Page 1

Handbook

BM 102

MICROFLEX

T D R Level gauge

GR

2-WIRE

Variable area flowmeters

Vor tex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

©

KROHNE 03/2004 7.02267.22.00

Subject to change without notice.

Page 2

Table of contents

Device description and range of applications ……………………………………………………….. 4

Principal gauge components ……………………..………………………………………………….…. 4

Items included with supply …………………………………………………..…………………….……. 6

Documentation supplied …………………………………………………..……………………….……. 6

Product liability and warranty ………………………….………………………………………….……. 6

1

Mechanical installation.........................................................................................................7

1.1 Handling and storage ..............................................................................................................7

1.2 Installation restrictions.............................................................................................................8

1.3 Mounting on the tank...............................................................................................................8

1.3.1 Installation instructions: general notes ....................................................................................8

1.3.2 Installation instructions: nozzle................................................................................................9

1.3.3 Installation instructions: Gauge - all applications...................................................................11

1.3.4 Specific installation instructions: gauge - liquid applications .................................................14

1.3.5 Specific installation instructions: gauge - solid applications ..................................................16

2

Electrical connections ........................................................................................................18

2.1 Electrical installation instructions...........................................................................................18

2.1.1 Wiring general notes .............................................................................................................18

2.1.2 Wiring connections: DIN connector .......................................................................................18

2.1.3 Wiring connections: M16 terminal box ..................................................................................19

2.1.4 ’Ex’ equalizing conductor ......................................................................................................19

2.2 Power Supply........................................................................................................................20

2.2.1 Non-hazardous-duty version .................................................................................................20

2.2.2 Hazardous-duty version ........................................................................................................21

2.3 Electrical output.....................................................................................................................22

2.3.1 Network options ....................................................................................................................22

2.3.2 HART® communication protocol...........................................................................................22

3

User interface ......................................................................................................................23

3.1 Power-on and start-up...........................................................................................................23

3.2 Available user interfaces .......................................................................................................23

3.3 Operator control ....................................................................................................................23

3.3.1 PCSTAR 2 for Windows : basic installation & operating instructions ....................................23

3.3.2 Summary of User Functions in PCSTAR 2 (F2 – Configuration)...........................................27

3.3.3 Quick Configuration: configuration examples........................................................................33

3.3.4 HART® Communicator: installation & operating instructions ................................................38

3.3.5 Characters available for alpha-numerical data functions in PC STAR 2 and on the HART®

console..................................................................................................................................46

3.3.6 Local user display (instruments equipped with DIN connectors only) ...................................47

3.4 BM 102 MICROFLEX T.D.R. meter characteristics...............................................................48

3.4.1 Gauge operating logic when the reflection is lost ..................................................................49

3.4.2 Gain and voltage amplitude ..................................................................................................50

3.4.3 Level measurement when more than one phase or layer in the tank ....................................56

4

Service / Maintenance.........................................................................................................57

4.1 Replacement of the signal converter.....................................................................................57

4.2 Fault clearing.........................................................................................................................59

2 BM 102

Page 3

5

Technical data.....................................................................................................................63

5.1 Technical data ......................................................................................................................63

5.1.1 Accuracy ............................................................................................................................... 65

5.1.2 Start-up characteristics .........................................................................................................66

5.2 BM 102 equipment architecture ............................................................................................67

5.2.1 BM 102 mechanical options (by probe type).........................................................................67

5.2.2 Definition of terms.................................................................................................................69

5.2.3 Probe measurement limits ....................................................................................................70

5.3 Gauge dimensions ................................................................................................................71

6

Measuring principle............................................................................................................72

6.1 General principle................................................................................................................... 72

6.1.1 Level measurement of one product.......................................................................................73

7

Certificates and Approvals ................................................................................................74

8

PCSTAR 2 software user’s guide ......................................................................................75

8.1 Software installation.............................................................................................................. 75

8.2 PCSTAR 2 software history .................................................................................................. 75

8.3 Supported networks ..............................................................................................................75

8.4 PCSTAR 2 functions .............................................................................................................75

8.4.1 F1 Help .................................................................................................................................76

8.4.2 F2-Connection: on-line functions ..........................................................................................76

8.4.3 F3 Exit:..................................................................................................................................84

8.4.4 F4 Serial (parameters): .........................................................................................................84

8.4.5 F5 Record (Reading): ...........................................................................................................84

8.4.6 F9 Colors ..............................................................................................................................87

8.4.7 Other important PCSTAR 2 functions ...................................................................................87

8.5 Fault Clearing PCSTAR 2 ..................................................................................................... 88

Appendix A: BM 102 Level Gauge Configuration Record ………………………………………... 89

Appendix B: BM 102 – CE Declaration of Conformity…………………………………………..…. 90

Appendix C: Returning a device for testing or repair to KROHNE …………………………..…. 91

BM 102 3

Page 4

Device description and range of applications

The BM 102 MICROFLEX level gauge uses the Time Domain Reflectometry (TDR) measuring

principle and two-wire technology for level measurement. It is designed solely for measuring the

distance, level, volume and ullage of liquids, pastes, slurries and powder products. It can continue to

measure the level or distance and total volume in applications with two products.

The level measurement data can be displayed and the gauge configured using either a HART

Handheld Communicator console (HHC) or a PC work station equipped with PCSTAR2 software

supplied as standard with the gauge.

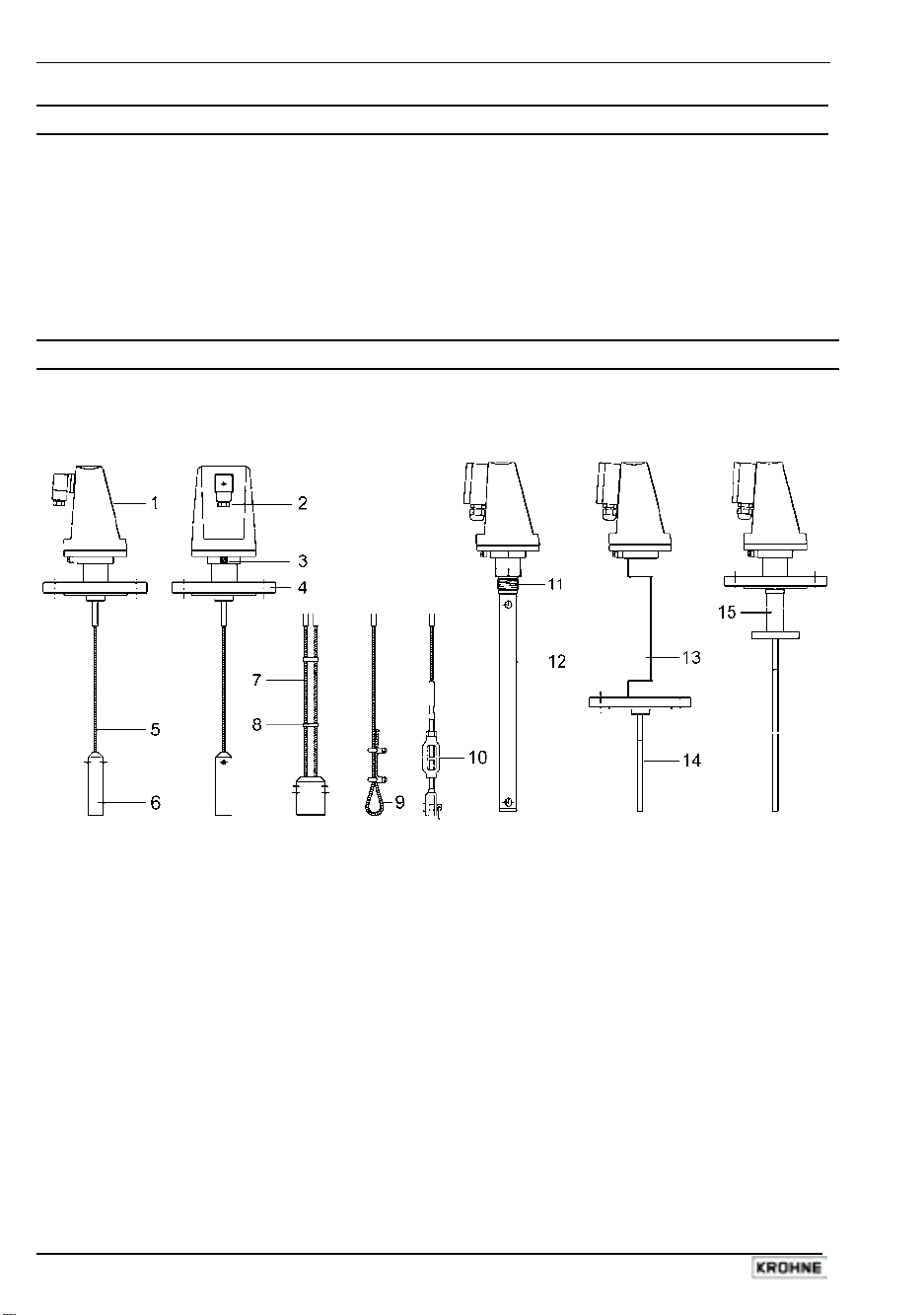

Principal gauge components

BM 102 housing and probes (non-Ex and Ex versions) with high-

temperature

option

with inactive

length

option

1 Nameplate (see next page for details)

2 Cable entry (output and power supply) to wiring compartment

3 Equi-potential bonding system connection (Ex – see section 2.1.4)

4 Flange (process connection onto tank or other suitable mounting)

5 Single cable probe

6 Counterweight (with threaded hole in base for anchoring)

7 Twin cable probe

8 Spacer

9 Chuck / ring (for single cable probes)

10 Turnbuckle (for twin or single cable probes)

11 Threaded process connection (e.g. 1” G, 1” NPT, …)

12 Coaxial probe

13 Extension tube for high temperature applications

14 Single rod probe

15 Inactive length: coaxial tube under the process connection (i.e. an inactive length of the

probe) for installations with long nozzles or concrete roofs – for single rod and single

cable probe versions only

4 BM 102

Page 5

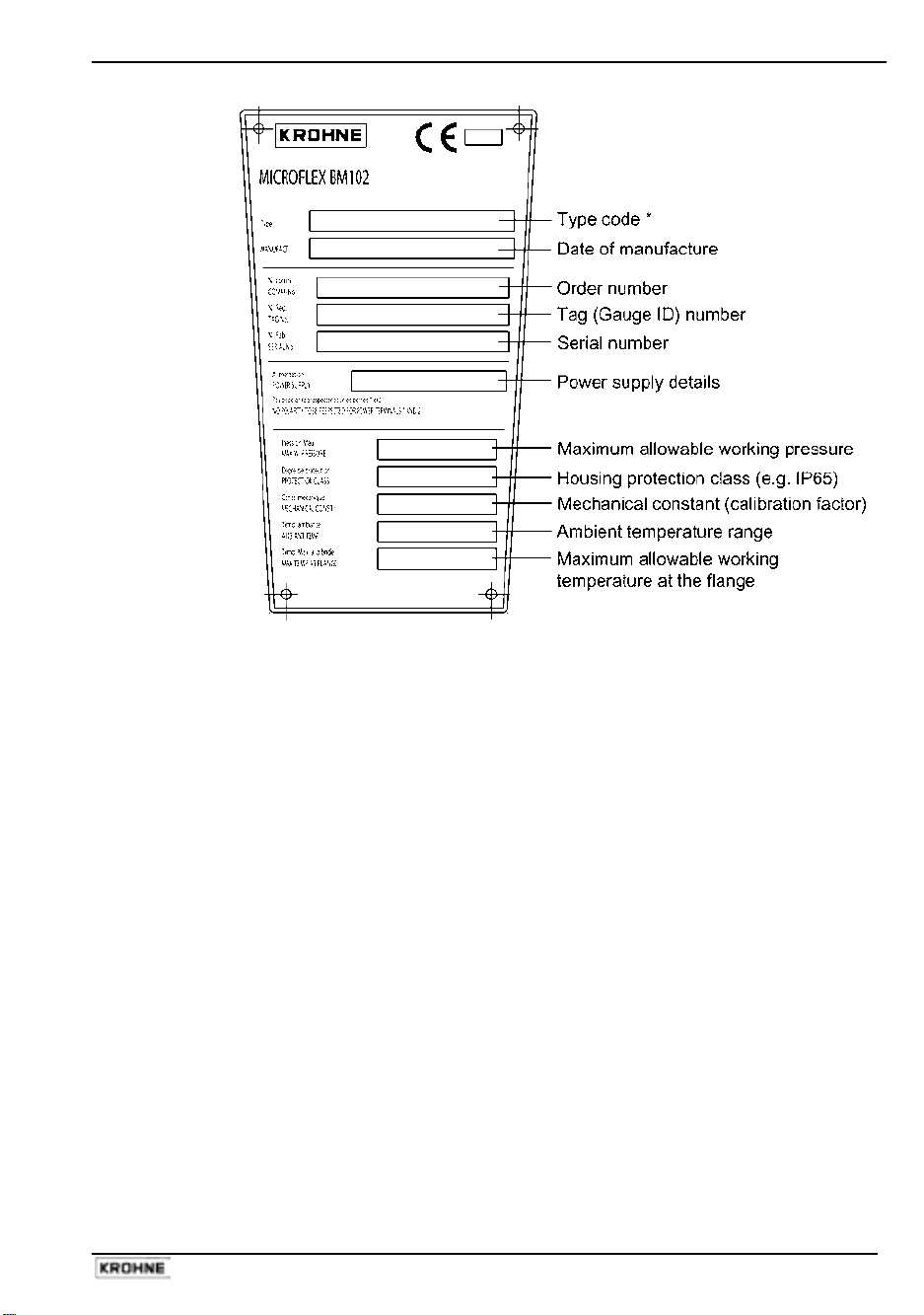

Standard nameplate

*eg. VF030415B0112110110100000. The “type code” gives the options chosen for this unit and is

defined in the BM 102 Data Sheet. This document is available from your local KROHNE Sales

office or on the “Download Centre” on KROHNE’s website http://www.krohne.com/.

BM 102 5

Page 6

Items included with supply:

The scope of supply encompasses:

• Signal converter with probe in the version ordered. The version is stated on the nameplate.

• PCSTAR 2 computer software for data display and gauge configuration.

Documentation supplied:

Installation & Operating instructions:

Installation, connection, start-up and safety advice in condensed form, but sufficient for most

applications. This is supplied as a printed document with the device delivered.

Handbook (this manual):

Detailed user manual and reference book, including how to configure meter parameters available in

the user menu and how to perform basic maintenance. This is not shipped with the level meter

ordered.

Supplementary Installation and Operating Instructions BM 102 KEMA 00 ATEX 1101X:

Supplementary instructions covering devices to be installed and used in hazardous areas. This

document is only supplied with specially approved instruments. This document is available from

your local KROHNE Sales office or on the “Download Centre” on KROHNE’s website

http://www.krohne.com/.

Product liability and warranty:

The BM 102 TDR level gauge is designed for measuring the distance, level, and volume of liquids,

pastes, slurries and powders. It may equally measure level, distance, total volume and ullage in

applications where two or more products are present.

Special codes and regulations apply to its use in hazardous areas. Please refer to the BM 102

MICROFLEX KEMA 00 ATEX 1101X Supplementary Installation and Operating Instructions for

further information. This document is available from your local KROHNE Sales office or on the

“Download Centre” on KROHNE’s website http://www.krohne.com/.

Responsibility as to suitability and intended use of these level gauges rests solely with the user.

Improper installation and operation of our level gauges may lead to loss of warranty.

In addition, the "General conditions of sale", forming the basis of the purchasing contract, are applicable.

If you need to return measuring instruments to KROHNE, please note the information given in

Appendix C. KROHNE regrets that they cannot repair or check your device unless it is

accompanied by the completed form.

The level gauge does not form part of an overfill protection system (as defined for example in

WHG: German water resources act) nor is it concerned by the Pressure Equipment Directive (PED)

97/23/EC.

6 BM 102

Page 7

1 Mechanical installation

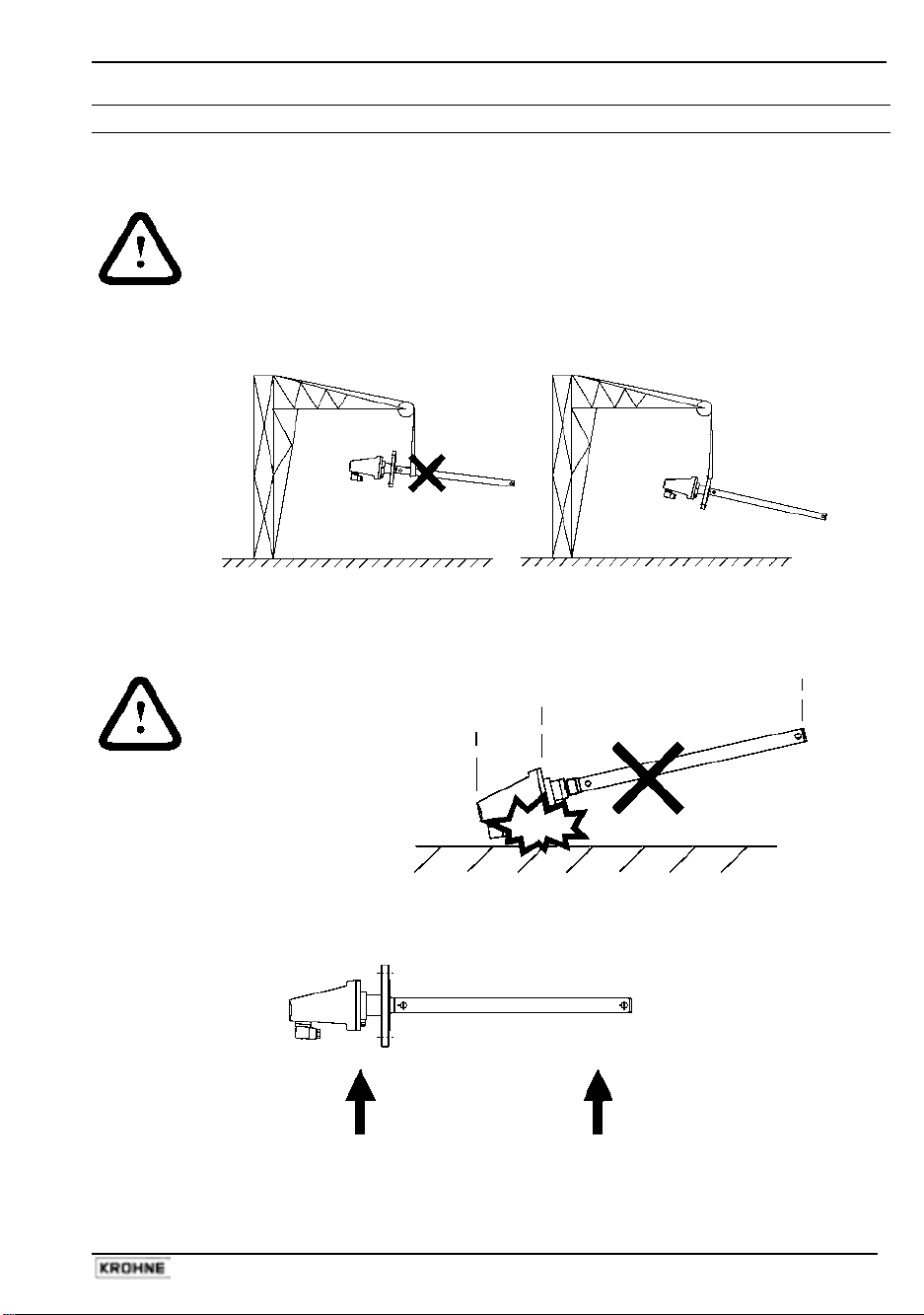

1.1 Handling and storage

To carry: the device will weigh between 3 kg or 7 lb and 12 kg or 25 lb. Carry using

both hands to lift the device carefully by the converter housing. If necessary, use

lifting gear.

