5

ADJUSTMENT

5. ADJUSTMENT

HOW TO USE THE ADJUSTMENT

SECTION ........................................................5-1

[1] Construction.........................................5-1

ADJUSTMENTS WHEN REPLACING

PARTS ............................................................ 5-1

LIST OF ADJUSTMENT ITEM .......................5-2

SETTING AND CHECKING WITH P

FUNCTION......................................................5-3

[1] P Button Operating Procedure............. 5-3

[2] Checking All Counter Data Information

.............................................................5-3

[3] Checking the Total Count / Start Date

.............................................................5-4

[4] Checking the PM Count / Start Date.... 5-4

[5] Checking the Drum Count....................5-4

[6] Checking the Developing Count .......... 5-4

Checking or Setting the Density Shift (text/

[7]

photo) ......................................................

[8] Checking or Setting the Density Shift

(text).....................................................5-5

[9] Checking or Setting the Density Shift

(photo)..................................................5-5

[10]Checking or Setting the Density Shift

(Increase contrast) ............................... 5-5

25 MODE ........................................................ 5-6

[1] Setting Method.....................................5-6

[2] Setting Software DIP SW..................... 5-6

[3] Tray Size Setting................................5-14

[4] PM Count Setting............................... 5-15

[5] Data Collection...................................5-16

[6] Parts counter......................................5-21

[7] Password setting................................5-26

[8] Setting Phone Number of the Service

Center ................................................5-28

5-5

[9] Setting the Serial Number.................. 5-28

[10]Displaying the ROM Version.............. 5-29

[11]KRDS Setting..................................... 5-30

[12]KRDS Set Up .....................................5-30

[13]Call setting menu mode ..................... 5-43

[14]KRDS Host Call .................................5-46

[15]KRDS Data List.................................. 5-47

[16]ISW Setting ........................................5-48

25 Mode Adjustment Item Table ..............5-51

36 MODE ...................................................... 5-52

[1] Setting Method...................................5-52

[2] High Voltage Adjustment ...................5-52

[3] Timing Adjustment ............................. 5-54

[4] Running Test Mode............................5-67

[5] Test Pattern Output............................5-68

[6] Test Pattern Density Adjustment ....... 5-75

[7] Image Quality Adjustment.................. 5-76

[8] List Print (Service data Print) ............. 5-79

36 mode adjustment items list.................. 5-80

47 MODE ...................................................... 5-92

[1] 47 Mode Setting Method....................5-92

[2] Initial Setting in the field ..................... 5-93

[3] Drum count reset ...............................5-93

[4] RADF original size detection adjustment

...........................................................5-94

[5] Electrical RDH memory check ........... 5-94

[6] RADF sensor adjustment................... 5-94

3

[7] Input check (code) list ........................ 5-95

3

[8] Output check (code) list ..................... 5-97

3

OTHER ADJUSTMENTS............................5-101

3

[1] Centering Adjustment ......................5-101

[2] Image Distortion Adjustment............ 5-102

[3] Paper Skew Adjustment...................5-104

MODEL

7040

MANUAL

SERVICE HANDBOOK

REVISED EDITION

3

DA TE

Mar. 1999

PAGE

–

METHOD

REPLACEMENT

ADJUSTMENT

HOW T O USE THE ADJUSTMENT SECTION

[1] Construction

This section details adjusting items and procedures. Use this

section for making adjustments and as a checklist before

implementing corrective measures in the field.

1. Does the power supply meet the requirements?

2. Is the power supply properly grounded?

3. Is the machine sharing its power source with another high

current consumption machine that draws large currents

intermittently? (e.g. an elevator, air conditioner, or other

source of electrical consumption)

4. Is the installation environment suitable?

a. The machine must be installed in a well-ventilated

place free from high temperature, high humidity and

direct sunlight.

b. The machine must be installed on a level floor.

5. Does the cause of a defective image lie in the original

itself?

6. Is the density adjusting control at the proper position?

7. Are the original glass and RADF platen guide clean?

8. Is the correct paper being used for the copy?

9. Are the copying materials and parts replaced when they

reach the end of their usable life? (developer, drum,

cleaning blade, etc.)

10. Is there toner in the toner cartridge?

The following items should also be observed when repairing

the machine.

1. Only one side of the AC power line is disconnected when

the main power of this machine is turned off. Always

unplug the machine before beginning work. If absolutely

necessary to work with the power on, exercise care to

avoid being caught in the scanning rear of the exposure

unit.

2. Special care should be taken when handling the fixing unit

since it operates at extremely high temperatures.

3. The developing unit is surrounded by a strong magnetic

field. Keep watches and metering equipment away from

it.

4. Avoid scarring the drum with tools or similar objects.

5. Do not touch IC pins with your bare hands.

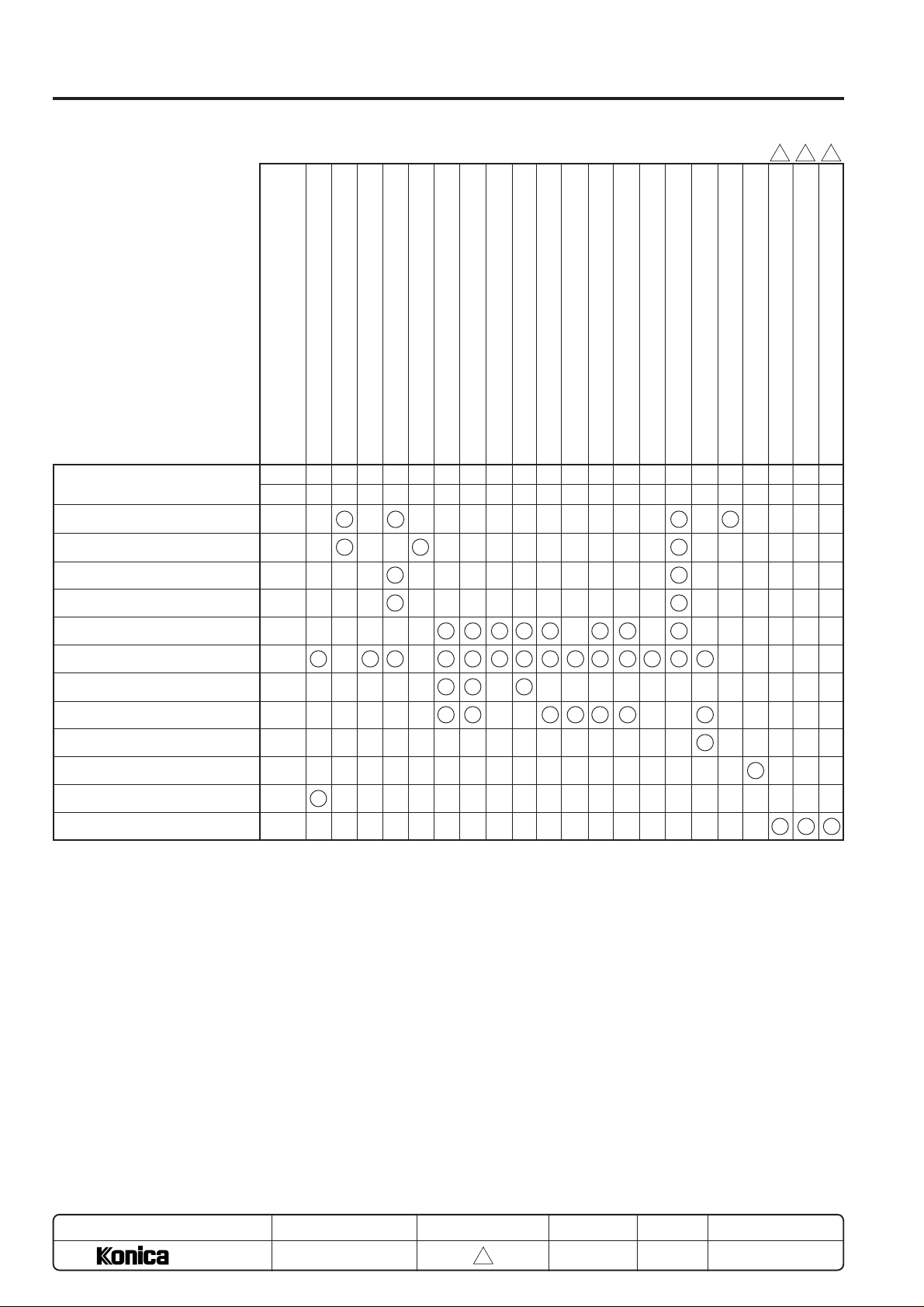

ADJUSTMENTS WHEN REPLACING PARTS

Adjustments (including checks) and settings are not only

required when a defective copy image occurs, but also after

replacing or reinstalling certain parts.

[How to Use the Tables]

The following items are used in the tables throughout this

section.

1. Mode

Indicates the adjustment mode.

[“25”] : 25 mode

[“36”] : 36 mode

[“47”] : 47 mode

2. Codes

Indicates the applicable code and/or Copy Quantity Setting

button for each mode.

3. Conditions

New: Indicates adjustment (including check) is required when

replacing a new part.

Reset: Indicates adjustment (including check) is required when

a part has been re-installed.

4. Symbols used in the tables

1 2 : .................. Indicates there is a priority sequence for

adjustments (including checks) and settings.

(Empty circle): Indicates adjustments (including checks)

and settings that can be carried out independently.

5 - 1

ADJUSTMENT

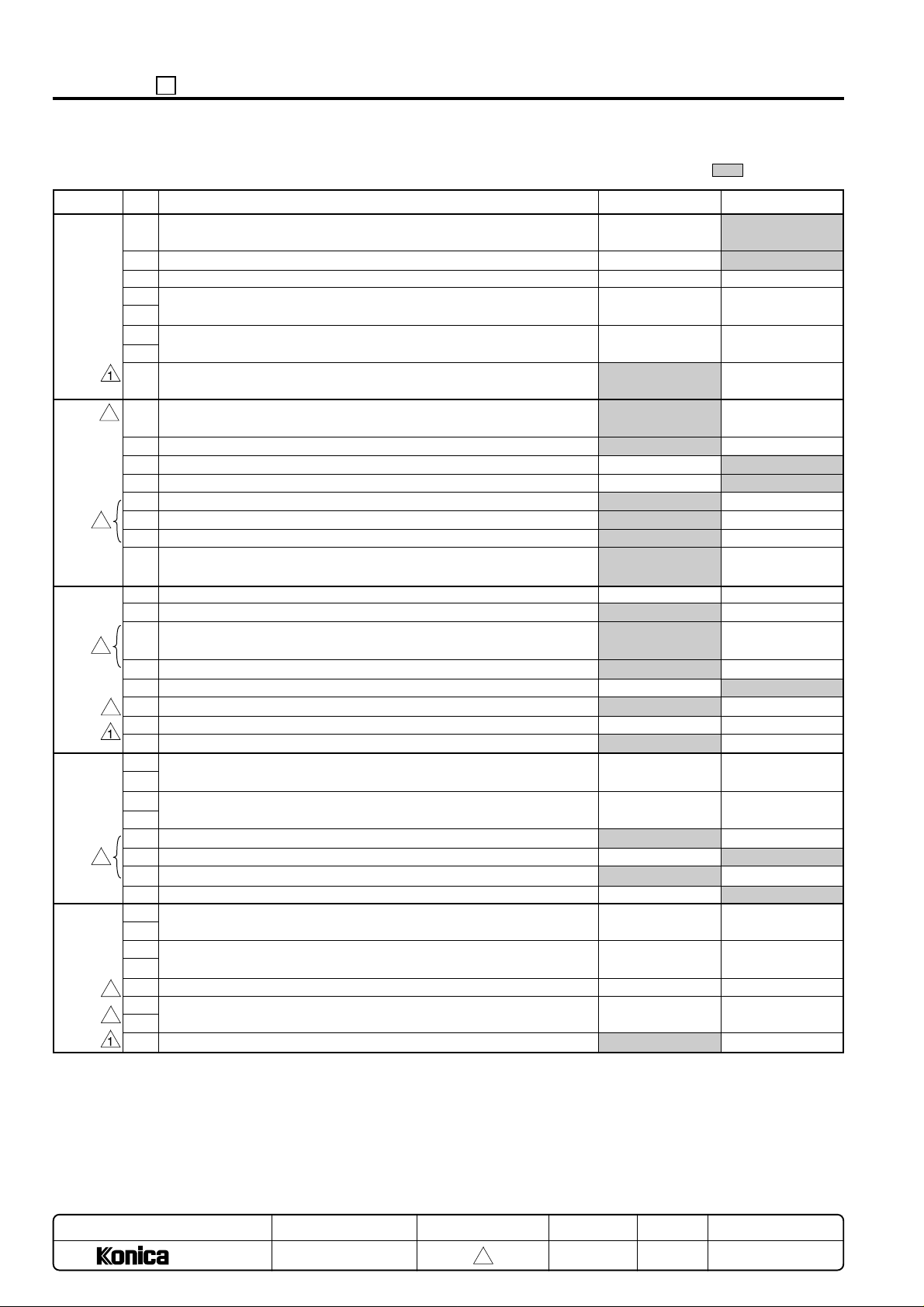

LIST OF ADJUSTMENT ITEM

Adjustment items

Tray size setting

PM count reset

PM cycle set

Charging grid voltage adjustment

L detection adjustment

Vertical magnification adjustment (Printer, Platen)

Drum

Part Name

Mode

Code252

New

25

3-1253-2361361362-1362-1362-1362-2362-2362-3362-4362-5362-6366-1366-24791-147198

2

Vertical magnification adjustment (RADF)

Horizontal magnification adjustment (Platen)

Restart timing adjustment (copier system)

Restart timing adjustment (RADF)

Paper feed loop amount adjustment

Leading edge original erasure adjustment

Centering adjustment

Image read point adjustment

PWM/Gamma correction

3

33 3

RADF scanning density adjustment

Drum count reset

Electrical RDH memory check

RADF sensor adjustment

RADF Original size adjustment (small size).

RADF Original size adjustment (large size).

47

47

69 00

47

69 01

69 02

1

Developer

Charging control plate

High voltage unit 1

Write unit

Parameter memory board

Rubber roller for paper feed unit

RADF

RADF slit glass (original glass (1))

Expansion memory

LCT (DB-608) paper size setting

DF control board

New

New

New

New/

Reinstall

New

New

New/

Reinstall

New

New/

Reinstall

–

New

1

1

1

4

1

2

3

1

2

∗

1

1

3

2

2

5

4

536

3

6

7

7

869

4

5

2

2

2

7

123

• “New” means replace with a new part and “Reinstall” means to reinstall the part.

• The circles will above a number when there is as adjustment priority.

∗ When the parameter memory board is renewed or replaced, remember to renew the developer also before conducting the L-

detection adjustment.

