Page 1

7 X 9 inside cover

Kodak DryView 8600 Laser Imaging System /

for Mammography

User Guide

8186546

74-0401-6533-9

3/00 Rev. B

Page 2

Classification, Warnings, and Cautions

Classification, Warnings, and Cautions

for DryView 8600 Laser Imager

Read and understand all instructions before using.

Classifications

UL Classified

File Number E163816

Control Number 48VF

Medical Equipment

UL 2601-1 CAN/CSA No. 601.1

!

Classified by Underwriters Laboratories Inc. With Respect to Electric Shock,

Fire, Casualty and Medical Hazards only in Accordance with UL 2601-1, CAN/CSA

C22.2 No. 601.1 and IEC 601.1.

!

WARNING

This equipment is operated with hazardous voltage which can shock,

burn, or cause death.

Remove wall plug before servicing equipment. Never pull on cord to remove from

outlet. Grasp plug and pull to disconnect.

Do not operate equipment with a damaged power cord.

Do not use an extension cord to power this equipment.

Use only the power cord supplied with the equipment.

Position the power cord so it will not be tripped over or pulled.

Connect this equipment to a grounded outlet.

!

WARNING

Not protected against ingress of liquids, including bodily fluids.

!

WARNING

For continued protection against fire, replace fuses only with fuses of the same type

and rating.

2000 March Rev. B 8186546

i

Page 3

DryView 8600 User Guide

Classification, Warnings, and Cautions

for DryView 8600 Laser Imager (continued)

Avoid touching the developer drum when removing film jams from the imager. The

developer drum may become hot during extended imager operation.

!

CAUTION

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC rules. Those limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

!

CAUTION

Do not use in the presence of flammable anesthetics, oxygen or nitrous oxide. This

equipment does not have a gas sealed electronics enclosure and could ignite any

flammable or explosive gases present in its environment.

ii

8186546 2000 March Rev. B

Page 4

Classification, Warnings, and Cautions

Classification, Warnings, and Cautions

for DryView 8600 Laser Imager (continued)

!

CAUTION

U.S. Federal law restricts sale of this device to or on the order of a licensed health

care practitioner.

!

CAUTION

This equipment is intended to connect to other medical devices. Installation and

service maintenance are to be performed only by qualified service personnel. The

Kodak PACS Link 9410 Acquisition System must be installed no closer than 1.8

meters from a patient bed or chair.

!

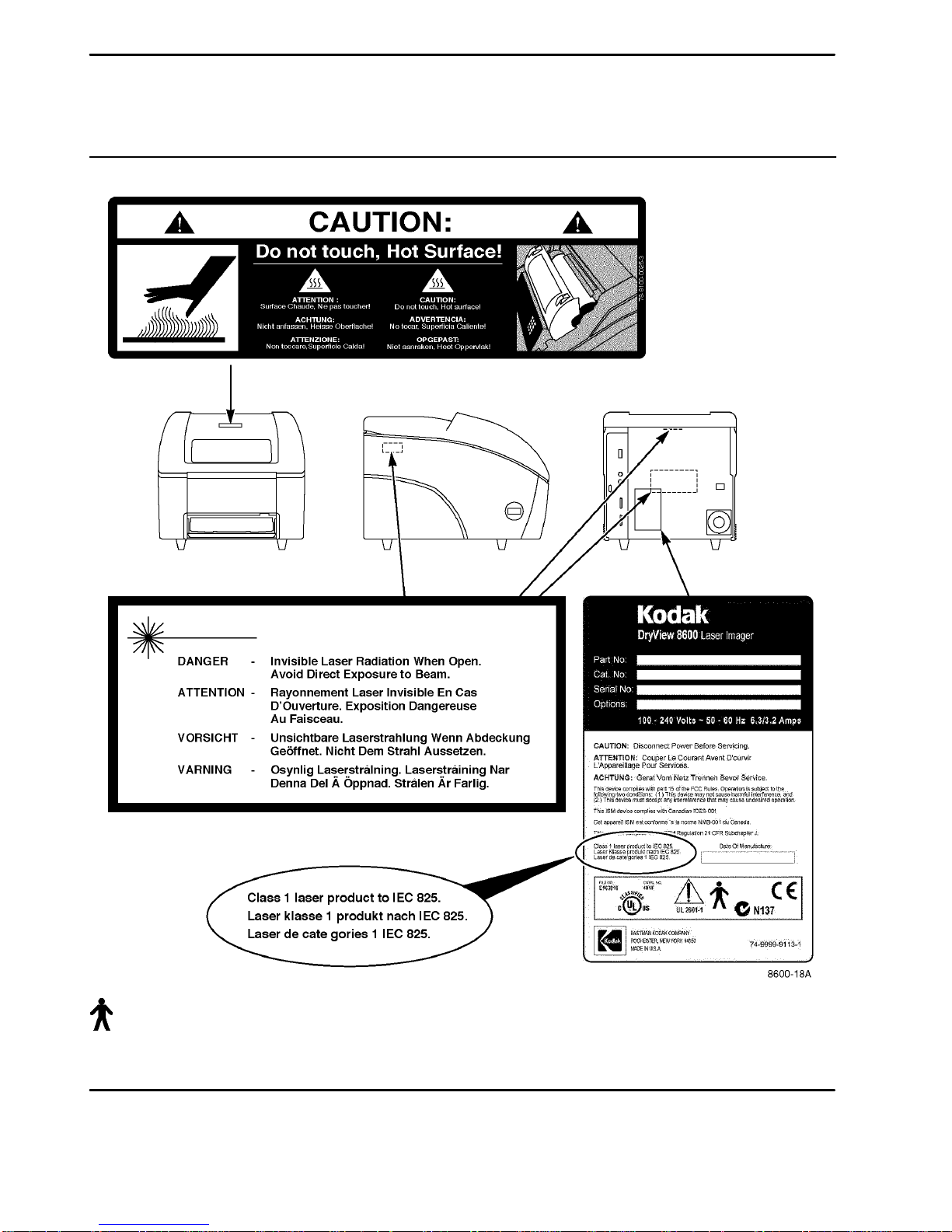

CAUTION

Avoid Laser Beam

This equipment employs an invisible 25 milliwatt laser beam. Laser

radiation may be present when the machine operates without panels or

covers installed.

Use of controls or adjustments, or performance of procedures other than those

specified herein, may result in eye damage.

Covers shall be removed by authorized service personnel only.

There are no “user” serviceable parts in this machine.

!

CAUTION

General External Cleaning: This equipment may be cleaned with a damp cloth

using water with mild detergent, or commercial electronic equipment cleaner.

!

CAUTION

Do not substitute or modify any part of this equipment without approval of Eastman

Kodak Company.

2000 March Rev. B 8186546

iii

Page 5

DryView 8600 User Guide

Classification, Warnings, and Cautions

for DryView 8600 Laser Imager (continued)

Type B Applied Part

iv

8186546 2000 March Rev. B

Page 6

Safety, EMC, and CE Marking Compliance

Safety, EMC, and CE Marking Compliance

Agency Approvals

This equipment has been tested for and complies with the following Safety and

Emission Standards. Certificates of Compliance and Declarations of Conformity

have been issued for the following areas:

Australia/New Zealand:

AS/NZS 3548:1992

AS 2211-1991

AS3200.1-1990/NZS 6150:1990

Canada:

C108.8-M1983 Class B (Conducted and Emitted EMI/RFI Specs)

CAN/CSA-C22.2 No. 601.1

Europe:

EN50082-1 (EMC)

EN55011 Group 1 Class B (Medical Device Safety)

EN60601-1 (Safety Medical Equipment)

EN60825:1991 (Laser Safety)

EN61000-3-2: Harmonics

IEC61000-3-3:1995 Voltage Fluctuations/Flicker

IEC61000-4-2:1995 ESD

IEC61000-4-3:1996 Radiated Radio Frequency

IEC61000-4-4:1995 Fast Transient/Burst

IEC61000-4-5:1995 Surge

IEC61000-4-6: Conducted Radio Frequency

IEC61000-4-8: Power Frequency Magnetic Fields

IEC61000-4-11: Dips and Interrupts

1999 June Rev. A 8186546

v

Page 7

DryView 8600 User Guide

Japan:

CISPR Group 1 Class B

USA:

47CFR15B Class B (Conducted and Emitted EMI/RFI Specs)

FDA: 21CFR CH-1. SCH-J. Part 1040 (Performance Standards for Light

Emitting Products)

UL 2601-1 (Medical and Dental Equipment)

IEC 601-1 (Medical Device Safety)

IEC 601-1-1 (EMC for Medical Devices)

IEC 825-1 (Laser Safety)

ROW:

CISPR 11 Group 1 Class B (Conducted and Emitted EMI/RFI Specs)

IEC 1000-4-2, 3, 4, 5, 6, 8, and 11

CE Marking:

This equipment is part of a medical system and conforms to the medical safety and

EMC in EN60601-1-1, EN60601-1-2, and the 93/42/EEC, MDD (Medical Device

Directive).

