OPERATION

GUIDE

Contents

Safety Information

User Instructions .................................................................................................................1

Machine Labels ...................................................................................................................2

Label Locations............................................................................................................2

Machine Installation and Power Requirements................................................................... 4

Machine Handling and Care................................................................................................6

Routine Safety.....................................................................................................................7

Finisher Capacity Requirements ......................................................................................... 8

DP65

Machine Information

Machine Configuration......................................................................................................10

External Machine.......................................................................................................10

External Machine Call-outs........................................................................................10

Optional Equipment ...................................................................................................12

Control Panel Layout.........................................................................................................14

Specifications.................................................................................................................... 15

Printing Operations

Introduction .......................................................................................................................19

Wake Up Screen........................................................................................................19

Warm Up Screen .......................................................................................................19

Control Panel ....................................................................................................................20

The Basic Screen..............................................................................................................20

Check Mode Message ......................................................................................................21

Check Screen ............................................................................................................21

Reservation List ................................................................................................................22

Screen Display...........................................................................................................22

Contents

Printing Operations (continued)

Help Mode.........................................................................................................................23

Stop Printing......................................................................................................................24

Change Job Order.............................................................................................................25

Job Deletion......................................................................................................................26

Previous Job List...............................................................................................................27

Non Complete Job List......................................................................................................28

Change Setting .................................................................................................................29

Output Modes

Non-Sort Mode Using Primary (Main) Tray.......................................................................30

Sort Mode Using Primary (Main) Tray...............................................................................31

Staple-Sort Mode Using Primary (Main) Tray ................................................................... 32

Fold Mode / Stitch & Fold Mode ........................................................................................33

Punch Mode......................................................................................................................34

Z-Fold Mode......................................................................................................................35

Three-Fold Mode...............................................................................................................36

Cover Sheet Feeder.......................................................................................................... 37

Manual Finishing ...............................................................................................................38

Output Mode for Machine without Finisher .......................................................................41

Maintenance & Supplies

Loading Paper...................................................................................................................42

Paper Indicator ( ) ......................................................................................................42

Paper Empty Indicator ( or )....................................................................................... 42

Using the HELP Key ..................................................................................................42

Loading Paper in Tray 1 and 2...................................................................................43

Loading Paper in Tray 3.............................................................................................44

Loading Paper in Multi-Sheet Bypass Tray................................................................45

Loading Paper in LCT (LT-402/LT-412) ..................................................................... 46

Loading Tabbed Sheets in Tray 1, 2, or 3..................................................................47

Loading Tabbed Sheets in Multi-Sheet Bypass Tray.................................................48

Loading Tabbed Sheets in LCT (LT-402/LT-412)...................................................... 49

Adding Toner.....................................................................................................................50

Inserting a New Staple Cartridge into FS-110/210 Finisher .............................................. 51

Empty Waste Basket of PK-110/120 Punching Kit............................................................52

Empty Waste Basket of PZ-108 Punching / Z-Folding Unit ..............................................53

Preventive Maintenance....................................................................................................54

Reading the PM Counter ...........................................................................................54

Printing the PM Counter.............................................................................................54

Clearing Mishandled Paper...............................................................................................55

Jam Location Screen .................................................................................................55

Key Operator Mode

To the Key Operator..........................................................................................................56

How to Access the Key Operator Mode.....................................................................57

Function Menu Map ..........................................................................................................58

Restrictions in Use ............................................................................................................60

Safety Information

User Instructions

The following pages include important safety information, which you must read and

understand before you attempt to operate the machine. If you have any concerns about safety

matters, please contact your service representative. Keep this manual located permanently

with the machine, so that this safety information is readily available.

Machine safety labels are attached to the internal area of the machine. The purpose of safety

labels is to alert you of imminent or potentially hazardous situations or conditions. Be sure to

heed all safety label information. If the safety labels become illegible due to soilage, etc.,

please contact your service representative for information about label replacements. Sample

safety labels are shown on the following page.

TO AVOID GETTING BURNED do not touch any part of the machine that you are advised not

to touch by a warning or caution label.

DO NOT REMOVE WARNING OR CAUTION LABELS.

Clean labels as needed to maintain legibility. If any warning or caution label is removed or

becomes illegible from soilage, please contact your service representative for information

about label replacements.

The following standard safety categories are commonly used on product labelling.

DANGER:

Danger indicates an imminent hazardous situation, which, if not avoided, will result in

death or serious injury.

Note:

The DANGER category is not required for this product, and is only included here for general user information.

WARNING:

Warning indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

CAUTION:

Caution indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate bodily injury.

NOTICE:

Notice provides information on the correct handling or use of the machine to prevent breakage of the printer

or some machine part, etc. It does not indicate concern for personal safety.

