Page 1

Installation and

operating instructions

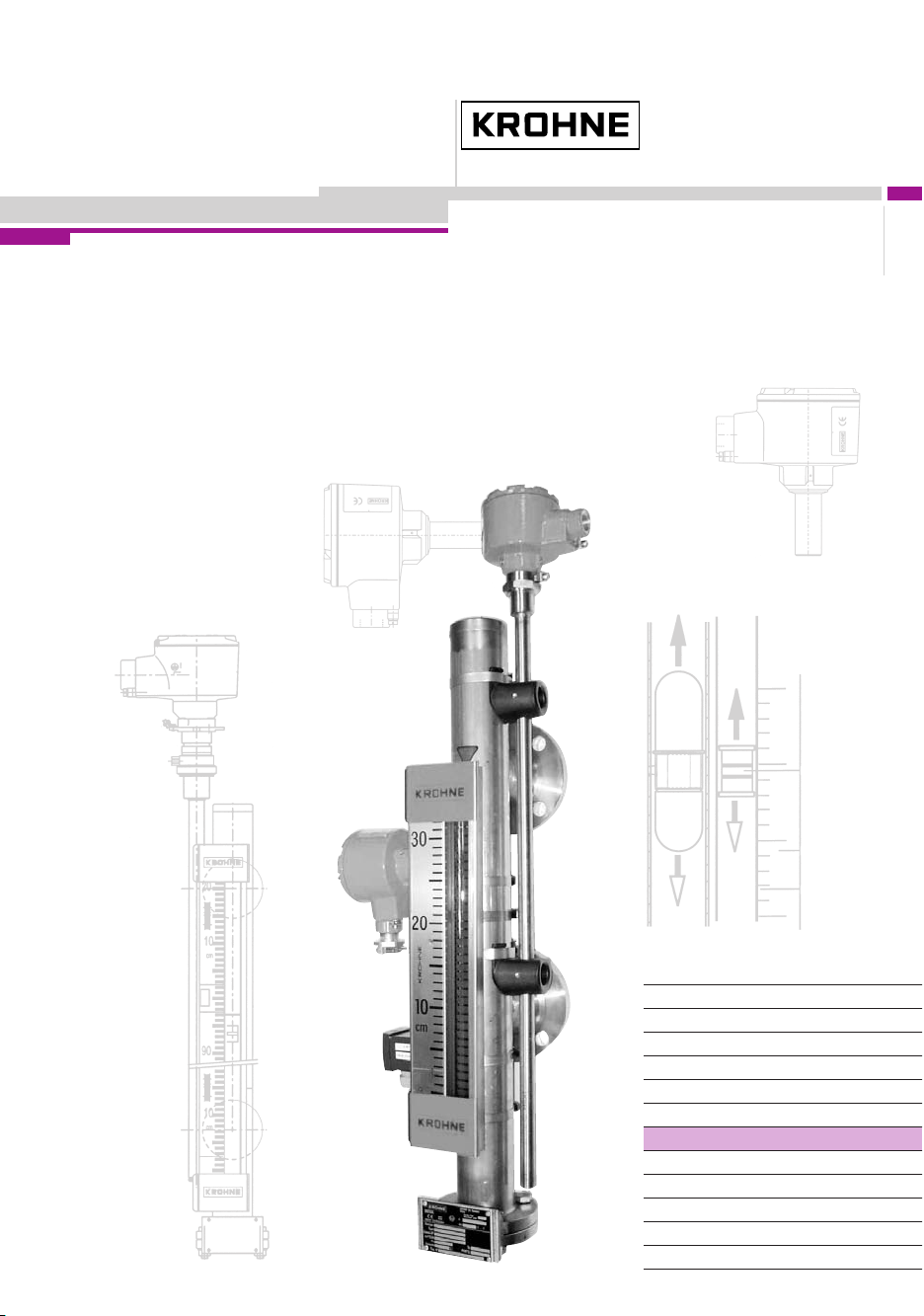

Bypass Level Indicator

BM 26 A

For level or interface

measurement of liquids

©

KROHNE 10/2006 7.02186.26.00

CMD

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications engineering

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Subject to change without notice.

Page 2

Contents

General advice on safety.............................................................................................................4

Description: BM 26 A bypass level indicator with magnetic flaps or bar scale ..................... 4

Documentation symbols ............................................................................................................. 5

Handling .......................................................................................................................................5

Product liability and warranty.....................................................................................................5

Items supplied.............................................................................................................................. 5

Standards / Approvals................................................................................................................. 6

Official approvals and certificates .............................................................................................7

Principal gauge components......................................................................................................7

1

Installation .........................................................................................................................8

1.1 Packing and storage .............................................................................................................8

1.2 BM 26 A construction details............................................................................................... 10

1.3 Mechanical installation requirements ..................................................................................12

1.4 Mounting on the tank........................................................................................................... 13

1.5 Start-up procedure ..............................................................................................................14

1.6 True level indication ............................................................................................................ 15

1.6.1 Level measurement using the local indicator and scale .................................................. 15

1.6.2 Floats ..................................................................................................................... 16

1.6.3 Changing the process conditions .................................................................................... 18

1.6.4 Correcting the scale position to accurately read true liquid level..................................... 20

1.6.5 Functional check of local level display (bar indicator only).............................................. 22

Level transducer .............................................................................................................23

2

2.1 General notes...................................................................................................................... 23

2.2 Transmitters ........................................................................................................................ 24

2.2.1 Transmitter versions for the BM 26 A.............................................................................. 24

2.2.2 Electrical connections .....................................................................................................24

3

Limit switches / contacts................................................................................................ 26

3.1 General notes...................................................................................................................... 26

3.2 Designation code for defining limit switch versions .............................................................26

3.3 Limit switch options for the BM 26 A (non-Ex)..................................................................... 26

3.4 Limit switch options for the BM 26 A (ATEX version) .......................................................... 27

3.5 How to use a limit switch..................................................................................................... 27

3.5.1 Operating principle .......................................................................................................... 27

3.5.2 Installation ..................................................................................................................... 27

3.5.3 Overall dimensions of limit switches mounted on measuring tube ..................................29

3.5.4 Limit switch dimensions (without bracket and clamp)...................................................... 30

3.5.5 Electrical connections .....................................................................................................31

3.6 Fine adjustments to the limit switch trigger point................................................................. 33

3.6.1 General notes.................................................................................................................. 33

3.6.2 Fine adjustments to the limit switch trigger point............................................................. 33

3.6.3 Switching point diagram and offset values for limit switches........................................... 34

2 Installation and Operating Instructions BM 26 A

Page 3

4

Special versions.............................................................................................................. 35

4.1 Low-temperature versions AG-TR-IC/TR............................................................................ 35

4.2 High-temperature versions HR-IC/HR................................................................................. 35

4.3 Heating system for measuring tube BM 26 A/B .................................................................. 36

4.4 Liquid/liquid interface measurement BM 26 A/TS ............................................................... 36

5

Maintenance .................................................................................................................... 37

6

Ordering spare parts ...................................................................................................... 37

7

Technical data................................................................................................................. 38

7.1 Technical data: BM 26 A ..................................................................................................... 38

7.2 Technical data: level transmitter modules ........................................................................... 40

7.3 Technical data: limit switches.............................................................................................. 41

7.4 Guide tube assembly materials........................................................................................... 42

7.4.1 Maximum operating conditions for BM 26 A with 316 Ti steel measuring tube ............... 42

7.4.2 Flange categories for operating conditions in a 316Ti steel measuring tube .................. 42

7.4.3 Maximum operating conditions for BM 26 A with 316 L steel measuring tube ................ 43

7.4.4 Flange categories for operating conditions in a 316L steel measuring tube ................... 43

7.5 BM 26 A weights and dimensions ....................................................................................... 44

7.5.1 Weights ..................................................................................................................... 44

7.5.2 Indicator dimensions ....................................................................................................... 44

7.5.3 Overall dimensions of measuring tube classes (with loose or welding neck flanges) ..... 44

7.5.4 Distance of welding neck flange raised facing from measuring tube axis ....................... 47

8

Measuring principle ........................................................................................................ 48

Appendices ................................................................................................................................ 49

Appendix A: Declaration of conformity: CE............................................................................ 49

Appendix B: Declaration of conformity: Pressure Equipment Directive 97/23/EC .............. 50

Appendix C: EC-Type Examination Certificate INERIS 02ATEX0088X ................................. 51

If you need to return level gauges for testing or repair to KROHNE..................................... 71

Installation and Operating Instructions BM 26 A 3

Page 4

General advice on safety

This manual gives a complete set of instructions for the installation, operation and maintenance of

the ATEX version of the BM 26 A Bypass Level Indicator.

This instrument is designed to function at near constant pressure conditions.

The instrument must be installed and used by suitably qualified personnel.

Our conformity declaration is limited to the parts of the level indicator that are under pressure,

excluding parts that may be dismantled (e.g. valves).

Events that are not taken into account in the calculations include: exceptional risks such as

earthquakes, bad weather, acts of destruction (such as sabotage, terrorism, vandalism, etc.) and

fire.

WARNING

Special regulations are applicable to the use of equipment in hazardous locations,

and these are described in this booklet. Data is supplied on explosion protection.

Description: BM 26 A bypass level indicator with magnetic flaps or bar scale

The BM 26 A bypass level indicator is used for measuring level, interface or volume in open or

pressurized tanks. It is mounted adjacent to the tank and uses the principle of communicating

vessels – the liquid level in the measuring tube corresponds to the liquid level in the tank. Due to its

design, the unit is suitable for use in connection with corrosive, toxic or flammable substances and in

severe service conditions.

The local indicator consists of:-

• A bar indicator (follower magnet) in a Pyrex glass tube as standard

• or a flap indicator (yellow/black magnetic flaps) in a Pyrex glass tube.

No power is required for local liquid-level indication.

Optionally, the unit can be equipped or retrofitted with an electrical analogue level transducer

system and/or limit switches.

Use in hazardous areas

The BM 26 A bypass level indicator is approved for use in explosive atmospheres when equipped

with the appropriate options. It is imperative that the approval certificate details and boundary

conditions are observed.

Special measures must be taken when using titanium floats in order to avoid

friction between the titanium and stainless steel causing sparks in an inflammable

gaseous environment.

The standard design calculation does not take into account the theoretical

coefficient of corrosion. The product circulating in the vessel must not have

properties that give rise to surface erosion.

4 Installation and Operating Instructions BM 26 A

Page 5

Documentation symbols

CAUTION

Information that, if not followed, may lead to actions resulting in incorrect

functioning of the device.

Handling

Product liability and warranty

The BM 26 A bypass level indicator is designed exclusively for liquid-level, liquid/liquid interface or

volume measurement, depending on the scale and float selected by the customer.

Special codes and regulations apply to its use in hazardous areas.

Responsibility as to suitability and intended use of this bypass level indicator rests solely with the

operator.

Improper installation and operation of these bypass level indicators may lead to loss of warranty.

In addition, the “General conditions of sale” forming the basis of the purchase contract are

applicable.

If the bypass level indicator needs to be returned to KROHNE, please read and follow the

instructions given at the end of this manual.

Items supplied

• BM 26 A bypass level indicator option: with or without current output or limit switches

• These installation and operating instructions

• Approval documents / certificates of conformity (for hazardous duty only)

Supplied without mounting accessories (stud bolts, flange gaskets and wiring to be provided by

customer).

WARNING

Information that, if not followed, may lead to actions resulting in measurement

error, personal injury and/or damage to the device.

Information and instructions for Ex applications

Information that must be used to observe the safety requirements for installation,

operation and maintenance in hazardous areas. If instructions are not followed, this

may result in personal injury, damage to the device and/or incorrect functioning of

the device.

WARNING

The device normally weighs from 14.5 kg or 32 lb to 40kg or 88 lb. Carry the device

using at least two people, lifting it by the process connections. Lifting gear may also

be used but no attempt should be made to lift the device by the measuring scale,

level transducer or other attached equipment.

Installation and Operating Instructions BM 26 A 5

Page 6

Special certificates (Optional: supplied on customer demand only)

• Test certificate to EN 10204: pressure test, dye penetration test, radiographic test, leak-tightness

test, ultrasonic test, helium leak test, surface cleanness and material

Standards / Approvals

In compliance with European Directive 94/9/EC (ATEX 100a), the bypass level

indicators described in these instructions conform to European Standards

EN50014, EN 50020, EN50018, EN13463-1 and EN 50284 and are certified for

use in hazardous locations by the INERIS certification agency under INERIS

02ATEX0088X when equipped with the appropriate options.

WARNING

The details given in this approval certificate together with its boundary conditions

must be observed.

This instrument also conforms to the European Union Pressure Equipment Directive 97/23/EC.

Ex Safety Instructions

ATEX-certified BM 26 A level indicators can be used in explosive atmospheres of all flammable

substances in Gas Group IIC (with the exception of cases given in these instructions) and

applications requiring Category 1 / 2 G and 1 G equipment. The instrument must be installed and

used by suitably qualified personnel.

Ex Equipment Category Definitions

Category 1 / 2 G – instruments

(for applications where the Exd-rated explosion-proof box is used)

The signal converter for current output and limit switch options are located in hazardous areas

requiring instruments qualified as being category 2. The process connection and tank wall form an

interface between zones for category 1 and 2 equipment. The indicator measuring elements (float

and measuring tube) are qualified as being category 1. The G rating means that the instrument is

qualified for gas environments.

Category 1 G - instruments

The signal converter for current output, limit switch options and measuring components are located

in hazardous areas requiring instruments qualified as being category 1.

6 Installation and Operating Instructions BM 26 A

Page 7

Official approvals and certificates

Application Approved by Instrument version Certification mark

ATEX certification

*This EC-type Examination Certificate is available on KROHNE’s download centre webpage on

http://www.krohne.com.

