Page 1

©

KROHNE 07/2003 7.02263.21.00

GR

Status: 05-1998

Installation and

operating instructions

C95 CI

Digital panel meter (6 digits)

Valid for instruments with version v.01

Variable area flowmeters

Vor tex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Australia

KROHNE Australia Pty Ltd.

Unit 19 No.9, Hudson Ave.

Castle Hill 2154, NSW

TEL.: +61(0)2-98948711

FAX: +61(0)2-98994855

e-mail: krohne@krohne.com.au

Austria

KROHNE Austria Ges.m.b.H.

Modecenterstraße 14

A-1030 Wien

TEL.: +43(0)1/203 45 32

FAX: +43(0)1/203 47 78

e-mail: info@krohne.at

Belgium

KROHNE Belgium N.V.

Brusselstraat 320

B-1702 Groot Bijgaarden

TEL.: +32(0)2-4 66 00 10

FAX: +32(0)2-4 66 08 00

e-mail: krohne@krohne.be

Brazil

KROHNE Conaut

Controles Automaticos Ltda.

Estrada Das Águas Espraiadas, 230 C.P.56

06835 - 080 EMBU - SP

TEL.: +55(0)11-4785-2700

FAX: +55(0)11-4785-2768

e-mail: conaut@conaut.com.br

China

KROHNE Measurement Instruments Co. Ltd.

Room 7E, Yi Dian Mansion

746 Zhao Jia Bang Road

Shanghai 200030

TEL.: +86(0)21-64677163

FAX: +86(0)21-64677166

Cellphone: +86(0)139 1885890

e-mail: info@krohne-asia.com

CIS

Kanex KROHNE Engineering AG

Business-Centre Planeta, Office 403

ul. Marxistskaja 3

109147 Moscow/Russia

TEL.: +7(0)095-9117165

FAX: +7(0)095-9117231

e-mail: krohne@dol.ru

Czech Republic

KROHNE CZ, spol.s r.o.

Sobe˘s˘ická 156

CZ-63800 Brno

TEL.: +420 545 532 111

FAX: +420 545 220 093

e-mail: brno@krohne.cz

Algeria

Argentina

Bulgaria

Camaroon

Canada

Chile

Columbia

Croatia

Denmark

Ecuador

Egypt

Finland

French Antilles

Greece

Guinea

Hong Kong

Hungary

Indonesia

Ivory Coast

Iran

Ireland

Israel

Japan

Jordan

Kuwait

Marocco

Mauritius

Mexico

New Zealand

Pakistan

Poland

Portu gal

Saudi Arabia

Senegal

Singapore

Slovakia

Slovenia

Sweden

Taiwan

Thailand

Turk ey

Tunesia

Venezuela

Yugoslavia

France

KROHNE S.A.S.

Usine des Ors

BP 98

F-26 103 Romans Cedex

TEL.: +33(0)4-75 05 44 00

FAX: +33(0)4-75 05 00 48

e-mail: info@krohne.fr

Germany

KROHNE Messtechnik

GmbH & Co. KG

Ludwig-Krohne-Straße

D-47058 Duisburg

TEL.: +49(0)203-301-0

FAX: +49(0)203-301 389

e-mail: krohne@krohne.de

India

KROHNE Marshall Ltd.

A-34/35, M.I.D.C.

Industrial Area, H-Block,

Pimpri Poona 411018

TEL.: +91(0)20-744 20 20

FAX: +91(0)20-744 20 40

e-mail: pcu@vsnl.net

Italy

KROHNE Italia Srl.

Via V.Monti 75

I-20145 Milano

TEL.: +39(0)2-4 30 06 61

FAX: +39(0)2- 43 00 66 66

e-mail:krohne@ krohne.it

Korea

Hankuk KROHNE

2 F,599-1

Banghwa-2-Dong

Kangseo-Ku

Seoul

TEL.: +82(0)2665-85 23-4

FAX: +82(0)2665-85 25

e-mail: flowtech@unitel.co.kr

Netherlands

KROHNE Altometer

Kerkeplaat 12

NL-3313 LC Dordrecht

TEL.: +31(0)78-6306300

FAX: +31(0)78-6306390

e-mail: postmaster@krohne-altometer.nl

KROHNE Nederland B.V.

Kerkeplaat 12

NL-3313 LC Dordrecht

TEL.: +31(0)78-6306200

FAX: +31(0)78-6306405

Service Direkt: +31(0)78-6306222

e-mail: info@krohne.nl

Norway

Krohne Instrumentation A.S.

Ekholtveien 114

NO-1526 Moss

P. O. Box 2178, NO-1521 Moss

TEL.: +47(0)69-264860

FAX: +47(0)69-267333

e-mail: postmaster@krohne.no

Internet: www.krohne.no

South Africa

KROHNE Pty.Ltd.

163 New Road

Halfway House Ext. 13

Midrand

TEL.: +27(0)11-315-2685

FAX: +27(0)11-805-0531

e-mail: midrand@krohne.co.za

Spain

I.I. KROHNE Iberia, S.r.L.

Poligono Industrial Nilo

Calle Brasil, n°. 5

E-28806 Alcalá de Henares-Madrid

TEL.: +34(0)91-8 83 21 52

FAX: +3 4(0)91-8 83 48 54

e-mail: krohne@krohne.es

Switzerland

KROHNE AG

Uferstr. 90

CH-4019 Basel

TEL.: +41(0)61-638 30 30

FAX: +41(0)61-638 30 40

e-mail: info@krohne.ch

United Kingdom

KROHNE Ltd.

Rutherford Drive

Park Farm Industrial Estate

Wellingborough,

Northants NN8 6AE, UK

TEL.: +44(0)19 33-408 500

FAX: +44(0)19 33-408 501

e-mail: info@krohne.co.uk

USA

KROHNE Inc.

7 Dearborn Road

Peabody,MA 01960

TEL.: +1-978 535-6060

FAX: +1- 978 535-1720

e-mail: info@krohne.com

Overseas Representatives

Other Countries:

KROHNE Messtechnik

GmbH & Co. KG

Ludwig-Krohne-Str.

D-47058 Duisburg

TEL.: +49(0)203-301 309

FAX: +49(0)203-301 389

e-mail: export@krohne.de

Subject to change without notice

Page 2

4.8 Access code p20

4.9 Programming of a new access code p20

4.10 Functions accessible in the main menu p20

4.10.1 - Display simulation p20

4.10.2 - Analog ouptut simulation p21

4.10.3 - Menu CLEAr : p21

Deleting of recorded alarms

4.10.4 - Menu CLr.tA : p21

Deleting of the recorded tare

5 . FUNCTIONS DIRECT FROM THE DISPLAY p21

5.1 Functions which require pressing only 1 key p21

5.1.1 - On the instant value display p21

a / Minimum value display p21

b / Maximum value display p21

c / Erasing of min. and max. values p22

5.1.2 - On the totalizer display p22

a / Upper part display p22

b / Access to the zero reset menu p22

5.2 Functions which require pressing several keys p22

5.2.1 - Display shifting p22

5.2.2 - Tare setting p23

5.2.3 - Changing of the displayed value p23

5.2.4 - Direct measure visualisation p23

5.2.5 - Visualisation and setting of alarm setpoints p23

6 . ERROR MESSAGES p23

7 . GENERAL WARRANTY TERMS p24

8 . LEXIQUE p24

9 . ANNEXE : MODBUS p28

9.1 Table of Modbus addresses p28

9.2 Description of born Modbus functions p29

9.3 Reading in double integer format p29

9.4 CRC16 calculation algorythm p30

S

Summary

1 . INTRODUCTION p2

2 . SPACE REQUIREMENTS p3

3 . WIRING p4

4 . PROGRAMMING p5

4.1 Communication with the instrument p5

4.2 Orientation through programming p6

4.3 Main menu p6

4.4 Programming menu p6

4.4.1 - Input programming p7

4.4.2 - Display programming p7

4.4.3 - Programming of the totalizer p8

4.4.4 - Programming of the analog output p8

4.4.5 - Programming of the digital output p9

4.4.6 - Programming of the LOGIC inputs p9

4.4.7 - Programming of the relay outputs p10

4.4.8 - Programming of the safeties p11

4.4.9 - Programming of the brightness, displays

and bargraph p12

4.4.10 - Programming exit p13

4.5 Input features and programming limits p13

4.5.1 - Current input p13

4.5.2 - Voltage input p14

4.5.3 - Instant value display p14

4.5.4 - Totalizer p15

4.5.5 - Display features p15

4.5.6 - LOGIC inputs p16

4.6 Output features and programming limits p17

4.6.1 - Analog output p17

4.6.2 - Digital output p17

4.6.3 - Relay outputs p17

4.6.4 - Safeties p18

4.7 Configuration reading p19

Page 3

S

The C95 CI is a totalling digital panel meter. The totalling function allows

converting any instant value, after integration, into a cumulated magnitude.

It can be connected to a flowmeter to display the instant flow and the

cumulated volume or weight, and also to a converter, for instance a

power converter to display the instant power and the energy consumption of an installation.

General features

- Instant value display on 5 digits (14mm) with scale factor adjusting

from -99 999 to 99 999

- Cumulated value display on a 6 digit counter (14mm) associated with

a second overstepping counter, allows totalling from -99 999 999 to

+999 999 999

- Totalizer memory saved in case of power supply cut

- Programming of the integration time (sec, min, hours) and of

a convertion coefficient (from 0,0001 to 999999)

- A bargraph allows a quick evaluation either of the instant value or

the cumulated value, and can also be used as indicator for various

functions (overstepping, LOGIC input, RS, etc...)

• Input

:

- Direct current or voltage, bidirectionnal

±100mV, ±1V, ±10V, ±300V, ±20mA

- Measurable scale overstepping from -5% to +5%

- Input impedance ≥1MΩ for voltage inputs

drop 0.9V max for the current input

- Enlarging effect possible

- Linear input with or without square root extraction and special curve

on 20 pt (programmable in X and in Y).

- Supply for 2 or 3 wire sensor for the current input : 26 VDC (±15%)

100mA protected from short-circuits.

11.. IINNTTRROODDUUCCTTIIOONN

•T

ransfer :

- Accuracy 0.05% of full scale at 25°C

- Thermic drift <150 ppm / °C

- Sampling time : 100ms

- Filtering : Programmable integration time (10 coefficients)

- Common mode rejection rate : 130 dB

- Serial mode rejection rate : 70 dB 50/60 Hz

- Insulation : Input / Power supply : 2.5kV 50 Hz 1 min

Input / Output : 2.5kV eff. 50 Hz 1 min

AAVVAAIILLAABBLLEE OOPPTTIIOONNSS

: (specify on order)

Insualted analog output

: A

Programmable on the instant or cumulated value

Active current output

Programmable scale ratio with enlarging effect.

Relay output

2 relays (R)

Programmable :

- As Pulse output with adjusting of the pulse weight

(-10 000 to +10 000) and of its duration

(100, 200 or 400 ms)

- In mode alarm on the instant or cumulated value

Mode setpoint or window.