MODEL

7040

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 2

3

DATE

Mar. 1999

PAGE

5-2

METHOD

REPLACEMENT

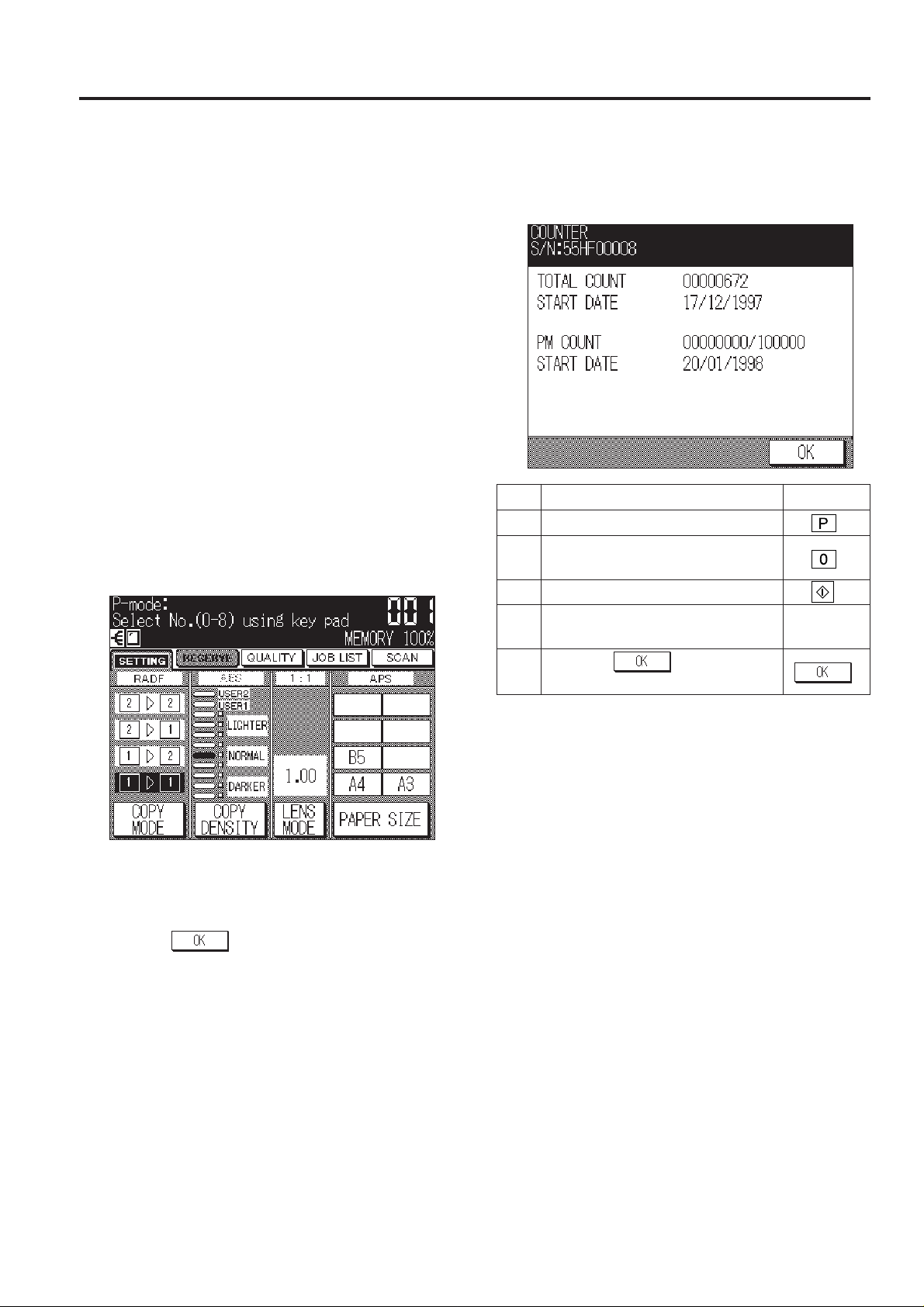

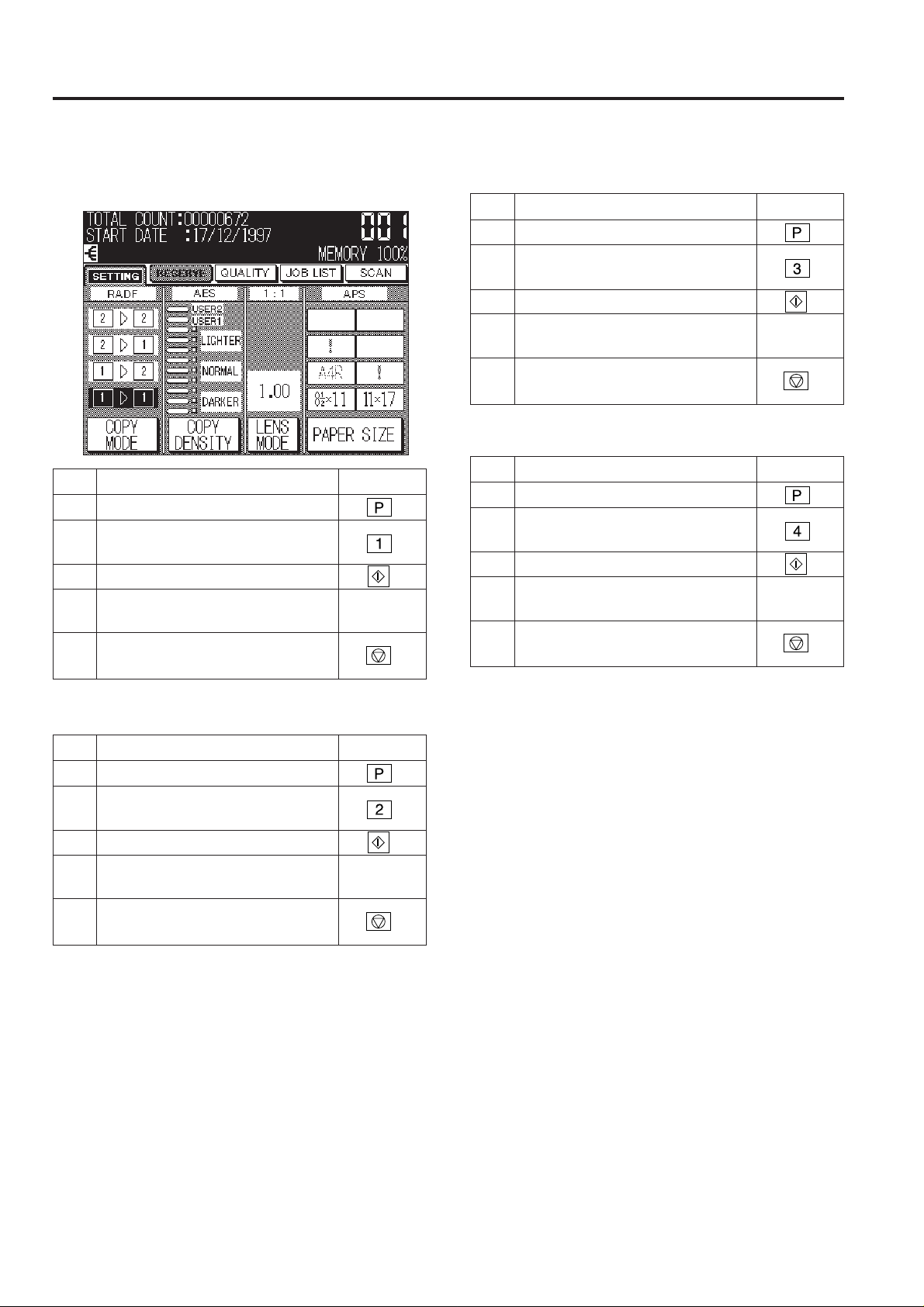

SETTING AND CHECKING WITH P FUNCTION

ADJUSTMENT

The P function enables display of the following parameters

using the P button.

0. Checking all counter data information

1. Checking the total count / start date

2. Checking the PM count / start date

3. Checking the Drum count

4. Checking the developing count

5. Checking or Setting the density shift (text/photo)

6. Checking or Setting the density shift (text)

7. Checking or Setting the density shift (photo)

8. Checking or Setting the density shift (Increase contrast)

This section explains the various functions which is exclusive

for the service technician.

For those used by the users, refer to “Operation section”.

[1] P Button Operating Procedure

a. Turn ON the SW1 (main power) and SW2 (sub power) to

display the basic screen.

b. Press the P button.

c. The P Mode Screen will appear.

[P Mode Screen]

[2] Checking All Counter Data Information

Display the total count, PM count and start date.

[Counter Check Screen]

OperationStep Operation procedure

1 Press the P button.

2 Press 0 from the copy quantity setting

button.

3 Press the Start print button.

4 Check the all counter data information

displayed in the message area.

5 Press the

basic screen.

key to return to

d. Use the copy quantity setting buttons to enter the desired

number, following the message on the operation panel.

e. Press Start print button to confirm the various data dis-

played in the message area.

f. Press the

the basic screen.

key or Stop/Clear button to return to

5 - 3

ADJUSTMENT

[Total Count / Start Date Check Screen]

[5] Checking the Drum Count[3] Checking the Total Count / Start Date

OperationStep Operation procedure

1 Press the P button.

2 Press 3 from the copy quantity setting

button.

3 Press the Start print button.

4 Check the drum count displayed in the

message area.

5 Press the Stop/Clear button to return

to the basic screen.

[6] Checking the Developing Count

OperationStep Operation procedure

1 Press the P button.

2 Press 1 from the copy quantity setting

button.

3 Press the Start print button.

4 Check the total count displayed in the

message area.

5 Press the Stop/Clear button to return

to the basic screen.

[4] Checking the PM Count / Start Date

OperationStep Operation procedure

1 Press the P button.

2 Press 2 from the copy quantity setting

button.

3 Press the Start print button.

4 Check the PM count displayed in the

message area.

5 Press the Stop/Clear button to return

to the basic screen.

OperationStep Operation procedure

1 Press the P button.

2 Press 4 from the copy quantity setting

button.

3 Press the Start print button.

4 Check the developing count displayed

in the message area.

5 Press the Stop/Clear button to return

to the basic screen.

5 - 4

ADJUSTMENT

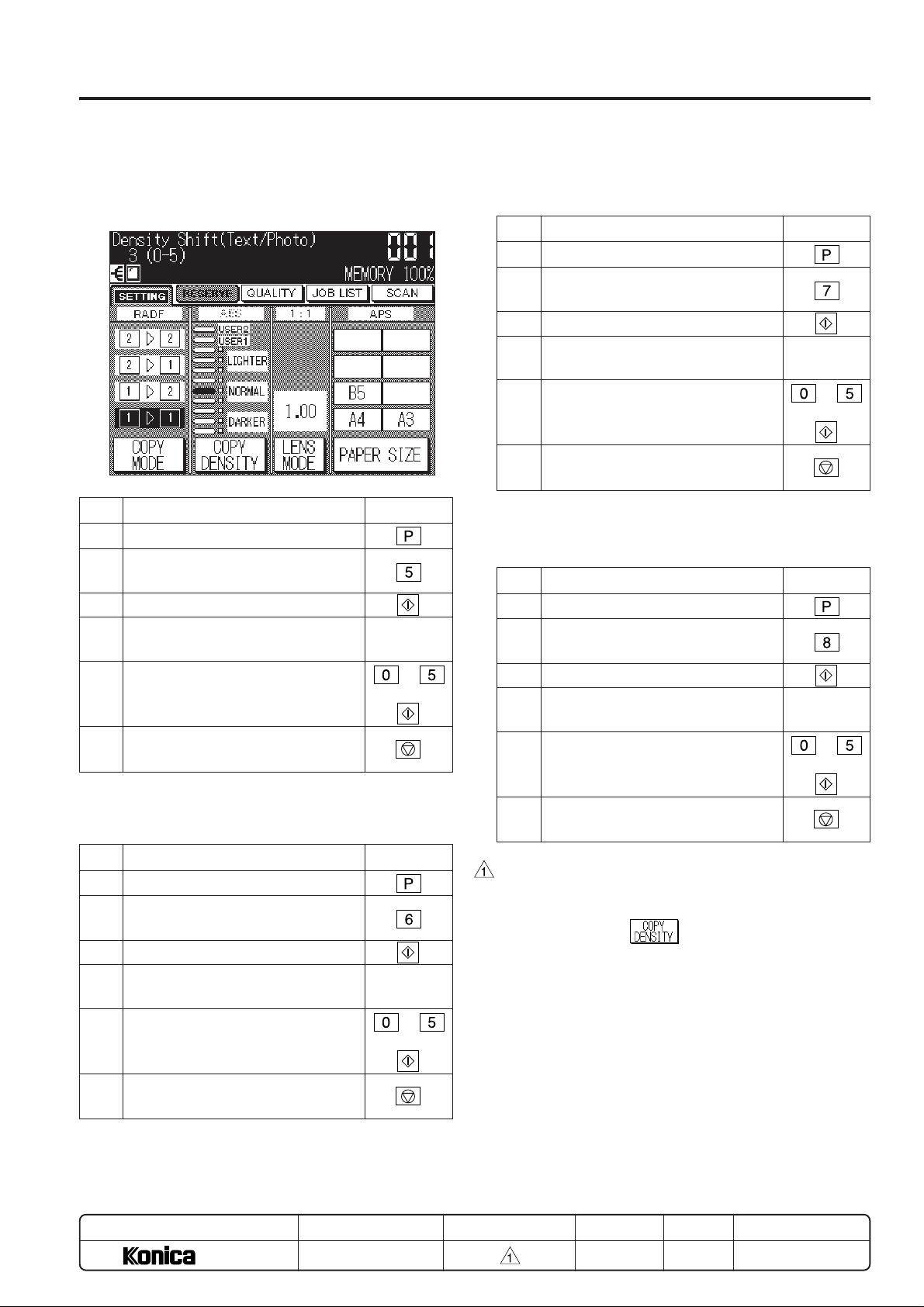

[7] Checking or Setting the Density Shift

(text/photo) (*1)

[Density Shift (text/photo) Check Screen]

Step Operation procedure

1 Press the P button.

2 Press 5 from the copy quantity setting

button.

3 Press the Start print button.

4 Check the density shift (text/photo)

displayed in the message area.

5 When changing the setting, enter a

value from the copy quantity setting

button and press the Start print button.

6 Press the Stop/Clear button to return

to the basic screen.

Operation

to

+

[8] Checking or Setting the Density Shift

(text) (*1)

[9] Checking or Setting the Density Shift

(photo) (*1)

Step Operation procedure

1 Press the P button.

2 Press 7 from the copy quantity setting

button.

3 Press the Start print button.

4 Check the density shift (photo) dis-

played in the message area.

5 When changing the setting, enter a

value from the copy quantity setting

button and press the Start print button.

6 Press the Stop/Clear button to return

to the basic screen.

Operation

to

+

[10] Checking or Setting the Density Shift

(Increase contrast) (*1)

Step Operation procedure

1 Press the P button.

2 Press 8 from the copy quantity setting

button.

3 Press the Start print button.

4 Check the density shift (Increase con-

trast) displayed in the message area.

5 When changing the setting, enter a

value from the copy quantity setting

button and press the Start print button.

6 Press the Stop/Clear button to return

to the basic screen.

Operation

to

+

Step Operation procedure

1 Press the P button.

2 Press 6 from the copy quantity setting

button.

3 Press the Start print button.

4 Check the density shift (text) displayed

in the message area.

5 When changing the setting, enter a

value from the copy quantity setting

button and press the Start print button.

6 Press the Stop/Clear button to return

to the basic screen.

MODEL

7040

SERVICE HANDBOOK

Operation

to

+

REVISED EDITIONMANUAL

• Setting value can be set each mode individually.

• Decreasing the setting value darken the copy density.

• When changing the setting value, all density area that

can be set with the

• Decreasing the setting value (copy density is darker) increase the toner consumption for one copy.

5 - 5

DATE

MAR. 1998

key is changed.

PAGE

5-5

REPLACEMENT

METHOD

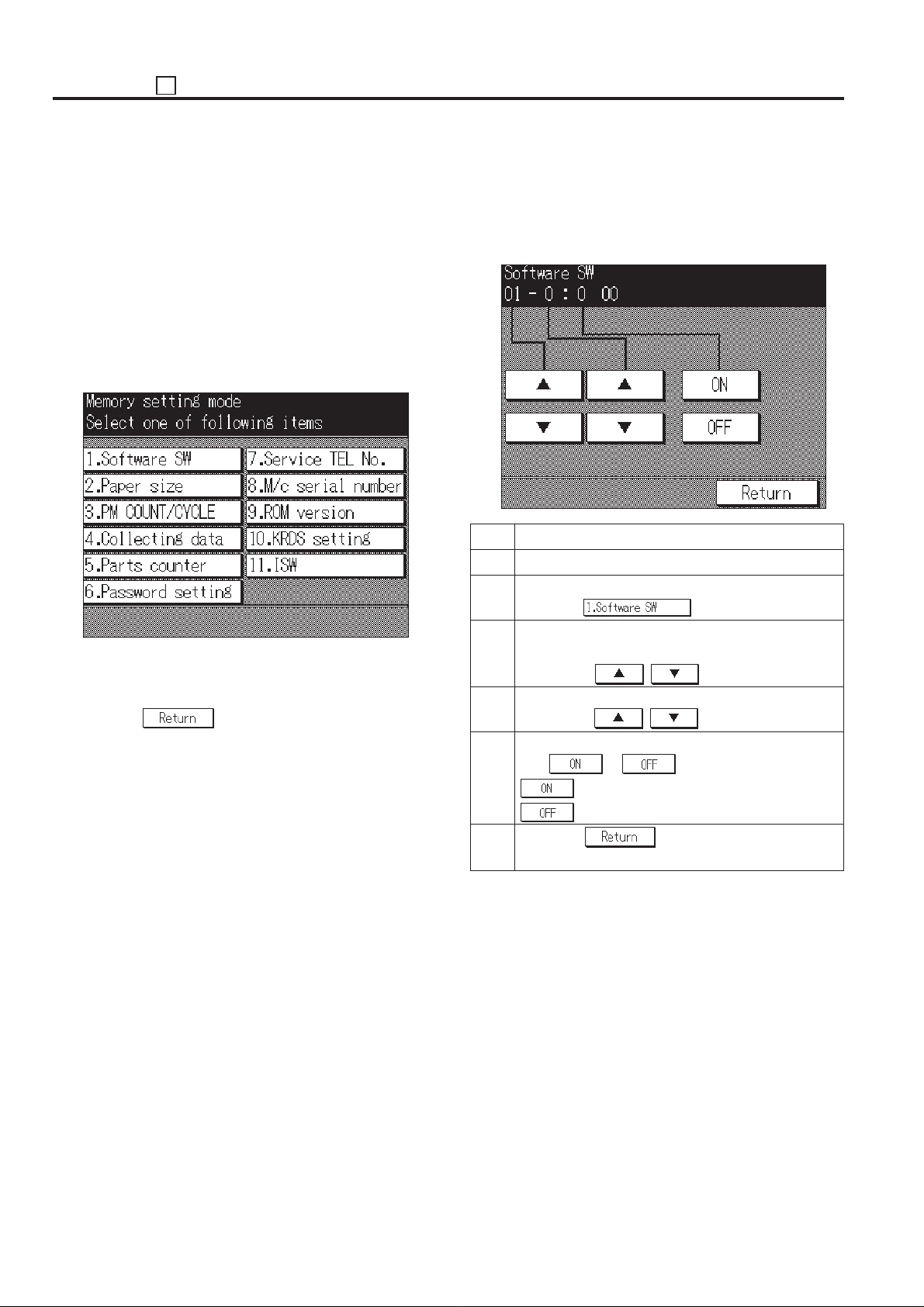

ADJUSTMENT 25

25 MODE

[1] Setting Method

A special operating mode called “25 Mode” has been provided

with this machine. This mode enables rewriting of the nonvolatile storage and specify other various settings.

1. Turn OFF the SW2 (sub power) when the SW1 (main

power) remains ON.

2. Turn the SW2 (sub power) ON while pressing 2 and 5 of

the copy quantity setting buttons. The 25 mode menu

screen will appear.

In the 25 mode normal copy operation becomes unavailable.

[25 MODE MENU SCREEN]

3. Press the desired item key on the LCD screen.

Each setting screen will appear.

4. Enter data in each selected screen.

5. Press the

entered.

6. Turn the SW2 (sub power) off to cancel the 25 mode.

7. New data will be effective after restarting.

key to check the data that has been

[2] Setting Software DIP SW

1. Setting method

This setting specifies the software DIP switch on the software

SW setting screen. (*1)

[Software SW setting screen]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the key.

3 [Software SW setting screen]

Select DIP switch number.

Use the left , key.

4 Select bit number of the DIP switch.

Use middle , key.

5 Select ON (=1) or OFF (=0) of the DIP switch.

Use or key.

: Set bit.

: Clear bit.

6 Press the key to return to the 25 mode

menu screen.

