Page 1

{TheoryGuide}{Production}{Health Group}{ExternalAndInternal}

Important

Publication No. 8F2924

30JUL07

Confidential

Restricted

Information

THEORY GUIDE

for the

Kodak DryView 6800 LASER IMAGER

Service Code: 1649

Qualified service personnel must repair this equipment.

© Carestream Health, Inc., 2007

Page 2

THEORY GUIDE

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Description Page

30JUL07

8F2924

Page

2 of 72

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Carestream Health, Inc., prior to publication.

No patent license is granted by this information.

Carestream Health, Inc., reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Carestream Health,

Inc., shall not be liable for any loss or damage, including consequential or special damages,

resulting from any use of this information, even if loss or damage is caused by Carestream

Health, Inc., negligence or other fault.

Table of Contents

Equipment Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Main Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Film Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Main Steps in the Film Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DICOM RASTER ENGINE (DRE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

MCS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DICOM RASTER ENGINE (DRE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Local Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Machine Control System (MCS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MCS Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MCS Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2

I

C BUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Communication Between MICRO BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Optics Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Components Controlled or Sensed by the MICROBOARDS . . . . . . . . . . . . . . . 19

POWER DISTRIBUTION BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

I2C Bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

MICROPROCESSOR FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page 3

THEORY GUIDE

30JUL07

8F2924

Page

3 of 72

Application Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Door Latch Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Unlock Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Turnaround Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

INTERLOCK SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

ROLLBACK/PICKUP ASSEMBLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Film Registration Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

PURPOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

FILM PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

REGISTRATION ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Registration Component Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Electrical Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

HOW THE REGISTRATION SUBSYSTEM FUNCTIONS . . . . . . . . . . . . . . . . 38

OPTICS/EXPOSURE TRANSPORT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

OPTICS ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Internal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

OPTICAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

OPTICS AY ELECTRONICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

“Imaging” Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

EXPOSURE TRANSPORT AY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

EXPOSURE TRANSPORT CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . 55

ISOLATION PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

THERMAL PROCESSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Transport Within the PROCESSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

SLACKLOOP AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

FLATBED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

COOLING SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

PROCESSOR CONTROL BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

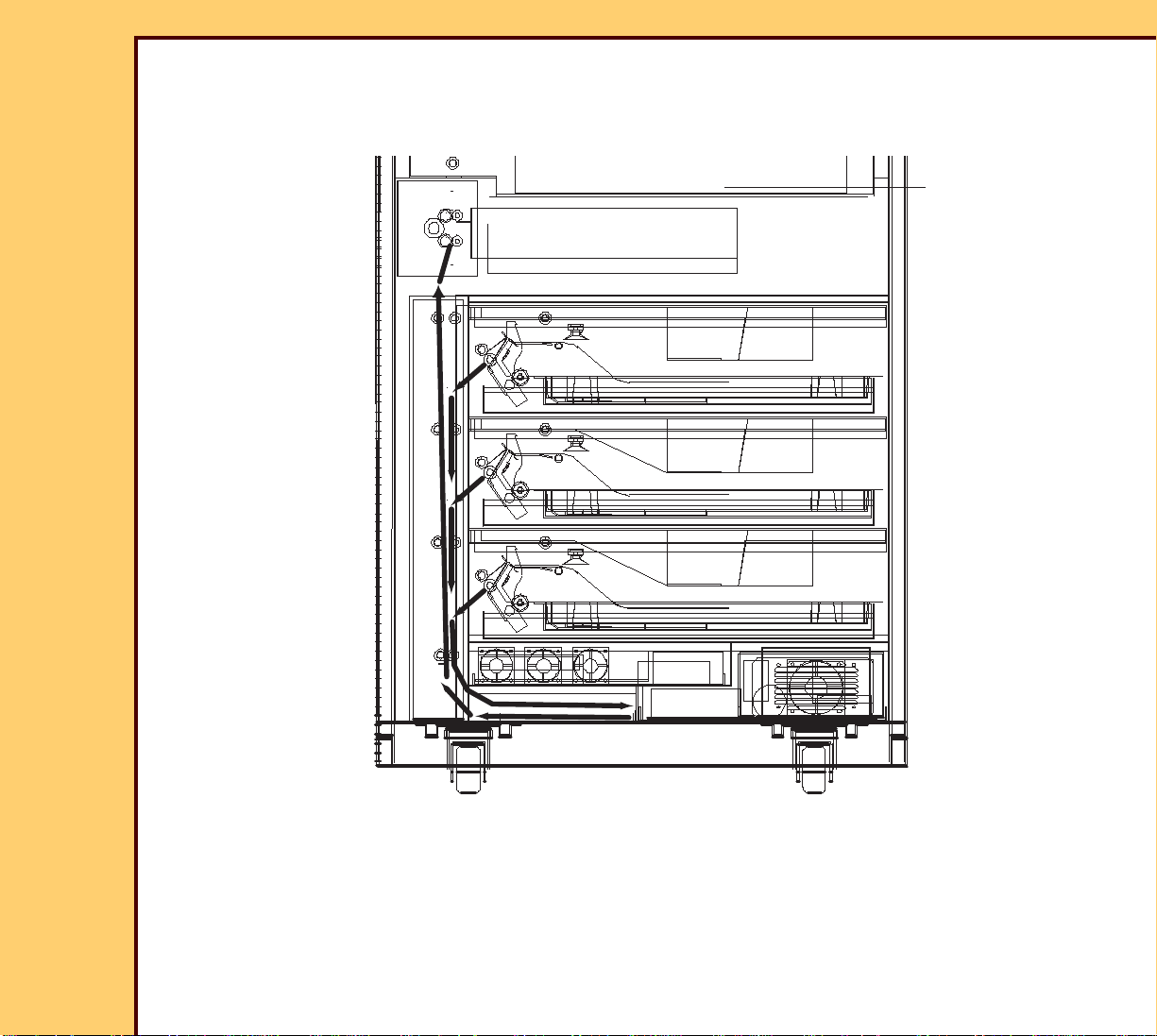

AIRFLOW in the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

APPLICATION SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

“Initialization” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Temperature Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

POWER MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Physical Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Page 4

THEORY GUIDE

30JUL07

8F2924

Page

4 of 72

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Fault Protection in the POWER MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Publication History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Page 5

