Page 1

Handbook

Handbook

BM 26 BASIC/ADVANCED

BM 26 BASIC/ADVANCED

BM 26 BASIC/ADVANCEDBM 26 BASIC/ADVANCED

Stainless Steel Bypass Level Indicators for applications

up to 40 bar / 580 psi

HandbookHandbook

© KROHNE 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 2

6

: IMPRINT :::::::::::::::::::::::::::::::::::::::

BM 2

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2012 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 3

BM 26 BASIC/ADVANCED

CONTENTS

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 Certification ...................................................................................................................... 5

1.3 Safety instructions from the manufacturer ..................................................................... 6

1.3.1 Disclaimer ............................................................................................................................... 6

1.3.2 Product liability and warranty ................................................................................................ 7

1.3.3 Information concerning the documentation........................................................................... 7

1.3.4 Warnings and symbols used................................................................................................... 8

1.4 Safety instructions for the operator................................................................................. 8

2 Device description 9

2.1 Scope of delivery............................................................................................................... 9

2.2 Device description .......................................................................................................... 10

2.3 Nameplates .................................................................................................................... 11

2.3.1 Visual Check.......................................................................................................................... 11

2.3.2 Nameplates........................................................................................................................... 11

2.3.3 Other device data .................................................................................................................. 14

3 Installation 15

3.1 Storage ........................................................................................................................... 15

3.2 Transportation ................................................................................................................ 16

3.3 Remove all packing before installation ......................................................................... 16

3.4 General requirements .................................................................................................... 18

3.4.1 Pressure and temperature ranges....................................................................................... 18

3.4.2 How to attach the bypass level indicator to the tank ........................................................... 19

3.5 Level indicator column................................................................................................... 21

3.6 Optional analog transmitter ........................................................................................... 22

3.7 Optional limit switch....................................................................................................... 23

3.8 Electromagnetic compatibility ....................................................................................... 26

4 Electrical connections 27

4.1 Optional analog transmitter ........................................................................................... 27

4.2 Optional limit switches ................................................................................................... 29

4.3 Protection category ........................................................................................................30

5 Start-up 31

5.1 Start-up checklist........................................................................................................... 31

5.2 Operating concept ..........................................................................................................31

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

3

Page 4

CONTENTS

BM 26 BASIC/ADVANCED

6 Operation 32

6.1 Local display options ......................................................................................................32

6.1.1 Level indicator column ......................................................................................................... 32

6.1.2 Analog transmitter (option) .................................................................................................. 33

6.2 Errors.............................................................................................................................. 37

6.2.1 Error indication ..................................................................................................................... 37

6.2.2 Error handling....................................................................................................................... 38

7 Service 41

7.1 Periodic maintenance..................................................................................................... 41

7.2 Keep the device clean..................................................................................................... 41

7.3 How to replace device components ............................................................................... 41

7.3.1 Service warranty ................................................................................................................... 41

7.4 Availability of services .................................................................................................... 42

7.4.1 General notes........................................................................................................................ 42

7.4.2 List of spare parts................................................................................................................. 42

7.4.3 List of accessories ................................................................................................................ 43

7.5 Availability of services .................................................................................................... 43

7.6 Returning the device to the manufacturer..................................................................... 44

7.6.1 General information.............................................................................................................. 44

7.6.2 Form (for copying) to accompany a returned device............................................................ 45

7.7 Disposal .......................................................................................................................... 45

8 Technical data 46

8.1 Measuring principle........................................................................................................46

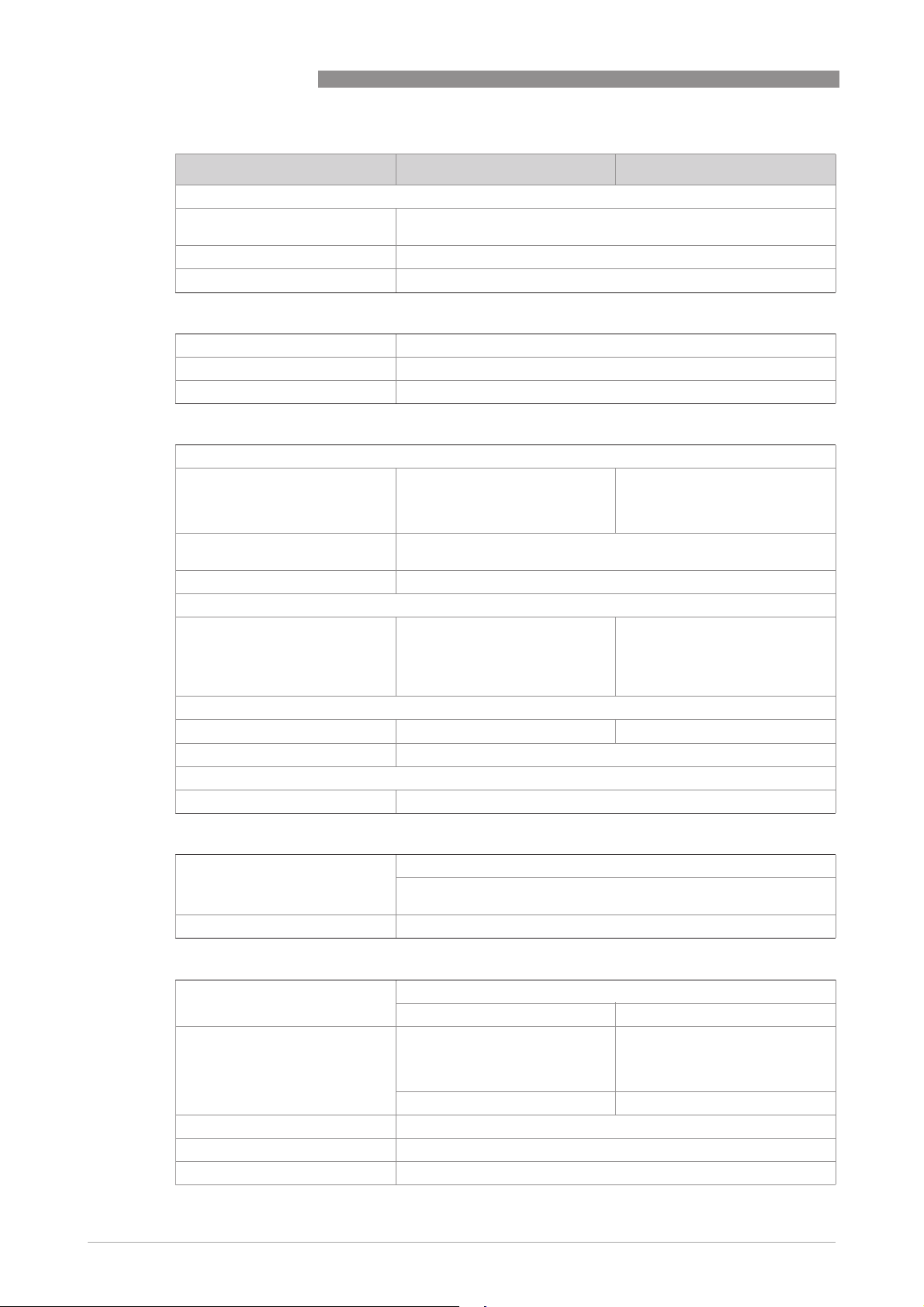

8.2 Technical data: general information .............................................................................. 47

8.3 Technical data: optional analog transmitter.................................................................. 51

8.4 Technical data: optional limit switches.......................................................................... 56

8.5 Basic version: Dimensions and weights ........................................................................ 58

8.6 Advanced version: Dimensions and weights.................................................................. 66

8.7 Analog transmitter: Dimensions and weight ................................................................. 74

8.8 Support bracket option: Dimensions and weight........................................................... 75

8.9 Guidelines for maximum operating pressure................................................................ 76

8.10 Floats ............................................................................................................................ 78

9 Appendix 79

9.1 Liquid level offset: description....................................................................................... 79

9.2 Liquid level offset: correction data ................................................................................ 80

9.3 Glossary .......................................................................................................................... 83

9.4 Order code ...................................................................................................................... 84

9.5 Spare parts code ............................................................................................................ 92

10 Notes 94

4

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 5

BM 26 BASIC/ADVANCED

1.1 Intended use

This magnetic level indicator measures the level or volume of liquids.

It is installed next to open or pressurized tanks. With the applicable options, it is resistant to

difficult service conditions and liquids that are poisonous, flammable, or that cause corrosion.

CAUTION!

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

1.2 Certification

SAFETY INSTRUCTIONS 1

In accordance with KROHNE’s commitment to customer service and safety, the level indicators

described in this handbook meet the following safety requirements:

• EMC Directive 2004/108/EC in conjunction with EN 61326-1: 2006

• Low Voltage Directive 2006/95/EC in conjunction with EN 61010-1: 2001

• Pressure Equipment Directive 97/23/EC in conjunction with CODAP® 2010

INFORMATION!

The optimized design of the Basic version is not subject to PED test requirements (CE marking is

not applicable). The Advanced version agrees with the requirements for CE marking.

The Low Voltage Directive is only applicable to limit switches (non-NAMUR option).

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

5

Page 6

1 SAFETY INSTRUCTIONS

1.3 Safety instructions from the manufacturer

1.3.1 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

BM 26 BASIC/ADVANCED

6

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 7

BM 26 BASIC/ADVANCED

1.3.2 Product liability and warranty

Bypass level indicators from KROHNE are designed solely for measuring the level and

volume of liquids.

Responsibility as to suitability and intended use of these level indicators rests solely with the

operator. The supplier does not accept any liability resulting from misuse by the operator.

Improper installation and operation of the level transmitters may lead to loss of warranty. In

addition, the “General conditions of sale“ which forms the basis of the purchase agreement are

applicable.

1.3.3 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

SAFETY INSTRUCTIONS 1

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

7

Page 8

1 SAFETY INSTRUCTIONS

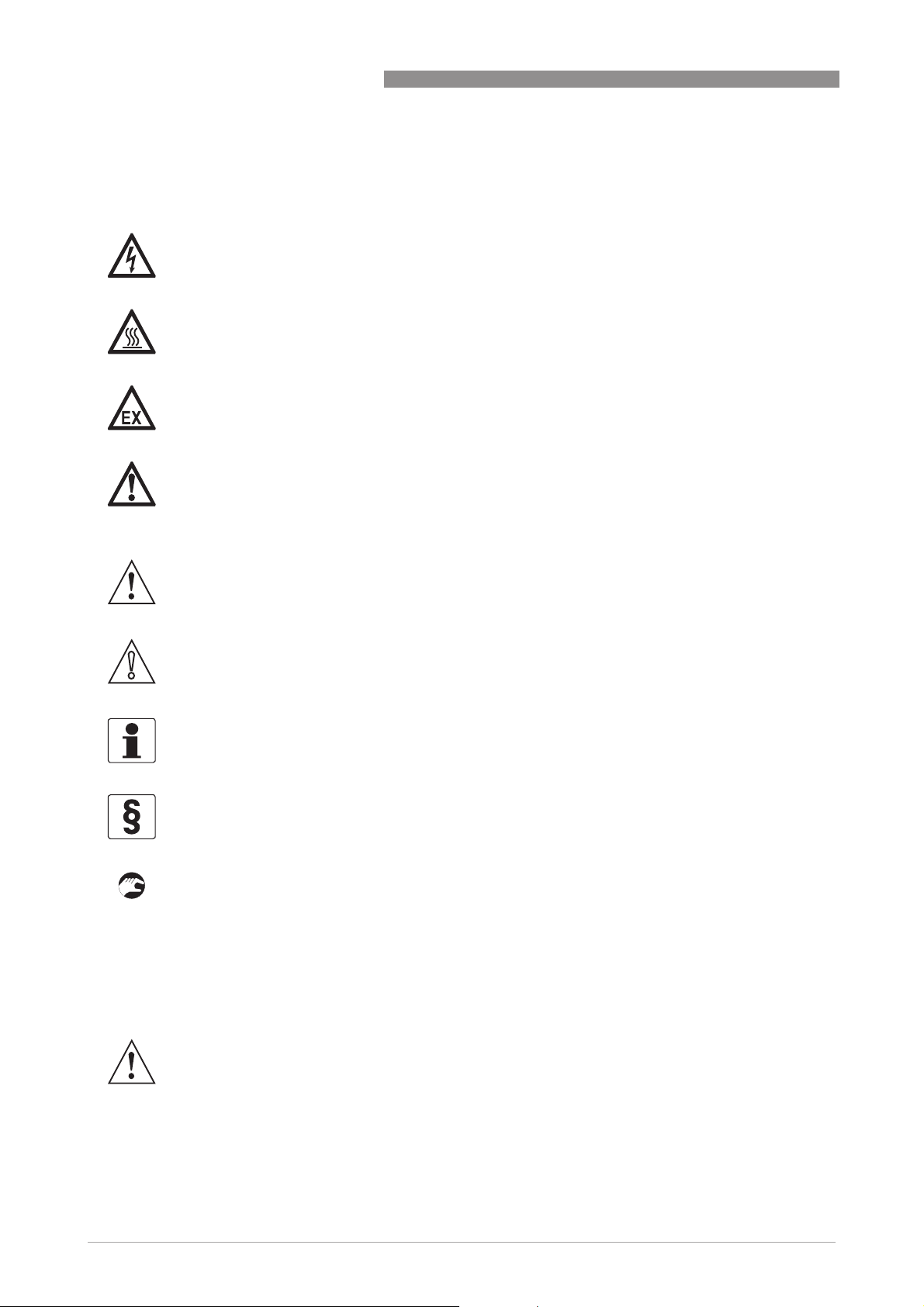

1.3.4 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

BM 26 BASIC/ADVANCED

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.4 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

8

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 9

BM 26 BASIC/ADVANCED

2.1 Scope of delivery

INFORMATION!

Check the packing list to see if you have received all that you require.

The device will be delivered in one box.