5 - 6

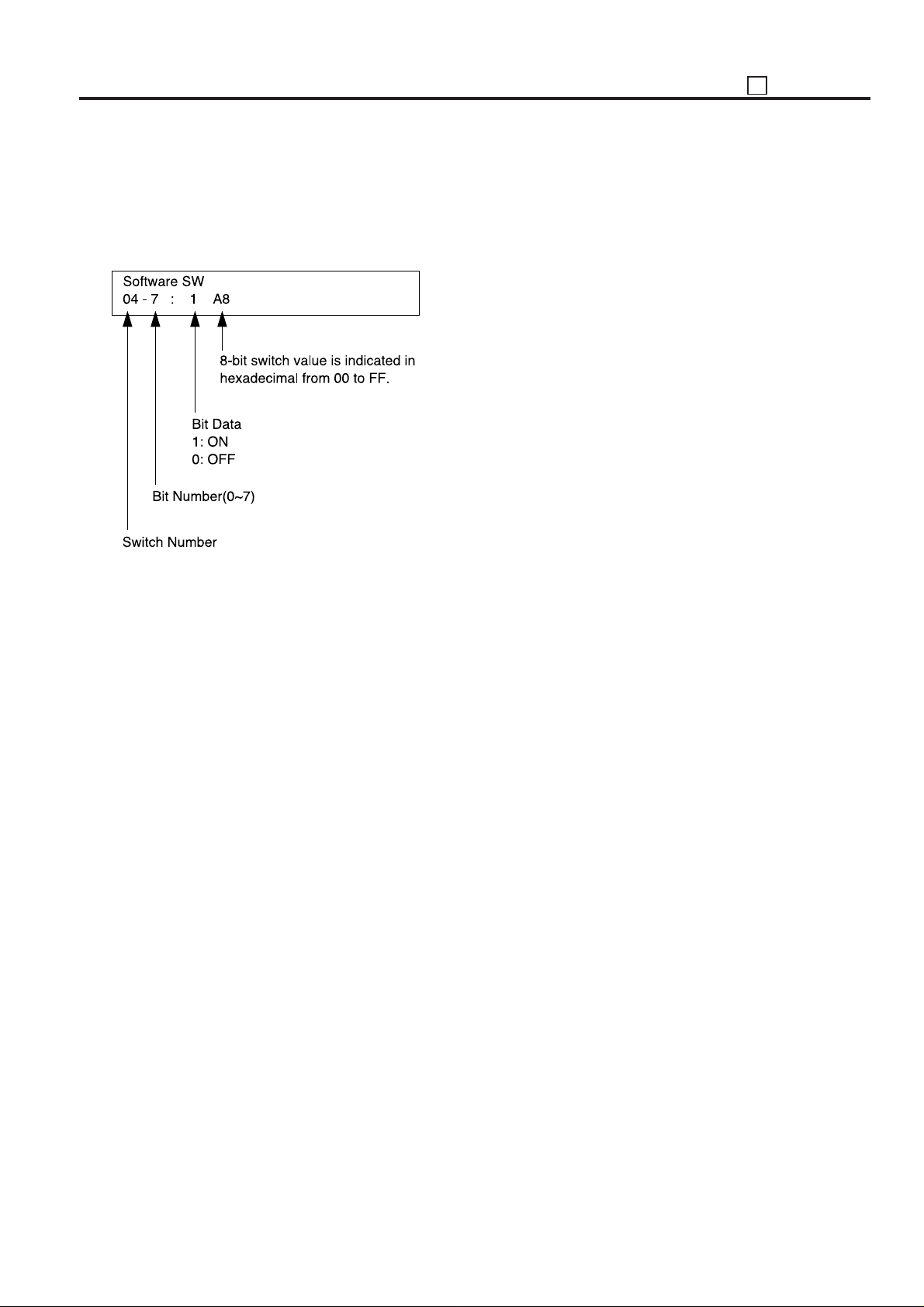

*1:

• The bit of the DIP switch is written in the non-volatile RAM

every time it is changed.

• The numbers shown in the message area are defined as

follows:

25 ADJUSTMENT

For each switch function, refer to “List of Software SW”.

5 - 7

ADJUSTMENT 25

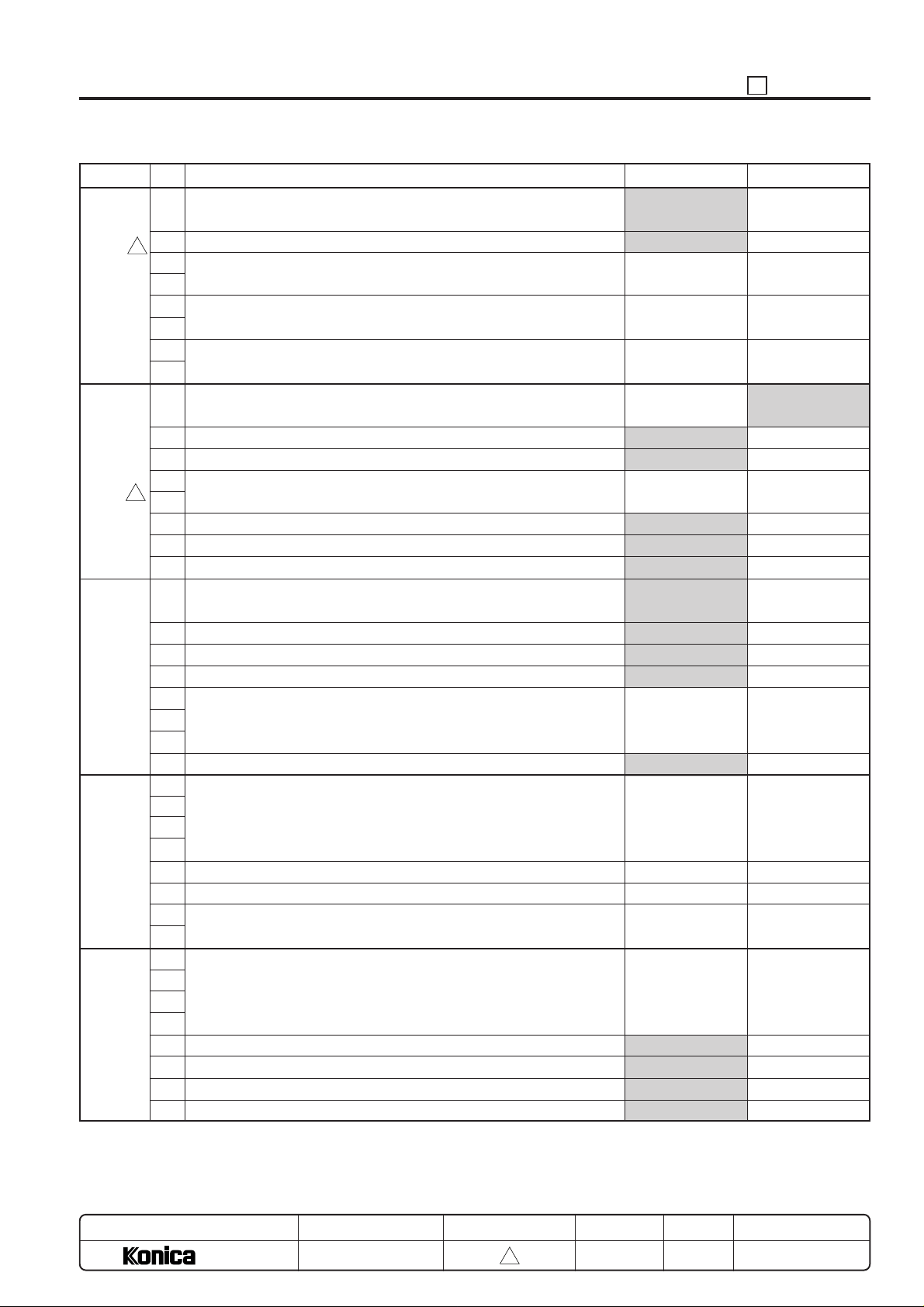

<List of Software SW> : Default value

DIPSW No.

DIPSW1

3

DIPSW2

3

3

DIPSW3

3

DIPSW4

3

DIPSW5

3

3

BIT

Operation when key counter is removed

0

A3 (11x17) count method

1

Function

2

Selection of maximum number of copies that can be stapled by FS-105

3

(for plain paper)

4

Selection of maximum number of copies that can be stapled by FS-105

5

(for thick paper)

6

Limitation of the number of the stapled copies set

7

Toner out halt condition 1

0

1

2

3

Folded original mode

4

Message for staple automatic release (1 shot) indication

5

Prohibit rotation key indication

6

Prohibition of non-image area erases, repeat (auto) and original posi-

7

tion correction

0

F34/F35/F36 latch

1

Toner out halt condition 2

2

EKC password image restore period for copy reservation.

3

4

By-pass feed non-standard size selection.

5

6

7

Toner level detection (“Supply toner” indication)

0

1

Number of copies allowed before machine stops after “Supply Toner”

2

indication.

3

Reserve list priority, delete key indication.

4

Prohibition of copy operation at low toner detection

5

Copy reservation for coin vendor use.

6

Image quality screen OK key display

7

Destination switchover

0

1

F4 size setting

2

3

RADF 8.5 x 11 size detection (At PS303 detection)

4

5

Fixing control temperature change.

6

Halftone fixing remedy (When the machine is not turned on for a long period.)

7

0

Ignore

Count as 1

*1

*2

No limit

Priory to DIP SW3-2

Do not change

Do not use

Do not use

No

Yes

No

No

No

When job completed

Normal

Do not use

No

Do not change

*3

*4

Display

No

Possible (Enabled)

Yes

*5

*6

8.5x11

*21

No

1

Instantaneous

stop jam

Count as 2

*1

*2

Temporary stop at

25 set

Immediately halts

after exiting paper

Do not use

Do not change

Do not change

Yes

No

Yes

Yes

Yes

At where number

of copies end

Immediately resumes

Do not change

Yes

Do not use

*3

*4

No Display

Yes

Not possible (Disabled)

No

*5

*6

11x17

*21

Yes

MODEL

7040

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 8

3

DATE

Mar. 1999

PAGE

5-8

METHOD

REPLACEMENT

25 ADJUSTMENT

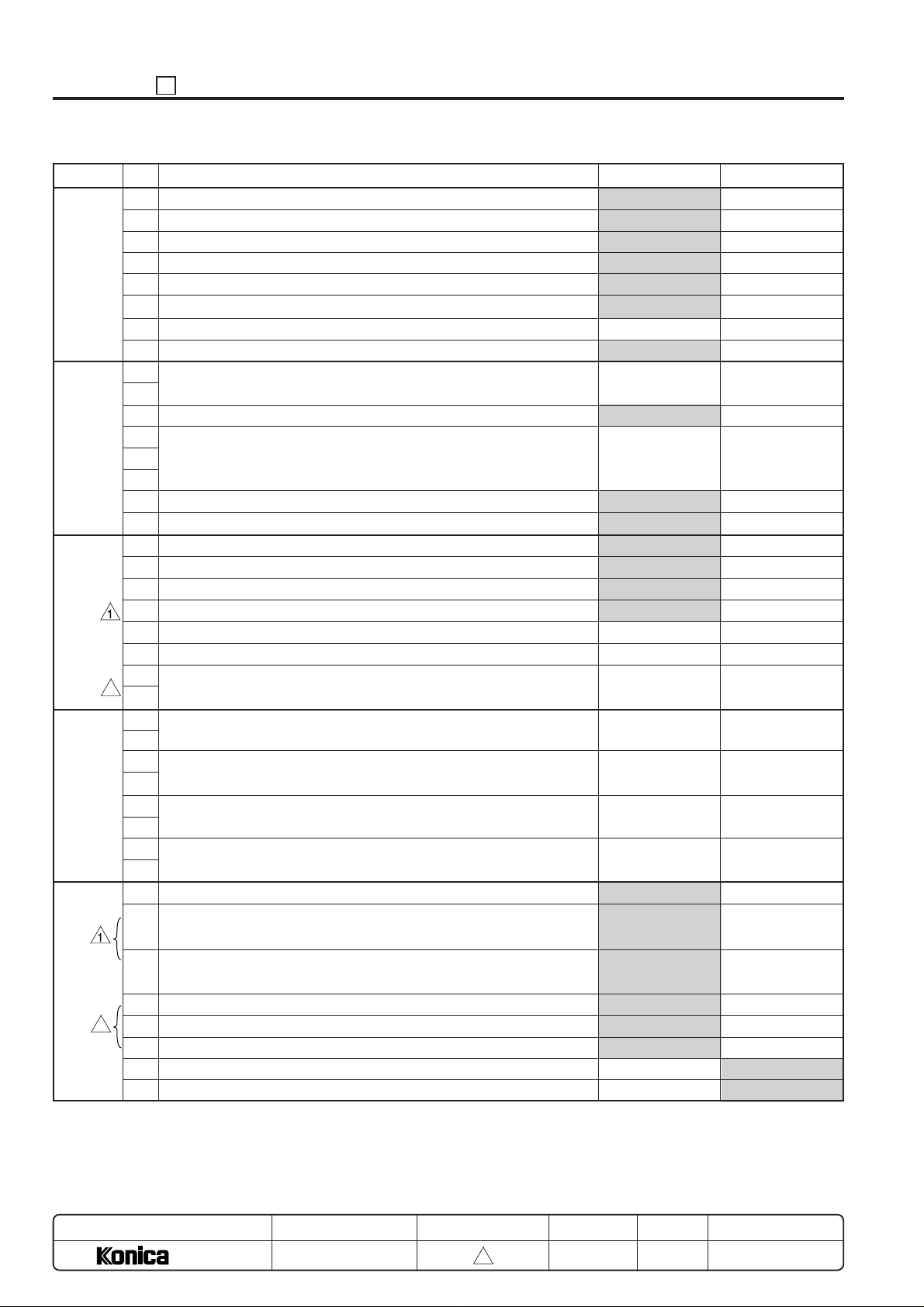

DIPSW No.

3

DIPSW6

DIPSW7

3

DIPSW8

DIPSW9

DIPSW10

BIT

0

Prevention of image faulty at high temperature and high humidity.

(When the machine is not turned on for a long period.)

1

K size selection (for Taiwan)

2

Paper feed control for thick paper

3

4

Polygon motor low speed rotation timing

5

6

Polygon motor low speed rotation selection

7

0

Judging of Image erase area

1

Selection of auto restart when paper is replenished.

2

8.5x11 APS (Japan, Europe), A4 APS (U.S.A.)

3

Non-standard size original platen APS

4

(When original is set more than 30mm away from scale plate)

5

Password request for 25/36/47 mode (Password: 9272)

6

Selection of A series size (European version)

7

Setting of displaying the full-auto screen

0

Selection of non-image area erase mode

1

Changing of key operator fixed magnification setting

2

Disabling copying when PM count reached.

3

Adjusting of LCD contrast to help screen.

4

Priority tray when APS is released.

5

6

7

Data collection (25 mode)

0

Selection of copy quantity limit

1

2

3

4

5

Message selection for P81

6

7

Setting of weekly timer daylight saving time

0

1

2

3

Selection of magnification mode when APS function is canceled.

4

Selection of setting screen message.

5

Displaying of icon to line 3

6

Displaying of JAM code

7

Function

0

Yes

AB type size

*7

*8

*9

Original size priority

No

Yes

*10

No

No

Yes

Rectangle erasure

Permit

Permit

No

*11

No

*12

*13

*14

Auto mode

Guidance display

No

No

1

No

K size

*7

*8

*9

Paper size priority

Yes

No

*10

Yes

Yes

No

Erasure for obliquely

placed original

Prohibit

Prohibit

Yes

*11

Yes

*12

*13

*14

Life size (1:1)

Machine state display

Yes

Yes

MODEL

7040

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 9

3

DATE

Mar. 1999

PAGE

5-9

METHOD

REPLACEMENT

ADJUSTMENT 25

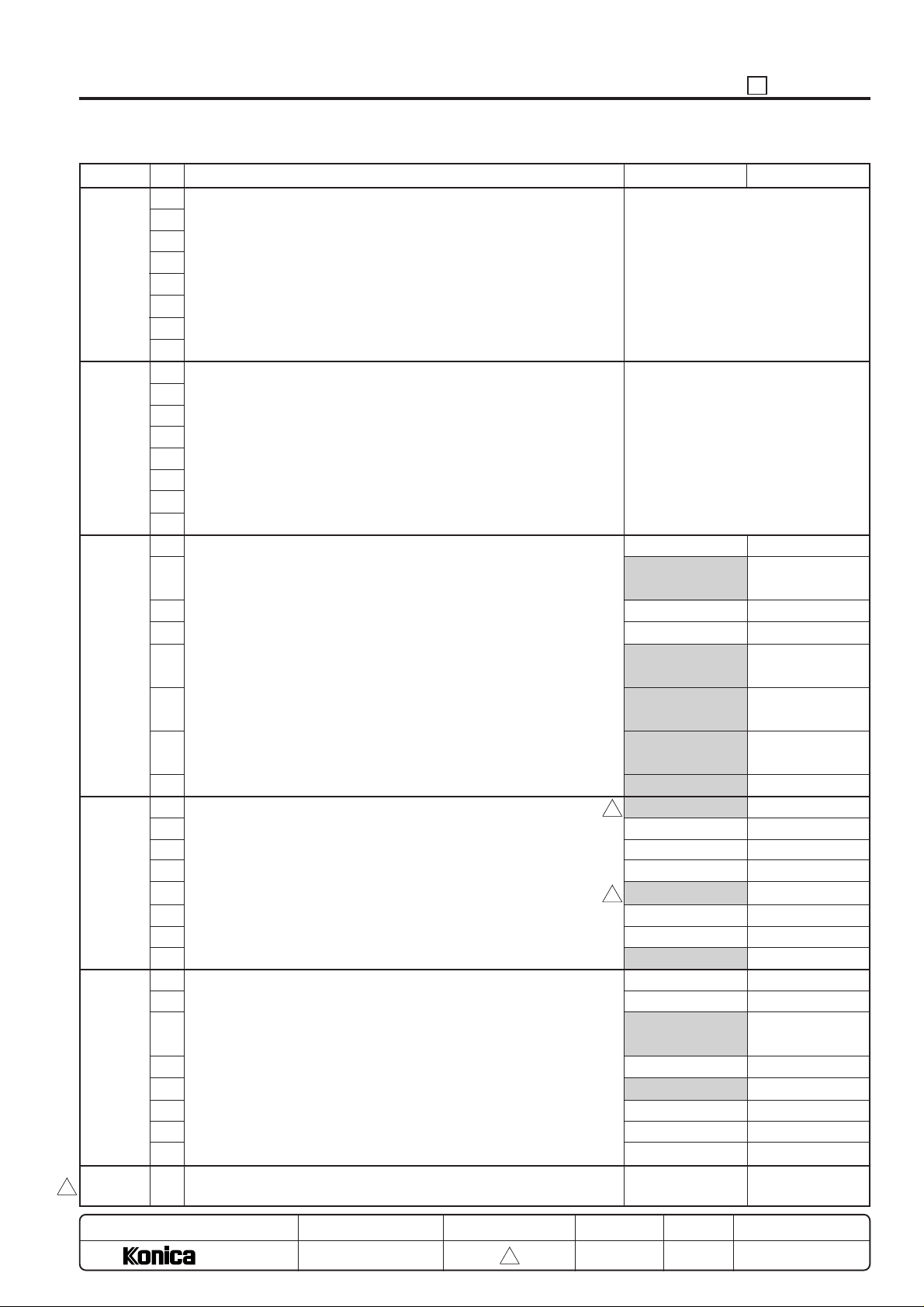

DIPSW No.