30JUL07

FILM SUPPLY

DRAWERS

POWER MODULE

TURNAROUND

PROCESSOR

PROCESSOR

FLATBED

EXPOSURE

TRANSPORT

OPTICS

DRUM

ASSEMBLY

REGISTRATION

ASSEMBLY

DRE

PROCESSOR

COOLING SECTION

ACCUMULATOR

LOCAL

PANEL

SORTER

Laser Beam

8F2924

Page

5 of 72

THEORY GUIDE Equipment Description

Section 1: Equipment Description

System Overview

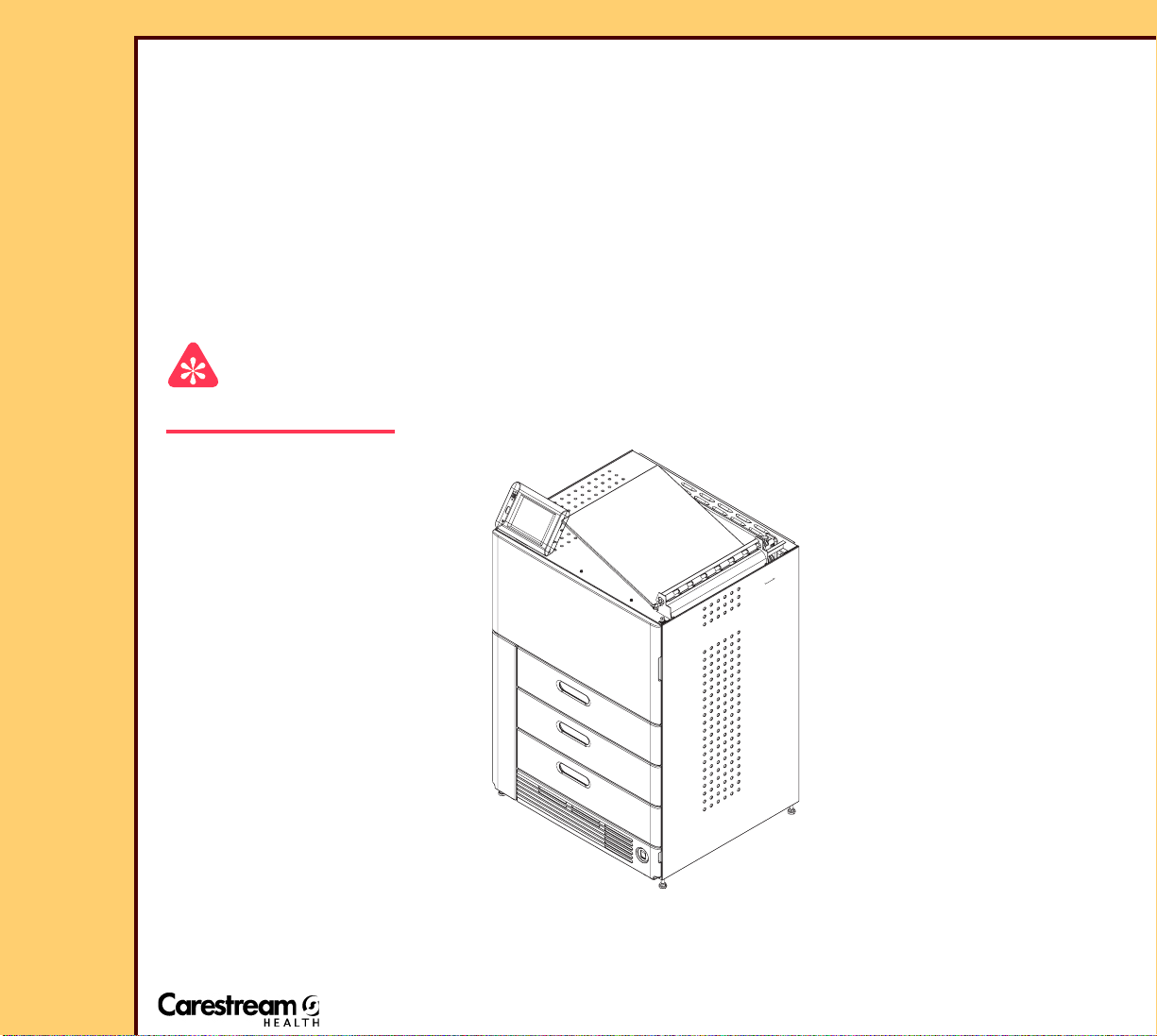

Main Assemblies

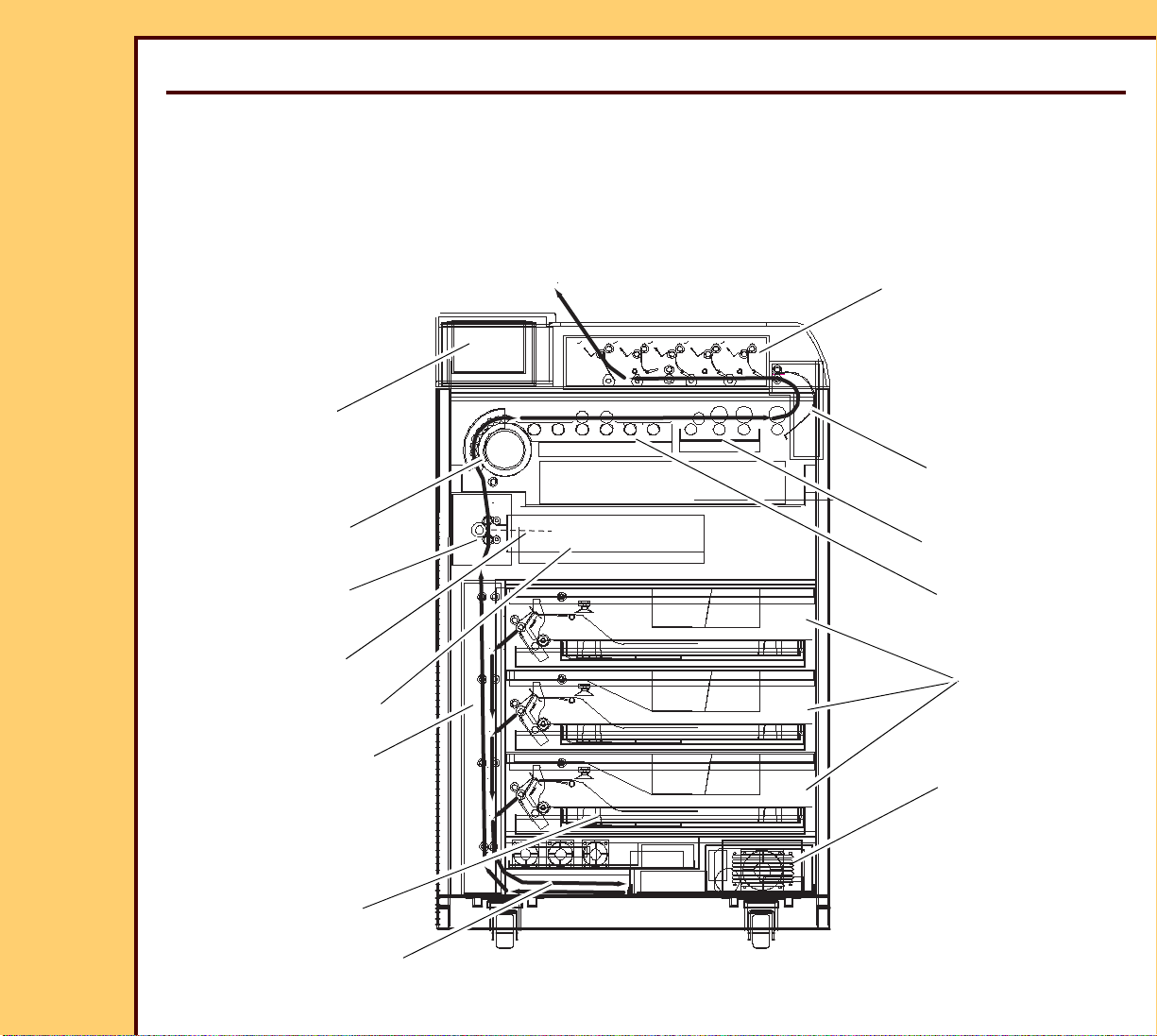

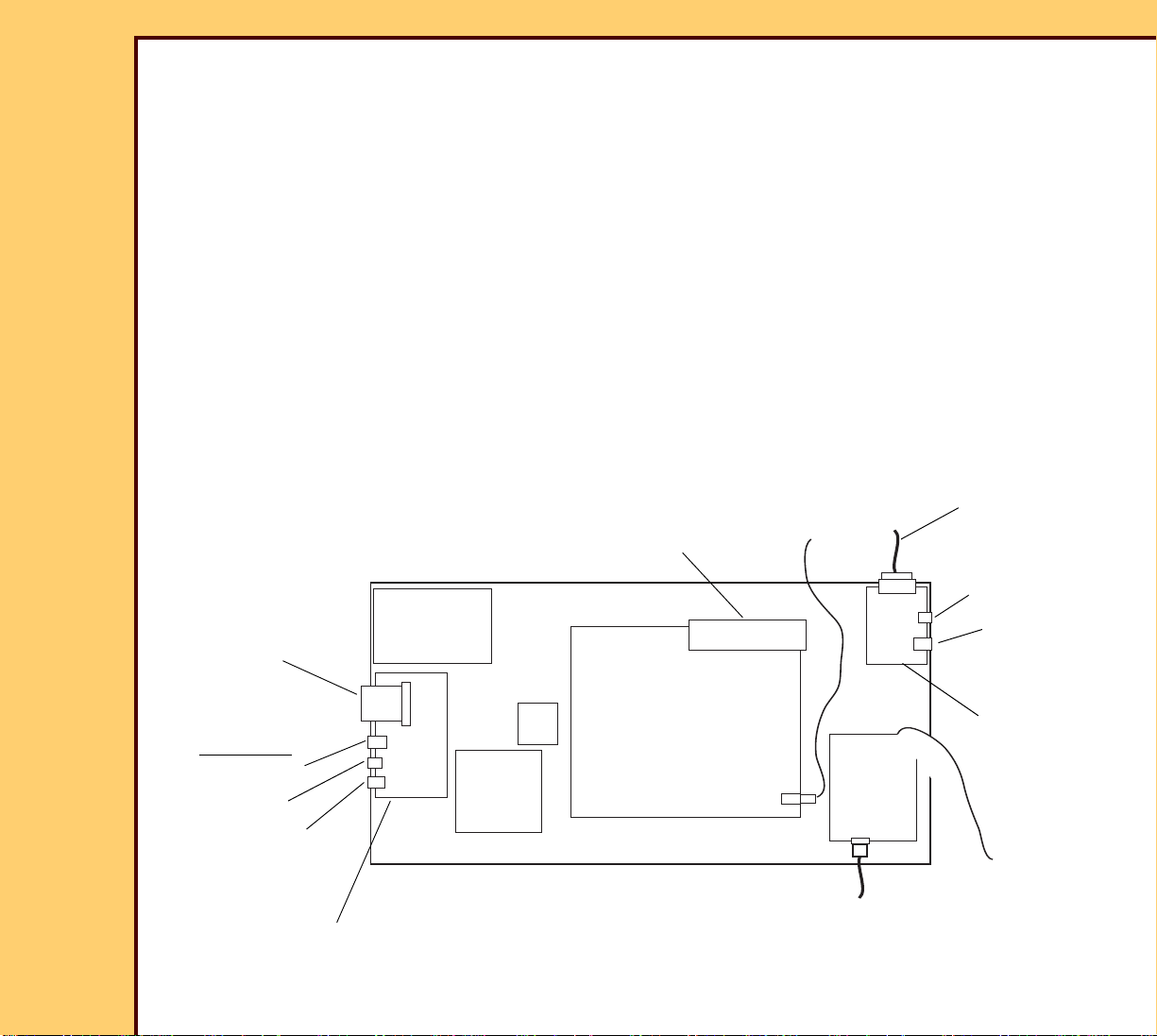

Figure 1 shows the main parts of the IMAGER:

Figure 1

Page 6

30JUL07

8F2924

Page

6 of 72

THEORY GUIDE Equipment Description

FILM SUPPLY

DRAWERS

Each DRAWER holds a film cartridge. The PICKUP

ASSEMBLY in the DRAWER feeds film to the

REGISTRATION ASSEMBLY. There can be 1,2 or 3

DRAWERS.

REGISTRATION

Orients film for the EXPOSURE TRANSPORT.

ASSEMBLY

EXPOSURE

TRANSPORT

Moves the film line by line past the scanning laser

beam.

OPTICS MODULE Generates a scanning laser beam that exposes the

film.

PROCESSOR

Rapidly heats the film to processing temperature.

DRUM

PROCESSOR

FLATBED

Keeps the temperature of the film until image is fully

developed.

PROCESSOR

Stops emulsion development and hardens the “base”.

COOLING SECTION

TURNAROUND Routes developed film to the SORTER or OUTPUT

TRAY.

SORTER Places film in 1 of 5 SORTER BINS. You can

configure the IMAGER to route films from each

connected MODALITY to a different BIN.

The SORTER is optional. If the IMAGER does not

have a SORTER, all completed films are sent to 1

OUTPUT TRAY.

- DICOM RASTER

ENGINE

A computer that runs the MIM software and the

MACHINE CONTROL SYSTEM (MCS) software that

controls the IMAGER.

Page 7

THEORY GUIDE Equipment Description

30JUL07

8F2924

Page

7 of 72

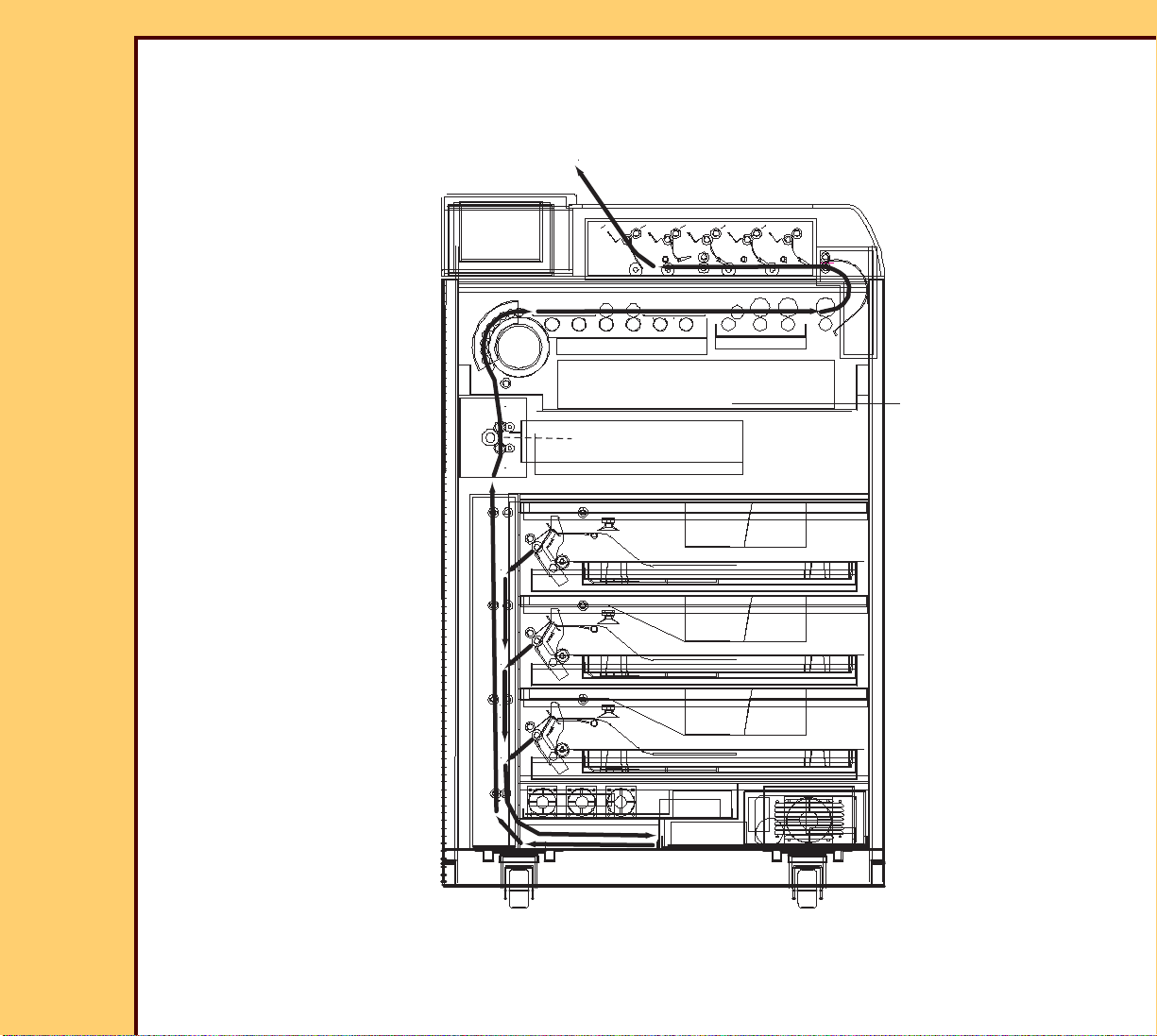

Film Path

Figure 2 shows the film path within the IMAGER.

Figure 2

Page 8

30JUL07

8F2924

Page

8 of 72

THEORY GUIDE Equipment Description

Main Steps in the Film Path

1. The MCS places an image into the IMAGE MEMORY on the DATAPATH

BOARD.

2. One of the PICKUP ASSEMBLIES feeds a sheet of film to the REGISTRATION

AY.

3. ROLLERS in the REGISTRATION AY move the film down until the trailing edge

of the film clears the PICKUP AY and is vertical. Depending on the size of the

film and the film DRAWER it comes from, the film might or might not extend all

the way into the ACCUMULATOR.

4. ROLLERS in the REGISTRATION AY reverse direction and feed film from the

ACCUMULATOR.

5. The film is “centered” and “deskewed” in the REGISTRATION AY.

6. ROLLERS in the REGISTRATION AY feed film up to the EXPOSURE

TRANSPORT.

7. The DATAPATH BOARD starts to read the image from IMAGE MEMORY “line-

by-line” and sends each line to the OPTICS MODULE. The OPTICS MODULE

generates a scanning laser beam for each image line.

8. ROLLERS in the EXPOSURE TRANSPORT move the film past the horizontal

scanning laser beam that exposes the film.

9. The leading edge of the film reaches the heated PROCESSOR DRUM and

starts to develop when the “lower” part of the film is moving through the

EXPOSURE TRANSPORT.

10. The film is moved through the THERMAL PROCESSOR by the rotating DRUM

and a series of ROLLERS. In the PROCESSOR:

- The DRUM rapidly heats the film to about 129 ° C.

- The film then moves through the heated FLATBED SECTION which

maintains a slightly lower temperature and completes processing the film.

- The film moves through the COOLING SECTION to remove heat from the

film to prevent density variations.

11. The developed film enters the TURN-AROUND which changes the film

direction and discharges it to the SORTER or EXIT TRAY.