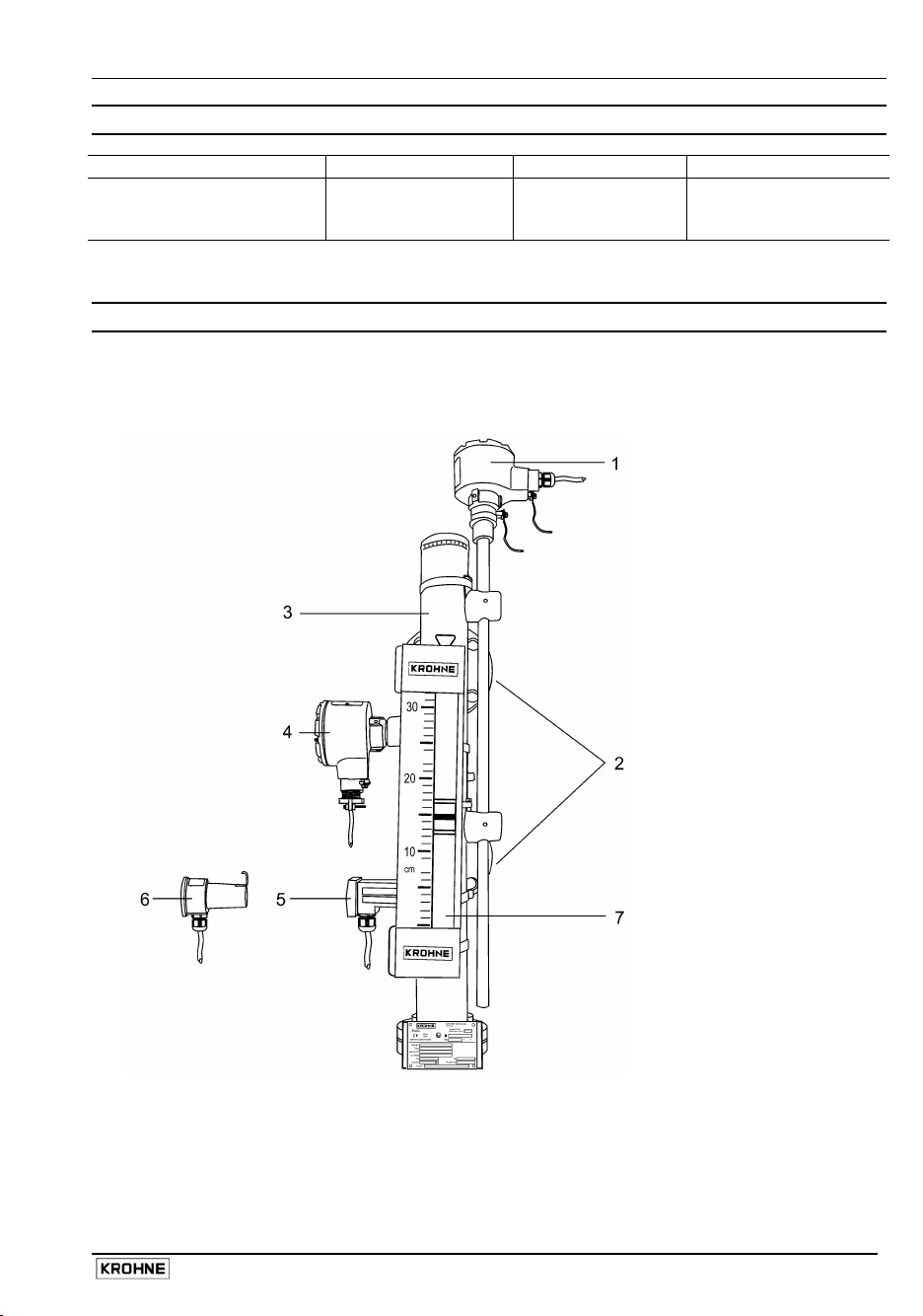

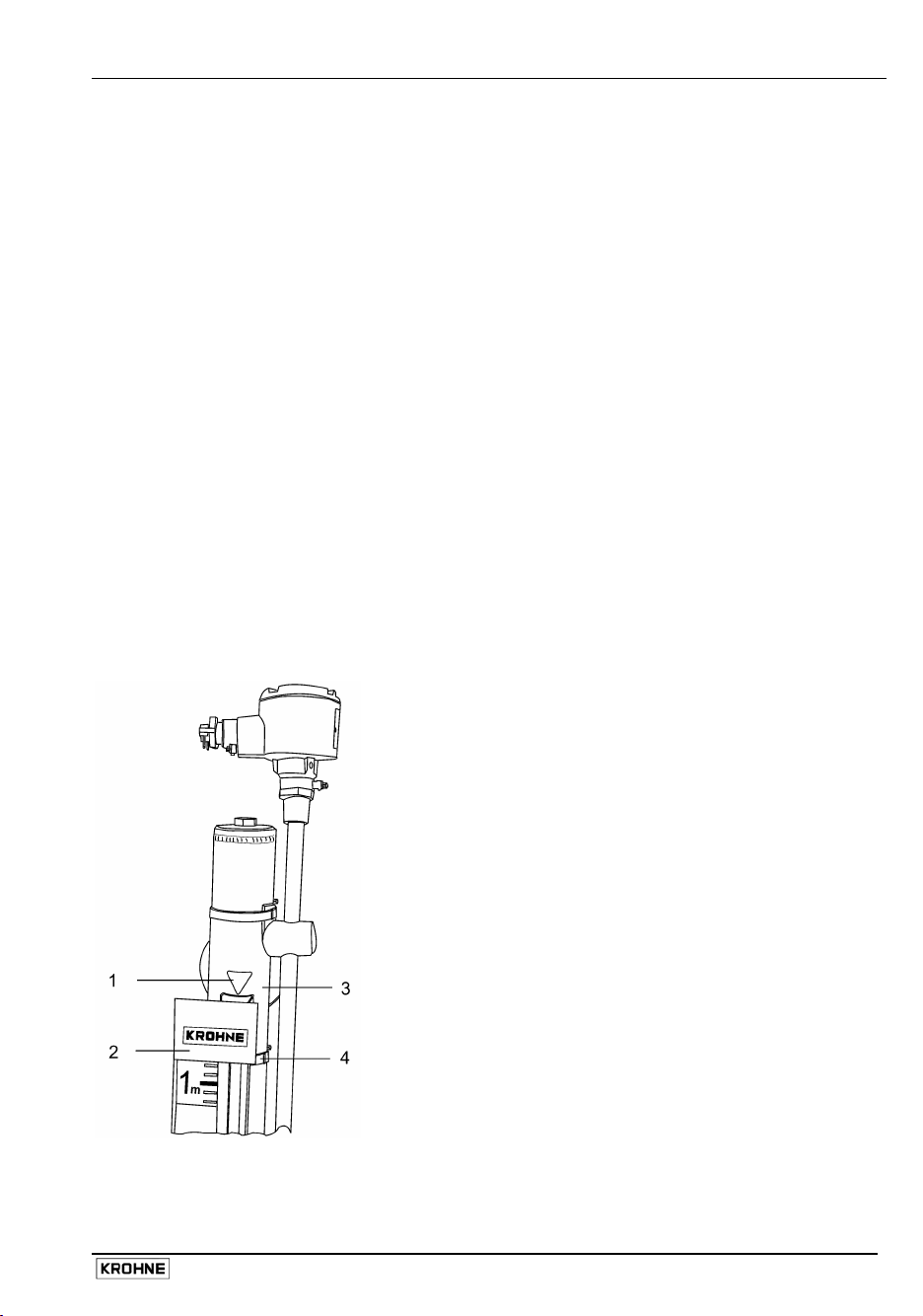

Principal gauge components

Installation and Operating Instructions BM 26 A 7

INERIS BM 26 A Certificate no.

INERIS 02ATEX0088X*

1

Level

transducer

(cable entry

fitting not

supplied)

2 Process

connections

3 Measuring tube

(bypass

chamber)

containing float

loaded with

magnets

4 MS 15 /EXD

limit switch

(cable entry

fitting not

supplied)

5 MS 15 /STD or

/EXI limit switch

6 MS 20 /STD or

/EXI limit switch

(shown

separate from

assembly, may

replace or be

used with items

4 and 5)

7 Scale clamped

adjacent to

measuring tube

integrating a

Pyrex tube with

float-following

indicator bar.

Page 8

1 Installation

1.1 Packing and storage

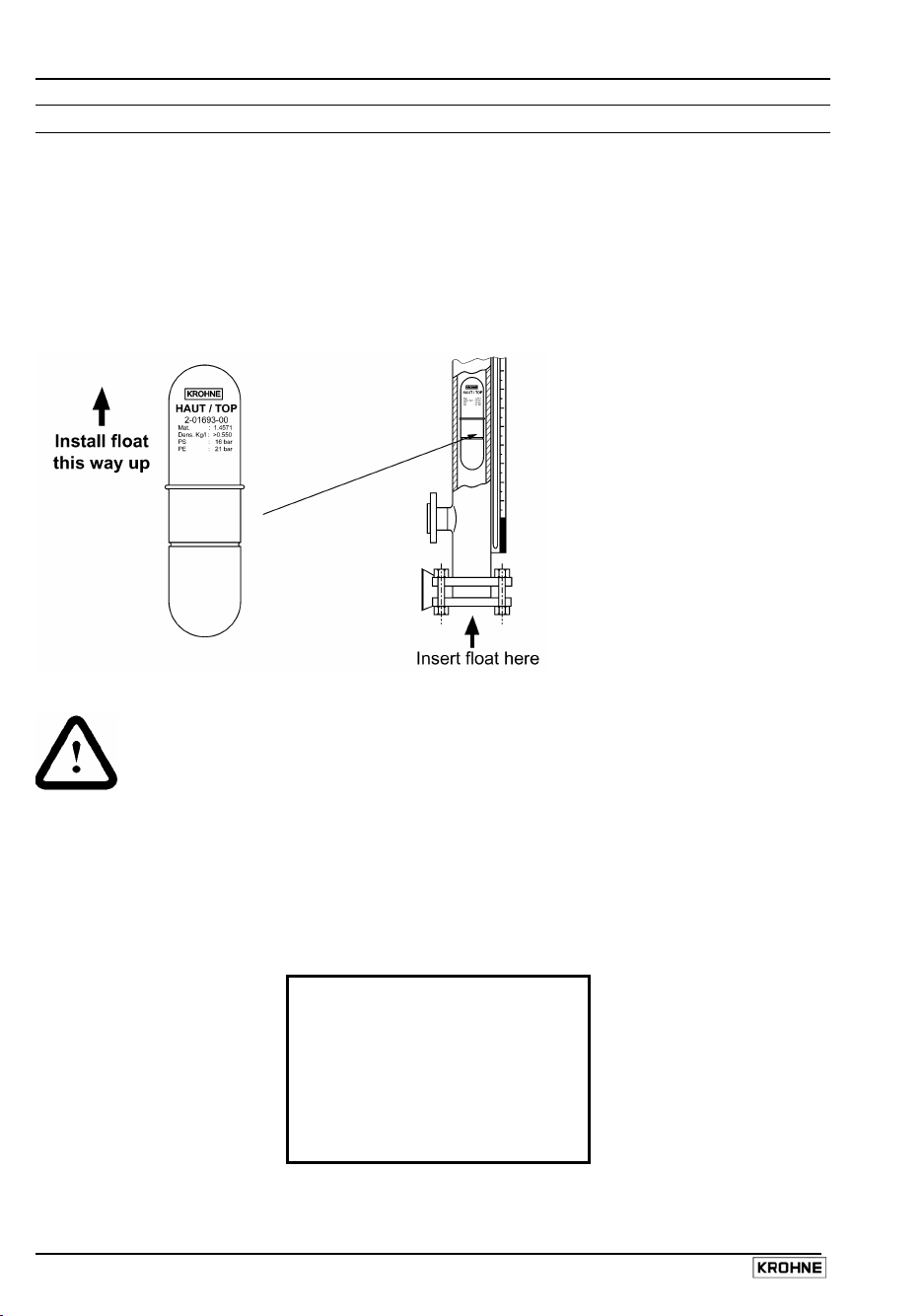

Floats packed separately

1

2 Align gaskets.

3 Tighten nuts using the correct torque with regards to the strength of bolts specified for the

To install, remove the bottom flange and insert the float – the right way up – into the guide

chamber.

vessel pressure rating, connecting flange and material.

CAUTION

Make sure that the guide tube is free of foreign bodies

(dirt, loose objects, etc.).

Floats held in position during transit by a plastic locking clip

This should be removed from the guide tube before installation through the bottom connection

flange. Follow the procedure below:

Step 1

Check measuring tube for a red sticker next to the bottom process connection.

ATTENTION!

Retirer la tige de sécurité

maintenant le flotteur

ATTENTION !

Take away transport safety

device for float

ACHTUNG !