DIPSW11

DIPSW12

DIPSW13

3

DIPSW14

DIPSW15

3

BIT

Tray screen OK key display

0

Magnification screen OK key display

1

Density screen OK key display

2

Copy mode screen OK key display

3

No “OK” switchover time

4

5

6

7

Initial copy mode

0

1

Initial image scanning mode

2

Setting of PM count at which copying is inhibited.

3

4

5

KRDS connection recognition

6

F/E screen switchover (except for F34, F35 and F36)

7

0

1

2

Fine line width smoothing filter

3

4

5

Non-original deletion threshold value change.

6

7

Operation when stapling is inhibited. (large size: except for A5R, B5R,

0

5.5x8.5R)

1

Operation when stapling is inhibited. (small size: except for A5R, B5R,

2

5.5x8.5R)

3

Operation without staple clip at an applicable position when the 1-

4

position stapling is selected.

5

Operation without staple clip at an applicable position when the 2-

6

position stapling is selected.

7

0

Waiting the print start at the copy reservation

1

(Countermeasure against paper wrinkling by the fixer).

Waiting the print start other than the copy reservation

2

(Countermeasure against paper wrinkling by the fixer).

Universal tray switch screen.

3

Face up paper exit selection during by-pass feed selection (Tray 1 or no FNS)

4

Universal tray switch screen A type row display.

5

Finisher tray 1 full-stack detection & auto tray switching.

6

Auto tray switching when finisher tray 2/3 full-stack is detected.

7

Function

0

Yes

Yes

Yes

Yes

Short

Do not change

Do not change

*15

RADF

*16

Not connect

No

Do not change

Do not change

Do not change

ON

*22

*17

*18

*19

*20

Do not change

Not waiting

Not waiting

Yes

Yes

Yes

No

No

1

No

No

No

No

Long

Do not use

Do not use

*15

Platen

*16

Connect

Yes

Do not used

Do not used

Do not used

OFF

*22

*17

*18

*19

*20

Do not used

Waiting

Waiting

No (special display)

No

No

Yes

Yes

MODEL

7040

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 10

3

DATE

Mar. 1999

PAGE

5-10

METHOD

REPLACEMENT

25 ADJUSTMENT

DIPSW No.

DIPSW16

DIPSW17

DIPSW18

DIPSW19

DIPSW20

DIPSW21

3

DIPSW24

BIT

Separation claw ON timing (400 dpi)

0

1

2

3

4

5

6

7

Separation claw OFF timing (400 dpi)

0

1

2

3

4

5

6

7

Unit isolation (1)

0

1

2

3

4

5

6

7

Unit isolation (2)

0

1

2

3

4

5

6

7

Unit isolation (3)

0

1

2

3

4

5

6

7

Preliminaries

~

-

Function

Separation claw ON timing (400 dpi)

Enter setting value by binary number.

Default value: 56 (111000)

Separation claw OFF timing (400 dpi)

Enter setting value by binary number.

Default value: 85 (1010101)

Tray 2 (copier) can

be used.

Tray 3 (DB upper)

can be used.

Tray 4 (DB middle) can be used.

Tray 5 (DB lower)

can be used.

DB can be used.

Printer board can be used

3

ADU can be used

3

RADF can be used.

Finisher tray 2/3

can be used.

Stapler can be used.

0

–

Tray 2 (copier) is

isolated.

Tray 3 (DB upper)

is isolated.

Tray 4 (DB middle) is isolated.

Tray 5 (DB lower)

is isolated.

DB is isolated.

Printer board is isolated

ADU is isolated

RADF is isolated.

Finisher tray 2/3

are isolated.

Stapler is isolated.

–

1

–

–

MODEL

7040

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 11

3

DATE

Mar. 1999

PAGE

5-11

METHOD

REPLACEMENT

ADJUSTMENT 25

*1: Selection of maximum number of copies that can be

stapled by FS-105 (for plain paper)

Mode

50 copies

45 copies

40 copies

35 copies

*2: Selection of maximum number of copies that can be

stapled by FS-105 (for thick paper)

Mode

20 copies

15 copies

25 copies

10 copies

*3: Toner level detection (“Supply toner” indication)

Mode

After 100 copies

After 1000 copies

After 2000 copies

After 3000 copies

3

*4: Number of copies allowed before machine stops after

“Supply Toner” indication.

Mode

0

1000

2000

3000

3

*5: Destination switchover

Mode

Japan

U.S.A.

Europe

Taiwan

1-4 1-3

00

01

10

11

1-6 1-5

00

01

10

11

4-1 4-0

00

01

10

11

4-3 4-2

00

01

10

11

5-1 5-0

00

01

10

11

*7: Paper feed control for thick paper

Mode

Normal

30 PPM

20 PPM

3

*8: Polygon motor low speed rotation timing

Mode

15 sec after job is completed

30 sec after job is completed

60 sec after job is completed

120 sec after job is completed

*9: Polygon motor low speed rotation selection

3

Mode

Low speed does not take place.

Low speed rotation; 20000 rpm

Stop

400 dpi rotation (33,070.9 rpm)

*10: Non-standard size original platen APS

Mode

Japan

U.S.A.

Europe

*11: Priority tray when APS is released

Mode

No preference

Lower tray; main body

DB1

DB2

DB3

Size

B5R

B6R

5.5 x 8.5R

8.5 x 11

B5R

A5R

8-6 8-5 8-4

000

010

011

100

101

6-3 6-2

00

01

10

6-5 6-4

00

01

10

11

6-7 6-6

00

01

10

11

7-4 7-3

00

10

00

01

00

10

*6: F4 size setting

Mode

8.5 x 13 (216 x 330)

8.25 x 13 (210 x 330)

8.125 x 13 (206 x 330)

8 x 13 (203 x 330)

MODEL

7040

5-3 5-2

00

01

10

11

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 12

3

DATE

Mar. 1999

PAGE

5-12

METHOD

REPLACEMENT

25 ADJUSTMENT

*12: Selection of copy quantity limit

Mode

Unlimited

1

3

5

9

10

20

30

50

99

*13: Message selection for P81

Set the key counter

Set the copy card

Insert a coin

*14: Setting of weekly timer daylight saving time

Mode

0 minutes

30 minutes

60 minutes

90 minutes

120 minutes

150 minutes

*15: Initial copy mode

*16: Setting of PM count at which copying is inhibited.

Mode

1000 copies

2000 copies

3000 copies

4000 copies

5000 copies

9-3 9-2 9-1 9-0

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

Mode

10-3 10-2 10-1 10-0

0000

0011

0110

1001

1100

1111

Mode

1-1

1-2

2-1

2-2

12-5 12-4 12-3

000

001

010

011

100

9-7 9-6

00

01

10

12-1 12-0

00

01

10

11

*17: Operation when stapling is inhibited. (large size)

Mode

Auto cancel

Auto switching to 1-position stapling

mode

Inhibit

Forced 2-position stapling mode operation

*18: Operation when stapling is inhibited. (small size)

Mode

Auto cancel

Inhibit

Forced 1-position stapling mode operation

*19: Operation without staple clip at an applicable position

when the 1-position stapling is selected.

Mode

Auto cancel

Inhibit

Forced 1-position stapling mode operation

*20: Operation without staple clip at an applicable position

when the 2-position stapling is selected.

Mode

Auto cancel

Inhibit

Forced 2-position stapling mode operation

*21: Fixing control temperature change

3

Mode

Normal control

+10°C

–10°C

Normal control

3

*22: Non-original deletion threshold value change.

Caution: Denser originals will be easier to detect as the

threshold value becomes smaller, however it will be

more susceptible to detection error from stray light.

Mode

Threshold value 80h

Threshold value 60h

Threshold value 50h

Threshold value 50h

14-1 14-0

00

01

10

11

14-3 14-2

00

10

11

14-5 14-4

00

10

11

14-7 14-6

00

10

11

5-6 5-5

00

01

10

11

13-7 13-6

00

01

10

11

MODEL

7040

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 13

3

DATE

Mar. 1999

PAGE

5-13

METHOD

REPLACEMENT

ADJUSTMENT 25

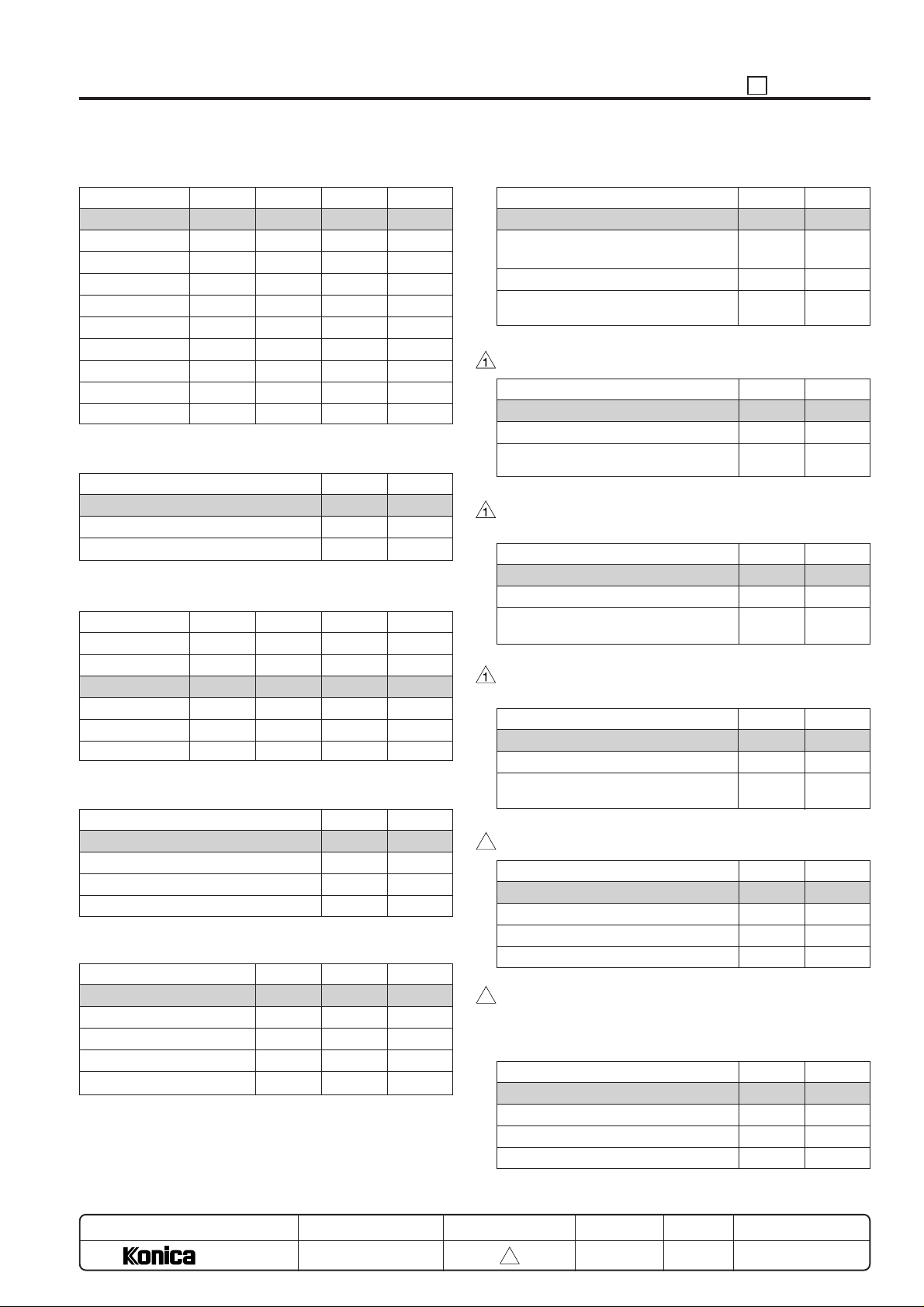

[3] Tray Size Setting

This function stores the paper size in the memory of the main

body if it has been changed .

[Tray size setting screen]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the

3 [ Tray size setting screen ]

Press the tray key to be changed.

4 Press the , key to select a paper size.

5 Press the key to return to the 25 mode

menu screen.

key.

Reference:

• Since the upper tray of the main body is the ADU, the

selection message is not displayed.

• When the DB-208 or DB-608 is not installed, the trays

of the DB section is not displayed.

• Availability of paper size depends on the selected

tray. The unavailable paper sizes will be skipped and

not displayed.

• New data on tray size will be written in non-volatile

RAM every time it is changed in this screen.

• The following table shows the paper sizes that can be

used in the LCT (DB-608).

Japan A4, A4R, B5, B5R, 8.5 x 11, 8.5 x 11R

Europe A4, A4R, B5, B5R, 8.5 x 11, 8.5 x 11R

U.S.A. 8.5 x 11, 8.5 x 11R, A4, A4R

Caution:

• The main body tray, all trays in the DB-208, the upper

tray of the DB-608 and the by-pass tray can not be

adjusted in the Non-volatile RAM. These trays detect

paper size via sensors.

• The size series of the universal tray can be selected

as follows.

· Destination setting

· AB series

· Inch series

• The screen is automatically changed from the optional

tray according to the type of trays.

5 - 14

25 ADJUSTMENT

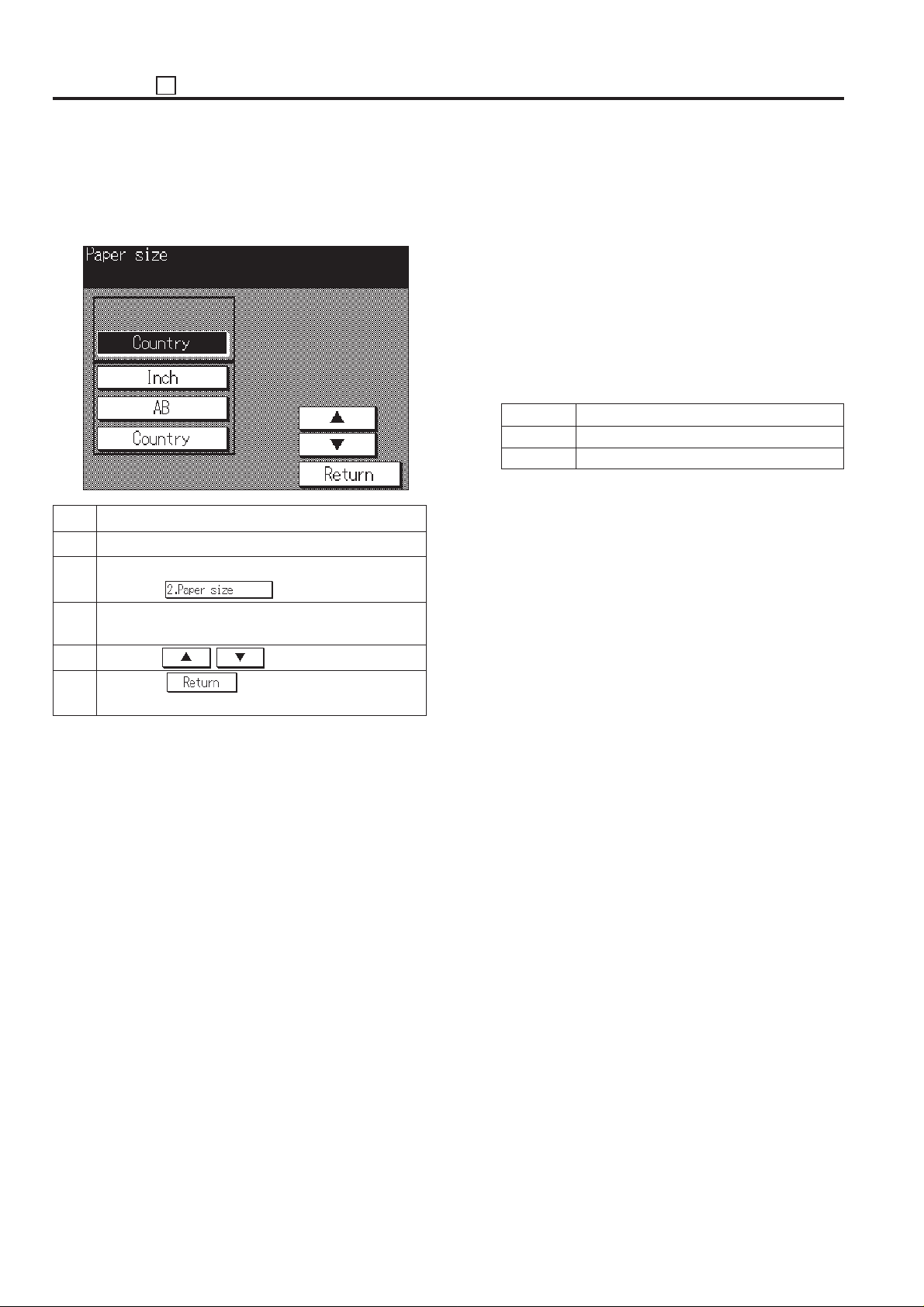

[4] PM Count Setting

This function resets the PM count and sets the PM cycle.

Care should be taken to reset the PM count properly.

[PM Count/Cycle setting menu screen]

1. PM count reset

Select whether to reset the count in the PM count reset screen.

