Konica Minolta KM256, KM512, KM1024 User Manual

1

Printer KONICA

( KM256/512/1024)

2

All rights is reserved by SHANGGHAI Printer TECHNOLOGY CO。, LTD

Thank you very much for purchasing Printer machine,to make sure the user knowing the

safety on the foundation of understanding the product performance completely. Please

read the operation manual carefully and maintain it.

Printer company’s equipment instruction and print procedure, only provide those

authorized legal holder to use by oneself. It is forbidden to copy and modification,

exchange or pass network and other the whole modes outward the boundary release its

complete contents and breach any above behavior, all beard burden pertaining to crime

responsibility and civil case recompense responsibility.

If contents and the product parameter of this manual have been already changed, we will

not notice you.

The Printer company has no responsibility for technique ,edit bug and negligence

appeared in this text.

We make a great effort to edit this user manual and detect this product, if you find any

miscount prints or false, please tell us .We will appreciate.

【The trademark declares 】

All trademarks , manufacturer and product denomination quoting in this book is as follows:

Printer is the registered design of the Printer technology company.

Windows 98, Windows ME, Windows2003, Windows2000, Windows XP, Windows VISTA,

and windows 7 are the registered designs of Microsoft company.

Photo shop is Adobe Corporation’s trademark.

Photo Print is the trademark of Photo print company of the United States.

KONICA is the trademark that belong to Japan KONICA company.

1

KONICA Printer

....................................................................................................................1

1 Safety Guidance

...................................................................................................................1

1-1 Safety precautions

.........................................................................................................1

1-2 General safety guidelines

. ............................................................................................ 1

1-3 Important safety guidelines

.......................................................................................... 1

1-4 Precautions when using the printer

............................................................................ 2

1-5 Danger of electric shock

............................................................................................... 2

1-6 Danger of scald

..............................................................................................................3

1-7 Fire disaster

..................................................................................................................... 3

1-8 Danger of mechanical

................................................................................................... 3

1-9 Danger of material (medium) overweight

................................................................ 4

1-10 The deal of ink

.............................................................................................................4

2 Printer Device demand

......................................................................................................4

2-1 Recommended computer hardware and software configuration

.......................... 4

2-2 Site preparation

. ............................................................................................................ 5

2-2-1 Working area. .......................................................................................................... 5

2-2-2 Environmental requirements . .................................................................................5

2-2-3 Floor requirements . ................................................................................................ 5

2-2-4 Load-bearing requirements .................................................................................... 6

2-2-5 Requirements for space reservations ....................................................................... 6

2-2-6 Safety requirements ................................................................................................. 6

Fire preventing ..........................................................................................................6

2-2-7 Electrical requirements ........................................................................................ 7

2-2-8 Operator requirements ............................................................................................ 7

2-2-9 Requirements of installation.................................................................................... 7

2-3 Check before installation

............................................................................................8

2-4 Shipment, unpacking and inspection

......................................................................... 9

2-4-1 Shipment.................................................................................................................. 9

2-4-2 unpacking ................................................................................................................ 9

2-4-3 inspection .............................................................................................................. 9

3 KONICA machine main parts picture

..................................................................... 10

4 Install the ground wire

.................................................................................................... 12

5 Hardware installation

.......................................................................................................14

5-1 About the print manage

.............................................................................................. 14

5-2 KM256/512/1024 carriage board connection and factory writer

....................... 18

KM512/1024 ................................................................................................................... 18

KM256 ............................................................................................................................ 20

2

5-3 power outlet

..................................................................................................................21

5-4 cleaning system

............................................................................................................22

5-5 the use of ink station and the automatic ink station

..............................................23

5-5-1.Power off the machine for protection ....................................................................23

5-5-2 Automatic protection capping................................................................................ 24

5-6

Platform Heater

............................................................................................................24

5-7 Media system( H.C machine)

.................................................................................... 27

5-8 Automatical pinch roller

............................................................................................. 33

5-9 Platform suction (E series and S series machine)

.................................................34

6. Software installation

.......................................................................................................35

6-1 Printer manager Installation

....................................................................................... 35

6-2 Introduction to software interface

............................................................................ 38

6-2-1 Toolbar introduction ..............................................................................................38

6-2-2 The introduction to the print information ..............................................................39

6-2-3 Introduction to the menu

........................................................................................ 40

6-3-2-1 JOB menu

.......................................................................................................40

6-2-3-2 "setting" menu

.................................................................................................. 40

6-2-3-3 Tools menu

......................................................................................................41

6-3 Hardware Setting

.........................................................................................................42

6-4 Calibration

..................................................................................................................... 43

7 Show the information of the software version and the help document

... 49

7-1 status bar

........................................................................................................................ 49

7-2 the dialog of the parameter

........................................................................................ 49

7-2-1the parameter setting...............................................................................................49

7-2-2 printer parameter ................................................................................................... 50

7-2-3 Calibration parameter ............................................................................................ 51

7-2-4 Preference set.........................................................................................................51

8 Maintenance

......................................................................................................................... 52

8-1 Scheduled maintenance guide

................................................................................ 52

8-2 Daily inspection and maintenance

........................................................................ 53

8-2-1 Head inspection and cleaning .............................................................................53

8-2-2 Print test sample to check whether it needs further calibration .......................... 54

9 common problems and solutions

............................................................................... 54

9-1 print head

....................................................................................................................... 55

9-2 media feeding/taking system

..................................................................................... 57

9-3 others

.............................................................................................................................. 57

10 customer service

..............................................................................................................61

1

1 Safety Guidance

1.1 Safety precautions

Before using the printer, please read the following safety precautions to make sure the

safety of using the equipment.

