Konica Minolta DRYPRO793 Installation Manual

LASER IMAGER

DRYPRO MODEL 793

INSTALLATION MANUAL

CODE NO.

0792 (UL), 0791 (CE)

No. 26-2, Nishishinjuku 1-chome, Shinjuku-ku, Tokyo 163-0512, Japan

Table of Contents

Foreword.........................................................................................................1

Ch.1 Pre-installation Information .................................................................9

1.1 Installation Work Flow ......................................................................................10

1.2 External Device Connection Configuration.......................................................11

1.3 Installation Preparations...................................................................................18

1.4 Part Names ......................................................................................................21

1.5 Structure...........................................................................................................27

Ch.2 Unpacking and Installation ................................................................29

2.1 Packing List ......................................................................................................30

2.2 Unpacking ........................................................................................................32

2.3 Checking Accessories ......................................................................................35

2.4 Removing Protection Hardware and Installing Optional Units..........................36

2.4.1 Protection Hardware (Red) List ..........................................................................................36

2.4.2 Removing Protection Hardware Securing Back of Exposure Unit......................................37

2.4.3 Removing Protection Hardware Securing Front of Exposure Unit .....................................38

2.4.4 Removing Protective Film from Exposure Unit Conveyor Rollers ......................................39

2.4.5 Removing Protection Hardware Securing Pickup Unit (X 2 trays) .....................................40

2.4.6 Installing Supply Unit (Option)............................................................................................43

2.4.7 Replacing the Removed Covers (1) ...................................................................................51

2.4.8 Removing Protective Sheet from Heat Processing Unit.....................................................55

2.4.9 Installing Heat Processing Unit ..........................................................................................60

2.4.10 Installing Deodorant Filter and Deodorant Filter Case .......................................................63

2.4.11 Installing Lis-793 (Option) ..................................................................................................65

2.4.12 Installing 1GB Print Memory (Option).................................................................................73

2.4.13 Replacing the Removed Covers (2) ...................................................................................75

2.5 Installing Accessories.......................................................................................76

2.5.1 Installing Exhaust Duct.......................................................................................................76

2.5.2 Installing Film Holder (Cable Protector) (Option) ...............................................................76

2.5.3 Changing Supply Tray Film Size Setting............................................................................77

2.5.4 Installing UPS (Option).......................................................................................................79

2.6 Starting Up .......................................................................................................81

2.6.1 Switching On Power ..................................................................................................................81

Ch.3 Setup ....................................................................................................83

3.1 Outline of DRYPRO 793 Setup ........................................................................83

3.2 Switching to the Service Maintenance Mode ...................................................86

3.3 Switching to the Normal Screen from the Service Maintenance Mode ............87

3.4 Film Setup ........................................................................................................88

3.5 SCP Setup........................................................................................................93

3.6 SCU Setup .......................................................................................................96

3.7 System Setup .................................................................................................102

3.8 User Registration............................................................................................105

3.9 Print Condition Setup .....................................................................................110

3.10 LUT Setup ......................................................................................................118

3.11 Time Set .........................................................................................................124

List of Time Zones .............................................................................................................................127

3.12 Maintenance Schedule ...................................................................................128

3.13 Sorter Setup ...................................................................................................131

Approval Number

11BZ0539

Commercial Name

Laser Imager DRYPRO Vstage MODEL 793

The following Medical Device approval applies:

Ch.4 Checking Image Quality ...................................................................135

4.1 Loading Film...................................................................................................136

4.2 Calibrating Internal Densitometer...................................................................140

4.3 Test Printing ...................................................................................................146

4.3.1 Printing Flat Pattern..........................................................................................................146

4.3.2 Printing SMPTE Pattern ...................................................................................................148

4.3.3 Flat Pattern Justification ...................................................................................................150

4.3.4 SMPTE Pattern Density Justification................................................................................150

4.4 Adjusting Image Data Write Start Position .....................................................154

Ch.5 Printing from and Backup of External Devices..............................159

5.1 Printing from External Devices .......................................................................160

5.2 Backup ...........................................................................................................161

5.2.1 CF Memory Data Backup (CF -> HDD)............................................................................161

5.2.2 Setting Data Backup (DRYPRO 793 -> Maintenance PC) ...............................................162

Ch.6 Web Maintenance Mode ...................................................................165

6.1 Outline of Web Maintenance Mode ................................................................166

6.2 Starting Up and Terminating Web Maintenance Mode ..................................167

6.3 Web Maintenance Mode Menus.....................................................................170

6.3.1 Film Setup

.....................................................................................................................170

6.3.2

SCP Setup

....................................................................................................................172

6.3.3

SCU Setup....................................................................................................................173

6.3.4 Border Custom Set

up ......................................................................................................176

6.3.4

System Setup...............................................................................................................177

6.3.5

User Registration ........................................................................................................179

6.3.6

Print Condition Setup.................................................................................................181

6.3.7

LUT Setup

.....................................................................................................................186

6.3.8

Setting Current Time and Date...............................................................................188

6.3.9

Maintenance Schedule Setup .................................................................................190

6.3.10

Sorter Setup .................................................................................................................191

Specifications.............................................................................................193

< 1 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

Foreword

This section sets out information with which the

service engineers must familiarize themselves before

proceeding with installation.

Foreword

< 2 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

1. To ensure safety, only qualified service engineers are permitted to open external covers or touch internal

components.

2. The device incorporates a laser unit (Class IIIb). Exposure of the eyes to the laser may result in serious injury.

Protective goggles must be worn at all while carrying out adjustments or repairs.

3. Under no circumstances should procedures or adjustments not detailed in this manual be attempted. Doing so

may result in harmful electromagnetic wave emissions.

4. Cautions indicated on warning levels must be observed at all times to ensure safety.

5. The device incorporates high-voltage components. Touching such components may result in electric shock:

care must be exercised.

6. Caution must be exercised to ensure that body parts or clothing do not become trapped in moving parts in the

device such as fans.

7. The weight of the device is approximately 255kg (285kg with sorter). Sufficient space to ensure safety must be

allowed during unpacking and installation.

8. Electrical circuitry in the device may be damaged by generation of static electricity. Care must be taken when

effecting repairs in handling both the main body and removed components.

9. Always ensure that the device power supply is switched off before disconnecting or connecting cables or

connectors. Under absolutely no circumstances should such procedures be attempted with the power supply on:

doing so may result in serious accidents.

10. Anti-static wrist bands must be worn at all times when handling circuit boards.

11. The device incorporates a lithium battery. Failure to follow correct procedure when replacing the battery may

result in damage: replacement should be carried out by a qualified service engineer.

12. DRYPRO 793 is a Class I laser device and is equipped with an interlock. The procedures detailed in this manual

must be followed when disengaging the interlock.

13. Disposal of the DRYPRO 793 main body (lithium battery (including hexavalent chromium, cadmium, mercury,

PBB, PBDE), fluorescent tube (in liquid crystal module), accessories, options, consumables, packing materials

and film must be carried out in accordance with relevant local ordinances and regulations.

Cautions Regarding Installation

The following cautions must be read before proceeding with installation and strictly observed.

Foreword

< 3 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

Warning Text (Signal Word)

Signal words indicate the degree of potential hazards in the product.

There are 3 degrees of caution levels, and each is used depending on the level of risk and damage caused by

incorrect use and mishandling.

DANGER

: Failure to observe the caution will produce high risk of serious or fatal injury.

WARNING

: Failure to observe the caution will produce moderate risk of serious or fatal injury.

CAUTION

: Failure to observe the caution will produce risk of moderate or light injury.

or damage to property.

Risk of the damage

Bodily injury

(and damage to property)

Damage to property only

Loss of life or serious injury

(Damage is serious)

High Low

DANGER WARNING

WARNING or CAUTION CAUTION

CAUTION

Moderate damage or light injury

(Damage is light)