- 1 -

Safety Information

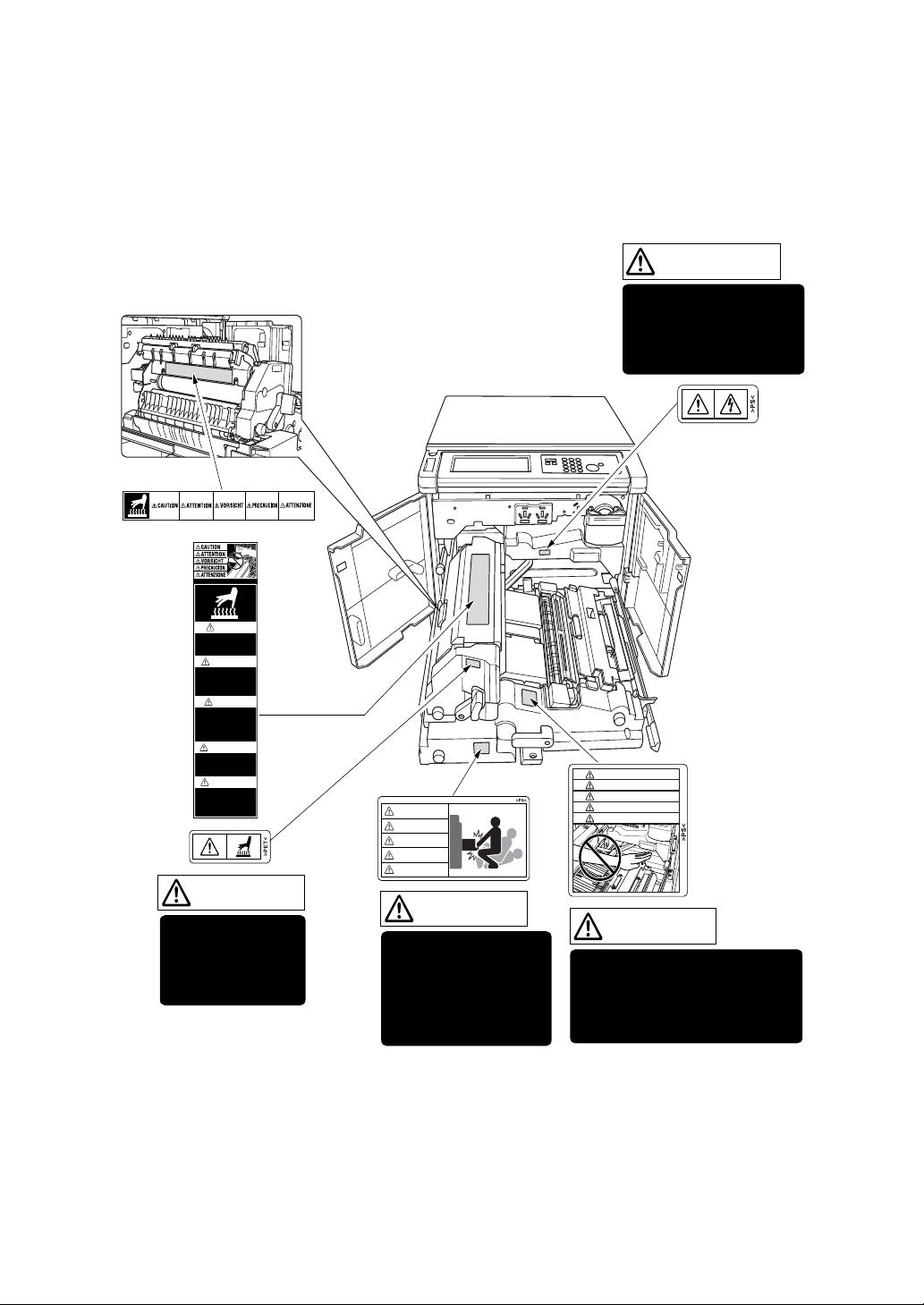

Machine Labels

Label Locations

CAUTION

High temperature!

Do not touch. Use care

when clearing paper.

ATTENTION

Température élevée!

Risque de brûlure. Soyez

prudent en retirant la

feuille coincée.

Brandverletzungsgefahr.

Bei Beseitigung von

Papierstaus vorsichtig

vorgehen.

¡Temperatura alta!

No tocar. Tener cuidado al

remover el papel.

Non toccare. Agire con

prudenza nel rimuovere la

carta.

VORSICHT

Heiße Oberfläche!

PRECAUCION

ATTENZIONE

Alta temperatura!

CAUTION

ATTENTION

VORSICHT

PRECAUCION

ATTENZIONE

WARNING

This area generates

high voltage. If touched,

electrical shock may

occur. DO NOT TOUCH.

CAUTION

ATTENTION

VORSICHT

PRECAUCION

ATTENZIONE

CAUTION

The fixing unit is

very hot. To avoid

getting burned, DO

NOT TOUCH.

CAUTION

The conveyance fixing

unit is heavy. Use care

and draw it out gently;

otherwise you may be

injured.

- 2 -

CAUTION

DO NOT put your hand between

the main body and developing

fixing unit; otherwise you may

be injured.

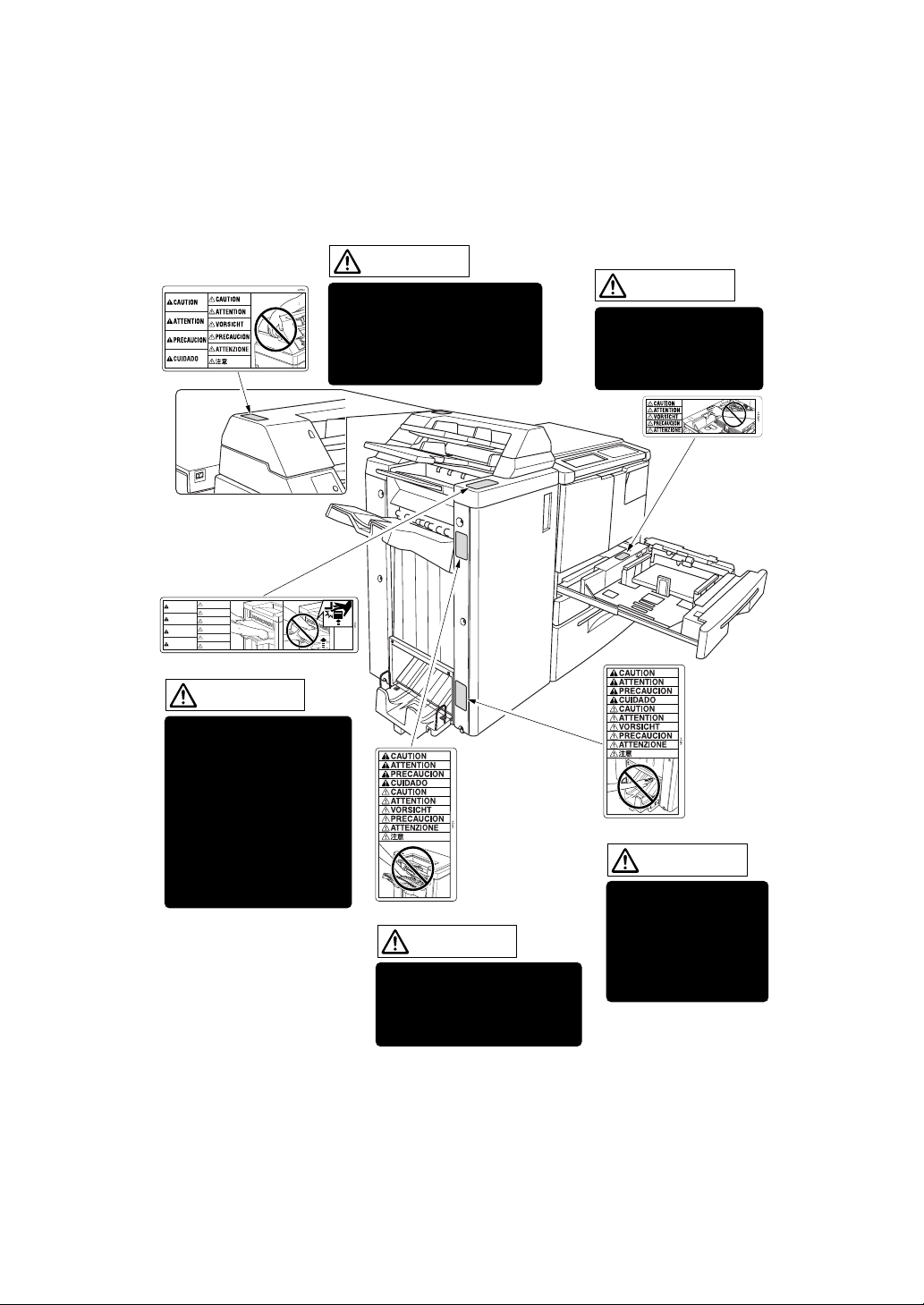

Safety Information

Machine Labels (continued)

Label Locations (continued)

(Finisher with PI-110

Cover Sheet Feeder only)

CAUTION

CAUTION

ATTENTION

ATTENTION

VORSICHT

PRECAUCION

PRECAUCION

ATTENZIONE

CUIDADO

(FS-110/FS-210 Finisher)

CAUTION

To avoid injury, DO NOT

put your hand on top of

the printed sheets. Be

sure to hold both sides of

the printed sheets when

removing them, and DO

NOT leave your hand on

the printed sheets while

the primary (main) tray

goes up.