Page 9

THEORY GUIDE Equipment Description

DRE

Modalities

DICOM

DRE

LOCAL

PANEL

Touchscreen Input

Image Data

DC Power

Customer

Network

DC PowerAC Power

AC Power

Speaker

Power Switch

POWER MODULE

AC Power

In

DRE

COMPUTER

Image

Control/

Status

USB Channel

MCS

(Print Engine)

30JUL07

8F2924

Page

9 of 72

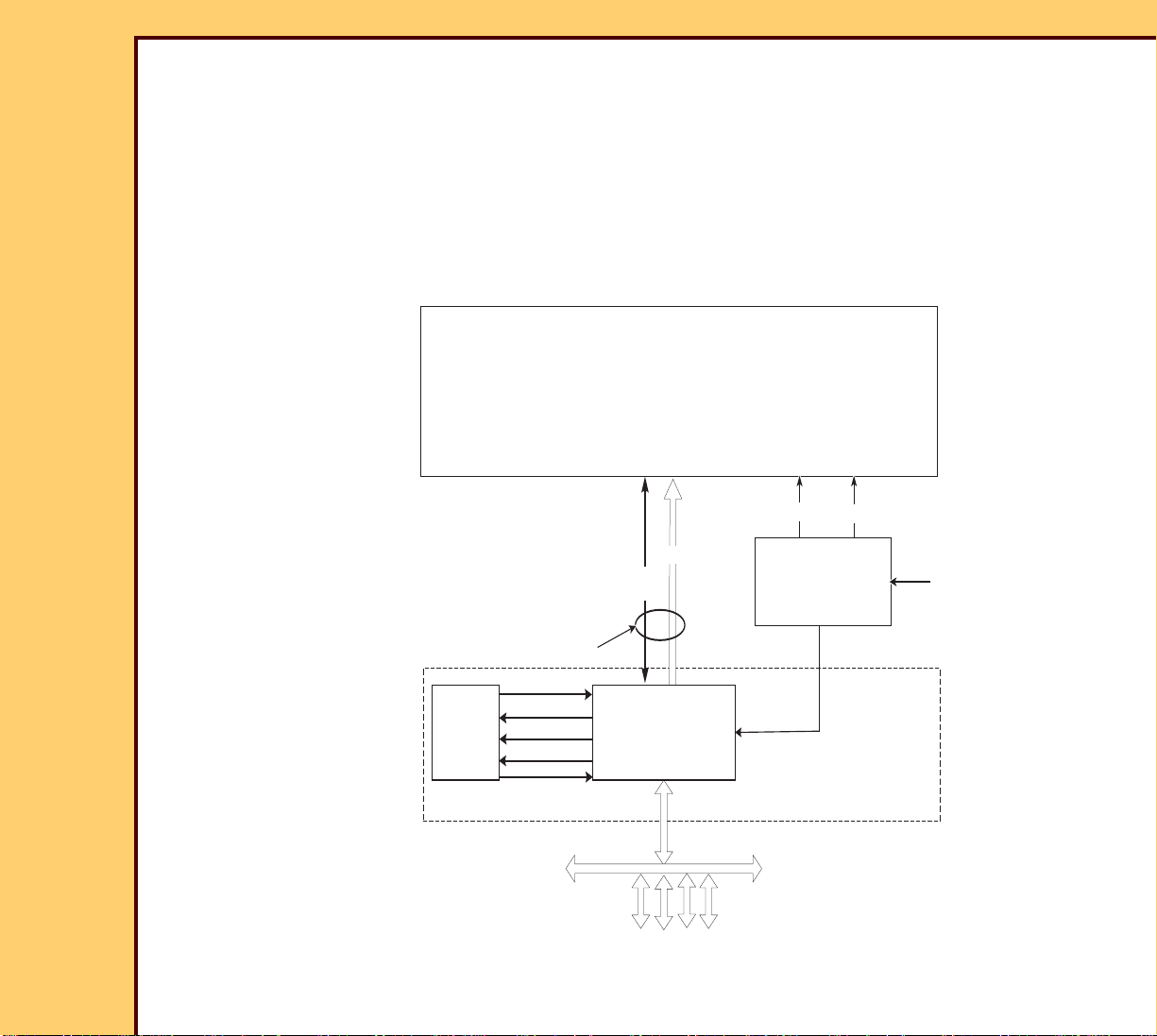

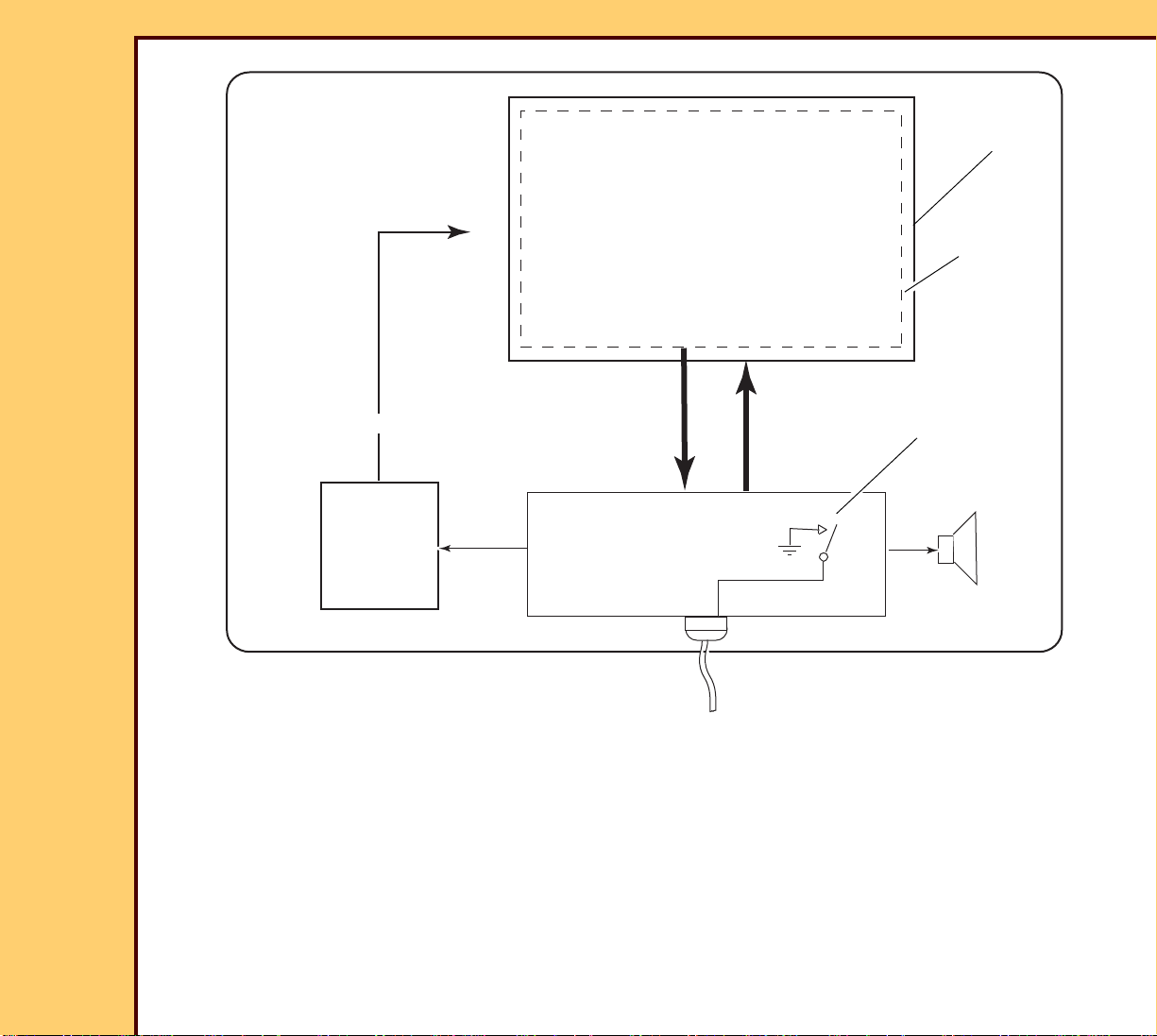

System Organization

Overview

The IMAGER has 3 main parts:

• The DICOM RASTER ENGINE (DRE)

• The MACHINE CONTROL SYSTEM (MCS)

• The POWER MODULE

Page 10

30JUL07

8F2924

Page

10 of 72

THEORY GUIDE Equipment Description

DICOM RASTER ENGINE (DRE)

The DRE system consists of the DRE COMPUTER and the LOCAL PANEL.

The DRE COMPUTER is a compact Pentium PC that runs the Microsoft Windows

XP operating system and several modules of the 6800 application software. With

the application software, the DRE functions as a MIM print server, within the

IMAGER, where the MCS is the print destination.

The DRE COMPUTER is responsible for acquiring print jobs from modalities on

the customer’s network and for queueing and rendering the incoming print jobs.

Formatted print jobs are forwarded, over a USB connection, to the MCS for

printing. The DRE COMPUTER also communicates with the LOCAL PANEL and

runs service tool software that can be accessed with a SERVICE PC.

The LOCAL PANEL is an 8 by 10-in. color FLAT PANEL DISPLAY that serves as

the operator interface for the IMAGER. In addition to the DISPLAY, it includes a

TOUCHSCREEN, a SPEAKER and a POWER SWITCH. Images displayed on the

LOCAL PANEL are sent from the DRE COMPUTER and TOUCHSCREEN

commands are sent to the DRE COMPUTER for interpretation and action.

MCS

The MCS is the “print engine” within the IMAGER. It receives formatted images

from the DRE and performs all of the electrical and mechanical functions

necessary to transport, expose and develop DryView film.

Power Module

The POWER MODULE supplies +5 V and +24 V DC power to the MCS

electronics and 120 V AC power to the DRE and to the HEATERS in the

THERMAL PROCESSOR. Input power can range from 90 to 250 V AC. For

energy saving purposes, the POWER MODULE includes a control input that

allows the DRE COMPUTER to shut off DC power to the MCS electronics and AC

power to the THERMAL PROCESSOR HEATERS.

For more information see POWER MODULE.

Page 11

30JUL07

8F2924

Page

11 of 72

THEORY GUIDE DICOM RASTER ENGINE (DRE)

Section 2: DICOM RASTER ENGINE (DRE)

The DRE is a PERSONAL COMPUTER (PC) with the Microsoft Windows XP Embedded

operating system. It runs application software that functions as a MIM PRINT SERVER and

software that prepares images for printing.

The DRE connects to the customer’s LOCAL AREA NETWORK and is responsible for

acquiring, queueing and rendering images from DICOM modalities on the LAN. Rendered

images are sent to the MCS for printing.

A single USB cable connects the DRE to the MCS. The USB interface can transfer several

channels of data simultaneously. It concurrently transfers commands, image data and

configuration from the DRE to the MCS. At the same time it transfers and status information

and diagnostic information returned from the MCS.

The DRE is mounted on a tray that slides out of the IMAGER for service. The main

components are

• PC MOTHERBOARD with a 1.6 GHz (or better) Intel Pentium M PROCESSOR

• A NETWORK BOARD in a PCI slot on the MOTHERBOARD

• HARD DRIVE

• DVD/CD DRIVE

• DC POWER SUPPLY for the MOTHERBOARD and accessories

• Cooling FAN

• INPUT CF BOARD - This BOARD performs 2 functions

– It provides an adaptor for a COMPACT FLASH (CF) CARD that connects to the IDE

controller on the MOTHERBOARD.

– It provides a service interface to the DRE. There are 3 CONNECTORS for service

tools:

> An RJ45 NETWORK CONNECTOR to connect a LAPTOP COMPUTER

> A USB CONNECTOR for connecting a USB MOUSE

> A PS2 CONNECTOR for connecting a KEYBOARD

Page 12

THEORY GUIDE DICOM RASTER ENGINE (DRE)

COMPACT

CARD

FLASH

DVD/CD

DRIVE

NETWORK

USB

KEYBOARD

CONNECTORS

INPUT CF

BOARD

FRONT

DC

POWER

SUPPLY

120 V AC

From POWER

MODULE

HARD

DRIVE

FAN

MOTHER

BOARD

LOCAL PANEL

USB

CONNECTOR

NETWORK

CONNECTOR

LVDS

BOARD

CABLE to

DATAPATH

USB CABLE to

BOARD

(for customer

network)

(for Service)

12 Volt Wake Up

Signal to the Power

Module

NETWORK

BOARD

30JUL07

8F2924

Page

12 of 72

• LVDS BOARD -This BOARD provides an interface between the MOTHERBOARD and the

LOCAL PANEL. It also provides 2 external connectors:

– An RJ45 NETWORK CONNECTOR for connecting the IMAGER to the customer’s

Ethernet/DICOM network

– A USB CONNECTOR for future use

A 26-pin cable connects the LVDS BOARD to the LOCAL PANEL. This cable carries the

image data for the LCD PANEL, input data from the TOUCH SCREEN, backlight brightness

signal, audio for the SPEAKER, +3.3, +5 and +12 V DC power, and a signal from the

POWER BUTTON on the LOCAL PANEL. LVDS is an abbreviation for “Low Voltage

Differential Signaling”, the transmission method used to send image data from the LVDS

BOARD to the LOCAL PANEL.

The following diagram shows the main components in the DRE and the external connection

points on the DRE.

Page 13

THEORY GUIDE DICOM RASTER ENGINE (DRE)

Note

30JUL07

8F2924

Page

13 of 72

The COMPACT FLASH (CF) CARD is used to backup and restore the IMAGER configuration

parameters. It also holds data required for startup and should not be removed or replaced

unless directed by a MODIFICATION INSTRUCTION or other approved procedure. The

IMAGER will not start up if the CF CARD is not present.

The DC POWER SUPPLY in the DRE supplies power to the MOTHER BOARD, HARD

DRIVE and DVD/CD DRIVE. A 12 V DC output from the DRE POWER SUPPLY serves as a

wake up signal to the IMAGER POWER MODULE.

The DRE POWER SUPPLY is controlled by the MOTHERBOARD. A logic signal from the

MOTHERBOARD turns the DRE POWER SUPPLY ON and OFF.

• When the IMAGER is “Ready” or in the “Energy Save” or “Sleep” modes, the

MOTHERBOARD turns the DRE POWER SUPPLY ON. The POWER SUPPLY provides

+3.3, +5, +12, and -12 V DC and the DRE is fully functional.

• When the IMAGER is in the “Power Off” state, the MOTHERBOARD turns off the DRE

POWER SUPPLY. In this condition, the POWER SUPPLY provides only +5 V DC standby

power to the MOTHERBOARD. Most functions on the MOTHERBOARD are suspended

but the 5V standby power enables the MOTHERBOARD to wakeup with a signal from the

POWER BUTTON on the LOCAL PANEL or from the Power Schedule set up on the

LOCAL PANEL.

The DRE POWER SUPPLY receives 120 V AC input power from the POWER MODULE. The

POWER SWITCH on the POWER MODULE must be ON for the DRE POWER SUPPLY to

supply either full power or +5 V standby power.