Recording of alarms.

Time delay and hysteresis adjustable on each setpoint.

Alarm messages

Insulated digital output

: N

RS 485 2 wire, protocole MODBUS-JBUS.

LOGIC input 2 insulated LOGIC inputs with programmable functions

Several types of totalizer zero reset

Integration stop and start

Display blocking

Display switching (instant value / totalizer)

Function tare,

min. and max. zero reset

Page 4

S

Protection :

Front face : IP 65

Case : IP20

Terminals : IP 20

Case

:

Self-extinguishing casing of

black UL 94 V0 ABS.

Connectors

plug-off connectors on

rear face for screwed conections

(2.5mm², flexible or rigid)

Display

: (14 mm)

Electroluminescent red (green optional)

4 alarm Leds

bargraph : 16 leds

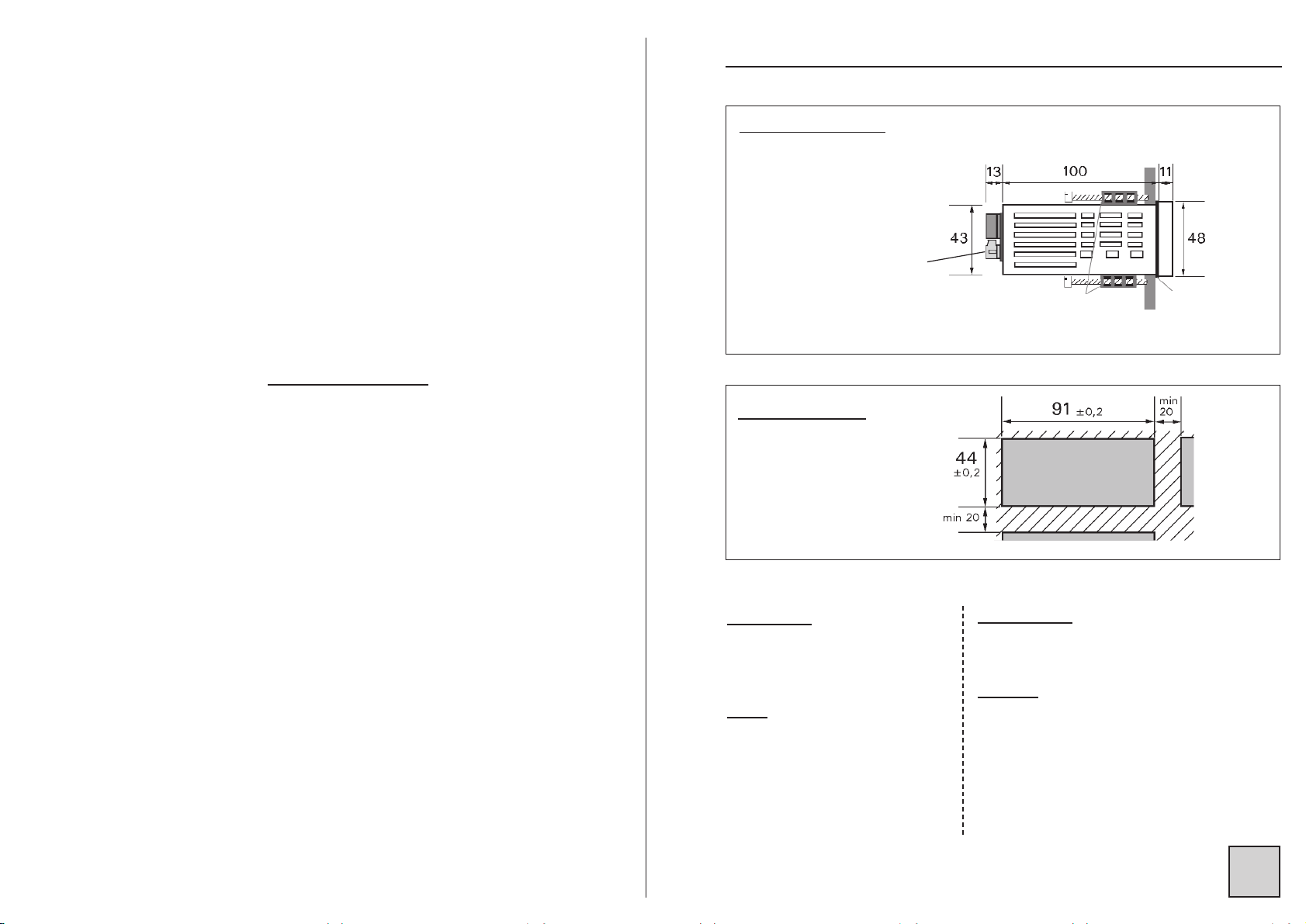

22.. SSPPAACCEE RREEQQUUIIRREEMMEENNTTSS

Case dimensions : (with terminals)

96 x 48 x 124 mm

Panel mounting

cut out 44 x 91 mm

external

seal

Fitting panel

max. thickness 30

case

tightenings

Terminals

• Power supply : (specify on order)

2 Versions : High Voltage or Low Voltage

High Voltage : 90...270 V

AC and 88 ...350 VDC 50/60/400 Hz

Low Voltage : 20...53 V

AC and 20...75 VDC 50/60/400 Hz

• Power draw : 7 W max. 10 VA max.

• Complies with standards EN 50081-2 on rejections and EN 50082-2;

on imunity (in industrial environment)

EN 61000-4-2 level 3, EN 61000-4-3 level 3,

EN 61000-4-4 level 4, EN 61000-4-6 level 3.

CE marking according to Directive EMC 89-336

Page 5

S

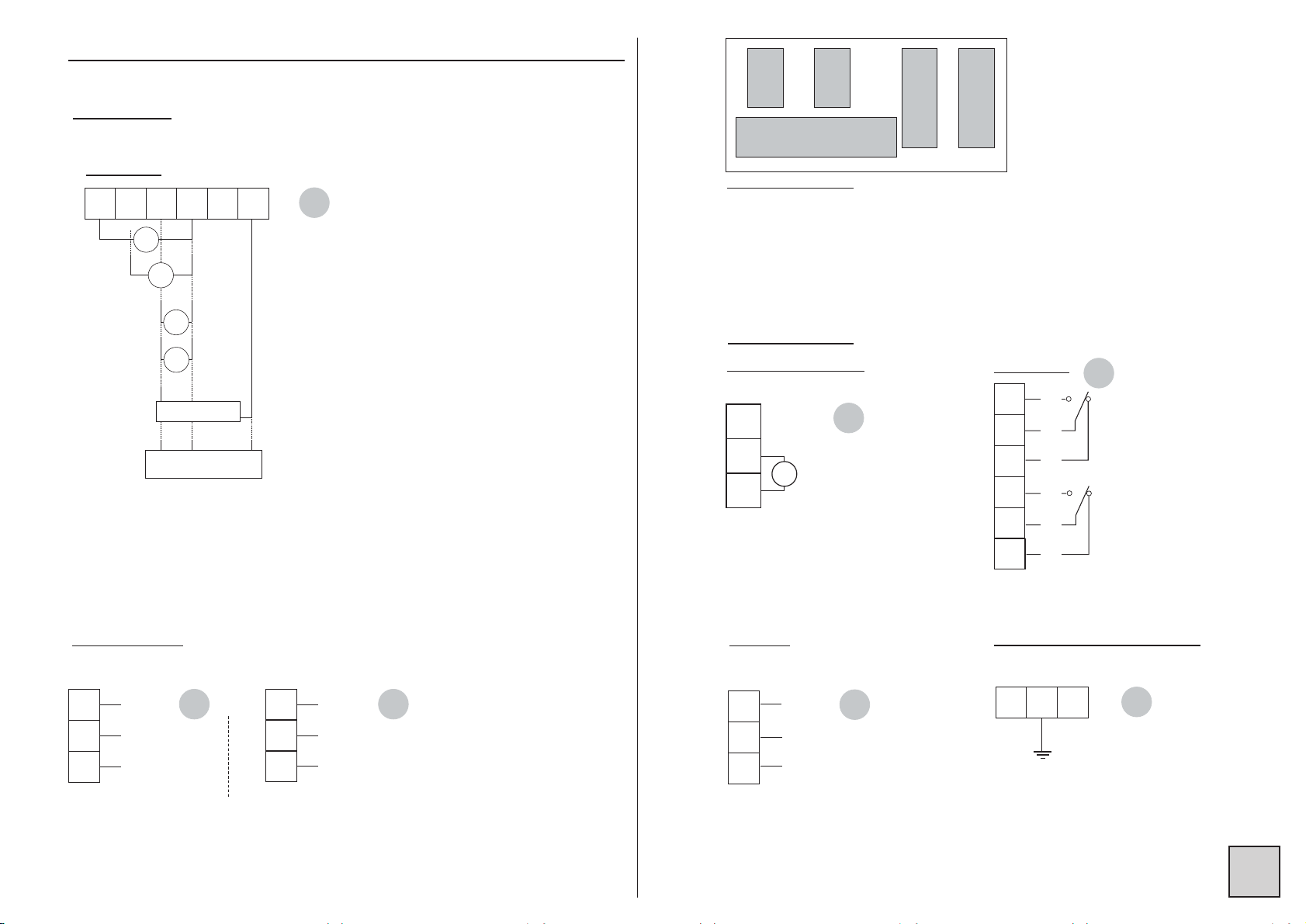

33.. WWIIRRIINNGG

20

21

22

1 2 3 4 5 6 7 8 9

Location of terminals

(view of case rear side)

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

C

E

D

B

A

4 5

6

1 2

3

7

8

9

-

~

~

+

AC

DC

INPUTS

OUTPUTS

(optional)

POWER SSUPPLY

300V

1V

10V

mV

mA

+ -

+ -

+ -

+ -

2-wire

transmitter

NC

3-wire

transmitter

+

-

IOUT

GND

VCC

26

27

28

29

30

31

2 RELAYS

T1

C1

R1

T2

C2

R2

T : ON

C : Common

R : OFF

0-4/20mA active

ACTIVE CURRENT

23

24

25

LOG 1

LOG 2

COM

LOGIC INPUTS

(optional)