CAUTION

DO NOT insert your finger into

the bottom of the upper part

of the feeder when returning

to its original position;

otherwise you may be injured.

(FS-210 Finisher)

CAUTION

Use care after opening the

paper exit outlet. DO NOT put

your hand into it; otherwise

you may be injured.

CAUTION

DO NOT put your hand

between the main body

and tray; otherwise you

may be injured.

(All trays)

(FS-210 Finisher only)

CAUTION

Inside the lower paper

exit outlet is the roller

drive unit. DO NOT put

your hand into it;

otherwise you may be

injured.

- 3 -

Safety Information

Machine Installation and Power Requirements

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN BODILY INJURY AND/OR MACHINE

DAMAG E.

❒ FIRE PREVENTION

Install machine away from flammable or volatile materials. Routinely check for abnormal heat

from power cord and/or plug.

❒ SHORT CIRCUIT FROM WATER DAMAGE

Do not install or operate this equipment outdoors near a lake, pond, or river, etc.; and do not

allow the machine to come in contact with splashes of rain, water, or any liquid.

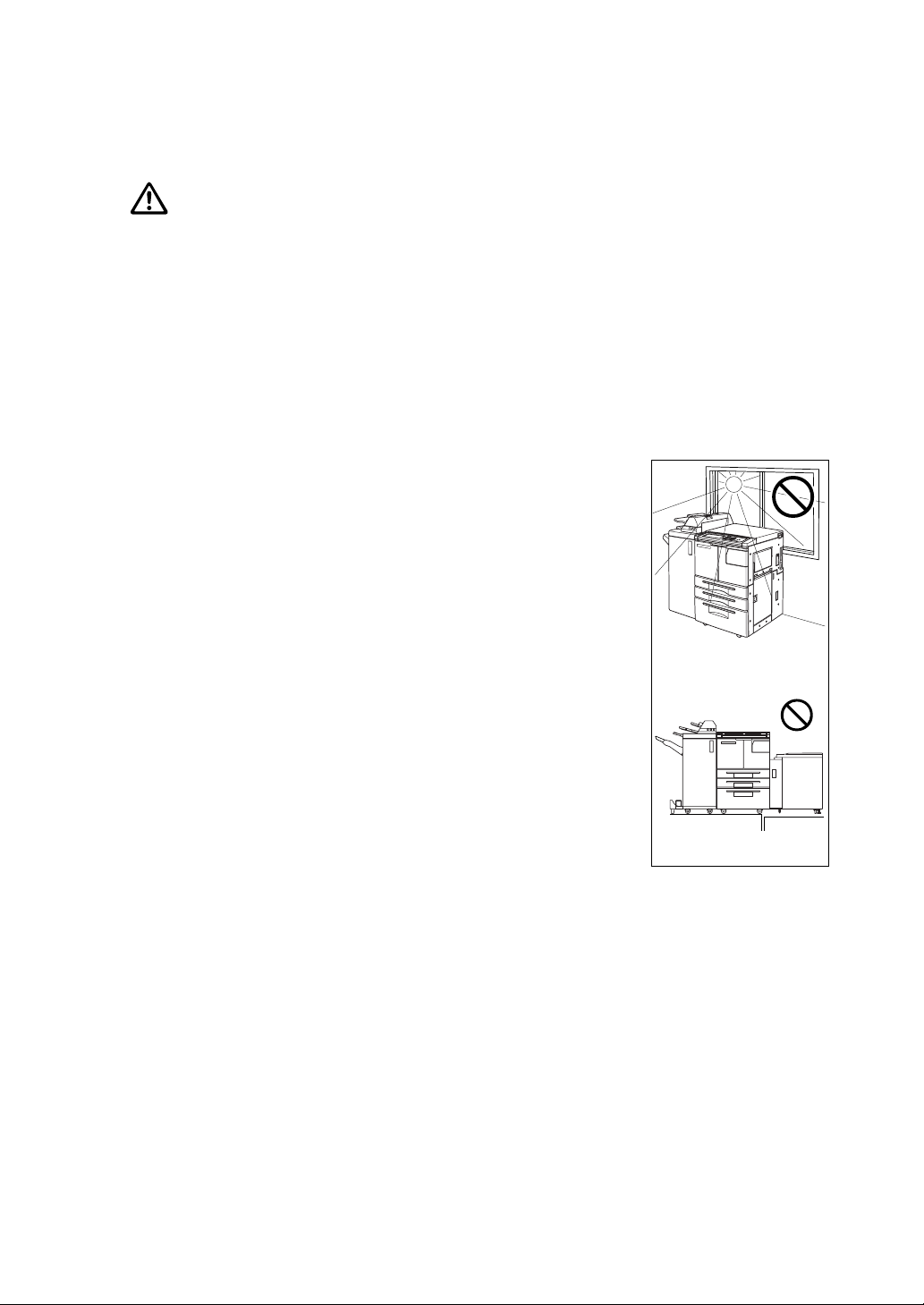

❒ TEMPERATURE AND HUMIDITY

Install the machine away from direct sunlight, heat sources (stoves,

heaters) and cold temperatures (air conditioners). Avoid any

environment that is outside 10°~30°C, with 10~80% humidity.

❒ VENTILATION

Do not allow the machine to come in contact with dust or ammonia

gas, or fumes from printing or cleaning solutions, etc.; otherwise,

image quality will be poor. Install the machine in a well-ventilated

area, for comfort; otherwise, an ozone odor will be detected during

large print runs. When in use, the printer generates ozone in

amounts too small to be hazardous to the human body.

Temperature

❒ VIBRATIONS

If the machine is constantly vibrated or jolted, trouble may occur.

Install the machine on a level, horizontal floor, free from vibrations.

❒ SPACE ALLOTMENT

Install machine in an area with adequate space for performing

Vibration

printer operations, replacing supply items, and conducting

preventive maintenance. See Site Requirements.

❒ MACHINE RELOCATION/TRANSPORTATION

Be sure to contact your service representative when moving or transporting the machine. If

you move the machine with the Memory unit installed, machine trouble may be caused by

vibration.

