Page 1

Handbook

Handbook

ALTOSONIC V12

ALTOSONIC V12

ALTOSONIC V12ALTOSONIC V12

12-chord ultrasonic gas flowmeter for custody transfer

HandbookHandbook

© KROHNE 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2013 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 3

ALTOSONIC V12

CONTENTS

1 Safety instructions 7

1.1 Intended use ..................................................................................................................... 7

1.2 Certifications .................................................................................................................... 7

1.3 Safety instructions from the manufacturer ..................................................................... 8

1.3.1 Copyright and data protection ................................................................................................ 8

1.3.2 Disclaimer ............................................................................................................................... 8

1.3.3 Product liability and warranty ................................................................................................ 9

1.3.4 Information concerning the documentation........................................................................... 9

1.3.5 Warnings and symbols used................................................................................................. 10

1.4 Safety instructions for the operator............................................................................... 10

2 Device description 11

2.1 Scope of delivery............................................................................................................. 11

2.2 Hardware description..................................................................................................... 11

2.2.1 Transducers .......................................................................................................................... 12

2.2.2 The electronic unit ................................................................................................................ 13

2.3 Software description ...................................................................................................... 14

2.4 Nameplates .................................................................................................................... 15

3 Installation 17

3.1 Notes on installation ......................................................................................................17

3.2 Storage ........................................................................................................................... 17

3.3 Transport ........................................................................................................................ 18

3.4 Pre-installation requirements ....................................................................................... 19

3.5 Installation...................................................................................................................... 19

3.5.1 Mounting position.................................................................................................................. 19

3.5.2 Pipe diameters and lengths.................................................................................................. 20

3.5.3 Flow conditioners.................................................................................................................. 20

3.5.4 Inlet and outlet for uni-directional use ................................................................................ 20

3.5.5 Control valves........................................................................................................................ 21

3.5.6 P and T sensors..................................................................................................................... 22

3.6 Temperatures ................................................................................................................. 23

4 Electrical connections 24

4.1 Safety instructions.......................................................................................................... 24

4.2 Opening and closing covers ........................................................................................... 24

4.3 Digital I/O connections ................................................................................................... 25

4.3.1 Pulse and frequency output.................................................................................................. 26

4.3.2 Status outputs ....................................................................................................................... 26

4.3.3 Emulation of a turbine meter ............................................................................................... 27

4.4 Serial data communication (RS 485).............................................................................. 28

4.5 Power connection ...........................................................................................................28

4.6 Cabling............................................................................................................................ 29

4.7 Grounding ....................................................................................................................... 30

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

3

Page 4

CONTENTS

ALTOSONIC V12

5 Start-up 31

5.1 Starting the signal converter ......................................................................................... 31

6 Operation 32

6.1 Display and operating elements .................................................................................... 32

6.1.1 Display in measuring mode with 2 or 3 measured values ................................................... 33

6.2 Menu overview................................................................................................................ 34

6.3 Access control and seals................................................................................................ 35

7 Software service tool 37

7.1 Introduction .................................................................................................................... 37

7.2 Installation of the software ............................................................................................ 37

7.3 Starting a session........................................................................................................... 37

7.4 Loading a monitoring configuration............................................................................... 42

7.5 Changing and saving a monitoring configuration .......................................................... 45

7.5.1 Creating a monitoring configuration .................................................................................... 45

7.5.2 Saving a monitoring configuration with a new name ........................................................... 48

7.5.3 Saving a monitoring configuration with its current name ................................................... 49

7.6 Creating a monitoring configuration.............................................................................. 50

7.7 Viewing data.................................................................................................................... 52

7.7.1 Unformatted data.................................................................................................................. 53

7.8 Customizing the way data is presented ......................................................................... 54

7.8.1 Setting up tabs in the user view window .............................................................................. 54

7.8.2 Creating a new grid definition............................................................................................... 56

7.8.3 Creating a new graphical presentation ................................................................................ 60

7.9 Creating reports ............................................................................................................. 61

7.9.1 Reporting related to parameter settings ............................................................................. 61

7.9.2 Reporting related to process values .................................................................................... 66

7.9.3 Reporting related to calibration parameters .......................................................................66

7.9.4 Reporting related to privileges............................................................................................. 66

7.10 Logging data from a flowmeter.................................................................................... 66

7.11 Customizing the data logging process......................................................................... 67

7.12 Adjusting parameter settings....................................................................................... 72

8 Service 73

8.1 Periodic maintenance..................................................................................................... 73

8.2 Cleaning.......................................................................................................................... 73

8.3 Exchange of transducers................................................................................................ 74

8.4 Exchange of transducers - Depressurised condition .................................................... 74

8.5 Exchange of transducers - Pressurised condition ........................................................ 79

8.5.1 Transducer retraction tool.................................................................................................... 81

8.5.2 Procedure to remove a transducer ...................................................................................... 82

8.6 Exchange of electronics unit .......................................................................................... 94

8.6.1 Field version.......................................................................................................................... 94

8.7 Battery maintenance ...................................................................................................... 96

8.8 Availability of services .................................................................................................... 96

4

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 5

ALTOSONIC V12

CONTENTS

8.9 Returning the device to the manufacturer..................................................................... 96

8.9.1 General information.............................................................................................................. 96

8.9.2 Form (for copying) to accompany a returned device............................................................ 97

8.10 Disposal ........................................................................................................................ 97

9 Technical data 98

9.1 Measuring principle........................................................................................................98

9.2 Transit time measuring principle .................................................................................. 98

9.3 Swirl compensation........................................................................................................ 99

9.4 Multipath ultrasonic flowmeters.................................................................................. 100

9.5 Technical data table ..................................................................................................... 101

9.6 Dimensions and weights .............................................................................................. 105

9.7 Flow table ..................................................................................................................... 110

10 Modbus protocol description and set-up 111

10.1 Introduction ................................................................................................................ 111

10.2 Physical Communication Layer.................................................................................. 111

10.3 Serial transmission format ........................................................................................ 112

10.3.1 ASCII mode........................................................................................................................ 112

10.3.2 RTU mode.......................................................................................................................... 113

10.4 Modbus message framing.......................................................................................... 113

10.4.1 Address Field (Device Address)........................................................................................ 114

10.4.2 Function Field ................................................................................................................... 114

10.4.3 Data Field .......................................................................................................................... 114

10.4.4 Error checking methods ................................................................................................... 114

10.4.5 Transmission gaps............................................................................................................ 115

10.4.6 Time out............................................................................................................................. 115

10.5 Supported functions ................................................................................................... 115

10.5.1 Function 01: READ COILS ................................................................................................. 116

10.5.2 Function 02: READ DISCRETE INPUTS............................................................................. 116

10.5.3 Function 03: READ HOLDING REGISTERS........................................................................ 117

10.5.4 Function 04: READ INPUT REGISTERS............................................................................. 117

10.5.5 Function 05: WRITE SINGLE COIL .................................................................................... 118

10.5.6 Function 06: WRITE SINGLE HOLDING REGISTER........................................................... 118

10.5.7 Function 08: DIAGNOSTICS............................................................................................... 118

10.5.8 Function 15: WRITE MULTIPLE COILS ............................................................................. 119

10.5.9 Function 16: WRITE MULTIPLE HOLDING REGISTERS.................................................... 119

10.5.10 Exception responses ....................................................................................................... 120

10.6 Handling of large data types ...................................................................................... 121

10.6.1 Integer (16 bit), Transmit sequence.................................................................................. 122

10.6.2 Long integer (32 bit), Transmit Sequence ........................................................................ 122

10.6.3 Single precision floating point (32 bit), transmit sequence ............................................. 123

10.6.4 Double precision floating point (64 bit), transmit sequence ............................................ 124

10.6.5 Long long (64 bit integer), transmit sequence ................................................................. 125

10.6.6 Maximum number requested items ................................................................................. 125

10.7 Default settings ..........................................................................................................126

10.8 Modbus register mapping .......................................................................................... 127

10.8.1 Input Registers (read-only): Integer (16-bit); address range 3000-3499 ........................ 127

10.8.2 Holding Registers (read/write): Integer (16-bit); address range 3500-3999................... 127

10.8.3 Input Registers (read-only): Long integer (32-bit); address range 5000-5499 ............... 128

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

5

Page 6

CONTENTS

10.8.4 Holding Registers (read/write): Long integer (32-bit), addres range 5500-5999............ 132

10.8.5 Input Registers (read-only): Double (64-bit floating point), address range 6000-6499 .. 133

10.8.6 Holding Registers (read/write): Double (64-bit floating-point), addr. range 6500-6999. 133

10.8.7 Input Registers (read-only): Float (32-bit floating-point), address range 7000-7499..... 133

10.8.8 Holding Registers (read/write): Float (32-bit) floating-point, address range 7500-7999 138

10.8.9 Input Registers (read-only): Long long (64-bit integer), address range 8000-8499........ 141

10.8.10 Holding Registers (read/write): Long long (64-bit integer), address range 8500-8999 142

ALTOSONIC V12

11 Notes 143

6

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 7

ALTOSONIC V12

1.1 Intended use

The ALTOSONIC V12 is a gas flowmeter for custody transfer applications.

The meter is suitable to operate at least under the following conditions:

• relative density from 0.55 and upwards

• methane concentrations 75...100%

CAUTION!

High levels of CO

absorption properties. It is recommended to submit a specification of the process medium to be

measured at the manufacturer for advice.

1.2 Certifications

LEGAL NOTICE!

The ALTOSONIC V12 custody transfer gas flowmeter meets the technical requirements and

standards applicable to equipment designed for use in different countries world wide.

SAFETY INSTRUCTIONS 1

can inhibit the operation of an ultrasonic flowmeter due to its acoustic

2

European Union (EU):

European Union (EU):

European Union (EU):European Union (EU):

• Pressure Equipment Directive 97/23/EC

• EMC directive 2004/108/EC, according to:

EN 50081-2

EN 61000-6 (part 1, 2 and 3)

EN 61326-1 (1997) and A1 (1998), A2 (2001)

• ATEX directive 94/9/EC according to:

EN 60079-0 (2006)

EN 60079-1 (Ex 'd')

EN 60079-7 (Ex 'e')

EN 60079-18 (Ex 'ma')

• Custody transfer approvals according to:

MID directive 2004/22/EC ((MID = Measurement Instrument Directive)

OIML R137-1 (International Organization for Legal Metrology)

• Fully compliant to AGA 9

• Fully compliant to ISO 17089

America:

America:

America:America:

• Certified for use in potentially explosive atmospheres according to FM:

FM3600

FM3615

Canada:

Canada:

Canada:Canada:

• CRN

• Certified for use in potentially explosive atmospheres according to CSA:

C22.2 No. 30

C22.2 No. 0.4

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

7

Page 8

1 SAFETY INSTRUCTIONS

Other standards:

Other standards:

Other standards:Other standards:

• IECEx PTB 10.0013X

INFORMATION!

Not all country specific approvals are listed here. Please consult KROHNE in case of a specific

approval that is not listed here.

1.3 Safety instructions from the manufacturer

1.3.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

ALTOSONIC V12

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.3.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

8

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 9

ALTOSONIC V12

1.3.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.3.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

9

Page 10

1 SAFETY INSTRUCTIONS

1.3.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

ALTOSONIC V12

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.4 Safety instructions for the operator

10

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 11

ALTOSONIC V12

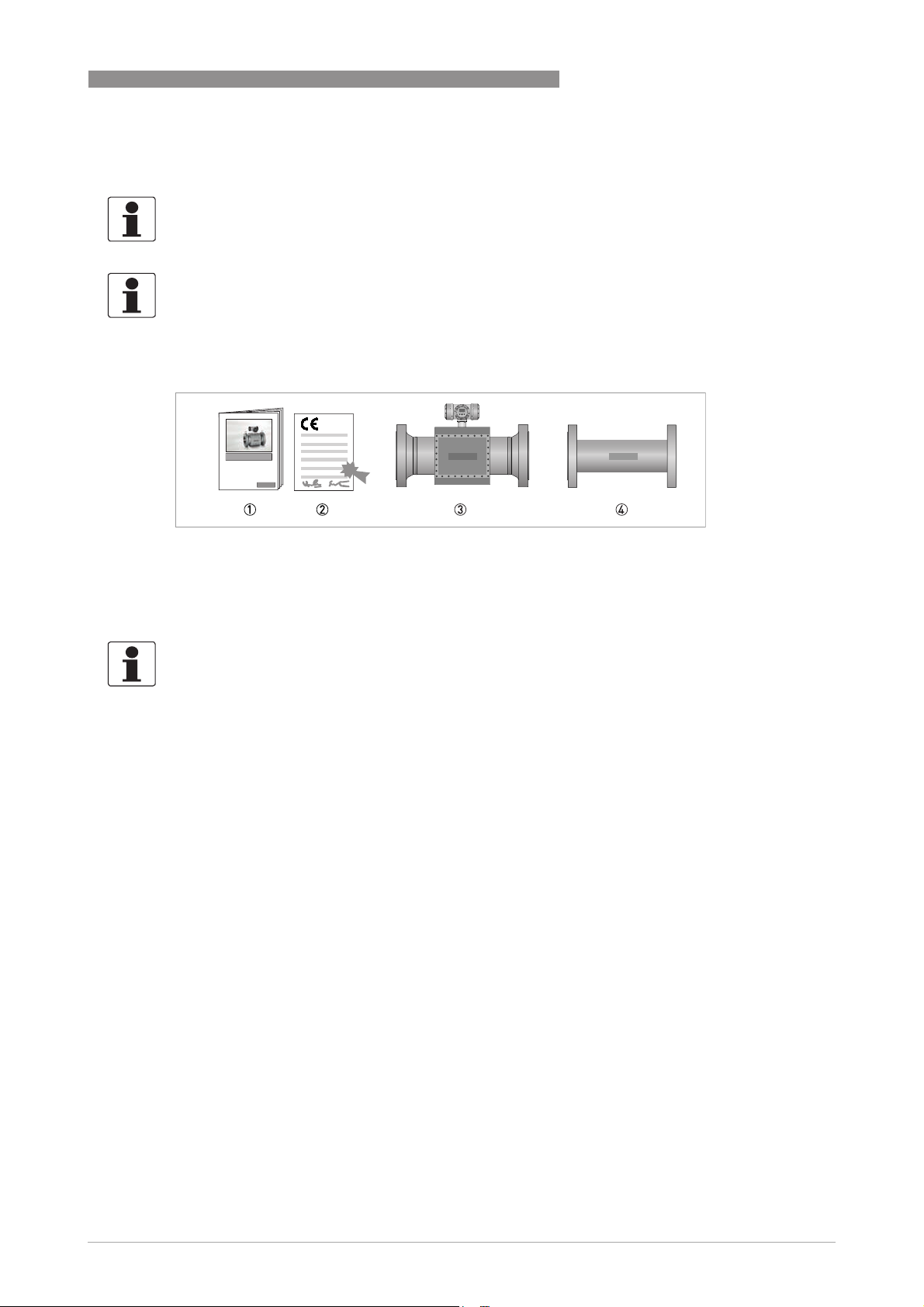

2.1 Scope of delivery

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

The instrument is delivered in a seaworthy, reinforced wooden crate. Inspect the packing

carefully for damages or signs of rough handling. Report damage to the carrier and to the local

office of the manufacturer.