20

21

22

DIGITAL

Data link RS 485

2 channels

32

33

34

LOG 1

LOG 2

COM

2 channels

B

A

COM

PROCESS

+ -

23

24

25

mA

RU

A

C

C E

D

B

A

Page 6

S

44.. PPRROOGGRRAAMMMMIINNGG

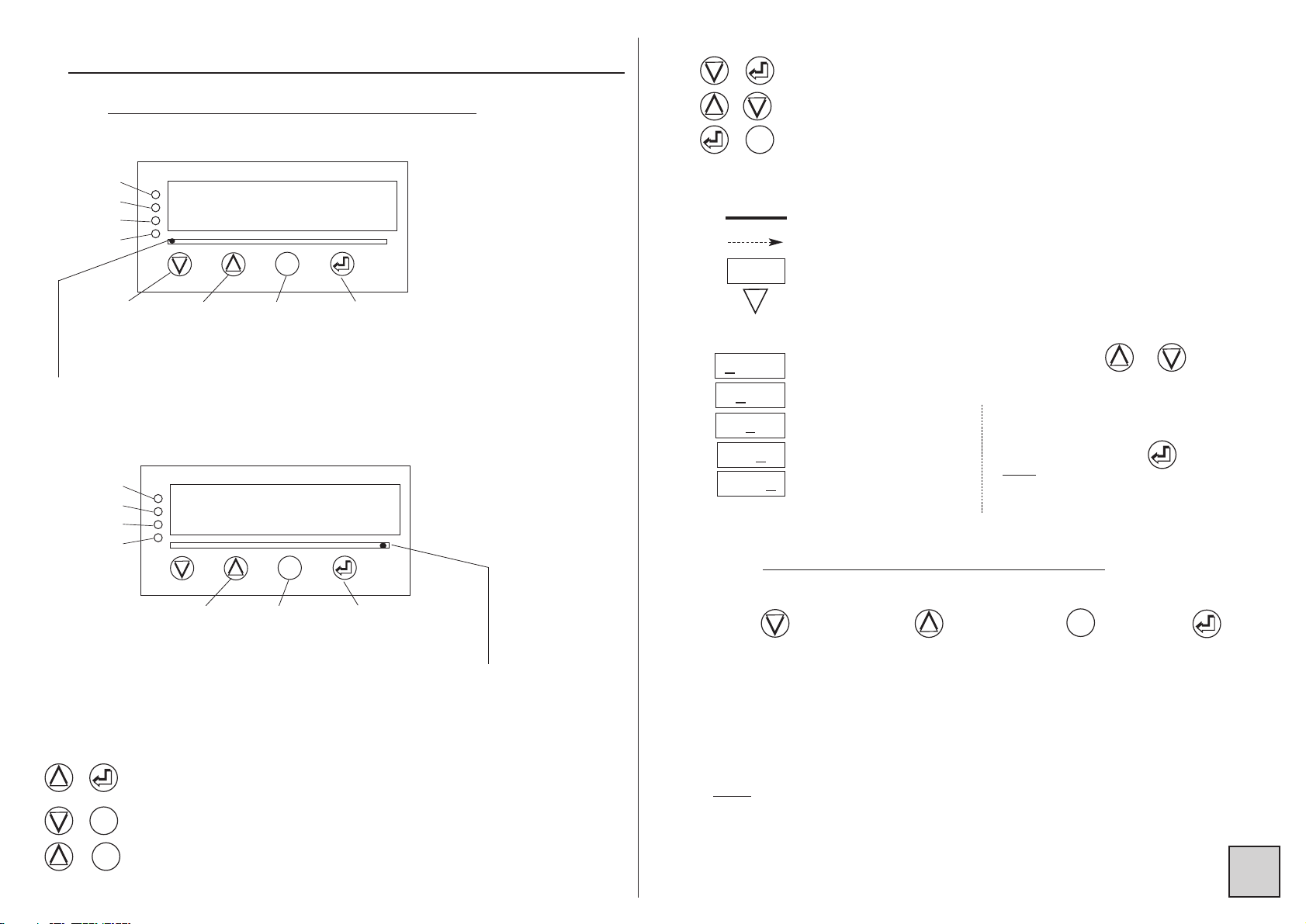

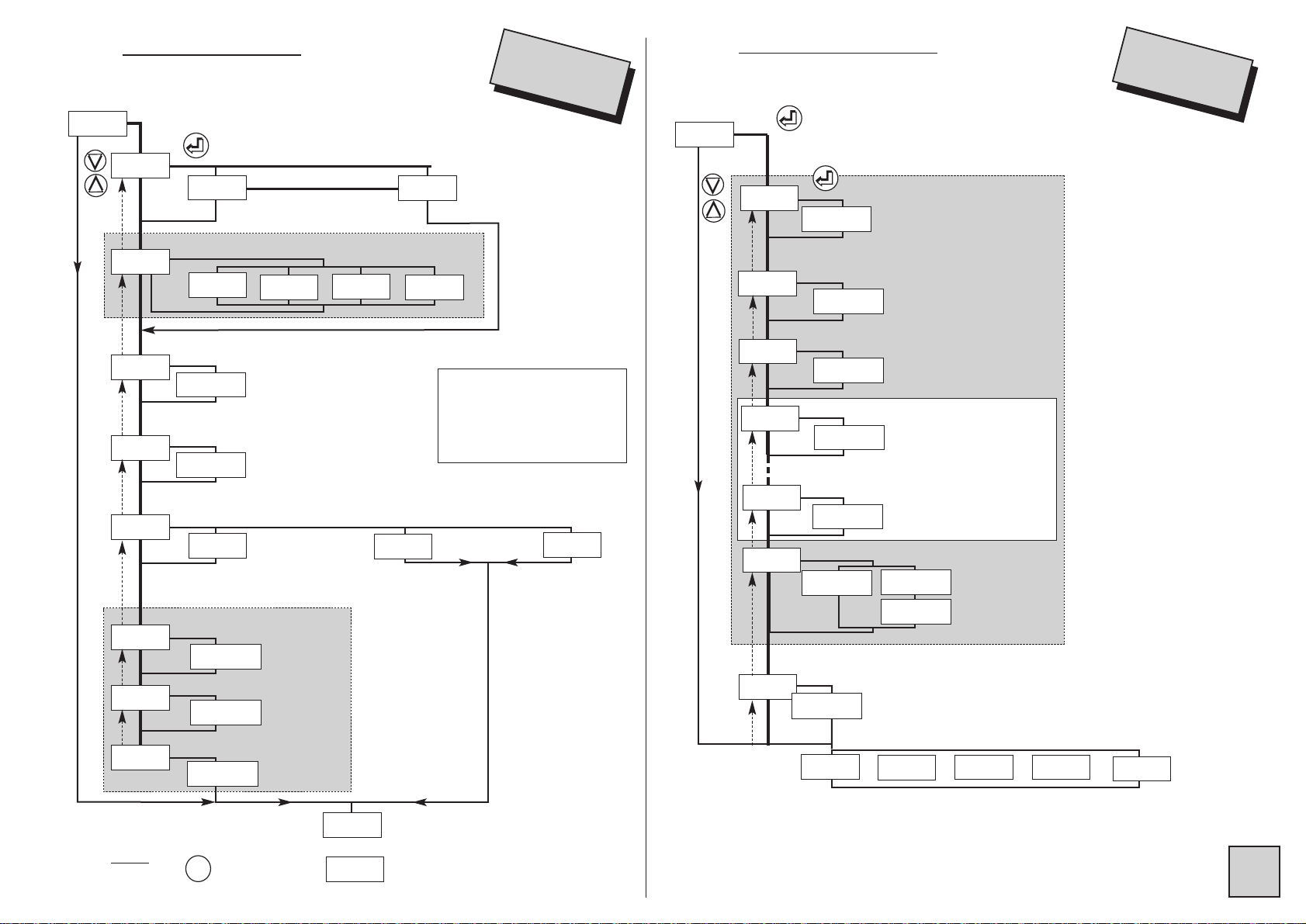

4.1 CCommunication wwith tthe iinstrument

Functions available from the instant measure :

Alarms

Led 1

Led 2

Led 3

Led 4

min. value

display

p21

Max. value

display

p21

min. and max.

zero reset

p22

Access to

the main

menu p6

Instant value display

Tare setting; (see p23)

Down scale display setting; (see p23)

Full scale display setting; (see p23)

Reading convention :

Move through main menu

Return to previous menu

Blinking display : awaiting validation or setting

Alternate information display

Entering of a parameter :

First start by increasing or decreasing

the 1st digit and the sign : from -9 to +9.

The 2nd from 0 to 9.

The 3rd from 0 to 9.

The 4th from 0 to 9.

The 5th from 0 to 9.

M

M

&

86888

86

588

865

28

8652

0

86520

«

Between each entering, validate

the cipher with key

Note

: The totalizer

parameters are entered on

6 digits.

Functions available from the totalizer :

Alarms

Led 1

Led 2

Led 3

Led 4

Display of the

oversteppings

counter.

(Hi.tot)

Access to

menu totalizer

zero reset

Access to

main

menu

Totalizer display

M

M

The Led under marking A blinks to indicate that

the displayed value is the instant value.

A B C D E F G H

The Led under marking H blinks to indicate that

the displayed value is the cumulated value.

A B C D E F G H

+

MM

MM

+

+

Further functions can be reached by pressing several keys :

Switching from instant value display to cumulated value display

and vice-versa;

Direct measure visualisation; (see p24)

Visualisation and setting of alarm setpoints; (see p24)

MM

MM

+

+

MM

MM

+

4.2 OOrientation tthrough pprogramming

Dialogue is ensured by the 4 keys located on the front face.

Move through

menus : downwards, or

decreasing of the

displayed value

Validation of

the displayed

parameter,

or access to

a sub-menu

Exit from a submenu to access

next menu /

access to the

programming

exit menu

Note

: In mode programming, the instrument will automatically resume

measuring with the previous configuration if no key is pressed during

1min.

MM

MM

Move through

menus : upwards,

or increasing of

the displayed

value

Only on the instant value display.