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

DEVICE DESCRIPTION 2

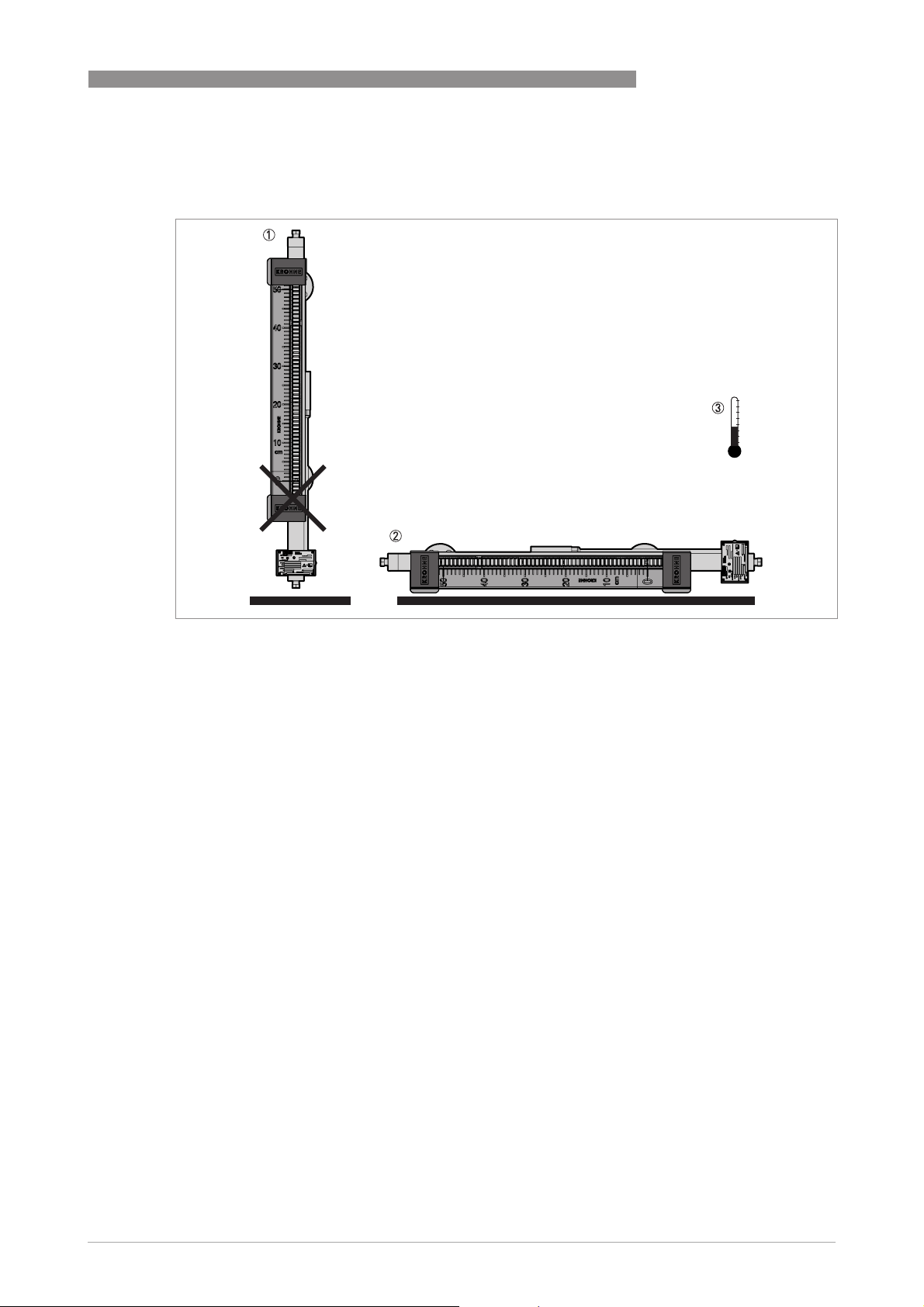

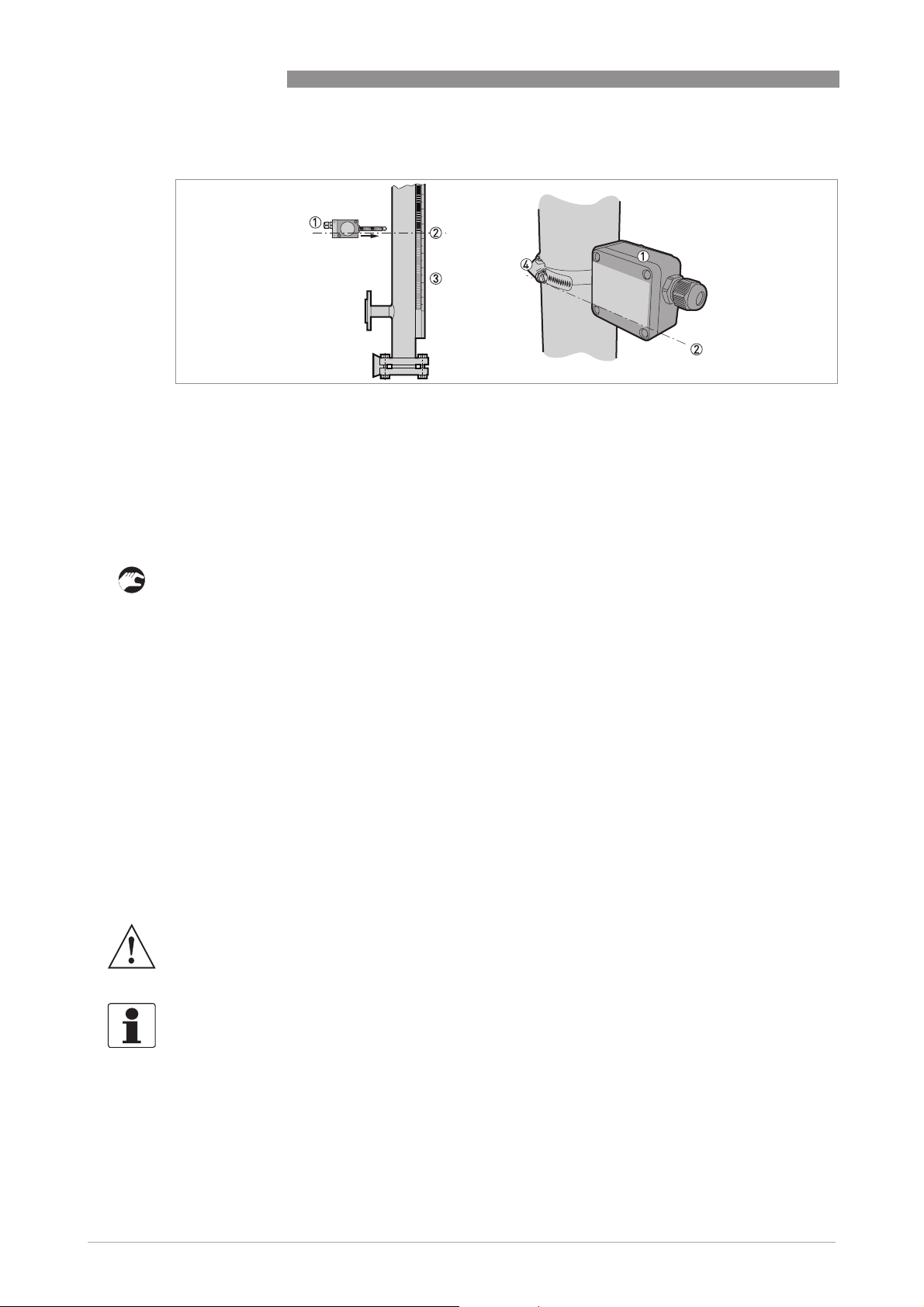

Figure 2-1: Scope of delivery

1 Measuring chamber with the indicator column and optional indicator scale

2 Optional analog transmitter

3 Optional limit switches (not attached to the device)

4 Magnet (to set the indicator column to zero after installation)

5 Quick Start and Handbook

INFORMATION!

No special tools, no training required!

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

9

Page 10

2 DEVICE DESCRIPTION

2.2 Device description

Magnetic level indicators have a measuring chamber that contains a magnetic float. It is

attached vertically to the side of open or pressurized tanks. A level indicator is attached adjacent

to the measuring chamber. As the float moves up and down, it rotates a column of flaps inside

the glass tube of the indicator. If an analog level transmitter is also attached adjacent to the

measuring chamber, it is possible to have an output current that can be monitored from a

remote station. Optional bistable switches let the user monitor important measurement limits.

BM 26 BASIC/ADVANCED

The measuring chamber of the Basic

232 psig (depending on the length of the chamber). It is unnecessary to test the measuring

chamber according to PED 97/23/EC as it does not have to comply with CE marking

requirements. It is also ideal for measuring liquids with a density ≥0.8 kg/l / ≥49.9 lb/ft³ and

temperatures up to 150°C/ 300°F.

The Advanced

Advanced version is ideal for measuring liquids with density range of 0.58...2.0 kg/l /

AdvancedAdvanced

36.2...124.8 lb/ft³, temperatures up to 300°C/ 570°F or pressures up to 40 barg / 580 psig.

Basic version has a maximum operating pressure of 16 barg /

BasicBasic

WARNING!

Pressure Equipment Directive 97/23/EC data

•

This device is designed to function at near constant pressure conditions. It is not designed for

operating conditions where vibration or fatigue stress is present.

•

Events that are not taken into account in the calculations include exceptional risks such as:

earthquakes, bad weather, fire etc.

•

The standard design calculation does not take into account the theoretical coefficient of

corrosion. The product circulating in the device must not have properties that give rise to

surface erosion.

•

Our conformity declaration is limited to the parts of the device that are pressurized. It does

not include parts that can be dismantled (valves, ...).

You can also order these accessories:

• Limit switches

10

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 11

BM 26 BASIC/ADVANCED

2.3 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

2.3.1 Visual Check

DEVICE DESCRIPTION 2

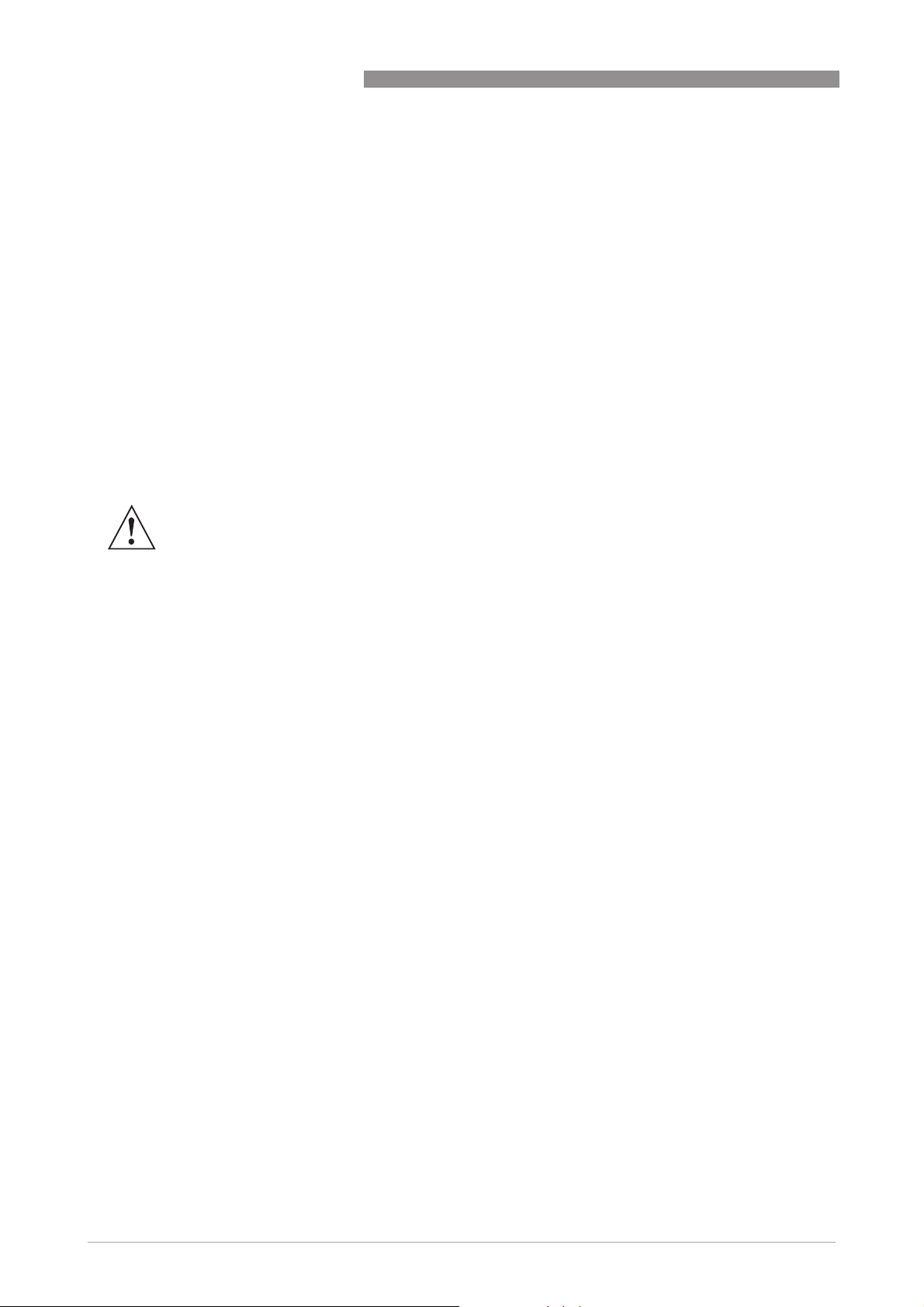

Figure 2-2: Visual check

• Check the delivery for damage.

• Are all the wetted components (chamber, flanges and gaskets) resistant to the product in the

tank?

• Compare the data on the nameplate with your order data.