DEVICE DESCRIPTION 2

Figure 2-1: Scope of delivery

1 Product documentation

2 CE Declaration

3 Flowmeter in ordered version

4 Optional: flow conditioner, spare parts and / or installed impact indicators

INFORMATION!

Calibration reports and project specific documents are in the meter's databook that is sent

separately.

2.2 Hardware description

The flowmeter is designed to meet explosion safety requirements based on:

• the application of an explosion proof (Ex d) electronics enclosure according to IEC 60079-1

• using Ex certified transducers according to IEC 60079-18

• using cables with an Ex d certified connector according to IEC 60079-1 to connect to the

transducers

• installation of the cabling between the electronics and the transducers complying with

enhanced safety

enhanced safety requirements according to IEC 60079-7.

enhanced safetyenhanced safety

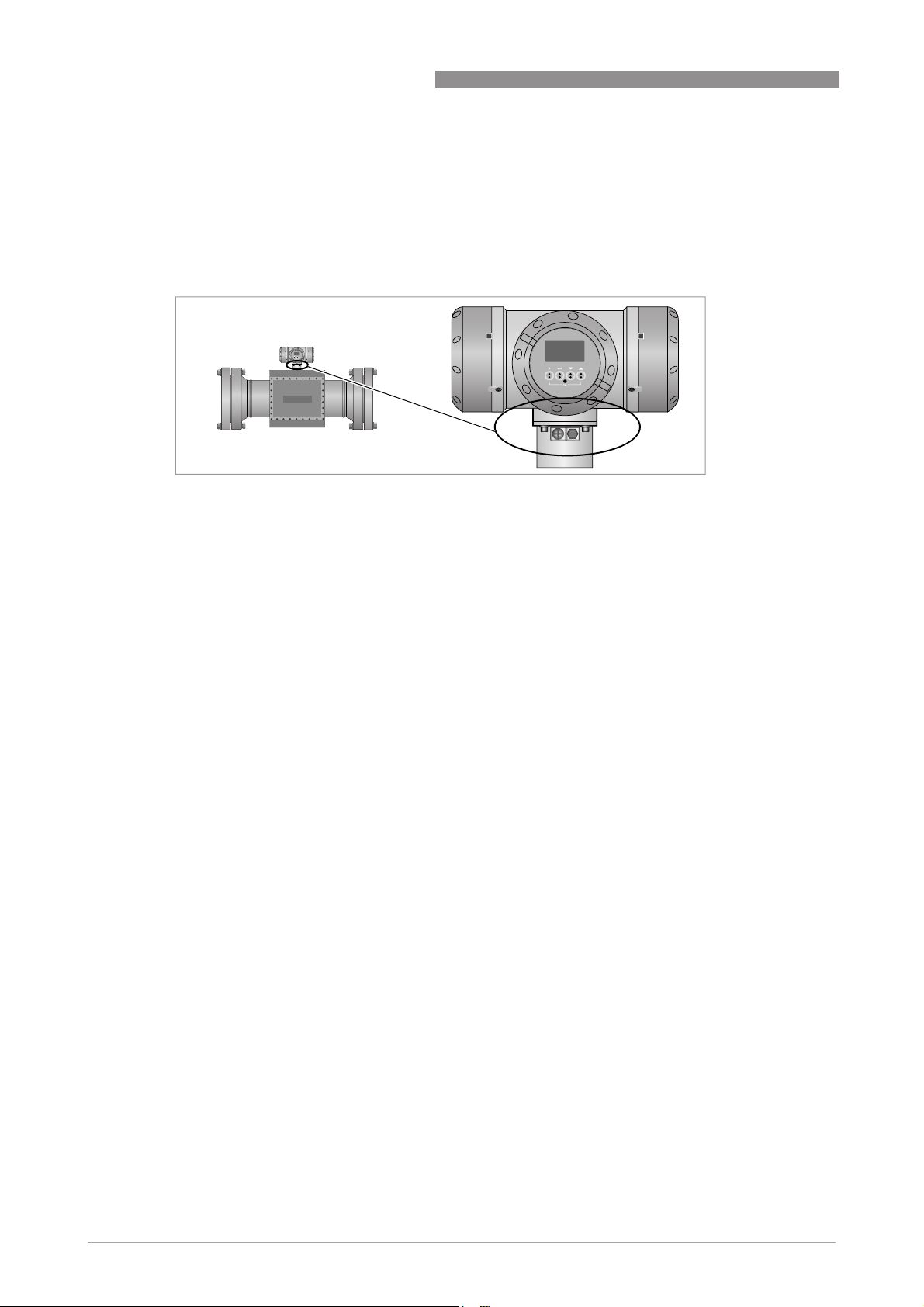

The flowmeter consists of a meter body with one or two (twin meter) electronic units installed on

top of it.

For smaller diameters the meter body is fully machined hence no welding is done.

For larger diameters the meter body is a welded construction.

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

11

Page 12

2 DEVICE DESCRIPTION

A series of acoustic transducer are installed on the inside of the meter body. Each pair of

ultrasonic transducers forms an acoustic measurement path. The acoustic measurement path

consists of one (direct) chord or two (reflective) chords.

The chords in the horizontal plane are used for flow measurement, the chords in the vertical

plane are used for diagnostics only. The reflective chords that are offset from the meter’s centre

line use acoustic mirrors to reflect the ultrasonic signal. The reflective chords that are in the

centre line of the meter reflect directly on the pipe wall. Direct chords do not reflect and

therefore do not require acoustic mirrors.

The transducers are electrically connected to the electronic unit on top of the meter by means of

coaxial cables. The cabling is protected against mechanical damage and moisture by means of

covers. The coaxial cables enter the electronics enclosure through its “foot” (or support). In this

foot an Ex d approved cable feed through is installed that closes this entry to the electronics

enclosure.

On the other side the coax cables are connected to the transducers, this connection is also done

by an Ex d approved connector

ALTOSONIC V12

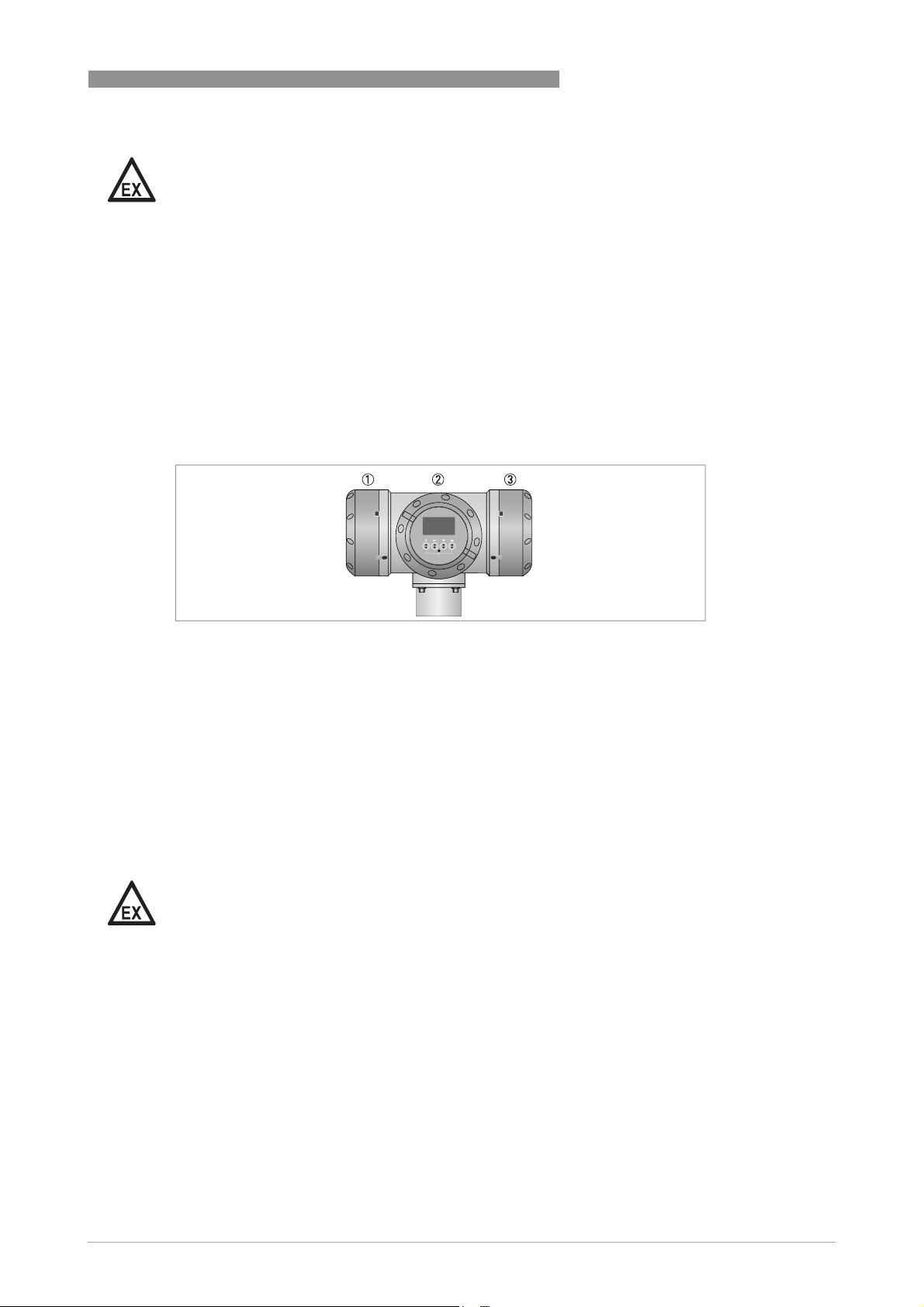

Figure 2-2: Location of sensors and electronic unit

2.2.1 Transducers

Acoustic signals are transmitted and received by means of ultrasonic transducers. The active

part of an ultrasonic transducer is a small disk of piëzo electric ceramic in the front of the

transducer. It is packaged (sealed) in a construction of metal parts and high grade epoxy or

inside a titanium housing. The front side of the transducer is exposed to the gas to be measured,

this results in the best efficiency for transmitting and receiving ultrasound.

Overview installation of transducer

Figure 2-3: Sensor assembly

1 Double O-ring

2 Slot in the socket

3 Ex-d socket

4 Ex-d plug

5 Alignment pin

6 Cap

7 Securing screw M2

8 Coaxial wire

9 Transducer nut

12

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 13

ALTOSONIC V12

DANGER!

The transducers have an Ex-d socket (socket, 3) that connects to an Ex-d plug 4 which

terminates a coaxial wire 8.

An alignment pin 5 on the connector engages with a slot in the Ex-d socket 2, this ensures that

the transducer is connected with the correct polarity. The cap 6, screwed on the Ex-d socket,

fastens the connector, a small securing screw (M2) 7 secures this cap. The transducers are

fastened in the meter body using a transducer nut with a hole in the centre 9. A double O-ring

1 seals the pressure inside the piping effectively from the outside world.

2.2.2 The electronic unit

The housing consists of three compartments. Each compartment has a removable cover that

gives access to the inside, in order to connect external wiring or to install or to replace

components.

DEVICE DESCRIPTION 2

Figure 2-4: Converter housing

1 Power supply / RS485 compartment / Optional diagnostics board

2 Electronics compartment

3 Connection compartment

Connection compartment

The compartment on the right side is the connection compartment, which contains only a block

with screw terminals. Signal wires from and to the electronics compartment are connected to

this terminal block. Wiring to other (external/auxiliary) equipment can be connected to the screw

terminals in this compartment.

Cables can enter this compartment through cable glands installed in either one of three

threaded holes M20x1.5.

DANGER!

Unused holes must be closed with Ex d approved blind stops.

Power supply / RS485 compartment

The compartment on the left side is used to install the power converter. This board also includes

two serial data ports (RS485). As an option an additional diagnostics processor board can be

installed. Wiring to external equipment or to a power source is attached to connectors with

screw terminals. These connectors engage directly with matching parts on the printed cicuit

boards.

Cables can enter this compartment through cable glands installed in either one of three

threaded holes M20x1.5.

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

13

Page 14

2 DEVICE DESCRIPTION

Electronics compartment

The compartment on the front has a cover with a glass window. It contains a frame with a

number of printed circuit boards. The boards have the following functions:

• Frequency and status output board

• Processor boards

• Sensor driver board

• Display module (connected tot the front side of the frame, can be seen through the cover with

the glass window)

2.3 Software description

The ALTOSONIC V12 contains a powerful microprocessor that controls the functions and

calculations it performs. The microprocessor executes program code consisting of several

modules, according to the functions it has to perform. By means of a set of parameters the

software can be configured to various sizes and models of flowmeters and according to specific

requirements depending of applications or customers.

ALTOSONIC V12

LEGAL NOTICE!

The parameters are stored in a configuration file. Configuration parameters are password

protected in order to prevent unauthorized modification. Access in order to read, view and

inspect parameter values is unrestricted.

Individual parameters are classified according to “roles” in order to define differentiated access

rights. Each “role” is associated with a “typical” user or operator having specific responsibilities

or duties. Users have to be registered with a user name and a password, when registered the

role of the user is also defined, and by consequence also the access rights of that user.

The following roles have been defined, listed in according to the rank in the hierarchy.