No attempt should be made to lift the instrument by its probe.

Caution:

The probe is a critical gauge component.

Do not damage– Handle with care!!!

Avoiding blows

When handling the BM 102, avoid hard blows, jolts, impacts, etc.

Caution:

Fragile electronics

Avoid bending (single rod and coaxial probes)

Support the probe to avoid bending.

Support probe here

BM 102 7

Page 8

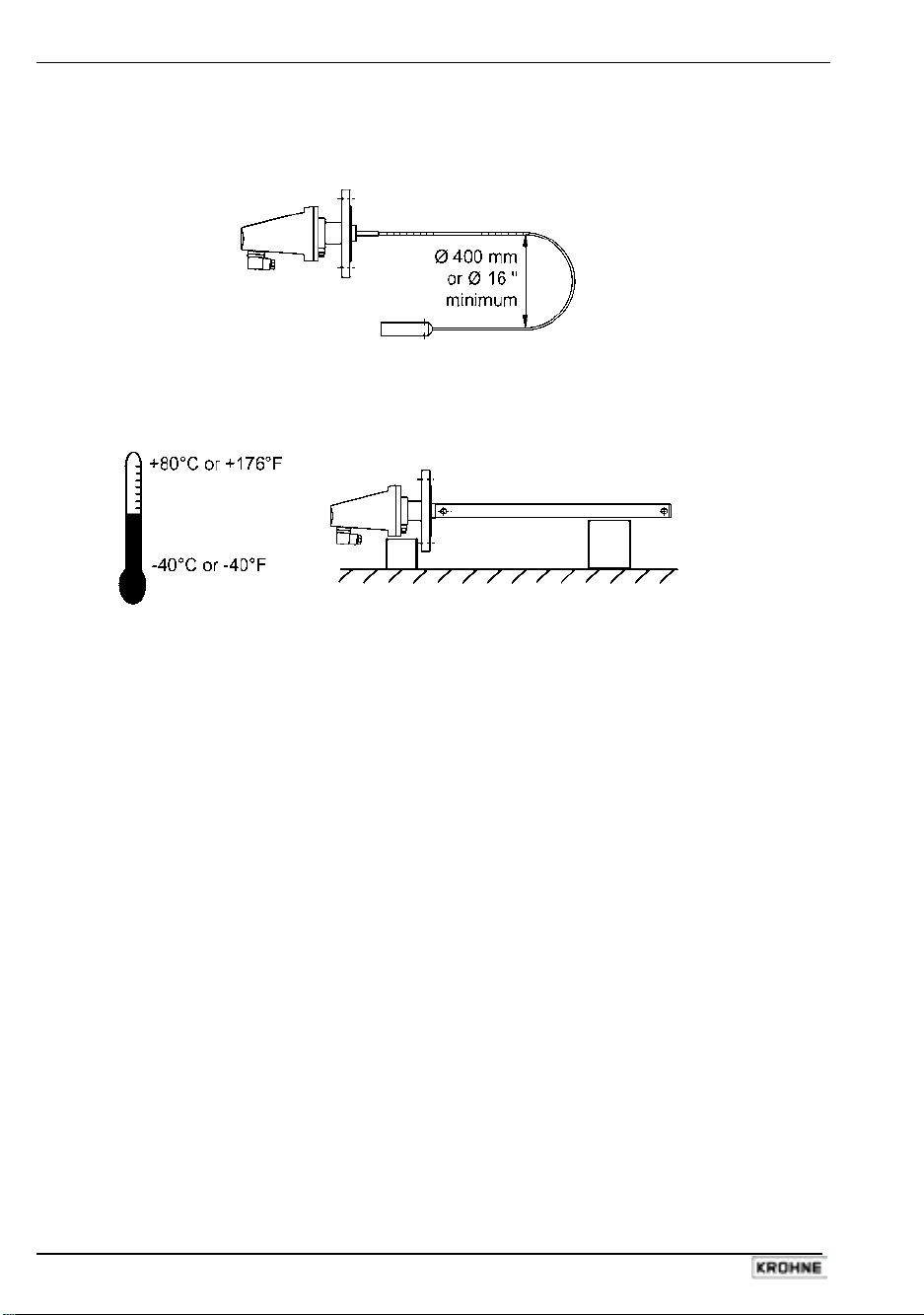

Avoid cable kinks and fraying

Do not coil the cable less than 400 mm or 16 “ in diameter. Cable kinks or fraying will cause

measurement errors.

Storage temperature

Store within the given storage temperature limits.

1.2 Installation restrictions

Hazardous-duty systems (Ex, FM,…)

• Refer to the BM 102 MICROFLEX KEMA 00 ATEX 1101X Supplementary Installation and

Operating Instructions for further information on installing gauges approved for use in

hazardous locations. This document is available from your local KROHNE Sales office or on the

“Download Centre” on KROHNE’s website http://www.krohne.com/.

• Check that the flange, gasket and probe materials are compatible with the product. Read the

information given on the converter nameplate, the flange markings and specifications in the

approval certificates.

1.3 Mounting on the tank

1.3.1 Installation instructions: general notes

The fitter should give some thought to tank fittings and tank shape.

• Nozzle position in relation to the tank walls and other objects inside the tanks

(Warning : this free area will depend on the probe type selected: refer to later on in this section)

• Type of tank roof, i.e. floating, concrete, integral, etc; and base, i.e. conical, etc.

Whenever working on an installation, remember to:

• Disconnect the power supply before starting work.

However,

• The gauge may be installed when the tank contains product.

8 BM 102

Page 9

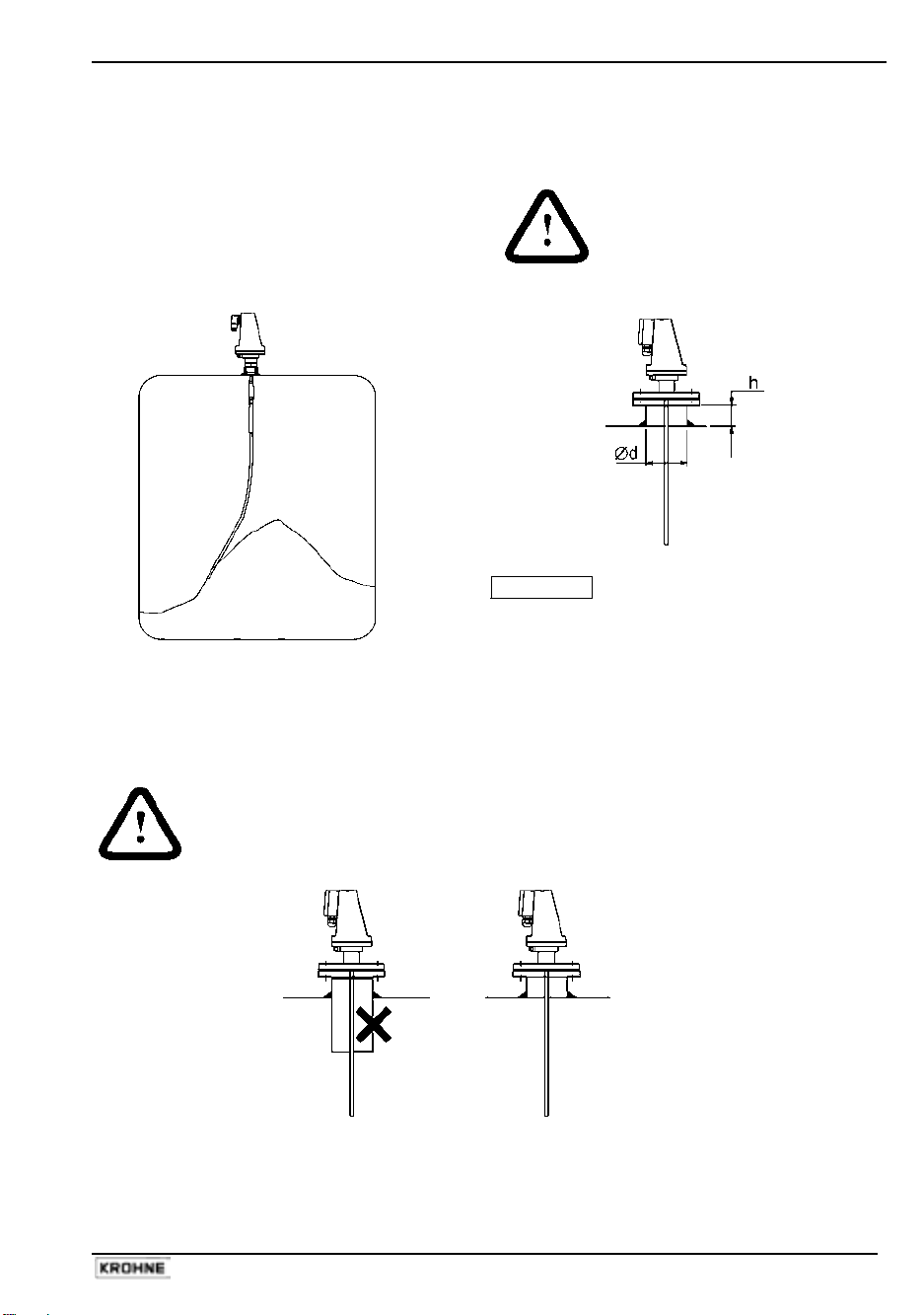

1.3.2 Installation instructions: nozzle

Threaded process connections Nozzle height

The simplest and most economic way is to

mount the BM 102 directly on the tank with a

GAS or NPT threaded connection.

Recommendation

Do not fit a nozzle longer than its

diameter , especially for single

probes and powder applications

Nozzles extending into tank

Caution:

Do not use nozzles that extend into the tank. This will disturb the electromagnetic

emitted pulse and the measurement.

h ≤ Ød

Contact KROHNE if this relationship cannot be

, where h = nozzle height and

d = nozzle diameter

respected.

BM 102 9

Page 10

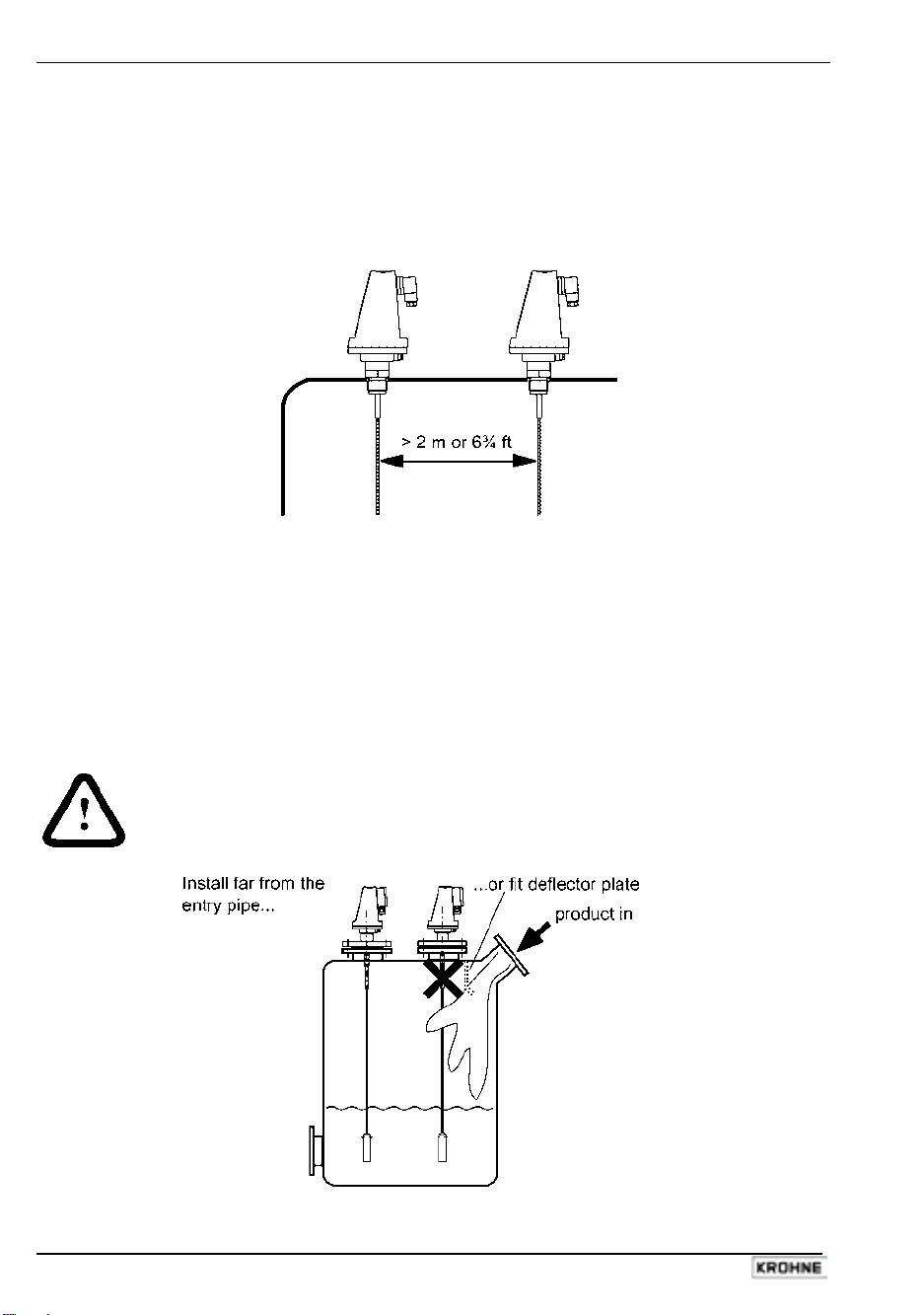

Installation of two devices

If two devices are to be used on the same tank, these should be mounted at a distance of at least

2 m or 6 ¾ ft away from each other. If not, interferences from the electromagnetic (EM) fields

generated by both instruments may cause measurement errors.

Not applicable to coaxial probes - the outer shell of the probe contains the EM field: no minimum

distance required.

Process connection

For the gauge to make accurate measurements:

• The tank process connection must be level.

• Ensure a good fit with the gauge process connection

• The tank roof should not deform under the weight of the gauge

Process connection and entry pipe

Caution:

Do not put the nozzle close to the entry pipe. Pouring the product directly onto the

probe will give false readings. Install deflector plate if impossible to distance gauge

from entry pipe.

10 BM 102

Page 11

Stilling wells

Tanks with floating roofs for petro-chemical applications: use a stilling well.

1 Stilling well

2 Tank

3 Floating roof

4 Product (petroleum applications)

5 Well fixed to tank base (no roof

deformation)

6 Sediment

1.3.3 Installation instructions: Gauge - all applications

BM102 gauges are designed to be mounted on a suitable process connection on a tank or sump.

Install the gauge using two people to avoid damaging the probe. Support the housing and the

probe.

Installation of single and twin cable probe level meters

Caution :

1

Do not over-bend

probe!

Inserting the probe:

2

hold more than one

metre above the

opening to avoid

cable bending.