2.3.2 Nameplates

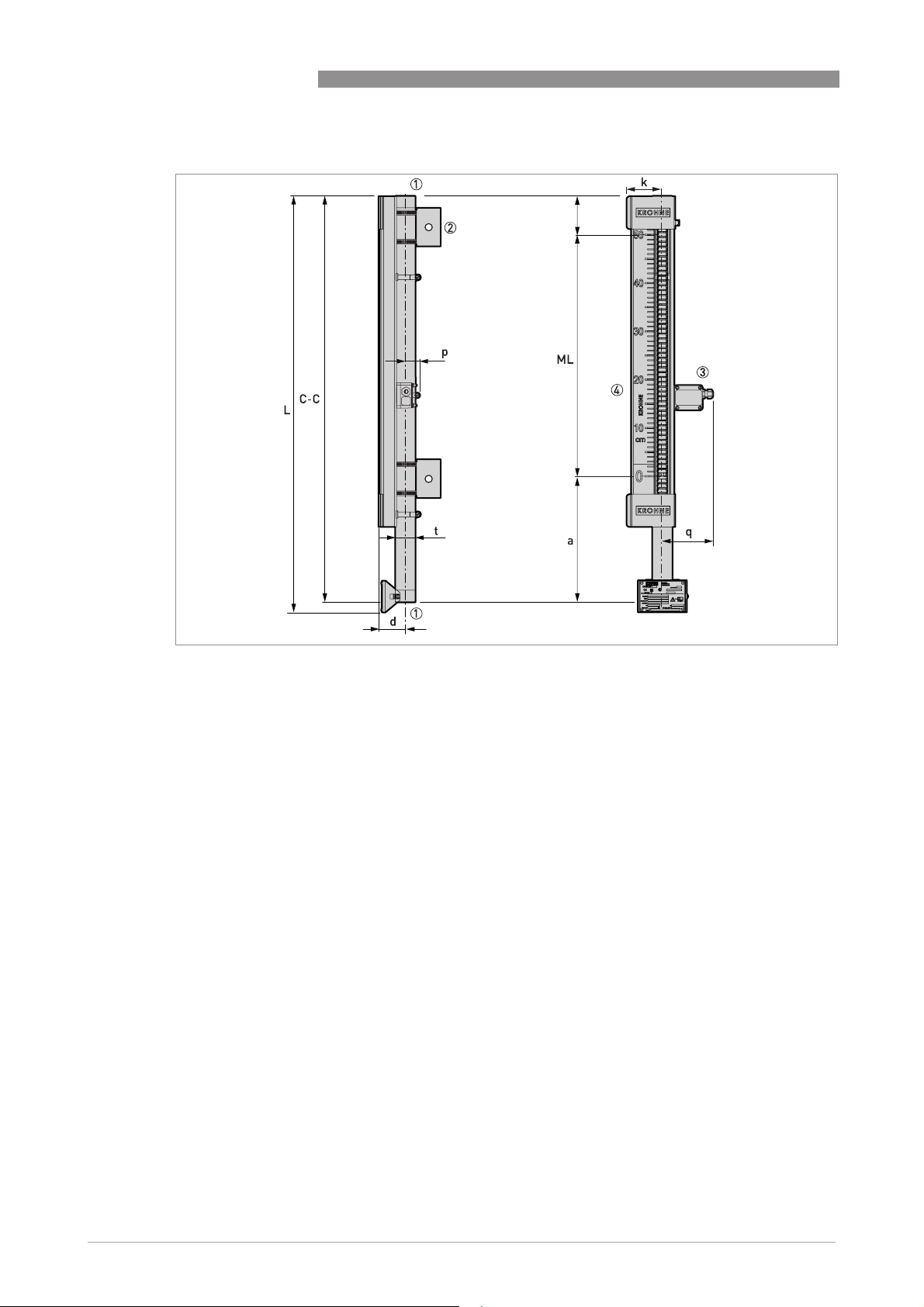

Figure 2-3: Location of device nameplates

1 Measuring chamber nameplate

2 Analog transmitter nameplate

3 Limit switch nameplate (housing cover)

4 Limit switch nameplate (housing)

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

11

Page 12

2 DEVICE DESCRIPTION

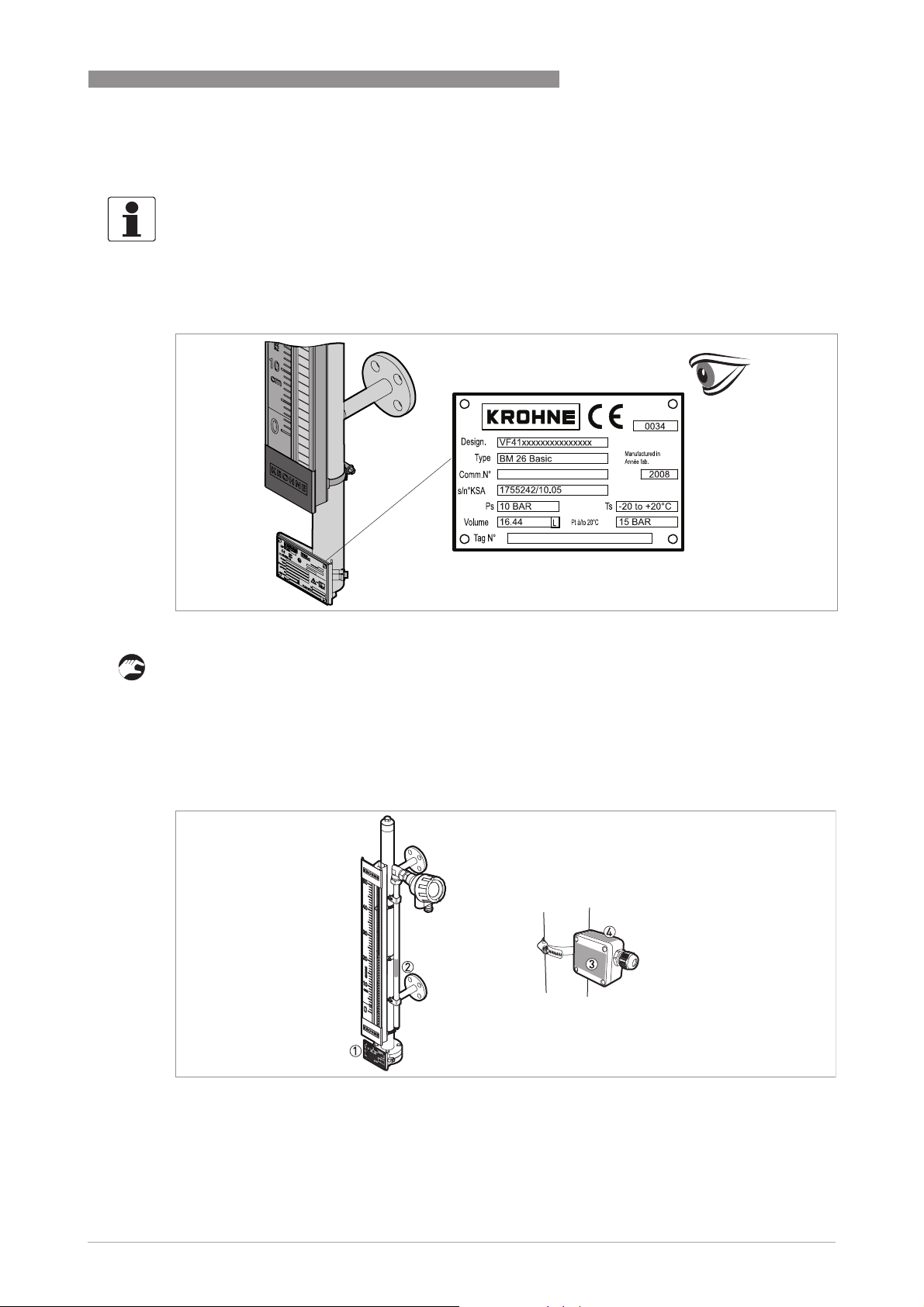

Figure 2-4: Basic version: Non-Ex nameplate

BM 26 BASIC/ADVANCED

L

Figure 2-5: Advanced version: Non-Ex nameplate

1 Customer tag number

2 Measuring tube volume in litres

3 Maximum allowable pressure (P

4 Factory serial number

5 Purchase order number

6 Model name and number

7 Designation code (VF code given in the order)

8 Year of manufacture

9 Maximum allowable temperature (T

10 Test pressure (P

ment Directive 97/23/EC.

at 20°C) - if the device agrees with the requirements of Categories I, II or III of the Pressure Equip-

t

)

s

)

s

L

12

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 13

BM 26 BASIC/ADVANCED

Figure 2-6: Limit switch: Non-Ex nameplate (housing cover)

1 Non-NAMUR option

2 NAMUR option

3 Model

4 Designation code (VF code given in the order)

5 Date of manufacture

6 Factory serial number and bar code

7 Electrical data

DEVICE DESCRIPTION 2

Figure 2-7: Limit switch: Non-Ex nameplate (housing)

1 Non-NAMUR option

2 NAMUR option

3 Electrical schema

4 Factory serial number

Figure 2-8: Analog transmitter: Non-Ex nameplate

1 Model

2 Designation code (VF code given in the order)

3 Date of manufacture

4 Factory serial number

5 Input voltage

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

13

Page 14

2 DEVICE DESCRIPTION

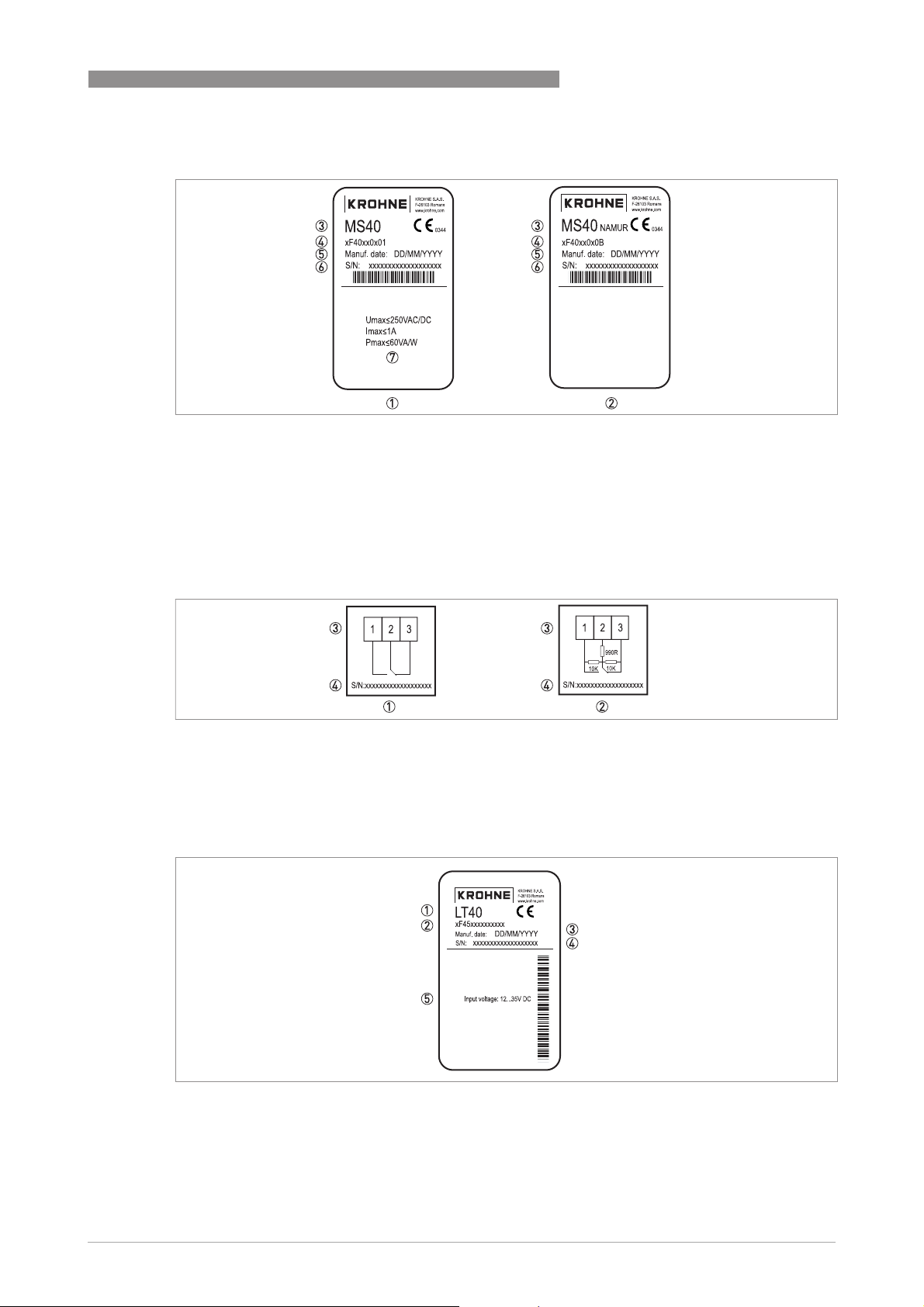

2.3.3 Other device data

The supplier's bottom logo plate has a sticker:

Figure 2-9: Other device data

1 Float data sticker

BM 26 BASIC/ADVANCED

Figure 2-10: Float data sticker

1 Test pressure, PT, in bar

2 Maximum allowable pressure, PS, in bar

3 Float drawing number

4 Float material

14

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 15

BM 26 BASIC/ADVANCED

3.1 Storage

INSTALLATION 3

Figure 3-1: Storage conditions

1 Do not keep the device in a vertical position before installation.

2 Put the device on its side.

3 Storage temperature range: -50…+80°C/ -58…+176°F

• Store the device in a dry and dust-free location.

• Store the device in its original packing.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

15

Page 16

3 INSTALLATION

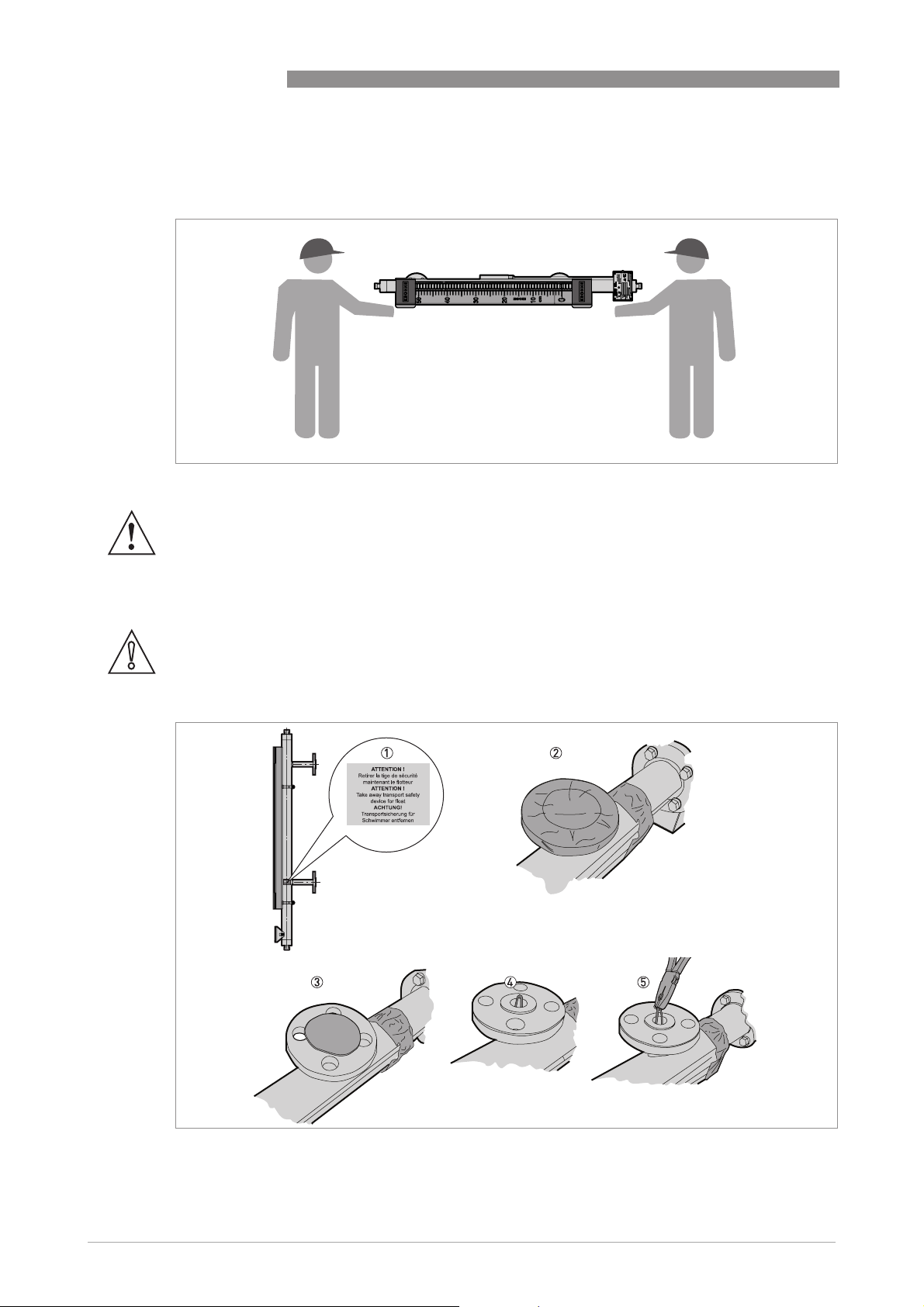

3.2 Transportation

Figure 3-2: Transportation

WARNING!