Roles and authorisation

Developer restricted to KROHNE R&D employees.

Factory restricted to KROHNE factory employees, to implement factory settings in the

Service restricted to authorized service personnel, to the discretion of KROHNE.

Calibrator restricted to personnel acting on behalf of a legal calibration station.

Supervisor restricted to personnel acting on behalf of the owner/operator of

Operator restricted to personnel acting on behalf of the owner/ operator of the meter (for day

meter.

the meter (administrator function), to the discretion of the owner/operator of the

meter.

to day operation), to the discretion of the owner/operator of the meter.

14

Only a higher rank user can register a lower rank user. Users can have the same rank.

In addition to restrictions depending of the defined role of a user, a physical “overwrite disable”

contact / jumper protects the configuration parameters. This disables any user from making

modifications to parameters that would influence the measured flow or volume value. This

prevents unintentional or unauthorized changes to the parameters and possibly invalidation of

the calibration.

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 15

ALTOSONIC V12

Normally the meter is delivered with a set of parameters suitable for the application.

In case a modification of the configuration file is made, this is stored in its data logging memory.

This information can be retrieved afterwards for auditing and verification purposes.

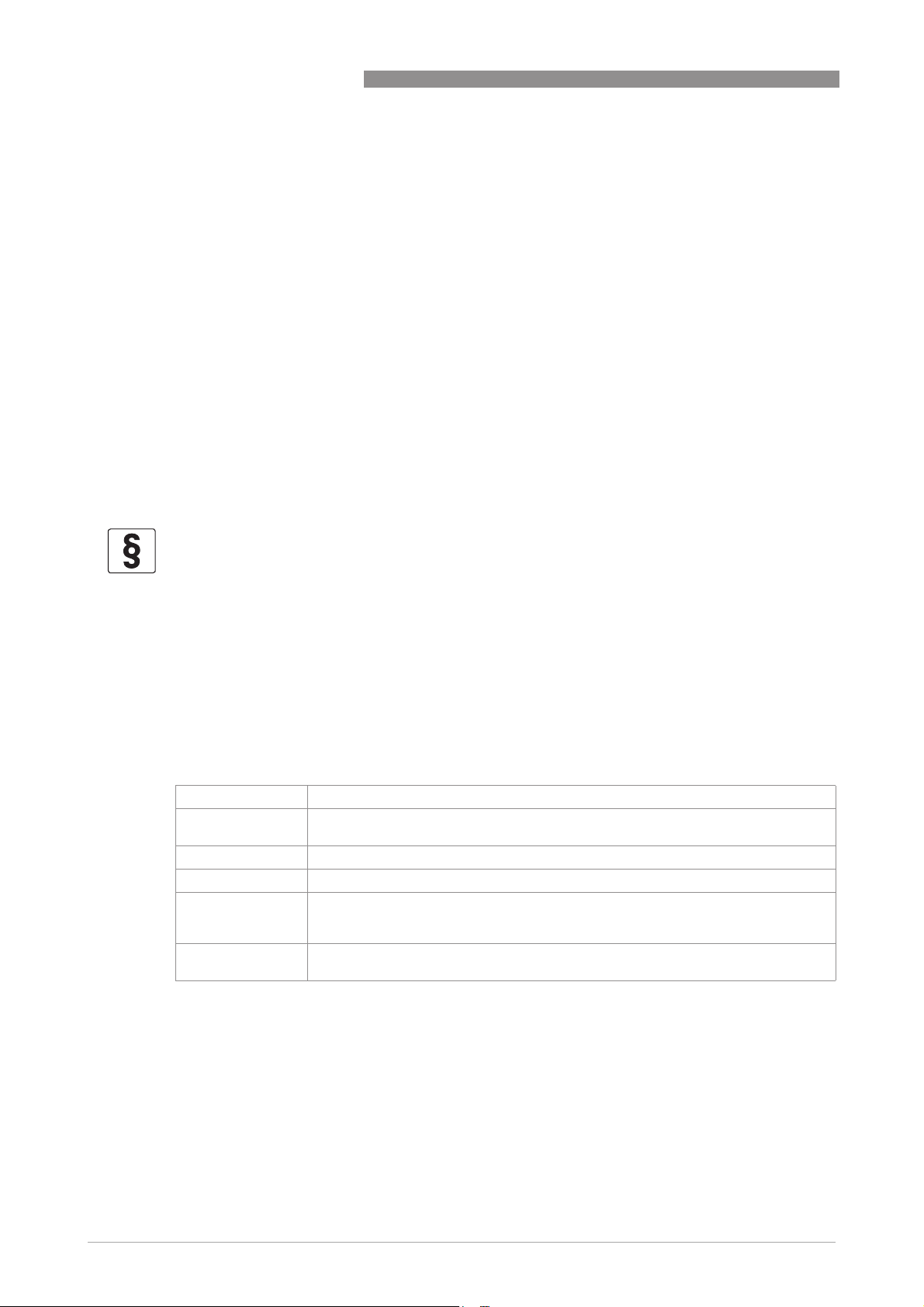

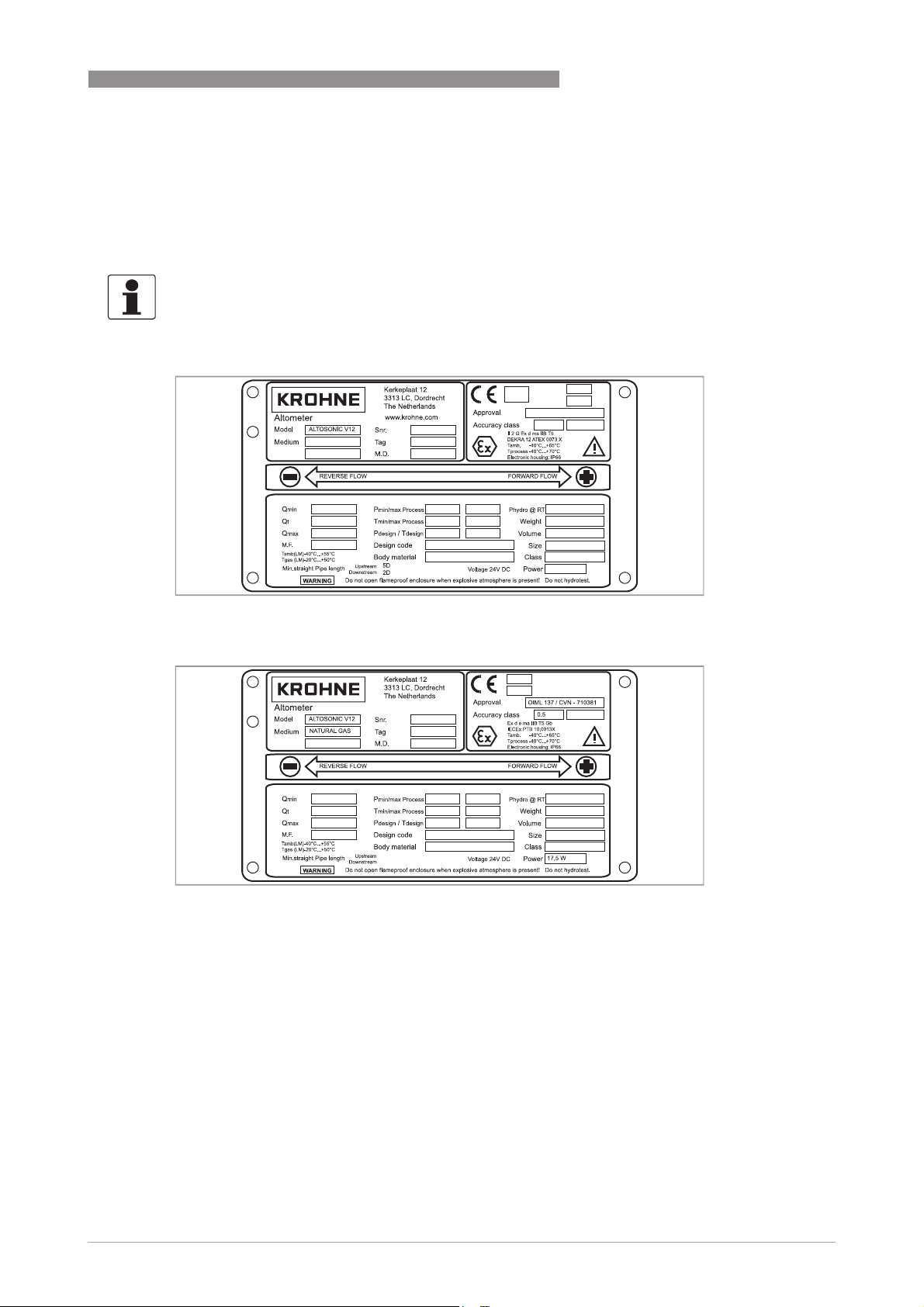

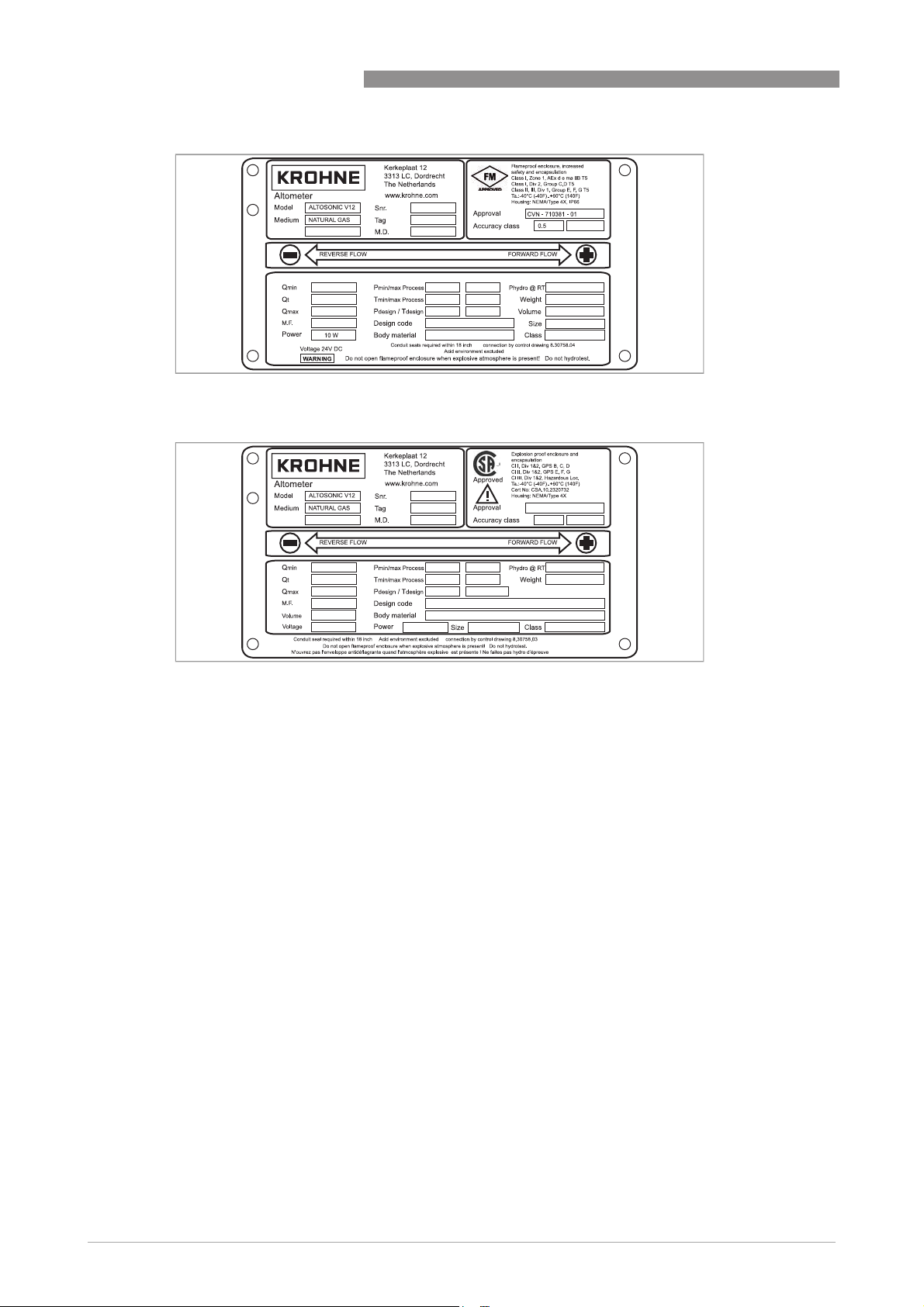

2.4 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION 2

Figure 2-5: Example of a ATEX nameplate

Figure 2-6: Example of a IECEx nameplate

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

15

Page 16

2 DEVICE DESCRIPTION

Figure 2-7: Example of a FM nameplate

ALTOSONIC V12

Figure 2-8: Example of a CSA nameplate

16

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 17

ALTOSONIC V12

3.1 Notes on installation

CAUTION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

Correct storage position

INSTALLATION 3

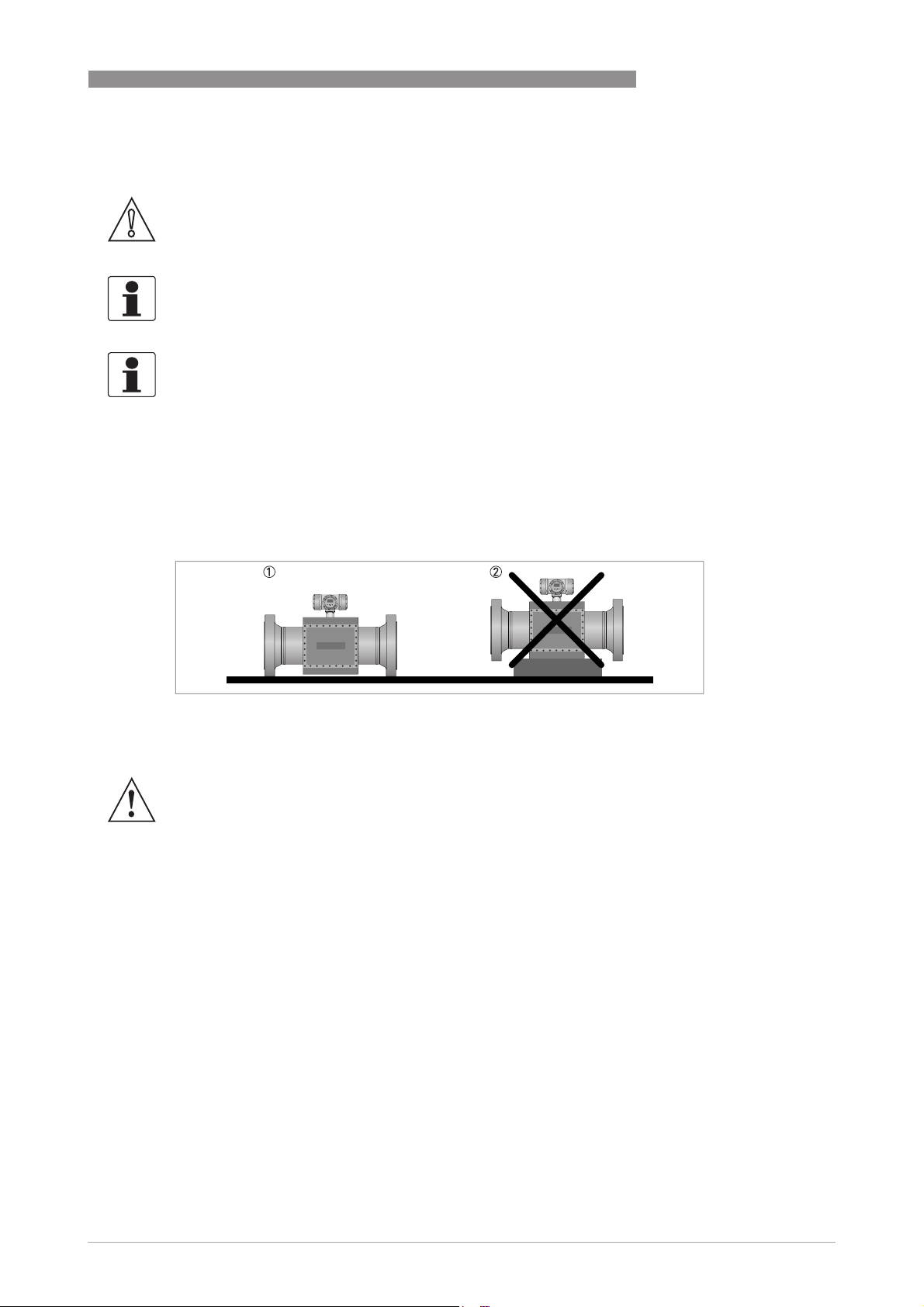

Figure 3-1: Storage

1 Correct position for all sizes

2 Position not allowed for flowmeters > 12"

WARNING!

Make sure that the extensions on the bottom of the flanges are in good order to prevent the

meter from rolling over. Otherwise take appropriate measures to prevent the meter from rolling

over.

Storage conditions

Maintain the following storage conditions to prevent the equipment from corrosion or early

failure:

• Humidity: <95 % RH (closed and heated storage area)

• Storage temperature: -40...+65º C / -40...+149º F

• Avoid direct solar radiation during long storage periods, store under a sunshade

How to prevent corrosion

Pay attention to the conservation of the inner pipe wall, especially for carbon steel meters.

Typical applications such as measuring dry natural gas (sales quality) or natural gas with a

corrosion inhibitor do not require an anti corrosion coating inside the meter tube. A coating can

even be regarded as unwanted because it may wear off, which will have an impact (although

minor) on the accuracy.

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

17

Page 18

3 INSTALLATION

However for storage and/or transportation additional protective measures are recommended.

Depending on how long the protection should last one of several methods can be considered:

1. For a storage period of less than one year, the inner pipewall should be protected by a corrosion

inhibitor such as Shell Ensys.

Do not apply the corrosion inhibitor on the acoustic transducers.

2. For a period of a year or longer, the pipewall should be protected by Tectyl or a similar product.

Do not apply Tectyl on the acoustic transducers.

3. Independend of the storage period, the inner pipewall can be protected by an oxygen free envi-

ronment. This can be created by mounting blind flanges, using a vacuum pump to remove the

air and subsequently filling the meter with nitrogen. It is recommended to place some bags of

silica gel inside the flowmeter. To protect against corrosion, the humidity should be less than

38% and/or oxygen should not be present. Special regulations may be applicable for transportation and storage of a pressurised flowmeter.

3.3 Transport

WARNING!

•

Even smaller size flowmeters have a considerable weight. Check the weight of your

flowmeter in order to select suitable means for transportation and lifting.

•

Use appropriate materials such as chains or hoisting straps that are in good condition.

•

Use the eye bolts on the meter body to attach chains or straps to lift the meter (if not present:

check condition of the threaded holes on the flanges and if okay screw eye bolts in the

threaded holes).

•

Never lift the meter using the converter housing to attach straps.

