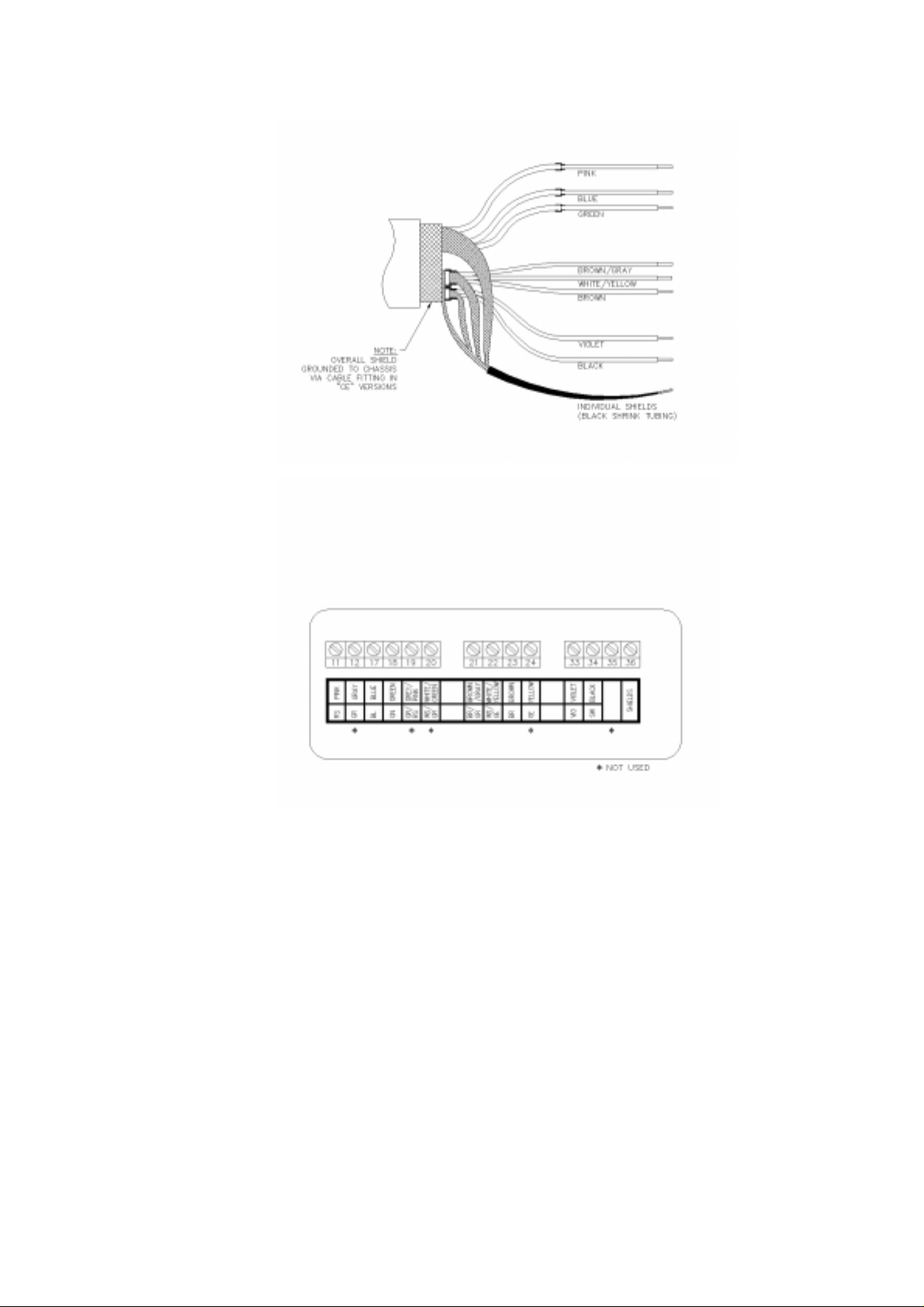

Page 25

Fig. 29: Signal cable terminations - converter end

Fig. 30: Converter terminal box connections

25

Page 26

Designation of terminals in t he Convert er Ter minal Box:

11

Sensor A +

12

not connected

17

Sensor B +

18

Sensor B –, A –

19

not connected

20

not connected

21

Temperature Sensor V –

22

Temperature Sensor I +, V +

23

Temp. I –

24

not connected

33

Exciter +

34

Exciter –

36

Chassis Signal Shield

pink

blue

green

-

brown/grey

yellow/white

brown

violet

black

black (shrink)

FITTING O VERALL SHIELD

Designation of terminals in t he Transducer Ter minal Box:

11

12

17

18

19

20

Sensor A +

Sensor A Sensor B +

Sensor B –

not connected

not connected

pink

jumper to 18

blue

green / jumper to 12

-

-

21

Temperature Sensor V –

22

Temperature Sensor I +, V +

23

Temp. I –

24

not connected

33

Exciter +

(MFS 2000 - All)

(MFS 3000 - All)

34

Exciter –

(MFS 2000 - Standard and EEx ib II B)

(MFS 3000 - Standard)

35

Exciter –

(MFS 2000 - EEx ib II C)

(MFS 3000 - EEx ib II C)

FITTING O VERALL SHIELD

brown/grey

yellow/white

brown

violet

black

black (alternate)

26

Page 27

For applicait ons where CE approval is requir ed, the BTS 12 L cable is prepared by Krohne to

the required length, ready for installation. For non-CE appli cat ions, the cable provided may be

prepared only at the converter end to permit t he customer to more easily route the cable

during instal l at ion, and tailor the length as needed. In these cases, the transducer end of the

signal cable will need to be prepared by the customer using the parts in the kit provided with

the cable. The kit contains the following items:

Connector Sleeves:

(2) - 1 mm

(6) - 0.5 mm

2

for violet and black wir e ends

2

for remaining wire ends

Shrink Tubes:

(1) - 35 m m long, φ12 mm (A)

(2) - 15 m m long, φ 6 mm (B)

(3) - 15 m m long, φ 3 mm (C)

Connector sleeves are to be crimped on to the wire ends indicated and shrink tubes A, B, and

C are to be installed as shown in Figure 31. Unused conductors should be cut back cleanly to

avoid interference with the active conductors and shields.

Figure 31: Stripping lengths and shrink tube locations for BTS 12 L signal cable transducer end