1.2 General safety guidelines.

Please read installation instructions before the printer is connected to the power.

Please turn off the printer immediately for any of the following situations. Please

unplug the power cord of machine from the power outlet and call the local dealer:

Power cord or plug is damaged;

Liquid run into the printer;

Appear smoking or unusual flavor on the printer;

Printer drops or drying system breakdown;

Printer's built-leakage circuit breakers (ground fault leakage protection) repeat

trips;

The fuse is broken;

The printer is not running.

For any of the following situations, please turn off the printer and unplug the power

cord of machine from the power outlet.

Thunderstorm;

The electricity is off during printing.

1.3 Important safety guidelines

Don’t place anything on the printer's platform and be careful not to spill liquid on the

printer;

The types of power source can be used only which is identified on the label of printer.

According to different countries and regions, 110V or 220V AC power source may be

preferred;

All devices are connected to a properly grounded outlet to avoid the equipments

switching between turning on and off are in the same circuit such as outlet and copier

or air conditioning system;

Avoid using the wall switch or automatic timer control socket;

Please make sure your computer system is far from potential sources of

electromagnetic interference, such as speaker or cordless phones;

2

Don’t use damaged or frayed power cord;

If you use additional power cord, remember that the total amperage of equipment

which is inserted attached power cord should not exceed the rating amperage of the

power source. Besides remember the total amperage of all equipments into the wall

should not exceed the rating amperage of wall socket;

1.4 Precautions when using the printer

Don’t move the print head by hand when turning on the printer or you may damage

the printer;

Always using the power switch to turn off the printer, when the key is pressed, the

power will be cut off; before the power is cut off, do not unplug the printer plug or

data line;

Please make sure the printer head is in the initial position and make it fixed before

moving the printer.

1.5 Danger of electric shock

There’s two power cords on the printer. Please unplug these two power cords before

repairing the printer. The printer can only be connected to the grounded AC power outlet.

To avoid the danger of electric shock, please notice the following:

Don’t attempt to remove drying or electrical control cabinet.

Don’t remove or open any other closed system cover or plug.

Don’t put any objects into the printer slot.

Warnings!

Drying system uses normal AC power. When using the system, do not

put your hand or other objects into it, otherwise it will result in body

injury or damage to the object.

Notice!

Blown fuse in the circuit may indicate failure of electric circuit in

system. Please call your local dealer and not attempt to replace the

fuse yourself.

3

1.6 Danger of scald

When the printer drying system is running at a high temperature, if you touch it, it may

cause burns. To avoid personal injury, please notice the following precautions:

Don’t touch the inside printer drying system’s cover. Even its power source is off, the

internal surface may still be very hot;

It should be particularly careful when touching the material drying channel.

1.7 Fire disaster

The temperature is high when the printer drying system is running. If the printer's

built-leakage circuit breakers (ground fault leakage protection) trip repeatedly, please call

your local dealer

To avoid the danger of fire disaster, please notice the following precautions:

Please use the power voltage specified on the nameplate.

To connect the power cord to dedicated circuit and in accordance with the rated

parameters of the wall outlet, using the branch circuit breakers protect each circuit.

Do not use a wiring board (inserted row) to connect two power cords.

Only use the power cord supplied with the printer by Printer

. Do not use damaged

power cord. Do not use the power cord supplied with other products.

Do not put any objects into the printer slot.

Be careful not to spill liquid on the printer.

Do not use spray containing flammable gases inside or near the printer.

Do not block or block the opening of the printer.

Do not attempt to remove drying system or electrical control cabinet.

Loading the material which can work at the 125 ° C (257 ° F) and the combustion

temperature is higher than 250 ° C (482 ° F).

1.8 Danger of mechanical

The moving parts of printer may cause personal injury. To avoid personal injury when

working near the printer, please notice the following precautions:

To make sure all clothes and body parts away from moving parts of the printer;

Do not wear necklaces, bracelets and other hanging objects;

If your hair is long, please prevent it falling into the printer;

Be careful not to let the sleeves or gloves be entangled by moving parts of the printer;

Do not touch the gear or move the roll during printing.

4

1.9 Danger of material (medium) overweight

When dealing with heavier substrate rolls, people should be particularly careful to avoid

injury.

It may need several people to carry heavier substrate rolls. People should be very careful

to avoid back strain and / or injury.

Please consider handling equipment by using forklifts, pallet trucks or others.

Please wear personal protective goods including work boots and gloves when handling

heavier substrate rolls.

