Page 1

GR/PRINTO

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications engineering

Engineering systems & solutions

©

KROHNE 09/2001 7.02368.21.00

Liquid level indicator

BW 25

Status: 10/99

Page 2

152

Liquid level indicator

BW 25

Level measurement of liquids, even at high

pressures using the displacement principle

Operating principle

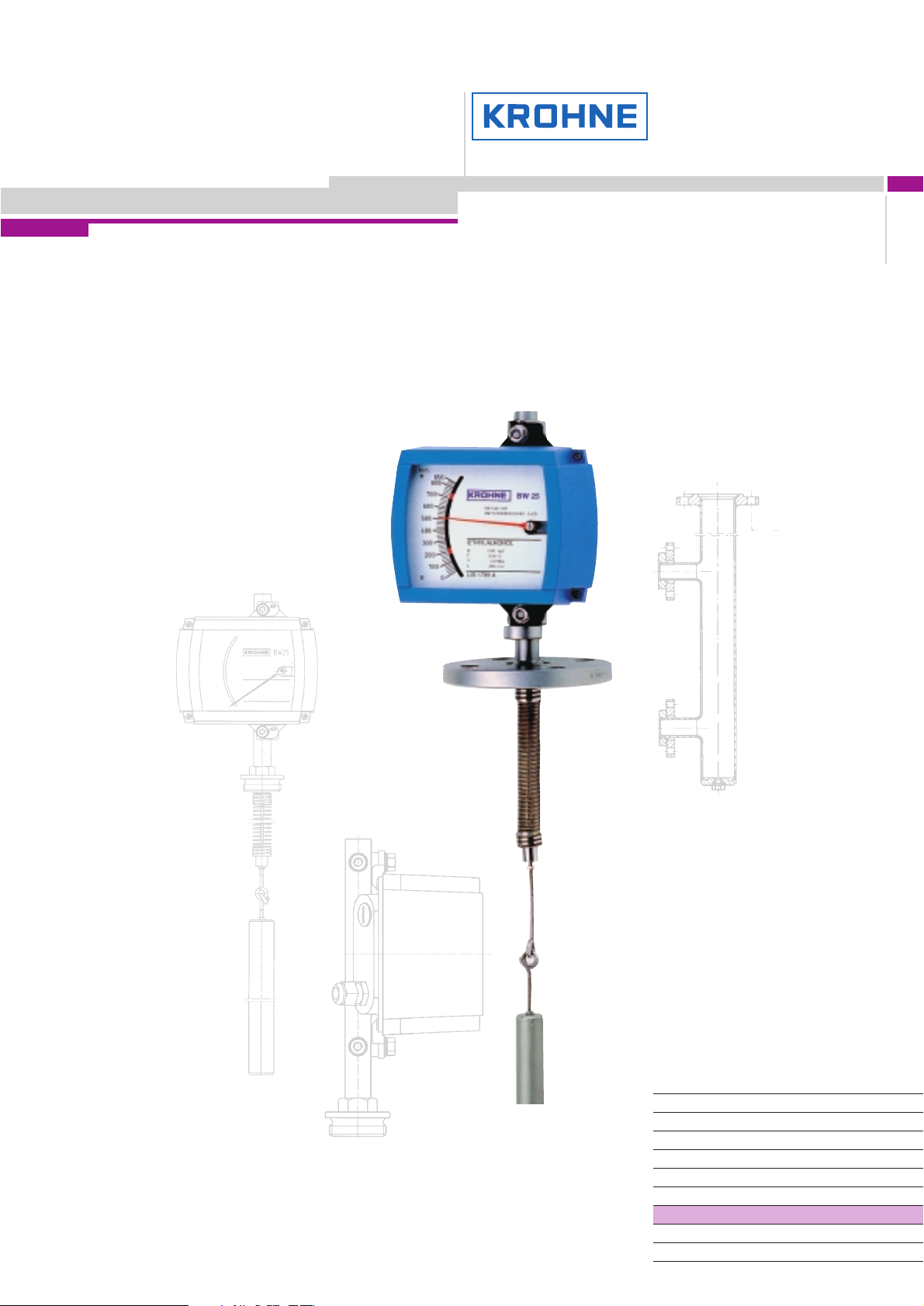

The BW 25 liquid level indicator operates

on the displacement principle.

The length of the displacement rod corresponds to the measuring range.