Page 7

S

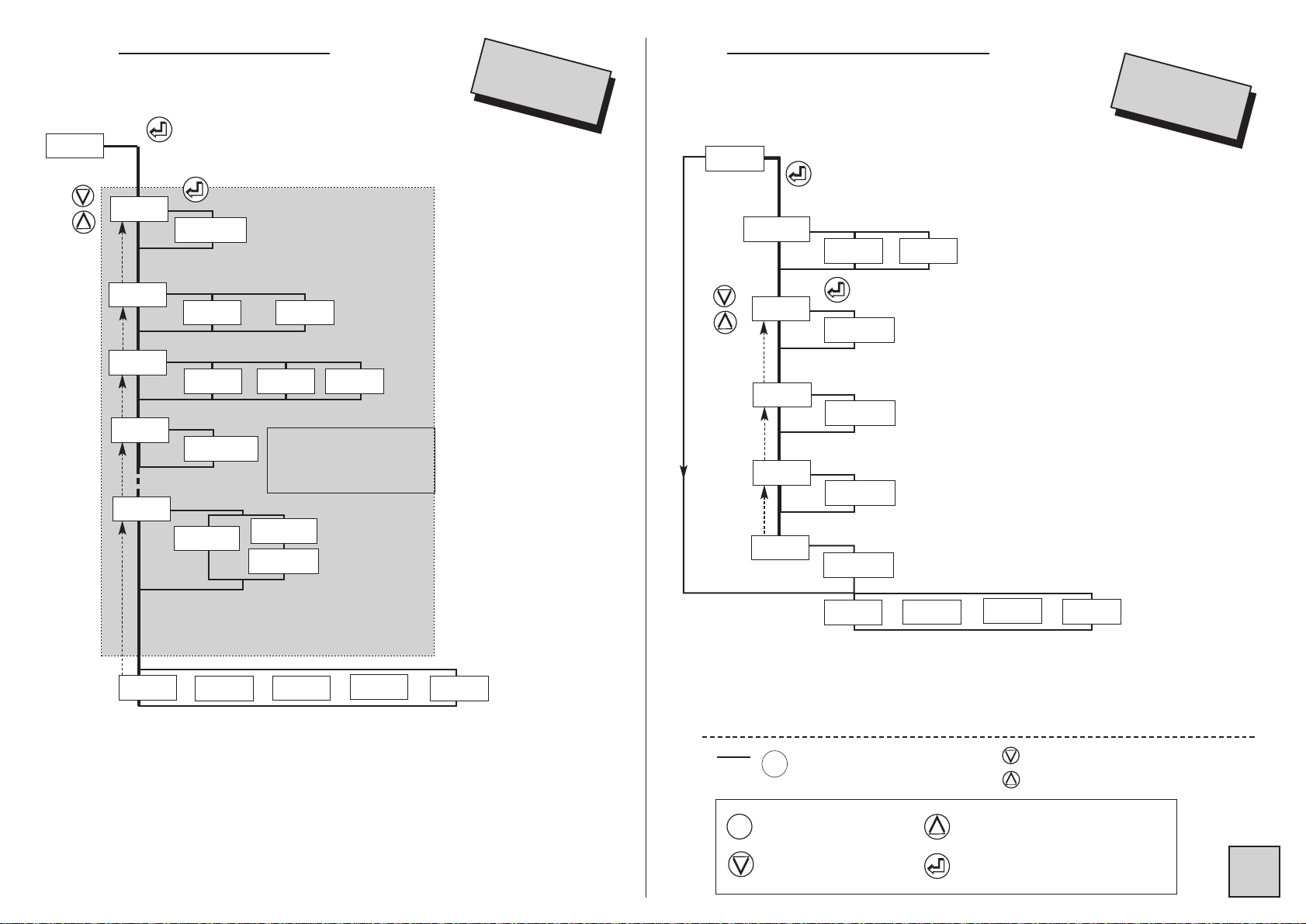

4.3 MMain mmenu

If code correct,

access to pro-

gramming

menu

Analog

output

simulation

Authorized by

access code

Erasing of

recorded

alarms

rEAd

ProG

CodE

88888

GEnE. CLEAr

«

«

«

«

«

Access code

programming

Display

simulation

instant or

cumulated

value, accor-

ding to type

of display

present before the access

to the menu

Authorized by

access code

(relay /analog

output)

(analog

output)

(relay output)

P.CodE

SIMUL

«

«

Tare zero

reset

Authorized by

access code

CLr.tA

«

menu

scroll

vertical

move

Entering of the access code.

The access to the programming

menu is protected by a 5-cipher

code.

The code on factory exit is 00000

(to change this code, see p20).

Configuration

reading

mode

M

M

4.4 PProgramming mmenu

(according to options)

dISPL.

totAl.

OUt.MA

JbuS

tor

rELAY

SECU

Pr.diS

SAvE

SAvE

Access to input programming p7

Access to the display factor programming p7

(instant value)

After programming the totalizer p8

Access to the analog output programming p8

(option analog output)

Access to the communication parameters p9

(option digital output)

Access to the programming of the LOGIC inputs p9

(option LOGIC inputs)

Access to the programming of the relays (2 relays) p10

(option relay output)

Access to the programming of the output, the relays, p11

in case of self-diagnosis and/or sensor rupture, and

access to disconnecting the sensor rupture

(option analog output or relays)

Access to the display programming : p12

Bargraph, display brightness

Access to the programming exit menu with or p13

without configuration saving

Note

:

⇒ Press to reach menu

⇒ In mode programming, the instrument will automatically resume measur-

ing with the former configuration if no key is pressed during 1min.

Move through menus / choice

InPut

Downwards move /

decrease

Validation / Vertical move

Menu exit / access

Upwards move / increase

M

M

Page 8

S

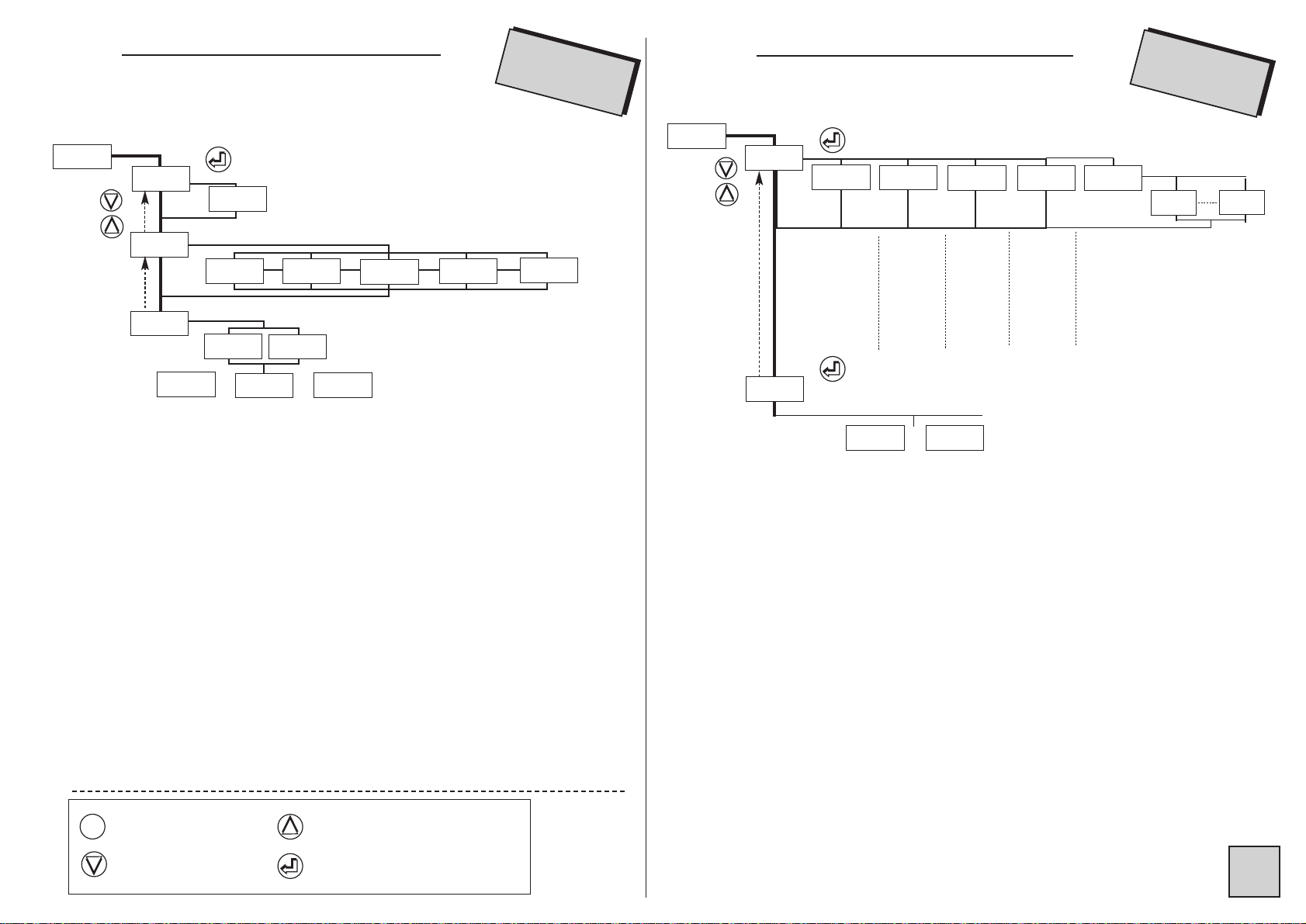

InPut

4.4.1 Input programming

voltage input

voltage input only

caliber choice

Special linearisation only

current input

down scale

-22.00 < x < 22.00 (mA)

-11.00 < x < 11.00 (10V)

-320.0 < x < 320.0 (300V)

-110.0 < x < 110.0 (0.1V)

-1.100 < x < 1.100 (1V)

from 1 to 18

linear

function

function square

root extraction

in mV, V or mA

according to

the type

special linear

function

M

M

diSPL.

Note :

Press key to reach menu

«

«

«

d.in

«

-888.88

«

root

diSPL.

U

MA

0-10

0-1300

0-0.1

«

LinEA.

«

nb

«

000018

«

A01

«

-888.88

«

A18

(1)

(1)

full scale

in mV, V or mA

according to

the type

«

F.in

«

-888.88

(1)

(1)

(1)

«

«

«

«

CALib

«

Li.SPE

«

Funct.

«

-888.88

«

tYPE

InPut

4.4.2 Displa

y programming

(instant value)

decimal point location

diSPL.

---.--

«

d.diSP

«

-88.888

«

F.diSP

«

-88.888

«

b01

display corresponding to

input down scale “d.in”

display corresponding to

input full scale “F.in”

setting in display points of

the same number of ordinates “bxx” and

abscisses “Axx”

setting in display

points

according to options

IntEG : coefficient from 0 to 10

integration indice

«

-88.888

«

b18

«

Cut.oF

«

-88.888

«

YES

«

-88.888

Out.MA

JbuS

tor

rELAY

«

IntEG.

«

000000

«

no

or or

or

or

«

«

Point

«

dISPL.

special linearisation

*

*

Changing this parameter

requires re-programming following parameters related to the

relays, the analog output, the

bargraph according to their dedication, as well as following

display parameters :

SPxx, hystx, do.diS, Fo.diS

d.bArG, F.bArG, d.diSP, FdiSP, bxx,

Cut.oF

SECU

Page 9

S

TotAl

totalizer decimal point

location

automatic

decimal pt

----.--

«

Auto.P

«

YES

«

nO

«

t.bASE

«

1

«

60

«

3600

«

Coeff

time setting for

the recording of

defects from 0 to

25.0

«

888.888

«

YES

«

88888.8

«

no

«

«

dP.tot

«

totAL.