1.10 The deal of ink

Keep the ink bottle on the place out of the reach of children. Don’t let children drink or

touch the ink bottle;

If the ink sticks to the skin, please wash with soap and water; If the ink is splashed into

eyes, wash eyes immediately with water;

Do not shake the ink bottle, this will lead to ink leakage;

The ink bottle need immediately removing, cleaning and drying after a period of

time(usually three months); Cleanliness is important when replacing new ink bottle to

ensure good printing quality;

Please process the waste ink according to local laws.

Warnings and notice

This manual uses the following symbols to ensure corrected using of the printer and to

prevent damage. Please follow the instructions marked with these symbols.

Warnings!

It may lead to serious personal injury even death if not to comply with the

guidelines marked with this symbol

s.

Cautions!

It may damage the printer if not to comply with the guidelines marked with

this symbols.

Notice! It

may result in minor personal injury or damage of the product if not to comply

with the guidelines marked with this symbols.

2 Printer Device demand

2-1 Recommended computer hardware and software

configuration

5

CPU: Intel Core Duo 2.50GHZ or above

Memory card: 2.00GB or above

Motherboard: INTEL G41 or above

Operating System: WINDOWS XP/VISTA/7 or above Microsoft operating systems

PC’s configure has a direct relation with the printer speed and stability

2-2 Site preparation

Customers are required to comply with the installation requirements and implement it for

the machine operation.

Sites and environment will directly affect the stability of the printer.

2-2-1 Working area

Listed below of working area is close to the Printer180 series photo machine (here in after

referred to as Machine) area, as shown. Emphasized that users should ensure that the

safety of operating staff within this region.

The scope of the working area are the length 7meters, width 4meters and height of

3meters.

Printer 3.2 series printers (1.8meter width) Dimensions: length 3.8 m, width 2.5m, height

2.5m.

2-2-2 Environmental requirements

Equipment should be away from the joint devices (fabric connected machine), or other

radio frequency interference. Floor should be easy cleaning and does not cause dust and

static electricity. In order to help operators and customers determinning the accuracy of

color, the environment should be neutral or gray color decoration and use of light

(fluorescent) lighting.

Machine should be installed in a clean, dustless, temperature and relative humidity

controlled environment within the following:

Altitude: below 1,000 meters sea level

Temperature: 15-35C

Relative Humidity: 40% -65%

Note: When the machine printing pictures, please do not use other USB devices such as U

disk or hard disk.

2-2-3 Floor requirements

Ground material in work area should be able to guarantee security system weight evenly

dispersed, during the installation process, the system should maintain accurate level to

ensure the print head moving correctly, in case of sliding and bending.

Cautions!

Floor in working area must prevent static and dust accumulation, if

necessary, laying a clean polished concrete floor tiles before

installation, do not make flooring

materials

like carpet

6

2-2-4 Load-bearing requirements

Net weight of 200-250KG

Machine largest volume materials is 60KG

Proposed to install the machine in four plate 20cm in diameter, or four 200 x 200mm or

more than 8mm thick steel plate

2-2-5 Requirements for space reservations

The front of equipment means the input side of printing. Equipment requires 1m

reservation in front, 0.5m on the back, 0.5 m in the left and right side. Besides, the space

reserved also includes the height of 2.5 meters above the ground. In addition, the machine

should also leave space for before and after for the loading screen, and supplies.

2-2-6 Safety requirements

Fire preventing

Ink and solvent must be packed in special non-combustible liquid storage cabinets or

separate storage room, and must be made clear identity to meet the professional

requirements of safety regulations.

The storage of ink and solvent must strictly abide by local ink storage use and storage of

fuel on the fire safety regulations.

Carbon dioxide and dry powder fire extinguishers should be placed in the obvious channel

and easy to take. They should be located in near equipment and non-flammable liquid

storage cabinet (room), in accordance with local regulatory requirements.

Ventilation

To prevent the accumulation of volatile gas causes danger, the place must be well

ventilated to ensure the working area air circulating 6 to 8 times per/hour, vents should be

low enough to prevent the vapors accumulating on the nearby floor.

When the media pass through the dryer, we need a exhaust system to drain away the

solvent gas evaporating from the ink..

Note: As the solvent gas is higher proportion than the air, it will accumulate nearby the

7

floor.

The electrical equipment near the working area must conform to GB / T standards, national

electrical codes provided on first level second-class venue, which is installed by a

corresponding qualified electrical contractor.

2-2-7 Electrical requirements

the machine equips with single-phase power, and requests a good independent grounding

cable. Grounding resistance is less than 10 Ohms.

Power supply voltage range of DC 220V (± 10%) AC 50Hz or 60Hz .The electrical power

line output must be installed by professional staff or contractors.

Circuit breaker ratings are as follows

Power\Voltage AV 220V AV 110V

Single-phase 10A/phase 20A/phase

Maximum power consumption is less than 2KW, average power consumption is 1.2 KW.

UPS can be 3KW, which can access the computer and the machine power.

The machine equips with a standard 5m cable.

2-2-8 Operator requirements

For machines operators, following requirements and responsibilities are needed:

Responsible for operation and maintenance of machine

Keep connection with Printer technical support service

Able to solve problems and maintenance through telephone

Experience with Windows and PC

The electronic and mechanical technical background

Capacity of color theory, knowledge of front and post-production printing.