A displacement body suspended on a

measuring spring is immersed in the liquid

and is subjected to an upthrust based on

Archimedes’ principle, this being proportional

to the mass of the liquid displaced. Every

change in the weight of the rod corresponds

to a certain change in the length of the

spring, and is therefore an indication of the

liquid level. Extension of the spring is transmitted by magnetic coupling from the measuring zone to an indicator. This transmission

method permits pressure-tight separation of

the measuring spring system and the scale.

Modular assembly,

replacement or

retrofit without

interruption of the

process

Pressure-tight

separation of

measuring

and display

parts

Interface

detection

possible

Displacement rod

available 0.3 – 6 m

(1 – 20 ft)

Resistant to high

pressures ≤ 700 bar

(10000 psig) and

high temperature

≤ 400°C (752°F)

;

;

;

;

;

Scale division

showing

… full tank

… level x

… empty tank

Height setting

for

… full tank

… level x

… empty tank

Level

F

G

F

A

FA = Buoyancy

F

G

= Weight

;

;

;

;

;

Page 3

Product

Overview

Ultrasonic

Buoyancy

Capacitance

Ultrasonic RadarUltrasonic Buoyancy TDR

Continuous, non-contact

Switches

Vibration

Continuous, contact

BW 25 153

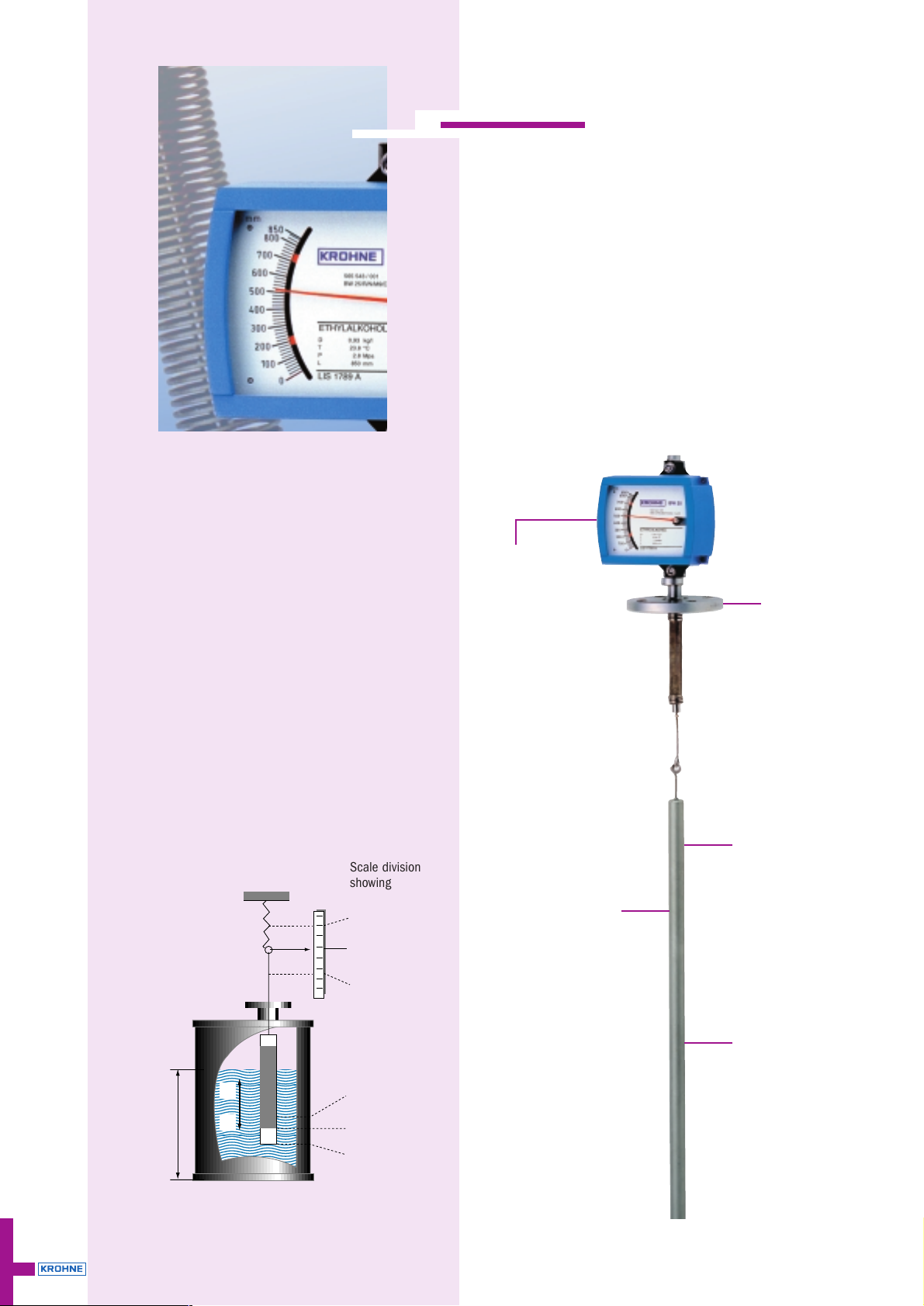

BW 25

Application range

The limit switch can be used for various materials.

This device is suitable for extreme ambient conditions.

Temperatures –60 … +400°C (–76 … +752°F)

Pressure Up to 700 bar (10 000 psig)

If the display cannot be installed from above, e.g. there is an agitator

in the container, it is possible to install it lateral with the special reference chamber.

In both cases it is important to note that the non-measurable depth

is 340 mm because of the spring mounting.

Modularity

The M9 indicator is of modular design.

This offers the following advantages:

● Electrical functions can be retrofitted

● Installation without interrupting the process

● No re-calibration necessary

● Easy and quick to replace through plug-in-technology

Product Ammonia

Pressure 450 bar (6525 psig)

Temperature 70°C (158°F)

Measuring range 1500 mm (4.9 ft)

With special versions it is possible to measure the level of the interface between two immiscible liquids of different densities. The displace rod

must be covered completely with liquid. The difference in density should be min. 100 g/l.