The indicator column is made of Pyrex

If you do not lift the device carefully, you can cause damage to the device.

®

glass.

BM 26 BASIC/ADVANCED

3.3 Remove all packing before installation

CAUTION!

Make sure that the measuring chamber does not contain unwanted objects (dirt etc.)

How to remove the float lock pin (devices with side process connections)

16

Figure 3-3: How to remove the float lock pin (devices with side process connections)

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 17

BM 26 BASIC/ADVANCED

How to remove the float lock pin (devices with side process connections)

1 Check the measuring chamber for a red sticker next to the bottom side process connection.

i Sticker text: ATTENTION! Take away transport safety device for float.

2 Remove the adhesive tape around the top and bottom process connections.

3 Remove the plastic protection from the top and bottom process connections.

4 Find the lock pin.

5 Remove the lock pin with a pair of pliers.

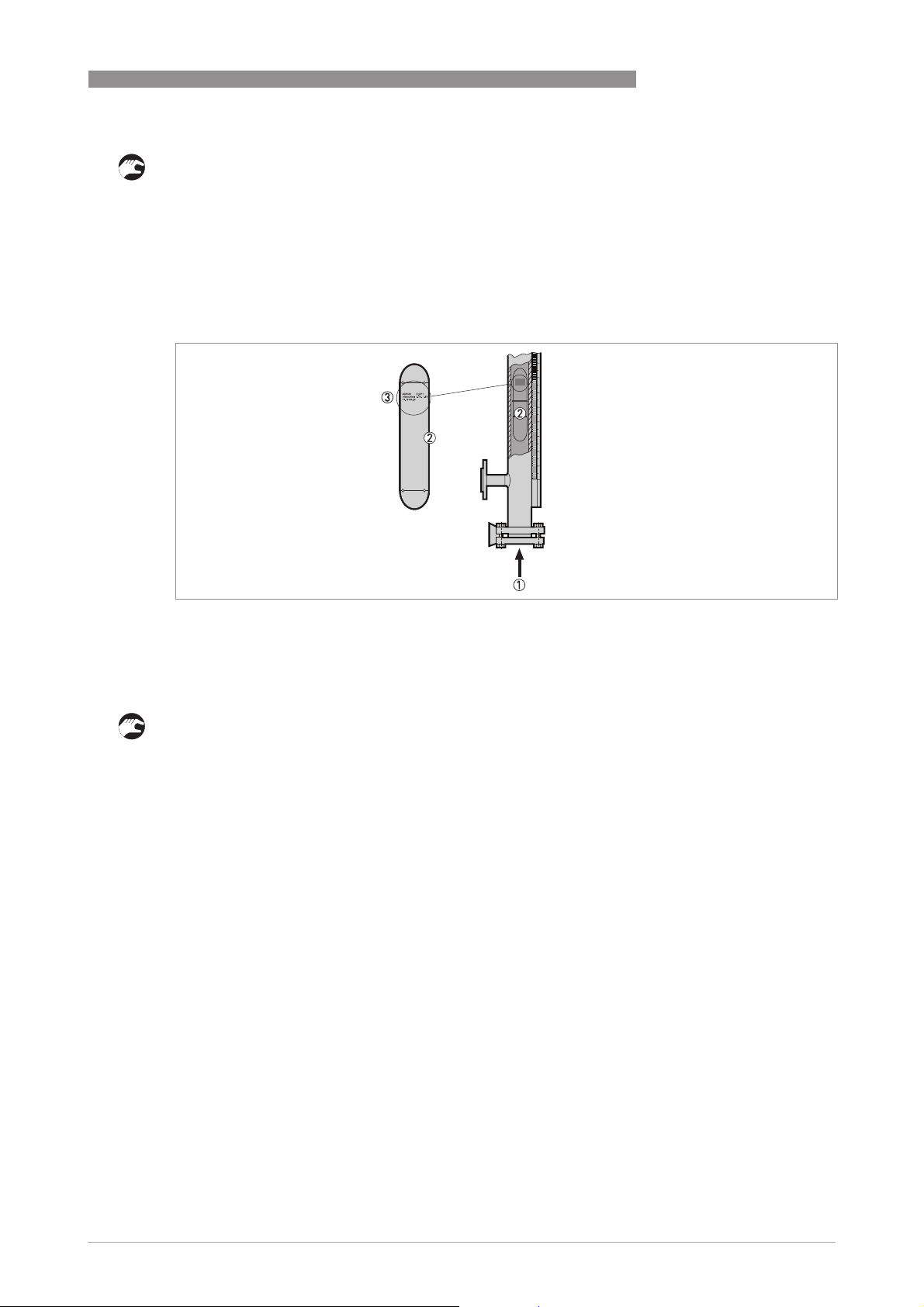

How to put the float in the measuring chamber

INSTALLATION 3

Figure 3-4: How to put the float in the measuring chamber (if it is delivered separately)

1 Put the float in here

2 Float

3 The float data (date of manufacture, P

the measuring chamber

, float material etc.) must be at the top of the float when you put the float in

s/Pt

How to put the float in the measuring chamber (if it is delivered separately)

• Remove the bottom blind flange or plug (if the basic version has the 1¼¨ drain option).

• Put the top of the float (the float data is on the top part of the float) in the measuring chamber

first.

• Align the gaskets.

• Tighten the nuts on the blind flange to the correct torque (11 Nm in operating conditions,

23.5 Nm in test conditions). The 1¼¨ plug must be tightened in agreement with good

engineering practice.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

17

Page 18

3 INSTALLATION

3.4 General requirements

3.4.1 Pressure and temperature ranges

BM 26 BASIC/ADVANCED

1 Process temperature

Basic version: -40…+150°C/ -40…300°F

Advanced version: -40...+300°C/ -40…570°F

Ex devices: refer to supplementary instructions

2 Maximum process pressure

Basic version: 16 barg / 232 psig (depends on the length of the measuring chamber. For more data, refer to

for maximum operating pressure

Advanced version: 40 barg / 580 psig (according to the flange pressure rating. For more data, refer to

maximum operating pressure

3 Ambient temperature

Non-Ex devices: -40…+80°C/ -40…+176°F

Ex devices: refer to supplementary instructions

on page 76).

on page 76).

Guidelines

Guidelines for

WARNING!

Refer to the operating conditions data on the device nameplate. The data is applicable to that

device.

WARNING!

PED 97/23/EC requirement:

PED 97/23/EC requirement: External pressure must be equal to atmospheric pressure.

PED 97/23/EC requirement:PED 97/23/EC requirement:

18

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 19

BM 26 BASIC/ADVANCED

3.4.2 How to attach the bypass level indicator to the tank

INSTALLATION 3

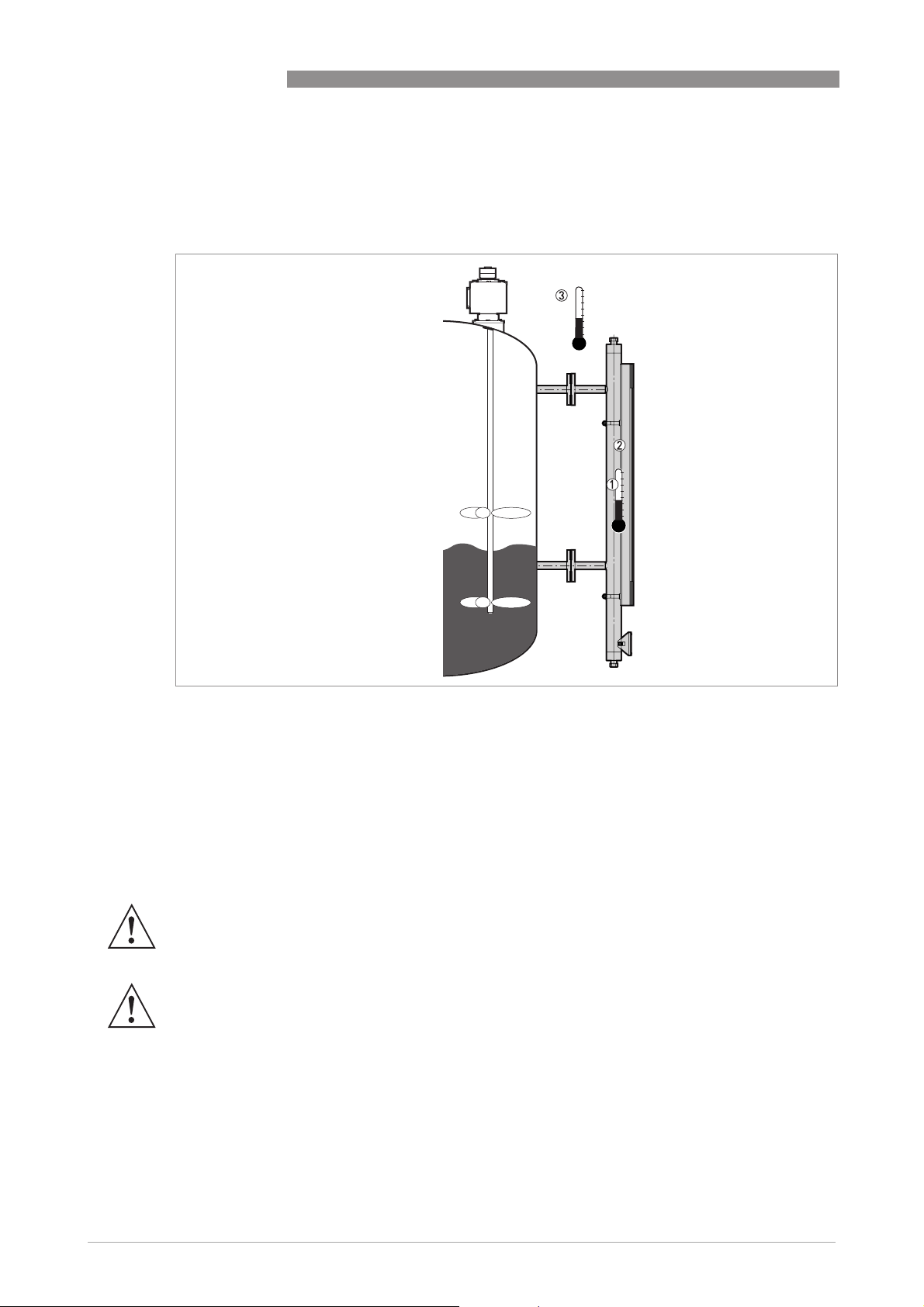

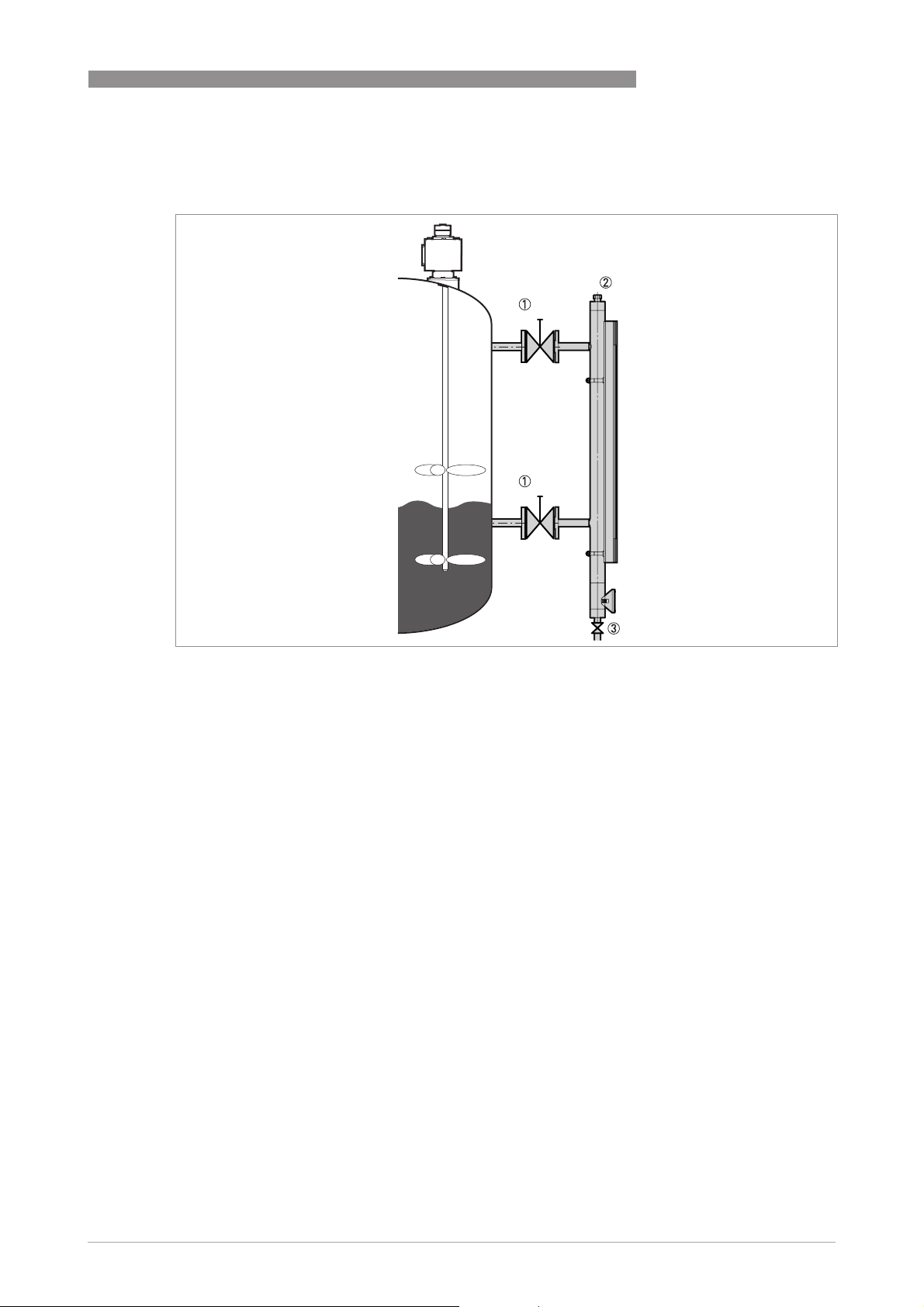

Figure 3-5: How to attach the bypass level indicator to the tank

1 Optional isolation valve

2 Optional vent

3 Optional drain with isolation valve

Obey the instructions that follow:

• Select bolts and gaskets (not supplied) that agree with the pressure rating of the process

connection and the operating pressure.

• Install the bypass level indicator vertically on the tank.

• Make sure that there is no contamination (dirt etc.) or unwanted objects in the measuring

chamber.

• Make sure that mechanical loadings do not cause damage to the process connections. If

necessary, put supports on the device.

• Install shut-off valves so that the device can be cleaned separately from the tank. Drain the

device only when it is isolated from the tank.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

19

Page 20

3 INSTALLATION

Figure 3-6: Stay away from the process connections

WARNING!

Stay away from the process connections. If you stand on the process connections, you can cause

damage to the device and the installation.

BM 26 BASIC/ADVANCED

DANGER!

°

Make sure that the outer surface temperature of the device is not more than 60

°

surface temperature is more than 60

C / 140°F, use the device with precautions that agree with

C / 140°F. If the

Health and Safety rules and regulations.