BM 102 11

Page 12

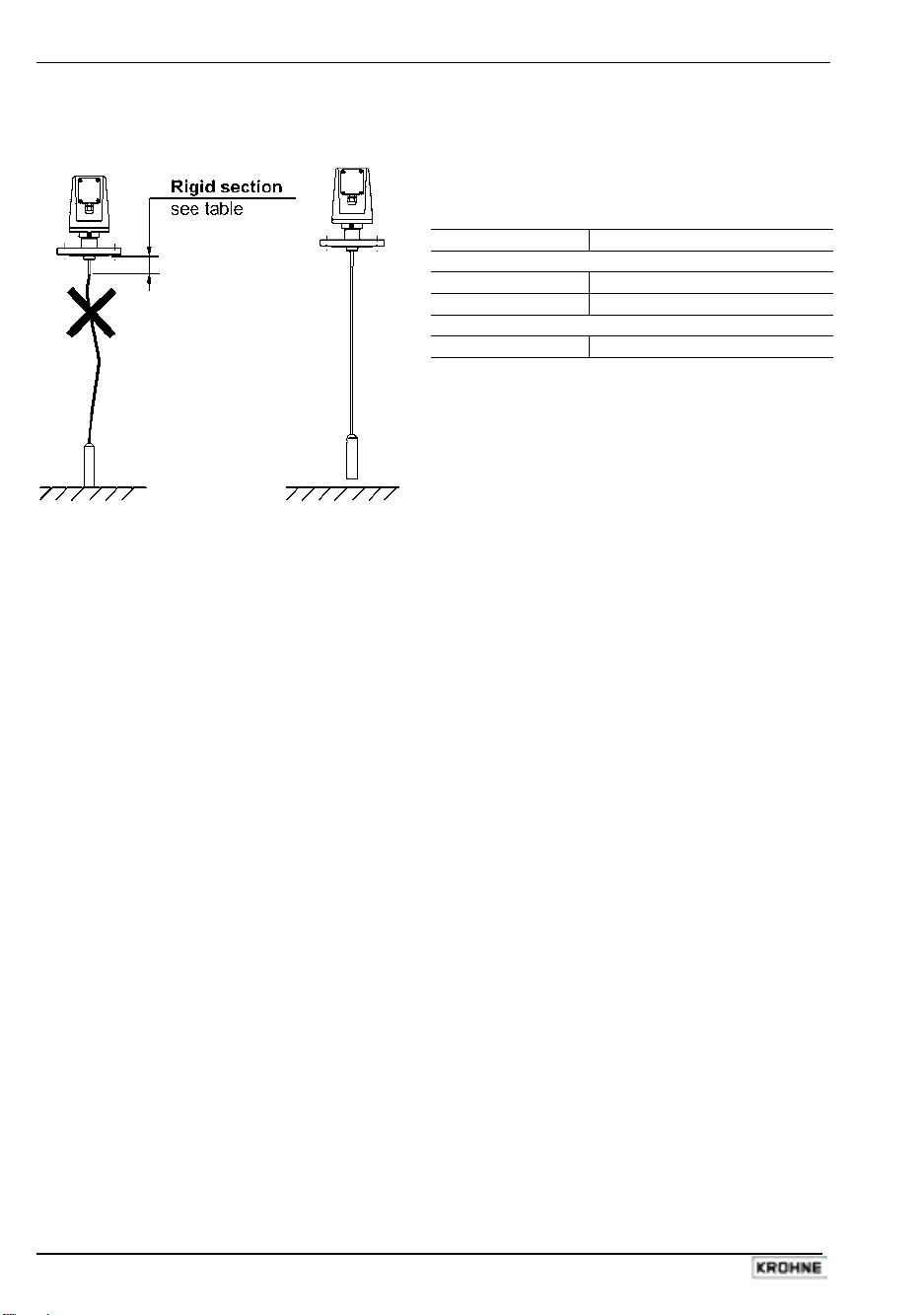

Probes: entanglement, straightness and tank bottom clearance

Rigid section length of single

and twin cable probes

Cable diameter Rigid section length

Single cable

Ø4mm or 0.15” 40mm or 1½”

Ø8mm or 0.15” 200mm or 8”

Twin cable

Ø4mm or 0.15” 40mm or 1½”

• Cable probes must be straight once inserted into the tank. They must also be far from other

objects (e.g. mixers) to avoid entanglement.

• In order to maintain the gauge’s operating characteristics, it is recommended to avoid touching

the tank bottom with the counterweights (for cable probes) or probe end (other types).

Objects (discontinuities) inside the tank that influence the probe’s EM (electromagnetic) field

Install the gauge far from protruding objects such as:

• Heating tubes,

• Sudden changes in tank cross-section,

• Tank wall reinforcements and beams,

• Weld lines and dip-stick pipes, etc...

TDR gauges generate electromagnetic (EM) fields when a measurement pulse is emitted. This field

is affected by any nearby discontinuities and these will weaken and potentially block the emitted

pulse. A minimum distance is recommended depending on the probe type to be installed. See the

table on the next page for recommended free space dimensions.

Alternatively, the fitter may use a reference chamber or stilling well. However, the chamber walls

must be smooth (i.e. no visible weld lines), straight and vertical to maintain the pulse strength and

gauge accuracy.

For clean applications only :

Coaxial (type 3) probes may be used close to or touching objects or walls as the EM field generated

by the probe is contained within the probe’s outer sheath (refer also to the EM field sizes/free area

given in the figures on the next page).

12 BM 102

Page 13

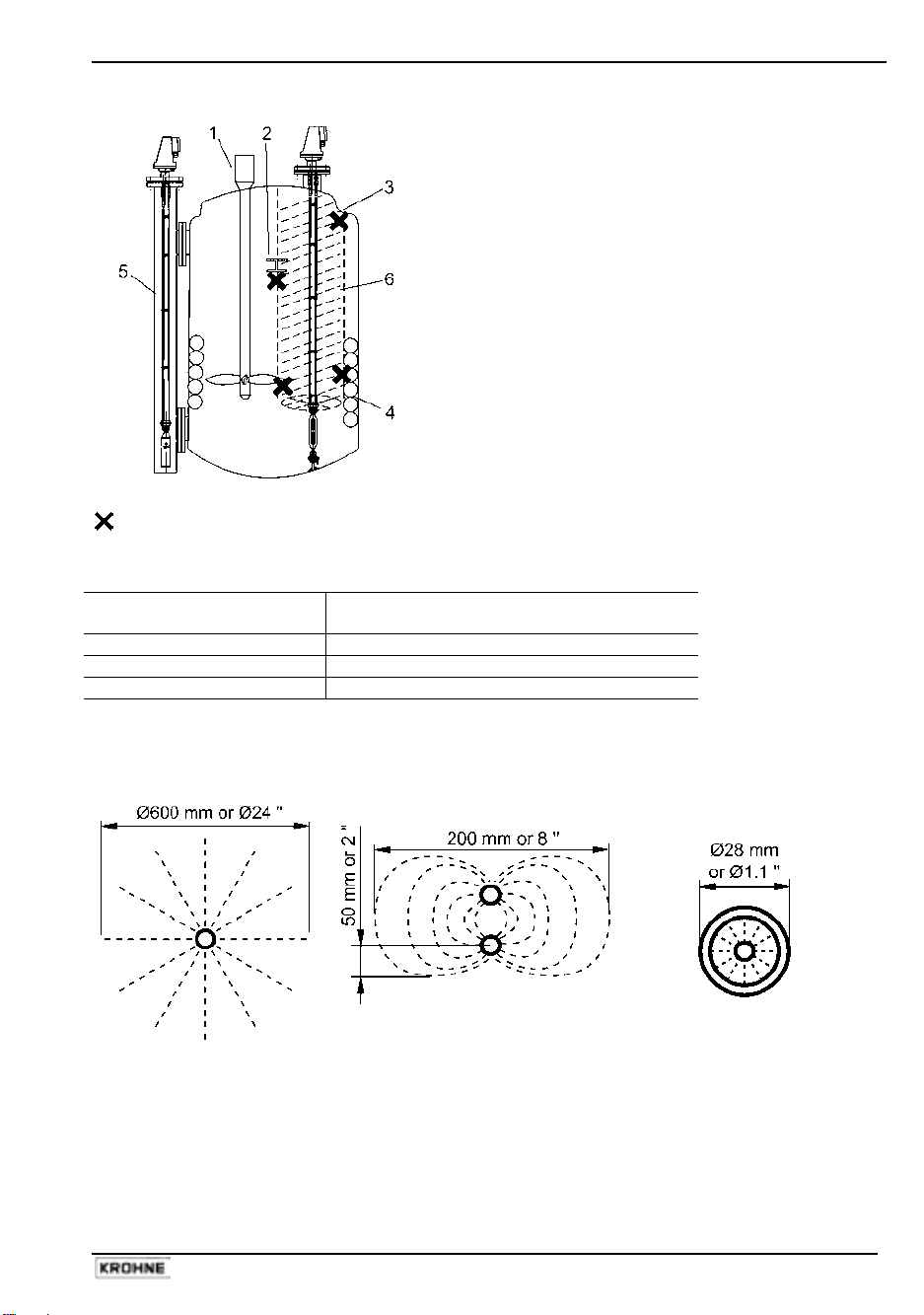

1 Agitator

2 Support beam perpendicular to the

pulse direction

3 Abrupt changes in tank cross section

4 Heating tubes

5 Alternative solution: reference chamber

-electromagnetic field is contained

within chamber

6 Gauge electromagnetic field:

Any intruding metallic object will be

detected in this zone if perpendicular to

the emitted pulse direction.

= Do not fit the gauge near to these objects.

Recommended minimum distance of probe from objects inside the tank

Probe Type

Minimum free space

Single (types 1,2 and 6) 300 mm or 12”

Twin (type 4) 100 mm or 4”

Coaxial (type 3) 0 mm or 0”

Electromagnetic field shape around probe, by type (not to scale)

Single (types 1,2 and 6) Twin (type 4) Coaxial (type 3)

No beam angle for any probe type.

BM 102 13

Page 14

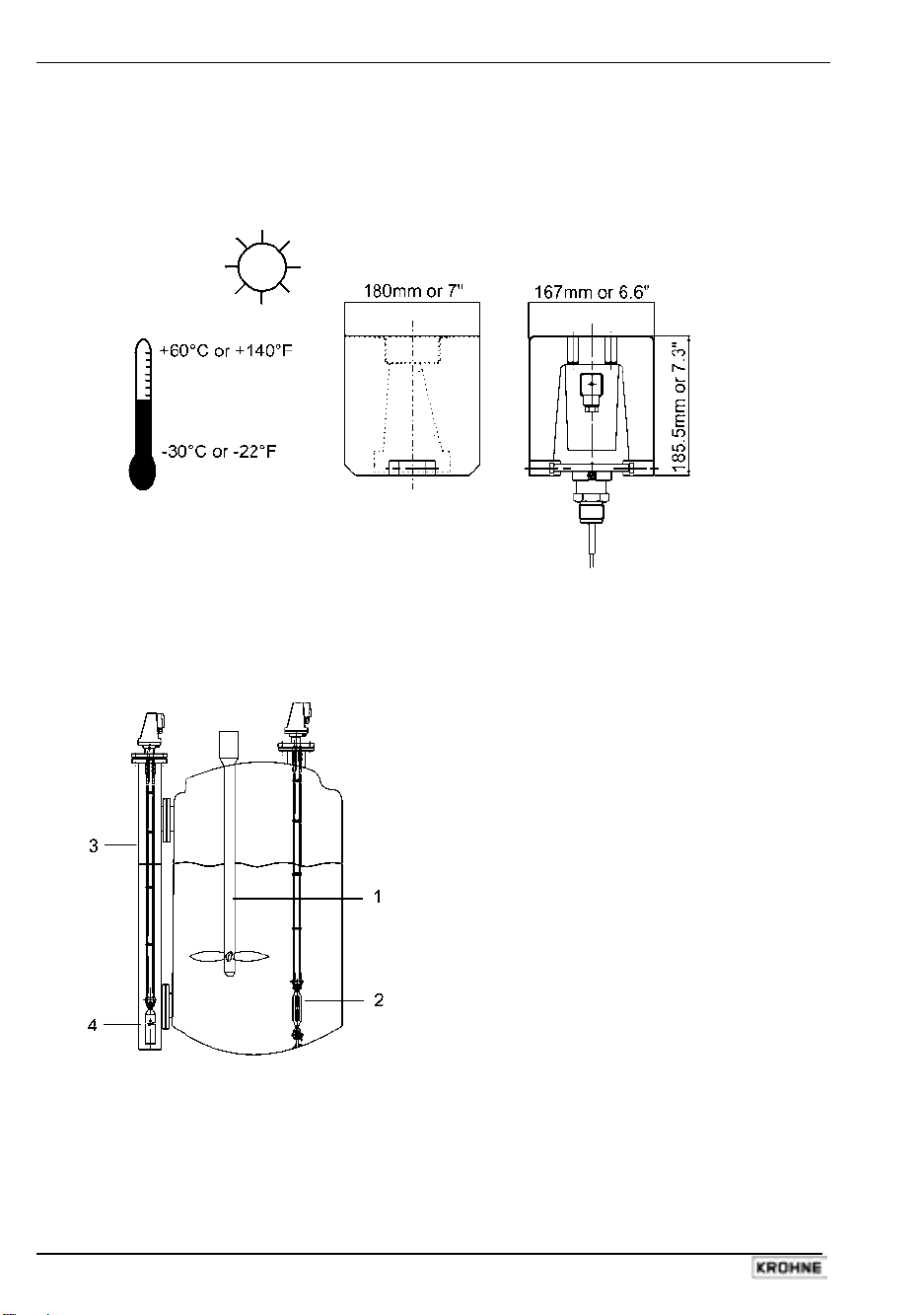

Avoid direct solar radiation

Fit a sunshade on the gauge for open-air installations: this is either supplied on demand by

KROHNE or provided by the customer. The ambient temperature limits of the gauge are given

below.

1.3.4 Specific installation instructions: gauge - liquid applications

Probe bending in agitated products: recommended solutions

1 Agitator

2 Turnbuckle for anchoring probe to

tank bottom

3 Bypass chamber

4 Probe and counterweight (centred on

request)

Mounting on a reference vessel or still well is ideal. To ensure that the probe does not come into

contact with the tank wall, the probe should be fixed to the bottom of the chamber or centred.

14 BM 102

Page 15

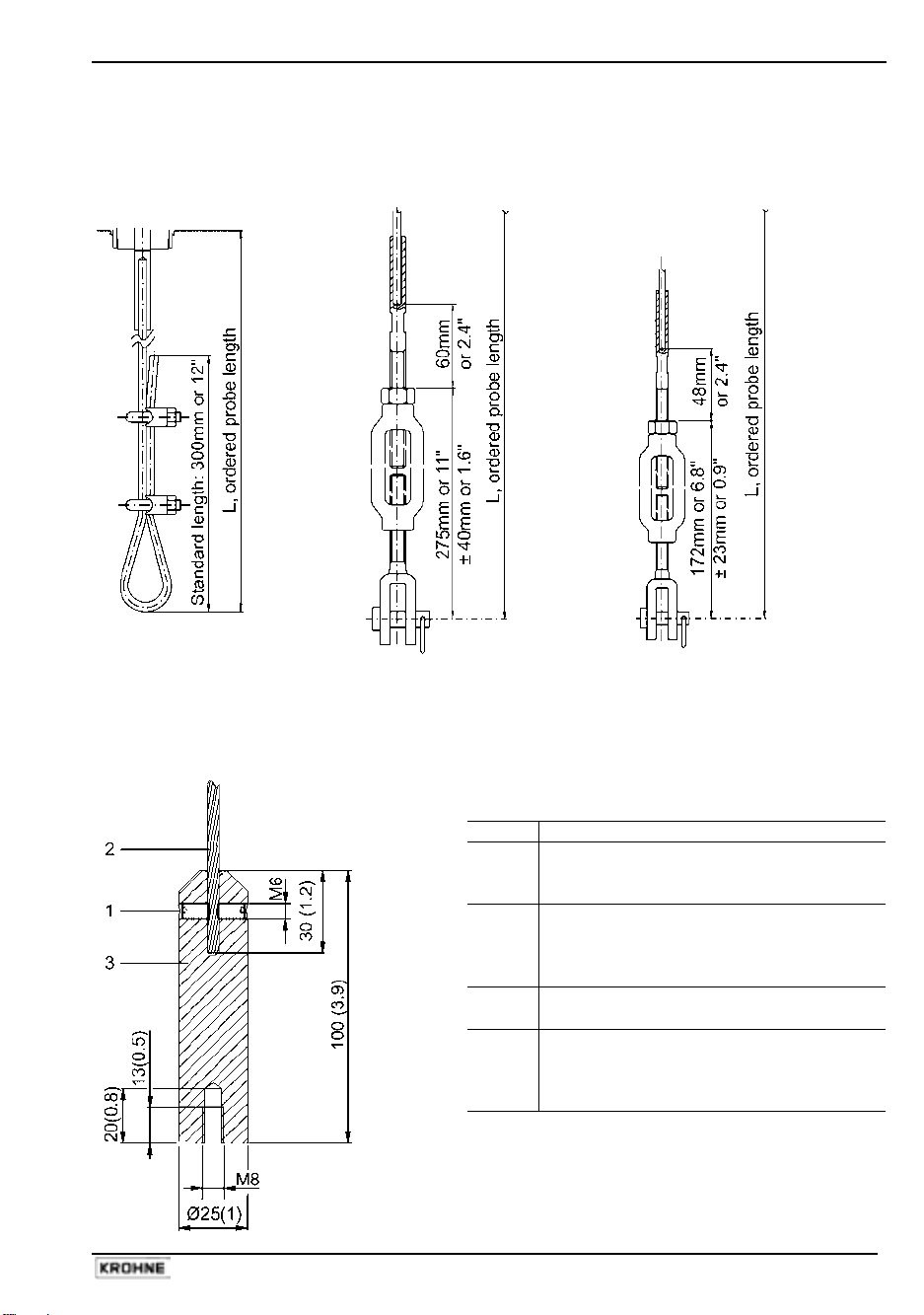

Fastening the probe to the tank bottom

Flexible probes can be fastened with a chuck (ring), turnbuckle or similar fastening device to the

tank bottom:

Chuck (ring) Turnbuckle for Ø8 mm cable

probes

Turnbuckle for Ø4 mm cable

probes

Shortening cable probes

If required, the cable probe can be shortened, but this applies only when used in liquids.

Procedure

Step Action

1 Detach socket set screw M6x10 (ISO

4026) with a 3mm Allen (hexagon) key

(ISO 2936).

2 Pull cable (2) out of counterweight (3)

and shorten to required length using

cable cutters to prevent the cable wires

and strands from splaying out.

3 Insert cable back into counterweight and

tighten down screws

4 Change configuration parameters to new

probe length; the reference point is the

top edge of the weight (user menu

function 1.1.6)

Dimensions in mm (inches).