27

Page 28

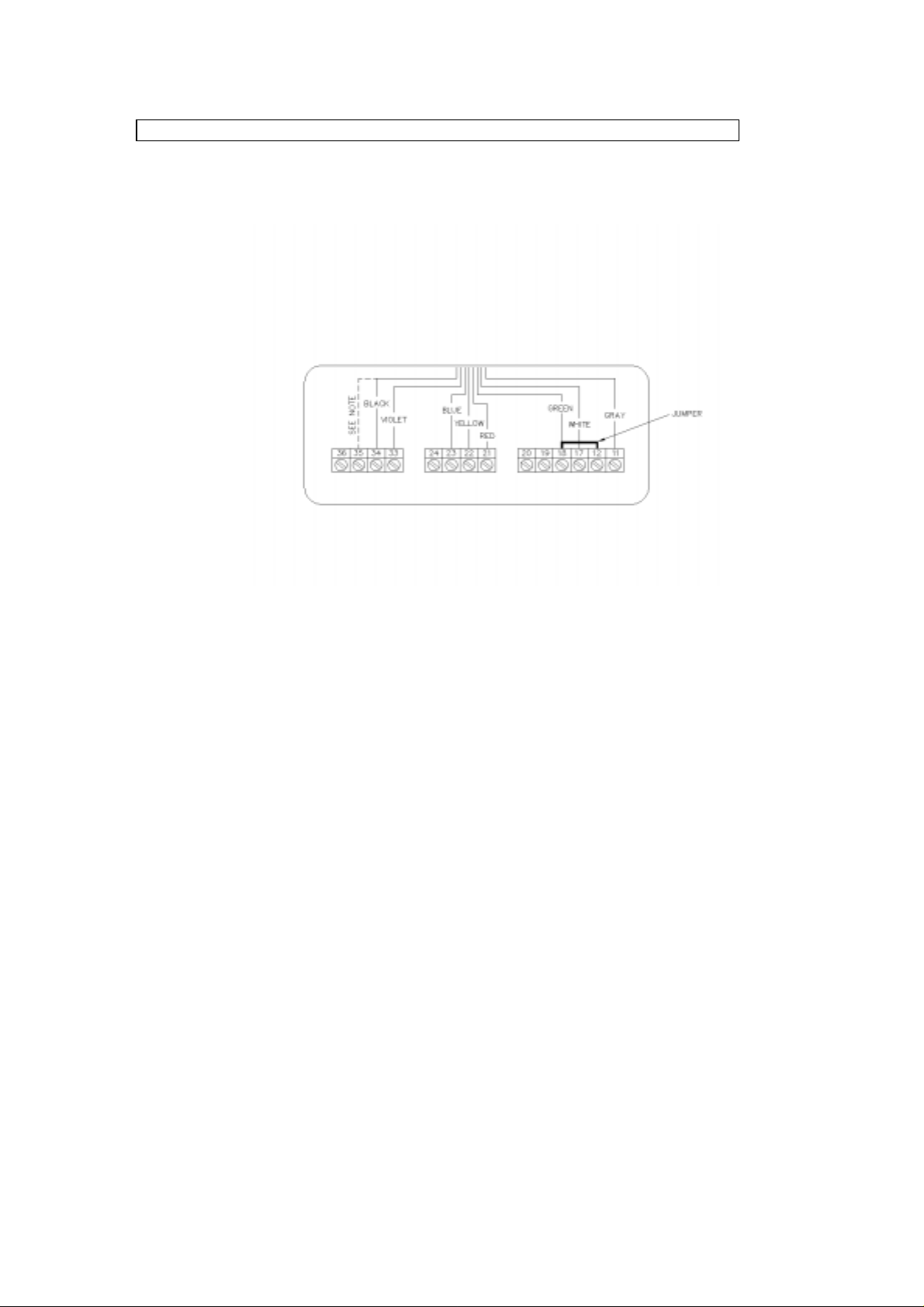

4.8 Connection diagram of compact versi on

The connection converter - transducer of the compact version will be carried out by the

manufacturer. A reconnection is onl y r equired in the case of a defective cable between

terminals and electronics module. You can see the connection of the converter cable in the

terminal box at Fi gur e 32.

Note:

MFM 2081 K

Black to 34 for Standard and EEx ib II B

Black to 35 for EEx ib II C

MFM 3081 K

Black to 34 for Standard

Black to 35 for EEx ib II C

Fig. 32: Connection compact version

28

Page 29

Part B MFC 081 Signal Convert er - Software Version P2.20

5. Operation of t he Si gnal conver t er

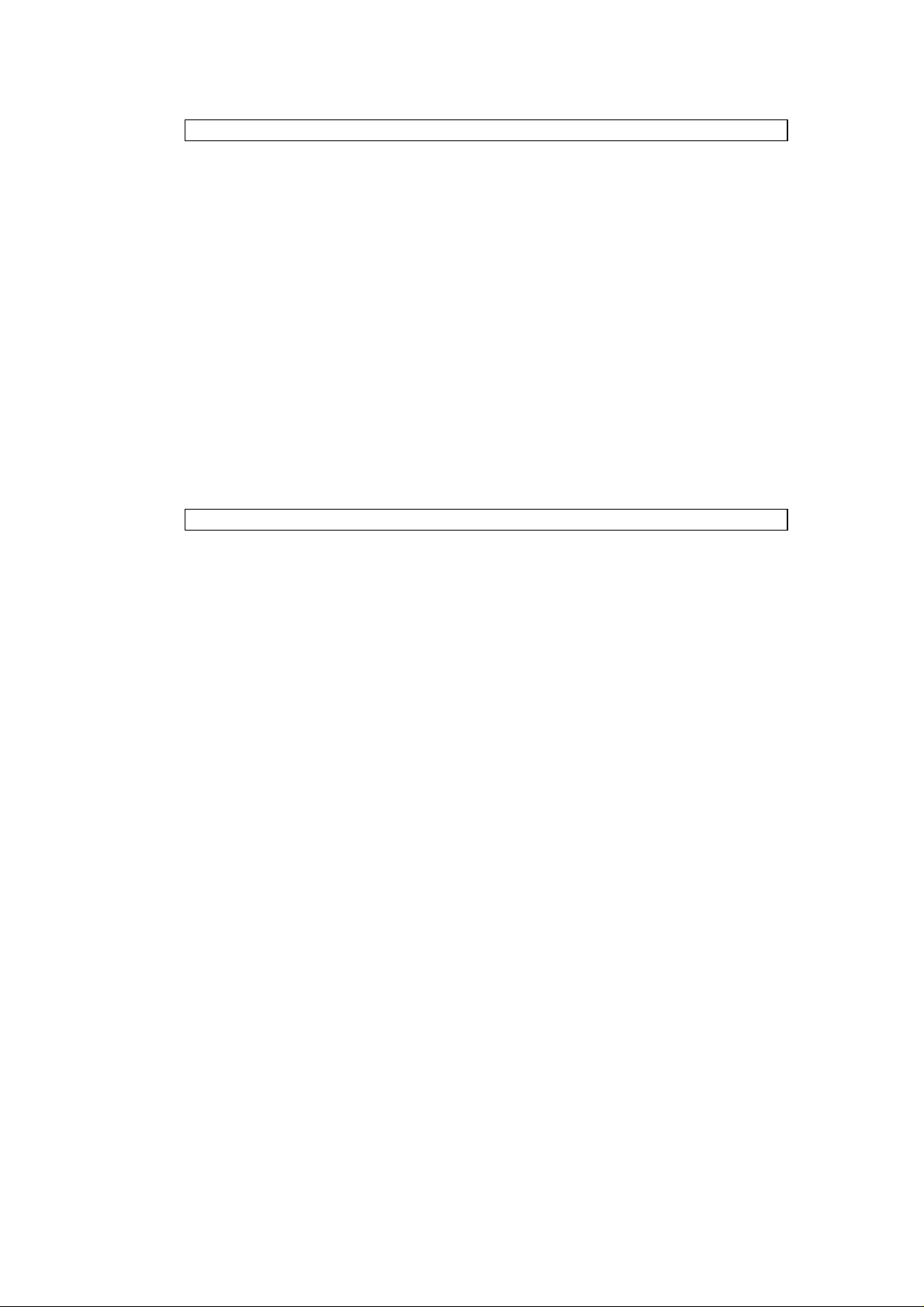

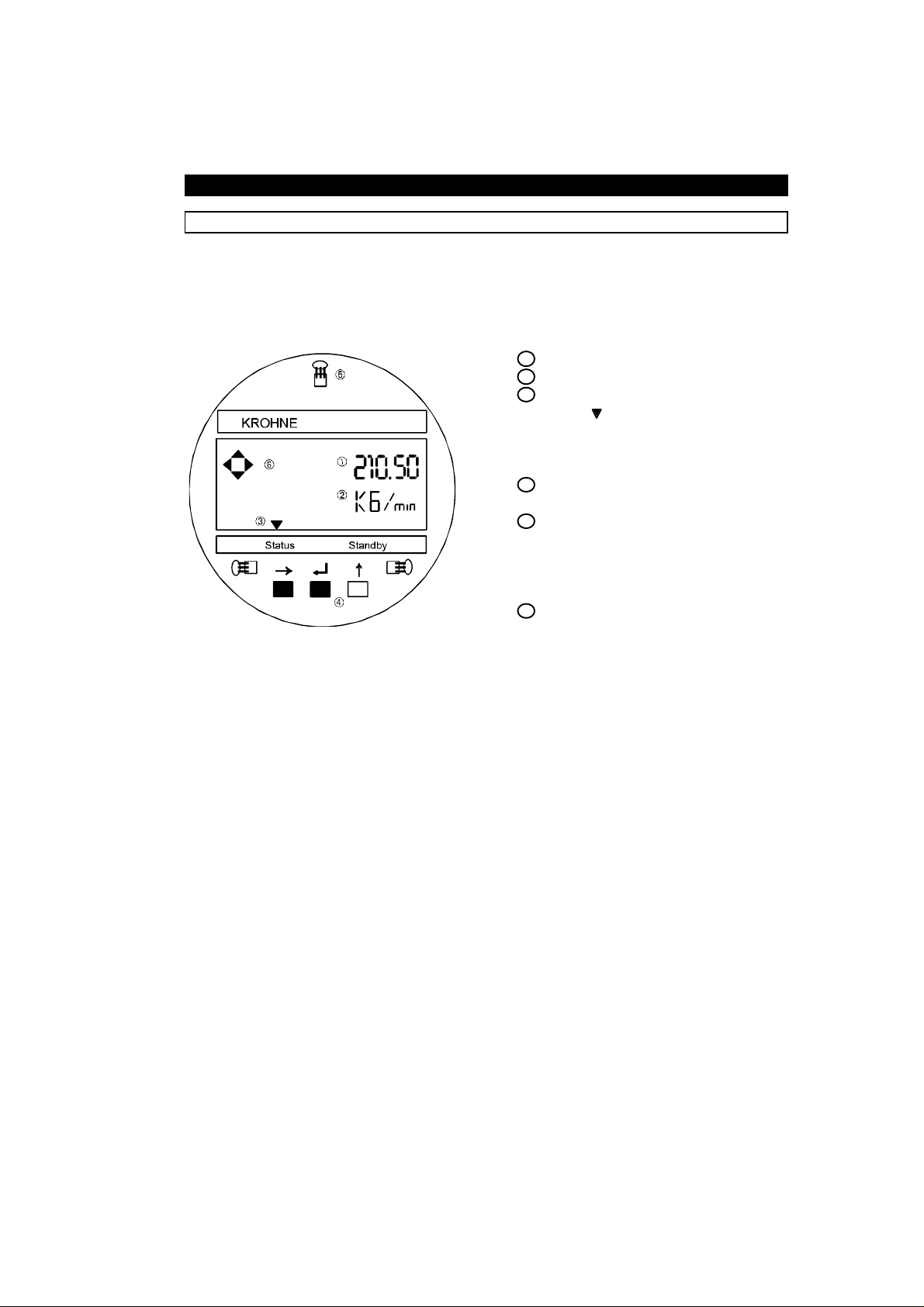

5.1 Operating and check el ements

The o perating el ements a re ac cessible af ter rem ovi ng the cover o f the electroni cs section

using the special wrench. The converter is also programm abl e with magnetic sensors and a

bar magnet without r em ovi ng t he covers of the electronic housing.

Caution: Do not damage the screw thread and the gasket, never allow dirt to accumulate,

and make sure they are well greased at all times.

1 Display 1st (top) line.

2 Display 2nd (middle) line.

3 Display 3rd (bottom) line,

MFC 081

arrows ( ) to identify the

state of the signal converter:

-

4 Keys for operator control of

the signal converter.

5 Magnetic sensors to set the

converter by means of a

handheld bar magnet without

opening the housing. Function

of sensors same as keys 4 .

6 Compass field, signals

actuation of a key.

message indicator

Status

Standby

mode.

The operator control concept consists of three levels (horizontal). See next page.

Setting level: This level is divided into three main menus:

Fct. 1.0 OPERATION: This menu contains only the m ost

import ant par ameters and functions of Menu 3 (instal l ) t o allow

rapid changes to be made during the measurement m ode.

Fct. 2.0 TEST: Test menu for checking the signal converter

(displays, outputs, measuring range), and the primary (transducer)

operation.

Fct. 3.0 INSTALL: All f l ow measurement- and flowmeter-specific

parameters and functions can be set in this menu.

Paramete r check l evel: Fct. 4.0 PARAM.ERROR: This level is not selectable.

After exiting from the “Setting l evel”, the signal converter checks

new data for plausibility. If an error is detected, the signal

converter indicates PARAM.ERROR in Fct. 4.0. In this menu, all

functions can be scanned and those changed that are not

“plausible”.

Reset/acknowledge This menu has two tasks and is selected via Entry Code 2

level (Quit): ( ↵ ↑ → )

1) Resetting of totalizer, provided that resetting is enabled under

Fct. 3.8. 5 ENABL. RESET, input YES.

2) Status message and acknowledgement (Quit) m essages that

have occurred since the last acknowledgement are indicated

in a list. After elimination of the cause(s) and

acknowledgement, these messages are deleted from the list.