❒ PLUG SOCKET

A plug socket is limited in capacity. Use an exclusive power source for this machine; otherwise,

overheating and/or smoking may occur. The total power consumption of the main body, plus all

peripherals, must not exceed the capacity of the main power supply.

Be sure the socket-outlet is near the equipment and is easily accessible.

- 4 -

Safety Information

Machine Installation and Power Requirements (continued)

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN MACHINE DAMAGE, OVERHEATING,

RISK OF ELECTR ICAL SHOCK , AND/OR PERSONAL INJURY.

❒ PLUG AND CORD (LEAD)

Unless the power plug is firmly inserted into the socket, overheating and/or smoking may

occur. Firmly insert the power cord plug into the electrical outlet before turning on the printer

power switch. If the inserted plug is loose in the socket, disconnect it, and consult an

electrician for repair; do not attempt to operate the machine.

Be sure the socket-outlet is near the equipment and is easily accessible.

A damaged power cord may result in overheating, short circuit or fire. Do not bend, crush,

wind, kick, or strike the cord with any item. Do not roll up the cord. If the main body power cord

is bent or damaged, immediately contact your service representative; do not attempt to repair

it yourself; do not continue to operate the machine.

❒ ADAPTERS AND PLURAL LOADS

Never use adapters and never connect plural loads or a branched socket to one socket outlet;

otherwise, overheating or fire may occur.

❒ EXTENSION CORDS (LEADS)

An extension cord or lead is limited in capacity. Unless the cord or lead has adequate capacity,

smoking and overheating may occur. Should smoking and/or overheating occur, contact an

electrician immediately. If you require further information about power requirements, power

consumption, extension cords, adapters and connectors, please contact your service

representative, and consult your electrician.

- 5 -

Safety Information

Machine Handling and Care

WARNING:

FAILURE TO HEED THE FOLLOWING WARNING MAY RESULT IN DEATH OR SERIOUS INJURY AND/OR

MACHINE DAMAGE.

❒ MACHINE CONTACT

Never touch internal high voltage areas, indicated with a WARNING label.

Never touch the drum surface.

Never put your hand into the developing unit when removing mishandled paper.

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN MACHINE DAMAGE, OVERHEATING,

AND/OR PERSONAL INJURY.

❒ MACHINE CONTACT

Never touch internal high temperature or magnetism areas, indicated with a CAUTION label.

Never insert your hand into the fixing unit when removing mishandled paper.

Never touch the inside of the main body for any purpose except

removing mishandled paper or adding toner.

Use care when pulling out the conveyance fixing unit.

❒ MACHINE CARE

Do not drop paper clips, staples or other small metallic objects into

the printer, or spill water or any other liquid into the machine.

Do not use the machine surface to support vases, books, etc.

These items will interfere with the work space and may cause

damage to the machine.

❒ ABNORMAL CONDITIONS

If any abnor mal sound, odor, or smoke generates from the

machine, immediately stop using the printer, turn off the main

power switch, disconnect the plug and contact your service

representative.

If a circuit breaker is tripped, or if a fuse blows, stop using the

machine and contact an electrician. If more detailed information is needed regarding the

power source or power consumption of this machine, contact your service representative.

❒ MACHINE MODIFICATION

Do not modify the machine in any way or remove any part or screw. Never attempt to perform

any maintenance function that is not specifically described in this manual. Do not connect the

machine with any options other than those specified.

- 6 -

Safety Information

Routine Safety

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN MACHINE DAMAGE, OVERHEATING,

AND/OR PERSONAL INJURY.

❒ PERIODIC CHECK

Check for loose connections or excessive heat on power plug, damage to power cord and/or

plug (creased, frayed, scratched or cut, etc.). Be sure the plug is inserted fully, and ground

wire is connected correctly. If any abnormality occurs, do not continue to operate the machine.

❒ SERVICE MESSAGES

If a service message displays, turn the machine off, disconnect the power cord from the outlet,

and report the condition to your service representative.

❒ TONER

Check to be sure toner in storage is out of the reach of children, or anyone incapable of using

supplies safely. Although toner is nontoxic, do not inhale toner or allow it to come in contact

with eyes. If inhalation or eye contact occurs, immediately consult a physician. Please refer to

the appropriate material safety data sheet for additional toner safety information.

❒ PAPER

• Do not use stapled paper or paper that conducts electricity (silver, carbon, etc.), otherwise

an accident may occur as a result of fire.

• To avoid machine trouble, do not use heat-sensitive paper, paper that conducts electricity

(silver, carbon, etc.), or coloured OHP film.

❒ CLEANING MATERIALS

Check the type of cleaning material used on your machine to be sure it is recommended by

Konica. If necessary, check with your service representative. Never use cleaning materials for

purposes other than cleaning, and be sure to keep all cleaning materials out of the reach of

children or anyone who is incapable of using them safely.

❒ POWER SAVER

Use Power Saver mode for short periods of machine inactivity. When not using the machine for

long periods of time, turn power off, unless the weekly timer function is operating.

❒ DISPOSAL OF THE PRINTER AND ACCESSORIES

Dispose of this printer and accessories according to your local regulations.

- 7 -

Safety Information

Finisher Capacity Requirements

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN BODILY INJURY AND/OR MACHINE

DAMAG E.

❒ FINISHER PAPER CAPACITY

To prevent paper misfeed, do not exceed the paper capacity of the Finisher.

FS-110/FS-210 Finisher paper weight: 60 g/m2 ~ 90 g/m

When the selected print quantity exceeds the maximum paper capacity, remove the printed

sheets from the finisher while the paper is exiting.

Paper capacities below are stated for 80 g/m2 paper unless otherwise indicated.

This Finisher also accepts wide types of the regular sizes stated below.

Finisher FS-110/FS-210

Primary (Main) tray: Non-sort/Sort/Group mode

500 sheets (A5, A5R, B6R)

3,000 sheets (A4, A4R, B5R, 8.5"x11", 8.5"x11"R)(FS-110)

2,500 sheets (A4, A4R, B5R)(FS-210)

1,500 sheets (A3, F4, B4)

The Secondary (sub) tray can be unloaded while the DP65 is running. Set

production is not limited by the capacity of the Secondary (sub) tray.

2

Primary (Main) tray: Punch mode (machine with PK-110/120 only)

3,000 sheets (A4)

1,500 sheets (A3)

The Secondary (sub) tray can be unloaded while the DP65 is running. Set

production is not limited by the capacity of the Secondary (sub) tray.

Primary (Main) tray: Staple-Sort / Staple-Sort + Z-Folding mode

1,000 sheets* (A3 ~ A4/A4R)

* The maximum capacity varies according to the number of prints to be stapled.

When using Z-Fold mode with Staple-Sort mode, the maximum capacity varies

according to the number of Z-folded sheet in one stapled set.