Transportsicherung für

Schwimmer entfernen

8 Installation and Operating Instructions BM 26 A

Page 9

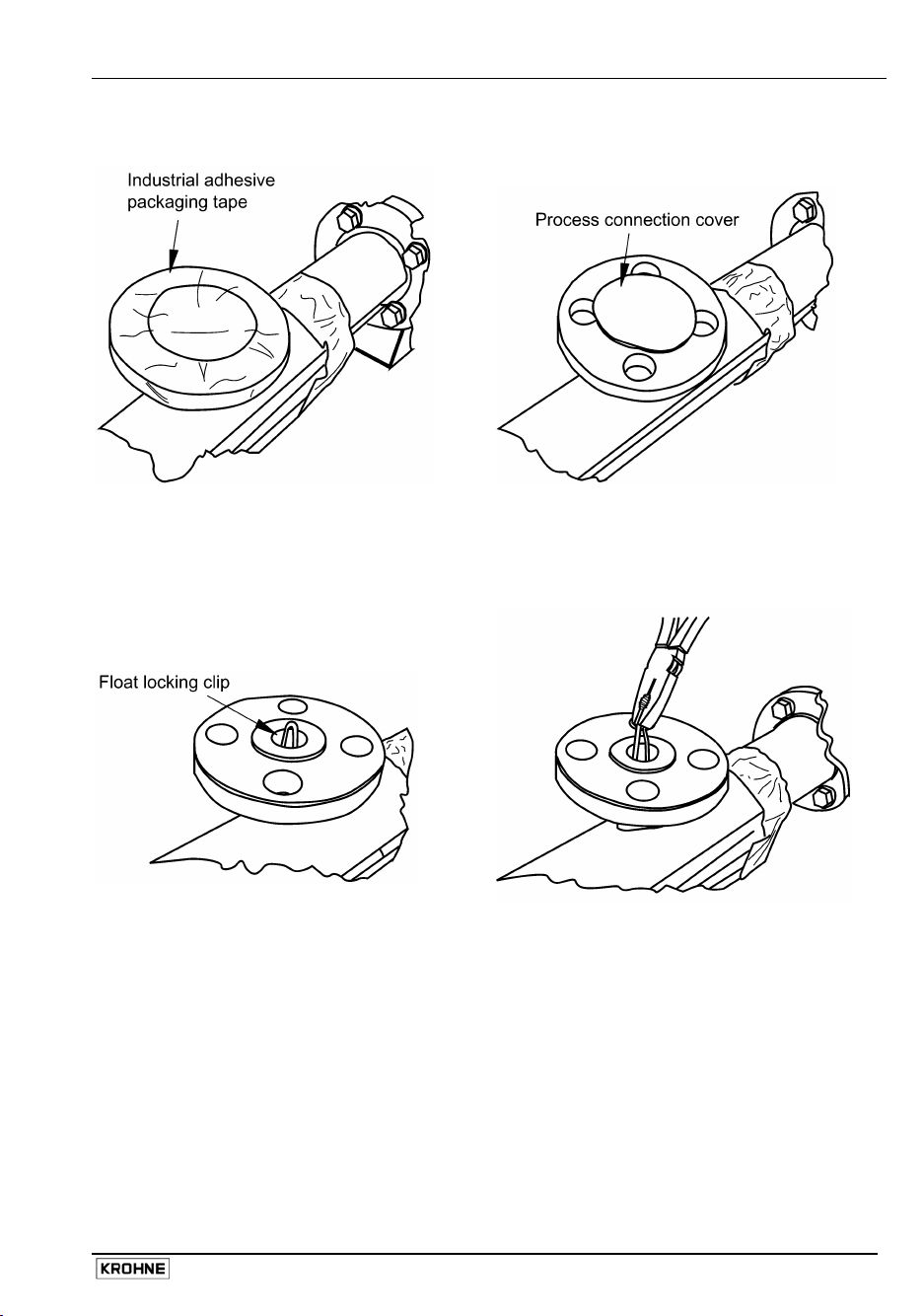

Step 2

Undo adhesive tape around

bottom process connection

Step 3

Remove process connection plastic

protective cover

Step 4

Locate clip

Step 5

Remove clip with a pair of pliers

Installation and Operating Instructions BM 26 A 9

Page 10

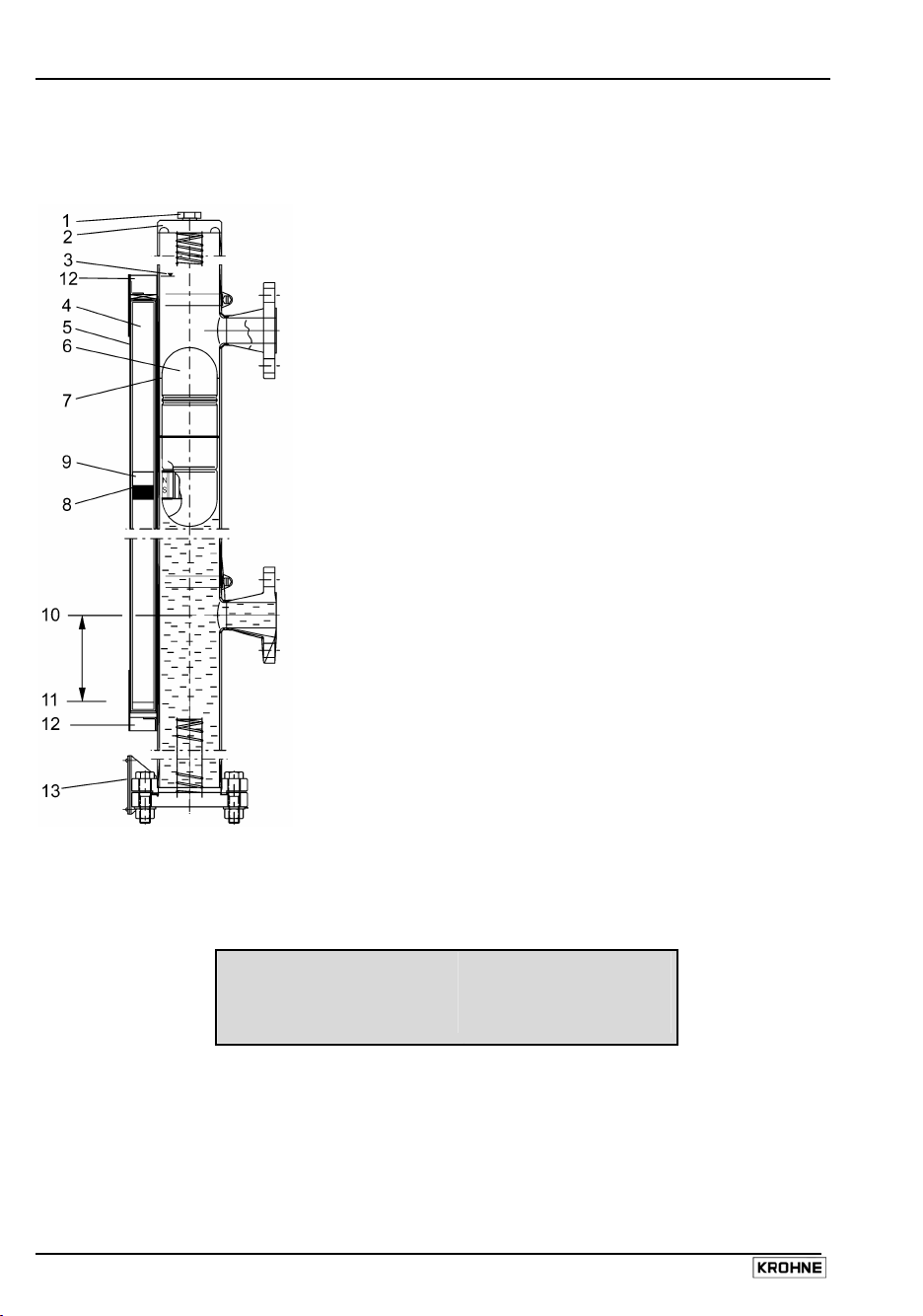

1.2 BM 26 A construction details

The diagram below shows a standard BM 26 A/C/RR without level transducer and switch options

1 Vent plug

2 Measuring tube

3 Red triangle reference mark giving

factory-calculated zero position of

measuring scale

4 Glass tube for indicator

5 Scale

6 Float (magnets mounted in lower half)

7 Liquid level

8 Mid-point of indicator

9 Indicator (standard follower bar)**

10 Zero point of measurement

(centreline of lower connecting flange)

11 Scale zero

12 Stop (red KROHNE plate)

13 Instrument nameplate

* optional flap indicator available (see section 8)

Details:

Item 12 – The red KROHNE plate at the bottom of the scale (item 5) has a label listing the product

and the operating conditions. For example :

Working pressure :

Working temperature :

Density :

Fluid :

6 bar g

25 C

0.778 s g.

cyclohexane

10 Installation and Operating Instructions BM 26 A

Page 11

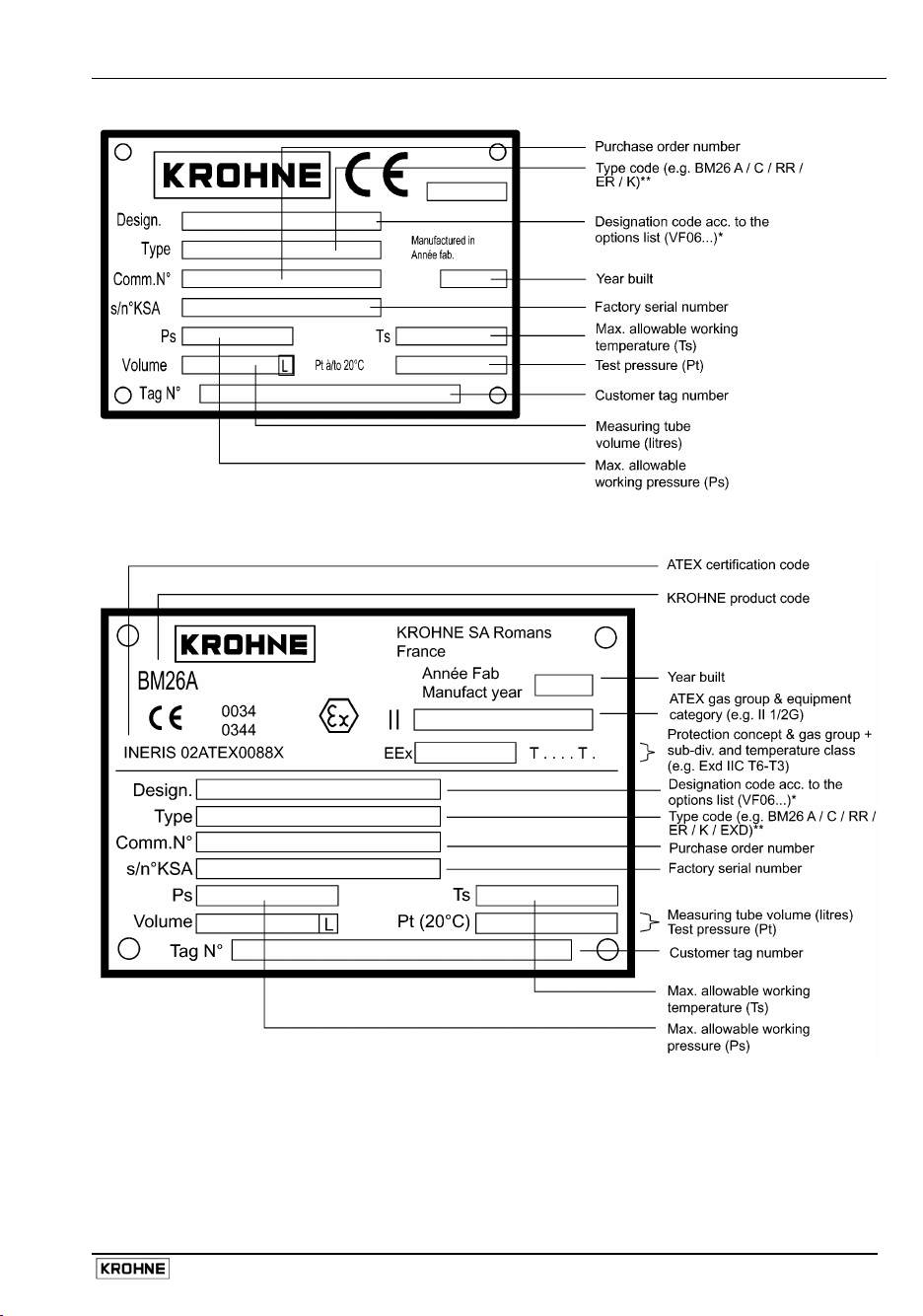

Item 13A – BM 26 A Standard nameplate

Item 13B – BM 26 A ATEX nameplate

* See BM 26 A Data Sheet for a list of standard options and designation codes

** Type code is defined as:

Product code/Process connections/Material code/Design/Level transducer/Contact/Approval

Installation and Operating Instructions BM 26 A 11

Page 12

Type code

Type code element Code Code definition

Product code BM 26 A Bypass Level Indicator (A model)

Process connections C

D

E

F

Construction material code RR Stainless steel

Design No info

B

AG

IC/TR

IC/HR

Level transducer No info

ER

Contact No info

K

Approval No info

EXI

EXD

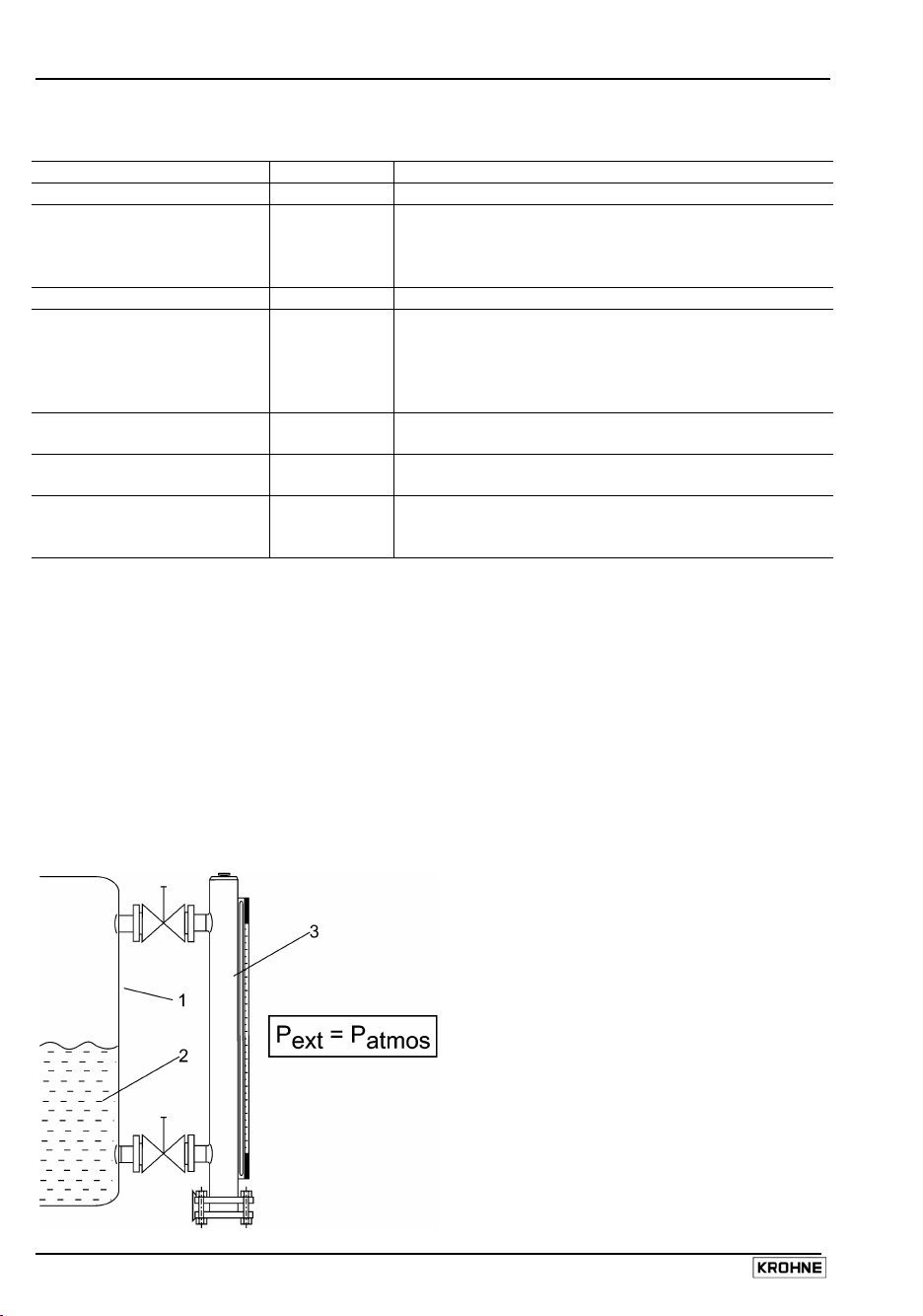

1.3 Mechanical installation requirements

Ensure that the requirements given below have been followed:

• The effective pressure of the installation (the maximum permitted by the pressure limiting valve)

must never be greater than the maximum permitted pressure, P

nameplate. The test pressure, P

• The user must be sure that materials in contact (guide tube, float, gaskets, etc) with the fluid

used are compatible with the fluid and conform to ageing characteristics of the fluid used and the

measurement environment. These have either been recommended in the instructions or form the

subject of a particular specification in the contract.

• The external pressure (P

ext

, is given on the order documents and BM 26 A nameplate.

t

) must be equal to atmospheric pressure(P

Two lateral connections

Two axial connections

One top lateral entry and one bottom axial exit

One bottom lateral entry and one top axial exit

Standard design

Heater

Anti-freeze version -40°C / -40°F

With low temperature insulation

With high temperature insulation

Without level transducer

With level transducer

Without limit switches

With limit switches

Standard, no approval

For EEx – intrinsically safe applications

For EEx – flameproof applications

, marked on the instrument

s

).

atmos

1 Tank

2 Liquid product

3 BM 26A level-liquid indicator

(measuring tube):

Vertical installation only!

12 Installation and Operating Instructions BM 26 A

Page 13

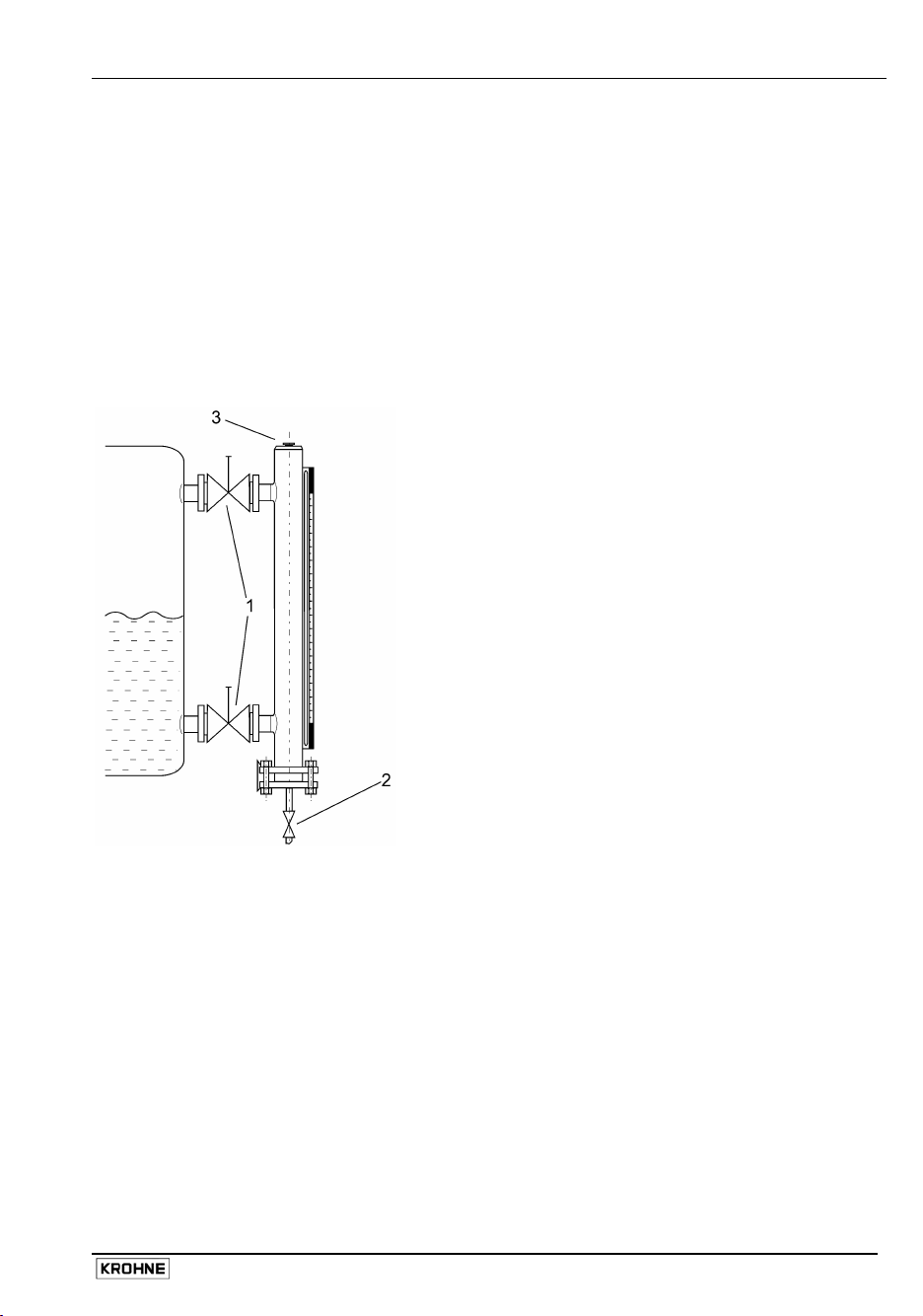

1.4 Mounting on the tank

• The BM 26 A bypass level indicator must be installed vertically on the tank

• When installing the BM 26 A bypass level indicator with or without the electrical level transducer

system, make sure that any magnetic fields generated by other equipment will not affect

measurements.