*

coefficient setting from

±0,0001 to +999 999

or -99 999

«

M.deF.

according to options

Out.MA

JbuS

tor

rELAY

SECU

or or

or

or

* Changing this parameter

requires re-programming following parameters related to the

relays, the analog output, the

bargraph according to their dedication

SPxx, hystx, do.diS, Fo.diS

d.bArG, F.bArG,

«

8888.88

«

dO.diS

Out.MA

analog output down scale

analog output full scale

display corresponding to output down scale

display corresponding to output full scale

00.00 < x < 22.00 (mA)

00.00 < x < 11.00 (V)

according to options

JbuS

tor

rELAY

SECU

or

or

or

See also output features p17

(4)

(4)

(4)

Option aanalog ooutput

«

8888.88

«

8888.88

«

8888.88

«

d.out

«

In5tA

«

totAL

«

PArA.0

«

F.out

«

FO.diS

Out.MA

M

M

Note :

Press to go on to next menu

Move through menus / choice

Downwards move /

decrease

Validation / vertical move

Menu exit / access

Upwards move / increase

M

M

4.4.3 Totalizer programming 4.4.4 Analog output programming

integration time

parameter dedicated to the output

Page 10

S

4.4.5 Pro

gramming of the digital output

slave number

must be included between 1 and 255

transmission speed (baud rate)

switching

between

instant value

/ cumulated

value

function

min.

and

max. 0

reset

(instant

value)

function

display

hold

function

tare

(on

instant

value

only)

function totalizer

see p14

«

SLAvE

«

-8888

«

bAUd

JBuS

4.4.6 Pr

ogramming of

the LOGIC inputs

ToR

«

9600

«

4800

«

2400

«

1200

«

19200

tor

rELAY

SECU

or

or

or

rELAY

SECU

«

tArE

«

totAL

«

Fct1

«

Fct5

«

dSP.to

«

HoLd

«

CLr.M

time delay before any response

OFF : delay = 20ms

On : delay = 75ms

«

On

«

OFF

«

dELAY

See also the features of the

digital data link

See also the features of the LOGIC input

Option ddigital ooutput

Option LLOGIC iinputs

«

tor 1

«

tor 2

JBuS

tor

Idem Tor 1

Downwards move /

decrease

Validation / vertical move

Menu exit / access

Upwards move / increase

M

M

Page 11

S

«

rEL.1

rELAY

«

Acti.1

«

On

«

ModE.1

«

SP 1

0002.00

«

HYSt.1

0000.00

«

«

«

tiME.1

00000.0

«

LEd 1

«

SP1.1

«

0002.00

«

SP1.2

«

0004.00

rELAY

hysteresis

adjustable in display

points

0 < tIME < 025.0

in 0.1s increases

function alarm recording

function alarm message display

enter 4 characters + decimal point

if option 2 relays, at the end of menu REL.2,

access to or

choice of the state of the relay

associated Led

ON : led lit when relay active

OFF : led still when relay active

time delay on the relay

SPI.2 must be ≥ SPI.I

active

idem

rEL.1

de-activated

mode setpoint

mode setpoint

access to SP1

access to SP1.1

«

OFF

«

On

«

MEM.1

«

no

«

YES

«

MESSI

«

no

AbCd.

rEL.2

SECU

Pr.diS

«

«

«

YES

(5)

See also the

features of the

relay outputs

p17

Option ooutput 22 rrelays

«

tYPE.1

AlArM PULSE

InStA. totAL.

«

PArA.1

«

OFF

if mode window programmed

if mode setpoint programmed

«

rEL.2

«

P.rAt

00000

«

P.tiME

100 200 400

setting of the pulse weight from

-10 000 to +10 000

pulse time in ms

operating mode

parameter dedicated to the alarm

4.4.7 Programming of the relay outputs

Page 12

SECU

S

See also the safety features p18

option

2 relays

if mV input

option analog output

if return value entered

if input mV or mA (if d.in and F.in> 3.5mA)

«

rEL.1

«

LO

HI

«

OFF

out.MA

state of relay 1 in case of sensor rupture

«

LO

HI

«

OFF

state of the relay in case

of sensor rupture

«

sensor rupture disconnection

«

YES

«

«

no

rEPLi

output value in case of sensor rupture

00.00<rEPLI<22.00 (mA)

«

OFF

«

On

OFF : sensor rupture inactive on the relay

In case of sensor rupture

LO : relay de-activated

HI : relay active

«

8888.88

option 2 relays

option analog output

if return value programmed

«

LO

HI

«

OFF

out.MA

state of relay 1 in case

of error self-diagnosis

«

«

YES

«

«

no

rEPLi

output value in case of self-diagnosis error

00.00<rEPLI<22.00 (mA)

OFF : self-diagnosis

inactive on the relay

In case of self-diagnosis

LO : relay de-activated

HI : relay active

«

8888.88

Pr.diS

«

ruPt.

«

SECU

«

dIAG.

«

«

«

rEL.1

«

«

CAPt.

«

rEL.2

«

LO

HI

«

OFF

state of the relay in case of

error self-diagnosis

«

rEL.2

«

*

*

*

*

*

If the relay is programmed in

mode pulses, its state on sensor

rupture or self-diagnosis is blocked on OFF.

4.4.8 Pr

ogramming of the safeties

Page 13

S

Pr.diS

«

On

«

OFF

«

YES

«

no

1 1 1 1

«

b.bArG

1 1 1 1

«

L.dIG

«

nuLL

SAvE

«

000600

«

d.bArG

«

000200

«

F.bArG

adjusting of the display brightness

on 4 levels

on 4 levels

bargraph and leds brightness

not enforced to

zero

erasing of unsignificant zeros

display corresponding to

0% of the bargraph

display corresponding to

100% of the bargraph

state of the last digit (right hand side)

(enforced to zero)

See also the display features p15

«

br.diG

Pr.diS

«

InStA.

«

totAL.

«

Indic.

«

PArA.b

«

no

«

tor 1

«

no

«

rS

«

LEdd

«

no

«

tArE.

«

LEdE

«

LEdb

«

no

«

tor 2

«

LEdC

function associated with led b

function associated with led c

function associated with led d

function associated with led e

«

no

«

M.dEF

«

LEdF

function associated with led f

«

no

«

dEP.to

«

LEdG

function associated with led g

no : no dedication

tArE : led lit if a tare has been

entered

no : no dedication

M.dEF : led lit in case an error has

been recorded

no : no dedication

dEP.to : led lit if overstepping on the

1st totalizer

>999 999 or < -99 999 (Hi.tot ≠ 0)

no : no dedication

tor 1 : led b dedicated to the

indication of logic input 1

no : no dedication

tor 2 : led c dedicated to the

indication of logic input 2

no : no dedication

rS : led lit in case of RS transmission

Choice of the bargraph operating mode

insta : on the instant value

total : on the totalizer

indic : use of the bargraph to indicate some functions

4.4.9 Programming of the brightness,

the displays and the bargraph

Page 14

S

SAvE

MA

SAvE

no

YES

exit with configuration saving

exit without

configuration

saving

revert to measure

display

4.5.1 Current input

• Linear :

Features

Measurable input limits : -22 to 22 mA

•

Unlinear :

Square root extraction

Note : The function square root extraction tends to amplify the input

signal background noise on getting near zero.

To avoid the ripples caused by this noise, just programme a cut-off value

(in display points), see p14.

Special linearisation :

For specific applications such as volume measurements, the meter can

memorise an unlinear curve programmable in X and in Y.

4.5 IInput ffeatures aand pprogramming llimits

«

root

«

Caliber

Display

resolution

Input stage

resolution

Accuracy

from -20 to

+20mA

± 1 digit 16 bits 0.05% of MR

Li.SPE

«

The curve resulting from your equation can be replaced by a series of

linear segments, with a maximum of 20 points

(19 segments).

Note

: The values of the abscises (x) have to go increasing d.in < value

of A01 < value of A02...< F.in.

Example

:

Say a layed cylindric tank, 1 meter high (h) and 1 meter long (l). A linear

0-20 mA sensor measures the height of the liquid surface line :

Meter input : height h

0 meter -> 0 mA (empty tank)

1 meter -> 20 mA (full tank)

with cos β/2 = (R-h)/R

Sin β /2 = C/2R

Meter display :

Empty tank volume d.diSP = 0.000

Full tank volume F.diSP =0.785

Volume = L [

π R² β /360 - C(R-h)/2]

Hence a curve of 10 equally long segments :

Etendue de mesure / nr of segments = 20mA/10 = 2mA length of

the segment. For 10 segments nb = 9 (11 points to be programmed,

including d.in and F.in).

Input

mA

d.in 0

A01 2

A02 4

A03 6

A04 8

A05 10

A06 12

A07 14

A08 16

A09 18

F.in 20

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0.00

73.74

106.26

132.84

156.93

180.00

203.07

227.16

253.74

286.76

360.00

0.00

0.60

0.80

0.92

0.98

1.00

0.98

0.92

0.70

0.60

0.00

0.000

0.041

0.112

0.198

0.293

0.393

0.492

0.587

0.674

0.745

0.785

d.diSP

B01

B02

B03

B04

B05

B06

B07

B08

B09

F.diSP

00.00

01.04

02.85

05.04

07.47

10.00

12.54

14.96

17.17

18.98

20.00

Height

m

Degree

Chord

m

Volume

m

3

Outps.

in mA

β

(R)

L (length)

C (chord)

R (ray)

h

(height)

Note : Exit from mode programming with configuration saving (SAvE, YES) will

automatically reset to zero the tare, the min. and max. and the recording of

alarms, as well as the pulse output buffers.

In case of modification of the decimal point location of the instant value or of

the totalizer, the instrument will propose after

SAvE YES all the decimal point rela-

ted parameters which have not been modified.

A

SAvE YES will not reset the totalizer to zero. If its parameters have been chan-

ged it will have to be reset to zero, in order to avoid an incoherent counting

(see p22).

4.4.10 Programming exit with or without saving

Page 15

S

Programming :

d.in = 0 mA F.in = 20 mA

nb = 9

d.disp = 0,000 m3F.disp = 0,785 m

3

Programming from A01 to A09 and from B01 to B09 according to table.

4.5.2 V

oltage input

• Linear : Features

0 2 4 6 8 10 12 14 16 18 20

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

20

18

16

14

12

10

8

6

4

2

0.11

0.04

0.20

0.29

0.39

0.49

0.59

0.67

0.75

0.79

volume

in m

3

output (mA)

Y

X

input (mA)

height (m)

U

«

Caliber

Display

resolution

Input stage

resolution

Accuracy

-100 to +100 mV

-1 to + 1 V

-10 to +10 V

-300 to 300 V

± 1 digit 16 bits 0.05% of MR

• Unlinear : (see p13)

Measurable limits : -5% to +5%

Example for caliber 1V : -1.1V to +1.1V

4.5.3 Instant v

alue displa

y :

Decimal point location for the instant value display

(4 decimals maximum).

Display corresponding to input down scale

Display corresponding to input full scale

Setting in display points of the ordinate for point Axx for

a special curve input (see unlinear input)

Expressed in display points.

− If display full scale > display down scale and if display ≤ cut off value,

then it is maintained at down scale.

− If display full scale < display down scale and if display ≥ cut off value,

then it is maintained at down scale.

••

Response time

:

Digital filtering integration indice :

Programmable from 0 to 10; to be used in case of unsteady input.

2 cycle times, i.e. 240 ms must be added to obtain the maximum response

time.

Note

: For the analog output response time, add 40ms to the values

shown in the table.

For the relays : add the time delay programmed on the alarms.

Point

d.diSP

F.diSP

bXX

Cut.oF

intEG

Typical response

time at 90%

120 ms 400 ms 600 ms

intEG

0 1 2

1 s

3

1.4 s

4

2 s

5

3 s 5 s 7.5 s

6 7 8

10 s

9

15 s

10

Page 16

Parameter applied to the bargraph

Bargraph on the instant value

Bargraph on the cumulated value

Bargraph in mode indication

Led marking b

No dedication (led still)

Led lit when logic input 1 is active

S

4.5.4 Totalizer

Totalizer decimal point location

(4 decimal maximum)

Fix decimal point

Automatic decimal point

Decimal point : The totalizer is displayed with a maximum of decimals, and the decimal point will move as the total increases, until

the number of decimals programmed in

Dp.tot is reached

eg. : programming of the decimal point = -.-on starting the totalizer indicates 00.0000. When it reaches

99.9999 it will indicate 100.000, and then 1000.00.

Integration time basis

: 1 sec : 60 sec : 3600 sec

Convertion coefficient : coefficient to be applied on the

instant value to calculate the cumulated value, adjustable

from ± 0.0001 to 999 999 or -99 999.

Eg. : if the instant value represents m

3

and you want to total up

liters, the coefficient will be equal to 1000.

Recording of defects.

No recording

Recording of defects (input electrical oversteppings or

sensor rupture) if defect present on the input during a time

≥ pro-

grammed time. Programming of the time from 0 to 25.0 sec, in 0.1

sec. increases.

Display of error messages alternating with the cumulated value if

recording. To reset the recording to zero, see p22 .

Dp.tot

Auto.P

no

yes

no

yes

t.BASE

1 60 3600

CoEFF

M.dEF

br.diG

1 1 1 1

4444

1 1 1 1

4444

br.bAr

L.dIG

nuLL

nuLL

YES

••

Last digit inhibition (low weight)

In mode programming, the menu L.dIG allows suppressing of the last

digit display, the latter being enforced to 0 if OFF is validated.

••

Erasing of unsignificant zeros

Suppresses the display of unsignificant zeros on the

left hand side.

Eg.

: Display value 0015

Display 0015

Display 15

Eg.

: Display value 00.15

Display 00.15

Display 0.15

••

Setting of the bargraph brightness

Lowest brightness Strongest brightness

The brightness level is visualised directly on the bargraph.

Caution : during setting, the bargraph no longer represents measure,

including also in mode reading.

=

nuLL

no

YES

=

=

nuLL

no

YES

=

=

4.5.5 Diplay features :

••

Adjusting of the digits brightness

Lowest brightness Strongest brightness

PArA.b

InStA

totAL

Indic

LEdb

no

tor1

••

Bargraph display factor

Display corresponding to the still bargraph (0%)

Display corresponding to the fully lit bargraph (100%)

In case of overstepping, the bargraph will start to blink. A sensor rupture

is indicated on the bargraph (if dedicated to the instant value) by the

lighting of one led out of two.

d.bArG

F.bArG

Page 17

S

Led marking e

No dedication (led still)

Led lit when a tare has been entered

Led marking f

No dedication (led still)

Led lit if defect recorded

Led marking g

No dedication (led still)

Led lit if overstepping of the 1st totalizer

-99 999 > counting > 999 999

(Hi.tot ≠0)

LEdE

no

tArE

LEdF

no

M.dEF

LEdG

no

dEP.to

Led marking c

No dedication (led still)

Led lit when logic input 2 is active

Led marking d

No dedication (led still)

Led lit during answering of the instrument on

the RS

LEd C

no

tor2

LEdd

no

RS

Switching to the cumulated value display if LOGIC activated,

if not instant value display.

Function on the totalizer

meter zero reset on ascending front, and counting.

zero reset on ascending front, and counting on low level

only

diSP

totAL

Fct1

Fct2

Fct3

24VDC

0V

counting counting counting

meter meter

zero reset zero reset

24VDC

0V

counting counting stopped counting

meter meter

zero reset zero reset

zero reset on ascending front, and counting on high level

only

Counting on high level only (no reset)

Counting on low level only (no reset)

24VDC

0V

counting counting stopped

meter meter

zero reset zero reset

24VDC

0V

counting counting stopped counting counting stopped

Fct4

24VDC

0V

counting stopped counting

Fct5

4.5.6 L

OGIC inputs

(optional)

• Board of 2 LOGIC inputs : Input signal 24 Vdc

Possible functions :

Holding of the instant value display in case of activation of the

LOGIC function. The display and the analog output if it is dedicated to the instant value remain fixed in case of variation of the input

signal. The relays and the totalizer carry on reacting to the input signal.

Min. and max. zero reset. The activation of the LOGIC

function resets the min. and max. to zero

Activation of function tare.

The meter switches to mode tare, the tare being the display

value present at the time of this activation.

HoLd

CLr.M

tArE

Page 18

S

4.6 OOutput ffeatures aand pprogramming llimits

4.6.1 Analog output

Current output 0/4-20mA active

• Accuracy 0.1 % in relation to the display (at +25°C)

• Residual ripple ≤ 0.2%

• Admissible load 0Ω≤ Lr ≤ 500Ω

• Programmable scale ratio with enlarging effect

• Response time : 40 ms in relation to the display

Out.MA

Parameter applied to the output

Output on the instant value

Output on the cumulated value

Analog ouput down scale (eg. 04.00 (4mA))

Analog output full scale (eg. 20.00 (20mA))

Display value corresponding to output down scale

Display value corresponding to output full scale

In mode measurement, the analog output can not overstepp 10% of the

greatest of the 2 values : d.out and F.out

F.out

dO.diS

FO.diS

d.out

TotAL

InStA

PArA.0

4.6.3 Relay outputs :

2 relay outputs

• Relays programmable independently in mode alarm, or as pulses output

• NO-NC contact 8 A - 250 V on resistive load

rEL.1

rEL.2

4.6.2 Digital output

:

- Data link RS485 (2 wire)

- Protocoles MODBUS-JBUS format of data : integer and double integer

- Exclusive transmission format : 1 bit start

8 bits without parity

1 bit stop

Slave number between 1 and 255

Transmission speed between 1200 and 19200 bauds

Time delay before any response

Complete description of option MODBUS : see annexe documentation : MODBUS/JBUS.

Including : table of modbus addresses, used functions, description of the

configuration bytes and advanced functions.

SLAvE

bAud

dELAY

Activation or de-activation of relay x

The state of relay x depends on the carried programming

Relay x remains still.

Choice of relay x operating mode

Mode alarm

Mode pulses

Parameter applied to alarm X

Alarm X on the instant value

Alarm X on the cumulated value

Act.X

On

OFF

tYPEX

AlArM

PulSE

PArA.X

InStA

totAL

Choice of the operating mode

••

Mode setpoint

OFF

ON

setpoint setpoint

Legend :

ON coil supplied

OFF coil not supplied

or

OFF

ON

ModE.x

Mode alarm

••

Mode window

OFF

OFF

OFF

ON

ON

ON

setpoint

set-

point

set-

point

or

SPX.2

SPX.1

SPX.2

SPX.1

Page 19

S

••

Mode setpoint

••

Mode window

Choice of the state of the relay associated led

The led indicates the alarm state.

Led lit when relay active (coil supplied)

Led still when relay active (coil supplied)

Hysteresis setting in display points .

The hysteresis is active on switching from lit led to still led; i.e.

on switching out of alarm, as the led represents the alarm state.

SP.X

SP.X

- Hystx

HYSt.x

LEdx

On

OFF

led lit

SPX.1

SPX.1

-Hyst.x

SPX.2

SPX.2

+Hyst.x

led lit

led still

led still

led still

CLEAr

MESSx

••

Display of alarm messages

A programmed alarm message can be made to appear alternating with

measure. The message will appear only during the alarm state, while the

associated led is lit.

••

Setting of setpoints : There are 2 ways to adjust setpoints.

- either in mode programming entering the correct access code

- or by pressing simultaneously on and if the access to quick

entering has been authorized during the code programming (see p20).

M

M

tiME.x

MEM.x

••

Time delay on the alarm

The time delay on the relay si adjustable from 000.0 to 025.0s, in 0.1s

increases

It is active both on switching and switching back.

••

Alarm recording

Allows recording of the alarm after a setpoint has been passed. Once

measure reverts below the alarm setpoint, the relay remains on and the

led blinks to warn the user that a setpoint has been passed (to reset the

recording of alarms to zero see menu p21).

Note

: Exit from mode programming wih configuration saving will reset

alarm recordings to zero.

Weight of the pulse to be applied on the totalizer unit

adjustable from -10 000 to +10 000.

eg. :

1 : one pulse at each increase of the totalizer unit

-1 : one pulse at each decrease of the totalizer unit

1000 : one pulse every 1000 increases of the totalizer unit

-1000 : one pulse every 1000 decreases of the totalizer unit

Pulse duration : 100ms, 200ms or 400ms.

Note : The programmed pulses duration applies both to the high and low

level, in order to allow some time between two consecutive pulses. When

the pulse frequency is too high in relation to the output capacity, they are

stored in a buffer, and restituted as soon as the frequency drops again. A

(

SAVE, YES), a totalizer zero reset or a power supply cut will reset the buf-

fers to zero.

P.rAt

P.tiME

Mode pulses

diAG

4.6.4 Safeties :

••

Self-diagnosis

:

The meter permanently watches any drifts that may surge on its components. The self-diagnosis serves to warn the user in case of abnormal

increase of these drifts, before they provoque false measures.

The self-diagnosis error information can be reported

:

· On the display

: An error message appears alternating with measure;

an error code is registered and can be read in menu About

Page 20

S

ruPt

OFF

OPEn

LO

HI

· On the analog output

If a return value has been programmed

Value included between : 0 and 22 mA

••

Sensor rupture

The sensor rupture can be detected on mV and current inputs if down

and full scale > 3.5 mA.

The sensor rupture information can be reported

:

· On the relay

No influence of the sensor rupture on the relay

Relay de-activated (coil not supplied) in case of sensor

rupture

Relay active (coil supplied) in case of sensor rupture

Note

: The led is either still or lit, according to its programming in menu

rELAY.

If the relay is programmed in mode pulses, its state on sensor rupture and

self-diagnosis error is blocked on position OFF.

· On the analog output

If a return value has been entered

Value between : 0 and 22 mA

OFF

LO

HI

· On the relays :

No influence of a self-diagnosis error on the relay

Relay de-activated (coil not supplied) in case of self-diagnosis

error

Relay active (coil supplied) in case of self-diagnosis error

Note : The led is either still or lit, according to its programming in menu

rELAY.

If the relay is programmed in mode pulses, its state on sensor rupture and

self-diagnosis error is blocked on position OFF.

••

Sensor rupture disconnection (If mV input)

The sensor rupture can be disconnected, in order not to disturb some

calibrators which may be sensitive to the rupture detection current.

In menu :

Activation of the sensor rupture, or not

Sensor rupture active

Sensor rupture disconnected

CAPt

SECU

OFF

On

rEAd

rEAd

InPut

diSPL

Out.MA

JbuS

totAL

rELAY

tor

Pr.diS

About

4.7 CConfiguration rreading

Reading of the input parameters

Reading of the instant measure display

parameters

Reading of the totalizer parameters

Reading of the analog output parameters

(option analog output)

Reading of the communication parameters

(option digital output)

Reading of the LOGIC input parameters

(option LOGIC input)

Reading of the alarm parameters

(option 2 relays)

Reading of the safety parameters for sensor

rutpure or self-diagnosis on the outputs

Reading of the display programming

parameters (leds, bargraph leds...)

Reading of the intrument’s own parameters

In each reading sub-menu, use keys and to move, and key

to visualise parameters

If no key is pressed during 20 s., the instrument will automatically

revert to measure display.

Validation /

Vertical move

SECU

Coding :

1 : Programming error

2 : Gain error

4 : Offset error

8 : Input calibration error

16 : Output calibration error

If the instrument detects for instance an offset error (4) and a gain error

(2) the error code value will be 6 (4+2).

· On the display

: Message

Note

: The sensor rupture detection has priority over the self-diagnosis.

Page 21

4.8 AAccess ccode

An access code adjustable from 00000 to 59999 serves to protect the

meter from unauthorized programming, and to lock access to some

functions.

00000 Factory code

x x x x x

0 to 5 Access to display shifting

6 to 9 No access

0 to 5 Access to display and output simulations

6 to 9 No access

0 to 5 Access to function “tare”

6 to 9 No access

0 to 5 Access to quick entering of alarm setpoints

6 to 9 No access

0 to 2 Access to the totalizer zero reset menu

3 to 5 No access

S

About

C95 CI

n

0

A0123

ProG

0 1.05

0Pt10.

Ar--.

Err.

0000

CH.SUM

FC4E

Validation / Vertical

move

instrument type

Sub-menu

instrument number

programme version

code of installed

options

error code in case of

error self-diagnosis

check sum of the

flash memory

X1 : - : No analog output

A : Analog output

X2 X3 : - - : No relay output

r- : Output 2 relays

X4 : - : No RS output

n : RS output

X5 - : No LOGIC input

t : 2 LOGIC inputs

00000

XXXXX

1 2 3 4 5

.

00000

XXXXX

1 2 3 4 5

.

4.9 PProgramming oof aa nnew aaccess ccode

P.CodE

no

Enter pre-

vious code

if code incorrect

(old)

display during 2s.

and revert to measure display

display during 2s.

if new code

≥60 000

if new code < 60 000

new code registered

Revert to measure

display

if code correct

(old)

Enter new

code

no

Reminder : If no key is pressed during 1 min, the instrument will automatically revert to measure display.

SIMUL

SIMUL

Display value

if

M

M

Pressing on

menu reverts

to measure

display.

4.10 FFunctions aaccessible iin tthe mmain mmenu

4.10.1 Display simulation

(accessible according to programmed access code and if option

relays or analog output)

The display canbe simulated with the meter in order to validate the

configuration of the analog output, alarm and pulse outputs in the installation.

The simulated display corresponds to the one (instant or cumulated

value) which was on display at the time of the access to this menu (the

blinking led A or H indicates the type of this value).

Enter new display value

Page 22

S

GEnE.

GEnE.

Output value

if

Enter value to

be injected

M

M

Pressing menu

reverts to

measure

display.

Note : The instrument carries on measuring during the simulation.

Only the analog output no longer reacts to measure.

CLEAr

4.10.3 Menu :Erasing of recorded alarms

If the function recording of alarms has been programmed, the relay

state will be recorded after a setpoint has been passed.

If the setpoint is passed back the other way, the relay state does not

change and the corresponding led starts to blink.

To come back to the normal state (led not blinking and relay in the correct state) use menu CLEAr.

M

M

CLEAr

recorded alarms are not

erased

erasing of recorded

alarms, and revert to

measure display

Reminder

: If no key is pressed during 20 s.,

the instrument will revert to measure display.

Note : Exit from mode programming with configuration saving will reset

alarm recordings to zero.

(accessible according to programmed access

code and if option analog output)

4.10.2 Analo

g output simulation (mode generator)

CLr.tA

4.10.4 Menu : Deleting of the programmed tare

M

M

CLr.tA

the recorded tare is not

suppressed

deleting of the recorded

tare, and revert to measure display

Reminder

: If no key is pressed during 20 s. , the instrument will

automatically revert to measure display.

Note : Exit from mode programming with configuration saving will

reset the tare to zero.

(accessible according to programmed access

code)

5.1 FFunctions wwhich rrequire ppressing oonly 11 kkey :

5.1.1 On instant value display

a / min. value display b/ Max. value display

InF.

02.00

Measure

display

Alternate information display

Minimum value

55.. FFUUNNCCTTIIOONNSS AACCCCEESSSSIIBBLLEE DDIIRREECCTTLLYY FFRROOMM

DDIISSPPLLAAYY

SUP.

08.00

Measure

display

Alternate information display

Maximum value

Note : The instrument does not measure during the simulation. The analog outputs, the alarm, the pulse outputs and the bargraph will react

according to the value entered for simulation purpose.

The totalizer stops during the simulation. It is saved, and will then be

restored.

If alarm messages have been programmed, they may appear during the

simulation.

Page 23

S

c / Deleting of maximum and minimum values

M

M

CLr.M

Measure

display

revert to measure display.

Reminder

: If no key is pressed during 20 s.,

the instrument will revert to measure display.

Note

: Exit from mode programming with configuration saving

will reset min. and max. values to zero

Deleting of recorded min. and

max., and revert to measure

display

5.1.1 On the totalizer display

a) Totalizer upper part display

Hi.tot

0010

Totalizer

display

number of overteppings on the

totalizer

The cumulated value is :

Hi.tot x 1 000 000 + totalizer value if totalizer ≥ 0

and Hi.tot x -100 000 + totalizer value if totalizer < 0

b) Access to the totalizer zero reset menu

rdEP

r.totA

Totalizer

display

Zero reset of error

recordings

Zero reset of the

totalizer, Hi.tot and

of error recordings

Access only if user code

<30 000

5.2 FFunctions wwhich rrequire ppressing sseveral kkeys

:

5.2.1 Display shifting (only on the instant value display)

(accessible according to programmed access code)

M

M

Display down scale shifting (AdJ.Lo)

Display full scale shifting (AdJ.Hi)

After injecting an input signal corresponding to the down (or full) display

scale, press simultaneously on keys and (or and ) The

message AdJ.Lo (AdJ.Hi) will appear alternating with the value, to indicate you are in menu adjustment.

The display down and full scale can be increased or decreased by pressing or .

Keep pressing during 3s. on key or to access a fast increasing or

decreasing of the display value.

Press to validate the shifting. Once all shiftings are validated, the

input thus shifted will keep its shifting even after a setting off tension.

Press (or do not press any key during 20 s) to revert to the

measure display without modifications.

M

M

M

M

Page 24

S

5.2.2 Tare setting (only on instant value display)

Press and to enforce the signal present on the input as display

down scale

Note : The tare is not recorded in case of power supply cut.

To suppress the tare, go into menu in the main menu p6.

Exit from mode programming with configuration saving will automatically

reset the tare to zero.

(accessible according to programmed access code)

d.dISP

CLr.tA

5.2.4 Direct measure visualising

Press and to visualise the signal directly without any processing

: scale factor, square root, linearisation

− in mV, V or mA.

M

M

5.2.3 Changing of the display

ed value

Press and to switch from the instant value to the totalizer, and

vice-versa.

Led marking A blinking : instant value.

Led marking H blinking : totalizer

5.2.5 Visualisation and setting of alarm setpoints

Setting of setpoints : There are 2 ways to adjust setpoints.

- either in mode programming entering the correct safety access code

- or by simultaneous pressing on and

MM

MM

Option 22 rrelays

MM

MM

The meter will then show the message SP.x or SPx.x alternating with

the value of the corresponding setpoint.

The various setpoint values can be accessed by or .

These setpoints can then be changed (according to the programmed

access code, see p20) pressing

Once the setpoint is adjusted, press to revert to the setpoints reading menu.

Once all setpoints are adjusted, just press and the meter will revert

to mode measure, taking the new values into account.

If no key is pressed during 60 s., the meter will revert to measure

display without taking the modifications of setpoint values into account.

66.. EERRRROORR oorr iinnddiiccaattiioonn MMEESSSSAAGGEESS

2000

OPEn

Err.1

Value in overstepping

Sensor rupture

«

01000

Counting overstepping

> 999 999 999

or < -99 999 999

«

----

O.L.

Er.xxx

Input upper or lower electrical

overstepping

Displayable value overstepping.

Self-diagnosis error

Value set out of range

On instant value display

On totalizer display

totalizer

OPEN -----

Electrical overstepping or

sensor rupture recorded.

or

Page 25

S

77.. GGEENNEERRAALL WWAARRRRAANNTTYY TTEERRMMSS

WARRANTY applying and duration

This appliance is garanteed for a duration of 1 year against any design

or manufacturing defects, under normal operating conditions.

Processing conditions * : Processing not under warranty will be submited to the acceptance of a repair estimate. The customer will return

the products at his charge, and they will be restored to him after processing. Without a written agreement on the repair estimate within 30

days, products will not be held.

* Complete warranty terms and details available on request.

88.. LLEEXXIIQQUUEE

Messages shown by the meter in mode programming and/or reading

GGeenneerraall aacccceessss

Access to the reading of the parameters

Access to the programming of input and output parameters

Code for access to the programming of input and output

parameters

Programming of a new access code

Access to display simulation

Access to a simulation of the analog output

Deleting of recorded alarms

Tare suppressing

rEAd

ProG

CLEAr

CLr.tA

CodE

SiMUL

P.CodE

GEnE

0-10

300

0-0. 1

Input 0 to 10 V (or -10/10V)

Input 0 to 300 V (or -300/300V)

Input 0 to 100 mV (or -100/100mV)

Input 0 to 1 V (or -1/+1V)

Input down scale

Input full scale

Choice of the processing function

Linear

Square root extraction

Special linearisation

Number of linearisation points

Abscisse of a special linearisation point

0-1

d.in

F.in

nb

Axx

Funct

LinEA.

Li.SPE

root

CALib

IInnppuuttss

Access to the input programming sub-menu

Input type

Voltage input

Current input

Choice of the voltage caliber

InPut

tYPE

MA

U

diSPL.

Point

--.-d.diSP

F.diSP

bxx

Cut.oF

IntEG.

Instant value

Access to the display programming sub-menu

Choice of the decimal point location

Decimal point location

Display down scale

Display down scale

Ordinate of a special linearisation point

Cut-off programmable or not

Integration indice

Totalizer

Choice of the decimal point location

Decimal point

Choice of the decimal point operating mode

fixed decimal point

automatic decimal point

dP.tot

----.-

no

Auto.P

yes

Page 26

LOGIC inputs

Access to the LOGIC inputs programming sub-menu

Programming of LOGIC input 1

Programming of LOGIC input 2

Function erasing of min. and max.