Page 14

30JUL07

8F2924

Page

14 of 72

THEORY GUIDE Local Panel

Section 3: Local Panel

The LOCAL PANEL, which connects by a CABLE to the LVDS BOARD in the DRE, contains:

• An LCD DISPLAY with miniature fluorescent BACKLIGHTS

• A TOUCH PANEL

• An DC-to-AC INVERTER POWER SUPPLY for the BACKLIGHTS

• A SPEAKER

• A momentary POWER SWITCH

• A LOCAL PANEL INTERFACE BOARD that connects to the to the LVDS BOARD in the

DRE

The LOCAL PANEL is not repaired in the field: it is replaced as a unit.

The following graphic is a block diagram of the LOCAL PANEL.

Page 15

30JUL07

+12 V DC

To BACKLIGHTS

100 V AC

TOUCH PANEL

LCD PANEL

To DRE

INVERTER

DC-to-AC

SPEAKER

MOMENTARY SWITCH

(POWER BUTTON)

LOCAL PANEL

INTERFACE BOARD

LOCAL

PANEL

8F2924

Page

15 of 72

THEORY GUIDE Local Panel

The cable that connects the LOCAL PANEL to the DRE carries:

• Image data for the LCD DISPLAY PANEL

• Input data from the TOUCH PANEL

• Closure signal (ground) from the MOMENTARY SWITCH

• Audio signal to the SPEAKER

• A backlight dimming signal

• +3.3, +5, and +12 V DC power

Page 16

30JUL07

8F2924

Page

16 of 72

THEORY GUIDE Machine Control System (MCS)

Section 4: Machine Control System (MCS)

The MCS is the print engine within the IMAGER. It is made up of both hardware and software

components.

MCS Functions

The MCS receives image data and commands from the DRE over the USB interface and is

responsible for controlling the mechanical and optics assemblies to transport, expose and

develop films. Once the DRE sends an image and print command, the MCS performs the

actions necessary to expose and print a film largely independent of the DRE.

MCS Hardware

The MCS hardware consists of several electro-mechanical subsystems, each controlled by a

“MICRO BOARD” - a circuit board containing a MICROPROCESSOR. Software in each

MICRO BOARD provides the control “intelligence” for the subsystems. An I2C BUS connects

a master MICROPROCESSOR on the DATAPATH BOARD to all of the other MICRO

BOARDS. The BUS is used to exchange commands and status information between the

master MICROPROCESSOR and the MICROROCESSORS on the other MICRO BOARDS.

The master MICROPROCESSOR controls the subordinate MICROBOARDS by sending

commands and receiving status information on the I2C BUS. Each MICROBOARD controls

the functions of its mechanical subsystem by controlling motors and reading sensors.

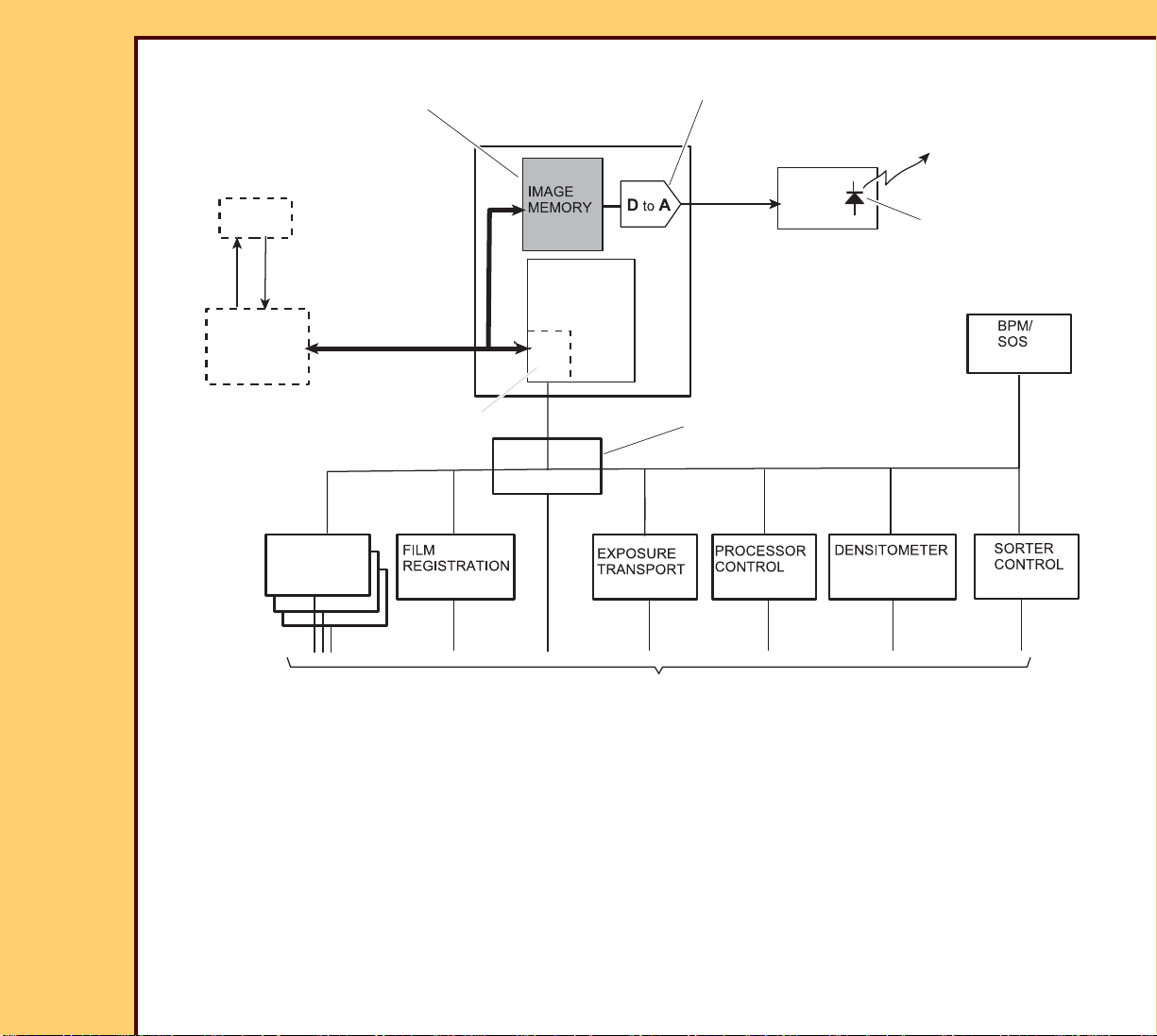

The following diagram shows how the MICROBOARDS are connected on the I2C BUS. The

DATAPATH MICROPROCESSOR is the primary control device with all other

MICROPROCESSORS subordinate.

Page 17

30JUL07

FILM

SUPPLY

LASER DRIVER

BOARD

POWER DISTRIBUTION

BOARD

USB

LOCAL

PA NE L

I2C

I2C

I2C

Modulated Laser

Beam - To Optics

DATAPATH BOARD

CONTROL

BOARDS

BOARD

BOARD

BOARD

BOARD

BOARD

BOARD

Laser Diode

Capacity:

1 Image

Digital - to - analog

conversion

To : MOTORS, HEATERS, SENSORS controlled or sensed by the MICROBOARDS

TRANSLATION

USB/I2C

DRE

PRIMARY

MICROPROCESSOR

8F2924

Page

17 of 72

THEORY GUIDE Machine Control System (MCS)

I2C BUS

The I2C is a low-speed, serial BUS with only 2 lines (plus ground). The BUS interconnects all

of the MICROBOARDS.The MICROCONTROLLERS and FLASH MEMORIES on the

MICROBOARDS connect to the BUS. Each device connected to the BUS has a unique

address.

Page 18

THEORY GUIDE Machine Control System (MCS)

30JUL07

8F2924

Page

18 of 72

The BUS is bidirectional. Any of the MICROPROCESSORS can initiate a data transfer on the

BUS. Several types of information are transferred on the BUS:

• Commands - These are sent from the MASTER MICROPROCESSOR, on the DATAPATH

BOARD, to cause a slave MICROPROCESSOR to perform an action, for example, to

“Execute Diagnostics” stored in the slave CPU. A command causes the slave to reply,

acknowledging that the command can be processed or that there is a problem which

prevents processing the command.

• MICROBOARDS return responses to commands to the DATAPATH BOARD.

• MICROBOARDS send status information to the DATAPATH BOARD.

• Software updates are downloaded to the MICROBOARDS.

Communication Between MICRO BOARDS

Communication between the DRE and the 11 MICRO-BOARDS is conducted over a USB

channel and an I2C bus. The 11 MICRO-BOARDS are all connected on a common I2C bus.

This bus is used to send commands from the DRE to the MICRO-BOARDS and return

responses from the MICRO-BOARDS. It is also used to load software or other data into

MICROPROCESSOR MEMORIES or NVRAM on the MICRO-BOARDS.

The I2C INTERFACE is a 2-wire BUS having a Serial Data, SDA, and a Serial Clock (SCL)

line. These wires connect information between the devices and the CPUs connected to the

BUS. Each CPU on the BUS is recognized by a unique address and can either receive or

transmit data. The CPU that starts a data transfer is a “master” and the receiving CPU is a

“slave.” Any of the CPUs on the BUS can be either a master or a slave. In practice, the

MASTER CPU will start all commands, and will normally be the master, and the CPUs for

modules on the BUS will be slaves. Three types of messages are used:

• Commands - These are sent from the MASTER CPU to cause a slave CPU to perform an

action, for example, to “Execute Diagnostics” stored in the slave CPU. A command causes

the slave to reply, acknowledging that the command can be processed or that there is a

problem which prevents processing the command.

• Replies - The slave must respond with a reply after each byte of a received command. If

the MASTER does not receive a reply within 100 ms after sending the command, it will

stop the process.

Page 19

THEORY GUIDE Machine Control System (MCS)

30JUL07

8F2924

Page

19 of 72

• Notification - These are sent from a slave CPU to the MASTER CPU indicating a changed

condition in the slave module.

Each type of message must be preceded by the address of the CPU for which it is intended.

Optics Module

Components Controlled or Sensed by the MICROBOARDS

The IMAGER has a number of rotary and linear MOTORS that power the functions of the

IMAGER and SENSORS. The SENSORS provide input to MICROPROCESSORS that control

the MOTORS.

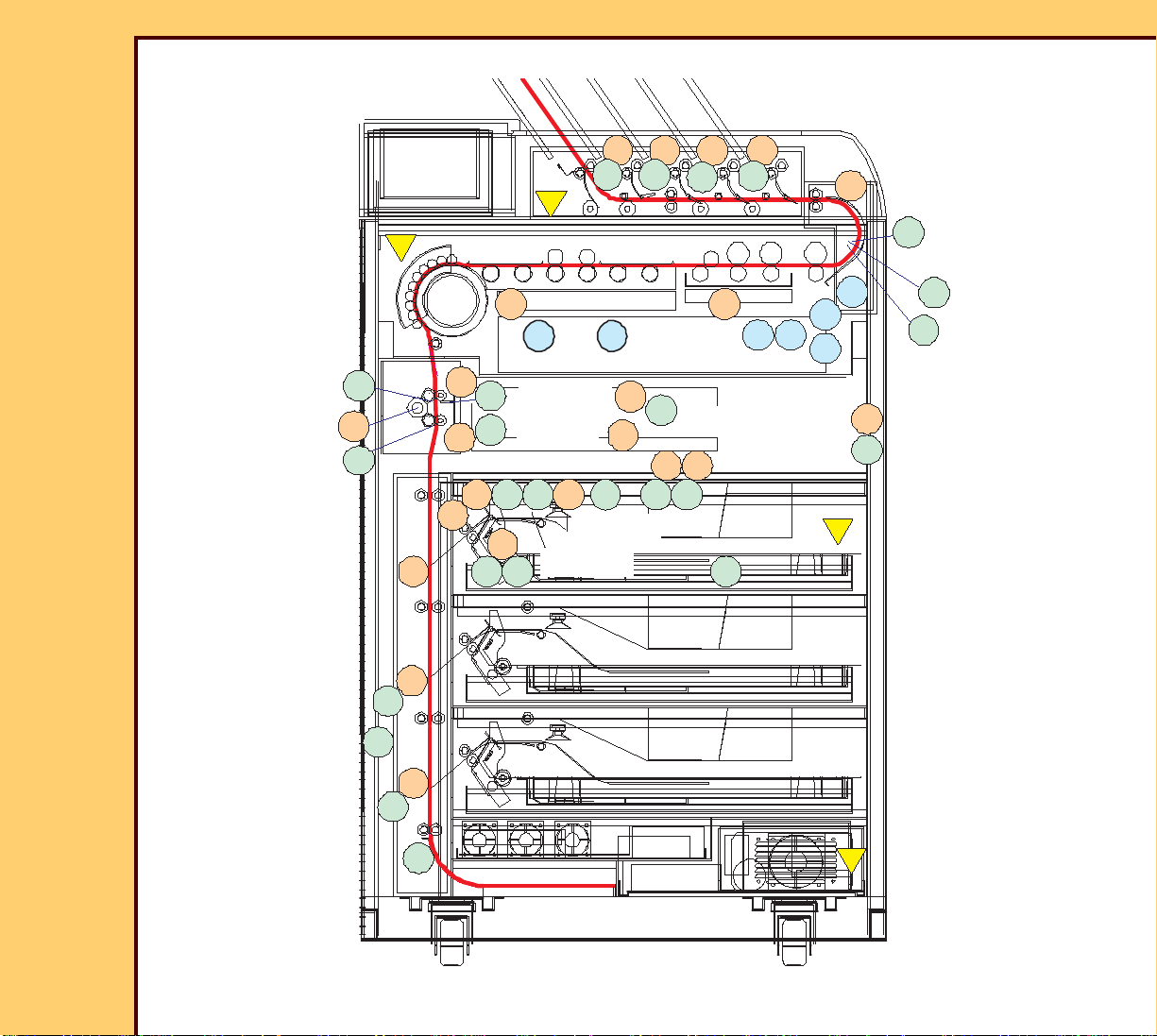

Figure 3 shows the approximate location of MOTORS and SENSORS in the IMAGER. Table

1 and Table 2 provide descriptions each MOTOR and SENSOR.

