Page 1

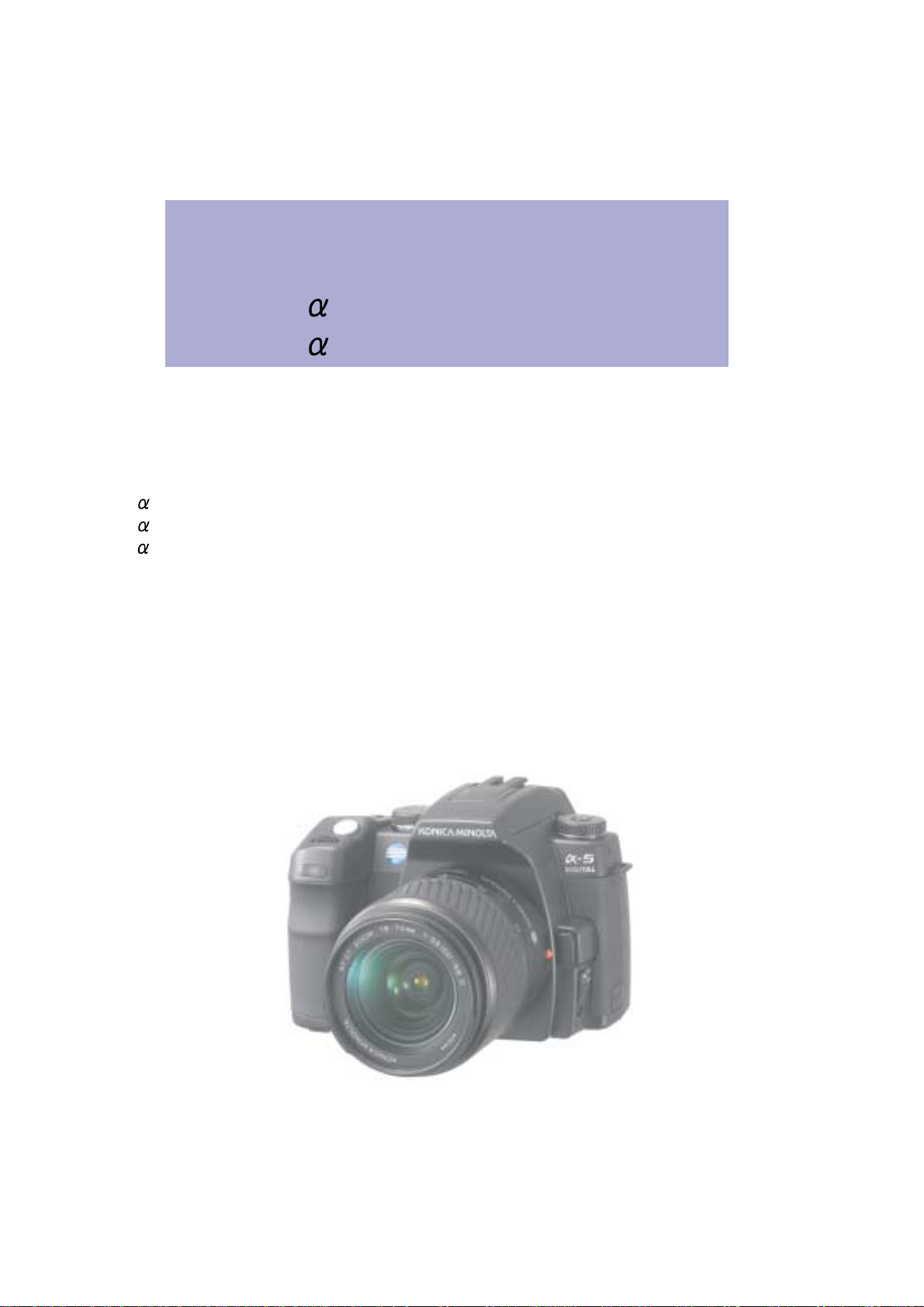

SERVICE MANUAL

DYNAX 5D

MAXXUM 5D

SWEET DIGITAL

5 DIGITAL

COMMON MODEL:

DYNAX 5D PEU/PHK/PAS/PAU/Mid-East-India/

MAXXUM 5D PUSA/ PCA/South-America/Taiwan (2186-300)

SWEET DIGITAL (Black) PJ (2186-600)

SWEET DIGITAL (Silver) PJ (2186-650)

5 DIGITAL PMSH-SKD model (2186-090)

Korea/Iran-Sylia (2186-100)

TECHNICAL ILLUSTRATION

PARTS NOTICE WITH PARTS LIST

TECHNICAL REPAIR MANUAL

KONICA MINOLTA PHOTO IMAGING, INC.

Page 2

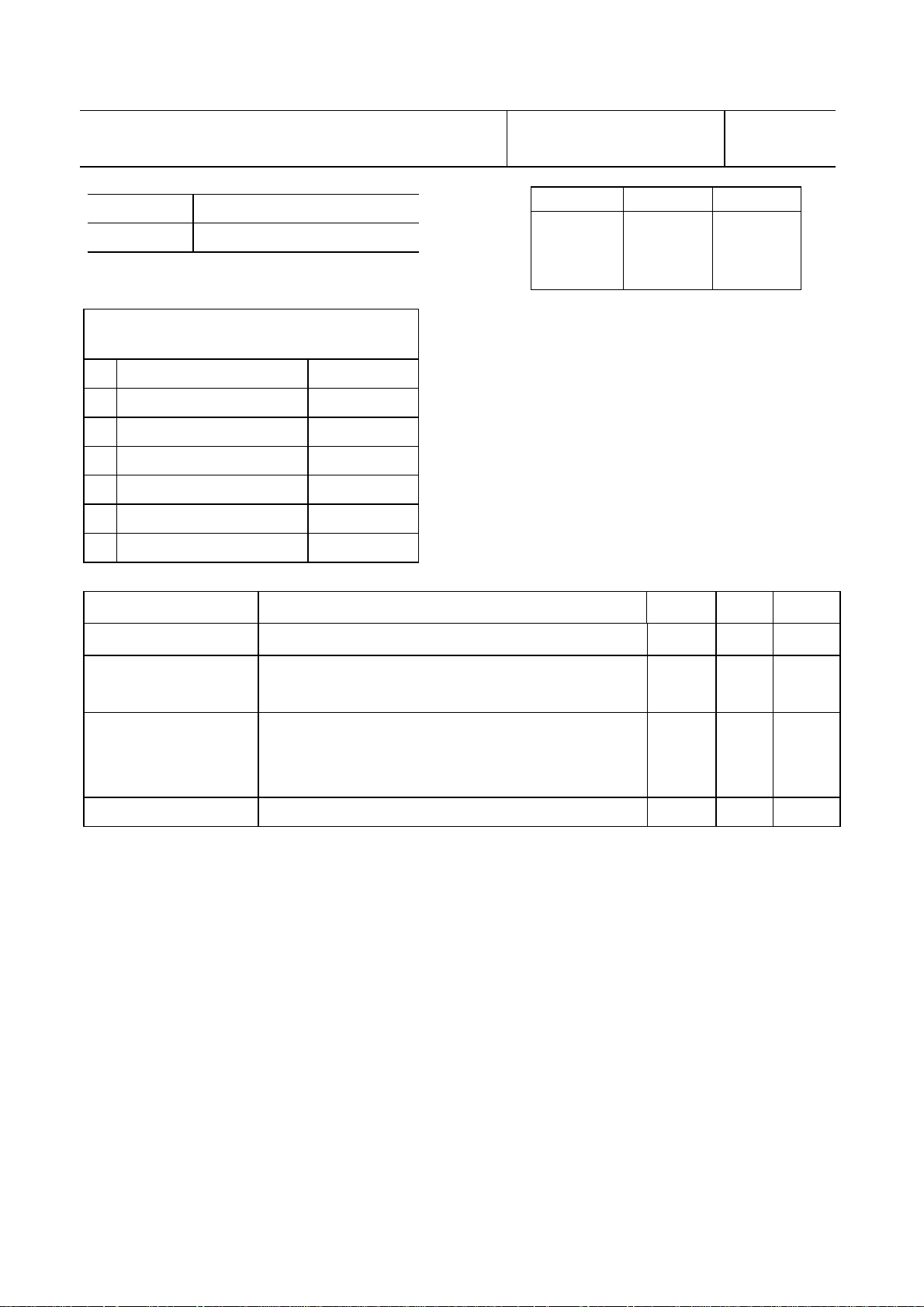

2186 Service Manual Index

Code

QS FA9220-2186-01

Page

1

Division Camera CS Division

Completed September 30, 2005

Section/

TTL number of pages

1 Service Manual Index 1

2 Specifications 1

3

Parts List Index 3

4

Parts List 12

5

Repair Guide 62

6

Trouble-Shooting Chart

7

Check List 8

9

Revision History

Date of issue/Version Reason (Revision part)

26/08/2005 First issued

Approved by Verified by Written by

Yata Ueno

Approved by Verified by Written

Yata

by

Masuda

Ueno

13/09/2005

30/09/2005

Error correction

(pg. 21,35,40,43,44,45,56,62 Repair Guide)

Error correction (pg. 12 Parts List)

LCD HARNESS (0442)

(RED and BLUE reverse-putt ing)

Yata

Yata

Masuda

Ueno

Ueno

KONICA MINOLTA PHOTO IMAGING, INC.

Page 3

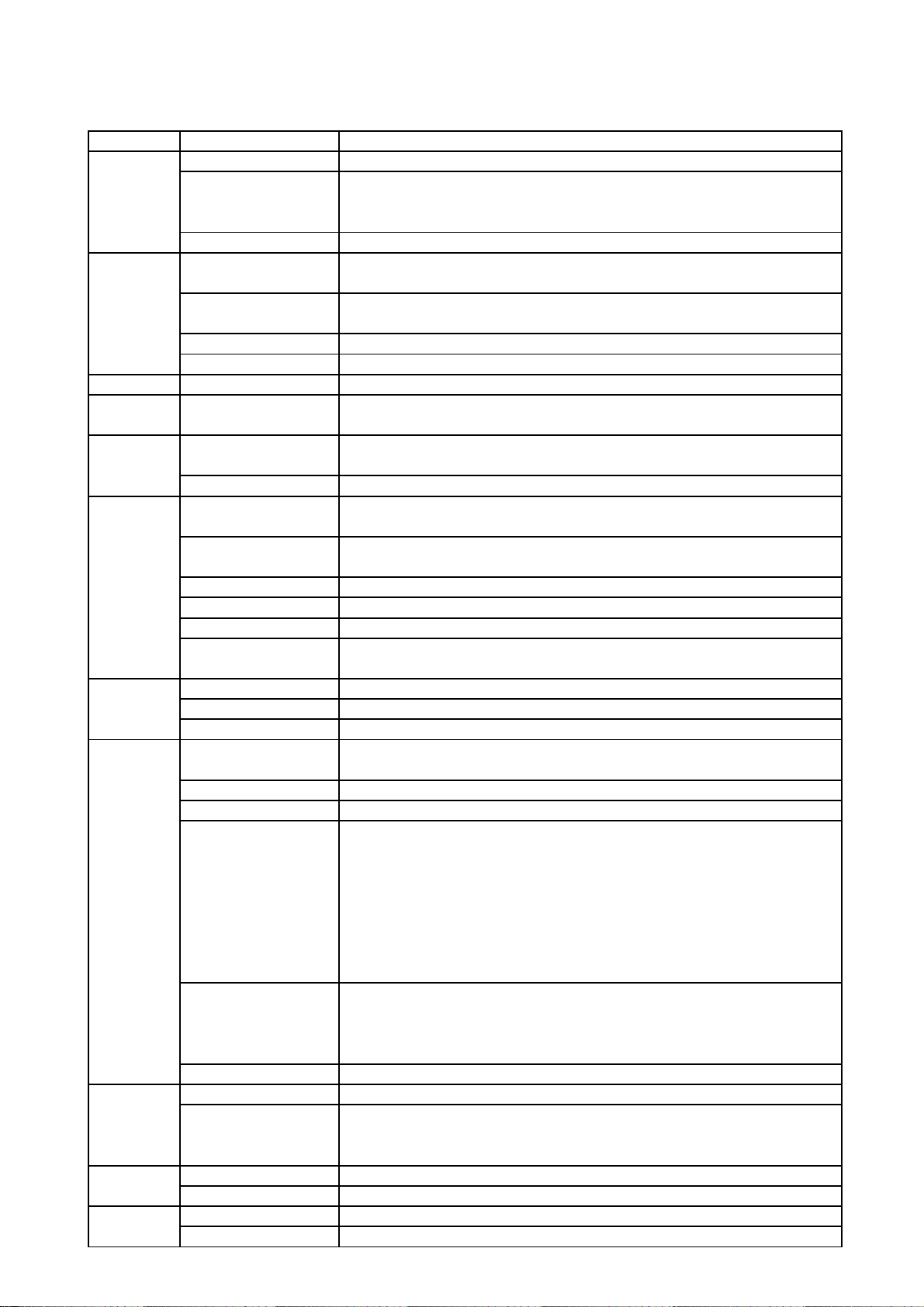

Specifications

(2186) 1

Type

Camera block

Recording

block

Viewfinder

LCD/Indication

Focus

Exposure

Flash

Recording

Playback

Others

Power/Battery

Input/Output

Dimensions

Weight

Type

Number of effective pixels

CCD

Unit cell size

Recording media

File format

Number of recorded pixels

Image quality modes

Viewfinder type

LCD monitor

Autofocus system

Autofocus area

Exposure mode

Metering

Exposure compensation

Camera sensitivity

Shutter

Shutter speed range

Flash metering

Guide number

Flash compensation

White balance control

Continuous advance

Color modes / Color space

Image correction

Playback functions

Printing output control

Battery

Battery performance (still)

PC interface

AV output

Dimensions (WxHxD)

Weight

Interchangeable-lens digital SLR camera

Approx. 6.1 million (3016x2008)

23.5mm x 15.7mm (APS-C size equivalent)

Interline primary-color, interlace scan

Total pixels: 6.3 million

7.8μm x 7.8μm

TypeⅠand TypeⅡCompactFlash cards, Microdrive,

SD memory card/ MultiMedia Card (with SD-CF1 in use)

JPEG/ RAW/ RAW+JPEG

[DCF 2.0 compliant, DPOF (supported by printing functions in ver. 1.1), Exif 2.21]

L: 3008x2000, M: 2256x1496, S: 1504x1000

Standard, Fine, Extra-Fine, RAW, Raw+JPEG (Fine)

Eye-level fixed pentaprism (Roof mirror type pentaprism (silver evaporated))

2.5 inch low-temperature polysilicon TFT color, back light LCD (with 3 fluoresent lamps)

Total pixels: 115,000 (approx.)

TTL phase-detection system with CCD line sensors

(9 points 8 lines with center cross-hair sensor)

Wide focus area, Any local focus area is selectable from 9 points sensors

P/ Auto mode (Programmed AE with program shift),

A (Aperture priority), S (Shutter priority), M (Manual)

TTL Metering using 14 segment. Honeycomb-pattern SPC.

(14 segments Honeycomb-pattern/ Center-weighted, Spot metering)

+/-2 Ev in 1/3 increments

Auto and 100, 200, 400, 800, 1600 and 3200 ISO equivalents.

Electronically-controlled, vertical-traverse, focal-plane shutter

30s - 1/4000s, Bulb

Flash sync.: 1/160s (Anti-shake OFF), 1/125 (Anti-shake ON)

ADI, Pre-flash TTL, Manual flash control

12 (in meters at ISO 100)

+/-2 Ev in 1/3 increments

Automatic, Preset (Daylight, Shade, Cloudy, Flash, Tungsten, Fluorescent),

Custom, Color temparature (Color temparature: 2500 to 9900K, CC Filter: 19 levels (M9 to G9)

Approx. 3 fps, Maximum 5 frames (RAW) (Maximum 3 frames (RAW+JPEG))

sRGB, Adobe RGB, Adobe RGB (ICC)

Color mode/ DEC (Digital Effect Control) function (*1): 10 modes (Natural Color,

Natural Plus, Portrait, Landscape, Sunset, Night view, Night portrait, B/W,

AdobeRGB, AdobeRGB (ICC)).

The contrast, color saturation, sharpness are also manually adjustable in +/- 2 steps. (*2) (*3)

*1: With this function, color space and settings of image processing such as contrast,

saturation, sharpness, white balance and a like will be controlled automatically.