• Select bolts and gaskets (supplied by customer) that correspond to the pressure rating of the

connecting flange and the operating pressure.

• The process connections (flanges) must fit perfectly, i.e. they must be centred, parallel and

bolted in a professional way, in order to avoid unnecessary mechanical stress on the installation.

• The tank must be free of contaminants. It is recommended to install shut-off elements, e.g.

cocks, valves, etc., between the tank and bypass level indicator to allow the bypass level

indicator to be cleaned independently of the tank. The drain plug in the bottom flange must also

be replaced by a drainage cock with discharge line.

1

Shut-off valve (top and bottom)

2

Drainage valve with discharge tube.

3

Vent plug

Installation and Operating Instructions BM 26 A 13

Page 14

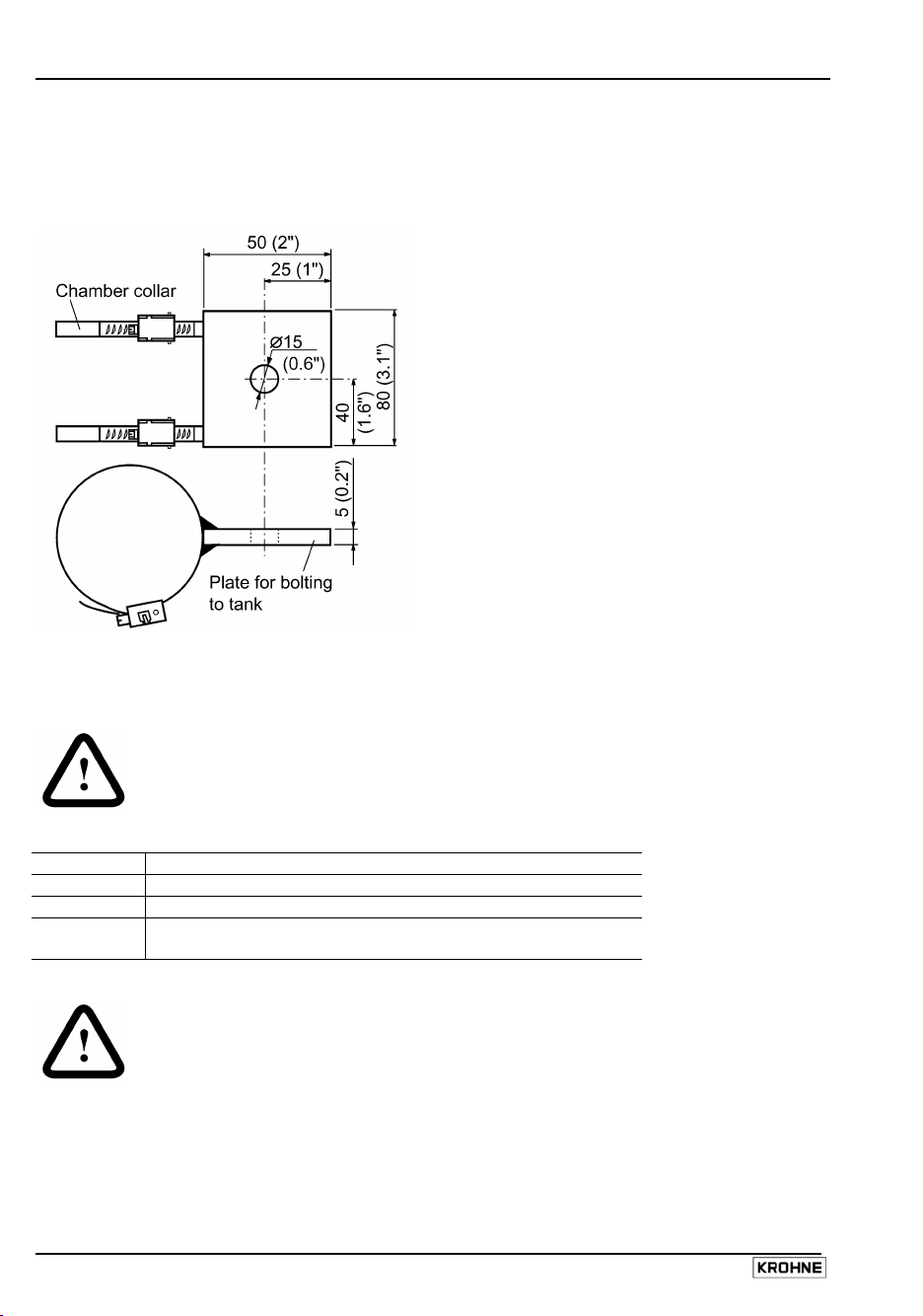

• Additional anchoring points between the BM 26 A and the tank are recommended for very high

installations (above 6 metres length for stainless steel). The standard anchor is a set of collars

welded to a plate. This is available on demand from KROHNE. See figure below for side and

plan view and dimensions in millimetres (inches).

1.5 Start-up procedure

WARNING

Take the necessary safety precautions when working with

pressurized tanks.

Step Action

1 Close drainage plugs and/or drainage cock .

2 Open shutoff elements at lower and upper connecting flange.

3 Adjust the position of the local measuring scale so that scale

level corresponds exactly to true level, see section 1.6.

WARNING

• The user must take the necessary steps to protect the installed instrument from

shock waves (water hammer). A pressure limiting valve must equally protect the

installation.

• The instrument must regularly undergo servicing to conform to the rules and

regulations applicable to the site that it is installed on.

• High Temperature versions - precautions must be taken to avoid burns to

operators.

14 Installation and Operating Instructions BM 26 A

Page 15

1.6 True level indication

1.6.1 Level measurement using the local indicator and scale

The float is equipped with a ring system of permanent magnets for transmission of liquid level to the

indicator. The indicator is linked magnetically to the magnet system in the float.

For design reasons, the minimum level in the measuring tube is given by the lower lateral flange

connection axis i.e. liquid level zero is the centreline of the lower connecting flange. As can be seen

in the diagram of the float and indicator in section 1.2, the bar follows the float below the liquid level.

There is a difference between true liquid level and the indicator position because:

• the float is immersed to a certain depth depending on the product density and float type,

• the float magnets are positioned below the float centreline in order for the float to have good

stability.

The scale is delivered correctly set up for measuring the product specified in the order. The red

reference mark at the top of the measuring tube (item 1 in the diagram below) shows where the top

of the scale must be clamped for the indicator to give an accurate reading of liquid level. No further

adjustment is necessary when the gauge is commissioned.

Note

If there is a large change in product density, a product other than the one specified in the order is

measured or a different float is installed, the scale on the BM 26 A may require adjusting to give an

accurate reading. Contact KROHNE for assistance (see also section 1.6.4 to correct the scale’s

position).

1 Reference mark : the top of the upper red

KROHNE plate must touch the bottom point

of the triangle

2 Scale

3 Measuring tube (containing float)

4 Top clamping collar ( scale-measuring tube)

Installation and Operating Instructions BM 26 A 15

Page 16

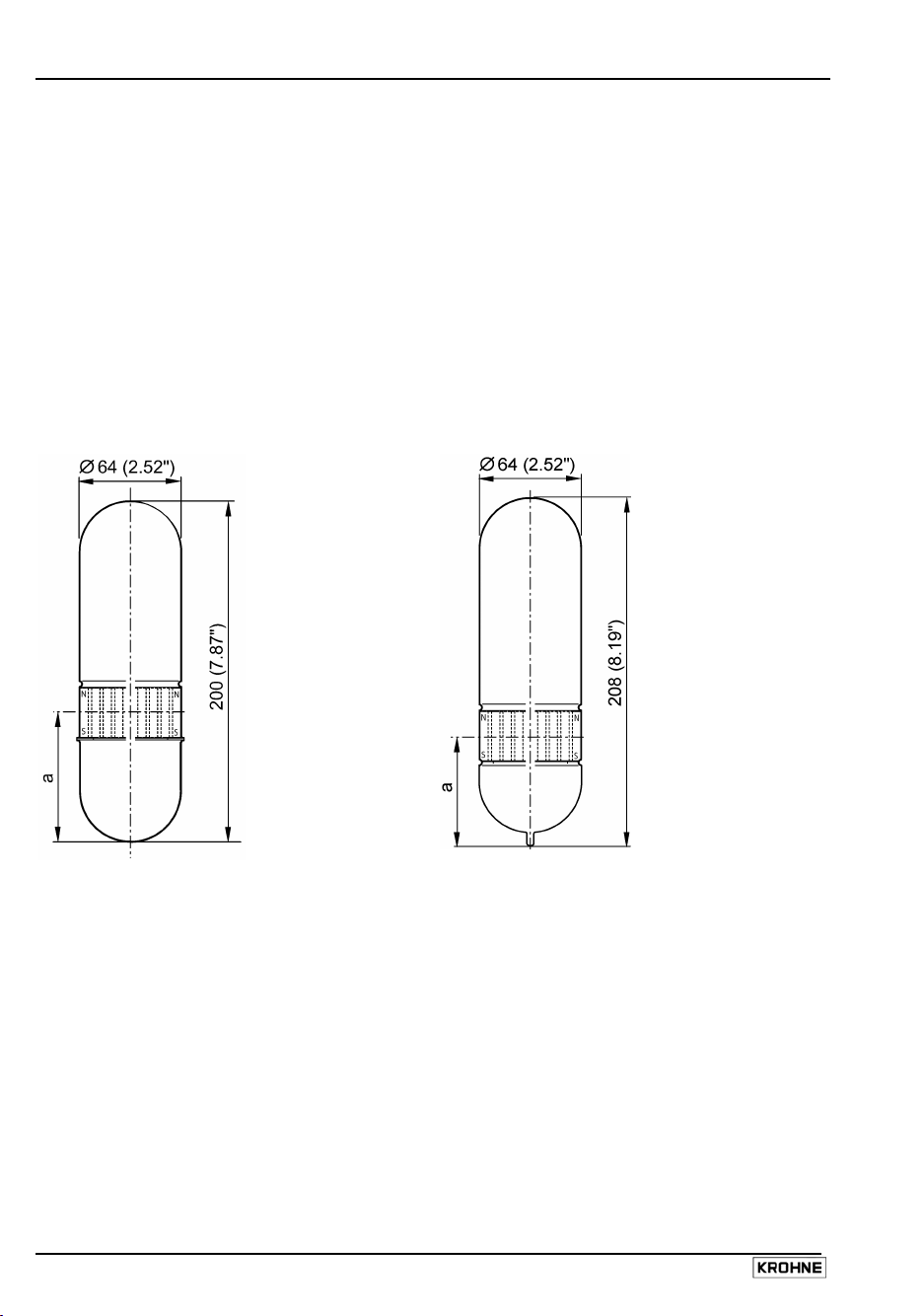

1.6.2 Floats

Four float types are used for liquid level measurement.

• Floats 1 and 2 are made of either 316L or 316Ti (as ordered).

• Floats 3 and 4 are made of titanium

The float number identifies the wall thickness of the float and the material used.

The dimension “a” in the diagrams below gives the distance from the base of the float to the centre

line of the integrated magnet system. This should be used in calculations for adjustments to the

measuring scale caused by differences between true liquid-level zero and indicated scale zero (see

section 1.6.4).

316L or 316Ti floats-No.1 and 2 Titanium floats-No. 3 and 4

where a = 47 mm or 1.85“ where a = 48 mm or 1.89“

and :

Float No.1 wall thickness = 1mm or 0.04”

Float No.2 wall thickness = 0.5mm or 0.02”

Dimensions in mm (inches)

Note

Minor variants of the above exist for particular applications: very low density products, interface

measurement applications and so on. Contact KROHNE for further information.

and :

Float No.3 wall thickness = 0.6mm or 0.024”

Float No.4 wall thickness = 1mm or 0.04”

16 Installation and Operating Instructions BM 26 A

Page 17

Density and operating temperature limits

Float

type

No. Min. density of product Product temperature

Min. Max.

kg/l lbs/

BM 26 A / Standard versions without approvals

1 0.82 51.19 – 200 – 325 300 570

2 0.55 34.34 – 200 – 325 300 570

3 0.50 31.21 – 200 – 325 300 570

4 0.60 37.46 – 200 – 325 300 570

Instruments or approved for use in Ex hazardous zones

BM 26 A / ATEX (local indicator with electrical equipment)

1 0.82 51.19 – 40 – 40 70 … 195* 160…380*

2 0.55 34.34 – 40 – 40 70 … 195* 160…380*

3 0.50 31.21 – 40 – 40 70 … 195* 160…380*

4 0.60 37.46 – 40 – 40 70 … 195* 160…380*

* The product temperature depends on the BM 26 A ATEX temperature class (T3 … T6). See

section 7.1 for further information.

Operating pressure limits

Float type

BM 26 A

No. Max. allowable operating pressure

At 20°C / 70°F At 100°C / 210°F At 200°C / 390°F At 300°C / 570°F

bar psig bar psig bar psig bar psig

Standard versions without approvals

1 55 800 41 600 37 535 32 465

2 23 335 12 175 10 145 9 130

3 23 335 13 190 10 145 8 115

4 55 800 31 450 24 350 19 275

Instruments approved for use in Zone 0

BM 26 A/ATEX (local indicator with electrical equipment)

1 55 800 41 600 – – – –

2 23 335 12 175 – – – –

3 23 335 13 190 – – – –

4 55 800 31 450 – – – –

Important note

Float test pressure is tested according to pressure equipment directive 97/23/EC and official

approvals.

Density and operating temperature limits

3

ft

Operating pressure limits of the float

°C °F °C °F

Installation and Operating Instructions BM 26 A 17

Page 18

1.6.3 Changing the process conditions

If the user wishes to use the BM 26 A to measure another product, then the following points should

be noted:

• Contact KROHNE for advice and information on equipment / product compatibility especially

where use in hazardous areas is concerned.

• Ensure that Pressure Equipment Directive 97/23/EC is observed, if relevant.