BM 102 15

Page 16

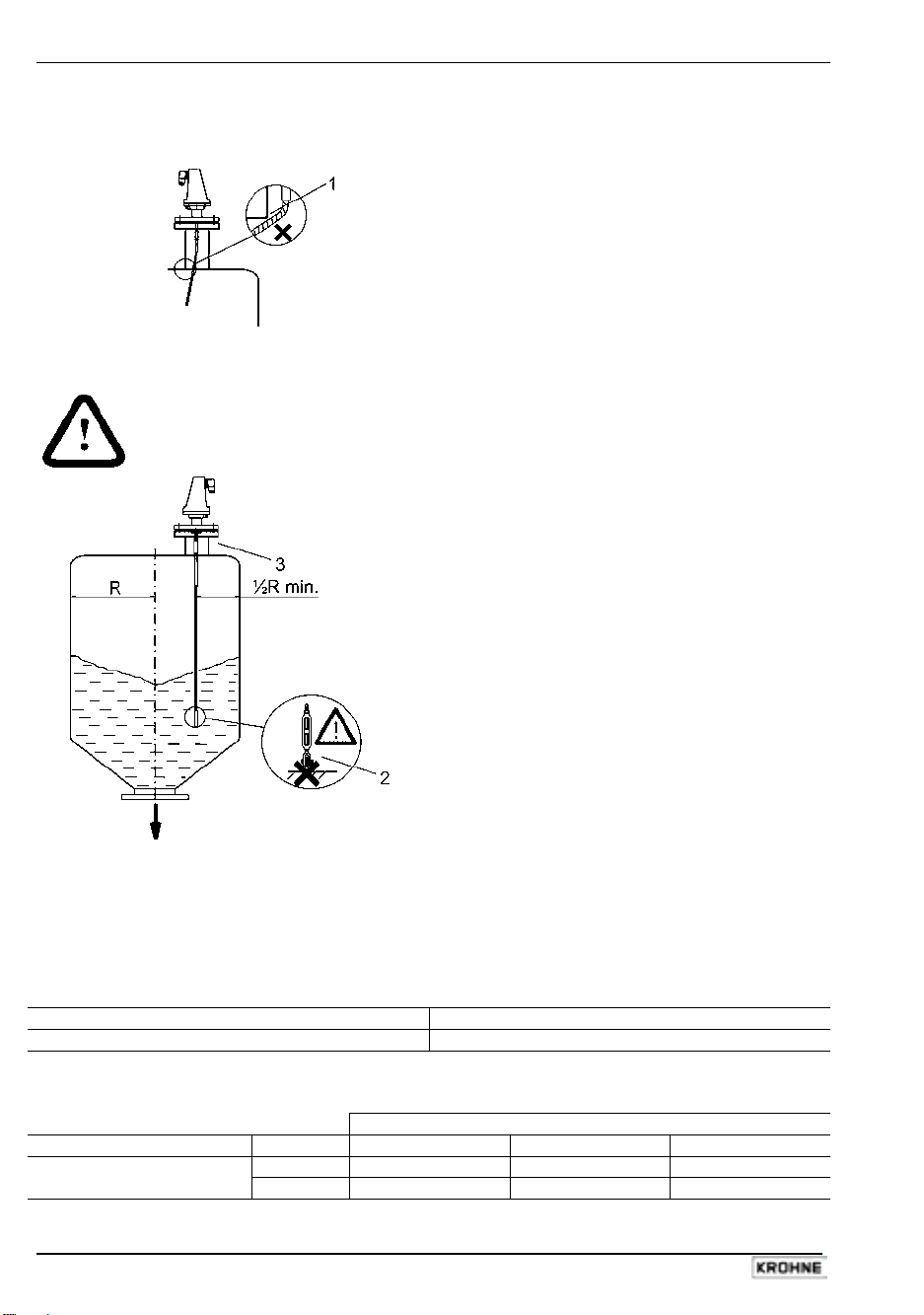

1.3.5 Specific installation instructions: gauge - solid applications

False readings:

1 Do not let probe touch the side of the nozzle

Conical silo nozzles, false readings and traction on the cable probes

Caution

High traction forces :

2

We recommend that the probe should not be

anchored to avoid excessive traction loads on

the cable.

Bending and traction:

3

Position the connection on the roof at ½

radius of the tank and with minimum nozzle

height. This will avoid damage due to bending

and traction during emptying.

Traction forces during emptying cycles for powder applications

Traction load is dependent upon the height and shape of the tank, product particle size & density,

and the rate at which the tank is emptied. The table below gives the load up to which cable probes

will hold.

Cable maximum design load, traction

Probe Maximum Load

Single cable Ø8 mm or Ø0.3” 3.5 T or 7700 lb

Traction on cable according to product (approximate value in metric tons)

Probe Length / m (ft)

Probe used Material 10 (33) 20 (65.5) 24 (79)

Cement 1.0 T or 2200 lb 2.0 T or 4410 lb 2.4 T or 5290 lb Single cable Ø8mm or

Ø0.3”

Flyash 0.5 T or 1100 lb 1.0 T or 2200 lb 1.2 T or 2650 lb

16 BM 102

Page 17

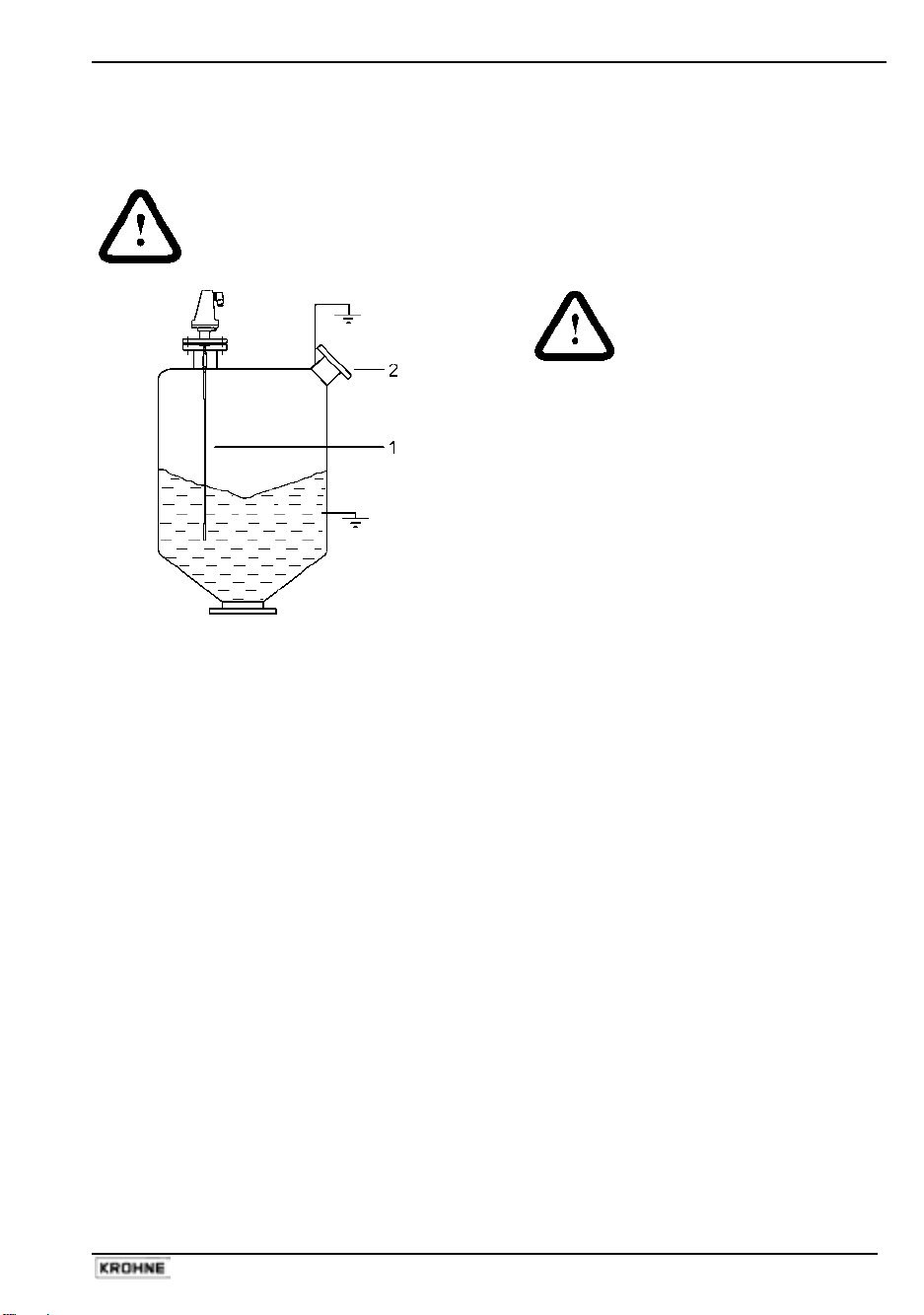

Electro static discharge (E.S.D.)

BM 102 non-Ex and Ex gauge electronics are shielded up to 4kV against E.S.D..

Note:

E.S.D. cannot be solved by BM102 E.S.D. protection. It is the customer’s

responsibility to avoid E.S.D. by grounding the tank, product and probe installation.

1

Danger of injury

The probe may receive an electrostatic

discharge during operation; earth the probe

by pushing it against tank wall with a

suitably isolated tool just before touching it

to avoid receiving a shock.

2 Earth the entry pipe and product.

Product deposits on the nozzle and probe

Product build-up can occur under the nozzle: this may weaken the pulse. Avoid cavities that permit

the build-up of deposits.

Tank roof deformation

Tank roofs should support loads of at least 3.5 tonnes or 7700lb for gauge installations using

Ø8mm or 0.3” (type 6) single cable probes.

BM 102 17

Page 18

2 Electrical connections

2.1 Electrical installation instructions

2.1.1 Wiring general notes

Connection to power is effected at the plug connector in the signal converter. Two wiring

compartments are available: DIN connector or M16 terminal box. Observe applicable rules and

regulations for cable connection: VDE 165 or equivalent national regulations.

Always disconnect from power supply before opening wiring compartment. This is not mandatory for

Exi applications.

Hazardous-duty systems

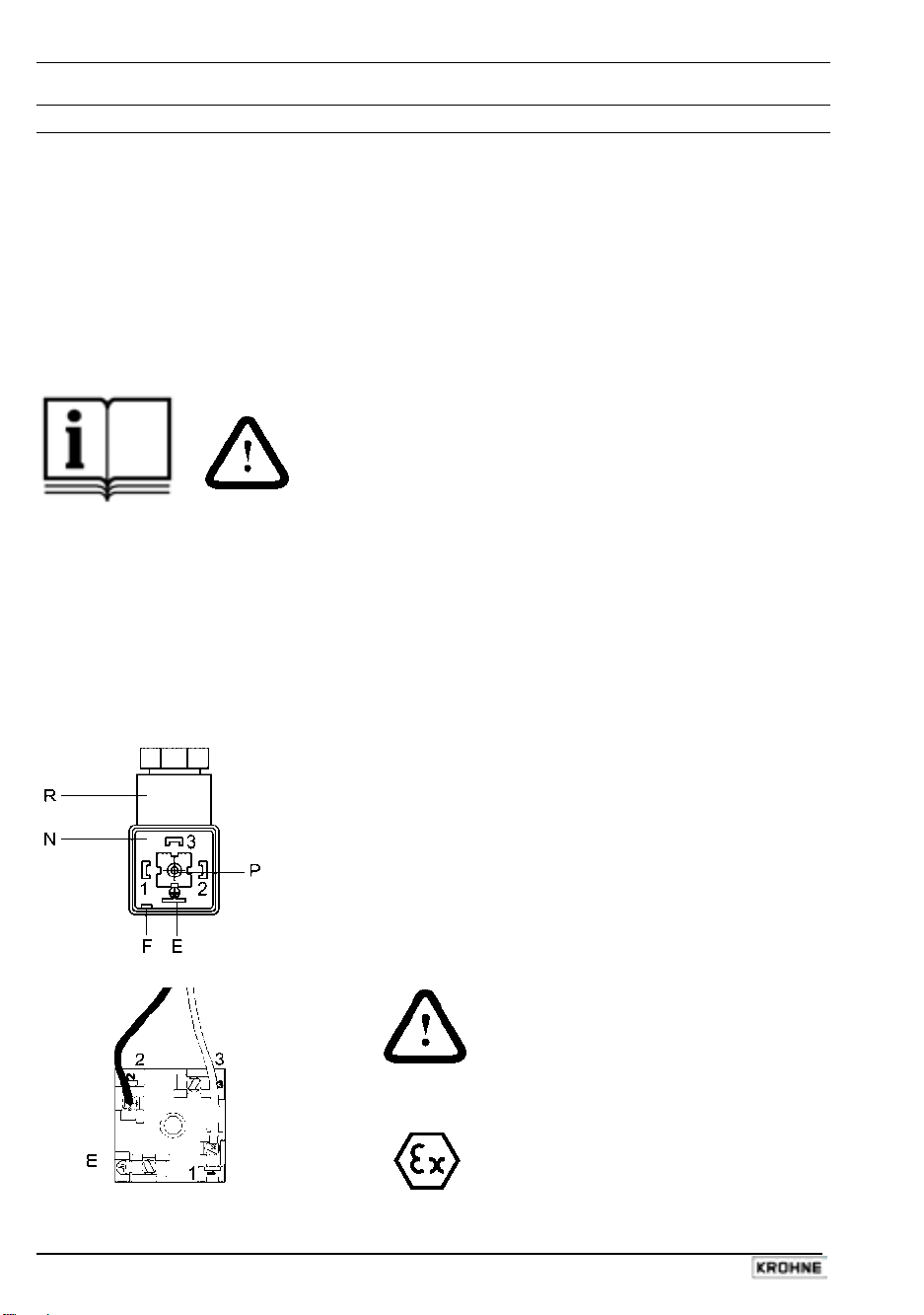

2.1.2 Wiring connections: DIN connector

Terminals: 3 poles and 1 x ground. Wire cross-section: max. 1.5 mm²

Cable entry: 1 x PG11, cable diameter: 8 … 10 mm (0.31 … 0.39”), IP 65

Shielding: do not connect to the DIN connector.

Signal cable: no shielding required

18 BM 102

Only certified intrinsically safe equipment may be connected to

the BM 102 in hazardous areas. Please refer to the BM 102

MICROFLEX KEMA 00 ATEX 1101X Supplementary Installation

and Operating Instructions for further information. This document

is available from your local KROHNE Sales office or on the

“Download Centre” on KROHNE’s website http://

www.krohne.com/.

(AWG 16)

1 Detach screw P and remove plug from signal

converter.

2 Separate part N from part R by inserting the flat

tip of a screwdriver into gap F.

3 Connect current loop to terminals 1 and 2 (any

polarity). Use ferrules to protect cable ends.

Terminals 3 and E are not connected.

4 Fit parts N and R together again.

5 Fit gasket, re-insert connector plug R on the

signal converter, and replace screw P.

Caution

Grounding terminal E is not connected to

the housing of the signal converter or to

the device flange. To avoid ground current

loops, the cable shielding may not be

connected at both ends.

Hazardous-duty systems

When used in hazardous areas, only one

intrinsically safe power supply may be

connected to terminals 1 and 2. Ground

terminal E and terminal 3 are not

connected.

Page 19

2.1.3 Wiring connections: M16 terminal box

Power terminals: Wire cross-section: max. 1.5 mm² (AWG 16)

Cable entry: 1 x M16 x 1.5, cable diameter: 3.5 … 8 mm (0.14 … 0.31”), IP 65

for USA: ½” NPT conduit connection

Shielding: Do not connect shielding to the terminal compartment.

Hazardous-duty systems

When used in hazardous areas, only one intrinsically safe power supply may be

connected to terminals 1 and 2. Ground terminal E is not connected.

Caution

Ground terminal, E, is not connected to the signal converter housing or to the device

flange. To avoid ground current loops, the cable shielding may not be connected at

both ends.

1 Detach the 4 screws, T, and remove cover from terminal

compartment.

2 Connect the cable ends, fitted with ferrules, to the power

terminal, U (not polarity sensitive).