[PM count reset screen]

2. Entering PM Count Start date

When resetting the PM count, it is necessary to input the start

date, and the screen below will appear automatically.

[PM Count Start date entering screen]

Step Operation procedure

1 [PM Count Start date entering screen]

Enter a PM count start date from the numeric key.

2 Press the

entered.

3 Press the key to return to the PM count/

cycle menu screen.

key to enter the data that has been

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the

3 [PM Count/Cycle Setting Menu Screen]

Press the key.

4 [PM count reset screen]

Press the key to reset the PM count.

Press the

count is not reset and to return to the PM count/cycle

setting menu screen.

key.

or key, then the PM

Caution: When pressing the key without press-

ing the

changed. It is necessary to reset the count again for

inputting the count.

key, the PM count start date is not

5 - 15

ADJUSTMENT 25

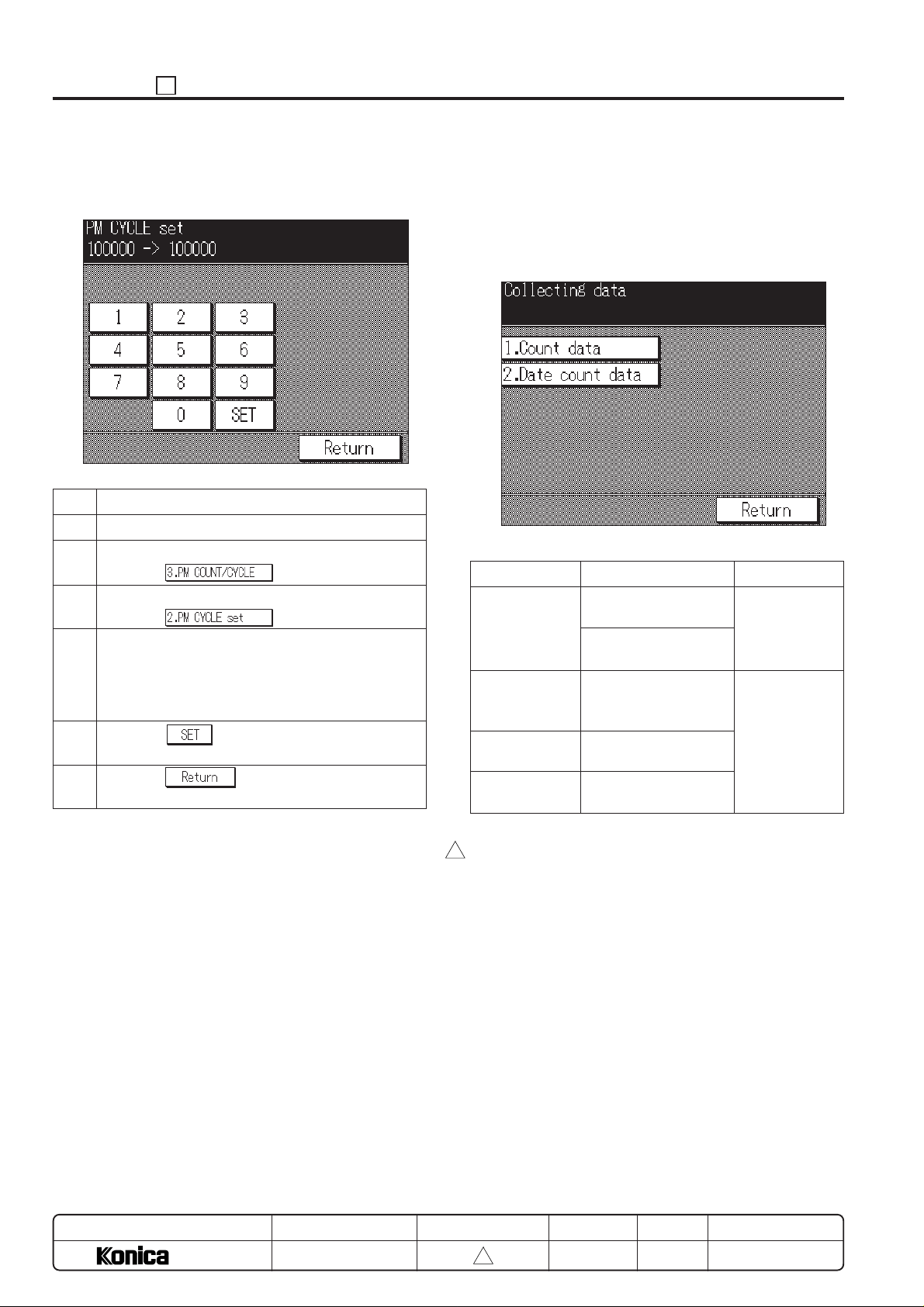

3. Setting PM cycle

This function sets the PM cycle.

[PM Cycle Setting Screen]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the

3 [PM Count/Cycle Setting Menu Screen]

Press the key.

4 [PM Cycle Setting Screen]

Enter PM cycle from the numeric key.

Enter upper 3-digit (hundred thousand, ten thou-

sand, thousand) only.

5 Press the

been entered.

6 Press the

cycle setting menu screen.

key to enter a PM cycle that has

key.

key to return to the PM count/

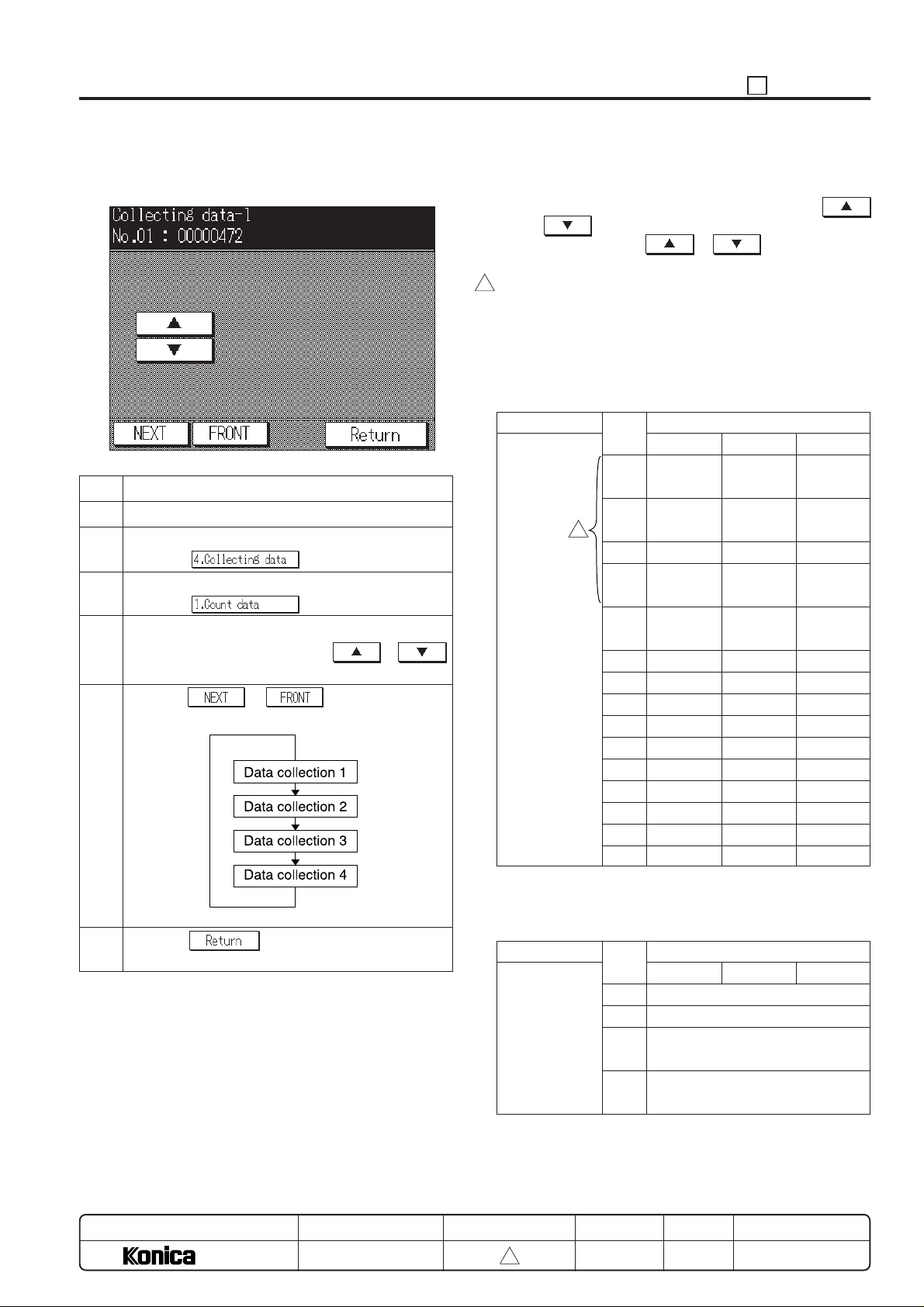

[5] Data Collection

This function enables viewing of the various data recorded in

the machine.

Also, it is possible for the collected data to be checked by KRDS

and management listing.

[Data collection menu screen]

<Data collection list>

Classification

Data collection 1

Data collection 2

Data collection 3

Data collection 4

Contents

Count number of copies by each size

Count RADF original

feed quantities

Count number of JAM

occurrence by each

point

Count number of copies by each mode

Count number of SC

occurrence

Pre-operation

– (*1)

Enter the 25

mode.

Select [1. Software SW].

Set the address

to 8-7:1 (*2)

MODEL

7040

MANUAL

SERVICE HANDBOOK

*1: Only data collection 1 can be checked in default.

*2: The setting is 25 mode, Dip-SW 8-7 to “1”.

3

REVISED EDITION

5 - 16

3

DATE

Mar. 1999

PAGE

5-16

METHOD

REPLACEMENT

25 ADJUSTMENT

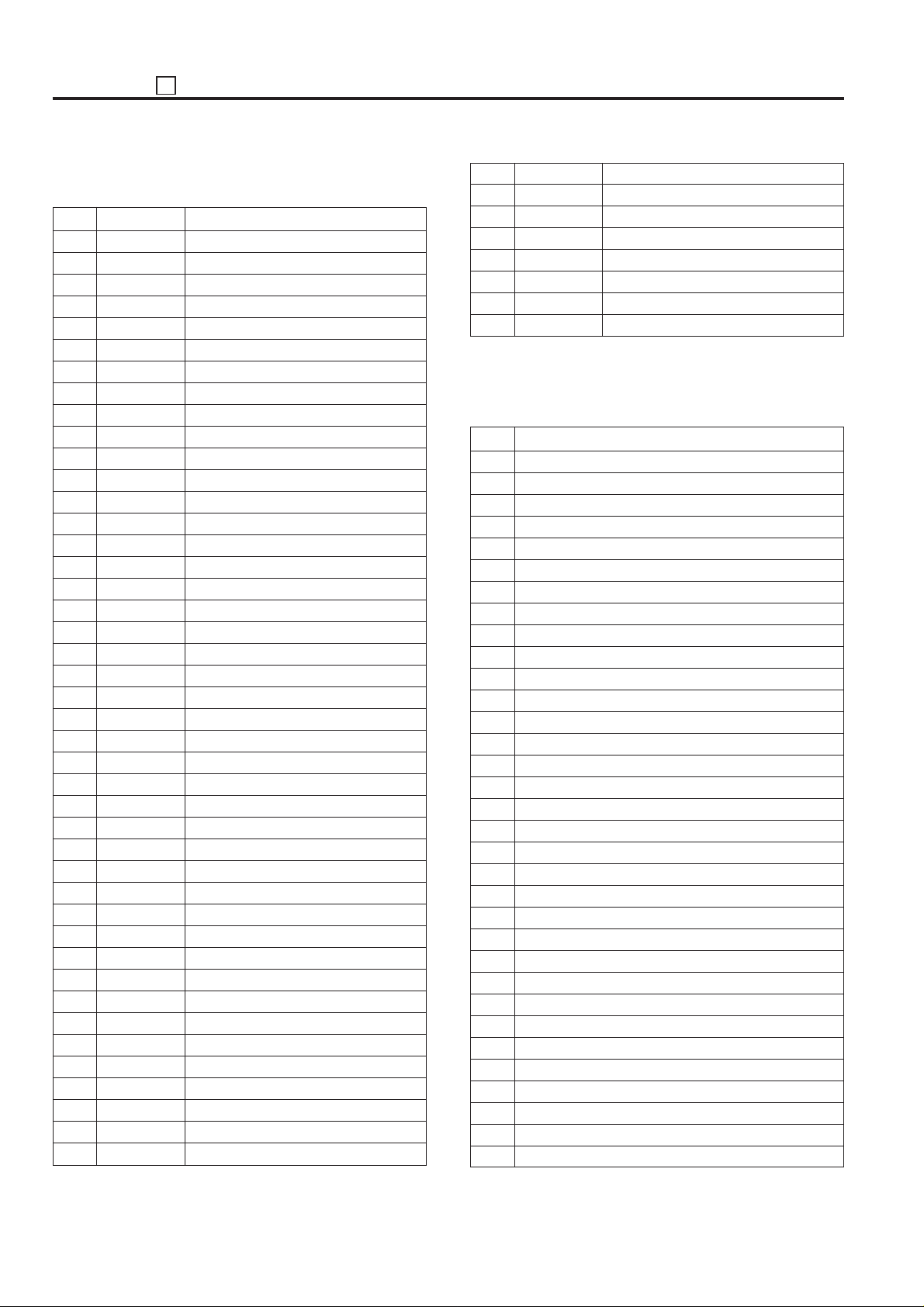

1. Operation procedure

[Data collection screen]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the key.

3 [Data collection menu screen]

Press the key.

4 [Data collection screen]

Change the data number with the

key.

5 Pressing or key enables to dis-

play next data collection screen. (*3)

or

(1) The data is displayed at the line 2 in the message display

area as “Data number (No.): Count value (000000)”.

(2) The data number can be changed by pressing the

or key.

(3) Press and hold the

next items continuously.

*3: In order to confirm collected data 2 to 4, set Dip-SW 8-7

3

to “1” beforehand.

or key to display the

2. Data collection details

(1) Data collection 1

a. Count number of copies by each size

Type

Count number

of copies by

each size

Size Paper size for destination

No. Japan Europe U.S.A

1 A4+A4R A4+A4R 8.5 x 11

2 B5+B5R B5+B5R 5.5 x 8.5

3

3 A5+A5R A5+A5R –

4 8.5 x 11 – –

+8.5 x 11R

5 AB series AB series Inch series

Special Special Special

6 A3R A3R 11 x 17R

7 A4R A4R 8.5 x 14R

8 A5R A5R 8.5 x 11R

9 B4R B4R 5.5 x 8.5R

10 B5R B5R –

11 B6R F4R –

12 Post card – –

13 – – –

14 8.5 x 11R – –

15 – – –

+8.5 x 11R

+5.5 x 8.5R

6 Press the key to return to the data collec-

tion menu screen.

MODEL

7040

MANUAL

SERVICE HANDBOOK

b. Count RADF original feed quantities

Type

Count RADF

original feed

quantities

REVISED EDITION

5 - 17

3

Maximum count number: 999,999

Size Paper size for destination

No. Japan U.S.A Europe

16 ADF mode original feed counter

17 RADF mode original feed counter

18 ADF mixed original mode original

feed counter

19 RADF mixed original mode

original feed counter

Maximum count number: 999,999

DATE

Mar. 1999

PAGE

5-17

METHOD

REPLACEMENT

ADJUSTMENT 25

(2) Data collection 2

Count number of JAM occurrence by each point

No. Jam Point

1 10-0 By-pass

2 11-0 –

3 12-0 Tray (main body)

4 13-0 DB upper tray

5 14-0 DB middle tray or LCT

6 15-0 DB lower tray

7 16-0 Paper feed jam

8– –

9– –

10 – –

11 30-0 Conveyance jam

12 31-0 Conveyance jam

13 – –

14 – –

15 32-0 Conveyance jam

16 33-0 Conveyance jam

17 34-1 Conveyance jam

18 34-2 Conveyance jam

19 34-3 Conveyance jam

20 34-4 Conveyance jam

21 34-5 Conveyance jam

22 97-1 Conveyance jam

23 92-0 Conveyance jam

24 – –

25 – –

26 61-0 DF-311

27 61-1 DF-311

28 62-0 DF-311

29 62-1 DF-311

30 62-2 DF-311

31 62-3 DF-311

32 62-4 DF-311

33 62-5 DF-311

34 63-0 DF-311

35 63-1 DF-311

36 63-2 DF-311

37 63-3 DF-311

38 63-4 DF-311

39 63-5 DF-311

40 63-6 DF-311

41 63-7 DF-311

42 72-10 FS-105

43 72-11 FS-105

No. Jam Point

44 72-12 FS-105

45 72-13 FS-105

46 72-14 FS-105

47 72-15 FS-105

48 72-16 FS-105

49 – –

50 – –

Maximum count number: 999,999

(3) Data collection 3

Count number of copies by each mode

No. Contents

1 Platen 1-1 mode

2–

3 ADF 2-1 mode

4 ADF 2-2 mode

5 ADF 1-1 mode

6 ADF 1-2 mode

7 Finisher (Staple mode)

8 Finisher (Sort mode)

9 Finisher (Group mode)

10 Finisher (No. of stapling)

11 1.0 magnification mode

12 Fixed ratio (E3: 1.41/2.00)

13 Fixed ratio (E2: 1.22/1.55)

14 Fixed ratio (E1: 1.15/1.29)

15 Fixed ratio (R1: 0.86/0.77)

16 Fixed ratio (R2: 0.82/0.65)

17 Fixed ratio (R3: 0.71/0.50)

18 Arbitrary magnification

19 Zoom

20 2.00 magnification

21 0.45 magnification

22 AMS mode

23 APS mode

24 AE mode

25 Interrupt mode

26 By-pass feed mode

27 Book copy mode

28 Frame erase mode

29 Fold erase mode

30 1.0 image shift mode

31 Reduction image shift mode

32 Thick paper

33 Thin paper

5 - 18

25 ADJUSTMENT

No. Contents

34 No. of paper feed quantities at inter-sheet mode

35 –

36 No. of paper feed quantities at OHP mode

37 No. of paper feed quantities at mixed original mode

38 Access number of the Job memory call mode

(Number of pressing the P button)