*2: When B/W is selected in color mode, optional setting of color saturation is disabled.

*3: When Zone matching is selected, optional setting of contrast disabled.

Single-frame (Image only, Image and various statuses,

Image and various statuses and Histogram), Index (Selectable from 4/9/16 frames),

Enlarged playback (Up to approx 5x), Luminance limit display, File browser,

Slideshow, Auto Rotation playback (ON/OFF selectable)

Exif Print, Print Image Matching III, PictBridge

One NP-400 lithium-ion battery

Approx. number of recorded image: 400 frames. (Conforming to CIPA standard

test method with a compact flash card and NP-400 lithium-ion battery)

*1 CIPA: Camera & Imaging Products Association

USB (Full-speed 12Mbps data transfer available with USB 2.0 compatible computer)

NTSC/PAL (selectable on the camera)

130.5 (W) x 92.5 (H) x 66.5 (D) mm

575g (approx.) without batteries or recording media

Page 4

INDEX

INDEX

INDEXINDEX

(2186) 1

2186-0110

2186-0121

2186-0122

2186-0131

2186-0134

2186-0135

2186-0141

2077-0145

2186-0146

2186-0150

2186-0154

2186-0155

2186-0166

2186-0174

2186-0180

2186-0210

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

11 2186-0521

11 2186-0526

11 2186-0580

9, 10 2186-0584

1 2186-0721

9, 10 2186-0901

3 2186-1130

10 2186-1001

10 2186-1002

7 2186-1003

8 2186-1004

8 2186-1005

9 2186-1012

1 2186-1013

7 2186-1021

4 2186-1040

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

6 2186-1116

6 2186-1119

5 2186-1120

5 2186-1126

4 2186-1127

4 2186-1128

2 2186-1131

8 2186-1132

3 2186-1133

2 2186-1143

3 2186-1144

2 2186-1145

2 2186-1146

2 2186-1151

8 2186-1153

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

11

11

10

11

11

11

11

1

1

1

1

PARTS LIST

1

3

3

8

8

2186-0254

2186-0265

2186-0271

2186-0402

2186-0406

2186-0407

2186-0408

2186-0410

2186-0412

2186-0414

2186-0420

2186-0427

2186-0441

2186-0442

2186-0473

2186-0500

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

6 2186-1041

5 2186-1042

4 2186-1043

2 2186-1065

2 2186-1066

10 2186-1071

1 2186-1072

2 2186-1073

4 2186-1076

8 2186-1078

8 2186-1079

8 2186-1081

2 2186-1082

1 2186-1083

8 2186-1086

5, 6, 7 2186-1087

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

8 2186-1156

8 2186-1159

1 2186-1171

8 2186-1172

3 2186-1173

8 2186-1175

8 2186-1176

8 2186-1301

1 2186-1302

2 2186-1303

1 2186-1304

8 2181-1305

8 2186-1305

8 2186-1307

8 2181-1311

8 2186-1317

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

8

8

4

2

2

2

2

1

1

1

1

9

1

1

1

9

2186-0503

2186-0506

2186-0514

2186-0515

......

......

......

......

5 2186-1088

5 2186-1106

7 2186-1107

7 2186-1115

......

......

......

......

8 2186-1318

11 2186-1320

11 2186-1321

11 2186-1322

.....

.....

.....

.....

9

10

10

10

Page 5

2 (2186)

INDEX

INDEX

INDEXINDEX

2186-1327

2186-1328

2186-1329

2186-1330

2186-1331

2186-1332

2186-1333

2186-1334

2186-1335

2186-1336

PARTS LIST

2186-1401

2186-1402

2186-1403

2186-1404

2186-1407

2186-1410

......

10 2186-1444

...... 10

......

......

......

......

......

......

......

......

......

......

......

......

......

......

11 2186-1446

11 2186-1476

2186-1445

9 2186-1469

9 2186-1470

9 2186-1471

9 2186-1473

9 2186-1474

9 2186-1475

9 2162-1477

9 2186-1477

9 2186-1479

9 2186-1481

9 2166-1485

9 2186-1511

......

..... 11

......

......

......

......

......

......

......

......

......

......

......

......

......

......

11 2186-1610

2186-1611

11 2186-1612

9 2186-1613

9 2186-1614

9 2089-1620

9 2089-1621

9 2186-1625

9 2186-1812

10 2186-1813

9

9 2186-2512

9 2186-2530

9 2186-2532

11 2186-2533

6 2186-2534

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

9

9

10

9

10

9

9

10

7

6

6

6

6

6

6

2186-1417

2186-1418

2181-1419

2186-1420

2186-1421

2186-1422

2186-1424

2186-1425

2186-1426

2186-1427

2186-1430

2186-1431

2186-1432

2186-1433

2186-1435

2186-1436

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

11 2181-1515

11 2186-1520

11 2163-1521

11 2186-1521

10 2186-1522

10 2186-1523

9 2186-1524

10 2186-1525

10 2186-1542

10 2186-1543

11 2162-1544

11 2186-1545

11 2162-1547

11 2186-1548

11 2186-1601

11 2186-1602

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

6 2186-2535

6 2162-2658

6 2162-2659

6 2181-2702

6 2186-2703

6 2181-2706

6 2186-2708

6 2186-2709

7 2186-2715

7 2186-2721

7 2186-2722

6 2181-2918

6 2181-2920

7 2186-2940

9 2186-2961

9

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

6

5

5

4

4

4

2

2

4

4

4

4

4

2, 11

4

2186-1440

2186-1441

2186-1442

2186-1443

......

......

......

......

10 2186-1603

10 2089-1607

10 2186-1608

10 2186-1609

......

......

......

......

9 2186-4033

9 2186-4401

9 2186-4402

9 2186-4403

.....

.....

.....

.....

3

12

12

12

Page 6

INDEX

INDEX

INDEXINDEX

(2186) 3

2186-4404

2186-4508

2186-4511

2186-4514

2186-4520

2181-5016

2186-5022

2186-5025

2186-5026

2186-5027

2186-5028

2186-5033

2186-5034

2186-5041

2098-5045

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

12 9391-0807-02

8 9391-0807-03

11 9391-0807-04

2 9391-0807-05

2 9747-1735-01

9391-1207-00

5 9391-1207-02

5 9391-1207-04

5 9391-1207-08

5 9391-1207-09

5 9747-1750-01

5 9384-2190-50

3 9384-2191-00

3 9747-1755-15

1 9384-2290-90

1

......

......

......

......

......

......

......

......

......

......

......

......

12 9746-2030-01

12

12 9747-1440-01

12 9747-1730-01

12 9747-1740-01

12 9747-1740-15

12 9747-1745-01

12 9747-1745-04

12 9747-1745-15

1, 4, 5, 8, 10 9747-1750-15

1, 2, 8, 10 9747-1755-04

1, 2, 5, 8, 11 9747-1775-01

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

2

7

8, 9, 11

3, 5, 7, 8, 9, 10

1, 2, 8, 10, 11

1

PARTS LIST

4, 5, 6, 7, 10

9

9

1, 6, 8

1

1

1

4

2186-5048

2082-5054

2186-5101

2186-5102

2186-5107

2181-5108

2186-5109

2186-5110

2186-5112

2181-5123

2181-5133

2186-5151

2186-5805

2186-5806

2186-5820

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

5 9611-1625-01

5 9611-2025-01

7 9611-2035-04

7 9611-2035-15

7

7 9721-0120-50

7 9749-1735-15

7 9744-1615-01

7 9744-1618-01

6 9744-1620-01

4 9744-1625-01

7 9744-1630-01

5 9744-1630-15

7 9744-1635-01

5 9744-1635-15

9744-1650-15

......

......

......

......

......

......

......

......

......

......

......

......

......

......

1 9748-2045-01

2, 3 9748-2050-01

1 9748-2050-15

1 9748-2055-01

9 9749-1730-01

2 9749-2035-01

4

1, 4 9758-0100-00

1, 3 9758-0150-00

4

1 9761-1470-01

4 9761-2055-01

1 9761-2055-04

1 9761-2060-01

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

2, 9

3

2

4

6

2, 8

8

4

9

1

8

6

10

9353-4361-13

9372-3960-02

9391-0807-00

9391-0807-01

......

......

......

......

8 9744-1665-04

9744-1665-15

10

9745-2025-01

12 9769-1740-01

12 9746-2025-01

......

......

......

......

1

1 9767-1435-01

2, 3 9769-1730-01

2

9796-2040-40

.....

.....

.....

.....

11

7, 8

7

4

Page 7

9747-1755-04(2)(-650)

9747-1755-15(2)(-090,-100,-300,-600)

9611-2035-04(-650)

9611-2035-15(-090,-100,-300,-600)

See Page 9,10

9761-1470-01

2186-5041-01

2098-5045-02

9744-1665-04(2)(-650)

9744-1665-15(2)(-090,-100,-300,-600)

B

9747-1755-15

9384-2191-00

(10X10mm)

9384-2190-50

(5X5mm)

2186-0134-01

2186-0408-02

C

9744-1620-01

A

9384-2290-90

(5X20mm)

2186-1043-02

9611-1625-01(2)

2186-0442-01

See Page 2

A

9747-1740-01(-650)

9747-1740-15(-090,-100,-300,-600)

C

2186-1301-01(-090)

2186-1302-01(-300)

2186-1303-01(-100)

2186-1304-01(-600)

2186-1305-02(-650)

See Page 8

D

9744-1625-01(4)

See Page 2

9747-1755-04(2)(-650)

9747-1755-15(2)(-090,-100,-300,-600)

B

9747-1750-01

2186-1307-01

2181-1311-01

See Page 11

9747-1740-15(2)

D

(2186-1079-03)

(2186-1076-02)

A

2186-0174-01

2186-1131-01

9747-1750-15(2)

2186-1130-01

See Page 11

2186-1128-01

2186-1127-02

9744-1650-15(2)

9744-1635-15

9744-1630-15(2)

