Page 1

07/2008

Installation and

Operating Instructions

OPTISENS

CAC 050

IAC 050

Measuring and control device

for conductivity measurements

Page 2

Content

Manual OPTISENS CAC 050 / IAC 050

0. Introduction......................................................................................................................................................................................... 3

0.1

General .................................................................................................................................................................................................................. 3

0.2

Legal matters ......................................................................................................................................................................................................... 3

0.3

Safety..................................................................................................................................................................................................................... 4

0.3.1 Documentation symbols......................................................................................................................................................................................... 4

0.4

Features................................................................................................................................................................................................................. 5

0.4.1 Device .................................................................................................................................................................................................................... 5

0.4.2 Controller................................................................................................................................................................................................................ 5

0.4.3 Connections ........................................................................................................................................................................................................... 5

1. Mechanical installation ...................................................................................................................................................................... 6

1.1

Installation of panel-mounting converters .............................................................................................................................................................. 6

1.2

Installation of wall-mounting converters................................................................................................................................................................. 7

2. Electrical connection.......................................................................................................................................................................... 8

2.1

Connection diagram panel-mounting converter..................................................................................................................................................... 9

2.2

Connection diagram wall-mounting enclosure..................................................................................................................................................... 10

3. Operation of the device.................................................................................................................................................................... 11

3.1

How to adjust parameters.................................................................................................................................................................................... 11

3.1.1 Selection between alternatives ............................................................................................................................................................................ 11

3.1.2 Adjustment of numerical parameters ................................................................................................................................................................... 12

3.2

Menu Overview .................................................................................................................................................................................................... 12

3.2.1 Main menu and basic settings ............................................................................................................................................................................. 12

3.3

Password and language ...................................................................................................................................................................................... 13

3.3.1 Enter password .................................................................................................................................................................................................... 13

3.3.2 Language ............................................................................................................................................................................................................. 13

4. Adjustments for the measurement ................................................................................................................................................. 14

4.1

Configuration of the converter.............................................................................................................................................................................. 14

4.2

c value (cell factor)............................................................................................................................................................................................... 15

4.2.1 Calibration via cell factor...................................................................................................................................................................................... 15

4.3

Cable compensation and averaging .................................................................................................................................................................... 16

4.3.1 Cable compensation (zero point correction) ........................................................................................................................................................ 16

4.3.2 Averaging............................................................................................................................................................................................................. 16

4.4

Temperature compensation................................................................................................................................................................................. 16

4.4.1 Calibration of the temperature measurement ...................................................................................................................................................... 17

4.4.2 Temperature coefficient ....................................................................................................................................................................................... 17

5. Adjustments of the controller.......................................................................................................................................................... 17

5.1

ON/OFF controller................................................................................................................................................................................................ 18

5.2

P / PI controller as impulse-frequency controller ................................................................................................................................................. 18

5.3

P / PI controller as pulse-pause controller ........................................................................................................................................................... 19

5.4

Activation and deactivation of the controller ........................................................................................................................................................ 20

5.5

Turn-on delay....................................................................................................................................................................................................... 20

5.6

External controller stop ........................................................................................................................................................................................ 20

5.7

Manual operation of the relays............................................................................................................................................................................. 21

5.8

Limit values .......................................................................................................................................................................................................... 22

5.8.1 Turn-on delay....................................................................................................................................................................................................... 22

5.9

Dosage check ...................................................................................................................................................................................................... 22

6. Alarm.................................................................................................................................................................................................. 23

6.1

Error messages.................................................................................................................................................................................................... 24

7. Output................................................................................................................................................................................................ 24

7.1

Current output ...................................................................................................................................................................................................... 25

7.2

Serial interface RS485 (option)............................................................................................................................................................................ 25

8. Operation and maintenance ............................................................................................................................................................ 25

8.1

Maintenance of the device................................................................................................................................................................................... 25

8.2

Display contrast ................................................................................................................................................................................................... 25

8.3

Exchange fuse ..................................................................................................................................................................................................... 25

8.4

Cleaning............................................................................................................................................................................................................... 25

8.5

Maintenance of the conductivity measurement ................................................................................................................................................... 26

8.6

Disposal ............................................................................................................................................................................................................... 26

8.7

Service ................................................................................................................................................................................................................. 26

8.7.1 Product info.......................................................................................................................................................................................................... 26

8.7.2 Analog inputs ....................................................................................................................................................................................................... 26

OPTISENS CAC 050 / IAC 050 2

Page 3

Manual OPTISENS CAC 050 / IAC 050

8.7.3 Erase settings (reset)........................................................................................................................................................................................... 26

9. Technical data................................................................................................................................................................................... 27

9.1

Technical data...................................................................................................................................................................................................... 27

9.2

Dimensions .......................................................................................................................................................................................................... 28

9.2.1 Panel-mounting enclosure ................................................................................................................................................................................... 28

9.2.2 Wall-mounting enclosure ..................................................................................................................................................................................... 28

10. Device return form............................................................................................................................................................................ 29

11. Customer settings - for reference ................................................................................................................................................... 30

0. Introduction

0.1 General

This manual applies to the following devices:

It contains technical information for the installation, start-up and maintenance. If you have any questions not

0.2 Legal matters

Device and type revision date

CAC 050 R 09/07

CAC 050 W 09/07

IAC 050 R 09/07

IAC 050 W 09/07

included in this manual please contact your supplier or the official representative of KROHNE Water Solutions

in your country.

Authorized personnel

Installation, connection, adjustment, start-up, and maintenance of the device are carried out by authorized

personnel with adequate qualification.

Liability

Responsibility as to suitability and intended use of these devices rests solely with the user. Improper

installation and operation may lead to loss of warranty. In addition, KROHNE Group's Standard General

Conditions of Sale and Delivery, found on the back of the invoice and forming the basis of the purchasing

contract, are applicable.

General limitation on liability

Unless otherwise expressly set forth in the Standard Terms and Conditions of Sale and Delivery, the Seller is

only liable for damages, whatever their legal basis is, in case they are based on willful action or gross

negligence. This limitation on liability does not apply in the event the Buyer raises claims relating to personal

injury or damages to property according to the product liability law based on a defect of the delivered goods.

Any advice given by the Seller, in particular regarding the application of the delivered goods, shall only commit

the Seller if given or confirmed in writing.

Returning the device

If you need to return the level gauge to the manufacturer or supplier, please read to the instructions and

complete the form given in the appendix.

Warranty

Please consult KROHNE Water Solutions General Terms and Conditions for information on guarantee and

liability.

3 OPTISENS CAC 050 / IAC 050

Page 4

0.3 Safety

0.3.1 Documentation symbols

Please check for damages immediately after receiving the devices and report any damages within 24 hours to

the delivering company. Never work with a damaged device.

Keep this manual at a safe place where you can always look up the safety instructions and the information on

handling and usage.

This device was designed and built according to the safety measurements for electronic devices and has left

our company in perfect working condition. To preserve this condition and to ensure safe usage follow all

instructions carefully and pay special attention to all warnings issued in this manual. If the device is visibly

damaged or has been stored inappropriately or if there are any doubts concerning safe usage, shut it down

and make sure it cannot be restarted by accident.

A set of symbols is used to give warnings or information relevant to particular applications. These are defined

below:

Caution / Attention

Information that, if not followed, may lead to actions resulting in incorrect functioning of the device.

Warning

Information that, if not followed, may lead to actions resulting in measurement error, personal injury and/or

NOTE

damage to the device.

Is used to highlight interesting details.

Manual OPTISENS CAC 050 / IAC 050

OPTISENS CAC 050 / IAC 050 4

Page 5

Manual OPTISENS CAC 050 / IAC 050

0.4 Features

0.4.1 Device

Cell factor (recommendation)

0.4.2 Controller

0.4.3 Connections

Measuring ranges

conductive

Measuring ranges

inductive

Measuring range temperature -30.0…+140.0°C

Display Measured value with dimension

Temperature compensation manually or automatically with Pt100 or NTC

Set points 2 set points with adjustable direction

Controller types ON/OFF controller with hysteresis

Hysteresis adjustable within the measuring range

P range XP adjustable within the measuring range

Integral time TN 0…2000 s

Least pulse 0.1…9.9 s

Pulse+ pause time 02…99 s

Impulse frequency 00…72 equiv. to 0...7200 pulses/h

Turn-on delay 0…200 s

Alarm function min. and max. limit and onset delay, power failure alarm,

Dosage control 0…2000 s

Relays 3 potential-free contacts (2x controller, 1x alarm)

Analog outputs 2x 0/4…20 mA galvanically isolated

Analog inputs 1 measuring input for conductivity sensor

Digital input external controller stop or lack-of-water indication

Serial interface (Option) RS485, Baud rate 9600, data format 8 Bit,

0.00…20.00 MΩ/cm c = 0.05/cm

0.000…2.000 µS/cm c = 0.05/cm

0.00…20.00 µS/cm c = 0.05/cm

0.0…200.0 µS/cm c = 0.05/cm

0.000…2.000 mS/cm c = 0.2/cm

0.00…20.00 mS/cm c = 1/cm

0.0…200.0 mS/cm c = 10/cm

0.00…2.00 mS/cm c see measuring cell

0.,0…200.0 mS/cm c see measuring cell

0…2000 mS/cm c see measuring cell

Temperature with dimension

Status display sensor, controller & alarm

P controller as Pulse-Pause-, Impulse-Frequency- or steady controller

PI controller as Pulse-Pause-, Impulse-Frequency- or steady controller

6 A, 250 V, max. 550 VA

max. loading 500 Ohm

1 measuring input for Pt100 or NTC

1start and 1stop bit, no parity

5 OPTISENS CAC 050 / IAC 050

Page 6

1. Mechanical installation

On Chapter 9.2 you will find detailed instructions for the installation.

For panel-type meters you have to prepare an opening of 92 x 92 mm / 3.6” x 3.6”. Install the device and fix it

with the two mounting clips which were part of the delivery.

You can install devices in wall-mounting enclosures either by hanging them upon the center slot or by sliding

the slot under a screw, which is an alternative for limited space. Either way you have to fix it additionally with

two screws.

Install the device in a place where it is not put under mechanical or chemical strain!