Secondary (Sub) tray: Non-sort mode

200 sheets max.

❒ FINISHER PAPER CAPACITY (continued)

Booklet tray (FS-210 only)

100 sheets max. (A3, F4, B4)

75 sheets max. (A4, A4R)

50 sheets max. in Three-Fold mode

(The maximum number of sheets varies, depending on the number of pages in the

booklet and whether Fold or Stitch & Fold is selected.)

- 8 -

Safety Information

Finisher Capacity Requirements (continued)

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN BODILY INJURY AND/OR MACHINE

DAMAG E.

❒ FS-210 FINISHER BOOKLET MODE OUTLET

Inside the Booklet mode outlet is the roller drive unit. DO NOT put your hand into it when

removing the folded or stitched & folded sheet; otherwise you may be injured.

❒ FS-110/FS-210 FINISHER PAPER EXIT OUTLET

To avoid injury when stapling large size prints, DO NOT put your hand into the open Paper exit

outlet.

❒ FS-110/FS-210 FINISHER PRIMARY (MAIN) TRAY

When printed materials are removed from the primary (main) tray of FS-110/FS-210 Finisher,

the tray goes up automatically. To avoid injury, DO NOT put your hand on top of the printed

sheets. Be sure to hold both sides of the printed sheets when removing them, and DO NOT

leave your hand on the printed sheets while the primary tray goes up.

- 9 -

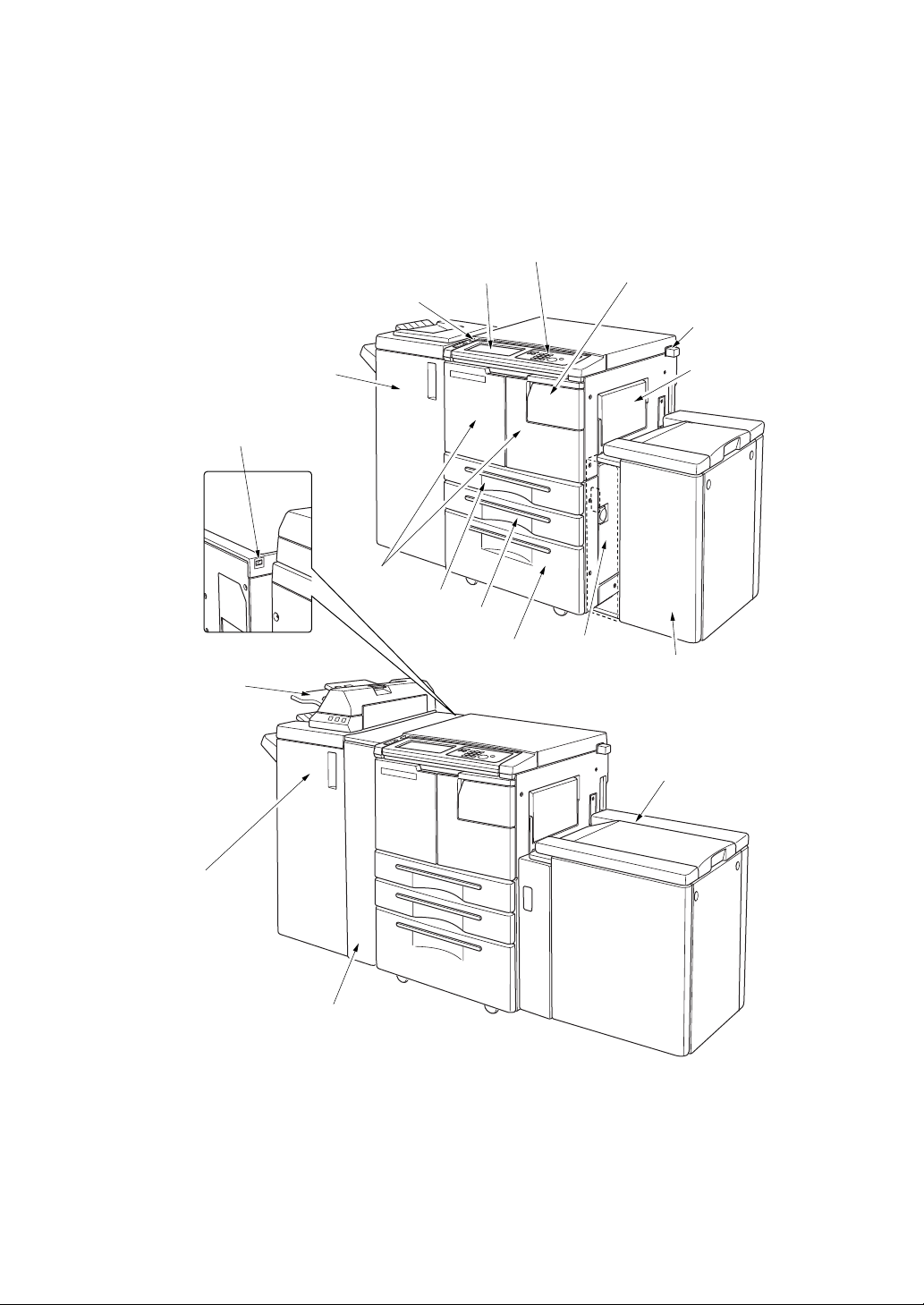

Machine Information

Machine Configuration

External Machine

11FS-110 Finisher

(option)

14 Main power switch

(Rear-left side of

main body)

12 PI-110 Cover

sheet feeder

(option)

15 LCD Touch screen

13 Power switch

9 Front doors

8 Tr a y 1

16 Control panel

7 Tr a y 2

6 Tr a y 3

1 Toner access door

5 Right side

door

2 Key counter

(option)

3 Multi-sheet

bypass tray

4 LT-402 Large

capacity tray

(option)

4 LT-412 Large

capacity tray

(option)

11 FS-210 Finisher

(option)

10 PZ-108 Punching /

Z-Folding Unit (option)

External Machine Call-outs

1 Toner access door opens to replenish the toner.

2 Key counter (option) manages the number of prints made on the machine.

3 Multi-sheet bypass tray used for small quantity printing onto plain paper or special

paper.

4 LCT: Large capacity tray LT-402/LT-412 option holds 4,000 sheets.

- 10 -

Machine Information

Machine Configuration (continued)

5 Right side door opens to allow removal of mishandled paper.

6Tray 3 (universal tray) is user-adjustable and holds 1,500 sheets of either A3 to A5.

7Tray 2 (universal tray) is user-adjustable and holds 500 sheets of either A3 to A5.

8Tray 1 (universal tray) is user-adjustable and holds 500 sheets of either A3 to A5.

NOTE: Tray 1, 2, 3, and LCT are available for loading wide types of the regular sizes specified above.