WARNING!

Pressure Equipment Directive 97/23/EC data

•

The process connections must be attached correctly to prevent mechanical stress. The axis

of the process connection must be parallel to and centred with the axis of the tank's process

connections. Tighten the process connections in agreement with the design code.

•

The user must take necessary steps to protect the installed device from shock waves (water

hammer). A pressure limiting valve must protect the installation.

•

The effective pressure of the installation (the maximum permitted by the pressure limiting

valve) must never be greater than the maximum permitted pressure, P

device nameplate.

•

Make sure that the parts in contact with the fluid are compatible with the fluid and conform to

the ageing characteristics of the measurement environment and the fluid used. These have

either been recommended in the instructions or form the subject of a particular specification

in the contract.

•

The external pressure, P

•

If stainless steel devices are more than 6 m / 20 ft high, we recommend more anchoring

, must be equal to atmospheric pressure, P

ext

points.

, marked on the

s

(P

atmos

ext

= P

atmos

).

20

CAUTION!

Before you fill the tank, make sure that the column of rotating flaps is set to zero (the flaps are

all black). If not, the device may incorrectly indicate the level.

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 21

BM 26 BASIC/ADVANCED

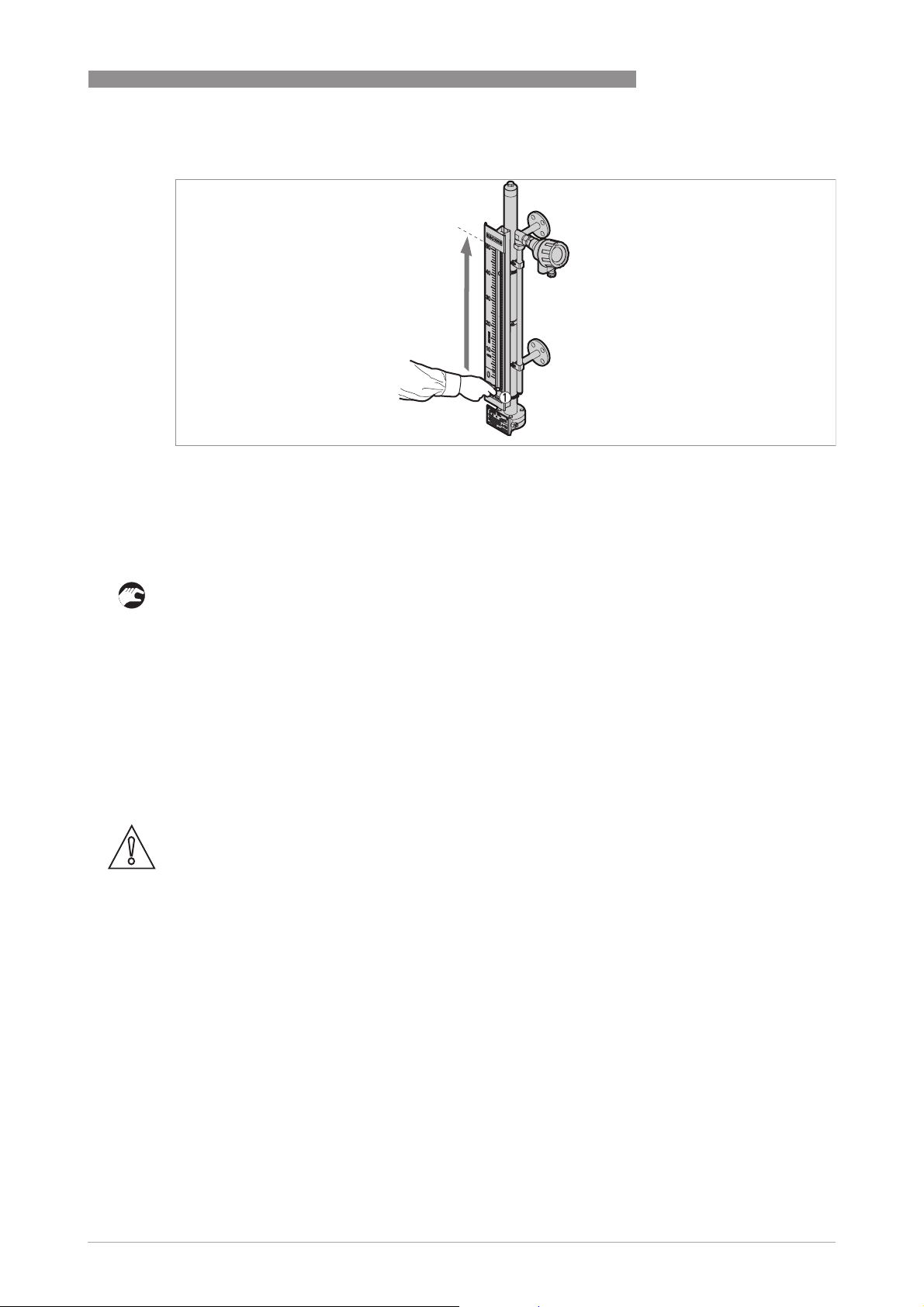

Figure 3-7: Set the indicator column to zero

1 Magnet - point the red end of the magnet at the glass tube

Equipment needed:

• Magnet (supplied with the device)

INSTALLATION 3

How to make sure the column of rotating flaps is set to zero

• Hold the magnet in front of the glass tube at the bottom of the indicator column.

i Make sure the red end of the magnet points at the glass tube.

• Move the magnet slowly up to the top the glass tube.

i The flaps all turn to black. The indicator column is set to zero. You can now fill the tank.

3.5 Level indicator column

The level indicator column is attached to the measuring chamber before delivery. Customer

order data is used to calibrate its position. No other adjustment is necessary.

CAUTION!

Customer order data is used to calibrate the device. If liquid density changes, the device will not

measure correctly. Please contact our nearest sales office for advice.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

21

Page 22

3 INSTALLATION

3.6 Optional analog transmitter

The analog transmitter is attached to the measuring chamber before delivery. Customer order

data is used to calibrate its position. No other adjustment is necessary.

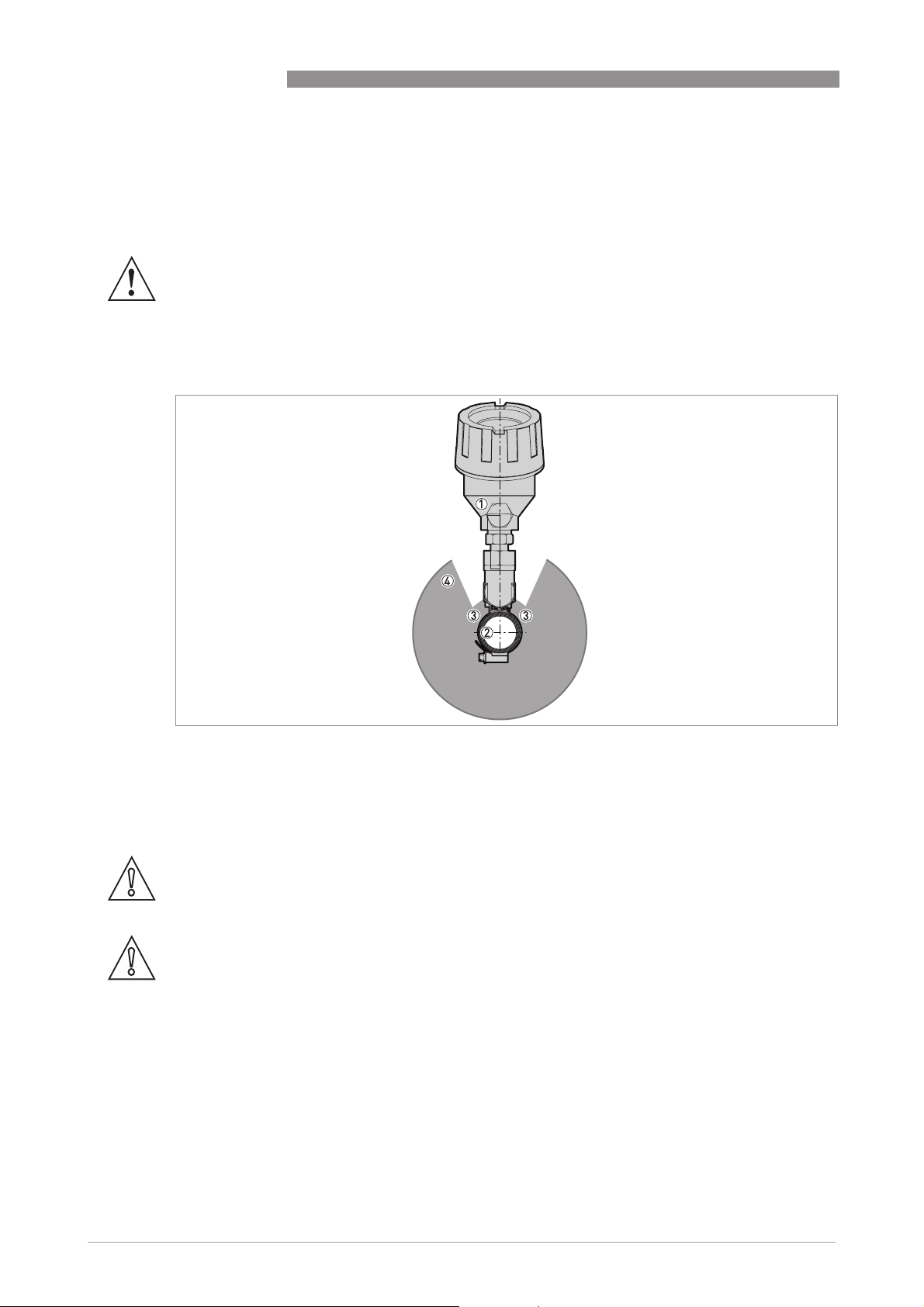

WARNING!

Too much heat can cause damage to the analog transmitter. If the process temperature is more

°

than 120

the process temperature is more than 150

transmitter.

C / 250°F, put insulation between the bypass chamber and the analog transmitter. If

BM 26 BASIC/ADVANCED

°

C / 300°F, do not cover any part of the analog

Figure 3-8: Analog transmitter and insulation for the bypass chamber

1 Analog transmitter

2 Bypass chamber (cross-section)

3 If temperature is more 120°C/ 250°F, put insulation between the bypass chamber and the analog transmitter

4 Insulation (cross-section). If temperature is more 150°C/ 300°F, do not cover any part of the analog transmitter with

insulation.

CAUTION!

Do not move the analog transmitter. If you adjust the position of this device, the current output

will be incorrect.

CAUTION!

Customer order data is used to calibrate the device. If liquid density changes, the device will not

measure correctly. Please contact our nearest sales office for advice.

22

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 23

BM 26 BASIC/ADVANCED

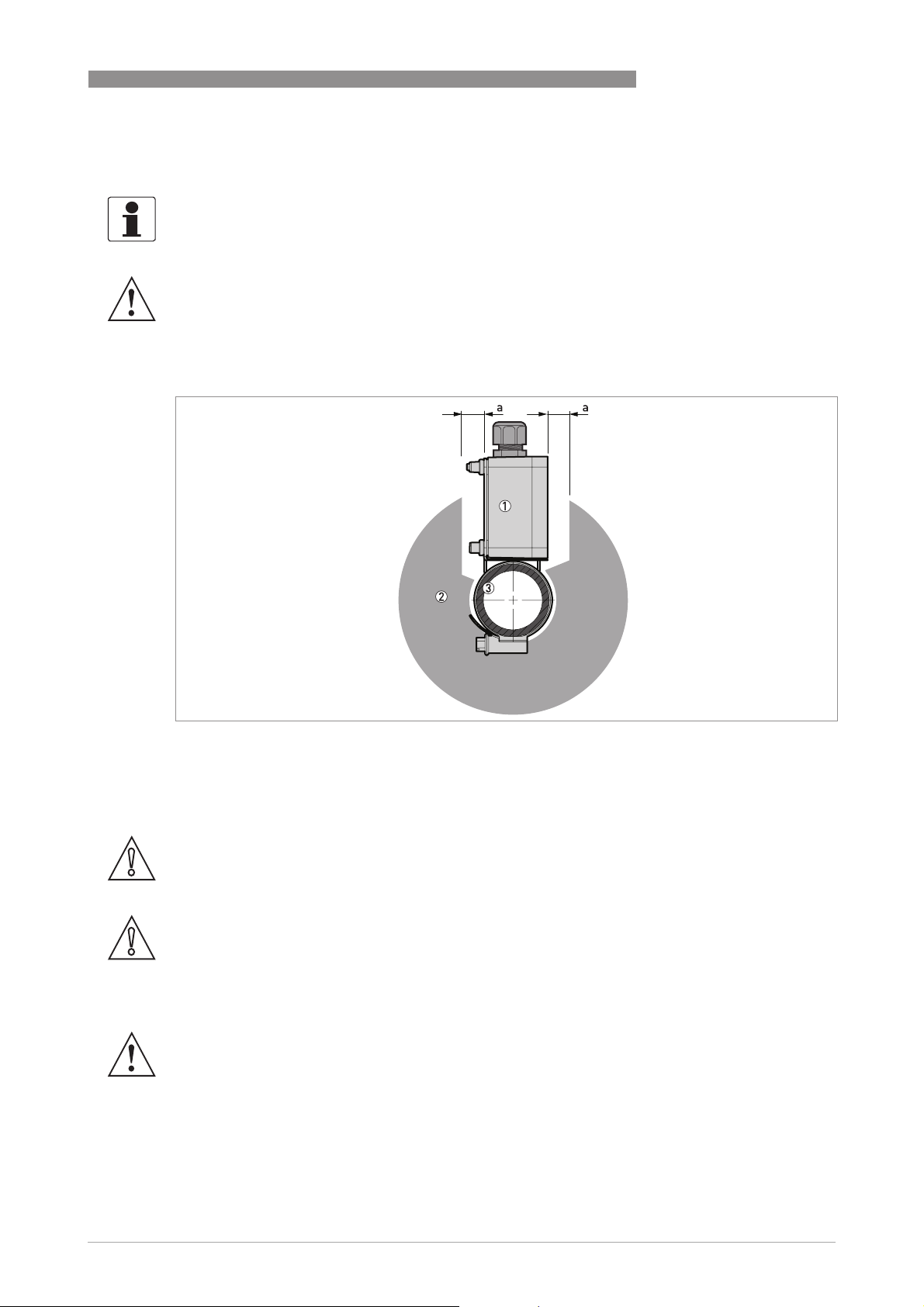

3.7 Optional limit switch

INFORMATION!

The level switches are not attached to the device before delivery. Remove the switches from the

packing and obey the instructions that follow.

WARNING!

Too much heat can cause damage to the limit switch. If you put insulation around the bypass

level indicator, do not cover the limit switch housing. Make sure that there is approximately

¨

15 mm / 0.6

of empty space between the limit switch and the insulation.

INSTALLATION 3

Figure 3-9: Limit switches and insulation for the measuring chamber

1 Limit switch housing

2 Insulation around the measuring chamber (cross-section)

3 Measuring chamber (cross-section)

Empty space between the limit switch and the insulation for the measuring chamber, a ≥15 mm / 0.6¨.