≤ 340 mm

Typical products are:

● Water, aqueous liquids

● Acids/alkalis

● Organic and inorganic solvents

Typical application in the chemical industry

Page 4

Technical data

Operating conditions

Product Liquids

Density ≥ 0.45 kg/l

Measuring range 0.3 – 6 m (1 – 20 ft)

Measuring accuracy ± 1.5 % of full scale range

Temperature –60 … +400°C (–76 … +752°F)

Ambient temperature ≤ 60°C (≤ 40°F)

Operating pressure

Standard 40 bar (580 psig)

Optional 700 bar (10000 psig)

Indication Linear scale markings

mm, cm, m, inch, ft, %, volume

Material

Housing Die-cast aluminium

Displacement rod

Standard Stainless steel 1.4571 (316 Ti)

Optional Titanium

Spring

Standard Stainless steel 1.4571 (316 Ti)

Optional (> 100°C /212°F) ATS 340

Flange with pressure gland Stainless steel 1.4571 (316 Ti)

Connection

Flange DIN 2501 or ANSI 16.5

Standard DN 50, PN 40

Optional DN 40/50/80/100, PN 40; DN 50, PN 64/100

1

1

/2”/ 2’’/ 3’’/ 4”, 150/300 lb

Screw G 1

1

/2’’

Others on request

Protection category (EN 60529 / IEC 529) IP 65

Electromagnetic compatibility (EMC) EN 50081-1, EN 50082-2

BW 25

154 BW 25

Responsibility for suitability and intended use of our instruments rests solely with the purchaser.

Page 5

Limit switches and electrical signal output

One or two limit switches can be built into the indicators.

Limit switches SC 3.5 N0

2-wire limit switches are connected in conformity with DIN 19234

(NAMUR). For operation, an isolation switching amplifier is required.

Technical data SC 3.5-N0

Connection 2-wire

Voltage 8 V DC

Ambient temperature –25 … +100°C (–13 … +212°F)

Protection category

to EN 60529 / IEC 529 IP 67

Self-inductance (L

i

) 150 µH

Self-capacitance (C

i

) 100 nF

Electromagnetic compatibility (EMC) EN 50081-2, EN 50082-2

Spark protection EEx ia IIC T6, EEx ib IIC T6

Approval PTB No. Ex-95.D.2195 X

Technical Data Auto cut-off

No-load voltage U

i

16 V

Short-circuit current I

i

52 mA

Output P

i

169 mW

Connection diagram

SC 3.5-N0

K1 = 1 Limit switch

K2 = 2 Limit switches

155BW 25

BW 25

Product

Overview

Ultrasonic

Buoyancy

Capacitance

Ultrasonic RadarUltrasonic Buoyancy TDR

Continuous, non-contact

Switches

Vibration

Continuous, contact

K1

K1

DC

12 3

brown black blue

K1

DC

456

brown black blue

K2

BN

BK

BU

DC

Connection diagram

ESK II- wire configuration, 4 – 20 mA

US= 12.7– 30 V

4 – 20 mA

Rext.