29

Page 30

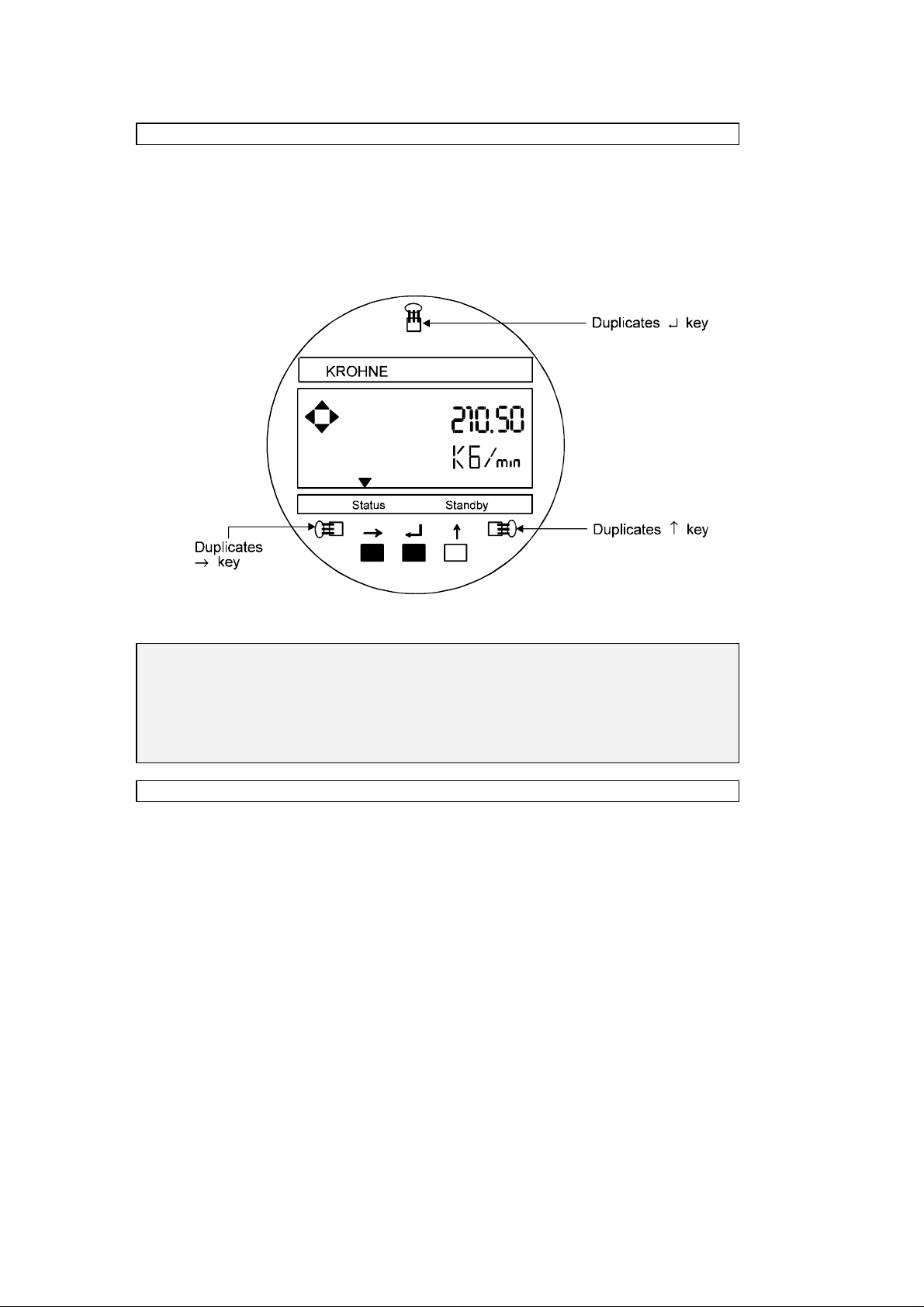

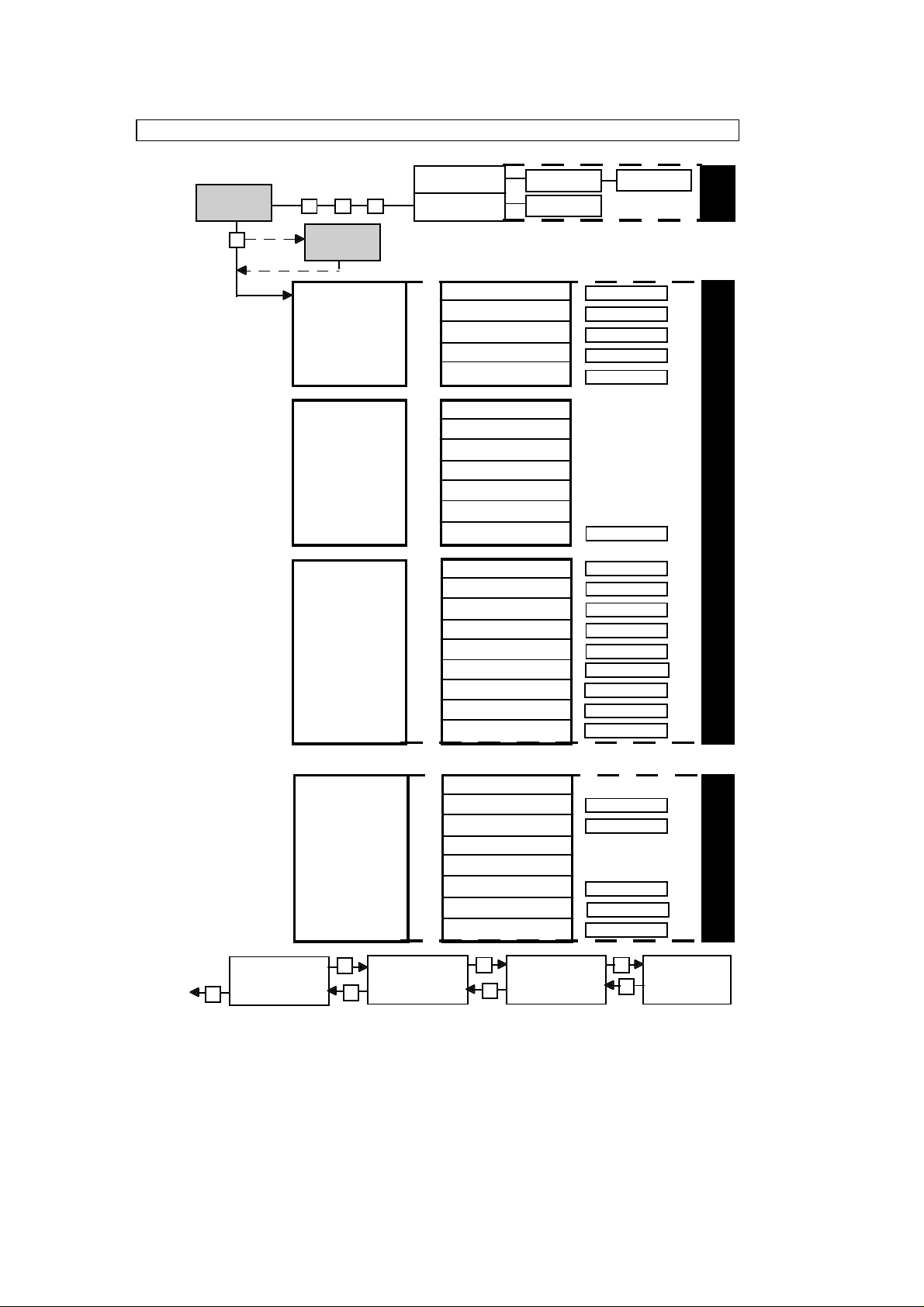

5.2 Krohne Operating Concept

↵

→

↵↵↵

↵

→

→

↵

↵

Measur ing Mode

210.50

kg/min

Split function s

of keys between

main and

submen us .

The blink ing

part of the

display (cursor)

that may be

changed is

in

bold

When in

RESET/QUIT

and progr amming

modes, outputs

remain active,

measuring

normally, except

in 2.0 TEST menu

when output is

being tes ted, and

when zeroing

flowm eter - 3.1 .1

and 1.1.1 MEAS.VALUE

Code 2

Code 1

- - - - - - -

.0 OPERATION

1

.0 TEST

2

.0 INSTALL

3

STATUS.LIST.

RESET TOTAL

When th is display appe ars, press entry code 1.

See Fct. 3.8.2 and 3.8.3. Factory setting:

1.1.0 BASIS.PARAM.

1.2.0 DISPLAY

1.3.0 CURRENT OUT I

1.4.0 PULS.OUTP.P

1.5.0 ALARM OUT A

2.1 TEST DISP

2.2 TEST I

2.3 TEST P

2.4 TEST A

2.5 TEST INP.E

2.6 TEST TEMP

2.7.0 TEST.PRIMRY

3.1.0 BASIS.PARAM

3.2.0 DISPLAY

3.3.0 CURRENT.OUT I

3.4.0 PULS.OUTP.P

3.5.0 ALARM.OUT.A

3.6.0 CTRL. INP.E

3.7.0 SYS.CTRL.S

3.8.0 USER DATA

3.9.0 TUBE PARAMS

Error List

RESET YES

RESET NO

1.1.1 - 1.1.

1.2.1 - 1.2.

1.3.1 - 1.3.

1.4.1 - 1.4.

1.5.1 - 1.5.

2.7.1 - 2.7.

3.1.1 - 3.1.

3.2.1 - 3.2.

3.3.1 - 3.3.

3.4.1 - 3.4.

3.5.1 - 3.5.

3.6.1 - 3.6.

3.7.1 - 3.7.

3.8.1 - 3.8.

3.9.1 - 3.9.

QUIT YES

QUIT NO

↑↑↑

4

7

3

3

3

4

8

8

4

4

4

2

4

8

11

RESET /

QUIT

PROGRAMMING LEVEL

Param. Check

and retu r n t o

measurement

mode

30

.0 PARAM.ERROR

4

Main Menu

Select with Key

↑

Submenu

Select with Key

↑

4.1 not used

4.2.0 CURRENT.OUT. I

4.3.0 ZERO SET

4.4 not used

4.5 not used

4.6.0 PULS.OUTP.P

4.7.0 PROC.ALARM

4.8.0 SYSTEM.CTRL

Function

Select with Key

↑

4.2.1 - 4.2.

4.3.1 - 4.3.

4.6.1 - 4.6.

4.7.1 - 4.7.

4.8.1 - 4.8.

2

2

2

2

2

Data Input

with Keys

LEVEL

PARAMETER CHECK

↑

Page 31

5.3 Key functions

Before pressing any keys on the MFC 081 converter, it should be noted that outputs rem ain in

the Measurement Mode (outputs are actively measuring) even when the converter is placed in

the Programm ing Mode with the following exceptions:

− when in the TEST menu (2.0) and act ual ly testing an output.

− after having m odi fied and accepted a parameter which will cause a given output to change,

eg. changing the range.

− when zeroing (1.1.1 and 3. 1.1) using the MEASURE. VALUE parameter at which time t he

flow must be shut off. The output associated with the flow rate defaults to its minimum

range value (0 or 4 mA, whichever is programmed) during zeroing. When using SET

VALUE, the output remains active, changing onl y by t he SET VALUE once it is accepted.

Function of the keys

Cursor

The location of the cursor on the display is i ndicated by flashing characters. This

could be a single digit when entering number; num eric si gn ( + or - ) ; measurement

units (g,kg, t etc.) ; or any ot her text field. Thr oughout this manual the location of the

cursor, in programming examples, will be indicated by parentheses ( ) around the

flashing characters.

↑ Select or Up Key. This key changes the field/digit under the cursor.

- Digit: Increase value by 1 for each key press. (0 follows 9).

- Dec. pt. Move decimal point. 0000( . ) 0000 changes to 00000(.) 000

- Menu Increase menu number by 1. i.e. Fct. 1.(1).0 changes to

Fct. 1.(2).0

When the menu number reaches its maximum the next ↑ changes

the number to 1. i.e. Fct 1.(5).0 changes to Fct 1.(1).0

- Text Change text field. i.e. “YES” to “NO” or “g” to “kg” to “ t” etc.