•

In case a fork lift will be used make sure that the flowmeter is secured against rolling off the

forks, or against straps sliding off the forks.

•

Verify local safety regulations, directives and company procedures with respect to hoisting,

rigging and transportation of (heavy) equipment.

ALTOSONIC V12

18

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 19

ALTOSONIC V12

3.4 Pre-installation requirements

INFORMATION!

The equipment is designed for safe operation under conditions according to the following

classifications:

•

Pollution degree 2: this means that normally only nonconductive (dry) pollution will occur.

Temporary conductivity caused by condensation can occur.

•

Protection class I: this means the equipment must be earthed.

•

Humidity: <95% RH

•

Ambient temperature: -40...+65°C / -40...+149°F

•

Suitable for indoor and outdoor use.

•

IP66 / NEMA 4X classification.

CAUTION!

The flowmeter should be protected from corrosive chemicals or gases and dust or particles

accumulation.

CAUTION!

Do not intend to perform a hydrostatic test of the installed flowmeter.

INSTALLATION 3

The flowmeter has been hydrostatically tested during manufacturing (see reports) and must not

be retested with the ultrasonic sensors installed. Water will protude in the sensor pockets and

remain. This will create acoustic shortcuts and possibly cause the flowmeter to start operating

in failure.

3.5 Installation

3.5.1 Mounting position

Install the ultrasonic gas flowmeter in horizontal position with the flow arrow indicator on the

nameplate or on the meter body in the direction of the positive (forward) gas flow.

Make sure that the converter is on top of the flowmeter after the installation.

Check the weight of the meter. Typically the weight of the meter will be considerably more than

the same length of pipe line.

To support the meter additional supports might be needed, preferably two, one on either side of

the meter.

Always support the meter at its flanges, the weight of the meter shall never rest on the case

around the transducers and the cabling.

If supports can not be placed under the meter flanges, supports may be placed under the mating

flanges of the pipeline. If supports can only be placed under the pipeline sections upstream or

downstream of the meter, these supports shall be as close as possible to the meter. In this case

a calculation must be made to verify that the load on the pipeline will not exceed acceptable

values.

The meter should be installed in the pipe line with gaskets, nuts and bolts according to the type

and size of the flanges of the gas flowmeter. The flanges of the meter should match with the

flanges of the pipeline where the meter should be installed.

Make sure that the gaskets do not protude into the flow as this can reduce the accuracy of the

flowmeter.

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

19

Page 20

3 INSTALLATION

In order to install the gas flowmeter, the pipeline must have a slot of such length that the meter

including the gaskets fits nicely in the slot. It should not be necessary to use excessive force to

tighten the bolts in order to close the gaps on either side of the meter.

Nor should the slot be too small, implying the slot has to be widened by applying brute force to fit

the meter and gaskets in the slot.

For tightening the bolts of the flanges, apply a lubricant as required, in accordance with the

materials as used and applicable standards.

Tighten the bolts of the flanges with a torque according to the standards applicable to the

flanges and materials used.

3.5.2 Pipe diameters and lengths

Make sure that the inner diameter of upstream and downstream pipes matches the specified

connection diameter of the ultrasonic flowmeter within 1%. Contact KROHNE if the iner diameter

deviates more than 1%.

ALTOSONIC V12

3.5.3 Flow conditioners

Although the flowmeter is a highly accurate device, an additional flow conditioner can be

installed upstream of the flowmeter in order to minimize measuring uncertainty, in particular

when a strongly distorted flow velocity profile has to be expected, or when the available space for

a metering run is critical. If a flow conditioner is used the total inlet length may be reduced to

only 5 DN: having 2 DN upstream of the flow conditioner and 3 DN in between the flow

conditioner and the flowmeter.

INFORMATION!

•

Preferred model is the “perforated plate” type. A “pipe bundle” type of flow conditioner is not

recommended.

•

When a flow conditioner is included in the metering run, it is strongly advised to use the same

flow conditioner and inlet pipe configuration during a flow (wet) calibration (see e.g. ISO17089

or AGA-9 for detailed requirements).

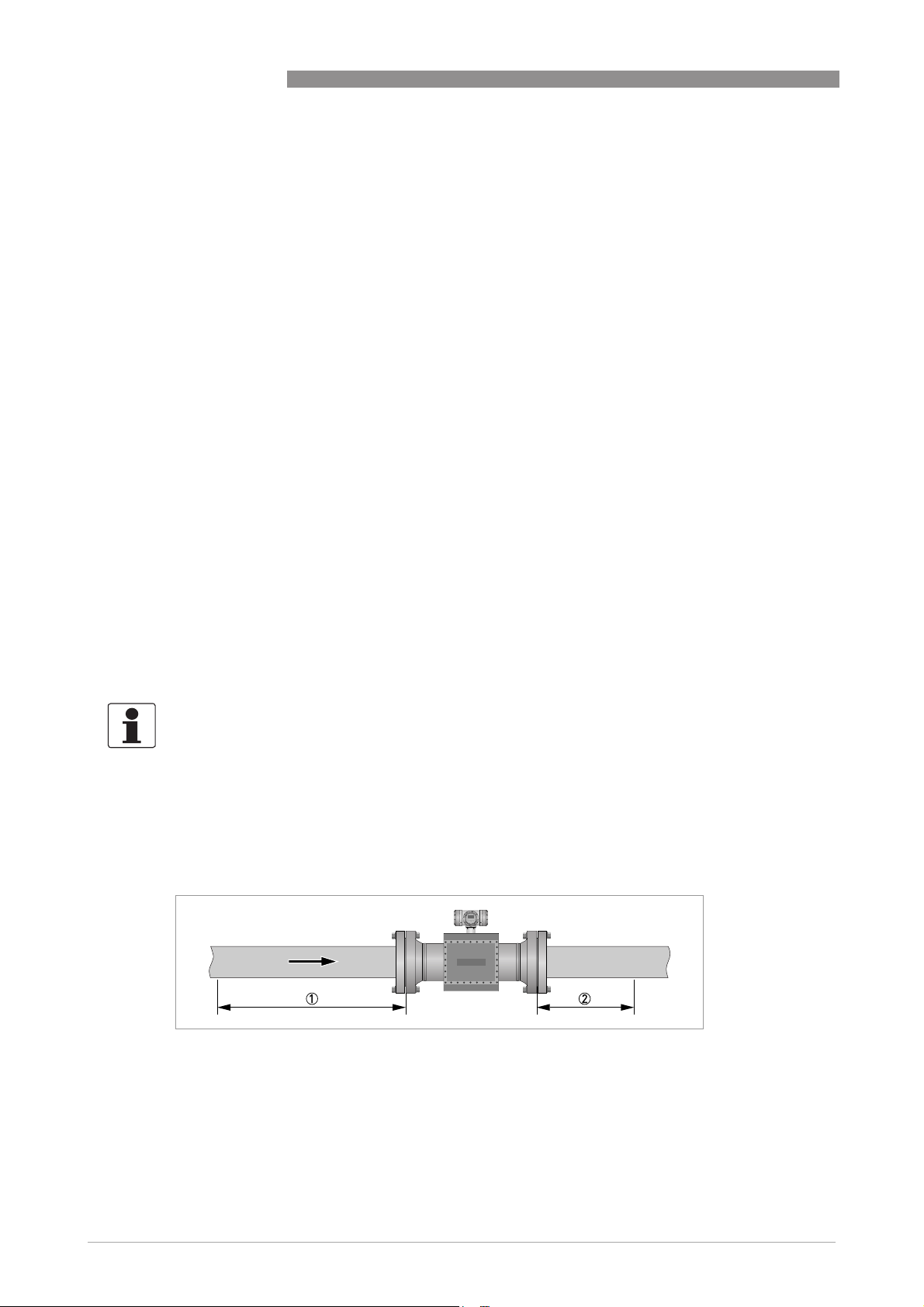

3.5.4 Inlet and outlet for uni-directional use

Without flow conditioner (OIML R137 class 0.5)