2186-1126-02

Page 8

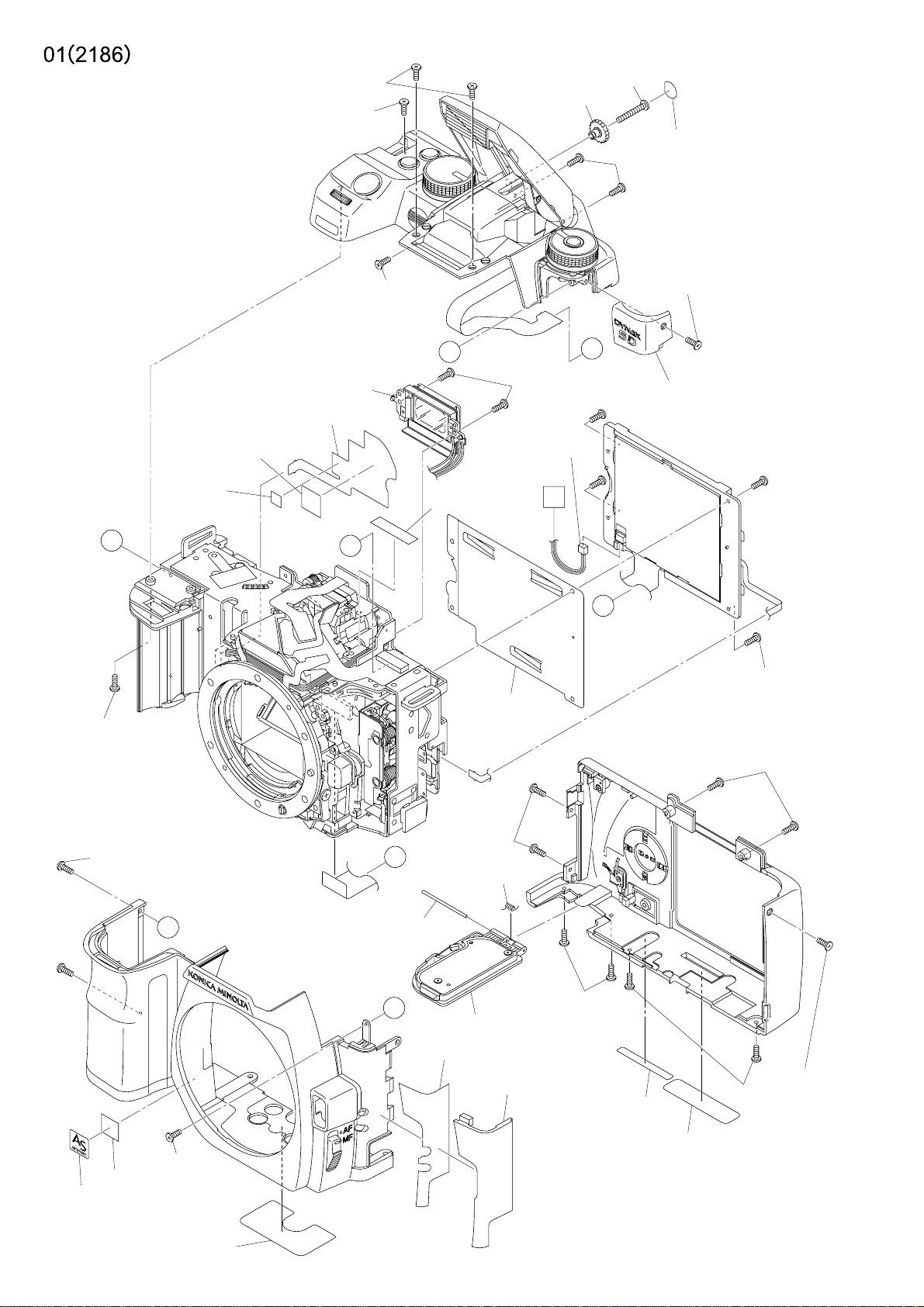

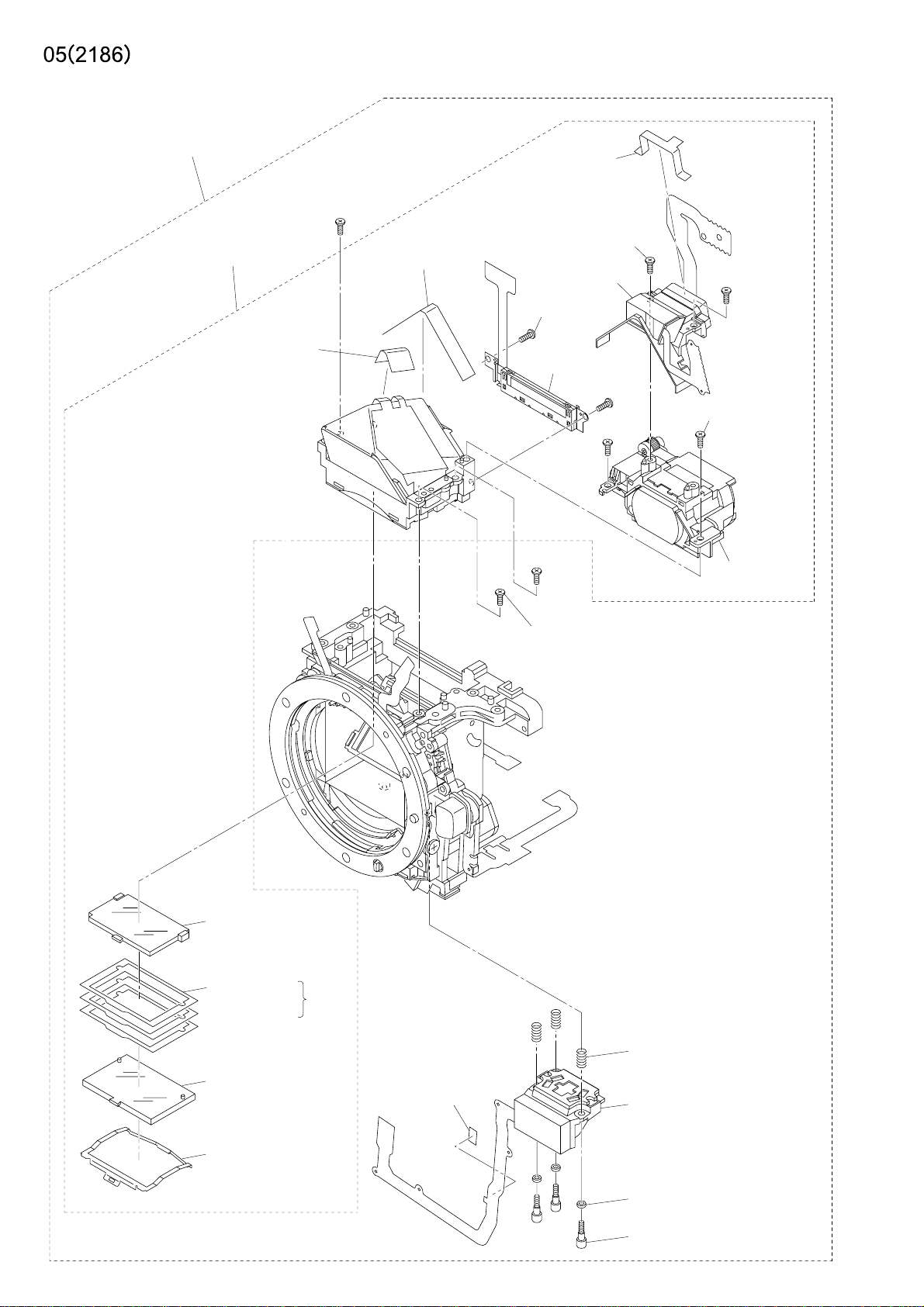

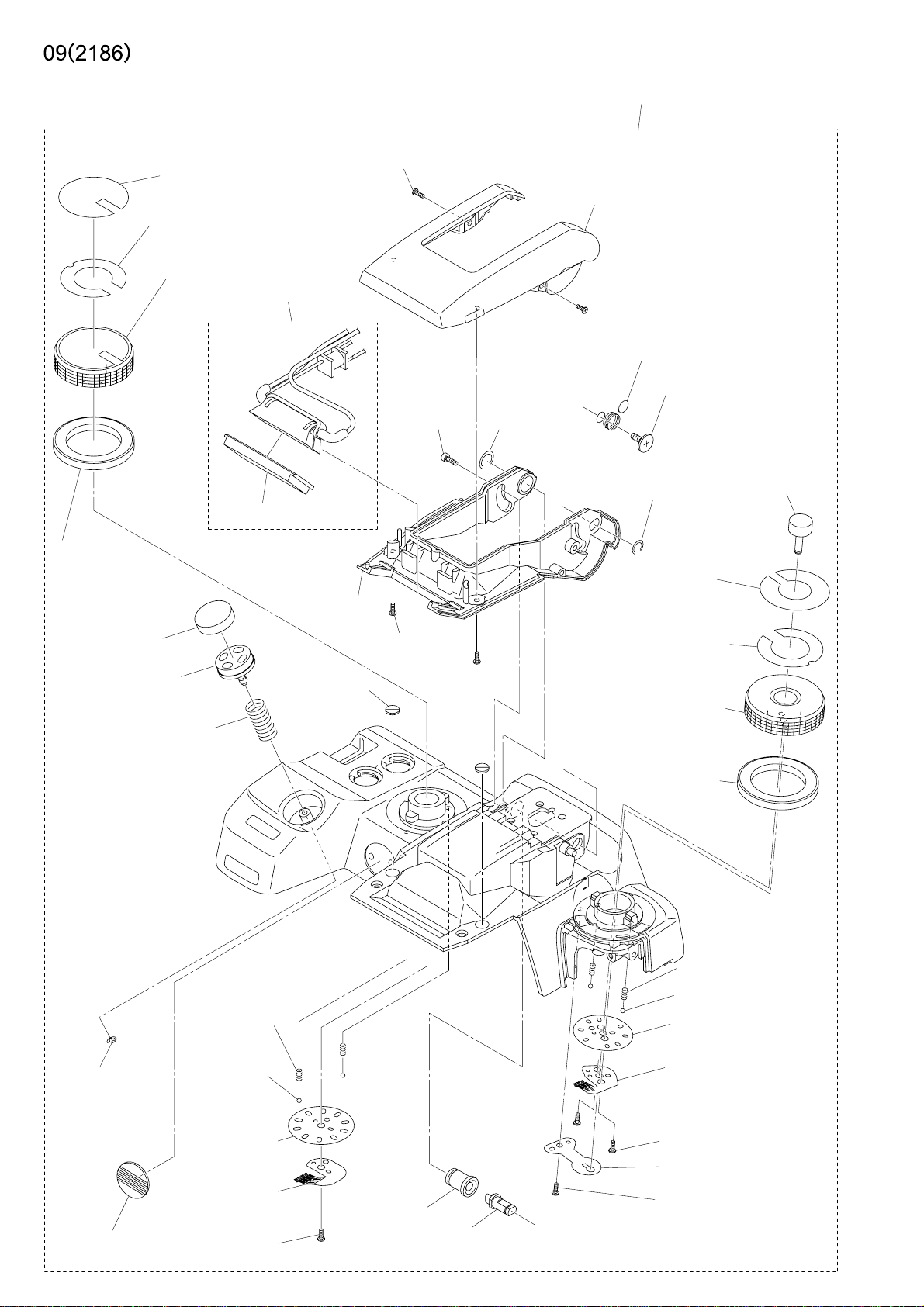

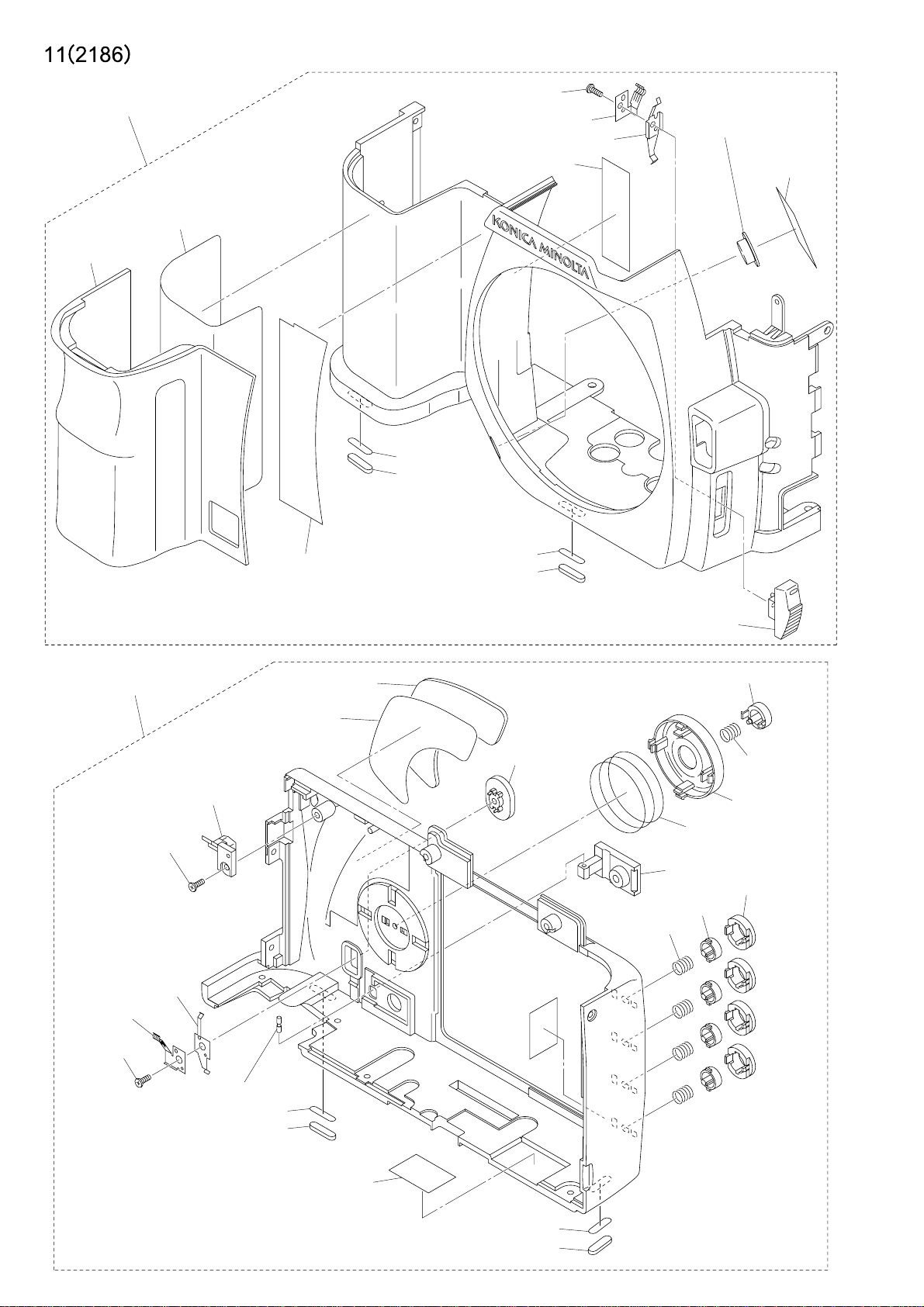

(2186) 1

PART NO PART NAME QTY.

2186-0134-01 EYE PIECE FRAME ASSY

2186-0174-01 BATTERY COVER ASSY

(2186-1076-02) BATTERY COVER HINGE SHAFT

(2186-1079-03) BATTERY COVER SP

2186-0408-02 SW FPC-1 ASSY

2186-0442-01 LCD HARNESS

2186-1043-02 LCD GND PLATE

2186-1126-02 STANDARD PLATE

2186-1127-02 PLACE PLATE MALAYSIA

2186-1128-01 BODY NO.PLATE

2186-1130-01 RUBBER L

2186-1131-01 RUBBER L TAPE

2186-1301-01 VERSION PLT A - 5

2186-1302-01 VERSION PLT MAXXUM - 5

2186-1303-01 VERSION PLT DYNAX - 5

2186-1304-01 VERSION PLT A - SWEET

2186-1305-02 VERSION PLT A - SWEET

2186-1307-01 AS NAME PLT D/SIDED TAPE

2181-1311-01 SHAKING PLATE

2186-5041-01 DIOPTER DIAL

2098-5045-02 DIOPTER-ADJUST SHEET

9384-2190-50 DOUBLE-FACED TAPE (PER ROLL)

9384-2191-00 DOUBLE-FACED TAPE (PER ROLL)

9384-2290-90

9611-1625-01 SCREW

9611-2035-04 SCREW (-650)

9611-2035-15 SCREW (-090, -100, -300, -600)

9744-1620-01 SCREW

9744-1625-01 SCREW

9744-1630-15 SCREW

9744-1635-15 SCREW

9744-1650-15 SCREW

9744-1665-04 SCREW (-650)

9744-1665-15 SCREW (-090, -100, -300, -600)

9747-1740-01 SCREW (-650)

9747-1740-15 SCREW (-650)

9747-1740-15 SCREW (-090, -100, -300, -600)

9747-1750-01 SCREW

9747-1750-15 SCREW

9747-1755-04 SCREW (-650)

9747-1755-15 SCREW (-650)

9747-1755-15 SCREW (-090, -100, -300, -600)

9761-1470-01 SCREW

POLYESTER TAPE (PER ROLL/60M) YELLOW

接眼枠セット

電池蓋セット

電池蓋ヒンジ軸

電池蓋SP

SWフレキ1セット

LCDハーネス

LCD GND板

定格銘板

生産地銘板

ボディNo.銘板

貼り皮L

貼り皮Lテープ

バージョン銘板α−5

バージョン銘板MUXXUM−5

バージョン銘板DYNAX−5

バージョン銘板α−SWEET

バージョン銘板α−SWEET

AS銘板貼付けテープ

手振れ銘板

視度調ダイヤル

視度調銘板

両面テープ

両面テープ

ポリエステルテープ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

4

2

1

2

2

2

1

2

3

1

2

4

1

5

1

PARTS LIST

Page 9

2186-0402-03

9747-1740-01

2186-0441-02

2186-0406-02

See Page 3

9384-2191-00(3)

(10X10mm)

D

B

B

2186-4520-01

D

A

C

A

2186-1173-01

9744-1615-01

2186-2708-02

9749-1735-15

2186-4514-01

2186-1021-01

9747-1740-01

2186-1175-01(2)

9384-2290-90

(5X20mm)

2186-2709-01

C

2186-1176-01

2186-0410-08

9745-2025-01(2)

2186-1078-02

2186-2940-01

2186-1012-01

2186-1013-03

9748-2050-15(2)

9747-1740-01

9748-2045-01

9384-2290-90

(5X10mm)

2186-1172-03

9745-2025-01(2)

A

See Page 1

9611-2025-01(2)

9384-2290-90

(5X20mm)

2186-1001-03

9748-2045-01

9746-2030-01

2186-2940-01

9746-2025-01(5)

2186-1004-04

9745-2025-01(2)