- Sign Toggle “+” to “-”

→

Cursor or Right Key. This key moves the cursor onto the next field to be edited.

(usually the next on the right).

- Number Move cursor from 12(3).50 to 123( . ) 50 t o 123. ( 5) 0

- Text Move to next field. i.e. (kg)/min to kg/(min)

- Menu Move to next menu column: i.e. from Fct 1.(2).0 to Fct. 1.2.(1)

or

if the cursor is already in the rightmost column: invoke that menu

function. i.e. from Fct. 1.2.(1) press → to edit MASS FLO W

format.

↵ Accept or Enter Key.

-Within a

Accept changes (if any) and exit the function.

function

-Menu Move cursor to the next column on the left.

i.e. from Fct. 1.2.(1) back to Fct. 1.(2).0

If the cursor is already in the leftmost column then ↵ exits the

menus. See next box: “To terminate” .

Note:

If numerical values are set that are outside the permissibl e input r ange, the displ ay

shows the min. or max. . acceptable value. After pressing the ↵ the number may be

corrected.

31

Page 32

5.3.1 How to enter programming mode

To start:

Display Comments

→ Press Fct. 1.0

If this appears, see previous box: “Function of the keys ” .

Operation

or

CodE 1

---------

If this appears on the display, set the 9-keystroke Entry

CodE 1 .

Factory setting: → → → ↵ ↵ ↵ ↑ ↑ ↑

1st- 8thplace

(key)

9th place

(key)

CodE 1

∗∗∗∗∗∗∗∗-

Fct. 1.0

Operation

CodE 1

(9 alpha

Each keystroke acknowledged by " ∗ " in display.

If this appears, see box: “Function of the keys ” on previous

page.

A wrong Entry CodE 1 was keyed in. Press any key and set

the correct 9-keystroke

characters)

5.3.2 How to terminate Programming mode

To termi nat e :

Press ↵ 1-3

times

↵ + 12.345

Fct (1).0

OPERATOR

kg/min

Press ↵ 1-3 times until t he cursor i s under the extreme

left menu column. (Fct. 1.0 , 2. 0 or 3. 0)

If no changes have been made to the system’s configuration return directly to the measurement mode.

or

(ACCEPT YES) Changes have been detected. Press ↵ to accept these

changes.

or

↑

(ACCEPT NO)

Press ↵ to reject changes and return directly to

measurement mode.

or

↑

(GO BACK)

Press ↵ to return to the menus, Fct. 1.(0) to make

further changes

↵ PARAM.CHECK Assuming ACCEPT YES was select ed,

the system now checks the new setting for errors.

After 1-2 sec. + 12.345

No errors detected. Return to measurement mode.

kg/min

or

Fct. (4).0

PARAM.ERROR

Errors were detected. The sub-menus of 4.0 will guide

the operator to those functions where problems have

been identified.

32

Page 33

Examples

The cursor (flashing par t of display) has a grey background in the foll owi ng exampl es:

To start programming

Measurement mode Programming mode

13.571

m3 / h r OPERAT I ON

PLEASE NOTE: When “yes” is set under Fct. 3.8.2 ENTRY CODE, the following will

appear in the display after pressing the → key:

CodE 1 - - - - - - - - -.

The 9-stroke entry code must now be entered.

Factory setting: → → → ↵ ↵ ↵ ↑ ↑ ↑.

Each keystroke is acknowledged by an “ ∗ “ in the display.

To termi nat e pr ogr amming

Press ↵ key repeatedly until one of the following m enus are displayed:

Fct. 1.0 OPERATION, Fct. 2.0 TEST or Fct. 3.0 I NSTALL

Fct. 3. 0

INSTALL. A C C E P T. Y E S

→

Press ↵key

↵

To accept the new paramet er s

Press ↵ to confirm.

“PARAM.CHECK” will appear in the display.

Fct. 1. 0

The measuring mode will continue after a few

seconds with the new parameters, when no

errors are detected.

When an error is detected the display will

indicate “Fct. 4.0 PARAM.ERROR”. The

error parameters can be called up in this

menu and corrected.

New parameters not t o be accepted

When the new parameters are not to be

accepted, the following keystrokes should be

executed: Press ↑ key. The display will

show “ACCEPT NO”. When the ↵ key is

then pressed, the instrument will return to the

measurement mode using the old

parameters.

33

Page 34

To change numeric val ues

Increase numeric value

210. 50

kg/mi n kg/mi n

To move the cursor (flashing digi t )

↑

210.60

To move to the right

210. 60

kg/mi n kg/mi n

To move the decimal point

→

210.6 0

To move to the right

21.060

kg/mi n kg/mi n

To change the text

M A S S F L O W D E N S I T Y

To change the units

↑

Select next text

↑

210. 60

Numeric values automat ically converted

Select new unit

210. 60

g/min k g/min

↑

Alternative time unit

210. 60

k g/min kg/m i n

To change from numeric values back to text

→

Alternative engineering units

210. 60

kg/mi n k g/min

Return to function display

10.3

Sec T IMECONST.

→

↵

0.21060

210.60

210.60

F c t. 1. 1. 3

34

Page 35

5.4 Table of programmable f unct ions

Fct. No. Text Description and settings

1.0 OPERATION Main menu 1. 0 Operation

1.1.0 BASIS.PARAM Submenu 1.1.0 Base data

1.1.1 ZERO SET Zero adjustm ent . See Fct. 3.1.1

1.1.2 L.F. CUTOFF Low flow cutoff. See Fct. 3.1.2

1.1.3 TIME CONST. Signal converter time const ant . See Fct. 3.1.3

1.1.4 STANDBY Switching between measur ing operation

and standby. See Fct. 3.1.4

1.2.0 DISPLAY Submenu 1.2.0 Displ a y

1.2.1 CYCL.DISP Switching between steady display and cyclic displ ay

1.2.2 STATUS MSG Select s which st at us messages should be displayed

1.2.3 MASS FLOW Unit for mass flow. See Fct. 3.2.3

1.2.4 MASS TOTAL Unit for mass total. See Fct. 3.2.4

1.2.5 DENSITY Unit for density. see Fct. 3.2.5

1.2.6 TEMPERAT Uni t f or t emperature. see Fct. 3.2.6

1.2.7 VOLUME.FLOW Unit for volume flow. See Fct. 3.2.7

1.2.8 VOLUME.TOTAL Unit for volume total. See Fct. 3.2.8

1.2.9 CONC.MEAS Parameters for concentration m easur ement.

See separate concentration measurement instruction

manual

1.2.10 CONC.MEAS See 1.2.9

1.2.11 CONC.MEAS See 1.2.9

1.3.0 CUR.OUTP. I Submenu 1.3. 0 Cur r ent output I.

1.3.1 FUNCTION I Function current out put I. see Fct. 3.3.1

1.3.2 MIN.VALUE* Mini mum range f or cur rent output I see Fct. 3.3.3

1.3.3 MAX.VALUE

*

Maximum range for cur r ent output I see Fct. 3.3.4

1.4.0 PULS.OUTP. P Submenu 1. 4. 0 Pul se, frequency output P. see Fct. 3.4.0

1.4.1 FUNCTION P Select. Parameter to be totalized

1.4.2 PULSE/MASS * Select. Pulse per unit

1.4.3 PULSE W IDTH * Select pulse width in milliseconds

1.5.0 ALARM.OUT.A Submenu 1.5.0 Process alarm output A. see Fct. 3.5.0

1.5.1 FUNCTION A Select alarm function. See Fct. 3.5.1

1.5.2 ACTIV.LEVEL Select. act i ve hi gh or low. See Fct. 3.5.2

*

Exact display de pends on selected function. See sub-menu 3.3.0

35

Page 36

Fct. No. Text Descri pt i on and settings

2.0 TEST Main Menu 2.0. Test functions

2.1 TEST DISP. Carry out display test.

Start with the key → (Duration of test approx. 30 sec.).

Stop test at any time with the ↵ key.

2.2 TEST I Test current out put I

* SURE (NO). Use the ↑ key to select YES, then press ↵.