11+

12

–

ESK II

Limit switches SB 3.5-E2-Y

This 3-wire limit switch has a 10 – 30 V DC connection.The switching

point is visible on the scale.

3-wire limit switches (with integrated preamplifier) can be connected

directly to a PLC.

Technical data SB 3.5-E2-Y

Electrical connection 3-wire

Voltage 10 – 30 V DC

No-load power consumption ≥ 15 mA

Continuous current 100 mA

Ambient temperature –25 … +70°C

(–13 … +158°F)

Protection category

to EN 60529/IEC 529 IP 67

Electromagnetic compatibility (EMC) EN 50081-2, EN 50082-2

Display LED

Connection diagram

SB 3.5-E2-Y

Electrical signal output ESK II

The ESK II can be installed in the indicators as an option.

Given an intrinsically safe feed unit, the transmitter may also be used

in hazardous areas.

Technical data

Electrical connection 2-wire

Power supply 12.7 – 30 V DC

Current output 4 – 20 mA

Power influence < 0.1%

Load resistance dependence < 0.1%

Temperature drift ≤ 5 µA/ K

Load impedance (U-12 V)/20 mA, max. 800 Ω

Ambient temperature –25 … +85°C

Effective inner self-inductance negligible

Effective inner self-capacitance ≤ 20 nF

Protection category

to EN 60529/IEC 529 IP 20

Spark protection EEx ia IIC T6

Approval PTB No. Ex-94.C.2067

Only for connection to intrinsically safe circuits with the following

peak values:

No-load voltage U

i

30 V

Short-circuit current I

i

100 mA

Output P

i

1 W

Page 6

BW 25

156 BW 25

Reference vessel

Connection DIN 2501 or ANSI B 16.5

Flanges DN 25/50, PN 40

11/2”– 2” / Class 150/300 lb

Drain

Plug

3

/8”

Other connections on request

3

/8”

dia. 130 (dia. 5.12”)

dia. 100

30 (1.18”)

181 (7.13”)

dia. D ≥ 20 ≥ (0.79”) acc. to operating data

Dimension C = length of displacer rod (measuring range) Dimensions in mm (inches)

Dimension C = Distance between sockets (measuring range)

Flange version Screw version

110 (4.35”) 70.5 (2.78”)

138 (5.43”)

222 (8.74”)

106 (4.17”)

M16x1.5

min. 340 (min. 13.4”)

c

G 1/2 A

≥ 340 (≥ 13.39”)

340 (13.39”)C

120 (4.72”)

(dia. 3.94”)

Special flange PN 40 (300 lb/RF)

dia. 72 (dia. 2.84”)

115

(4.53”)

Page 7

157BW 25

BW 25

Product

Overview

Ultrasonic

Buoyancy

Capacitance

Ultrasonic RadarUltrasonic Buoyancy TDR

Continuous, non-contact

Switches

Vibration

Continuous, contact

Approvals

Application

With explosion protection:

In stationary storage tanks for flammable liquids of

dangerous materials classes AI, AII and B, excl.

carbon disulphide (CS2), in Zone 0.

Note: Certified devices are not standard versions! Deviations in design and technical data are possible!

Instrument version

BW 25 /... /. /.. /.. /.. – .. / Z0

Certification mark

PTB No. III B/S 1970

Type code

Instrument

BW 25 Liquid level indicator

Material (flange)

R Stainless steel 1.4571

Measuring section

N No reference vessel

B Reference vessel

Top-mounted indicator

M 9 Indicator M 9

Built-in equipment

KI.. Limit switch SC 3.5-N0 with 1–2 contacts

KD.. Limit switch SB 3.5-E2-Y with 1–2 contacts

ESK Electrical signal output

ESK/K.. Electrical signal output and 1–2 limit switches

Safety function

Ex Explosion-protected electrical equipment

Application

N Non-Ex

Z0 Flammable liquids of dangerous materials classes AI, AII and B

Options

TS Liquid/liquid interface detection

BW 25

Page 8

Notes

Loading...

Loading...