9746-2030-01

Page 10

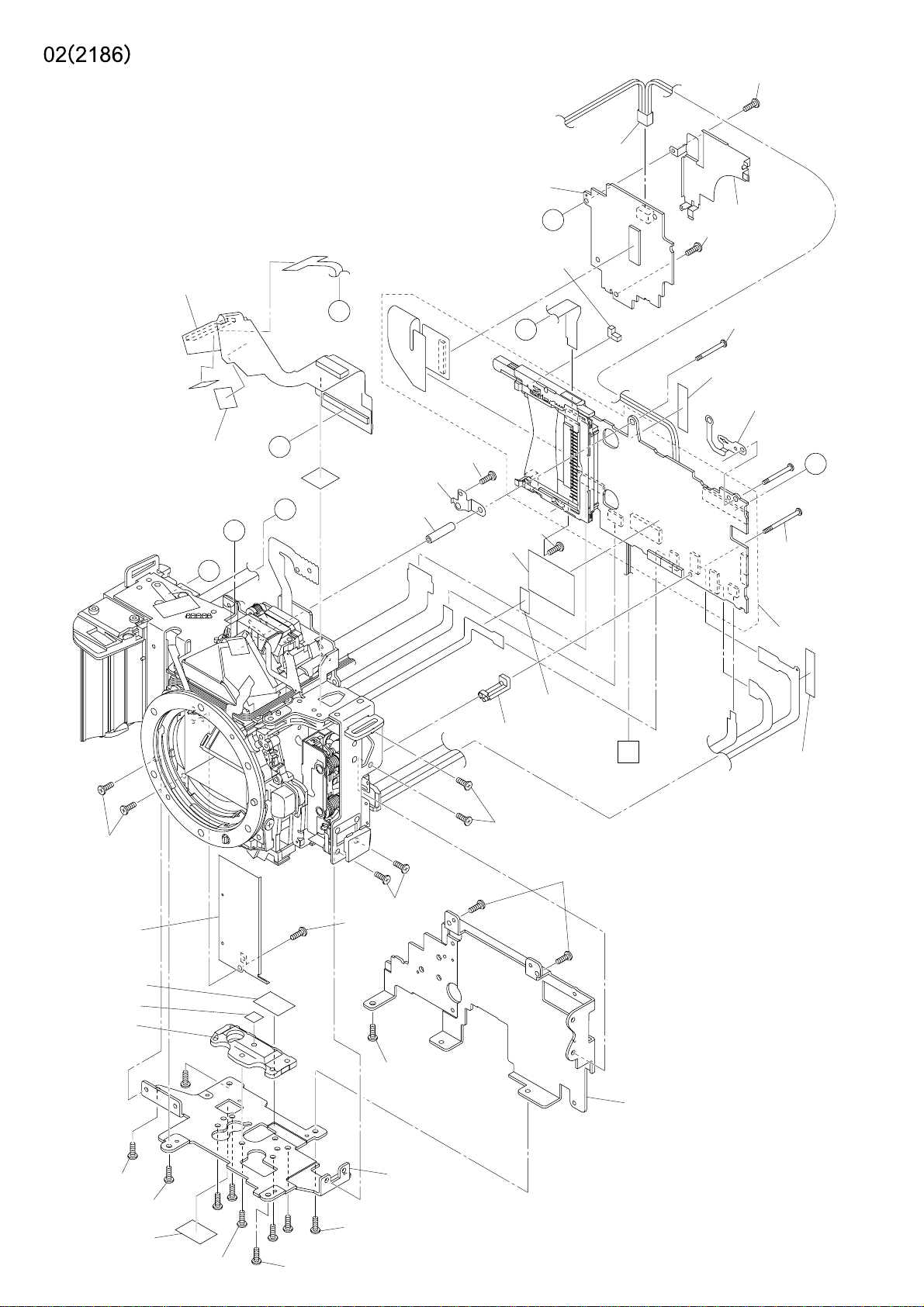

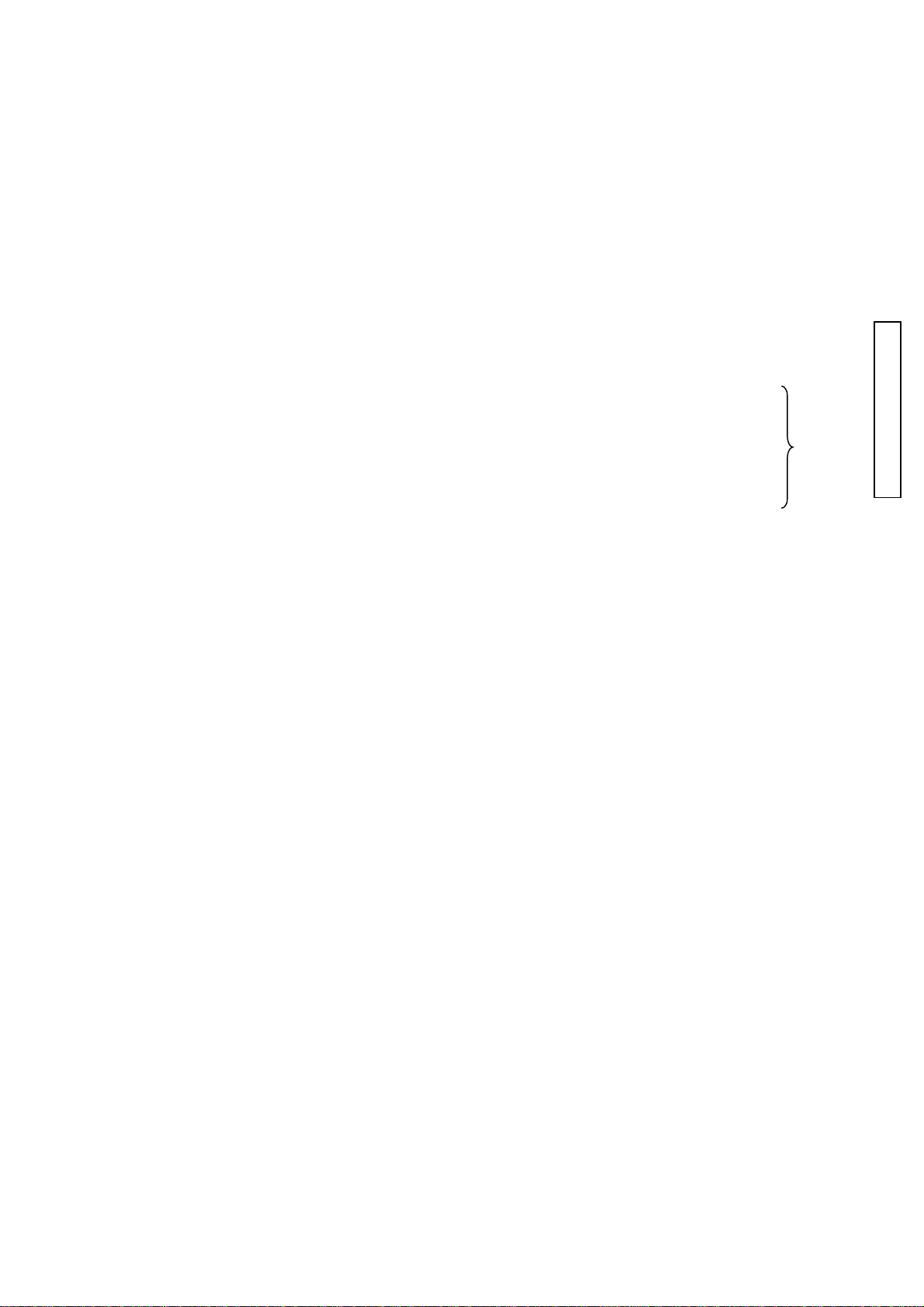

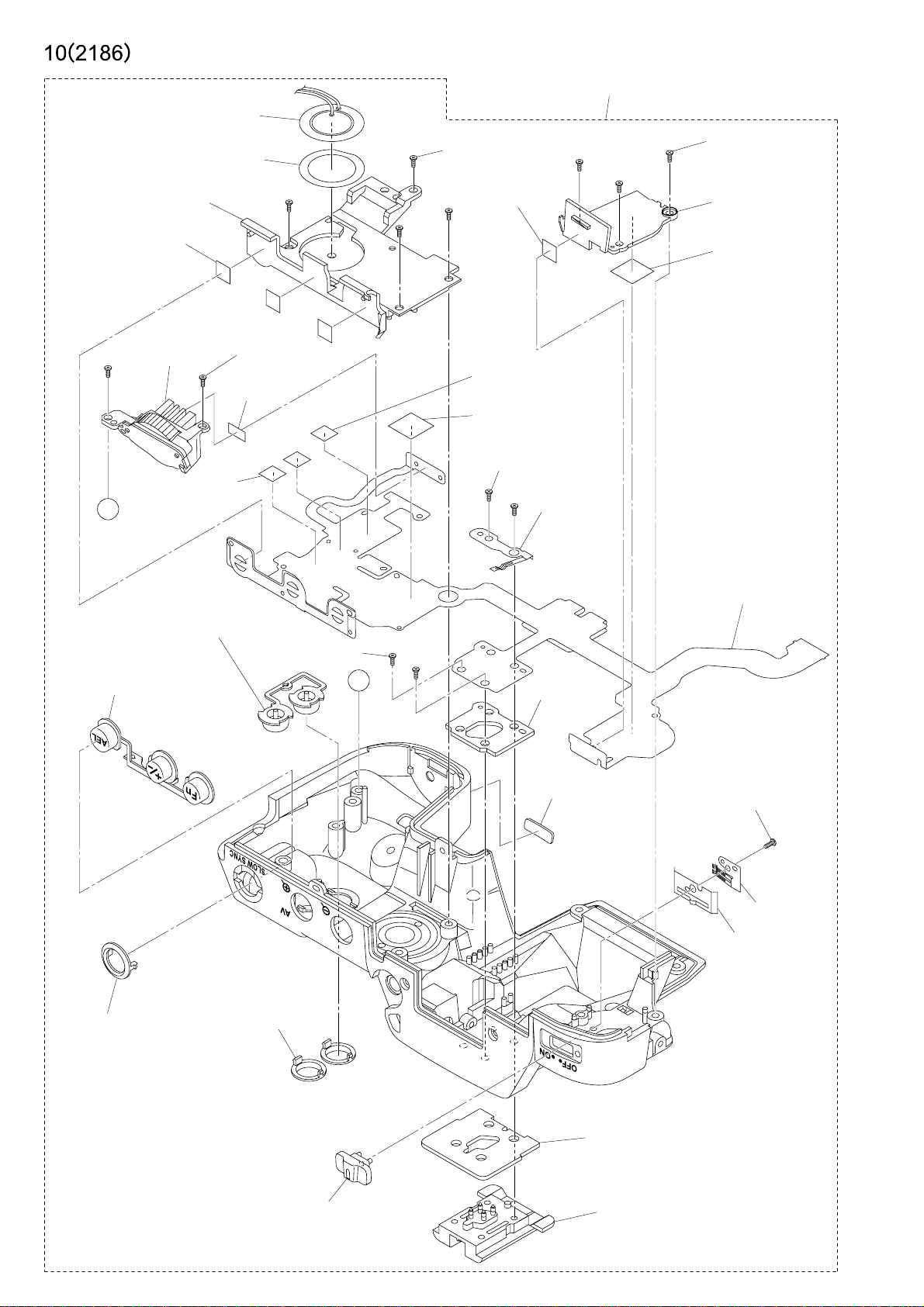

(2186) 2

PART NO PART NAME QTY.

2186-0402-03 DCDC PCB ASSY

2186-0406-02 I/O FPC ASSY

2186-0410-08 MAIN PCB ASSY

2186-0441-02 POWER SUPPLY HARNESS

2186-1001-03 MAIN CHASSIS

2186-1004-04 BOTTOM MAIN PLATE

2186-1012-01 TRIPOD LIGHT LEAK TAPE

2186-1013-03 TRIPOD SCREW

2186-1021-01 SHIELD PLATE

2186-1078-02 CCD FPC PRESSING SHEET

2186-1172-03 MAIN BOARD SUPPORT PLATE B

2186-1173-01 MAIN BOARD SUPPORT PLATE AXIS

2186-1175-01 MAIN PCB HOLDING SCREW A

2186-1176-01 MAIN PCB HOLDING SCREW B

2186-2708-02 CCD PLATE LUG PLATE 1

電源基板セット

I/Oフレキセット

メイン基板セット

電源ハーネス

メインシャーシ

下面シャーシ

三脚遮光テープ

三脚ねじ

シールド板

CCDフレキ押えシート

メイン基板保持台B

メイン基板保持軸

メイン基板保持ねじA

メイン基板保持ねじB

CCDシャーシ用ラグ板1

1

1

1

1

1

1

PARTS LIST

1

1

1

1

1

1

2

1

1

2186-2709-01 CCD PLATE RAG PLATE 2

2186-2940-01 TAPE

2186-4514-01 SHIELD FPC

2186-4520-01 ACCESS LIGHT SHIELD TAPE

9384-2191-00 DOUBLE-FACED TAPE (PER ROLL)

9384-2290-90

9611-2025-01 SCREW

9744-1615-01 SCREW

9745-2025-01 SCREW

9746-2025-01 SCREW

9746-2030-01 SCREW

9747-1740-01 SCREW

9748-2045-01 SCREW

9748-2050-15 SCREW

9749-1735-15 SCREW

POLYESTER TAPE (PER ROLL/60M) YELLOW

CCDシャーシ用ラグ板2

テープ

シールドフレキ

アクセス遮光シート

両面テープ

ポリエステルテープ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

1

2

1

1

3

3

2

1

6

5

2

3

2

2

1

Page 11

9745-2025-01

9748-2050-01(2)

2186-1003-03

See Page 8

9748-2050-01

9748-2050-01

9747-1735-01

2186-5034-01

9748-2050-01

9747-1735-01

2186-5033-01

9745-2025-01(2)

2186-1005-03

2186-1066-02

9611-2025-01(2)

9744-1625-01(2)

2186-4033-01

2186-0141-02

2186-1146-02

2186-1144-02

9748-2050-01

See Page 5,6,7

Page 12

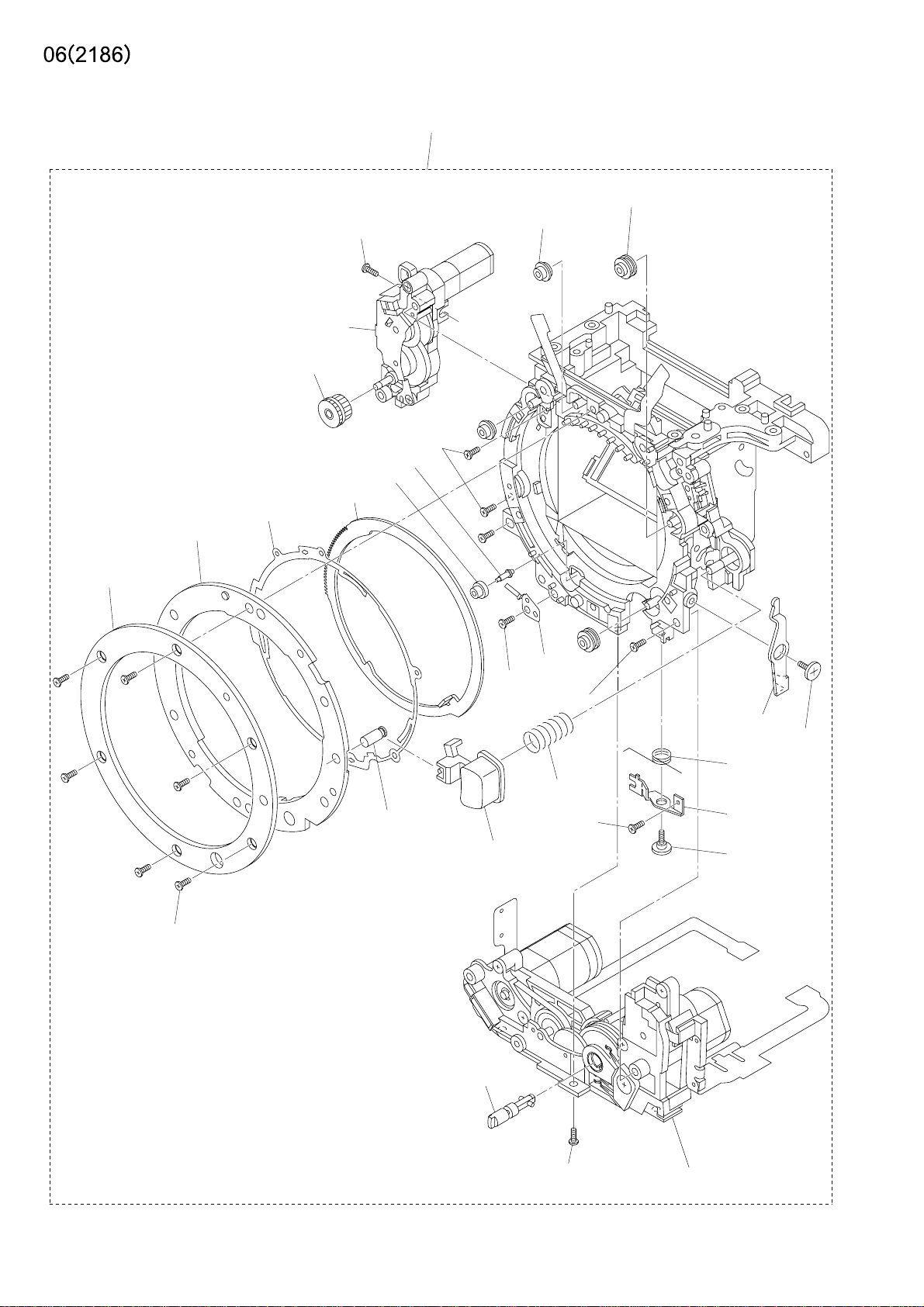

(2186) 3

PART NO PART NAME QTY.

2186-0141-02 REMOTE TERMINAL HOLDER ASSY

2186-1003-03 SUS PLATE L

2186-1005-03 EYELET REINFORCEMENT PLATE

2186-1066-02 EYELET L

2186-1144-02 REMOTE COVER

2186-1146-02 REMOTE SHEET

2186-4033-01 REMOTE FPC

2186-5033-01

2186-5034-01

9611-2025-01 SCREW

9744-1625-01 SCREW

9745-2025-01 SCREW

9747-1735-01 SCREW

9748-2050-01 SCREW

PENTA PROTECTION PLATE RAG PLATE 1

PENTA PROTECTION PLATE RAG PLATE 2

リモートホルダーセット

シャーシL

吊環補強板

吊環L

リモート蓋

リモートシート

リモコンフレキ

ペンタ保護板用ラグ板1

ペンタ保護板用ラグ板2

ねじ

ねじ

ねじ

ねじ

ねじ

1

1

1

1

1

1

1

PARTS LIST

1

1

2

2

3

2

6

Page 13

(2186-0412-01)

9748-2055-01

2186-2961-02

A

B

9748-2055-01(2)

9744-1620-01

A

B

2181-2920-03

9758-0100-00

C

2186-2703-02(3)

[9384-2190-50]

(3.5X10mm)

2181-2918-01

9747-1775-01

2186-2722-03(3)

2186-0901-01

2181-2706-01(3)

9796-2040-40(3)

9747-1745-01(4)

2186-0271-01

2186-2715-01

2181-2702-01

2186-2721-01

9744-1618-01

9744-1630-01

C

2186-1171-01

9744-1635-01

2186-0721-01

2186-0210-01

2181-5133-02

See Page 5

Page 14

(2186) 4

PART NO PART NAME QTY.