20

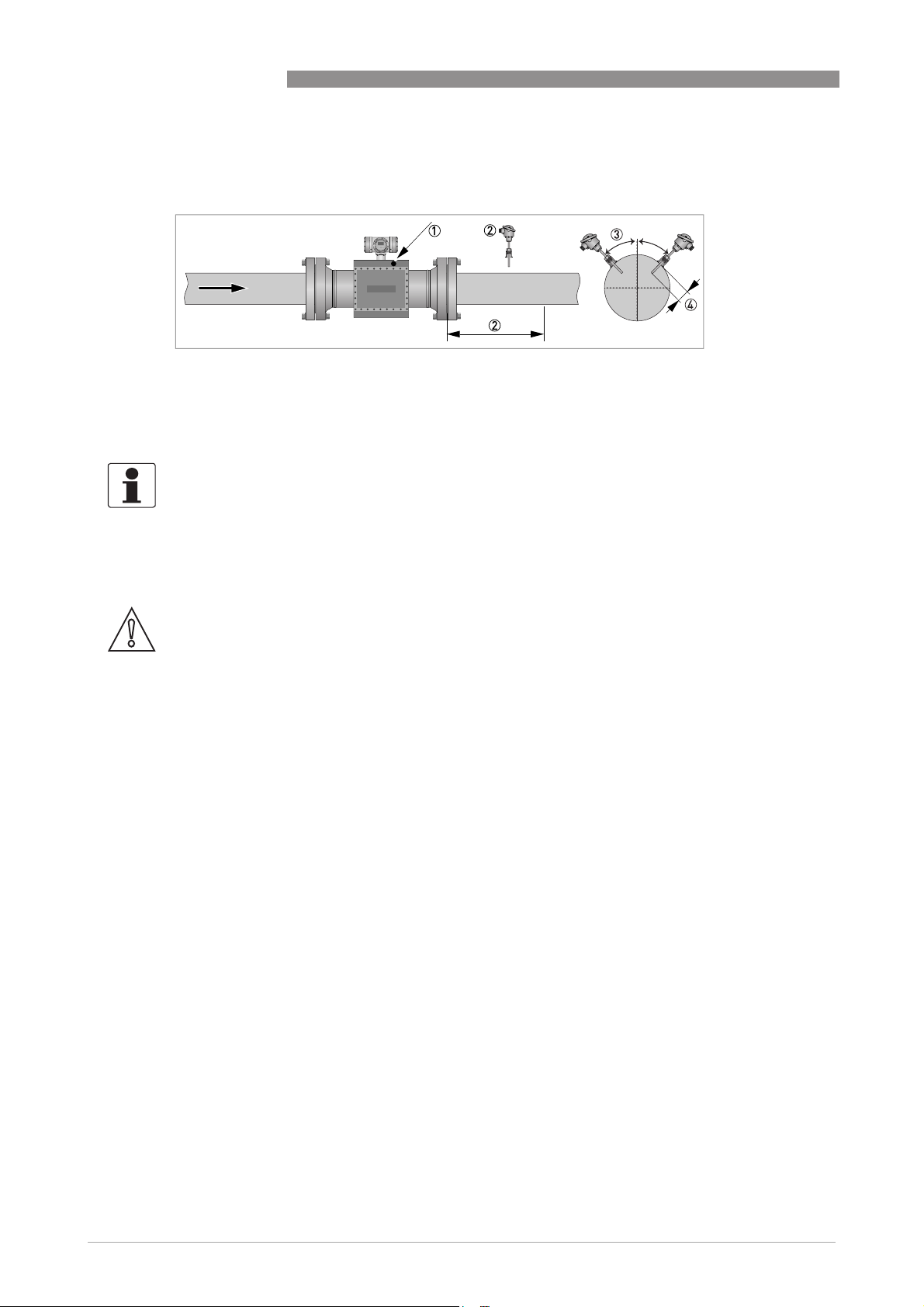

Figure 3-2: Reguired straight lengths for inlet and outlet

1 Inlet section: 10 DN

2 Outlet section: 3 DN

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 21

ALTOSONIC V12

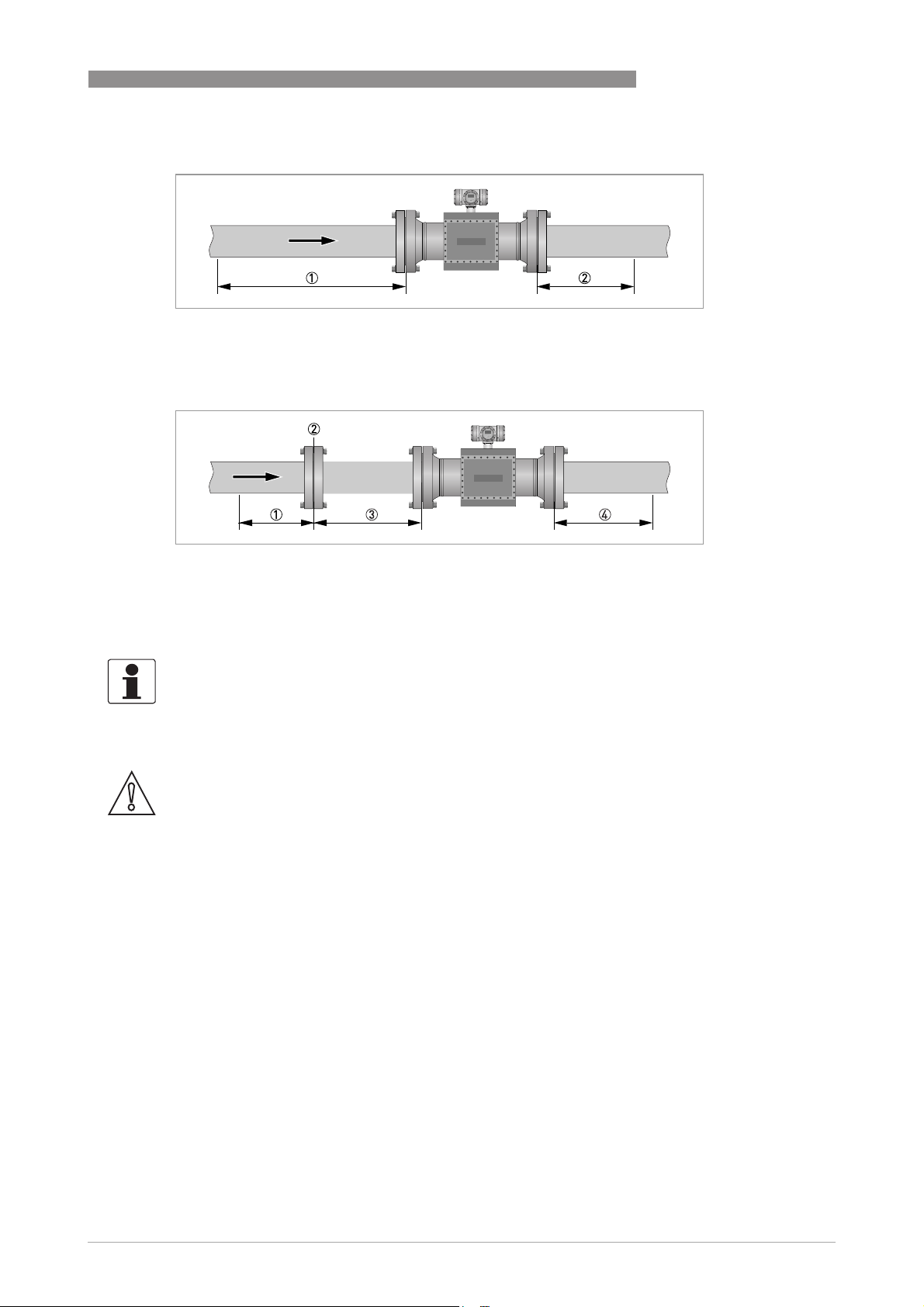

Without flow conditioner (AGA9, ISO 17089 and OIML R137 class 1)

Figure 3-3: Reguired straight lengths for inlet and outlet

1 Inlet section: 5 DN

2 Outlet section: 3 DN

With flow conditioner

INSTALLATION 3

Figure 3-4: Reguired straight lengths for inlet and outlet

1 Inlet section before flow conditioner: 2 DN

2 Flow conditioner (perforated plate)

3 Inlet section after flow conditioner: 3 DN

4 Outlet section: 3 DN

INFORMATION!

Contact KROHNE for recommendations on bi-directional use.

3.5.5 Control valves

CAUTION!

Under circumstances ultrasonic gas flowmeters can suffer from interference from noise

generated by pressure control valves (PCV). In case the frequency spectrum of the PCV-noise

extends in the range of the operation frequency of the ultrasonic transducers and the strength of

the noise results in a signal to noise ratio smaller than the critical value, the ultrasonic

flowmeter will not be able to operate. Consult the manufacturer for advice in case a PCV with

high pressure cut will be operated close to the ultrasonic flowmeter.

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

21

Page 22

3 INSTALLATION

3.5.6 P and T sensors

Figure 3-5: Location of pressure and temperature transmitters

1 Install pressure transmitters on body of flowmeter at Pr point

2 Install temperature transmitter at 2...5 DN downstream of flowmeter

3 Install temperature transmitter under 45 degrees

4 Install temperature transmitter with an insertion depth between 0.1 and 0.33 of nominal pipe diameter.

INFORMATION!

•

See ISO 17089 for further details.

•

Use a PT 100 element with thermowell and transmitter as temperature transmitter.

Preferably use tapered thermowells to avoid vibrations.

•

Connect the pressure transmitter to the Pr-point in the meter body using an intermediate

isolation valve and/or valve manifold.

ALTOSONIC V12

CAUTION!

Either use a suitable blind plug or blind flange (and sealing as required) to blind the pressure

port, or a sense line should be connected in an appropriate way.

A sense line should be properly supported to avoid vibrations and to prevent the weight of the

sense line to apply a load on the connection at the pressure port.

22

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 23

ALTOSONIC V12

3.6 Temperatures

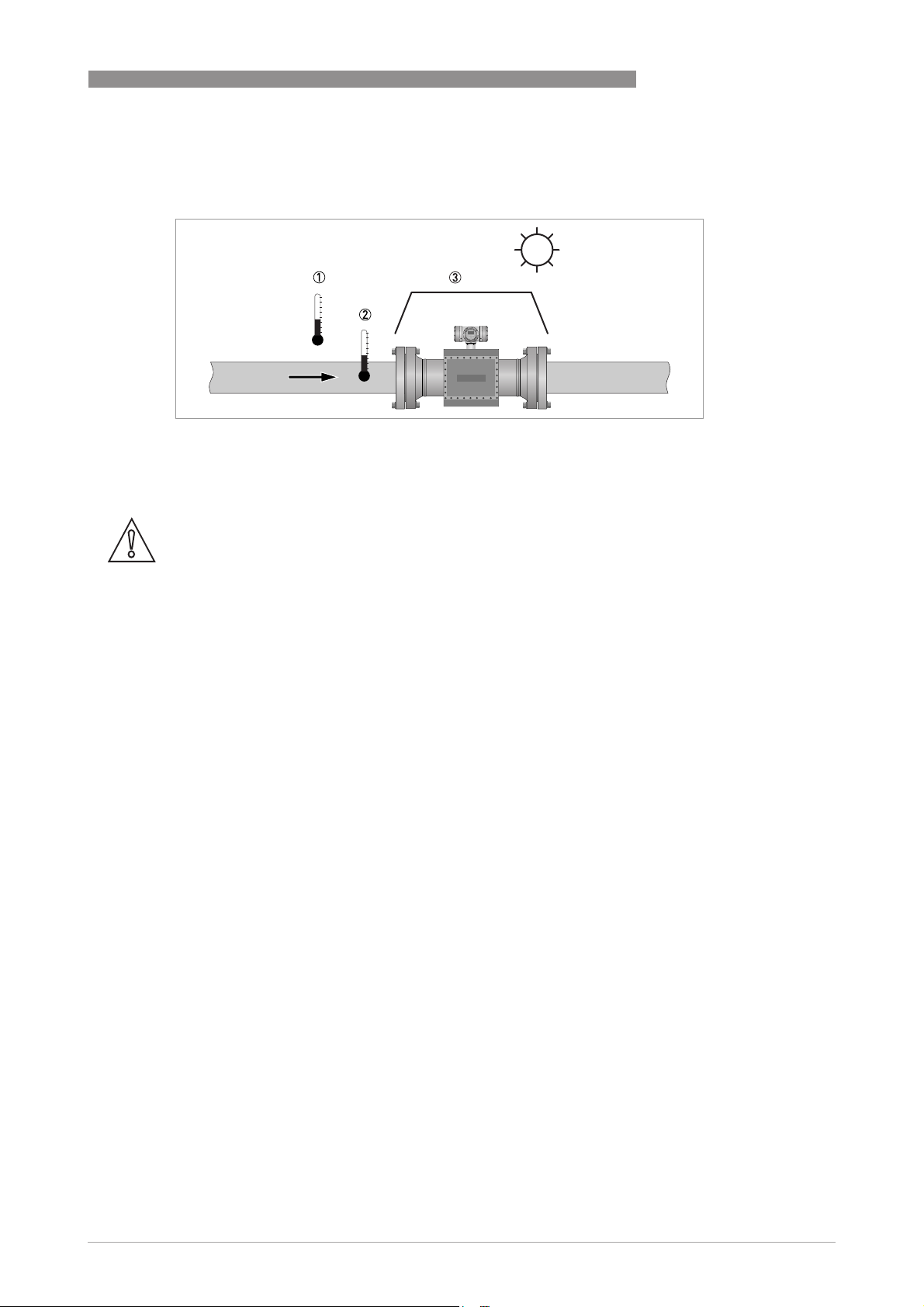

Figure 3-6: Temperatures

1 Ambient temperature

2 Process gas temperature

3 Use a sun shade to protect the flowmeter against direct solar radiation.

CAUTION!

SUNSHADE

SUNSHADE

SUNSHADESUNSHADE

Direct solar radiation introduces temperature gradients in the metering section and must be

avoided as much as possible. Use a sunshade or canopy over the flow, pressure and temperature

transmitters for protection against direct exposure to sunshine. Another option is to thermally

insulate the complete metering section including the transmitters.

INSTALLATION 3

For more detailed information about temperatures, refer to

Technical data table

on page 101.

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

23

Page 24

4 ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

ALTOSONIC V12

DANGER!

For FM installations, cables must be used that are resistant to high temperatures.

For all other applications, cable must be used that are resistant to high temperatures if the

°

process temperature is 65

C (149°F) or higher.