Foreword

< 4 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

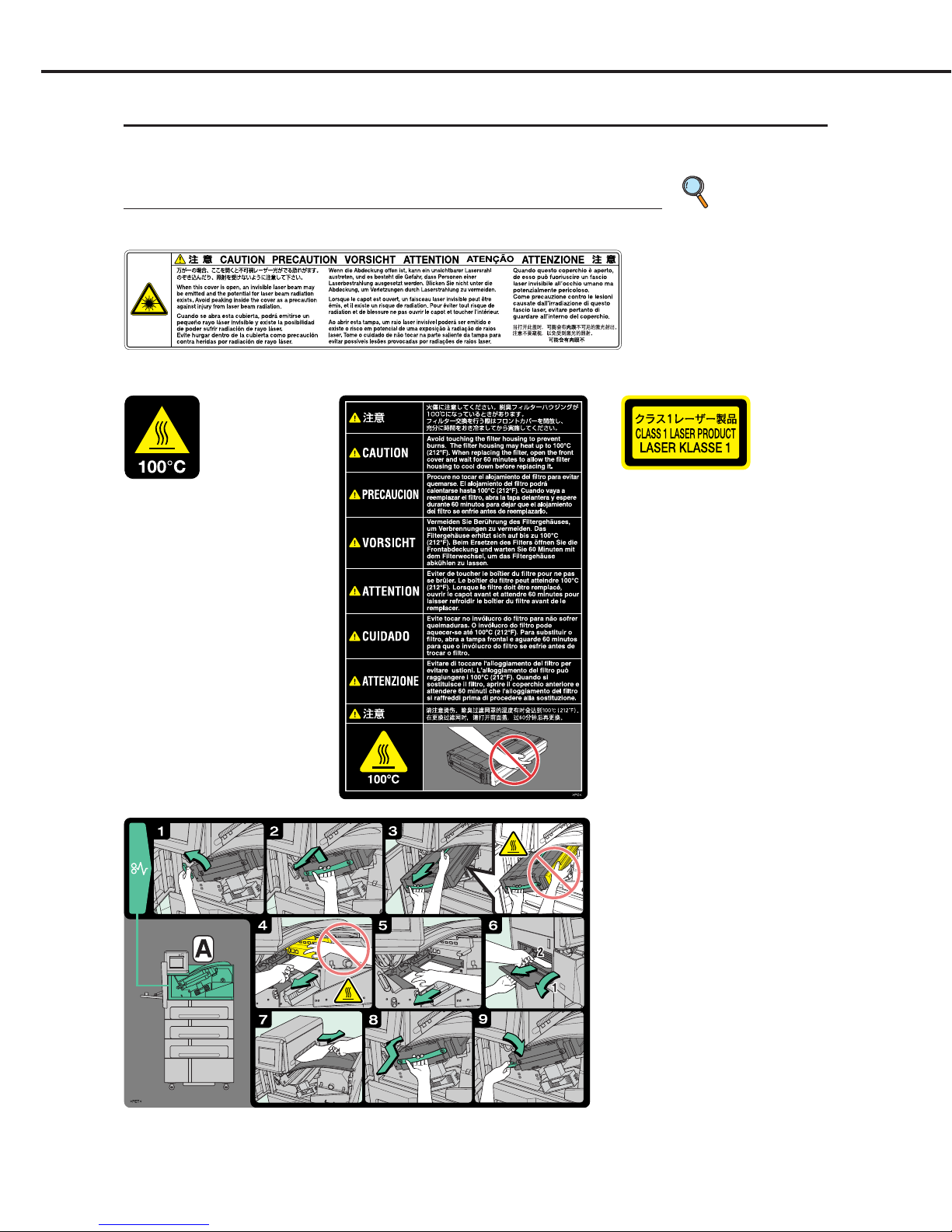

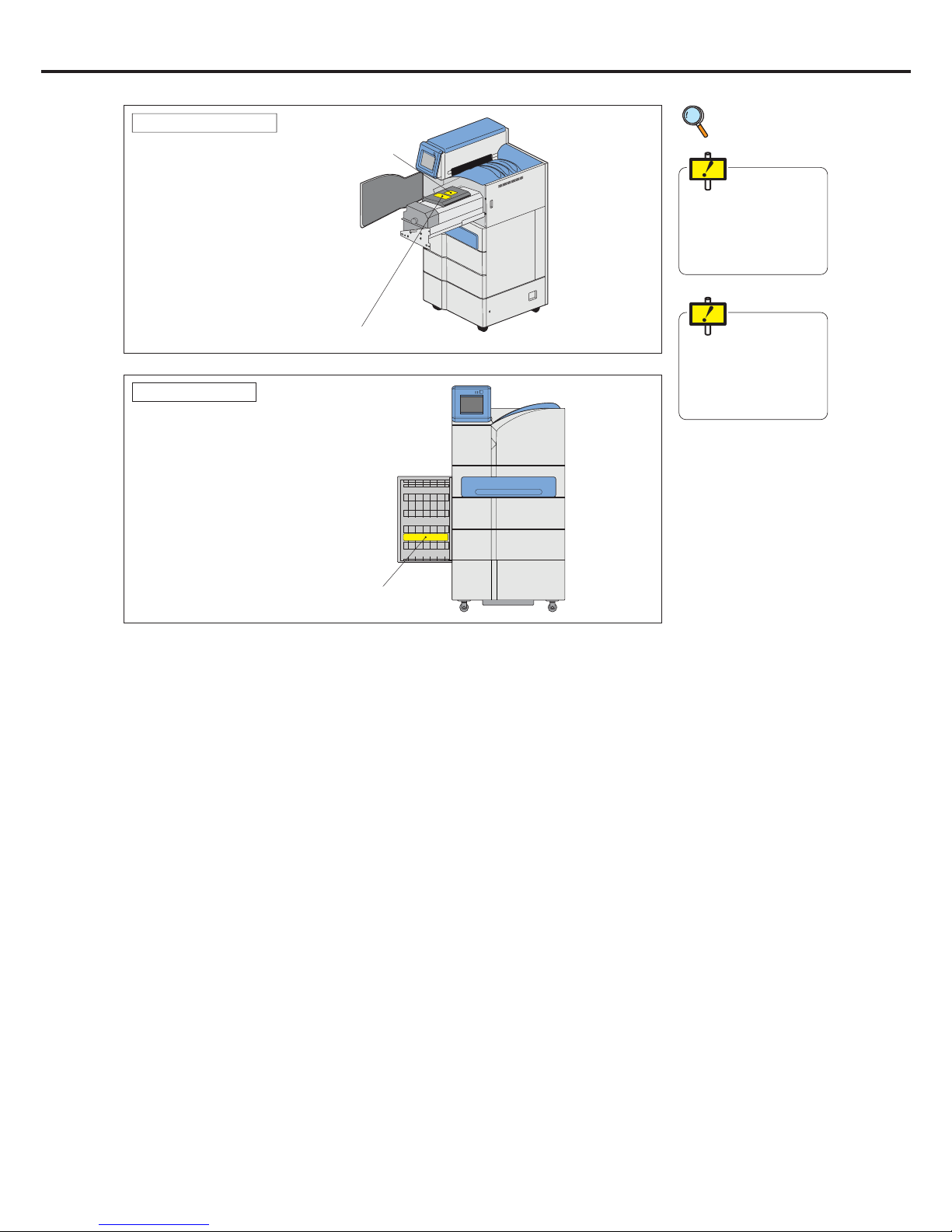

Warning Labels

Warning labels on the DRYPRO 793 are affixed at the locations shown below, and indicate possible danger

to the user.

Description of Warning Labels

p.7 Locations of

Warning

Labels

(1) Laser Caution Label

(2) High Temp. 100

: Label-1

(4) Class1 Laser Product Label

(5) Jam Release Label-A

(3) High Temp. 100: Label-2

Foreword

< 5 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

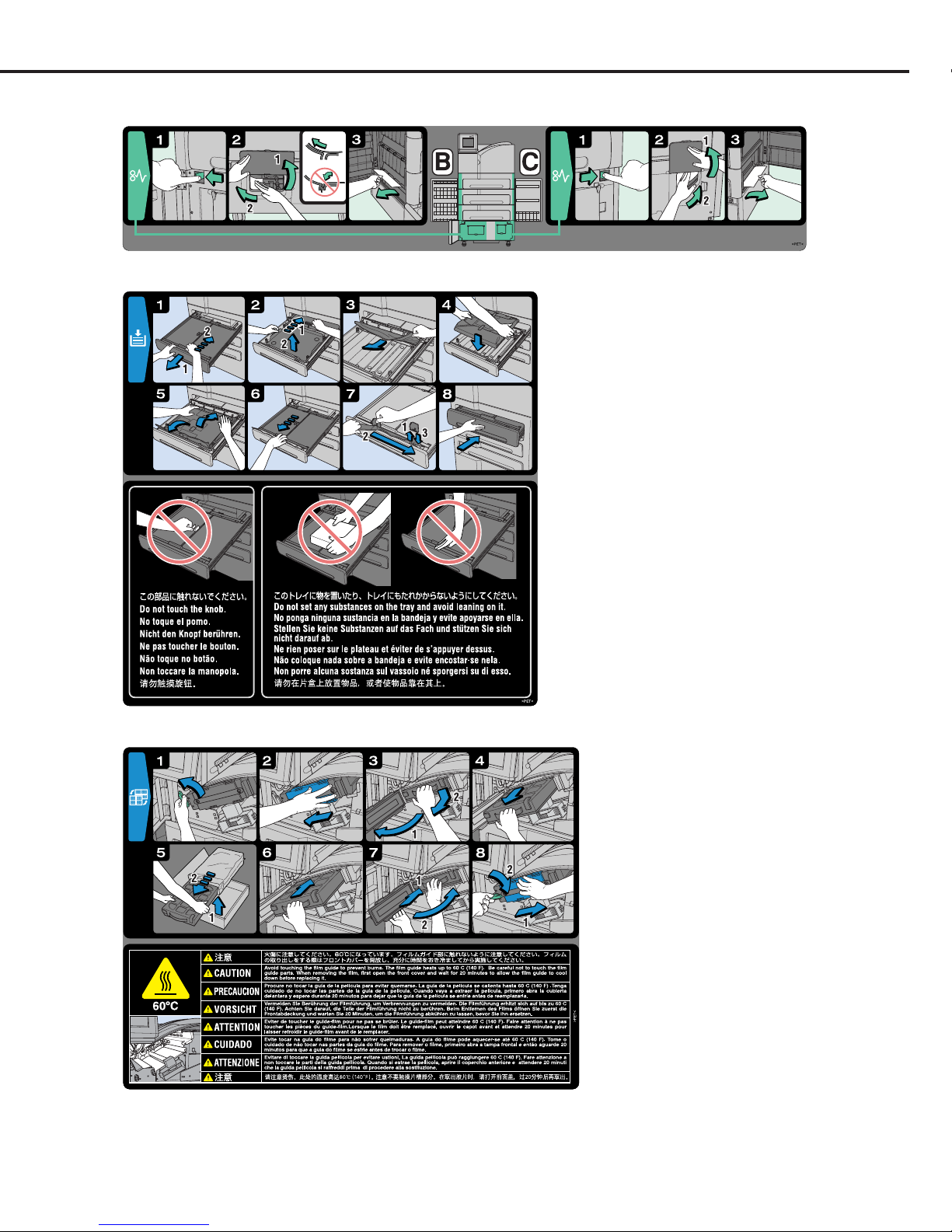

(7) Film Loading Label

(8) Deodorant Filter Change Label

(6) Jam Release Label-B•C

Foreword

< 6 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

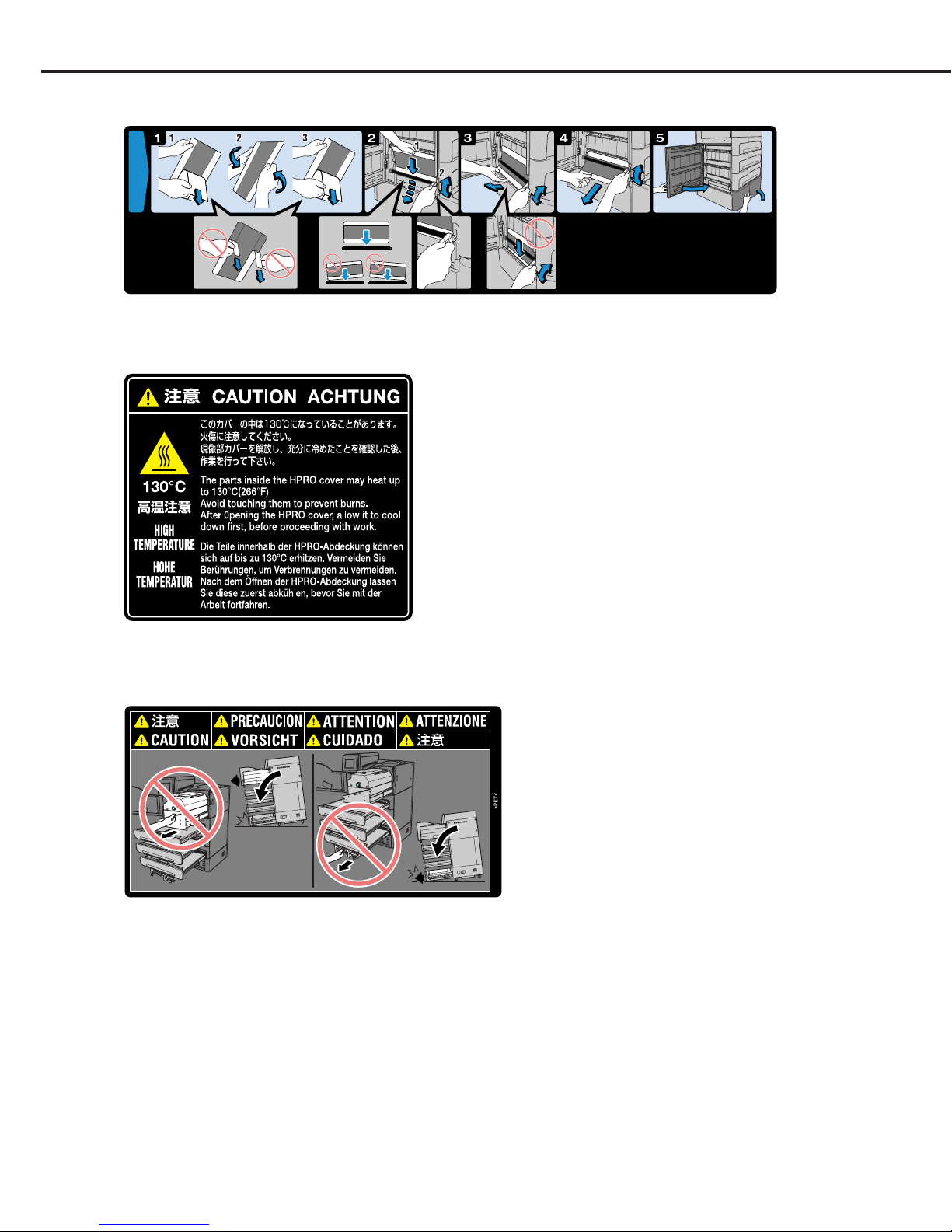

(10) High Temp. 130: Label

(11) Label Indicating Danger of Toppling

(9) Cleaning Roller Cleaning Label

Foreword

< 7 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

To avoid the risk of

burns or electrocution,

ensure that labels do

not become grimy.

Labels that have

become illegible or have

peeled off should be

replaced.

