Tank Level Monitoring System

Operator’s manual

Rev. 1.08

May 2004

CARGOMASTER® 5

CARGOMASTER®5

Contact information

KROHNE Skarpenord

Strømtangvn. 21

N-3950 Brevik

NORWAY

Telephone: +47 3556 1220

FAX: +47 3556 1221

E-mail: ksl@krohne.no

Operators M anual - 2

CARGOMASTER®5

Contents

1. Introduction.................................................. ......................................... 6

A brief system overview............................................... .. ... .. ..... .. .. ... .... ... .. .. ... ..... .. .. ... .... ... .. .. ....... ..7

Mechanical/Electrical.............................................................................................................7

Computer program............................................ ..... .. ... .. ..... .. .. ..... .. ... .. ..... .. ... .. ..... .. .. ... .... ... .. ....9

Help system .................. .. .. ..... .. ... .. ..... .. ... .. ..... .. .. ..... .. ... .. ..... .. .. ... ..... .. .. ... .... .. ... .. ..... .. ... .... .......10

Precautions...................................................................................................................................10

2. Basics ........................... ............................................... ........................ 11

Login/logout.............................................................................................. ...................................11

Navigation....................................................................................................................................11

Keyboard.................................................... ...........................................................................11

Mouse / Trackball .................................................. .. ... .... ... .. .. ..... .. ... .. ..... .. .. ... ..... .. .. ... .... ... ....11

Selecting view...................... .. .. ... .... ... .. .. ... ..... .. .. ... .... ... .. .. ..... .. ... .. .. ..... .. ... .. ..... .. ... .. .. ..... .........12

Quick Start........................... .. .. ..... .. ... .. ..... .. ... .. ..... .. .. ... .... ... .. .. ..... .. ... .. ..... .. ... .. ..... .. .. ... ..................13

Step 1 – Check status ......................................................................... ...................................13

Step 2 – Activating online mode ................................................................. ..........................13

Step 3 – Select tanks to view.................................. ...............................................................13

Step 4 - Select your preferred View......................................................................................14

3. A Planning Example........................................................................... 15

Online or Planning mode?................................................. ............................ .......................16

Creating a new planning condition..............................................................................................16

Prepare for loading............................ .. .. ..... .. ... .. ..... .. ... .. ..... .. .. ..... .. ... .. ..... .. .. ... .... ... .. ... .... ... ...........17

Define Group................................................. .. ..... .. .. ... .... ... .. ..... .. .. ... .... ... .. ... .... ... .. .. ..... .. .......17

Select tanks........................................................ ............................ ............................. ...........18

Density settings ............................................. .... ... .. ..... .. .. ... .... ... .. .. ..... ... .. .. ..... .. ... .... ... .. .. .......19

Alarm settings.................................... ....................................................................................19

Zero adjust – sensor optimization................................................................................ .........20

Bringing the new condition online............................................................ ............................20

4. Reference ............................................................................................ 22

Groups.................................................... ......................................................................................22

Group modes.........................................................................................................................22

Setting up a new group........................... .. ..... .. .. ... .. ..... .. .. ... .. ..... .. .. ... .. ..... .. ... .. .. ... .... ... .. .. ... ... .23

Edit existing group................................................... ... .... ... .. .. ..... .. ... .. ..... .. ... .. ..... .. .. ... .. .........24

Add or remove tanks in groups.................................................................................. ...........24

Density settings ............................................. .... ... .. ..... .. .. ... .... ... .. .. ..... ... .. .. ..... .. ... .... ... .. .. .......25

Alarm Settings.......................................................................................................................26

Zero adjustment...................................... ............................ ...................................................26

Finish Time calculations..................................................................................... .........................27

Partial load or discharge operations..................... .. ......................................................................27

Scratch groups.............................................................................................................. ................29

Partial sums..................................................... ............................ ............................ ..............29

Handle Alarms .............................................................................................................................30

Acknowledge - Silence ..........................................................................................................30

Overview................................................................................................................................30

ValueTable info.................................................... .. .. ..... .. ... .. ..... .. .. ... ..... .. .. ... .... ... .. .. ..... .. .......31

Adjust alarm limits................................................. ..... .. .. ..... .. ... .. ..... .. ... .. ..... .. .. ... .... ... .. .. .......31

Alarms on - off................................................................................................ .......................32

Available Alarm Types..........................................................................................................32

Online Window......................................................................................................................33

Alarms in network ............................... ..... .. .. ..... ... .. .. ..... .. ... .. ..... .. .. ... .... ... .. ..... .. ... .. ..... .. .. ... ....34

Alarm master/slave ........................................................................................................ .......35

3 - Operators Manual

CARGOMASTER®5

Zero adjustments........................................... ...............................................................................36

Tank pressure sensors................................................. ..........................................................36

Line sensors.............................................. ............................ .................................................36

Vapor sensors.................................................. ............................ ............................ ..............36

Hints for successful zero setting ...........................................................................................37

Krohne BM70 radar..............................................................................................................37

Reports.............................................................................................................. ............................38

Loadcalc.............................. ............................ .............................................................................39

Stability Results.....................................................................................................................40

Hull Stress .............................................................................................................................41

GMT / local time................................. ..... .. ... .. ..... .. .. ... .... ... .. ..... .. .. ... .... ... .. ... .... ... .. .. ..... .. ..............42

Trim – List - Draft................................................ .. .. ... .... ... .. .. ... .... ... .. .. ..... .. ... .. ..... .. ... .. .. ..............43

Adjusting................................................................................................................................44

Handle conditions ............................................................................ ............................ ................45

Condition Manager.............................................. .... ... .. .. ..... .. ... .. ..... .. ... .... ... .. .. ..... .. ... .. ..... .. ..45

Online Condition............................ .......................................................................................45

Planning .......................................... ......................................................................................46

Tankplan.......................................................................................................................................46

Show tank or group details ............................... ... .. .. ..... .. ... .. .. ..... .. ... .. .. ..... ... .. .. ..... .. ... .. .. ..... ..46

Adjusting the view.......................................................................................................... .......47

Group Information................................................................................................................47

Tank Information...................................................................................................................48

Valuetable................................ .....................................................................................................51

Adjusting the view.......................................................................................................... .......51

Add or remove tanks from view ............................... .............................................................52

Change column content.........................................................................................................52

View a different group.................................................................................................... .......53

Select layer............................................... ............................ .................................................53

The Sum field................................................................................................................ .........54

Keyboard shortcuts for ValueTable................ ......................................................................54

Valuetable codes ............................................. ......................................................................54

Bargraphs ............................................... ............................ ..........................................................55

Change Value Type................................................ ...............................................................55

Right-click Options ................. ..... .. ... .. ..... .. ... .. ..... .. .. ... .... ... .. .. ..... .. ... .. ... .... ... .. .. ..... .. ... .. ..... ....55

Adjust fontsize ............................................ ... .. .. ..... .. ... .. ..... .. .. ... .... ... .. .. ..... .. ... .. ..... .. ... .. .........55

Line/Vapors..................................................................................................................................56

Keyboard shortcuts .................................................. ..... .. ... .. ..... .. .. ... .... ... .. ..... .. .. ... ..... .. .. ... .... .......56

Normal shortcuts.................................... .. .. ..... .. ... .. ..... .. .. ..... .. ... .. ..... .. .. ..... ... .. .. ..... .. ... .... .......57