Page 20

THEORY GUIDE Machine Control System (MCS)

F5 F6

S12

S1 S2S3S4 S5

S6 S7S8

S9

S10

S11

S13

S14

S15

M1

M2

M3

M4 M5

M6

M7

M8

M9

M10

M11

M12

M13 M14

M15

M16M17

M18M19

F1

F2

F3

S4 - PU Roller Position

M14 - Temp

Cooling Drive

S19

M20

i1

i2

i3

i4

M22

M21

S24

S23 S22

S21

S20

S25

F7

F4

30JUL07

8F2924

Page

20 of 72

Figure 3 MOTORS and SENSORS

Page 21

30JUL07

Note

8F2924

Page

21 of 72

THEORY GUIDE Machine Control System (MCS)

In the following tables: For components in the PICKUP or ROLLBACK ASSEMBLIES, x will

be U, M or L, for the UPPER, MIDDLE or LOWER FILM DRAWER.

Table 1 MOTORS

Designator/

Location

M1x

Pickup

M2x

Pickup

M3x

Pickup

M4x

Pickup

M5x

Pickup

M6

Rollback

M7

Registration

Name Location

PICKUP FEED

ROLLER OPEN/

CLOSE MOTOR

Descriptio

n/

Function

PICKUP ROLLER

Open/

Close

PICKUP ROLLER

drive

PICKUP PICKUP

drive

PICKUP PICKUP

PUMP

PICKUP PICKUP

RELIEF

VALVE

ROLLBACK ROLLBAC

K DRIVE

MOTOR

Registration Centering

MOTOR

Motion Typ e

Rotational DC GEAR

MOTOR

Home/

Default

Home =

Open

Limit =

Close

Rotational STEPPER Off On

Rotational DC GEAR

MOTOR

Home = Up

(film at

feed)

Limit =

Cartridge

bottom

Rotational

Linear

Rotational,

Reversing

STEPPER Home =

ARMS

retracted

actuated

= ARMS

extended

to film

size

Limit

Page 22

THEORY GUIDE Machine Control System (MCS)

30JUL07

8F2924

Page

22 of 72

Table 2 SENSORS

Designator Location

S1x PICKUP Home

SENSOR

Description/

Function

Type Default

Interrupt

SENSOR

Blocked =

PICKUP

home

Sensed

Position

Unblocked =

PICKUP not

home

Page 23

30JUL07

8F2924

Page

23 of 72

THEORY GUIDE POWER DISTRIBUTION BOARD

Section 5: POWER DISTRIBUTION BOARD

Functions

The POWER DISTRIBUTION BOARD (PDB) performs several functions:

• Distributes +5 volt and +24 volt DC power to all other CIRCUIT BOARDS except the DRE

and LOCAL PANEL.

• Provides the logic for the system

• Connects the I2C bus to all of the MICRO BOARDS

• Controls the LATCH MOTOR that unlocks the front DOORS and FILM DRAWERS

• Controls the TURNAROUND MOTOR

Figure 4 on page Page 24 is a block diagram of the PDB.

Power Distribution

The POWER MODULE supplies +5-volt and +24-volt DC power to the PDB. The PDB

provides +5-volt power, either directly or indirectly, to all CIRCUIT BOARDS except the DRE

and LOCAL PANEL. There is no switching or control of +5-volt power on the PDB.

The PDB provides +24-volt power to the MICRO BOARDS subject to inputs from the

INTERLOCK SWITCHES or SERVICE SWITCH. The logic on the PDB may interrupt +24-volt

power to some or all of the MICRO BOARDS depending on the inputs.

I2C Bus

The PDB provides I2C bus connections between the DPB and all the other MICRO BOARDS.

The I2C bus simply passes through the PDB. There is no control or switching of the bus on

the PDB.

Page 24

THEORY GUIDE POWER DISTRIBUTION BOARD

MICROPROCESSOR

INTERLOCK

LOGIC

MOTOR

DRIVER

MOTOR

DRIVER

NVRAM

From DPB

I2C Bus

To a l l M I C R O

BOARDS

+5V

+24V

From Power

MODULE

INTERLOCK

SWITCHES

FILM-AT-ENTRANCE

To F R B

DOOR LATCH

SENSOR

FRONT DOOR

SERVICE

AIR INTAKE

DOOR

LATCH

MOTOR

TURNAROUND

MOTOR

To all CIRCUIT

BOARDS

To M I C R O

BOARDS

I2C Bus

+24V Interlock

Voltages

SWITCH

SORTER

INTERLOCK

FILM DRAWER

JUMPERS

30JUL07

8F2924

Page

24 of 72

Figure 4 PDB Block Diagram

MICROPROCESSOR FUNCTIONS

The MICROPROCESSOR in the PDB controls the DOOR LATCH MOTOR and the

TURNAROUND MOTOR. The MICROPROCESSOR receives an input from the DOOR

LATCH SENSOR and connects to the 2 MOTOR DRIVERS that energize the 2 MOTORS.

Page 25

THEORY GUIDE POWER DISTRIBUTION BOARD

Note

30JUL07

8F2924

Page

25 of 72

The output of the DOOR LATCH SENSOR is low when the FRONT DOOR is locked and high

when the DOOR is unlocked.

Application Software

Application software that runs in the MICROPROCESSOR communicates with the

MCS software to control the 2 MOTORS and report status to the MCS. The

application software also performs initialization tests upon power-up, when a reset

command is received from the MCS or when the RESET SWITCH on the PDB is

pressed. The application software performs MOTOR diagnostic tests and memory

tests when the MCS sends diagnostic commands.

Door Latch Motor

The DOOR LATCH MOTOR is a linear stepper MOTOR that, when energized, lifts

a LATCH ROD. that locks and unlocks the FRONT DOOR and DRAWERS.

The LATCH ROD has 2 positions: up and down. When the ROD is down, the

FRONT DOOR and the FILM DRAWERS are locked and the PROCESSOR

DRAWER is unlocked (but secured by latches on the DRAWER SLIDES). When

the ROD moves up, it unlatches the FRONT DOOR. The DOOR remains

unlatched until it is pushed closed. If the ROD is held up, the FILM DRAWERS are

unlocked but the PROCESSOR DRAWER is locked. This mechanism prevents the

FILM DRAWERS and PROCESSOR DRAWER from being pulled out at the same

time.

The LATCH ROD can be operated manually from inside the AIR INTAKE DOOR.

Unlock Functions

In response to commands from the MCS, the application software controls the

DOOR LATCH MOTOR to perform the following unlock functions.

• When “Unlock Film Supply” is selected on the LOCAL PANEL, the LATCH

MOTOR lifts and holds the LATCH ROD up. The FRONT DOOR and FILM

DRAWERS are unlocked but the PROCESSOR DRAWER is locked. The

LATCH MOTOR holds the ROD up until the FRONT DOOR is closed.

Page 26

THEORY GUIDE POWER DISTRIBUTION BOARD

Note

30JUL07

8F2924

Page

26 of 72

• When “Unlock Processor” is selected on the LOCAL PANEL, the LATCH

MOTOR lifts the ROD briefly to unlatch the FRONT DOOR then immediately

lowers the ROD to lock the FILM DRAWERS. The FRONT DOOR can be

opened and the PROCESSOR DRAWER can be pulled out.

Turnaround Motor

The TURNAROUND MOTOR is a rotary stepper MOTOR that drives ROLLERS in

the TURNAROUND that move film to the SORTER or OUTPUT TRAY. Application

software in the PDB MICROPROCESSOR operates the TURNAROUND MOTOR

in response to commands from the MCS:

1. When a film is exiting the EXPOSURE TRANSPORT, the MCS notifies the

PDB application to “Transport Film to the Densitometer”.

2. A software timer is started to track the progress of film through the

PROCESSOR and toward the TURNAROUND ROLLERS.

3. When the timer indicates that the film is approaching the first TURNAROUND

ROLLER, the application runs the TURNAROUND MOTOR at the same speed

as the PROCESSOR.

4. When the film passes the DENSITOMETER FILM PRESENT SENSOR, S18,

the application delays until the trailing edge of film clears the COOLING

SECTION ROLLERS and then runs the TURNAROUND MOTOR at high speed

to “kick” the film out of the TURNAROUND.

5. The application allows time for the film to exit to the SORTER or OUTPUT

TRAY and then turns off the TURNAROUND MOTOR.

If the film is a calibration sheet, the high-speed “kick” is not started while the film

is in the densitometer.

Page 27

THEORY GUIDE POWER DISTRIBUTION BOARD

Legend

PDB = Component located on the PDB

PMOD = Component located in the POWER MODULE

DPB = Component located on the DPB

V24 = + 24 volts DC

-AVCC = -5volts DC for analog circuits

Jumpers located on the DRAWER-side

of the BLINDMATE CONNECTOR

for each DRAWER

120V AC = 120 volts AC for PROCESSOR HEATERS

30JUL07

8F2924

Page

27 of 72

INTERLOCK SYSTEM

Figure 5 is a simplified diagram of the Interlock circuits. All INTERLOCK SWITCHES must

be closed for the IMAGER to operate normally. Table 3 on Page 28 shows the effect of

opening each INTERLOCK SWITCH.

Components in the INTERLOCK SYSTEM are located on the PDB, the PCB, the DPB and in

the POWER MODULE. For details of cabling between the INTERLOCK SWITCHES and other

interlock components, refer to the FUNCTIONAL BLOCK DIAGRAMS for the IMAGER.

V24

Air Intake

Door Switch

V24

Upper

Drawer

Jumper

Main Door

Switch

NC

PDB

D11

Middle

Drawer

Jumper

V24

Lower

Drawer

Jumper

PDB

K1

PDB

K3

PDB

D8

PDB

V24

K2

Service Switch

(Normal Mode)

NO

V24

DRAWER_HAZARD_24

V24_HAZ

PMOD

K2

120VAC

FILM SUPPLY BOARDS

Upper, Middle, Lower

REGISTRATION BOARD

EXPOSURE TRANSPORT BOARD

PROCESSOR CONTROL BOARD

TURNAROUND MOTOR

LATCH MOTOR

PROCESSOR HEATERS

Sorter

Interlock

Switch

NC

V24

NC

PDB

K4

LASER_HAZARD_24

SORT_HAZ_V24

-AVCC

DPB

K1

Laser

Hazard

Relay

LASER DRIVER

SORTER CONTROL

BOARD

Page 28

THEORY GUIDE POWER DISTRIBUTION BOARD

30JUL07

8F2924

Page

28 of 72

Table 3 INTERLOCK SWITCH ACTIONS

TURNAROUND/

EXPOSURE

INTERLOCK SWITCH

and Condition

SORTER

DIVERTERS

TRANSPORT/

PROCESSOR/

REGISTRATION/

LATCH MOTOR

FILM

SUPPLY

120VAC POWER

to PROCESSOR

MAIN DOOR - Open OFF OFF OFF OFF OFF

SORTER - Open OFF ON ON ON ON

Any DRAWER -

ON ON OFF ON OFF

Open

AIR INTAKE DOOR

ON ON OFF ON OFF

- Open

SERVICE SWITCH -

ON ON ON ON OFF

in Service Mode

All SWITCHES

ON ON ON ON ON

Closed - Normal

Mode

SERVICE SWITCH

ON ON ON ON OFF

Unplugged

LASER

FILM DRAWER INTERLOCK JUMPERS - The BLINDMATE CONNECTOR on each FILM

DRAWER has a JUMPER that acts as an INTERLOCK SWITCH when the DRAWER is

opened. Figure 6 on Page 32 shows how these JUMPERS are connected. If either the

LOWER DOOR ACCESS SWITCH or any of the FILM DRAWERS are open, the interlock

circuit is broken and power to the LASER DRIVER BOARD and FILM SUPPLY BOARDS is

interrupted.

Page 29

THEORY GUIDE POWER DISTRIBUTION BOARD

PDB

K3

1111

10101 24242424 24241 1

1111 1111

10101010

LOWER ACCESS

DOOR SWITCH

V24

Fixed Side

DRAWER

BLINDMATE

CONNECTORS

UPPER

DRAWER

DRAWER

DRAWER

MIDDLE

LOWER

DRAWER

DRAWER

Open

JUMPERS

Interlock Circuit

RELAY controls

power to

Laser and

FILM SUPPLY

BOARDS

Interlock Circuit

Interrupted

Side

30JUL07

8F2924

Page

29 of 72

Figure 5

Page 30

30JUL07

8F2924

Page

30 of 72

THEORY GUIDE ROLLBACK/PICKUP ASSEMBLIES

Section 6: ROLLBACK/PICKUP ASSEMBLIES

To Be Supplied

Page 31

30JUL07

8F2924

Page

31 of 72

THEORY GUIDE Film Registration Assembly

Section 7: Film Registration Assembly

PURPOSE

The purpose of the FILM REGISTRATION SUBSYSTEM is to orient a sheet of

film for entry to the EXPOSURE TRANSPORT. The film is positioned so that:

• Notch is down

• Emulsion towards the OPTICS MODULE

• Film is “centered” on the EXPOSURE TRANSPORT ROLLERS.

• Film is “deskewed” - vertical edges of the film are aligned, parallel with film

direction.