A Technical File and Declaration of Conformity with the Essential Requirements of

the Medical Device Directive have been prepared and signed by the appropriate

personnel and are located at:

Kodak AG

Quality Services and Product Safety

70323 Stuttgart Germany

Telephone 49-0711-40-06-5291

vi

8186546 1999 June Rev. A

Page 8

Safety, EMC, and CE Marking Compliance

FCC:

This device complies with the limits for a Class B digital device listed in Part 15 of

the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that

may cause undesired operation.

Industry Canada:

This Class B digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe B respecte toutes les exigences du Règlement

sur le matérial brouilleur du Canada.

EU:

This equipment complies with the January 1996 EU Community EMC Requirements,

per EN55011 Class B.

1999 June Rev. A 8186546

vii

Page 9

DryView 8600 User Guide

BLANK PAGE

viii

8186546 1999 June Rev. A

Page 10

Table of Contents

PLEASE NOTE

The information contained herein is based on the experience

and knowledge relating to the subject matter gained by Eastman

Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this

information without notice and makes no warranty, express or

implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special

damages, resulting from the use of this information, even if loss

or damage is caused by Kodak’s negligence or other fault.

Table of Contents

Description Page

Classification, Warnings, and Cautions i. . . . . . . . . . . . . . .

Safety, EMC, and CE Marking Compliance v. . . . . . . . . . . .

Section 1 – Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Kodak DryView 8600 Laser Imaging System / for

Mammography 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How the DryView 8600 Laser Imager Works 1-2. . . . . . . . .

Automatic Image Quality Control 1-3. . . . . . . . . . . . . . . . . . .

Systems Connecting to the DryView 8600 Laser Imager 1-3

Service and Installation 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMPORTANT NOTICE TO PURCHASER 1-4. . . . . . . . . . . .

Section 2 – Controls and Indicators 2-1. . . . . . . . . . . . . . . . . .

DryView 8600 Laser Imager Controls – Main 2-1. . . . . . . .

Local Panel Controls and Indicators 2-2. . . . . . . . . . . . . . . . .

(Optional) Remote Keypad Controls and Indicators 2-3. . .

System Setup 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Setup Menus 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Buttons 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Format 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Change Procedure 2-8. . . . . . . . . . . . . . . . . . . . . . . . . .

1999 June Rev. A 8186546

Parameter Menu Table 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

Page 11

DryView 8600 User Guide

Description Page

Section 3 – Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4 – Quality Control Procedures 4-1. . . . . . . . . . . . . .

Section 5 – Troubleshooting 5-1. . . . . . . . . . . . . . . . . . . . . . . . .

System Power Up 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Producing a Print from a Host Modality 3-2. . . . . . . . . . . . . .

Producing a Print Using the Keypad 3-2. . . . . . . . . . . . . . . .

Requesting Contrast Samples and Changing

the Contrast Setting 3-6. . . . . . . . . . . . . . . . . . . . . . . .

Digital Modality with Host Control 3-6. . . . . . . . . . . . . . . .

Digital Modality with Remote Keypad 3-7. . . . . . . . . . . .

Loading/Unloading the Film Tray 3-8. . . . . . . . . . . . . . . . . . .

Running a QC Baseline Test 4-1. . . . . . . . . . . . . . . . . . . . . . .

Running a Daily QC Test 4-4. . . . . . . . . . . . . . . . . . . . . . . . . .

Local Panel and Remote Keypad Message Types 5-1. . . .

Local Panel Messages 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearing Film Jams – General 5-7. . . . . . . . . . . . . . . . . . . . . .

Inserting the Film Saver and Removing the Film Tray 5-8.

Clearing Jams from the Film Tray Area 5-9. . . . . . . . . . . . . .

Clearing Jams from the Exposure Area 5-10. . . . . . . . . . . . . .

Clearing Jams from the Developer and Exit Areas 5-11. . . .

Safety Precautions 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearing the Developer or Exit Jam 5-12. . . . . . . . . . . . . .

System Tests 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Menus 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Buttons 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print QC Step Wedge 5-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print SMPTE Pattern 5-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Test 5-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Software Versions 5-17. . . . . . . . . . . . . . . . . . . . . . . . .

Display System Configuration 5-18. . . . . . . . . . . . . . . . . . . . . .

Configuration Menu Table 5-19. . . . . . . . . . . . . . . . . . . . . . . . .

Calling for Support 5-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

8186546 1999 June Rev. A

Page 12

Table of Contents

Description Page

Section 6 – Specifications 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Environment 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Non-Operating Environment: Shipping and Storage 6-1. . .

Interface Modules 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Interfaces 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Film Characteristics 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Agency Compliance 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restrictions 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 7 – Technical Information 7-1. . . . . . . . . . . . . . . . . . . .

Spectral Sensitivity 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Quality 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Sharpness 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Image Quality Control 7-2. . . . . . . . . . . . . . . . . . .

Less Impact on the Environment 7-3. . . . . . . . . . . . . . . . . . .

Storage and Handling of Undeveloped Film 7-4. . . . . . . . . .

Handling of Developed Film 7-4. . . . . . . . . . . . . . . . . . . . . . . .

Archivability of Developed Film 7-5. . . . . . . . . . . . . . . . . . . . .

Exposure to Moisture 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Odor Dissipation 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heat Dissipation 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Film Recycling 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Training Guidelines 1. . . . . . . . . . . . . . . . . . . . . . . .

1999 June Rev. A 8186546

xi

Page 13

DryView 8600 User Guide

BLANK PAGE

xii

8186546 1999 June Rev. A

Page 14

Section 1 – Introduction

Introduction

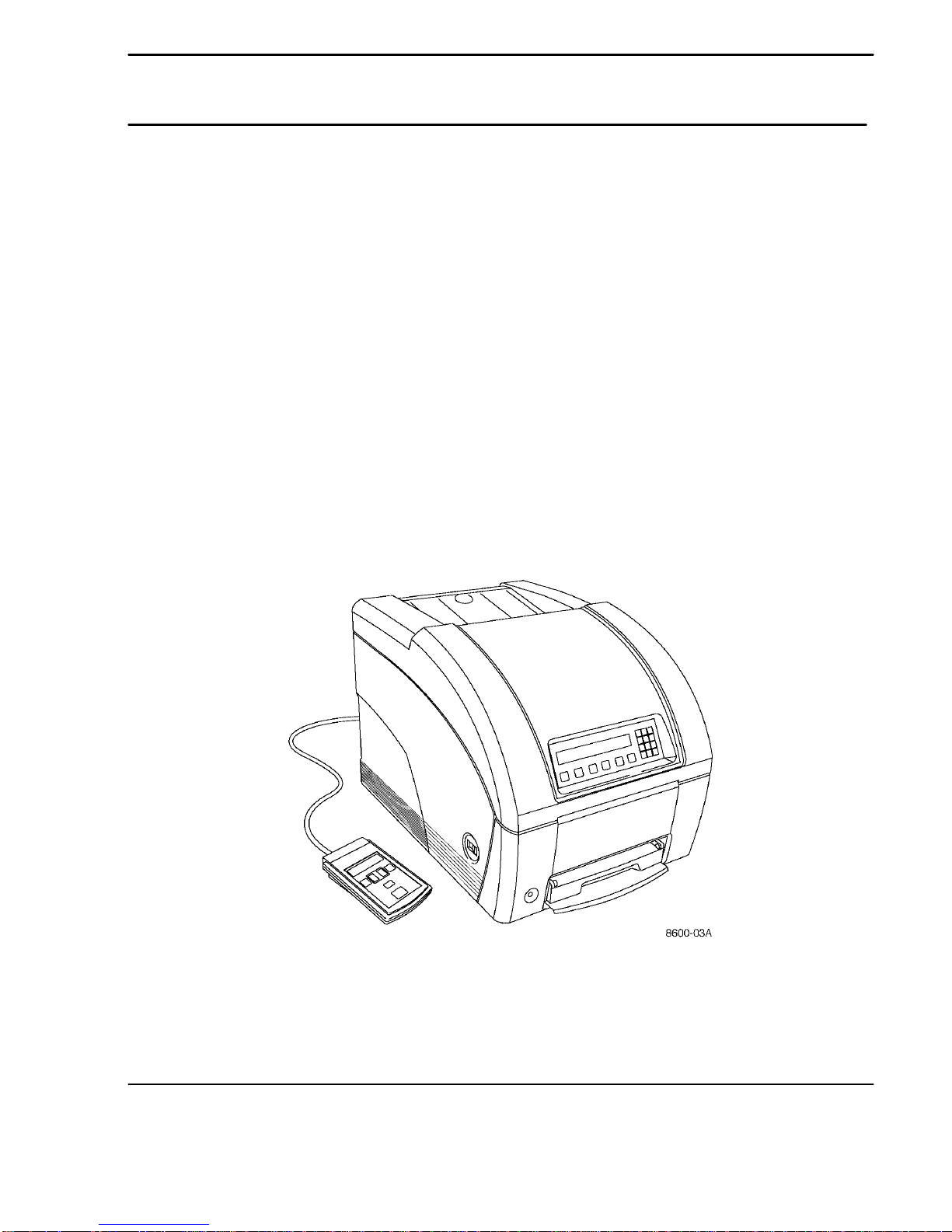

The Kodak DryView 8600 Laser Imaging System / for Mammography

The Kodak DryView 8600 Laser Imager / for Mammography is a continuous tone

laser imager with an integrated photothermographic film developer. The imager

produces high-quality monochrome images, using an optical laser scanning system,

a data control system that manages external data flow, and a film developer.