2186-0210-01 SHUTTER ASSY

2186-0271-01 CCD ASSY

(2186-0412-01) CCD FPC ASSY

(9384-2190-50) DOUBLE-FACED TAPE (PER ROLL)

2186-0721-01 MAIN PLATE ASSY

2186-0901-01 SLIDER ASSY

2186-1171-01 MAIN BOARD SUPPORT PLATE A

2181-2702-01 LPF PRESSING PLT

2186-2703-02 AORI ADJ SPRING

2181-2706-01 AORI ADJ SCREW

2186-2715-01 CCD LPF MASK SHEET

2186-2721-01 CCD SLANTING STOPPER

2186-2722-03 CAP WASHER

2181-2918-01 CCD UNDER PLATE

2181-2920-03 CCD UNDER PLT SPRING

2186-2961-02 SLIDER STOPPER PLATE

2181-5133-02 SHUTTER CHARGE GEAR

シャッターセット

CCDセット

CCDフレキセット

両面テープ

メイン台板セット

スライダーセット

メイン基板保持台A

LPF押え板

あおり調整SP

あおり調整ねじ

LPFマスクシート

偏心ピンストッパー

あおり調整軸ワッシャ

CCD板

CCD板SP

スライダーストップ板

シャッターチャージギヤ

1

1

1

1

1

1

1

1

3

3

1

1

3

1

1

1

1

PARTS LIST

9744-1618-01 SCREW

9744-1620-01 SCREW

9744-1630-01 SCREW

9744-1635-01 SCREW

9747-1745-01 SCREW

9747-1775-01 SCREW

9748-2055-01 SCREW

9758-0100-00 STEEL BALL

9796-2040-40 WASHER

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

スチールボール

ワッシャ

1

1

1

1

4

1

3

1

3

Page 15

2186-0500-01

(2181-0580-01)

[9384-2290-90]

(9X15mm)

[2186-5022-01]

[9747-1745-01](2)

[2186-5048-02]

[2186-0506-01]

[9747-1735-01](2)

[2186-0503-01]

[9747-1745-01](2)

[2186-0584-01]

[2186-5820-01]

2186-5025-01

~

[2186-5028-01]

[2186-5805-02]

(Some)

(9384-2190-50)

(3X5mm)

(9747-1745-01)(3)

See Page 6

(2162-2659-01)(3)

(2186-0265-02)

[2181-5016-01]

(2082-5054-01)(3)

(2162-2658-01)(3)

Page 16

(2186) 5

PART NO PART NAME QTY.

2186-0500-01 MIRROR BOX ASSY

(2186-0265-02) AF MODULE ASSY

(2186-0580-01) PENTA ASSY

[2186-0503-01] INF LCD HOLDER ASSY

[2186-0506-01] TOUKO ASSY

[2186-0584-01] DIOPTER ASSY

[2181-5016-01] FRESNAL SPRING

[2186-5022-01] SPC LIGHT SHIELD SHEET

2186-5025-01 VB WASHER A (0.05mm)

2186-5026-01 VB WASHER B (0.1mm)

2186-5027-01 VB WASHER C (0.15mm)

[2186-5028-01] VB WASHER D (STD WASHER) (0.2mm)

[2186-5048-02] PENTA PREVENTION SHEET

[2186-5805-02] FRESNAL

[2186-5820-01] SI SCREEN

ミラーボックスセット

AFモジュールセット

ペンタセット

IF LCDホルダーセット

投光セット

視度調セット

焦点板SP

SPC遮光シート

VBワッシャA

VBワッシャB

VBワッシャC

VBワッシャD

ペンタ防塵シート

焦点板

SIスクリーン

1

1

1

1

1

1

1

PARTS LIST

1

Some

1

1

1

[9384-2290-90]

[9747-1735-01] SCREW

[9747-1745-01] SCREW

(2162-2658-01) AF ADJUSTMENT SCREW

(2162-2659-01) AF ADJUSTMENT SP

(2082-5054-01) WASHER

(9384-2190-50) DOUBLE-FACED TAPE (PER ROLL)

(9747-1745-01) SCREW

POLYESTER TAPE (PER ROLL/60M) YELLOW

ポリエステルテープ

ねじ

ねじ

AF調整ねじ

AF調整SP

ワッシャ

両面テープ

ねじ

1

2

4

3

3

3

1

3

Page 17

2186-0500-01

(9747-1750-01)

(2186-2532-02)(2)

(2186-2533-02)(2)

(2163-1521-01)

(2186-1524-03)

(2186-0254-01)

(2186-2512-01)

(2186-2530-02)

(2186-1511-02)

(9747-1750-01)(2)

(2186-2535-01)

(2186-2534-01)

(2181-1515-01)

(2186-1813-01)

(9747-1745-01)

(2181-5123-01)(2)

(2162-1547-01)

(2186-1525-01)

See Page 7

(2186-1522-01)

(9749-1730-01)

(2186-1523-01)

(2186-1520-01)

(9761-2055-04)(6)

(2186-1545-02)

(2186-0526-01)

(9747-1745-01)

(2186-1521-01)

(2186-0521-01)

Page 18

(2186) 6

PART NO PART NAME QTY.

2186-0500-01 MIRROR BOX ASSY

(2186-0254-01) APERTURE ASSY

(2186-0521-01) AF CHARGE ASSY

(2186-0526-01) AF COUPLER ASSY

(2186-1511-02) A-MOUNT SPRING

(2181-1515-01) LENS LOCK PIN

(2186-1520-01) COUPLER LEVER

(2163-1521-01) BAYONET MOUNT

(2186-1521-01) COUPLER LEVER SHAFT

(2186-1522-01) COUPLER LINKAGE LEVER

(2186-1523-01) COUPLER LEVER SPRING

(2186-1524-03) MOUNT SPACER

(2186-1525-01) COUPLER LEVER ADJ SCREW

(2186-1545-02) LENS LOCK BUTTON

(2162-1547-01) LENS LOCK SP

ミラーボックスセット

絞り台板セット

AFチャージ台板セット

AFカプラーセット

リングSP

レンズロックピン

カプラーレバー

マウント

カプラーレバー軸

カプラー連動レバー

カプラーレバー付勢SP

マウントスペーサ

カプラーレバー調整ねじ

レンズロック釦

レンズロックSP

1

1

1

1

1

1

1

PARTS LIST

1

1

1

1

1

1

1

1

(2186-1813-01) MOUNT RAG PLATE 2

(2186-2512-01) APERTURE LINKAGE GEAR

(2186-2530-02) APERTURE RING

(2186-2532-02) ROLLER -A

(2186-2533-02) ROLLER -B

(2186-2534-01) ROLLER -C

(2186-2535-01) ROLLER -C SHAFT

(2181-5123-01) SCREW AF CHARGE BS PLT

(9747-1745-01) SCREW

(9747-1750-01) SCREW

(9749-1730-01) SCREW

(9761-2055-04) SCREW

マウント用ラグ板2

絞り連結ギヤ

絞りリング

リングローラーA

リングローラーB

リングローラーC

リングローラーC軸

AF/チャージ台板ねじ

ねじ

ねじ

ねじ

ねじ

1

1

1

2

2

1

1

2

2

3

1

6

Page 19

(2186-0150-01)

(9769-1740-01)

2186-0500-01

(2186-5110-01)

(9769-1730-01)

(2186-5110-01)

(9769-1730-01)

(2186-0514-01)

(9769-1740-01)

(2186-0180-01)

(2186-5151-01)

(2186-5109-01)

(9747-1745-01)(2)

[2186-5806-02]

(2186-1812-01)

(2186-0515-01)

(2181-5108-02)

(9747-1735-01)(4)

(2186-5101-01)

(2186-5107-02)

(2186-5102-01)

(9747-1440-01)

(2186-1543-02)

(2162-1544-01)

(2186-1542-01)

(2186-5112-01)

(2186-1548-01)

Page 20

(2186) 7

PART NO PART NAME QTY.

2186-0500-01 MIRROR BOX ASSY

(2186-0150-01) BL CONTACT HOLDER ASSY

(2186-0180-01) FRONT FRAME ASSY

(2186-0514-01) MAIN MIRROR HOLDER UNIT

[2186-5806-02] MAIN MIRROR

(2186-0515-01) SUB MIRROR HOLDER ASSY

(2186-1542-01) SLLK CONTACT A

(2186-1543-02) SLLK CONTACT B

(2162-1544-01) SLLK CONTACT SPACER

(2186-1548-01)

(2186-1812-01) MOUNT RAG PLATE1

(2186-5101-01) MIRROR DRIVING LEVER

(2186-5102-01) MAIN MIRROR DRIVING LEVER

(2186-5107-02) MIRROR OVER CHARGE SP

(2181-5108-02) MIRROR DRIVE SP

LENS LOCK BUTTON HOLDING BASE PLATE

ミラーボックスセット

BL接片ホルダーセット

前枠セット

主ミラーホルダーセット

主ミラー

サブミラーホルダーセット

SLLK接片A

SLLK接片B

SLLK接片スペーサー

レンズロック釦保持台板

マウント用ラグ板1

ミラー駆動レバー

主ミラー駆動レバー

ミラーオーバーチャージSP

ミラー駆動SP

1

1

1

1

1

1

1

PARTS LIST

1

1

1

1

1

1

1

1

(2186-5109-01) SUB MIRROR DRIVING SP

(2186-5110-01) M.MIRROR HOLDER PRESSING PLT

(2186-5112-01) MIRROR DRIVING BASE PLT

(2186-5151-01) FLARE CUTTER SHEET

(9747-1440-01) SCREW

(9747-1735-01) SCREW

(9747-1745-01) SCREW

(9769-1730-01) SCREW

(9769-1740-01) SCREW

サブミラー駆動SP

主ミラーホルダー押え板

ミラー駆動台板

フレア防止シート

ねじ

ねじ

ねじ

ねじ

ねじ

1

2

1

1

1

4

2

2

2

Page 21

9761-2055-01

2186-1088-01

9384-2290-90

(9X15mm)

2186-1153-02

2186-1151-02

9769-1730-01

2186-1156-01

9747-1735-01

9747-1735-01

2186-0155-01

2186-1072-01

2186-1065-02

2186-1159-01

2186-0154-01

2186-1071-03

9747-1740-01

9749-2035-01(2)

2186-1002-04

9384-2191-00

(6X20mm)

2186-0414-02

2186-4508-02

2186-1086-01

9747-1750-01

2186-1087-01

2186-1082-02(2)

9747-1730-01(2)

2186-1083-01

2186-1081-02

9749-1735-15

9353-4361-13

9747-1740-01(2)

2186-0473-01

2186-0427-03

9747-1740-01(2)

2186-1073-01

2186-1041-02

2186-1042-02

2186-1040-02

2186-0420-03

9384-2190-50(3)

(5X5mm)

Page 22

(2186) 8

PART NO PART NAME QTY.

2186-0154-01 CF CARD COVER HINGE SHAFT-A ASSY

2186-0155-01 CF CARD COVER HINGE SHAFT-B ASSY

2186-0414-02 GYRO FPC ASSY

2186-0420-03 SW FPC-2 ASSY

2186-0427-03 DC JACK PCB ASSY

2186-0473-01 FLASH PCB ASSY

2186-1002-04 SUS PLATE G

2186-1040-02 LCD HOLDER

2186-1041-02 LCD WINDOW

2186-1042-02 LCD WINDOW ATTACHMENT SHEET

2186-1065-02 EYELET G

2186-1071-03 BATTERY CHAMBER

2186-1072-01 BATTERY CHAMBER SHEET

2186-1073-01 BATTERY FORCING SP

2186-1081-02 BATTERY LOCK PLATE

2186-1082-02 BATTERY CONTACT

2186-1083-01 BATTERY LOCK PLATE FORCING SP

CFカードカバー軸Aセット

CFカードカバー軸Bセット

ジャイロフレキセット

SWフレキ2セット

DCジャック基板セット

フラッシュ基板セット

サブシャーシG

LCDホルダー

LCD窓

LCD窓貼付けシート

吊環G

電池室

電池室シート

電池付勢SP

電池ロック爪

電池接片

電池ロック爪付勢SP

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

PARTS LIST

2186-1086-01 FLASH PCB GAP HOLDER

2186-1087-01 LUG PLATE 1

2186-1088-01 LUG PLATE 2

2186-1151-02 CF CARD COVER

2186-1153-02 CF CARD COVER CLICK PLATE

2186-1156-01 CF CARD DISPLAY SHEET

2186-1159-01 CF CARD COVER SP

2186-4508-02 GYRO FPC TAPE

9353-4361-13 LCD 101

9384-2190-50 DOUBLE-FACED TAPE (PER ROLL)

9384-2191-00 DOUBLE-FACED TAPE (PER ROLL)

9384-2290-90

9747-1730-01 SCREW

9747-1735-01 SCREW

9747-1740-01 SCREW

9747-1750-01 SCREW

9749-1735-15 SCREW

POLYESTER TAPE (PER ROLL/60M) YELLOW

フラッシュ基板絶縁ホルダー

ラグ板1

ラグ板2

CFカード蓋

CFカード蓋クリック板

CFカード表示シート

CFカード蓋SP

ジャイロフレキテープ

LCD101

両面テープ

両面テープ

ポリエステルテープ

ねじ

ねじ

ねじ

ねじ

ねじ

1

1

1

1

1

1

1

1

1

3

1

1

2

2

5

1

1

9749-2035-01 SCREW

9761-2055-01 SCREW

9769-1730-01 SCREW

ねじ

ねじ

ねじ

2

1

1

Page 23

(2186-1334-02)(-650)

(2186-1479-02)(-090,-100,-300,-600)

(2186-1477-01)

(2186-1317-01)(-650)

(2186-1401-01)(-090,-100,-300,-600)

(2186-0166-01)

2186-0131-01(-650)

2186-0135-01(-090,-100,-300,-600)

(9747-1745-04)(2)(-650)

(9747-1745-15)(2)(-090,-100,-300,-600)

(2186-1335-01)(-650)

(2186-1601-02)(-090,-100,-300,-600)

(2186-1609-01)

(2186-1613-01)

(2186-1318-01)

(-650)

(2186-1403-02)

(-090,-100,-300,-600)

(2186-1402-03)

(2186-1424-01)

(2186-1404-01)

[2186-1603-01]

(2186-1602-02)

(2186-1608-01)(2)

(2089-1607-02)

(9747-1745-15)(2)

(2089-1620-01)

(2186-1333-02)

(-650)

(2186-1474-02)

(2089-1621-01)

(2186-1332-02)

(-650)

(2186-1473-02)

(-090,-100,-300,-600)

(2186-1477-01)

(2186-1331-02)

(-650)

(2186-1470-01)

(-090,-100,-300,-600)

(2186-1330-03)

(-650)

(2186-1469-04)

(-090,-100,-300,-600)

(-090,-100,-300,-600)

(9721-0120-50)

(2181-1305-01)

(2162-1477-01)(2)

(9758-0150-00)(2)

(2186-1407-01)

(2186-1410-01)

(9748-2045-01)

(2186-1610-01)

(2186-1611-01)

(2162-1477-01)(2)

(9758-0150-00)(2)

(2186-1471-01)

(2186-1475-01)

(9747-1735-01)(2)

(2186-1481-02)

(9747-1730-01)

Page 24

(2186) 9

PART NO PART NAME QTY.