9 Front door opens to the internal printer to allow clearing of mishandled paper.

10 PZ-108 Punching / Z-Folding unit (option) punches file holes and/or Z-folds the output

prints.

11 FS-110/210 Finisher (option) sorts, staple-sorts, and groups into finished sets.

With PK-110/120 Punching kit (option) installed, file holes can be punched in the output

prints. FS-210 folds or stitches & folds prints into booklet-styled sets, and also folds max.

3 prints in three.

12 PI-110 Cover sheet feeder (option) loads cover sheet paper and feeds the sheet as

cover.

13 Power switch turns printer power On/Off when pressed.

14 Main power switch

15 LCD touch screen displays interactive operation screens.

16 Control panel controls printer operations.

- 11 -

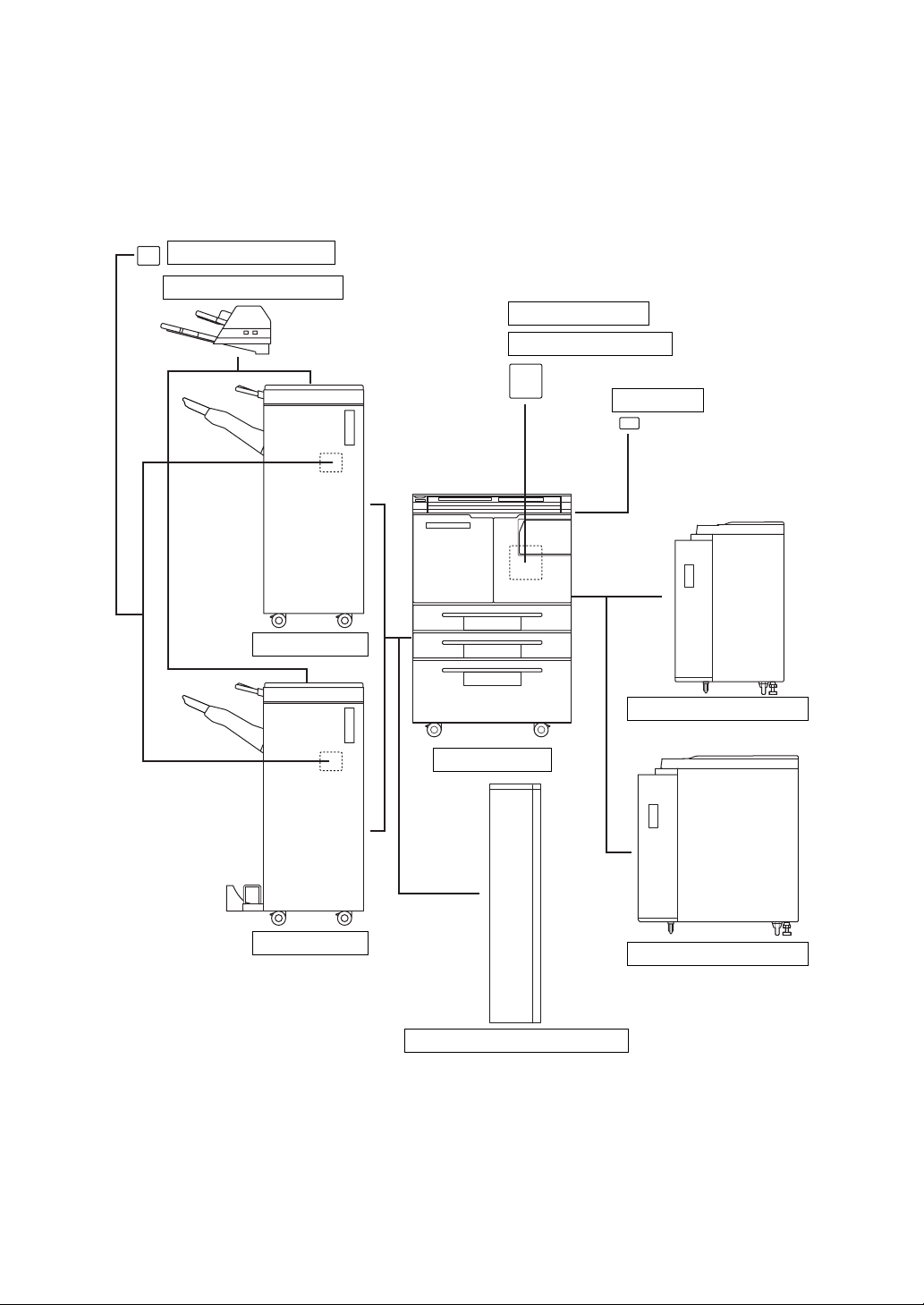

Machine Information

Machine Configuration (continued)

Optional Equipment

PK-110/120 Punching kit

PI-110 Cover sheet feeder

PS-351 Postscript 3

IP-511 Printer controller

Key counter

FS-110 Finisher

FS-210 Finisher

LT-402 Large capacity tray

DP65 main body

LT-412 Large capacity tray

PZ-108 Punching / Z-Folding unit

- 12 -

Machine Information

Machine Configuration (continued)