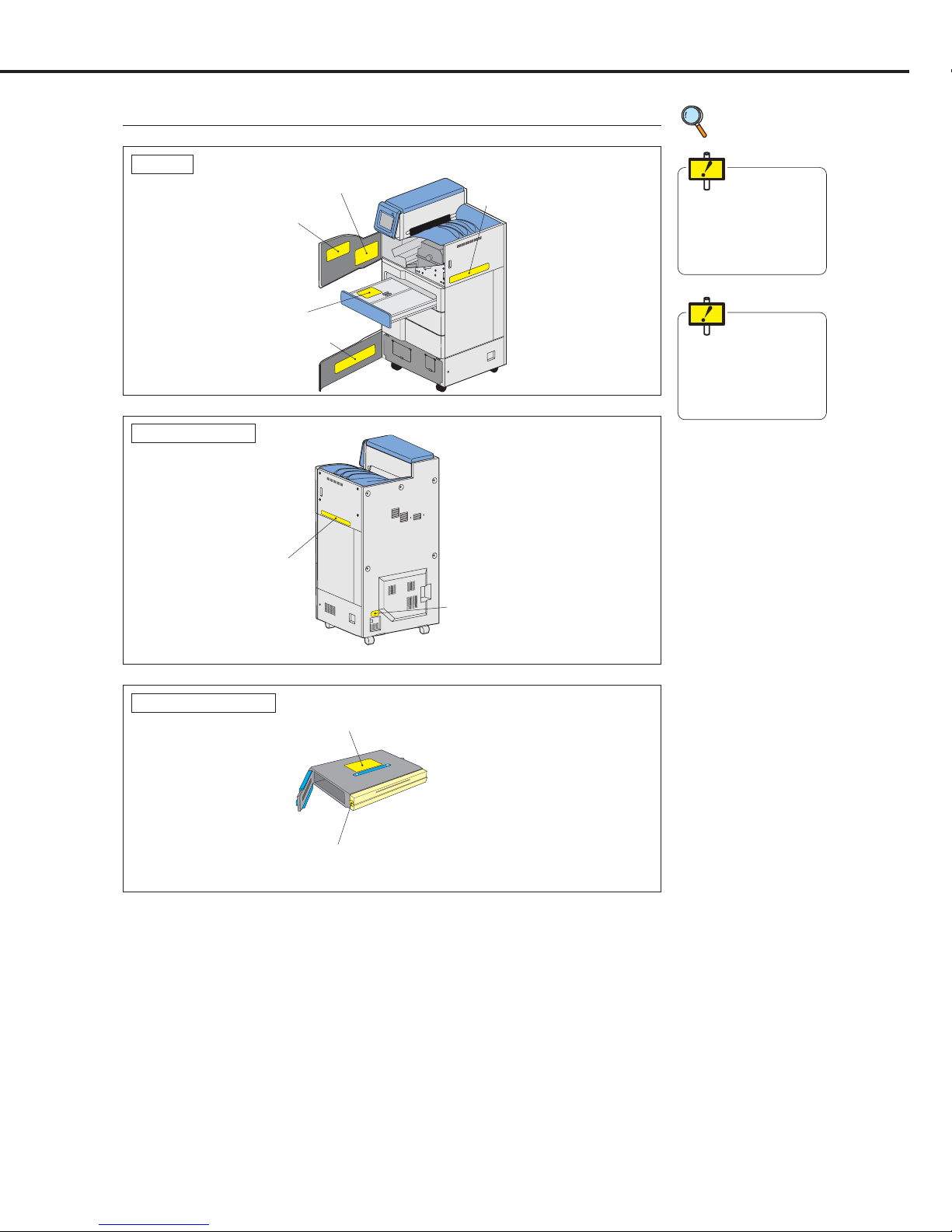

Locations of Warning Labels

p.4 Description

of Warning

Labels

(6) Jam Release Label B-C

(5) Jam Release Label A

(8) Deodorant Filter Change Label

(1) Laser caution Label

(7) Film Loading Label

(1) Laser Caution Label

(4) Class 1 Laser Product Label

Internal

Rear and Left Side

(3) Deodorant Filter Housing High Temp. 100; Label

(2) High Temp. 100; Label

Deodorant Filter Case

Foreword

< 8 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

(11) Label Indicating Danger of Toppling

(10) High Temp. 130; Label

HPRO Unit Cover

To avoid the risk of

burns or electrocution,

ensure that labels do

not become grimy.

Labels that have

become illegible or have

peeled off should be

replaced.

p.4 Description

of Warning

Labels

(9) Cleaning Roller Cleaning Label

Cleaning Rollers

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

< 9 >

Pre-installation

Information

This chapter presents information to be read and

assimilated before proceeding with installation.

1

Chap.

Ch.1 Pre-installation Information

< 10 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

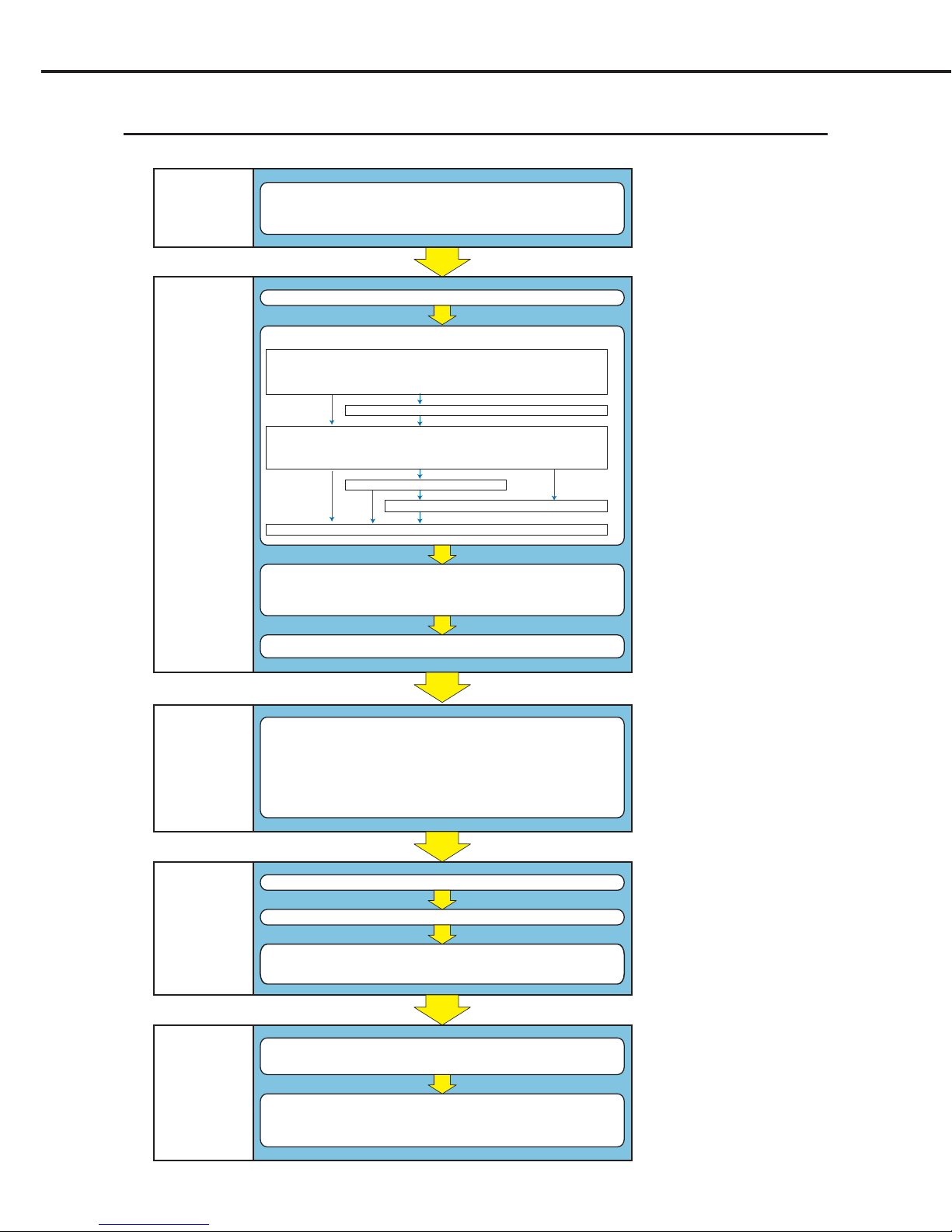

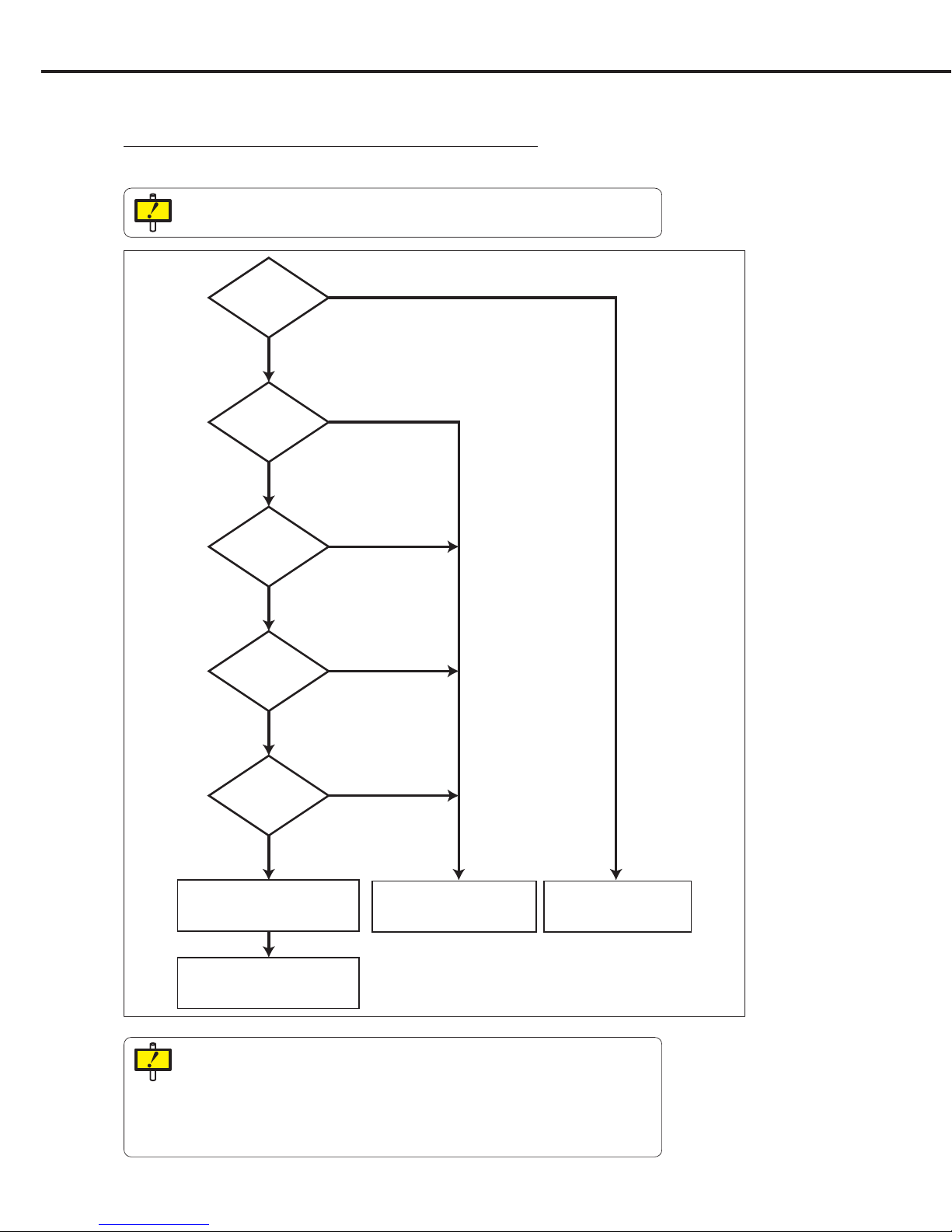

1.1 Installation Work Flow

For maximum efficiency, the installation procedure should be carried out in the sequence detailed below.

Checking Image

Quality

(Ch.4)

Removing Potective Hardwares and installing options

2.4.2 Removing Potective Hardware Securing Back of Exposure Unit (p.00)

2.4.3 Removing Potective Hardware Securing Front of Exposure Unit (p.00)

2.4.4 Removing Protective Sheet from Exposure Unit Conveyor Rollers (p.00)

2.4.5 Removing Potective Hardware Securing Pickup Unit (X 2 trays) (p.00)

2.4.7 Installing Cover (1) (p.00)

2.4.8 Removing Protective Sheet from Heat Processing Unit (p.00)

2.4.9 Installing Heat Processing Unit (p.00)

2.4.10 Installing Deodorant Filter and Deodorant Filter Case (p.00)

2.4.13 Installing Cover (2) (p.00)

Preparations

- Checking installation conditions (p.00)

- Checking the network (p.00)

- Preparation of tools (p.00)

Service Maintenance Mode Settings

(Operation Panel or WEB maintenance PC)

3.4 Film Settings (p.00)

3.5 SCP Settings (p.00)

3.6 SCU Settings (p.00)

3.7 System Settings (p.00)

3.8 User Registration (p.00)

3.9 Print Condition Settings (p.00)

3.10 LUT Settings (p.00)

3.11 Setting Current Time and Date (p.00)

3.12 Regular Inspection Settings (p.00)

3.13 Sor ter Settings (p.00)

Test Printing

Start Up

Installing Accessories

- Exhaust Duct (p.00)

- Film Holder (p.00)

- UPS (Option)

Unpacking (p.00)

Installation

(Ch.2)

Preparations

(Ch.1)

Settings

(Ch.3)

- Flat Pattern Printing (p.00) - SMPTE Pattern Printing (p.00)

Calibration of Internal Densitometer (p.00)

Loading film (p.00)

Printing

from and Backup

of External

Devices

(Ch.5)

Checking printing from external devices

(Network cable connections, clamp installation)

(p.00)

Backup

- CF Memory Data Backup (CF -> HDD) (p.00)

- Setting Data Backup (DRYPRO 793 -> Maintenance PC) (p.00)

2.4.6 Installing Supply Unit (Option) (p.00)

2.4.11 Installing Lis-793 (p.00)

2.4.12 Installing 1GB Print Memory (p.00)

Ch.1 Pre-installation Information

< 11 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

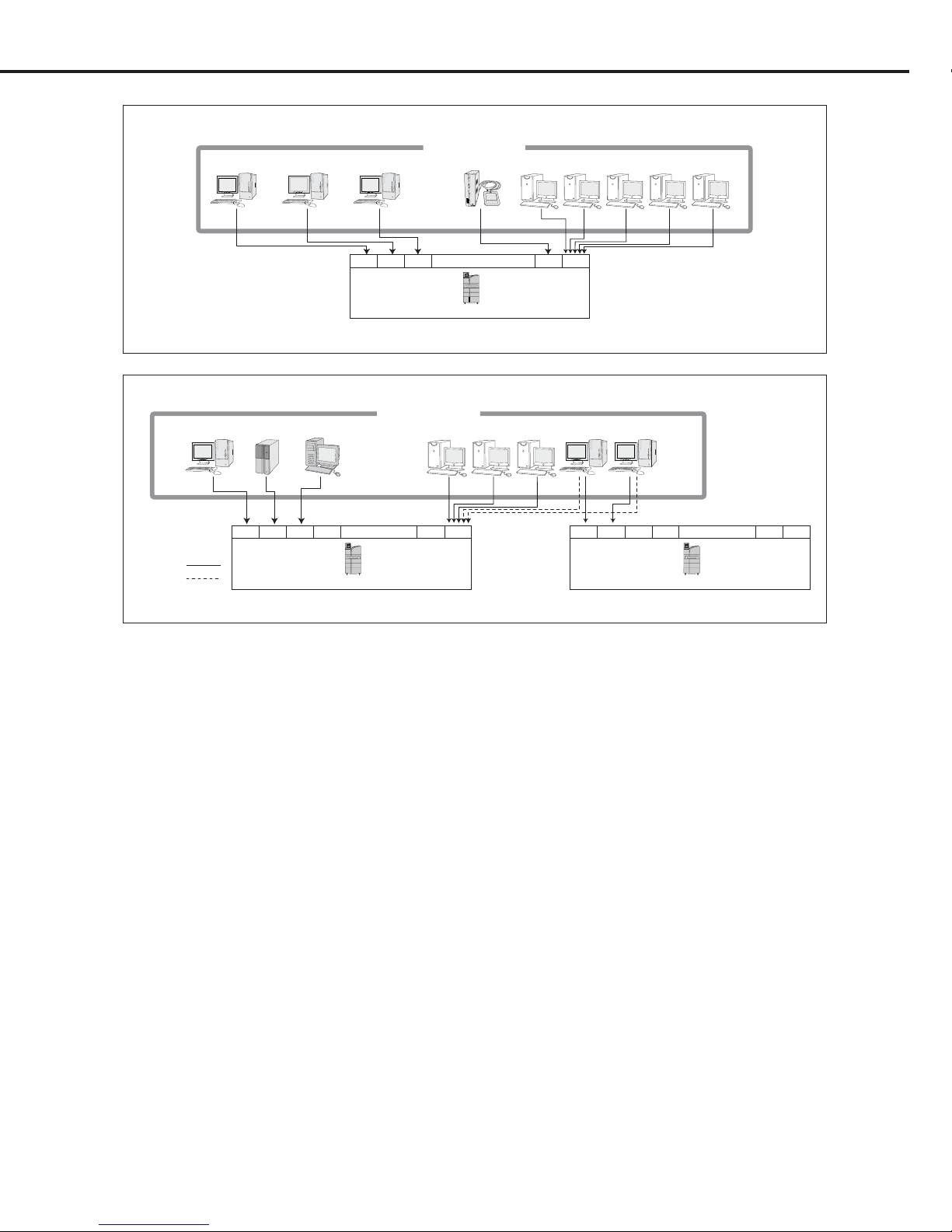

1.2 External Device Connection Configuration

This section details the configuration of external device connection to DRYPRO 793.

Normally, DRYPRO 793 has a maximum external device connection capacity of 16CH. (Basic specification)

In cases where capacity in excess of 16CH is required, or where multiple devices are to be connected under

the same settings, connection of up to 20CH is possible under certain conditions. (Expanded port

specification)

The connection configurations are shown below.

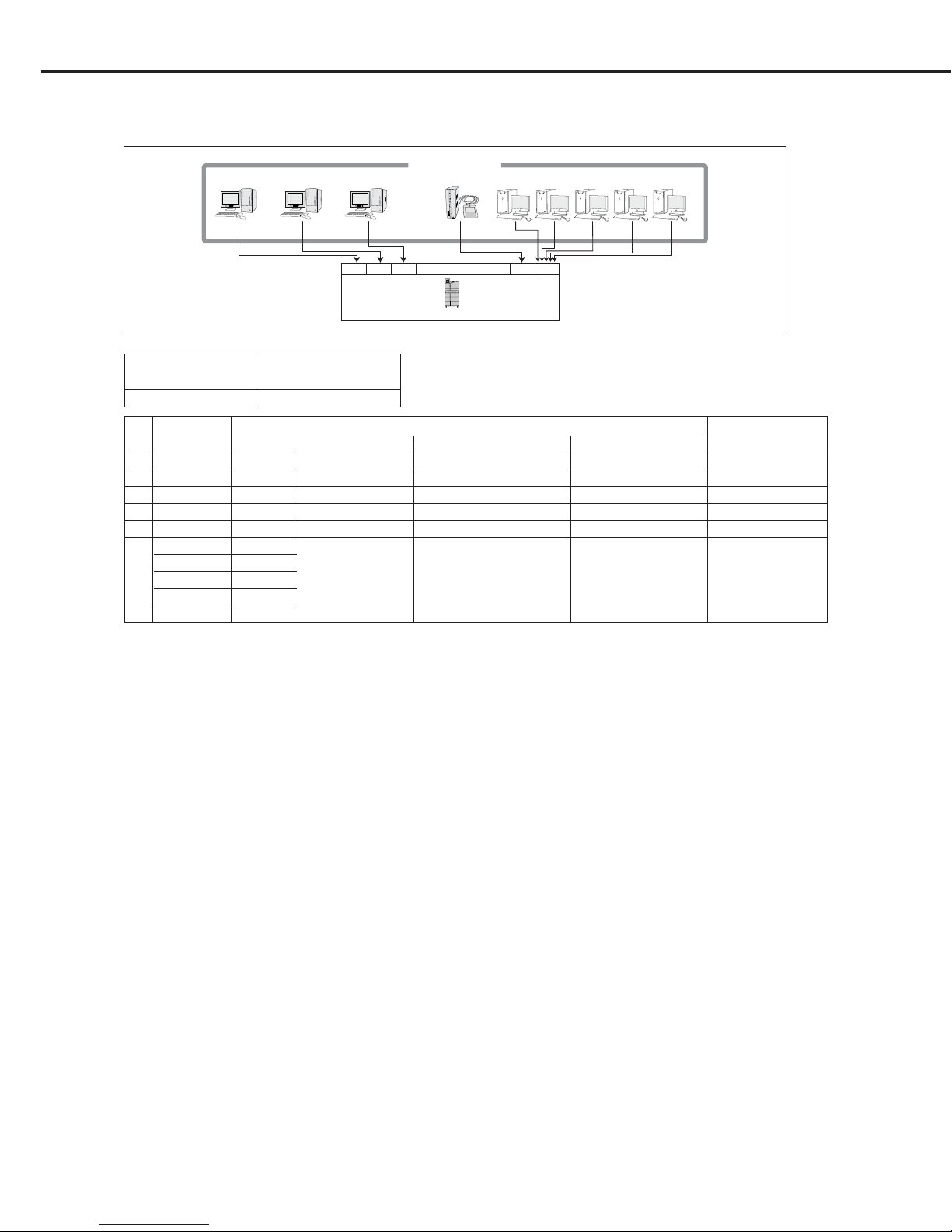

1.2.1 Basic Specification

In the basic specification, DRYPRO 793 has a maximum external device connection capacity of

16CH.

In cases where devices of other manufacturers are to be connected for direct DICOM input, a

DRYPRO multi-client license is required for the 2ch or more.

Total : 16 devices

CH1 CH2 CH3

. . . . . . . . . . . .

. . . . . . . . . . . . . .

CH15 CH16

Printlink3 Printlink3CS-1 CS-1 CS-1

DRYPRO 793

Example of 16ch in the Basic Specification

Ch.1 Pre-installation Information

< 12 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

1.2.2 Expanded Port Specification

Conditions

The expanded port specification includes 5ch in addition to 15ch of the basic specification,

producing a total of 20ch.

The expanded channel configuration enables connection of a maximum of five additional

external devices to 1ch of the basic specification. The following conditions apply to the

external devices connected to the expanded port.

1. No. of Expanded ch : 5ch

2. Devices that may be connected : KDIS devices (RS Series, IS Series, Liteview)

REGIUS Series (backup settings only)

3. No. of sheets to be processed : Devices with maximum daily print count of 20

sheets.

4. Setting Restrictions : Unlike the basic specification, channel-specific LUT

settings or print condition settings cannot be made

for external devices connected to the expanded

5ch.

The LUT setting is fixed at linear and the print

condition settings are common to the expanded

5ch.

5. Preparations : Before making expanded port settings, the Konica

Minolta sales department should be contacted for

details of system drawings.

Settings

In normal SCU settings, the "expanded port no." + "AE Title" setting is essential: with

DRYPRO 793, however, additional channels may be allocated to a 1ch expanded port without

AE title. (The port to which the additional channels are to be allocated is determined under

[SERVICE 1] - [SCP SETUP].

Use of the expanded port enables connection of a maximum of 20ch.

The expanded port and AE title of the external devices connected are set in the blank column.

Ch.1 Pre-installation Information

< 13 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

Total: 20 Devices

LiteViewPrintlink3CS-1 CS-1 CS-1 Liteview Liteview Liteview Liteview

CH1 CH2 CH3

. . . . . . . . . . .

. . . . . . . . . .

CH15 CH16

DRYPRO 793

Total: 20 Devices

. . . . . . . . . . . .

LiteViewREGIUS IMPrintlink2CS-1/CS-2 CS-1/CS-2 CS-1/CS-2Liteview Liteview

Backup

Standard

CH1 CH2 CH3 CH4

. . . . . . . . . . .

CH15 CH16

DRYPRO 793

CH1 CH2 CH3 CH4

. . . . . . . . . .

CH15 CH16

DRYPRO 793

Example of 15ch Basic Specification + 5ch Expanded Port Specification

Example of 15ch Basic Specification + 5ch Expanded Port Specification (2ch set as backup)

Ch.1 Pre-installation Information

< 14 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

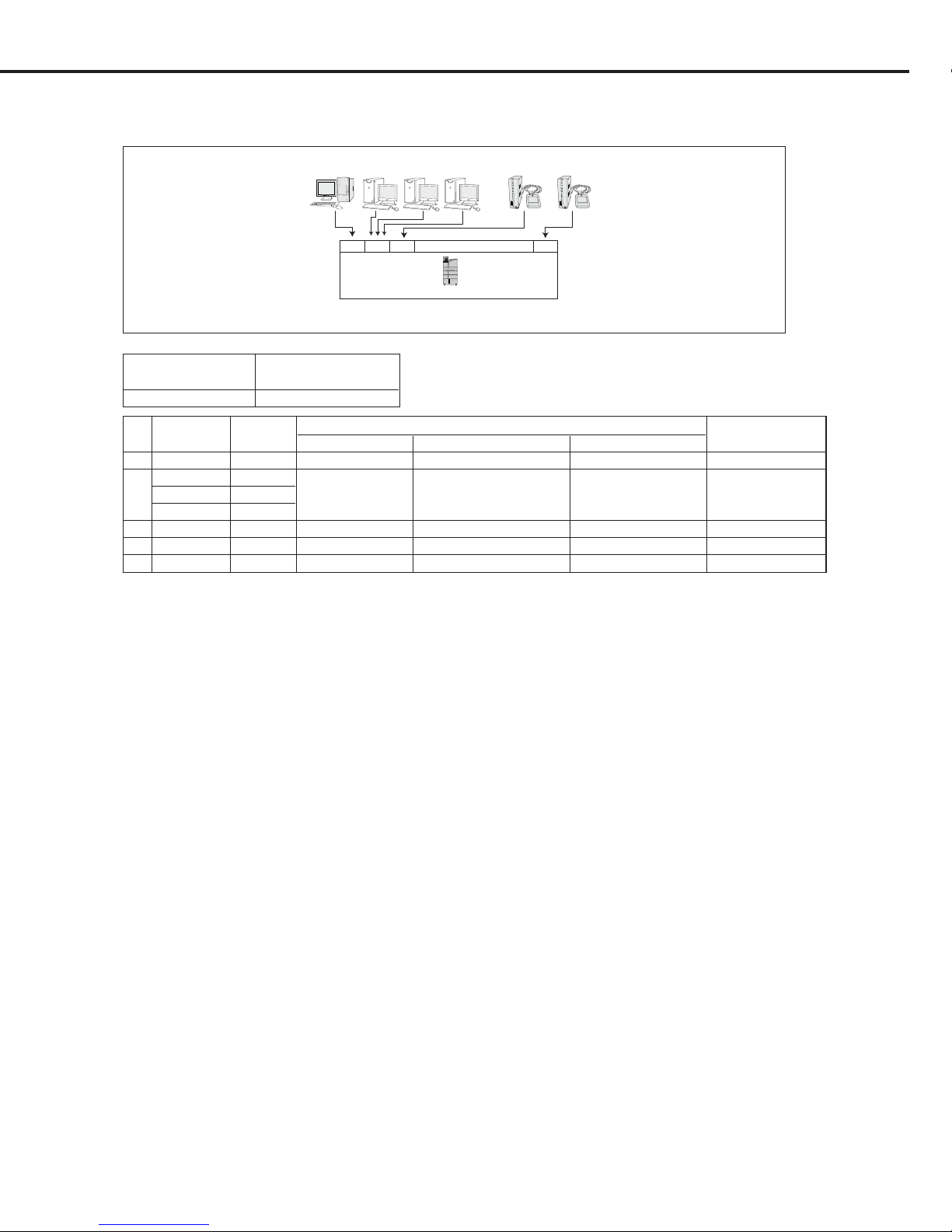

Connection to

17 or more external

devices?

Connection to

20 or fewer external

devices?

2 or more

devices connected to

the expanded

port?

5 or fewer

devices connected to

the expanded

port?

3 or fewer

devices connected to

the expanded

port?

Connection in the

expanded port specification

should be made to 1 DRYPRO 793.

External devices should be

connected to 2 or more

DRYPRO 793 units.

Connections should be made

to 1 DRYPRO 793 unit is

the basic specification.

YES

NO

NO

NO

NO

NO

YES

YES

YES

YES

Adjustments should be made so

that three of the external devices are

not allocated to the expanded port.

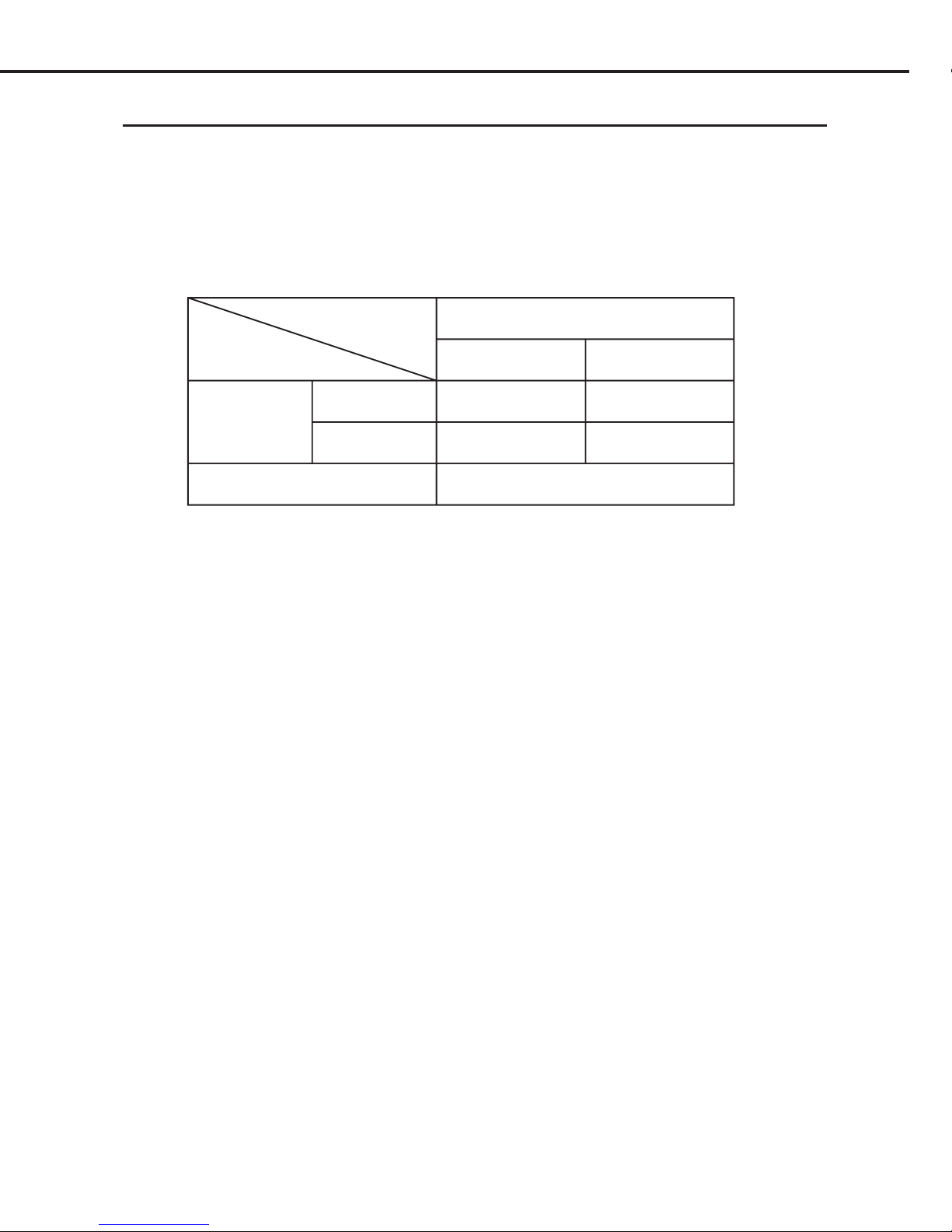

Flow Chart Showing Determination of Basic

Specification/Expanded Port Specification

A flow chart showing how to determine whether the connections should be made in the basic or

expanded port specification is set out below.

In cases where there is sufficient space and more than one DRYPRO 793 installed,

the basic specification should be selected.

Conditions for devices allocated to the expanded port.

- KDIS devices (RS Series, IS Series, Liteview) or REGIUS Series (backup settings

only)

- Maximum daily print count of 20 sheets per device.

- LUT setting fixed to "linear".

- Print conditions common to the additional 5ch.

Ch.1 Pre-installation Information

< 15 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

Illustrations of Examples of Basic/Expanded Port

Specification Settings

Differences in settings between the connections in basic and expanded are detailed below.

CH

Connected Connection SCU Setting

Print Condition SETUP,

Device Spec. Use of Input Device Input Device IP Address Input Device AE Title

LUT SETUP

1 CS-1 Basic ON 192.168.20.90 KC_CS1L_U001

Individual Settings Possible

2 CS-1 Basic ON 192.168.20.91 KC_CS1L_U001

Individual Settings Possible

3 CS-1 Basic ON 192.168.20.92 KC_CS1L_U001

Individual Settings Possible

... ... ... ... ... ... ...

15 PrintLink3 Basic ON 192.168.20.104 KC_PRINK3_U001

Individual Settings Possible

16 PrintLink3 Basic ON 192.168.20.105 KC_PRINK3_U002

Individual Settings Possible

SCP SETUP

Expanded Port Channel Function

DRYPRO 793 NO SELECT

Illustration of Example or Basic Configuration Settings

(Connection to 16 external devices in basic configuration.)

Total : 16 devices

CH1 CH2 CH3

. . . . . . . . . . . .

. . . . . . . . . . . . . .

CH15 CH16

Printlink3 Printlink3CS-1 CS-1 CS-1

DRYPRO 793

p.93 SCP SETUP

p96 SCU SETUP

Ch.1 Pre-installation Information

< 16 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

Illustration of Example for Expanded Port Configuration Settings 1

(Connection to 20 external devices with CH4 set as the expanded port)

Total: 20 Devices

LiteViewPrintlink3CS-1 CS-1 CS-1 Liteview Liteview Liteview Liteview

CH1 CH2 CH3

. . . . . . . . . . .

. . . . . . . . . .

CH15 CH16

DRYPRO 793

CH

Connected Connection SCU Setting

Print Condition SETUP,

Device Spec. Use of Input Device Input Device IP Address Input Device AE Title

LUT SETUP

1 CS-1 Basic ON 192.168.20.90 KC_CS1L_U001

Individual Settings Possible

2 CS-1 Basic ON 192.168.20.91 KC_CS1L_U001

Individual Settings Possible

3 CS-1 Basic ON 192.168.20.92 KC_CS1L_U001

Individual Settings Possible

... ... ... ... ... ... ...

15 PrintLink3 Basic ON 192.168.20.104 KC_PRINK3_U001

Individual Settings Possible

LiteView Expanded

LiteView Expanded

16 LiteView Expanded ON (Blank) (Blank)

Common Settings

LiteView Expanded

LiteView Expanded

SCP SETUP

Expanded Port Channel Function

DRYPRO 793 CH 16

Ch.1 Pre-installation Information

< 17 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

Illustration of Example for Expanded Port Configuration Settings 2

(Connection to 20 external devices with CH2 set as the expanded port)

Liteview Printlink3 Printlink3CS-1 Liteview Liteview

CH1 CH2 CH3

. . . . . . . . . . . . . .

CH16

DRYPRO 793

CH

Connected Connection SCU Setting

Print Condition SETUP,

Device Spec. Use of Input Device Input Device IP Address Input Device AE Title

LUT SETUP

1 CS-1 Basic ON 192.168.20.90 KC_CS1L_U001

Individual Settings Possible

LiteView Expanded

2 LiteView Expanded ON (Blank) (Blank)

Common Settings

LiteView Expanded

3 PrintLink3 Basic ON 192.168.20.92 KC_PRINK3_U001

Individual Settings Possible

... ... ... ... ... ... ...