* 0 mA will be output from the converter. Use the ↑ key

to select test currents from the list below.

0 mA, 2 m A, 4 mA, 10 mA, 16mA, 20 mA, 22 mA.

To exit test mode, press the ↵ key at any time.

2.3 TEST P Test frequency output P

* SURE (NO). Use the ↑ key to select YES ,then

press ↵ key.

2.3.1 FREQUENCY * LEVEL LOW 0 volt DC level will be output from the

converter.

Use the ↑ key to select test signals from t he list below.

* LEVEL HIGH ( + V v o lts dc)

* 1 Hz * 100 Hz

* 10 Hz *1000 Hz

2.3.2 TEST PULSE * Test Pulse

Use the ↑ key to select desired pulse width from the list

below:

∗ 0.4 mSec ∗ 100.0 mSec

∗ 1.0 mSec ∗ 500.0 mSec

∗ 10.0 mSec

Then press ↵. The system now sends pulses of the

required width. To stop the test press ↵ twice.

2.4 TEST A Test alarm out put

* SURE (NO). Use the ↑ key to select YES, then

press ↵

* LEVEL LOW. 0 Volts is out pu t on the alarm terminal.

Press the ↑ key to switch output to:

* LEVEL HIGH . +2 4V d c is output o n the alarm termi n a l.

To exit test mode, press the ↵ key at any time.

2.5 TEST INP.E Test control input

The actual input level, HI or LO, and t he selected

functions are displayed see Fct. 3.6.1

End test by pressing the ↵ key.

2.6 TEST TEMP. Test t emperature

Start with the → key. The temperature in °C is displayed.

Use the ↑ key to display the temperature in °F.

End the test by pressing

↵ key

2.7.0 TEST.PRIMRY. Sub menu 2.7.0 Test primar y head values.

2.7.1 SENSOR A Monitor t he amplitudes of sensor A and B

2.7.2 SENSOR B as percentage of their max. value. ( 80% is i deal )

Start test with the → key. End the test with the ↵ key.

2.7.3 FREQUENCY Monitor the primary head frequency.

Start test with the → key. End the test with the ↵ key.

2.7.4 INSTAL.FACT. Monit or t he pr i mary head's drive level.

Start test with the → key. End test with the ↵ key.

36

Page 37

Fct. No. Text Descri pt i on and settings

3.0 INSTALL. Main menu 3.0 Installation

3.1.0 BASIS.PARAM Submenu 3.1.0 Base data

3.1.1 ZERO SET Zero adjustm ent .

Use the ↑ key to select between MEASURE.VAL.

and SET VALUE then press the ↵ key.

* MEAS.VALUE (ensure "ZERO" flow in the pip eline)

1) Select: CALIB.YES or NO

2) If YES: Cal ibration (approx. 20 sec. dur at ion)

Display: Actual flow rate as percent of the

maximum rated flow for t he pri mary head. (Q

3) Select: ACCEPT YES or NO

* SET.VALUE Direct input of a zero flow offset.

Units: As selected by Fct. 1.2.1 or 3.2.1

3.1.2 L.F. CUTOFF Low flow cutoff

Value: 0 to 10 percent of nominal f low

3.1.3 TIME CONST. Time constant for output of measured values

Range 0.5 ... 20 sec. (Option: 0,2 ... 20 sec.)

3.1.4 STANDBY Use the key ↑ to switch between three modes

of operation, then press ↵:

* MEASURE

* STANDBY (tube vibrating, Mass Flow set to zero)

* STOP (tube drive stopped)

Note: It is not possible to switch directly

from STOP to STANDBY.

3.1.5 PRIMRY.TYPE Type of the pr i mary head **

Using the ↑ key select the primary head type

that is connected to the converter:

* 1.5 E * 10 P * 800 P

* 10 E * 60 P * 1500 P

* 30 E * 300 P

3.1.6 CF5 Primary head constant . * *

Displays the primar y head constant as st amped

on the primary head’s data plat e.

3.1.7 FLOW DIR. Define direction of flow.

Select either FORWARD or BACKWARD

3.1.8 FLOW MODE Define whether bi-directional or uni -directional

flow is expected. Select either:

* FLOW > 0 ( I gnor e negative flows)

* FLOW < 0 ( I gnor e positive flows)

* FLOW +/ - ( Al low positive and negative flows)

100%

)

** These menus are protected by the Code 4 password, see Fct. 3.8.8

37

Page 38

Fct. No. Text Descri pt i on and settings

3.2.0 DISPLAY Submenu 3.2.0 DISPLAY

3.2.1 CYCL. DISP. Cyclic display required?

Setting NO or YES. If YES is selected then in

measurement mode the display will switch from Mass

Flow to Density to Total t o Tem peratur e every 4 seconds.

3.2.2 STATUS MSG. Which status messages to be displayed ?

* NO MESSAGE (= no warning messages in ma in

display, warning syst em i gnor es status of out puts)

* PRIMRY.HEAD (= light warning messages in the

main display, warning system ignor es status of

outputs)

* OUTPUT (= output saturati on/ alarm stat us

messages in the main display)

* ALL MSG. (= all warning messages in the main

display. System responds to output st atus)

3.2.3 MASS FLOW Units and format for m ass f low display

* g, kg, t, oz, lb per s, min, h, d

* Number of digits af t er the decimal poi nt selectable.

3.2.4 MASS TOTAL Units and format for totaliser

* g, kg, t, oz, lb

* Number of digits af t er the decimal poi nt selectable.

3.2.5 DENSITY Unit s and f or mat for density*

* g, kg, t, per cm3, dm3, litre, m3 or

oz, lb per in3 ,ft3 , USgal, gallon or SG ( Specific

Gravity relative to water at 20°C)

* Number of digits af t er the decimal poi nt selectable.

3.2.6 TEMPERAT. Units for temperature

*°C or °F

* Format fi xed at 1 decimal place

3.2.7 VOLUME.FLOW Units and for mat for volume flow

* Select OFF (no volume flow displ ay) or

*cm3, dm3, litre, m3 , in3 ,ft3 , USgal, or gall on

per

* s, min, hr , day

* Number of digits af t er the decimal point selectable.

3.2.8 VOL.TOTAL Units and format for t ot alizer

cm3, dm3, liter, m3, inch3, ft3, US gal, gallon.

3.2.9 to 3.2.11 Concentration menu when installed.

Please refer to separate Concentration instruction manual

* See Section 6.13 for special density functions: Specific Gravity, Referred Density (option) ,

and Fixed Density (option).

38

Page 39

Fct. No. Text Descri pt i on and settings

}

3.3.0 CUR.OUTP. I Submenu Curr ent output I

For systems with 2 or more current outputs see Sect. 5.7

3.3.1 FUNCTION I Function current out put I

* OFF (O/P current = 0 mA)

* MASS FLOW ( Mass f low in range MIN [Fct. 3. 3.3] to

MAX [Fct. 3.3.4] output as cur rent in range [Fct 3.3.2]

0/4-20mA)

* DENSITY (Density in range MIN [Fct. 3.3.3] t o MAX

[Fct. 3.3.4] out put as current in range [Fct 3.3.2]

0/4-20 mA)

* TEMPERAT. (Temperature in range MIN [Fct. 3.3.3] to

MAX [Fct. 3.3.4] output as cur rent in range [Fct 3.3.2]

0/4-20 mA)

* VOLUME.FLOW (Volume flow in range MIN [Fct. 3. 3. 3]

to MAX [Fct. 3.3.4] out put as current in range

[Fct 3.3.2] 0/ 4- 20 mA)

Solute flow Concentration measurement

Conc. by mass functions avail able if installed

Conc. by volume (see sep. instruction manual).