The FILM REGISTRATION SUBSYSTEM has:

• FILM REGISTRATION AY

• ACCUMULATOR

• FILM REGISTRATION CIRCUIT BOARD

• FILM REGISTRATION application software that runs in a MICROPROCESSOR

on the FILM REGISTRATION BOARD

The FILM REGISTRATION BOARD is connected to a number of electrical

components within the FILM REGISTRATION AY:

• VERTICAL TRANSPORT MOTOR - operates the 4 DRIVE ROLLERS.

• FILM CENTERING MOTOR - operates the CENTERING FINGERS.

• FILM CLAMPING MOTOR - opens and closes the NIP ROLLERS for the top 3

drive ROLLER pairs.

• HOME POSITION SENSOR for FILM CENTERING MOTOR

• HOME POSITION SENSOR for CLAMPING MOTOR

• FILM POSITION SENSOR in the ACCUMULATOR

The FILM REGISTRATION application controls film registration functions by

operating the 3 MOTORS in the assembly, based on commands from the MCS

and inputs from the 3 SENSORS in the FILM REGISTRATION AY.

Page 32

THEORY GUIDE Film Registration Assembly

REGISTRATION

ASSEMBLY

ACCUMULATOR

EXPOSURE

TRANSPORT

DRIVE

ROLLER SETS (4)

FILM GUIDE

30JUL07

8F2924

Page

32 of 72

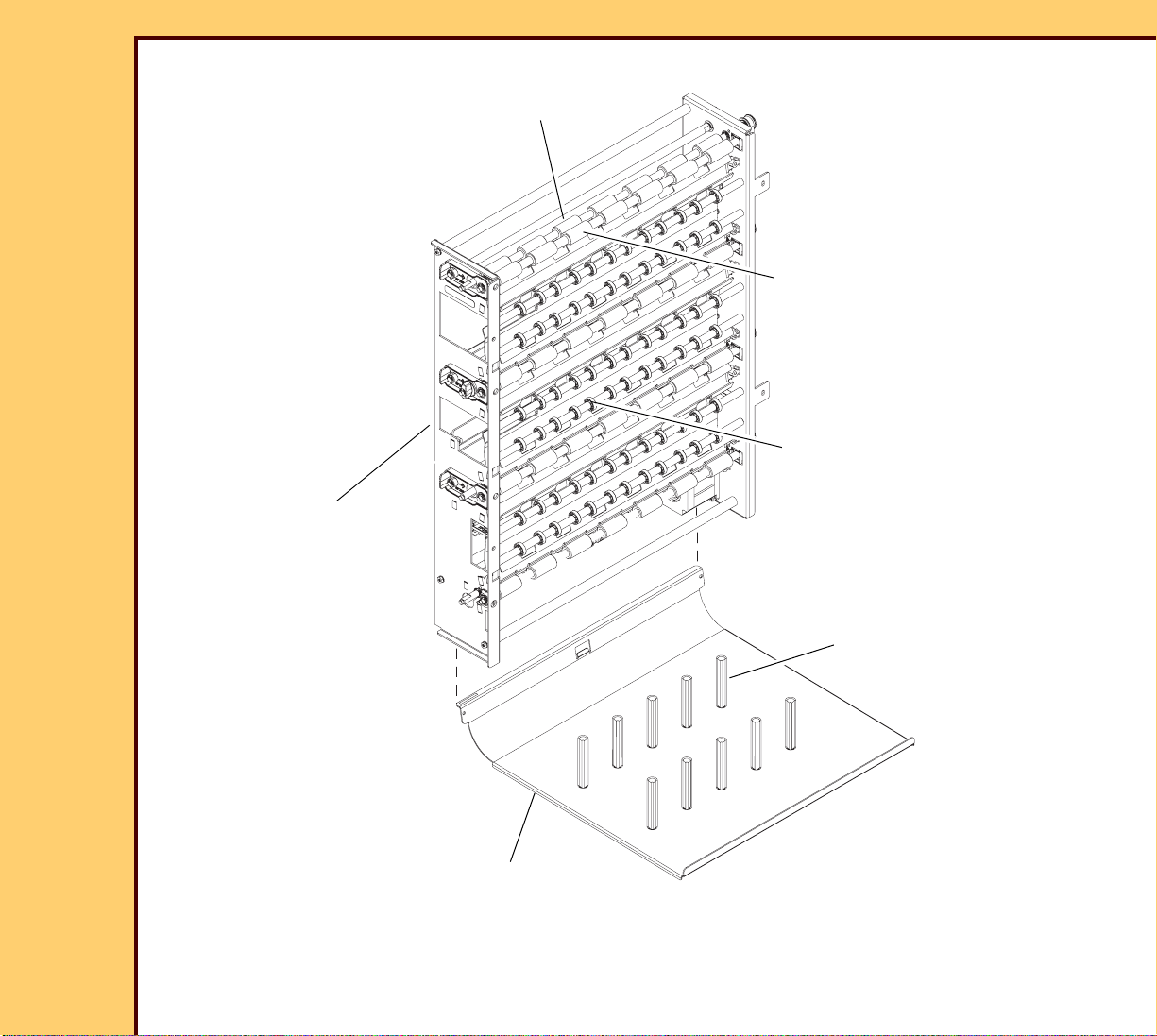

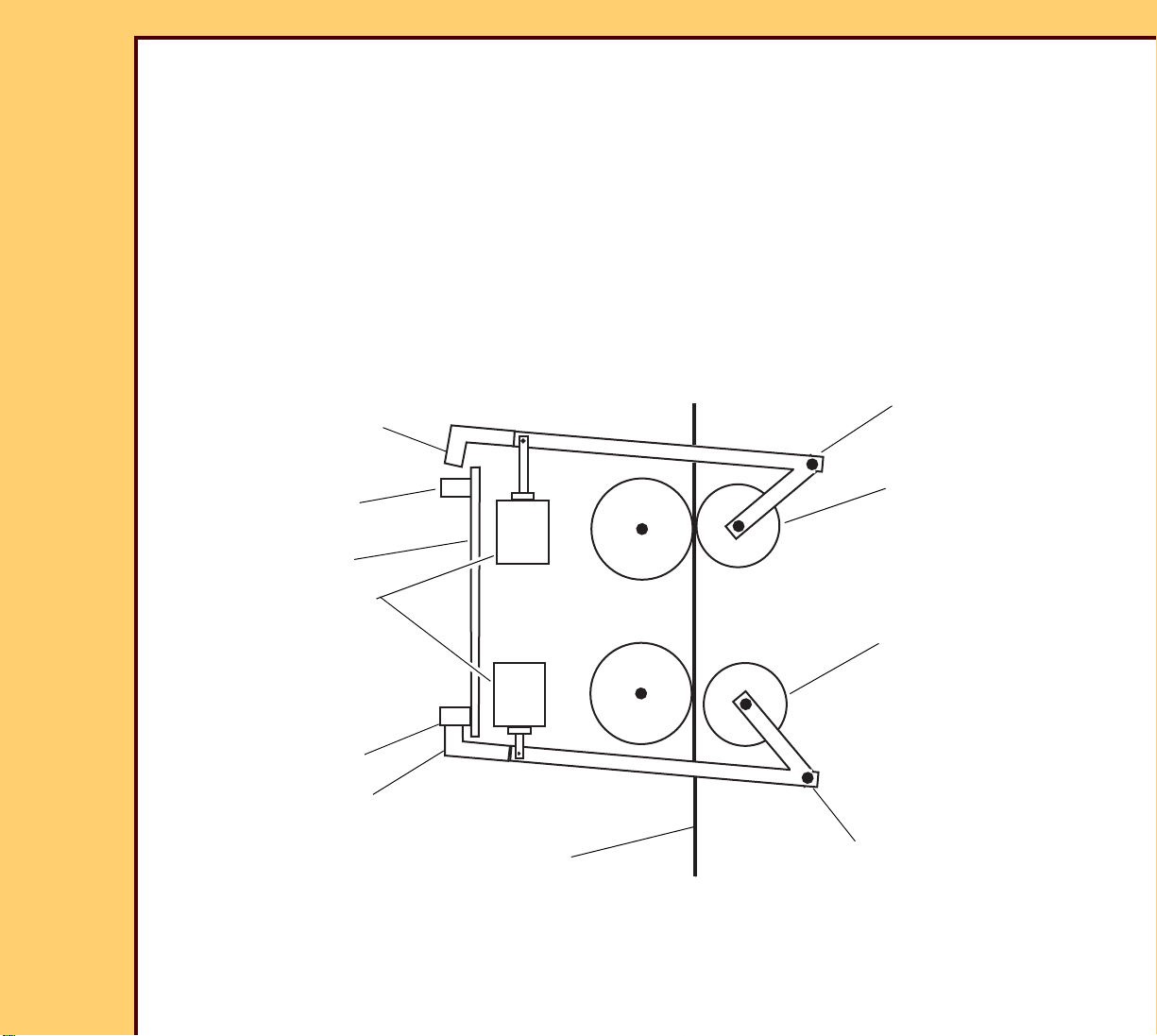

The following drawing shows the position of the FILM REGISTRATION ASSEMBLY

and ACCUMULATOR.

Figure 6

Page 33

THEORY GUIDE Film Registration Assembly

30JUL07

8F2924

Page

33 of 72

FILM PATH

Figure 7 shows the film path through the FILM REGISTRATION SUBSYSTEM.

Figure 7

REGISTRATION ASSEMBLY

The following 2 graphics show the main components in the FILM REGISTRATION

AY.

Page 34

THEORY GUIDE Film Registration Assembly

REGISTRATION

ASSEMBLY

ACCUMULATOR

DRIVE

ROLLERS (4)

NON-POWERED

NIP ROLLERS (4)

IDLER

ROLLERS (6)

GROOVES

30JUL07

8F2924

Page

34 of 72

Figure 8 REGISTRATION ASSEMBLY - VIEW FACING FILM SUPPLY DRAWERS

Page 35

THEORY GUIDE Film Registration Assembly

REGISTRATION

CENTERING MOTOR - M7

TRANSPORT

MOTOR - M8

ROLLER ACTUATOR

MOTOR M9

ACCUMULATOR

HOME SENSOR

CENTERING MOTOR

HOME SENSOR - S10

ACTUATOR

S11

SENSOR - S9

CENTERING FINGER

CENTERING

FINGER

CIRCUIT BOARD

30JUL07

8F2924

Page

35 of 72

Figure 9 REGISTRATION ASSEMBLY - VIEW TOWARD OUTSIDE OF IMAGER

H210_1002DC

Page 36

30JUL07

8F2924

Page

36 of 72

THEORY GUIDE Film Registration Assembly

Registration Component Functions

• DRIVE ROLLERS - 4 pairs of ROLLERS transport the film down and then up

to the EXPOSURE TRANSPORT. Each pair of ROLLERS has a “powered”

ROLLER and a NIP ROLLER that is not “powered”. The top 3 NIP ROLLERS

are opened and closed by the ROLLER ACTUATOR MOTOR. The bottom pair

does not open.

• FILM GUIDES - To be supplied

• IDLER ROLLERS - To be supplied

• ACCUMULATOR - This TRAY “attaches” to the bottom of the REGISTRATION

ASSEMBLY. It catches the film sheet at the end of the down path, before it is

moved upward to the EXPOSURE TRANSPORT.

• TRANSPORT MOTOR - M8: Operates the 4 DRIVE ROLLERS.

• ROLLER ACTUATOR MOTOR - M9: Opens and closes the top 3 NIP

ROLLERS.

• ACTUATOR HOME SENSOR - S11: Indicates if the NIP ROLLERS are open or

closed.

• CENTERING MOTOR - M7: Operates the CENTERING FINGERS.

• CENTERING MOTOR HOME SENSOR - S10: Provides a signal when the

CENTERING FINGERS are in the home position. Home is the fully extended

position.

• CENTERING FINGERS - The 2 CENTERING FINGERS move in from each

side to center the film within the REGISTRATION AY.

• ACCUMULATOR SENSOR - S9: to be supplied

• FILM REGISTRATION BOARD - Controls the Film Registration MOTORS.

Page 37

30JUL07

MICRO

PROCESSOR

MOTOR

DRIVER

MOTOR

DRIVER

MOTOR

DRIVER

FILM REGISTRATION BOARD

Film Registration

Application Program

8F2924

Page

37 of 72

THEORY GUIDE Film Registration Assembly

Electrical Components

Figure 10 FILM REGISTRATION Block Diagram

Figure 10 shows the electrical components in the FILM REGISTRATION

SUBSYSTEM.

The MICROPROCESSOR runs the film registration application. With commands

from the MCS and inputs from the 3 SENSORS, the application operates the 3

MOTORS to control the film registration process.

Page 38

30JUL07

8F2924

Page

38 of 72

THEORY GUIDE Film Registration Assembly

HOW THE REGISTRATION SUBSYSTEM FUNCTIONS

The following sequence shows the main steps in the film registration process. This

process is controlled by the application program in the MICROPROCESSOR on

the FILM REGISTRATION BOARD.

1. The MCS sends a “Film Coming” command to the FILM REGISTRATION

BOARD. This command includes:

- Film size

- Film DRAWER

2. The leading edge of film is transported from the PICKUP and enters the FILM

REGISTRATION AY.

3. The leading edge of film contacts the LEFT FILM GUIDE and moves down into

the top pair of DRIVE ROLLERS.

4. The TRANSPORT MOTOR runs at full speed in the down direction.

5. The ROLLER ACTUATOR MOTOR closes the top 3 NIP ROLLERS.

6. The TRANSPORT MOTOR runs in the down direction until film is clear of the

PICKUP.