Special shortcuts:................................ .. ..... ... .. .. ..... .. ... .. .. ..... .. ... .. ..... .. .. ... .. ..... .. ... .. ..... .. .. .......57

Keyboard shortcuts for Valuetable.......................................................................................58

Density variables..........................................................................................................................58

Units ..................................................................... ........................................................................59

Preferences....................... ......................................................... ............................ .......................60

Pictures tab ................................................... ........................................................................60

Calculations tab:................................. ..... .. ... .. ..... .. .. ... .... ... .. ..... .. .. ... .... ... .. ... .... ... .. .. ..... .. .......61

Fonts tab................................................................................................................................62

Terminal support (VT100)......................... ..... .. ... .. ..... .. .. ... .... ... .. .. ..... .. ... .. ..... .. .. ... .... ... .. ... .. ..... ....62

How to use.............................................................................................................................62

5. Maintenance............................................................................ ............ 64

Sensor disable.......................... ............................. ............................ ............................ ................64

Backup – restore......................................... ... .. .. ..... .. ... .. ..... .. .. ..... .. ... .. ..... .. ... .. .... ... .. .. ..... ..............64

Backup..................................... ............................. .................................................................64

Export of Logger Data..........................................................................................................65

Export of System Logs...................................................................... ............................ .........65

Restore All........................................... .. ... ..... .. .. ... .... ... .. .. ..... .. ... .. .. ..... .. ... .. ..... .. ... .. ..... .. .. .......65

Restore User Data Only................................................ ........................................................66

Replace sensor..................................... ............................ ............................ .................................66

Replacement procedure ........................................................................................................66

Operators M anual - 4

CARGOMASTER®5

Offset and gain adjustments................................... ......................................................................68

Offset adjustment...................................................................................................................68

Gain adjustment....................................................................................................................70

Level from bottom and upper sensors. ..................................... .. .. ... .. ..... .. .. ... .. ..... .. ... .. .. ... .... ... .. ..71

Redundancy for Ballast tanks...............................................................................................71

Appendix........................................................................................................ 73

A. Tank names conversion........................ .. ... .... ... .. .. ..... .. ... .. ..... .. .. ... ..... .. .. ... .... ... .. .. ..... .. ... .. ..73

B. Loadcalc Stability Criteria ......................................................................... .......................73

C. Note on free surfaces............................ ............................ ............................ .....................73

D. Gas/LPG Tanker Units............................. ... ..... .. .. ... .. ..... .. .. ... .... ... .. .. ... .... ... .. ... .... ... .. .. ..... ..74

Description of units.................................... ............................ ...............................................74

E. Ground insulation monitor for Radar power....................................................... ..............76

5 - Operators Manual

CARGOMASTER®5

1. Introduction

This manual covers the use of the CARGOMASTER® computer and its

software portion. You will, however, find a few important notes on

maintenance and precautions regarding the mechanical and e l e ctric al

installations. New users are encouraged to read the “Basics” section carefully.

The CARGOMASTER® software, or computer program, is designed to utilize

groups and conditions. This means organizing your tanks (or grades) into

groups for more convenient handling of densities, alarm settings etc.

Furthermore, your different groups setup may be saved and retrieved as

conditions. This opens for planning a voyage in advance, and reuse of

frequently used tank/cargo allocations. These issues are discussed further in

the Basics section.

The examples throughout this manual are gathered from M/T

SKARPEFJORD, a highly hypothetical vessel designed to include most

common configuration options available. Your vessel will probably look

somewhat different, but the procedures and the way to work the program will

be representative for most installations.

Operators Manual - 6

CARGOMASTER®5

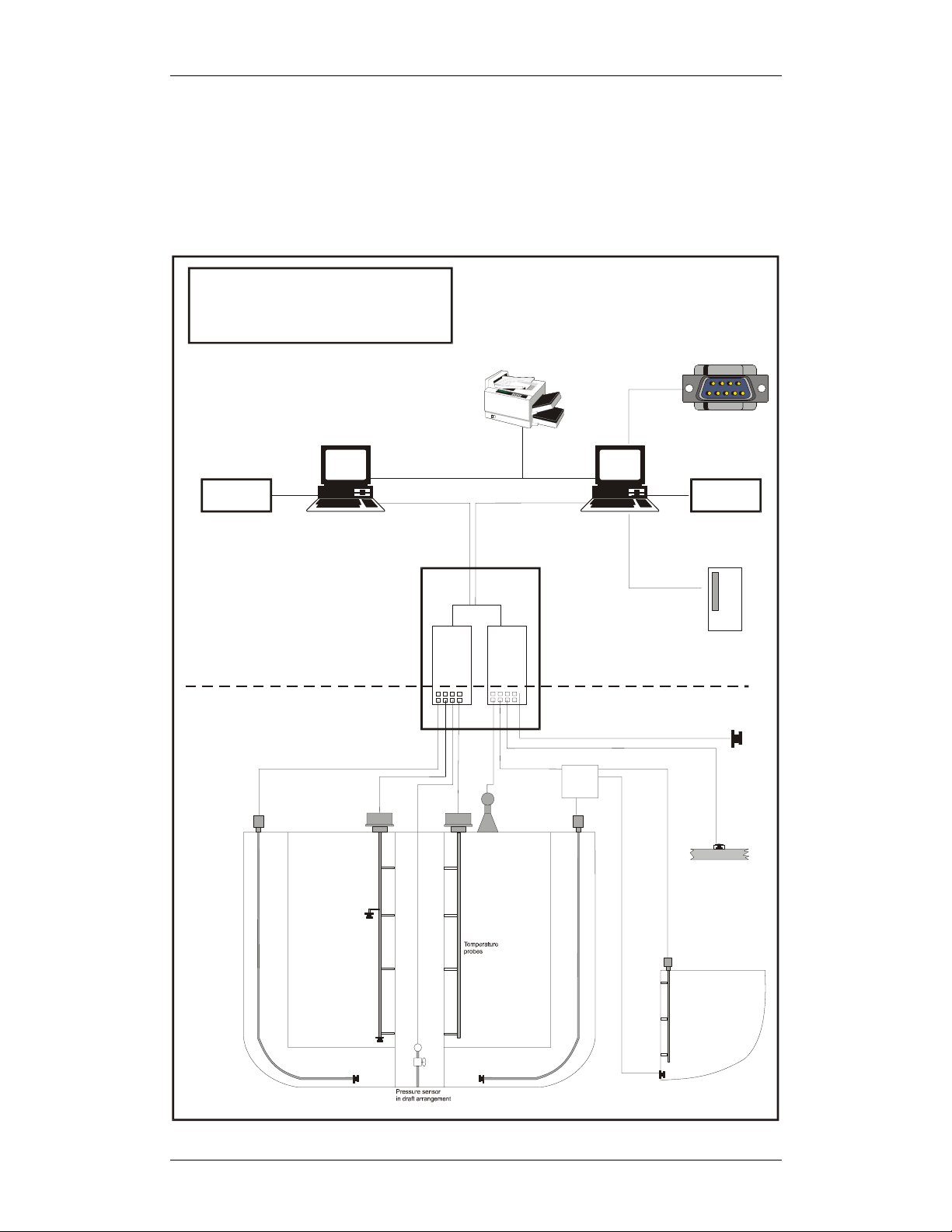

A brief system overview

Mechanical/Electrical

A complete CARGOMASTER® system includes quite a few components.