2-2-9 Requirements of installation

Installation requires that equipment must be installed in a horizontal place. Leveling the

equipment from front to back according to the level after moving the equipment in place .

It’s good for easy maintenance and cooperation in daily operation if installing a telephone

nearby operator console.。

Tips!

Hazardous waste disposal requirements should be consistent with

relevant

specific

special storage

and handling

requirements.

Warnings!

Make sure the equipment connected to grounded cord before

electrifying, the ground-to-ground resistance is not more than 10 ohms.

8

2-3 Check before installation

The voltage at working place should be reported to dealer in advance.

The power input jack of machine power is on the left side of equipment back.

The temperature of air-conditioning in room should be sufficient to following

temperature (15 - 35 ℃).

Customers should prepare appropriate tool to install the machine in advance: a

forklift over 1-ton or a crane over 1-ton. Customers must notify Printer company

all tools used, otherwise the resulting delay will be charged.

In the absence of engineers , the customer cann’t open the boxes. Any damage to

boxes should be photographed before the engineer arrives and immediately

report to the dealer.

Customers must finish all preparation and cleaning work before the engineer

arrives because dust may cause some damage to the machine.

Customers should prepare other necessary device such as Apple Computer and

Photo shop, Freehand, Illustrator etc. software that Apple Computer uses and

100M computer network.

During the installation, there’re at least two skilled computer operators next to

the machine. It’s better if they have printing experience.

Customers should be trained before starting production alone if their operators is

lack of enough experience.

The ink takes long time from order to delivery, In order not to affect the

production, customer should place orders in advance.

To minimize downtime, the manufacturer has chosen to provide some spare parts

and advise clients to buy some spare parts. If these parts have been used, please

order from Kanger immediately to make sure no shortage

9

Please note shipping boxes labeled "left" and "after" message in handling.

Please read engineer’s installation and checking file carefully. Each on the form

must be labeled "Yes". And fax it to the dealer’s customer service maintenance

center before the installation.

2-4 Shipment, unpacking and inspection

2-4-1 Shipment

When loading, please notice the signs on the surface of wooden box :Handle with care,

Don’t stack heavy objects on it and pay attention of rains. The vehicles must drive

smoothly during transportation without brakes sharp turns etc. which will result in the

beating and rollover of wooden box.

2-4-2 unpacking

If the box has been damaged before opening, took photos, and immediately offered

treatment scheme, report to Printer company.

Demolition cover wooden box.

Dismantling the big bolts around the wooden cases, removable around plank.

Move out of the machine and inventory random items。

2-4-3 inspection

By one count, installed engineers present random items.

Inventory finished, customers sign in the list and installed engineer take it back. If