CAUTION!

If liquid density changes, the switch will not detect level correctly. Recalculate the position of the

switch according to the true liquid density and repeat the installation procedure that follows.

CAUTION!

The switching point of the switch when the level increases is not in the same as the switching

point of the switch when the level decreases. Does the limit switch have to be open when the

float is above (for HIGH limit switches) or below (for LOW limit switches) the switching point? For

more data, refer to Definition of switching point offset

Definition of switching point offset.

Definition of switching point offsetDefinition of switching point offset

WARNING!

If you put insulation around the bypass level indicator, do not cover the limit switch housing. Too

much heat can cause damage to the limit switch.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

23

Page 24

3 INSTALLATION

Figure 3-10: How to attach a limit switch

1 Limit switch

2 Switching point centreline

3 Level indicator and optional measuring scale

4 Limit switch clamp

Equipment needed:

• Large slotted tip screwdriver (not supplied)

BM 26 BASIC/ADVANCED

Installation procedure

• Use the clamp to attach the limit switch to the measuring chamber. Do not tighten the clamp.

i The cable gland must be at the bottom of the housing.

• Move the limit switch until the switching point centreline is at the level required. Refer to the

level indicator scale to help you position the limit switch.

i If the indicator column does not have the scale option, it will be necessary to calculate the

vertical offset of the float magnet in relation to the level of the liquid (depends on the liquid

density). Adjust the switch position for the float magnet offset. For the vertical offset tables,

refer to the appendix in the Handbook.

• Adjust the switch position for the switching point offset.

i If the limit switch is set to LOW limit

LOW limit (the switch is open

LOW limitLOW limit

open when the float is below the

openopen

switching point), move the switch up a small distance to adjust for the offset. If the limit

switch is set to HIGH limit

HIGH limit (the switch is open

HIGH limitHIGH limit

open when the float is above the switching point),

openopen

move the switch down a small distance to adjust for the offset. For more data, refer to

Definition of switching point offset

Definition of switching point offset and Switching point offset values

Definition of switching point offsetDefinition of switching point offset

Switching point offset values.

Switching point offset valuesSwitching point offset values

• Tighten the limit switch clamp.

WARNING!

Make sure the cable gland is on the bottom the housing and is tight to stop liquid entering the

housing.

INFORMATION!

Liquid level offset

Liquid level offset

Liquid level offsetLiquid level offset

For a description of the liquid level offset, refer to Liquid level offset: description on page 79

the graphs and other correction data, refer to

Liquid level offset: correction data on page 80

. For

.

24

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 25

BM 26 BASIC/ADVANCED

Definition of switching point offset

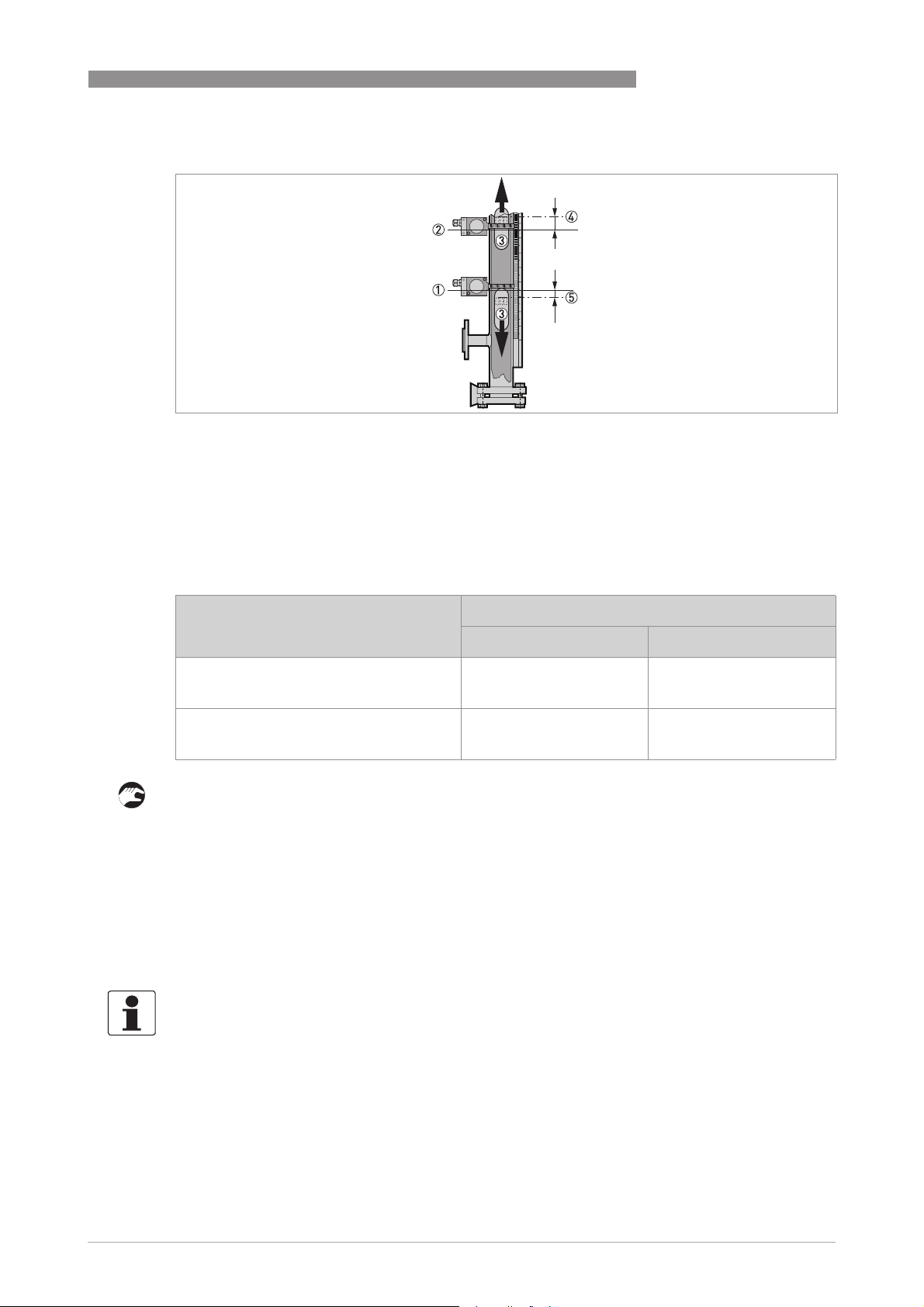

Figure 3-11: Switching point offset

1 Zero point of the limit switch

2 Zero point of the limit switch

3 Float and float magnet (switching point is in relation to the top of the magnet)

4 True switching point above a limit switch (the switch is open when the liquid level goes above this point - a HIGH limit

switch)

5 True switching point below the limit switch (the switch is open when the liquid level goes below this point - a LOW limit

switch)

INSTALLATION 3

a

a

HIGH limit

HIGH limitHIGH limit

LOW limit

LOW limitLOW limit

Switching point offset values

Conditions Switching point offset, a

mm inches

When the switch must be open above the

switching point (a HIGH limit

move the switch below the switching point:

When the switch must be open below the

switching point (a LOW limit

move the switch above the switching point:

HIGH limit switch),

HIGH limitHIGH limit

LOW limit switch),

LOW limitLOW limit

15 0.6

0 0

Installation of a limit switch for float failure detection

• Make sure the measuring chamber is empty and the float is in the chamber.

• Attach a limit switch to the bottom of the measuring chamber. Do not tighten the clamp.

• Connect the limit switch to the electrical circuit. Make sure that it is set to LOW limit

data, refer to

Optional limit switches

on page 29.

LOW limit. For more

LOW limitLOW limit

• Energize the electrical circuit.

• Lift the limit switch up the measuring chamber until the limit switch status changes to open

open.

openopen

• Hold the limit switch tightly in this position and tighten the clamp.

i The limit switch is in the correct position.

INFORMATION!

The float will go to the bottom of the measuring chamber for the reasons that follow:

•

damaged or corroded float (float failure),

•

liquid density that does not correspond to the specifications received with the order and

•

draining the measuring chamber

For more data, refer to Errors

Errors on page 37.

ErrorsErrors

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

25

Page 26

3 INSTALLATION

3.8 Electromagnetic compatibility

The design of the device agrees with European Standard EN 61326-1 and Immunity and

Emissions requirements for industrial environments.

BM 26 BASIC/ADVANCED

26

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 27

BM 26 BASIC/ADVANCED

4.1 Optional analog transmitter

• Remove the terminal compartment cover.

• Connect the device to the electrical circuit. Obey the national electrical codes.

ELECTRICAL CONNECTIONS 4

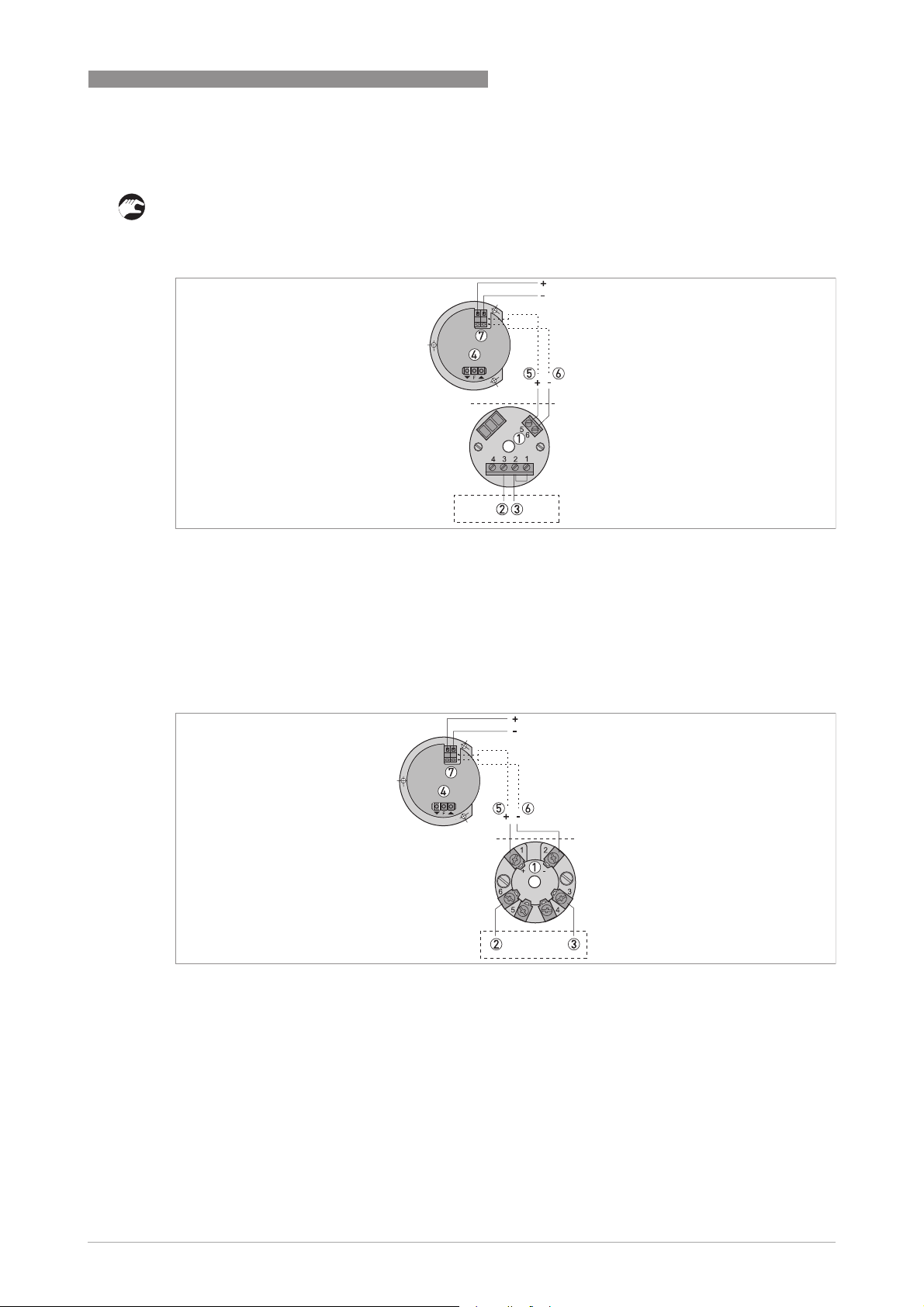

Figure 4-1: Electrical schematic for the 4...20 mA output module

1 Power supply terminals

2 Internal wiring - brown wire

3 Internal wiring - red wire

4 Optional LCD indicator

5 Power supply (+) - if optional LCD connected - red wire

6 Power supply (-) - if optional LCD connected - black wire

7 LCD power supply terminal (10...35 VDC)

Figure 4-2: Electrical schematic for the 4...20 mA + HART output module

1 Power supply terminals

2 Internal wiring - brown wire

3 Internal wiring - red wire

4 Optional LCD indicator

5 Power supply (+) - if optional LCD connected - red wire

6 Power supply (-) - if optional LCD connected - black wire

7 LCD power supply terminal (10...35 VDC)

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

27

Page 28

4 ELECTRICAL CONNECTIONS

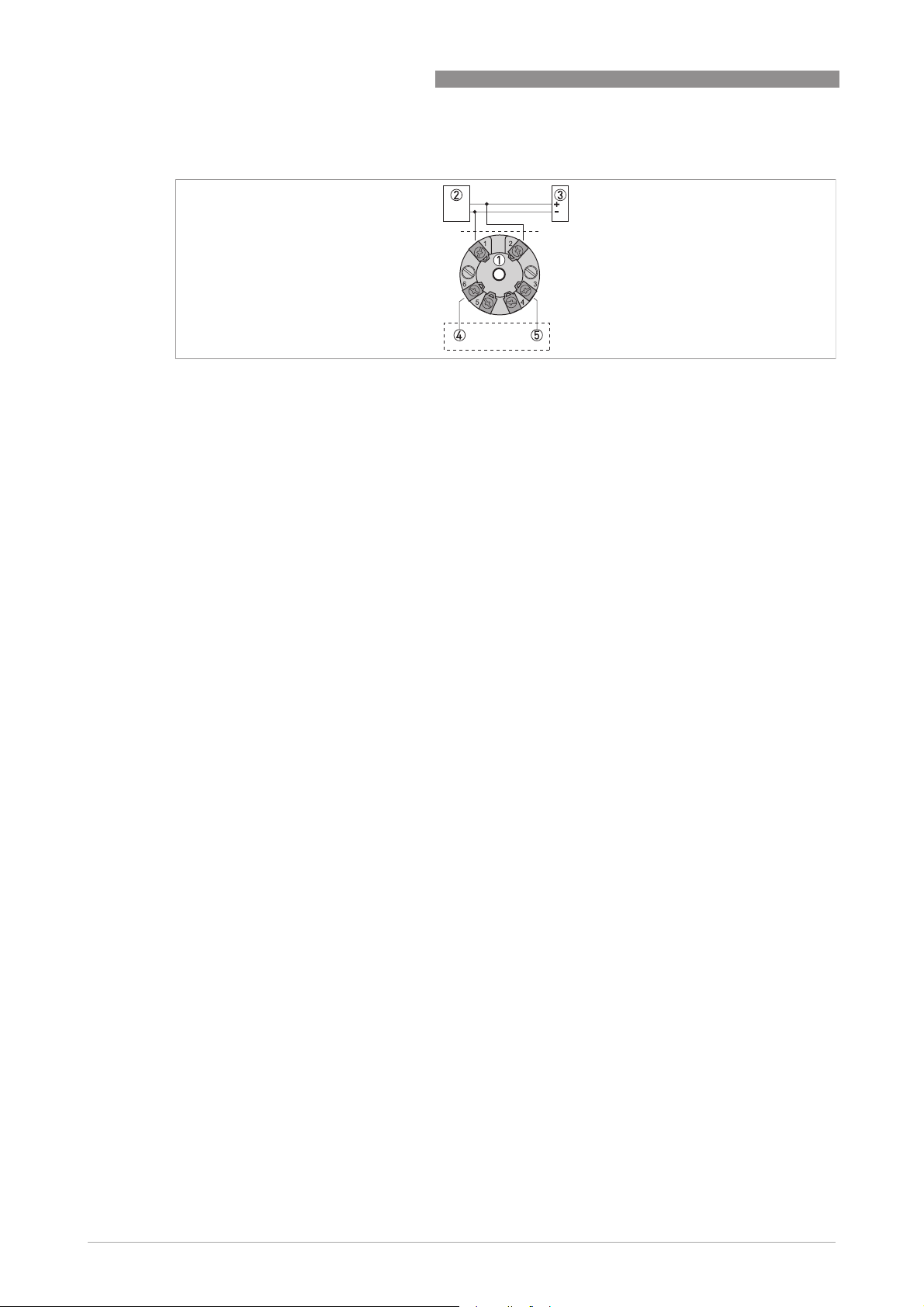

Figure 4-3: Electrical schematic for the FOUNDATION™ Fieldbus / PROFIBUS PA module

1 Bus connection terminals

2 Segment coupler

3 Bus termination

4 Internal wiring - orange wire

5 Internal wiring - brown wire

BM 26 BASIC/ADVANCED

For more electrical data, refer to

Technical data: optional analog transmitter

on page 51.

