Page 1

SERVICE MANUAL

Models

LT-402/LT-412

JANUARY 2004

CSM-LT402

KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC.

Page 2

Page 3

LT-402/LT-412

SERVICE MANUAL

JANUARY 2004

Used on Konica Models

7155/7165/7255/7272

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Minolta Business

Solutions U.S.A., Inc. strongly recommends that all

servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Minolta Business Solutions U.S.A., Inc., makes no representations or warranties, either expressed or implied, that the information contained in this service manual is complete or

accurate. It is understood that the user of this manual

must assume all risks or personal injury and/or damage to the equipment while servicing the equipment for

which this service manual is intended.

Corporate Publishing Department

© 2004, KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

CONTENTS

SAFETY AND IMPO RTANT WARNING ITEMS

Refer to the 7155/7165/7255/7272 Service Manual

1. OUTLINE

LT-402/LT-412 PRODUCT SPECIFICATIONS.........1-1

CENTER CROSS-SECTIONAL DRAWING..............1-2

DRIVE SYSTEM DRAWING......... ............... ..............1-3

[1] Paper feed drive section.. .. ................... ......1-3

[2] Stacked paper up/down wire drive section.1-4

2. UNIT EXPLANATION

PAPER FEED SECTION...........................................2-1

[1] Composition ...............................................2-1

[2] Mechanisms ...............................................2-1

[3] First paper feed control ..............................2-2

[4] Up/down plate drive control........................2-4

[5] Remaining paper detection/No paper

detec tio n control.........................................2-5

3. DISASSEMBLY/ASSEMBLY

PAPER FEED SECTION...........................................3-1

[1] Cleaning the Paper Dust Removing Brush.3-1

[2] Cleaning the LT feed PS (PS106)/

LT first pa pe r feed P S(PS1 07 ) ...................3-1

[3] Removing and Reinstalling the

Paper Feed Roller Unit...............................3-2

[4] Replacing the Paper Feed Roller Rubber/

Feed Roller Rubber....................................3-2

[5] Replacing the Double Feed

Prevention Roller Rubb er...........................3-3

[6] Replacing the LT feed MC (MC101)/

LT first pa pe r feed MC (MC102)..... ............3-5

[7] Replacing the LT-402 Up/Down Wires .......3-6

[8] Replacing the LT-412 Up/Down Wires .....3-10

Page 6

Blank page

Page 7

SAFETY WARNINGS

[1] Modifications Not Authorized by

Konica Minolta

Konica Minolta equipment is renowned for their high

reliability. This reliability is achieved through high-quality

design and a solid service network.

Unauthorized modifications involve a high risk of degrading performance and safety. Such modifications are therefore strictly prohibited. The points listed below are not

exhaustive, but they illustrate the reasoning behind this

policy.

PROHIBITED ACTIONS :

(1) Using extension cables or a different power cord

than specified by Konica Minolta.

(2) Using other fuses than specified by Konica

Minolta. Safety will not be assured, leading to a

risk of fire and injury.

(3) Disabling fuses or bridging fuse terminals with

wire, metal clips, solder or similar. (This applies

also to thermal fuses.)

(4) Removing air filters (except for replacement).

(5) Disabling relay functions (such as wedging pa-

per between relay contacts, etc.).

(6) Disabling safety functions (interlocks, safety cir-

cuits, etc.). Safety will not be assured, leading to

a risk of fire and injury.

(7) Performing actions to equipment not described

in the instruction manual or the service hand-

book.

(8) Using parts other than specified by Konica

Minolta.

[2] Checkpoints When Performing On-

site Service

Konica Minolta equipment is extensively tested before

shipping, to ensure that all applicable safety standards

are met, in order to protect the customer and customer

engineer from the risk of injury. However, in daily use, any

electrical equipment may be subject to parts wear and

eventual failure. In order to maintain safety and reliability,

the customer engineer must perform regular safety checks.

(3) Be sure to disconnect the power cord of the

equipment from the AC outlet.

Simply turning off the power switch is not sufficient, because paper feed units or other electrical equipment may be powered also when the

power switch is turned off.

(4) Proceed with special care when performing op-

eration checks or adjustment while the unit is

powered. When carrying out operation checks or

adjustment while external covers are removed,

the risk of electrical shock exists when touching

parts which carry high voltage or electrical charge.

The risk of injury exists when touching moving

parts such as gears or chains.

2. Safety Checkpoints

The following list is not exhaustive, but it includes actions

which must be carried out at every on-site service.

CAUTION:

(1) Check external covers and the frame for sharp

edges, burrs, or nicks.

(2) Check external covers and hinges for loosening

or damage.

(3) Check wiring for squeezing or damage.

(4) Check power cord for insulation problems (con-

ductor must not be exposed).

(5) Check power cord and cable ties etc. for loosen-

ing from frame.

WARNING:

(1) Verify that the equipment is properly grounded. If

a problem is detected, establish a proper ground

connection.

(2) Connecting the ground lead to an improper point

such as listed below results in a risk of explosion

and electric shock.

Unsuitable ground points:

- Gas pipe

- Lightning rod

- Telephone line ground

- Plastic water pipe or water pipe or faucet that

has not been approved by authorities for

grounding use

1. Advance Preparation for Safety Checks

CAUTION:

(1) Wear clothing that facilitates work and is de-

signed for safety.

(2) Carry out all procedures carefully to prevent in-

jury.

3. Description of Safety Checks

CAUTION:

(1) Before performing safety check work, read all

relevant documentation (service handbook, technical notices, etc.) and proceed according to the

prescribed procedure, using only the prescribed

tools. Do not carry out any adjustments not

described in the documentation.

Page 8

(2) If the power cord is damaged, replace it only with

the specified power cord. If the power cord insulation has been damaged and there are exposed

sections, short- circuits and overheating may

occur, leading to a serious fire risk.

(3) Do not route the power cord so that it can be

stepped on or pinched. Otherwise overheating

may occur, leading to a serious fire risk.

(4) When disconnecting any cables, always grasp

the connector and not the cable (especially in the

case of AC and high-voltage leads).

(5) Carefully remove all toner remnants from electri-

cal parts, electrodes, etc.

(6) Make sure that wiring cannot come into contact

with sharp edges, burrs, or other pointed parts.

(7) Double-check to make sure that all screws, com-

ponents, wiring, connectors, etc. that were removed for safety check maintenance have been

reinstalled in the original location. (Pay special

attention to forgotten connectors, pinched cables,

forgotten screws, etc.)

(8) When installation and preventive maintenance,

verify that the power cord has been securely

plugged into the AC outlet. Contact problems

may lead to increased resistance, overheating,

and the risk of fire.

WARNING:

Before disassembling or adjusting the equipment, make sure that the power cord has been

disconnected.

[4] Measures to Take in Case of an

Accident

(1) If an accident has occurred, the distributor who has

been notified first must immediately take emergency

measures to provide relief to affected persons and to

prevent further damage.

(2) If a report of a serious accident has been received

from a customer, an on-site evaluation must be

carried out quickly and Konica Minolta must be

notified.

(3) To determine the cause of the accident, conditions

and materials must be recorded through direct onsite checks, in accordance with instructions issued

by Konica Minolta.

(4) For reports and measures concerning accidents,

consult your superior, and follow the regulations set

in "Standards for the Control Program for Measures

Against Electrical Equipment Accidents".

[5] Conclusion

(1) Safety of users and customer engineers depends

highly on accurate maintenance and administration.

Therefore, safety can be maintained by the appropriate by the proper daily service work conducted by the

customer engineer.

(2) When performing service, equipment on the site

must be tested for safety. The customer engineer

must verify the safety of parts and ensure appropriate management of the equipment.

[3]

Handling of Materials for Servicing

CAUTION: Alcohol-based and acetone- based

cleaners are highly flammable and

must be handled with care. When

using these materials for cleaning

parts, observe the following precau-

tions.

(1) Disconnect the power cord from the AC outlet.

(2) Use only a small amount of cleaner at a time and

take care not to spill any liquid. If this happens,

immediately wipe it off.

(3) Perform cleaning only in an environment where

sufficient ventilation is assured. Breathing large

quantities of organic solvents can lead to discomfort.

(4) Do not replace the cover or turn the unit on before

any solvent remnants on the cleaned parts have

fully evaporated.

Page 9

1

OUTLINE

Page 10

Blank page

Page 11

LT-402/LT-412 PRODUCT SPECIFICATIONS

LT-402/LT-412

[1] Type

Type:

Side mount type large volume paper f ee d tray

[2] Functions

Standard size paper :

LT-402

• Metric area

A4 / B5 / 8.5 x 11

Wide paper (314mm x 223m m max .)

• Inch area

8.5 x 11 / A4

Wide paper (314mm x 223m m max .)

LT -412

• Metric area

A3 / B4 / A4 / A4R / F4

11 x 17 / 8.5 x 14 / 8.5 x 11 / 8.5 x 11R

Wide paper (314mm x 459m m max .)

• Inch area

11 x 17 / 8.5 x 14 / 8.5 x 11 / 8.5 x 11R

A3 / B4 / A4 / A4R / F4

Wide paper (314mm x 459m m max .)

Maximum quantity:

4000 sheets (80 g/m

2

or 20lbs)

[4] Maintenance

Maintenance:

Same as the main body

Machine life:

Same as the main body

[5] O perating Environment

Temperature:

10°C to 30°C (50°F to 86°F)

Humidity:

10% to 80%RH

Note:

The information herein may be subject to

change for improvement without notice.

[3] Machine Data

Power source

24V DC/5V (supplied from the main body),

AC27.3V

Max. power consum ption

LT-402 Max. 82W

LT-412 Max. 100 W

Weight

LT-402 Approx. 30 kg

LT-412 Approx. 42 kg

Machine dimensions

LT-402 430(W) x 639(D) x 690(H) mm

LT-412 670(W) x 639(D) x 695(H) mm

1-1

Page 12

LT-402/LT-412

CENTER CROSS-SECTIONAL DRAWING

Feed roller

Conveyance roller

Paper feed roller

Top cover

Up/down wire

(the other side

wire as well)

Double feed

prevention roller

Up/down plate

1-2

Page 13

DRIVE SYSTEM DRAW I NG

[1] Paper feed drive section

LT First paper feed SD

(SD100)

LT-402/LT-412

Feed roller

Paper feed roller

FRONT

Conveyance roller

LT paper feed motor

(M101)

LT First paper feed MC

(MC 102)

LT feed drive MC

(MC101)

1-4

FRONT

Double feed

prevention roller

Feed roller

1-3

Paper feed roller

Page 14

LT-402/LT-412

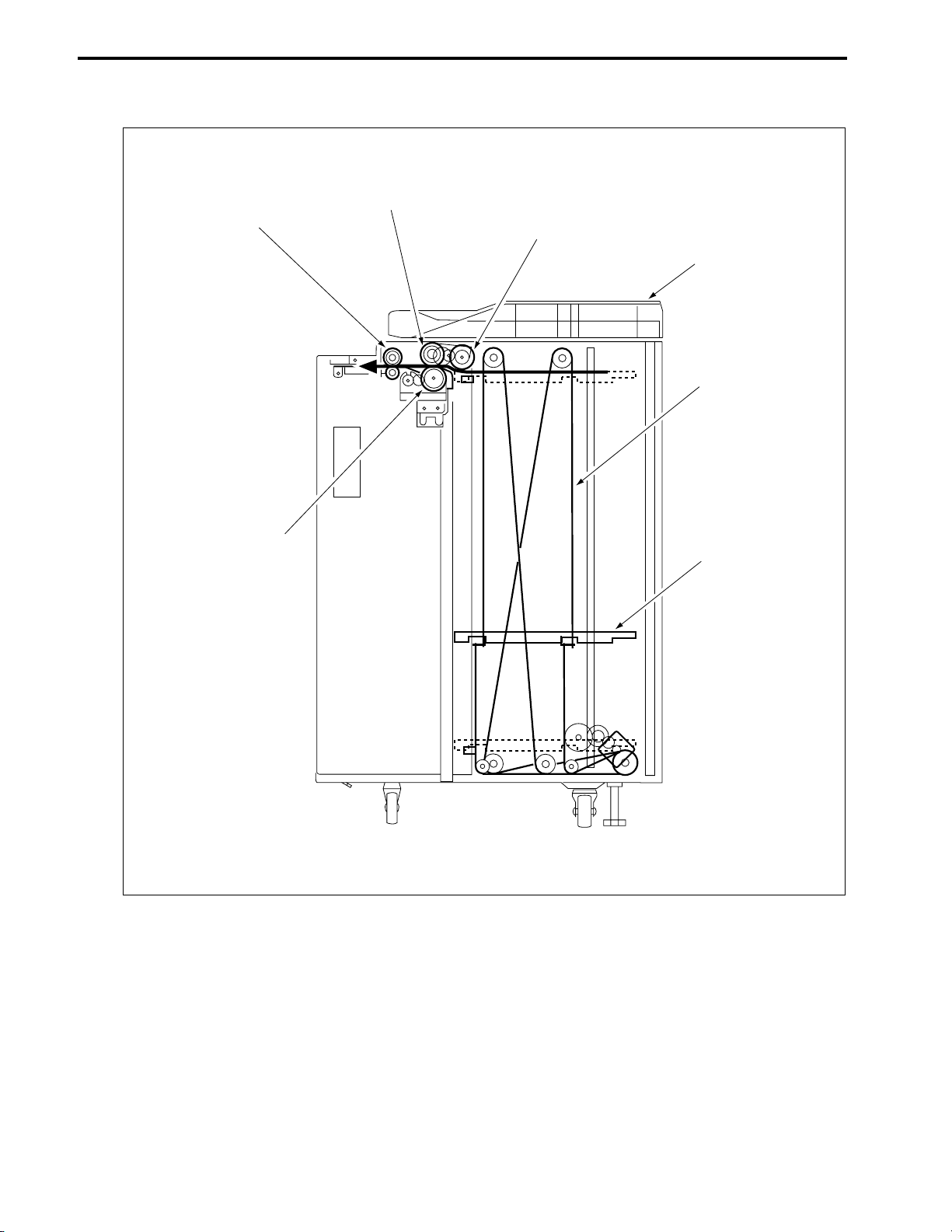

[2] Stack ed paper up/down wire dri ve sec tion

a. LT-402

Up/down plate

FRONT

LT up/down motor

(M100)

Up/down shaft

1-4

Page 15

b. LT-412

LT-402/LT-412

Up/down plate

FRONT

LT up/down motor

(M100)

Up/down shaft

1-5

Page 16

Blank page

Page 17

2

UNIT EXPLANATION

Page 18

Blank page

Page 19

PAPER FEED SECTION

[1] Composition

LT feed MC (MC101)

LT paper

feed motor

(M101)

LT first paper feed MC (MC102)

LT first paper feed SD

(SD100)

Paper dust

removing brush

Conveyance

roller

LT-402/LT-412

LT feed PS (PS106)

LT first paper

feed PS (PS107)

Up/down wire

(the other side wire as well)

LT up/down motor

(M100)

Remaining paper detection gear

[2] Mechanisms

Mechanism Method

Paper lifting *1 Wire drive

Paper feed Paper feed roller

No paper detection

Remaining paper

detection *2

Paper conveyance Roller conveyance

*1 Pape r l ifting

a.Up/down plate lifting drive operation

The up/down plate is lifted with the up/down

wires. When the top cover closes, LT up/down

motor (M100) rotates and the up/down plate connected to the up/down wires rises.

b.Up/down plate down drive operation

The up/down plate autom atically lowers by 120

mm when the top cover is opened.

Subsequently , it is lowered by 120 mm each time

LT tray down drive switch (SW100) is pressed.

Photo sensor (PS108)

+actuator

Remaining paper detection gear+ photo sensor

(PS102, PS103, PS104,

PS105)

Up/down plate

LT tray down drive switch (SW 100)

*2 Re m ainin g paper det ection

The LCT is equipped with a remaining paper

detection gear which rotates together with L T up/

down motor (M100) driving the up/down plate.

The remaining paper detection gear has an actuator to turn ON/OFF LT remaining paper detection PS1 (PS102), L T remaining paper detection

PS2 (PS103), L T remaining paper detection PS3

(PS104), and L T remaining paper detection PS4

(PS105).

2-1

Page 20

LT-402/LT-412

Each sensor is turned ON/OFF according to the

rotating position of the remaining paper detection gear and since this is linked with the up/down

position of the up/down plate, the remaining

paper quantity in the LCT can be determined by

monitoring the ON/OFF of each sensor. The

remaining paper quantity detected with the four

sensors is displayed on the main body display.

a. LT-402

LT remaining paper

LT up/down motor (M100)

detection PS1

(PS102)

Actuator

LT remaining

paper detection

PS2 (PS103)

LT remaining

paper detection

PS3 (PS104)

Gear for M100

Remaining

LT remaining paper

detection PS4 (PS105)

paper detection

gear

b. LT-412

LT remaining

paper detection

PS2 (PS103)

LT remaining paper

detection PS1 (PS102)

LT remaining paper

detection PS3 (PS104)

[3] First paper feed control

UPOP_PS

S_GND

CONV_PS

S_GND

PR_PS

SIDOP_PS

24V

CONT

24V

CONT

24V

CONT

5V

5V

LT DB

HTR101

MAIN BODY

24V

PGND

5V

SGND

IO_DTXD

IO_UCLK

LCT_LATCH

IO_DCLK

ERR_OUT4

IO_URXD

ACK4

REQ4

The first paper is fed by the paper feed roller and

the feed roller driven by M101(LT paper feed) via

MC101(LT feed MC). The paper feed roller and

feed roller touche the paper when SD100 (L T first

feed) is ON, feeding the paper to the conveyance

roller. Then, SD100 (LT first paper feed) turns

OFF to release the paper feed roller and feed

roller from the paper. The conveyance roller is

also driven by M101, by turning ON MC102 (LT

first feed MC), paper is fed to the main body.

The related signals are: PS100 (LT top cover

open/close detection), PS106 (LT feed), PS107

(LT first feed), and PS110 (LT jam access door

open/close detection).

PS100

PS106

PS107

PS110

MC101

MC102

SD100

Actuator

Remaining paper

detection gear

Gear for M100

LT remaining paper

detection PS4 (PS105)

2-2

Page 21

LT-402/LT-412

1. Operation

a. First paper feed timing

(1) Start of first pa per feed

At predefined interval after the START button is

pressed.

(2) Start of se cond a nd subsequent papers

When PS106 (L T feed) is turned OFF by the preceding paper.

(3) OFF timing

When the main body M7 (paper exit) turns OFF.

b. Interlock

The power supply line of M101 (L T paper feed) is

equipped with MS101 (LT interlock/1) and

MS102 (LT interlock/2). When the top cover is

opened, MS101 turns OFF, and when the jam

access door is opened MS102 turns OFF,

thereby cutting off the power supply to M101.

Furthermore, the top cover is equipped with

PS100 (LT top cover open/close detection) and

the jam access door is equipped with PS110 (L T

jam access door open/close detection) and

when either of these doors is opened during

paper feed, the M101 drive signal is turned OFF

to stop the paper feed operation.

c. Internal heater

The LCT is equipped with HTR101 (LT internal

heater) to protect the paper from humidity.

HTR101 is directly controlled by the main body

PRCB (printer control board) rather than by the

LTDB (LT drive board).

2. Signals

a. Input signal s

(1) UPOP_PS (PS100 to LTDB)

Top c over open /clos e detection signal

[L]: Cover opened

[H]: Cover closed

(2) CONV_PS (PS106 to LTDB)

Conveyance roller ex it paper detection signal

[L]: Paper detected

[H]: Paper not detected

(3) PR_PS (PS107 to LTDB)

Conveyance roller entrance (pre-registration

position) paper detection signal

[L]: Paper detected

[H]: Paper not detected

(4) SIDOP_PS (PS110 to LTDB)

Jam access door open/close detection signal

[L]: Door opened

[H]: Door closed

(5) LCTM_EM (M101 to LTDB)

M101 rotation error detection signal

[L]: M101 rotating

[H]: M101 not rotating

(6) IO_DTXD (MAIN BODY to LTDB)

Serial data to tra nsmi t mai n body PRCB (printer

control board) operating status to LT DB

(7) LCT_LATCH (MAIN BO DY to LTDB)

IO_DTXD signal latch signal

(8) IO_DCLK (MAIN BODY to LTDB)

IO_DTXD signal clock signal

(9) ERR_OUT4 (MAIN BODY to LTDB)

Signal to notify LT DB (L T drive board) when there

is error in the main body

(10) ACK4 (M AIN BO DY to LTDB )

Serial data transmission enable signal from LCT

to main body PRCB (printer control board)

2-3

Page 22

LT-402/LT-412

b. O ut put sign als

(1) CONT (LTDB to MC101)

MC101 (LT feed MC) ON/OFF drive signal

[L]: MC101 ON

[H]: MC101 O FF

(2) CONT (LTDB to MC102)

MC102 (LT first paper feed MC) ON/OFF drive

signal

[L]: MC102 ON

[H]: MC102 O FF

(3) CONT (LTDB to SD100)

SD100 ( L T first paper feed) ON/OFF drive signal

[L]: SD100 ON

[H]: SD100 O FF

(4) LCTM_CONT (LTDB to M101)

M101 (LT p aper feed) ON/OFF control signal

[L]: M101 ON

[H]: M101 OFF

(5) IO_URXD (LTDB to MAIN BODY)

Serial data to transmit th e LTDB ( LT drive board)

operating status to main body PRCB

(6) IO_UCLK ( LTDB to MAIN BODY)

IO_URXD signal clock signal

(7) REQ 4 (LTDB to MAIN B ODY)

Serial data send request signal from LCT to main

body PRCB

(8) LCTM_CLK (M101 to LT DB)

M101 (LT paper feed) rotational speed control

clock signal

(9) LCTM_F/R (M101 to LTDB)

M101 (L T paper f eed) rotational direction indication signal

This machine always indicates [H]: normal rotation.

[4] Up/down plate drive control

LT DB

MAIN BODY

24V

PGND

SGND

IO_DTXD

IO_UCLK

LCT_LATCH

IO_DCLK

ERR_OUT4

IO_URXD

ACK4

REQ4

5V

When the top cover opens or closes, M100 (LT

up/down motor) rotates forward or backward to

move the up/down plate up or down. The up/

down plate descends by 120 mm each time

SW100 (L T tr a y down drive) is press ed while the

top cover is opened.

The related signals are PS100 (LT top cover

open/close detection), PS101 (LT lower limit

detection), and PS109 (L T upper limit detection).

1. Operation

a. Up/down plate descend timing

(1) ON timing

When the top cover is opened and PS100 (LT top

cover open/close detection) is turned OFF , M100

rotates backward to lower the up/down plate.

When SW100 (LT tray down drive) turns ON by

pressing, M100 rotates backward to move the

up/down plate down.

(2) OFF timing

M100 turns OFF at predefined interval after

PS100 turns O FF or SW1 00 tur ns ON . This in

turn lowers the up/down plate by 120 mm.

(3) Others

The up/down plate descends by 120 mm eac h

time SW100 is pressed until PS101 tur ns ON to

indicate the bo tto m limi t of the up/do wn plate.

UPOP_PS

S_GND

SIG

S_GND

DW_SW

UP_PS

S_GND

5V

5V

5V

D1

D2

PS100

PS101

SW100

PS109

M100

2-4

Page 23

LT-402/LT-412

b. Up/down plate ascend timing

(1) ON timing

When the top cover is closed and PS100 (L T top

cover open/close detection) is turned ON, M100

(LT UP/DOWN) rotates forward to raise the up/

down plate.

(2) OFF timing

When the up/down plate r ises and PS109 (LT

upper limit detection) turns ON to indi cate the

detection of the topmost paper, M100 (LT UP/

DOWN) turns OFF and stops the up/down plate.

The up/down plate also stops when the top cover

is opened and PS100 (LT top cov er open/ close

detection) turns OFF.

2. Signals

a. Input signals

(1) SIG (PS101 to LTDB)

Up/down plate lower limit detection signal

[L]: Up/down plate not at lower limit

[H]: Up/down plate at lower limit

(2) UP_PS (PS109 to LTDB)

Up/down plate uppe r limit detection signal

[L]: Up/down plate not at upper limit

[H]: Up/down plate at upper limit

(3) DW_SW (SW100 to LTDB)

SW100 (L T tr ay down switc h) ON/OFF detection

signal

[L]: SW100 ON

[H]: SW100 OFF

b. Output signal

(1) D1, 2 (LTDB to M100)

M100 (LT UP/DOWN) drive signal

These signals switches the direction of the drive

current to control the rotation direction of M100.

[5] Remaining paper det ection/ No paper

detection control

LT DB

MAIN BODY

24V

PGND

SGND

IO_DTXD

IO_UCLK

LCT_LATCH

IO_DCLK

ERR_OUT4

IO_URXD

ACK4

REQ4

5V

The remaining paper quantity is detected by

PS102 (LT remaining paper detection 1), PS103

(LT remaining paper detection 2), PS104 (LT

remaining paper detection 3), and PS105 (LT

remaining paper detection 4) and no paper

detection is made by PS108 (L T no paper detection).

The signals d etected by thes e sensors are controlled by L TDB (L T drive board) and displayed on

the main body display.

1. Operation

a. Remai ning paper dete ction c ontrol

The remaining paper quantity is determined from

the ON/OFF combination of sensors PS102 (LT

remaining paper detection 1), PS103 (L T remaining paper detection 2), PS104 (LT remaining

paper detection 3), and PS105 (LT remaining

paper detection 4) which detect the rotational

position of M100 (LT UP/DOWN) that is driving

the up/down plate. Each sensor turns ON or

OFF according to the pos ition of the remaining

paper detection gear which is linked with the

rotation of M100.

The remaining paper quantity is detectable at

eight levels, but it is displayed on the main body

display as five levels.

SIG

S_GND

SIG

S_GND

SIG

S_GND

SIG

S_GND

0_PS

S_GND

5V

5V

5V

5V

5V

D1

D2

PS102

PS103

PS104

PS105

PS108

M100

2-5

Page 24

LT-402/LT-412

<Remaining paper quantity and display>

Stacked

paper

quantity

0 to 700 OFF OFF OFF OFF 1 flashing

701 to 1200 ON OFF OFF OFF 1 on

1201 to 1700 ON ON OFF OFF 2 on

1701 to 2200 ON ON ON OFF 2 on

2201 to 2700 ON ON ON ON 3 on

2701 to 3200 OFF ON ON ON 3 on

3201 to 3700 OFF OFF ON ON 4 on

3701 or more OFF OFF OFF ON 4 on

Caution:

b. No paper detection control

When there is no more paper inside the LCT,

PS108 (LT no paper detection) turns O N an d a

message is displayed on the main body display.

PS102 PS103 PS104 PS105

The remaining paper quantity is indicated on

the control panel with four horizontal bars.

Stacked paper quantity differs depending on

the thickness of the paper.

Remaining

paper quantity

display

2. S ignals

a. Input signals

(1) SIG (PS102 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS102 OFF

[H]: PS102 ON

(2) SIG (PS103 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS103 OFF

[H]: PS103 ON

(3) SIG (PS104 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS104 OFF

[H]: PS104 ON

(4) SIG (PS105 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS105 OFF

[H]: PS105 ON

(5) 0_PS (PS108 to LTDB)

LCT no paper d etection signal

[L]: No paper

[H]: Paper present

2-6

Page 25

3

DISASSEMBLY/ASSEMBLY

Page 26

This section explains how to disassemble and reassemble the machine.

When disassembling and reassembling the machine, follow the precautions given below.

1. Be sure the power cord has been unplugged from the wall outlet.

2. Th e disassembled parts must be reas sembled following the disassembly procedure in reverse unless otherwise specified.

3. Care s hould be taken not to lo se small par ts. Care should also be

taken not to install small parts in wrong places.

4. Do not operate the machine before inst alling all the disassembled

parts completely.

5. Rem oval of some screws is prohibited in this section. Never loosen

them.

Page 27

PAPER FEED SECTION

LT-402/LT-412

[1] Cleaning the P aper Dust Rem oving

Brush

Caution:If LT is connected to the main

body , make sure that main body

power plug is disconnected

from the power outlet.

a. Procedure

(1) Open the top cover.

(2) Remove six screws to detach the paper feed

cover B.

Top

cover

Screws

Screws

[2] Cleaning the LT feed PS (PS 106)/LT

first pap er fe ed PS (PS 107)

Caution:If LT is connected to the main

body , make sure that main body

power plug is disconnected

from the power outlet.

a. Procedure

(1) Looking into the paper exit side of the LCT from

below, and clean sensors through the cavity for

LT feed PS (PS106) and the cavity for LT first

paper feed (PS107) using a blower brush.

Cavity for PS106

Cavity for PS107

Paper

exit

side

Paper feed cover B

(3) Insert a flat bladed screwdriver in the cavities (in

two locations) for paper dust removing brush to

release the locking lugs, then remove the paper

dust removing brush.

Paper dust removing brush

Cavity

Locking lugs

(4) Clean the paper dust removing brush using a

blower brush.

(5) Reinstall the above part s following the removal

steps in reverse.

3-1

Page 28

LT-402/LT-412

[3] Removing a nd Reinstalling the P aper

Feed Roller Unit

Caution: If LT is connected to the main

body , make sure that main body

power plug is disconnected

from the power outlet.

a. Procedure

(1) Open the top cover.

(2) Remove the spring from the paper feed roller

unit.

Top cover

Spring

Remove

this.

Paper feed roller unit

[4] Replacing the P aper Feed Roller Rub -

ber/Feed R olle r Rubb er

Caution:If LT is connected to the main

body , make sure that main body

power plug is disconnected

from the power outlet.

a. Procedure

(1) Remove the paper feed roller unit.

(2) Remove the bearing an d paper feed reference

actuator.

Paper feed reference actuator

Paper feed roller unit

(3) A fter removing two stop rings, remove the two

bearings outward to remove the paper feed roller

unit.

Paper feed roller unit

Bearing

Stop ring

Bearing

Stop ring

Bearing

(3) Remove two stop rings.

(4) Remove two bearings outward to detach the

roller section from the roller fitting.

Roller fitting

Stop rings

Bearing

Bearing

(4) Rei nstall the above parts following the removal

steps in reverse.

3-2

Page 29

LT-402/LT-412

(5) Remove the bearing from the opposite side of the

coupling, then remove the paper feed roller from

the shaft.

(6) Remove the stop ring to pull the feed roller from

the shaft.

(7) Remove the rubber from each roller.

Coupling

Feed roller

Paint mark

Paper feed

roller

Bearing

Paper feed roller rubber

Shaft

Shaft

Stop ring

Feed roller rubber

[5] Replacing the Double Feed Preven-

tion Roller Rub ber

Caution:If LT is connected to the main

body , make sure that main body

power plug is disconnected

from the power outlet.

a. Procedure

Caution:

(1) Remove the paper feed roller unit.

(2) Remove two screws to detach the double feed

prevention roller unit cover.

With the power held on, press the LT

tray down s witch (SW100) to move the

up/down plate down to the bottom in

advance.

Double feed

Double feed

prevention roller

prevention roller unit cover

(8) Reinstall the above part s following the removal

steps in reverse.

Caution1:

Make sure rollers and rubber portions are oriented properly when

reinstalling them.

Caution2:

Make sure the one-way clutch direction is correct.

Caution3:

Check whether grease or the like is

present on each roller.

Screws

3-3

Page 30

LT-402/LT-412

(3) Rem ove two screws to detach the double feed

prevention roller unit.

Caution:

When reinstalling the double feed prevention roller unit, tighten the screws

on the rear side first.

Double feed prevention roller unit

Screws

(4) Remove two stop rings, fit the shaft into the D-cut

in the fitting, and remove the double feed prevention roller together with the shaft.

Double feed prevention roller

D-cut

(5) Remove the double feed prev ention roller rubber

from the double feed prevention roller.

Paint mark

Double feed

prevention roller

Shaft

Double feed

prevention roller

rubber

(6) Reinstall the double feed prevention roller in the

reverse order of the removal procedure.

Caution1:

Make sure the double feed prevention roller rubber is oriented properly

when reinstalling it.

Caution2:

Check whether scratch or the like is

visible on the pet cover for the drive

gear.

Caution3:

Check whether grease or the like is

present on double feed prevention

roller.

Stop ring

3-4

Page 31

LT-402/LT-412

[6] Replacing the LT feed MC (MC101)/L T

first paper feed MC (MC102)

a. Procedure

(1) Open the top cover.

(2) Remove the spring from the paper feed roller

unit.

(3) Remove two screws to detach the top cover.

Top cover

Screws

(4) Remove three screws to detach the clutch

replacement cover.

(5) Disconnect two relay connectors (CN765,

CN766) of the clutches.

(6) Remove the stop ring to detach each clutch.

LT first paper feed MC (MC102)

LT feed MC (MC101)

Stop ring

Relay connector

(CN766)

Relay connector (CN765)

Stop ring

(7) Reinstall the above part s following the removal

steps in reverse.

Caution:

When installing each MC, make sure

that the stopper of each clutch is on

the predefined position.

Clutch

replacement cover

Screws

3-5

Page 32

LT-402/LT-412

[7] Replacing th e LT-402 Up/Down W ir es

Caution:

a. Procedure

(1) Open the top cover.

(2) Remove the clutch replacement cover.

(3) Remove five screws to detach the right side

cover.

With the power held o n, press the LT

tray down switch (SW100) to move the

up/down plate down to the bottom in

advance.

Screws

Right side

cover

Screws

(5) Remove twelve screws to detach the rear cover.

Screw

Screws

Screws

Screws

Rear cover

(6) Remove the five relay connectors (CN749,

CN780, CN781, CN782, CN783) to disconnect

the wiring harness from the up/down motor

mounting assembly.

(7) Remove the E-ring to detach the up/down gear.

(8) Pull the pin from the shaft.

(9) Remove the E-ring to detach the bearing.

(10) Remove three screws to detach the up/down

motor assembly.

(4) A fter opening the jam access door, remove six

screws to detach the front cover.

Caution:

When removing the front cover, close

the jam access door after removing

the screws.

Jam access door

Screws

Right side cover

Screws

Relay connector

Up/down

motor mounting

assembly

Shaft

(CN749)

Screw

Pin

Screw

Bearing

E-ring

Relay

connector

(CN780)

Relay

connector

(CN781)

Relay

connector

(CN782)

Relay

connector

(CN783)

Screw

Up/down

gear

E-ring

3-6

Page 33

(11) Replace the up/down wire following the instruc-

tions in “Removing Up/Down Wires’’ and “Installing Up/Down Wires.’’

LT-402/LT-412

Caution:

Wire A

Wire B

Wire C

Wire D

Two sets of four up/down wires with

different length, one set at the front

and the other at the back, are used.

Wires with the same length can be

used either at the front or back if they

are used in the same location.

1323.6mm

1250.3mm

769.3mm

661mm

3-7

Page 34

LT-402/LT-412

<Removing the Up/Down Wires>

Wire A

Wire B

Wire B

Wire A

Up/down plate

2. Release the metal

ball to remove wire

C.

18.Release the metal

ball to remove wire

A.

4. Release the metal

ball to remove wire

D.

14.Release the metal

ball to remove wire

A.

7. Release the metal

ball to remove wire

C.

9. Release the metal

ball to remove wire

D.

12.Release the metal

ball to remove wire

B.

Wire C

Wire D

6. Remove the E-ring.

8. Remove the pulley.

10.Remove the pulley.

FRONT

Up/down

shaft

16.Release the metal

ball to remove wire

B.

Wire D

Wire C

1. Remove the E-ring.

3. Remove the pulley.

5. Remove the pulley.

15.Remove the Ering, then remove

the pulley to

release wire B.

11.Remove the E-ring,

then remove the

pulley to release

wire B.

13.Remove the pulley to

release wire A.

3-8

17.Remove the pulley

to release wire A.

Page 35

<Installing the Up/Down Wires>

LT-402/LT-412

Wire A

Wire B

7. Insert wire A in the

pulleys, then attach a

metal ball.

15.Insert wire C in the

pulleys, then attach a

metal ball.

12.Insert wire D in the

pulleys, then attach a

metal ball.

10.Insert wire B in the

pulleys, then attach a

metal ball.

Wire C

Wire D

13.Insert wire C in the up/

down shaft, attach a

pulley, and secure the

pulley with an E-ring.

14.Wind wire C around

the pulley by 6 turns in

such a manner that the

wire can be pulled

from over the pulley.

Wire B

Wire A

FRONT

Up/down plate

1. Insert wire A in

6. the up/down

shaft, attach

pulleys, then

pull the wire

from under the

pulleys.

Up/down

shaft

20.Insert wire B in the pulleys,

then attach a metal ball.

2. Insert wire A in the pulleys,

then attach a metal ball.

17.Insert wire D in the pulleys,

then attach a metal ball.

5. Insert wire B in the pulleys,

then attach a metal ball.

Wire D

Wire C

18.Insert wire C in the up/

down shaft, attach a

pulley, and secure the

pulley with an E-ring.

19.Wind wire C around

the pulley by 6 turns

in such a manner that

the wire can be pulled

from over the pulley.

6 turns

6 turns

11.Insert wire D in the up/

down shaft, attach a

pulley, and wind wire

D around the pulley by

six turns in such a

manner that the wire

can be pulled from

over the pulley.

6 turns

3. Insert wire B in the up/

8. down shaft, attach a

pulley, and secure the

pulley with E-rings.

4. Pull wire B from under the

9. pulleys.

3-9

16.Insert wire D in the up/

down shaft, attach a

pulley, and wind wire

D around the pulley by

six turns in such a

manner that the wire

can be pulled from

over the pulley.

6 turns

Page 36

LT-402/LT-412

(12)After installing the up/down wires, make s ure the

up/down wires are passe d in the grooves in the

pulleys properly and wires do not run on the

sides of the pulleys. Also make sure the up/down

plate can be m oved up and down smoothly by

hand.

Caution: If the up/down plate does not move up

and down smoothly, reinstall the up/

down wires.

(13)Ins tall the up/down wire drive motor assembly,

up/down gear, and relay connectors, following

the removal steps in reverse.

(14) R emove th e E -ring to d etach the idle gear.

(15)Rotat e the remaining paper detection gear until

the round hole in this gea r is aligned with the

oblong hole in the up/down motor mounting

assembly.

Caution: Align when the up/down plate is in low-

est position.

Up/down motor

mounting assembly

Remaining paper

detection gear

[8] Replacing the LT - 412 Up/Dow n Wires

a. Procedure

Caution: With the power held on, press the LT

tray down switch (SW100) to move the

up/down plate down to the bottom in

advance.

(1) Remove the clutch replacement cover, side

cover (right), front cover , and rear cover f ollowing

the steps (1) to (5) in [7] Replacing the LT-402

Up/Down Wires.

(2) Remove the E-ring.

(3) Remove the five screws to detach the gear cover .

(4) Remove the two bearings.

Screw

Screw

E-ring

Screws

Bearing

Gear cover

Bearing

Round

hole

Idle gear

E-ring

Oblong

hole

(16)I ns tall the idle gear.

(17)A ttach the covers following the removal steps in

reverse.

Caution1: After replacing the up/down wires,

make horizontal and centering

adjustment of the up/down plate.

(Refer to “ADJUSTMENT SECTION.”)

(5) Remove the gear A.

(6) Remove the E-ring to remove gear B.

(7) Remove the detent pin for gear B from the up/

down pulley shaft.

(8) Remove the E-ring and bearing to remove gear

C.

Gear A

Pin

Gear B

Bearing

Up/down pulley shaft

Gear C

E-ring

E-ring

3-10

Page 37

LT-402/LT-412

g

(9) Remove the bearing behind gear C.

(10) Remove the E-ring to remove the up/down gear.

(11) Remove the detent pin for up/down gear from the

up/down pulley shaft.

(12) Remove the E-ring to remove gear D.

(13) Remove the E-ring to remove the remaining

paper detection gear.

(14)Remove four relay connectors (CN780, CN781,

CN782, and CN783) to disconnect the wiring

harness from the up/down motor mounting

assembly.

Relay connector

(CN780)

Remaining paper

detection gear

Gear D

E-ring

Relay

connector

(CN781)

Relay connector

(CN782)

Up/down

motor mounting

assembly

(17) Replace the up/down wires following the instruc-

tions in “Removing the Up/Down Wires” and

“Installing Up/Down Wires.”

Caution: Two sets of four up/down wires with

different length, one set at the front

and the other at the back, are used.

Wires with the same length can be

used either at the front or back if they

are used in the same location.

1057.3mm

Wire A

692.1mm

Wire B

1321.7mm

Wire C

1303.1mm

Wire D

Pin

Up/down

gear

E-ring

Up/down pulley shaft

Bearing

Relay

connector

(CN783)

E-ring

(15) Remove the E-ring to remove the bearing.

(16) Remove the six screws to remove the up/down

motor mounting assembly.

Up/down motor mounting assembly

Screws

Bearing

E-rin

Screws

3-11

Page 38

LT-402/LT-412

<Removing the Up/Down Wires>

Wire C

Wire D

14.Release the metal

ball to remove wire

D.

7. Release the metal

ball to remove wire

A.

9. Release the metal

ball to remove wire

B.

12.Release the metal

ball to remove wire

C.

Wire C

Wire D

Up/down plate

2. Release the metal

ball to remove wire

A.

18.Release the metal

ball to remove wire

D.

4. Release the metal

ball to remove wire

B.

16.Release the metal

ball to remove wire

C.

Wire B

Wire A

1. Remove the E-ring.

3. Remove the pulley.

Wire A

6. Remove the E-ring.

8. Remove the pulley.

10.Remove the pulley.

Wire B

FRONT

11.Remove the E-ring,

then remove the

pulley to release

wire C.

Up/down shaft

13.Remove the pulley to

release wire D.

5. Remove the pulley.

15.Remove the E-ring,

then remove the

pulley to release

wire C.

17.Remove the pulley

to release wire D.

3-12

Page 39

<Installing the Up/Down Wires>

LT-402/LT-412

Wire C

Wire D

Wire C

Wire D

7. Insert wire D in the

pulleys, then attach a

metal ball.

15.Insert wire A in the

pulleys, then attach a

metal ball.

12.Insert wire B in the

pulleys, then attach a

metal ball.

10.Insert wire C in the

pulleys, then attach a

metal ball.

Wire A

Wire B

13.Insert wire A in the up/down

shaft, attach a pulley, and

secure the pulley with an E-ring.

14.Wind wire A around the pulley

by 6 turns in such a manner

that the wire can be pulled

from over the pulley.

6 turns

11.Insert wire B in the up/down shaft,

attach a pulley, and wind wire B

around the pulley by six turns in

such a manner that the wire can

be pulled from over the pulley.

Up/down plate

FRONT

3. Insert wire C in the up/down

8. shaft, attach a pulley, and

4. Pull wire C from under the

9. pulleys.

Up/down

shaft

1. Insert wire D in the

6. up/down shaft, attach

pulleys, then pull wire

D from under the

pulleys.

secure the pulley with E-rings.

20.Insert wire A in the

pulleys, then attach a

metal ball.

2. Insert wire D in the

pulleys, then attach a

metal ball.

17.Insert wire B in the

pulleys, then attach a

metal ball.

5. Insert wire C in the

pulleys, then attach a

metal ball.

Wire B

Wire A

18.Insert wire A in the up/

down shaft, attach a

pulley, and secure the

pulley with an E-ring.

19.Wind wire A around the

pulley by 6 turns in such

a manner that the wire

can be pulled from over

the pulley.

6 turns

16.Insert wire B in the up/

down shaft, attach a

pulley, and wind wire B

around the pulley by six

turns in such a manner

that the wire can be

pulled from over the

pulley.

6 turns

6 turns

3-13

Page 40

LT-402/LT-412

(18) After installing the up/down wires, check whether

they are engaged with the pulleys proper ly and

whether they do not ride over the pulleys. Next,

move the up/down plate manually to check

whether it moves up and down smoothly.

Caution: If the up/down plate does not move

smoothly, remove the up/down wires

and install them again.

(19) Install the up/down motor mounting assembly,

relay connectors, remaining paper detection

gear, gear D, and up/down gear following the

removal steps in reverse.

(20)Rotat e the remaining paper detection gear until

the round hole in this gea r is aligned with the

oblong hole in the up/down motor mounting

assembly.

Up/down motor

mounting assembly

Remaining paper

detection gear

Oblong hole

Round hole

Caution: Align them when the up/down plate is

at the bottom.

(21)Install gear C.

(22)Attach the other gears, gear cover, and external

covers following the removal steps in reverse.

Caution: After replaci ng the up/down wires,

make horizontal and centering adjust-

ment of the up/down plate. (Refer to

“ADJUSTMENT SECTION.”)

3-14

Loading...

Loading...