there are omissions, please indicate in the list, Printer company will fill up

immediately。

10

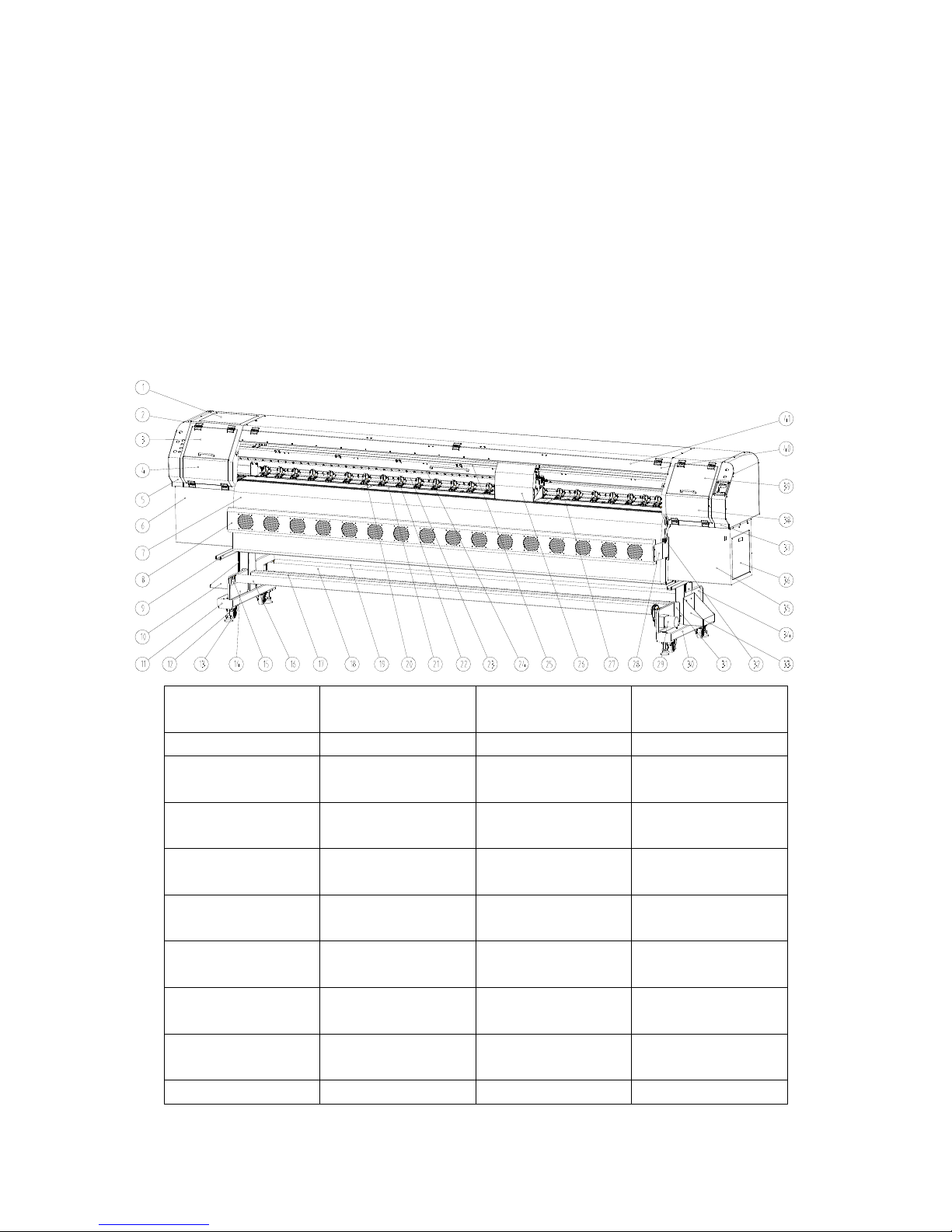

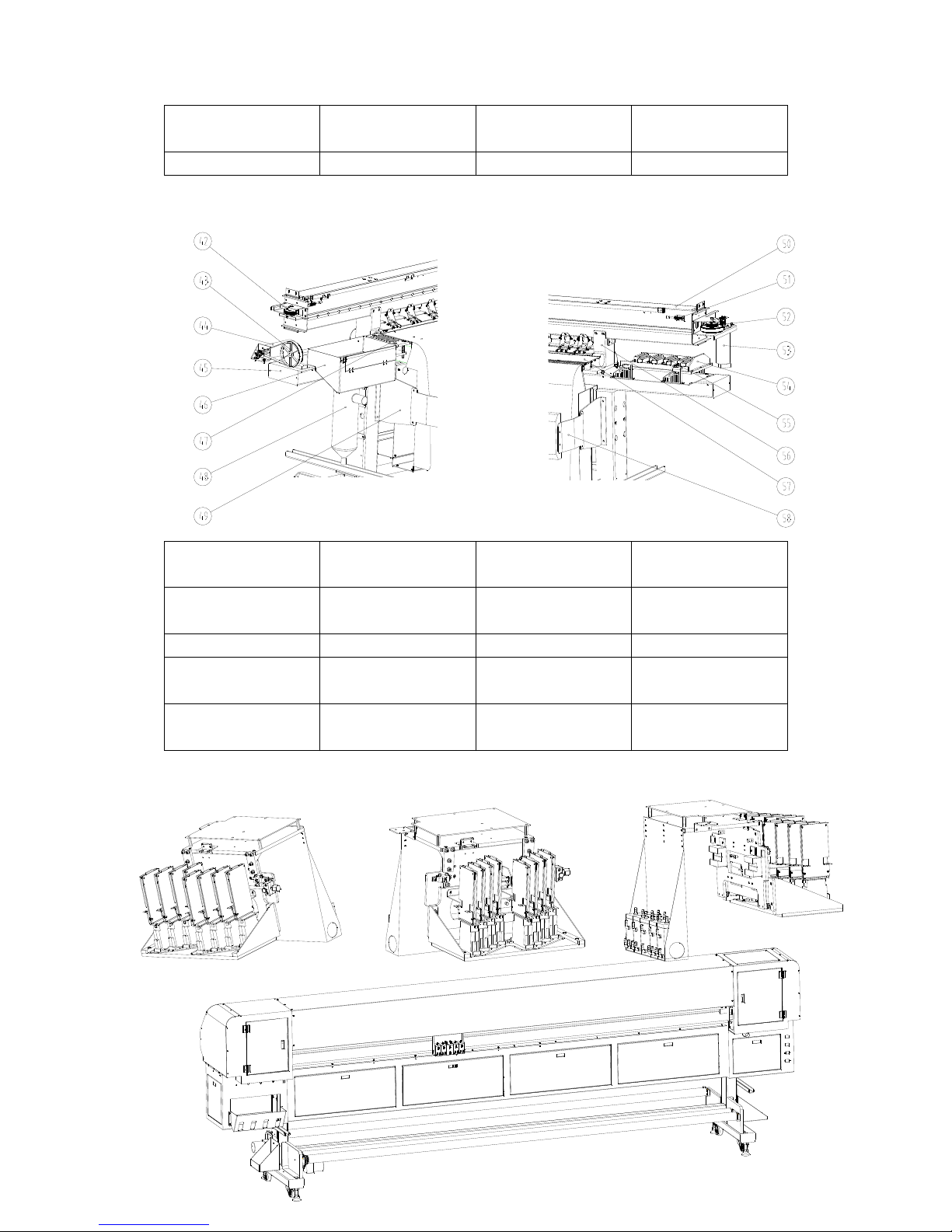

3 KONICA machine main parts picture

Main parts instruction

front

1、left-up lid 2、hinge 3、left-front-up lid 4 、 left-front-down

lid

5、left-up box 6、left-down box 7、heater front lid 8、fan lid

9、lift stick 10 、 left ink tank

shelf

11、left main leg 12、adjust leg

13、roller 14 、 media-up left

baffle

15media-up left

bracket

16、media-up roller

17、down beam 18 、 rubber feed

roller

19、feed roller 20、media pressure

21、air draft 22 、 pinch roll

system

23、fasten shaft 24liner slider

25、raster 26、carriage 27 、 fasten shaft

bracket

28、junction plate

29、media-up motor 30、right main leg 31、media-up right

baffle

32、fasten handle