The imager uses 8 by 10-inch (20.3 by 25.4 cm) Kodak DryView Mammography

Laser Imaging Film. Each film package contains 100 sheets of film.

The imager produces the first print in approximately 185 seconds, and subsequent

prints at approximately 25 prints per hour. It can produce output from more than one

modality.

The imager acquires, formats and prints images under control of a host modality.

The operator uses a local panel on the imager for control of various local functions.

No machine maintenance is required of the operator.

Figure 1-1. Kodak DryView 8600 Laser Imager / for Mammography

1999 June Rev. A 8186546

1-1

Page 15

DryView 8600 User Guide

How the DryView 8600 Laser Imager Works

Each time it receives a print command, the imager prints an image using the

following sequence.

Note

The circled numbers in Figure 1-2 match the sequence steps. Dashed lines

show the film path.

1. Feed film – The feed area drives a sheet of film from the supply tray and feeds it

into the separation rollers.

2. Separate film – The separation rollers check for more than one sheet, then drive

a single sheet of film into the exposure module.

3. Expose film – A laser beam exposes the film. The film is then guided into the

film developer.

4. Develop film – The film develops as it passes over the heated developer drum.

5. Check image quality – The film is routed from the film developer, through the

densitometer, and out to the receive tray.

Figure 1-2. Print Sequence

1-2

8186546 1999 June Rev. A

Page 16

Section 1 – Introduction

Automatic Image Quality Control

The built-in densitometer is a key element in the Automatic Image Quality Control

(AIQC) process. It enables the imager to automatically adjust image processing

parameters to produce the best image. The imager adjusts these parameters each

time it prints a calibration film. A calibration film is printed when:

The DryView 8600 Laser Imager is powered on.

The film tray is inserted in the imager.

A calibration film is requested from the setup menu.

The imager has not been used for 8 hours, and any type of print is

requested.

The imager reactivates from Energy Saver mode.

Note

If the Energy Saver mode is activated, the DryView 8600 Laser Imager shuts

down its heaters and motors after 3 hours of inactivity. Any button pressed

reactivates the imager to automatically warm up to operating temperature.

Also, the imager reactivates if it is sent an image. A calibration film prints once

the imager reaches operating temperature.

Systems Connecting to the DryView 8600 Laser Imager

The DryView 8600 Laser Imager is used in full-field digital mammography (and in

other digital mammography applications) to reproduce digitized radiograph images

received from a digital radiography modality.

!

Warning

J1 (input/output) is intended for interconnection to equipment that complies

with the appropriate IEC 601-1/IEC 601-1-1 harmonized national standards

when interconnected.

Service and Installation

U.S. Connection: 120 volts Line to Neutral

Only factory-trained personnel are authorized to install and service the DryView

8600 Laser Imager. Circuit drawings are made available to the service technician.

1999 June Rev. A 8186546

1-3

Page 17

DryView 8600 User Guide

IMPORTANT NOTICE TO PURCHASER

Kodak warrants that the Kodak DryView 8600 Laser Imager will be free from defects

in parts, material and manufacture for the period of one (1) year from the date of

installation. For defects occurring during the warranty period and about which Kodak

has received notice during the warranty period, Kodak will provide Buyer with free

replacement parts and labor to replace warranty-covered items.

THIS WARRANTY IS MADE IN LIEU OF ALL OTHER PRODUCT WARRANTIES

EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY

AND FITNESS, AND THOSE ARISING FROM A COURSE OF DEALING OR

USAGE OF TRADE.

The express warranty does not apply to the following: expendable parts; defects or

damage incurred in transportation to the end-user; defects or damage due to

neglect, misuse, operator error, improper installation or alteration of the DryView

8600 Laser Imager; or operation of the DryView 8600 Laser Imager out of

specification.

EXCEPT FOR THE EXCLUSIVE REMEDY STATED ABOVE, KODAK IS NOT

LIABLE FOR DIRECT DAMAGES. KODAK WILL NOT IN ANY EVENT BE LIABLE

FOR INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, REGARDLESS

OF THE LEGAL THEORY ASSERTED, INCLUDING NEGLIGENCE AND STRICT

LIABILITY.

1-4

8186546 1999 June Rev. A

Page 18

Section 2 – Controls and Indicators

Controls and Indicators

DryView 8600 Laser Imager Controls – Main

The imager uses the following controls. The numbered descriptions below

correspond to the numbered callouts in Figure 2-1.

1. Local Panel – Uses a two-line display with 40 characters per line to provide

status, setup, and test information. The panel contains six function buttons and a

numeric keypad. (See page 2-2 for details.)

2. Power Switch – Controls power to the imager.

3. Film Saver – Protects film from exposure when the film tray is temporarily

removed from the DryView 8600.

4. Remote Keypad –Displays control settings for the imager and allows you to

adjust these settings. (See page 2-3 for details.) This keypad is an option and

will not be used in all applications.

5. Manual Film Tray Release button – Allows the film tray to be removed without

the DryView 8600 Imager being powered on. Insert the film saver before using

this button or the film will be exposed.

Figure 2-1. DryView 8600 Laser Imager – Controls and Indicators

1999 June Rev. A 8186546

2-1

Page 19

DryView 8600 User Guide

Local Panel Controls and Indicators

The numbered descriptions below correspond to the numbered callouts in

Figure 2-2.

1. Display – Uses a two-line, alphanumeric display to provide status, setup, and

test information on the DryView 8600 Imager.

2. A and B Setup (buttons) – Select one of the two input modules for parameter

setup or changes. (B Setup is not currently used.)

3. Test (button) – Accesses the test menu.

4. Down and Up Arrows (buttons) – Scroll the display and move the display

cursor, when present.

5. Exit (button) – Allows user to exit any menu or local panel operation.

6. Enter (button) – Accepts entry. Executes commands or advances menu.

7. Numeric Keypad (buttons) – Allows user to enter numeric information.

8. Clear (button) – Clears (deletes) entries.

Figure 2-2. Local Panel

2-2

8186546 1999 June Rev. A

Page 20

Section 2 – Controls and Indicators

(Optional) Remote Keypad Controls and Indicators

The numbered descriptions below correspond to the numbered callouts in Figure

2-3.

1. Imager Ready (indicator) – When illuminated, indicates that the imager is

operational.

2. Check Imager (indicator) – Flashes to indicate a fault or out of film condition.

An associated error message is displayed on the local panel.

3. Memory Full (indicator) – When illuminated, indicates that there is insufficient

memory available to acquire another image. This condition is reported only to the

user whose image memory area is full. The condition should automatically

correct itself as the imager prints films and frees memory space.

2

1

9

10

8

3

4

5

6

7

1999 June Rev. A 8186546

Figure 2-3. Remote Keypad (Optional)

2-3

Page 21

DryView 8600 User Guide

4. Format Selected (indicator) – Displays the number of images (1, 2, 4, or 6) to

be printed on one sheet of film.

5. Select (button) – Selects the number of images to be printed on one sheet of

film. Sequences the Format Selected indicator through 1, 2, 4, and 6.

6. Print (button) – Prints the selected image(s). Pressing this button while the

PRESS PRINT for ADDITIONAL copy indicator is illuminated prints another

copy of the selected image(s).

7. Acquire (button) – Acquires images.

8. Press PRINT for ADDITIONAL copy (indicator) – When illuminated, tells you

that a print is developing and indicates that you can create an additional print if

you press the Print button while the indicator is illuminated.

9. Images Acquired (indicator) – Indicates the number of images acquired to be

printed on one sheet of film. The indicator only displays a number less than or

equal to the number displayed by the Format Selected indicator.

Note

If the imager is in the Autoprint mode, the print cycle begins automatically when

the number in the Images Acquired indicator equals the number in the Format

Selected indicator. When the number in the Images Acquired indicator is less

than the Format Selected indicator, you can press the Print button to start

printing.

10. Erase (button) – Deletes images in the reverse order from that in which they

were acquired. The last image acquired is the first deleted. As images are

deleted, the Images Acquired indicator decrements.

System Setup

The DryView 8600 Laser Imager provides setup menus that configure and adjust

the default settings (parameters) that control functions such as printing or image

density. Default settings are the values that are loaded when you switch on the

imager. (When your imager is installed, it is set up to work for your environment, so

you should rarely need to access and change the default function settings. They

should be changed only after consultation with the lead interpreting physician and a

Kodak representative.)

2-4

8186546 1999 June Rev. A

Page 22

Section 2 – Controls and Indicators

If the DryView 8600 Laser Imager is being used in a DICOM network, the Density,

Contrast, Print Contrast Samples, Sharp/Smooth, Gamma Table, Image Size, and

Detector Size parameters can be changed only at the modality or in the PACS Link

9410 Acquisition System. Changes in the PACS Link 9410 Acquisition System are to

be performed only by a Kodak service representative.

The general setup menus are accessed in the order shown below. Individual menu

descriptions are listed alphabetically in Table 2-1.

General Setup Menus

2.