2186-0131-01 TOP COVER ASSY (-650)

2186-0135-01 TOP COVER ASSY (-090, -100, -300, -600)

(2186-0166-01) REFLECTOR ASSY

[2186-1603-01] FLASH PANEL

(2181-1305-01) VI EMBLEM

(2186-1317-01) MODE DIAL (-650)

(2186-1401-01) MODE DIAL (-090, -100, -300, -600)

(2186-1318-01) MODE DIAL DECORATION RING (-650)

(2186-1403-02)

MODE DIAL DECORATION RING (-090, -100, -300, -600)

(2186-1330-03) WB DIAL DECORATION RING (-650)

(2186-1469-04)

WB DIAL DECORATION RING (-090, -100, -300, -600)

(2186-1331-02) WB DIAL (-650)

(2186-1470-01) WB DIAL (-090, -100, -300, -600)

(2186-1332-02) WB DIAL NAME PLATE (-650)

(2186-1473-02)

WB DIAL NAME PLATE (-090, -100, -300, -600)

(2186-1333-02) WB BUTTON (-650)

(2186-1474-02) WB BUTTON (-090, -100, -300, -600)

(2186-1334-02) MODE DIAL NAME PLATE (-650)

(2186-1479-02)

MODE DIAL NAME PLATE (-090, -100, -300, -600)

(2186-1335-01) FLASH CASE (UPPER) (-650)

(2186-1601-02)

FLASH CASE (UPPER) (-090, -100, -300, -600)

(2186-1402-03) RELEASE BUTTON CAP

(2186-1404-01) RELEASE BUTTON SP

(2186-1407-01) MODE DIAL CLICK PLATE

(2186-1410-01) MODE DIAL CONTACT

(2186-1424-01) RELEASE BUTTON

(2186-1471-01) WB DIAL CLICK PLATE

(2186-1475-01) WB DIAL DETECT CONTACT

(2162-1477-01) DIAL CLICK SP

(2186-1477-01) WB / MODE NAME PLATE TAPE

(2186-1481-02) WB BUTTON SP

(2186-1602-02) FLASH CASE (BOTTOM)

(2089-1607-02) SCREW

(2186-1608-01) FLASH CUSHION RUBBER

(2186-1609-01) F SNAP ACTION SP

(2186-1610-01) ROTATION AXIS (L)

(2186-1611-01) ROTATION AXIS (R)

(2186-1613-01) SNAP SUPPORTING SCREW

(2089-1620-01) C-RING

(2089-1621-01) C-RING

(9721-0120-50) E-RING

(9747-1730-01) SCREW

(9747-1735-01) SCREW

(9747-1745-04) SCREW (-650)

(9747-1745-15) SCREW (-650)

(9747-1745-15) SCREW (-090, -100, -300, -600)

(9748-2045-01) SCREW

(9758-0150-00) STEEL BALL

上カバーセット

上カバーセット

発光部セット

発光パネル

VIエンブレム

モードダイヤル

モードダイヤル

モードダイヤル化粧リング

モードダイヤル化粧リング

WBダイヤル化粧リング

WBダイヤル化粧リング

WBダイヤル

WBダイヤル

WBダイヤル文字板

WBダイヤル文字板

WB釦

WB釦

モードダイヤル文字板

モードダイヤル文字板

発光部ケース(上)

発光部ケース(上)

レリーズ釦キャップ

レリーズ釦SP

モードダイヤルクリック板

モードダイヤル接片

レリーズ釦

WBダイヤルクリック板

WBダイヤル接片

露出ダイヤルクリックSP

WB文字板テープ

WB釦SP

発光部ケース(下)

ねじ

フラッシュクッション

フラッシュスナップアクションSP

回転軸L

回転軸R

ねじ

Cリング

Cリング

Eリング

ねじ

ねじ

ねじ

ねじ

ねじ

ねじ

スチールボール

1

1

1

1

1

1

1

PARTS LIST

1

1

1

1

1

1

1

1

1

1

1

1

4

2

1

1

1

2

1

1

1

1

1

1

1

1

2

2

2

4

1

4

Page 25

(9372-3960-02)

(2186-1443-01)

(9747-1740-01)(4)

2186-0131-01(-650)

2186-0135-01(-090,-100,-300,-600)

(9747-1740-01)(3)

(2186-1441-02)

(9384-2190-50)(3)

(5X5mm)

(2186-0146-01)

(9384-2190-50)(2)

(5X5mm)

A

(2186-1327-03)

(-650)

(2186-1440-03)

(-090,-100,-300,-600)

(2186-1320-03)

(-650)

(2186-1421-02)

(-090,-100,-300,-600)

(9747-1745-01)(2)

(9384-2190-50)

(3X6mm)

(9761-2060-01)(2)

(9384-2190-50)

(5X5mm)

(9384-2190-50)

(5X5mm)

(9384-2191-00)

(10X10mm)

(9761-2060-01)(2)

(2186-1625-02)

A

(2186-1612-01)

(2186-1476-01)

(9384-2191-00)

(10X10mm)

(2186-0407-02)

(2186-1328-01)(2)

(-650)

(2186-1442-01)(2)

(2186-1321-01)

(-650)

(2186-1422-01)

(-090,-100,-300,-600)

(-090,-100,-300,-600)

(2186-1322-03)(-650)

(2186-1425-02)(-090,-100,-300,-600)

(2186-1120-02)

(2186-1614-02)

(2077-0145-01)

(9747-1735-01)

(2186-1427-01)

(2186-1426-02)

Page 26

(2186) 10

PART NO PART NAME QTY.

2186-0131-01 TOP COVER ASSY (-650)

2186-0135-01 TOP COVER ASSY (-090, -100, -300, -600)

(2077-0145-01) FLASH ACC SHOE SET

(2186-0146-01) FRONT DIAL HOLDER ASSY

(2186-0407-02) TOP COVER FPC ASSY

(2186-1120-02) SELF WINDOW

(2186-1320-03) 3 COMBINED BUTTON (-650)

(2186-1421-02)

3 COMBINED BUTTON (-090, -100, -300, -600)

(2186-1321-01) AEL BUTTON RING (-650)

(2186-1422-01) AEL BUTTON RING (-090, -100, -300, -600)

(2186-1322-03) MAIN SW CHANGEOVER LEVER (-650)

(2186-1425-02)

MAIN SW CHANGEOVER LEVER (-090, -100, -300, -600)

(2186-1327-03) 2 COMBINED BUTTON (-650)

(2186-1440-03)

2 COMBINED BUTTON (-090, -100, -300, -600)

(2186-1328-01) MODE BUTTON RING (-650)

(2186-1442-01)

MODE BUTTON RING (-090, -100, -300, -600)

上カバーセット

上カバーセット

アクセサリーシューセット

前ダイヤルホルダーセット

上カバーフレキセット

セルフ窓

3連釦

3連釦

AEL釦リング

AEL釦リング

メインSWレバー

メインSWレバー

2連釦

2連釦

モード釦リング

モード釦リング

1

1

1

1

1

1

PARTS LIST

1

1

1

2

(2186-1426-02)

(2186-1427-01)

MAIN SW CHANGEOVER LEVER CLICK PLATE

MAIN SW CHANGEOVER LEVER CONTACT

(2186-1441-02) MODE DIAL PLATE

(2186-1443-01) BUZZER ATTACHMENT TAPE

(2186-1476-01) WB DIAL BASE PLATE

(2186-1612-01) HOT SHOE MOUNTING PLATE

(2186-1614-02) HOT SHOE PLATE

(2186-1625-02) PU DETECT CONTACT

(9372-3960-02) BUZZER

(9384-2190-50) DOUBLE-FACED TAPE (PER ROLL)

(9384-2191-00) DOUBLE-FACED TAPE (PER ROLL)

(9747-1735-01) SCREW

(9747-1740-01) SCREW

(9747-1745-01) SCREW

(9761-2060-01) SCREW

メインSWレバークリック板

メインSW接片

モードダイヤル台板

ブザー貼付けテープ

WBダイヤル台板

シュー取付板

シュー敷板

PU検知接片

ブザー

両面テープ

両面テープ

ねじ

ねじ

ねじ

ねじ

1

1

1

1

1

1

1

1

1

8

2

1

7

2

4

Page 27

2186-0121-01(-090,-100,-300,-600)

2186-0122-01(-650)

(2186-1115-01)

(2186-1119-02)

(9767-1435-01)

(2186-1133-01)

(2186-1132-01)

(2186-1445-01)

(2186-1446-01)

(2186-4511-01)

(2186-1336-01)

(-650)

(2166-1485-01)

(-090,-100,-300,-600)

(9384-2290-90)

(9X20mm)

2186-0110-01

(9747-1740-01)

(2181-1419-03)

(2186-1420-02)

(2186-1417-02)

(2186-1116-01)

(2186-1106-01)

(2186-1107-01)

(2186-1133-01)

(2186-1132-01)

(2186-1418-03)

(2186-1329-03)(-650)

(2186-1444-02)(-090,-100,-300,-600)

(2186-1431-02)

(2186-1433-01)

(2186-1430-03)

(2186-1432-01)

(2186-1143-02)

(2186-1436-01)(4)

(2186-1435-02)(4)

(2186-1433-01)(4)

(9747-1730-01)

(2186-1145-01)

(2186-1133-01)

(2186-1132-01)

(2186-2940-01)(2)

(2186-1133-01)

(2186-1132-01)

Page 28

(2186) 11

PART NO PART NAME QTY.

2186-0110-01 BACK COVER ASSY

(2186-1106-01) BACK COVER RUBBER

(2186-1107-01) BACK COVER ATTACHMENT TAPE

(2186-1132-01) FRONT COVER BOTTOM RUBBER

(2186-1133-01) DOUBLE SIDE TAPE

(2186-1143-02) DC JACK COVER

(2186-1145-01) DC COVER PIN

(2186-1417-02) ACCESS LAMP WINDOW

(2186-1418-03) ANTI SHAKE SW CHANGEOVER LEVER

(2181-1419-03) TEBURE CLICK PLATE

(2186-1420-02) ANTI SHAKE SW CONTACT

(2186-1430-03) CROSS BUTTON

(2186-1431-02) DECISION BUTTON

(2186-1432-01) CROSS BUTTON SP

(2186-1433-01) DECISION BUTTON SP

(2186-1435-02) 4 COMBINED BUTTON

(2186-1436-01)

4 COMBINED BUTTON DECORATION RING

後カバーセット

後カバーゴム

後カバーゴム貼付けテープ

底面ゴム

底面ゴムテープ

DCジャックカバー

DCカバーピン

アクセスランプ窓

手振れSWレバー

手振れクリック板

手振れSW接片

十字釦

決定釦

十字釦SP

決定釦SP

4連釦

4連釦飾りリング

1

1

1

2

2

1

1

1

1

1

1

1

1

1

5

4

4

PARTS LIST

(2186-2940-01) TAPE

(9747-1730-01) SCREW

(9747-1740-01) SCREW

2186-0121-01

2186-0122-01 FRONT COVER ASSY (-650)

(2186-1115-01) RUBBER DOUBLE SIDE TAPE A

(2186-1116-01) RUBBER DOUBLE SIDE TAPE B

(2186-1119-02) GRIP COVER

(2186-1132-01) FRONT COVER BOTTOM RUBBER

(2186-1133-01) DOUBLE SIDE TAPE

(2186-1329-03) AF/M CHANGEOVER LEVER (-650)

(2186-1444-02)

(2186-1336-01) PREVIEW BUTTON (-650)

(2166-1485-01) PREVIEW BUTTON (-090, -100, -300, -600)

(2186-1445-01) AF/M CHANGEOVER CONTACT

(2186-1446-01) MAIN SW CLICK PLATE

FRONT COVER ASSY (-090, -100, -300, -600)

AF/M CHANGEOVER LEVER (-090, -100, -300, -600)

テープ

ねじ

ねじ

前カバーセット

前カバーセット

グリップゴム両面テープA

グリップゴム両面テープB

グリップゴム

底面ゴム

底面ゴムテープ

AF/M切替えレバー

AF/M切替えレバー

プレビュー釦

プレビュー釦

AF/M切替え接片

AF/Mクリック板

2

1

1

1

1

1

1

2

2

1

1

1

1

(2186-4511-01) INSULATING SHEET

(9384-2290-90)

(9767-1435-01) SCREW

POLYESTER TAPE (PER ROLL/60M) YELLOW

絶縁シート

ポリエステルテープ

ねじ

1

1

1

Page 29

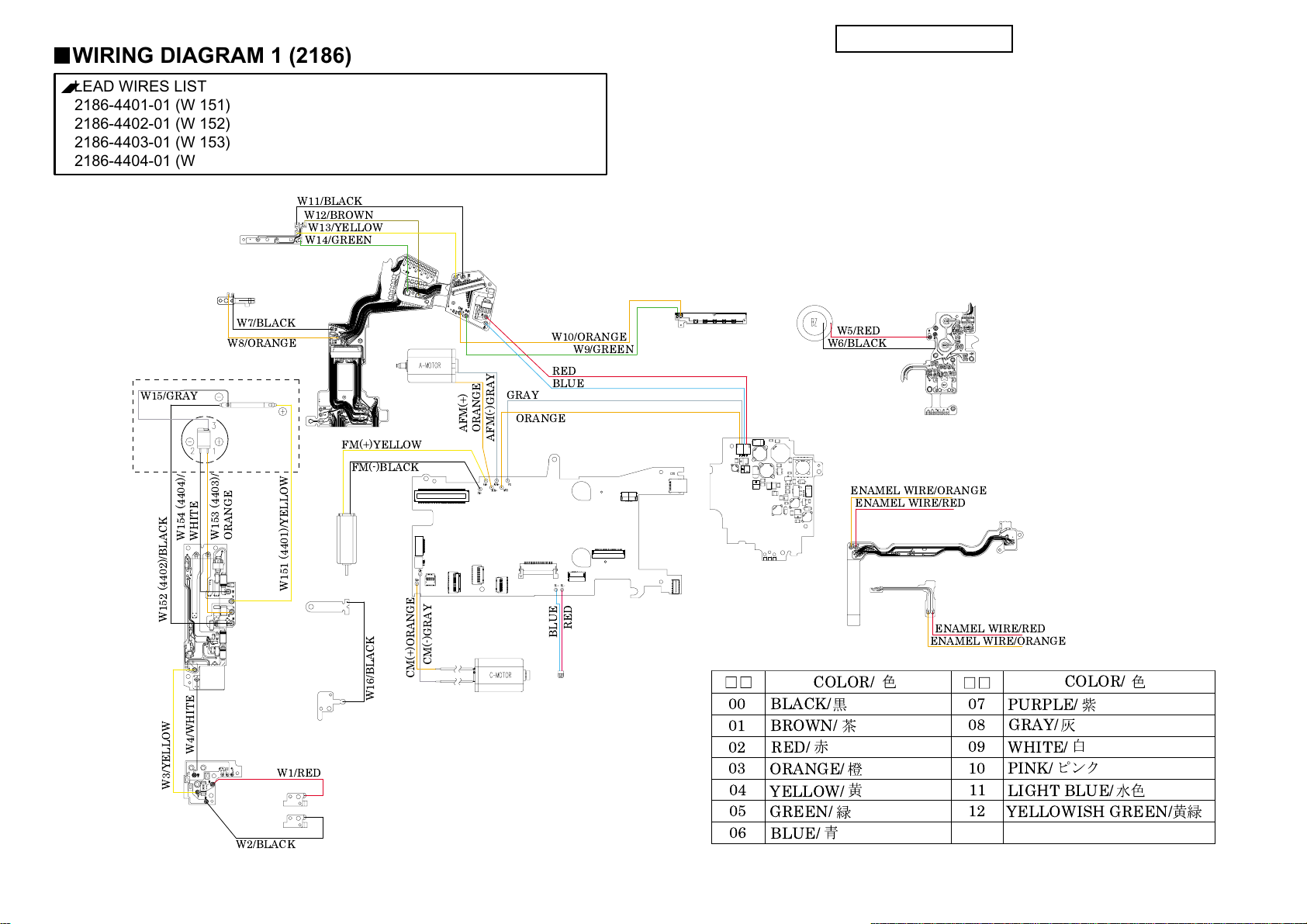

WIRING DIAGRAM 1 (2186)

■

LEAD WIRES LIST

2186-4401-01 (W 151)

2186-4402-01 (W 152)

2186-4403-01 (W 153)

2186-4404-01 (W 154)

EYE PIECE FRAME

ASSY (0134)

9391-0807 9391-1207-

W11/BLACK

W12/BROWN

W13/YELLOW

W14/GREEN

□□

(W 5, 6, 7, 8, 9, 10, 11, 12, 13, 14)

□□

(W 1, 2, 3, 4, 15, 16)

PARTS LIST

12 (2186)

SLLK CONTACT A (1542)

SLLK CONTACT B

(1543)

REFLECTOR ASSY (0166)

W15/GRAY

W154 (4404)/

W152 (4402)/BLACK

W3/YELLOW

DC JACK PCB

ASSY (0473)

W7/BLACK

W8/ORANGE

W153 (4403)/

ORANGE

WHITE

W4/WHITE

W2/BLACK

LUG PLATE 2 (1088)

W151 (4401)/YELLOW

FLASH PC

ASSY (0473)

W1/RED

AF CHARGE

ASSY (0521)

FM(+)YELLOW

FM(-)BLACK

APERTURE ASSY (0254)

CM(-)GRAY

CM(+)ORANGE

W16/BLACK

LUG PLATE 1 (1087)

BATTERY CONTACT (1082)

AF CHARGE ASSY (0521)

I/O FLEXIBLE ASSY

(0406)

GRAY

AFM(+)

ORANGE

ORANGE

AFM(-)GRAY

W10/ORANGE

W9/GREEN

RED

BLUE

MAIN PCB ASSY (0401)

RED

BLUE

LCD HARNESS (0442)

INF LCD HOLDER

ASSY (0503)

POWER SUPPLY

HARNESS (0441)

00

01

02

03

04

05

06

BUZZER (9372-3960)

W5/RED

W6/BLACK

DCDC PCB ASSY (0402)

ENAMEL WIRE/ORANGE

COLOR/

BLACK/

BROWN/

RED/

ORANGE/

YELLOW/

GREEN/

BLUE/

TOP COVER FPC ASSY (0407)

ENAMEL WIRE/RED

SLIDER ASSY (0901)

ENAMEL WIRE/RED

ENAMEL WIRE/ORANGE

07

08

09

10

11

12

COLOR/

PURPLE/

GRAY/

WHITE/

PINK/

LIGHT BLUE/

YELLOWISH GREEN/

Page 30

REPAIR GUIDE

(2186) 1

REPAIR GUIDE

This repair guide section contains the disassembly and adjustment procedures.