33、right ink tank

shelf

34、right feed baffle 35、right-down box 36、right-down box

side lid

37、right up box 38 、 39 、 right-front-up 40、middle-front lid

11

right-front-down

box lid

box lid

41、center lid

Left side of the machine right side of the machine

42、fasten belt roll 43 、 shut down

system

44、Y axis motor 45、frame

46、waste ink box 47、header air draft

panel

48、gas and liquid

detach box

49 、 big junction

plate

50、up beam 51、buffer stick 52、bistage belt roll 53、x axis motor

54、hydrate lid 55、hydrate cap 56 up beam

junction plate

57、vacuum panel

58、small junction

plate

Carriage

Back of the machine

12

User Manual Power cable

Printer CD Software

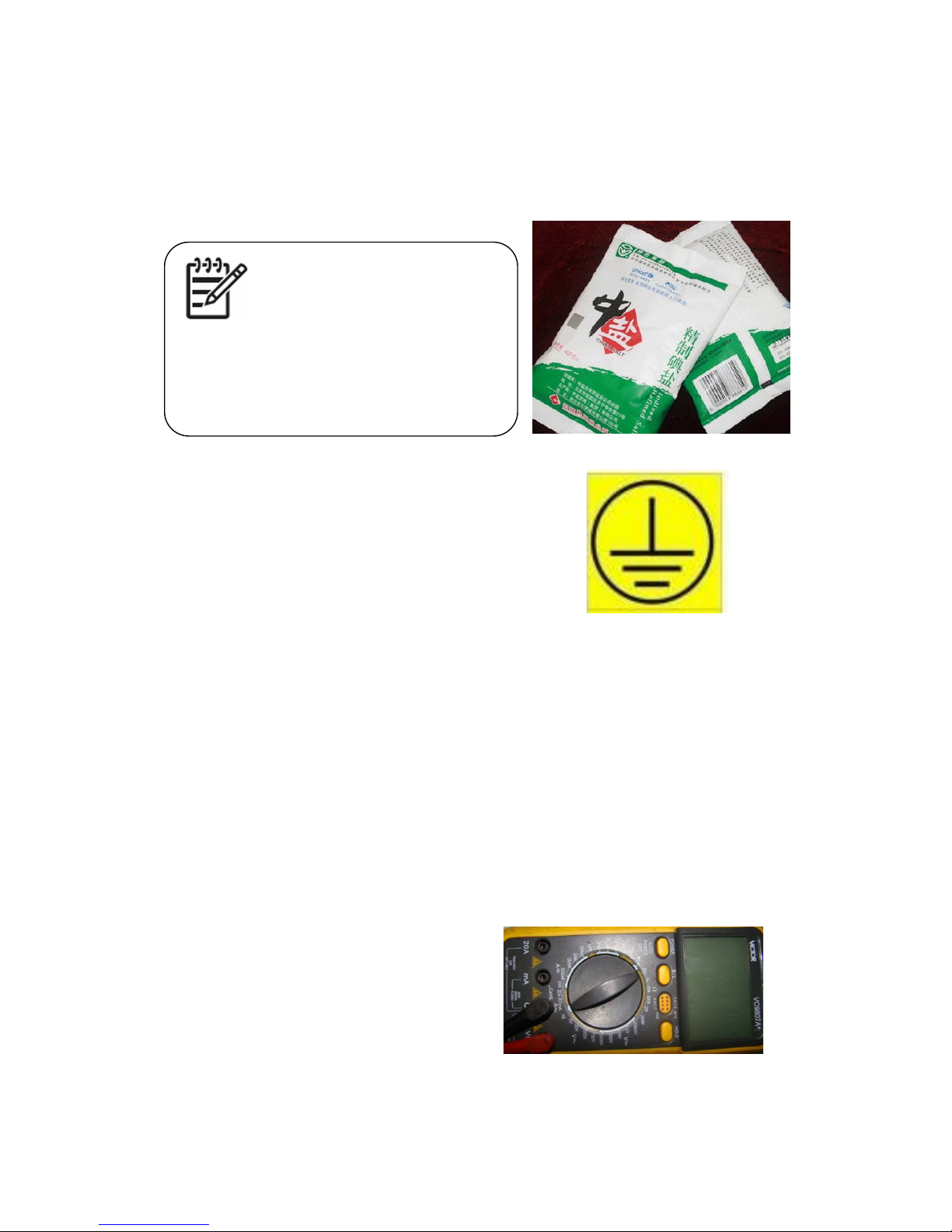

4 Install the ground wire

(1) Bury an iron bar

Bury a 1m-1.5m iron bar (diameter

1CM-2CM) into moist soil.

