SERVICE MANUAL

MODEL

PI-108

Post Inserter

(With Parts Catalog)

JANUARY 2002

CSM - PI108

Blank page.

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the 7075/7085 service handbook on page ...... vii

1. OUTLINE

PI-108 PRODUCT SPECIFICATIONS .................... 1-1

CENTER CROSS SECTION ................................... 1-2

DRIVE SYSTEM DIAGRAM .................................... 1-3

[1] Paper Feed Drive Section ........................... 1-3

[2] Sheet Tray Drive Section ............................ 1-3

2. UNIT EXPLANATION

PAPER FEED SECTION ......................................... 2-1

[1] Composition ................................................ 2-1

[2] Mechanisms ................................................ 2-1

[3] Feed Control ............................................... 2-3

3. DISASSEMBLY/ASSEMBLY

PAPER FEED SECTION ......................................... 3-1

[1] Replacing a Paper-Feed Roller and Feed

Roller ........................................................... 3-1

[2] Replacing the Rubber, Double-Feed-

Prevention Roller ........................................ 3-3

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

CONTENTS

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

1

OUTLINE

1 OUTLINE

1 OUTLINE

Blank page

PI-108 PRODUCT SPECIFICATIONS

PI-108

[1] Type

Type:

Sheet feeder employing torque-limiter

separation

[2] Functions

Automatic sheet feed (online operation):

The PI-108 automatically feeds sheets into the

finisher in accordance with instructions from

the copier.

Manual sheet feed (offline operation):

User feeds sheets into finisher by operating

the PI-108 controls.

User can select from three finishing modes.

• Booklet mode (available only if mounted to the

FS-108BM/FS-211)

• Single-staple mode (staple at rear)

• Two-staple mode (flat stapling)

[3] Applicable paper

Plain paper

high-quality paper, recycled paper, etc.

2

(60g/m

Special paper

Printing paper

Paper sizes:

• Metric area

A3, B4, A4R, A4, B5, A5

Wide paper (Max. 314x445mm)

• Inch area

11x17, 8.5x14, 8.5x11R, 8.5x11, 5.5x8.5,

8x13

Wide paper (Max. 314x445mm)

Paper staking capacity:

Up to 250 sheets (when using 130g/m2 or

35 lbs equivalent paper), to max. height of

40mm

or 17 lbs to 90g/m2 or 24 lbs)

• OHP film

• Label paper

• Blueprint master paper

• 50 to 59g/m

paper

• 91 to 200g/m2 or 24 lbs to 45 lbs high-quality

paper

• Double-sided art paper

• Mat paper

• High-quality paper

2

or 13 lbs to 16 lbs high-quality

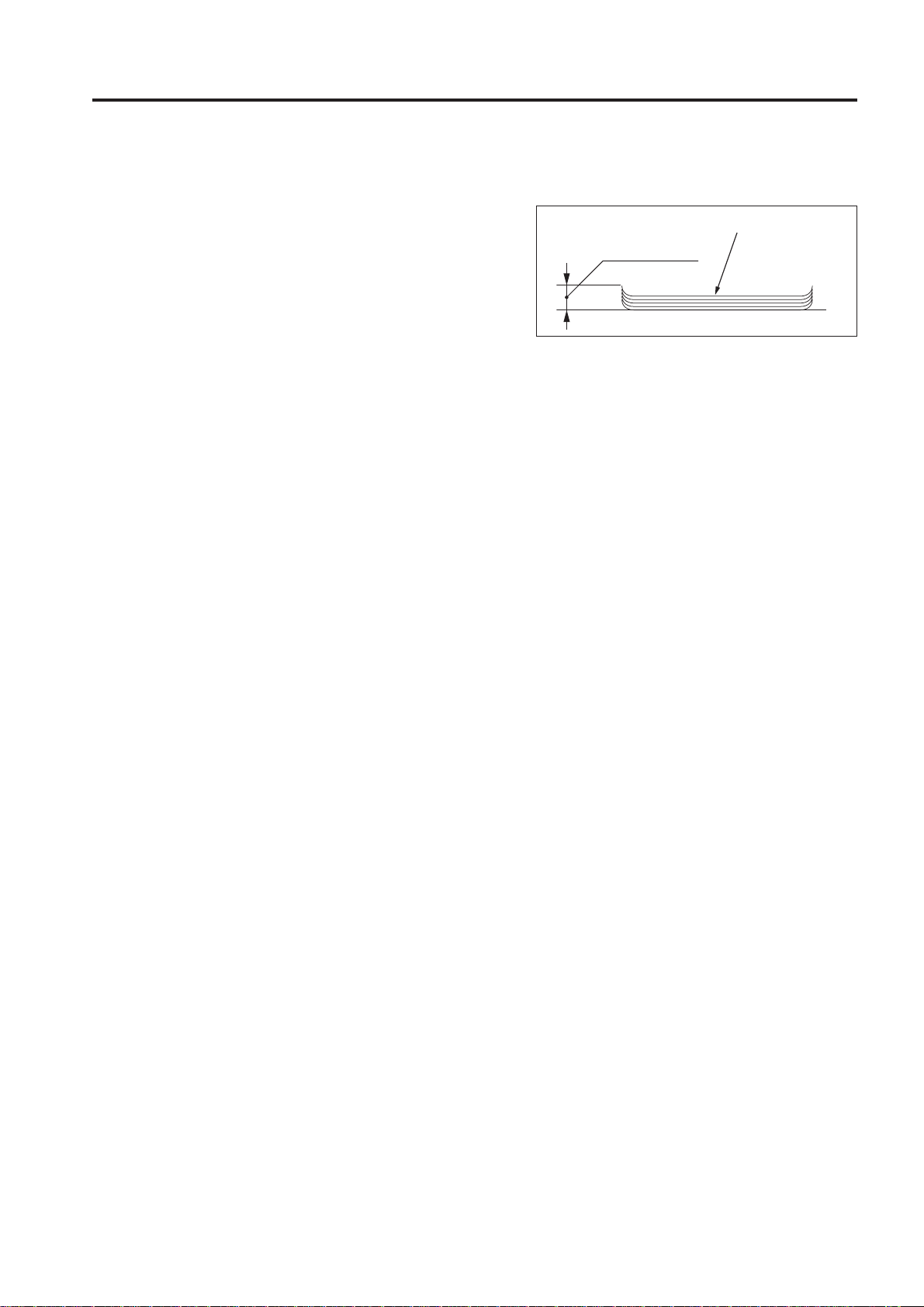

Paper curling:

Max. 10mm

5 sheets of copy paper

Amount of curl

[4] Machine Data

Power Source:

24VDC, 5VDC (supplied from finisher)

Maximum Power Consamption: Max. 25VA

Weight: Approx. 5kg

External dimensions:

Approx. 330(W) x 120(H) x 456(D) (mm)

[5] Maintenance

Maintenance: Same as the main body.

Service life: Same as the main body.

[6] Machine Operating Environment

Temperature: 10˚C to 30˚C(50˚F to 86˚F)

Humidity: 10% to 80% RH

Note: The information herein may subject to change

for improvement without notice.

1 OUTLINE

1 - 1

PI-108

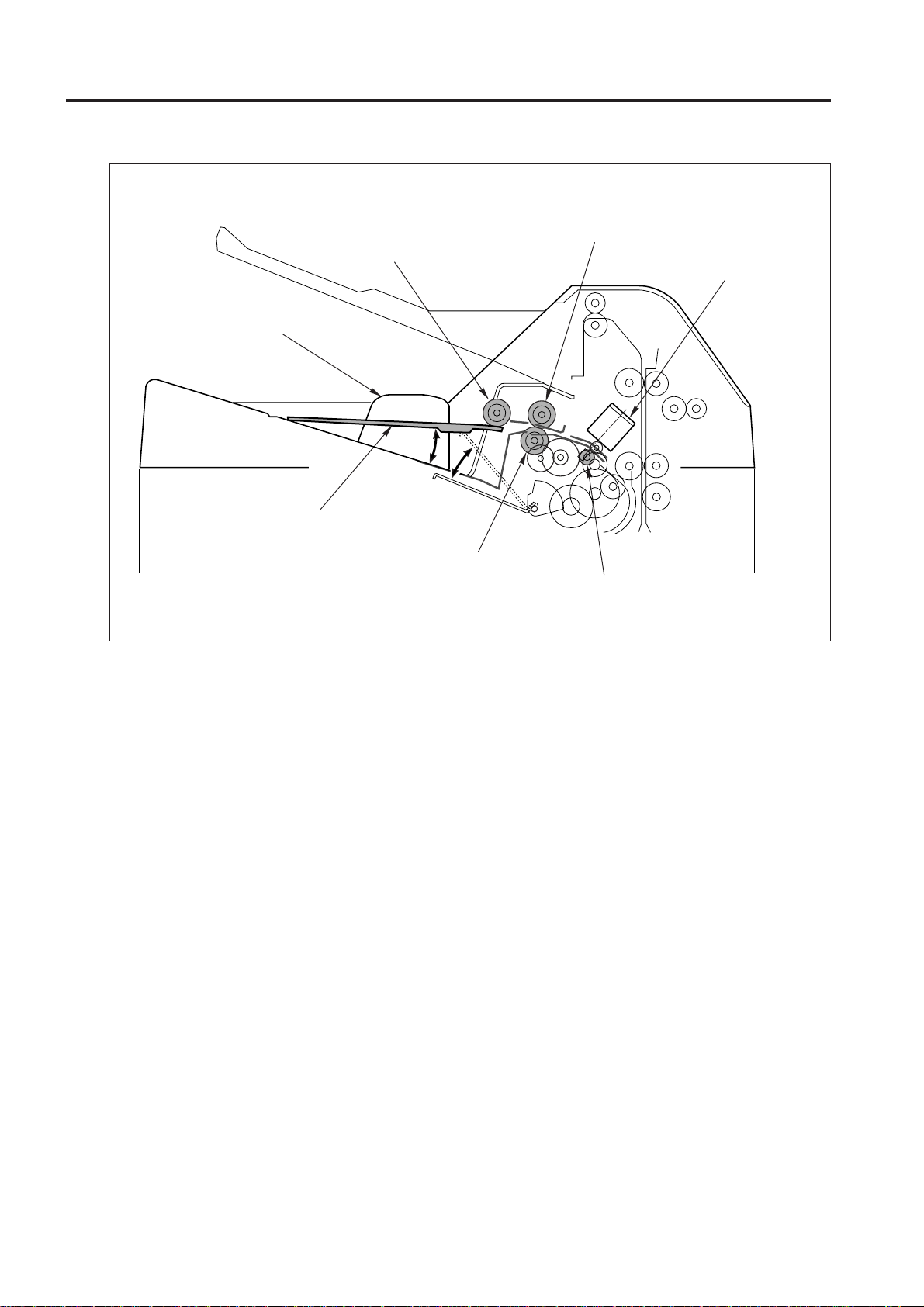

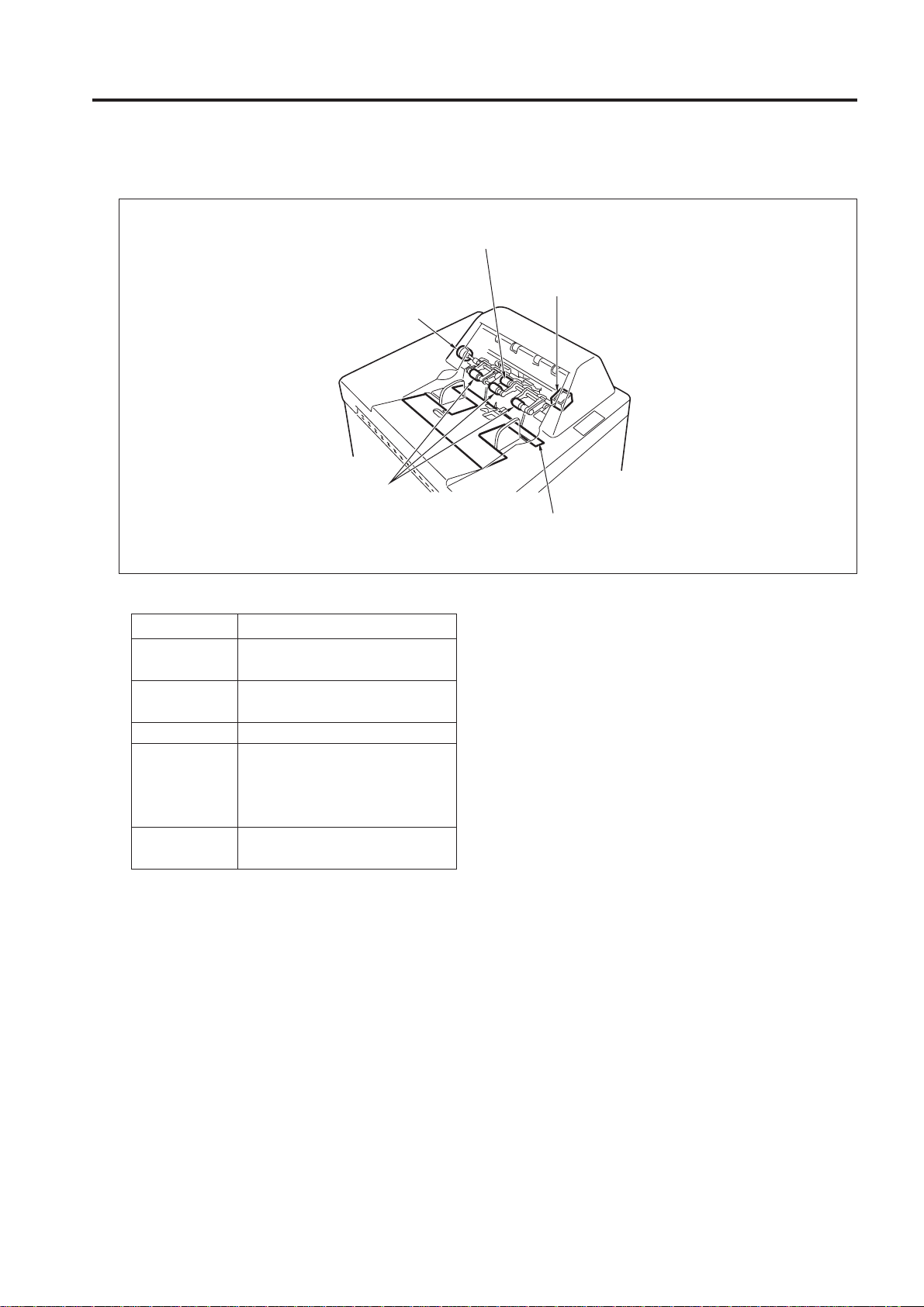

CENTER CROSS SECTION

1 OUTLINE

Paper feed roller

Width regulation plates

Sheet tray

Feed roller

Sheet tray motor (M201 )

Double-feed prevention roller

Conveyance roller

1 - 2

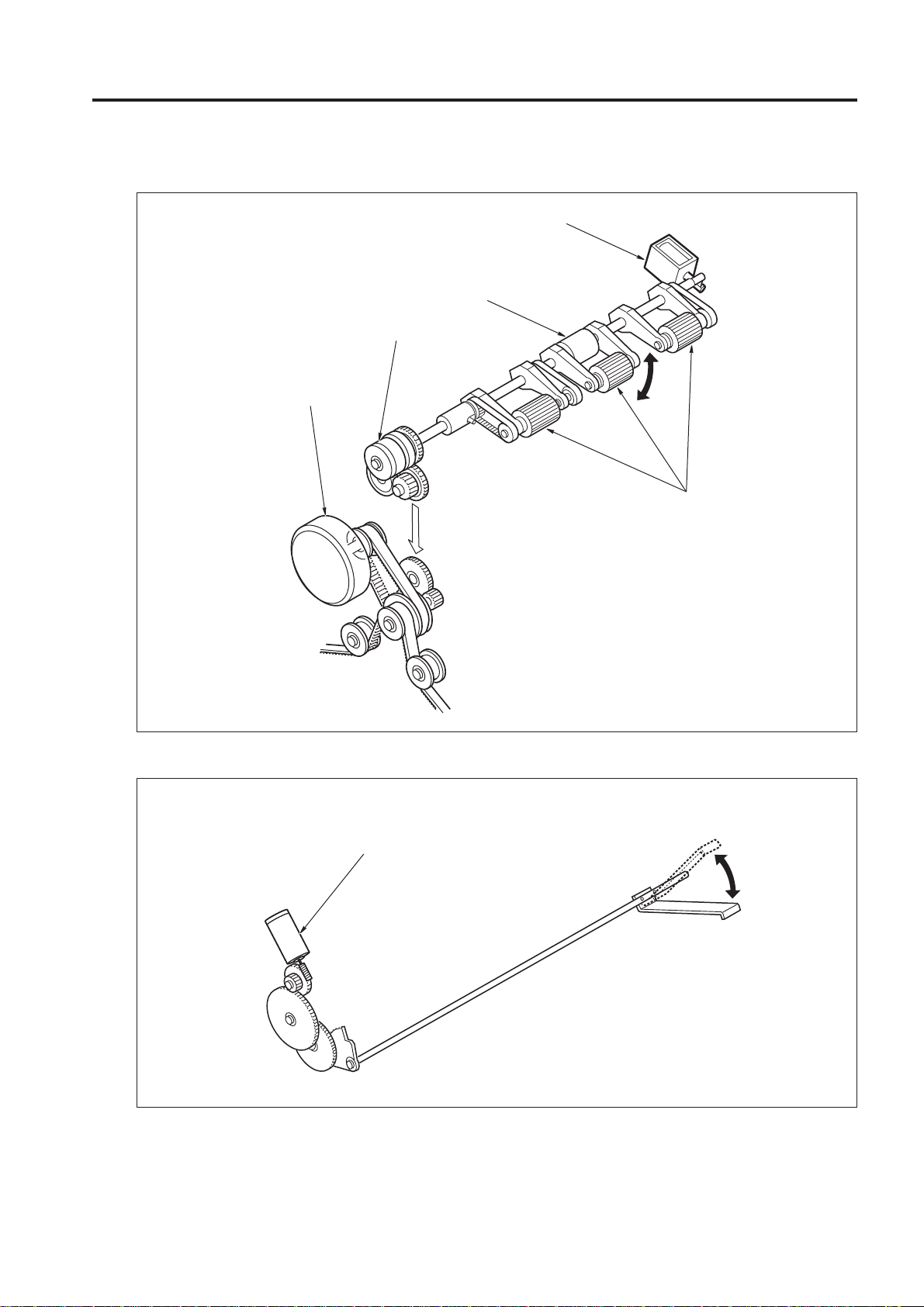

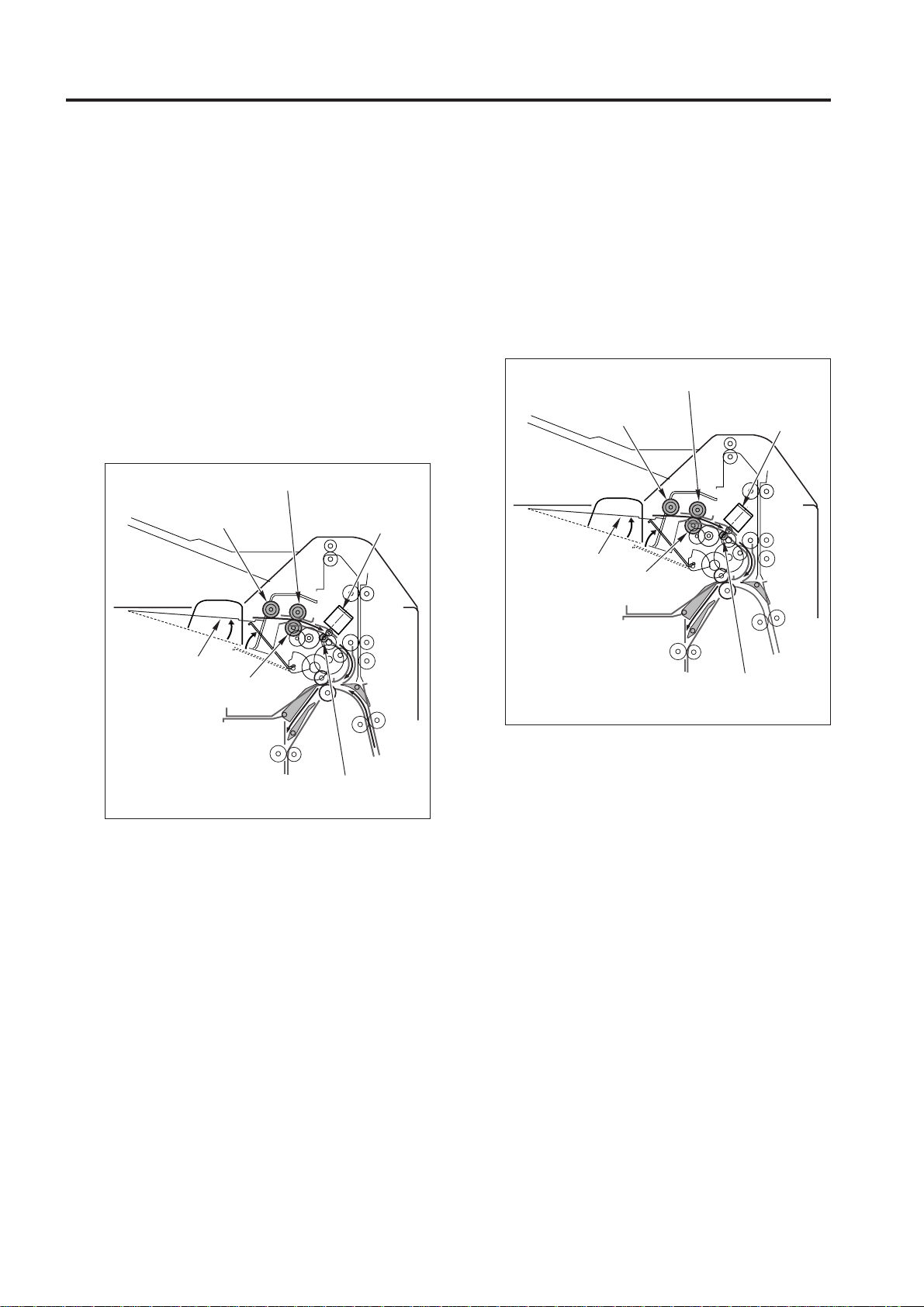

DRIVE SYSTEM DIAGRAM

PI-108

[1] Paper Feed Drive Section

Paper feed clutch (MC201)

FNS conveyance motor (M1)

1 OUTLINE

Paper-feed solenoid (SD201)

Feed roller

Paper feed roller

[2] Sheet Tray Drive Section

Sheet tray motor (M201)

1 - 3

PI-108

1 OUTLINE

Blank page

1 - 4

2

UNIT EXPLANATION

2 UNIT EXPLANATION

2 UNIT EXPLANATION

Blank page

PAPER FEED SECTION

[1] Composition

Conveyance MC (MC201)

Paper feed roller

PI-108

Feed Roller

Paper feed SD (SD201)

2 UNIT EXPLANATION

Sheet tray

[2] Mechanisms

Mechanism

*1 Paper feed

Double-feed

prevention

Conveyance

Paper lift

Sheet size

detection

Method

Paper feed roller (3)

Feed roller (1)

Double-feed-prevention roller

(1)

Conveyance roller

Sheet tray

Sheet tray motor (M201)

+ Tray upper/lower limit

detection sensor

Sheet size detection sensor

+ Sheet size VR

2 - 1

PI-108

*1: Sheet feeding processes

a. Automatic Sheet Feeding (online operation)

Sheet tray motor (M201) raises the sheet tray.

Paper feed solenoid (SD201) and paper-feed MC

(MC201) goes on, causing the paper-feed, feed,

and double-feed-prevention rollers to turn. This

action feeds sheets, one by one, into the stacker

section. The rollers are driven by FNS conveyance motor (M1) via a timing belt.

Sheets are stacked as cover sheets onto paper

from the copier, and the results are then proc-

2 UNIT EXPLANATION

essed by the FNS (single staple, double staple,

or booklet generation).

Paper feed roller

Feed roller

Sheet tray motor

(M201)

b. Manual Sheet Feeding (offline operation)

Sheet tray motor (M201) raises the sheet tray.

Paper feed (SD201) and paper-feed MC (MC201)

goes on, causing the paper-feed, feed, and double-feed-prevention rollers to turn. This action

feeds all of the sheets from the sheet tray into

the stacker section. The FNS carries out the required finishing (single stapling, double stapling,

or booklet generation).

Feed roller

Paper feed roller

Sheet tray

Double-feed

prevention roller

Sheet tray motor

(M201)

Sheet tray

Double-feed

prevention roller

Conveyance roller

Conveyance roller

2 - 2

Loading...

Loading...