There are both mechanical and electrical parts, as well as computer programs

involved in the process of monitoring the various tanks on your vessel. (See

Fig. 1) presents the most common parts of such a system, and indicates a few

different options. CARGOMASTER® is a modular system so all these options

may not be configured and installed on your vessel.

A few words on some of the various system parts:

CCU: Short for CARGOMASTER® Computer Unit.

Ordinary PC type computers, however configured and

type approved for maritime use. Normally, these

computers are powered via an

Power Supply. A laser printer is also handy, and is

needed in order to get printed reports. In order to

retrieve gauging data, the CCU needs to be connected

to the

UPS – Uninterruptable

SCU: Short for Signal Control Unit. This is where all data is

collected from the various transmitters or gauges and

forwarded to the CCU.

Other systems: CARGOMASTER® supports an array of protocols to

communicate with other vessel systems, usually trough

a RS232 or 485 serial interface.

Gauges: CARGOMASTER® can utilize a variety of

sensors/transmitters, primarily the native

CARGOMASTER® types. The range includes

ballast/line pressure sensors, the combined

pressure/temperature cargo sensors, radar transmitters,

various temperature transmitters, and various 4-20mA

transmitters. CARGOMASTER® can also retrieve

data from 3

Junction boxes: Some of the CARGOMASTER® junction boxes,

rd

party systems.

normally the ones fitted on cargo tanks, host electronic

equipment like AD cards. The boxes are designed to

withstand rough weather conditions, and should not be

opened except for required servicing. Also boxes

placed inside trunks, engine room etc. may have

electronics inside. Please consult the electrical

drawings for the system installed on your vessel for

further details.

AD/TI/RI cards: The Analogue/Digital cards, commonly placed in the

7 - Operators Manual

various junction boxes, converts analogue signals from

the cargo and ballast sensors into digital data and

CARGOMASTER

System overview

CARGOMASTER®5

transmits these to the TI (Tank Input) cards placed

inside the SCU. The TI card receives the data, and

feeds them trough Zener-barriers, necessary for safe

electrical connection between Safe and Hazardous

areas. Radar transmitters have their own interface card

– the

purpose.

®5

CCU 2 (optional)

RI (Radar Interface), specially designed for this

Printer

Other systems

Computer network

UPSUPS

CCU1

Safe area

Hazardous

area

Junction box

for ballast tank

Junction box

for cargo tank.

AD card and

inert pressure sensor

inside

Combined

pressure and

temperature

sensors in cargo tank

SCU

1234

Meters,horns,

displays etc.

Tank input cardTank input cardTank input card

Tank input card

Radar

for cargo tank

Multi-tank

junction box

w/ AD card

Atmospheric

reference sensor

and inclinometers

Optional

temperature

probing

Line and pump

pressures

Fuel, service

and misc tanks

Pressure sensor

in ballast tank

Fig. 1 Cargomaster connections

Pressure

sensor

Operators Manual - 8

Computer program

CARGOMASTER®5

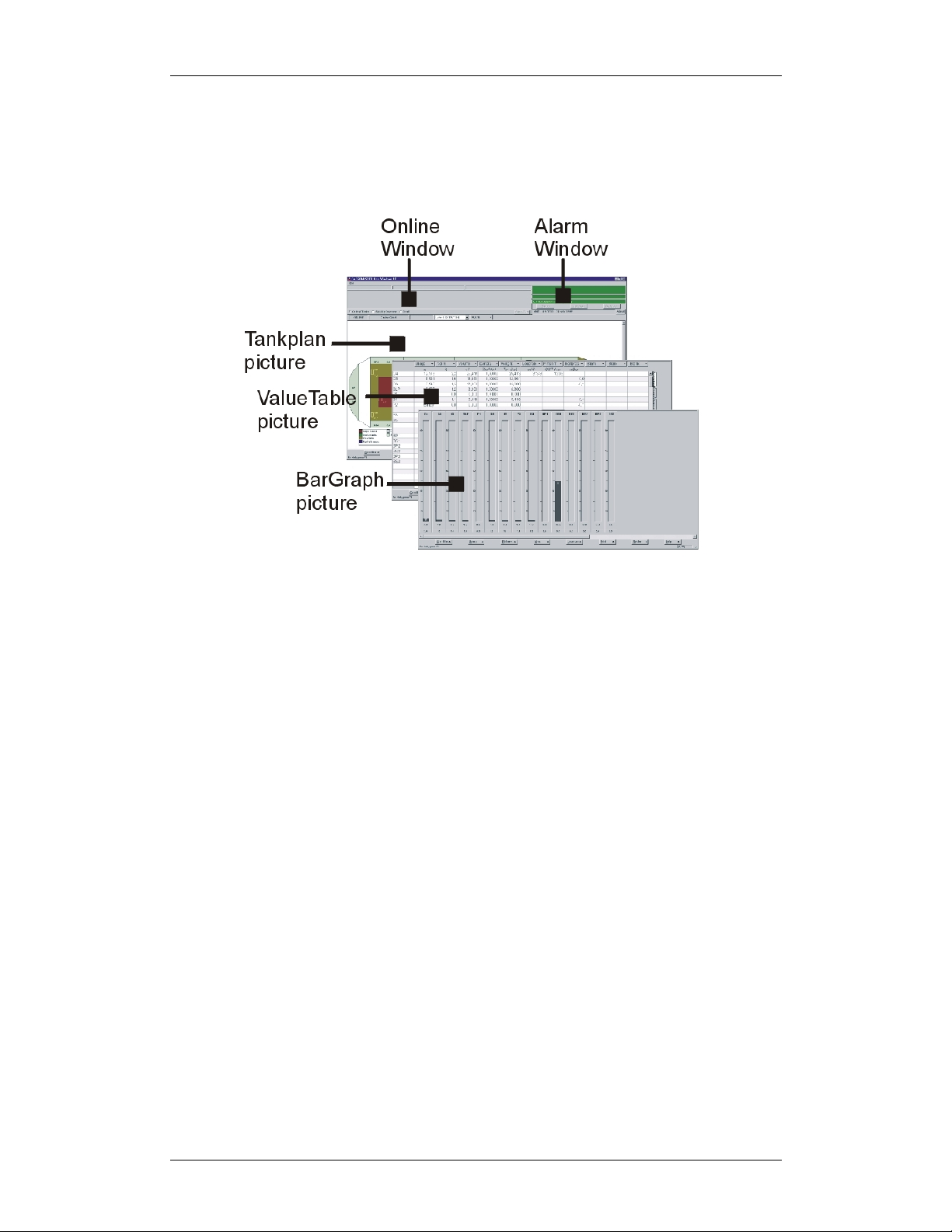

Screenshot 1 Screen layout for the CARGOMASTER program.

Online window: Displays important online data from the tanks, even

when working on planning conditions.

Alarm window: Green background when no active alarms, red

background whenever any active or non-acknowledged

alarms

Pictures: Numerical or graphical presentation of data

9 - Operators Manual

CARGOMASTER®5

Help system

CARGOMASTER® provides an online Help system, containing most of the

text found in this manual. The help system is contexts sensitive, aiming at

providing help on the specific issue you are working on.

Accessing: You can access the help system from anywhere within

the CARGOMASTER® program - just press the

button.