Notice!

Please confirm whether

the iron bar is buried

near the transformer or

other national power /

communication cables

or facilities, the iron bar

should be away from

these facilities

1M-1.5M

13

(2) Irrigate salt water

Take 500g salt and 1000g water to mix

and then pour the salt water to the

iron bar.

(3) Wiring

Get a wire more than 2 flat, weld the

wire to the iron bar with electric welding

torch (uneasy to fall off) .Please

connect the other end of ground signs

on the machine screws at the nail. If

you do not find the mark on the

machine, connect to the exposed parts

of the machine (the parts without

painting, such as castor and public

wiring board ground)

(4)Measurement of ground resistance

When the machine power on, measure

the machine phase and the zero line

with electric pen (methods of

measurement refer to relative literature)

Then turn off the machine, make the

Multimeter to the smallest gear

resistance, measure the resistance

between the ground and the zero line,

resistance should be less than 10 ohms

Notice

!

The

salt must dissolve into

water completely.

Pour the iron bar with salt

water once a month to

guarantee the iron

conductivity.

14

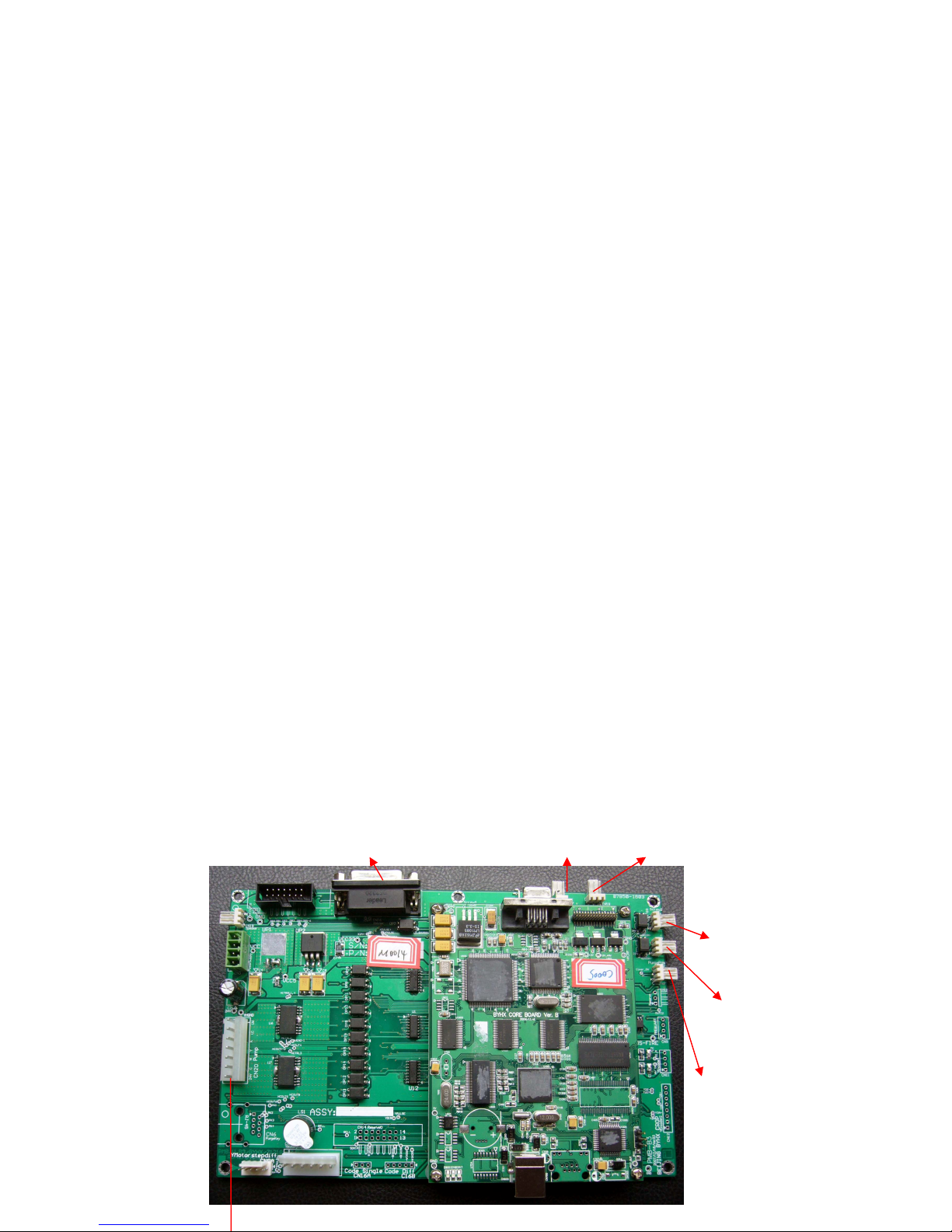

5 Hardware installation

5-1 about the print manage

Printer ( KM256/512/1024 ) consist of print system and heating

system,all support by AC power supply alone.