3 Shut the terminal compartment.

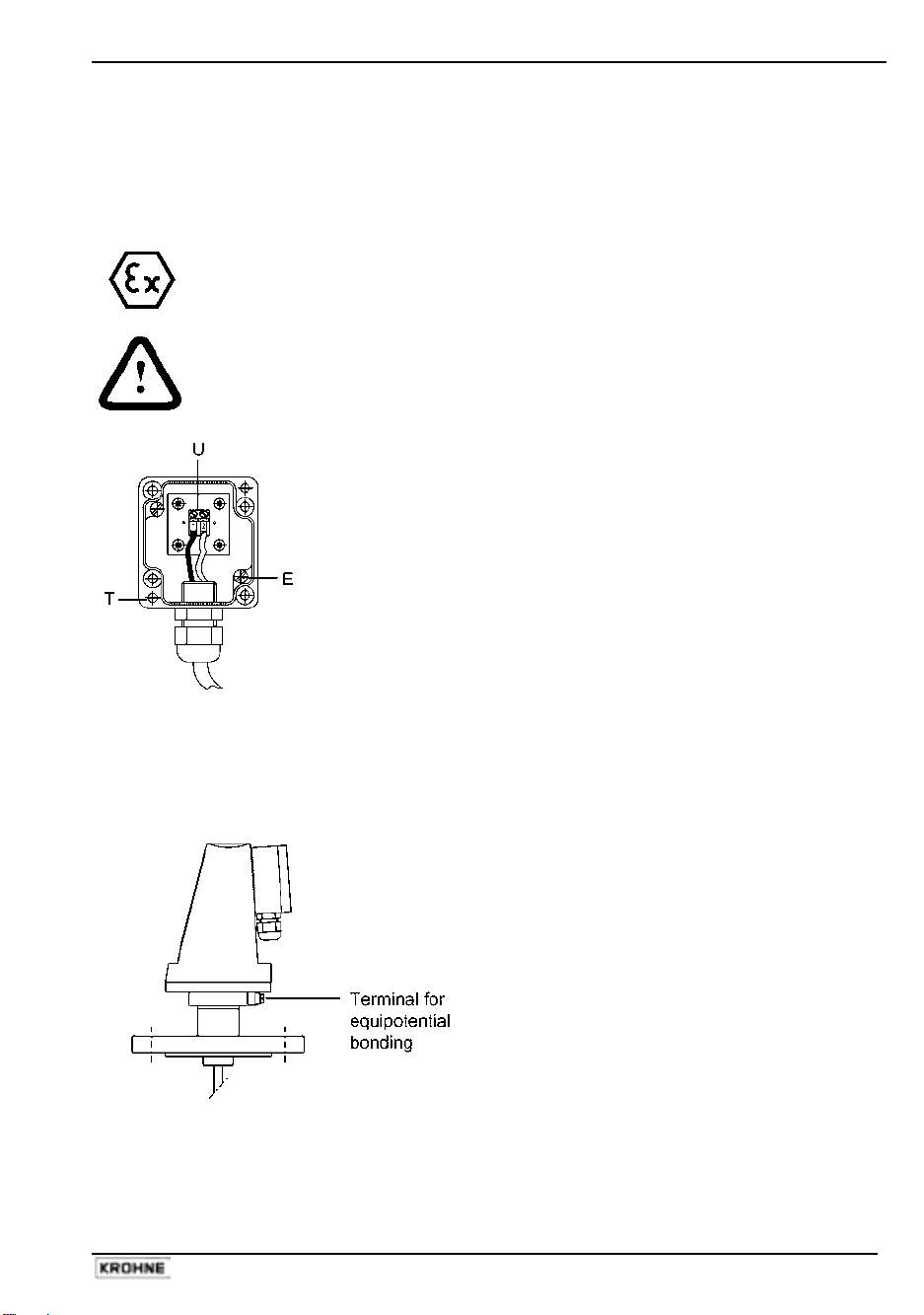

2.1.4 ’Ex’ equalizing conductor

Refer to the BM 102 MICROFLEX KEMA 00 ATEX 1101X Supplementary Installation and

Operating Instructions for further information.

Terminal for equipotential bonding

U-clamp terminal,

max. conductor cross-section:

4 mm²/6.2 • 10-3 sq.in. on ’neck’ of signal

converter

BM 102 19

Page 20

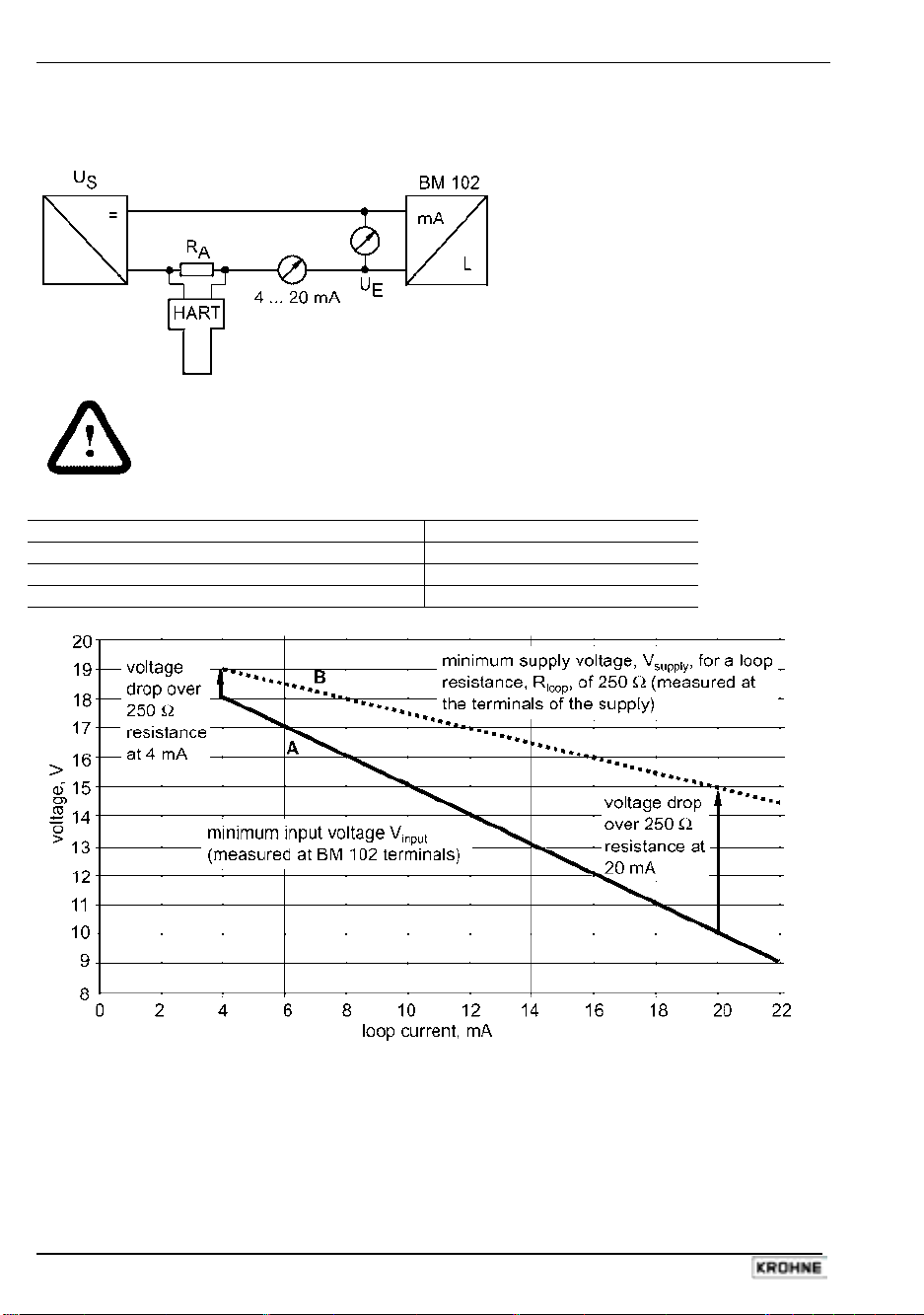

2.2 Power Supply

2.2.1 Non-hazardous-duty version

Power supply

Rated voltage 24 V DC

Max. voltage

(U

input

Min. voltage

(U

input

HART

+ R

cable

+ R

A supply voltage above 35 V DC can cause irreparable damage to the signal

converter. Also, power supply voltages above the specified max. values and below

the specified min. values can lead to faulty measurements or to a device reset.

Load impedance R

Loop resistance, R

Min. R

Max. R

R

HART

0 ohms

loop

750 ohms

loop

resistance for HART® communication 250 ohms (recommended)

loop

R

loop

):

):

ammeter

35 V DC

’Ex’ = 28 V DC

dependent on

load impedance,

see graph below

Line A = minimum voltage at the BM 102 terminals

Line B = voltage drop caused by a 250 ohm loop resistance

20 BM 102

Page 21

Example for calculating the power supply:

The voltage drop is tested at 22 mA.

U

power min. 22

U

power min. 22

= 22 mA x load impedance + Uinput min. 22

= 22 mA x 250 ohms + 10 V = 5.5 V + 10 V = 15.5 V

In order to cover the whole current range, the voltage drop must also be tested at 4 mA.

By analogy, the following applies:

U

power min. 4

U

power min. 4

= 4 mA x load impedance + Uinput min. 4

= 4 mA x 250 ohms + 18 V = 1 V + 18 V = 19 V

At a load impedance of 250 ohms, a power supply voltage of 19 V is sufficient to energize the

current device range of 4 to 20 mA.

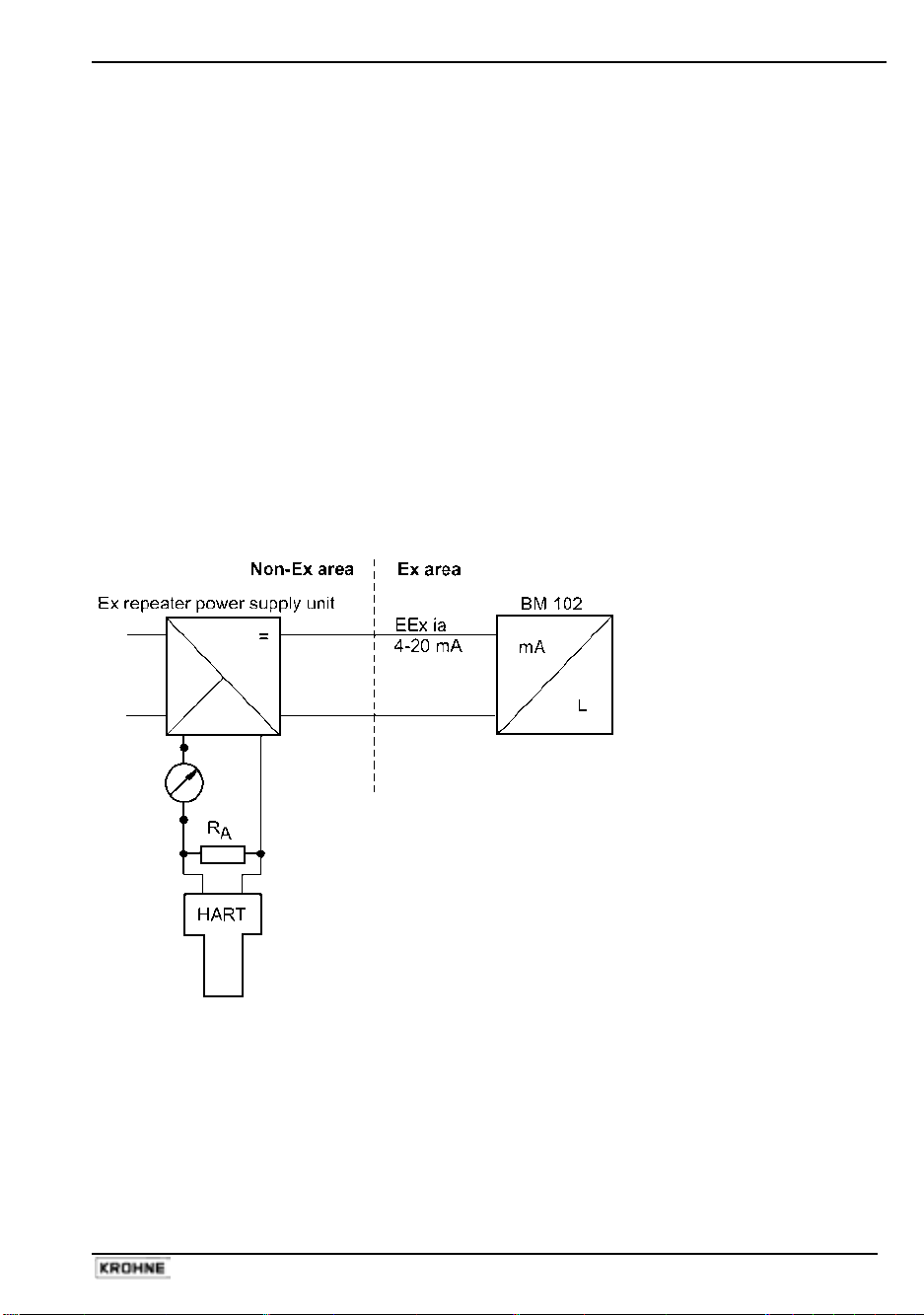

2.2.2 Hazardous-duty version

The certified device may only be used with other ’Ex’ certified equipment. The minimum electrical

safety data indicated on the nameplate must be observed. To ensure proper operation, the

minimum parameters specified above in section 2.2.1 for the power supply must be observed to

ensure that a given 4 to 20 mA converter is adequate for use with the BM 102. Refer to the BM

102 MICROFLEX KEMA 00 ATEX 1101X Supplementary Installation and Operating Instructions

for further information. This document is available from the “Download Centre” on KROHNE’s

website http:// www.krohne.com/.

In addition, the connected

equipment must be HART

®

compatible so that it can be

operated with the

communication software or

the HART® communicator.

An ’Ex’ repeater power

supply unit must be used.

For calculation of the supply

voltage the same applies as

for the non-’Ex’ version.

-

BM 102 21

Page 22

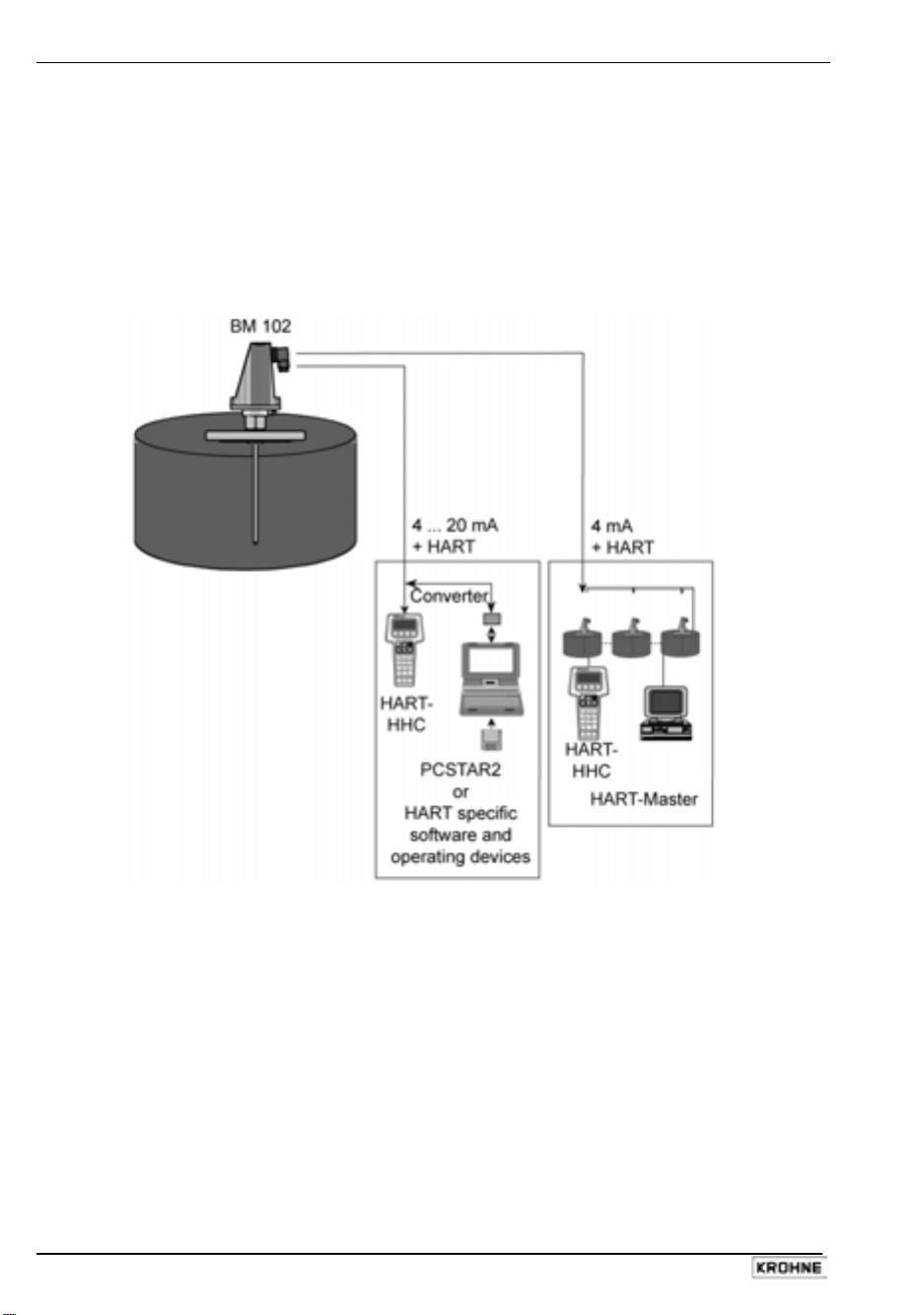

2.3 Electrical output

2.3.1 Network options

The output is available in 2 versions:

1. Current output HART®, passive, HART® protocol

2. Current output Ex-ia HART

All versions with HART® protocol can be operated with the PC-STAR 2 program.

®

intrinsically safe; passive, HART® protocol

2.3.2 HART

In accordance with the Rosemount Standard, HART® communication can be used with a BM 102.

It is used as a point-to-point connection between the BM 102 as slave and the HART

®

communication protocol

®

master.

Additional information

The following can be called up via the following interfaces:

• Current output: 22 mA for error signal.

• Digital HART

®

interfaces: scanning of error flags and error messages.

22 BM 102

Page 23

3 User interface

3.1 Power-on and start-up

The BM 102 is pre-configured in accordance to customer order specifications and measurements

can be made immediately. A start-up time of less than 23 seconds should be allowed for once

connected and the power is switched on.

If the probe length has been shortened since delivery, please refer to section 3.3.1: Summary of

User Functions, user function 1.1.6: Probe length to modify configured probe length.

3.2 Available user interfaces

Measurements may be taken using either:

• PC STAR 2 software

• HART® Handheld Communicator (HHC)

• DA 06 local indicator

Included as standard with the instrument. The

basic installation & operating instructions are

presented in section 3.3.1 (requires PC

workstation).

Sold separately. Automatic recognition of the

instrument when connected. A list of HHCaccessible parameters is given in section 3.3.4.

Sold as an option for devices equipped with DIN

connectors. For displaying readings only. Refer to

section 3.3.6 for technical data.

3.3 Operator control

You can configure the device by way of the HHC or the PC-STAR 2 software. This is explained

further in sections 3.3.1 and 3.3.2. Operator control via the separate HHC is described in the

operating instructions supplied with the communicator.