16 PrintLink3 Basic ON 192.168.20.104 KC_PRINK3_U001

Individual Settings Possible

SCP SETUP

Expanded Port Channel Function

DRYPRO 793 CH 2

Ch.1 Pre-installation Information

< 18 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

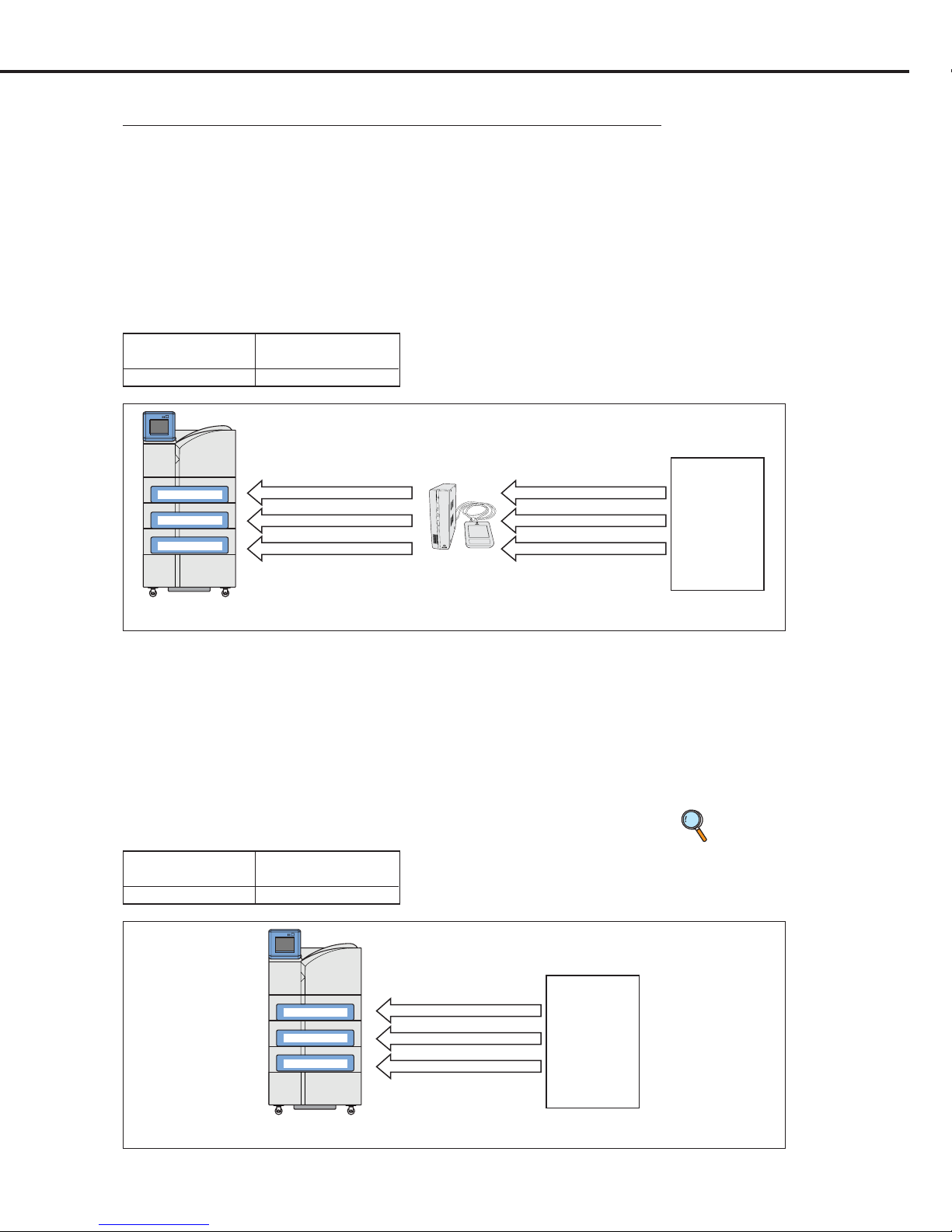

Connected to CS3 (Venus PCM Mode)

CS-3DRYPRO 793

14x17 BLUE Dmax3.0

11x14 DR BLUE Dmax4.0

8x10 DR BLUE Dmax4.0

Tray-1 : 14x17 B

Tray-2 : 11x14 M

Tray-3 : 8x10 M

SCU Setting

Size Type Check

DRYPRO 793 ON

1.2.3 25µ Output

For a Regius-PCM system, the DRYPRO 793 super-fine mode (25µm) is required.

For connections to Regius contact mammography/normal photography and other modalities, the

normal mode (43.7µm) is used.

DRYPRO 793 requires the conditions shown below for 25µm output.

- 1GB expanded print memory.

- Loaded with mammography-dedicated film (film type <M>).

An example of output in the 25µm mode is shown below.

For 25um output, a command for output on the "DR BLUE FILM" film type must be

sent from CS-3.

For 25um output, giga-bit Ethernet is recommended to ensure a large image size.

Ch.1 Pre-installation Information

< 19 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

Connection to Devices of other Manufacturers Using Printlink

The "BLUE FILM" output command from devices of other manufacturers must be converted to

"DR BLUE FILM" (Konica Minolta's unique standard) and sent to DRYPRO 793. For details of he

method of conversion and other relevant information, refer to the Printlink Manual.

Printlink

DRYPRO 793

14x17 BLUE Dmax3.0

11x14 DR BLUE Dmax4.0

8x10 DR BLUE Dmax4.0

14x17 BLUE Dmax3.0

11x14 BLUE Dmax4.0

8x10 BLUE Dmax4.0

Device of Other

Manufacturer

Tray-1 : 14x17 B

Tray-2 : 11x14 M

Tray-3 : 8x10 M

SCU Setting

Size Type Check

DRYPRO 793 ON

1.2.4 Mammo-film Output

In mammo-mode of other manufacturers, DRYPRO 793 high-density output (Dmax 4.0) is

required. For Regius normal photography and other modalities, Dmax 3.0 is used.

DRYPRO 793 requires the conditions shown below for Dmax 4.0 output.

- Loaded with mammography-dedicated film (film type <M>).

An example of mammo-film output is shown below.

Connection with Devices of other Manufacturers without Printlink

To send a direct output command from the device that cannot change the Dmax, the following

settings must be made in DRYPRO 793.

[PRINT SETUP]

[PRINT CONDITION]

[Maximum density] : "400"

[Maximum/minimum density value used] : "DICOM"

[Parameter priority setting] : DENSITY MAX set to ON.

DRYPRO 793

14x17 BLUE Dmax3.0

11x14 BLUE Dmax4.0

8x10 BLUE Dmax4.0

Device of Other

Manufacturer

Tray-1 : 14x17 B

Tray-2 : 11x14 M

Tray-3 : 8x10 M

SCU Setting

Size Type Check

DRYPRO 793 OFF

p.110 PRINT

CONDITION

SETUP

Ch.1 Pre-installation Information

< 20 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

1.3 Installation Preparations

The following items should be checked before proceeding with installation.

1.3.1 1Checking Installation Conditions

Check to ensure that the place of installation meets the following requirements.

Checking the Place of Installation

- There must be no risk of exposure to water.

- There must no risk of exposure to the harmful effects of high pressure, extreme

temperatures, humidity, poor ventilation, direct sunlight, dust, salt, combustible

gases or sulphur.

- There must be no risk of tilting, exposure to vibration or shock (including transport).

- There must be no chemicals must be stored at the place of installation.

- There must be no risk of gaseous emissions.

- Ventilation must be sufficient to disperse any odours produces by DRYPRO 793.

- There must be sources of noise in the vicinity.

- There must be sufficient space to ensure that there will be no risk of tripping over or

pulling on power or ethernet cables.

- There must be sufficient space to ensure that air inlets and outlets at the side and

rear of the unit are not obstructed.

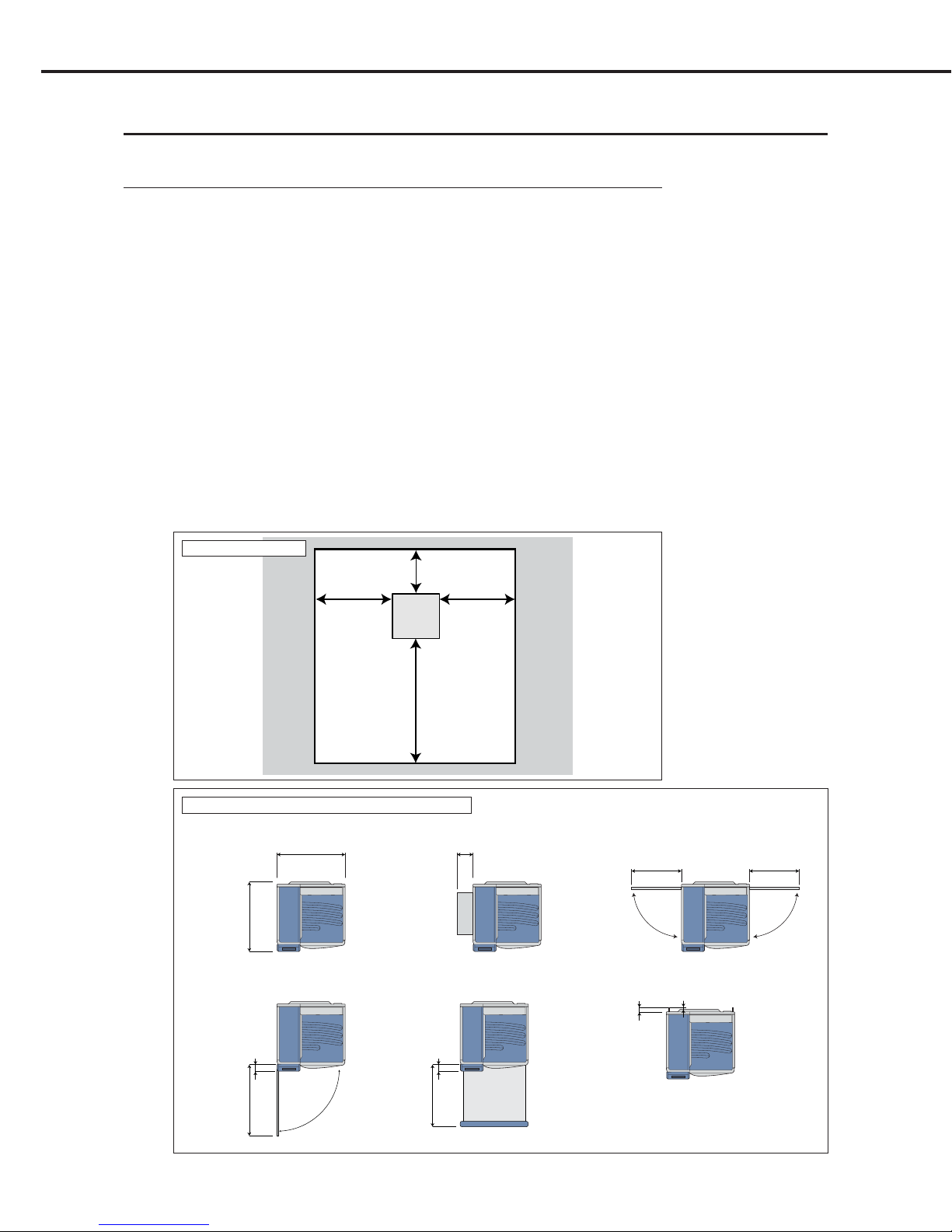

- The installation space must meet the dimensional requirements shown below.

1000mm minimum

100mm minimum

500mm minimum

DRYPRO

793

Front of

Main Body

500mm minimum

Installation Space

630mm

740mm

195mm

460mm

With upper and lower front covers open

(to replace deodorant filter or resolve jams)

With supply tray open (to load films)

With ejection panel open (to resolve jams)Normal

When installing exhaust duct and clamp

675mm

54mm

26mm

With left/right panels open (to resolve jams)

62mm

580mm

62mm

460mm

Maximum Space Requirements for DRYPRO 793

Ch.1 Pre-installation Information

< 21 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

Checking Power Supply Conditions

Check to ensure that a power outlet meeting the requirements below is available at

the place of installation.

- Voltage : AC120V (UL), AC220V-240V (CE)

- Frequency : 60Hz (UL), 50/60Hz (CE)

- Maximum current consumption: 9A(UL), 4.5A(CE)

- Ground : Type D

Checking the Place of Unpacking

Check to ensure that a space of 2.5m or more is allowed at the front (the side where

the locking screws are located) of the palette.

When unpacking DRYPRO 793, be sure to unload the unit from the front of the

palette.

Checking the Route of Transportation

Check to ensure that the route from the place of unpacking and the place of

installation meets the following requirements.

- Ensure that there are no steep gradients or steps that are likely to expose

DRYPRO 793 to shocks during transport.

- Ensure that entrances into and exits from any rooms through which DRYPRO 793

will be transported are of adequate dimensions to allow safe passage.

- Ensure that the floors on the rout of transportation are capable of supporting the

weight of DRYPRO 793 (approximate weight: 255kg (without sorter), 285kg (with

sorter) without warping or buckling.