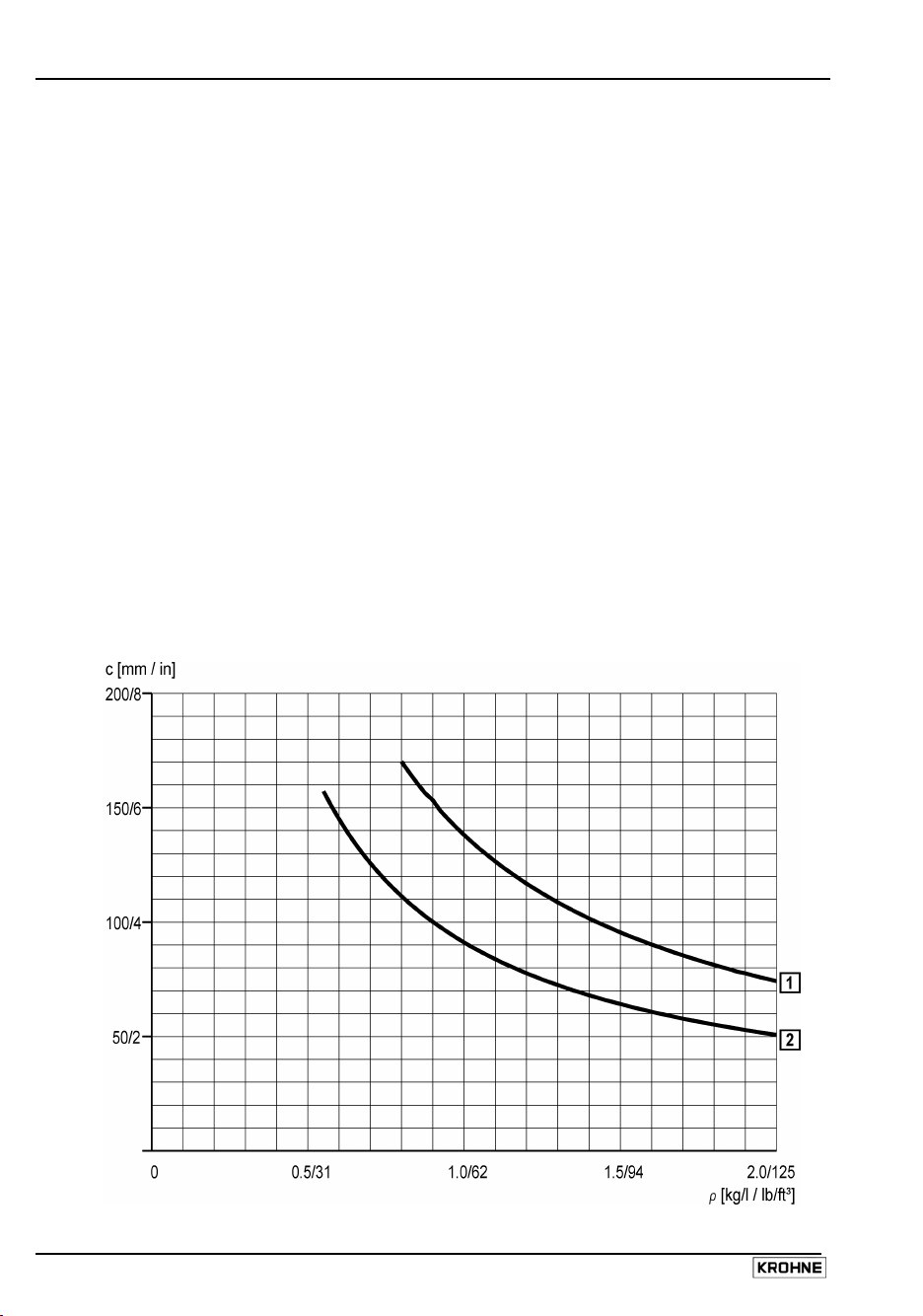

• The depth of immersion “c” (see section 1.6.4) of the float increases as product density

decreases. This depth is also dependent on the float model (No. 1, 2, 3 or 4) and material used

(316L, 316Ti or titanium). The new depth of immersion “c” is shown on the two line graphs

below. Further information is available from KROHNE on request to accurately calibrate your

instrument. When contacting KROHNE remember to:

− quote KROHNE references (order / fabrication no.) for the BM 26 A in question

− identify the new product and give its density at the new operating conditions.

− give information about the old application. Floats may have been especially adapted

for specific applications; for example: density- adjusted (pressurized) or floats for low

density applications and floats with ballast for interface measurement.

• The top of the float must be no more than 35mm or 1.38” above the product surface to ensure

reliable floatability and accurate measurement.

Graph 1: Float immersion depth against product density

Line 1 : Float no. 1 made of 316Ti (1.4571) or 316L (1.4404), wall thickness 1mm or 0.04”

Line 2 : Float no. 2 made of 316Ti (1.4571) or 316L (1.4404), wall thickness 0.6 mm or 0.02”

Where c is immersion depth and ρ is product density

18 Installation and Operating Instructions BM 26 A

Page 19

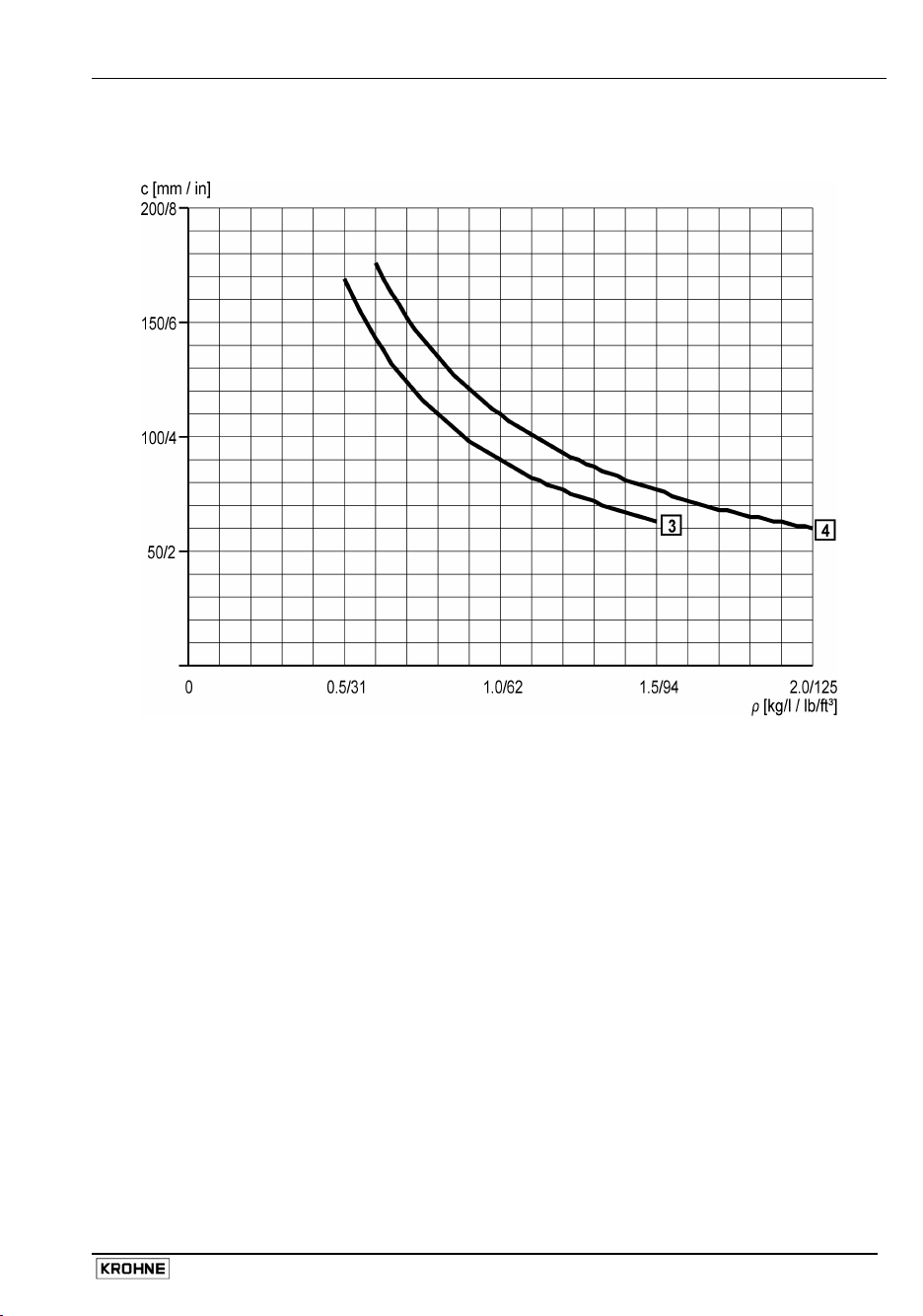

Graph 2: Float immersion depth against product density

Line 3 : Float no. 3 made of titanium, wall thickness 0.6 mm or 0.024”

Line 4 : Float no. 4 made of titanium, wall thickness 1 mm or 0.04”

Where c is immersion depth and ρ is product density

Installation and Operating Instructions BM 26 A 19

Page 20

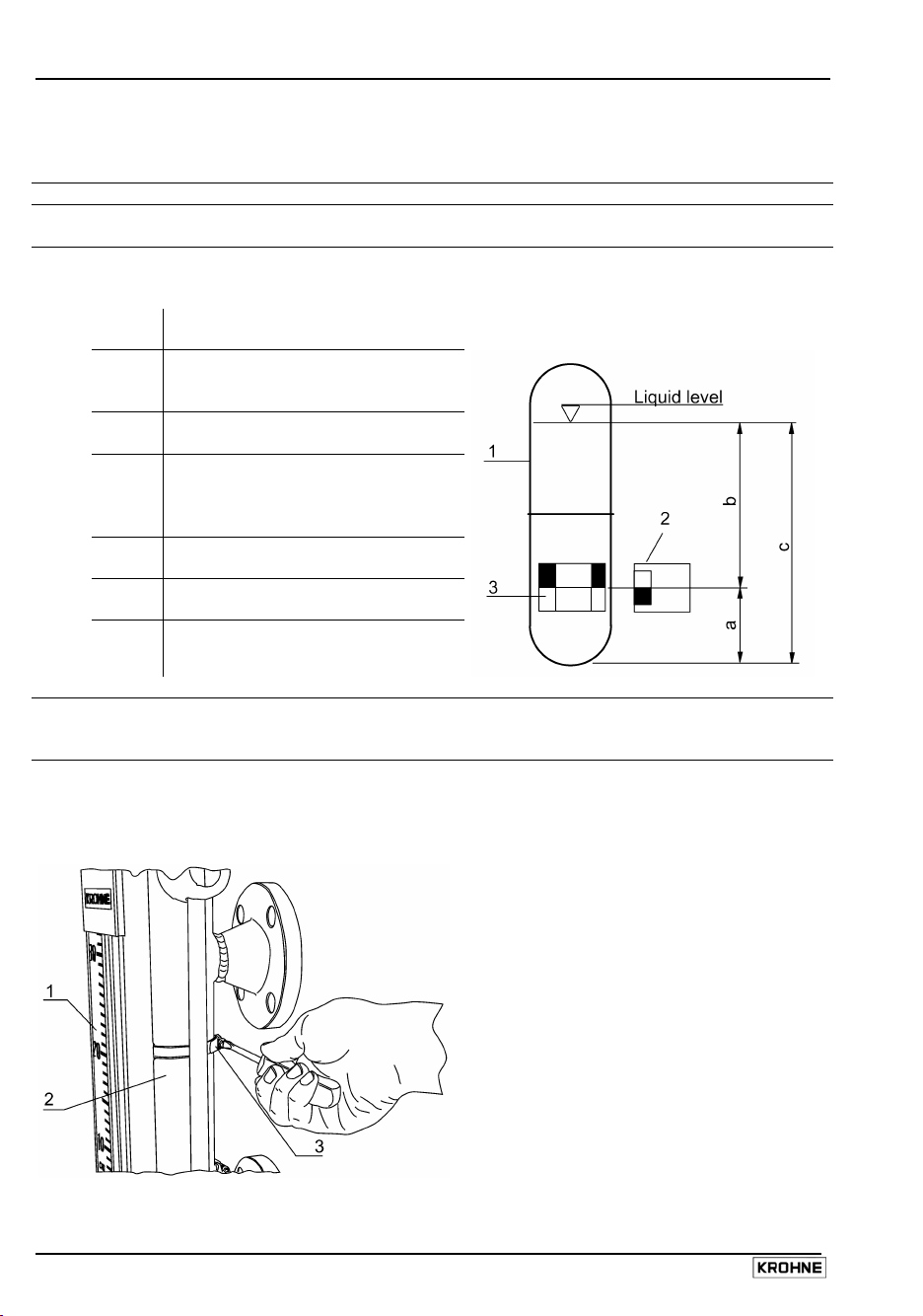

1.6.4 Correcting the scale position to accurately read true liquid level

The scale* can be corrected by the customer using the following procedure:

Step Action

1 Find the float immersion depth “c” (supplied by KROHNE, refer also to section 1.6.3).

2 Subtract the dimension “a”, float base to magnet centreline (given on the float dimensioned

drawing in Section 1.6.2), from “c” to get the dimension “b”, scale correction factor.

b = c – a (difference between liquid level

c = float immersion depth (a function of

a = distance from centerline of magnet

1 = Float

2 = Follower magnet of indicator (or limit

3 = Position of magnets mounted in the

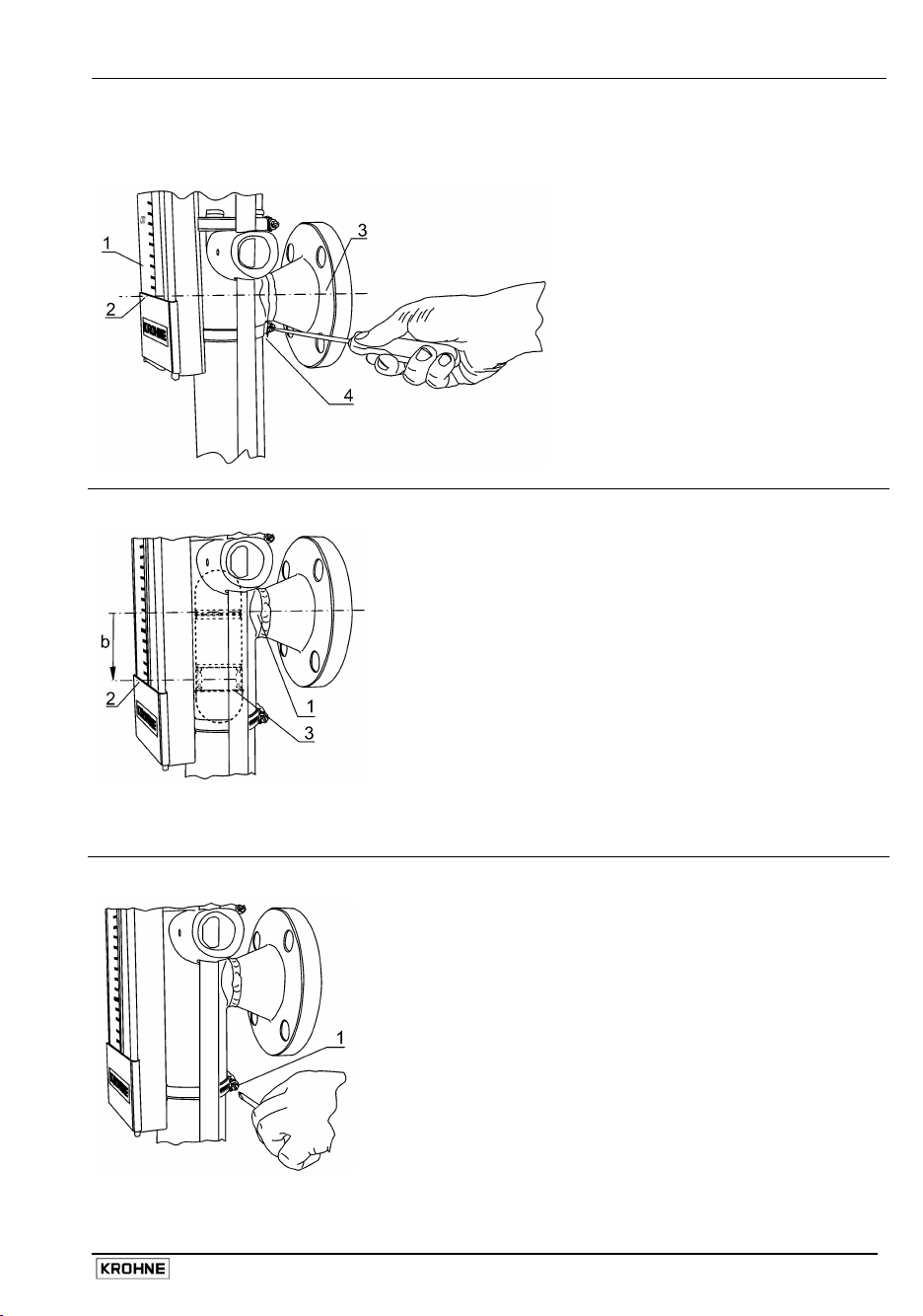

3 Loosen the two clamp collars holding the measuring scale onto the measuring tube using a

4 Bring the zero point (top of the lower red KROHNE plate) on the scale into line with the

4a Undo top collar

*This information also applies to the initial setting up of limit switches – however, the fitter should

also remember to take into account the limit switches offset trigger point (see section 3.6).