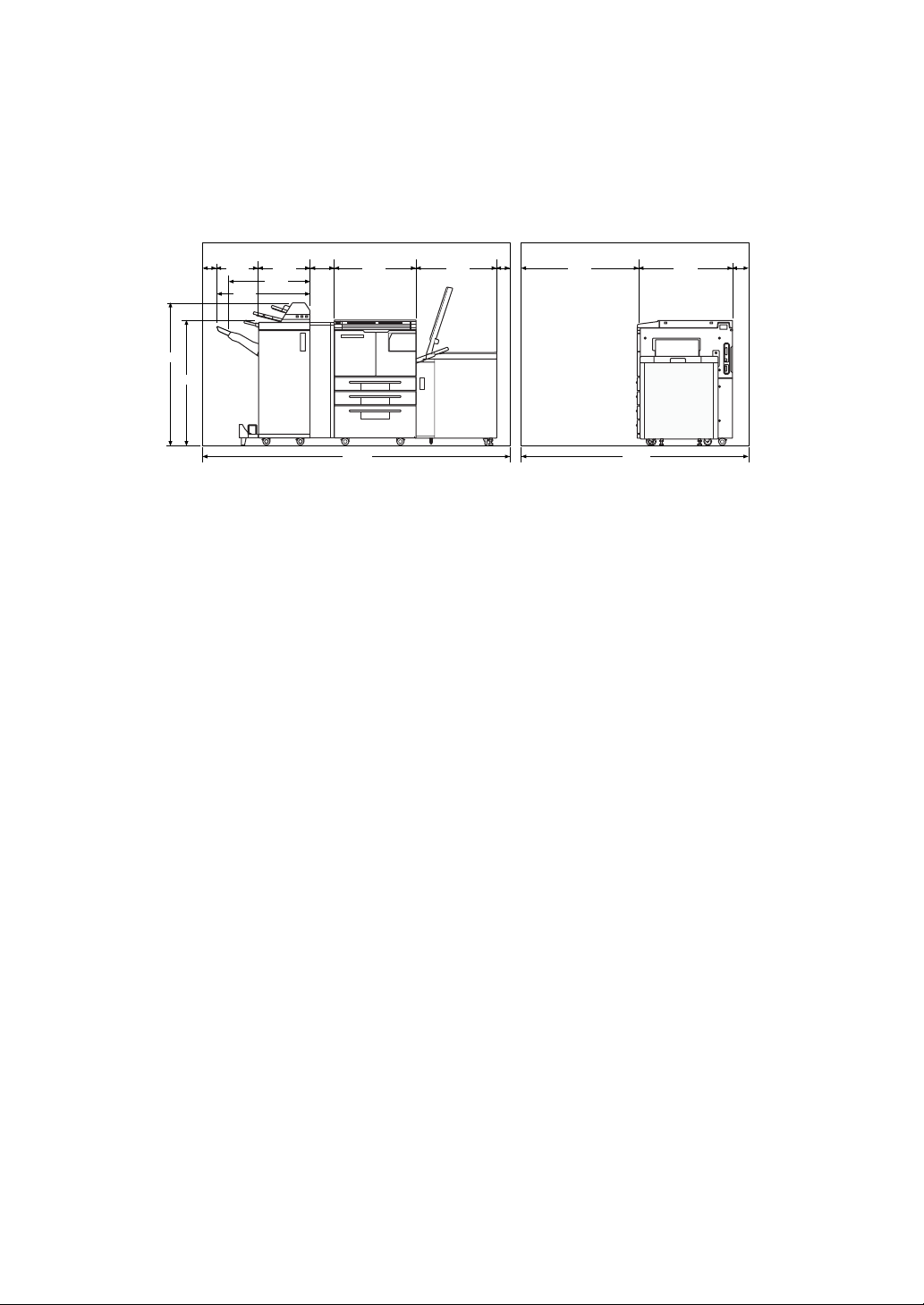

1140

990

100

331

741

656

410

174

650 670

100

950

Unit: mm

760

120

2435

1830

DP65 + FS-210 Finisher + PZ-108 Punching / Z-Folding unit

+ PI-110 Cover sheet feeder + LT-412 Large capacity tray

NOTES:

1 Dimensions are in inches with millimeters included in parentheses.

2 The Finisher main tray of the FS-110/210 Finisher gradually goes down while printed material is output. DO NOT

allow any object to interfere with the operation of the tray on the left side of the Finisher, as interference may cause

damage to the Finisher.

- 13 -

Machine Information

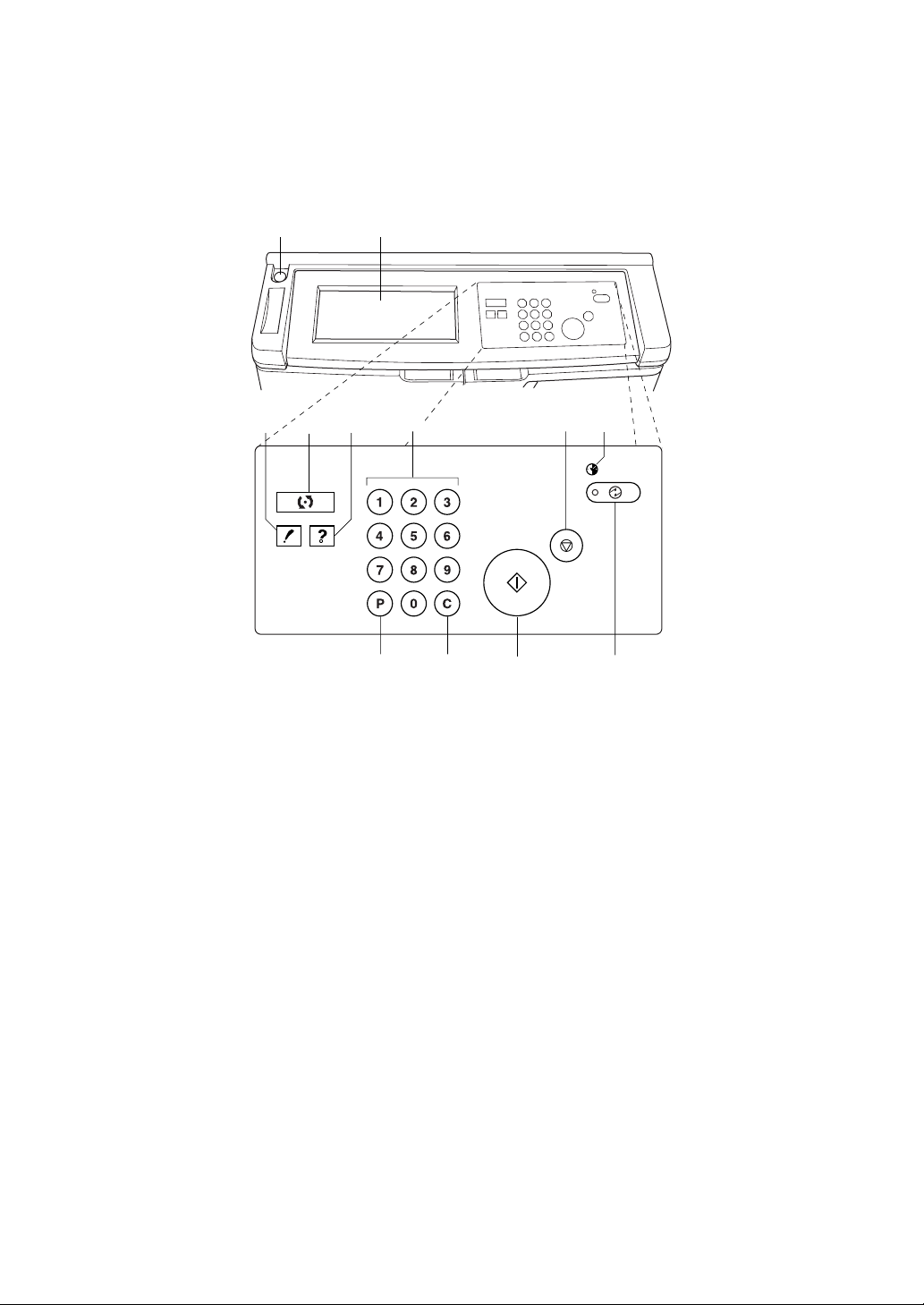

Control Panel Layout

12

34

1 Power switch turns printer power On/Off when pressed.

2 LCD touch screen displays machine and printing status, help information, interactive

screens, and touch keys for selecting all functions.

