Page 1

BW25

BW25

BW25BW25

Level meter

Handbook

Handbook

HandbookHandbook

© KROHNE 09/2010 - 4000432302 MA BW25 R05 en

Page 2

: IMPRINT ::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2010 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 3

BW25

CONTENTS

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 Certifications .................................................................................................................... 5

1.3 Safety instructions from the manufacturer ..................................................................... 6

1.3.1 Copyright and data protection ................................................................................................ 6

1.3.2 Disclaimer ............................................................................................................................... 6

1.3.3 Product liability and warranty ................................................................................................ 7

1.3.4 Information concerning the documentation........................................................................... 7

1.3.5 Warnings and symbols used................................................................................................... 8

1.4 Safety instructions for the operator................................................................................. 8

2 Device description 9

2.1 Scope of delivery............................................................................................................... 9

2.2 Device version................................................................................................................. 10

2.3 Nameplate ...................................................................................................................... 11

2.4 Description code............................................................................................................. 12

3 Installation 13

3.1 Notes on installation ......................................................................................................13

3.2 Storage ........................................................................................................................... 13

3.3 Installation condititions ..................................................................................................13

3.4 Installation...................................................................................................................... 14

4 Electrical connections 15

4.1 Safety instructions.......................................................................................................... 15

4.2 Electrical connection indicator M9................................................................................. 16

4.2.1 Limit switch........................................................................................................................... 16

4.2.2 Electrical signal output ESK ................................................................................................. 19

4.3 Electrical connection indicator M10............................................................................... 21

4.3.1 Electrical connection and functions ..................................................................................... 21

4.3.2 M10 Power supply - current output...................................................................................... 21

4.3.3 M10 switching outputs B1 and B2 ........................................................................................ 24

4.4 Grounding ....................................................................................................................... 26

4.5 Protection category ........................................................................................................26

5 Start-up 27

5.1 Start-up........................................................................................................................... 27

5.2 Indicator M10 .................................................................................................................. 27

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

3

Page 4

CONTENTS

BW25

6 Operation 28

6.1 Operating elements........................................................................................................ 28

6.2 Basic principles of operation.......................................................................................... 29

6.2.1 Functional description of the buttons................................................................................... 29

6.2.2 Navigation within the menu structure.................................................................................. 29

6.2.3 Changing the settings in the menu....................................................................................... 30

6.2.4 Measures in the event of faulty indications.......................................................................... 30

6.3 Overview of the most important functions and indicators............................................. 31

6.4 Error messages.............................................................................................................. 32

6.5 Menu indicator M10 ........................................................................................................ 34

6.5.1 Factory Settings .................................................................................................................... 34

6.5.2 Menu structure ..................................................................................................................... 35

6.5.3 Menu explanations................................................................................................................ 36

7 Service 39

7.1 Maintenance ................................................................................................................... 39

7.2 Spare parts availability...................................................................................................39

7.3 Availability of services .................................................................................................... 39

7.4 Returning the device to the manufacturer..................................................................... 39

7.4.1 General information.............................................................................................................. 39

7.4.2 Form (for copying) to accompany a returned device............................................................ 41

7.5 Disposal .......................................................................................................................... 41

8 Technical data 42

8.1 Operating principle......................................................................................................... 42

8.2 Technical data................................................................................................................. 43

8.3 Dimensions ..................................................................................................................... 48

9 Notes 50

4

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 5

BW25

1.1 Intended use

The level meter is suitable for measuring liquids and separation layers in liquids.

The devices are especially well suited for the measurement of:

• Liquids

• Water

• Chemicals with low corrosiveness

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Responsibility for the use of the measurement devices with regard to suitability, intended use

and corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

Do not use any abrasive or highly viscous media.

SAFETY INSTRUCTIONS 1

1.2 Certifications

CE marking

The device fulfils the statutory requirements of the following EC directives:

• Pressure Equipment Directive 97/23/EC Article 3.3

• EC directive 94/9 EC - ATEX directive

• EMC Directive 89/336/EC

as well as

• EN 61010

• EMC specification acc. to EN 61326/A1

• NAMUR recommendations NE 21 and NE 43

The manufacturer certifies successful testing of the product by applying the CE marking.

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

5

Page 6

1 SAFETY INSTRUCTIONS

1.3 Safety instructions from the manufacturer

1.3.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

BW25

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.3.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect, incidental, punitive and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

6

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 7

BW25

1.3.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.3.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

7

Page 8

1 SAFETY INSTRUCTIONS

1.3.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

BW25

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.4 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