* DIRECTION (Negative flow gives current of 0/4 m A,

positive flow gives current of 20 mA)

3.3.2 RANGE I Range for curr ent output I: Select from the following

by pressing ↑ key and then ↵ key

* 0-20 mA

* 4-20 mA

* 0-20/22 mA (O / P = 22 mA when error detected)

* 2/4-20 mA (O/P = 2 mA when error detected)

* 3.5/4-20 mA (O/P = 3.5 mA when error detected)

3.3.3 MIN.VALUE Value of measured quantity as set by Fct. 3.3.1

or MIN. FLOW, t hat cor r esponds to the m inimum output current

or MIN. DENSITY (0 or 4 mA as set by 3.3.2)

or MIN. TEMP.

or MIN V.FLOW

or CONC.OPTI O NS Menu not available if Function 3.3.1 is set to OFF or

DIRECTION

3.3.4 MAX.VALUE Value of measur e d quant i ty as set by Fct. 3.3.1

or MAX. FLOW, t hat corresponds to an output current of 20 mA

or MAX. DENSI T Y,

or MAX TEMP

or MAX V.FL OW

or CO NC.O PTIONS Menu not available if Function 3.3. 1 is set to OFF or

DIRECTION

39

Page 40

Fct. No. Text Descri pt i on and settings

}

3.4.0 PULS.OUTP. P Submenu 3.4.0 Frequency output P

3.4.1 FUNCTION P Function frequency output P

* OFF (Output = 0V DC)

* MASS FLOW ( F r equency output 0 to MAX Freq. Hz =

Mass Flow in range: MIN. FLOW to MAX FLOW as set

in Fct. 3.4. 3 and 3. 4. 4)

* MASS TOTAL(1 pulse = fi xed m as s as set in Fct 3.4. 2)

* DENSITY (Frequency output 0 to MAX Freq. Hz =

Density in range: MIN.DENSITY to MAX.DENSITY as

set in Fct. 3.4.3 and 3. 4. 4)

* TEMPERAT. (Frequency output 0 to MAX Freq. Hz =

Temperature in range: MIN. TEMP to MAX. TEMP as

set in Fct. 3.4.3 and 3. 4. 4)

* VOLUME.FLOW(Fr equency output 0 to MAX Freq. Hz

= Volume flow i n r ange: MIN. V. FLO W to MAX.

V.FLOW as set i n Fct . 3.4.3 and Fct. 3.4.4)

* VOL.TOTAL(1 pulse = fixed volume as set in Fct 3.4.2)

Solute flow

Solute total Concentration parameters if

Conc. by mass option installed. See separate

Conc. by volume instructi on manual.

* DIRECTION (Negative flow gives output of 0 volts DC,

Positive flow gives output of +V volt s DC)

3.4.2 PULSE/MASS Mass per pulse value for function TOTAL MASS

or PULSE/VOL. Volum e per pul se value for functi on VO L. TOTAL

or PULSE/TIME Maxim um frequency value for functions MASS FLO W,

DENSITY, TEMPERATUR and VOLUME.FLOW or

CONC.OPTIONS. Not accessible for functions OFF and

DIRECTION.

3.4.3 MIN.VALUE Value of measured quantity that cor r esponds t o

or MIN. FLO W, 0 Hz output

or MI N. DENSITY,

or MIN. TEMP.

or MIN. V.FLOW

or CONC.OPTIONS

or PULSE.WI DTH For function s MASS TO TAL, VOL.TOTAL OR

SOL.TOTAL. Not accessible for f unct i ons OFF and

DIRECTIONS

3.4.4 Full Scale Value of measured quanti ty that corresponds to

or MAX. FL OW, Max. Fr equency

or MAX. DENSITY

or MAX TEMP.

or MAX V.FL OW

or CONC.OPTI O NS Not accessibl e for f unct ions OFF, DIRECTION, TOTAL

MASS TOTAL, or VO L. TOTAL

40

Page 41

Fct. No. Text Descri pt i on and settings

}

3.5.0 ALARM.OUT.A Sub menu 3.5.0 Process alarm output

3.5.1 FUNCTION A Function for alarm out put P

* OFF (Output goes to its inactive state)

* MASS FLOW ( Alarm a ctive if mass flo w goes outside

limits as set in Fcts. 3.5.3 and 3. 5. 4)

* MASS TOTAL (Alar m activ e if totaliser goes outside

limits as set in Fcts. 3.5.3 and 3. 5. 4)

* DENSITY (Alarm active if density goes outside li mits

as set in Fcts. 3.5.3 and 3. 5. 4)

* TEMPERAT. (Alarm active if temperature goes outside

limits as set in Fcts. 3.5.3 and 3. 5. 4)

* VOLUME.FLOW (Alarm active if volume flow go

outside limits as set in Fcts. 3.5.3 and 3. 5. 4)

* VOL.TOTAL (Alarm active ...

Solute flow Concentration option

Conc. by mass if i nst alled. See separate

Conc. by volume i nst r uction manual

* I 1.SAT (Alarm act ive if value output on current output

exceeds the range as set in Fct. 3.3.3 and 3.3.4)

* P 1.SAT (Alarm acti ve if value output on pulse output

is either: > 1.3 x Max Limi t as set in Fct 3.3.4 or

< Min Limi t as set i n Fct 3. 3. 3

* ANY O/P.SAT (Alarm acti ve if value output on either

current or pulse output exceeds the selected ranges)

* SEVERE ERR. (Output act ive if a severe error is

detected)

* ALL MSG. (Output active if any warnings occur)

* DIRECTION (Output active for posi t ive flows, inactive

for negative flows)

3.5.2 ACTIV.LEVEL Select the desir ed vol t age l evel for the active stat e

* ACTIVE.HIG H (24 V dc); I NACTIVE LOW (0 Vdc)

* ACTIVE LOW (0 V dc) ; INACTIVE HIG H (24 Vdc)

3.5.3 MIN. LIMIT Minimum all owabl e val ue f or functions

TOTAL MASS, MASS FLOW, DENSITY,

TEMPERATUR and VOLUME.FLOW

Units: depend on function but will correspond

to those set in Fcts. 3.2.1 to 3.2.5

or Not accessible for all other functi ons

3.5.4 MAX. LIMIT. Maximum allowable val ue for functions

MASS TOTAL, MASS FLOW, DENSITY,

TEMPERATUR and VOLUME.FLOW

Units: depend on function but will correspond

to those set in Fcts. 3.2.1 and 3. 2. 5

or Not accessible for all other functi ons

41

Page 42

Fct. No. Text Descri pt i on and settings

3.6.0 CTRL.INP.E Submenu 3.6.0 Control input

3.6.1 FUNCTION E Function of the control input

* OFF (control i nput inactive)

* STANDBY (When active converter switches to

STANDBY)

* ZERO SET (Zero calibration tr i ggered on the transit i on

from i nact ive to active on the control input)

* RESET TOTAL (Totaliser reset to zero on the tr a ns ition

from i nact ive to active on the control input)

* CLEAR. MSG. (Status warnings cleared on the

transition f r om inactive to acti ve on the control input)

3.6.2 ACTIV.LEVEL Set the desire d vol t age l evel for the input to be act ive

* ACTIVE LOW (0 to 2 V)

* ACTIVE.HIGH (4 to 24 V)

3.7.0 SYS.CTRL S Submenu 3. 7. 0 System control

3.7.1 FUNCTION S Function for system control

* OFF (System control inact i ve)

* FLOW = O FF ( Mass flow readings forced to zero,

totaliser frozen)

* FLOW = 0/ RST. ( Mass flow readings forced to zero,

totaliser frozen while active but reset to zero

as condition becomes inacti ve. Not available with

Custody Transfer Protection)

* OUTPUTS OFF (Forces all outputs to t heir O FF st ates)

3.7.2 REFERENCE Condit i on f or triggering the above f unct ion

* DENSITY (Function is triggered if density goes outside

Max or Min limit s as set in Fct s 3. 7. 3 and 3.7.4)

* TEMPERATUR (Function is t r i ggered if tem peratur e

goes outside Max or Min limits as set in Fct 3. 7. 3 and

3.7.4) Function not available with Custody Transf er

Protection.

3.7.3 MIN. LIMIT. Minim um allowable value of t emperature or densit y

selected in Fct. 3. 7. 2

Units: depend on function but will correspond

to those set in Fct. 3.2.1 and 3. 2. 5

Function not avail able with Custody Transfer Protection.

3.7.4 MAX. LIMIT. Maximum allowable val ue of temperatur e or densi t y

selected in Fct. 3. 7. 2

Units: depend on function but will correspond

to those set in Fct. 3.2.1 and 3. 2. 5

Function not avail able with Custody Transfer Protection.