Help Index: Use the Index tab to search topics

Search: Use the Search tab to search single words, phrases or

abbreviations

Favorites: You can add to the Favorites tab any page in the help

system. This is convenient for quick access to

frequently viewed pages.

Printing: Clicking the printer symbol will print the page you are

currently viewing (Or you can right-click the page with

the mouse and select the print option there...)

F1

Precautions

Although the mechanical and electrical parts of CARGOMASTER® are

virtually free of maintenance, they are vulnerable to certain physical impacts.

So, even though it may seem obvious- please

• Do NOT expose gauges to sandblasting!

• Do NOT overpaint gauges!

• Please take care when cleaning tanks – even small strokes or impacts on

the sensor diaphragms may alter the sensors characteristics in such a way

that it will become unusable!

• Do NOT replace any seals, o-rings or gaskets with parts that are not clearly

specified for this equipment!

Operators Manual - 10

2. Basics

Login/logout

To log in on a CARGOMASTER® computer, use the username CMV5

without any password.

If you receive messages that say something like “You don’t have the right

privileges....” you might need to log in as username

case you must use the password

CARGOMASTER®5

administrator. In this

ntconf1

We strongly recommend the CARGOMASTER® program being run under the

CMV5 user.

A CARGOMASTER® computer is designed to be running 24 hours a day – 7

days a week

Navigation

Keyboard

Using the keyboard is the fastest way to navigate the CARGOMASTER®

program, utilizing the keyboard shortcuts built into the program. The keyboard

shortcuts are listed in the Reference chapter.

All menu buttons that have an underscored letter are accessed by pressing that

letter simultaneously with the

pressing and holding the

Mouse / Trackball

All items are accessible from mouse or trackball. Note that in this on li ne help

click refers to clicking the left mouse /trackball button once. Right-click

means clicking the right mouse button once.

left button twice, rather rapidly. The speed at which a double-click must be

done is an adjustable feature within Microsoft Windows; See the MS

Windows documentation for further information.

Alt key. E.g. the Condition menu is accessed by

Alt key, then press and release the C key.

Double-click means clicking the

Right clicking will in most cases bring up a context-menu, which will be

specific to the item that was clicked.

11 - Operators Manual

CARGOMASTER®5

Selecting view

CARGOMASTER® offers three different ways to view data. They are

accessed either by keyboard shortcuts, or by selecting the Pictures button in

the bottom of the screen. Select one of the following:

TankPlan – Graphical tank layout, with color

coding of groups

ValueTable – Numeric spreadsheet, pure

numbers only

BarGraph – Vertical bars representing levels,

volumes etc.

Table 1 Shortcuts for view selection

Click the view you want, or use the shortcuts. E.g. Shift+F3 means holding

down the

SHIFT key and then pressing, and releasing, the F3 key.

Note that there are two of each

Shift, Ctrl or Alt keys - only the left Alt key

will work with this while all Shift and Ctrl keys will work.

Operators Manual - 12

Quick Start

This part was written for users that are new to the CARGOMASTER®5

system. By paying attention to the four steps below, you should be able to

monitor what’s going on right now. (Don’t be confused if your screen doesn’t

match the example below exactly).

CARGOMASTER®5

Step 1 – Check status

CARGOMASTER® may operate in either Online or Planning mode. (You

will find more information regarding these two modes later on in this manual).

For now, we will be running in Online mode, so check whether the text at

circle #1 (above) reads ONLINE: or PLANNING: If it shows ONLINE that’s

fine, and you can move on to step 3. If it shows PLANNING (Like the

example does) please continue with step 2.

Step 2 – Activating online mode

Assuming the system is NOT running in online mode, click the button in the

lower left corner of the screen (The one inside circle #2) – It is named

“Condition”. From the menu that appears, click “Current Online”. Verify that

the text at circle #1 now reads “Online”. If so, move on to step 3. (Otherwise,

you may have to repeat step 2)

Step 3 – Select tanks to view

This step requires that you (or someone else) know which tanks that currently

have ongoing operations. We assume those are the tanks you prefer to

13 - Operators Manual

CARGOMASTER®5

monitor? The example above shows the “Miscellaneous” group, but you can

select any existing group listed here – a click on the little down-arrow to the

right will reveal available groups. Just click on the group you want to view.

Note that whatever the screen looked like when you started, by selecting any

group here, the

ValueTable (numeric) view will come to focus. Step 4 shows

you how to change this.

Step 4 - Select your preferred View

After completing Step 3 you should be monitoring the real situation of your

tanks. You have two other choices on how to view the gauging data – the

BarGraph and the TankPlan views. Try them both, and figure out for yourself

what suits your needs.

The different vies are selected by clicking the “Pictures” button at the bottom

of the screen (As indicated in the example above).

Operators Manual - 14

CARGOMASTER®5

3. A Planning Example

CARGOMASTER® considers any tank to be of a certain type. The native

types are Cargo, Ballast, Fuel/Lubrication, Temperature, Solids or Misc.

Tanks of the same type may be grouped together. This is a convenient, and

necessary feature whenever the volume of a certain cargo – or grade grows

beyond the capacity of one single tank. Treating several tanks as a group

allows for controlling e.g. density and alarm settings from one single point.

You will also be able to print out survey- and other reports with totals for the

whole group. (CARGOMASTER® also allows tanks from various groups be

treated together without breaking up the groups – more on that in Reference -

Groups)

All configurations of groups can be stored and recalled at a later point. This

allows for re-use of specific voyage, discharge or loading configurations. If

you have set up one or more groups of tanks, with applied alarm settings,

densities etc., you can save or retrieve it under a preferred label. Such a label is

in CARGOMASTER® defined as a condition.

As an aide for preparing in advance or to test a specific configuration, a

CARGOMASTER® condition can be set to operate in Planning mode.

This chapter will take you on a little tour aboard the chemical tanker MT

SKARPEFJORD. First, we will create a new condition. Within this condition

we will create a new group containing multiple tanks. Finally, we will set this

condition into online mode.

Since hardly any vessels are configured the same way, this example can only

serve as an indication on how to use the CARGOMASTER® program and it’s

basic functions. Let us start with a glance at a few terms:

15 - Operators Manual

CARGOMASTER®5

Online or Planning mode?

The normal state for a CARGOMASTER® condition to run during loading /

discharge operations would be online mode. In online mode, all values

presented on the screen will be read from the gauges installed in the various

tanks.

Planning mode is somewhat different. Here, to let you test any distribution of

cargo in tanks, you may insert your own values in e.g. the VOL% fields.

Combined with the Loadcalc (which is optional) the operator can quickly

determine whether the suggested cargo load will be within safe stability limits.

It is not recommended to run any conditions in planning mode during load

or discharge operations!

Vessels carrying the same cargo all the time, like crude oil tankers, and maybe

even oilrigs will often be running the same online condition for all situations.

On such vessels it will be less likely that any new cargo distribution across

multiple tanks would occur.

Note: An Online condition will always be running in the background whenever working with

a planning condition. This ensures that alarms and data presented in the Online windo w w ill

always be real-time data.