28

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 29

BM 26 BASIC/ADVANCED

4.2 Optional limit switches

Figure 4-4: Terminal compartment

1 Terminal compartment cover

2 Bistable reed switch

3 Output terminal

• Remove the terminal compartment cover.

• Connect the device to the electrical circuit. Obey the national electrical codes.

ELECTRICAL CONNECTIONS 4

1 2 3

WARNING!

If the switch is set to LOW limit

LOW limit, make sure that switch is open

LOW limitLOW limit

position.

If the switch is set to HIGH limit

HIGH limit, make sure that switch is open

HIGH limitHIGH limit

position.

Figure 4-5: Electrical schema

1 Non-NAMUR version

2 NAMUR version

For more electrical data, refer to

open when the float is below the switch

openopen

open when the float is above the switch

openopen

Technical data: optional limit switches

on page 56.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

29

Page 30

4 ELECTRICAL CONNECTIONS

4.3 Protection category

For the IP categories of the accessories for the device, refer to the table that follows:

Protection categories according to EN 60529

Equipment housing IP category

Analog transmitter

Non-Ex / Ex i (without indicator) 54

Non-Ex / Ex i (with indicator) 66

Limit switches

Non-Ex / Ex i 66

DANGER!

Make sure the cable gland is watertight.

BM 26 BASIC/ADVANCED

Figure 4-6: Protection category

How to make sure that the electrical installation agrees with the protection category

• Make sure that the gaskets are not damaged.

• Make sure that the electrical cables are not damaged.

• Make sure that the electrical cables agree with the national electrical code.

• The cables are in a loop in front of the device 1 so water cannot enter the housing.

• Tighten the cable glands 2.

• Close unused cable glands with dummy plugs 3.

30

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 31

BM 26 BASIC/ADVANCED

5.1 Start-up checklist

Check these points before you use the device:

• Are all the wetted components (chamber, flanges and gaskets) resistant to the product in the

tank?

• Does the information on the nameplate agree with the operating data?

• Did you correctly install the device on the tank?

• Do the electrical connections agree with the national electrical codes?

DANGER!

Make sure that the device and the installation agrees with the requirements of the Ex certificate

of compliance.

Start-up procedure

• Attach the drainage plugs or close the drainage cock.

• Slowly open the shut-off valves on the top and bottom process connections.

WARNING!

Risk of damage to the device from shock waves. Open the valves slowly to prevent damange from

water hammer. Use a pressure-limiting valve to prevent damage to the installation.

START-UP 5

WARNING!

The device must have regular servicing to agree with rules and regulations of the site it is

installed on.

WARNING!

High-temperature versions: risk of burns. Do not go too near to the device.

5.2 Operating concept

You can read measurements in several ways:

• Level is indicated by a column of rotating flaps.

• Level is detected by optional limit switches installed at important points adjacent to the

measuring chamber.

• Level is monitored remotely by an optional analog transmitter (2-wire, reed-chain) adjacent

to the measuring chamber. There is a large choice of outputs (4...20 mA, 4...20 mA + HART,

FF and PROFIBUS PA). An LCD indicator option is also available for this transmitter.

CAUTION!

Customer order data is used to calibrate the device. If liquid density changes, the device will not

measure correctly. For more data, refer to Error handling on page 38

.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

31

Page 32

6 OPERATION

6.1 Local display options

6.1.1 Level indicator column

BM 26 BASIC/ADVANCED

Figure 6-1: Display of data on a indicator column

1 Standard level indicator without a measuring scale

2 Optional measuring scale in m/cm, ft/in or m³

3 Yellow flaps: level of the liquid in the tank

4 Black flaps: empty volume

5 Red flaps: float failure

WARNING!

If the red flaps are shown, either:

•

the float sunk to the bottom of the measuring chamber,

•

the measuring chamber has been completely drained or

•

the product density is less than the value given in the order.

Contact your nearest sales office for advice.

32

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 33

BM 26 BASIC/ADVANCED

6.1.2 Analog transmitter (option)

General notes

General notes

General notesGeneral notes

The analog transmitter has transmitter modules for analog and digital outputs. The user can do

the configuration of 4...20 mA + HART®, FOUNDATION™ Fieldbus and PROFIBUS PA® modules.

Use the web links in the table that follows to download the software and device description files.

Configuration data for transmitter modules

OPERATION 6

Transmitter Manufacturer User configuration

Yes / No?

4...20 mA INOR No - -

4...20 mA + HART® PR Yes PReset 1 "PRetop 5335" HART DD,

FOUNDATION™

Fieldbus

PROFIBUS PA® PR Yes PReset 1 "5350" GSD files 1

1 Go to the PR electronics website: www.prelectronics.com (Download Center > Software)

PR Yes PReset 1 "5350" DD files 1

Software Device description

files

AMS and DTM files

1

For more data about the configuration of the 4...20 mA + HART®, FOUNDATION™ Fieldbus and

PROFIBUS PA® modules, you can download technical documents from the PR electronics

website: www.prelectronics.com (Download Center > Manuals - Data Sheets - Certificates).

Figure 6-2: Analog transmitter with the optional indicator

1 Non-Ex and Ex i converter housing option

2 4-digit indicator (LCD)

The indications on the LCD are in millimetres by default, but inches and % can also be selected.

The configuration of the indicator is given in the procedures that follow:

WARNING!

Do not open the housing and configure the indicator in a hazardous area.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

33

Page 34

6 OPERATION

BM 26 BASIC/ADVANCED

Figure 6-3: Get access to the keypad on the indicator board

Equipment needed

• Sheet of stickers with measurement units (mm, inches and %)

• Small slotted tip screwdriver (not supplied)

Get access to the keypad on the indicator board

1 Remove the transmitter housing cover.

2 Remove the screws that hold the indicator board on the housing.

3 Turn the indicator board to use the 3-button keypad ([], [FFFF] and []) on the back of the board

to change the units. Refer to the tables that follow for key functions and the example procedure for configuration of the indicator.

4 Attach the indicator board to the housing.

5 Put the sticker with the correct measurement unit over the default units under the indicator

screen.

6 Attach the transmitter housing cover.

34

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 35

BM 26 BASIC/ADVANCED

Figure 6-4: Back and front view of the indicator

1 Back of the indicator board (3-button keypad at the bottom)

2 Front of the indicator board (span range menu in program mode shown)

Key functions

Key Menu level Function level

[FFFF] (3 seconds) Access to program mode -

[FFFF] (1 second) Access to the function. Confirm the new parameter and go back

[] (down) Move down the list of functions Select parameter / decrease the value of

[] (up) Move up the list of functions Select parameter / increase the value of

[] + [] Escape - go back to the indication Escape - go back to the menu 1

1 This does not confirm that you selected a new parameter

OPERATION 6

to the menu.

the parameter. Push [] intermittently

to decrease the value in increments of

0.1. Push [] continuously to decrease

the value in increments of 1.

the parameter. Push [] intermittently

to increase the value in increments of

0.1. Push [] continuously to increase

the value in increments of 1.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

35

Page 36

6 OPERATION

Menu overview

Function Function description Range/Selection list Default

BM 26 BASIC/ADVANCED

Decimal Point (dP) Push [] or [] to select

the decimal point position.

Push [FFFF] to confirm.

Zero point (ZErO) Push [] or [] to select

the minimum value. Push

[FFFF] to confirm.

Span range (SPAn) Push [] or [] to select

the maximum value. Push

[FFFF] to confirm.

Input current limit (Li) Do not use. n/a 0

Filter (FiLt) Do not use. n/a 2

Resolution (riS) Do not use. n/a 1

0…3 1

-1999…+9999 0.0

-1999…+9999 100.0

Example procedure: Change the indicator units from mm to %

• Push [FFFF] for 3 seconds (button on the back of the indicator board) to access Program mode

i In program mode dP

• Push [] 1 time to get to the zero point (ZErO

dP is displayed.

dPdP

ZErO) function.

ZErOZErO

• Push [FFFF] to access the span range parameter. Make sure that the value is 0.0. Push [] + []

(Escape) to go back to the menu.

• Push [] 1 time to get to the span range (SPAn

SPAn) function.

SPAnSPAn

• Push [FFFF] to access the span range parameter.

Program mode.

Program modeProgram mode

i The current value is 600 (example value).

• Push [] to decrease the value to 100.

• Push [FFFF] to confirm the parameter and go back to the menu.

• Push [] + [] (Escape) to go back to the indication.

i The indication will display a value between 0 and 100 based on a current output of 4...20 mA.

• Put a new sticker (%) on the front of the indicator board.

36

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 37

BM 26 BASIC/ADVANCED

6.2 Errors

6.2.1 Error indication

Indicator column

OPERATION 6

Figure 6-5: Error displayed on the indicator column

1 Indicator column (rotating flaps)

2 Red flaps: float failure

Analog transmitter

-OL OL

Figure 6-6: Error displayed on the optional LCD indicator for the analog transmitter

1 Error message if current output is < 3.6 mA

2 Error message if current output is > 22 mA

Limit switches

Limit switches can be used to indicate error conditions (Float failure, level detection etc.). For

more data, refer to

Optional limit switch

on page 23.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

37

Page 38

6 OPERATION

6.2.2 Error handling

Indicator column

Float failure The red flaps at the bottom of the

The level of the liquid is at or

above the maximum level, but

the indicator column doe not

indicate that level has

reached its maximum limit

yet.

The indicator column

indicates that the liquid is at

or below the minimum level,

but the level of the liquid is

still above the minimum limit.

The level of the liquid is below

the maximum level, but the

indicator column indicates

that level has already reached

its maximum limit.

The indicator column is not

yet at the minimum level, but

the level of the liquid is at or

below the minimum limit.

BM 26 BASIC/ADVANCED

Error Description Corrective action

indicator column are shown. The

float has sunk to the bottom of the

measuring chamber.

The density of the liquid is lower

than the value given in the

customer order data. The float is

too low in the liquid.

The density of the liquid is lower

than the value given in the

customer order data. The float is

immersed more than it should be.

The density of the liquid is higher

than the value given in the

customer order data. The float is

not sufficiently immersed.

The density of the liquid is higher

than the value given in the

customer order data. The float is

immersed more than it should be.

Make sure the measuring chamber

has not been completely drained.

Make sure the true density of the

liquid corresponds to the value

given in the order data. Contact

your local sales office to make sure

that the float is for the correct

density range.

If the float is damaged or corroded,

it is necessary to replace the float.

Order a new float from your local

sales office. Isolate the measuring

chamber and drain the liquid.

Remove the bottom plate flange

and the float. If your device is a

basic version, you will only be able

to remove the float if it has the

1¼ NPT connection at the bottom

of the measuring chamber

Make sure that the density of the

liquid is stable. Contact your local

sales office for advice.

Make sure that the density of the

liquid is stable. Contact your local

sales office for advice.

Make sure that the density of the

liquid is stable. Contact your local

sales office for advice.

Make sure that the density of the

liquid is stable. Contact your local

sales office for advice.

38

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 39

BM 26 BASIC/ADVANCED

Error Description Corrective action

Analog transmitter

Optional LCD indicator status: OLCurrent output is more than 22 mA

Optional LCD indicator status:

-OL

The level of the liquid is at or

above the maximum level, but

the analog transmitter output

doe not indicate that level has

reached its maximum limit

yet.

The analog transmitter output

indicates that the liquid is at

or below the minimum level,

but the level of the liquid is

still above the minimum limit.

The level of the liquid is below

the maximum level, but the

analog transmitter output

indicates that level has

already reached its maximum

limit.

The analog transmitter output

is not yet at the minimum

level, but the level of the

liquid is at or below the

minimum limit.

(more than 20 mA, if this option is

selected in the indicator). Overfill.

The level of the liquid is above the

maximum limit (if the indicator is

configured for level indication).

Current output is more than 22 mA

(more than 20 mA, if this option is

selected in the indicator). The

analog transmitter has been

moved. A value more than 20 mA

no longer represents the

maximum limit.

Current output is more than 22 mA

(more than 20 mA, if this option is

selected in the indicator). The

analog transmitter is defective. A

value more than 20 mA no longer

represents the maximum limit.

Current output is less than 3.6 mA

(less than 4 mA, if this option is

selected in the indicator). The level

of the liquid is below the minimum

limit (if the indicator is configured

for level indication).

Current output is less than 3.6 mA

(less than 4 mA, if this option is

selected in the indicator). The

analog transmitter has been

moved. A value less than 4 mA no

longer represents the minimum

limit.

Current output is less than 3.6 mA

(less than 4 mA, if this option is

selected in the indicator). The

analog transmitter is defective. A

value less than 4 mA no longer

represents the minimum limit.

The density of the liquid is lower

than the value given in the

customer order data. The float is

too low in the liquid.

The density of the liquid is lower

than the value given in the

customer order data. The float is

too low in the liquid.

The density of the liquid is higher

than the value given in the

customer order data. The float is

too high in the liquid.

The density of the liquid is higher

than the value given in the

customer order data. The float is

too high in the liquid.