8

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 9

BW25

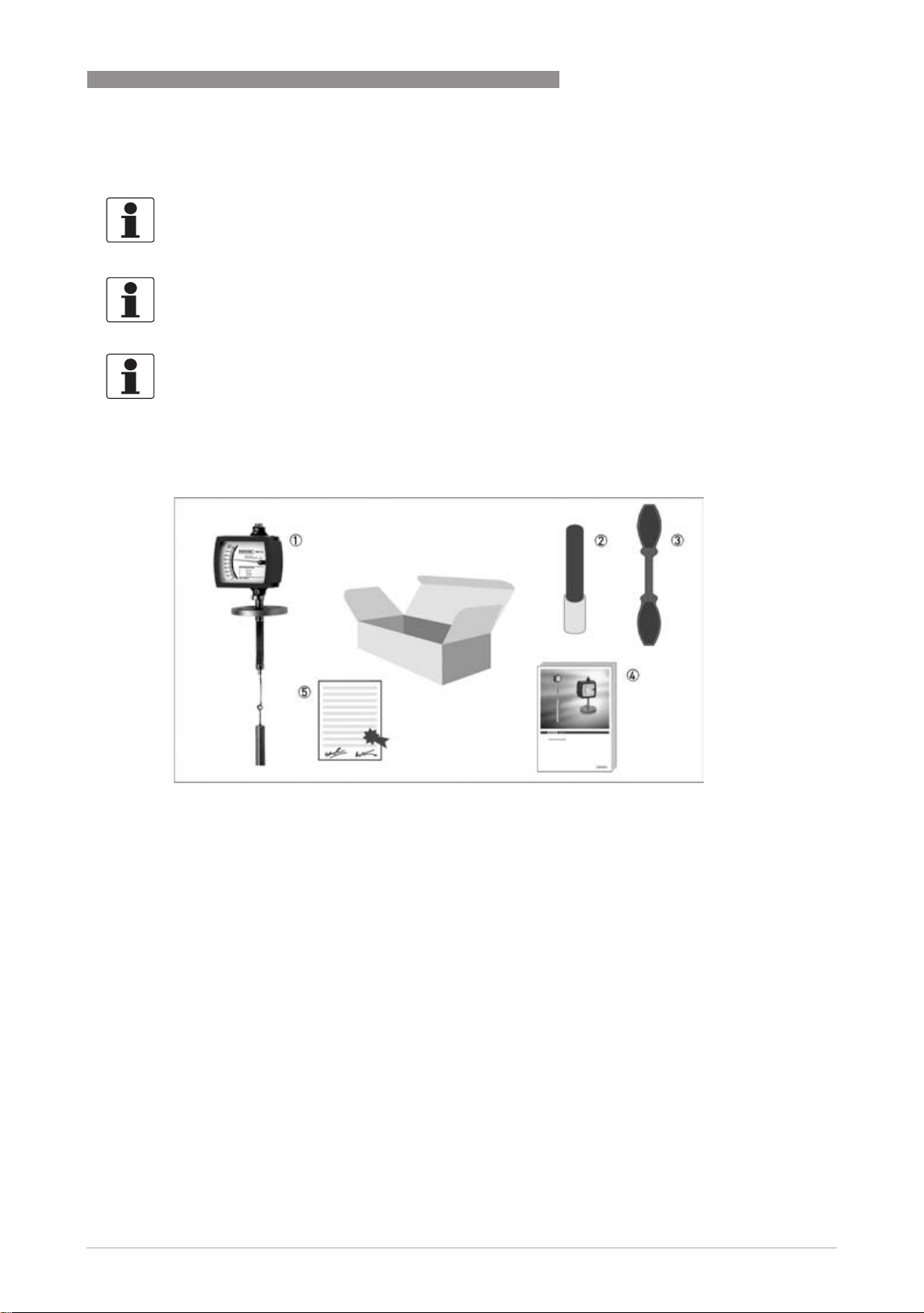

2.1 Scope of delivery

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION 2

1 Measuring device in ordered version

2 For indicator M10 - bar magnet

3 For indicator M10 - key

4 Handbook

5 Certificates, calibration report (supplied to order only)

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

9

Page 10

2 DEVICE DESCRIPTION

2.2 Device version

1 BW25 with indicator M9

2 BW25 with indicator M10

1 BW25/M9

• Local indicator without auxiliary power

• Max. 2 limit switches, type NAMUR, NAMUR safety-oriented

• 2-wire current output 4…20 mA, HART

®

communication

BW25

2 BW25/M10

• Ex d flameproof enclosure

• 2 digital adjustable limit switches, 2-wire open collector or type NAMUR

®

• 2-wire current output 4…20 mA, HART

communication

10

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 11

BW25

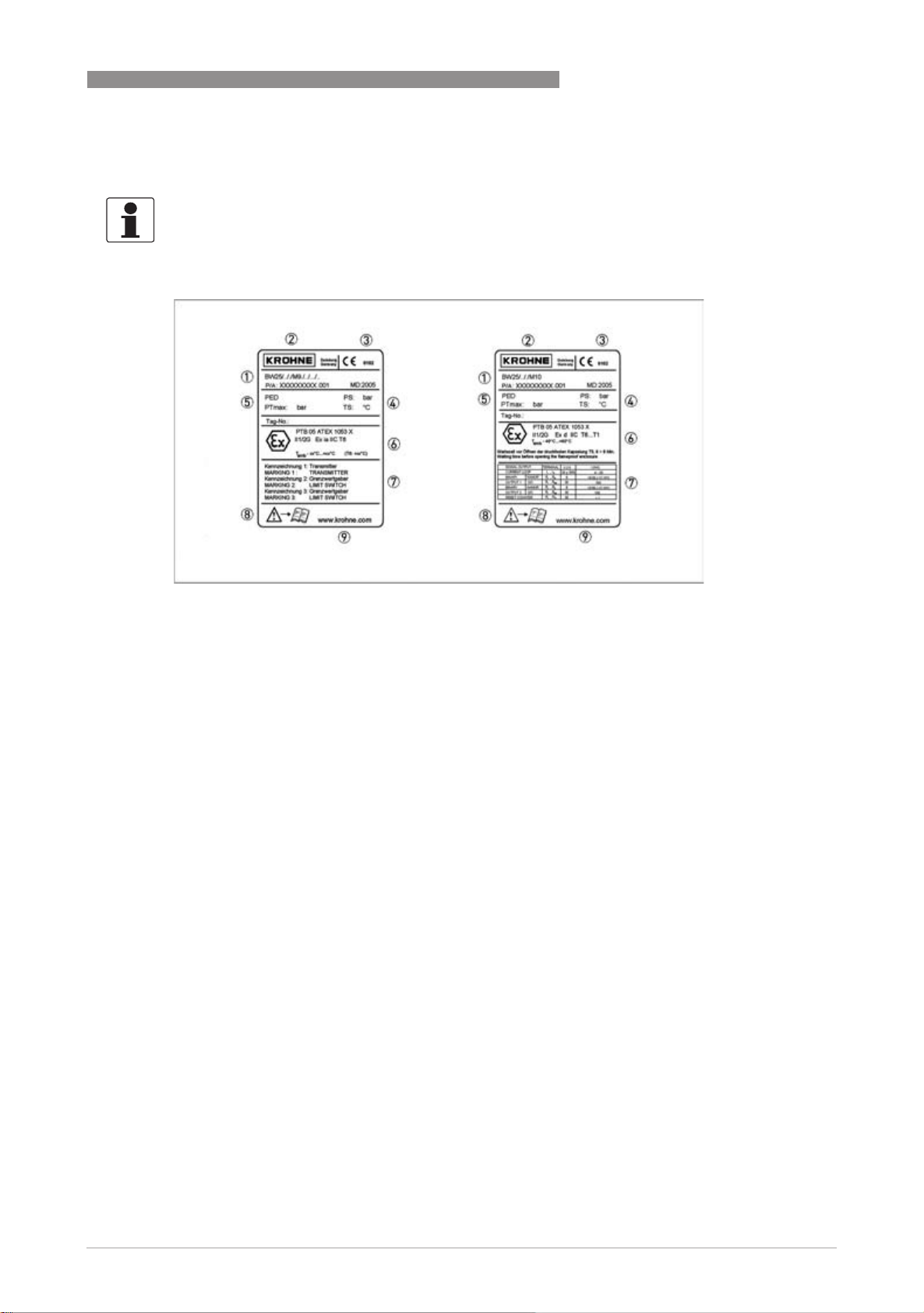

2.3 Nameplate

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION 2

Figure 2-1: Nameplates on the indicator

1 Device type

2 Manufacturer

3 Notified ATEX body

4 Sizing data: temperature & pressure rating

5 PED data

6 Ex data

7 Electrical connection data

8 Note manual

9 KROHNE website

Additional markings on the indicator

• SO - sales order / item

• PA - order

• Vx - product configurator code

• AC - article code

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

11

Page 12

2 DEVICE DESCRIPTION

2.4 Description code

The description code* consists of the following elements:

1 Materials / versions

RR - Stainless Steel

Ti - rust-proof steel (device flange), titanium (displacement rod)

2 Version with bypass chamber

B - with bypass chamber

3 Series of indicators

M9 - Indicator M9 standard indicator

M9S - Indicator with knock-resistant sight glass

M9R - Indicator in Stainless Steel housing

M9T - Stainless steel indicator with knock-resistant sight glass

M10 - Indicator or signal converter M10

BW25

4 High temperature version

HT - Version with HT extension

5 Electrical signal output

ESK - Electronic transmitter

6 Limit switch

K1 - One limit switch

K2 - Two limit switches

* positions which are not needed are omitted (no blank positions)

12

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 13

BW25

3.1 Notes on installation

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

• Store the device in a dry and dust-free location.

• Avoid lasting direct exposure to the sun.

• Store the device in its original packing.

• The permissible storage temperature for standard devices is -40...+80°C / -40...+176°F.

INSTALLATION 3

3.3 Installation condititions

CAUTION!

When installing the device, the following points must be observed:

•

Before installation, compare the serial number of the display (nameplate) with the serial

number on the displacement rod, the flange and the magnet.

•

In the case of level displays with a bypass chamber, the BW25 serial number on the bypass

chamber should be compared with the serial number on the display.

•

Avoid combining parts with differing serial numbers.

•

Ensure the material compatibility of the parts in contact with the product.

•

Screws, bolts and gaskets are to be provided by the customer and must be selected in

accordance with the pressure rating of the mounting flange or the operating pressure.

•

Align the gaskets. Tighten the nuts with the tightening torques of the appropriate pressure

rating.