Checking the Area where Power and Ethernet Cables will be Laid

The person responsible for laying cables must check the following items.

- The location of the hub to which DRYPRO 793 will be connected, the route along

which the Ethernet cable will be laid and the required cable length.

- The location of the power outlet (3P) to which DRYPRO 793 will be connected, the

route along which the power cable will be laid and the required cable length.

Check also to ensure that cables will be laid along a safe route, not, for example,

crossing corridors.

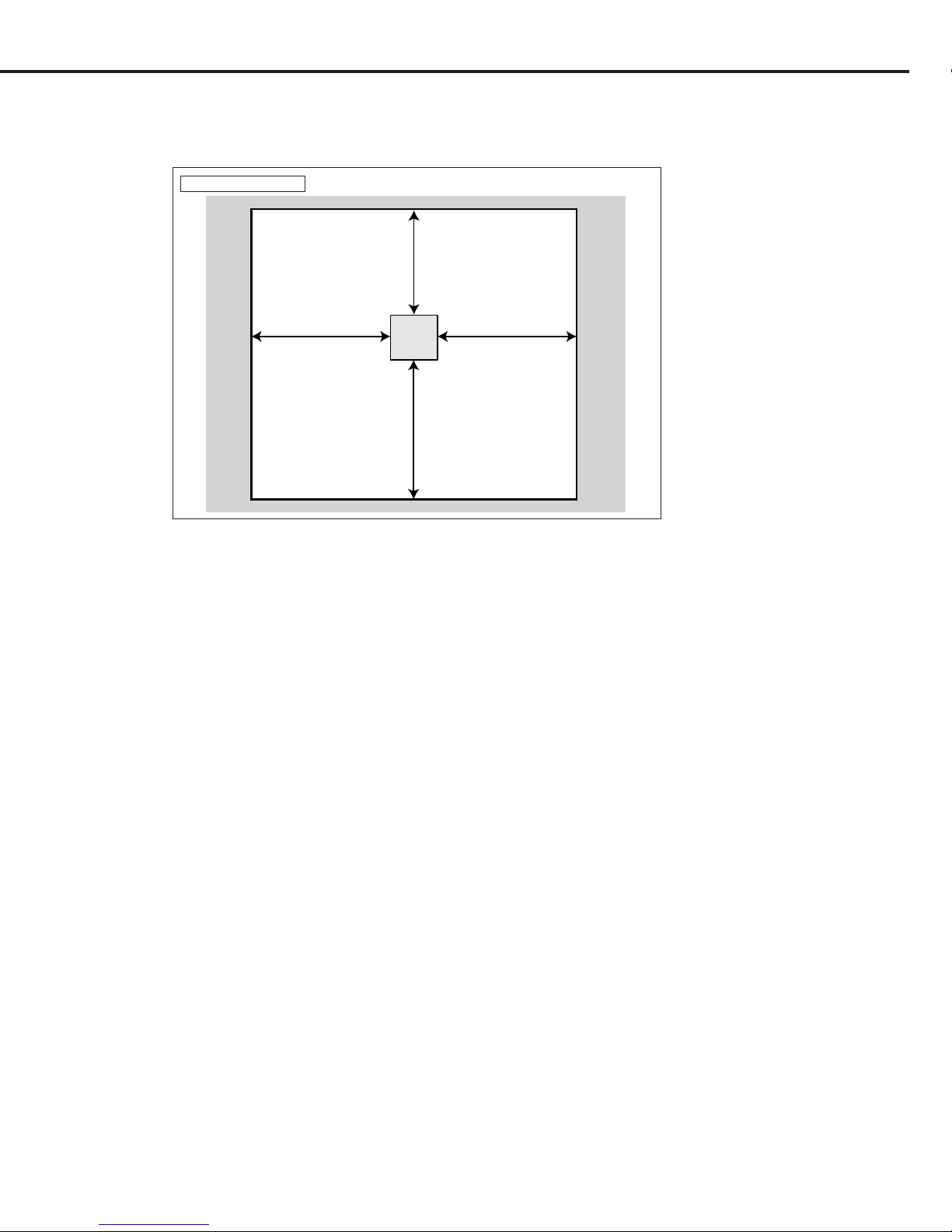

Checking Maintenance Space

Check to ensure that the place of installation allows for the maintenance space

dimensions shown below.

1000mm minimum

1000mm minimum 1000mm minimum

800mm minimum

DRYPRO

793

Front of

Main Body

Maintenance Space

Ch.1 Pre-installation Information

< 22 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

1.3.2 Checking the Network

The following points should be checked with the facility network administrator in advance of

installation.

DRYPRO 793 (SCP) Related Settings

- IP addresses and sub-net masks (when DHCP server is not used) of DRYPRO

793, maintenance PC and gateways.

- DRYPRO 793 host name.

- DRYPRO 793 AE title and port number (print service).

Diagnostic Device Related Settings

- Number of diagnostic devices connected to DRYPRO 793.

- IP address of each diagnostic device.

- AE title of each diagnostic device.

- Port number of each diagnostic device (N-EVENT REPORT service).

- Print conditions used by each diagnostic device (format, film size).

Maintenance PC

- Model with 10BaseT/100BaseTX/1000BaseT network ports.

- PC with TCP/IP protocol installed.

- PC with Windows2000/XP OS.

- PC with Internet Explorer (version 5.5 or higher).

- PC with environment capable of executing Java script with the Web browser.

Equipment for Network Connection

- Hub (Used for direct connection to DRYPRO 793 and maintenance PC).

Hub with auto-negotiation capabilities as 100Base-TX hub recommended.

- Ethernet Cables

(For DRYPRO 793 -> Hub connection and maintenance PC -> Hub connection)

CAT5E or CAT6 should be used for 1000Base-T.

Tools

- Box Cutter

- Phillips screw driver

- Long phillips screw driver (90mm or longer) for disengaging the front cover lock.

- Flat head screw driver

- Radio pliers

- 13mm box wrench (with a long section below the neck). Alternatively, socket

wrench (with extension cover)

- Portable densitometer: X-Rite 331 (used to check image)

- Magnifying glass (used to check image)

1.3.3 Equipment and Tools Required for Installation

Before proceeding with installation, check to ensure that the following equipment and tools are

available.

p.93 SCP SETUP

p.96 SCU SETUP

Ch.1 Pre-installation Information

< 23 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

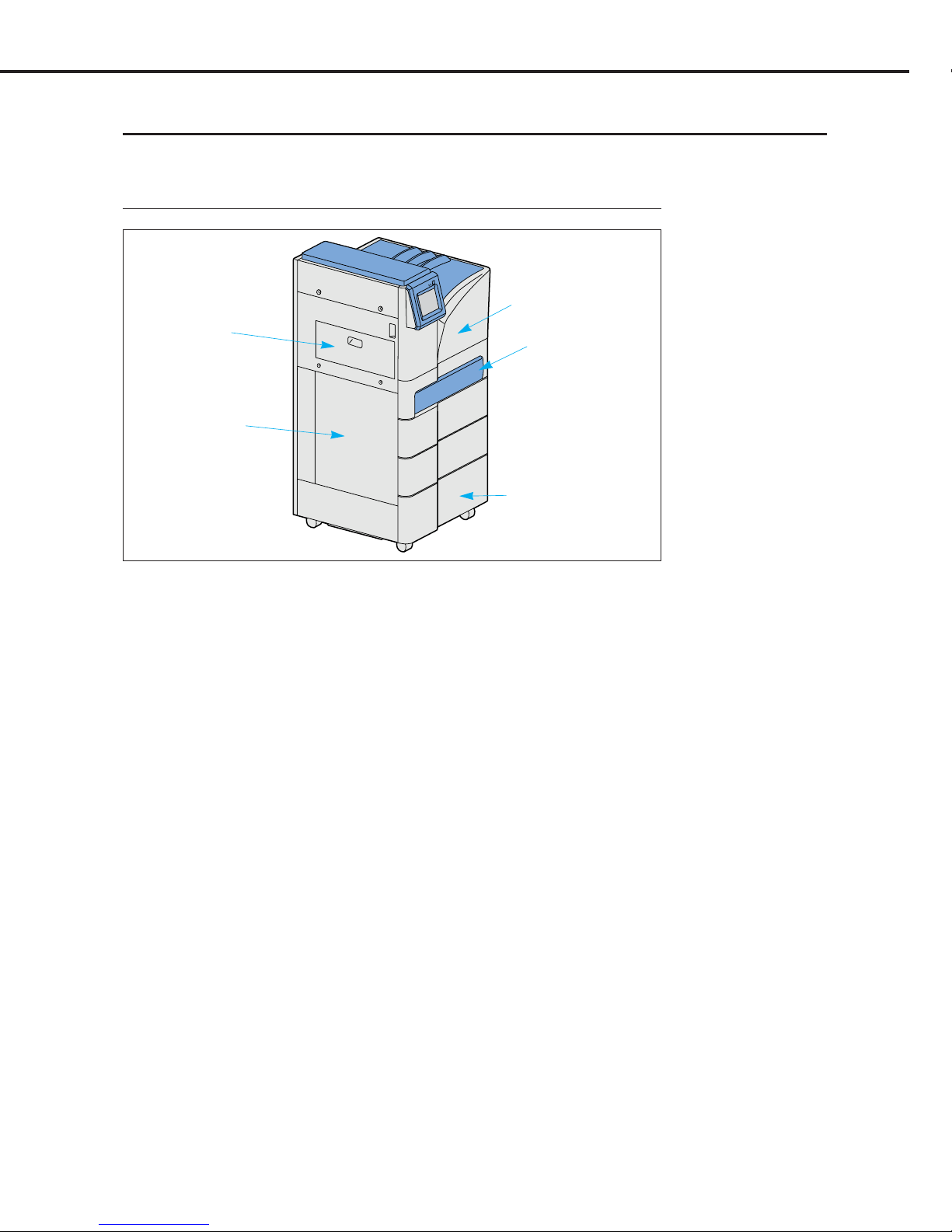

1.4 Part Names

DRYPRO 793 Part names required for installation are detailed below.

1.4.1 Front, Top and Left Sides

1) Front Upper Cover

3) Front Lower Cover

2) Supply Tray 1

4) Exit Cover

5) Left Cover

1) Front Upper Cover

When a film jam occurs I the HPRO

(heat processing unit)/cooling unit, open

this cover to remove the jammed film.

This cover is also opened to replace the

deodorant filter.

2) Supply Tray 1

(Standard: 1 tray, with option: 3 trays)

Film is loaded in these trays.

3) Front Lower Cover

When a film jam occurs in the descent

or elevator transport units or the film

justification unit, this cover may be

opened to remove the jammed film. It is

also possible to access the film from

this opening and feed it through to the

left or right covers.

4) Exit Cover

When a film jam occurs in the ejection

unit, this cover may be opened to

remove the jammed film.

5) Left Cover

When a film jam occurs in the descent

transport unit, this cover may be opened

to remove the jammed film.

This cover may also be removed to

carry out cleaning of the cleaning roller.