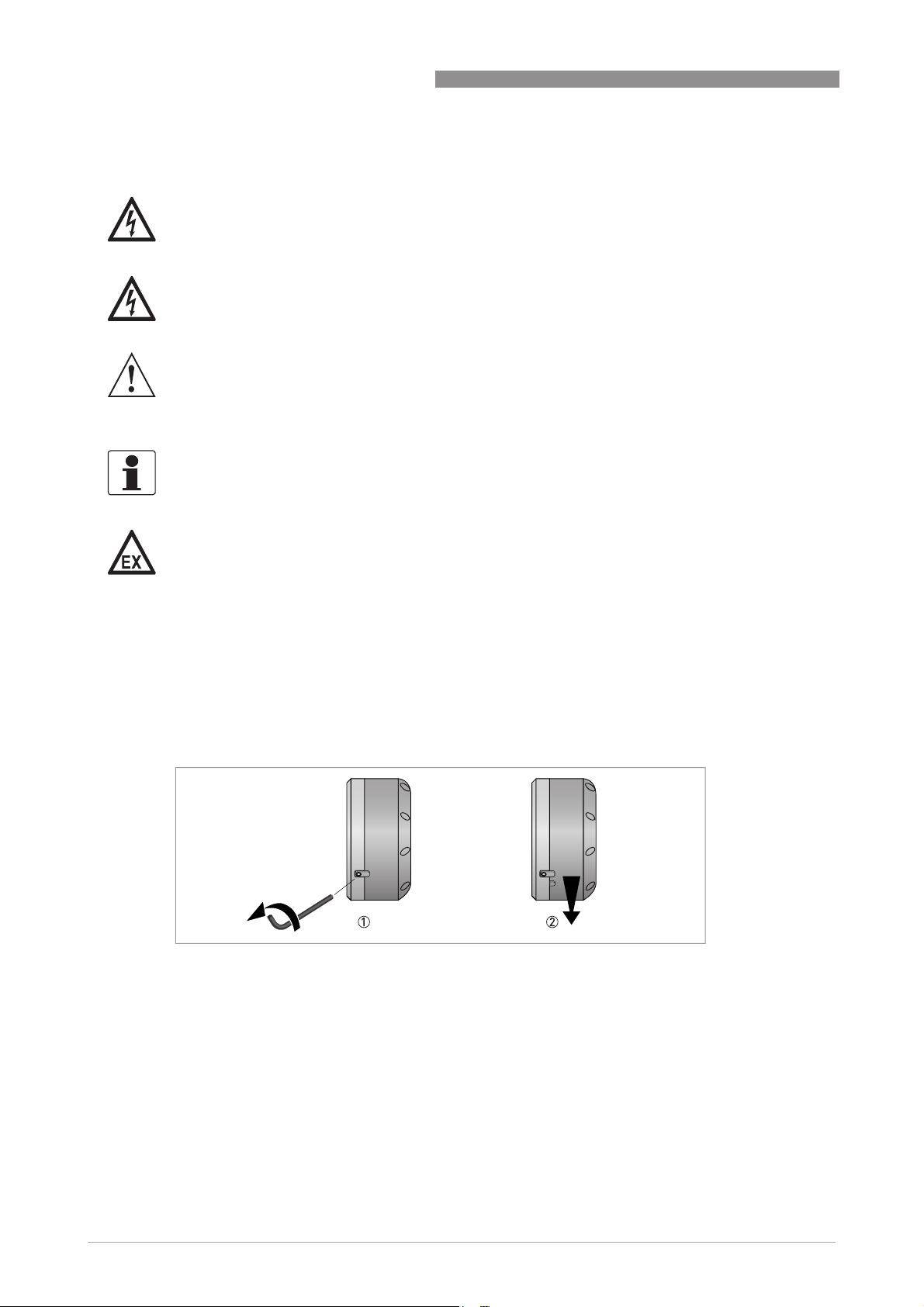

4.2 Opening and closing covers

All covers are equipped with an interlocking device to prevent unauthorized or inadvertent

opening and removal of the covers. Before a cover can be turned counter clockwise, the

interlocking device has to be released as shown in the figure below.

Figure 4-1: Opening cover with interlocking device

1 Loosen the hex screw with a 2.5 mm Allen key.

2 Turn the cover counter clockwise to open the cover.

24

Closing the covers is done in the reverse order. Turn the cover until the little know on the cover

is located under the interlocking device, then fasten the interlocking device.

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 25

ALTOSONIC V12

4.3 Digital I/O connections

WARNING!

1. In order to prevent unauthorized or inadvertent opening and removal of the covers, an inter-

locking device is provided for each cover. Before a cover can be rotated (counter clockwise) for

opening, release this interlocking device with a 2.5 mm Allen key.

2. The foot of the converter housing provide an earthing point, this must be connected to the near-

est safety earth conductor.

3. Only open the converter housing one minute after the power has been switched off and after it

has been verified that there is no risk due to the presence of potentially explosive gas.

• The digital outputs are passive open collector outputs, galvanically isolated from each other

and from the main circuit. To use these outputs an external voltage source and current

limiting resistors must be used. (NEC class 2 power supply (max. 100 VA, 24 VDC, IEC 610101, clause 6.3.1 and 6.3.2)

• For frequencies above 100 Hz, use shielded cables in order to reduce radiation from

electrical interferences (EMC).

• Terminal A+ is not used.

ELECTRICAL CONNECTIONS 4

Figure 4-2: Digital I/O as NPN transistor

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

25

Page 26

4 ELECTRICAL CONNECTIONS

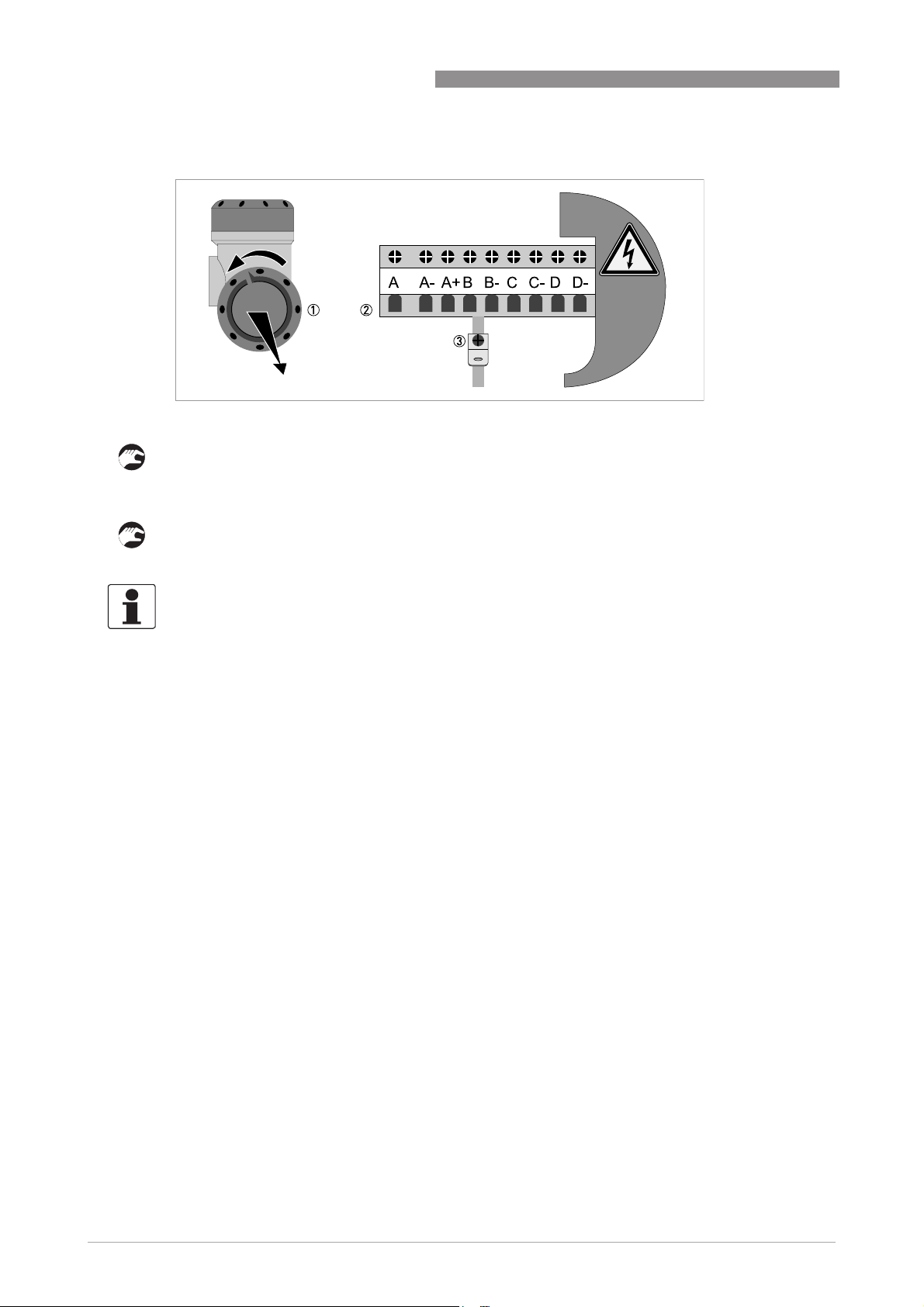

Figure 4-3: Terminal compartment for inputs and outputs in field housing

1 Open the housing cover.

2 Push the prepared cable through the cable entry and connect the necessary conductors.

3 Connect the shield if necessary.

• Close the cover of the terminal compartment.

• Close the housing cover.

ALTOSONIC V12

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

4.3.1 Pulse and frequency output

Default the first digital I/O connection is set as a pulse/frequency output, having a frequency

proportional to the volume flow rate (actual volume: under process conditions). It is possible to

assign another variable to control this output (defined by means of parameter settings).

4.3.2 Status outputs

Default the next three digital I/O connections are defined as status outputs (Data not valid, Fail

unreliable and Reverse flow). However the function of these outputs can be programmed to

various alarms or status signals. One of the status outputs may be programmed to a second

pulse output, having the same frequency as the first pulse output, however the phase difference

can be set to either 0, 90, 180 or 270 degrees.