39 Pre-heat mode

40 Copy quantity is set to 1.

41 Copy quantity is set between 2 and 5.

42 Copy quantity is set between 6 and 10.

43 Copy quantity is set to 11 or above.

44 Inter-sheet

45 –

46 Photo mode

47 –

48 Verti./Horiz. zoom mode

49 Book memory mode

50 Single step mode

51 Text/Photo mode

52 Text mode

53 Arbitrary density mode

54 No. of paper feed quantities at OHP mode 2

55 No. of paper feed quantities at inter-sheet and thick

paper mode

56 –

57 Image insert mode

58 Chapter management mode

59 Combination mode

60 Repeat mode

61 Reverse image mode

62 Non-image area erase mode

63 Increase contrast mode

64 Auto layout copy

65 Face up output

66 Rotation sort

67 –

68 Copy quantity of paper feed from tray 2

69 Copy quantity of paper feed from tray 3

70 Copy quantity of paper feed from tray 4

71 Copy quantity of paper feed from tray 5

72 Copy quantity of paper feed from tray 6

73 Finisher, Number of stapling (front)

74 Finisher, Number of stapling (rear)

75 Number of copies for booklet mode copy

3

Maximum count number: 99,999,999

(4) Data collection 4

Count number of SC occurrence (F code)

Error code

No. (decimal number)

Main code Sub code

1 10-1

2 10-2

3 10-3

4 18-1

5 18-2

6 18-3

7 18-4

8 18-5

9 26-0

3

10 28-1

11 28-2

12 28-3

13 34-1

14 34-2

15 34-3

16 34-4

17 35-1

18 35-2

19 36-1

20 36-2

21 40-0

22 41-1

23 46-0

24 46-8

25 46-10

26 46-11

27 49-2

28 49-4

29 49-6

30 51-2

31 51-3

32 51-4

33 51-5

34 51-6

35 51-7

36 52-1

37 52-2

38 52-3

39 52-4

Classification

Communication abnormality

Paper feed lifting abnormality

High voltage power

source abnormality

Fixing high temperature

abnormality

Fixing low temperature

abnormality

Broken fixing sensor

Optics system abnormality

Image processing abnormality

Motor speed abnormality

Fan lock abnormality

MODEL

7040

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 19

3

DATE

Mar. 1999

PAGE

5-19

METHOD

REPLACEMENT

ADJUSTMENT 25

Error code

No. (decimal number)

Main code Sub code

40 56-1

41 56-2

42 56-3

43 56-4

44 56-5

45 56-6

46 56-7

47 56-8

48 56-9

49 56-10

50 60-0

51 67-1

52 67-2

53 67-3

54 70-0

55 77-1

56 77-2

57 77-3

58 77-4

59 77-5

60 77-6

61 77-7

62 77-8

63 77-9

64 77-10

65 77-21

66 77-22

67 77-30

68 80-1

69 80-2

70 80-3

71 80-4

72 80-5

73 81-1

74 81-2

75 88-0

76 89-1

77 89-2

78 89-3

79 89-4

80 89-5

81 89-6

Classification

Image control communication abnormality

Operation control section system error

RADF abnormality

Finisher abnormality

Non-volatile memory

abnormality

Flash ROM abnormality

Image processing abnormality

Control board communication abnormality

Error code

No. (decimal number)

Main code Sub code

82 56-11

83 87-0

3

84 52-5

3

Maximum count number: 9,999

Classification

Control abnormality

Print controller transmission abnormality

Fan lock abnormality

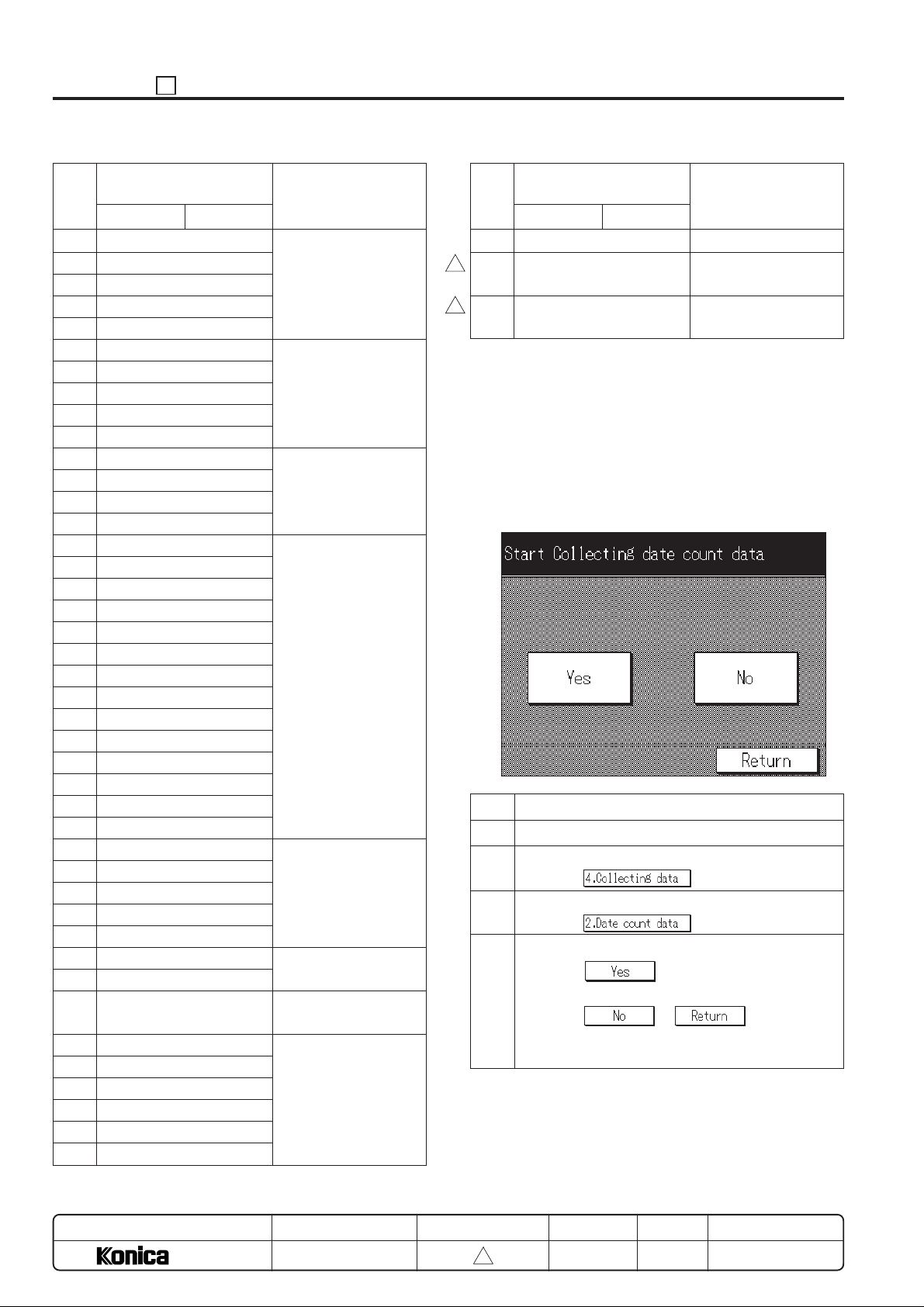

3. Starting Periodic Date Collection

Reset the periodic data from the setting periodic collection start

date. Make a date that this operation is performed as a new

periodic collection start date. The periodic data can be checked

with the KRDS and management list.

[Starting periodic date collection screen]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the key.

3 [Data collection menu screen]

Press the key.

4 [Starting periodic date collection screen]

Press the

collection.

Press the or key, then data

collection start date is not reset and return to the data

collection menu screen.

key to start the periodic data

MODEL

7040

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 20

3

DATE

Mar. 1999

PAGE

5-20

METHOD

REPLACEMENT

25 ADJUSTMENT

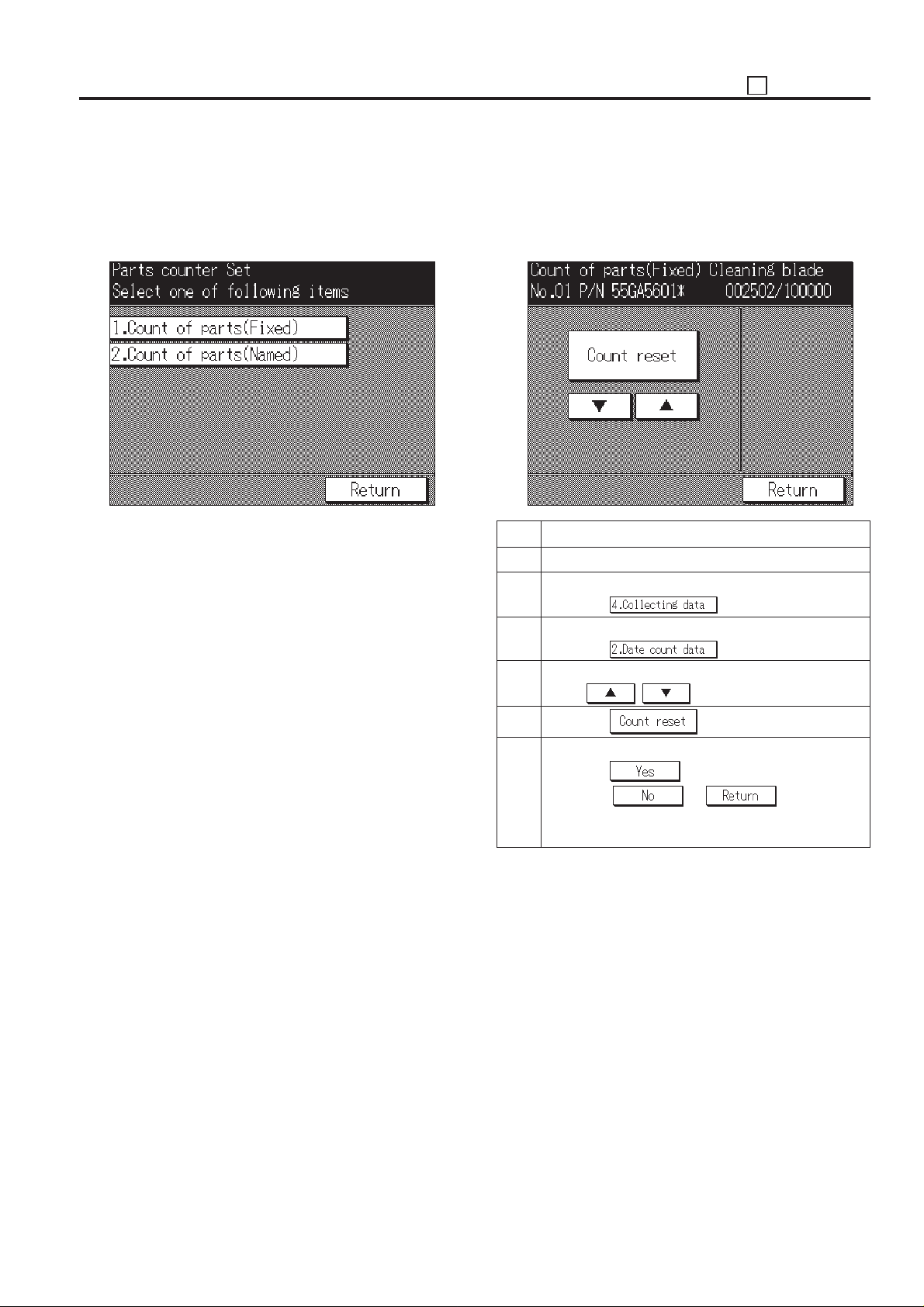

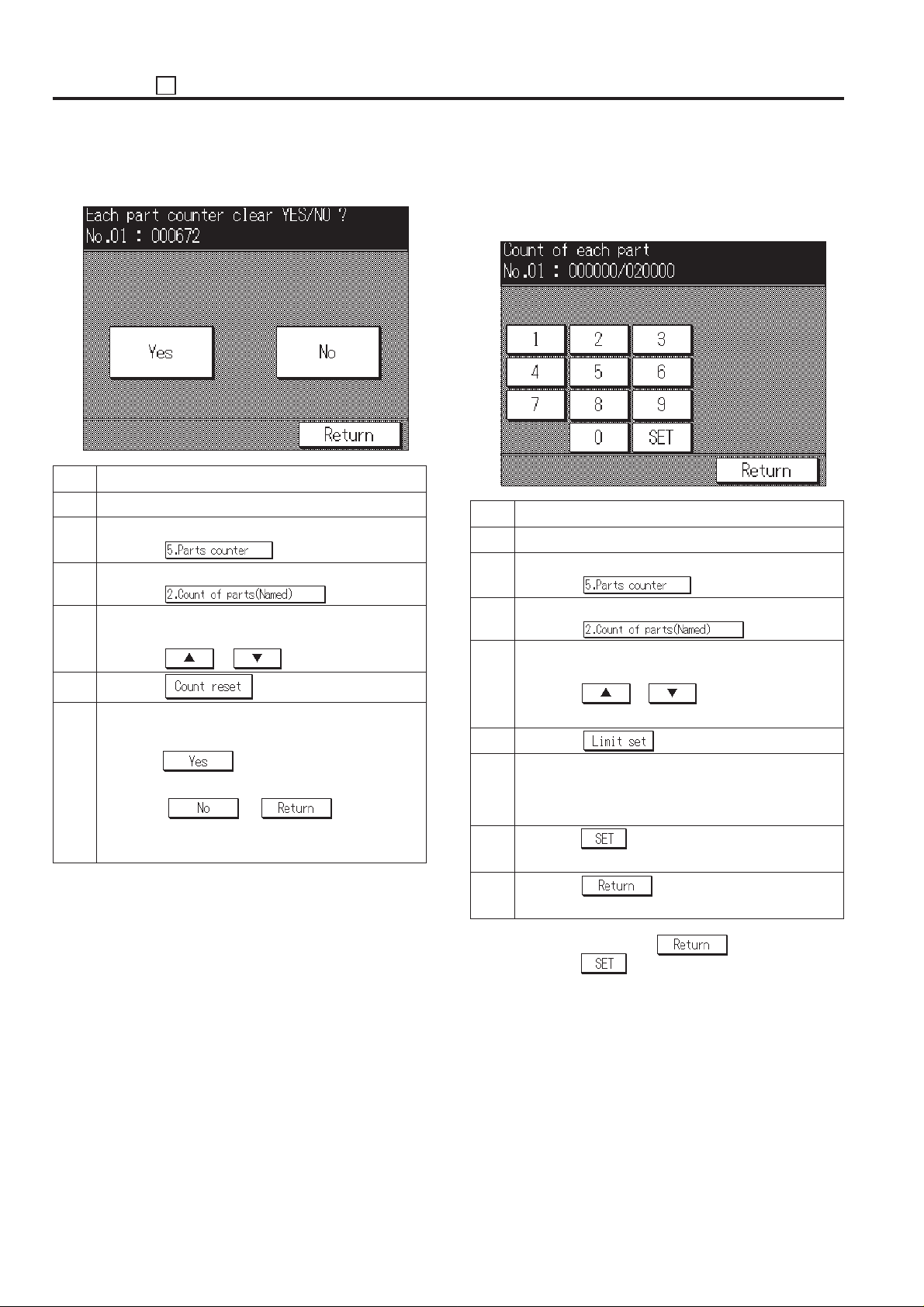

[6] Parts counter

Perform the copy count display, count clear, limit value setting

and arbitrarily parts to be replaced setting to the data of the

parts to be replaced (fixed/arbitrarily).

[Parts counter menu screen]

1. Copy count display and count reset by parts to

be replaced (fixed)

Set the parts name of the fixed parts to be replaced (Fixed),

parts No. and copy count display, and count reset.

[Copy count screen by parts to be replaced (Fixed)]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the key.

3 [Parts Counter Menu Screen]

Press the key.

4 [Copy count screen by parts to be replaced (Fixed)]

Press , key to select the data.

5 Press the key.

6 [Count reset screen by parts to be replaced (fixed)]

Press the

Press the or key, then the

copy count is not reset and return to the copy count

screen by parts to be replaced.

key to clear the copy count.