•

Do not lay signal cables directly next to cables for the power supply.

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

13

Page 14

3 INSTALLATION

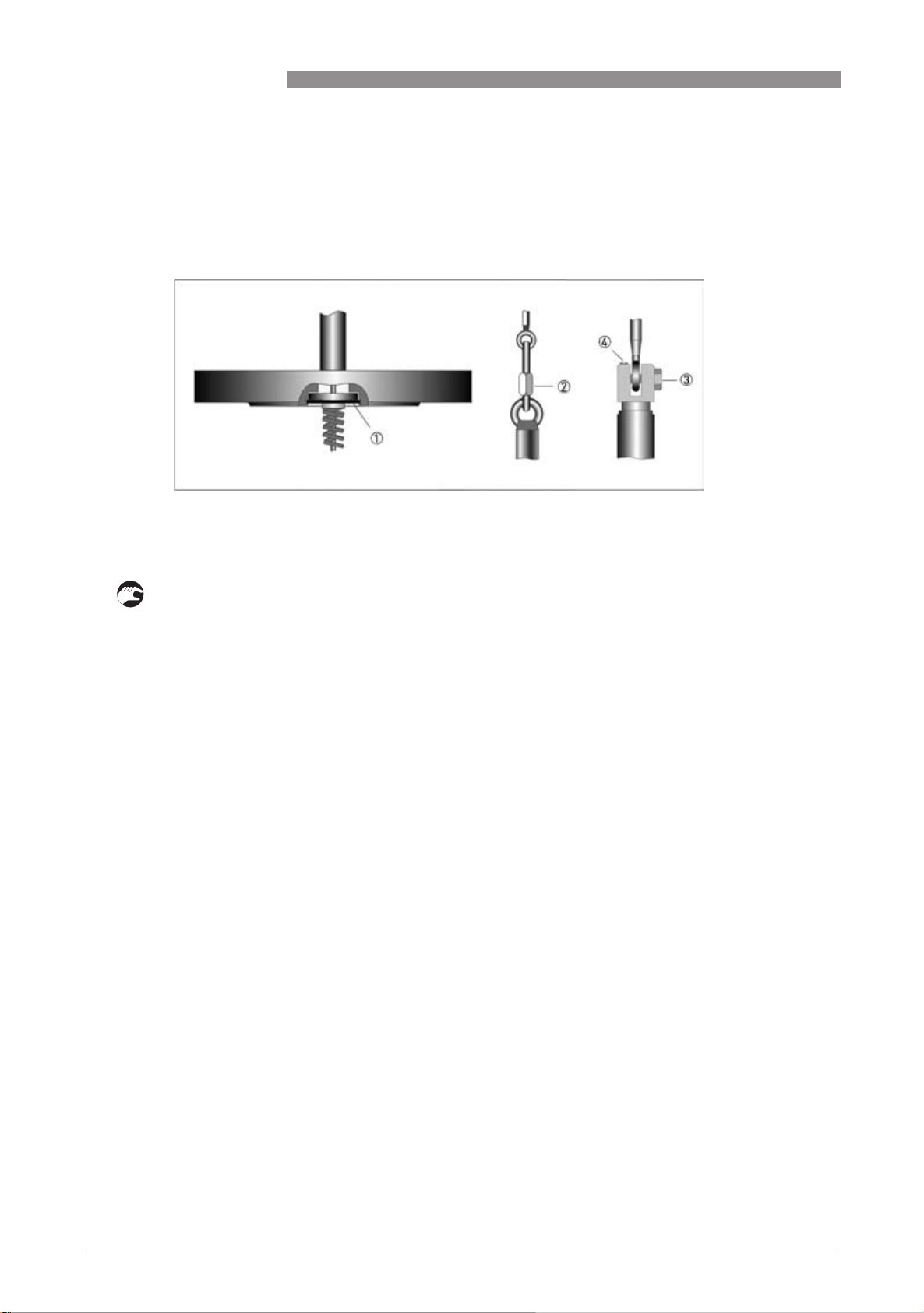

3.4 Installation

The sealing surface of the tank flange must be horizontal to ensure the perfect function of the

level measurement unit.

1 Lock ring

2 Quick-action lock

3 Retaining screw

4 Cover stop

BW25

• Insert the spring suspension pin in the flange system and secure it with a retaining ring 1.

• Install the retaining ring 1 properly and check for a correct seat all round.

• Place the seal on the tank flange.

• Suspend the displacer body on the spring suspension pin.

• Tighten the locking elements of the quick-action lock 2 (standard) or, with the variant, 3 and

4 and check for a tight fit.

• Insert the displacer element and the spring suspension pin into the tank through the tank

flange or into the preinstalled bypass chamber.

• Tighten the flange connection.

14

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 15

BW25

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

ELECTRICAL CONNECTIONS 4

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

15

Page 16

4 ELECTRICAL CONNECTIONS

4.2 Electrical connection indicator M9

4.2.1 Limit switch

Indicator M9 can be equipped with a maximum of two electronic limit switches. The limit switch

functions with a slot sensor which is operated inductively through the semicircular metal vane

belonging to the measuring pointer. The switching points are set through the contact pointers.

The position of the contact pointer is indicated on the scale.

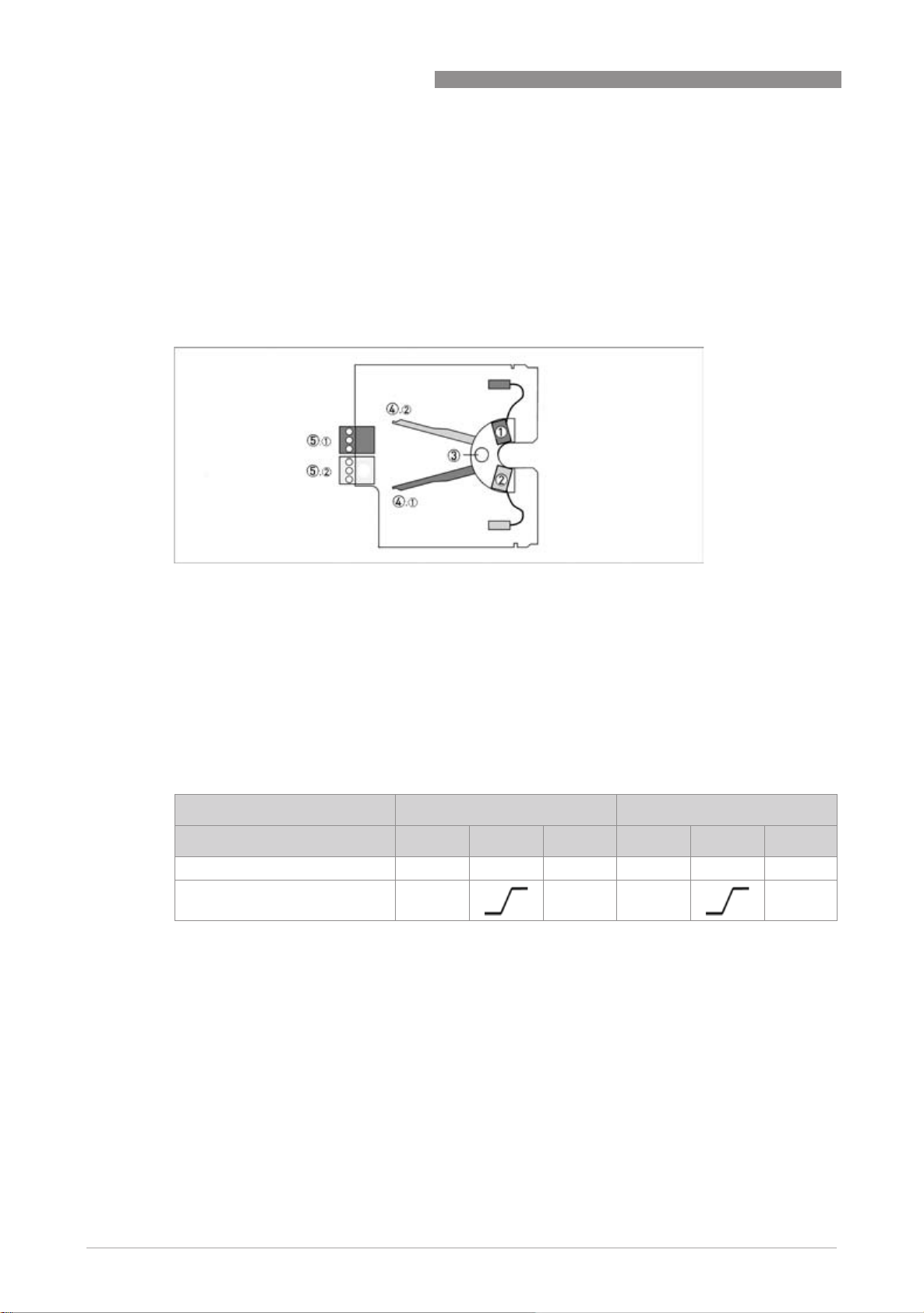

Limit switch module

BW25

1 Min. contact

2 Max. contact

3 Locking screw

4 Maximum pointer

5 Connection terminal

The connecting terminals have a pluggable design and can be removed in order to connect the

lines. The built-in contact types are shown on the nameplate of the indicator.

Electrical connection of the limit switches

Contact MIN MAX

Terminal no. 1 2 3 4 5 6

Connection 2-wire NAMUR - + - +

Connection 3-wire + - + -

16

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 17

BW25

ELECTRICAL CONNECTIONS 4

Limit switch connection terminals

1 2-wire limit switch NAMUR

2 3-wire limit switch

3 Terminal connection min contact

4 Terminal connection max contact

5 3-wire load

6 NAMUR isolated switching amplifier

7 3-wire power supply

Limit setting

1 Contact pointer MAX

2 Contact pointer MIN

3 Locking screw

Setting is carried out directly via contact pointers 1 and 2 :

• Slide the scale away

• Loosen the locking screw 3 slightly

• Slide the scale back to the latching point

• Set contact pointers 1 and 2 to the desired switching point

After setting has been carried out: Fix the contact pointers with the locking screw 3.

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

17

Page 18

4 ELECTRICAL CONNECTIONS

Switch contact definition

1 MIN contact

2 MAX contact

3 Pointer vane with switching vane

If the measuring pointer vane goes into the slot an alarm is triggered. If the pointer vane lies

outside the slot sensor, a wire break also causes the alarm to be triggered.

The 3-wire limit switch does not have any wire break detection

BW25

Definition MinMin - MaxMax

1 MIN 2 contact or MAX 1 contact

2 MIN 1 contact or MAX 2 contact

Current consumption in the position shown:

Contact Type Current

MIN 1 NAMUR ≤ 1 mA

MIN 2 NAMUR ≤ 1 mA

MAX 1 NAMUR ≥ 3 mA

MAX 2 NAMUR ≥ 3 mA

18

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 19

BW25

4.2.2 Electrical signal output ESK

The connecting terminals of the ESK have a pluggable design and can be removed in order to

connect the cables.

1 ESK2A current transmitter

2 Power supply 12...30VDC

3 Measurement signal 4...20 mA

4 External load, HART

®

communication

ELECTRICAL CONNECTIONS 4

The circuitry for connection to other devices such as digital evaluator units or process control

equipment must be designed with special care. In some circumstances, internal connections in

these devices (e.g. GND with PE, ground loops) may lead to impermissible voltage potentials,

which can compromise the function of the device itself or a connected device. In such cases a

protected extra-low voltage (PELV) is recommended.

1 Terminal connection

2 Converter supply isolator with electrical isolation

3 Power supply (see supply isolator information)

4 Measurement signal 4...20mA

5 External load, HART

®

communication

HART® communication

When HART® communication is carried out with the ESK, this will not in any way impair analog

measured-data transmission (4...20 mA). Exception: multidrop operation. In multidrop operation

®

a maximum of 15 devices with HART

function can be operated in parallel, whereby their analog

outputs are switched inactive. (I approx. 4 mA per device).

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

19

Page 20

4 ELECTRICAL CONNECTIONS

Power supply

INFORMATION!

The supply voltage has to be between 12 VDC and 30 VDC. This is based on the total resistance of

the measuring loop. To determine this, add up the resistances of each component in the

measuring loop (not including the level meter).

The required supply voltage can be calculated using the formula below:

.

= R

U

ext.

where

U

ext.

= the total measuring loop resistance.

R

L

INFORMATION!

The power supply has to be able to supply a minimum of 22 mA.

22 mA + 12 V

L

= the minimum supply voltage and

BW25

Load for HART® communication

INFORMATION!

®

For HART

communication a load of at least 230 ohm is required.

The maximum load resistance is calculated as follows:

DANGER!

Use a twisted two-core cable to prevent electrical interference from impeding the DC output

signal.

In some cases a shielded cable may be necessary. The cable shield may only be earthed

(grounded) at one place (on the power supply unit).

Configuration

The ESK can be configured via HART® communication. DD (Device Description) for AMS 6.x and

PDM 5.2 as well as a DTM (Device Type Manager) are available for configuration (go to download

centre at www.krohne.com).

20

With the integrated HART

values can be monitored.

®

communication, the current level can be transmitted. Two limit

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 21

BW25

4.3 Electrical connection indicator M10

4.3.1 Electrical connection and functions

The display can be removed after the housing lid has been unscrewed. The connection terminals

have a spring locking system.

Terminal connection

1 Power supply - current output

2 Switching output B1

3 Switching output B2

4 Not used for BW25

ELECTRICAL CONNECTIONS 4

4.3.2 M10 Power supply - current output

The electrical connection is reverse-polarity protected.

M10 - terminal connection I

1 Terminal connection

2 Power supply 16...32VDC

3 Measurement signal 4...20 mA

4 External load, HART

®

communication

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

21

Page 22

4 ELECTRICAL CONNECTIONS

The circuitry to other devices must be designed with especial care. In some circumstances

internal connections in these devices (e.g. GND with PE, ground loops) may lead to

impermissible voltage potentials, which can compromise the function of the device itself or a

connected device. In such cases a protected extra-low voltage (PELV) is recommended.

1 Terminal connection

2 Converter supply isolator with electrical isolation

3 Power supply (see supply isolator information)

4 Measurement signal 4...20mA

5 External load, HART

®

communication

BW25

HART® communication

When HART® communication is carried out with the M10, this will not in any way impair analogue

measured data transmission (4...20 mA).

Exception for multidrop operation. In multidrop operation, a maximum of 15 devices with

®

HART

TM function can be operated in parallel, for which the current outputs are switched to

inactive (I approx. 4 mA per device).

Power supply

INFORMATION!

The supply voltage has to be between 16 VDC and 32 VDC. This is based on the total resistance of

the measuring loop. To determine this, add up the resistances of each component in the

measuring loop (not including the level meter).

The required supply voltage can be calculated using the formula below:

.

= R

U

ext.

22 mA + 16 V

L

where

U

= the minimum supply voltage and

ext.

R

= the total measuring loop resistance.

L

22

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 23

BW25

ELECTRICAL CONNECTIONS 4

INFORMATION!

The power supply has to be able to supply a minimum of 22 mA.

Load for HART® communication

INFORMATION!

®

For HART

The maximum load resistance is calculated as follows:

DANGER!

Use a twisted two-core cable to prevent electrical interference from impeding the DC output

signal.

In some cases a shielded cable may be necessary. The cable shield may only be earthed

(grounded) at one place (on the power supply unit).

communication a load of at least 230 ohm is required.

Configuration

The electronic M10 indicator can be configured using HART® communication. DD (Device

Description) for AMS 6.x and PDM 5.2 as well as a DTM (Device Type Manager) are available for

configuration (go to download centre at www.krohne.com).

®

The current level can be transmitted using the integral HART

can be monitored.

communications. Two limit values

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

23

Page 24

4 ELECTRICAL CONNECTIONS

4.3.3 M10 switching outputs B1 and B2

The switching outputs are electrically isolated from each other and from the current output.

CAUTION!

The switching outputs can only be operating if the power supply is applied to terminals I+ and I-.

Switching outputs B1 and B2 can be electrically connected in two ways:

• NAMUR switching output - Ri approx. 1kOhm

• Low-resistance switching output with PNP technology

M10 - switching outputs

BW25

1 NAMUR terminal connection

2 Isolation switching amplifier

3 PNP technology terminal connection

4 Power supply

5 Load

Switching values

NC contact NO contact

NAMUR OC NAMUR OC

Switching value reached ≤1 mA ≤1 mA > 3mA max. 100 mA

Switching value not reached > 3mA max. 100 mA ≤1 mA ≤1 mA

24

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 25

BW25

ELECTRICAL CONNECTIONS 4

Switching capacity of B1 and B2 with PNP technology

Due to the PNP technology and the associated protective elements, there is a voltage drop Uv for

the load to be operated.

Switching capacity of B1 and B2

1 Max. switching current I [mA]

2 Minimum load impedance R

3 Power supply U

ext.

[Ohm]

L

Power loss of B1 and B2

1 Load impedance RL 100 Ohm

2 Load impedance R

3 Power loss U

4 Power supply U

d

1000 Ohm

L

ext.

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

25

Page 26

4 ELECTRICAL CONNECTIONS

4.4 Grounding

1 Grounding on the flange

2 Grounding indicator M9

3 Grounding indicator M10

DANGER!

The grounding wire may not transfer any interference voltage.

Do not use this grounding wire to ground any other electrical devices.

BW25

4.5 Protection category

The measuring device meets all requirements of protection category IP67, NEMA 4x.

DANGER!

After all servicing and maintenance work on the measuring device, the specified protection

category has to be ensured again.

Therefore it is essential to observe the following points:

• Use only original gaskets. They must be clean and free of any damage. Defective gaskets must

be replaced.

• The electrical cables used must be undamaged and must comply with regulations.

• The cables must be laid with a loop 3 upstream of the measuring device to prevent water

from getting into the housing.

• The cable feedthroughs 2 must be tightened.

• Close the unused cable feedthroughs using blanking plugs 1.

26

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 27

BW25

5.1 Start-up

CAUTION!

When starting up the device, the following points must be observed:

•

Compare the serial number on the indicator (nameplate) with the serial number on the

displacement rod, the pressure sleeve and the flange.

•

Avoid assembling components that have different serial numbers.

•

Ensure material compatibility of the wetted parts.

•

The indicator system has been factory set such that when the displacement rod is not

immersed (empty tank) the indicator shows "0" at an operating temperature of 20

•

Do not change the factory setting of the pointer. This applies in particular where high

pressures and high temperatures are involved.

5.2 Indicator M10

INFORMATION!

The device is always preset for the user and his application.

START-UP 5

°

C.

Start

After the device is switched on, the display shows the following in sequence

• "Test",

• the device type and

• the version number.

Afterwards the device performs a self-test and switches to measurement mode. Here all of the

parameters preset for the customer are analysed and checked for plausibility, and the current

measured value is displayed.

Operation

INFORMATION!

The device is low-maintenance

Comply with the application limits with regard to temperature of the medium and ambient

temperature.

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

27

Page 28

6 OPERATION

6.1 Operating elements

BW25

The device is operated with the cover on the front open, using the mechanical keys

cover closed using a bar magnet

bar magnet.

bar magnetbar magnet

keys, or with the

keyskeys

CAUTION!

The switching point of the magnetic sensors is directly under the glass disc over the appropriate

circle. Only touch the circle vertically and from the front using the bar magnet. Touching it from

the side may cause a malfunction.

Figure 6-1: Display and operating elements

1 Enter button (circuit for bar magnet)

2 Up button (circuit for bar magnet)

3 Right button (circuit for bar magnet)

4 Display

The mechanical keys and keys for the bar magnet have the same functionality. In this

documentation the keys are represented as symbols to describe the operating functions:

M10 operation keys

Button Symbol

right →

up ↑

Enter ^

28

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 29

BW25

6.2 Basic principles of operation

6.2.1 Functional description of the buttons

OPERATION 6

→

↑

^

Switch from measuring mode to menu mode

Switch to one menu level lower

Open menu item and activate change mode

In change mode:

In change mode: Move the input cursor one position to the right; after the last digit the

In change mode:In change mode:

input cursor jumps back to the beginning.

In measuring mode:

In measuring mode: Switch between measured values and error messages

In measuring mode:In measuring mode:

Change between the menu items within a menu level

In change mode:

In change mode: Changing parameters and settings; running through the available

In change mode:In change mode:

characters; shifting the decimal point to the right.

Switch to one menu level higher

Return to measuring mode with a query whether the data should be accepted

6.2.2 Navigation within the menu structure

Navigation within the menu is by means of the → and ^ buttons. Pressing button → takes you

one menu lower, ^ takes you one menu higher.

If you are already located at the lowest level (function level), you can use the button → to go the

the change mode, which can be used to set data and values.

If you are located at the first level (main menu), you can use the ^ key to exit the menu mode and

return to the measuring mode.

Measuring

mode

→ Main menu↑→ Sub-menu↑→ Function

^^^^ ^^^^ ^^^^ ^^^^

↑

→ Edit

→ ↑ ^^^^

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

29

Page 30

6 OPERATION

6.2.3 Changing the settings in the menu

Starting operation

Starting operation

Starting operationStarting operation

Operation is started using the → key

If a different key is pressed, it is necessary to wait 5 seconds before activating the → key.

If a control lockout is set, the code → → → ^ ^ ^ ↑ ↑ ↑ must be entered. If no key is pressed

within 5 seconds, code input is exited.

Exiting operator input

Exiting operator input

Exiting operator inputExiting operator input

Operation is exited by pressing the ^ key several times.

If data have been changed:

Save Yes → Changes saved.

Save No ^^^^ Changes not saved.

CAUTION!

Each time parameters or settings are changed, the measuring device carries out an internal

plausibility check.

If implausible inputs have been made, the indicator remains in the current menu, and the

changes are not accepted.

An update is carried out and the display returns to measuring mode.

The display returns to measuring mode.

BW25

Example: changing the default parameter from mmmm to cm

Display Display

Example: 5.0

1x → Fct. 1111.0

2x ↑ Fct. 3333.0

1x → Fct 3.1111

12x ↑ Fct 3.13

m

OPERATION

INSTALLATION

LANGUAGE

13

1313

END&UNIT

6.2.4 Measures in the event of faulty indications

If the indications on the display or the responses to keypad commands are faulty, you have to do

a hardware reset. Switch the power supply OFF and ON again.

cm

cmcm

1x → Fct. 3.13.1111

1x → 5.0000

6x ↑ 500

1x ^^^^ Save Yes

3x ^^^^ 500

LEVEL

m

cm

cm

30

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 31

BW25

6.3 Overview of the most important functions and indicators

INFORMATION!

A complete list of all functions and short descriptions is provided in the appendix. All default

parameters and settings are adapted for the specific customer.

Level Designation Explanation

1.4 TIME CONST. Time constant, damping value [s]

1.5.2 ERROR Error indicator

Yes: Error messages are deleted

No: error messages are suppressed.

2.1 4-20mA OUT Check current output

2.2 -

2.4

3.1 LANGUAGE Select the menu language

3.13.1 LEVEL Maximum level of the liquid

OUTPUT B Testing the switching output

The value set is represented by a 20 mA analogue current output.

If the current value exceeds the preset value, an alarm is indicated.

OPERATION 6

M10 level units

The following units are supported: m - cm - mm - inch - feet

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

31

Page 32

6 OPERATION

6.4 Error messages

Error message Description Category Remedy

BW25

NOT LINEARIZED Linearization faulty or

not activated =

measuring error

NEW LINEARI.

TABLE BAD

Faulty or non-existent

data in the

linearisation table =

measuring error

NOT

MONOTONOUS

The sequence of the

linearisation values

does not rise

monotonously.

FIRST NOT 0 % The first level value of

the linearisation table

is not 0%

LAST NOT 100 % The last level value of

the linearisation table

is not 100%

LINEARIZATIO

UNDER CONFIG

The device is in

linearization mode =

measuring error

UNIT SYSTEM

CONFLICT

The unit of the

linearisation value is

not correct for the

select level meter.

TOO FEW

ENTRIES

The linearisation

table does not have

enough support

points.

NO ZERO CAL OF AOThe analog output

zero point 4.00 mA is

not calibrated. =

Possible

measurement error

in the process control

system

NO F.SC. CAL OF AOThe current output

100% = 20.00mA is

not calibrated. =

potential measuring

error in process

control

NO TEMP.

COMPENSATION

The sensor

temperature

compensation of the

device is faulty or has

not been carried out =

possible measuring

error

OUTPUT NOT

LINEARIZED

Linearization is not

activated = measuring

error

Errors Activate linearization or carry it out again

(HART

®

communication and linearization

software are required; the original calibration

values must be known), or send the device

back to the manufacturer for linearization.

Error Check linearization or carry it out again

(HART

®

communication and linearization

software are required; the original calibration

values must be known), or send the device

back to the manufacturer for a check of the

linearization.

Error Check linearization and/or carry it out again

(HART

®

communication and linearization

software are required), or send the device

back to the manufacturer for linearization.

Error Complete the linearization and activate it

(HART

®

communication and linearization

software are required), or send the device

back to the manufacturer for linearization.

Error Correct error, carry out linearization again if

necessary (HART

®

communication and

linearization software are required), or send

the device back to the manufacturer for

linearization.

Error Carry out linearization at at least 5 points

(HART

®

communication and linearization

software are required), or send the device

back to the manufacturer for linearization.

Warning Perform calibration using ammeter and menu

3.10 or using standard HART

®

tools/process

control system and poss. external ammeter.

Caution: during calibration, switch the

measuring point to manual control.

Warning Perform calibration using ammeter and menu

item 3.11 or using standard HART

®

tools and

external ammeter if necessary. Caution:

during calibration, switch the measuring point

to manual control.

Error The device, together with an indication of the

error, must be sent back to the manufacturer

for checking.

Error Activate linearization or carry it out again

(HART

®

communication and linearization

software are required; the original calibration

values must be known), or send the device

back to the manufacturer for linearization.

32

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 33

BW25

OPERATION 6

Error message Description Category Remedy

FRAM WRITE

FAULT

ROM/FLASH

ERROR

RESTART OF

DEVICE

MULTIDROP

MODE

CRYSTAL OSC

FAULT

REF VOLTAGE

FAULT

SENSOR A FAULT

SENSOR B

FAULT

MEMORY

CORRUPTION

AO FIXED The current output is

AO SATURATED Current output

Internal

communication error

Memory error

detected during selftest.

A device restart has

taken place

The HART® multidrop

mode is activated.

The current output is

set to a fixed value of

4.5 mA.

Internal error in

device

Internal memory

error, caused by a

hardware or software

problem

set to a fixed value.

saturated

Error Check whether the display is plugged in

Error Restart the device. If the error occurs again:

Information The device has been restarted using menu

Information

Error The device must be sent back to the

Error Restart the device; if the error occurs again

Information The current output is fixed and does not

Information The current output is saturated at 20.4 or 22.0

correctly and restart the device. If the error

occurs again: send the device back to the

manufacturer with an indication of the error.

send the device back to the manufacturer with

an indication of the error.

item 1.5.2 since the last time the error

messages were reset.

The HART® multi-drop mode is activated by

selecting a polling address not equal to 0

using menu item 3.9. Polling address 0

reactivates the current output.

manufacturer with an indication of the error.

the device must be sent back to the

manufacturer with an indication of the error.

reflect the measured value. This is the case in

multidrop mode, with current output

test/calibration using the menu or HART

mA (depending on whether the alarm current

is activated or deactivated in menu item 3.12),

and is no longer coupled with the measured

value.

®

DDs ("driver") for HART

®

HART

DTMs are available at the KROHNE Download Center.

®

Tools, process control (e.g. Siemens PDM or AMS) PACTware™ and

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

33

Page 34

6 OPERATION

6.5 Menu indicator M10

6.5.1 Factory Settings

Menu Function Setting

1.1.1 Switching value B1 0.0

1.1.2 Hysteresis B1 0.0

1.2.1 Switching value B2 0.0

1.2.2 Hysteresis B2 0.0

1.3 Display Flow rate

1.4 Time constant 3 s

1.5.2 Reset error NO

3.1 Language DEUTSCH

3.2 Function B1 INACTIVE

3.3 Contact B1 NC contact

3.4 Function B2 INACTIVE

3.5 Contact B2 NC contact

3.9 Multidrop polling address 0

3.12 Alarm current OFF

3.13.1 Level meter see nameplate

3.15 Input code NO

BW25

INFORMATION!

The measuring device has been preset at the factory in accordance with the customer order.

Therefore subsequent configuration via the menu is only necessary if the intended use of the

device is changed.

34

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 35

BW25

6.5.2 Menu structure

Menu Sub-menu 1 Sub-menu 2

1111 Operation 1.2 OUTPUT B2 1.1.1 Switching value B1

2222 Test & Info 2.1 4...20 mA output

3333 Installation 3.1 Language

OPERATION 6

1.1.2 Hysteresis B1

1.2 OUTPUT B2 1.2.1 Switching value B2

1.2.2 Hysteresis B2

1.3 Display

1.4 Time constant

1.5 Reset 1.5.1 Inactive

1.5.2 Error reset

2.2 OUTPUT B1

2.3 OUTPUT B2

2.4 Inactive

2.5 Serial no.

2.6 Software Version

2.7 Tag no.

3.2 Function B1

3.3 Contact B1

3.4 Function B2

3.5 Contact B2

3.6 Inactive

3.7 Inactive

3.8 Inactive

3.9 Multidrop

3.10 Calibration 4mA

3.11 Calibration 20mA

3.12 Alarm current

3.13 Upper range value and unit 3.13.1 Level

3.13.2 Inactive

3.14 Inactive 3.14.1 Inactive

3.14.2 Inactive

3.14.3 Inactive

3.15 Input code

3.16 Basic setting

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

35

Page 36

6 OPERATION

6.5.3 Menu explanations

BW25

Level Designation Selection/input

Explanation

options

1.1.1 OUTPUT B1 INACTIVE

LEV.VALUE B1 Level value switching point. A numeric value between 0.0 ...

1.1.2 OUTPUT B1 HYST.B1 Hysteresis setting for the level value switching point. Value

100% of the level value can be set. If the current level value

exceeds this set switching point, then output B1 is

activated.

Note

Note

NoteNote

The function NC or NO can be selected using menu 3.3.

range 0…switching point. Example: If, under 1.1.1, a

switching point of 200 is set, a hysteresis value of 0...200

can be set. If a value of 0 is entered, this output has no

hysteresis. If a value of 20 is entered, the output works as

follows: If the current level value exceeds the value of 200,

the output switches. 3 If the current level value is under

the hysteresis value of 180, the switching output returns to

its normal state. 4

Note

Note

NoteNote

If this function is inverted, the output under menu 3.3 must

be set from NO 1 to NC 2 or vice versa. This function is

not activated with the counter switching point.

1.2.1 OUTPUT B2 INACTIVE

LEV.VALUE B2 See LEV.VALUE B1

1.2.2 OUTPUT B2 HYST.B2 See HYST. B1

1.3 DISPLAY LEVEL

%

LEVEL & %

1.4 TIME CONST. Setting : 1 ... 20 seconds

Note

Note

NoteNote

The settable time constant affects the current output and

the displayed current level. It thus allows attenuated

depiction when the display is not calm. If the current level

is polled via HART communication, then the transferred

measured value is dependent on the time constant.

36

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 37

BW25

OPERATION 6

1.5.1 Inactive

1.5.2 RESET ERROR YES - NO

2.1 4-20mA OUT The analogue current output can be set to fixed values in 10

2.2 OUTPUT B1 OPEN The function assignment in menu 3.2 is not taken into

CLOSED

2.3 OUTPUT B2 OPEN The function assignment in menu 3.2 is not taken into

CLOSED

2.4 Inactive

3.1 LANGUAGE ENGLISH

DEUTSCH

FRANCAIS

ITALIANO

ESPANOL

CESKY

POLSKI

NEDERLANDS

3.2 FUNCTION B1 INACTIVE Output B1 is switched off.

SWITCHING

POINT

3.3 CONTACT B1 NC contact Output B1 is normally closed. If an alarm situation occurs,

NO CONTACT Output B1 is normally open. If an alarm situation occurs,

3.4 FUNCTION B2 INACTIVE See FUNCTION B1

SWITCHING

POINT

3.5 CONTACT B2 NC contact See CONTACT B1

NO CONTACT See CONTACT B1

3.6 Inactive

3.7 Inactive

3.8 Inactive

3.9 MULTIDROP 0…15 Multi-drop mode means that the device is continuously

% increments from 4.00...20.00mA. This function has no

influence on the binary switching outputs.

Note

Note

NoteNote

This test function is switched off in multi-drop mode.

Display: "NOT AVAILABLE".

consideration here.

consideration here.

The output B1 switches at a set value depending on the

current level value.

the contact opens.

the contact closes.

See FUNCTION B1

®

working in bus mode via HART

parallel devices). The analogue current output is then fixed

to 4.1 mA. Measured values are transmitted via HART

communication (max. 15

®

communication. However, the display allows local reading

of the measured values. The polling address can be set to 1

.... 15. Larger whole numbers are not permitted. If the

polling address is set to 0, HART

The device functions as analogue. The current output of 4-

20mA is active. Standard HART

®

bus mode is switched off.

®

communication is further

guaranteed.

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

37

Page 38

6 OPERATION

BW25

3.10 4mA CALIBR. This menu item allows precise calibration of the current

3.11 20mA CALIBR. This menu item allows precise calibration of the current

3.12 ALARM

CURRENT

3.13 END & UNIT The level meter and end value can be changed.

3.13.1 LEVEL For a units list, see Section 7.4 of the manual

3.13.2 Inactive

3.14 Inactive

3.15 INP. CODE YES The input code is used to prevent authorised adjustment of

3.16 BASIC

SETTING

OFF Measured values > 100% are indicated as a current signal

ON In the event of an error the current output is set to the fixed

NO

YES This menu item can be used to select the calibrated basic

NO

output. The device generates a fixed analogue output of

4.00 mA. If the measured value differs from the one

displayed, the measured value must be entered. When the

menu is exited, the corrected value is saved.

output. The device generates a fixed analog output of 20.00

mA. If the measured value deviates from the displayed one,

then the measured value must be input. When the menu is

exited, the corrected value is saved.

up to a maximum of 22 mA.

value of 22m A.

the measurement parameters. The input code is not active

by default. If YES is selected, the last code entered must be

typed in. The default code is: → → → ^ ^ ^

↑ ↑ ↑ If, after confirmation with YES, the key → is pressed,

then a new individual, nine-digit code can be typed in. The

display shows the required key combination.

setting. This can be helpful if operating data have been

changed a number of times. This menu item cannot be

used to reset the calibration.

38

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 39

BW25

7.1 Maintenance

During routine operational maintenance of the system, the level meter should also be checked

for soiling, corrosion and mechanical wear or damage to the displacer rod, pressure sleeve and

the display.

We advise that inspections be carried out at least once per year. The device must be removed

before cleaning.

CAUTION!

Before dismantling, ensure that the tank is depressurised and vented.

In the case of devices used for measuring aggressive media, appropriate safety precautions

must be taken with regard to residual liquids on the measuring unit.

Avoid electrostatic charges when cleaning the surfaces (e.g. sight window)!

7.2 Spare parts availability

The manufacturer adheres to the basic principle that functionally adequate spare parts for each

device or each important accessory part will be kept available for a period of 3 years after

delivery of the last production run for the device.

SERVICE 7

This regulation only applies to spare parts which are subject to wear and tear under normal

operating conditions.

7.3 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, technical support and training.

INFORMATION!

For more precise information, please contact your local representative.

7.4 Returning the device to the manufacturer

7.4.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

39

Page 40

7 SERVICE

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralizing, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

BW25

40

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 41

BW25

7.4.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

SERVICE 7

This medium is: water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

7.5 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

41

Page 42

8 TECHNICAL DATA

8.1 Operating principle

The device works according to the displacement principle.

The length of the displacer rod 4 corresponds to the measuring range 2.

The displacer rod 4 suspended from a measuring spring 1 is immersed in the liquid and

detects a lifting force, which is proportional to the mass of the displaced liquid.

Each change to the rod weight corresponds to the change in the length of the spring and is thus a

measure of the filling height.

The expansion of the spring and thus the measuring stroke is transmitted to a display using a

solenoid coupling from the measuring chamber.

If the device cannot be installed from above, e.g. because there is an agitator in the tank, then

there is a special bypass chamber available for side mounting.

The lift of the proportional rod is dependent on the density of the product.

The level indication must be displayed for the liquid to be measured.

The difference in density between the tank atmosphere and liquid must be at least 100 g/l.

The atmospheric pressure and temperature must be known.

Due to the length of the spring suspension pin 3, the unmeasureable area is L = 340 mm.

BW25

42

1 Measuring spring

2 Measuring range

3 L ≥ 340mm

4 Displacer rod

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 43

BW25

8.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local representative.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Application range Level measurement

Operating method / measuring principle Displacement principle

Measured value Level, separating layer

Measuring accuracy

Standard < 1.5% full scale value

Min. measuring range 0.3 m / 12"

Max. measuring range 6 m / 20 ft

Medium Liquids

Density

TECHNICAL DATA 8

≥ 0.45 kg/l / 28.1 lbs/ft

3

Materials

Housing Aluminium with artificial resin coating

Housing option Stainless steel (indicator M9)

Displacer rod Stainless steel 1.4404

Displacer rod option Titanium

Spring Stainless steel 1.4571 (T

Spring option ATS 340 (T

Flange Stainless steel 1.4404

Pressure sleeve Stainless steel 1.4404

> 100°C / 212°F)

m

< 100°C / 212°F)

m

Process connections

Max. operating pressure 40 bar - optional to 400 bar / 580 - optional 5802

Standard flange DN50 - PN40 / 2" ASME 300 lbs

Optional flange ...DN100 - ...PN400 / …4" ASME ...2.500 lbs

psig

Approvals

ATEX, indicator M9 with electrical installations Cat. II 1/2G, EEx ia IIC T6

ATEX, indicator M10 Cat. II 1/2G, EEx d IIC T6

ATEX, indicator M9 without electrical installations

for Zone 0 tanks Cat. II 1/2 Gc

for Zone 1.21 Cat. II 2 GD

for Zone 2.22 Cat. II 3 GD

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

43

Page 44

8 TECHNICAL DATA

Temperatures

Indicator M9 without electrical installations

Product or flange temperature -40…+400°C -40...+752°F

Ambient temperature T

Storage temperature -40…+60°C -40...+140°F

Indicator M9 with electrical installations

Product or flange temperature -20…+295°C -4...+563°F

Product or flange temperature, HT version -40…+400°C -40...+752°F

Ambient temperature T

Storage temperature -40…+60°C -40...+140°F

Indicator M10

Product or flange temperature -40…+200°C -40...+392°F

Ambient temperature T

Storage temperature -40…+60°C -40...+140°F

amb.

amb.

amb.

BW25

-40…+60°C -40...+140°F

-40…+60°C -40...

-40…+60°C -40...+140°F

44

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 45

BW25

TECHNICAL DATA 8

Technical data, indicator M9

M9 cable glands

Cable gland Material Cable diameter

M 16x1.5 Standard PA 3...7 mm 0.118...0.276"

M20 x 1.5 PA 8...13 mm 0.315...0.512"

M 16x1.5 Nickel-plated brass 5...9 mm 0.197...0.355"

M20 x 1.5 Nickel-plated brass 10...14 mm 0.394...0.552"

M9 limit switches

Terminal connection

Limit switch I7S23,5-N

NAMUR yes yes yes no

Connection type 2-wire 2-wire 2-wire 3-wire

Switching element

function

Nominal voltage U

Pointer vane not detected ≥ 3 mA ≥ 3 mA ≤ 1 mA ≤ 0.3 VDC

Pointer vane detected ≤ 1 mA ≤ 1 mA ≥ 3 mA UB - 3 VDC

Continuous current - - - max. 100 mA

No load current I

1 safety oriented

0

0

2

2.5 mm

SC3,5-N0

NC contact NC contact NO contact PNP NO contact

8 VDC 8 VDC 8 VDC 10...30 VDC

- - - ≤ 15 mA

SJ3,5-SN 1 SJ3,5-S1N 1 SB3,5-E2

M9 current output ESK2A

Terminal connection

Power supply 12...30 VDC

Min. power supply for HART TM 18 VDC

Measuring signal 4.00...20.00 mA = 0...100% level value in 2-wire technology

Power supply influence < 0.1%

Dependence on external resistance < 0.1%

Temperature influence < 5 uA / K

Max. external resistance / load 800 Ohm (30 VDC)

Min. load for HART TM 250 Ohm

Software firmware version 02.14

Ident No: 3210680500

2.5 mm

2

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

45

Page 46

8 TECHNICAL DATA

M9 ESK2A HART

ESK2A HART® configuration

Manufacturer name (code) KROHNE Messtechnik (69 = 45h)

Model name ESK2A (226 = E2h)

HART TM protocol revision 5.9

Device revision 1

Physical layer FSK

Device category Transmitter without galvanic isolation

M9 ESK2A process variable

ESK2A process variable, level Values [%] Signal output [mA]

Over range +102.5 (± 1%) 20.24...20.56

Device error identification > 106.25 > 21.00

Maximum 131.25 25

Multi-drop operation - 4.5

Min. U

ext.

BW25

12VDC

Technical data, indicator M10

Cable gland Standard: without

Terminal connection

Power supply 24 VDC +/- 30%

Min. power supply for HART TM 18 VDC

Measuring signal 4.00...20.00 mA = 0...100% level value in 2-wire technology

Power supply influence < 0.1 %

Dependence on external resistance < 0.1 %

Temperature influence < 5 µA/K

Max. external resistance / load ≤ 630 Ohm

Min. load for HART ≥ 250 Ohm

Software firmware version 02.14

Ident No: 3209470500

2,5mm

2

M10 HART

Manufacturer name (code) KROHNE Messtechnik (69 = 45h)

Model name M10 (234 = EA)

HART TM protocol revision 5.9

Device revision 1

Physical layer FSK

Device category Transmitter

46

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 47

BW25

TECHNICAL DATA 8

M10 process variable

Values [%] Signal output [mA]

Over range +105 (± 1%) 20.64...20.96

Device error identification > 110 > 21.60

Maximum 112.5 22

Multi-drop operation - 4.5

Min. U

ext.

M10 binary output

Two binary outputs Galvanically isolated

Operating mode Switch output NAMUR or open collector

Configurable as switch contact or pulse

NAMUR switch output

Power supply U

Signal current > 3 mA switching value not

Switch output, open collector

Power supply 8...30 VDC

Pmax 500 mW

Imax 100mA

ext.

12 VDC

output

8VDC

reached;

Open / closed or max. 10 P/s

< 1 mA switching value

reached

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

47

Page 48

8 TECHNICAL DATA

8.3 Dimensions

Dimensions with M9 indicator

Front view Side view Side view HT

BW25

HT - high temperature version

a b c d e f g h j k

[mm] 181 110 138 168 min. 340

["] 7.13 4.33 5.44 6.62 min 13.39

1 Length of the displacer rod (measuring area)

2 According to the operating conditions

1

1

≥ 20 2 106 303 185

≥ 0.79 2 4.18 11.94 7.29

48

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 49

BW25

TECHNICAL DATA 8

Dimensions M10 indicator and bypass chamber

Indicator M10 front

view

Indicator M10 side

view

Bypass

chamber.

Dimensions with M10 indicator

a b c d e f

[mm] 71 64 37 124 302 114

["] 2.8 2.5 1.5 4.9 11.9 4.5

Dimensions of bypass chamber

a b c d e f g

[mm]

["]

1 Connection according to DIN EN 1092-1

2 Length of the displacer rod (measuring area)

3 Connection according to ASME B16.5

1 1

3 3

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

340 72 115

13.4 2.8 4.5

2

2

120

4.7

49

Page 50

9 NOTES

BW25

50

www.krohne.com 09/2010 - 4000432302 MA BW25 R05 en

Page 51

BW25

NOTES 9

www.krohne.com09/2010 - 4000432302 MA BW25 R05 en

51

Page 52

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Measuring systems for the oil and gas industry

• Measuring systems for sea-going tankers

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

D-47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

© KROHNE 09/2010 - 4000432302 MA BW25 R05 en - Subject to change without notice.

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...