26

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 27

ALTOSONIC V12

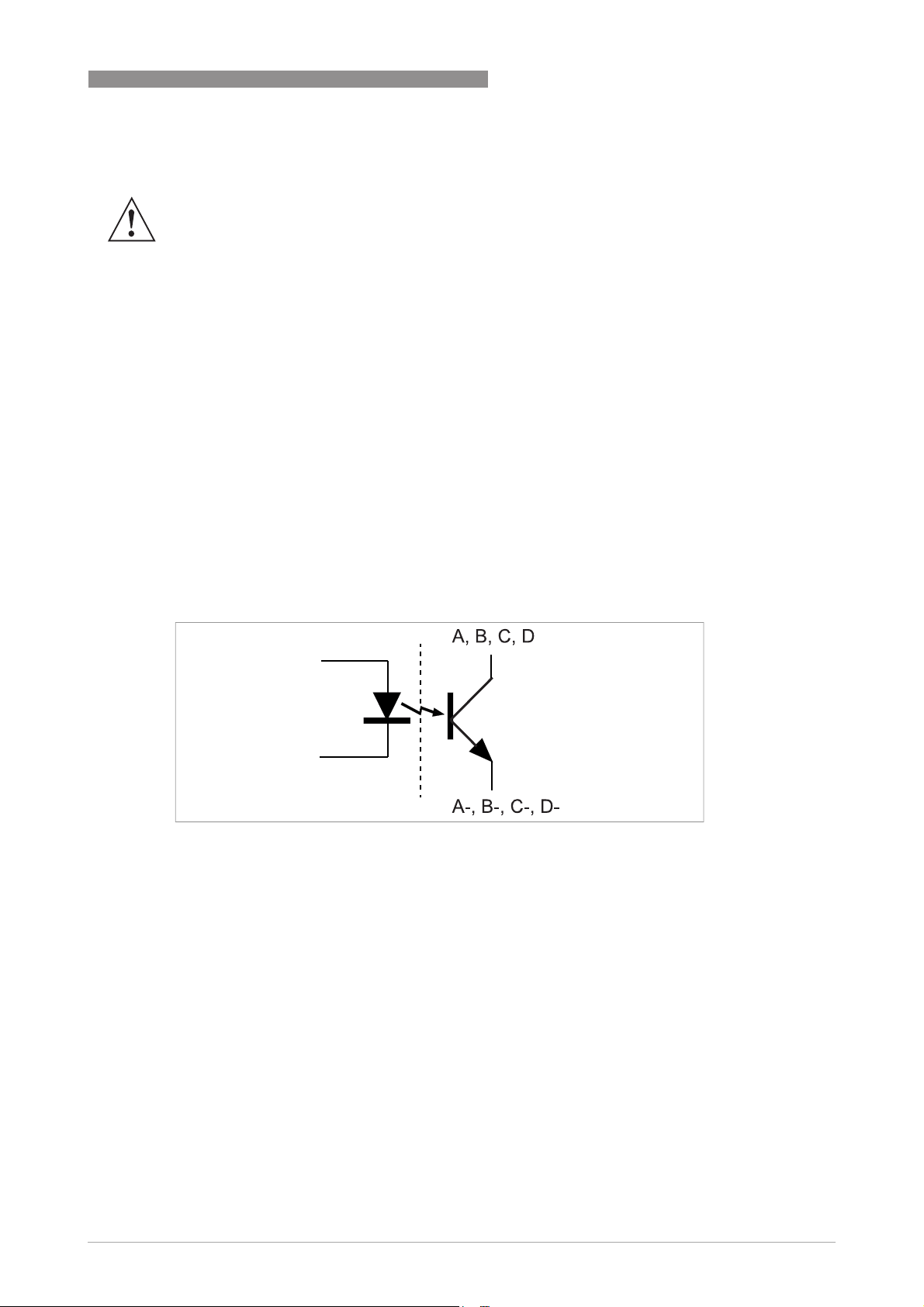

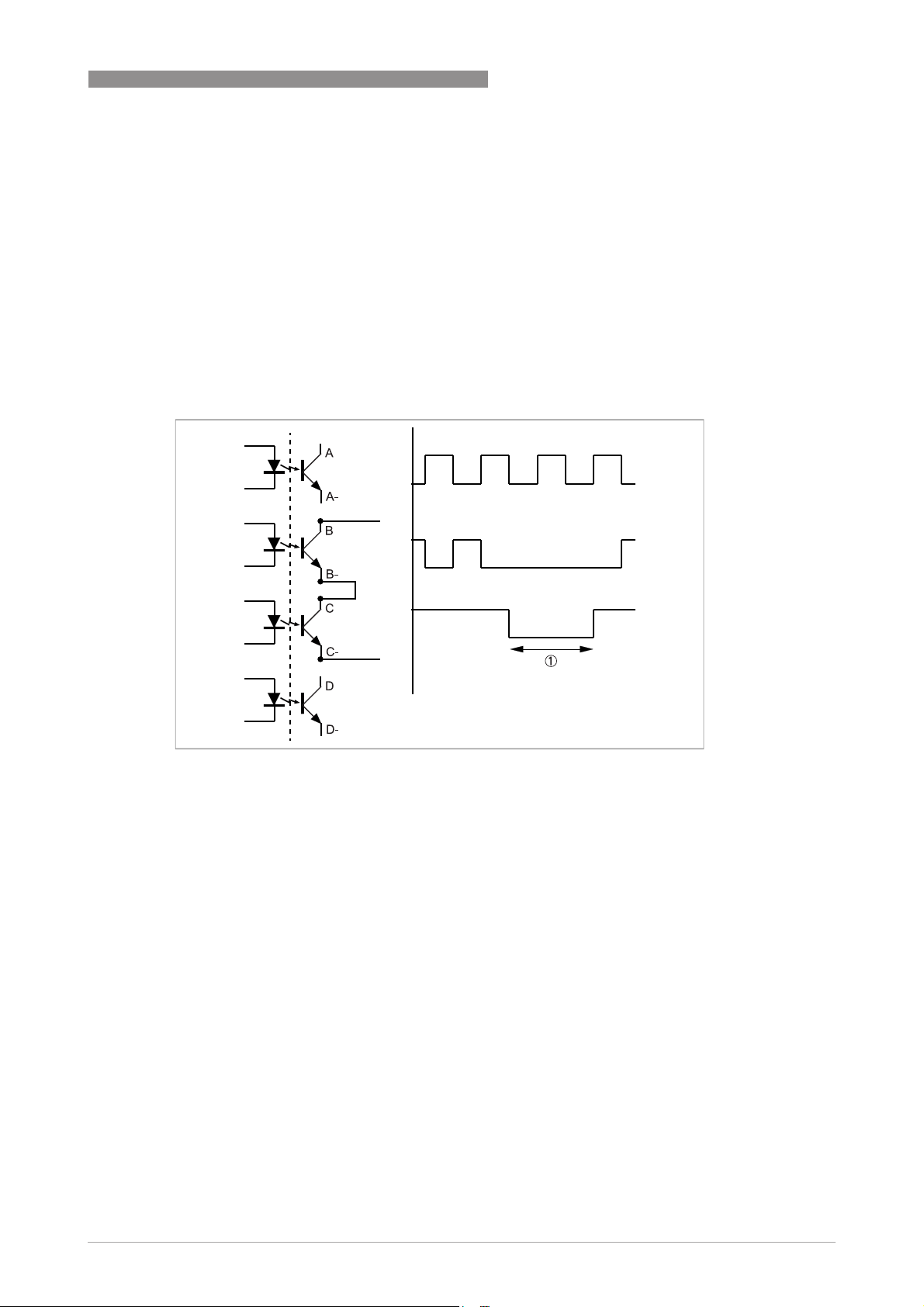

4.3.3 Emulation of a turbine meter

If the ultrasonic flowmeter should emulate a turbine meter, the following set up and settings can

be implemented:

• A/A-: Frequency output related to the line flow

• B/B-: Frequency output inverted related to the line flow whereby this frequency output will

stop operating if data valid alarm on status bit C/C- will occur.

Place the frequency output B/B in series with status bit C/C- as presented in the figure shown

below.

ELECTRICAL CONNECTIONS 4

Figure 4-4: Connection diagram for turbine emulation

1 Alarm

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

27

Page 28

4 ELECTRICAL CONNECTIONS

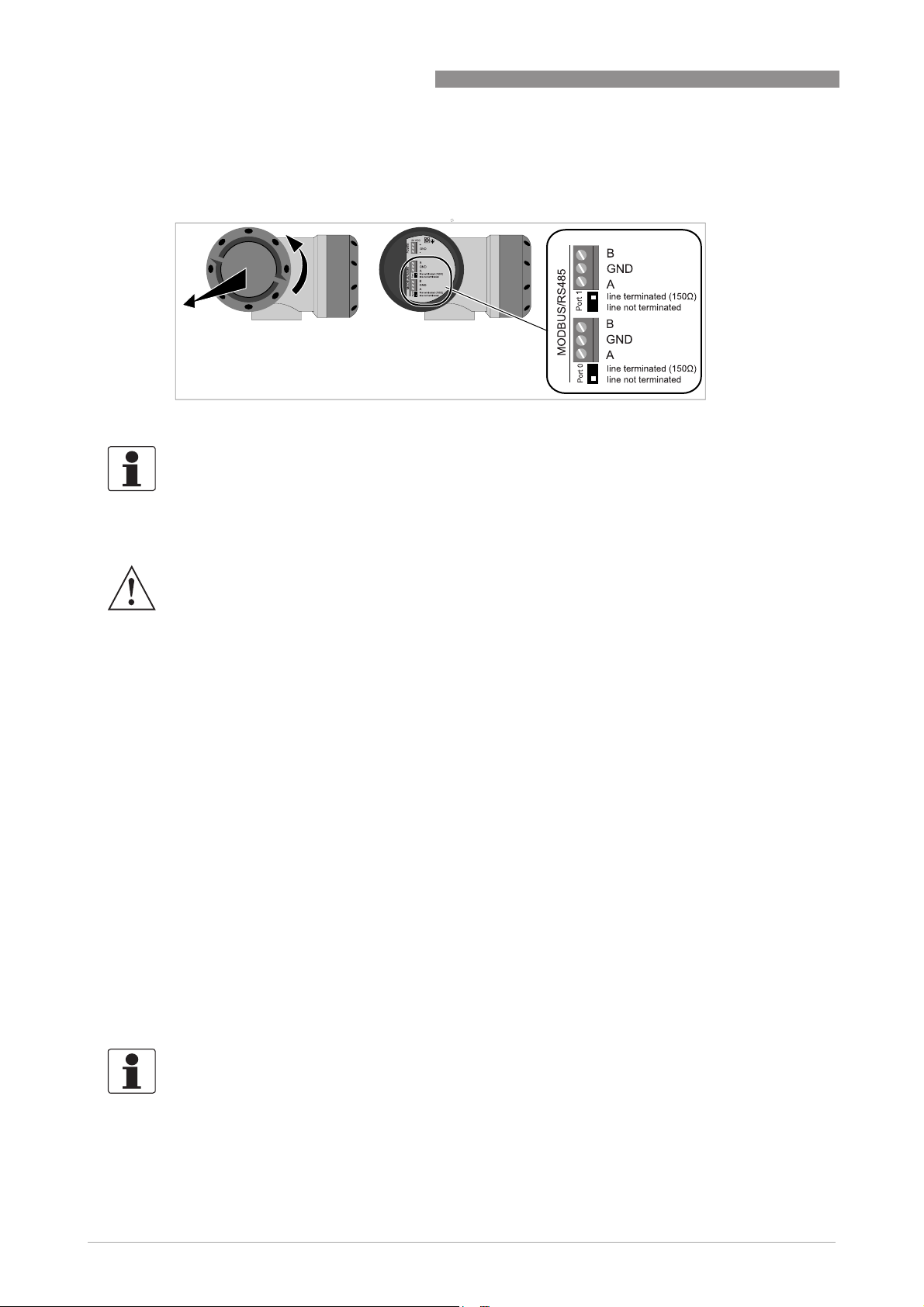

4.4 Serial data communication (RS 485)

Figure 4-5: Connection of serial data communication

INFORMATION!

For more information about Modbus, refer to Modbus protocol description and set-up on page

.

111

ALTOSONIC V12

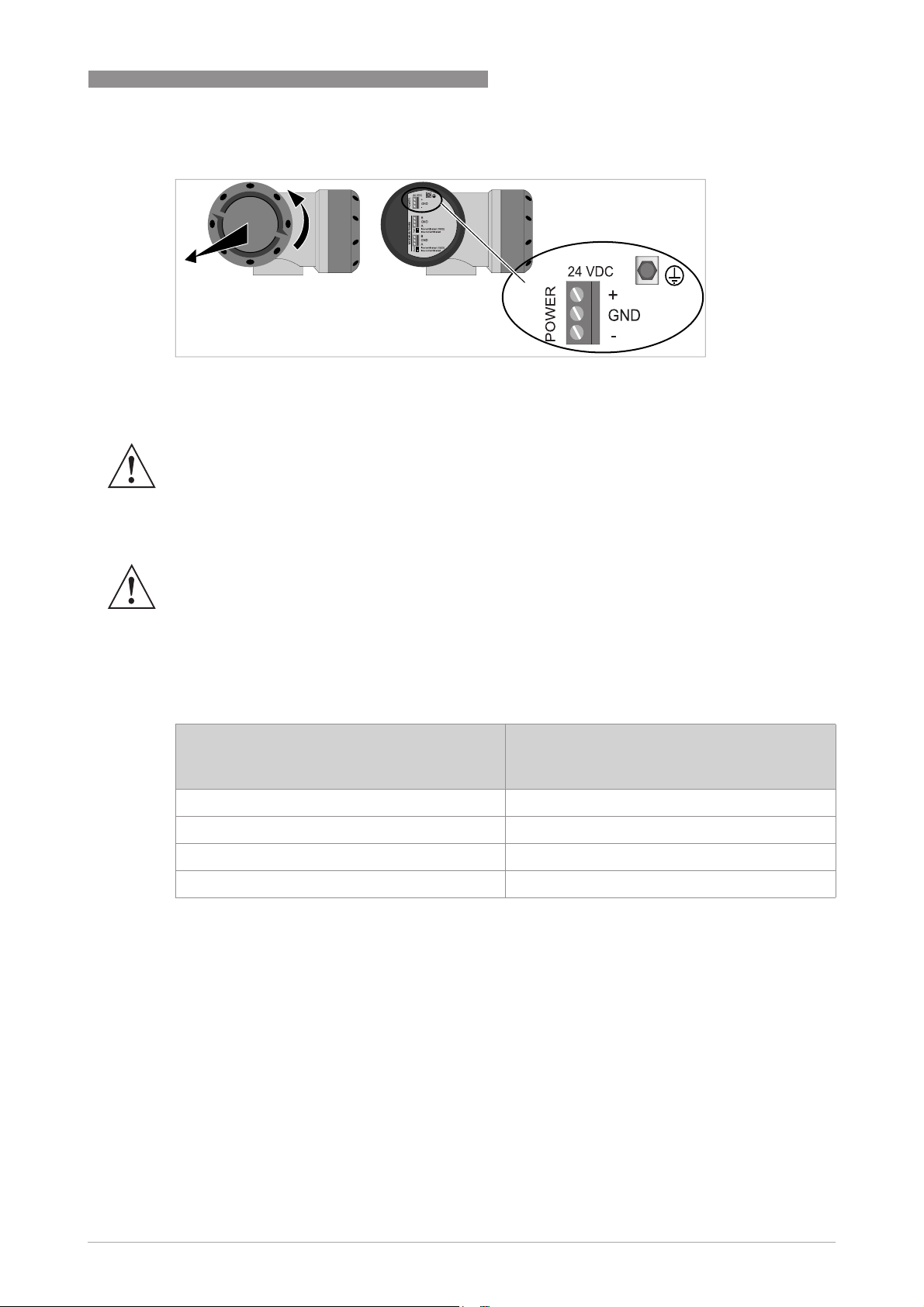

4.5 Power connection

WARNING!

•

Use a 24 VDC power supply to power the flowmeter, which complies to NEC class 2 (max. 100

±

VA, 24 VDC

consumption is 17 W. The power supply must be able to supply 3 A (needed during start-up).

•

The protective earth conductor (1...4 mm2, AWG 17...AWG 11) of the power supply must be

connected to the protective conductor clamp terminal size M5, which is press-fitted in the

terminal compartment.

•

Use a cable entry to lead the power supply cable to the electronics. The power delivered from

the power converter inside the unit is limited to a maximum of 15 W according to the

”

principle (when the admissible internal power consumption is exceeded the delivered

back

power is reduced to zero). Separately the current consumption is limited to appr. 1A.

Requires typically 3 x 1.5 mm

•

Connection to a flow computer, a data acquisition system or process control system by

means of digital output signals; requires as a maximum 4 pairs of wires of 0.75 mm

18) copper each.

•

Connection by means of a RS 485 data line to a device for logging or monitoring data or

running a software service tool for performing a function check or a service jobs; requires a

shielded pair of two twisted conductors of 0.75 mm

•

Connection to a data acquisition system by means of digital signals; requires a shielded pair

of two twisted conductors of 0.75 mm

•

Connection to safety / protective ground (earthing) ; requires insulated wire, minimum copper

cross section area 4 mm

10% , see also IEC 61010-1, clause 6.3.1 and 6.3.2). The maximum power

2

(AWG 15) conductors.

2

(AWG 18) copper each.

2

(AWG 11).

2

(AWG 18) copper each.

“

fold-

2

(AWG

28

INFORMATION!

•

The protective conductor clamp or GND of the connector can be used for the shielding of the

cable.

•

The electronics is protected against connecting a power supply with the wrong polarity.

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 29

ALTOSONIC V12

Figure 4-6: Location of power connector

4.6 Cabling

WARNING!

•

•

ELECTRICAL CONNECTIONS 4

Replace any unused cable gland by an Ex-d blind plug!

The temperature rating of all cables must have a temperature rating of at least 65°C. In case

°

the process design temperature exceeds 65

least as high as the maximum process design temperature.

C, the cables must have a temperature rating at

WARNING!

In respect of the model of the cable glands used, the outer diameter of the cable must be

between 6.5 and 14 mm. Unused cable glands must be replaced by Ex d approved blind stops.

We recommend to use screened cable with twisted pairs for connecting power, serial outputs

and the status signals. The screen can be used to connect the ground terminal.

Length of power supply cable vs diameter

Length of cable between power supply and

flowmeter

[m]

70

100

200

400

Required minimum copper cross section

2 x 0.5 mm2 (AWG 20)

2 x 0.75 mm2 (AWG 18)

2 x 1.5 mm2 (AWG 15)

2 x 4 mm2 (AWG 11)

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

29

Page 30

4 ELECTRICAL CONNECTIONS

4.7 Grounding

There are two screw connection points (one M5 thread and one M4 thread) to attach a ground

conductor. They can be used to connect the upstream and downstream piping to the flowmeter

(Equipotential).

Figure 4-7: Location of grounding connectors

ALTOSONIC V12

30

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 31

ALTOSONIC V12

5.1 Starting the signal converter

The measuring device, consisting of the measuring sensor and the signal converter, is supplied

ready for operation. All operating data have been set at the factory in accordance with your order

specifications.

CAUTION!

The used power supply must be able to supply at least 3 A during the start-up of the converter.

When the power is switched on, a self test is carried out (KROHNE logo is visible during the test).

After that the device immediately begins measuring, and the current values are displayed.

START-UP 5

Figure 5-1: Displays in measuring mode (examples for 2 or 3 measured values)

x, y and z denote the units of the measured values displayed

It is possible to change between the two measured value windows, the trend display and the list

with the status messages by pressing the keys ↑ and ↓.