5 - 21

ADJUSTMENT 25

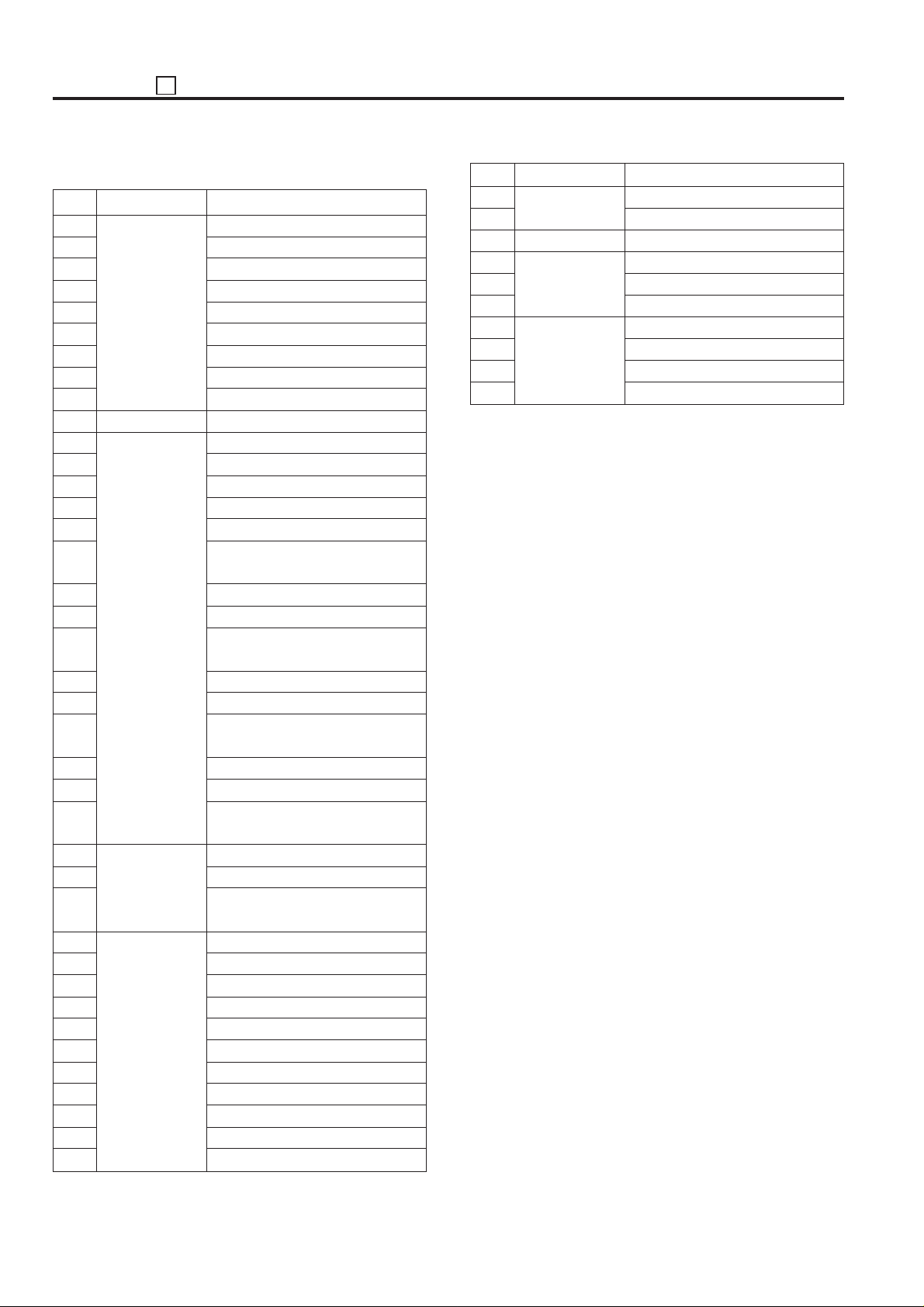

[< List of Parts to be Replaced (fixed) >

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

Unit

Drum cartridge

(include charging corona unit)

Developing unit

Paper feed unit

By-pass paper

feed unit

Fixing unit

Cleaning blade

Charging wire

Charging control plate

Cleaner mount assembly

Charging wire cleaning block (C)

Charging wire cleaning block (D)

Transfer/Separation charging wire

OPC drum

Separation claw

Developer

(Tray: 1) –

(Tray: 1) –

(Tray: 1) –

(Tray: 2) Separation rubber

(Tray: 2) Paper feed rubber

(Tray: 2) Double feed prevention

rubber

(Tray: 3) Separation rubber

(Tray: 3) Paper feed rubber

(Tray: 3) Double feed prevention

rubber

(Tray: 4) Separation rubber

(Tray: 4) Paper feed rubber

(Tray: 4) Double feed prevention

rubber

(Tray: 5) Separation rubber

(Tray: 5) Paper feed rubber

(Tray: 5) Double feed prevention

rubber

(By-pass) Separation rubber

(By-pass) Paper feed rubber

(By-pass) Double feed prevention

rubber

Fixing cleaning roller

Fixing roller (A)

Fixing cleaning pad

Fixing roller (upper)

Fixing claw (upper)

Heat insulating sleeve

Fixing roller (lower)

Fixing claw (lower)

Fixing bearing (upper)

Bearing

Fixing bearing

Parts name

No.

40

41

42

43

44

45

46

47

48

49

Unit

Fixing unit

Machine inside

DF-311

FS-105

Parts name

Fixing heater lamp 1

Fixing heater lamp 2

Toner filter

Paper feed roller

Separation roller

Separation pad

(Tray 2) Paper exit roller (A)

(Tray 3) Paper exit roller (A)

Staple unit (front)

Staple unit (rear)

5 - 22

25 ADJUSTMENT

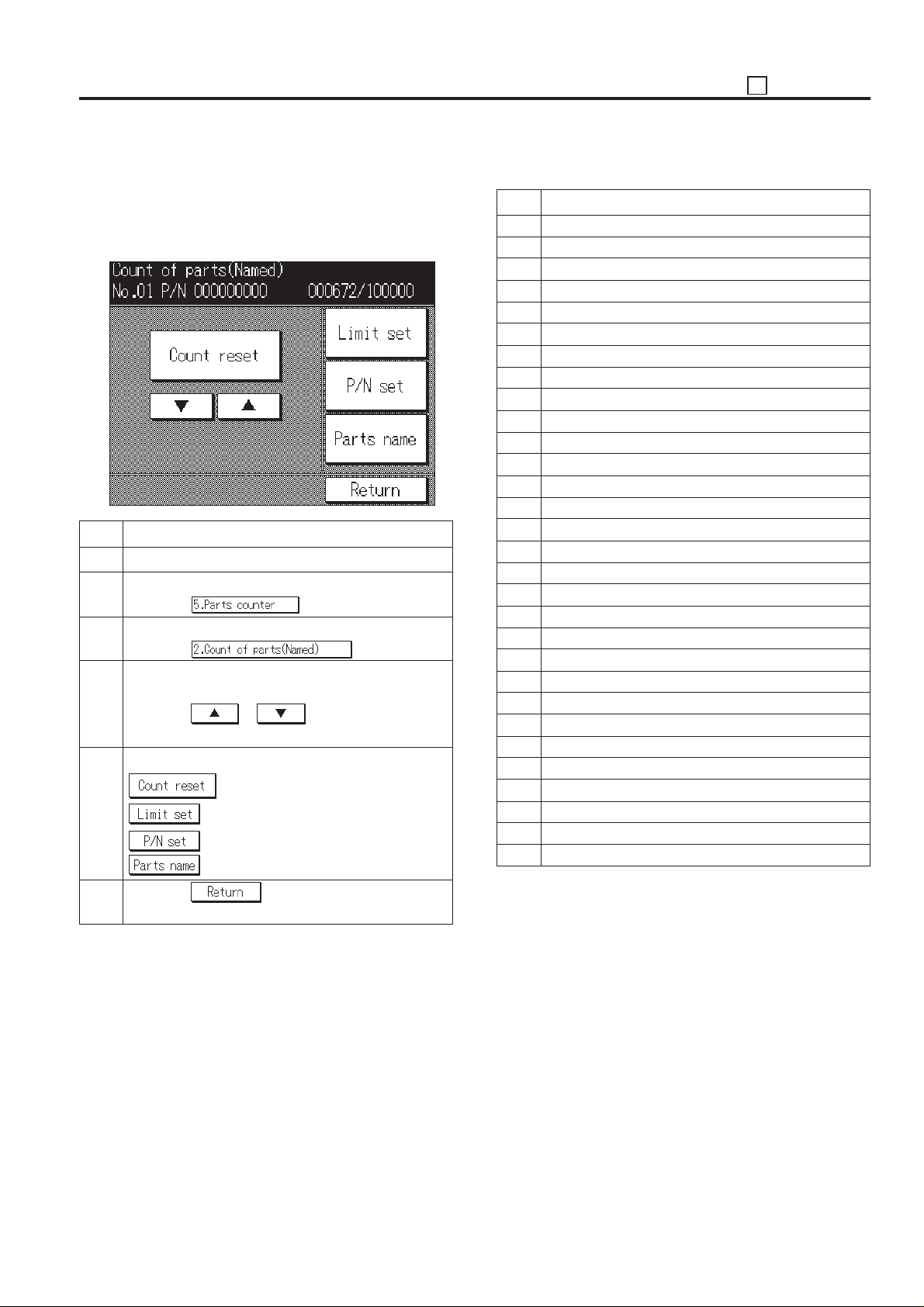

2. Copy count display and count reset by parts to

be replaced (Named; arbitrarily)

Set the limit value for the parts to be replaced, parts No., parts

name setting, copy count display and count reset.

[Copy count screen by parts to be replaced (Named)]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the key.

3 [Parts counter menu screen]

Press the key.

4 [Copy count screen by parts to be replaced

(Named)]

Press the or to select the data to be

set or changed.

5 Following items can be set below.

: To clear the copy count.

: To enter the limit value (6-digit).

: To enter the parts number (9-digit).

: To enter the parts name.

< List of Parts to be Replaced (arbitrarily) >

No.

When copy count (at the paper exit is completed)

1

When copy count (at the paper exit is completed)

2

When copy count (at the paper exit is completed)

3

When copy count (at the paper exit is completed)

4

When copy count (at the paper exit is completed)

5

When copy count (at the paper exit is completed)

6

When copy count (at the paper exit is completed)

7

When copy count (at the paper exit is completed)

8

When copy count (at the paper exit is completed)

9

When copy count (at the paper exit is completed)

10

When copy count (at the paper exit is completed)

11

When copy count (at the paper exit is completed)

12

When copy count (at the paper exit is completed)

13

When copy count (at the paper exit is completed)

14

When copy count (at the paper exit is completed)

15

When copy count (at the paper exit is completed)

16

When copy count (at the paper exit is completed)

17

When copy count (at the paper exit is completed)

18

When copy count (at the paper exit is completed)

19

When paper is fed from tray 5 (DB-208)

20

When paper is fed from by-pass tray

21

22

When paper is fed from tray 2

23

When paper is fed from tray 3

24

When paper is fed from tray 4

25

When paper is fed from ADU

26

When paper is exited from main body

27

When original is fed into RADF

28

When original is fed into RADF

29

When original is fed into RADF

30

Count timing

–

6 Press the key, then return to copy count

screen by parts to be replaced.

5 - 23

ADJUSTMENT 25

(1) Count resetting method

[Count reset screen by parts to be replaced (Named)]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the key.

3 [Parts counter menu screen]

Press the key.

4 [Copy count screen by parts to be replaced

(Named)]

Press the or to select the data.

5 Press the key.

6 [Count reset screen by parts to be replaced

(Named)]

Press the key to clear the copy count that

has been selected.

Press the or key, then the

copy count is not reset and return to the copy count

screen by parts to be replaced (Named).

(2) Count limit setting method

Enter the new limit value from the numeric key on the screen.

[Count limit setting screen by parts to be replaced

(Named)]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the key.

3 [Parts counter menu screen]

Press the key.

4 [Copy Count Screen by parts to be replaced

(Named)]

Press the or to select the data to be

set or changed.

5 Press the key.

6 [Copy count limit setting screen by parts to be

replaced (Named)]

Enter new value using the numeric keys.

7 Press the key to enter the limit value that has

been entered.

8 Press the key to return to the copy count

screen by parts to be replaced (Named).

Caution: When pressing the key without press-

ing the

changing a new limit value and returns to the copy

count screen by parts to be replaced (Named).

Reference:

The right side of the limit value will be marked as “*”

if the copy count exceeds its limit value.

key, the setting is complete without

5 - 24

25 ADJUSTMENT

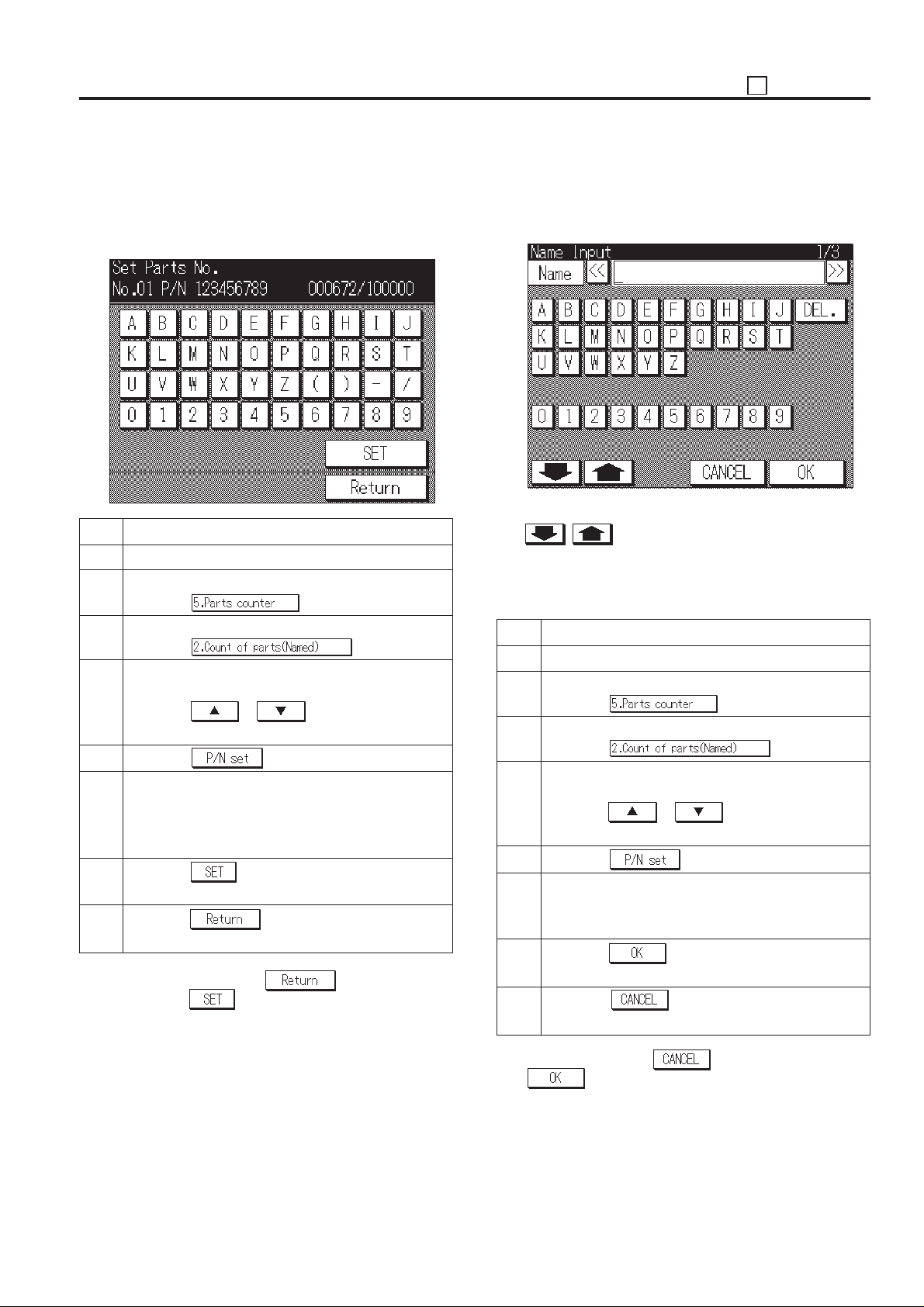

(3) Parts No. setting

Enter the new parts No. (9-digit) from the numeric and alphabet

keys on the screen.

[Parts No. setting screen by parts to be replaced

(Named)]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the

3 [Parts counter menu screen]

Press the key.

4 [Copy Count Screen by parts to be replaced

(Named)]

Press the

set or changed.

5 Press the key.

6 [ Parts No. Setting Screen by parts to be replaced

(Named)]

Enter new parts No. using the numeric and alphabet

keys.

7 Press the key to enter the parts No. that has

been entered.

8 Press the key to return to the copy count

screen by parts to be replaced (Named).

Caution: When pressing the key without press-

ing the

changing a new parts No. and returns to the copy

count screen by parts to be replaced (Named).

or to select the data to be

key, the setting is complete without

key.

(4) Parts name setting

Enter the new parts name from the keys on the screen.

[Parts Name Setting Screen by parts to be replaced

(Named)]

There are three screen in the input screen and are changed

with

• Alphabet (a capital letter), numeric number

• Alphabet (a small letter), numeric number

• Symbol, numeric number

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

3 [Parts counter menu screen]

4 [Copy Count Screen by parts to be replaced

5 Press the

6 [Parts Name Setting Screen by parts to be re-

7 Press the key to enter the parts name that

8 Press the key to return to the copy count

*1: When pressing the key without pressing the

, key.

Press the

Press the key.

(Named)]

Press the or to select the data to be

set or changed.

placed (Named)]

Enter new parts name using the keys on the screen.

has been entered. *1

screen by parts to be replaced (Named).

key, the setting is completed without setting a

parts name and returns to the copy count screen by parts

to be replaced (Named).

key.

key.

5 - 25

ADJUSTMENT 25

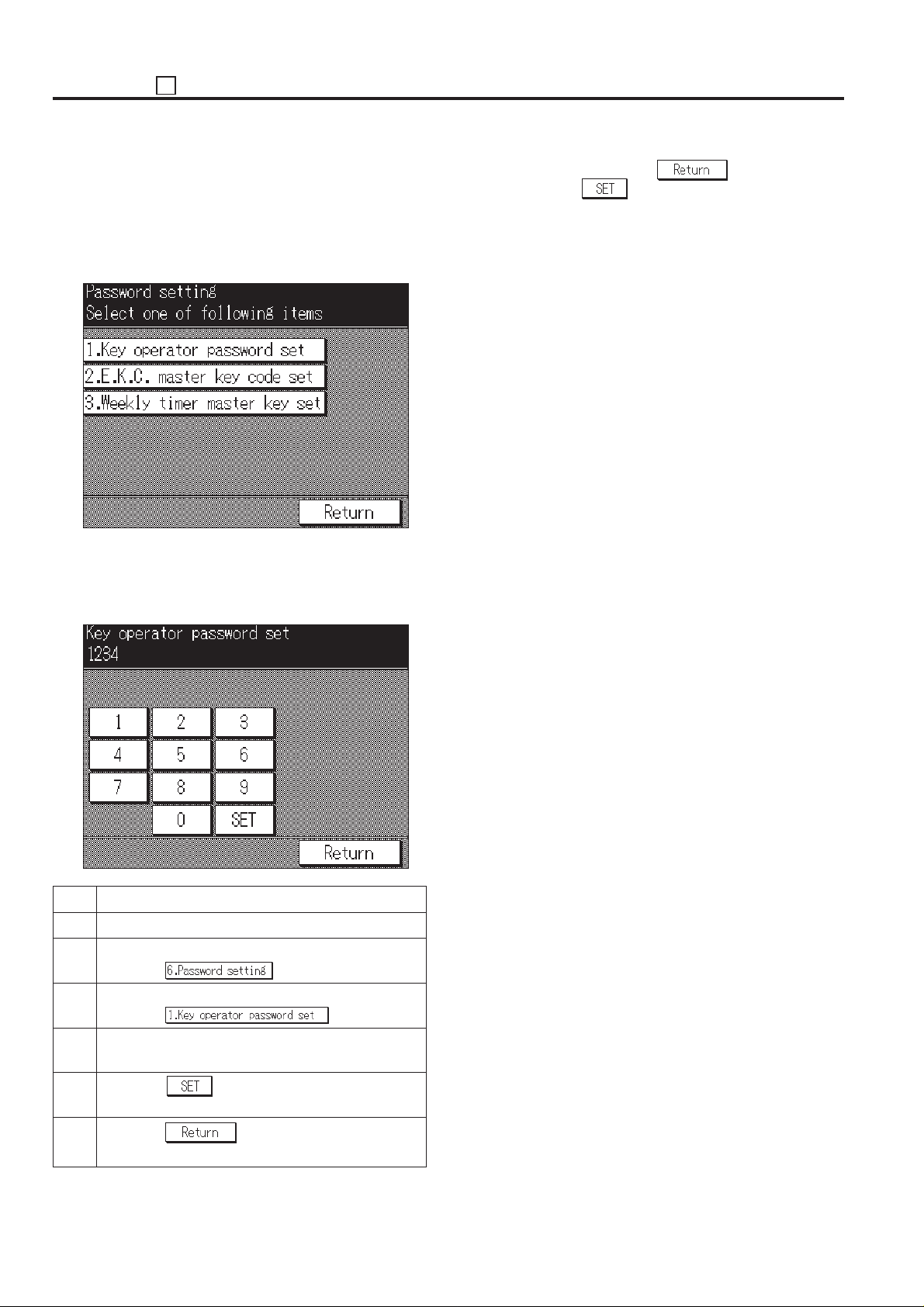

[7] Password setting

This function sets the password to enter each mode.