3 CHECK displays a screen showing all settings that are selected for the current job.

4 MODE switches the machine operation mode.

5 HELP displays a screen with help for the currently selected function, or to access the Key

Operator Mode Screen.

6 Keypad enters numeric values.

7 STOP/PAUSE stops the printing sequence; deletes the stored memory.

8 TIMER lights when the timer function is set.

9 POWER SAVER ON/OFF activates power-saving mode for times when the printer is

inactive, or activates timer interrupt mode when weekly timer function is active.

10 START restarts printing after mishandled paper is cleared or the paper tray is replenished

with paper.

11 CLEAR QTY. allows resetting of print quantity.

12 [P] (counter) displays the Counter Screen or accesses programming modes for setting

special functions.

5

678

1112

910

- 14 -

Machine Information

Specifications

Product Name Konica DP65

Engine Type Dual Beam Laser, Electrostatic

Engine Speed 65 pages per minute

Recommended Operating Environment 10°~30°C; 10~80% RH

Warm Up Approx. 6 min. 20°C; 50% RH

First Print Out Time Approx. 3.4 sec. for 8.5"x11"

Voltage AC230V / 50HZ

Grounding Isolation recommended

Power Consumption Max. 1,900 VA (full option)

Noise Level (full system) Approx. 78 dB (A) or less, during printing

Toner Black, cartridge type

Paper Source Main body trays 1/2/3; 500/500/1,500 sheets

LCT tray 4; 4,000 sheets

Multi-sheet bypass tray; 100 sheets

Tray 1/2/3 user adjustable

LCT adjusted by your service representative

Paper Exit Tray 100 sheets (80 g/m2)

Paper Weight 60 g/m2 ~ 90 g/m2 recommended

(Max. range: 60 g/m2 ~ 200 g/m2 in duplex mode,

50 g/m2 ~ 59 g/m2 in simplex mode)

OHP sheet, Transparency, Labels, Tab, 3-hole

Options Finisher (FS-110/FS-210)

Cover Sheet Feeder (PI-110)

Punching Kit (PK-110/120)

Punching / Z-Folding Unit (PZ-108)

Large Capacity Tray (LCT) (LT-402/LT-412)

Image Processor (IP-511)

PostScript Unit (PS-351)

Machine Weight 190 kg

+55 kg w/FS-110 Finisher

+65 kg w/FS-210 Finisher

+10.5 kg w/PI-110 Cover sheet feeder

+2 kg w/PK-110 Punching kit

+3 kg w/PK-120 Punching kit

+38 kg w/PZ-108 Punching / Z-Folding unit

+30 kg w/LCT (LT-402)

+42 kg w/LCT (LT-412)

Specifications Subject To Change Without Notice

- 15 -

Machine Information

Specifications (continued)

Machine Dimensions Main Body

Automatic Duplex Unit (ADU) Paper size: A3 to A5

Stapling Finisher (FS-110/210) Power source: Main body

Width: 650 mm

Depth: 760 mm

Height: 994 mm

Stapler-Finisher (FS-110/210)

Width: 656 mm

Depth: 656 mm

Height: 990 mm

Cover Sheet Feeder (PI-110)

Width: 511 mm

Depth: 620 mm

Height: 220 mm

Punching Kit (PK-110)

Width: 68 mm

Depth: 442 mm

Height: 120 mm

Punching Kit (PK-120)

Width: 130 mm

Depth: 470 mm

Height: 115 mm

Punching / Z-Folding Unit (PZ-108)

Width: 169 mm

Depth: 660 mm

Height: 930 mm

Paper weight: 60 g/m2 ~ 200 g/m

Non-stack type

Non-sort/Sort/Group mode:

500 sheets A5, A5R, B6R

3000 sheets A4, A4R, B5R (FS-110 Finisher)

2500 sheets A4, A4R, B5R (FS-210 Finisher)

1500 sheets A3, F4, B4

Size A3, B4, F4, A4R, A4, B5, A5

Staple-sort mode:

1000 sheets*

Size A3, B4, F4, A4R, A4, B5, A5

* Variable according to the number of pages to be

stapled.

2

Specifications Subject To Change Without Notice

- 16 -

Machine Information

Specifications (continued)

Stapling Finisher (FS-110/210) (continued)

Fold / Stitch & Fold mode (FS-210 only):

100 sheets (A3, B4)

75 sheets (A4R)

Size A3, B4, A4R

* The maximum number of sheets varies,

depending on the number of pages in the booklet

and whether Fold or Stitch & Fold is selected.

Three-Fold mode (FS-210 only):

50 sheets (folding one sheet in three)

Size A4R

Staple Cartridge 5000 staples/cartridge

Cover Sheet Feeder (PI-110) Power source: Finisher

Paper size:

Upper tray A4, A4R, B5, B5R, A5

Lower tray A3, B4, A4, A4R, B5, B5R, A5

Paper weight in cover sheet mode: 50 ~ 200 g/m

Paper weight:

Manual stapling: 50 ~ 200 g/m

Manual punch: 50 ~ 170 g/m

Manual stitch & fold: 60 ~ 200 g/m

Manual three-fold: 80 g/m

Punching Kit (PK-110/120) Paper size: A3, B4, F4, A4, B5

Paper weight: 60 ~ 170 g/m

Number of holes: 4 holes

Hole diameter: 6.5 mm ± 0.5 mm

Hole pitch: 80 mm ± 0.5 mm

Weight:

PK-110: 2 kg

PK-120: 3 kg

Power source: Finisher

Punching / Z-Folding Unit (PZ-108) Paper size: (Punch) A3, B4, F4, A4, B5

(Z-Fold) A3, B4

Paper weight: 60 ~ 170 g/m2 (60 ~ 90 g/m2 for ZFold mode)

(Punch mode)

Number of holes: 4 holes

Hole diameter: 6.5 mm ± 0.5 mm

Hole pitch: 80 mm ± 0.5 mm

(Z-Fold mode)

Folding type: Z-fold for A3, double-fold for B4

Folded width: 209 mm or less for A3

181 mm or less for B4

Weight: 38 kg

Power source: supply from outlet

Specifications Subject To Change Without Notice

- 17 -

2

2

2

2

2

2

Machine Information

Specifications (continued)

Large Capacity Tray (LT-402) Paper type: Plain paper (50 ~ 200 g/m2)

Large Capacity Tray (LT-412) Paper type: Plain paper (50 ~ 200 g/m2)

Paper size: A4

Dimensions: Width 430 mm

Depth 639 mm

Height 690 mm

Weight: 30 kg

Power source: supply from main body

Paper size: A3, B4, A4, A4R

Dimensions: Width 670 mm

Depth 639 mm

Height 695 mm

Weight: 42 kg

Power source: supply from main body

Specifications Subject To Change Without Notice

- 18 -

Loading...

Loading...