For the assembly procedure, follow the reverse procedure.

SYMBOLS

■:Cautions and keypoints

: Grease

: Adhesive

: Tool

CONTENTS Page CONTENTS Page

■Precautions --------------------------------------------- 2

■Chemicals ----------------------------------------------- 2

■Plastic parts -------------------------------------------- 2

■PCBs ----------------------------------------------------- 2

■Unleaded solder ---------------------------------------- 2

■Discharge------------------------------------------------ 3

■To activate without exterior parts ----------------- 3

1. Disassembly of the exterior parts ------------------ 4

■ Wires arrangement----------------------------------- 6

2. Disassembly of the I/O FPC ASSY,

MAIN PCB ASSY ---------------------------------- 8

3. Disassembly of the SUB PLATE L,

BATTERY CHAMBER--------------------------- 11

4. Disassembly of the CCD ASSY,

SHUTTER ASSY----------------------------------13

■CCD inclination adjustment / repair-------------16

5. Disassembly-1 of the MIRROR BOX ASSY -----17

6. Disassembly-2 of the MIRROR BOX ASSY -----19

7. Disassembly-3 of the MIRROR BOX ASSY -----22

8. Disassembly of the BATTERY CHAMBER,

LCD 101 ---------------------------------------------24

9. Disassembly of the TOP COVER ASSY---------- 27

10. Disassembly of the FRONT COVER ASSY,

BACK COVER ASSY -----------------------------31

■Required adjustment, setting and confirmation

items after repairing (exchanging parts)----- 33

■Related adjustment and

required setting items ----------------------------34

■Viewfinder Back Adjustment ---------------------- 35

■Preparing the 2186 adjustment program -------36

■Starting up the 2186 adjustment program

(in the adjustment mode). -----------------------37

■Adjustment of the PI-PR---------------------------- 38

■Adjustment of the frequency for

camera shaking (FREQUENCY) --------------38

■Adjustment of the servo for

camera shaking (SERVO) ----------------------- 38

■Adjustment of the gyro for

camera shaking (GYRO) ------------------------39

■Adjustment of CCD Vsub voltage (VSUB) ------ 39

■Setting for the adjustment of

CCD AORI & CENTER -------------------------- 40

■Adjustment / Checking of

CCD AORI & CENTER -------------------------- 41

■Manual Set SS & X-Sync. Time-lag Check-----43

■Adjustment Manual Set SS ------------------------44

■Preparation before AF adjustment --------------- 45

■AF Area Adjustment---------------------------------46

■Pitch Yaw Adjustment ------------------------------47

■FLATNESS Adjustment---------------------------- 48

■EZ Check / Adjustment ----------------------------- 48

■EZ SH I F T---------------------------------------------- 51

■Aperture Preset Check / Adjustment ------------52

■Check / Adjustment of the AE (AE) --------------53

■Sensitivity adjustment (CCD GAIN)-------------54

■Adjustment of the defective pixel

(DEFECT PIXEL)--------------------------------- 54

■Adjustment of white balance (WB) --------------- 55

■Adjustment of the camera shaking

compensation (SHAKE GAIN) -----------------56

■FLASH LEVEL SHIFT ----------------------------- 57

■Setting of Destination (DESTINATION)-------- 57

■CAMERA LOG ---------------------------------------58

■LCD All Segment On ------------------------------- 58

■Light Source-A Maintenance ----------------------59

■Error code on adjustment program--------------- 60

■Measuring instrument ------------------------------62

■Subsidiary Materials---------------------------------62

Page 31

2 (2186)

Chemicals

Handle chemicals of high volatility with care, use of which will affect to your health and environment.

1. Store them sealed in a specific place to prevent exposure to high temperature or direct sunlight.

2. Avoid dividing them into small containers and prevent vaporization.

3. Keep containers sealed when not in use.

4. Avoid using them as much as possible. When required, remove only required amount from the

container to make full use.

Plastic parts

1. When cleaning plastic parts, use cleaning paper or cloth. Never use thinner, ketone, ether.

2. When installing plastic parts, insert the specific screws vertically to the parts. (Be careful not to

tighten too much.

PCBs

Since PCBs use MOS IC, you must reduce static electricity. When repairing a PCB itself, or when

wiring, please perform your work as illustrated below.

If grounding is impossible, connect a cable to a steel desk or shelf.

Unleaded solder

REPAIR GUIDE

This model uses lead-free solder.

The cautions on use:

1. A soldering iron tip temperature of 280 - 350℃ is sufficient, but when it cannot melt solder, use a

higher temperature for a short period of time.

2. Be sure to control soldering iron tips used for lead-free solder and those for leaded solder so they are

managed separately.

This is because mixing lead-free solder and leaded solder will cause detachment phenomenon.

■■

■ Precautions

■■

Keep touching the conductiveKeep touching the conductive

Keep touching the conductive

Keep touching the conductiveKeep touching the conductive

mat while you work.mat while you work.

mat while you work.

mat while you work.mat while you work.

Conductive MatConductive Mat

Conductive Mat

Conductive MatConductive Mat

GNDGND

GND

GNDGND

1M1M

1M

1M1M

ΩΩ

Ω

ΩΩ

Page 32

(2186) 3

REPAIR GUIDE

Discharge

Before disassembly, be sure to discharge the main condenser in the following manner.

WHITEWHITE

WHITE

WHITEWHITE

YELLOWYELLOW

YELLOW

YELLOWYELLOW

Short-circuit with discharger or resistor of 200-300 ohm/3w.

Check voltage to make sure it is discharged.

To activate without exterior parts

Short-circuit the pattern -a of I/O FLEXIBLE ASSY with solder.

When using replacement I/O FLEXIBLE ASSY, no need to short these patterns because it has pattern-b.

*Before installing BACK COVER ASSY, be sure to unsolder the pattern-a or to cut the pattern-b.

aa

a

aa

bb

b

bb

I/O FLEXIBLE ASSYI/O FLEXIBLE ASSY

I/O FLEXIBLE ASSY

CutCut

Cut

CutCut

I/O FLEXIBLE ASSYI/O FLEXIBLE ASSY

Page 33

4 (2186)

1. Disassembly of the exterior parts

Disassemble it in order of step 1to 8.

REPAIR GUIDE

9611-2035-04(-650)9611-2035-04(-650)

9611-2035-04(-650)

9611-2035-04(-650)9611-2035-04(-650)

9611-2035-159611-2035-15

9611-2035-15

9611-2035-159611-2035-15

(-090,-100,-300,-600)(-090,-100,-300,-600)

(-090,-100,-300,-600)

(-090,-100,-300,-600)(-090,-100,-300,-600)

TOP COVER ASSYTOP COVER ASSY

TOP COVER ASSY

TOP COVER ASSYTOP COVER ASSY

EYE PIECE FRAME ASSYEYE PIECE FRAME ASSY

EYE PIECE FRAME ASSY

EYE PIECE FRAME ASSYEYE PIECE FRAME ASSY

■■

Fig. 4Fig. 4

■

Fig. 4

■■

Fig. 4Fig. 4

9384-2191-009384-2191-00

9384-2191-00

9384-2191-009384-2191-00

(10x10mm)(10x10mm)

(10x10mm)

(10x10mm)(10x10mm)

9384-2190-509384-2190-50

9384-2190-50

9384-2190-509384-2190-50

(5x5mm)(5x5mm)

(5x5mm)

(5x5mm)(5x5mm)

B

9747-1755-04(2)(-650)9747-1755-04(2)(-650)

9747-1755-04(2)(-650)

9747-1755-04(2)(-650)9747-1755-04(2)(-650)

9747-1755-15(2)9747-1755-15(2)

9747-1755-15(2)

9747-1755-15(2)9747-1755-15(2)

(-090,-100,-300,-600)(-090,-100,-300,-600)

(-090,-100,-300,-600)

(-090,-100,-300,-600)(-090,-100,-300,-600)

⑤⑤

⑤

⑤⑤

■■

Fig. 2Fig. 2

■

Fig. 2

■■

Fig. 2Fig. 2

See Page 27.See Page 27.

See Page 27.

See Page 27.See Page 27.

SW FPC-1 ASSYSW FPC-1 ASSY

SW FPC-1 ASSY

SW FPC-1 ASSYSW FPC-1 ASSY

⑦⑦

⑦

⑦⑦

9744-1620-019744-1620-01

9744-1620-01

9744-1620-019744-1620-01

⑧⑧

⑧

⑧⑧

C

A

9611-1625-01(2)9611-1625-01(2)

9611-1625-01(2)

9611-1625-01(2)9611-1625-01(2)

See Page 8.See Page 8.

See Page 8.

See Page 8.See Page 8.

2098-50452098-5045

2098-5045

2098-50452098-5045

9761-1470-019761-1470-01

9761-1470-01

9761-1470-019761-1470-01

50415041

5041

50415041

9744-1665-04(2)(-650)9744-1665-04(2)(-650)

9744-1665-04(2)(-650)

9744-1665-04(2)(-650)9744-1665-04(2)(-650)

9744-1665-15(2)9744-1665-15(2)

9744-1665-15(2)

9744-1665-15(2)9744-1665-15(2)

(-090,-100,-300,-600)(-090,-100,-300,-600)

(-090,-100,-300,-600)

(-090,-100,-300,-600)(-090,-100,-300,-600)

VERSION PLTVERSION PLT

VERSION PLT

VERSION PLTVERSION PLT

9747-1740-04(-650)9747-1740-04(-650)

9747-1740-04(-650)

C

A

9747-1740-04(-650)9747-1740-04(-650)

③③

③

③③

9747-1740-159747-1740-15

9747-1740-15

9747-1740-159747-1740-15

(-090,-100,-300,-600)(-090,-100,-300,-600)

(-090,-100,-300,-600)

(-090,-100,-300,-600)(-090,-100,-300,-600)

LCD 101LCD 101

LCD 101

LCD 101LCD 101

■■

■

■■

See Page 24.See Page 24.

See Page 24.

See Page 24.See Page 24.

9744-1625-01(4)9744-1625-01(4)

9744-1625-01(4)

9744-1625-01(4)9744-1625-01(4)

Fig. 3Fig. 3

Fig. 3

Fig. 3Fig. 3

9747-1755-159747-1755-15

9747-1755-15

9747-1755-159747-1755-15

13071307

1307

13071307

13111311

1311

13111311

See Page 8.See Page 8.

See Page 8.

See Page 8.See Page 8.

9747-1755-04(2)(-650)9747-1755-04(2)(-650)

9747-1755-04(2)(-650)

9747-1755-04(2)(-650)9747-1755-04(2)(-650)

9747-1755-15(2)9747-1755-15(2)

9747-1755-15(2)

9747-1755-15(2)9747-1755-15(2)

(-090,-100,-300,-600)(-090,-100,-300,-600)

(-090,-100,-300,-600)

(-090,-100,-300,-600)(-090,-100,-300,-600)

B

9747-1750-019747-1750-01

9747-1750-01

9747-1750-019747-1750-01

D

10761076

1076

10761076

BATTERYBATTERY

BATTERY

BATTERYBATTERY

COVER ASSYCOVER ASSY

COVER ASSY

COVER ASSYCOVER ASSY

■■

Fig. 1Fig. 1

■

Fig. 1

■■

Fig. 1Fig. 1

④④

④

④④

A

9384-2290-909384-2290-90

9384-2290-90

9384-2290-909384-2290-90

(5x20mm)(5x20mm)

(5x20mm)

(5x20mm)(5x20mm)

■■

Fig. 5Fig. 5

■

Fig. 5

■■

Fig. 5Fig. 5

9747-9747-

9747-

9747-97471740-15(2)1740-15(2)

1740-15(2)

1740-15(2)1740-15(2)

②②

②

②②

10791079

1079

10791079

FRONTFRONT

FRONT

FRONTFRONT

COVER ASSYCOVER ASSY

COVER ASSY

COVER ASSYCOVER ASSY

See Page 31.See Page 31.

See Page 31.

See Page 31.See Page 31.

11311131

1131

11311131

9747-9747-

9747-

9747-97471750-15(2)1750-15(2)

1750-15(2)

1750-15(2)1750-15(2)

11301130

1130

11301130

D

10431043

1043

10431043

⑥

BACK COVER ASSYBACK COVER ASSY

BACK COVER ASSY

BACK COVER ASSYBACK COVER ASSY

See Page 31.See Page 31.

See Page 31.

See Page 31.See Page 31.

②②

②

②②

11281128

1128

11281128

PLACE PLATEPLACE PLATE

PLACE PLATE

PLACE PLATEPLACE PLATE

⑥⑥

⑥⑥

9744-1650-15(2)9744-1650-15(2)

9744-1650-15(2)

9744-1650-15(2)9744-1650-15(2)

9744-9744-

9744-

9744-97441635-151635-15

1635-15

1635-151635-15

9744-1630-15(2)9744-1630-15(2)

9744-1630-15(2)

9744-1630-15(2)9744-1630-15(2)

11261126

1126

11261126

①①

①

①①

Page 34

REPAIR GUIDE

■■

Fig. 1Fig. 1

■

Fig. 1

■■

Fig. 1Fig. 1

Removal the BATTERY COVER ASSY Removal the BATTERY COVER ASSY

Removal the BATTERY COVER ASSY

Removal the BATTERY COVER ASSY Removal the BATTERY COVER ASSY

BATTERY COVER ASSYBATTERY COVER ASSY

BATTERY COVER ASSY

BATTERY COVER ASSYBATTERY COVER ASSY

■■

Fig. 3Fig. 3

■

Fig. 3

■■

Fig. 3Fig. 3

Removal the LCD 101 Removal the LCD 101

Removal the LCD 101

Removal the LCD 101 Removal the LCD 101

SW FPC2 ASSYSW FPC2 ASSY

SW FPC2 ASSY

SW FPC2 ASSYSW FPC2 ASSY

ConnectorConnector

Connector

ConnectorConnector

■■

Fig. 2Fig. 2

■

Fig. 2

■■

Fig. 2Fig. 2

Removal the TOP COVER ASSY Removal the TOP COVER ASSY

Removal the TOP COVER ASSY

Removal the TOP COVER ASSY Removal the TOP COVER ASSY

TOP COVER ASSYTOP COVER ASSY

TOP COVER ASSY

TOP COVER ASSYTOP COVER ASSY

ConnectorConnector

Connector

ConnectorConnector

ConnectorConnector

Connector

ConnectorConnector

(2186) 5

TOP COVER FPC ASSYTOP COVER FPC ASSY

TOP COVER FPC ASSY

TOP COVER FPC ASSYTOP COVER FPC ASSY

04420442

0442

04420442

■■

Fig. 4Fig. 4

■

Fig. 4

■■

Fig. 4Fig. 4

Stick SW FPC 1 ASSY of 1001 Stick SW FPC 1 ASSY of 1001

Stick SW FPC 1 ASSY of 1001

Stick SW FPC 1 ASSY of 1001 Stick SW FPC 1 ASSY of 1001

10011001

1001

10011001

■■

Fig. 5Fig. 5

■

Fig. 5

■■

Fig. 5Fig. 5

9384-2191-009384-2191-00

9384-2191-00

9384-2191-009384-2191-00

(10x10mm)(10x10mm)

(10x10mm)

(10x10mm)(10x10mm)

9384-2190-509384-2190-50

9384-2190-50

9384-2190-509384-2190-50

(5x5mm)(5x5mm)

(5x5mm)

(5x5mm)(5x5mm)

LCD 101LCD 101

LCD 101

LCD 101LCD 101

10011001

1001

10011001

FM (+)/YELLOWFM (+)/YELLOW

FM (+)/YELLOW

FM (+)/YELLOWFM (+)/YELLOW

FM (-)/BLACKFM (-)/BLACK

FM (-)/BLACK

FM (-)/BLACKFM (-)/BLACK

AFM (+)/ORANGEAFM (+)/ORANGE

AFM (+)/ORANGE

AFM (+)/ORANGEAFM (+)/ORANGE

AFM (-)/GRAYAFM (-)/GRAY

AFM (-)/GRAY

AFM (-)/GRAYAFM (-)/GRAY

SW FPC 1 ASSYSW FPC 1 ASSY

SW FPC 1 ASSY

SW FPC 1 ASSYSW FPC 1 ASSY

ConnectorConnector

Connector

ConnectorConnector

9384-2290-909384-2290-90

9384-2290-90

9384-2290-909384-2290-90

(5x20mm)(5x20mm)

(5x20mm)

(5x20mm)(5x20mm)

Page 35

6 (2186)

■■

■ Wires arrangement

■■

REPAIR GUIDE

Page 36

(2186) 7

REPAIR GUIDE

Page 37

8 (2186)

2. Disassembly of the I/O FPC ASSY, MAIN PCB ASSY

Disassemble it in order of step 1to 5.