In the 25 mode menu screen, select the [6. Password setting],

then appear the password setting menu screen will appear.

Select the password to be adjusted/entered in this screen.

[Password setting menu screen]

1. Setting Key Operator Password

This function sets the password to enter the key operator

mode.

[Key operator password setting screen]

Caution: When pressing the

ing the

ever the new password will not be entered and the

password setting menu screen will return.

Reference:

When setting a password to “0000”, the key operator mode can

be used without a password.

key, the setting is complete. How-

key without press-

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the

3 [Password Setting Menu Screen]

Press the key.

4 [Key operator password setting screen]

Enter 4-digit new password from the numeric key.

5 Press the key to set the password that has

been entered.

6 Press the key to return to the password

setting menu screen.

key.

5 - 26

25 ADJUSTMENT

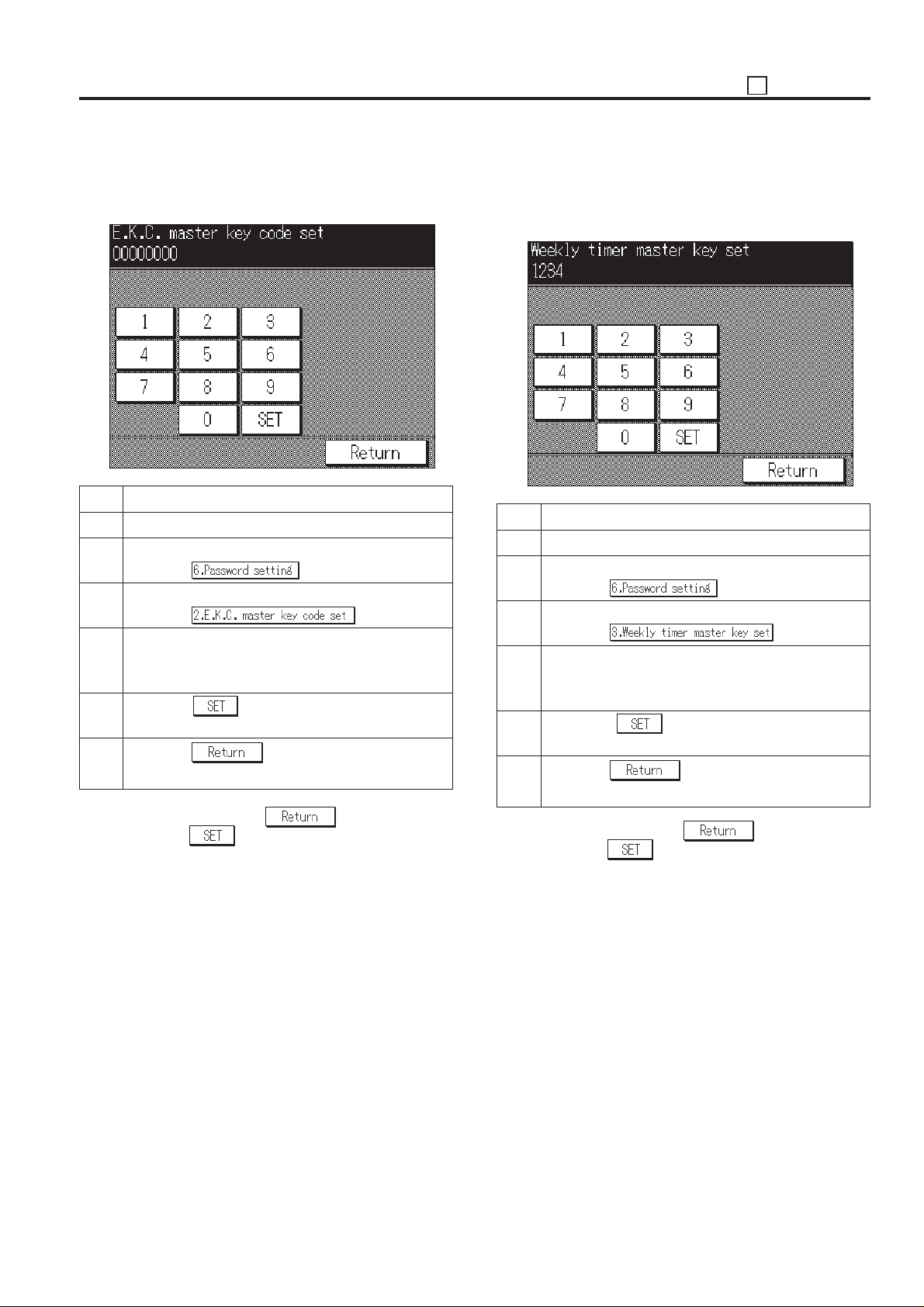

2. Setting the EKC Master Key Code

This function sets the EKC master key code.

[EKC master key code setting screen]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the key.

3 [Password Setting Menu Screen]

Press the key.

4 [EKC master key code setting screen]

Enter 8-digit new EKC master key code using the

numeric key.

5 Press the key to enter the EKC master key

code that has been entered.

6 Press the key to return to the password

setting menu screen.

Caution: When pressing the key without press-

ing the

changing a new EKC master key code and returns

to the password setting menu screen.

Reference:

When setting the EKC master key code to “00000000”, the

EKC setting mode can be used without a password (EKC

master key code).

key, the setting is complete without

3. Setting the Weekly Timer Master Key Code

This function sets the weekly timer master key code required

for entering the various weekly timer set mode.

[Weekly timer master key code setting screen]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the key.

3 [Password Setting Menu Screen]

Press the key.

4 [Weekly timer master key code setting screen]

Enter 4-digit new weekly timer master key code using

the numeric key.

5 Press the key to enter the weekly timer

master key code that has been entered.

6 Press the key to return to the password

setting menu screen.

Caution: When pressing the key without press-

ing the

changing a new weekly timer master key code and

returns to the password setting screen.

Reference:

When setting the master key code to “0000”, the weekly timer

mode can be used without a password.

key, the setting is complete without

5 - 27

ADJUSTMENT 25

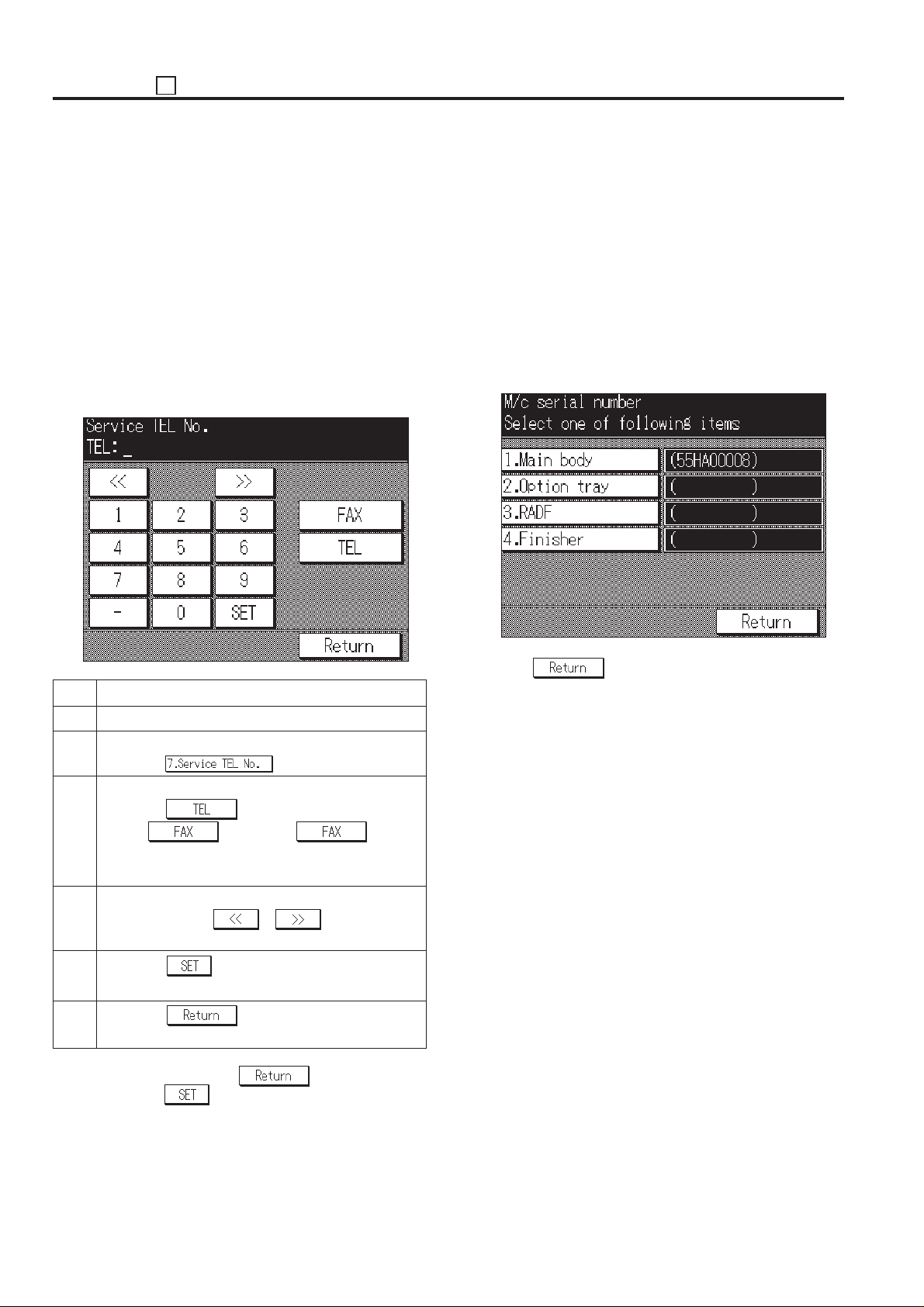

[8] Setting Phone Number of the Service

Center

This function displayes the phone and fax numbers of the

service center which is indicated on the screen if a service call

is required.

This function is not related to KRDS functions. It is designed

only for indicating the data on the screen.

1. Setting phone and fax number of the service

center

Select [7. Service TEL No.] in the 25 Mode Screen.

Service Center Number Setting Screen will appear.

[Service center number setting screen]

[9] Setting the Serial Number

This function is used to display, set and change the serial

number of the main body or optional units.

The serial numbers can be read from KRDS.

1. Serial number display procedure

Select [8. M/c serial number] in the 25 Mode Screen. The serial

number setting screen will appear.

The item name and serial number are displayed on the serial

number setting menu screen. Each serial number is displayed

at the right side of the each unit.

[Serial Number Setting Screen]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the

3 [Service center number setting screen]

Press the key to set the phone number

and the key to set the number,

and input the number (Max. 16-digit) using the numeric keys on the screen.

4 When input has been mistaken, rewrite it after mov-

ing the cursor with

with the Stop/clear button to input again.

5 Press the key to enter the number that has

been entered.

6 Press the key to return to the 25 mode

menu screen.

Caution: When pressing the key without press-

ing the

ever the new phone number will not be entered and

the 25 mode menu screen will return.

key, the setting is complete. How-

key.

or key, or delete all

Press the key to end setting and return to the 25

mode menu screen.

Caution: If the unit (option) is not installed, the serial number

is not displayed.

5 - 28

25 ADJUSTMENT

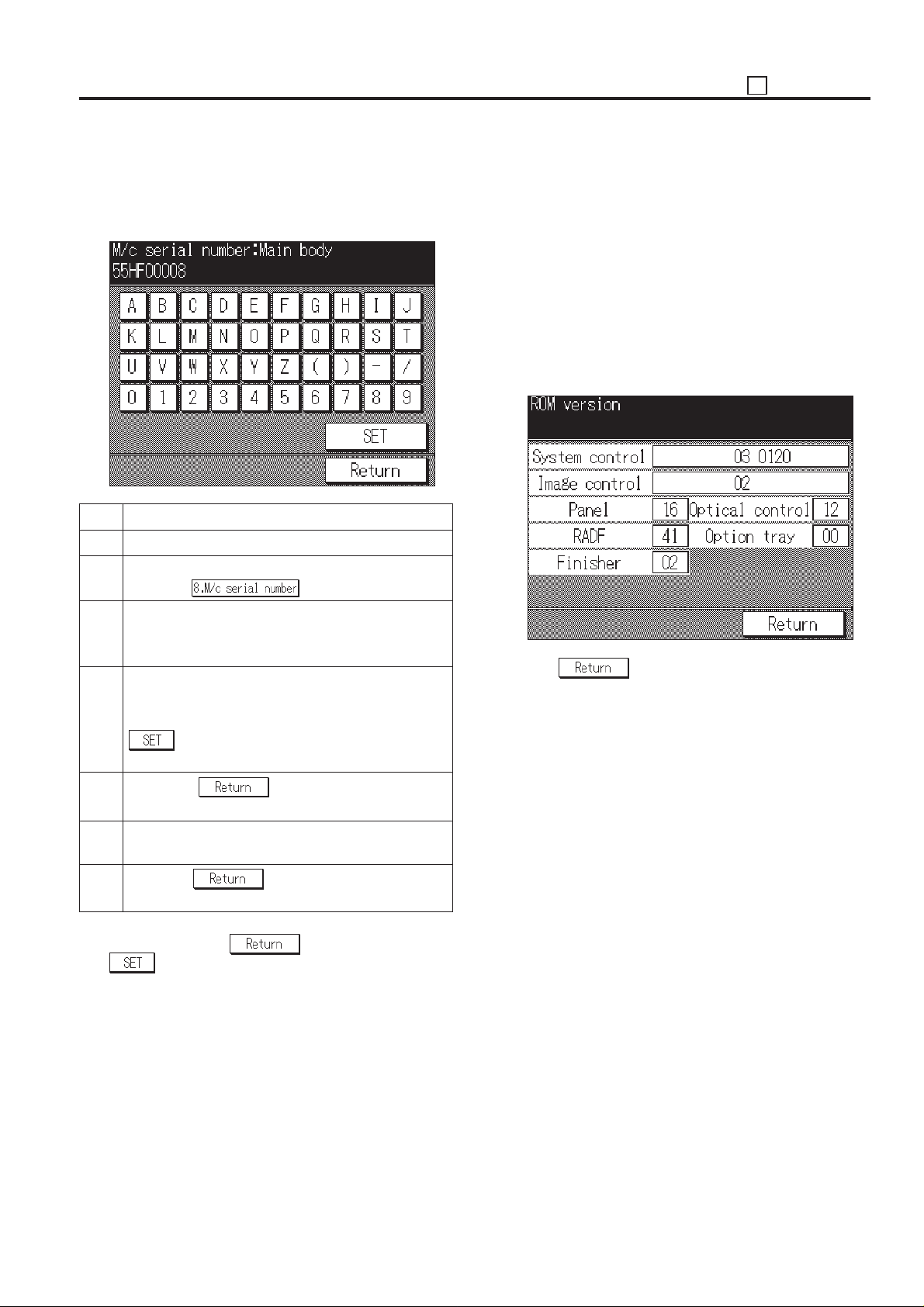

2. Setting and changing serial number

On the serial number setting screen, select the desired item,

then each serial number setting screen will appear.

[Serial number setting screen]

Step Operation procedure

1 Enter the 25 mode.

2 [25 Mode Menu Screen]

Press the key.

3 [Serial number setting menu screen]

Press the key corresponding to the desired item on

the screen.

4 [Serial number setting screen]

Enter the 9-digit serial number from the alphabet and

numeric keys on the screen and then press the

key to enter the number that has been en-

tered.

[10] Displaying the ROM Version

Display ROM version mounted to the machine.

1. ROM version viewing method

In the 25 mode menu screen, select [9. ROM version], then

appear the ROM version display screen will appear.

The item name and ROM version are displayed on the ROM

version display screen. Each serial number is displayed at the

right side of each item.

When there is an option not installed, the applicable position is

a blank.

[ROM Version Display Screen]

Press the key to end this screen and return to the

25 Mode Screen.

5 Press the key to return to the serial

number setting menu screen. *1

6 When changing the serial number of other item,

repeat steps 3 to 5.

7 Press the key to return to the 25 mode

menu screen.

*1: When pressing the key without pressing the

key, the setting is complete. However the new

serial number will not be entered and the serial number

setting menu screen will return.

5 - 29

Loading...

Loading...