Ch.1 Pre-installation Information

< 24 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

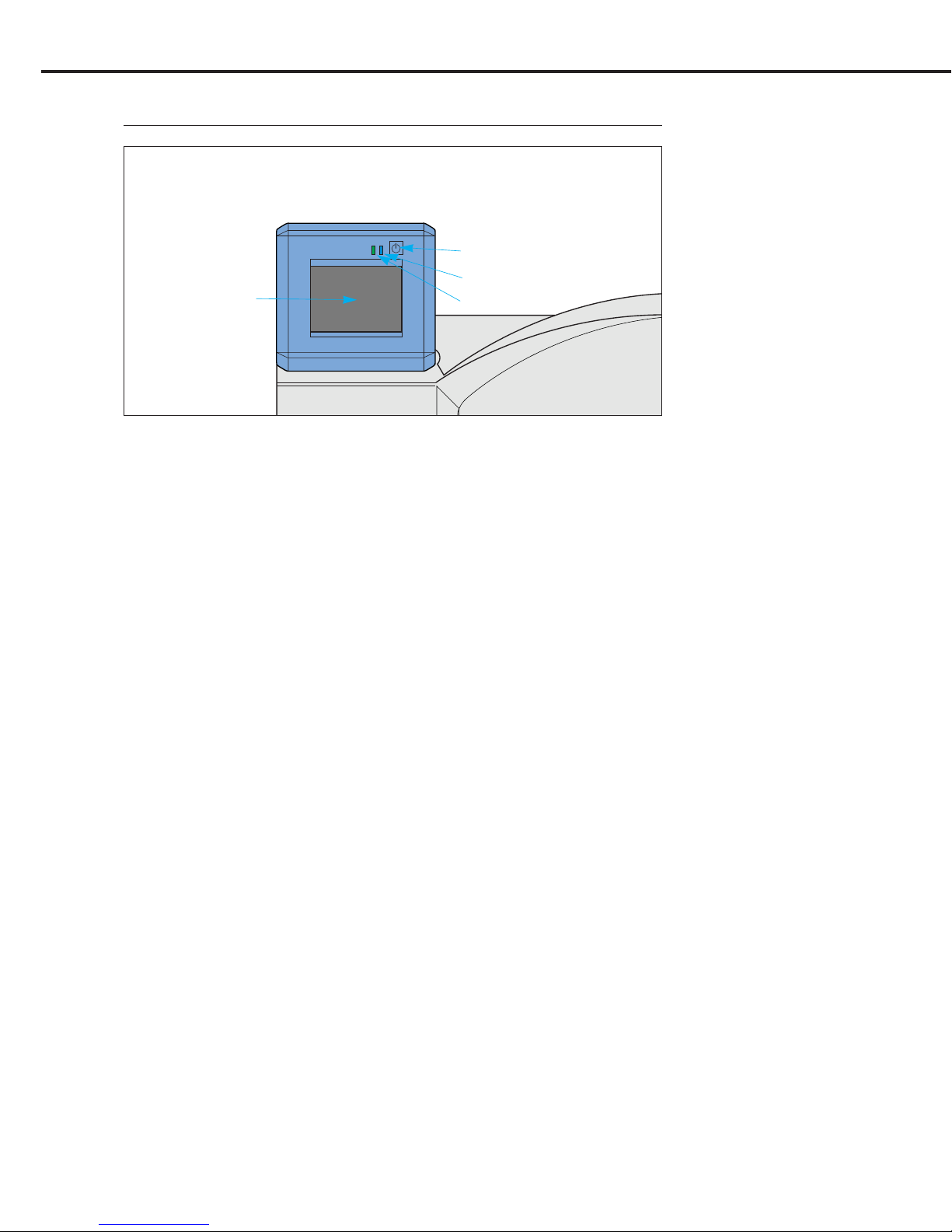

1) Operation Panel

Operates and performs various setting for DRYPRO 793. Also displays various

messages.

2) Operation Button

Starts up or shuts down DRYPRO 793.

3) Operation Lamp

Operating : Constant blue

Start Timer ON : Constant blue

Shutdown Processing : Flashing blue

Power OFF (breaker ON) : Constant Orange

Power OFF (breaker OFF) : Extinguished.

4) Timer Lamp (Green)

Illuminates when the start timer is ON.

1.4.2 Operation Panel

2) Operation Button

3) Operation Lamp

4) Timer Lamp

1) Operation Panel

Ch.1 Pre-installation Information

< 25 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

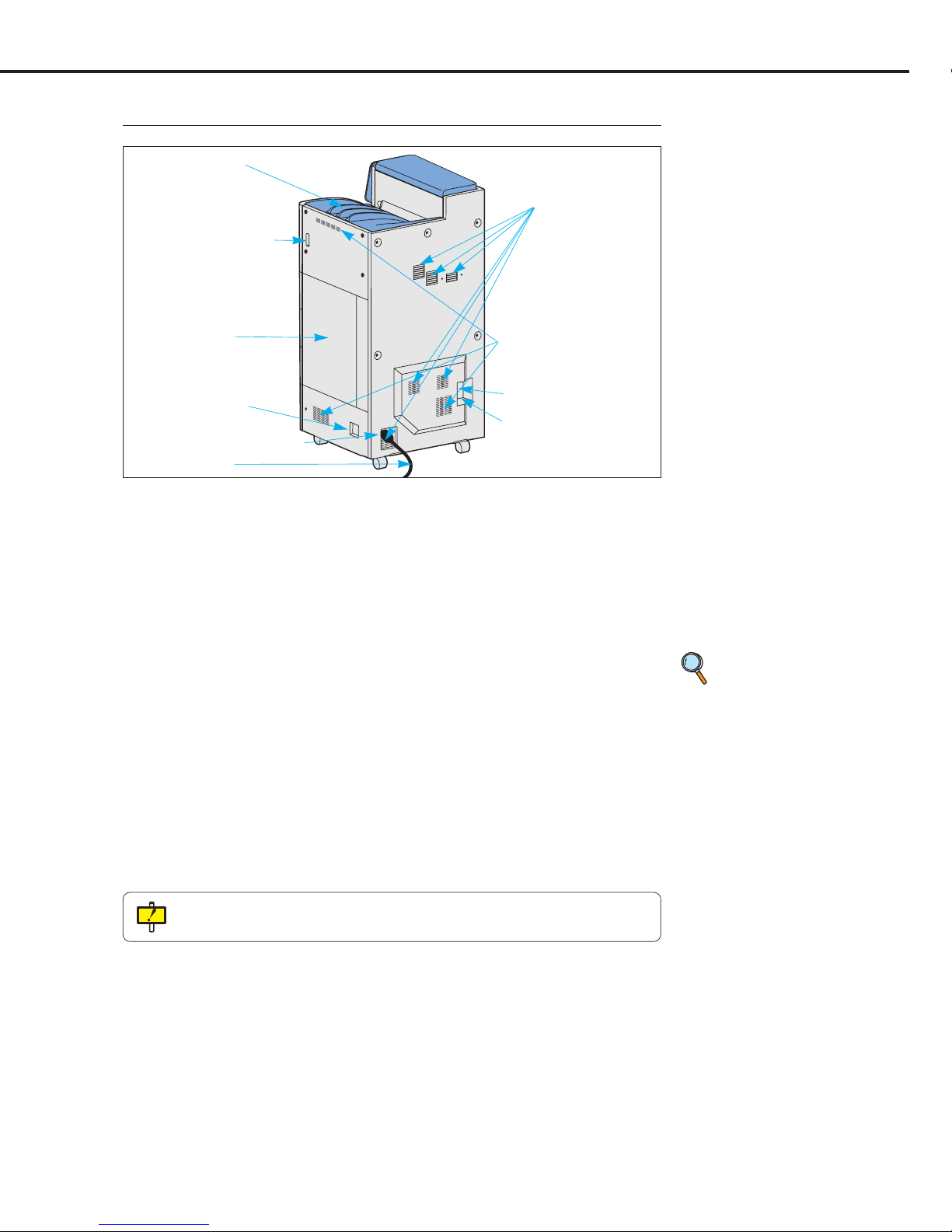

1.4.3 Rear and Right Sides

p.24 Ethernet Port

LEDs

6) Power Cable

7) Outlet

9) Ethernet Port

5) Power Cable Connector

1) Film Exit Tray

Printed films are output to this tray.

When an optional 6ch sorter is installed,

films are output to the sorter.

2) Front Upper Cover Release Lever

Releases the front upper cover lock

when it is necessary to open the cover.

3) Right Cover

When a film jam occurs in the elevator

transport unit, this cover may be opened

to remove the jammed film.

4) Power Breaker

Turns ON/OFF main power.

5) Power Cable Connector

Connects the power cable.

6) Power Cable

Connects DRYPRO 793 to the facility

power outlet.

7) Outlet (4 locations)

Air used to cool the inside of the unit is

released from these ports.

8) Inlet

(2 on the right side, 1 on the rear side)

Takes in air to cool the inside of the

unit.

9) Ethernet Port

Provides connection to the network.

10) Serial Port

The cable from the backup battery, if

used, is connected to this port.

10) Serial Port

8) Inlet

4) Power Breaker

3) Right Cover

2) Front Upper Cover

Release Lever

1) Film Exit Tray

Do not leave films equivalent to one package (= 125 sheets) or more on the Film Exit

Tray.

Ch.1 Pre-installation Information

< 26 >

DRYPRO Vstage MODEL 793 Installation Manual Ver.1.00 2004.11

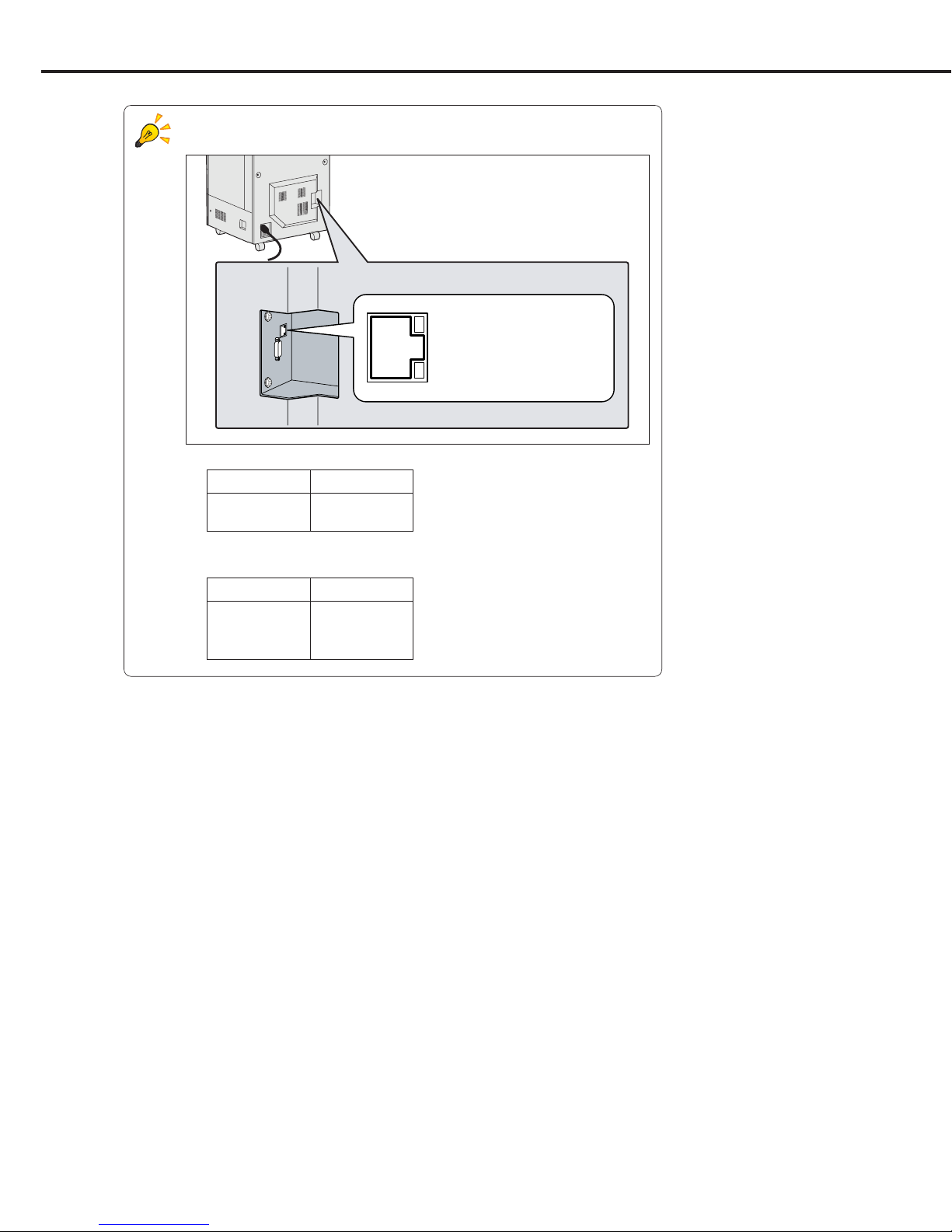

LEDs at the Ethernet Port

Two LEDs at the Ethernet port indicate the following.

- Link/Activity LED

- Com. Speed LED

Com. Status LED

10Mbps Extinguished

100Mbps Constant orange

1000Mbps Constant green

Com. Status LED

Link Constant orange

Activity Constant green

Link / Activity LED

Com. Speed LED

Lower right of the rear side

Loading...

Loading...