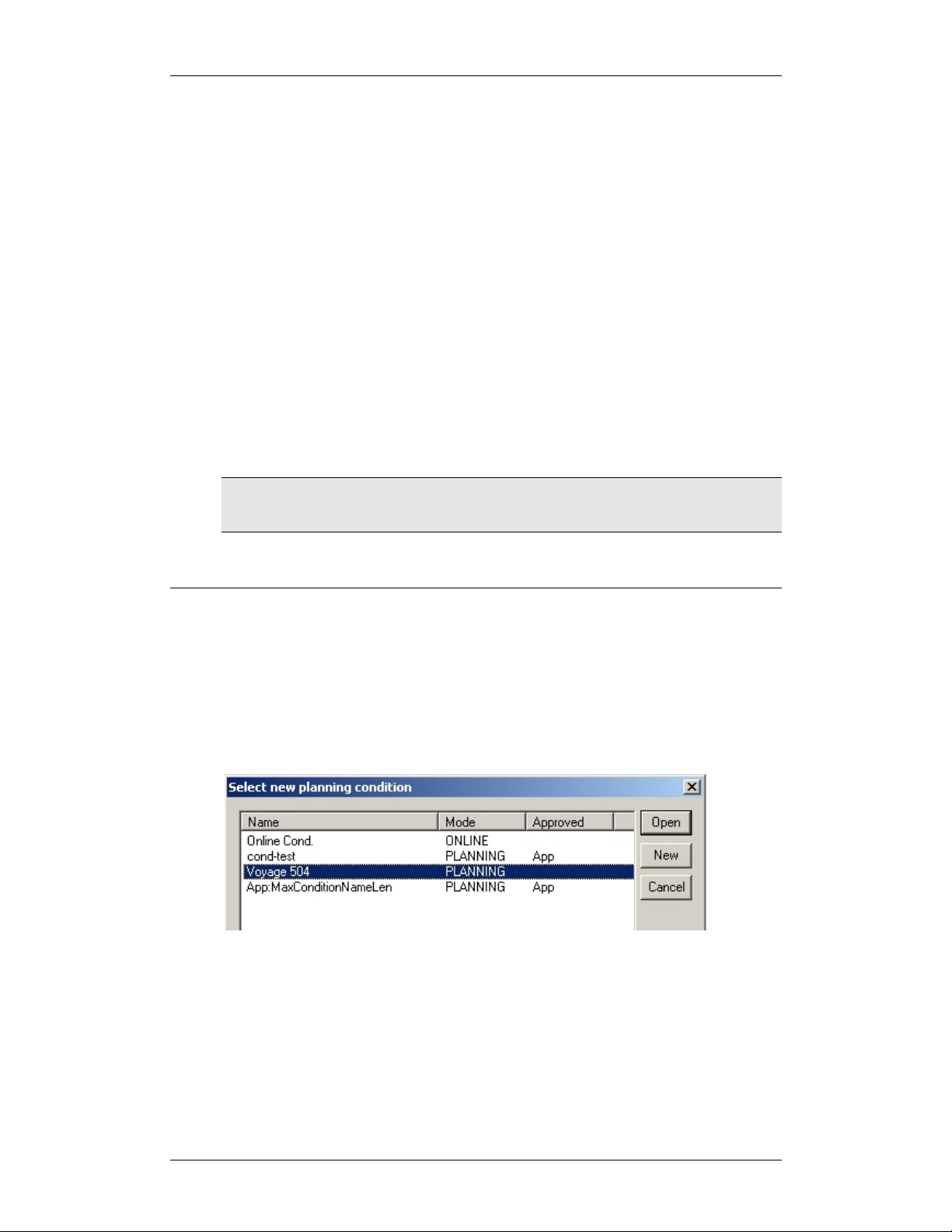

Creating a new planning condition

Let us start with that – creating a new planning condition where we can set up

our new tank groups:

In the lower left corner of the screen, there is a button called “Condition”. Click it.

(Or, press

“Select new planning condition” dialogue. Select “New” (

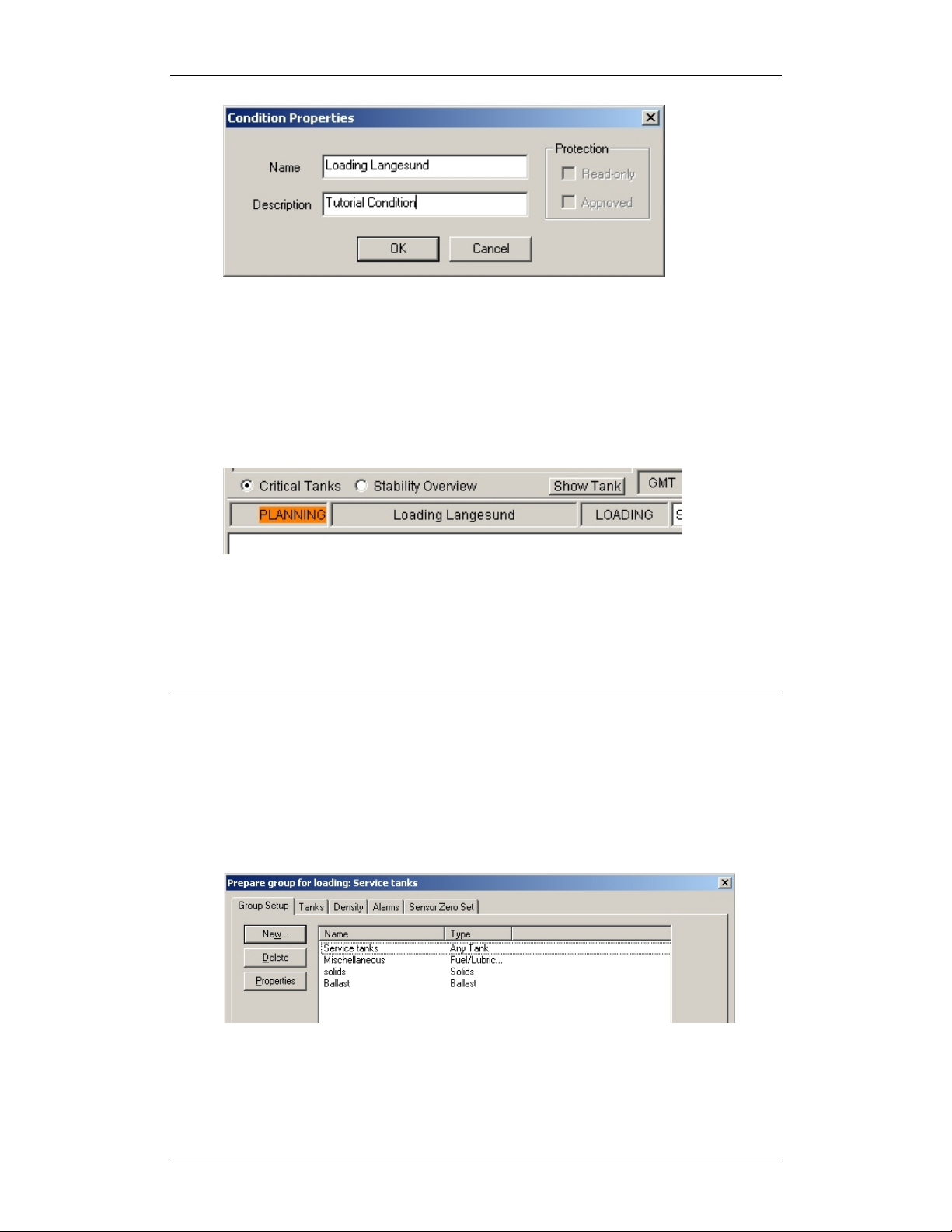

A new “pop-up” appears, called “Condition Properties”. In our example, we call the

new condition “Loading Langesund”. We also gave a description for this condition as

you see in the figure below. You may name your conditions whatever you like.