1.

Format

See page 2-11

Mode

See page 2-12

1.

2.

3.

4.

5.

6.

7.

8.

Density *

Contrast *

Print Contrast

Samples *

Sharp/Smooth *

Polarity

Number of

Copies **

Autoprint **

Film Layout **

See page 2-10

See page 2-10

See page 2-13

See page 2-13

See page 2-12

See page 2-12

See page 2-9

See page 2-10

Keypad Format **9.

Audible Alerts **

10.

Exposure Index

11.

12.

13.

14.

15.

16.

Perform

Calibration

Date/Time

Gamma Table *

Image Size *

Detector Size *

See page 2-11

See page 2-9

See page 2-10

See page 2-12

See page 2-10

See page 2-11

See page 2-11

See page 2-10

* If the system is in a DICOM network, this parameter can be changed only at the

modality or in the PACS Link 9410 Acquisition System.

** Applicable to the optional Remote Keypad only.

1999 June Rev. A 8186546

2-5

Page 23

DryView 8600 User Guide

Menu Buttons

Use the following buttons to access and change parameter menus (see Figure 2-4):

1. A Setup (button) or B Setup (button) – Selects an input menu for setup. (B

Setup is not used in DICOM network installations.)

2. Down Arrow (button) – Scrolls to the next parameter menu. From the last

menu, scrolls to the first menu.

3. Up Arrow (button) – Scrolls to the previous parameter menu. From the first

menu, scrolls to the last menu.

4. Enter (button) – After you access a parameter menu, opens an editable display.

When you enter a new value for a parameter, pressing the Enter button enters

the new value for the parameter.

5. Exit (button) – Cancels changes entered in an editable display and restores the

original values or settings. Continued pressing allows quick exit of setup function.

6. Clear (button) – Clears an incorrect entry. If you enter values that are out of

range for a display, an audible signal sounds. To delete the incorrect value, press

the Clear button.

2-6

Figure 2-4. Menu Buttons

8186546 1999 June Rev. A

Page 24

Section 2 – Controls and Indicators

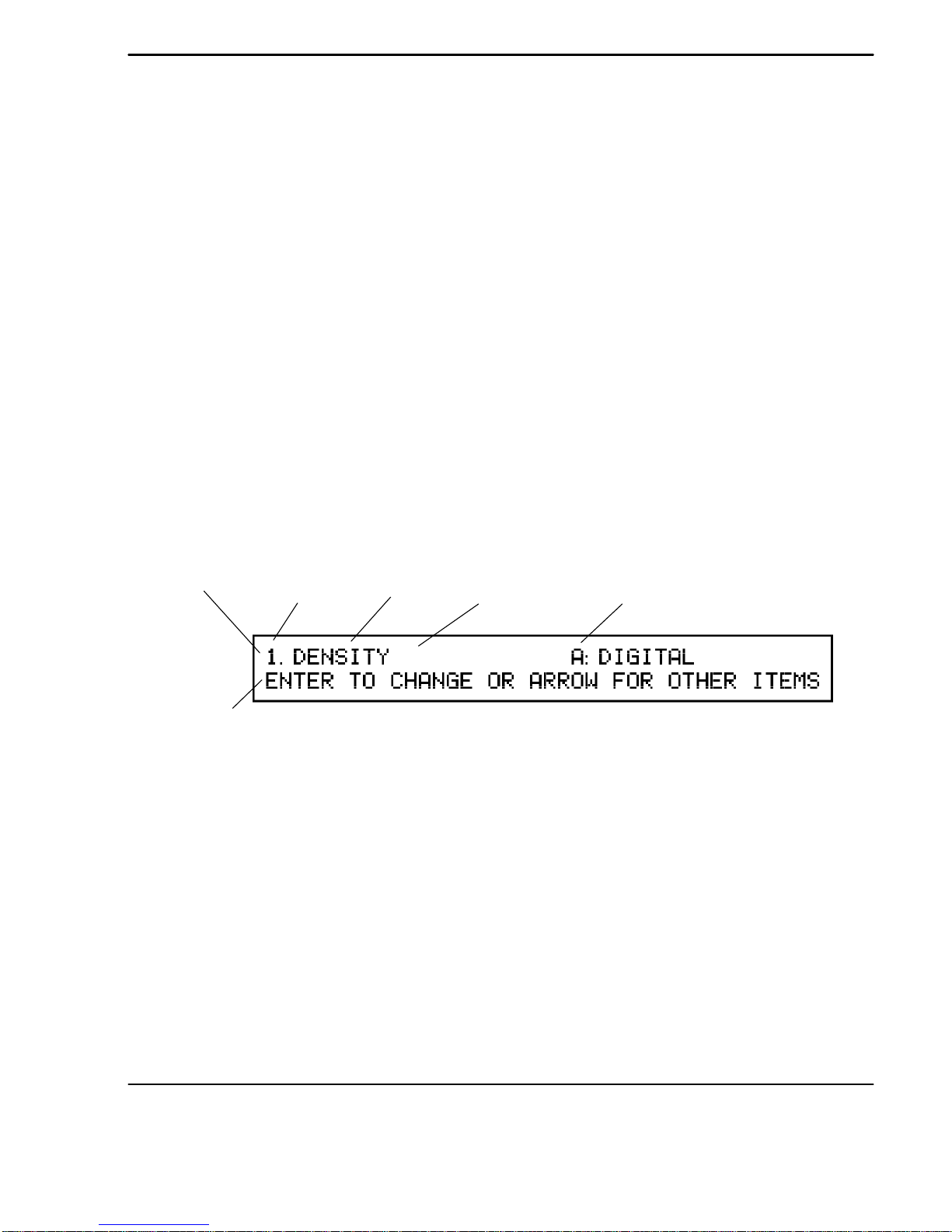

Menu Format

Parameter menus display information about the menu and the parameter.

The first menu for each parameter:

Tells you the menu number

Identifies the parameter

Lists the current value for the parameter

Identifies the current input module selected

Provides information about changing the parameter and continuing to the next

menu.

Subsequent menus tell you:

What to enter

The range of possible values for the parameter.

A sample parameter menu is shown in Figure 2-5, followed by the general procedure

used to change a parameter.

Information

Line

Action Line

Menu

Number

Parameter

Current

Value

6

Figure 2-5. Parameter Menu Display

Input

Module

1999 June Rev. A 8186546

2-7

Page 25

DryView 8600 User Guide

Menu Change Procedure

To change an individual parameter:

1. Select an input module by pressing either the A Setup or B Setup button.

(B Setup is not currently used.)

2. Access the parameter menu by using the Down or Up Arrow buttons to scroll

through the list.

Note

The location of each parameter menu is shown earlier in this section.

3. When the correct parameter is displayed, press Enter to access the parameter ’s

change menus.

You may find that you need to change information in a series of menus.

Each menu display contains an Information line (upper line) and an Action line

(lower line) instruction. (The Action line tells you how to change the parameter

and how to continue.)

4. Use the arrow buttons or the numeric keypad to change the value and then

continue to the next menu as instructed.

Note

If you enter a value that is out of range, the imager beeps. Clear the entry by

pressing the Clear button (see step 5) and re-entering the appropriate value.

5. When you have made changes to a menu, press one of the following buttons to

exit the menu:

To accept the changes and exit to the previous menu, press Enter.

To cancel the changes and exit to the previous menu with the original values

displayed, press Exit.

To delete a change and re-enter values for a parameter, press Clear. (Clear

does not exit from the current menu.)

Each parameter menu is listed in alphabetical order in Table 2-1.

2-8

8186546 1999 June Rev. A

Page 26

Parameter Menu Table

Section 2 – Controls and Indicators

Table 2-1. Parameter Menus

Parameter Menu

Description

Audible Alerts – Provides a one beep indication at the keypad for

each successful image acquisition.

– Provides three short beeps at the keypad to alert

the operator that image acquisition has failed. Retry

another image acquisition.

Selections:

ON = Alarm sounds

OFF = No alarm sounds

(This parameter applies only to the optional keypad.)

Autoprint Determines whether the imager prints images as

soon as the Images Acquired and Format Selected

indicators on the keypad display the same value.

Selections:

ON:

Prints when the Images Acquired and

Format Selected indicators display the same

value.

1999 June Rev. A 8186546

To print fewer images than indicated by the

Format Selected indicator, press Print as

soon as Images Acquired shows the number

of copies you want.

OFF:

Prints only when you press the Print button.

Note: To print contrast samples, Autoprint must be

set to OFF.

(This parameter applies only to the optional keypad.)

2-9

Page 27

DryView 8600 User Guide

Parameter Menu Description

Contrast Controls the amount of contrast in an image. Contrast

is the difference between the lighter and darker areas

of an image.

Range: 1 to 12

Use the contrast samples to choose the best value

and enter the number for that value.

(In a DICOM network, this parameter can be changed

only at the modality or in the PACS Link 9410

Acquisition System.)

Date/Time Changes date and time.

Press Enter to access each part of the date in turn or

the time.

A blinking cursor identifies the current value for each

part of the date or time.

Either use the numeric keypad to enter a new value,

or use the arrow buttons to change the value

displayed (such as the month or the year).

Density Controls the density of the image.