ATTENTION

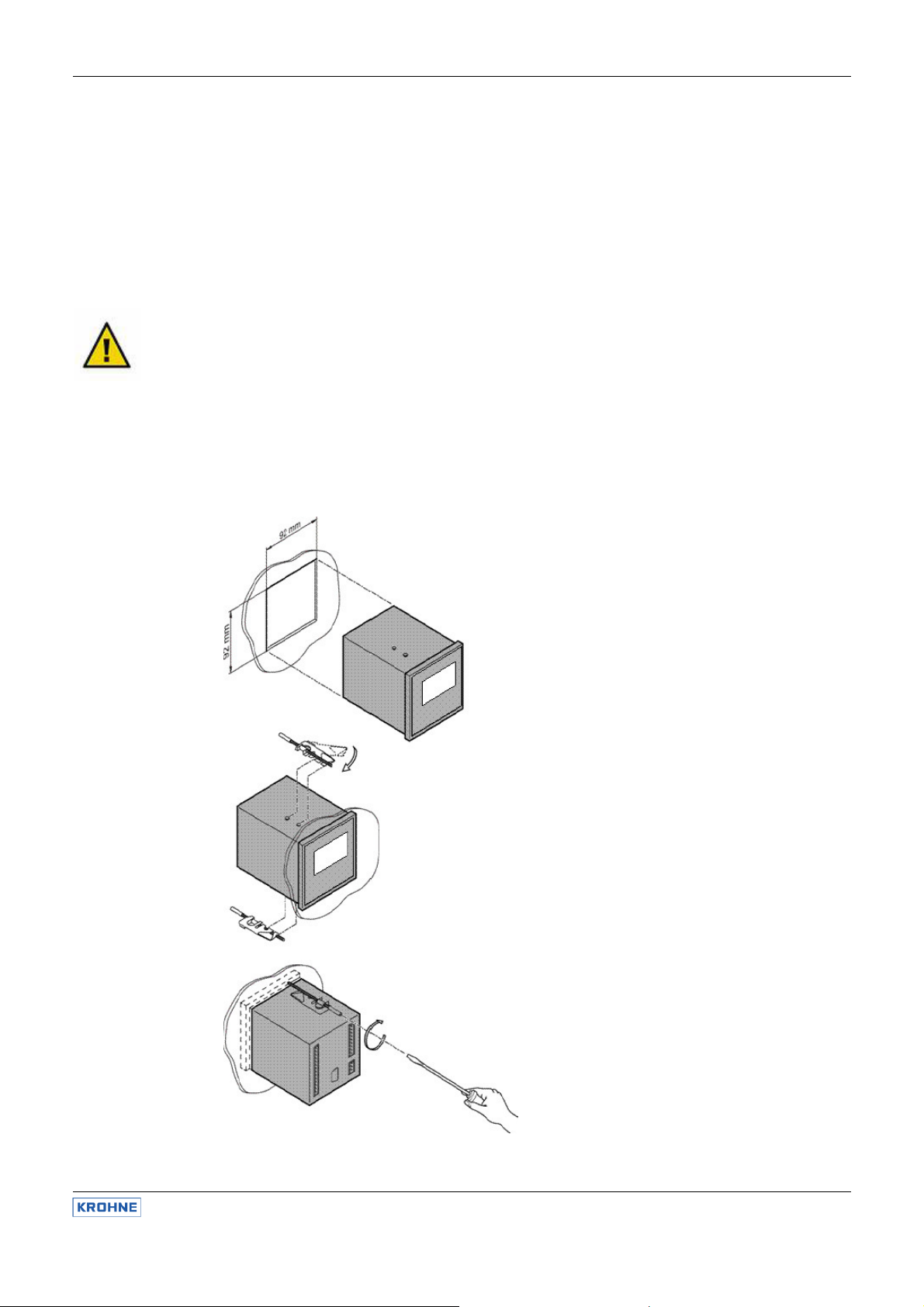

1.1 Installation of panel-mounting converters

Mind the protection class:

• Panel mounting version: IP 54 (front), IP 30 (Housing)

• Wall mounting version: IP 65 (closed terminal cover)

Prepare an opening of 92 x 92 mm / 3.6” x 3.6”.

Install the device from the front side and fix it with the

two mounting clips which were part of the delivery.

Screw tight until the device is fixed perfectly.

Manual OPTISENS CAC 050 / IAC 050

OPTISENS CAC 050 / IAC 050 6

Page 7

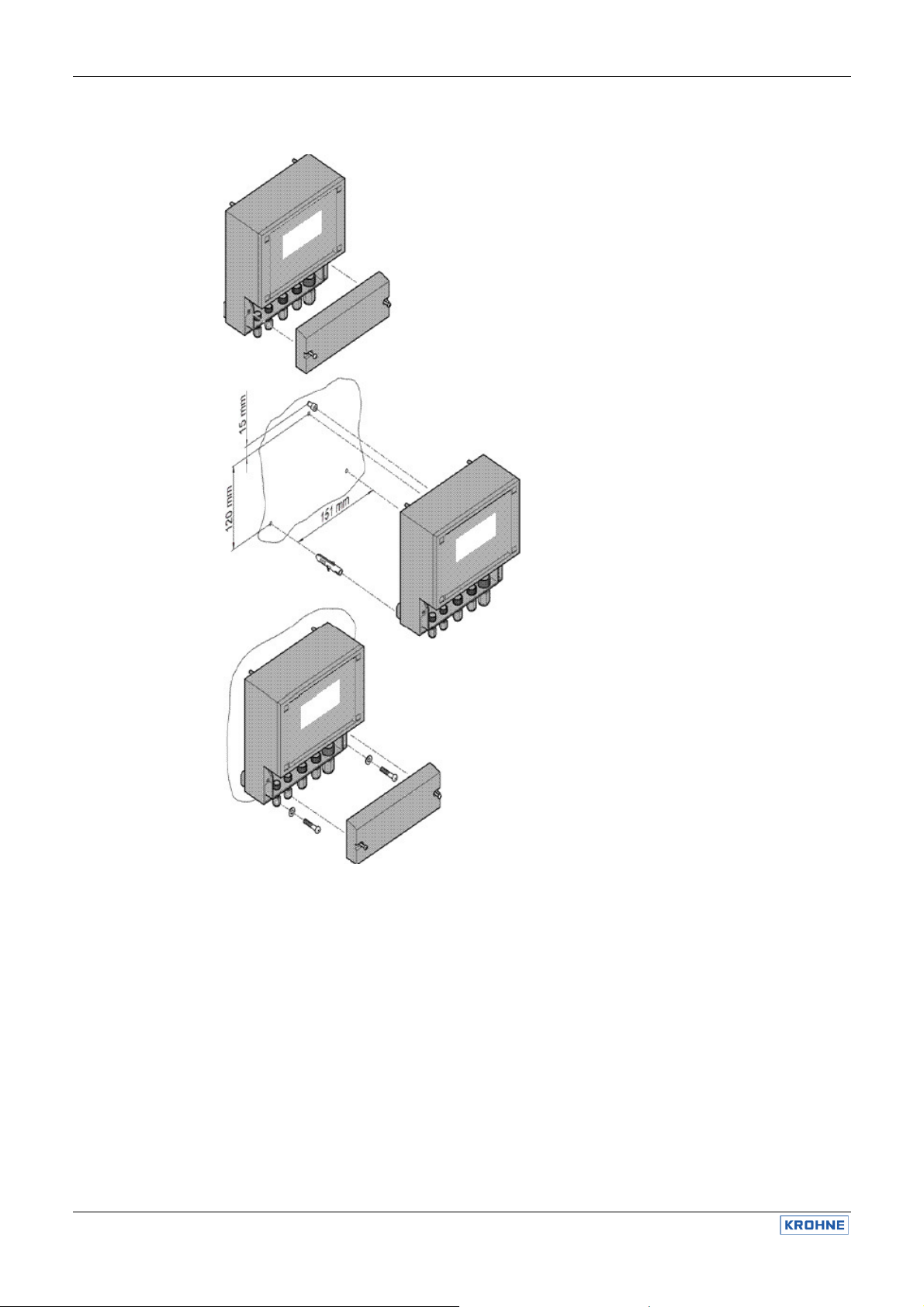

1.2 Installation of wall-mounting converters

Manual OPTISENS CAC 050 / IAC 050

Unscrew the terminal cover.

Drill three holes (max. M5) according to the drawing.

Mind that there are two ways for installation:

(1) You can hang the device upon the upper screw.

In that case drill the upper hole 120mm / 4.7” above

the lower two.

(2) Or you can slip the fixture on the back of the

device under the upper screw. In that case the upper

hole has to be another 15mm / 0.6” higher.

Insert the upper screw and make sure to leave at

least 3 mm between wall and screw head for the

fixture.

Mount the device and fix it with the two lower

screws. Close the terminal cover or start with the

connections.