7. The TRANSPORT MOTOR stops with the film in the ACCUMULATOR.

8. The TRANSPORT MOTOR runs at full speed in up direction.

9. The ACTUATOR MOTOR opens the 3 NIP ROLLERS.

10. The TRANSPORT ROLLERS run at low speed.

11. The CENTERING MOTOR moves the CENTERING FINGERS in to center the

film.

12. The TRANSPORT MOTOR stops and the NIP ROLLERS close.

13. The application reports “Centering” completed to the MCS.

14. The MCS sends a “Transport” command to the FILM REGISTRATION BOARD.

15. TRANSPORT MOTOR runs until the leading edge of film is in the EXPOSURE

TRANSPORT ROLLER.

16. ACTUATOR MOTOR opens the NIP ROLLERS.

17. TRANSPORT MOTOR stops.

Page 39

THEORY GUIDE Film Registration Assembly

30JUL07

8F2924

Page

39 of 72

18. The application notifies the MCS that “Transport” is completed.

Film registration is complete. Film motion is now controlled by the EXPOSURE

TRANSPORT.

Page 40

30JUL07

OPTICS AY

ISOLATION

PLATE

EXPOSURE

TRANSPORT AY

8F2924

Page

40 of 72

THEORY GUIDE OPTICS/EXPOSURE TRANSPORT ASSEMBLY

Section 8: OPTICS/EXPOSURE TRANSPORT ASSEMBLY

The OPTICS/EXPOSURE TRANSPORT ASSEMBLY has 3 main parts, the OPTICS AY, the

EXPOSURE TRANSPORT AY and the ISOLATION MOUNT.

Figure 11

• The OPTICS AY produces a scanning laser beam that exposes 1 line on the film. Each

scan is one line of an image. See OPTICS AY on Page 41.

• The EXPOSURE TRANSPORT moves the film past the scanning line to expose an image.

See EXPOSURE TRANSPORT AY on Page 50.

• The main purpose of the ISOLATION MOUNT is to prevent image artifacts caused by

external vibration or vibration produced within the IMAGER. See ISOLATION MOUNT on

Page 58.

Page 41

30JUL07

BPM/SOS BOARD

Scanning Line

8F2924

Page

41 of 72

THEORY GUIDE OPTICS ASSEMBLY

Section 9: OPTICS ASSEMBLY

The OPTICS AY receives digital image data from the DRE, converts this data to a scanning

laser beam that exposes film “line-by-line” when it is moved past the scanning line. Unlike

other DryView IMAGERS, the scanning is one-dimensional. The laser beam moves left to

right but does not move up or down. The film is moved past the scanning line by the

EXPOSURE TRANSPORT to expose a page.

None of the components in the OPTICS AY are field replaceable. If a malfunction occurs in

either the OPTICS or ELECTRONICS, the OPTICS AY is replaced.

Internal Configuration

The OPTICS AY has both OPTICAL COMPONENTS and CIRCUIT BOARDS. The following

figure shows the OPTICAL COMPONENTS and 1 of the 3 CIRCUIT BOARDS in the OPTICS

AY. The other BOARDS, the DATAPATH BOARD and LASER DRIVER BOARD are on the

bottom of the AY, protected by a COVER.

Figure 12 OPTICS AY - Top View, Cover Removed

Page 42

30JUL07

Modulated Analog

Image Signal - from

LASER DRIVER BOARD

LASER DIODE - on the

INPUT OPTICS

POLYGON

MIRROR

BPM/SOS

BOARD

BEAM

SPLITTER

Scan Line

AT T E N U AT O R F I LT E R

LASER DRIVER BOARD

8F2924

Page

42 of 72

THEORY GUIDE OPTICS ASSEMBLY

OPTICAL COMPONENTS

Figure 13 shows the LENSES, MIRRORS and other OPTICAL COMPONENTS in the

OPTICS AY. The only moving parts are the POLYGON MIRROR, the SPINNER MOTOR (not

shown), the ATTENUATOR FILTER, and the ATTENUATOR MOTOR (not shown).

Figure 13

Figure 14 shows another view of scanning LENSES and MIRRORS.

Page 43

THEORY GUIDE OPTICS ASSEMBLY

Film

Film

Direction

PHOTO

SENSOR

BPM/SOS

BOARD

BEAM

SPLITTER

30JUL07

8F2924

43 of 72

Figure 14

Page

Page 44

THEORY GUIDE OPTICS ASSEMBLY

LASER DIODE

(on LASER DRIVER

POLARIZING

CUBE

FOLD

MIRROR

BEAM

SPLITTER

AT TE NUAT OR

FILTER

Feedback

Beam - To

LASER DRIVER

BOARD

Analog Image

COLLIMATOR

Signal

BOARD)

CYLINDER

LENSES

SPHERICAL

LENS

30JUL07

8F2924

Page

44 of 72

Figure 15 shows the INPUT OPTICS that generates and shapes the laser beam.

Figure 15 Input OPTICS

The LASER DIODE, located on the LASER DRIVER BOARD, emits a beam of light. The

COLLIMATOR converts the beam to a “more-nearly” parallel beam.

The image signal that drives the LASER DIODE is an analog version of the pixel stream that

represents 1 line of the image. This input signal changes the power of the laser beam when it

scans across the film.

A small fraction of the laser beam is sent back to a PHOTO SENSOR on the LASER

DRIVER BOARD by the BEAM SPLITTER. This feedback is used to “stabilize” the laser drive

circuits.

Page 45

THEORY GUIDE OPTICS ASSEMBLY

30JUL07

8F2924

Page

45 of 72

The ATTENUATOR is a “variable-density” FILTER that is moved in the laser beam path to

change the power of the laser beam. An ATTENUATOR MOTOR and DRIVE MECHANISM,

controlled by the BEAM POWER MONITOR (BPM) BOARD, moves the ATTENUATOR. An

ATTENUATOR HOME SENSOR that connects to the BPM BOARD indicates when the

ATTENUATOR is positioned at the home position.

OPTICS AY ELECTRONICS

The OPTICS ELECTRONICS has 4 CIRCUIT BOARDS.

• DATA PATH BOARD (DPB)

• LASER DRIVER BOARD

• BEAM POWER MONITOR/ START OF SCAN BOARD (BPM\SOS BOARD)

• START OF PAGE BOARD (SOP BOARD)

The first 3 BOARDS are in the OPTICS AY. The SOP BOARD is located in the EXPOSURE

TRANSPORT and, unlike the other 3 BOARDS, can be replaced in the field.

DATAPATH BOARD - This BOARD has 3 main functions:

• It provides the path for image data from the DRE to the OPTICS AY.

• It connects the DRE to the I2C bus that is shared by all of the MICRO BOARDS.

• It drives the SPINNER MOTOR for the POLYGON MIRROR in the OPTICS AY.

Figure 16 is a simplified block diagram of the DATAPATH BOARD.

Page 46

THEORY GUIDE OPTICS ASSEMBLY

To LASER

DRIVER

BOARD

SOP

sos

FPGA

IMAGE

MEMORY

D-to-A

Converter

USB

CONTROLLER

MICRO

PROCESSOR

and

Image data

and commands

USB

DRE

DATA PAT H BO A RD

To/From all MICRO BOARDS

SPINNER

MOTOR

BPM/SOS BOARD

SOP SENSOR

I2C BUS

Code

FLASH

MEMORY

FPGA

CONFIG.

FLASH

MEMORY

Analog LASER

Drive Signal

30JUL07

8F2924

Page

46 of 72

Figure 16

The DATAPATH BOARD connects to the USB port on the DRE. The DRE sends both image

data and commands across the USB interface. A CONTROLLER on the BOARD does a

translation between the USB protocol and the I2C protocol. The DRE sends commands to the

MICRO BOARDS on the USB /I2C path and the MICRO BOARDS return status information

to the DRE on this path.

The DATAPATH BOARD has MEMORY for 1 image. When the DRE sends an image, it is

placed in the image MEMORY. Each line of the image is then read from MEMORY. A

DIGITAL-TO-ANALOG CONVERTER changes each pixel to an analog voltage value. This

changing voltage controls the power of the LASER when the beam scans across the film.

The FPGA (“Field Programmable Gate Array”) is a complex circuit chip that is programmed to

write an image into the IMAGE MEMORY and then read it during the “imaging” process.

Page 47

THEORY GUIDE OPTICS ASSEMBLY

30JUL07

8F2924

Page

47 of 72

SOP (START OF PAGE) BOARD - This BOARD has a PHOTOSENSOR and an AMPLIFIER.

It provides a film position indication when the leading edge of the film crosses the scanning

laser beam. When the film blocks the beam from reaching the PHOTOSENSOR, the SOP

BOARD sends a signal to the DATAPATH BOARD to start exposure of the film.

BPM/SOS (BEAM POWER MONITOR/START OF SCAN) BOARD - This BOARD has 4

functions:

• It detects when the laser beam is at the beginning of the scan and sends a start-of-scan

pulse to the DATAPATH BOARD.

• It samples the power level of the laser beam and sends a power level reading to the MCS

when asked for.

• It controls the laser beam ATTENUATOR MECHANISM based on commands from the

MCS.

• It measures the laser beam drive voltage and reports the value to the MCS when asked

for.

This BOARD has a PHOTOSENSOR that is positioned at the start of the laser beam scan

path. This SENSOR detects the start of a scan and is also used to measure the power level

of the laser beam. The BOARD connects to the ATTENUATOR MOTOR and the

ATTENUATOR HOME POSITION SENSOR. It has a MICROPROCESSOR that

communicates with the MCS on the I2C BUS and runs the application software that controls

the functions of the BOARD.

LASER DRIVER BOARD - This BOARD has the LASER DIODE that emits the laser beam

used to expose film. It has electrical circuits to drive the LASER DIODE and a

PHOTOSENSOR that receives a feedback beam “split off” from the main laser beam. The

feedback is used to “stabilize” the laser drive circuits. This BOARD receives DC power and

image data from the DATAPATH BOARD. For each line in the image, the DATAPATH BOARD

sends an analog laser drive signal that represents the image.

“Imaging” Process

In the “imaging” process the OPTICS assembly converts a digital image to an image on film.

Figure 17 shows the main ELECTRONICS and OPTICAL COMPONENTS in this process.

Page 48

THEORY GUIDE OPTICS ASSEMBLY

LASER

DRIVER

BOARD

SOP

sosFPGA

IMAGE

MEMORY

D-to-A

Converter

USB

CONTROLLER

MICRO

PROCESSOR

Image DATA

USB

DRE

DATAPATH BOARD

SOP SENSOR

BPM/SOS

BOARD

30JUL07

8F2924

Page

48 of 72

The digital image sent by the DRE is a collection of 14-bit pixel values that is organized into

image lines. Each line in the digital image is 1 scan line on film.

Figure 17

Before the “imaging” process begins:

• The POLYGON MIRROR is “spinning”.

• The LASER generates a beam that reaches the SOP SENSOR on each scan.

• The MCS has started the steps to pick up and transport a film to the IMAGING

ASSEMBLY. The EXPOSURE TRANSPORT will move the film past the scanning line at

the proper rate.

Page 49

THEORY GUIDE OPTICS ASSEMBLY

30JUL07

8F2924

Page

49 of 72

The steps in the “imaging” process are:

1. The DRE does 3 tasks at the same time:

- Sends data for 1 image across the USB channel.

- Samples the BEAM POWER MONITOR and sets the ATTENUATOR.

- Loads parameters in the FPGA (example, the number of lines and pixels in the

image).

2. The USB CONTROLLER moves the image data on to the IMAGE MEMORY through the

FPGA.

3. When the leading edge of film interrupts the laser beam, the START-OF-PAGE SENSOR

sends a signal to the FPGA.

4. The FPGA starts reading lines of data from the IMAGE MEMORY.

5. When the BPM/SOS BOARD detects the start of a scan, it sends a SOS pulse to the

FPGA.

6. When it receives a SOS pulse, the FPGA starts to send a line of pixels in a serial bit

stream to the “D-to-A” CONVERTER.

7. When the laser beam scans across the film, the “D-to-A” CONVERTER converts the

stream of pixels to an analog signal that represents the image line.

8. During the scan, the analog signal drives the LASER DIODE on the LASER DRIVER

BOARD. The power of the laser beam changes when the “amplitude” of the analog signal

changes.

9. Each time the FPGA detects an SOS pulse, the “D-to-A” conversion process repeats for

the next line of data.

Page 50

30JUL07

OPTICS AY

EXPOSURE

TRANSPORT AY

8F2924

Page

50 of 72

THEORY GUIDE EXPOSURE TRANSPORT AY

Section 10: EXPOSURE TRANSPORT AY

Function

The function of the EXPOSURE TRANSPORT AY is to move a sheet of film past the laser

scan line at a constant velocity and at a precise fixed distance from the MIRROR.

• Film velocity is 29.185 mm/sec (1.15 in./sec).

• Focal distance is 210 mm (8.26 in.) at the scan center.

Figure 18

Figure 19 is a larger view of the EXPOSURE TRANSPORT.

Page 51

THEORY GUIDE EXPOSURE TRANSPORT AY

ROLLER DRIVE

SHAFT

FILM-AT- ENTRANCE

ENTRANCE

NIP ROLLER

ENCODER

MOTOR - M12

DRIVE ROLLER

BELT

EXPOSURE TRANSPORT

BOARD

SENSOR

BELT

TENSIONER

30JUL07

8F2924

Page

51 of 72

Figure 19

Figure 20 shows the main parts in the EXPOSURE TRANSPORT.