(In a DICOM network, this parameter can be changed

only at the modality or in the PACS Link 9410

Acquisition System.)

Detector Size Specifies the size of the pixels in the image to be

printed. This parameter is unused when Image Size

is Scale to Fit.

Note: This parameter is not user-adjustable.

Exposure Index This setting is for service only. Do not change.

Film Layout Allows you to select Format and Mode. (See those

entries in this table.)

(This parameter applies only to the optional keypad.)

2-10

8186546 1999 June Rev. A

Page 28

Section 2 – Controls and Indicators

Parameter Menu Description

Format Determines the number of images that print on a

single sheet of film.

Gamma Table Specifies which of two sets of gamma tables will be

used to control image brightness and density: (1)

transmittance or (2) linear optical density.

The DryView 8600 creates the two sets of 16 gamma

tables each time it self-calibrates. The gamma tables

are used by the DryView 8600 in conjunction with

the current contrast setting to provide grayscale

optimization.

Note: This parameter is not user adjustable. The

appropriate set of gamma tables is selected by the

Field Engineer with the user’s input at installation.

Image Size Defines the size of the printed image.

Scale to Fit: Image will be magnified or

reduced to fit the image area on the film,

unless the parameter is overridden by the

modality.

Note: This parameter is not user adjustable.

Keypad Format Determines the default number that displays on the

Format Selected indicator. The Format parameter

controls the number of images that print on a single

sheet of film.

Range: 1, 2, 4, and 6

If you change this value at the keypad, the new value

is not retained when you switch off the imager. When

the imager is switched on again, the default value

present before the manual change will be

re-displayed.

(This parameter applies only to the optional keypad.)

1999 June Rev. A 8186546

2-11

Page 29

DryView 8600 User Guide

Parameter Menu Description

Mode Allows setting printing mode to Landscape or Portrait.

Number of Copies Changes the number of copies printed.

Range: 1 to 99

(This parameter applies only to the optional keypad.)

Perform Calibration Prints a calibration step wedge using current settings,

then calibrates the densitometer.

Press Enter to start the calibration.

If a problem occurs during calibration, the imager

displays an error message. Refer to Troubleshooting,

Table 5-1, for information on how to deal with the

problem.

Polarity Determines whether image is printed as a positive or

negative.

Selections:

POSITIVE

If the acquired image is positive, prints a

positive image and vice versa.

NEGATIVE

Reverses the acquired print (a positive

acquired image is printed as a negative and

vice versa).

2-12

8186546 1999 June Rev. A

Page 30

Section 2 – Controls and Indicators

Parameter Menu Description

Print Contrast Samples Prints contrast samples (uses the last acquired image

for the sample and current density).

To print samples, press Enter.

During printing, print progress is indicated. If no fault

appears during printing, returns to the Print Contrast

Samples menu. To stop printing, press Exit.

(In a DICOM network, this parameter can be changed

only at the modality or in the PACS Link 9410

Acquisition System.)

Sharp/Smooth Determines the sharpness or smoothness of the

printed image. Smooths out the jagged edges of the

pixels in an image as specified.

Selections:

Range: 1 to 6 or Auto

1 = Sharpest image

6 = Smoothest image

Auto = The imager determines the

best setting for the size of the image.

Current setting is marked by an asterisk (*).

(In a DICOM network, this parameter can be changed

only at the modality or in the PACS Link 9410

Acquisition System.)

1999 June Rev. A 8186546

2-13

Page 31

DryView 8600 User Guide

BLANK PAGE

2-14

8186546 1999 June Rev. A

Page 32

Section 3 – Operation

Operation

System Power Up

Set the imager power switch to ON. The following sequence occurs:

1. The imager performs a series of self-diagnostic tests.

2. If the power-on self-test is successful, the machine warms up for about 25

minutes.

3. After warmup, the machine calibrates the densitometer lamp.

4. After calibrating the densitometer lamp, the machine prints a calibration step

wedge.

Note

The system displays a message for each stage of system power up.

Figure 3-1. Power Switch, Local Panel and Optional Remote Keypad

2000 March Rev. B 8186546

3-1

Page 33

DryView 8600 User Guide

Producing a Print from a Host Modality

After warmup and calibration, the DryView 8600 Laser Imager is ready to print.

Print commands are issued and controlled from the digital host modality.

Producing a Print Using the Optional Keypad

Note

The following procedure does not apply if the DryView 8600 Laser Imager is

being used in a DICOM network.

1. Power on the imager.

2. Wait for the green Imager Ready (1) indicator to illuminate.

3. Press Select (2) repeatedly until the desired number appears on the Format

Selected indicator (3).

Note

You can select a format only if no images are acquired or all acquired images

are printed.

4. To start image acquisition, press Acquire (4) or use the optional foot activated

switch (Foot Switch).

If acquisition is successful, the Images Acquired (5) indicator increments

and one short beep is sounded.

If acquisition is unsuccessful:

– The audible alarm of three short beeps sounds (if set to ON).

– The Images Acquired (5) indicator does not increment.

– The Check Imager (6) indicator lights

– An associated message appears on the local panel.

Note

The failure indication is visible only at the keypad where acquisition was

unsuccessful. After an unsuccessful attempt, you should try to acquire an

image again. If the acquire is successful, the Check Imager (6) indicator turns

off and the Images Acquired (5) indicator increments and one short beep is

sounded.

5. Repeat step 4 until all images are acquired.

3-2

8186546 2000 March Rev.B

Page 34

Section 3 – Operation

Note

To delete images in reverse order, starting with the most recently acquired

image, press the Erase button (7). The Images Acquired (5) indicator

decrements as the images are deleted.

6

1

5

10

3

2

7

9

8

4

2000 March Rev. B 8186546

Figure 3-2. Optional Keypad

3-3

Page 35

DryView 8600 User Guide

6. To print the images acquired at any time, press the Print button (8). Any blank

image locations are printed at background density.

Note

If Autoprint is ON, images also print when the number in the Images Acquired

indicator (5) equals the number in the Format Selected indicator (3).

Note

The number of images printed is determined by the Number of Copies to Print

setting.

7. To print additional copies, press Print (8) whenever the Press PRINT for

ADDITIONAL copy indicator (9) is illuminated. Each button press prints one

additional copy.

Note

If the Memory Full indicator (10) lights, wait until the indicator goes out before

pressing Acquire again.

Note

If the Check Imager indicator (6) lights with no associated beep when the

acquisitions are successful, there is a condition such as out of film, or film jam

at the imager, which is not currently affecting acquisitions.

Note

If a film jam occurs during printing, the Check Imager indicator (6) lights, and

the local panel displays an associated message. Clear the jam (see page 5-7,

Troubleshooting, for instructions). When the jam is cleared, the machine

restarts the print sequence.

3-4

8186546 2000 March Rev.B

Page 36

Section 3 – Operation

6

1

5

10

3

2

7

9

8

4

2000 March Rev. B 8186546

Figure 3-3. Optional Keypad

3-5

Page 37

DryView 8600 User Guide

Requesting Contrast Samples and Changing the Contrast Setting

The user can adjust both density and contrast for printed images. The density

setting is incremental, which means that the maximum density of a printed image

increases as the number of the density setting is increased.

The contrast setting is not incremental. The user must select a desired setting from

contrast examples of a printed image. You must select the procedure to print

contrast samples for the modality that you are using.

Note

If the DryView 8600 is being used in a DICOM network, the following

procedures to request contrast samples and adjust contrast do not apply.

Digital Modality with Host Control

A modality with host control capabilities usually defines and sends the density and

contrast information to the imager when the image data is sent, overriding the values

set at the imager’s local panel. If the modality does not send density and contrast

information, the user can define the settings at the local panel.

1. At the host, acquire an image, but do not send a print command.

2. On the DryView 8600 local panel, press

A

Setup

or

B

(see Figure 3-4) to select

Setup

the menu that represents the host-controlled modality from which you will print

contrast samples.

3. Press

to go to item 3, Print Contrast Samples, and then press

Enter

.

(The DryView 8600 automatically prints 12 copies of the previously acquired

image at different contrasts.)

4. Select the image that you prefer, and note the image number associated with it.

5. On the local panel, press

to go to item 2, Contrast.

6. Following the instructions on the display, change the contrast setting to the

number previously selected from the contrast samples. Then press

7. After setting the contrast, press

to return the DryView 8600 to service.

Exit

Enter

.

3-6

8186546 2000 March Rev.B

Page 38

Section 3 – Operation

Figure 3-4. Changing the Contrast Setting

Digital Modality with Remote Keypad

1. On the modality, select and display the image you want to use for printing

contrast samples.

2. On the DryView 8600 remote keypad, select a format other than 1. (For

example, use 2, 4, or 6.)

3. Press Acquire on the keypad.

4. On the local panel, press

A

Setup

or

B

to select the menu that represents the

Setup

host-controlled modality from which you will print contrast samples.

5. On the local panel, press

then press

. (The DryView 8600 automatically prints 12 copies of the

Enter

to go to item 3, Print Contrast Samples, and

previously acquired image at different contrasts.)

6. Select the image that you prefer, and note the image number associated with it.

7. On the local panel, press

to go to item 2, Contrast.

8. Following the instructions on the display, change the contrast setting to the

number previously selected from the contrast samples, then press

Enter

.

9. After setting the contrast, press

2000 March Rev. B 8186546

to return the DryView 8600 to service.

Exit

3-7

Page 39

DryView 8600 User Guide

Loading/Unloading the Film Tray

Note

Leave the DryView 8600 Laser Imager on while loading or unloading the film

tray. If you remove power from the imager while the system is in use, any

previously acquired images stored in memory will be lost.

1. When 100 sheets of Kodak DryView Mammography Laser Imaging Film have

been used, the tray unlocks automatically, and instructions for tray removal are

displayed on the local panel. (See Figure 3-5.)

2. Swing open the handle of the film tray.

3. Important: Remove the old film insert and any unused “liner” sheet of film from

the tray and dispose of them per local disposal regulations. (The liner sheet

contains a trace of silver.)

Note

Before loading a new package of film, clean the inside surface of the film tray,

including the ramp and top edge of the tray. Use an alcohol soaked pad such

as TexPad TX801.

4. Press the film package down in the tray as follows: Press the film package to the

left, against the soft guide, with the black plastic bag tail lapping through the

handle, and the label up. Press down firmly using both hands so the film

package sits flat against the bottom of the tray.

5. Swing the handle of the film tray back in place.

6. Remove the tear strip from the black plastic bag.

7. Slide the tray back into the imager slot.

8. To remove the black plastic bag so the imager can access the Kodak DryView

Mammography Laser Imaging Film, pull the black plastic bag tail firmly and

smoothly. The entire film bag should slide out.

9. Dispose of the black plastic bag.

10. To continue processing images, press

on the local panel.

Enter

3-8

8186546 2000 March Rev.B

Page 40

Section 3 – Operation

2000 March Rev. B 8186546

Figure 3-5. Loading/Unloading Film

3-9

Page 41

DryView 8600 User Guide

BLANK PAGE

3-10

8186546 2000 March Rev.B

Page 42

Section 4 – Quality Control Procedures

Section 4 – Quality Control Procedures

Compliance Guidance – Quality Control for Laser Imagers used in

Digital Mammography Systems

These Quality Control Procedures are intended to provide guidance for

mammography facilities and their personnel. They represent the equipment

manufacturer’s views on the appropriate procedures for conducting Quality Control

tests for digital mammography and observing the Mammography Quality Standards

Act (MQSA). The following procedures represent acceptable ways of doing the tests,

but unlike regulations, they are not binding. Alternate procedures may be used if

they satisfy the requirements of the applicable statute, regulations, or both. It is the

responsibility of the mammography facility to read, understand, and follow the

regulations.

Under its own authority, a state may impose requirements more stringent than those

imposed in the FDA Mammography Quality Standards Act. A facility should check

with state or local authorities regarding their requirements.

Automatic Image Quality Control and the QC Process

The Kodak DryView 8600 Laser Imager / for Mammography has a built-in Automatic

Image Quality Control (AIQC) system that automatically compensates for film lot

variations, ensuring consistent print densities. The MQSA requires that the

mammography facility establish a quality control (QC) process that verifies the

effectiveness of the AIQC system. Kodak’s recommendations below are based on

the MQSA and the QC process described in the Radiologic Technologist’s

Section of

the Mammography Quality Control Manual, W 1999, published by the American

College of Radiology. This QC process has been adapted to apply to the special

features of Kodak DryView Mammography Laser Imaging Film and the

characteristics of the Kodak DryView 8600 Laser Imager. The procedures outlined

below assume that the user has been trained in operation of the Kodak DryView

8600 Laser Imager.

Running a QC Baseline Test

Per the MQSA, a baseline test must be run when the 8600 is first installed, and must

be repeated every time a box of film with a different emulsion number is used. This

test sets up a baseline set of film parameter values that shall be used as a standard

for comparison in daily quality control tests. Kodak recommends the procedure

described below as a means of complying with this regulation.

2000 March Rev. B 8186546

4-1

Page 43

DryView 8600 User Guide

Procedure for the Installing Field Engineer – The installing field engineer verifies

that the 8600 meets its performance specifications, runs the baseline test described

below, and prints a clinical image of the site’s choice. The site’s responsible

healthcare professional is asked to approve that the 8600 produces an acceptable

clinical image. If the image is not acceptable, the field engineer repeats his

procedures until the settings for the baseline print produce acceptable clinical

images.

Procedure for the QC Technologist – After an acceptable installation, the user

facility’s technologist must repeat the baseline test whenever a change occurs in

emulsion lots.

Baseline Test

1. Apply power to the 8600 and allow it to warm to READY, as indicated on the

local panel. The 8600 will print a film calibration sheet, to put its Automatic Image

Quality Control (AIQC) system in control.

2. Print a QC Step Wedge test film. ( Refer to page 5-15 in this User Guide for the

procedure. See Figure 4-1 on the next page for a sample step wedge,)

3. Repeat printing QC Step Wedge films until you have accumulated five test films.

4. Using a densitometer, read and record the density of each step (1 through 21) on

each of the five test films. (For consistency from film to film, always read density

at the center of each wedge.)

Note

You can choose to use a clear area on the test films instead of the actual step

1 to take the “step 1” density readings.

5. Determine and record the average of the five densities read for each step.

6. Select from the average values calculated from the 21 steps to determine the

film parameter values as follows:

a. Determine which step has a density closest to 2.20. Then determine which

step has a density closest to but not less than 0.45. Designate the difference

between these densities as Density Difference (DD).

b. Determine which step has an average density closest to but not less than

1.20. Designate this step as Medium Density (MD).

c. Designate the average for Step 1 (or the clear area on the film) as Base Plus

Fog.

4-2

8186546 2000 March Rev. B

Page 44

Section 4 – Quality Control Procedures

d. Record the numeric values of DD, MD and Base Plus Fog on the center lines

of the Laser imager QC Chart. (See Figure 4-2.) Record also the step

numbers involved.

2000 March Rev. B 8186546

Figure 4-1. QC Step Wedge

4-3

Page 45

DryView 8600 User Guide

Density

Difference

HD Step #___

–HD Step #___

Medium

Density

Step #___

Base

Plus Fog

Figure 4-2. Quality Control Chart

4-4

8186546 2000 March Rev. B

Page 46

Section 4 – Quality Control Procedures

Running a Daily QC Test

The MQSA requires that a sensitometric test be run daily and that clinical images be

made only when the control chart is within the control ranges. Kodak recommends

the following laser imager test. Perform this test daily before clinical mammograms

are run, to ensure quality output. Plot the values obtained from the test on the Laser

Imager QC Chart for comparison with the film parameter values established in the

baseline test.

1. Apply power to the 8600 and allow it to warm to READY, as indicated on the

local panel. (The 8600 will print a film calibration sheet, indicating that its

Automatic Image Quality Control system is functioning.)

2. Print a QC Step Wedge film per the procedure on page 5-15 of this User Guide.

3. Use a densitometer to read the designated steps on the test film. Read at the

center of each step. If a clear area on the film was used instead of step 1 in the

baseline tests (see page 4-2), use a clear area in this QC test.

4. Record the date on the control chart. Then plot the DD, MD, and Base Plus Fog

values in the appropriate column on the chart.

5. Determine if any of the values exceeds the control limits for the parameter.

Note

The numbers above and below the center lines on the chart indicate the

control limits. For example, for DD or MD, 0.10 above or below the center line is

approaching the limit, but is acceptable. However, 0.15 above or below the line

is not acceptable.

6. If the values did not exceed a control limit, examine the chart and see if there is

a trend which suggests possible future problems. (This could be, for example,

three or more data points for DD, MD or Base Plus Fog in succession moving

upward or downward.) If the data points have not exceeded the limits, clinical

mammograms can continue to be run.

7. If any value exceeds a control limit, DO NOT run clinical mammograms until the

problem is corrected. Proceed as follows:

a. Circle the out of control point(s) on the chart.

b. Correct the problem. (The fault could be in the film, imager or densitometer,

or in the performance of the QC procedure.)

c. Note the cause of the problem in the “Remarks” section of the control chart.

d. Repeat the step wedge test and graph the parameters on the control chart.

2000 March Rev. B 8186546

4-5

Page 47

DryView 8600 User Guide

BLANK PAGE

4-6

8186546 2000 March Rev. B

Page 48

Section 5 – T roubleshooting

Section 5 – Troubleshooting

Local Panel and Remote Keypad Message Types

The local panel displays two types of messages:

Status Messages – Provide information and require no operator action.

Error Messages – Indicate an error condition inside the imager. Some

messages tell you what action to take to fix the error, but in some cases a

service call is needed to deal with a problem. If the error message does not clear

after you perform the specified action, call for service.

Table 5-1 lists all messages that can appear on the two lines of the local panel

display:

The Information Line (line 1) of each display contains the error title and (in most

cases) a two-digit error code.

The Action Line (line 2) contains additional information/procedures about the

error condition.

Note

The keypad indicates that an error has occurred by flashing the Check Imager

indicator, which refers the operator to the imager’s local panel for more detailed

error information.

Local Panel Messages

If the Operator Action specified in Table 5-1 does not correct the machine problem,

call for service (see page 5-20).

Table 5-1. Operator Related Local Panel Messages

Message

ASIC LINE BUFFER F AIL (48)

CALL SERVICE – PRESS ENTER TO

CONTINUE

ASIC SELF TEST F AIL (60)

CALL SERVICE – PRESS ENTER TO

CONTINUE

Power the imager off, wait 10-20

seconds, then power back on. If

message reappears, call for service.

Power the imager off, wait 10-20

seconds, then power back on. If

message reappears, call for service.

Operator Action

2000 March Rev. B 8186546

5-1

Page 49

DryView 8600 User Guide

Message Operator Action

A TO D CONVERTER FAILURE (88)

POWER IMAGER OFF, THEN BACK ON

CALIBRATION FAILED (69)

PRESS ENTER TO LOAD DEFAULT GAMMA

TABLES

CALIBRATION FAIL: Dmin HI, Dmax XXX.X (70)

PRESS ENTER TO BUILD GAMMA TABLES

DEVELOPER OVER TEMPERATURE (17)

POWER IMAGER OFF, THEN BACK ON

DEVELOPER UNDER TEMPERATURE (19)

POWER IMAGER OFF, THEN BACK ON

Power the imager off, wait 10-20

seconds, then power back on. If

message reappears, call for service.

Press Enter. Then stand by while

imager automatically loads default

tables. Make sure to check image

quality.

Press Enter. Then stand by while

imager automatically builds gamma

tables. If image quality is unacceptable,

use new film.

Unable to control temperature. Power

imager off, wait 10-20 seconds, then

power back on. If message reappears,

call for service.

Unable to control temperature. Power

imager off, wait 10-20 seconds, then

power back on. If message reappears,

call for service.

DOUBLE FILM FEED – REMOVE MISFEED (24)

INSERT FILM SAVER TO REMOVE FILM TRAY

Insert the film saver and remove the film

tray. Discard any sheets of film that are

jammed in the machine. If problem

persists, call for service.

DYNAMIC RAM FAILURE (72)

CALL SER VICE – PRESS ENTER TO CONTINUE

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

FILM TRAPPED INSIDE EXPOSURE AREA (23)

CALL SERVICE – IMAGER IS INOPERABLE

Insert the film saver. Raise the cover

and remove the film from the exposure

area. Close the cover and remove the

film saver. Press Enter to continue. If

film can’t be removed, call for service.

FILM TRAY EMPTY – INSERT FILM (29) Imager is out of film. Remove film tray

and load a new film package.

FILM TRAY UNLOCKED (11).

INSERT FILM TRAY FULLY TO CLEAR ERROR

Remove and reinsert film tray into

Imager.

5-2

8186546 2000 March Rev. B

Page 50

Section 5 – T roubleshooting

Message Operator Action

FLASH EPROM FAILURE (75)

CALL SERVICE – PRESS ENTER TO

CONTINUE

GALVANOMETER FAILURE (45)

CALL SERVICE – PRESS ENTER TO

CONTINUE

IMAGE MEMORY FOR INPUT A (B) IS FULL

(80) PRESS ENTER TO CONTINUE

IMAGER OFF-LINE

PRESS ENTER TO PLACE IMAGER IN

SERVICE

IMAGER OPEN (16)

CLOSE COVER

INPUT A (B) ACQUISITION TIMEOUT (66) Retry image acquire. Check wire

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

Press Enter to continue. As films are

printed, memory will become available.

Press Enter to place imager in service.

Be sure the top cover is closed and

latched.

connections from the modality to the

imager. If problem persists, call for

service.

INPUT A (B) DMA F AILURE (74)

CALL SERVICE – PRESS ENTER TO

CONTINUE

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

INPUT A (B) FIFO NOT EMPTY FAILURE (67) Reacquire the image to be printed.

INPUT A (B) HEADER FAILURE (64) Try acquiring an image again. If problem

persists, call for service.

INPUT A (B) IDENTIFY ERROR (63)

CALL SERVICE – PRESS ENTER TO

CONTINUE

INPUT A (B) IMAGE SIZES NOT IDENTICAL

(35) PRESS ENTER TO CONTINUE

INPUT A (B) IMAGE TOO LARGE TO PRINT

(37)

PRESS ENTER TO CONTINUE

INPUT A (B) OVERFLOW FAILURE (65) Try acquiring an image again. If problem

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

Verify the image is the same size as the

previously captured image.

Maximum image size is 6.1 megabytes.

Retry with a smaller image.

persists, call for service.

2000 March Rev. B 8186546

5-3

Page 51

DryView 8600 User Guide

Message Operator Action

INPUT A (B) PROGRAM MEMORY FULL

PRESS ENTER TO CONTINUE

INPUT A (B) SYNC FAILURE (39) Power imager off, wait 10-20 seconds,

Press Enter to continue.

then power back on. If message

reappears, call for service.

INPUT A (B) UNDERFLOW FAILURE (62) Try acquiring an image again. If problem

persists, call for service.

INSERT FILM TRAY (12) Insert the film tray.

INSUFFICIENT MEMORY FOR IMAGE FILE A

(B) (81) PRESS ENTER TO CONTINUE

INSUFFICIENT MEMORY FOR PRINTSET A (B)

(82) PRESS ENTER TO CONTINUE

INVALID DATA RECEIVED FROM INPUT A (B)

(53) - PRESS ENTER TO CONTINUE

LAMP FAILED TO REACH TEMPERATURE (71)

PRESS ENTER TO LOAD DEFAULT GAMMA

TABLES

Press Enter to continue. As films are

printed, memory will become available.

Press Enter to continue. As films are

printed, memory will become available.

Call for service.

Call for service.

LASER BOARD FAILURE (46)

CALL SERVICE – PRESS ENTER TO

CONTINUE

LOADING DEFAULT GAMMA TABLES Automatic operation. Verify image

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

quality.

LOCAL PANEL BUFFER OVERFLOW (85)

CALL SERVICE – PRESS ENTER TO

CONTINUE

LOCAL PANEL RAM FAILURE (73)

CALL SERVICE – PRESS ENTER TO

CONTINUE.

MAXIMUM DENSITY LESS THAN 3.5 No action required.

NO IMAGE ACQUIRED ON INPUT A (B) (68)

PRESS ENTER TO CONTINUE

NON-VOLATILE CLOCK RAM FAILURE (96)

CALL SERVICE – PRESS ENTER TO

CONTINUE

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

Reacquire an image.

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

5-4

8186546 2000 March Rev. B

Page 52

Section 5 – T roubleshooting

Message Operator Action

NON-VOLATILE RAM FAILURE (97)

CALL SERVICE – PRESS ENTER TO

CONTINUE

NO RESPONSE FROM KEYPAD A (B) (78)

PRESS ENTER TO CONTINUE

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

NO RESPONSE FROM INPUT A (B) Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

PERFORMING CALIBRATION None.

PERFORMING SELF-TEST None.

POWER DISTRIBUTION FAILURE (49)

TURN OFF IMAGER – CALL SERVICE

Power imager off, wait 10-20 seconds,

then power back on. If message

reappears, call for service.

PRINT JOB LIST FULL (86)

PRESS ENTER TO CONTINUE

REGULATING TEMPERATURE Imager adjusting temperature. If not

Wait until some films have printed

before sending more images to print.

completed in 45 minutes, call service.

REMOVE FILM FROM EXIT AREA (28)

INSERT FILM SAVER TO REMOVE FILM TRAY

Insert the film saver. Raise the cover

and remove film from the exit area.

Close cover and remove the film saver.

Press Enter to continue.

REMOVE FILM SAVER (31) Remove the film saver from the tray.

REMOVE FILM TRAY (40) Insert film saver and remove film tray.

REMOVE, LOAD, AND INSERT FILM TRAY (12) Remove the film tray, load film, and

re-install the film tray.

REMOVE, LOAD, AND INSERT FILM TRAY (30)

PRESS ENTER WHEN READY TO REMOVE

TRAY

Press Enter. Remove the film tray, load

film, and re-install the tray.

2000 March Rev. B 8186546

5-5

Page 53

DryView 8600 User Guide

Message Operator Action

REMOVE MISFEED FROM DEVELOPER AREA

(27)

INSERT FILM SAVER TO REMOVE FILM TRAY

REMOVE MISFEED FROM EXPOSURE AREA

(22) INSERT FILM SAVER TO REMOVE FILM

TRAY

REMOVE MISFEED FROM FILM TRAY (20)

INSERT FILM SAVER TO REMOVE FILM TRAY

REPEATED ERROR DURING EXPOSURE (50)

PRESS ENTER TO PRINT ALL QUEUED

IMAGES

TIMEOUT WAITING FOR FILM TRAY REMOVAL

– PRESS ENTER WHEN READY TO REMOVE

TRAY

Film stopped in the developer area.

Check for blockage of film path from

developer. Insert film saver. Raise cover

and open the developer cover. Remove

the film sheet and close the developer

cover. Close the cover and remove the

film saver. Press Enter to continue.

Insert film saver. Raise cover and

remove film from exposure area. Close

cover and remove film saver. Press

Enter to continue.

Insert film saver. Remove film tray.

Remove misfed film sheet.

Press Enter to print all queued images.

Call for service if error persists.

Press Enter. Then remove the film tray

when the release latch is activated.

UNABLE TO FEED FILM (33)

PRESS ENTER TO TRY AGAIN

Message is displayed after third attempt

to feed film. Insert the film saver and

remove the film carrier from the imager.

Gently shake the film carrier. Remove

any film stuck in film tray cavity of

imager and reinsert tray. Press Enter to

try again.

UNABLE TO UNLOCK FILM TRAY (34)

REMOVE FILM TRAY MANUALLY TO

CONTINUE

UNASSIGNED ERROR CONDITION Call for service.

VERY FEW STEPS IN TOE OF DLOG E CURVE

VERIFY IMAGE QUALITY

WAIT FOR SHEET TO EXIT BEFORE

REMOVING TRAY FROM IMAGER

WARMING UP None.

Manually depress the film carrier

release button on the imager and

remove film tray manually.

Examine the quality of the calibration

print. You may have to try new film.

Wait for sheet to exit before removing

tray from imager.

5-6

8186546 2000 March Rev. B

Page 54

Section 5 – Troubleshooting

Clearing Film Jams – General

The film jam areas referred to in local display error messages are shown in

Figure 5-1.

A is the film tray area, where film misfeeds can possibly occur.

B and C identify the rollers on either side of the exposure area.

D and E identify the developer and film exit areas.

E

C

D

Film Tray

B

A

8300–1

83L

Figure 5-1. Possible Film Jam Locations

The following pages provide procedures for clearing film jams from all the areas

identified above. Before performing any of the procedues you must install the film

saver on the film tray, and remove the film tray from the machine.

Note

Shutting off power to clear a film jam is not required. Shutting off the power

deletes all currently acquired (but unprinted) images and may clear some

error messages. If you do this, you will have to resend the unprinted images to

the imager.

2000 March Rev. B 8186546

5-7

Page 55

DryView 8600 User Guide

Inserting the Film Saver and Removing the Film Tray

1. Insert the film saver and remove the film tray as shown in Figure 5-2.

2. If the film tray does not pull out, use a pen or pencil to push the tray release

button located on the left side of the film tray. See Figure 5-3.

Figure 5-2. Inserting the Film Saver and Removing the Film Tray

Film Tray

Release Button

8300-135A

Figure 5-3. Releasing the Film Tray

5-8

8186546 2000 March Rev. B

Page 56

Section 5 – T roubleshooting

Clearing Jams from the Film Tray Area

1. Check to see if a jam has occurred in the film tray, or film is partially protruding

from the tray.

2. Check inside the tray opening of the machine for jammed film.

3. If you cannot locate the jam, raise the top cover after pushing in the button on

the right side of the machine (see Figure 5-4). Then proceed to the next

paragraph.

2000 March Rev. B 8186546

Figure 5-4. Raising the Top Cover

5-9

Page 57

DryView 8600 User Guide

Clearing Jams from the Exposure Area

With the top cover open, allow time for the developer to cool. Visually check for a

film jam in the interior of the machine.

1. Lift the wire guide for access to film in the bottom of the machine. See Figure

5-5.

2. Place the wire guide in the upward position as shown in Figure 5-5.

3. Remove any film jams.

4. Return the wire guide to its original position. Make sure it snaps into place.

1

3

2

4

Figure 5-5. Clearing Film Jams in the Exposure Area

5-10

8186546 2000 March Rev. B

Page 58

Section 5 – T roubleshooting

Clearing Jams from the Developer and Exit Areas

Safety Precautions

Take care working around the developer area. The developer drum is hot during

normal system operation. When the machine top cover is raised, power is

disconnected from the drum and it begins to cool down. However, up to an hour may

elapse before the drum is cool.

!

Caution

Do not touch the developer drum.

8300-128A

2000 March Rev. B 8186546

5-11

Page 59

DryView 8600 User Guide

Clearing the Developer or Exit Jam

1. Open the top cover and unlatch the developer assembly cover (see Figure 5-6).

2. Open the developer assembly cover and allow time for the developer to cool.

3. Pull to remove any jammed film. (Caution: The film may still be hot.) To aid in

removing the film, you may rotate the drum by turning the gear on the left side of

the drum.

4. Close and latch the cover.

1

8300-32A

3

2

8300-33A

4

Figure 5-6. Clearing Film Jams from the Developer and Exit Areas

Note

Check to see that all jams reported by error messages have been corrected. If

additional error messages have occurred, they may recur after the power-up

self test. If they do, refer to Table 5-1 for instructions.

5-12

8300-34A

8300-35A

8186546 2000 March Rev. B

Page 60

Section 5 – T roubleshooting

System Tests

Use the test menus to test DryView 8600 Laser Imager operation.

Note

While running system tests, you cannot acquire and print images.

You can run the following tests on the imager:

1. QC Step Wedge – Prints a QC step wedge for use in the daily quality control

process (see Section 4).

2. Print SMPTE Pattern – Prints four stored test pattern images on one film.

3. Keypad Test – Tests keypad and individual key functions.

4. Display Software Versions – Displays versions for software programs that run

the imager.

5. Display System Configuration – Displays current system configuration values

such as image memory, contrast and density parameters for each input (user).

Test Menus

QC Step Wedge

See page 5-15

Print SMPTE

Pattern 4:1

See page 5-15

Keypad Test

See page 5-16

Display Software

Versions

See page 5-17

Display System

Configuration

See page 5-18

2000 March Rev. B 8186546

5-13

Page 61

DryView 8600 User Guide

Menu Buttons

Use the following buttons to access, start, and exit test menus:

1. Test Button – Accesses test menus.

2. Down Arrow Button – Scrolls to the next test. From the last test, scrolls to the

first test.

3. Up Arrow Button – Scrolls to the previous test. From the first test, scrolls to the

last test.

4. Enter Button – After you access a test menu, allows required conditions to be

set or starts a test.

5. Exit Button – Cancels a test or a parameter change.

5-14

Figure 5-7. Menu Buttons

8186546 2000 March Rev. B

Page 62

Print QC Step Wedge

To print a QC step wedge:

Section 5 – T roubleshooting

1. Access the QC Step Wedge menu by pressing

2. Initiate the test print by pressing

Enter

.

Test

.

If the step wedge prints successfully, the Print QC Step Wedge menu is

again displayed.

If a fault occurs, an error message is displayed.

3. To cancel the test, press

. The system displays a “PRINT CANCELLED BY

Exit

OPERATOR” message.

4. To return to “System Ready,” press

Exit

.

Print SMPTE Pattern

To run a Print SMPTE Pattern test:

1. From the QC Step Wedge menu, press

to access the Print SMPTE Pattern

display.

2. To print the SMPTE pattern, press

Enter

.

Follow instructions on the local panel to set up conditions for the test.

If the print completes successfully, the Print SMPTE Pattern menu is

displayed.

If a fault occurs, an error message is displayed.

3. To cancel the print, press

. The system displays a TEST CANCELLED BY

Exit

OPERATOR message.

4. To return to the first Print SMPTE Pattern menu, press

Exit

.

2000 March Rev. B 8186546

5-15

Page 63

DryView 8600 User Guide

Keypad Test

Before you can run a keypad test, a remote keypad must be attached to the imager.

To run a keypad test for one of the input modules :

1. From the Print SMPTE Pattern display, press

to access the Keypad Test

menu.

2. To start the Keypad Test, press

Enter

.

During the first part of the keypad test, the menu shows test progress.

3. When the first part of the test is complete, the menu prompts you to press any

key. To test individual key function, press each key in turn.

Each time you press a key, the menu should identify the pressed key.

Example: If you press

4. To cancel the test, press

, the menu should show that you pressed it.

Erase

. The system displays a “TEST CANCELLED BY

Exit

OPERATOR” message.

5. To return to the first Keypad Test menu, press

Exit

.

6. To perform the keypad test on the other input module, press

steps 2 through 5.

5-16

8186546 2000 March Rev. B

and repeat

Page 64

Section 5 – T roubleshooting

Display Software Versions

The imager contains the following types of software.

Imager Firmware

VRTX32

Contrast Tables

Convolution Kernel

If you need to check the version of one of these software programs, access the

software versions as follows:

1. From the Keypad Test display, press

to access the Display Software

Versions menu. Use this menu to access the software versions.

2. To see the current Imager Firmware version, press

Enter

IMAGER FIRMWARE 2.0

3. To access the VRTX32 version, press

:

VRTX32 1.0.8

4. To access the Contrast Tables version, press

:

CONTRAST TABLES 6.0.1

5. To access the Convolution Kernel version, press

:

CONVOLUTION KERNEL 1.0.5

:

6. To return to the Display Software Versions menu, press

2000 March Rev. B 8186546

Exit

.

5-17

Page 65

DryView 8600 User Guide

Display System Configuration

This parameter allows the system configuration values to be displayed. The

configuration values appear in the order listed below:

1.

2.

3.

4.

5.

6.

7.

DRAM

Contrast Tables

Density

Convolution

Copies

User’s ID

Protocol

See page 5-19

See page 5-19

See page 5-19

See page 5-19

See page 5-19

See page 5-19