7 OPTISENS CAC 050 / IAC 050

Page 8

2. Electrical connection

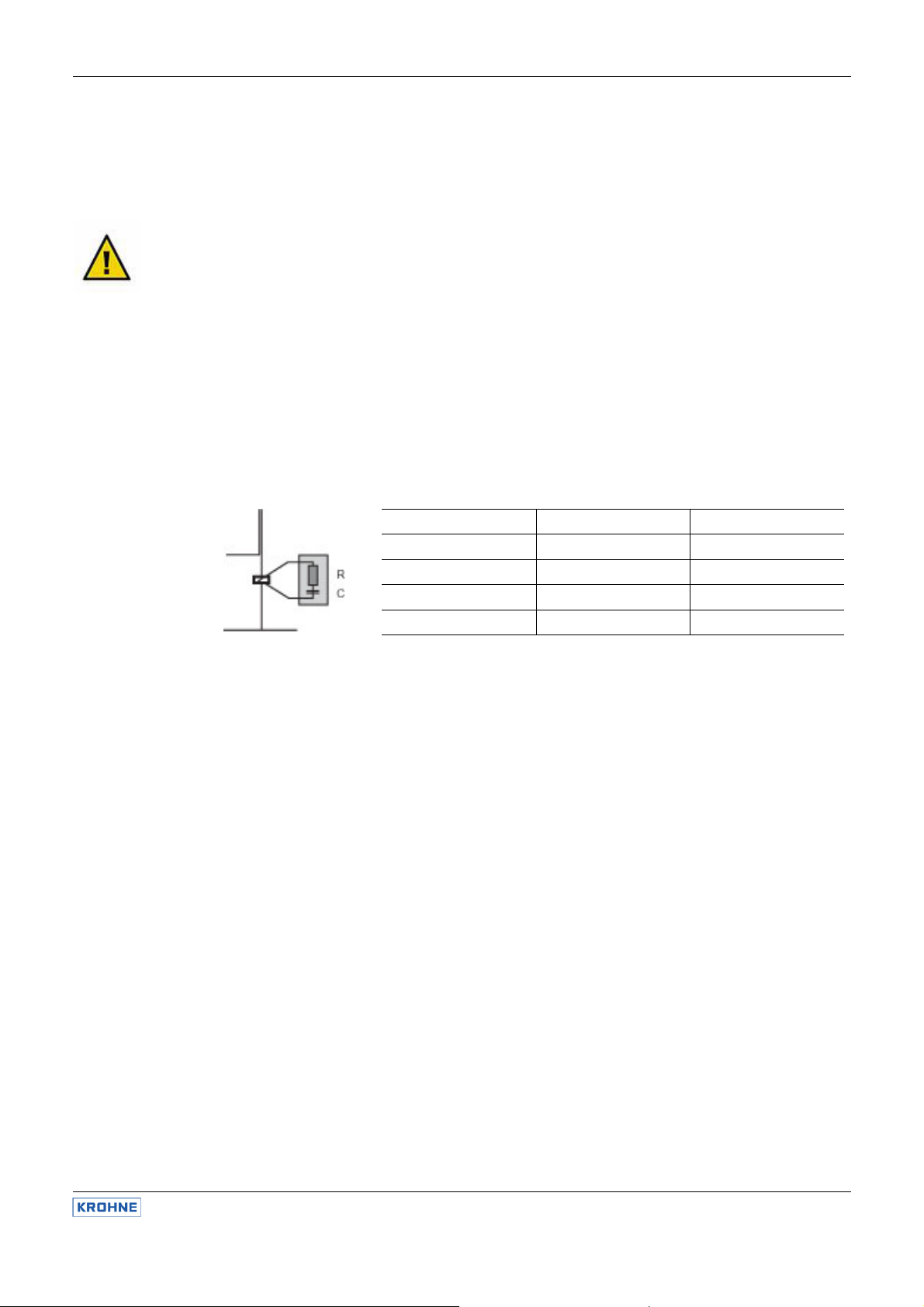

ATTENTION

You will find a detailed connection diagram on the following pages.

Before connecting the power supply check the information on the nameplate of the device!

Input, output and control lines must be installed separate from each other and separate from power lines!

For inputs and outputs use screened lines and connect the screen on one side only.

The conductivity measurement is interference-sensitive. Use a special screened cable and over long

distances or in humid atmosphere additionally an impedance converter.

For the connection of the temperature sensor use a low-resistance cable with a large diameter.

When using the relays, mind that with inductive loads, interference must be suppressed. If that is not

possible, the relay must be protected at the terminal block in the converter by a resistance-capacitance filter

or, in case of direct current, by a free- wheeling diode.

Manual OPTISENS CAC 050 / IAC 050

Current up to Capacitor C Resistance R

60 mA 10 nF 260 V 390 Ohm 2 Watt

70 mA 47 nF 260 V 22 Ohm 2 Watt

150 mA 100 nF 260 V 47 Ohm 2 Watt

1.0 A 220 nF 260 V 47 Ohm 2 Watt

OPTISENS CAC 050 / IAC 050 8

Page 9

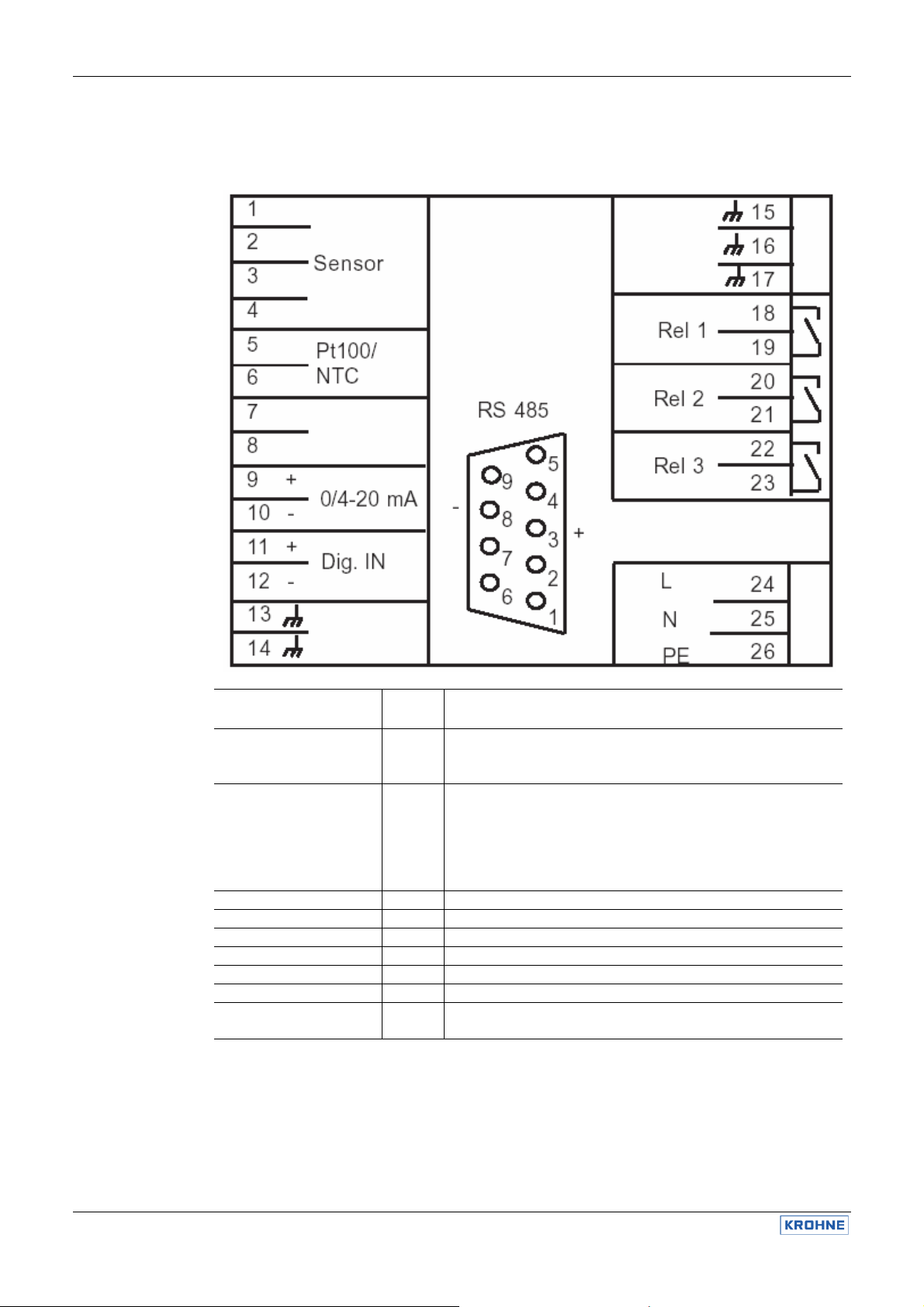

2.1 Connection diagram panel-mounting converter

Manual OPTISENS CAC 050 / IAC 050

NOTE

Connection

Conductivity sensor

conductive (CAC)

Conductivity sensor

inductive (IAC)

Pt 100 (CAC) / NTC (IAC) 5 + 6

Analog output 11 + 12 9 = + , 10 = - , max. burden 500 Ohm

Relay 1 18 + 19

Relay 2 20 + 21

Relay 3 22 + 23 Alarm relay

Power supply 24 – 26 check information given on name plate

RS485 (option) Sub-D 3 = +, 8 = -

When using different sensors or cables refer to the instructions for connection and cable color specifications

given there.

Termin

als

2 + 3

5 + 6

1 – 4

5 + 6

Notes

2 = Inner electrode = white

3 = Outer electrode = brown

Integrated Pt 100 = yellow & green

Measurement = cable #3

1 = screen, 2 = core cable #3

Voltage supply = cable #1

3 = screen, 4 = core cable #1

Integrated NTC = cable #2

5 = screen, 6 = core cable #2

4/7 bridged activates terminating resistance

9 OPTISENS CAC 050 / IAC 050

Page 10

2.2 Connection diagram wall-mounting enclosure

Manual OPTISENS CAC 050 / IAC 050

NOTE

Connection

Conductivity sensor

conductive (CAC)

Conductivity sensor

inductive (IAC)

PT 100 (CAC) / NTC (IAC) 4 + 5

Display contrast Display Potentiometer to adjust brightness

Analog output 11 + 12 11 = + , 12 = - , max. load 500 ohm

Relay 1 14 + 15

Relay 2 16 + 17

Relay 3 18 + 19 Alarm Relais

Power supply 20 - 22 Check information given on name plate

RS 485 (option) 23 + 24 23 = + , 24 = - , Jumper A activates terminating resistance

Digital input 26 + 27 26 = + , 27 = - , external controller stop and / or low water indication

When using different sensors or cables refer to the instructions for connection and cable color specifications

given there.