Item Description

and indicator position due to product

density)

product density), see section 1.6.3.

system to the float base, see

dimensioned float drawings in

section 1.6.2.

switch)

float

screwdriver or 8 mm wrench.

centreline of the bottom lateral process connection.

1 Measuring scale

2 Measuring tube

3 Top measuring scale collar

20 Installation and Operating Instructions BM 26 A

Page 21

4b Undo bottom collar

4c Zero the scale (default)

1 Measuring scale

2 Bottom of scale (item 1) indicated

by top of red KROHNE plate.

Default position is on the same level

as item 3.

3 Centreline of bottom lateral process

connection.

4 Bottom measuring scale clamp

5 Move the measuring scale down the measuring tube to set to by “b” mm.

1 Centreline of bottom lateral process

connection.

2 Bottom of scale (item 1) indicated

by top of red KROHNE plate.

3 Position of float (dashed lines)

when measuring tube filled up to

the centre line of bottom lateral

process connection.

6 Retighten the two collars holding the measuring scale onto the measuring tube.

B Move scale down measuring tube

by “b” mm. The bottom of the scale

will then be at the same level as the

magnets in the float

1 Measuring scale collar screw

Installation and Operating Instructions BM 26 A 21

Page 22

1.6.5 Functional check of local level display (bar indicator only)

Step Action Comments

1 Break the magnetic bond between the

float and the indicator bar using a bar

magnet.

2 Retrieve the indicator the bottom of the

tube with a bar magnet. Lift up the tube.

3 End of the procedure. If the indicator bar fails to bond

*See diagram in section 1.2.

The indicator bar (9*) will drop down and

disappear behind the red cover (12*) on

the front scale.

The indicator will again magnetically bond

with the float at the correct indicated value.

magnetically, please contact KROHNE for

assistance.

22 Installation and Operating Instructions BM 26 A

Page 23

2 Level transducer

2.1 General notes

In addition to the local scale indicator, the BM 26 A can be fitted with a level transducer that

transmits a magnetically-actuated 4 to 20 mA analogue current output for monitoring level outside a

hazardous zone.

This type of indication uses a stainless steel tube containing a resistive reed contact chain that is

clamped adjacent to the measuring tube. The position of the float magnet in the measuring tube

determines the output. This output is calibrated at the factory and does not require any further

adjustment when the BM 26 A is commissioned.

The transducer reading is converted into a current output of 4 to 20 mA by the transmitter that is

potted into the transducer housing. The transmitter module used is detailed in the following subsection (detailed technical data is given in section 7.2). The intrinsically safe transmitter may be

used with or without a galvanically-isolated 4 to 20 mA output for the BM 26 A Eex ia version.

BM 26 A Std/ EEx i/EEx d with level transducer (aluminium transmitter housing)

1 Cable entry.

Only Ex i or Ex d-certified

components and cable entry

fittings to be connected!

With M20 x 1.5 thread.

Optional: M25 x 1.5

NPT¾

2 Level transducer housing

3 Stainless steel tube-encased

reed chain

4 BM 26 A measuring tube and

scale with magnetic following

level-indicator

5 PE Ground terminals.

Both terminals must be

connected to Ground!

Dimensions in mm and (inches)

Installation and Operating Instructions BM 26 A 23

Page 24

2.2 Transmitters

The BM 26 A can be equipped with a level transducer. The level transducer is defined by the type of

communication used (ER – electronic remote), housing protection (Ex d, Ex I etc.), housing material

(AL – aluminium) and transmitter module.

2.2.1 Transmitter versions for the BM 26 A

Version designation Housing protection Transmitter module

ER/STD/AL/D Without (non-Ex)

ER/EXI/AL/D EXI (EEx ia)

ER/EXD/AL/D EXD (EExd )

ER/STD/AL/E Without (non-Ex)

ER/EXI/AL/E EXI (EEx ia)

ER/EXD/AL/E EXD (EEx d)

ER/STD/AL/F Without (non-Ex)

ER/EXI/AL/F EXI (EEx ia)

ER/EXD/AL/F EXD (EEx d)

2.2.2 Electrical connections

WARNING

Do not remove the transducer cover until the power supply

has been disconnected

PR 5343B : 4-20mA (top view)

D PR 5343B

4-20mA

E PR 5350B

PROFIBUS PA / FF

F PR 5335B

4-20mA+HART

24 Installation and Operating Instructions BM 26 A

Page 25

PR 5350B : PROFIBUS PA / FF

PR 5335B : 4-20mA+HART

WARNING

Refer to section 7.2 for technical information on the use of equipment in hazardous

locations.

®

Installation and Operating Instructions BM 26 A 25

Page 26

3 Limit switches / contacts

3.1 General notes

To signal specific liquid levels, the BM 26 A bypass level indicator can be equipped with 13 different

types of limit switch that are clamped to the measuring tube and are adjustable over the whole

measuring range. They are actuated by a magnet incorporated into the float. The operating

conditions define which limit switches may be used. Refer to section 7.3 for detailed technical data

on each type of limit switch.

The limit switches are delivered separate from the BM 26 A gauge and have to be mounted on site.

See sections 3.5 to 3.6 for installation instructions.

3.2 Designation code for defining limit switch versions

Housing

protection

STD (Without) LC (Low power

EXI (EEx ia)

EXD (EEx d)

3.3 Limit switch options for the BM 26 A (non-Ex)

Designation Housing

MS20/STD/L

C/PC/NN/BT

MS15/STD/L

C/PC/NO/BT

MS15/STD/L

C/AL/NN/HT

MS15/STD/L

C/AL/NO/HT

MS15/STD/H

C/PC/NN/BT

MS15/STD/H

C/AL/NN/HT

Cut-out

power

Housing

material

NAMUR

conformity

Process

temperature

applications

PC (Polycarbonate /

cut-out)

HC (High power

Standard)

AL (Aluminium) NO (NAMUR) HT (High

cut-out)

protection

Housing

material

Power cut-out Process temperature Ambient

Without PC 30VA

<250°C <480°F -20...+120 -5...+245

NN (NonNAMUR)

temperature

/ °C

BT (Low

temperature)

temperature)

Ambient

temperature

/ °F

0.5A

230V AC

Without PC NAMUR <250°C <480°F -20...+120 -5...+245

Without ALU 20VA

<300°C <570°F -20...+120 -5...+245

1.5A

250V AC

Without ALU NAMUR <300°C <570°F -20...+120 -5...+245

Without PC Max.: 100VA

<250°C <480°F -20...+120 -5...+245

Min.: 3VA

1.5 A

250V AC

Without ALU Max.: 100VA

<300°C <570°F -20...+120 -5...+245

Min.: 3VA

1.5A

250V AC

26 Installation and Operating Instructions BM 26 A

Page 27

3.4 Limit switch options for the BM 26 A (ATEX version)

Designation Housing

MS20/EXI/LC/

protection

EXI* PC 0.5A* ** ** Ui

PC/NN/BT

MS15/EXI/LC/

EXI* PC NAMUR ** ** Ui

PC/NO/BT

MS15/EXI/

EXI* ALU 1.5A* ** ** Ui

LC/AL/NN/HT

MS15/EXI/

EXI* ALU NAMUR ** ** Ui

LC/AL/NO/HT

MS15/EXD/LC/A

EXD ALU 20VA

L/NN/HT

MS15/EXD/LC/A

EXD ALU NAMUR ** ** U

L/NO/HT

MS15/EXD/HC/A

EXD ALU Max.:*****

L/NN/HT

* To be connected to a certified intrinsically-safe power supply only.

** Dependant on ATEX temperature class. Refer to section 7.1 for further information.

*** The current value is not imposed, however the power supply must be intrinsically-safe.

**** The voltage value is not defined, however the power supply must be intrinsically-safe.

3.5 How to use a limit switch

3.5.1 Operating principle

The MS 15/STD, MS 15/EXI, MS 15/EXD, MS 20/STD and MS 20/EXI limit switches consist of a

reed contact that is actuated directly by the magnet system in the float. Due to their bi-stable

switching characteristic, the switching state is maintained until the float magnet system again

deactivates the limit switch in the opposite direction. Line-side connection of a suitable isolation

switching amplifier is recommended.

3.5.2 Installation

1 Attach the switch to the measuring tube at the desired level using the metal collar supplied.

2 Adjust the switch level to take into account the difference between indicated level and true level

(see section 1.6.4).

3 Adjust the switch level to take into account limit switch trigger point offset (see section 3.6.2).

Note:

Due to its bi-stable characteristic, the switch can be operated in open-circuit or closedcircuit mode (see section 3.5.5 Electrical connections), when appropriately connected.

Housing

material

Power

cut-out

1.5A

250V AC

Min.: 3 VA

1.5 A

250 V AC

Process

temperature

Ambient

temperature

** ** U

** ** U

Power supply

characteristics

****

I

100mA

i

C

0

i

L

0

i

24V

***

I

i

C

0

i

0

L

i

****

500mA

I

i

C

0

i

L

i

24V

I

***

i

C

0

i

L

0

i

380VAC

max

I

1,5 A

max

P

20 VA

max

380VAC

max

1,5 A

I

max

P

20 VA

max

380VAC

max

1,5 A

I

max

P

20 VA

max

Installation and Operating Instructions BM 26 A 27

Page 28

Clamping in position on measuring tube

MS 15 /STD/…/PC/…/BT or MS 15/EXI/…/PC/…/BT

MS 15/STD/…/AL/…/HT, MS 15/EXD/…/AL/…/HT, or MS 15/EXI/…/AL/…/HT

1 Limit switch clamp

2 Limit switch bracket

3 Measuring scale

4 Measuring tube

5 2 M4 screws (for

6 Switching point

7 MS 15 /STD or /EXI

1 1 x locking screws M6

2 Limit switch

3 Limit switch clamp

clamp

bracket)

centerline

Fine adjustment:

See procedure,

section 3.6

limit switch cover

-use 3 mm Allen key

bracket

4 Measuring tube

5 Measuring scale

clamp

6 Switching point

centerline

Fine adjustment:

See procedure,

section 3.6

7 Cover lock:

M3 screw -

use 2mm Allen key

8 MS15 EXD

28 Installation and Operating Instructions BM 26 A

limit switch cover

9 Cable fitting (not

supplied by KROHNE)

Page 29

MS 20 /STD or /EXI

1 Limit switch clamp (switch

has an integral bracket)

2 Measuring scale clamp

3 Measuring tube

4 Switching point centerline

Fine adjustment:

See procedure, section 3.6

5 MS20 /STD or /EXI

limit switch cover

3.5.3 Overall dimensions of limit switches mounted on measuring tube

MS 15/STD/…/PC/…/BT and

MS 15/EXI/…/PC/…/BT

* Item 1: limit switch collar screw

MS 20/STD and MS 20/EXI

MS 15/STD/…/AL/…/HT,

MS 15/EXI/…/AL/…/HT, and /EXD/…/AL/…/HT

1 Metal clamping collar screw

2 MS 20 limit switch

3 Measuring tube

Dimensions in mm (inches)

Installation and Operating Instructions BM 26 A 29

Page 30

3.5.4 Limit switch dimensions (without bracket and clamp)

MS 15/STD/…/PC/…/BT

and /EXI/STD/…/PC/…/BT

with PG13.5 fitting

Side view Side view

MS 15/STD/…/AL/…/HT,

MS 15/EXI/…/AL/…/HT,

and MS 15/EXD/…/AL/…/HT

without cable fitting (supplied by customer)

Top view

MS 20/STD and /EXI with PG9 fitting and integrated bracket

Side view

Dimensions in mm (inches)

30 Installation and Operating Instructions BM 26 A

Page 31

3.5.5 Electrical connections

Unscrew the housing cover at the rear. For further technical data, see Section 7.3. Use connections

that are certified for Exd applications for EXD casings. Wire as shown below:

WARNING

Do not remove the limit switch cover until the power supply has been disconnected

MS 15 limit switches

STD/…/PC/…/BT or EXI/…/PC/…/BT terminals

1 Terminals

2 Cable entry fitting

STD/…/AL/…/HT, EXI/…AL/…/HT, or EXD/…/AL/…/HT terminals

1 Terminals

2 Hole with M20 x 1.5

PG 13.5

thread. Cable fitting

supplied by customer

Installation and Operating Instructions BM 26 A 31

Page 32

STD/…/PC/NO/BT or EXI/…/PC/NO/BT (NAMUR) terminals

1 Terminals

2 Cable entry fitting

PG 13.5

MS 20 limit switches

STD and EXI terminals

1 Cable entry fitting PG9

2 Terminal block

3 Blue wire (terminal 1)

4 Black wire (terminal 3)

5 Brown wire (terminal 2)

32 Installation and Operating Instructions BM 26 A

Page 33

3.6 Fine adjustments to the limit switch trigger point

3.6.1 General notes

Due to the way the reed switch switches from one state to another and the geometry of magnets

integrated into the float, different switching points are obtained when the float moves up or down.

This must be taken into account when positioning the limit switch.

The assembler must equally remember that as with the local display, limit switch position must take

into account the fact that indicated level is lower than true level.

By default, indicated level is lower than true level by “b” mm. This should be adjusted during

commissioning (see section 1.6.4). When the float moves up, the switch is triggered with the float

offset by “d” mm. When the float moves down, the switch is triggered with the float offset by “e” mm

(see section 3.6.3).

Hysteresis: see section 7.3.

3.6.2 Fine adjustments to the limit switch trigger point

Step Action

1 Choose the true level at which the limit switch should signal “limit reached“.

2 Adjust the switch position using the procedure in Section 1.6.4 to take into account the

difference between true liquid level and indicated level (magnet position). Move switch down

measuring tube by “b” mm.

3 Refer to the table in section 3.6.3: “Switching point offsets“. Find the limit switch offset based

on the limit switch type and the direction in which the float is moving for the switch to be

triggered. Example: if the switch has to trigger when the float moves upwards then a MS

15/STD switch needs to be moved down the measuring tube by 5mm or 0.2 ”.

4 Loosen the collar holding the limit switch onto the measuring tube.

5 Now re-position again to take into account the switch trigger points -Move the switch up or

down the measuring tube by the amount required for the offset as indicated in the table and

drawing in section 3.6.3.

6 Retighten the collar holding the limit switch onto the indicator tube.

Installation and Operating Instructions BM 26 A 33

Page 34

3.6.3 Switching point diagram and offset values for limit switches

Item Description

0 zero scale mark

b difference between liquid level and scale reading due to product density

L level indication (limit value) on the scale

d trigger point offset of limit switch when the float goes up (distance between contact

centreline and level indication or limit value - see table below)

e trigger point offset of limit switch when the float goes down (distance between contact

centreline and level indication or limit value)

Switching point offsets

Offset due to direction of

float displacement

Limit switch d (Up) e (Down)

mm inch mm inch

MS 15/STD

MS 15/EXI

MS 15/EXD

MS 20/STD

MS 20/EXI

– 5

– 5

– 0.2

– 0.2 – 5

– 5

– 0.2

– 0.2

Dimensions in mm (inches)

34 Installation and Operating Instructions BM 26 A

Page 35

4 Special versions

4.1 Low-temperature versions AG, TR or IC/TR

Version BM 26 A/AG: to -40°C or -40°F

Version BM 26 A/TR: to -200°C or -330°F

Version BM 26 A/IC/TR: to -200°C or -330°F

All components are made of solid CrNi steel grade 316 Ti (equivalent to 1.4571) or 316 L (equivalent

to 1.4404). The measuring tube in the BM 26 A/IC/TR has glass wool insulation and aluminium

cladding. The float magnets are made of a special material.

The scale indication is magnified by plexitherm glass for easier reading. The ambient temperature

and product temperature will have been specified by the customer to ensure insulation is

appropriate. The socket length to the connecting flange will have been specified by the customer if

insulation is supplied by the customer.