3.3.1 PCSTAR 2 for Windows : basic installation & operating instructions

Software description

PC STAR 2 is a Windows program that permits clear and concise display of data and configuration

of the BM 102 from a remote location. The program is available in English, German or French.

PC-STAR 2 system requirements

• PC with at least 486 processor 75 MHz, recommended: Pentium 120 MHz or higher

• Microsoft Windows 9x, Me, 2000, NT and XP*

• min. 16 MB main memory (RAM)

• min. 3 MB available hard disk storage

• 3 ½ “ Floppy disk drive

• Mouse or other pointing device

• Serial RS 232 port

* XP may not be automatically recognized by PCSTAR 2 in versions prior to V2.01. Refer to

Section 8.5 for the corrective procedure.

BM 102 23

Page 24

Installing and connecting PCSTAR 2 to the gauge

1. Connect the HART® adapter (not included in supply) through a load impedance of 350 ohms

maximum (for hazardous-duty purposes, fix to the non-intrinsically safe side of the repeater

power supply unit) and plug it into a serial interface on your PC. The repeater power supply

unit must have HART® capability.

2. Installing the program: Access the files on the floppy disk supplied with the instrument and

execute the file "setup.exe" and follow the instructions on the screen.

3. Running the program: once the program is installed, execute the program. The screen shown

below will be displayed.

24 BM 102

Page 25

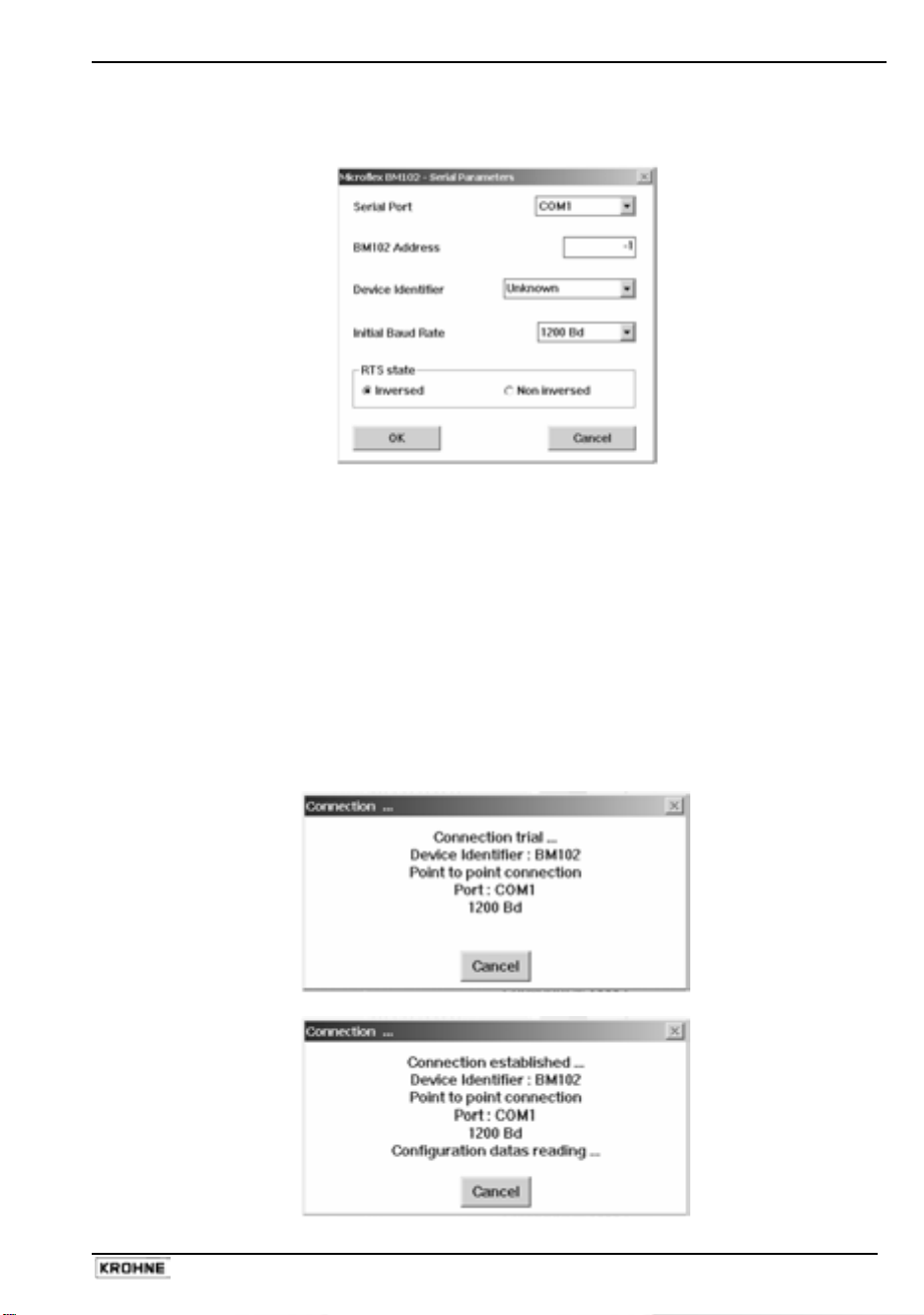

4. Define device interface: type F4 or left-click on “F4-Serial” at the bottom of the screen - to

define the interface to which the device is to be connected.

Serial Port The serial port allows the user to select a free serial port (COM 1 to 4) on the

computer.

BM102 Address Type the “Address” that you have given a gauge (a value between 0 and 15)

and press ENTER or OK. This will select the required device. If you are in a

point to point network leave the box at its default value (-1).

Device Identifier Device Identifier refers to the “Device number” given in User Function No.

1.4.4.

Initial baud rate Transmission rate of data. Has a default value of 1200 bd.

RTS state The RTS state depends on the type of RS232 converter used. For

RS232<>HARTTM(i.e. VIATOR from MACTEK) use inversed RTS state.

5. On-line connection with the gauge: Press F2 or left-click on “F2-Connection” to set up the

connection with the device - the configuration parameters are automatically loaded into the

computer.

then …

BM 102 25

Page 26

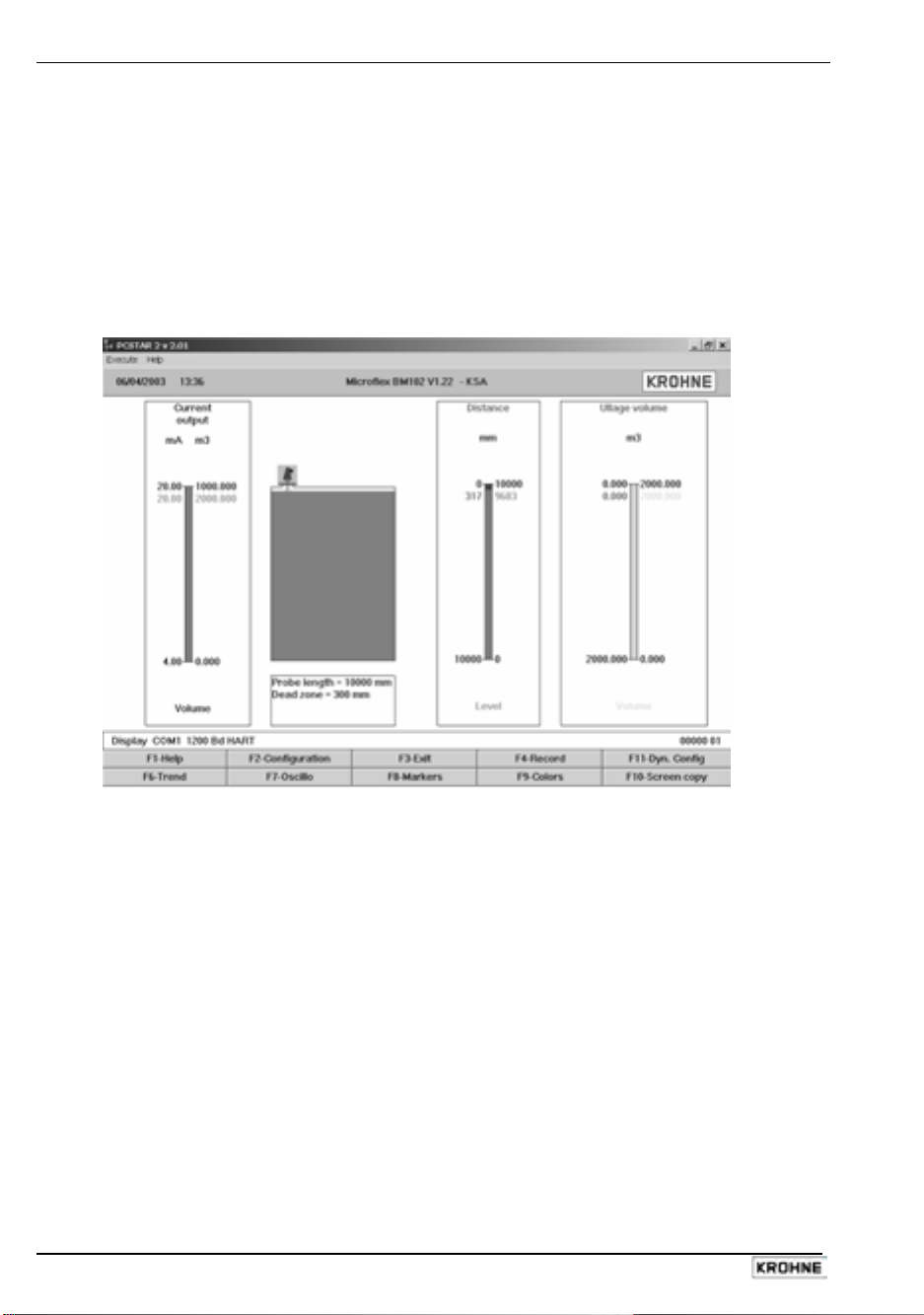

6. After the connection has been established, the following screen is shown. This will show the

current status of the tank. No further configuration should be necessary. The following functions

are available on the screen and will be discussed further in section 8.4:

• F2 – Device configuration: a summary of the parameters are given on the next page,

• F7 – Oscilloscope function: have all reflections occurring at the probe displayed,

• F11 – Dynamic/on-line device configuration,

• F4 – View and record all information during operation,

• F6 – Trend: observe the level trend since start of the program,

• F8 – Marker: read the status of the device

• and F10 – make printouts (screen shots).

26 BM 102

Page 27

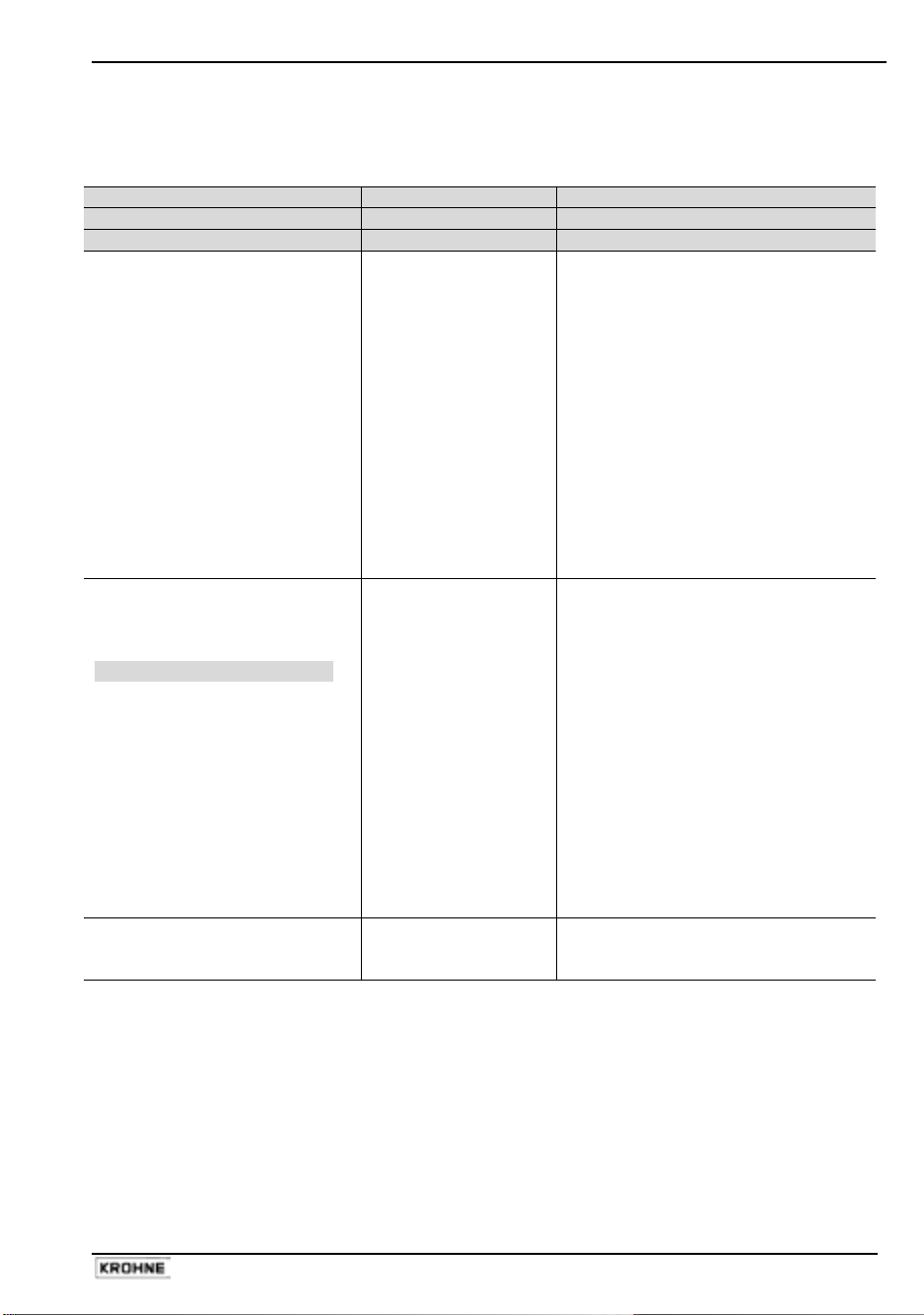

3.3.2 Summary of User Functions in PCSTAR 2 (F2 – Configuration)

The table below provides an overview of all parameters that can be set in the configuration menu

using F2 in PCSTAR2. Reset default values are in bold type in the “Input Range” column.

Function Input Range Description

1.0.0 Operation

1.1.0 Basic parameters

1.1.1 Tank height

Enter 0 … 60 m or

0 … 197 ft.

As per order

The tank height forms the basis for

calculating level measurements and

for the relevant current output. It is

defined as the distance between the

lower flange surface and the

reference point at the bottom of the

tank.

The output unit is determined via Fct.

1.2.4.: Length Unit

The set tank height is the upper limit

for Fct. 1.3.4: Scale I1 max (if Fct.

1.3.1 is set to “Level” or “Distance”).

Note: the device will not measure

beyond the programmed probe length

if the current output is configured to

measure distance or level .

1.1.2 Dead zone

Warning : Critical Parameter

Enter a value

Fct.1.5.1(Detection

delay) … probe

length.

• Twin probe with

probe length<1m

or 3.3 ft

0.2 m or 8 in

• Single probe or

twin probe with

probe

length >1m

The dead zone is the minimum

measuring distance from the process

connection (reference point) to the

surface of the product. So as not to

impair measurement accuracy, the

minimum values given in Section

5.2.3 should be adhered to.

The BM 102 will ignore signals in the

dead zone and display the last

reading taken.

The output unit is set via Fct. 1.2.4:

Length Unit

or 3.3 ft

0.4 m or 16 in

• Coaxial probe

0 m or 0 in

1 … 100 seconds 1.1.3 Time constant

5 seconds

This function filters possible signal

fluctuations when the liquid is

turbulent.

BM 102 27

Page 28

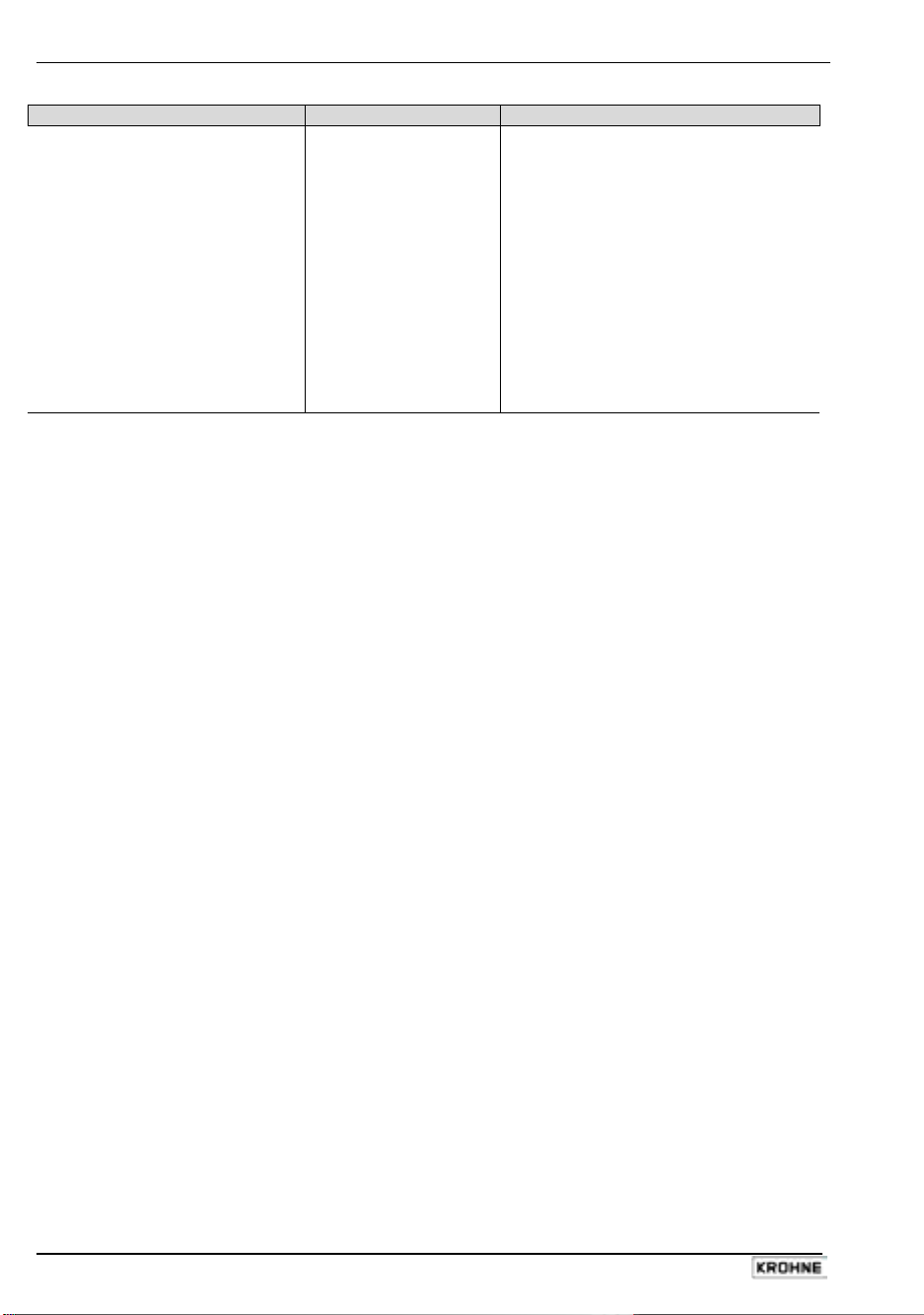

Function Input Range Description

1.1.6 Probe length

Enter 0.1 m or 3.9” …

probe length (max.:

24000 mm or 78¾ ft.)