Termin

als

1 – 2

4 + 5

1 - 4 Measurement = cable #3

Notes

1 = Inner electrode = white

2 = Outer electrode = brown

Integrated Pt 100 = green & yellow

1 = core, 2 = screen cable #3

Voltage supply = cable #1

Integrated NTC = cable #2

4 = screen, 5 = core cable #2

OPTISENS CAC 050 / IAC 050 10

Page 11

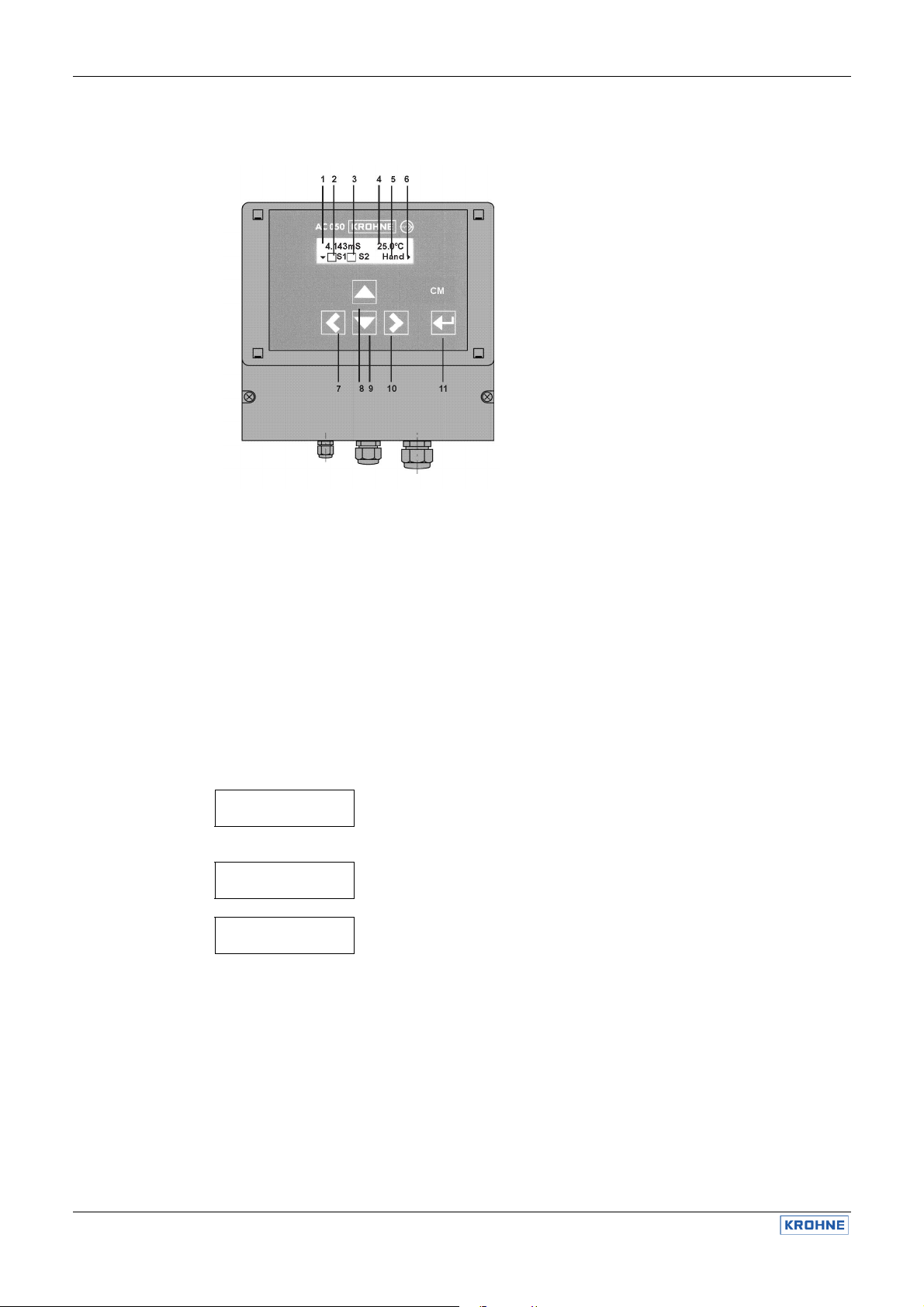

3. Operation of the device

3.1 How to adjust parameters

3.1.1 Selection between alternatives

When turned on the device shows the measured values of conductivity and temperature together with the

controller mode (Man) and the status of the relays S1 and S2 (both OFF).

With five membrane keys you can move within the menu:

• With key you enter the main menu.

• With keys and you move up and down in the menu.

• With key you address a menu or parameter.

• With key you leave a menu without storing

• With key “Enter“ changes are stored.

For your convenience triangles in the display indicate the directions you can take from your position in the

menu.

Temp. comp.

Manual.

Temp. comp.

Auto

Temp. comp.

Manual.

For many parameters you have the choice between two or more alternatives, for e. g. between manual and

automatic temperature compensation. For these parameters you need only key. Switch from one

alternative to the next until you either come back to where you started or until you reach the alternative you

were looking for.

With these parameters any changes are immediately valid - there is no need to store the change.

Manual OPTISENS CAC 050 / IAC 050

1 Measured value

2 Status relay 1

3 Status relay 2

relay OFF

relay ON

4 Temperature

5 Controller

AUTO: controller ON

MAN : controller OFF (manual operation

of the relays)

6 Orientation aids

7 Key left ()

8 Key up ()

9 Key down ()

10 Key right ()

11 Key “Enter“

1) When you address a parameter the actual setting is displayed.

2) Switch to the next alternative setting with key.

3) When you have come to the last alternative, pressing the key once

more will bring you back to the start.

11 OPTISENS CAC 050 / IAC 050

Page 12

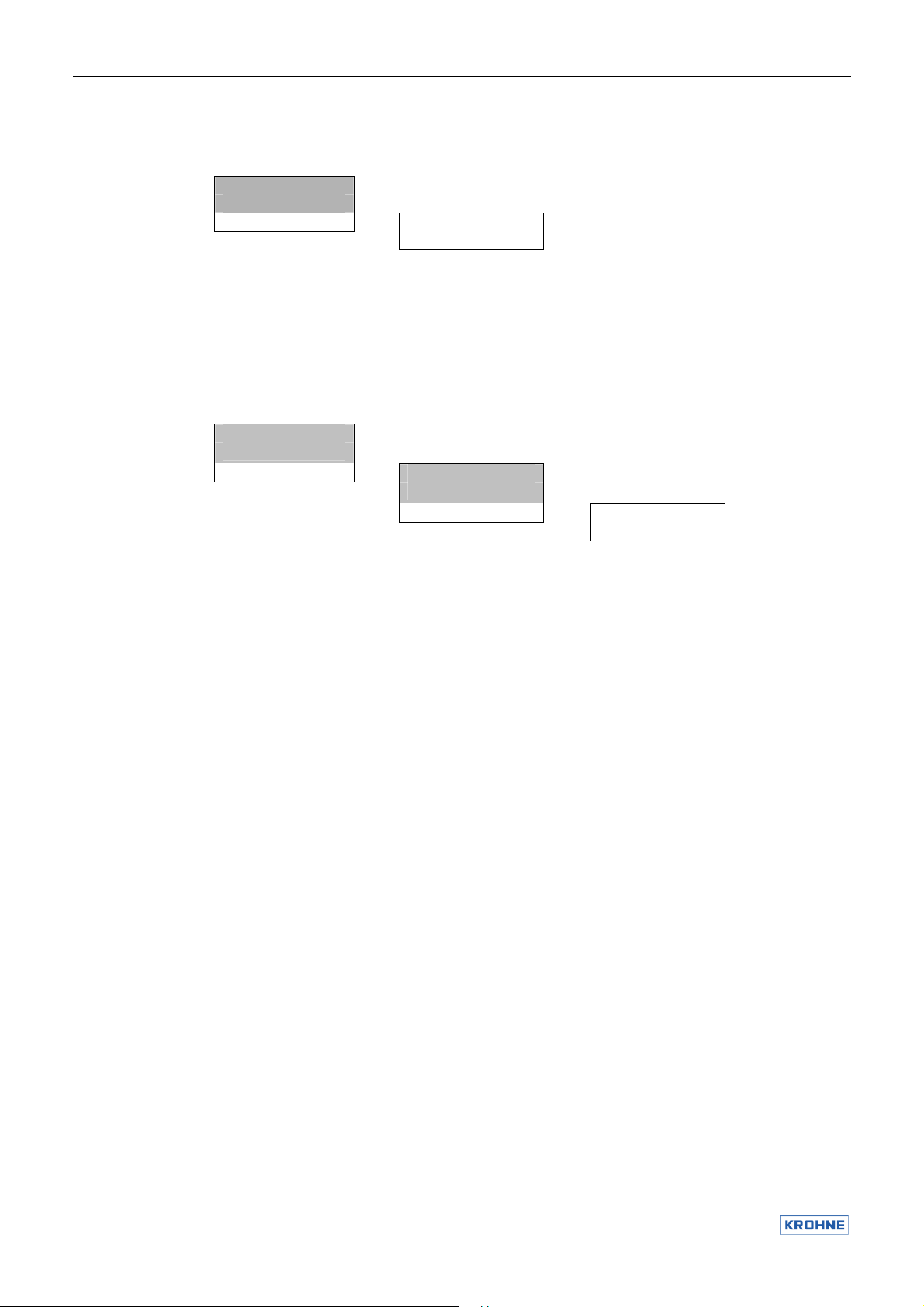

3.1.2 Adjustment of numerical parameters

Enter password

058

Enter password

058

Enter password

062

3.2 Menu Overview

3.2.1 Main menu and basic settings

Numerical parameters can only be altered when a double arrow is visible behind the number. This double

arrow appears when you address the parameter with key.

Adjust the parameter with keys and . A short pressure on the key changes the last decimal by 1. If you

keep the key pressed, the value will continue changing until the pressure is released.

Store the changes with key „Enter“. The double arrow disappears.

6.98 mS 25.0°C

S1 S2 Auto

Main menu

Temp. comp. Temperature compensation

Enter password Password function

Set points Controller settings - set points, P ranges, I functions

Limit values Alarm function

Basic settings

Service Contr. settings

Turn-on delay

Analog output

Language

Temp. coeff.

Cell factor

Cable Comp.

Bus address

Meas. range

Averaging

The parameters are sorted into two menus: In the main menu you will find all functions which are used

regularly. The menu basic settings contain all parameters which are set just once during start-up.

On the following pages you will find information on how to adjust parameters and which parameters you

need for which application. The information follows the following scheme:

1) General adjustments: password and language

2) Adjustments for measurement: cable compensation and temperature compensation, averaging and

adjustment of the cell factor

3) Adjustments of the controller: selection of the controller version and corresponding parameters

4) Adjustments to read out data: analog, digitally and/or as alarm

Manual OPTISENS CAC 050 / IAC 050

1) Address the parameter with key .