42

Page 43

Fct. No. Text Descri pt i on and settings

3.8.0 USER DATA Submenu 3.8.0 User data

3.8.1 LANGUAGE Language for display text

* GB/USA (= English)

* F (= French)

* D (= German)

3.8.2 ENTRY.CODE1 Entry code for accessing menus requi r ed?

* NO (Entry to menus with the → key only)

* YES(Entry with → key and 9-keystroke code see

Fct 3.8.3)

3.8.3 CODE 1 Set Code 1 (Fct. 3.8.2 mu s t be set to YES otherwis e this

function is not available)

* Factory setting: → → → ↵ ↵ ↵ ↑ ↑ ↑

* If a different code is required:

press any 9-keystroke combination and then press the

same key combination agai n. Each keystroke is

acknowledged by "*". CODE WRONG (incorrect entry)

appears if 1st and 2nd entries are not the same. Press

↵ then → keys and repeat the procedure.

3.8.4 LOCATION Tag name setting ( measuring point number)

Required only for flow m eters using the MIC 500 Hand

Held Comm unicator (HHC), c onnected to cur r ent out put ) ..

Factory setting: “MFC 081”

Characters assignable to each place:

A...Z / 0...9 / + / - / * / = / // ( > = blank character)

3.8.5 ENABL. RESET Allow totaliser r eset f r om the

RESET/ACKNOWLEDGE

menu or wit h Cont r ol.Input E

Select : NO/ YES

3.8.6 CSTDY CODE 3 Custody transfer requir ed?

The function is protected by the CODE E password. Aft er

pressing the → key enter a 9-keystroke password. If incorrect, 9 characters are displayed which can be decoded

in the factory, otherwise select:

* NO ( No prot ecti on)

* YES (Custody Tr a ns fer Protection required)

3.8.7 CODE 3 CodE E setting (9 characters). (If custody transfer

is active then this functi on i s unavai lable)

* Factory setting: ↵ → ↑ ↵ ↑ → ↵ → ↑

* If a different code is required, press any 9-keystroke

combinati on and then press the same key combination

again. Each keystroke is acknowledged by "*".

CODE WRONG appears if 1st and 2nd entri es are not the

same. Press ↵ then → keys and repeat the procedure.

3.8.8 PARAM.CODE 4 Extr a c od e ↵ ↑ to al l ow subsequent access to Menus:

Fct. 3.1.5 Fct. 3. 9. 1 - 3. 9. 9

Fct. 3.1.6

43

Page 44

Fct. No. Text Description and settings

3.9.0 TUBE PARAMS Submenu 3.9.0 Transducer calibration and

compensation parameters*

3.9.1 Fgw CF1 Drive frequency - water: from Calibration Certificate

3.9.2 Fcw CF2 Coriolis frequency - water: from Calibration

Certificate

3.9.3 Fgl CF3 Drive f r equency - air : from Cal i br at ion Certificate

3.9.4 Fcl CF4 Coriolis frequency - air: from Calibration Certificate

3.9.5 GK CF5 Transducer mass f l ow cal i br a t i on constant: from

Calibration Certificate

3.9.6 LIN CF6 Linearity adjustment: from Calibration Certificate

3.9.7 Tcl CF7 Mass flow temperature compensation: fr om

Calibration Certificate

3.9.8 Tc0 CF8 Mass flow tem per at ur e compensation at zero flow:

from Calibration Certificate

3.9.9 TcD CF9 Density temperatur e compensation: f r om Calibrati on

Certificate

3.9.10 D.REF.WATER Use ↑ key to select between two modes, then press ↵ to

select submenu and then ↑ for choice of parameters

* MEAS.VALUE

CALIB. NO

CALIB. YES

* SET VALUE

freq Hz

temp °C (°F)

density g/cm

3

3.9.11 D.REF.AIR Use ↑ key to select between two modes, then press ↵ to

select submenu and then ↑ for choice of parameters

* MEAS.VALUE

CALIB. NO

CALIB. YES

* SET VALUE

freq Hz

temp °C (°F)

density g/cm

3

* Many, but not necessarily all, compensation parameters are shown on instrument data

plate.

These menus, except 3.9.10 and 3.9.11, are protected by the Code 4 password; see

Fct. 3.8.8.

44

Page 45

Fct. No. Text Description and settings

4.0 PARAM.ERROR Main Menu 4.0 Parameter error

4.1 Not Used

4.2.0 CUR.OUTP.I Range settings incorrect

LOW SCALE ≥ FULL SCALE

4.2.1 LOW SCALE Low scale range for cur r ent out put I see Fct. 3.3.3

4.2.2 FULL SCALE Full scale range for current out put I see Fct. 3.3.4

4.3.0 ZERO Zero calibrati on i ncor r ect .

The measured zero offset must be less than ±10 %

of the primary head’s full scale fl ow rat ing.

4.3.1 ZERO SET Zero calibration see Fct. 3.1.7

4.3.2 PRIMRY.TYPE Type of primary head see Fct. 3.1.5

4.4 Not Used

4.5 Not Used

4.6.0 PULS.OUTP. P Range setting i ncor r ect

LOW SCALE ≥ FULL SCALE

4.6.1 LOW SCALE Low scale range for pul se out put see Fct. 3.4.3

4.6.2 FULL SCALE Full scale range for pulse output see Fct. 3.4.4

4.7.0 PROC. ALARM Minimum and maximum lim i t s incorrect

MIN.LIMIT > 96 % of MAX.LIMIT

4.7.1 MIN.LIMIT Mi ni mum limit f or r ange checking see Fct. 3.5.3

4.7.2 MAX.LIMIT Maximum l imit f or ra nge checki ng see Fct. 3.5.4

4.8.0 SYS.CTRL.S Minimum and maximum li mits incorr ect

MIN.LIMIT > 96 % of MAX.LIMIT

4.8.1 MIN. LIMIT Minimum li mit for condition checking see Fct. 3.7.3

4.8.2 MAX. LIMIT Maximum limit for condit ion checking see Fct. 3.7.4

5.5 Reset / Quit Menu - Totali zer reset and st at us i ndication acknowledgement

Totalizer reset

Button Display Descr i pt i on

10.36

Measurement mode

kg

↵ CodE 2

Enter access Code 2 for reset/quit menu: ↑ →

– –

↑ → RESET.TOTAL Totalizer reset menu

Only appears if “yes” progr ammed in Fct. 3. 8. 5. Reset

enable No or Yes. If “no” is program med “status li ght ”

only appears. See next section.

↑ RESET.YES If the reset function i s enabled RESET YES will be

shown, press ↵ to execute the function.

To cancel the reset operation press ↑ to get RESET

NO and then press ↵

If the reset function is disabl ed by menus Fct. 3. 8. 5 or

3.8.6 then BLOCKED is displayed. Press ↵ to continue

↵↵ 0.00

kg

Assuming RESET YES was selected the totalisers will

now be cleared.

45

Page 46

View status message( s) and qui t

Button Display Descr i pt i on

0.36

kg/min

∇

↵ CodeE 2

Measurement mode

The p resen ce of the ∇ m ar ker above Status on t he

display indicat es the presence of warning messages in

the status list.

Enter access code for reset/quit m enu: ↑ →

– –

∇

↑→ RESET.TOTAL

Totalizer reset menu.

∇

↑ STATUS.LIST

View/Quit Status message menu

∇

→ ≡ 1 Err ≡

MASS FLOW

∇

This display shows that there is just 1 warning in the list,

in thi s c a se MASS FLOW. The ≡ symbols indicate that

this is a new error and not one that has been previously

acknowledged. Use either the ↑ or → keys to view other

messages in the list. Otherwise press ↵ to exit.

→ ≡ 1 Err ≡

QUIT YES

∇

At the end of the message list the QUIT YES prompt i s

shown. Selecti n g YES will clear if possible messages in

the list.

To cancel the operation press ↑ to get QUIT NO and

then press ↵

↵ STATUS.LIST Assumi ng t he conditions that caused the message have

passed (i.e. mass flow is back wit hin the meter’s range)

then the Status marker, ∇ will disappear.

↵ 0.36

kg/min

Assuming RESET YES was selected, t he to talisers will

now be cleared.

46

Page 47

5.6 Status messages