The environment requirement:

temperature:18-30

humidity:60%-80%

power:3500W 左右 recommend use stable power supply

The install of the ground wire:connect the ground wire to the public

ground junction plate,use the multimeter to the AC 200 V switch,black pen

to the ground wire,red pen to the input zero wire,the number less than

1 is ok.

Print system

Consist of three parts: the main board ,the carriage board and the control

software.with USB 2.0 to connect the computer.

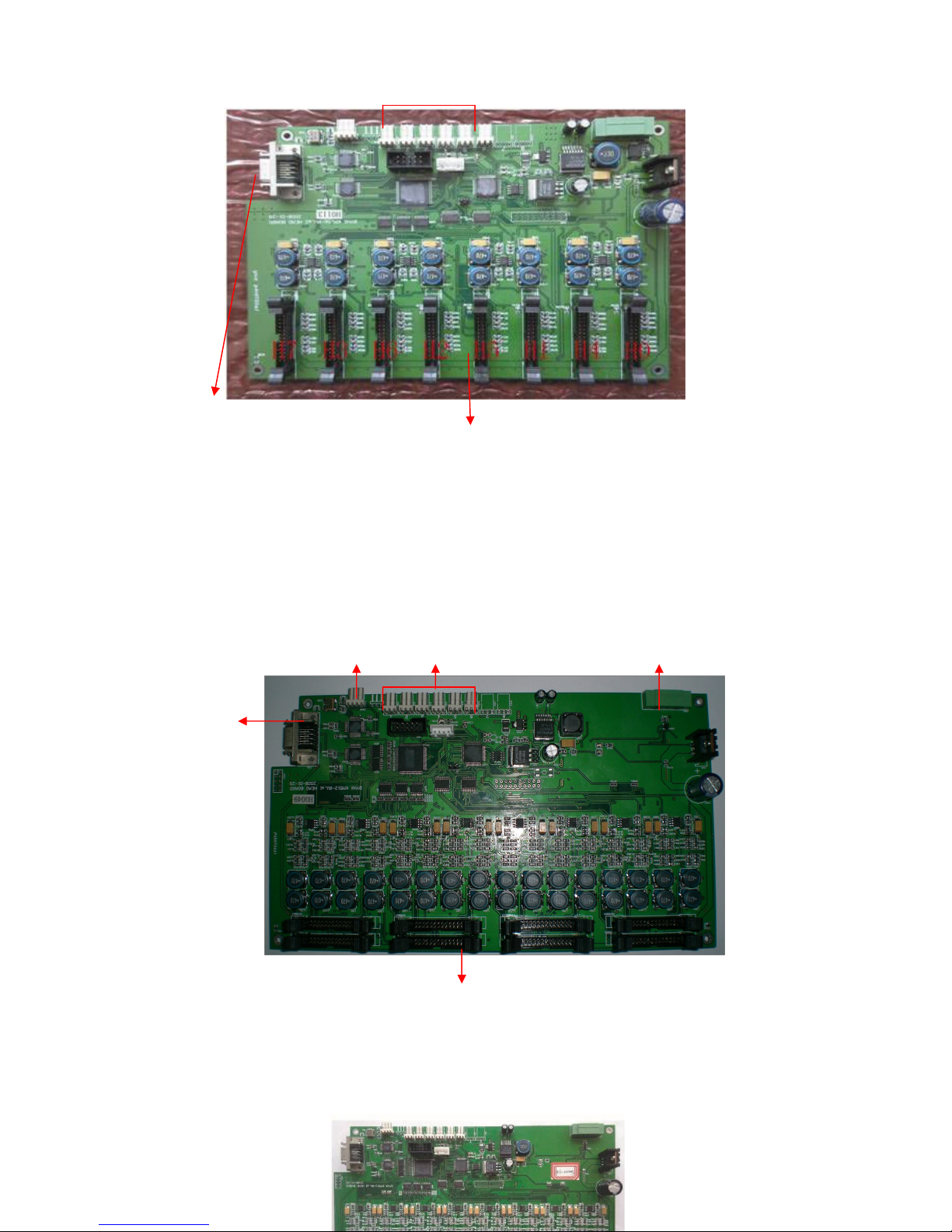

.Main board

CN16:to x motor CN17:right stop CN18:left stop

CN4:origi

n senor

CN5:terminal

senor

CN7:vacuum

15

To pump CN8:Ymotor USB2.0 to computer

....KM256 carriage board

Sub ink tank senor

Raster encoder (LcLmYMCK) power(24v)

16

To main board

To KM256 print heads

. KM512 carriage board

Sub ink tank senor

Raster encoder (LcLmYMCK) power(24v)

To main

board

To KM512 print heads

carriage board to the print heads

(KM512/1024)

17

Loading...

Loading...