Version AG Version TR Version IC/TR

1 Plexitherm glass 1 Measuring tube 1 Measuring tube

2 Indicator scale 2 Indicating tube with indicator 2 Insulation (lagging)

3 Indicating tube with indicator 3 Plexitherm glass 3 Indicating tube with indicator

4 Measuring tube 4 Insulation 4 Plexitherm glass

5 Aluminium cladding

Dimensions in mm (inches)

4.2 High-temperature versions HR or IC/HR

The BM 26 A/HR and BM 26 A/IC/HR versions are suitable for applications in the range from

200°C or 390 °F to 300°C or 570°F. All components are made of solid stainless CrNi steel. The

measuring tube in the BM 26 A/IC/HR version has glass wool insulation and aluminium cladding.

1 Measuring tube

2 Insulation (lagging)

3 Indicating tube with indicator

4 Aluminium cladding

Installation and Operating Instructions BM 26 A 35

Page 36

4.3 Heating system for measuring tube BM 26 A/B

For extreme operating conditions, the measuring tube is fitted with a heating jacket with 2 standard

Ermeto 12 connections, for heat transfer fluid or steam heating. See section 7.1 for more technical

data.

The maximum allowable operating pressure, Pmax, of the heating medium depends on the length of

the measuring chamber.

Measuring chamber length, L Pmax*

m ft bar psig

0 < L ≤ 2 0 < L ≤ 6.5 10 145

2 < L ≤ 4 6.5 < L ≤ 13 7 101.5

4 < L ≤ 6 13 < L ≤ 19.5 5 72.5

* The heating steam or cooling fluid must have a temperature in the range of -200°C to +400°C /

-330°F to 750°F. Insulation of the measuring tube is recommended.

If operating conditions outside the ranges above are necessary, please contact KROHNE.

1. Heating medium inlet

2. Heating system

3. Measuring tube

4.4 Liquid/liquid interface measurement BM 26 A/TS

If a tank contains two liquids with different densities, the level of the interface can be measured

by means of an adapted float loaded with ballast. The floats buoyancy properties permit it to float on

the surface of the heavier liquid and ignore the lighter liquid. The difference in liquid densities must

be at least 100 g/l or 6.24 lb/ft

3

, with the float being fully submerged in the lighter liquid.

36 Installation and Operating Instructions BM 26 A

Page 37

5 Maintenance

The instrument will not normally require any maintenance. However, flushing the instrument is

recommended from time to time if the tank product is contaminated or has a tendency to form

deposits. In order to do this, open the drain plug or drain valve and flush out. If the float also requires

cleaning, remove it from the bottom of the measuring tube after first closing off the shut-off

elements.

WARNING

Follow accident prevention regulations carefully when working with pressurized tanks

and dangerous chemical products

6 Ordering spare parts

The following details are required for ordering spares:

1. Commission number of the level gauge (see instrument nameplate)

2. Instrument type, model, description, nominal size of process connections (DN)

3. Construction materials

Note:

Please specify flange spacing (measuring range ie. the distance between the process

connections axes) or the KROHNE Comm. No. from the initial order.

Installation and Operating Instructions BM 26 A 37

Page 38

7 Technical data

7.1 Technical data: BM 26 A

Instrument type BM 26 A

Measuring range

Standard 0.3 … 6 m / 1 … 20 ft

Accuracy

Min. product density

Viscosity

Max. allowable operating

pressure at 20°C / 70°F*

Indicator

Standard linear indicator with cm/m graduation

Optional linear scale with inch/feet, % or volume

graduation, as required; flap indicator without

Mounting position

Protection (indicator) to EN 60529

Pressure vessel approvals

Electromagnetic compatibility (EMC)

Process temperature

Standard, with flap or bar indicator -40°C…+200°C or -40…+390°F

Optional, non- Ex -200°C … +300°C / -325 … +570°F *,**

Other approvals

ATEX

INERIS 02ATEX0088 X

ATEX applications: special conditions for safe use

BM 26 A Bypass Level Indicator for all options

Temperature class*** Process temperature Ambient temperature range

T6 T(fluid) <= 70°C / 158°F -40 to +60°C / -40 to +140°F

T5 T(fluid) <= 95°C / 203°F -40 to +50°C / -40 to +122°F

T4 T(fluid) <= 130°C / 266°F -40 to +50°C / -40 to +122°F

T3 T(fluid) <= 195°C / 383°F -40 to +40°C / -40 to +104°F

* dependent on material, flange pressure rating and float pressure resistance

** higher on request

*** the temperature category of the BM 26 A depends on the options fitted to the

indicator, the ambient temperature and the process temperature

± 10 mm / ± 0.4” of measured value

0.5 kg/l … 3.0 kg/l / 31.2 … 187 lb/ft

≤ 5000 mPa.s / 3.360 lb/ft.s

40 bar / 580 psig (information on higher

pressure levels available on request)

scale; flap indicator with scale in cm/m,

inch/feet, % or volume graduation, as required

vertical

IP 68 (equivalent to NEMA 6)

Pressure equipment directive 97/23/EC.

to EN 50081-1, EN 50082-2 & EN61326 (1+2)

ATEX II 1/2 G or ATEX II 1 G

EEx d ia IIC T3 … T6 or EEx d IIC T3 … T6 ;

EEx ia IIC T3 … T6

3

38 Installation and Operating Instructions BM 26 A

Page 39

Connecting flanges

to DIN 2501:

Standard DN 25, PN 40 Form B1 (EN 1092-1)

Option DN 15 to DN 50, PN 16 or PN 40

to ASME B 16.5:

for the heating jacket

Connecting tube (standard) For Ermeto 12 screw joint

to DIN 2501 DN 15, PN 40

to ASME B 16.5 ½”, 150LB/RF or 300LB/RF

Pipe 12 x 1 mm (0.47” x 0.04”)

Information on other standards and pressure ratings supplied on request

Materials (BM 26 A without options)

Level transducer (reed chain)

see section 7.2 for technical data on

½” to 2”, ASME150LB/RF or 300LB/RF

Stainless steel 316 L or Ti

current output 4 … 20 mA

current output 4 … 20 mA + HART

output PROFIBUS PA/FF

transmitter module options

Installation and Operating Instructions BM 26 A 39

Page 40

7.2 Technical data: level transmitter modules

Name PRETOP 5343B PR 5350B PR 5335B

Description

4 … 20mA. Conversion of

resistance variation to

analogue current signals.

PROFIBUS PA or FF.

Conversion of resistance

variation.

4-20mA+HART

Conversion of resistance

variation to analogue

current signals.

Connection of up to 15

transmitters to a digital 2wire signal with HART

communication.

4 … 20 mA

(limits : 3.5 & 23 mA) and

HART® protocol (loop link)

Output

4 … 20 mA

(limits : 3.5 & 23 mA)

PROFIBUS

®

PA protocol

Profile A&B, ver. 3.0 (EN

50170 vol.2) or

FOUNDATION™

Fieldbus protocol

Max. load RL

Measuring

error

Power supply

Ambient

temperature

(U – 8)

0.023

8 … 35Vdc

8 … 30Vdc (ATEX)

Refer to table in “ATEX applications: special conditions for safe use”, section 7.1

Ohms

- (U – 8) Ohms

0.023

± 10 mm

9 … 32Vdc

9 … 30Vdc (ATEX)

8 … 35Vdc

8 … 30Vdc (ATEX)

Approvals

Ex EEx ia, EEx d

Max power

dissipated by

Exd housing,

P

max

Max voltage

for Exd

housing, U

Max safety

5 W

36 V

max

values for Exi

applications

Terminal

block

28V

U

i

30 V

28V

Ii 120mA 120mA 120mA

Pi 0.84W 0.84W 0.84W

Ci 1nF 2nF 1nF

Li 10µH 1µH 10µH

®

.

40 Installation and Operating Instructions BM 26 A

Page 41

7.3 Technical data: limit switches

Limit switch MS 20/STD MS 20/EXI

Max. switching capacity

Ambient temperature

Process temperature

Protection category

to EN 60529

Cable entry

Max. safety values

Housing material

Hysteresis

Weight

Limit switch MS 15/STD MS 15/EXI MS 15/EXD MS15/*/NAMUR

max. switching capacity

LC (low power cut-out)

max. switching capacity

HC (high power cut-out)

Ambient temperature

Process temperature HT

(high)

Process temperature BT

(low)

Protection category

to EN 60529

Cable entry PC

AL

Max. safety values

Housing material BT

HT

Hysteresis

Weight PC

AL

* For these characteristics refer to the other columns in the table above for STD (i.e. non-Ex),

EXI or EXD switches – depending on which official approval has been selected.

** standard thread (fitting not supplied). Optional: M25 x 1.5 or NPT ¾.

*** Refer to table in “ATEX applications: special conditions for safe use”, section 7.1

**** The value is not defined, however the power supply must be intrinsically-safe

***** U

= 380 V CA, I

max

30 VA 0.5 A

0.5 A, 230 V AC

–20°C … 120°C

–4°F … 250°F

-20°C … +80°C

-4°F … 175°F (T6) or

-20°C … +95°C

-4°F … 200°F (T5)

< 250°C / < 480°F < 250°C / < 480°F

IP 65 IP 65

NEMA 4/4X NEMA 4/4X

PG 9 PG 9

- Ui= ****

Ii = 100 mA

Ci= 0 nF, Li= 0 µH

polycarbonate polycarbonate

0

0

85 g / 0.2 lb 85 g / 0.2 lb

20 VA 1.5 A According to

1.5 A, 250 V AC

20 VA

1.5 A

NAMUR 19234

250 V CA*****

Max. 100 VA

Min. 3VA

1.5 A

-

Min. 3 VA

1.5 A

250 V CA*****

*

250 VA

–20°C … 120°C *** *** *

–4°F … 250°F

< 250°C

*** *** *

< 480°F

< 300°C

*** *** *

< 570°F

IP 65 IP 65 IP 65 *

NEMA 4/4X NEMA 4/4X NEMA 4/4X

PG 13.5

M 20 x 1.5**

- Ui=****

Polycarbonate

Aluminium

0 0 0

130 g / 0.3 lb

1200 g / 2.6 lb

= 1,5 A, P

max

max

PG 13.5

M 20 x 1.5**

M 20 x 1.5**

***** *. For Exi :

Ii =500 mA

Ci=0nF,Li= 0µH

Polycarbonate

Aluminium

Aluminium

130 g / 0.3 lb

1200 g / 2.6 lb - 1200 g / 2.6 lb

= 20 VA

*

Ui=24V, Ii = ****,

Ci=0nF, Li= 0µF

*

*

*

Installation and Operating Instructions BM 26 A 41

Page 42

7.4 Guide tube assembly materials

Version Flange Gaskets Measuring tube

Material Diameter

mm inches

BM 26A 316Ti (1.4571)

316L (1.4404)

7.4.1 Maximum operating conditions for BM 26 A with 316 Ti steel measuring tube

according to European Union Pressure Equipment Directive 97/23/EC

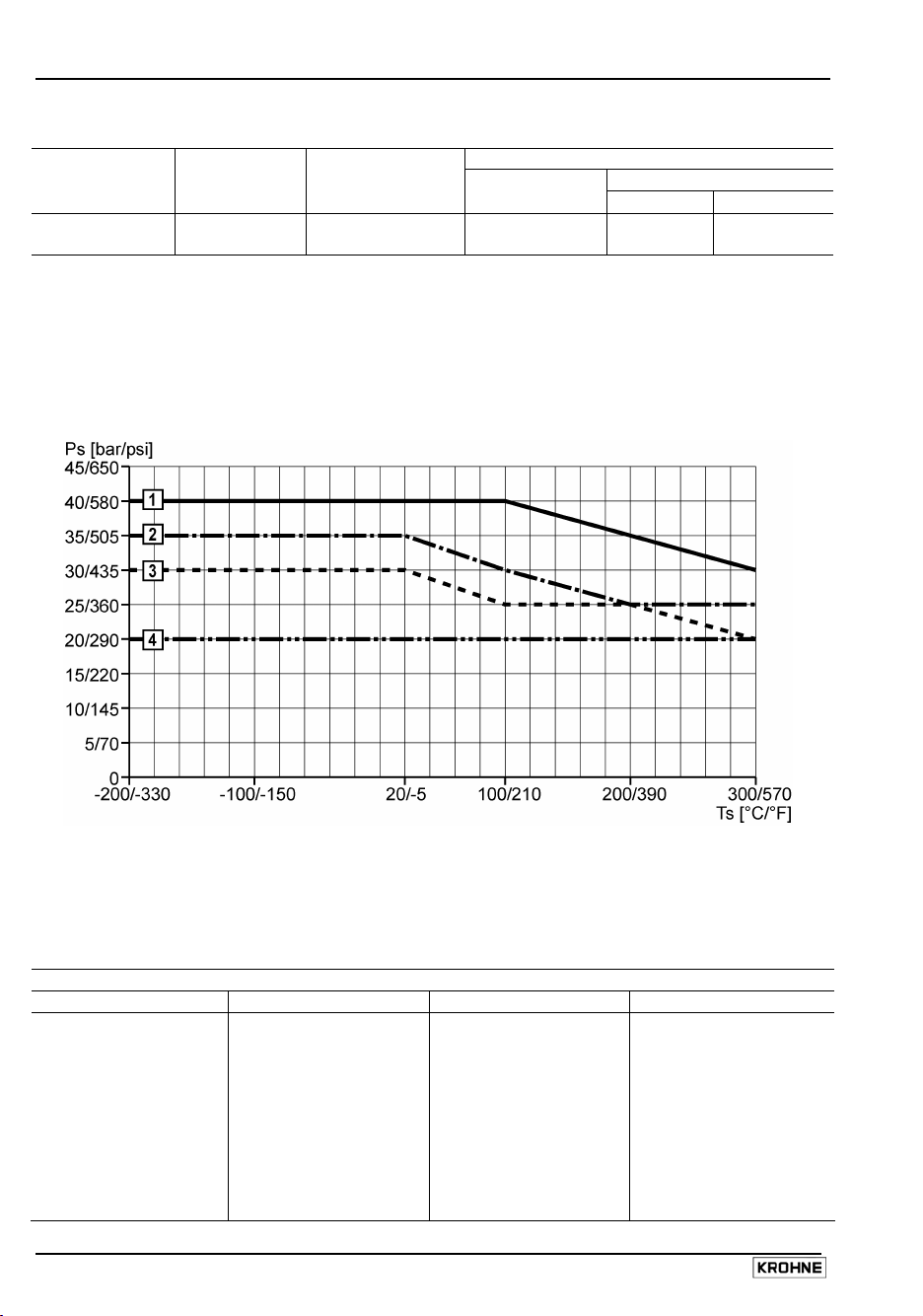

The graph below shows the maximum allowable process pressure, Ps, for a given process

temperature, Ts, in a 316Ti measuring chamber of a given nominal diameter (the flanges being

grouped into 4 categories).

aramide

(PTFE optional)

316Ti (1.4571)

316L (1.4404)

72 x 2.3 2.83 x 0.091

Higher operating pressures may be approved by KROHNE following analysis of customer

specifications. Maximum product temperature is dependant on the application and is defined by the

customer in the product order options list.

7.4.2 Flange categories for operating conditions in a 316Ti steel measuring tube

Flange Categories

1 2 3 4

DN15 PN40 DN50 PN40 DN40 PN40 ½ " ASME 150LB

DN20 PN40 DN50 PN40 WN DN40 PN40 WN ¾ " ASME 150LB

DN25 PN40 2" ASME 300LB 1" ASME 150LB

DN15 PN40 WN 1"½ ASME 150LB

DN20 PN40 WN 2" ASME 150LB

DN25 PN40 WN

½ " ASME 300LB

¾ " ASME 300LB

1" ASME 300LB

1"½ ASME 300LB

42 Installation and Operating Instructions BM 26 A

Page 43

7.4.3 Maximum operating conditions for BM 26 A with 316 L steel measuring tube

according to European Union Pressure Equipment Directive 97/23/EC

The graph below shows the maximum allowable process pressure, Ps, for a given process

temperature, Ts, in a 316L measuring chamber of a given nominal diameter (the flanges being

grouped into 4 categories)

Higher operating pressures may be approved by KROHNE following analysis of customer

specifications. Maximum product temperature is dependant on the application and is defined by the

customer in the product order options list.

7.4.4 Flange categories for operating conditions in a 316L steel measuring tube

Flange Categories

1 2 3 4

DN15 PN40 DN25 PN40 DN40 PN40 ½ " ASME 150LB

DN20 PN40 DN25 PN40 WN DN40 PN40 WN ¾ " ASME 150LB

DN15 PN40 WN 1" ASME 300LB DN50 PN40 1" ASME 150LB

DN20 PN40 WN DN50 PN40 WN 1"½ ASME 150LB

½ " ASME 300LB 1"½ ASME 300LB 2" ASME 150LB

¾ " ASME 300LB 2" ASME 300LB

Installation and Operating Instructions BM 26 A 43

Page 44

7.5 BM 26 A weights and dimensions

7.5.1 Weights

For units with 1 m or 3.28 ft flange spacing. The weight for every additional 100 mm or 3.94’’

between flanges is given in brackets.

Version Weight in

kg lbs

BM 26 A/STD 14.5 (0.51) 31.96 (1.12)

BM 26 A/EXD 20.6 (0.82) 45.50 (1.81)

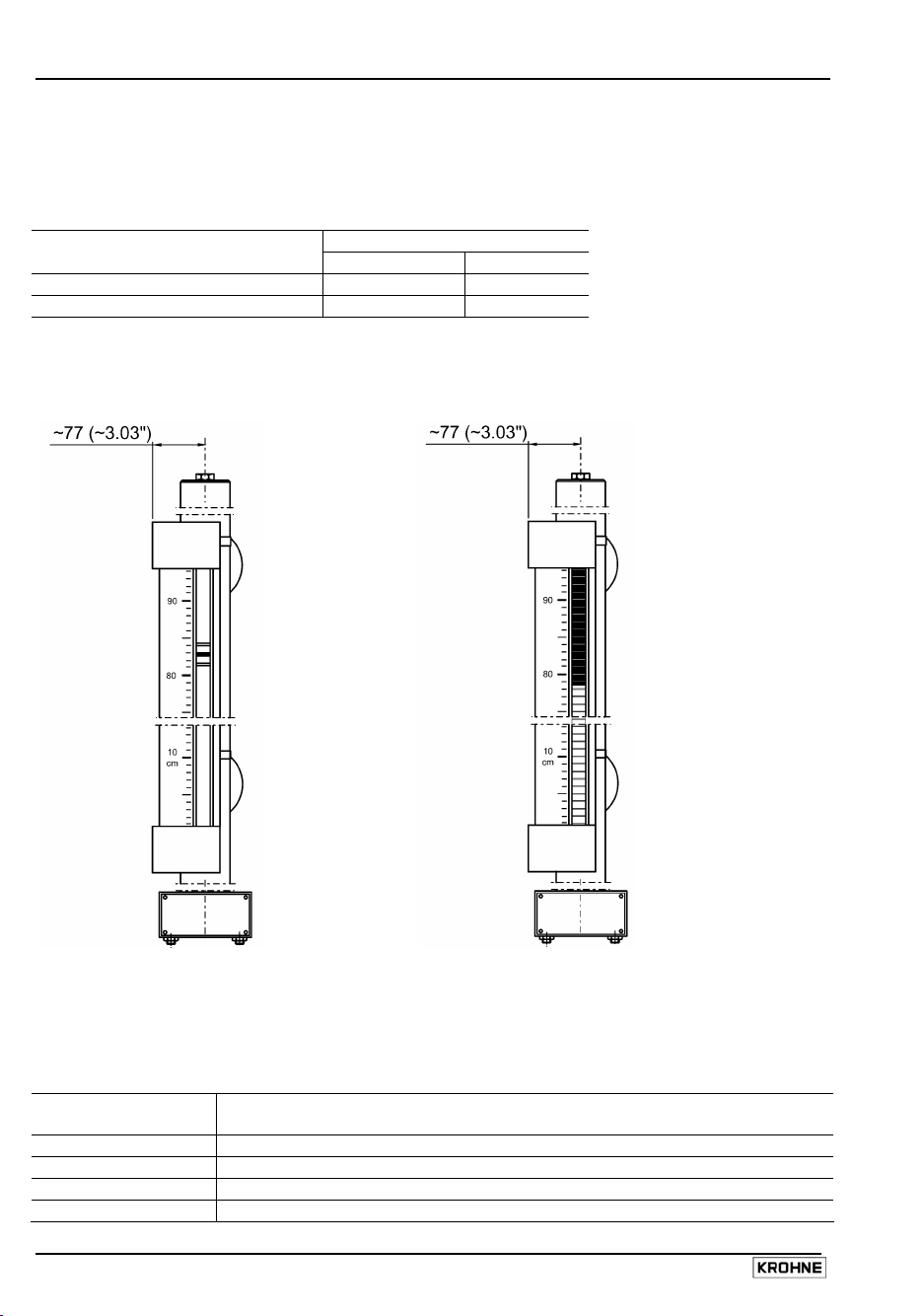

7.5.2 Indicator dimensions

BM 26 A with standard bar indicator BM 26 A with optional flap indicator

Dimensions in mm and (inches)

7.5.3 Overall dimensions of measuring tube classes (with loose or welding neck flanges)

The BM 26 A is divided into four different classes that define the positions of the process

connections.

BM 26 A measuring

tube class

BM 26 A/C Equipped with two lateral connections

BM 26 A/D Equipped with two axial connections

BM 26 A/E Equipped with one lateral entry and one bottom axial exit connection

BM 26 A/F Equipped with one lateral entry and one top axial exit connection

44 Installation and Operating Instructions BM 26 A

Description

Page 45

BM 26 A/C/RR BM 26 A/C/RR

Welding neck flange Loose (EN-DIN) flange

BM 26 A/C/B BM 26 A/C/AG BM 26 A/C/IC/TR or /HR

(heater sub-type C) (anti-freeze sub-type C) TR low, HR high temp.

Loose (EN-DIN) flange Welding neck flange Loose (EN-DIN) flange

(lagged)

The dimensions are given in mm (inches).

Installation and Operating Instructions BM 26 A 45

Page 46

BM 26 A/D/RR BM 26 A/D/RR

Welding neck flange Loose (EN-DIN) flange

BM 26 A/E/RR BM 26 A/E/RR

Welding neck flange Loose (EN-DIN) flange

The dimensions are given in mm (inches).

46 Installation and Operating Instructions BM 26 A

Page 47

BM 26 A/F/RR BM 26 A/F/RR

Welding neck flange Loose (EN-DIN) flange

The dimensions are given in mm (inches).

7.5.4 Distance of welding neck flange raised facing from measuring tube axis

Refer to the diagrams in section 7.5.3

Flange, process connection ratings BM 26 A tube axis to

DN 15 PN 40, welding neck flange 79.5 / 3.13“

DN 20 PN 40, welding neck flange 81.5 / 3.21“

DN 25 PN 40, welding neck flange 81.5 / 3.21“

DN 40 PN 40, welding neck flange 86.5 / 3.41“

DN 50 PN 40, welding neck flange 89.5 / 3.52“

½” ASME 150LB, welding neck flange 89.5 / 3.52“

1” ASME 150LB, welding neck flange 97.5 / 3.84“

1”½ ASME 150LB, welding neck flange 103.5 / 4.07“

2” ASME 150LB, welding neck flange 104.5 / 4.11“

¾” ASME 150LB, welding neck flange 93.5 / 3.68“

½” ASME 300LB, welding neck flange 93.5 / 3.68“

¾” ASME 300LB, welding neck flange 98.5 / 3.88“

1” ASME 300LB, welding neck flange 103.5 / 4.07“

1”½ ASME 300LB, welding neck flange 109.5 / 4.31“

2” ASME 300LB, welding neck flange 111.5 / 4.39“

* Dimensions in X mm / X inches

flange raised facing*

Installation and Operating Instructions BM 26 A 47

Page 48

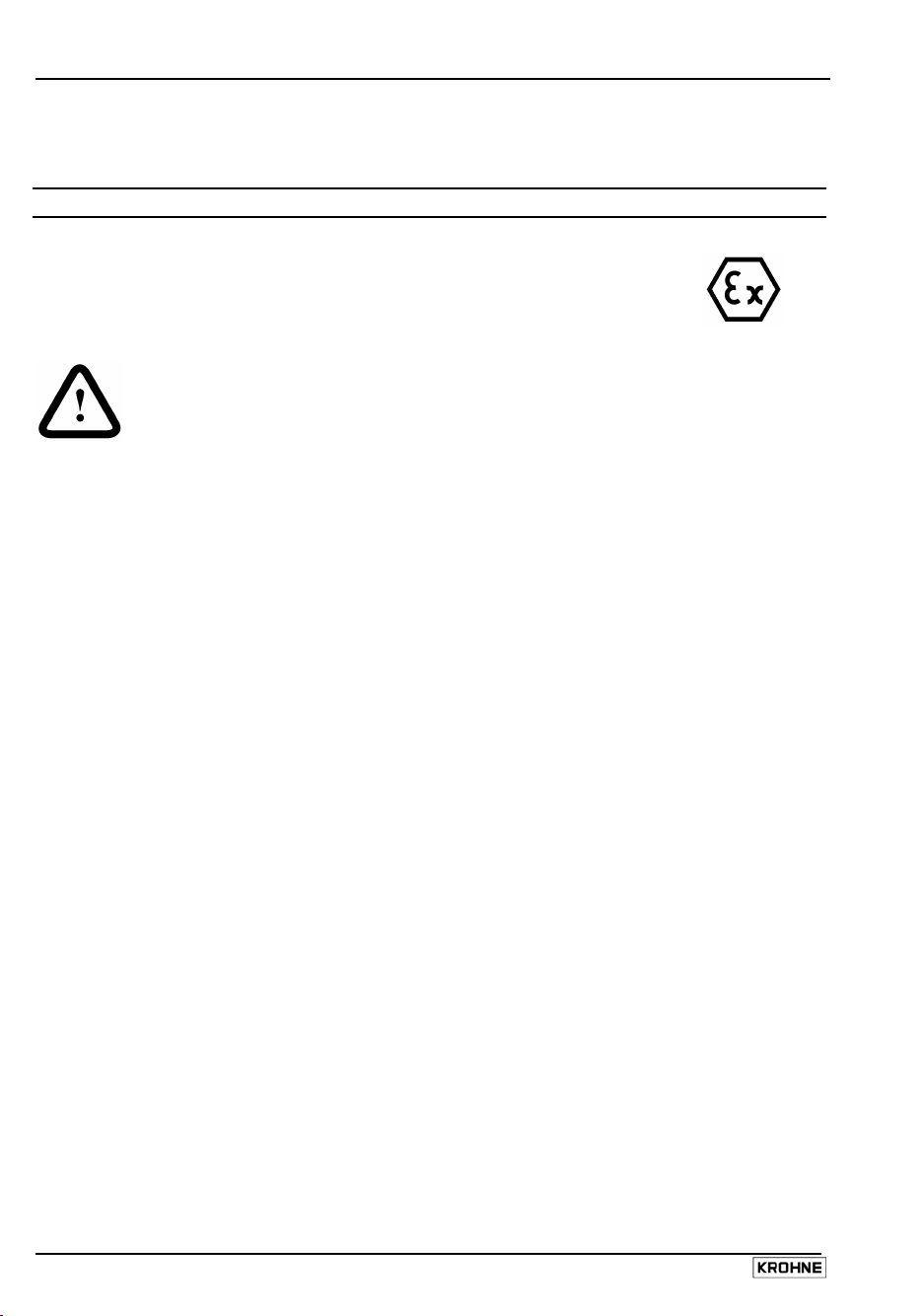

8 Measuring principle

The instrument operates on the principle of communicating tubes. The measuring tube is connected

as adjacent to the tank (i.e. a bypass chamber) such that the same conditions are obtained in the

tube as those in the tank.

The float is equipped with a number of permanent magnets to transmit measured values to the local

indicator. Two methods of local indication are used:

Standard bar indicator

The indicator tube contains a magnetised indicator bar that follows changes in floater position.

1 Indicator tube

2 Bar (float-following indicator)

3 Measuring scale

4 Magnets set inside the float

5 Measuring tube

Optional flap indicator

The magnet mounted in the float activates (rotates) the magnetic flaps according to the liquid level in

the indicating section of the indicator. The column of reversed yellow magnetic flaps, or the vertical

position of the follower magnet, is the indication of the liquid level. Additionally, the liquid level can

be read off from a large-size scale in various units of length or graduations showing percentages or

volumes.

Remote indication is possible by choosing the level transducer and level switch options. Information

on their working principles and characteristics are given in sections 2 and 3 respectively.

1 Black front face of flap indicator

2 Flap rotates as magnet in float

moves past this point

3 Yellow reverse face of flap

indicator

4 Flap indicator tube

5 Magnets set inside the float

6 Measuring tube

7 Measuring scale

48 Installation and Operating Instructions BM 26 A

Page 49

Appendices

Appendix A: Declaration of conformity: CE

Installation and Operating Instructions BM 26 A 49

Page 50

Appendix B: Declaration of conformity: Pressure Equipment Directive 97/23/EC

50 Installation and Operating Instructions BM 26 A

Page 51

Appendix C: EC-Type Examination Certificate INERIS 02ATEX0088X

Installation and Operating Instructions BM 26 A 51

Page 52

52 Installation and Operating Instructions BM 26 A

Page 53

Installation and Operating Instructions BM 26 A 53

Page 54

54 Installation and Operating Instructions BM 26 A

Page 55

Installation and Operating Instructions BM 26 A 55

Page 56

56 Installation and Operating Instructions BM 26 A

Page 57

Installation and Operating Instructions BM 26 A 57

Page 58

58 Installation and Operating Instructions BM 26 A

Page 59

Installation and Operating Instructions BM 26 A 59

Page 60

60 Installation and Operating Instructions BM 26 A

Page 61

Installation and Operating Instructions BM 26 A 61

Page 62

62 Installation and Operating Instructions BM 26 A

Page 63

Installation and Operating Instructions BM 26 A 63

Page 64

64 Installation and Operating Instructions BM 26 A

Page 65

Installation and Operating Instructions BM 26 A 65

Page 66

66 Installation and Operating Instructions BM 26 A

Page 67

Installation and Operating Instructions BM 26 A 67

Page 68

68 Installation and Operating Instructions BM 26 A

Page 69

Installation and Operating Instructions BM 26 A 69

Page 70

Notes

70 Installation and Operating Instructions BM 26 A

Page 71

If you need to return level gauges for testing or repair to KROHNE

If installed and operated in accordance with these operating instructions, your level gauges will

rarely present any problems.

Should you nevertheless need to return a BM 26 A unit for checkout or repair, please pay strict

attention to the following points:

Due to statutory regulations concerning protection of the environment and the health and safety of

our personnel, KROHNE may only handle, test and repair returned level gauges that have been in

contact with liquids if it is possible to do so without risk to personnel and environment. This means

that KROHNE can only service your unit if it is accompanied by a certificate in line with the following

model confirming that the level gauge is safe to handle.

If the unit has been operated with toxic, caustic, flammable or water-endangering liquids, you are

kindly requested

• to check and ensure, if necessary by rinsing or neutralizing, that all cavities are free from such

dangerous substances.

(Directions on how you can find out whether the unit has to be opened and then flushed out or

neutralized are obtainable from KROHNE on request.)

• to enclose a certificate with the level gauge confirming that it is safe to handle and stating the

liquid used.

KROHNE regret that they cannot service your level gauge unless accompanied by such a certificate.

Specimen certificate

Company: Address:

Department: Name:

Tel. No.:

The enclosed liquid level gauge

Type:

KROHNE Order No. or Series No.:

has been operated with the following liquid:

Because this liquid is

water-endangering

toxic

caustic

flammable

we have

checked that all cavities in the unit are free from such substances

flushed out and neutralized all cavities in the unit

We confirm that there is no risk to man or environment through any residual liquid contained in this

level gauge.

Date: Signature:

Company stamp:

Installation and Operating Instructions BM 26 A 71

Loading...

Loading...