2) A double triangle appears behind the number indicating that the

number can be changed now with keys and .

3) Store the new value with key „Enter“. The double arrow disappears the new value is stored.

Display of the measured values

Press key to enter the main menu.

Basic settings

Cal. Pt 100 / NTC

All parameters which are set just once

at the beginning can be found in the

menu “basic settings“

OPTISENS CAC 050 / IAC 050 12

Page 13

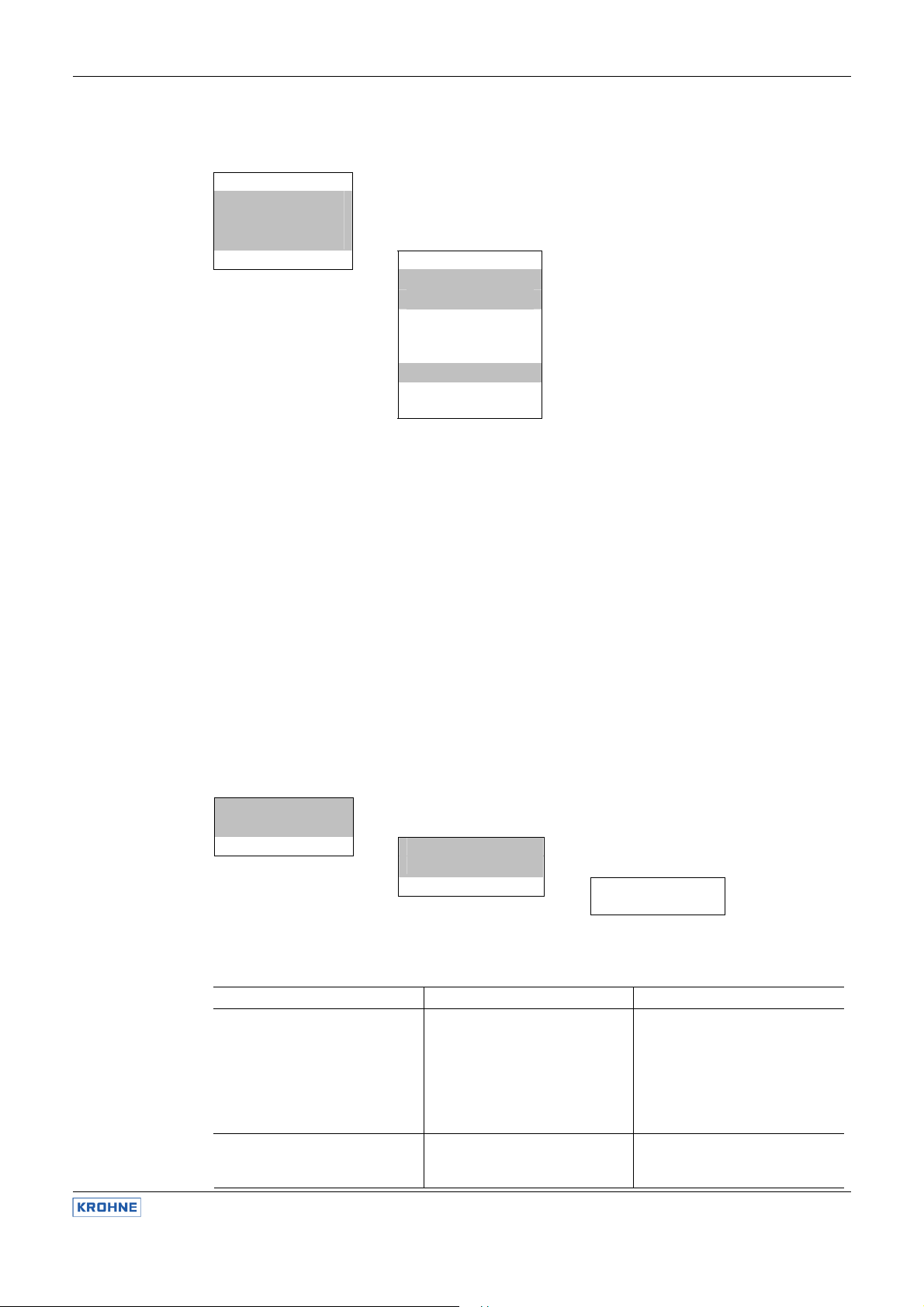

3.3 Password and language

3.3.1 Enter password

3.3.2 Language

Main menu

.

.

Enter password

056 Code

To get access to the various parameters you have to enter the correct password:

• Code 11 gives access to the parameters „calibration“, „temperature compensation“, and „set points“.

• Code 86 gives access to all parameters and functions.

With any other number it is impossible to select, view or change any parameter.

Main menu

.

.

Basic settings

Language

For the communication with the device you can choose from a variety of languages.

Since choosing a language is part of the basic settings, it requires code 86. If a different code is set, you will

be asked to enter the correct password.

Manual OPTISENS CAC 050 / IAC 050

Enter password

Basic settings

.

.

Language

We speak

English

13 OPTISENS CAC 050 / IAC 050

Page 14

4. Adjustments for the measurement

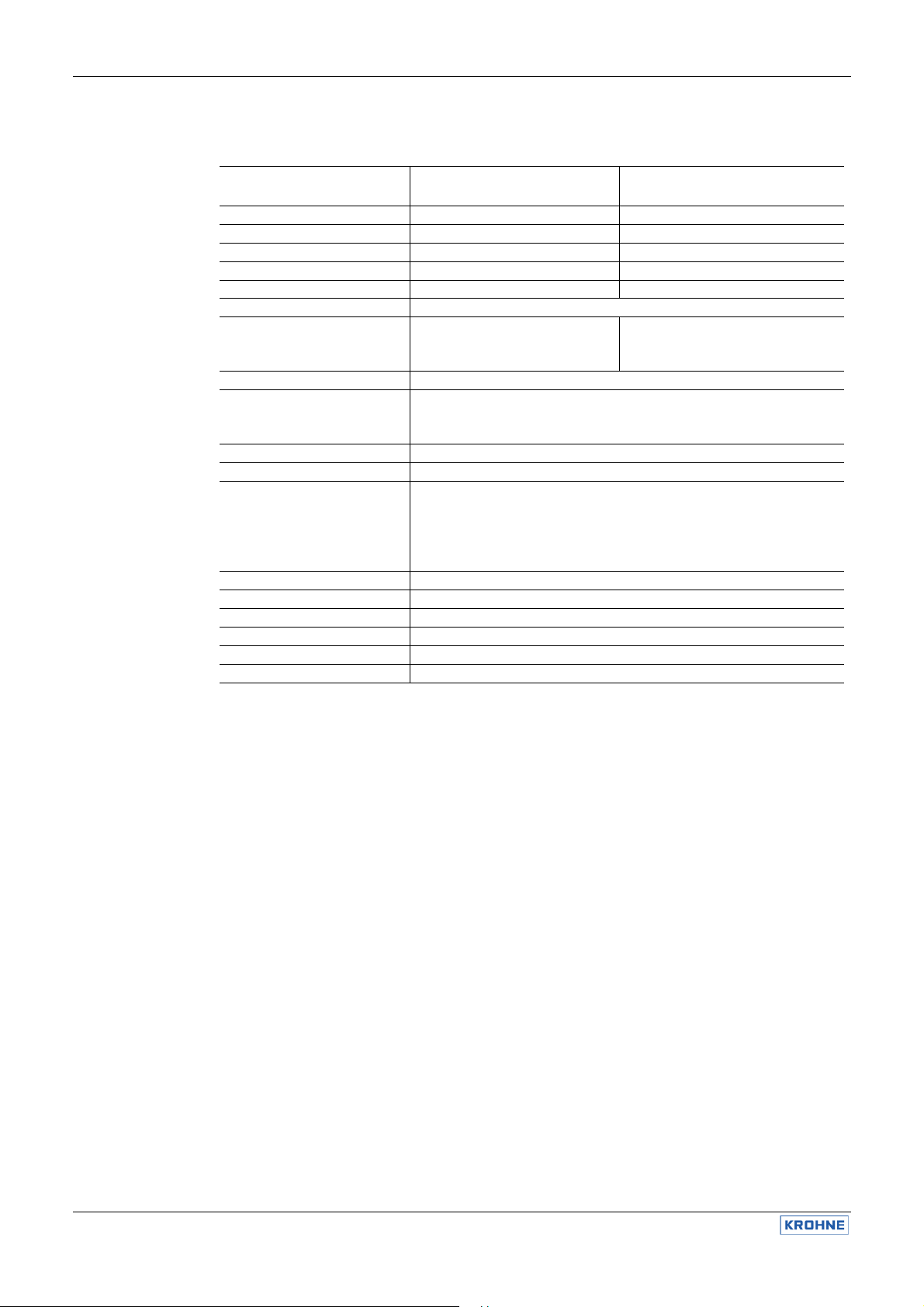

4.1 Configuration of the converter

OPTISENS CAC 050 / IAC 050 14

Main menu

Temp. comp.

.

.

.

Basic settings

Temp. coeff. Adjustment of the deviation per °C

Cell factor c Adjustment of the cell factor (sensor charact.)

Cable comp. Zero point correction (cable capacitance)

Meas. range Selection of the measuring range

Averaging Activation of a smoothing function

The conductivity measurement is influenced by temperature. This influence is compensated automatically or

manually. For manual compensation the temperature is entered manually, for automatic compensation a

temperature sensor must be connected. Compensation is carried out linearly using a temperature coefficient

in %/K which depends upon the composition of the test water.

The capacitance of the sensor cable can lead to a slight deviation of the measurement. This deviation can be

eliminated by cable compensation.

Especially in the lower measuring ranges the measurement tends to get a bit unsteady due to the high

resistance of the water. The signal can be smoothed out by activating an averaging function.

Conductivity sensors are optimized for certain measuring ranges by their geometric dimensions. These

define the cell factor (c value). If you want to use a sensor with a different cell factor or if you want to

calibrate the measurement, adjust the cell factor accordingly.

All these adjustments are part of the basic settings, since they are carried out only once at the beginning.

Main menu

.

.

Basic settings

Configuration

Temp. sensor

The devices CAC 050 and IAC 050 2 analog inputs:

Input 1 is for conductivity measurements (conductive with CAC 050, inductive with IAC 050) for a variety of

measuring ranges:

Method Measuring range Sensor

conductive 0.00...20.00 MOhm/cm c = 0.05/cm with Pt100

0.000...2.000 µS/cm c = 0.05/cm with Pt100

0.00...20.00 µS/cm c = 0.05/cm with Pt100

0.0...200.0 µS/cm c = 0.05/cm with Pt100

0.000…2.000 mS/cm c = 0.2/cm with Pt100

0.00...20.00 mS/cm c = 1/cm with Pt100

0.0...200.0 mS/cm c = 10/cm with Pt100

0.00...20.00 mS/cm Sensor with NTC

0.0...200.0 mS/cm Sensor with NTC

0...2000 mS/cm Sensor with NTC

Manual OPTISENS CAC 050 / IAC 050

Selection between automatic and manual temperature compensation,

adjustment of temperature for manual compensation.

Basic settings

Cal. temp. Calibration of the temperature measurement.

.

.

.

Basic settings

.

.

Configuration

Measurement

Page 15

NOTE

4.2 c value (cell factor)

4.2.1 Calibration via cell factor

NOTE

Input 2 is for temperature measurements.

At works the CAC 050 is configured for the measuring range 0.000…2.000 mS/cm.

The IAC 050 is configured for the measuring range 0.0…200.0 mS/cm.

With code 99 you can change the configuration. If you have entered code 99, a new menu appears at the

end of the list of basic settings called “configuration“.

Displayed is always the actual active configuration. With key you can switch from one alternative to the

next, i. e. for measurement from one measuring range to the next and for temperature from Pt100 to NTC.

Press the key again until you reach the desired configuration or return to the original setting.

A variety of conductive sensors is available with optimized design for certain measuring ranges, expressed in

the c value. Whenever you select a measuring range in the menu “configuration“, the converter automatically

selects the appropriate c value. In the basic settings use the menu “cell factor c“ to check, change or adjust

the c value according to your sensor.

Main menu

.

.

Basic settings

Cell factor c

Please make sure that the cell factor of the sensor is appropriate for the selected measuring range. In

contrast to the device which can be used for all ranges, the sensor’s applicability is limited by its geometrical

design, i. e. the size and arrangement of its electrodes. The cell factor is the numerical expression of this

design. With this cell factor the device can process the measurement and calculate standardized conductivity

values.

The cell factor is a sensor characteristic. You will find it indicated on the sensor. Prior to measurement, check

that the cell factor stored in the device corresponds to the sensor used.

The cell factor of a sensor can change slightly due to pollution or aggressive cleaning. It might even be

influenced by the armature. These deviations can be eliminated by determining the conductivity with a

comparative method and adjusting the cell factor until the measured value displayed by the device equals

this conductivity.

This calibration is only as good as the comparative method! Since it requires sophisticated equipment and

some skills, we advise to do it only if the highest precision is required. Usually the errors caused by

temperature measurement or inappropriate temperature coefficients are much higher than the deviations of

the cell factor.

Manual OPTISENS CAC 050 / IAC 050

Cell factor c

Cell factor c

0.050

Basic settings

.

.

15 OPTISENS CAC 050 / IAC 050

Page 16

4.3 Cable compensation and averaging

4.3.1 Cable compensation (zero point correction)

4.3.2 Averaging

4.4 Temperature compensation

Main menu

.

.

Basic settings

Cable comp.

Averaging

The cable connecting the sensor to the device can cause a capacitive error. To detect and eliminate this

error, connect the sensor to the device and let the dry sensor hang free in the air. If the measured value

displayed is not zero, then compensate by pressing keys and. Now the value displayed is zero.

Especially in the lower ranges the signal might become a bit unstable, due to the very high resistance of the

solution. In that case you can smooth out the signal by averaging over subsequent measurements. When the

averaging function is activated, the average is displayed instead of the single measured values.

Main menu

Temp. comp.

.

.

.

.

.

Auto comp. Manual comp.

Temperature

25.0°C

Basic settings

Temp. coeff.

Select between two ways of compensation:

1) Automatic compensation with temperature sensor

Mind that the temperature sensor should always measure the temperature around the conductivity sensor.

When conductivity sensor and temperature sensor are not immersed in the same solution, better switch to

manual compensation.

2) Manual compensation

If the temperature can be regarded as constant, you can enter the temperature manually instead of

measuring it continuously. The device will then compensate the temperature error of this temperature.

Basic settings

.

.

.

.

.

.

Automatic

compensation

Temp. comp.

Basic settings

Cal. temp.

.

.

.

.

Manual OPTISENS CAC 050 / IAC 050

Cable compensation

0.00 mS

press& simultaneously

Averaging

Averaging

ON

Manual

compensation

Temp. comp.

Calibration

temperature

Cal. temp.

0.0°C

Temperature

coefficient

Temp. coeff.

2.5%/K

OPTISENS CAC 050 / IAC 050 16

Page 17

4.4.1 Calibration of the temperature measurement

4.4.2 Temperature coefficient

When using a 2-wire connection for the temperature sensor, please check the temperature measurement in

the beginning. If the displayed temperature differs from the real temperature, enter the deviation as

correction in the basic settings. This correction will be added to all temperature measurements. If your

calibration was correct, the temperature displayed is now equal to the real temperature.

The temperature influence on the conductivity depends upon the composition of the solution and often

cannot be expressed by a simple equation. Instead the temperature dependency is compensated using a

linear coefficient given as deviation in % per K.

For most applications a coefficient of 2.5%/K can be used to good results. For ultra-pure water better select

the non-linear compensation “pure water“.

5. Adjustments of the controller

Main menu

.

.

Set points

.

.

Basic settings

Contr. settings

Turn-on delay

For any type of controller you have to enter one or two set points, and you have to tell the device whether

these set points are reached by increasing or decreasing the measured value.

You can choose between three different controller versions:

ON/OFF controller

The ON/OFF controller switches ON if the measured value exceeds the set point and OFF if it drops back

below it or vice versa. Dosage is always carried out with 100% (ON) or 0% (OFF). The parameter for an

ON/OFF controller is the hysteresis.

P controller

The P controller or proportional controller reduces the dosage in the vicinity of the set point proportional to

the control deviation. This is easily achieved if the analog output is used as steady control output. If the

relays are used, the proportional reduction is achieved by either reducing the switch frequency (Impulsefrequency controller) or reducing the time within a given period of time in which the relay is ON (pulse-pause

controller). The parameters for a P controller are the P range and the impulse- frequency or the pulse+

pause time and the minimum pulse. (See Point 5.3)

PI controller

The PI controller is a P controller with an additional I function. Adjustments and parameters are the same as

for a P controller. Additionally the integral action time has to be adjusted which determines the I function.

The I function eliminates the P controller’s disadvantage of a remaining steady-state deviation.

Manual OPTISENS CAC 050 / IAC 050

Selection of ON/OFF, P or PI controller, adjustment of P ranges and I

functions for 2 set points.

Basic settings

.

.

Adjustment of frequencies and pulse/pause

times, hysteresis, direction of the control

action, delay

17 OPTISENS CAC 050 / IAC 050

Page 18

5.1 ON/OFF controller

5.2 P / PI controller as impulse-frequency controller

Main menu

.

.

Set points

.

.

.

1,50 mS controller versions for S1

0,00 mS

Integral time S1

Set point S2

0,50 mS Controller Settings

P range S2

0,00 mS .

Integral time S2 Direction S1

000 sec. Raise

Direction S2

Basic settings

Contr. settings

For an ON/OFF controller you have to set the following parameters:

1) Set points S1 and S2

Set point S1 refers to relay 1, set point S2 refers to relay 2.

2) P range and integral action time for S1 and S2

For an ON/OFF controller set P range = 0 and integral time = 0.

3) Acting direction for S1 and S2

Select “raise“ if the dosage raises the measured value.

Select “lower“ if the dosage lowers the measured value.

4) Optionally a hysteresis

The hysteresis prevents fast switching in the vicinity of the set point. If hysteresis is activated (by setting a

value > 0) the relay switches only when the set point is exceeded by half the hysteresis.

Main menu

.

.

Set points

.

.

.

controller version

1,50 mS Controller versions for S1

P range S1 and S2

0,00 mS

Integral time S1

000 sec.

Basic settings

Contr. settings

Manual OPTISENS CAC 050 / IAC 050

Set point S1

You can choose different

P range S1 and S2

000 sec.

Basic settings

.

Set points and

.

Lower

Hysteresis

0,01 mS

Set point S1 You can choose different

Set point S2

0,50 mS

P range S2

0,00 mS

Integral time S2

000 sec

Basic settings

.

Controller settings

Pulse-Freq. S1

00*100 l/h

Pulse-Freq. S2

00*100 l/h

Direction S1

Raise

Direction S2

Lower

OPTISENS CAC 050 / IAC 050 18

Page 19

5.3 P / PI controller as pulse-pause controller

For an impulse-frequency controller you have to set the following parameters:

1) Set points S1 and S2

S1 refers to relay 1, S2 refers to relay 2.

2) P range and integral action time for S1 and S2

Adjust a P range > 0. For a P controller set integral time = 0, for a PI controller set an integral time > 0.

3) The acting direction for S1 and S2

Select „raise“ if the dosage raises the measured value.

Select „lower“ if the dosage lowers the measured value.

4) Pulse-frequencies for S1 and S2

Enter the maximum pulse-frequency that corresponds to 100% dosage.

Main menu

.

.

Set points

.

.

.

Set points S2 Direction S1

0.50 mS Raise

P range S2

0.00 mS lower

Integral time S2 .

000 sec. .

Basic settings

Contr. settings

For a pulse-pause controller you have to set the following parameters:

1) Set points S1 and S2

S1 refers to relay 1, S2 refers to relay 2.

2) P range and integral action time

Adjust a P range > 0. For a P controller set integral time = 0, for a PI controller set an integral time > 0.

3) Pulse-frequencies for S1 and S2

Both frequencies must be set to 00, otherwise the controller will act as an impulse-frequency controller.

4) The acting direction for S1 and S2

Select „raise“ if the dosage raises the measured value.

Select „lower“ if the dosage lowers the measured value.

5) Pulse + pause time

Define a period of time during which the relay is proportionally to the control deviation ON (pulse) or OFF (pause),

respectively.

Manual OPTISENS CAC 050 / IAC 050

You can choose different

Set points and

controller version

Set point S1 and S2

1,50 mS Controller settings

P range S1 Pulse-Freq. S1

0.00 mS

Integral Time S1 Pulse-Freq. S2

000 sec. 00*100 l/h

Basic settings

.

00*100 l/h

Direction S2

Pulse+Pause

10 s

Least Pulse

0.1 s

controller versions for S1

The pulse+pause

time must be twice as

long as the least

pulse time

19 OPTISENS CAC 050 / IAC 050

Page 20

5.4 Activation and deactivation of the controller

The controller is activated and deactivated from the main display without any menus. Press key to switch

from Manual Mode (controller OFF) to Automatic Mode (controller ON) and vice versa. The actual mode is

indicated in the display.

Make sure that the controller is deactivated before connecting dosing pumps or other actuators!

CAUTION

5.5 Turn-on delay

5.6 External controller stop

NOTE

Main menu

.

.

Basic settings

Contr. settings

OFF

ON

Turn-on delay

180 s

Set a delay time which has to pass before the controller is activated after start-up or power interrupt. This

allows the measurement to settle and prevents inappropriate dosage of chemicals.

You can activate or deactivate the controller with an external switch by using the digital input. This feature

requires no settings or adjustments. If the digital input is short- circuited, the controller stops, and the

message „external controller stop“ appears in the display.

This feature can also be used as lack-of water indication. Just connect a level sensor to the digital input.

Manual OPTISENS CAC 050 / IAC 050

Basic settings

.

.

Turn-on delay

Turn-on delay

Turn-on delay

OPTISENS CAC 050 / IAC 050 20

Page 21

5.7 Manual operation of the relays

1.402 mS 25.0°C

S1 S2 Auto

1.402 mS 25.0°C

S1 S2 Man

1.402 mS 25.0°C

S1 S2 Man

1.402 mS 25.0°C

S1 S2 Man

1.402 mS 25.0°C

S1 S2 Man

1.402 mS 25.0°C

S1 S2 Man

1.402 mS 25.0°C

S1 S2 Man

1.402 mS 25.0°C

S1 S2 Man

1.402 mS 25.0°C

S1 S2 Man

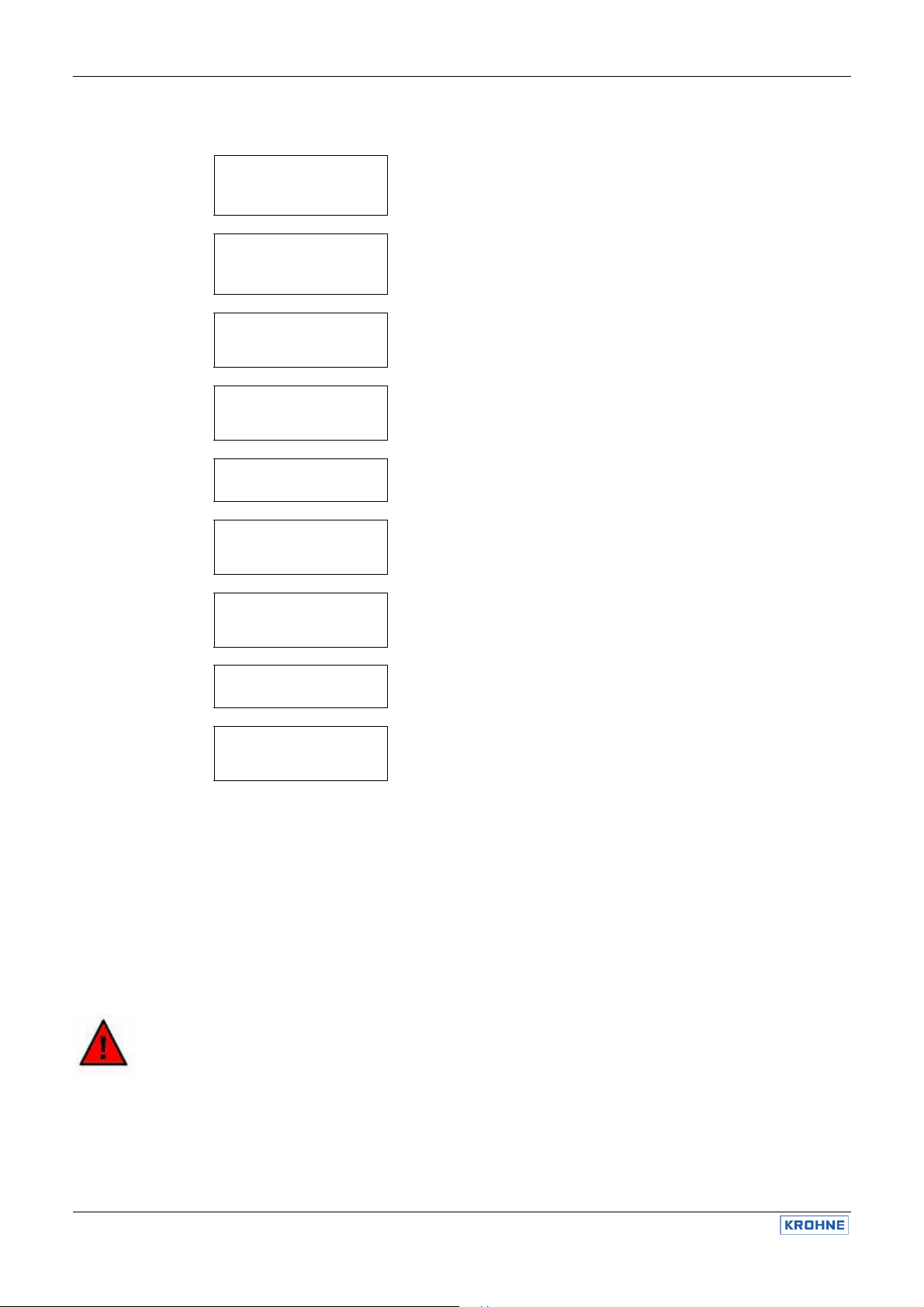

For manual operation you need no menu.

• With key you switch OFF the controller.

• With key you switch between Manual operation <> operation mode S1 <> operation mode S2 <>

manual operation.

• In the operation mode you can switch ON and OFF the selected relay with key .

• A flashing square indicates that the relay is in operation mode.

• A dark square indicates that the relay is switched ON.

• A light square indicates that the relay is switched OFF.

If you switch ON a relay it stays ON until you switch it OFF again manually!

Manual OPTISENS CAC 050 / IAC 050

1) If the controller is ON, switch it OFF with key .

Instead of „Auto“ the display shows „Man“.

2) Switch to the operation mode of S1 with key.

The square to the left of S1 starts to flash.

3) Switch ON relay 1 with key .

The square to the left of S1 gets dark.

4) Switch OFF relay 1 again with key .

The square gets light.

5) Switch to the operation mode of S2 with key.

The square to the left of S2 starts to flash.

6) Switch ON relay 2 with key .

The square to the left of S2 gets dark.

7) Switch OFF relay 2 again with key .

The square gets light.

8) Leave the operation mode of relay 2 with key .

Both squares appear light, none flashes - You have left the operation

mode.

WARNING

21 OPTISENS CAC 050 / IAC 050

Page 22

5.8 Limit values

NOTE

5.8.1 Turn-on delay

5.9 Dosage check

NOTE

NOTE

Manual OPTISENS CAC 050 / IAC 050

Main menu

.

.

Limit values

2.00 mS

Limit S2

1.00 mS

Turn-on delay

005 sec.

For the alarm, you can adjust two limits:

• Limit 1 is an upper limit. If the measured value exceeds limit 1, an alarm is issued.

• Limit 2 is a lower limit. The alarm is issued if the measured value drops below limit 2.

In case of alarm the display shows the message „limit 1“ (or 2, respectively) and relay 3 is switched ON. This

relay can be used to activate an external horn or lamp.

The limit function is active only if the controller is set on automatic mode. When you switch the controller to

MAN, the alarm is extinguished.

In some applications it happens regularly that the measured value exceeds a limit for a short period of time.

To avoid having an alarm issued under these circumstances you can adjust a turn-on delay which has to

pass before an alarm is issued. If the turn- on delay time is >0 then the alarm is issued only if the cause of

alarm remains longer than the specified turn-on delay time.

Main menu

.

.

Basic settings

Contr. settings

Dosage check S2

00 min

In the basic settings of the controller you can define, how long a controller is supposed to dose with 100%

without raising alarm.

If the controller output is 100% for more than the specified time, this is interpreted as an indication of failure,

and the device issues an alarm and deactivates the controller, thus stopping further dosage.

The dosage check is a safety catch to prevent hazardous chemicals to be set free in case of a defective

dosing tube or tube connection.

In case of an alarm due to dosage check, only the controller concerned is deactivated.

If you set the dosage check time to 0 minutes, the dosage check function is deactivated.

Limit values

Limit S1

Basic settings

.

.

Controller settings

Dosage check S1

00 min

OPTISENS CAC 050 / IAC 050 22

Page 23

6. Alarm

Manual OPTISENS CAC 050 / IAC 050

Additional to the limit function the device provides various check functions that raise alarm.

In case of an alarm, relay 3 switches, undelayed, and the cause of the alarm is indicated in the display.

If the cause of alarm is such that control is no longer possible or might even be dangerous, the controller is

automatically deactivated until the alarm is switched off.

Switching off the alarm is done automatically by the device as soon as the cause of alarm is eliminated.

Sensor check during measurement

During measurement all connected sensors are checked. If an analog input does not receive a correct signal,

for e. g. if a cable is broken or a sensor damaged, an alarm is issued, and the controller deactivated. Alarm

and controller stop remain until the analog input receives correct signals again.

Dosage control

If a controller output is 100% longer than the defined dosage time, an alarm is issued, and the corresponding

controller is deactivated. The alarm remains until the controller output drops below 100% - it can also be

extinguished by setting the controller to manual mode.

Cause of alarm only active in AUTO mode deactivates controller

Error input 1 no yes

Error input 2 no yes

Limit yes no

Dosage yes yes

23 OPTISENS CAC 050 / IAC 050

Page 24

6.1 Error messages

7. Output

Manual OPTISENS CAC 050 / IAC 050

Error message Cause Action

Error input 1 The conductivity sensor gives no

signal.

Error input 2 The temperature sensor gives no

signal.

Please check the connections, the cable

and the sensor for signs of damage.

Please check the connections, the cable

and the sensor for signs of damage. This

message also appears if automatic

temperature compensation was selected

although no temperature sensor was

used.

Limit 1 / 2 The measured value exceeded limit

1 (or dropped below limit 2,

Please check the dosing and readjust the

control parameters, if necessary.

respectively).

Dosage Pump 1 (or 2, resp.) feeds with

100% for more than the defined

period of time.

Ext. controller stop The digital input has been short-

circuited.

Please check the dosing, especially the

feeding tubes and connections. Caution!

Carefully check for leaking chemicals!

This only indicates the external controller

stop. If, however, you have connected a

level sensor, this message appears due

to the „lack of water“ alarm.

Main menu

.

.

Basic settings

Analog output

Basic settings

.

.

.

0 – 20 mA 4-20 mA

.

.

0.00mS Corresp. to 4 mA

Analog output

Select output -between 0-20 mA and

Selection

Begin 0/4 mA -of the measured value

End 20 mA -of the measured value

2.00 mS Corresp. to 20 mA

Analog output -between readout of the

Measuring value Measurement or the

Control values

Serial interface

RS485 (option)

Bus address

Nr. 00

Bus address

Set a number between

0 and 31 to address the

device via data bus.

OPTISENS CAC 050 / IAC 050 24

Page 25

7.1 Current output

7.2 Serial interface RS485 (option)

You can read out the measured value as 0/4…20 mA signals via the current output.

With the setting 4…20 mA the resolution is lower, but defective cable connections are immediately evident.

With the parameters Begin and End you define which part of the measuring range you want to read out.

Alternatively you can use the current output as steady-state controller output. In that case assign the current

output to controller S1 or S2, respectively.

The devices are available with serial interface RS485 by means of which they can be integrated in a data

bus system. Via the interface, all settings, measured and control values as well as any error messages can

be read out digitally.

Devices with RS485 are automatically delivered with the leaflet „Information on the RS485“ which contains

instructions on the communication and a complete list of the functions available via interface.

8. Operation and maintenance

8.1 Maintenance of the device

8.2 Display contrast

8.3 Exchange fuse

The device does not require any maintenance. There is no need for readjustment. If you want to have the

device checked regularly, you are welcome to send it to KROHNE Water Solutions. Alternatively the device

can be checked on site by one of our engineers.

With devices in wall-mounting enclosures the display contrast can be adjusted to the actual light conditions

by means of a potentiometer. It is indicated in the connection diagram with the word „display“.

Devices in wall-mounting enclosures have an internal fuse which has to be replaced at need. You will find a

spare fuse fixed to the inside of the terminal cover. Information on the fuse can be found in the chapter

„Technical data“.

To exchange the fuse, open the front carefully. The fuse is located on the right hand side. It is kept in place

by a Bayonet lock. Turn the lock to the left until the fuse pops up. Exchange it and fix the new fuse by turning

the lock to the right. Put the front back on and fix it tightly.

Disconnect the power supply before opening the device!

Manual OPTISENS CAC 050 / IAC 050

WARNING

Mind that the cable connections to the front are not damaged, broken or torn during the process!

ATTENTION

8.4 Cleaning

25 OPTISENS CAC 050 / IAC 050

The front and the display should not get in touch with organic solutions such as methanol. Never let water

get inside the device. We suggest to simply use a damp cloth for cleaning.

Page 26

8.5 Maintenance of the conductivity measurement

8.6 Disposal

8.7 Service

8.7.1 Product info

8.7.2 Analog inputs

8.7.3 Erase settings (reset)

The metallic surfaces of the sensors must be cleaned regularly. Slight changes of the sensor due to usage,

aggressive cleaning or even installation conditions can be corrected by means of adjustment of the c value in

the basic settings.

For disposal please notice that the device contains electrolyte capacitors which have to be disposed

separately.

Main menu

.

.

.

.

.

Service

Analog inputs

Input 1 003

Input 2 25.0°C

Erase settings

Press &

In this menu you will find information which is especially important for any inquiries, updates or problems.

These figures allow a precise identification of the device (hardware and software).

Here you can see the raw data the device obtains from the sensors. They are not influenced by

compensations or calibration and offer valuable information in case of problems with the measurement or the

device.

If you have problems interpreting this data, send them to your supplier together with the device data and ask

for support.

With this function you can erase all customer settings and restore the original at-works data.

The process takes some 30 seconds. When it is finished the display will show the measured value, and the

controller will switch off.

Unit no.

No. 041

Software date

M/Y 1.00

Service

Product info

Manual OPTISENS CAC 050 / IAC 050

Product. date

M/Y 1.00

Analog inputs

Analog inputs

Erase settings

simultaneously

OPTISENS CAC 050 / IAC 050 26

Page 27

9. Technical data

9.1 Technical data

Manual OPTISENS CAC 050 / IAC 050

Feature

Version panel-type converter wall-mounting enclosure

Dimensions (w x h x d) 96 x 96 x 127 mm / 3.8 x 3.8 x 5” 165 x 160 x 80 mm / 6.5 x 6.3 x 3.1”

Weight 0.8 kg / 1.8 lbs 1.0 kg / 2.2 lbs

Terminals screw terminals max. 1.5 mm2 Spring terminals max. 1,5 mm2

Protection class IP 54 (front), IP 55 (front door) IP 65

Power supply 230 V +6/-10 %, 50/60 Hz, optional 110 V or 24 V

Internal fuse none 230 V: 63 mA slow

Power consumption 10 VA

Display LCD, 2-line, 2x16 characters, illuminated background

Current output 0/4...20 mA, galvanically isolated, max. loading 500 Ohm

Interface (option) RS485, Baud rate 9600, data format 8Bit, 1 Start and 1 Stop bit

Controller ON/OFF controller with hysteresis, P or PI controller as Pulse- Pause- or

Set points 2 set points adjustable within the measuring range

Alarm function with min. and max. limit and turn-on delay

Contact rating 6 A/ 250 V, max. 550 VA resistive load (with RC protective circuit)

Operation temperature 0…+50°C / 32…+120°F

Storage temperature -20…+65°C / -5…+150°F

Humidity max. 90% at 40°C /105°F non-condensing

CAC 050 R

IAC 050 W

measured value and temperature with dimensions indication of relay

status

Impulse-frequency controller, steady controller, bidirectional PI control

action, adjustable onset-delay, dosage control function, manual operation

of the relays, controller stop via external switch or level sensor (lack-ofwater sensor)

CAC 050 W

IAC 050 W

110 V: 125 mA slow

24 V: 800 mA semi-slow

27 OPTISENS CAC 050 / IAC 050

Page 28

9.2 Dimensions

9.2.1 Panel-mounting enclosure

Manual OPTISENS CAC 050 / IAC 050

9.2.2 Wall-mounting enclosure

OPTISENS CAC 050 / IAC 050 28

Page 29

Manual OPTISENS CAC 050 / IAC 050

10. Device return form

This device has been carefully manufactured and

tested. If installed and operated in accordance with

these operating instructions, it will rarely present any

problems. Should you nevertheless need to return a

device for inspection or repair, please pay strict

attention to the following points:

Due to statutory regulations on environmental

protection and safeguarding the health and safety of

our personnel, KROHNE Water Solutions may only

handle, test and repair returned devices that have

been in contact with products without risk to personnel

and environment.

This means that KROHNE Water Solutions can only

service this device if it is accompanied by the

following certificate confirming that the device is safe

to handle.

If the device has been operated with toxic, caustic,

flammable or water-endangering products, you are

kindly requested:

• to check and ensure, if necessary by rinsing or

neutralizing, that all cavities are free from such

dangerous substances,

• to enclose a certificate with the device confirming

that is safe to handle and stating the product

used.

We cannot service this device unless accompanied by

such a form.

S P E C I M E N certificate

Email:…………………………………………………...

The enclosed device

Type:……………………………………………………………………………………………………………………………

KROHNE Water Solutions Order No. or Series No.:……………………………………………………………………..

has been operated with the following liquid:……………………………………………………………………………….

Company:………………………………………………. Address:…………………………………………………

Department:…………………………………………… Name:……………………………………………………

Tel. No.:……………………………………………….. Fax No.:……………………………………………........

Because this liquid is

water-hazardous toxic caustic.. flammable

we have

checked that all cavities in the device are free from such substances

flushed out and neutralized all cavities in the device

We confirm that there is no risk to humans or environment through any residual liquid contained in this device.

29 OPTISENS CAC 050 / IAC 050

Page 30

11. Customer settings - for reference

OPTISENS CAC 050 / IAC 050 30

Device

Type: ………………. date of installation: ……………….

Serial number: ………………. Software version: ……………….

Measurement

c value: ………………... Averaging

Temperature compensation

Temperature: …………….°C Correction: …………….°C

Temperature

Analog output

Output

for conductivity

Controller S1 Controller S2

Start: ……………………

End: ……………………

Controller

Controller S1 Controller S2

Acting direction Acting direction

raise lower raise lower

Set point: …………………… Set point: ……………………

Hysteresis: …………………… Hysteresis: ……………………

P range: …………………… P range: ……………………

Integral time: …………………..s Integral time: …………………..s

Pulse+ pause time: …………………..s Pulse+ pause time: …………………..s

Minimum pulse: …………………..s Minimum pulse: …………………..s

Pulse frequency: …………….*100/h Pulse frequency: …………….*100/h

Dosage check: ……………. min Dosage check: ……………. min

Turn-on delay

Delay time: ……………… sec.

Alarm

Limit S1 …………………… Limit S2 ……………………

Delay time: ……………… sec.

Serial interface RS 485

Bus address: ……………………

Identification / location: ………………………………………………….

conductive inductive

Manual

linear Pure water

coefficient:

0…20mA 4…20mA

Manual OPTISENS CAC 050 / IAC 050

activated:

……………..%/°C

Automatic

Pt100 NTC

yes no

Loading...

Loading...