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

31

Page 32

6 OPERATION

6.1 Display and operating elements

Figure 6-1: Display and operating elements (Example: flow indication with 2 measuring values)

1 Indicates a possible status message in the status list

2 Field with product name, indication whether CT parameters have been locked (closed lock symbol) and the page num-

ber that is shown on the display

3 Indicates when a key has been pressed

4 1st measured variable in large representation

5 Keys (see table below for function and representation in text)

6 Interface to the GDC bus (not present in all signal converter versions)

7 Infrared sensor (not present in all signal converter versions)

ALTOSONIC V12

INFORMATION!

•

The switching point for the 4 optical keys is located directly in front of the glass. It is

recommended to activate the keys at right angles to the front. Touching them from the side

can cause incorrect operation.

•

After 5 minutes of inactivity, there is an automatic return to measuring mode. Previously

changed data is not saved.

32

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 33

ALTOSONIC V12

OPERATION 6

Key Measuring mode Menu mode Submenu or function

mode

> Switch from measuring

mode to menu mode;

press key for 2.5 s

^ Reset of display Return to measuring

or Switch between the five

screens: M1, M2, G1, S0,

Version and modbus

settings.

Esc (> + ↑) - - Return to menu mode

Table 6-1: Description of key functionality

Access to displayed

menu, then 1st

submenu is displayed

mode but prompt

whether the data should

be saved

Select menu Select submenu or

Access to displayed

submenu or function

Press 1 to 3 times,

return to menu mode,

data saved

function

without acceptance of

data

6.1.1 Display in measuring mode with 2 or 3 measured values

Parameter and data

mode

For numerical values,

move cursor

(highlighted in blue) one

position to the right

Return to submenu or

function, data saved

Use cursor highlighted

in blue to change

number, unit, setting

and to move the decimal

point

Return to submenu or

function without

acceptance of data

Figure 6-2: Example for display in measuring mode with 2 or 3 measured values

1 Indicates a possible status message in the status list

2 Lock, indicating that programming is not possible

3 Actual screen

4 First measured variable in large depiction

5 Depiction with 3 measured values

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

33

Page 34

6 OPERATION

6.2 Menu overview

ALTOSONIC V12

Menu

Description

number

4.1.2 Settings

4.1.2.1 Language

4.1.2.2 Default Page

4.1.2.3 Bargraph Labrl

4.1.3 Measurement Page 1

4.1.3.1 Number of lines

4.1.3.2 Line Settings 1

4.1.3.3 Line Settings 2

4.1.3.4 Line Settings 3

4.1.4 Measurement Page 2

4.1.4.1 Number of lines

4.1.4.2 Line Settings 1

4.1.4.3 Line Settings 2

4.1.4.4 Line Settings 3

4.1.5 Graphical Page

4.1.5.1 Show Value

4.1.5.2 Graph type

4.1.5.3 Minimum

4.1.5.4 Maximum

4.1.5.5 Time

Settings

SettingsSettings

Measurement Page 1

Measurement Page 1Measurement Page 1

Measurement Page 2

Measurement Page 2Measurement Page 2

Graphical Page

Graphical PageGraphical Page

34

4.1.6 Status Page

4.1.6.1 Reset Errors

Status Page

Status PageStatus Page

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 35

ALTOSONIC V12

6.3 Access control and seals

All acoustic transducers and the electronics unit of ALTOSONIC V12 can be exchanged without

the need for recalibration. The only exception is the board that holds all Custody Transfer (CT)

settings. After initial calibration of the ALTOSONIC V12 all CT settings are stored inside the

meter and a dipswitch no 4 is put in the locked position. The dipswitches are subsequently

sealed by the calibration facility, guaranteeing no un-authorised changes can be made to the

meter. Contact KROHNE in case the board with the sealed dipswitches needs to be replaced.

OPERATION 6

Figure 6-3: Location of DIP switch for sealing

1 Turn cover counter clockwise and remove the cover.

2 Pull the metal grips to remove the display.

3 Remove the plastic cover with a screwdriver.

4 Locate the DIP switch number 4:

ON = free

OFF = locked.

CAUTION!

The CT approval is no longer valid if the dipswitch number 4 is switched to ON!

The cover of the electronics can be sealed too (optionally).

Figure 6-4: Optional sealing of cover

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

35

Page 36

6 OPERATION

INFORMATION!

The sealing of the cover is not required and can be broken without affecting the CT approval.

The nameplate must be sealed to the flowmeter, as shown in the figure below. Alternatively the

nameplate can be welded on the flowmeter or be mounted with rivets, so that removal without

destroying the name plate is not possible.

ALTOSONIC V12

Figure 6-5: Sealing of nameplate

36

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 37

ALTOSONIC V12

7.1 Introduction

The KROHNE Flowmeter Configuration and Monitoring Tool is a software package to support the

application of the ALTOSONIC V12 ultrasonic gas flowmeters. It is designed to be used with a PC

with a Windows operating system and can be downloaded from www.krohne.com.

It can:

• collect data from a flowmeter

• present data from a flowmeter

• verify / set / adjust parameters used by the software inside the flowmeter.

The software can be operated using different communication methods such as:

• TCP/IP

• Modbus

• USB

7.2 Installation of the software

SOFTWARE SERVICE TOOL 7

After the software has been installed properly, the Windows Program menu will have an item

KROHNE Custody Transfer Products with sub item KROHNE Flow Meter Configuration &

Monitoring Tool.

7.3 Starting a session

CAUTION!

To secure reliable operation of the meter, access is limited by means of passwords. Different

levels of passwords are available for staff with the proper skills and authorization to allow them

to perform the jobs they are entitled to.

INFORMATION!

A session is the activity starting with establishing communication (connecting) with a meter. A

session ends when the communication process with a meter is terminated (disconnecting).

During a session data can be collected from a meter in order to monitor and evaluate the

performance, the collected data may be stored as a log file and parameters can be adjusted.

After the program is launched a blank screen will appear with only a number of menu pull down

buttons on the menu bar on the upper left side of the computer screen.

Figure 7-1: Start-up screen, upper part

The lower left corner of the screen shows a status bar with some information fields and status

fields or status indicators.

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

37

Page 38

7 SOFTWARE SERVICE TOOL

Figure 7-2: Start-up screen, lower part

The first field is an information field, reserved to show the communication method in operation.

Without an active communication the first and the second fields will show a dash.

When communication with a flowmeter has been established, the second field will show the

address of this flowmeter, valid for the communication method in operation.

ALTOSONIC V12

Figure 7-3: Connect the device

1. Choose and click the menu pull down button Device.

A menu will open with the options Connect, Reconnect and Disconnect.

2. Click Connect (at this time the only valid option).

This will open a dialog box asking to select or confirm the communication method you intend to

use.

Figure 7-4: Communication interfaces

38

1. Click OK to confirm if you want to select the option as displayed or - if not -

2. Click the down button to have the other options displayed.

3. Select and click the option you need.

4. Click OK to confirm.

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 39

ALTOSONIC V12

KROHNE Flowmeter Configuration and Monitoring Tool will now send a message, asking for a

response from any meter that is able to communicate using the selected communication

method.

SOFTWARE SERVICE TOOL 7

Figure 7-5: Settings for Modbus port 0

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

39

Page 40

7 SOFTWARE SERVICE TOOL

ALTOSONIC V12

Figure 7-6: Settings for Modbus port1

When using TCP/IP (network environment) a dialog box will appear listing the responding

meters. If multiple instruments are present in the same network a list will be presented.

The other communication option are peer-to-peer and will request for setting up the

communication link.

An arrow in the most left column in the dialog box marks the meter selected to start a

communication session.

40

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 41

ALTOSONIC V12

Figure 7-7: Select the device

1. To confirm the selection, click on the arrow in the most left field of the row with the meter se-

lected by default.

2. To select another meter: move the arrow to the row with the meter you want to communicatie

with, click in the most left field of the row showing the meter.

3. Confirm your choice by clicking OK.

SOFTWARE SERVICE TOOL 7

In case that you do not get a response from any meter or you don’t get a response from the

meter you want to communicate with. Reasons can be:

• there is no ultrasonic flowmeter operational, or

• the meter you want to communicate with is not connected to a power source, or

• the communication line is not properly connected.

If this happens you can press the button “Rescan” after the problem is solved. MCST will now

resend the message, asking for a response from any meter that is able to communicate using

the selected communication method. If the problem has been solved properly, the meter that

you are looking for will be listed in the dialog box.

You have now selected a communication method and a meter. The selected communication

method and flowmeter address will now appear in the respective information fields in the status

bar at the bottom of the screen.

Figure 7-8: Selection at the bottom of the screen

Type your name and password in the dialog box and click OK.

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

41

Page 42

7 SOFTWARE SERVICE TOOL

Figure 7-9: Login dialog box

Standard: User: operator / Password: operator

or User: supervisor / Password: supervisor

ALTOSONIC V12

The selected communication method and flowmeter address will appear in the respective

information fields in the status bar at the bottom of the screen.

Figure 7-10: Status bar information

7.4 Loading a monitoring configuration

INFORMATION!

There are two different methods to obtain data from a flowmeter.

•

Request information on a specific data item: if it is a parameter the current value will be

reported, this is a static value. If it is a variable, the value will be reported and updated every 2

seconds.

•

Define a selection of data that the flowmeter will send as a package and update at specific

rate. This way the data collecting process is customized to collect only those variables or data

elements that one really needs or wants to be monitored and / or logged (as the meter

produces a large amount of data it will not be possible to collect and update all the variables

in a short time interval).

“

The option

flowmeter at a specific update rate. This option is used to define the set of data that will be

collected from the flowmeter: this set of data will be available to be displayed simultaneously.

The specification of such a set of data is stored in a monitoring configuration file, a file with an

extension

installation package. Once a monitoring configuration is loaded, the monitoring process can be

started and stopped.

Configure” is available to customize the selection of data to be sent from the

“

.mon ” . A default monitoring configuration file can be found in the software

42

To load a monitoring configuration:

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 43

ALTOSONIC V12

Step 1:

Step 1: Click the button “File” to open the File menu.

Step 1:Step 1:

Step 2:

Step 2: Select the option “Open Monitoring Configuration”.

Step 2:Step 2:

Figure 7-11: File menu

SOFTWARE SERVICE TOOL 7

A browser window will open.

Figure 7-12: Open monitoring configuration

Step 3:

Step 3: Select a monitoring configuration file and click “Open”.

Step 3:Step 3:

INFORMATION!

You can create and save one or more monitoring configurations of your own, according to your

own preferences. Later it will be explained how you can do this.

As a start you can select the default monitoring configuration file.

A dialog box will appear, asking whether you want to start the monitoring function now:

Step 4:

Step 4: Click “Yes” to start the monitoring function.

Step 4:Step 4:

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

43

Page 44

7 SOFTWARE SERVICE TOOL

The monitoring status field updates from “Mon.OFF” to “Mon.ON”, and turns from yellow into

green.

Figure 7-13: Green status field

Alternatively you can configure the software to automatically find a monitoring configuration file

and start monitoring immediately after the program is launched.

Step 5:

Step 5: Click the “Tools” button to open the tools menu.

Step 5:Step 5:

ALTOSONIC V12

Figure 7-14: Tools menu

Step 6:

Step 6: Click “Settings”. A window “Settings” with 4 tabbed sheets will open.

Step 6:Step 6:

44

Figure 7-15: Settings

Step 7:

Step 7: On the sheet ”Auto start” select the box “Start monitoring after connecting”.

Step 7:Step 7:

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 45

ALTOSONIC V12

Step 8:

Step 8: You can:

Step 8:Step 8:

• click the button “Use current configuration”, or

• click “Browse” to open another window This is an identical browse window as used before to

Step 9:

Step 9: Click “OK” to confirm the settings.

Step 9:Step 9:

The next time you launch the program the steps 1...4 will be skipped.

find a monitoring configuration file.

Select the file you want to use to start monitoring the next time you connect to a meter.

SOFTWARE SERVICE TOOL 7

7.5 Changing and saving a monitoring configuration

7.5.1 Creating a monitoring configuration

When opening the KROHNE Flowmeter Configuration and Monitoring Tool the default settings

are such that a default monitoring file is loaded and that a default user view is activated. Also the

KROHNE Flowmeter Configuration and Monitoring Tool will start logging directly. All these

features will be discussed in the next paragraphs. If due to unforeseen reasons the default start

up settings does not start up in the paragraphs below the different steps are discussed to

activate monitoring, user view and logging.

In order to modify the selection of data available for monitoring, change the monitoring

configuration.

Step 1:

Step 1: Click the button “Monitoring” to open the monitoring menu.

Step 1:Step 1:

Figure 7-16: Monitoring menu

Step 2:

Step 2: Click the option “Configure…”.

Step 2:Step 2:

In case a monitoring session is active the message box as below will appear.

Figure 7-17: Warning for running session

www.krohne.com04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

45

Page 46

7 SOFTWARE SERVICE TOOL

Step 3:

Step 3: Click “Yes” to stop the monitoring activity.

Step 3:Step 3:

INFORMATION!

Note that the instrument itself will not stop measuring! Only the presentation of measuring

results will be interrupted.

The Monitoring Configuration dialog appears:

ALTOSONIC V12

Figure 7-18: Monitoring configuration

Step 4:

Step 4: Click “Edit List” . The Monitoring List editor dialog appears:

Step 4:Step 4:

Figure 7-19: Monitoring list

46

www.krohne.com 04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

Page 47

ALTOSONIC V12

Variables can be added to the list of values to be collected from the meter and become available

for presentation:

Step 5:

Step 5: Open the tree structure in the left panel, and select the variable name to be added to the

Step 5:Step 5:

list.

Step 6:

Step 6: Click the button pointing to the right in the center panel. The item will now appear in the

Step 6:Step 6:

list in the right panel.

Similarly variables can be deleted from the list of values to be collected from the meter, these

values will no longer be available for monitoring / logging.

Step 7:

Step 7: In the right panel, click in the box to the left of the name/description of the variable to be

Step 7:Step 7:

deleted, the pointer will not move to this line. This will also enable the button in the center panel

with the arrow pointing to the left.

Step 8:

Step 8: Click on this button to remove the selected item from the list.

Step 8:Step 8:

Step 9: