Page 1

SERVICE MANUAL

Model

LT-723

FEBRUARY 1999

CSM-LT723

KONICA BUSINESS TECHNOLOGIES, INC.

Page 2

Page 3

LT-723

SERVICE MANUAL

FEBRUARY 1999

Used on Konica 7823

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Technologies strongly recommends that all servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Business Technologies,

Inc., makes no representations or warranties, either

expressed or implied, that the information contained in

this service manual is complete or accurate. It is understood that the user of this manual must assume all risks

or personal injury and/or damage to the equipment while

servicing the equipment for which this service manual

is intended.

Corporate Publications Department

© 2001, KONICA BUSINESS TECHNOLOGIES, INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

GENERAL, MECHANICAL/ELECTRICAL

1. SPECIFICATIONS ........................................................................................... M-1

2. PARTS IDENTIFICATION ........................ ........................... ........................... .M-1

3. CROSS-SECTIONAL VIEW ............................................................................M-2

4. DRIVE SYSTEM ..............................................................................................M-3

5. ELECTRICAL COMPONENT LAYOUT ...........................................................M-4

6. MECHANICAL DESCRIPTIONS ..................................................................... M-5

6-1. Mechanical Operation and Control of Paper Plate Lifting ........................M-5

6-2. Mechanical Operation and Control of Paper Take-Up, Separation,

and Transport ............................................... ............................ ...............M-7

6-3. Paper Empty Detecting Mechanism .................................. ......................M-9

6-4. Paper Dehumidifier Heater ......................................................................M-10

DIS/REASSEMBLY, ADJUSTMENT

1. DISASSEMBLY ...............................................................................................D-1

2. PAPER WIDTH CONVERSION .......................................................................D-3

3. IMAGE POSITION ADJUSTMENT ..................................................................D-5

MISFEED DETECTION&

MALFUNCTION DETECTION

1. PAPER MISFEED DETECTION ......................................................................T-2

1-1. Misfeed Detection Timing ............................................................. ...........T-2

1-2. Misfeed Troubleshooting Procedures .................... ................ ..................T-2

2. MALFUNCTION DETECTION ......... .............................. .............. ....................T-4

2-1. Malfunction Detection Timing ..................................................................T-4

2-2. Malfunction Troubleshooting Procedures ................................................T-4

i

Page 6

Page 7

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Installation Environment

Safety considerations usually are directed toward

machine design and the possibility of human error. In

addition, the environment in which a machine is operated must not be overlooked as a potential safety

hazard.

Most electrical equipment is safe when installed in a

normal environment. However, if the environment is

different from what most people consider to be normal, it is conceivable that the combination of the

machine and the room air could present a hazardous

combination. This is because heat (such as from

fusing units) and electrical arcs (which can occur

inside switches) have the ability to ignite flammable

substances, including air.

When installing a machine, check to see if there

is anything nearby which suggests that a poten-

tial hazard might exist. For example, a laboratory

might use organic compounds which, when they

evaporate, make the room air volatile. Potentially dangerous conditions might be seen or smelled. The

presence of substances such as cleaners, paint thinners, gasoline, alcohol, solvents, explosives, or similar items should be cause for concern.

If conditions such as these exist, take appropriate

action, such as one of the following suggestions.

effect may be caused by altering any aspect of the

machine’s design. Such changes have the potential

of degrading product performance and reducing

safety margins.

For these reasons, installation of any modification not

specifically authorized by Konica Business Machines

U.S.A., Inc., is strictly prohibited.

The following list of prohibited actions is not all-inclusive, but demonstrates the intent of this policy.

• Using an extension cord or any unauthorized

power cord adapter.

• Installing any fuse whose rating and physical size

differs from that originally installed.

• Using wire, paper clips, solder, etc., to replace or

eliminate any fuse (including temperature fuses).

• Removing (except for replacement) any air filter.

• Defeating the operation of relays by any means

(such as wedging paper between contacts).

• Causing the machine to operate in a fashion other

than as it was designed.

• Making any change which might have a chance

of defeating built-in safety features.

• Using any unspecified replacement parts.

• Determine that the environment is controlled

(such as through the use of an exhaust hood) so

that an offending substance or its fumes cannot

reach the machine.

• Remove the offending substance.

• Install the machine in a different location.

The specific remedy will vary from site to site, but the

principles remain the same. To avoid the risk of injury

or damage, be alert for changes in the environment

when performing subsequent service on any machine, and take appropriate action.

Unauthorized Modifications

Konica copiers have gained a reputation for being

reliable products. This has been attained by a combination of outstanding design and a knowledgeable

service force.

The design of the copier is extremely important. It is

the design process that determines tolerances and

safety margins for mechanical, electrical, and electronic aspects. It is not reasonable to expect individuals not involved in product engineering to know what

General Safety Guidelines

This copier has been examined in accordance with

the laws pertaining to various product safety regulations prior to leaving the manufacturing facility to

protect the operators and service personnel from

injury. However, as with any operating device, components will break down through the wear-and-tear of

everyday use, as will additional safety discrepancies

be discovered. For this reason, it is important that the

technician periodically performs safety checks on the

copier to maintain optimum reliability and safety.

The following checks, not all-inclusive, should be

made during each service call:

CAUTION: Avoid injury. Ensure that the copier is

disconnected from its power source before continuing.

• Look for sharp edges, burrs, and damage on all

external covers and copier frame.

• Inspect all cover hinges for wear (loose or broken).

• Inspect cables for wear, frays, or pinched areas.

v

Page 8

SAFETY PRECAUTIONS

• Ensure that the power cord insulation is not damaged (no exposed electrical conductors).

• Ensure that the power cord is properly mounted

to the frame by cord clamps.

• Check the continuity from the round lug (GND) of

the power cord to the frame of the copier -- ensure

continuity. An improperly grounded machine can

cause an electrically-charged machine frame.

Safeguards During Service Calls

Confirm that all screws, parts, and wiring which are

removed during maintenance are installed in their

original positions.

• When disconnecting connectors, do not pull the

wiring, particularly on AC line wiring and high

voltage parts.

• Do not route the power cord where it is likely to

be stepped on or crushed.

• Carefully remove all toner and dirt adhering to any

electrical units or electrodes.

• After part replacement or repair work, route the

wiring in such a way that it does not contact any

burrs or sharp edges.

• Do not make any adjustments outside of the

specified range.

Applying Isopropyl Alcohol

Care should be exercised when using isopropyl alcohol, due to its flammability. When using alcohol to

clean parts, observe the following precautions:

• Remove power from the equipment.

• Use alcohol in small quantities to avoid spillage

or puddling. Any spillage should be cleaned up

with rags and disposed of properly.

• Be sure that there is adequate ventilation.

• Allow a surface which has been in contact with

alcohol to dry for a few minutes to ensure that the

alcohol has evaporated completely before applying power or installing covers.

Summary

It is the responsibility of every technician to use professional skills when servicing Konica products. There

are no short cuts to high-quality service. Each copier

must be thoroughly inspected with respect to safety

considerations as part of every routine service call.

The operability of the copier, and more importantly,

the safety of those who operate or service the copier,

are directly dependent upon the conscientious effort

of each and every technician.

Remember...when performing service calls, use good

judgement (have a watchful eye) to identify safety

hazards or potential safety hazards that may be present, and correct these problem areas as they are

identified -- the safety of those who operate the copier

as well as those who service the copier depend on it!

vi

Page 9

GENERAL,

MECHANICAL/

ELECTRICAL

Page 10

Page 11

1 SPECIFICATIONS

Name : LT-723

Type : Cassette type large capacity tray

Installation : Fixed to the copier using a dedicated Base with Slide Rails

Type of Paper :

Size of Paper : A4 crosswise, B5 lengthwise, B5 crosswise, Letter

Capacity : 1,000 sheets

Power Supply : DC5V, DC24V (supplied from the copier)

Power Consumption : 30W or less

Dimensions : 358 (W) x 446 (D) x 289 (H) mm

Weight : 10.7 kg (main body + rails)

Environmental Requirements: Same as the copier

Plain paper weighing 60 to 90 g/m

crosswise

2

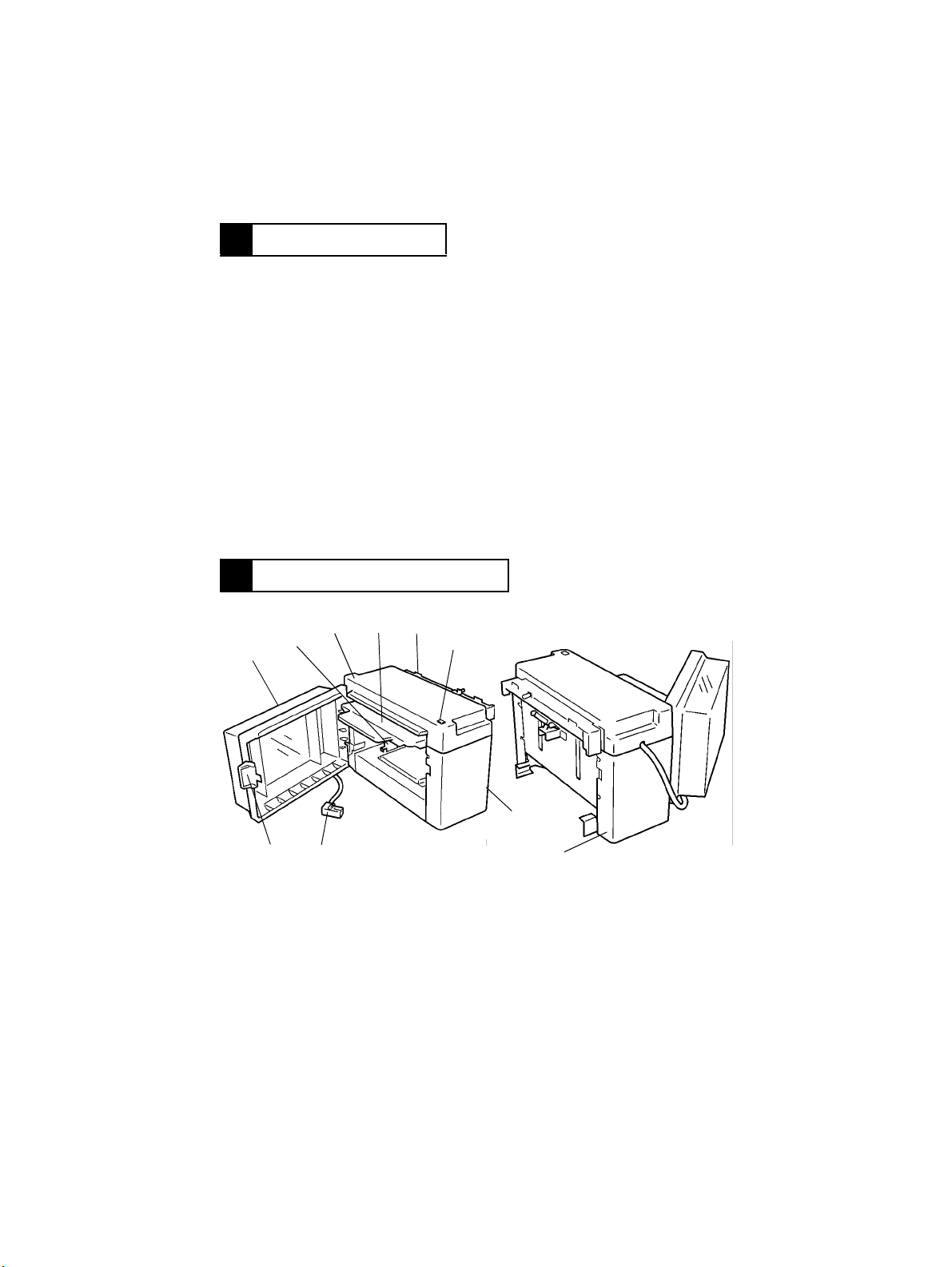

2 PARTS IDENTIFICATION

34

2

1

8

9

1. LCT Door

2. Edge Guide

3. Top Cover

4. Paper Plate

5. Paper Transport Port

5

4605M006AA

6

7

10

6. Paper Plate Descent Switch S1B

7. Front Cov er

8. Relay Cord

9. Door Unlocking Lever

10. Rear Cover

M-1

4605M007AA

Page 12

3 CROSS-SECTIONAL VIEW

Paper Plate Upper Position Sensor PC2

Paper Empty Sensor PC3

LCT Door

Edge Guide

Paper Feed Roll

Paper Separator

Roll

Paper Take-Up Roll

Paper Plate

M-2

4605M008AA

Page 13

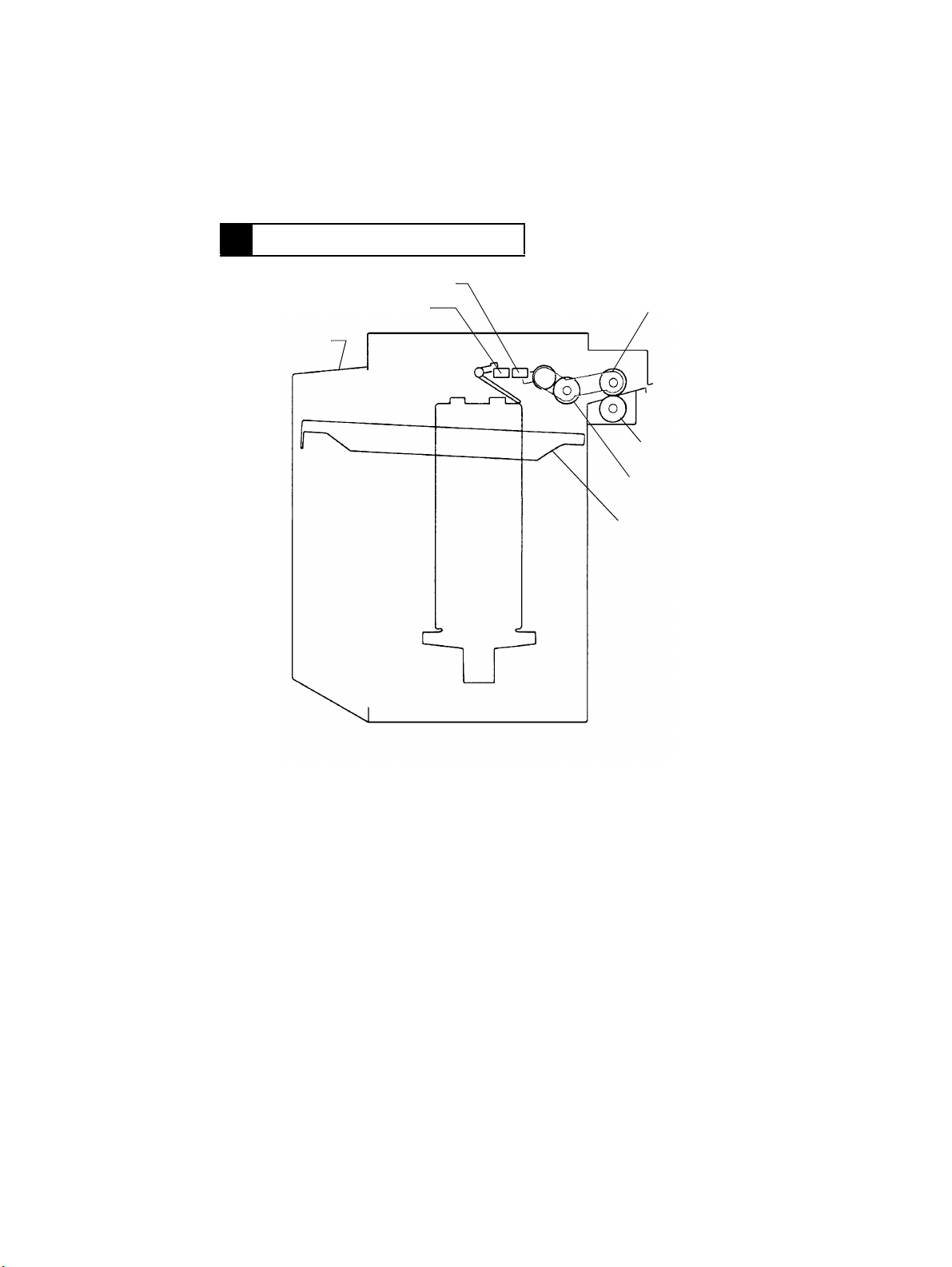

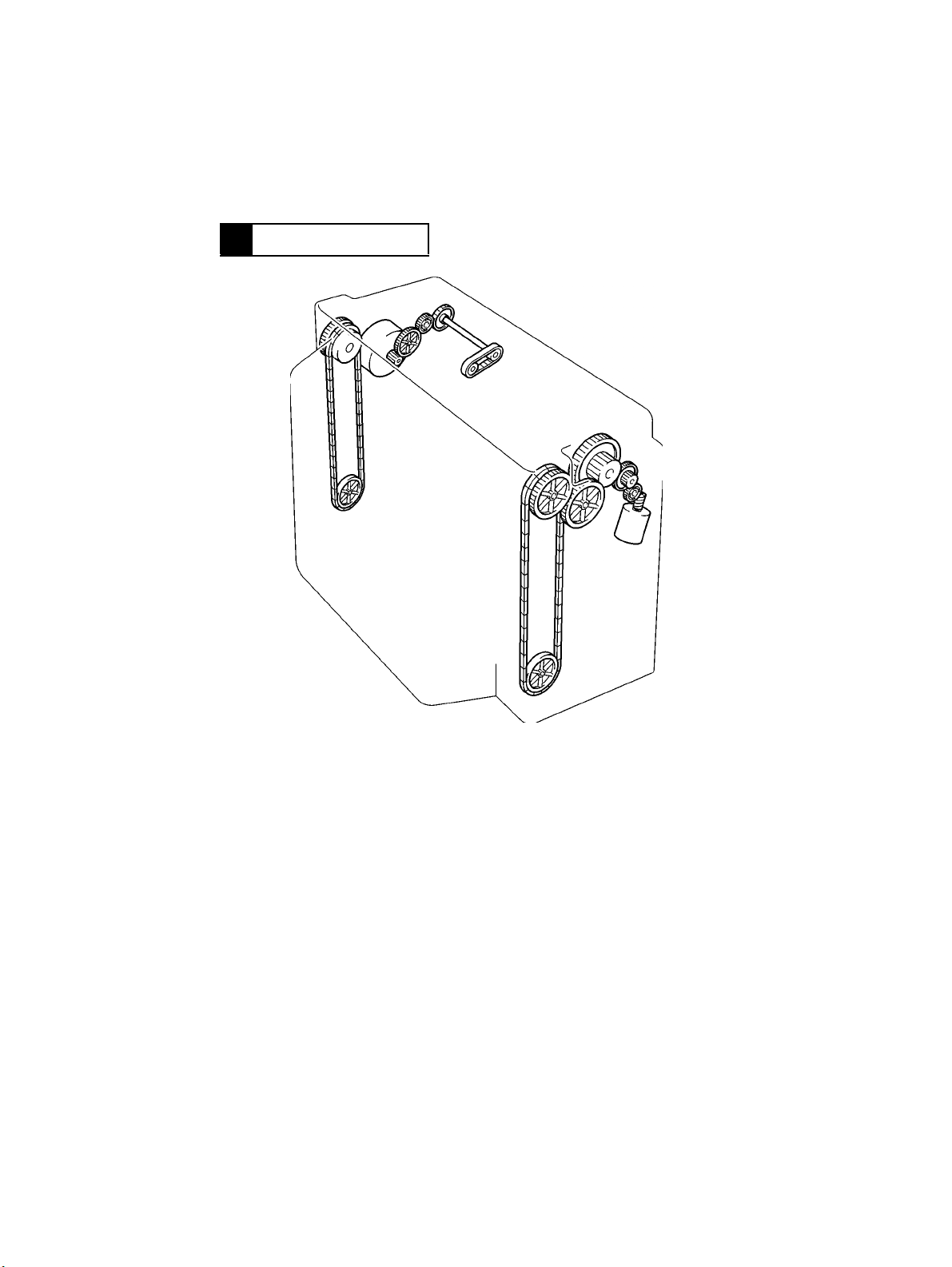

4 DRIVE SYSTEM

A

B

4605M009AA

A : Paper Take-Up Motor M2 : Drives the Paper Take-Up, Feed, and Separator Rolls.

B : Elevator Motor M1 : Moves the Paper Plate up and down.

M-3

Page 14

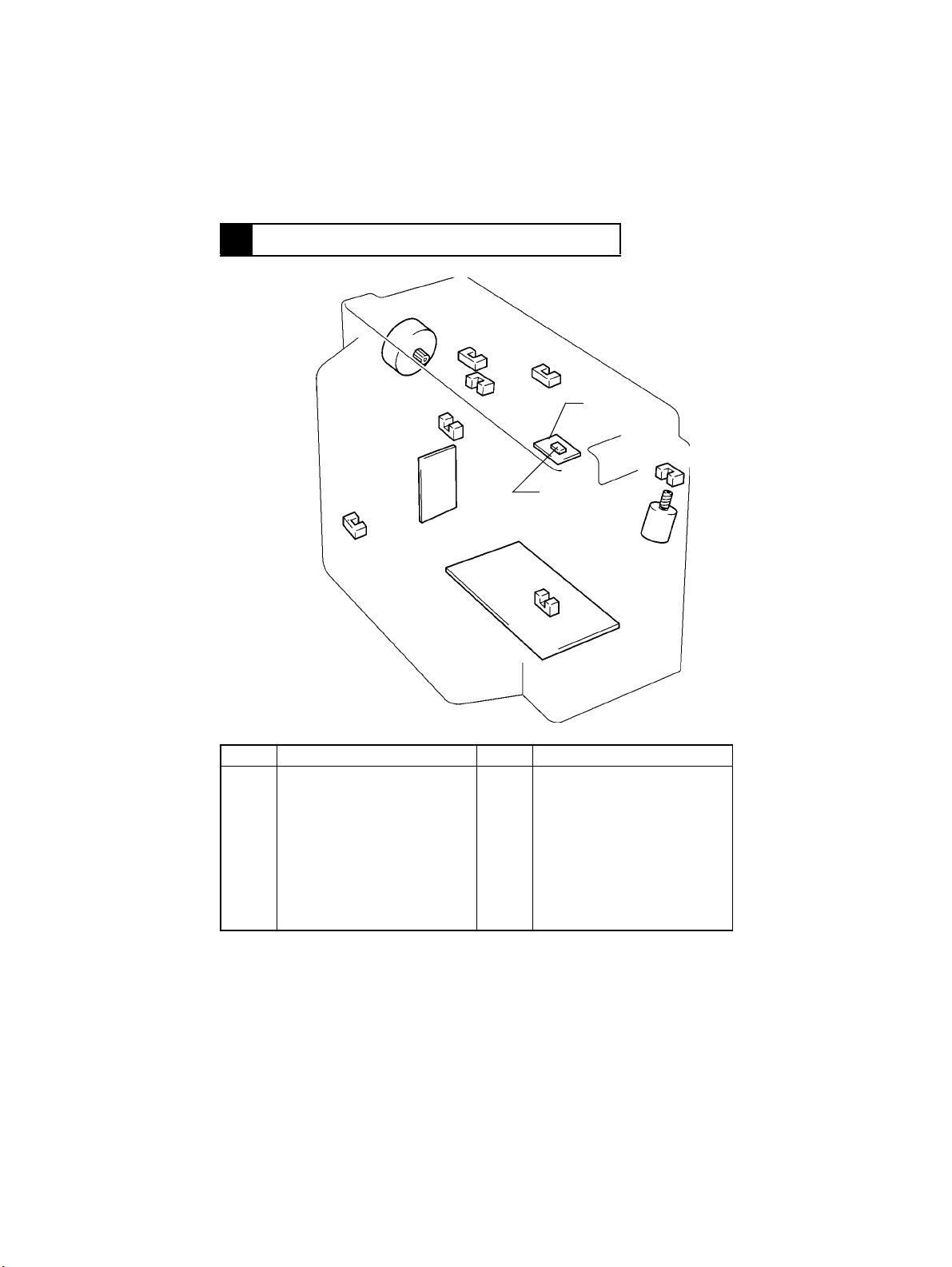

5 ELEC TRICAL COMPONENT LAYOUT

M2

PC2

PC6

PWB-A

PC4

Symbol Name Symbol Location

PWB-A

PWB-B

M1

M2

H1

S1B

Master Board

Paper Plate Descent Switch

Board

Elevator Motor

Paper Take-Up Motor

Paper Dehumidifier Heater

Paper Plate Descent Switch

PC3

PC1

PC2

PC3

PC4

PC5

PC6

PC7

PC5

PWB-B

S1B

H1

PC7

Elevator Pulse Sensor

Paper Plate Upper Position

Sensor

Paper Empty Sensor

Paper Plate Lower Position

Sensor

Paper Take-Up Sensor

LCT Set Detecting Sensor

LCT Door Open/Close Detecting

Sensor

M1

4605M010AA

PC1

M-4

Page 15

6 MECHANICAL DESCRIPTIONS

6-1. Mechanical Operation and Control of Paper Plate Lifting

•

The Paper Plate is moved up and do wn by the chains and gears which are driven by Elevator Motor M1.

< M1 Tur ning Forward = Ascent >

Paper Plate Upper Position Sensor PC2

Elevator Motor M1

4605M011AA

< M1 Turning Backward = Descent >

Paper Plate

Lower Position

Sensor PC4

4605M012AA

M-5

Page 16

<Mechanical Operation>

- Ascent Motion -

The LCT Door is closed.

(LCT Door Open/Close Detecting Sensor PC7 is blocked L.)

Elevator Motor M1 turns forward. (The Paper Plate starts its ascent motion.)

The Paper Plate moves up and the paper stack blocks L Paper Plate

M1 is deenergized. (The Paper Plate completes its ascent motion.)

The Paper Take-Up Roll gradually lowers to eventually unbloc k H PC2.

M1 turns forward to raise the Paper Take-Up Roll, thus blocking L PC2.

✽

This sequence of operations is repeated to maintain a given pressure

between the paper stack and Paper Take-Up Roll.

Paper Plate Descent Switch S1B is actuated or paper runs out.

M1 turns backward. (The Paper Plate starts its descent motion.)

The Paper Plate lowers to block L Paper Plate Lower Position Sensor PC4.

M1 is deenergized. (The Paper Plate completes its descent motion.)

Upper Position Sensor PC2.

- Paper Take-Up Sequence -

Sheets of paper are taken up.

M1 is deenergized.

- Descent Motion -

<Control>

•

M1 is turned forward, backward, stopped, and braked by the signals output from IC1A-42

and 43 on Master Board PWB-A.

M1

Forward (Ascent) H L

Backward (Descent) L H

Stopped H H

Braked L L

IC1A

Pin 42 Pin 43

M-6

Page 17

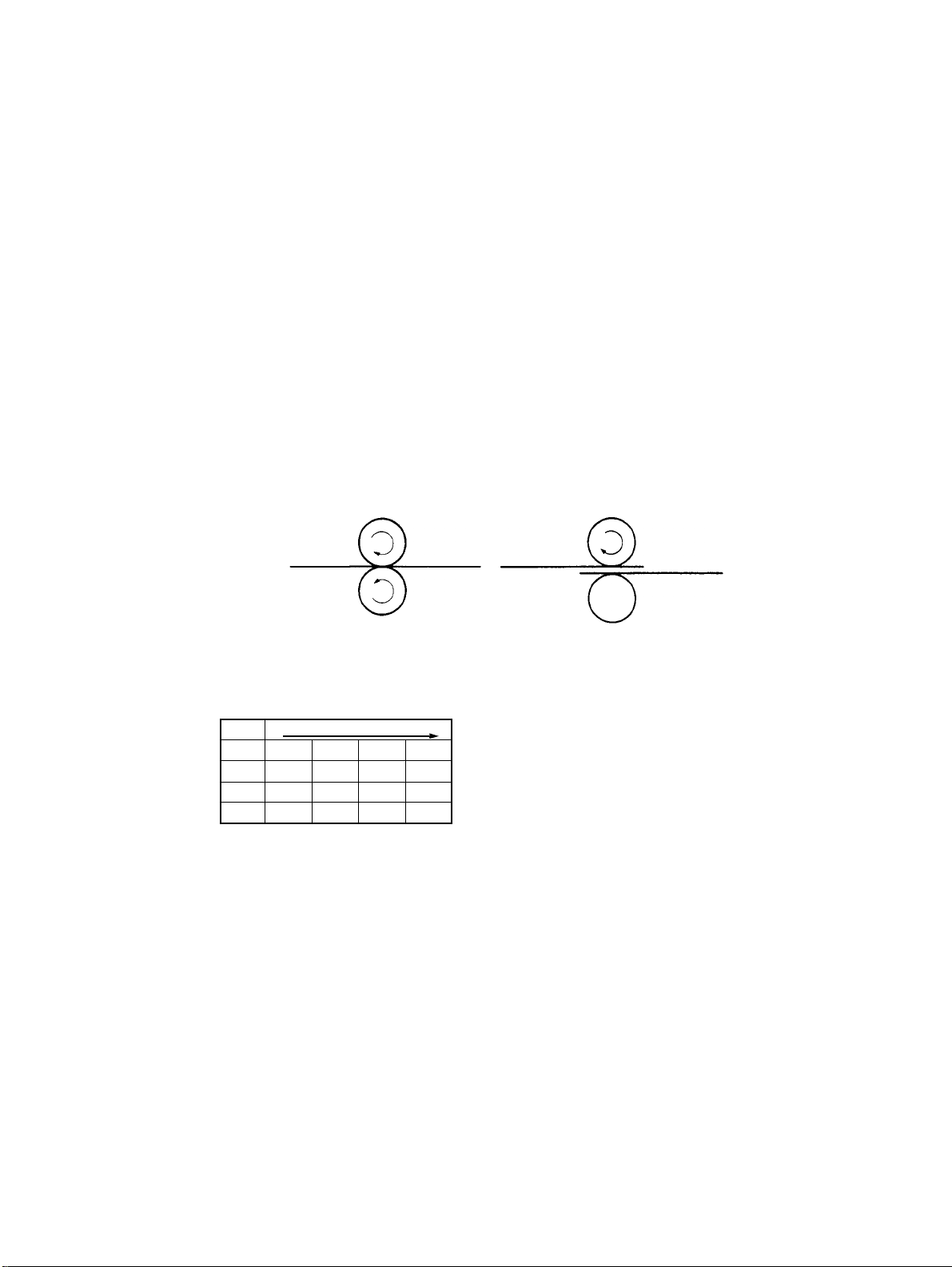

6-2. Mechanical Operation and Control of Paper T a ke-Up, Sep-

aration, and Transport

<Paper Take-Up Mechanical Operation>

The Start key is pressed. (The copy cycle is started.)

Paper Take-Up Motor M2 is energized.

Drive from M2 is transmitted via gears and belt.

The Paper Feed, Separator, and Take-Up Rolls turn counterclockwise.

Paper is transported through the LCT.

Paper Take-Up Motor M2

Paper Take-Up Roll

4605M013AA

Paper Feed Roll

Paper Separator Roll

4605M002AA

M-7

Page 18

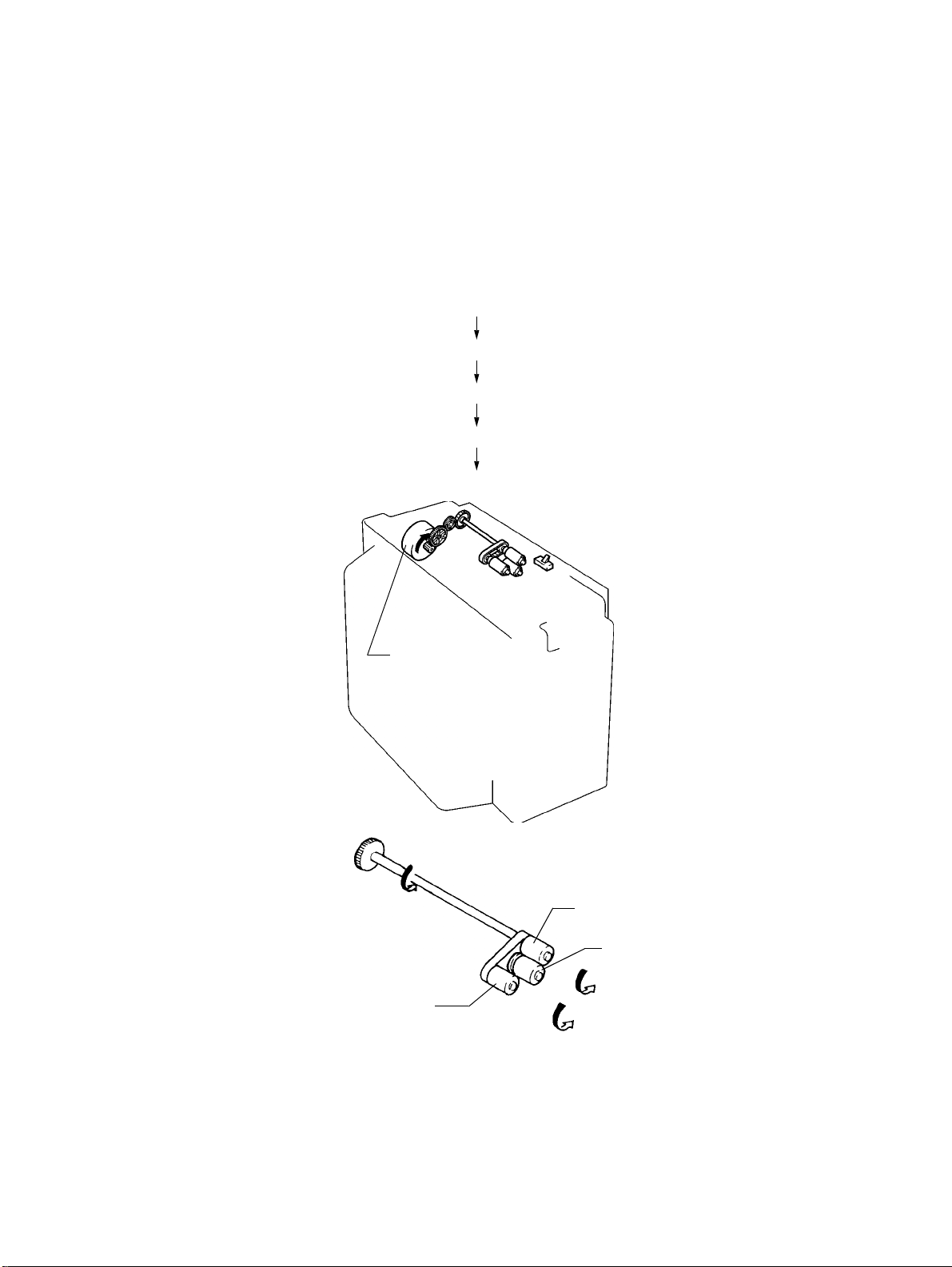

<Paper Separation Mechanical Operation>

•

When two or more sheets of paper are taken up by the Paper Take-Up Roll, the paper

separating mechanism prevents the second and subsequent sheets of paper from being

fed together with the first one. The mechanism consists of the Paper Feed Roll, Paper

Separator Roll, and torque limiter.

•

When only one sheet of paper is taken up:

The turning torque of the Paper Feed Roll is transmitted to the Paper Separator Roll via

the sheet of paper being fed in; however, it is greater than the static torque of the Paper

Separator Roll (torque limiter), which causes the Paper Separator Roll to be turned by

the Paper Feed Roll, thus transporting the sheet of paper.

•

When two or more sheets of paper are taken up at the same time:

The coefficient of friction between the first sheet and the second and subsequent sheets

of paper is small and the static torque of the torque limiter keeps the Paper Separator

Roll stationary .This stops the second and subsequent sheets of paper from being fed in,

allowing only the first sheet of paper to be fed in.

- Single-Sheet Feed - - Multiple-Sheet Feed -

1285M012

<Paper Take-Up Control>

•

Rotation of Paper Take-Up Motor M2 is controlled by the pulse signals output from IC2A1, 2, 4, and 17 of Master Board PWB-A.

IC2A Rotation

1LLHH

2HHL L

17 L H H L

4HL LH

1285M013

M-8

Page 19

6-3. Paper Empty Detecting Mechanism

<Paper Empty Detection Timing>

1. The LCT Door is opened.

2. Paper Plate Descent Switch S1B is pressed under normal operating conditions.

3. Paper Empty Sensor PC3 is blocked.

If Paper Plate Upper Position Sensor PC2 is unblocked when PC3 is blocked, the Paper

Plate is then lowered until Paper Plate Lower Position Sensor PC4 is blocked.

<Resetting Paper Empty Condition>

1. Close the LCT Door.

2. Add paper (if the LCT has run out of paper).

Paper Plate Upper Position Sensor PC2

Paper Empty Sensor PC3

1258M020AA

M-9

Page 20

<Paper Empty Sensor PC3>

When Paper is Present When Paper in not Present

4605M003AA

1258M021AA

Paper Plate Upper Position Sensor PC2

When Top Level is Detected When Top Level is not Detected

4605M004AA

4605M005AA

6-4. Paper Dehumidifier Heater

•

When paper in the LCT grows damp, its electrical resistance is decreased, which aggravates the image transfer efficiency resulting in void image and other image problems.

The Paper Dehumidifier Heater (20W) is provided to prevent this problem.

•

The heater is turned ON when the power cord of the copier is plugged in, and kept ON at

all times except while the copier Main Motor M1 remains energized.

M-10

Page 21

DIS/REASSEMBLY,

ADJUSTMENT

Precautions for Disassembly, Reassembly, and Adjustment

CAUTION

1. Before attempting to disassemble the LCT, always make sure that no power is being

supplied from the copier.

2. While power is being supplied to the LCT, do not attempt to remove/install the print

jacks from/to the PWBs or unplug/plug in the connectors.

3. If the LCT is run with its covers removed, use care not to allow your clothing to be

caught in revolving parts.

4. The basic rule is do not run the LCT with any of its parts removed.

5. A toothed washer is used with the screw that secures the ground wire to ensure positive

conduction. Do not forget to include this washer at reassembly.

6. To reassemble the LCT, reverse the order of disassembly unless otherwise specified.

7. Do not attempt to remove or loosen the screws to which red paint has been applied.

8. Screws to which blue paint has been applied may be removed; howev er, be sure to

make an adjustment after reinstalling the screws.

Purpose of Application of Red Paint

Red paint is applied to the screws of parts that cannot be readjusted, set, or reinstalled in

the field.

Page 22

Page 23

1 DISASSEMBLY

Important

The Paper Plate must be lowered before attempting to start the disassembly procedures.

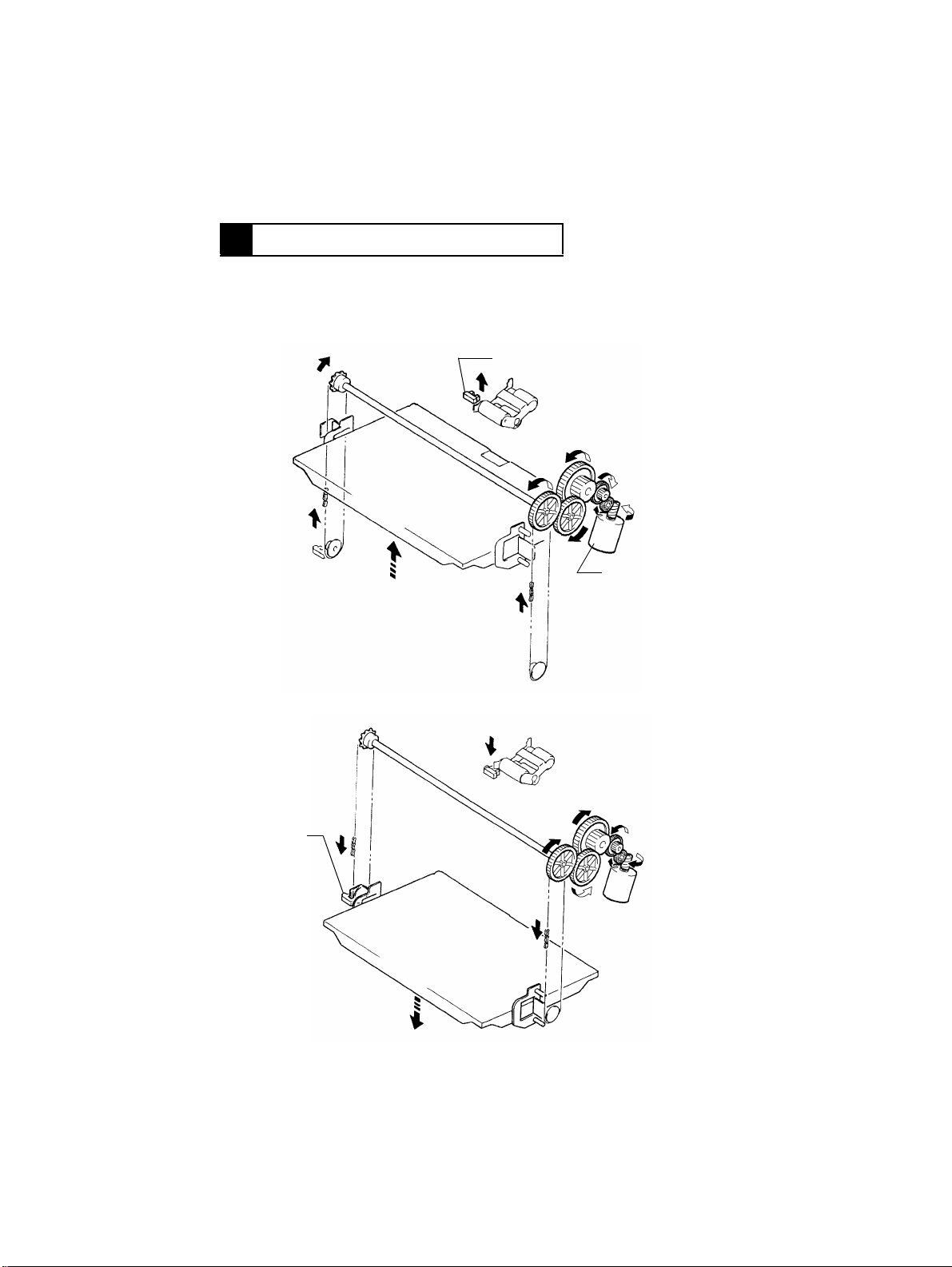

1. Removal of the Paper Take-Up/Feed Rolls

1. Remove the Top Cover.

NOTE:

Unplug the connector for Paper Plate Descent

Switch S1B.

4605D001AA

2. Snap off the C-clip from the Paper Feed Roll shaft

and remove the timing belt.

4605D002AA

3. Unhooking the springs in the Paper Separator Roll

unit, slide the Paper Take-Up Roll Assy and

remove the bushing to remove the Paper Take-Up

Roll Assy.

4605D003AA

4605D004AA

NOTE:

When the Paper Take-Up Roll Assy, use care not to

allow it to hit against Paper Plate Upper Position Sensor PC2.

4. Remove the Paper Feed Roll and one-way clutch.

D-1

Page 24

5. Snap off the C-clip and pull out the Paper Take-Up

4605D005AA

2. Removal of the Paper Separator Roll

1. Remove one screw that secures the Paper Separa-

4605D006AA

2. Unhooking the springs in the Paper Separator Roll

4605D007AA

Roll shaft to remove the Paper Take-Up Roll.

tor Roll Assy.

unit, remove the Paper Separator Roll Assy.

1258D013AA

4605D008AA

3. Snap off the E-rings and remove the bushings on

both ends. Then, remove t he P aper Separator Roll

shaft.

4. Snap off the E-ring and remove the Paper Separator Roll.

D-2

Page 25

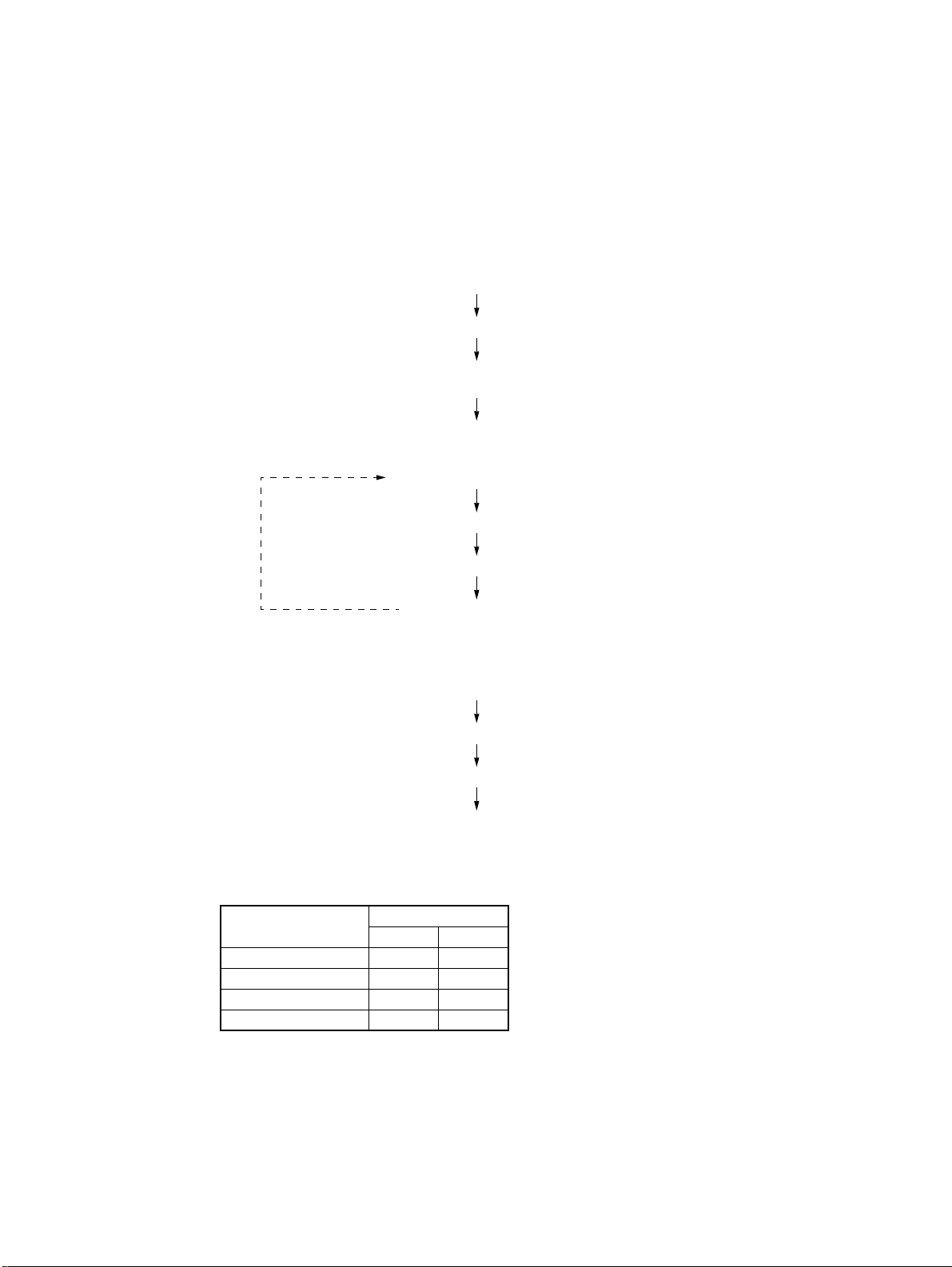

2 PAPER WIDTH CONVERSION

1. Bring the Paper Plate to its uppermost position.

Slide the LCT away from the copier and remove

the LCT Door.

4605U011AA

2. Loosen the two screws. Then, with the Top Cover

slightly raised, unplug the connector of Paper Plate

Descent Switch S1B.

Remove the Top Cover.

4605U012AA

3. Remove the positioning screws of Edge Guides.

4605U013AA

4605U014AA

4. Remove the Edge Guides.

D-3

Page 26

AC D D CA

B

B

4605U015AA

4605U013AA

4605U012AA

5. Fit the Edge Guides into the slots corresponding to

the paper size to be used.

- Slot-to-Paper-Size Correspondence A ... A4 cross wise

B ... Letter crosswise

C ... B5 crosswise

D ... B5 lengthwise

6. Slightly raising the Edge Guides, tighten the positioning screws.

7. Connect the Top Cover connector and reinstall the

Top Cover.

8. Reinstall the LCT Door.

4605U011AA

D-4

Page 27

3 IMAGE POSITION ADJUSTMENT

1. Set the copier into the Service mode and select

“Machine Adjust.”

4605D021CA

2. Select “PRT Area.”

4605D022CA

3. Select “Left Margin.”

4605D023CA

4605D024CA

4. Select “LCT” and press the Start key to let the

copier start a test print cycle.

D-5

Page 28

4605D024CA

Feeding Direction

4605D020AA

4605D019AA

5. Measure the void image width on the test print.

Specifications.....3 mm±1.5 mm

6. If the measurement falls outside the specified

range, adjust the void image width using ▲or

▼

key .

Make a test print again to check for cor rect adjustment.

7. If the void image width does not fall within the

specified range even through these adjustments on

the Touch Panel, move the Rail Assy to the rear or

front to make a mechanical adjustment.

D-6

Page 29

MISFEED DETECTION&

MALFUNCTION DETECTION

General Precautions

CAUTION

1. When servicing the LCT with its covers removed, use utmost care to prevent your

hands, clothing and tools from being caught in revolving parts.

2. Before attempting to replace parts and unplugging connectors, make sure that no

power is being supplied from the copier.

3. In whatever situations, terminals and PWB patterns other than connectors specified in

the text must not be shorted.

4. When creating a closed circuit and measuring a voltage across connector pins specified in the text, be sure to use the green wire (GND).

5. Keep all disassembled parts in good order and keep tools under control so that none

will be lost or damaged.

Reading the Text

1. If a component on a PWB or any other functional unit including a motor is defective, the

text only instructs you to replace the whole PWB or functional unit and does not give

troubleshooting procedure applicable within the defective unit.

2. The text assumes that there are no breaks and shorts in the harnesses and all connectors are plugged into the right positions.

Page 30

Page 31

- Sensor Check Procedure -

<Procedure>

1. When a paper misfeed or malfunction occurs, identify the possibly defective controlled

part or parts on the circuit diagram.

2. Open the “State Confirm” screen, as selected from the Service Mode menu. Then,

show the screen that contains the part or parts picked out in step 1) from among Switch

1 (Paper) or Switch 2 (Option).

3. Force to change the status of the sensor selected and check at that time that the signal

state changes on the screen.

Example

If Paper Take-Up Sensor PC5 is considered defective when a paper misfeed occur s:

<Procedure>

1. Remove the sheet of misfed paper.

2. Select “Switch 2 (Option)” of “State Confirm” available from the Service mode.

4605D025CA

3. Check that Pap. Trans is Off on the screen.

4. Move the PC5 actuator with a sheet of paper to block PC5.

5. Check that the state of Pap. Trans. has changed to On from Off.

On: PC5 is operational.

Set : LCT-to-copier connector

Path Set : LCT Set Detecting Sensor PC6

Cover Open : LCT Door Open/Close Detecting Sensor PC7

Pap. Empty : Paper Empty Sensor PC3

Upr. Limit : Paper Plate Upper Position Sensor PC2

Lwr. Limit : Paper Plate Lower Position Sensor PC4

Pap. Trans : Paper Take-Up Sensor PC5

Off: PC5 is defective

T-1

Page 32

1 PAPER MISFEED DETECTION

1-1. Misfeed Detection Timing

Type Detection Timing

Paper left When the copier Power Switch is turned ON or a paper misfeed

Paper take-up failure

detection

Paper take-up trailing

edge detection

1-2. Misfeed Troubleshooting Procedures

1. Misfeed Before Start of Copy Cycle (Paper Left)

Step Check Item Result Action

1 Is there a sheet of paper being fed

in the LCT, blocking the sensor?

LCT paper take-up section: Paper

Take-Up Sensor PC5

2 Is PC19 or PC5 mounted in a cor-

rect position, or does the sensor

actuator move correctly?

3 Does PWB-I receive the output sig-

nal of PC19 or PC5 properly?

PC19: PWB-I on copier

PC5: PWB-I on copier

PC19: If “Front Mid” fully operational when checked with Switch 1

(Paper)?

PC5: If “Pap. Trans.” fully operational when checked with Switch 2

(Option)?

or malfunction is reset, Paper Take-Up Sensor PC5 or Transport Roller Sensor PC19 is unblocked (H).

PC5 is not unblocked (H) even after the lapse of about 1 sec.

after Paper Take-Up Motor M2 has been energized.

PC5 is not blocked (L) even after the lapse of about 4.5 sec.

after it has been unblocked (H).

YES Remove the sheet of paper being

fed.

NO Check the mounting position or

actuator.

YES Replace PWB-A (C-101) or PWB-I

(copier).

NO Check the wiring between PWB-I

and sensor and, if it is intact,

change PC19 or PC5.

T-2

Page 33

2. Misfeed After Copy Cycle Has Been Started

Step Check Item Result Action

1 Does the paper being used meet

product specifications?

2 Is the paper curled, waved, or

damp?

3 Does Paper Take-Up Motor M2 turn

when the Start key is pressed?

4 Is a drive voltage output from PWB-

A to M2?

Does the voltage across PJ6A-4

and GND change from approx.

DC0V when a paper misfeed is

reset and Start key pressed?

5 Is the Paper Take-Up/Feed/Separa-

tor Roll dirty, worn, or deformed?

6 Is the guide plate along the paper

path dirty or deformed?

7 Is Transport Roller Sensor PC19 or

PC5 mounted at the correct position? Does the sensor actuator

make a correct motion?

8 Does PWB-I receive the output sig-

nal of PC19 or PC5 properly?

PC19: PWB-I on copier

PC5: PWB-I on copier

PC19: If “Front Mid” fully operational when checked with Switch 1

(Paper)?

PC5: If “Pap. Trans.” fully operational when checked with Switch 2

(Option)?

NO Instruct the user to use paper that

meets product specifications.

YES Change the paper. Instruct the

user in how to store the paper.

YES Check each part for possible over-

load.

YES Check the wiring between PWB-A

and M2 and, if it is intact, change

M2.

NO Change PWB-A.

YES Clean or change the defective roll.

YES Clean, correct, or change the

defective guide plate.

NO Check the mounting position or

actuator.

YES Replace PWB-A (C-101) or PWB-I

(copier).

NO Check the wiring between PWB-I

and sensor and, if it is intact,

change PC19 or PC5.

✽

: If these procedures do not remedy the problem, check the copier. (See TROUBLE-

SHOOTING of the copier service manual.)

T-3

Page 34

2 MALFUNCTION DETECTION

2-1. Malfunction Detection Timing

Malfunction Code Malfunction Detail Detection Timing

Paper Plate Upper

Position Sensor PC2

is not activated.

C09XX

Elevator

malfunction

C0

Paper Plate Lower

C2

Position Sensor PC4

is not activated.

2-2. Malfunction Troubleshooting Procedures

1. C09C0

Step Check Item Result Action

1 Does the Paper Plate lower after the

malfunction has been reset?

2 Is PC2 or PC3 mounted at the correct

position? Does the sensor actuator

make a correct motion?

3 PC2: If “Upr. Limit” fully operational

when checked with Switch 2 (Option)?

4 Does PWB-I receive the output signal

from PC3 correctly?

Does the voltage across PJ4A-8B and

GND change from DC0V to DC5V

when PC3 is unblocked?

5 Does the drive transmission mecha-

nism from M1 remain intact?

6 Is a signal output from PWB-A to M1?

Does the voltage across ✽ and GND

change from DC0V to DC24V when

the malfunction is reset and the copier

Front Door opened and closed?

✽

During ascent: PJ2A-2

During descent: PJ2A-1

•

PC2 is not blocked (L) e v en after the lapse of

10 sec. after Elevator Motor M1 has been

energized.

•

PC2 is not blocked (L) e v en after the lapse of

3 sec. after Paper Empty Sensor PC3 has

been unblocked (H).

•

PC4 is not blocked (L) e v en after the lapse of

10 sec. after M1 has been energized.

NO Go to step 5.

NO Check the mounting position or

actuator.

YES Change PWB-A (C-101) or

PWB-I (copier).

NO Check the wiring between

PWB-I and sensor and, if it is

intact, change PC2.

YES Change PWB-A (C-101) or

PWB-I (copier).

NO Check the wiring between

PWB-I and sensor and, if it is

intact, change PC3.

NO Check the drive transmission

mechanism (gears, chains,

etc.) from M1.

YES Check the wiring between

PWB-A and sensor and, if it is

intact, change M1.

NO Change PWB-A.

✽

: If these procedures do not remedy the problem, check the copier. (See TROUBLE-

SHOOTING of the copier service manual.)

T-4

Page 35

2. C09C2

Step Check Item Result Action

1 Does the P aper Plate lo wer after the malfunction

has been reset?

2 Is PC4 mounted at the correct position? Does

the sensor actuator make a correct motion?

3 PC4: If “Lwr. Limit” fully operational when

checked with Switch 2 (Option)?

4 Does the drive transmission mechanism from

M1 remain intact?

5 Is a signal output from PWB-A to M1? Does the

voltage across ✽ and GND change from DC0V

to DC24V when the malfunction is reset and the

copier Front Door opened and closed?

✽

During ascent : PJ2A-2

During descent : PJ2A-1

✽

: If these procedures do not remedy the problem, check the copier. (See TROUBLE-

SHOOTING of the copier service manual.)

NO Go to step 5.

NO Check the mounting

position or actuator.

YES Change PWB-A.

NO Check the wiring

between PWB-A and

sensor and, if it is

intact, change PC2.

NO Check the drive trans-

mission mechanism

(gears, chains, etc.)

from M1.

YES Check the wiring

between PWB-A and

sensor and, if it is

intact, change M1.

NO Change PWB-A.

T-5

Page 36

Page 37

MAINTENANCE

SCHEDULE

Page 38

Page 39

OPTIONS MAINTENANCE SCHEDULE FOR 7823

This Maintenance Schedule is intended to be used as reference information for establishing effective field service activi-

ties. To keep the copiers in as optimum a condition as possible, it is recommended that the maintenance jobs described in

this schedule be carried out.

It should be noted, however, that frequency of maintenance jobs determined by the number of copies is simply a guide-

line. Therefore, service management personnel can revise or amend this schedule by taking into account their own indi-

vidual field experiences. We feel that this will ensure more effective copier maintenance for your customers.

*The maintenance cycle numbers given below represent the readings on the PM Counter of the copier.

C : Cleaning R : Replacement Unit: 1000 Copies

All information contained in this manual is subject to change.

LT-723

NOTE: K = 1,000 copies

PM Parts

Maintenance Cycle (K)

Parts No. QTY Reference Page

C R

Paper Take-Up Roll 100 200 11UW45430 1 D-2

Paper Feed Roll 100 200 11UW45430 1 D-2

Separator Roll Assy 100 200 11UW45510 1 D-2

Page 40

Page 41

WIRING

DIAGRAMS

Page 42

Page 43

W-1

Page 44

W-2

Page 45

PARTS CATALOG

Model

LT-723

FEBRUARY 1999

KONICA BUSINESS TECHNOLOGIES, INC.

Page 46

Page 47

How to use this catalog

This parts catalog includes illustrations and part numbers for all replacement parts and assemblies used in this model.

Model-specific parts are identified in the illustrations with reference

numbers. Use the reference number to locate the corresponding part

number on the facing page.

Common hardware items, such as screws, nuts, washers, and pins, are

identified in the illustrations with reference letters. Use the reference letter to locate the corresponding part number on the hardware listing in the

lower right hand corner of the facing page.

If you know a part number, but don’t know where the part is used, use

the numerical index to determine the page number and reference number for that part. Because some common parts are used in several

places, there may be more than one entry. Refer to the illustrations to see

where the part may be used.

If you know a part’s description, but don’t know where to look to find

the part number, use the alphabetical index to determine likely page and

reference numbers. Then look at the illustrations to determine that you

have identified the correct part. Locate the part number using the listing

on the opposite page.

Retail pricing that appears with the numerical index, while valid when

this catalog was printed, is subject to change without notice. The prices

are only suggested prices and are provided only for reference. Dealers

may determine their own selling prices. For up-to-date pricing, refer to

current Konica price lists or contact the Konica Parts Distribution Center.

How to order parts

Use standard Konica parts ordering procedures to obtain these parts. For

ordering options, contact Konica’s Parts Distribution Center.

When ordering parts, be sure to specify part numbers exactly as listed in

this catalog.

NOTE: Electrical parts may include previously used components.

Model LT-723 Konica Business Technologies, Inc. Page iii

1st Edition February, 1999

Page 48

This page left blank intentionally.

Page iv Konica Business Technologies, Inc. Model LT-723

February, 1999 1st Edition

Page 49

How to use this catalog . . . . . . . . . . . . . . . . . . . . . . . . . iii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Machine parts

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Paper Transport Section . . . . . . . . . . . . . . . . . . . . . 6

Alphabetical index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Numerical index, Retail price list . . . . . . . . . . . . . . . . . . . . 11

Contents

Model LT-723 Konica Business Technologies, Inc. Page 1

1st Edition February, 1999

Page 50

Housing

Page 2 Konica Business Technologies., Inc. Model LT-723

February, 1999 1st Edition

Page 51

REF. PART NUMBER DESCRIPTION

NO.

1 11UW97010 Label, open

2 11UW97020 Label, jam removal

3 11UW12010 Top cover

4 11UW12020 Side cover

5 11UW12030 Button

6 11UW-9010 PW board (B) (NO IC)

7 11UW12040 Door

8 11UW12050 Lock release lever

9 11UW10010 Support

10 11UW43010 Rail

HARDWARE

REF.

LTR.

a 25TU01520

b 25TU02850

c 11UW01240

PART

NUMBER

Model LT-723 Konica Business Technologies., Inc. Page 3

1st Edition February, 1999

Page 52

Frames

Page 4 Konica Business Technologies., Inc. Model LT-723

February, 1999 1st Edition

Page 53

REF. PART NUMBER DESCRIPTION

NO.

1 11UW45010 Positioning pin

2 11UW45020 Cover

3 11UW45030 Seal

4 11UW45040 Actuator

5 11UW45050 Set plate

6 11UM85010 Photosensor

7 11UW45530 Bracket

8 11UW90010 Harness

9 11UW-9020 PA board (A)

10 25TU30240 PWB support

11 25TU60860 PWB support

12 11UW45060 Bracket

13 11UW45070 Hinge (upper)

14 11UW45080 Guide roller

15 11UW97030 Label, paper maximum

16 11UW45090 Guide

17 11UW45100 Actuator

18 11UW45110 Hinge (lower)

19 11UW45120 Ground plate

20 11UW90020 Harness

21 11UW45130 Table

22 11UW45140 Polyester film

23 11UW45150 Paper plate

24 11UW45160 Bracket

25 11UW45170 Bracket

26 11UW97040 Label (Do Not Load)

27 11UW45180 Cover

28 11UW83010 Panel heater

29 11UW45190 Cover

30 12ZN44300 Label (Caution: Hot)

31 25TU40540 Holder

32 11UW45200 Polyester Film

33 11UW45210 Washer

34 11UW45220 Ground plate

35 11UW45230 Torsion spring

36 11UW45240 Actuator

37 11UW45250 Torsion spring

38 11UP10210 Stopper

39 11UW45270 Actuator

40 11UW45280 Torsion spring

41 11UW45290 Cover

42 11UW45300 Bracket

43 11UW45310 Friction sheet

44 11UW45320 Top frame

HARDWARE

REF.

LTR.

a 25TU02460

b 25TU02410

c 11UW01240

d 25TU02840

e 25TU01440

f 25TU02480

g 11UW01270

h 25TU02830

j 11UW01260

k 11UW01320

m 11UW01310

n 25TU02140

PART

NUMBER

Model LT-723 Konica Business Technologies., Inc. Page 5

1st Edition February, 1999

Page 54

Paper Transport Section

Page 6 Konica Business Technologies., Inc. Model LT-723

February, 1999 1st Edition

Page 55

REF. PART NUMBER DESCRIPTION

NO.

1 25TU75560 Bushing

2 11UW77010 Gear (Z=44)

3 11UW77020 Gear (Z=26)

4 11UW75010 Bushing

5 11UW77030 Gear (Z=38)

6 11UW45330 Bracket

7 11UW80010 Motor

8 11UW77040 Sprocket (Z=13)

9 11UW77050 Chain (L=65)

10 11UW45340 Mounting plate

11 11UW45350 Cover

12 11UW45360 Shaft

13 11UW77060 Gear (Z=36)

14 11UW77070 Gear (Z=32)

15 11UW77080 Gear (Z=16,20)

16 11UW80020 Motor

17 11UW45370 Cushion

18 11UW77090 Bracket

19 11UW45380 Bracket

20 11UW45390 Synchronizing disk

21 11UW77100 Gear (Z=14,63)

22 11UW77110 Gear (Z=23,45)

23 11UM85010 Photosensor

24 11UW45400 Bracket

25 11UP10210 Stopper

26 25TU42320 Stopper ring

27 11UW45420 Shaft

28 11UW45430 Roller

29 11UW45440 Collar

30 11UW45450 Holder

31 11UW75020 Bushing

32 11UW77510 Timing belt

33 11UW76510 Pulley (Z=18)

34 11UW45460 Washer

35 11UW45470 Weight

36 11UW45480 Pressure spring

37 11UW76520 Pulley (Z=21)

38 11UW45490 Shaft

39 11UW45500 Shaft

40 11UW45510 Separator roller

41 11UW45520 Holder

42 11UW00140 Cable tie

42 25TU00140 Cable tie

43 11UW00150 Edge cover

44 25TU05250 Wiring saddle

45 25TU05220 Wiring saddle

HARDWARE

REF.