Function display holding

Function Tare

Totalizer display / instant value display

Function on the totalizer

Function type X

S

FctX

tor

tor 1

tor 2

CLr.M

HoLd

tArE

dSP.to

totAL

Choice of the time basis

second

minute

hour

Convertion coefficient

Recording of errors, or not

t.baSE

CoeFF

MdeF

1

60

3600

Pr.diS

br.diG

br.bAr

1 1 1 1

4444

1 1 1 1

4444

L.dIG

On

OFF

nuLL

no

YES

Display parameters

Display features programming sub-menu

Adjusting of the digits brightness (4 levels)

Lowest brightness Strongest brightness

Adjusting of the bargraph brightness

Lowest brightness Strongest brightness

Last digit (low weight)

Last digit in service Last digit enforced to 0

Deleting of unsignificant zeros

Yes No

Display corresponding to an extinguished bargraph (0%)

Display corresponding to a fully lit bargraph

(100%)

Bargraph in mode indication

Led marking b

No dedication (led still)

Led lit when LOGIC input 1 is active

Indic

LEdb

no

tor1

d.bArG

F.bArG

Led marking c

No dedication (led still)

Led lit when LOGIC input 2 is active

Led marking d

No dedication (led still)

Led lit during RS response from the

instrument

LEd C

no

tor2

LEdd

no

RS

Parameter applied to the bargraph

Bargraph on the instant value

Bargraph on the cumulated value

PArA.b

InStA

totAL

Led marking e

No dedication (led still)

Led lit when a tare has been entered

Led marking f

No dedication (led still)

Led lit in case an error has been recorded

Led marking g

No dedication (led still)

Led lit in case of totalizer ovestepping

-99 999< counting > 999 999

LEdE

no

tArE

LEdF

no

M.dEF

LEdG

no

dEP.to

Analog

Access to the current output programming sub-menu

Parameter applied to the output

Out.MA

PArA.O

Page 27

S

Output on the instant value

Output on the cumulated value

Analog output down scale

Analog output full scale

Access to programming of the display for output down scale

Access to programming of the display for output full scale

d.out

F.out

InStA

totAL

dO.diS

FO.diS

19200

dELAY

Digital output

Access to the RS output programming sub-menu

Slave number

Transmission speed (baud rate)

Possible speeds

Possible speeds

Time delay before any response

Delay 75ms Delay 20ms

bAud

SLAuE

1200

JbuS

OFF

On

Setpoint value in mode setpoint

1st setpoint value in mode window

2nd setpoint value in mode window

Hysteresis value in display points

Time delay on relay X

SPx.1

SPx.2

HYSt.x

tiME.x

SPx

Relay outputs : x : 1 à 2

Access to the relay outputs programming sub-menu

Access to the programming of relay x

Activation of relay output 1

Activation De-activation

Relay operating mode

Mode alarm

Mode pulses

Parameter applied to the alarm

Alarm on the instant value

Alarm on the cumulated value

Relay x operating mode

Mode setpoints

Mode window

OFF

ModE.x

__1

--

--

1__

ActiX

tYPE.X

PArA.X

ALArM

PuLSE

inStA

totAL

rEL.x

On

rELAY

_1--1_

-

1__1

-

Programming of the relay associated led

Led lit when relay active (coil supplied)

Led still when relay active (coil supplied)

Recording of alarm X

Recording No recording

Alarm message

Message No message

Pulse weight

LEdx

On

OFF

MEM.x

MESSx

P.rAt

no

YES

no

YES

Pulse duration

100 ms

200 ms

400 ms

P.time

100

200

400

rEL.X

OFF

rUPt

CAPt.

OFF

LO

H I

SECU

Safeties

Access to the safeties programming sub-menu

Programming of the sensor rupture safety

Sensor rupture activation (or not)

De-activated Active

State of relay X in case of sensor rupture

No sensor rupture associated with the relay

Relay de-activated in case of sensor rupture

(coil not supplied)

Relay active in case of sensor rupture

(coil supplied)

On

Page 28

Reading of the instrument internal features

Access to the internal features reading sub-menu

Instrument type : C95 CI

Identification number

Programme version

Programme version number

Option code

Option code value

Self-diagnosis error

Type of error

Check sum display

Check sum value

S

YES

rEPLi

out.MA

dIAG.

Return value (or not) on the output

in case of sensor rupture

Return value required No return value

Return value

Programming of the self-diagnosis safety

State of relay X in case of self-diagnosis error

No self-diagnosis associated with the relay

Relay de-activated in case of self-diagnosis error

(coil not supplied)

Relay active in case of self-diagnosis error

(coil supplied)

rEL.X

OFF

LO

H I

no

Return value (or not) on the output

in case of self-diagnosis error

Return value required No return value

Return value

out.MA

no

YES

rEPLi

About

C95 CI

n

0

A0006

PrOG

01.05

OPtIO.

Ar---.

Err.

SAvE

YES

no

0000

CH.SuM

FC4E

Configuration saving

Configuration saving

Recording No recording

Further functions

Minimum value display

Maximum value display

Deleting of min. and Max.

Zero reset of the error recordings

Totalizer zero reset

Value of the oversteppings couter

InF.

SuP.

CLr.M

r.dEP

r.tot

Hi.tot

Err.1

OPEn

2000

OL

----

Er.xxx

Error messages

Value set out of range

Sensor rupture

Blinking measure : measure in overstepping

Displayable value overstepping

Upper or lower electrical overstepping on the input

Self-diagnosis error

«

Page 29

S

Address

196

197

198

200

202

204

206

208

290

291

State of the totalizer

Value of the oversteppings counter

Value of the totalizer

Value of the analog output

in µA

Minimum value of the displayed

value

Maximum value of the displayed

value

Instant measure displayed

Direct measure

State of relay 1

State of relay 2

Format

integer

integer

double integer

double integer

double integer

double integer

double integer

double integer

integer

integer

nb of words

1

1

2

2

2

2

2

2

1

1

99.. AANNNNEEXXEE :: MMOODDBBUUSS

9.1 Ta

ble of modbus addresses

••

Direct measure :

Value without scale factor for inputs 100 mV, 1V, 10V, 300V, 20 mA :

- in mV for the 10V input

- in 10

th

of mV for the 1V input

- in µA for the mA input

- in 100 thof mV for the mV input

- in 100 thof V for the 300V input

••

State of the relays

:

bit 15

bit 7

bit 6

bit 0

1 : Led lit

1 : Led blinking : mode

recording and measure

not in alarm area

1 : Relays ON

Alarm recorded

••

Instant measure :

The instant measure value is shown on the display without the decimal point.

To read the decimal point value, read the word at address 120.

bit 15

bit 2

bit 1

bit 0

*Decimal point location

1 : Display with 4 decimals

2 : Display with 3 decimals

3 : Display with 2 decimals

4 : Display with 1 decimal

5 : Display with 0 decimals

••

Value of the totalizer :

The totalizer value is :

if value negative :

value of the oversteppings counter x -100 000 + totalizer value

if value positive :

value of the oversteppings counter x 1 000 000 + totalizer value

To know the decimal point, read the word at address 138.

Address 138

:

bit 15

bit 2

bit 1

bit 0

Location of the totalizer decimal point

1 : Display with 4 decimals

2 : Display with 3 decimals

3 : Display with 2 decimals

4 : Display with 1 decimal

5 : Display with 0 decimals

bit 15

bit 2

bit 1

bit 0

1: sensor rupture error

recorded

1: electrical overstepping error recorded

positive overstepping of

the oversteppings

counter Hi.tot > 1000

negative overstepping

of the oversteppings

counter Hi.tot < -1000

••

State of the totalizer :

bit 4bit 5

bit 3

totalizer overstepping

(oversteppings counter

Hi.tot ≠ 0)

Address 120 :

Page 30

S

2 bytes

CRC 16

Slave

number

1 byte

1 byte

2 bytes

Function

3 or 4

CRC 16

1st word

MSB

address

LSB

Number

MSB

of words

LSB

2 bytes

2 bytes

Slave

number

1 byte

1 byte

1 byte

2 bytes

Function

3 or 4

CRC 16

Number

of bytes

read

Response pattern :

1st word

MSB

value

LSB

2 bytes

2nd word

MSB

value

LSB

2 bytes

Slave

number

1 byte

1 byte

2 bytes

Function

16

CRC 16

1st word

address

Nbr of

words to

be enfor.

Writing of N words : Function N°16 :

Request pattern

:

Value of the words

to be enforced

2 bytes 2 bytes

Number

of words

to be enf.

2 bytes

Nbr of

bytes to

be enfor.

1 byte

n bytes

Slave

number

1 byte

1 byte

1 byte

Function161st word

address

Response pattern :

2 bytes

CRC 16

Slave

number

1 byte

1 byte

2 bytes

Function

6

CRC 16

Word

address

Writing of 1 word : Function N°6 :

Request pattern

:

2 bytes

Value of

word to

be enfor.

2 bytes

Value of

word to

be enfor.

2 bytes

Slave

number

1 byte

1 byte

2 bytes

Function6Word

address

2 bytes

CRC 16

Slave

number

1 byte

1 byte

1 byte

Function

requested with

MSB=1

Error

code

Response pattern :

Exception pattern :

V

alues of the error codes :

1 : Function code unknown

2 : Address incorrect

3 : Data incorrect

9 : Writing impossible

Request pattern

:

254 03

00000000

CRC 160 206

9.3 Reading in double inte

ger format

:

Example : Reading of the displayed measure

Request

:

0 2

Address

Reading

of n words

Slave

number

byte 3

00000000

byte 4

00010011

byte 1

10001000

byte 2

0

Sign : 0 positive

1 negative

0 19 136

Number of words

254 3 4 19

••

Response with a positive measure :

136

0

CRC 160

Measure value :

measure

byte 1

byte 2

byte 3

byte 4

2 bytes

11111111

byte 3

11111111

byte 4

11101100

byte 1

01111000

byte 2

Sign : 1 negative : inverting of bits and adding of 1.

Measure = byte 3 x 2563+ byte 4 x 2562+ byte 1 x 256 + byte 2

= 0 x 256

3

+ 0 x 256

2

+ 19 x 256 + 136

= 5000

Reading of address 120 => decimal point = 2 => displayed meas. 50.00

254 3 4 236

••

Response with a negative measure :

120 255

CRC 16255

measure

byte 1

byte 2

byte 3

byte 4

2 bytes

9.2 Description of born Modbus functions :

Reading of N words : Function n°3

Page 31

S

00000000

byte 3

00000000

byte 4

00010011

byte 1

10000111

byte 2

00000000

byte 3

00000000

byte 4

00010011

byte 1

10001000

byte 2

0

0 19 136

Plus 1

Invertion

Measure = -(byte 3 x 2563+ byte 4 x 2562+ byte 1 x 256+ byte 2)

= -( 0 x 256

3

+ 0 x 256

2