As per order

This value must be equal to the exact

length of the probe. This value should

be modified when the probe has been

replaced or shortened (cable probes).

The output unit is set via Fct. 1.2.4

Length Unit.

An automatic search for the probe tip

can be carried out when the tank is

empty to update the parameter using

the function F11 in the “Dynamic

Configuration” menu.

Probe length may be set greater than

tank height but less than 24 m or

78¾ ft. for special installations.

28 BM 102

Page 29

Function Input Range Description

1.2.0 Display To display readings in the form

and units required

1.2.4 Length unit

Select m, cm, mm,

inch, ft or optional

unit*

mm

Unit for display of level and distance.

*When “optional unit” selected, you

get to the menu item Fct. 1.2.6: New

unit and can there define userdefined units.

The unit selected here is used in the

following functions:,

Fct. 1.1.1 Tank height,

Fct. 1.1.2 Dead zone,

Fct. 1.1.6 Probe length,

Fct. 1.5.1 Detection delay and

Fct. 1.7.2 Input table*.

If “Level” or “Distance” is selected in

fct. 1.3.1, then the units selected will

also be used in these functions:

Fct. 1.3.3 Scale I1 min. and

Fct. 1.3.4 Scale I1max..

In addition the displayed value will

use the selected unit.

1.2.5 Volume unit

Select m³, l, US Gal,

ft³, bbl, m³/h, ft³/h, kg,

metric tonnes or tons

US

³

m

Unit of displayed volume / conversion

value.

Conversion means converting a level

value into a “conversion value”

(usually volume) in order e.g. to

realize a non-linear function as a

factor of the level.

The unit selected here is also valid for

the following function:

Fct. 1.7.2 Input table.

If “Volume” or “Ullage volume” is

selected in fct. 1.3.1, then the units

selected will also be used in these

functions:

Fct. 1.3.3 Scale I1 min.

Fct. 1.3.4 Scale I1 max.

1.2.6 New unit (length) Appears only when “Optional unit” is

selected in Fct. 1.2.4: Length unit.

1.2.6.2 Unit fact.

4 ASCII characters 1.2.6.1 Unit name

Unit

Min.: > 0.0

Max.: 100 000

1.0

Name of the new unit (max. 4

characters)

Reference for the conversion factor is

the millimetre.

At a conversion factor of 10, the new

unit is equivalent to 10 mm.

At a conversion factor of 0.1, the new

unit is equivalent to 0.1 mm.

* This list is not exhaustive and also includes the Dynamic configuration menu functions in

PCSTAR 2.

BM 102 29

Page 30

Function Input Range Description

1.3.0 Current output I This configures the current output.

These functions are independent

from what is displayed.

1.3.1 Current 1 item

Select Off, Level,

Distance, Volume* or

Selection of the required function for

the current output.

Ullage volume*

Level

1.3.2 Current 1 range

Select 4-20mA or 420mA + 22 mA on

error.

4-20mA

This parameter defines the status

which the current output assumes in

the event of a fault:

4-20 mA (last measured value held in

the event of a fault)

4-20 mA / E = 22 mA (is set to 22 mA

in the event of a fault).

1.3.3 Scale I1 min.

1.3.4 Scale I1 max.

Enter a value from 0

mm** to a value lower

than that entered for

Fct. 1.3.4 Scale I

max.

As per order

Enter value higher

than the value

selected under Fct.

1.3.3. “Scale I min.”

up to tank height or

the maximum volume

table value***

As per order

This function defines the lower limit

of the analog measuring range.

It is 4 mA.

The value of this parameter always

has to be lower than the value

selected for Fct. 1.3.4: Scale I1 max.

This function defines the upper limit

of the analog measuring range. It is

20 mA.

The value of this parameter must

always be:

- lower than or equal to the value

selected under Fct. 1.1.1: Tank height

or the maximum volume table value,

- higher than the value selected under

Fct. 1.3.3: Scale I1 min., otherwise an

error message will appear during

parameter check.

1.3.5 Error delay

Select No delay, 10

sec., 20 sec., 30 sec.,

1 min., 2 min., 5 min.

or 15 min.

No delay

This menu is only available when

(4-20 mA / E = 22 mA) has been

selected under Fct. 1.3.2: Current 1

range. With this parameter, a time

delay can be defined for transition of

the current output to 22 mA after an

error has been noted. During the

delay, measurement and the analog

output are held. When the error

disappears, the delay also serves to

return to the measuring mode.

* complete fct. 1.7.2 “Input table” before selecting “volume “ or “ullage volume”.

** or other unit selected in fct. 1.2.4 Length Unit, 1.2.5 Volume Unit depending on the item

selected in fct. 1.3.1 Current 1 Item.

*** depends on the value selected in fct. 1.3.1 Current 1 Item.

30 BM 102

Page 31

Function Input Range Description

1.4.0 User data

1.4.3 Checksum Read only This value is used for identification of

the device software version. The

checksum is tested when starting.

This helps to detect any problems

with the microcontroller.

(Tag number)

1.4.4 Device number**

00000 01

This parameter assigns an

identification number to the device.

A text consisting of max. 8 ASCII

characters can be entered.

1.4.5 Serial number Read only This parameter serves to identify the

respective measuring device. This

number cannot be changed and sets

the address for use with HART

®

interfaces.

1.4.6 French command number Read only Factory-programmed number, to be

quoted in case of warranty and

service claims.

1.4.7 German command

number

Read only Factory-programmed number, to be

quoted in case of warranty and

service claims.

1.4.8 Option**

(Descriptor)

This function can be used for entering

text of max. 15 ASCII characters

(customer information only)

1.4.9 Probe type

Single rod, Twin rod,

Single cable, Single

cable +

Information on probe type supplied

with signal converter. This is a readonly parameter.

counterweight, Single

cable without

counterweight, Twin

cable, Twin cable +

counterweight,

Coaxial, Special 1,

Special 2 or Special 3

As per order

** Refer to section 3.3.5: Characters available for alpha-numerical data functions in PC STAR 2

and on the HART

®

console.

BM 102 31

Page 32

Function Input Range Description

1.5.0 Application For difficult applications

1.5.1 Detection delay

Enter a value 0 mm /

0 in. to Fct. 1.1.2

Dead zone

As per order

This function can be used to define

an area directly below the flange in

which interference reflections (e.g.

from the tank nozzle) are masked.

This value has to be smaller than or

equal to the dead zone (Fct. 1.1.2.).

1.6.0 Serial I/O

(serial input/output)

For integrating into a signal

network. Standard hardware

platform for HART® is the current

loop with superposed FSK signals.

For a multidrop application the

current output is set to “OFF” and

consequently to a constant 4 mA.

With a multidrop bus, up to 15

HART® devices can be operated.

1.6.2 Address

Addresses from

0 to 15

0

With this function, every device

connected to a bus is assigned an

address between 0 and 15 (HART®

protocol). If several devices are

connected to a digital bus, each

device must be assigned a unique

address under which it can then be

identified in the bus.

0 = Analogue output active

1 - 15 = Multi-drop mode active,

analogue output inactive

1.7.0 Volume table For calibrating the gauge for

volume measurement.

1.7.2. Input table

Select point 01 to 20,

enter level and then

volume values

respectively.

0

(conversion table

not created, volume

measurement not

possible)

This function is used for setting up

the strapping table (level/volume). Up

to 20 points can be assigned. Every

new point must be larger than the

preceding one. The units of length

and volume can be changed later

without affecting the settings in the

table.

The units selected for length and

volume in fct.s 1.2.4 and 1.2.5 will be

used here.

32 BM 102

Page 33

3.3.3 Quick Configuration: configuration examples

The minimum functions (fct.) to be configured for a simple measurement are listed below:

Functions Definition

PCSTAR 2 HART®

1.1.1 2.1.1.1 Tank Height

1.1.2 2.1.1.4 Dead zone

1.3.1 … 4 2.1.3.1 … 4 Current Output

1.7.0 2.1.7.0 Volume table*

*For volume measurements

Example procedures for each set of functions are given on the following pages. Each procedure is

given in a series of steps in table form and is according to the PCSTAR 2 F2-Configuration

parameter list. Please refer to section 3.3.4 for the equivalent parameters available on the HART®

Communicator.

Definitions for quick configuration

* where PCSTAR 2 Fct. 1.3.1 (HART® Fct. 2.1.3.1) Current I1 Item is configured to “Level”

Typical gauge used for quick configuration examples:

Probe type: twin Ø4 mm or 0.15 ” cable probe (type 4)

Product measured:

Tank height:

(PCSTAR 2: Fct. 1.1.1,

®

HART

: Fct. 2.1.1.1)

Dead zone:

(PCSTAR 2: Fct. 1.1.2,

®

HART

: Fct. 2.1.1.4)

Probe length, L

:

1

Water (dielectric constant, εr = 80)

10000.00 mm or 33 ft.

0.15 m or ½ ft. (see “probe measurement limits” in section 5.2.3

for the Ø4 mm or 0.15” twin cable probe, type 4)

9.00 m or 29.5 ft. (do not modify unless advised to)

(PCSTAR 2: Fct. 1.1.6

HART®: Fct. 2.1.1.2)

BM 102 33

Page 34

Tank height: configuration of user menu PCSTAR 2 function 1.1.1 (HART® Fct. 2.1.1.1)

This function is usually either defined as true tank height or as factory configured probe length, L

(see diagram on preceding page) if the former is not supplied by the customer in the order.

Why change the tank height?

• setting the distance in PCSTAR 2 Fct 1.1.1 (HART

®

Fct. 2.1.1.1) to L1 avoids having a non-

measurable zone underneath the probe where the measurement on the display freezes.

• when setting up a measurement scale as explained on the following pages, this means that

the level at the end of the probe will be taken as zero instead of the tank bottom.

How tank height affects measurement when either Level or Distance is measured

1 Tank height

2 Measurable height

(factory configured

probe length, L

)

1

3 Non-measurable

zone

4 With true tank

height (1) set in

Function 1.1.1 of

the User’s menu.

5 With factory-

configured probe

length, L

, set in

1

Function 1.1.1 of

the configuration

menu.

Example procedure 1 (using PCSTAR 2):

• to change true tank height (10000mm or 33 ft) to factory configured probe length, L1 (9000mm

or 29½ ft) , and then save the new parameter. Refer to item 5 in the diagram above.

Step Action Data entered / value set

1 Press F2 to connect to the

device

2 Press F2 to enter configuration

Tank status screen displayed

(level reads 6750 mm)

Configuration menu displayed

menu

3 Click on the data set field for

Fct. 1.1.1 Tank height

This field currently reads

10000.00 (mm)

4 Type in the new value 9000.00

5 Press the button “F6-Send to

n/a

BM102” for the BM 102 to

immediately accept the new

value.

6 Press “F3-Exit” to quit the

configuration menu.

Tank status screen displayed

(level now reads 5750 mm)

1

34 BM 102

Page 35

Dead zone: configuration of user menu PCSTAR 2 function 1.1.2 (HART® Fct. 2.1.1.4)

The top dead zone is the minimum measuring distance between the gauge flange facing (the

reference point) and the product. The various probes for the BM 102 have differing top dead

zones and these are given in section 5.2.3: Probe measurement limits.

Why is configuration of the dead zone important?

The gauge will not display measurements taken here – the reading is blocked on reaching this

zone. This will avoid the gauge confusing the true level with a parasite (i.e. flange) as the product

nears the tank fitting and thereby displaying a false reading. It should be noted that although the

reading is frozen, the gauge will continue to follow the reflection. The PCSTAR 2 F8-marker menu

will display “Tank full” in this zone.

What is the difference between these functions:

PCSTAR 2 Fct 1.1.2/ HART

PCSTAR 2 Fct 1.5.1/ HART

®

Fct. 2.1.1.4: Dead zone

®

Fct. 2.1.5.3: Detection delay?

The “detection delay” function masks all signals (i.e. none are detected by the gauge) up to a

defined distance from the flange facing. The detection delay zone size is never greater than the

dead zone size. The PCSTAR 2 F8-marker menu will display “Tank full” and “Level lost” in this

zone. This is illustrated below – the value in the box is the displayed value:

1 Height of tank fitting

2 Detection delay

(Fct.1.5.1=120mm)

3 Dead zone limit

(Fct.1.1.2=150mm)

4 Emitted signal

5 Flange reflection

(masked)

6 Masked zone (all

signals here are

ignored)

7 Level reflection

outside dead zone –

true level displayed

8

Level reflection inside

dead zone – level at

dead zone limit

displayed (frozen)

9

Level reflection inside

detection delay zone

– not detected by

gauge and level at

dead zone limit

displayed (frozen)

*(3) = 8850 mm - dead zone configured limit in terms of level

BM 102 35

Page 36

How to set an analogue current output scale

User menu functions 1.3.1 to 1.3.4

This set of functions allows users to set up a scale. The minimum (4mA) and maximum (20mA)

values of an analogue current output should ideally lie within the device’s active measuring zone,

as the device will freeze when the signal is lost.

Refer to the measurement limits table for each probe type in the introduction. Refer also to the

start of section 3.3.3 for the advantages of changing tank height.

Example procedure 2 (using PCSTAR 2):

To personalise a measurement scale

• select “Level” as the current output parameter for the scale to be set up from the tank bottom

• select 4 … 20 mA current range with an error output at 22 mA

• choose suitable minimum and maximum values for the scale.

Step Action Data entered / value set

1 Press F2 to connect to the device Tank status screen displayed (level reads

5650 mm)

2 Press F2 to enter configuration menu Configuration menu displayed

3 Scroll down the screen and click on

This field currently reads “distance”

the data set field for Fct. 1.3.1:

Current 1 item. This will reveal a

scroll menu.

4 Use mouse to scroll down data set

This field now reads “level”

field. Click on the new value.

5 Scroll down to Fct. 1.3.2: Current 1

This field currently reads “4-20 mA”

range and click on data set field. This

reveal a scroll menu.

6 Use mouse to scroll down data set

This field now reads “4-20 mA / E = 22 mA”

field. Click on the new value.

7 Scroll down to Fct. 1.3.3: Scale I1 min

This field currently reads “0000 mm”

and click on data set field.

8 Enter the new value. This will give the

This field now reads “1000 mm”

level that corresponds to the

minimum output of 4 mA.

9 Scroll down to Fct. 1.3.4: Scale I1

max and click on data set field.

10 Change to 8850 mm. This will give

This field currently reads “6000 mm”

(std. default: 6000 mm)

This field now reads “8850 mm”

the level that corresponds to the

maximum output of 20 mA. (and sets

max. output at the top dead zone

limit)

11 Press F6-Send to BM102 to

n/a

immediately update the device

configuration.

12 Press F3-Exit to quit the configuration

menu screen.

Tank status screen displayed (level reads

5650 mm)

Setting up a volume table

Refer to procedure 3.

36 BM 102

Page 37

How to configure the gauge to give volume readings

User menu PCSTAR 2 function 1.7.2 (HART

®

submenu 2.1.7)

• To be able to measure the volume, a conversion table (strapping table) will need to be created

using the PCSTAR 2 program or the HART® communicator.

• The strapping table assigns defined volumes to the various levels.

• In the case of non-symmetrical tanks, e.g. tanks with dished bottom, the accuracy of

volumetric measurement will depend on the number of entered “level/volume pairs”. The

maximum number of pairs (points) that can be set is 20. The volume is linearly determined

(interpolated) between 2 points.

• The conversion table is generally used for volume, but can also be used for mass and flow.

Five points have been set in the following example.

Procedure 3: creating a strap table the probe by assigning a volume to a user-defined level

(using PCSTAR 2)

Step Action Data entered/value selected

1 Connect to the gauge as described in section 3.3.1. n/a

2 Press function key F2 or left click on F2-connection at

n/a

the bottom of the window. This will open the user

configuration menu.

3 Go to user function 1.1.1: Tank height to enter value

6.00 m or 19.69 ft*

(click on field and type in value)

4 Go to user function 1.1.2: Dead zone to enter blocking

0.40 m or 1.31 ft*

distance value.

5 Go to user function 1.1.6: Probe length to enter value 5.80 m or 19.03 ft*

6 Go to user function 1.2.4: Length Unit to select length

m or ft

units.

7 Go to user function 1.2.5: Volume unit to select volume

m³ or ft³

units

8 Go to user function 1.7.2: Input table. A maximum of 20

See table below

points can be entered. For each point a level and a

volume must be entered. Each point should have a

value higher than preceding one.

Input table

Point Level Volume

1 0.0 m or 0.0 ft 0.0 m³ or 0.0 ft³

2 0.20 m or 0.66ft 0.5 m³ or 17.66 ft³

3 0.75 m or 2.46ft 1.0 m³ or 35.31 ft³

4 1.00 m or 3.28ft 1.5 m³ or 52.97 ft³

5 5.60 m or 18.37ft 16.8 m³ or 593.3 ft³

*Max. level = tank height – dead zone

= 6.00 m – 0.40 m or 19.69 ft – 1.31 ft

= 5.60 m or 18.37 ft, equivalent to a volume of 16.80 m³ or 593.3 ft³

Note:

The level can effectively be measured between 0.20 m or 8” and 5.60 m or 18½ ft. When the

product level drops below the tip of the probe, the BM 102 will indicate that there is still remains of

0.20 m or 8”. Accordingly, the BM 102 can only indicate a level between 0.20 m or 8” and 5.60 m

or 18½ ft, since it only measures along the probes. The size of the dead zone depends on the

installation and on the probe type.

BM 102 37

Page 38

Supplementary procedure for setting the 4 … 20 mA current to output volume readings

(using PCSTAR 2)

Step Action Data entered/value selected

1 Go to user function 1.3.1 ”Current 1 item” to select

Volume

measurement function.

2 Go to user function 1.3.2 ”Current 1 range” to set fault

4 … 20 mA

status

3 Go to user function 1.3.3 “Scale I1 min” to enter

0.50 m³ or 17.66 ft³

volume value for the minimum output (4 mA)

4 Go to user function 1.3.3 “Scale I1 max” to enter

16.80 m³ or 52.97 ft³

volume value for the maximum output (20 mA)

5 Either save the new configuration to disk by left-

n/a

clicking on F5-Save to disk and download it onto the

BM 102 using the F6-Send to BM102 key.

6 Press F3 to exit the configuration menu. n/a

3.3.4 HART

Display and configuration can also be carried out with a HART

®

Communicator: installation & operating instructions

®

communicator. Operator control via

the separate HHC is described in detail in the operating instructions supplied with the HHC.

Basic instructions for taking measurements

Communicator layout

1

Two-pin jack for loop connectors

2 LCD

3 Function keys (F1 … F4)

4 Action keys

On/off UP

n/a

Arrow

LEFT

Arrow

DOWN

Arrow

RIGHT

Arrow

Other functions:-

LEFT Arrow: Previous menu key

RIGHT Arrow: Select key

38 BM 102

Page 39

Wiring, standard (non-Ex)

Caution

Refer to the HHC manual for wiring instructions when in an explosive atmosphere.

Displaying readings

Use the UP and DOWN arrows to move to the correct line and then select with the RIGHT Arrow.

HART Communicator

1

1 Offline

2 → Online

3 Frequency Device

4 Utility

F1 F2 F3 F4

2

BM102:00000 01

Online

1 → <Process Var.>

2 <Config./Test>

3 <Access/Rights>

4 <Watch status>

5 <HART Variables>

SAVE

F1 F2 F3 F4

Main menu Online menu

BM102:00000 01

3

<Process Var.>

1 → <Measurements>

2 <Input/Outputs>

4

BM102:00000 01 ♥

<Measurements>

1 → Lvl 878.00 mm

2 Dist 121.00 mm

F1 F2 F3 F4

SAVE HOME

HELP SAVE HOME

F1 F2 F3 F4

Measurement & input and output functions menu Measurement display function

BM 102 39

Page 40

Configuration: summary of user functions via HART® Communicator HC 275

Reset default values are in bold type in the “Input Range” column. Refer to the HART

®

HC275

Communicator operating instructions for further operating details.

Function (Fct.) Input Range Description

1.0 PROCESS VAR.

1.1.0 MEASUREMENTS

1.1.1 LEVEL Level value.

1.1.2 DISTANCE Distance value.

1.1.3 VOLUME Volume value if a strapping table is

programmed.

1.1.4 ULLAGE VOLUME Ullage Volume value if a strapping

table is programmed.

1.2.0 INPUTS/OUTPUTS

1.2.1 FUNCTION I Function associated to the current

output (Primary Variable).

1.2.2 I Current output value (mA)

1.2.3 % Percentage of PV range.

40 BM 102

Page 41

Function (Fct.) Input Range Description

2.0 CONFIG./TEST

2.1.0 OPERATION

2.1.1.0 BASIS PARAMETER

2.1.1.1 TANK HEIGHT

Enter 0 up to

60000 mm or 2362”

As per order

Tank height.

The tank height is defined as the

distance between the bottom of the

tank and the lower flange surface.

2.1.1.2 PROBE LENGTH

Enter 0 mm up to

< 24000 mm or

1063”

As per order

This value has to be equal to the

exact length of the probe. The only

situation for changing this value is if

the probe length has been changed.

2.1.1.3 TIME CONSTANT

2.1.1.4 DEAD ZONE Enter a value

Warning : Critical Parameter

Enter to

100 seconds

5 seconds

Fct.1.5.1(Detection

delay) … probe

length.

• Twin probe with

Probe length

The time constant allows filtering of

possible signal fluctuations when the

product surface is turbulent.

Measurements near the flange may

not be precise or reliable.

Measurement may not be precise in

an area less than this recommended

value, depending on the probe type.

<1 m or 3.3 ft

0.2 m or 8 in

• Single probe or

twin probe with

probe length

>1m or 3.3 ft

0.4 m or 16 in

• Coaxial probe

0 m or 0 in

2.1.1.5 SENSOR INFO

2.1.1.5.1 Sensor upper limit = Probe length Read only Menu. Upper sensor limit.

2.1.1.5.2 Sensor lower limit = 0 Read only Menu. Lower sensor limit.

2.1.1.5.3 Sensor min. span = 1 mm or 0.04” Read only Menu. Sensor minimum

span.

2.1.2.0 DISPLAY

2.1.2.1 LENGTH

2.1.2.1.1 LENGTH UNIT

Select m, cm, mm,

inch, Ft, optional

unit

mm

Length unit of displayed value (level /

distance).

The optional unit allows the user to

define a new unit (name and factor)

see menu 2.1.2.1.3

2.1.2.1.2 DISPLAY FORMAT

0, 1, 2, 3, 4, 5,

exponential format,

auto

2

Number of decimal places. Defines

the displayed length values format

(option of the HART® communicator

H275).

BM 102 41

Page 42

Function (Fct.) Input Range Description

2.1.2.1.3.0 DEFINE NEW UNIT

4 ASCII characters 2.1.2.1.3.1 UNIT NAME

“unit”

Optional unit name. User has to enter

the unit name before using it in the

menu “LENGTH UNIT”.

2.1.2.1.3.2 UNIT FACTOR

Enter 0.0 to

100000

1.0

Optional unit factor. User has to enter

the Unit Factor before using it in the

menu “LENGTH UNIT”.

With a factor 1.0, the unit is

equivalent to one millimeter.

With a factor 1000.0, the unit is

equivalent to one meter.

2.1.2.2.0 VOLUME

2.1.2.2.1 VOLUME UNIT

2.1.2.2.2 DISPLAY FORMAT

Select m3, l, US

Gal, Ft3, bbl, M3/h,

Ft3/h, kg, Metric

Tons, US Tons

m³

0, 1, 2, 3, 4, 5,

exponential format,

auto

2

Unit for conversion values ("volume

table").

The selected unit is only used to

display the conversion value from the

strapping table.

Number of decimal places. Defines

the displayed volume value format.

(Option of the HART® communicator

H275).

2.1.3.0 ANALOG OUTPUT

2.1.3.1 FUNCTION I

2.1.3.2 RANGE I

Select Level,

Distance, Volume,

Ullage Volume

Level

Select 4-20 mA or

4-20 mA + 22 mA if

error

4-20 mA

Current output function (measured

value to be displayed). Volume

functions will appear if a volume table

exists in menu 2.1.7.0

Current output range 4 … 20 mA (1st

choice). When the BM 102 is in error

mode, the current output is frozen

except if the second choice is

selected and then the current output

is fixed at 22 mA.

2.1.3.3 ERROR DELAY

Select No delay, 10

s, 20 s, 30 s, 1 mn,

2 mn, 5 mn, 15 mn

No delay

This menu is available in case the

range I menu is set to 4-20 mA with

error 22 mA.

This parameter sets the delay before

the current output goes to 22 mA

after the error mode occurred.

2.1.3.4 SCALE I

min. 4 mA

2.1.3.5 SCALE I

max. 20 mA

Enter 0 to Scale I

max.

As per order

Enter Scale I min to

tank height

As per order

Input the lower range value

(corresponding to 4 mA) depending of

the parameter 2.1.3.1 chosen.

Input the upper range value

(corresponding to 20 mA) depending

of the parameter 2.1.3.1 chosen.

42 BM 102

Page 43

Function (Fct.) Input Range Description

2.1.4.0 USER DATA

2.1.4.1 TAG

00000 01

Tag number of device.

2.1.4.2 SERIAL NUMBER Read only menu. Each device has its

own serial number.

2.1.4.3 FRENCH

COMMISSION

NUMBER

Read only menu.

This number is factory set. Refer to

this number in case of warranty or

service claims.

2.1.4.4 GERMAN

COMMISSION

NUMBER

Read only menu.

This number is factory set. Refer to

this number in case of warranty or

service claims.

2.1.4.5 RELEASE NUMBER Read only menu.

Release number of the device

(Software and Hardware version).

2.1.4.5 PROBE TYPE

Rod, Twin Rod,

Cable, Cable

Read only menu.

Probe type attached to the flange.

+counterweight,

Cable without

counterweight,

Twin Cable, Twin

Cable +

counterweight,

Coax, Special 1,

Special 2, Special 3

As per order

2.1.4.5 CHECKSUM Read Only menu.

Similar to the release number. This

parameter allows to identify the

software version of device.

BM 102 43

Page 44

Function (Fct.) Input Range Description

2.1.5.0 APPLICATION

2.1.5.1.0 THRESHOLD

2.1.5.1.1 LEV. PULSE AMP. Read only value. Dynamic value.

Amplitude of level pulse in millivolts.

2.1.5.1.2 LEV. PULSE GAIN Read only value.

Dynamic value.

Amplification of level pulse (gain 0, 1,

2, or 3).

2.1.5.1. THRESHOLD

Enter a value from

50mV to 25000mV

500 mV G3 at 1 m

Threshold of the level pulse (in

millivolts). The threshold evolves in

terms of gain amplification factor

changing by the electronic converter.

2.1.5.2 DISTANCE INPUT

Enter a value from

Fct. 2.1.1.4: Dead

zone to fct. 2.1.1.2:

Probe length

This function forces the BM 102 to

search for the product surface in a

zone other than the actual measuring

zone. If there is no level signal, you

can enter an estimated value.

2.1.5.3 DETECTION DELAY

Enter a value 0mm

or 0in to Fct.

2.1.1.4: Dead zone

As per order

This function forces the instrument

not to analyse reflections in a zone

directly below the flange. The entered

value of the detection delay must be

smaller than the "dead zone" value.

2.1.5.4 SEARCH PROBE END The search zone

for the probe end is

from Fct 2.1.5.3

Detection delay up

to Fct. 2.1.1.1 Tank

height.

Automatically measures the probe

length. The tank must be empty. Tak

height must be configured to a value

greater than the estimated probe

length. Measured in the units

configured in fct. 2.1.2.1.1.

2.1.5.5 RESET BM 102 Restarts the BM 102.

2.1.6.0 SERIAL I/O

Enter 0 to 15 2.1.6.1 ADDRESS

0

Sets the address of the device for

connection to a HART multidrop

network. The current output switches

to 4 mA.

0 = 4 … 20 mA output current active

1 – 15 = in multidrop mode (4 mA)

2.1.7.0 STRAP TABLE

2.1.7.1 VOLUME UNIT

Select m3, l, US

Gal, Ft3, bbl, M3/h,

Ft3/h, kg, Metric

Tons, US Tons

Unit for conversion values ("volume

table"). The selected unit is used to

define the strapping table values.

Liter [l]

0 to 20 points 2.1.7.2 INPUT TABLE

0

(i.e. no volume

table)

This function defines the strapping

table. The maximum number of points

is 20. Each subsequent value must

be greater than the previous one. The

length and volume units can be

changed later without affecting the

settings in the table. Calculations are

done automatically in the instrument.

2.1.7.3 DELETE TABLE This function deletes the strapping

table.

44 BM 102

Page 45

Function (Fct.) Input Range Description

2.2.0 TESTS

2.2.1 TEST OUTPUT Select 4 mA, 20

mA, Other

This function allows the current

output to be tested.

The output can be set to one of the

listed values. With a reference

ammeter, the calibration of the

current output can be verified.

2.3.0 SERVICE Restricted access factory

configuration menu. These

parameters may be accessed via

Fct. 3.2 “Specialist PSW

(password).

3.0 ACCESS RIGHTS

3.1 MAINTENANCE PSW

Yes or no. Enter 9character code if

“Yes”.

No

Disables the access lock on the

configuration menu.

The password must contain exactly 9

characters.

E, R or U are used only. The

password is displayed in a scrambled

format. It allows KROHNE to decode

the password in case it was forgotten.

3.2 SPECIALIST PSW See KROHNE

Service centre or

Specialist access to the Service

Parameters.

BM 102 Service

Manual for code.

4.0 WATCH STATUS Displays the status of the device.

5.0 HART® VARIABLES

5.1 MANUFACTURER

Read only menu.

KROHNE

5.2 MODEL

Read only menu.

BM 102

5.3 FLD DEV REV

1.0

5.4 SOFTWARE REV

1.0

5.5 HARDWARE REV

1.0

Field device revision.

Read only menu.

Software revision.

Read only menu.

Hardware revision.

Read only menu.

5.6 DEVICE ID Read only menu. The device ID is

also the serial number of the device.

5.7 MESSAGE 32 bytes of ASCII characters

5.8 DESCRIPTOR 16 bytes of ASCII characters.

Equivalent to PCSTAR2 Fct. 1.4.8

5.9 DATE Month Day Year (xx / xx / xx).

5.10 NUM RESP PREAM Number of preamble in the response

frame of the device.

5.11 TAG Tag name of the BM 102.

5.12 POLL ADDRESS Address of the device.

BM 102 45

Page 46

3.3.5 Characters available for alpha-numerical data functions in PC STAR 2 and on the

HART® console

This concerns the following functions:

PCSTAR 2 fct. 12.6.1: Unit name, fct. 1.4.4: Device number, fct. 1.4.8: Option

®

console (HHC) fct. 5.7 Message, fct. 5.8 Descriptor, fct. 5.11 Tag

HART

@ H P X Space ( 0 8

A I Q Y ! ) 1 9

B J R Z “ * 2 :

C K S [ # + 3 ;

D L T \ $ ‘ 4 <

E M U ] % - 5

F N V ^ & . 6

G O W _ ‘ / 7

=

>

?

46 BM 102

Page 47

3.3.6 Local user display (instruments equipped with DIN connectors only)

The BM 102 local indicator is available as an option. This fits onto the BM 102’s standard DIN

connector. Data can be read from an LED display. The gauge configuration menu cannot be

accessed with this option. For non-Ex applications only. Please refer to the DA 06 Supplementary

instruction manual for further information.

Technical data: DA 06 Plug-in Display (non-Ex)

DA 06 Plug-in display (supplied separately) DA 06 Plug-in display mounted on BM 102 gauge

Measuring range: -1999 to 9999 digits (min. and max. values user defined)

Display: 4-digit, 7.6 mm or 0.3” high, red LED display, display housing

can be turned through 330°

Accuracy: 0.1 % +/- 1 digit

Adjustable parameters: Scaling, decimal point, attenuation, switching point, delay

Min. / max. value memory: Displays the minimum and maximum values recorded during

operation.

Housing: Plastic, PA 6.6 / polycarbonate 47mm X 47mm x 68 mm or 1.9” x

1.9” x 2.7” (h x w x d), housing can be turned by 300°

Protection: IP 65 (EN 60529)

Temperature range (ambient)

Electronic system:

0°C … +60°C or 32°F … 140°F

Storage: -30°C … +80°C or -22°F … 176°F

Electrical connection: Adapter for plug as per DIN 43650

Input signal 4…20 mA / 2-wire

Max. voltage drop over unit Approximately 6 V DC

Switching output1 open collector (PNP),

max. 125 mA,

on and off delay: 0 to 100 seconds,

temperature influence: 0.1% / 10 K

CE conformity EN 50081-1 and EN 50082-2

BM 102 47

Page 48

3.4 BM 102 MICROFLEX T.D.R. meter characteristics

This subsection explains:

• the four principle configurations for setting up a measurement scale and what the user should

be aware of in each case;

• what happens when the tank is full or empty;

• what is the level threshold and how to modify it and

• what happens when level is measured when more than one product in the tank;

The measurement scale: five possible configurations for analogue current output – with

“Level” selected in PCSTAR 2 function 1.3.1: Current 1 Item

A

Tank height (Fct. 1.1.1)

B

Probe length (Fct. 1.1.6)

C

Detection delay (Fct. 1.5.1)

D

Non-measurable zone

E

Minimum distance between nonmeasurable zone and dead zone

(Fct.: 1.1.2 – Fct.: 1.5.1)

The configurations described below are illustrated in the above diagram:

(1) The “current output” range is smaller than the optimal measuring range.

(2) The “current output” range is equal to the optimal measuring range:

Scale min.: 4 mA (Fct. 1.3.3) = tank height – probe length

Scale max.: 20 mA (Fct. 1.3.4) = tank height – dead zone