LTR.

a 25TU02410

b 25TU02840

c 11UW01330

d 11UW01320

e 11UW01240

f 11UW01250

g 11UW01230

h 11UW01340

j 11UW01210

k 11UW01220

PART

NUMBER

Model LT-723 Konica Business Technologies., Inc. Page 7

1st Edition February, 1999

Page 56

This page left blank intentionally.

Page 8 Konica Business Technologies, Inc. Model LT-723

February, 1999 1st Edition

Page 57

Alphabetical index

PART PAGE REF.

DESCRIPTION NO. NO.

A

Actuator . . . . . . . . . . 5 4

Actuator . . . . . . . . . . 5 17

Actuator . . . . . . . . . . 5 36

Actuator . . . . . . . . . . 5 39

B

Bracket . . . . . . . . . . . 5 7

Bracket . . . . . . . . . . . 5 12

Bracket . . . . . . . . . . . 5 24

Bracket . . . . . . . . . . . 5 25

Bracket . . . . . . . . . . . 5 42

Bracket . . . . . . . . . . . 7 6

Bracket . . . . . . . . . . . 7 18

Bracket . . . . . . . . . . . 7 19

Bracket . . . . . . . . . . . 7 24

Bushing . . . . . . . . . . 7 1

Bushing . . . . . . . . . . 7 4

Bushing . . . . . . . . . . 7 31

Button . . . . . . . . . . . 3 5

C

Cable tie . . . . . . . . . . 7 42

Chain (L=65) . . . . . . . . 7 9

Collar . . . . . . . . . . . . 7 29

Cover . . . . . . . . . . . . 5 2

Cover . . . . . . . . . . . . 5 27

Cover . . . . . . . . . . . . 5 29

Cover . . . . . . . . . . . . 5 41

Cover . . . . . . . . . . . . 7 11

Cushion . . . . . . . . . . 7 17

D

Door . . . . . . . . . . . . 3 7

PART PAGE REF.

DESCRIPTION NO. NO.

G

Gear (Z=14,63) . . . . . . . 7 21

Gear (Z=16,20) . . . . . . . 7 15

Gear (Z=23,45) . . . . . . . 7 22

Gear (Z=26) . . . . . . . . 7 3

Gear (Z=32) . . . . . . . . 7 14

Gear (Z=36) . . . . . . . . 7 13

Gear (Z=38) . . . . . . . . 7 5

Gear (Z=44) . . . . . . . . 7 2

Ground plate . . . . . . . . 5 19

Ground plate . . . . . . . . 5 34

Guide . . . . . . . . . . . . 5 16

Guide roller . . . . . . . . . 5 14

H

Harness . . . . . . . . . . 5 8

Harness . . . . . . . . . . 5 20

Hinge (lower) . . . . . . . . 5 18

Hinge (upper) . . . . . . . . 5 13

Holder . . . . . . . . . . . 5 31

Holder . . . . . . . . . . . 7 30

Holder . . . . . . . . . . . 7 41

L

Label (Caution: Hot) . . . . 5 30

Label (Do Not Load) . . . . 5 26

Label, jam removal . . . . . 3 2

Label, open . . . . . . . . . 3 1

Label, paper maximum . . . 5 15

Lock release lever . . . . . 3 8

M

Motor . . . . . . . . . . . . 7 7

Motor . . . . . . . . . . . . 7 16

Mounting plate . . . . . . . 7 10

PART PAGE REF.

DESCRIPTION NO. NO.

Photosensor . . . . . . . . 7 23

Polyester Film . . . . . . . . 5 32

Polyester film . . . . . . . . 5 22

Positioning pin . . . . . . . 5 1

Pressure spring . . . . . . . 7 36

Pulley (Z=18) . . . . . . . . 7 33

Pulley (Z=21) . . . . . . . . 7 37

R

Rail . . . . . . . . . . . . . 3 10

Roller . . . . . . . . . . . . 7 28

S

Seal . . . . . . . . . . . . . 5 3

Separator roller . . . . . . . 7 40

Set plate . . . . . . . . . . 5 5

Shaft . . . . . . . . . . . . 7 12

Shaft . . . . . . . . . . . . 7 27

Shaft . . . . . . . . . . . . 7 38

Shaft . . . . . . . . . . . . 7 39

Side cover . . . . . . . . . 3 4

Sprocket (Z=13) . . . . . . 7 8

Stopper . . . . . . . . . . . 5 38

Stopper . . . . . . . . . . . 7 25

Stopper ring . . . . . . . . 7 26

Support . . . . . . . . . . . 3 9

Synchronizing disk . . . . . 7 20

T

Table . . . . . . . . . . . . 5 21

Timing belt . . . . . . . . . 7 32

Top cover . . . . . . . . . . 3 3

Top frame . . . . . . . . . . 5 44

Torsion spring . . . . . . . . 5 35

Torsion spring . . . . . . . . 5 37

Torsion spring . . . . . . . . 5 40

E

Edge cover . . . . . . . . . 7 43

F

Friction sheet . . . . . . . . 5 43

P

PA board (A) . . . . . . . . 5 9

PW board (B) (NO IC) . . . 3 6

PWB support . . . . . . . . 5 10

PWB support . . . . . . . . 5 11

Panel heater . . . . . . . . 5 28

Paper plate . . . . . . . . . 5 23

Photosensor . . . . . . . . 5 6

Model LT-723 Konica Business Technologies, Inc. Page 9

1st Edition February, 1999

W

Washer . . . . . . . . . . . 5 33

Washer . . . . . . . . . . . 7 34

Weight . . . . . . . . . . . 7 35

Wiring saddle . . . . . . . . 7 44

Wiring saddle . . . . . . . . 7 45

Page 58

This page left blank intentionally.

Page 10 Konica Business Technologies, Inc. Model LT-723

February, 1999 1st Edition

Page 59

Numerical index

PART PAGE REF.SUGGESTED

NUMBER NO. NO. RETAIL

11UM85010 . . . 5 6

11UM85010 . . . 7 23

11UP10210 . . . 5 38

11UP10210 . . . 7 25

11UW-9010 . . . 3 6

11UW-9020 . . . 5 9

11UW00140 . . . 7 42

11UW00150 . . . 7 43

11UW10010 . . . 3 9

11UW12010 . . . 3 3

11UW12020 . . . 3 4

11UW12030 . . . 3 5

11UW12040 . . . 3 7

11UW12050 . . . 3 8

11UW43010 . . . 3 10

11UW45010 . . . 5 1

11UW45020 . . . 5 2

11UW45030 . . . 5 3

11UW45040 . . . 5 4

11UW45050 . . . 5 5

11UW45060 . . . 5 12

11UW45070 . . . 5 13

11UW45080 . . . 5 14

11UW45090 . . . 5 16

11UW45100 . . . 5 17

11UW45110 . . . 5 18

11UW45120 . . . 5 19

11UW45130 . . . 5 21

11UW45140 . . . 5 22

11UW45150 . . . 5 23

11UW45160 . . . 5 24

11UW45170 . . . 5 25

11UW45180 . . . 5 27

11UW45190 . . . 5 29

PART PAGE REF.SUGGESTED

NUMBER NO. NO. RETAIL

11UW45200 . . . 5 32

11UW45210 . . . 5 33

11UW45220 . . . 5 34

11UW45230 . . . 5 35

11UW45240 . . . 5 36

11UW45250 . . . 5 37

11UW45270 . . . 5 39

11UW45280 . . . 5 40

11UW45290 . . . 5 41

11UW45300 . . . 5 42

11UW45310 . . . 5 43

11UW45320 . . . 5 44

11UW45330 . . . 7 6

11UW45340 . . . 7 10

11UW45350 . . . 7 11

11UW45360 . . . 7 12

11UW45370 . . . 7 17

11UW45380 . . . 7 19

11UW45390 . . . 7 20

11UW45400 . . . 7 24

11UW45420 . . . 7 27

11UW45430 . . . 7 28

11UW45440 . . . 7 29

11UW45450 . . . 7 30

11UW45460 . . . 7 34

11UW45470 . . . 7 35

11UW45480 . . . 7 36

11UW45490 . . . 7 38

11UW45500 . . . 7 39

11UW45510 . . . 7 40

11UW45520 . . . 7 41

11UW45530 . . . 5 7

11UW75010 . . . 7 4

11UW75020 . . . 7 31

PART PAGE REF.SUGGESTED

NUMBER NO. NO. RETAIL

11UW76510 . . . 7 33

11UW76520 . . . 7 37

11UW77010 . . . 7 2

11UW77020 . . . 7 3

11UW77030 . . . 7 5

11UW77040 . . . 7 8

11UW77050 . . . 7 9

11UW77060 . . . 7 13

11UW77070 . . . 7 14

11UW77080 . . . 7 15

11UW77090 . . . 7 18

11UW77100 . . . 7 21

11UW77110 . . . 7 22

11UW77510 . . . 7 32

11UW80010 . . . 7 7

11UW80020 . . . 7 16

11UW83010 . . . 5 28

11UW90010 . . . 5 8

11UW90020 . . . 5 20

11UW97010 . . . 3 1

11UW97020 . . . 3 2

11UW97030 . . . 5 15

11UW97040 . . . 5 26

12ZN44300 . . . . 5 30

25TU00140 . . . . 7 42

25TU05220 . . . . 7 45

25TU05250 . . . . 7 44

25TU30240 . . . . 5 10

25TU40540 . . . . 5 31

25TU42320 . . . . 7 26

25TU60860 . . . . 5 11

25TU75560 . . . . 7 1

Model LT-723 Konica Business Technologies, Inc. Page 11

1st Edition February, 1999

Page 60

This page left blank intentionally.

Page 12 Konica Business Technologies, Inc. Model LT-723

February, 1999 1st Edition

Loading...

Loading...