③③

③

③③

04410441

0441

04410441

■■

Fig. 3Fig. 3

■

Fig. 3

■■

Fig. 3Fig. 3

B

DCDC PCB ASSYDCDC PCB ASSY

DCDC PCB ASSY

DCDC PCB ASSYDCDC PCB ASSY

■■

Fig. 6, 7Fig. 6, 7

■

Fig. 6, 7

■■

Fig. 6, 7Fig. 6, 7

9747-1740-019747-1740-01

9747-1740-01

9747-1740-019747-1740-01

10211021

1021

10211021

9747-1740-019747-1740-01

9747-1740-01

9747-1740-019747-1740-01

I/O FPC ASSYI/O FPC ASSY

I/O FPC ASSY

I/O FPC ASSYI/O FPC ASSY

9384-2191-00(2)9384-2191-00(2)

9384-2191-00(2)

9384-2191-00(2)9384-2191-00(2)

(10x10mm)(10x10mm)

(10x10mm)

(10x10mm)(10x10mm)

■■

Fig. 2Fig. 2

■

Fig. 2

■■

Fig. 2Fig. 2

REPAIR GUIDE

See Page 11.See Page 11.

See Page 11.

See Page 11.See Page 11.

9745-2025-01(2)9745-2025-01(2)

9745-2025-01(2)

9745-2025-01(2)9745-2025-01(2)

■■

■

■■

Fig. 1Fig. 1

Fig. 1

Fig. 1Fig. 1

②②

②

②②

9384-2191-009384-2191-00

9384-2191-00

9384-2191-009384-2191-00

(10x10mm)(10x10mm)

(10x10mm)

(10x10mm)(10x10mm)

■■

Fig. 2Fig. 2

■

Fig. 2

■■

Fig. 2Fig. 2

B

D

A

MAIN PCB ASSYMAIN PCB ASSY

MAIN PCB ASSY

C

A

D

MAIN PCB ASSYMAIN PCB ASSY

9744-1615-019744-1615-01

9744-1615-01

9744-1615-019744-1615-01

27082708

2708

27082708

■■

Fig. 11Fig. 11

■

Fig. 11

■■

Fig. 11Fig. 11

11731173

1173

11731173

■■

Fig. 12Fig. 12

■

Fig. 12

■■

Fig. 12Fig. 12

9749-9749-

1735-151735-15

9749-

1735-15

9749-9749-

1735-151735-15

45144514

4514

45144514

■■

Fig. 8Fig. 8

■

Fig. 8

■■

Fig. 8Fig. 8

11721172

1172

11721172

■■

■

■■

9745-2025-01(2)9745-2025-01(2)

9745-2025-01(2)

9745-2025-01(2)9745-2025-01(2)

9384-2290-909384-2290-90

9384-2290-90

9384-2290-909384-2290-90

(5x10mm)(5x10mm)

(5x10mm)

(5x10mm)(5x10mm)

Fig. 10Fig. 10

Fig. 10

Fig. 10Fig. 10

See Page 4.See Page 4.

See Page 4.

See Page 4.See Page 4.

45204520

4520

45204520

■■

■

■■

A

Fig. 4Fig. 4

Fig. 4

Fig. 4Fig. 4

11751175

1175

11751175

9384-2290-909384-2290-90

9384-2290-90

9384-2290-909384-2290-90

(5x20mm)(5x20mm)

(5x20mm)

(5x20mm)(5x20mm)

■■

Fig. 5Fig. 5

■

Fig. 5

■■

Fig. 5Fig. 5

27092709

2709

27092709

■■

Fig. 9Fig. 9

■

Fig. 9

■■

Fig. 9Fig. 9

11751175

1175

11751175

9384-2290-909384-2290-90

9384-2290-90

9384-2290-909384-2290-90

(5x20mm)(5x20mm)

(5x20mm)

(5x20mm)(5x20mm)

④④

④

④④

C

11761176

1176

11761176

9745-2025-019745-2025-01

9745-2025-01

9745-2025-019745-2025-01

9748-2045-019748-2045-01

9748-2045-01

9748-2045-019748-2045-01

9746-2030-019746-2030-01

9746-2030-01

9746-2030-019746-2030-01

9746-2025-01(5)9746-2025-01(5)

9746-2025-01(5)

9746-2025-01(5)9746-2025-01(5)

29402940

2940

29402940

10131013

1013

10131013

29402940

2940

29402940

10121012

1012

10121012

9748-9748-

9748-

10781078

1078

10781078

9746-2030-019746-2030-01

9746-2030-01

9746-2030-019746-2030-01

9748-9748-

9747-1740-019747-1740-01

9747-1740-01

9747-1740-019747-1740-01

10041004

1004

10041004

9745-2025-019745-2025-01

9745-2025-01

9745-2025-019745-2025-01

2050-15(2)2050-15(2)

2050-15(2)

2050-15(2)2050-15(2)

9748-2045-019748-2045-01

9748-2045-01

9748-2045-019748-2045-01

⑤⑤

⑤

⑤⑤

9611-2025-01(2)9611-2025-01(2)

9611-2025-01(2)

9611-2025-01(2)9611-2025-01(2)

10011001

1001

10011001

①①

①

①①

Page 38

REPAIR GUIDE

■■

Fig. 1Fig. 1

■

Fig. 1

■■

Fig. 1Fig. 1

I/O FLEXIBLE ASSYI/O FLEXIBLE ASSY

I/O FLEXIBLE ASSY

I/O FLEXIBLE ASSYI/O FLEXIBLE ASSY

■■

Fig. 3Fig. 3

■

Fig. 3

■■

Fig. 3Fig. 3

POWER SUPPLY HARNESSPOWER SUPPLY HARNESS

POWER SUPPLY HARNESS

POWER SUPPLY HARNESSPOWER SUPPLY HARNESS

ConnectorConnector

Connector

ConnectorConnector

■■

■

■■

■■

■

■■

Fig. 2Fig. 2

Fig. 2

Fig. 2Fig. 2

9384-2191-009384-2191-00

9384-2191-00

9384-2191-009384-2191-00

(10x10mm)(10x10mm)

(10x10mm)

(10x10mm)(10x10mm)

Fig. 4Fig. 4

Fig. 4

Fig. 4Fig. 4

(2186) 9

9384-2191-00 (2)9384-2191-00 (2)

9384-2191-00 (2)

9384-2191-00 (2)9384-2191-00 (2)

(10x10mm)(10x10mm)

(10x10mm)

(10x10mm)(10x10mm)

45204520

4520

45204520

■■

Fig. 5Fig. 5

■

Fig. 5

■■

Fig. 5Fig. 5

MAIN PCB ASSYMAIN PCB ASSY

MAIN PCB ASSY

MAIN PCB ASSYMAIN PCB ASSY

ConnectorConnector

Connector

ConnectorConnector

9384-2290-909384-2290-90

9384-2290-90

9384-2290-909384-2290-90

(5x20mm)(5x20mm)

(5x20mm)

(5x20mm)(5x20mm)

POWER SUPPLYPOWER SUPPLY

POWER SUPPLY

POWER SUPPLYPOWER SUPPLY

HARNESSHARNESS

HARNESS

HARNESSHARNESS

MAIN PCB ASSYMAIN PCB ASSY

MAIN PCB ASSY

MAIN PCB ASSYMAIN PCB ASSY

■■

Fig. 6Fig. 6

■

Fig. 6

■■

Fig. 6Fig. 6

DCDC PCB ASSYDCDC PCB ASSY

DCDC PCB ASSY

DCDC PCB ASSYDCDC PCB ASSY

SolderSolder

Solder

SolderSolder

Page 39

10 (2186)

■■

Fig. 7Fig. 7

■

Fig. 7

■■

Fig. 7Fig. 7

DCDC PCB ASSYDCDC PCB ASSY

DCDC PCB ASSY

DCDC PCB ASSYDCDC PCB ASSY

■■

Fig. 9Fig. 9

■

Fig. 9

■■

Fig. 9Fig. 9

ConnectorConnector

Connector

ConnectorConnector

MAIN PCB ASSYMAIN PCB ASSY

MAIN PCB ASSY

MAIN PCB ASSYMAIN PCB ASSY

■■

■

■■

Fig. 8Fig. 8

Fig. 8

Fig. 8Fig. 8

■■

■

■■

Fig. 10Fig. 10

Fig. 10

Fig. 10Fig. 10

MAIN PCB ASSYMAIN PCB ASSY

MAIN PCB ASSY

MAIN PCB ASSYMAIN PCB ASSY

45144514

4514

45144514

REPAIR GUIDE

■■

Fig. 11Fig. 11

■

Fig. 11 ■■

■■

Fig. 11Fig. 11

27092709

2709

27092709

27082708

2708

27082708

■■

■

Fig. 12Fig. 12

Fig. 12

Fig. 12Fig. 12

11721172

1172

11721172

11731173

1173

11731173

Page 40

REPAIR GUIDE

3. Disassembly of the SUB PLATE L, BATTERY CHAMBER

Disassemble it in order of step 1 to 3.

9745-2025-019745-2025-01

9745-2025-01

See Page 23.See Page 23.

See Page 23.

See Page 23.See Page 23.

③③

③

③③

9748-2050-019748-2050-01

9748-2050-01

9748-2050-019748-2050-01

9745-2025-019745-2025-01

9748-2050-019748-2050-01

9748-2050-01

9748-2050-019748-2050-01

9747-1735-019747-1735-01

9747-1735-01

9747-1735-019747-1735-01

50345034

5034

50345034

■■

Fig. 2Fig. 2

■

Fig. 2

■■

Fig. 2Fig. 2

9748-2050-019748-2050-01

9748-2050-01

9748-2050-019748-2050-01

REMOTE FPCREMOTE FPC

REMOTE FPC

REMOTE FPCREMOTE FPC

■■

Fig. 1Fig. 1

■

Fig. 1

■■

Fig. 1Fig. 1

9748-2050-01(2)9748-2050-01(2)

9748-2050-01(2)

9748-2050-01(2)9748-2050-01(2)

SUS PLATE LSUS PLATE L

SUS PLATE L

SUS PLATE LSUS PLATE L

②②

②

②②

10661066

1066

10661066

9744-1625-01(2)9744-1625-01(2)

9744-1625-01(2)

9744-1625-01(2)9744-1625-01(2)

01410141

0141

01410141

(2186) 11

9745-2025-01(2)9745-2025-01(2)

9745-2025-01(2)

9745-2025-01(2)9745-2025-01(2)

10051005

1005

10051005

9611-9611-

9611-

9611-96112025-01(2)2025-01(2)

2025-01(2)

2025-01(2)2025-01(2)

11461146

1146

11461146

9748-2050-019748-2050-01

9748-2050-01

9748-2050-019748-2050-01

■■

Fig. 4Fig. 4

■

Fig. 4

■■

Fig. 4Fig. 4

9747-1735-019747-1735-01

9747-1735-01

9747-1735-019747-1735-01

50335033

5033

50335033

■■

Fig. 3Fig. 3

■

Fig. 3

■■

Fig. 3Fig. 3

①①

①

①①

See Page 13.See Page 13.

See Page 13.

See Page 13.See Page 13.

11441144

1144

11441144

Page 41

12 (2186)

■■

Fig. 1Fig. 1

■

Fig. 1

■■

Fig. 1Fig. 1

FPC of AF CHARGE ASSYFPC of AF CHARGE ASSY

FPC of AF CHARGE ASSY

FPC of AF CHARGE ASSYFPC of AF CHARGE ASSY

REMOTE FPCREMOTE FPC

REMOTE FPC

REMOTE FPCREMOTE FPC

■■

Fig. 2Fig. 2

■

Fig. 2

■■

Fig. 2Fig. 2

FPC of AF MODULE ASSYFPC of AF MODULE ASSY

FPC of AF MODULE ASSY

FPC of AF MODULE ASSYFPC of AF MODULE ASSY

■■

■

■■

Fig. 3Fig. 3

Fig. 3

Fig. 3Fig. 3

FPC of SHUTTER ASSYFPC of SHUTTER ASSY

FPC of SHUTTER ASSY

FPC of SHUTTER ASSYFPC of SHUTTER ASSY

50335033

5033

50335033

REPAIR GUIDE

■■

Fig. 4Fig. 4

■

Fig. 4

■■

Fig. 4Fig. 4

50345034

5034

50345034

9748-2050-019748-2050-01

9748-2050-01

9748-2050-019748-2050-01

SUS PLATE GSUS PLATE G

SUS PLATE G

SUS PLATE GSUS PLATE G

Page 42

(2186) 13

REPAIR GUIDE

4. Disassembly of the CCD ASSY, SHUTTER ASSY

If CCD ASSY (0271) is exchanged for new one, exchange the bar code on the MAIN PCB ASSY (0410) for

the bar code put on the new CCD ASSY.

Disassemble it in order of step 1 to 4.

CCD FPC ASSYCCD FPC ASSY

CCD FPC ASSY

CCD FPC ASSYCCD FPC ASSY

■■

Fig. 1Fig. 1

■

Fig. 1

■■

Fig. 1Fig. 1

2181-27022181-2702

2181-2702

2181-27022181-2702

27212721

2721

27212721

9747-1745-01(4)9747-1745-01(4)

9747-1745-01(4)

9747-1745-01(4)9747-1745-01(4)

CCD ASSYCCD ASSY

CCD ASSY

CCD ASSYCCD ASSY

27152715

2715

27152715

①①

①

①①

9744-16189744-1618

9744-1618

9744-16189744-1618

9748-2055-019748-2055-01

9748-2055-01

9748-2055-019748-2055-01

A

B

9748-2055-01(2)9748-2055-01(2)

9748-2055-01(2)

9748-2055-01(2)9748-2055-01(2)

2181-29202181-2920

2181-2920

2181-29202181-2920

■■

Fig. 5Fig. 5

■

Fig. 5

■■

Fig. 5Fig. 5

2181-29182181-2918

2181-2918

2181-29182181-2918

9758-0100-009758-0100-00

9758-0100-00

29612961

2961

29612961

■■

■

■■

SLIDER ASSYSLIDER ASSY

SLIDER ASSY

SLIDER ASSYSLIDER ASSY

9758-0100-009758-0100-00

Fig. 2Fig. 2

Fig. 2

Fig. 2Fig. 2

9744-1620-019744-1620-01

9744-1620-01

9744-1620-019744-1620-01

9384-2190-509384-2190-50

9384-2190-50

9384-2190-509384-2190-50

(3.5x10mm)(3.5x10mm)

(3.5x10mm)

(3.5x10mm)(3.5x10mm)

■■

Fig. 4Fig. 4

■

Fig. 4

■■

Fig. 4Fig. 4

②②

②

②②

2181-2706(3)*12181-2706(3)*1

2181-2706(3)*1

2181-2706(3)*12181-2706(3)*1

A

C

9747-1775-019747-1775-01

9747-1775-01

9747-1775-019747-1775-01