Alt + C). Then, select the “planning” option (press P). This should open the

Alt + N)

Screenshot 2 The New planning condition dialogue

Operators Manual - 16

CARGOMASTER®5

Screenshot 3 Naming the new condition

By pressing “OK” (or hit the Enter button) this condition is now created, and

set active. This will also show in the main views. First, the mode field should

now have a blinking orange background behind the text “Planning”. Next, the

name of the condition should appear to the right of this field. See below.

Screenshot 4 Verifying that the corre ct condition is active

With our new condition up running, we are ready for the group setup. Or, as

it’s called in CARGOMASTER® - “Prepare for loading”.

Prepare for loading

Define Group

In the port of Langesund we will be taking approximately 1.900 m³ of

Sulphuric Acid.

Press

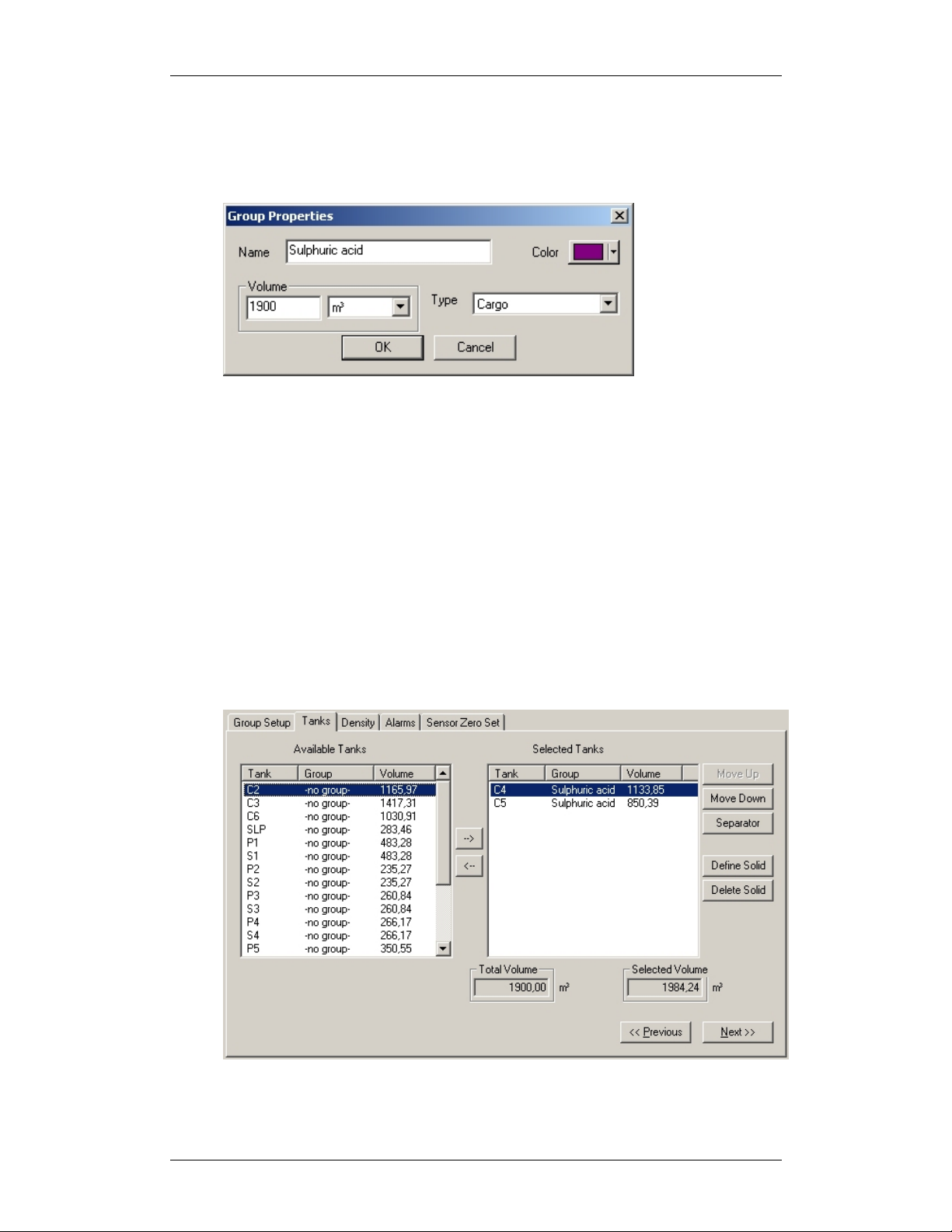

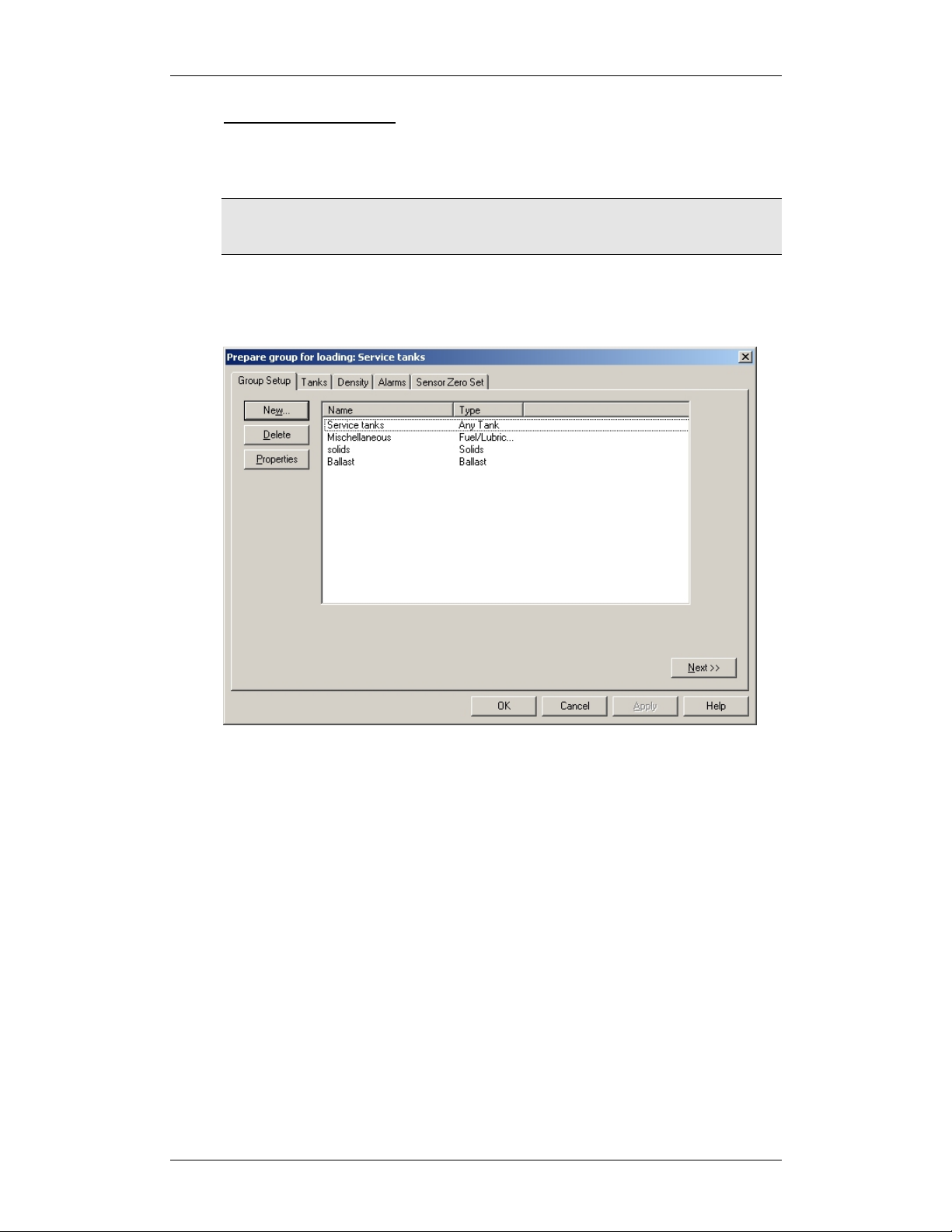

F2 to bring up the “Prepare group for loading” dialogue:

Screenshot 5 Prepare for Loading – Group Setup

17 - Operators Manual

CARGOMASTER®5

This window contains multiple TAB’s, each showing different “pages”. On the

first page, showing above, already existing groups are listed.

CARGOMASTER® allows for a total of 60 groups in one condition.

Selecting the

New option, we will create a group to carry our Sulphuric Acid:

Screenshot 6 Prepare for loading – Group Properties

Here, we have given the group a name, specified a Cargo type tank, we have

selected a color to identify the group in the TankPlan view and, finally, we

have entered an estimated volume of 1.900m³.

Select tanks

Next step is to allocate sufficient tank capacity for this grade. By clicking the

Tanks tab, or the Next button, we bring up a list of available tanks of the

selected type. Some tanks that are already allocated to other groups may also