OPERATION 6

Lower the level of liquid below the

maximum limit.

Contact your local sales office for

advice.

Contact your local sales office for

advice.

Increase the level of liquid until it is

above the minimum limit.

Contact your local sales office for

advice.

Contact your local sales office for

advice.

Make sure that the density of the

liquid is stable. Contact your local

sales office for advice.

Make sure that the density of the

liquid is stable. Contact your local

sales office for advice.

Make sure that the density of the

liquid is stable. Contact your local

sales office for advice.

Make sure that the density of the

liquid is stable. Contact your local

sales office for advice.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

39

Page 40

6 OPERATION

Limit switch

The limit switch is in highhigh (maximum) position and

set to HIGH limit

HIGH limit. Status

HIGH limitHIGH limit

OPEN

OPEN.

OPENOPEN

The limit switch is in low-low

(minimum) position and set to

LOW limit

LOW limit. Status OPEN

LOW limitLOW limit

The limit switch is in the float

failure position and set to

LOW limit

LOW limit. Status OPEN

LOW limitLOW limit

The level switch does not

detect the minimum limit

correctly.

The level switch does not

detect the maximum limit

correctly.

BM 26 BASIC/ADVANCED

Error Description Corrective action

OPEN.

OPENOPEN

OPEN.

OPENOPEN

Overfill? The level of the liquid is at

or above the maximum limit (if the

indicator is configured for level

indication).

Tank empty? The level of the liquid

is at or below the minimum limit (if

the indicator is configured for level

indication).

Float failure. The float has sunk to

the bottom of the measuring

chamber.

The limit switch (set to LOW limit

is open (off), but the level of the

liquid is still above the minimum

limit. The density of the liquid is

lower than the value given in the

customer order data.

The limit switch (set to LOW limit

is not yet open (off), but the level of

the liquid is at or below the

minimum limit. The density of the

liquid is higher than the value given

in the customer order data.

The level of the liquid is at or above

the maximum level, but the limit

switch (set to HIGH limit

open (off). The density of the liquid

is lower than the value given in the

customer order data.

The level of the liquid is below the

maximum level, but the limit

switch (set to HIGH limit

(off). The density of the liquid is

higher than the value given in the

customer order data.

HIGH limit) is not yet

HIGH limitHIGH limit

HIGH limit) is open

HIGH limitHIGH limit

LOW limit)

LOW limitLOW limit

LOW limit)

LOW limitLOW limit

Lower the level of liquid below the

maximum limit.

Increase the level of liquid until it is

above the minimum limit.

It is necessary to replace the float.

Order a new float from your local

sales office. Isolate the measuring

chamber and drain the liquid.

Remove the bottom plate flange

and the float. If your device is a

basic version, you will only be able

to remove the float if it has the

1¼ NPT connection at the bottom

of the measuring chamber.

Make sure that the density of the

liquid is stable. Recalculate the

liquid density and repeat the

installation procedure for the limit

switch.

40

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 41

BM 26 BASIC/ADVANCED

7.1 Periodic maintenance

This device does not normally need maintenance. If the liquid is contaminated or build-up of

deposits is possible, we recommend that you flush the device regularly.

WARNING!

Pressure Equipment Directive 97/23/EC data

Pressure Equipment Directive 97/23/EC data

Pressure Equipment Directive 97/23/EC dataPressure Equipment Directive 97/23/EC data

The device must be regularly serviced to conform to the rules and regulations applicable to the

site that it is installed on.

WARNING!

Follow accident prevention regulations carefully when working with pressurized tanks and

dangerous chemical products.

How to flush the device

• Open the drain plug or drain valve.

• Flush the chamber.

WARNING!

If you remove the float, close the shut-off valves.

SERVICE 7

Float removal procedure (not for basic version without 1¼¨ plug)

• Close the shut-off valves.

• Remove the bottom process connection counter-flange or plug.

• Remove and clean the float.

7.2 Keep the device clean

DANGER!

If you rub the anti-freeze cover option with a dry cloth, there is a risk of electrostatic discharge.

Clean the anti-freeze cover option only with a damp cloth.

7.3 How to replace device components

7.3.1 Service warranty

Maintenance is not necessary for most applications.

Servicing by the customer is limited by warranty to

• The removal and installation of switches. For more data, refer to Optional limit switch

page 23.

• The removal and installation of the float. For more data, refer to Remove all packing before

installation

installation on page 16.

installationinstallation

Optional limit switch on

Optional limit switchOptional limit switch

Remove all packing before

Remove all packing before Remove all packing before

The indicator column and switches can be removed under process conditions.

Use only KROHNE-authorized service staff to repair the device.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

41

Page 42

7 SERVICE

7.4 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local sales office.

7.4.1 General notes

We supply spare parts and accessories for this device. When you order a spare part or

accessory, please give the reference numbers that follow:

7.4.2 List of spare parts

For the measuring chamber:

• Floats

BM 26 BASIC/ADVANCED

Float designation Product density Part number

[kg/l] [lb/ft³]

Basic version

Float 1 0.8...1.19 49.9...74.3 F3187980500

Advanced version

Float 1 0.58...0.7 36.2...43.7 F3187981900

Float 2 0.7...0.99 43.7...61.8 F3187981600

Float 3 0.99...2 61.8...124.8 F3187980900

For the analog transmitter:

• Transmitter modules. For more data, refer to

Order code

on page 84.

INFORMATION!

Supply this data when you order spare parts:

•

Device serial number

•

Manufacturer's order number

•

Floats only: Float material (on the float data sticker at the bottom of the indicator column)

•

Floats only: Maximum allowable pressure, Ps and test pressure, Pt (on the float data sticker)

42

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 43

BM 26 BASIC/ADVANCED

7.4.3 List of accessories

For the measuring chamber:

• Limit switch, non-NAMUR

• Limit switch, NAMUR

INFORMATION!

For more data on the limit switches, refer to Technical data: optional limit switches on page 56

For the 2-wire, loop-powered analog transmitter:

• AS 24 power supply unit 24 VDC / 230 VAC

• AS 24 power supply unit 24 VDC / 110 VAC

• PROF SI 24075 intrinsically-safe power supply unit (with galvanic separation)

• C 95 Basic univeral power supply (Panel mount, 2 relays, 4-digit local indicator and non-Ex)

• C 95 Basic univeral power supply (Panel mount, 2 relays, 4…20 mA output, 4-digit local

indicator and non-Ex)

SERVICE 7

.

INFORMATION!

For more data on the C 95 power supply, refer to the technical datasheet in our download centre.

7.5 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local sales office.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

43

Page 44

7 SERVICE

7.6 Returning the device to the manufacturer

7.6.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralising, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

BM 26 BASIC/ADVANCED

44

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 45

BM 26 BASIC/ADVANCED

7.6.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. No.: Fax No.:

The meter enclosed, type:

Manufacturer's Order or Serial No.:

SERVICE 7

has been operated with the following liquid:

Because this liquid is: hazardous to water

toxic

caustic

flammable

We have checked that all cavities in the unit are free from

such substances.

We have flushed out and neutralized all cavities in the unit.

We herewith confirm that in returning this unit there is no risk to man or environment through any

residual liquid contained in it.

Date: Company stamp:

Signature:

7.7 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

45

Page 46

8 TECHNICAL DATA

8.1 Measuring principle

The device operates on the principle of communicating tubes. The measuring chamber is

connected adjacent to the tank. The process conditions in the measuring chamber are the same

as those of the tank.

A float is in the measuring chamber. The float contains magnets that rotate the flaps in the

indicator column and operate the optional limit switches and analog transmitter on the side of

the measuring chamber. The position of the magnets does not correspond to the level of liquid

so the scale is offset at the factory to take into account this difference. The offset of the magnets

depends on the liquid density. Refer to the illustration that follows:

Magnet offset

BM 26 BASIC/ADVANCED

Figure 8-1: Magnet offset

1 True level of the liquid

2 Top of the float magnet (which corresponds to the level shown on the indicator column)

3 Difference (offset) between the true level of the liquid and the top of the float magnet (depends on the liquid density)

4 Indicator column of yellow/black rotating flaps (with the optional scale)

46

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Page 47

BM 26 BASIC/ADVANCED

8.2 Technical data: general information

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Measuring principle Bypass level indicator (principle of communicating tubes). A float in

Application range Level indication of liquids for

Measured value

Measured value

Measured valueMeasured value

Primary measured value Level of the float magnets in the measuring chamber

Secondary measured value Level and volume of the liquid in the measuring chamber

the measuring chamber (Ø42 mm / 1.7¨) is magnetically-coupled to a

mechanical level indicator.

low-pressure applications and in

storage tanks

TECHNICAL DATA 8

Basic Advanced

Level indication of liquids in

applications up to 40 barg /

580 psig

Design

Options and variants

Options and variants

Options and variantsOptions and variants

Variants Lateral / lateral process connections

Axial / axial process connections

Top lateral / bottom axial process connections

Top axial / bottom lateral process connections

Options Support bracket (a wall support for long bypass level indicators)

Analog transmitter without display (converter with 4...20 mA,

4...20 mA + HART®, PROFIBUS PA or FF output module mounted at

the top or bottom of the reed chain) 1

Analog transmitter with display (4...20 mA or 4...20 mA + HART®

converter mounted at the top or bottom of the reed chain)

1¼¨ threaded cover (for

installation/ removal of the float)

Anti-freeze cover for glass indicator tube (when the ambient

temperature is -40...-20°C / -40...-4°F)

- OPTIFLEX 1300 C with Ø2 mm

- OPTIFLEX 1300 C (if DN40 PN40

- OPTIWAVE 7300 C (if welded

Accessories Bistable limit switches (NAMUR or non-NAMUR)

Measuring range (ML) 0.3…5.3 m / 1…17.4 ft 0.3…5.3 m / 1…17.4 ft

-

single cable probe (if ½ BSPP top

axial connection is selected)

top axial connection is selected )

antenna or DN40 PN40 top axial

connection is selected)

(longer on request)

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

47

Page 48

8 TECHNICAL DATA

Display and user interface

Display and user interface

Display and user interfaceDisplay and user interface

Display Indicator column with magnetically-coupled yellow/black rotating

Float failure indication Red/black rotating flaps at the bottom of the indicator column

Scale marking options No scale; m + cm; ft + inches; %

Measuring accuracy

Accuracy ±10 mm / 0.4¨

Repeatability ±10 mm / 0.4¨ (when density is constant)

Maximum rate of change 2 m/minute / 6.5 ft/minute

Operating conditions

Temperature

Temperature

TemperatureTemperature

Process -40…+150°C/ -40…+300°F

Ambient temperature -40…+80°C/ -40…+176°F (Ex: see supplementary instructions or

Storage temperature -50…+80°C/ -58…+176°F

Pressure

Pressure

PressurePressure

Max. allowable operating

pressure

Chemical properties

Chemical properties

Chemical propertiesChemical properties

Density 0.8…1.19 kg/l / 49.9...68.7 lb/ft³ 0.58…2 kg/l / 36.2...124.8 lb/ft³

Viscosity ≤ 5000 mPas / ≤ 3.360 lb/ft³

Other conditions

Other conditions

Other conditionsOther conditions

Ingress protection IP 68

Basic Advanced

flaps; no indicator column

(Ex: see supplementary

instructions or approval

certificates)

approval certificates)

16 barg / 232 psig (according to

the length of the measuring

chamber. Also refer to

Guidelines for maximum

operating pressure

on page 76.)

BM 26 BASIC/ADVANCED

-40...+300°C/ -40…+570°F

(Ex: see supplementary

instructions or approval

certificates)

40 barg / 580 psig (according to

the flange pressure rating. Also

refer to

operating pressure

Guidelines for maximum

on page 76.)

48

Installation conditions

Recommendations Mount vertically on the side of tanks

Fit isolation valves on process connections to permit maintenance of

the bypass chamber (optional)

Dimensions and weights Refer to "Technical data: Dimensions and weights"

Materials

Chamber Standard: Stainless steel (1.4404 / 316L)

- Option: Hastelloy® C-276 2

Float Standard: Stainless steel

(1.4404 / 316L)

- Option: Hastelloy®

Indicator rail Stainless steel

Indicator tube Pyrex® glass (glass tube with a true hermetic seal) 3

Scale (option) Stainless steel

www.krohne.com 10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Stainless steel (1.4404 / 316L);

Titanium (for data on material

selection, refer to

78)

Floats

on page

Page 49

BM 26 BASIC/ADVANCED

Process fitting Standard: Stainless steel (1.4404 / 316L)

Gaskets Teflon® tape 4 Standard: Aramid; Teflon® tape

Braid insulation - Ceramic fibre (insulation

Anti-freeze cover for glass

indicator tube (option)

Process connections

Threaded pipes ½...¾ NPT; G ½...¾

Smooth pipes, 10S ½¨; ¾¨ in 10S

Flange version

Flange version

Flange versionFlange version

EN DN15…40 (Form B1) in PN16 / 40 DN15…50 (Form B1, C or E) in

ASME ½…1½¨ (RF) in 150 lb / 300 lb ½…1½¨ (RF) in 150 lb / 300 lb;

TECHNICAL DATA 8

Basic Advanced

- Option: Hastelloy® C-276 (for the

wetted parts of EN loose flanges

only)

- Options: Graphite; PTFE

between the indicator column

and the measuring chamber

when the process temperature is

+100...+300°C / +210...+570°F)

Plexiglas®

PN16 / 40;

DN15…50 (Form B1, C or E) in

PN63 / 100; others are available

on request

Note: Hastelloy® C-276 flange

connections are only available as

loose flanges with form B1

others are available on request

Drain and vent connections

Drain options

Drain options

Drain optionsDrain options

Thread Standard: cover with 3/8 NPT

Flange - Options: all process connection

Vent options

Vent options

Vent optionsVent options

Thread Standard: without (convex cap) Standard: 3/8 NPT plug

Flange - Options: all process connection

plug

Option: cover with 1¼ NPT plug Options: on page 66

Option: cover with 3/8 NPT plug Options: flange with ½ NPT plug;

Standard: flange with ½ NPT plug

options

flange with G ½ plug; DN40 top

flange (for radar or TDR level

transmitter) with ½ NPT lateral

vent plug; welded antenna with

½ NPT lateral vent plug; ½ BSPP

screw connection for

OPTIFLEX 1300 C and Ø2 mm

single cable probe, with ½ NPT

lateral vent plug; all process

connection options

options

www.krohne.com10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

49

Page 50

8 TECHNICAL DATA

Power supply

Limit switches Refer to "Technical data: optional level switches"

Analog transmitter Refer to "Technical data: optional analog transmitter"

Input and output

Parameter Level detection or indication

Output signal Refer to "Technical data: optional level switches" and "Technical

Approvals and certification

CE CE marking not applicable (not

Explosion protection

Explosion protection

Explosion protectionExplosion protection

ATEX II 1 G or II 1/2 G (measuring chamber)

Other standards and approvals

Other standards and approvals

Other standards and approvalsOther standards and approvals

PED Not subject to PED test

Vibration resistance Vibration class 4M4 according to EN 60721-3-4

Construction code Standard: "CODAP® 2010"