show. The two columns on this page displays tankname, any existing group

allocation and the tank’s 98% volume capacity.

Screenshot 7 Prepare for Loading – Tanks tab

Operators Manual - 18

CARGOMASTER®5

For this example we have selected the C4 and C5 tanks, whose joint 98%

capacity is just above the expected volume we need.

The

-> and <- arrow buttons are used for selecting / de-selecting tanks. The

buttons on the right are used for altering the order of the tanks, including

separators for increased readability.

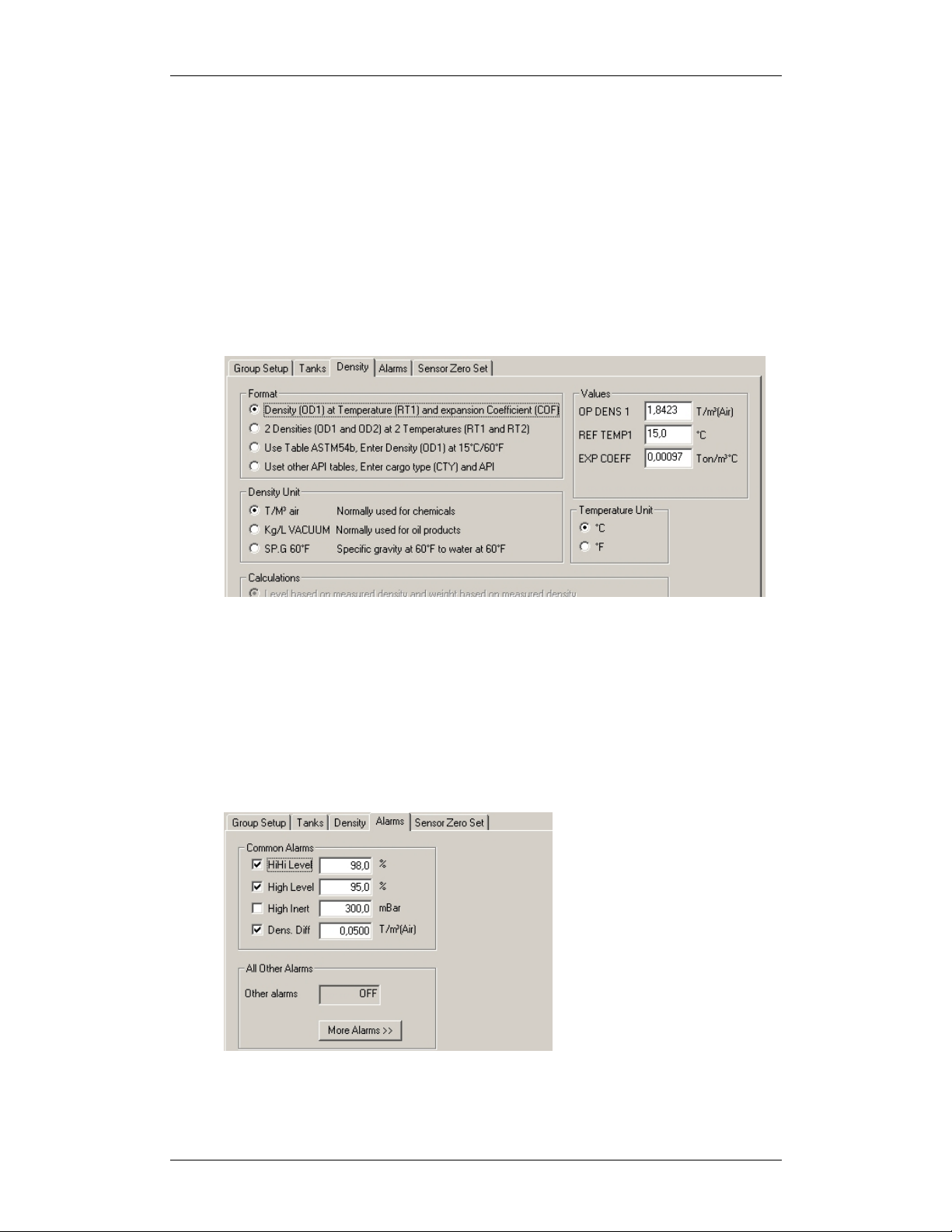

Density settings

The 3rd step in this process is to enter the correct density or API. The Density

tab gives several choices.

Screenshot 8 Prepare for loading – Density settings

We have entered the characteristic density for this cargo, according to the

shore specifications. You can read more about the density settings and

possible options regarding CARGOMASTER®’s ability to measure the exact

density in the Reference section of this manual.

Alarm settings

Selecting the Alarms tab, should bring up the following page:

Screenshot 9 Prepare for Loading – Alarms tab

19 - Operators Manual

CARGOMASTER®5

Here, we have enabled alarms for 98%, 95% and for a difference in density of

more than 0.05 T/m³ between the OD1 value (See above) and the actual

measured density.

Pressing the More Alarms button will open for even more alarm options,

however not necessarily relevant to a loading situation… Alarm limits and

enabling may also be found in the ValueTable view (Alt + F3).

Zero adjust – sensor optimization

There is one final step to this sequence. The zero adjustment of any pressure

sensors found in the tanks belonging to this group. However, some restrictions

for zero adjustment apply:

• To zero adjust any Inert Gas Pressure (IGP) sensors, the tank must be open

to air.

• To zero adjust any bottom or upper sensors, the sensors cannot be

submerged in fluid.

• Temperature elements do not normally need zero adjustment.

• The atmospheric (reference) sensor should NOT be adjusted!

We recommend zero adjustment to be performed immediately before loading.

More details about this issue are found in Zero adjustments on page 36.

Bringing the new condition online

With our new condition running in Planning mode, we are now ready to start

loading. Or are we?

In the opening of the chapter “A planning Example” we wrote that

It is not recommended to run any conditions in planning mode during load

or discharge operations

And why is that? When running in planning mode, data will not be updated in

the ordinary views. Any warnings or info that displays in the Online Window

will only be valid for the currently running online condition, and so will any

active alarms. This means we will have to bring our planning condition Online

before attempting to start the loading operations.

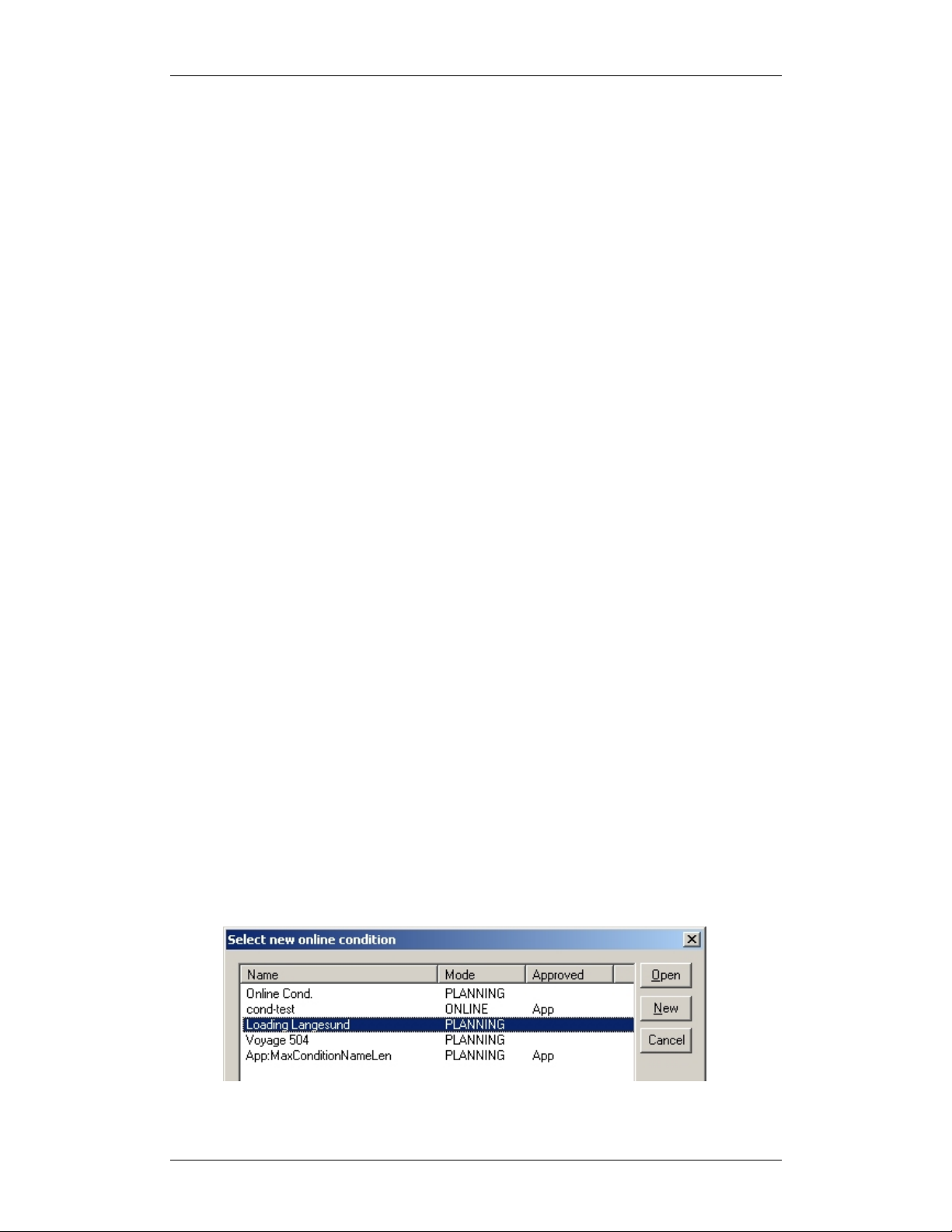

Press

Ctrl + Alt + F1 (Or select Condition – Online from the bottom menu

buttons)

Screenshot 10 The Online Condition selector

Operators Manual - 20

CARGOMASTER®5

When we created the new condition, another condition was already running in

Online mode. There will always be an Online condition; without that, the

CARGOMASTER® will not run. This also means that you cannot have the

same condition both Online and Planning at the same time.

To bring our condition Online, select it (like in Screenshot 10) and hit Open.

Checking the mode and name of the current condition should now show on the

main screen, li ke below:

Screenshot 11 Condition running in Online mode

21 - Operators Manual

CARGOMASTER®5

4. Reference

Groups

CARGOMASTER® sees any tank to be of a certain type. The native types are

Cargo, Ballast, Fuel/Lubrication, Temperature, Solids or Misc types. Tanks of

the same type can be grouped together. (Scratch Groups can be used to group

tanks of different types)

Groups are usually set up from the Loading menus (F2), but single tanks can

be added or removed from a group within the ValueTable also.

By organising tanks into groups one achieves common handling of densities,

alarm limits, grade sums and averages and sorted survey reports.

Group modes

Groups may be set in different modes. Each mode has a specific set of alarms

and limits.

Loading: A new group is automatically set in loading mode.

Loading mode enables typical alarm settings and levels

that apply for a loading situation. Suggested alarms are

HH Level, H Level, H Inert and Density Difference.

Discharge: Suggested alarms enabled for this mode are LoLo

Vol%, Lo Vol% and LO Inert.

Seagoing: Suggested alarms are Volume change (See note), high

and low temperatures and high and low inert pressures.

Set group to loading

Press F2 or select menu Group – Loading. Select the group you want to set to

Loading and click OK.

Set group to Discharge

Press Shift+F2 or select menu Group – Discharge. Select group and click OK.

Operators Manual - 22

CARGOMASTER®5

Set group to Seagoing

Accessed by pressing Alt+F2 or select menu Group – Seagoing. You will be

asked whether to set one or all groups in this mode. Check/uncheck the

different alarms to enable/disable and adjust any alarm limits as needed.

Note: The Volume Change option will set the HiVol and LoVol limits in accordance to

the current level, so that if current Volume is 70%, the HiVol will be 73% and the LoVol w ill

be set at 67%.

Setting up a new group

Accessed from Group- Loading or press F2.

Screenshot 12 The Group Set up tab

: Creates a new group in loading mode. The dialogue

New

Delete: Deletes the currently selected group or groups.

Properties: Here you can display or edit name, color, volume and

23 - Operators Manual

window lets you specify a name for the group, the

color for which it is displayed in TankPlan, required

volume for the group and what type of tanks the group

should host.

type for the currently selected group

Loading...

Loading...