Page 52

THEORY GUIDE EXPOSURE TRANSPORT AY

EXIT NIP

ROLLER AY

EXIT NIP

ROLLER MOTOR

ENTRANCE NIP

ROLLER AY

ENTRANCE NIP

ROLLER MOTOR

EXPOSURE

TRANSPORT

BOARD

ROLLER DRIVE

MOTOR, M12

SHAFT

ENCODER

EXIT DRIVE

ROLLER

ENTRANCE

DRIVE ROLLER

FILM

GUIDES

SOP/BPM

BOARD

BELT for

DRIVE ROLLER

ENTRANCE

Pivot Point

Pivot Point

30JUL07

8F2924

Page

52 of 72

Figure 20

How It Works

Figure 21 is a simplified view of the ROLLERS that move film through the EXPOSURE

TRANSPORT. The 2 DRIVE ROLLERS are operated by the ROLLER DRIVE MOTOR, M12.

The MOTOR connects directly to the shaft of the EXIT DRIVE ROLLER. The ENTRANCE

DRIVE ROLLER is operated by a BELT and PULLEY from the EXIT DRIVE ROLLER.

Page 53

THEORY GUIDE EXPOSURE TRANSPORT AY

EXIT NIP

ROLLER

EXIT DRIVE

ROLLER

Laser Beam

ENTRANCE NIP

ROLLER

FILM-AT-ENTRANCE

FILM

ENTRANCE DRIVE

ROLLER

To PROCESSOR

From REGISTRATION AY

SOP BOARD

SENSOR

SENSOR, S12

FILM GUIDE

FILM GUIDE

30JUL07

8F2924

Page

53 of 72

Each DRIVE ROLLER has a companion NIP ROLLER that is opened and closed by a

LINEAR STEPPER MOTOR. Film is moved upward when a NIP ROLLER closes and holds

film against the adjacent DRIVE ROLLER. The speed of the SERVO MOTOR and opening

and closing of the 2 NIP ROLLERS is controlled by software on the EXPOSURE

TRANSPORT BOARD.

Figure 21

Page 54

THEORY GUIDE EXPOSURE TRANSPORT AY

30JUL07

8F2924

Page

54 of 72

The following sequence occurs when a film is moved through the EXPOSURE TRANSPORT.

1. Before film arrives, the NIP ROLLERS are pre-set:

- The ENTRANCE NIP ROLLER is moved to the closed position.

- The EXIT NIP ROLLER is moved to a partially closed position.

2. Film is moved up to the EXPOSURE TRANSPORT by the REGISTRATION AY.

3. Film leading edge “passes” the FILM-AT-ENTRANCE SENSOR, S12. This starts a

software timer.

4. Film enters the ENTRANCE ROLLERS.

5. NIP ROLLERS in the REGISTRATION AY open after FILM-AT-ENTRANCE signal. Film

motion is now controlled by the EXPOSURE TRANSPORT.

6. The ENTRANCE ROLLERS drive the film upward.

7. Film leading edge blocks the laser beam at the SOP SENSOR, S13.

The SOP signal does not affect the EXPOSURE TRANSPORT but it does start the

exposure process when film is in the EXPOSURE TRANSPORT.

8. The scanning laser beam starts to expose the film.

9. The EXIT NIP ROLLER starts to close - 1.25 seconds after film reaches the FILM-AT-

ENTRANCE SENSOR.

10.The ENTRANCE NIP ROLLER starts to open partly - 1.75 seconds after film reaches the

FILM-AT-ENTRANCE SENSOR.

11.The EXIT ROLLERS drive film for the remainder of the exposure.

12.Film enters the PROCESSOR.

Film development begins as exposure continues in the EXPOSURE TRANSPORT.

13.Film trailing edge “passes” the FILM-AT-ENTRANCE SENSOR, S12. This starts a software

timer.

14.The EXIT NIP starts to open - 3.0 seconds after the trailing edge “passes” the FILM-AT-

ENTRANCE SENSOR, S12

15. ENTRANCE and EXIT NIP ROLLERS are moved “home” (full-open) and then pre-set in

preparation for the next film.

Page 55

30JUL07

S15

3 PHASE

MOTOR

DRIVER

Feedback

SHAFT

ENCODER

EXPOSURE TRANSPORT

DRIVE MOTOR

MOTOR

DRIVER

MOTOR

DRIVER

ENTRANCE NIP

MOTOR

EXIT NIP

MOTOR

3 PHASE

DRIVE

BRIDGE

M12

M10

M11

MOTOR

CONTROL

ELECTRONICS

MICROPROCESSOR

RAM

MEMORY

256K x 16

EEPROM

MEMORY

64K

NVRAM

I2C Bus

EXIT ROLLER

SENSOR

ENTRANCE

ROLLER

SENSOR

FILM AT

ENTRANCE

SENSOR

EXPOSURE TRANSPORT BOARD

S14

S12

MCS Commands

Status

DSP and

CPLD

T

o/From

the PDB

8F2924

Page

55 of 72

THEORY GUIDE EXPOSURE TRANSPORT AY

EXPOSURE TRANSPORT CONTROL SYSTEM

The EXPOSURE TRANSPORT BOARD (ETB) controls the functions of the EXPOSURE

TRANSPORT. Figure 24 shows how the ETB connects to the external components it controls.

Figure 22

ETB - The ETB controls the speed of the EXPOSURE TRANSPORT DRIVE MOTOR, M12

and also controls the 2 linear STEPPER MOTORS, M10 and M11, that open and close the

ENTRANCE and EXIT NIP ROLLERS. Application software that runs in the

MICROPROCESSOR and in the DSP (DIGITAL SIGNAL PROCESSOR) provides the control

intelligence.

The MOTOR CONTROL ELECTRONICS has 2 complex microcircuits: a DSP and a CPLD

(COMPLEX PROGRAMMABLE LOGIC DEVICE). The DSP has a MICROPROCESSOR and

runs a part of the application software.

There are “testpoints” and LEDs on the ETB. Some of these are useful for trouble shooting.

See the FUNCTIONAL BLOCK DIAGRAMS for a description of the test points and LEDs.

Page 56

THEORY GUIDE EXPOSURE TRANSPORT AY

NIP ROLLER

MOTORS

EXIT NIP

ENTRANCE NIP

Pivot Point

Pivot Point

FLAG

FLAG

EXIT ROLLER

ENTRANCE ROLLER

ROLLER - open

ROLLER - closed

SENSOR, S14

SENSOR, S15

Film

ETB

30JUL07

8F2924

Page

56 of 72

EXPOSURE TRANSPORT DRIVE MOTOR and SHAFT ENCODER - This 3-phase SERVO

MOTOR is “powered” by a 3-phase AC voltage generated by the MOTOR CONTROL

ELECTRONICS. MOTOR speed is controlled by controlling the frequency of the AC MOTOR

voltage. When the MOTOR turns, the SHAFT ENCODER, mounted on the MOTOR SHAFT,

provides a stream of pulses, 2000 pulses per revolution. Feedback from the SHAFT

ENCODER is used in a closed loop control system to monitor and control the speed of the

SERVO MOTOR.

NIP ROLLER MOTORS - These 2 MOTORS are linear STEPPER MOTORS that open and

close the NIP ROLLERS. These MOTORS can move the NIP ROLLERS to the fully opened

“Home” position, the fully closed position or any position in between. Figure 23 shows a

simplified diagram of the mechanism that opens and closes the NIP ROLLERS

Figure 23 NIP ROLLER MECHANISM

FILM AT ENTRANCE SENSOR, S12 - This reflective SENSOR is located on the film guide at

the entrance to the EXPOSURE TRANSPORT BOARD. The SENSOR emits a light beam and

also has a detector to sense reflected light. The output of the SENSOR is high when no light

Page 57

THEORY GUIDE EXPOSURE TRANSPORT AY

30JUL07

8F2924

Page

57 of 72

is reflected back. When film enters the light path, light is reflected back to the SENSOR

causing the output to “go” low. The application software on the ETB uses the output of this

SENSOR to time the opening and closing of the NIP ROLLERS.

ENTRANCE ROLLER SENSOR, S14 - This SENSOR indicates when the ENTRANCE NIP

ROLLER is at the full open position. The SENSOR BODY is mounted on the ETB. When the

ENTRANCE NIP ROLLER is fully open. a flag on the NIP ROLLER mechanism blocks the

light beam in the SENSOR BODY, causing the output to change state.

EXIT ROLLER SENSOR, S15 - This SENSOR indicates when the EXIT NIP ROLLER is at

the full open position. The SENSOR BODY is located on the ETB and operates identically to

the ENTRANCE ROLLER SENSOR.

Page 58

30JUL07

8F2924

Page

58 of 72

THEORY GUIDE ISOLATION PLATE

Section 11: ISOLATION PLATE

To Be Supplied

Page 59

30JUL07

DRUM

FLATBED

COOLING

SECTION

PREVENTATIVE

MAINTENANCE

MODULE

FILM

PAT H

SLACK

LOOP

FROM

EXPOSURE

ROLLERS

TRANSPORT

8F2924

Page

59 of 72

THEORY GUIDE THERMAL PROCESSOR

Section 12: THERMAL PROCESSOR

Purpose

The purpose of the PROCESSOR is to:

• Develop the film image.

• Collect vapors (out-gasses) released when the film is heated.

This PROCESSOR is different from the PROCESSORS in all other DryView

IMAGERS. In this PROCESSOR film is developed in 2 stages. The DRUM first

rapidly heats the film to processing temperature. The film then moves into the

heated FLATBED AREA to complete the process. Most vapors are released after

the film is transported from the DRUM, which accounts for less FAZ on the DRUM

than in other DryView IMAGERS.

Figure 24 PROCESSOR - Side View

Page 60

THEORY GUIDE THERMAL PROCESSOR

30JUL07

8F2924

Page

60 of 72

Because film remains on the DRUM only to “pre-heat”, the DRUM moves faster

than in other DryView IMAGERS.

The PROCESSOR is on a DRAWER that pulls out. Using the SERVICE SWITCH,

service technicians can operate the PROCESSOR when it is extended.

Main Components

• SLACKLOOP AY- A set of 3 ROLLERS at the entrance to the PROCESSOR

that make a loop in the film to prevent tension in the film between the

PROCESSOR and the EXPOSURE TRANSPORT. The purpose is to prevent

the film from sending vibration from the DRUM back to the EXPOSURE

TRANSPORT.

• DRUM - Heats the film rapidly to processing temperature, 129° C ± 0.1° C.

• FLATBED - Keeps processing temperature, about 1° C less than the

temperature of the DRUM, to develop the image.

• COOLING SECTION - Removes heat from the film to stop image development

and harden the base.

• PREVENTIVE MAINTENANCE MODULE (PMM)- Captures and condenses

vapors released from the film when heated.

• PROCESSOR CONTROL BOARD (PCB) - This CIRCUIT BOARD has 2

MICROPROCESSORS and other ELECTRONICS that control HEATERS,

FANS and transport MOTORS in the PROCESSOR. Temperature “setpoints”

and other parameters are stored in NVRAM.

• PROCESSOR application software - Runs in the 2 MICROPROCESSORS on

the PCB to control HEATERS, cooling FANS and the 2 transport MOTORS in

the PROCESSOR.

Transport Within the PROCESSOR

Film is moved through the PROCESSOR by the rotating DRUM and ROLLERS in

the FLATBED and COOLING SECTION. A 24 V DC STEPPER MOTOR operates

the DRUM. A second 24 V DC STEPPER MOTOR operates the ROLLERS in the

FLATBED and COOLING SECTION. Both MOTORS connect to MOTOR DRIVERS

on the PCB. The speed of both MOTORS is controlled by the PROCESSOR

Page 61

THEORY GUIDE THERMAL PROCESSOR

30JUL07

8F2924

Page

61 of 72

CONTROL BOARD based on speed “setpoints” in NVRAM. Transport time through

the PROCESSOR is 22.5 seconds which is a throughput of 160 films per hour.

SLACKLOOP AY

The SLACKLOOP AY is a set of 3 ROLLERS before the entrance to the DRUM

that make a slight loop in the film. The loop is a “shock absorber” between the

EXPOSURE TRANSPORT and the PROCESSOR. It isolates the EXPOSURE

TRANSPORT from impact when the leading edge of the film contacts the DRUM

and it prevents the film from sending vibration from the PROCESSOR back to the

EXPOSURE TRANSPORT. The SLACKLOOP AY has no MOTORS or

ACTUATORS.

DRUM

The DRUM HAS 3 heat zones. Each zone includes a 120 V AC HEATER and a

RTD TEMPERATURE SENSOR. SLIP RINGS on the SHAFT of the DRUM provide

electrical connections to the PCB.

To control temperature of the DRUM, the PROCESSOR application software scans

the RTD SENSORS and switches 120 V AC power to the 3 HEATERS ON and

OFF to keep the temperature “setpoints” in NVRAM.

FLATBED

A DRIVE TRAIN sends power from the DRUM MOTOR to the DRUM.

A DRUM COVER provides access for cleaning the DRUM and clearing film jams.

The FLATBED is a covered area with HEATERS above and below the film path.

There are 8 heat zones with 8 RTD TEMPERATURE SENSORS. In the FLATBED

BASE below the film there are 9 HEATERS and 6 RTDs. Above the film, in the

FLATBED COVER, there are 2 HEATERS and 2 RTDs. For “over-temperature”

protection there are 3 THERMAL CUTOFF DEVICES in the FLATBED BASE and

2 in the COVER.

The PROCESSOR application software scans the RTD SENSORS and switches

120 V AC power to the 8 heat zones ON and OFF to keep processing

temperature. If a high temperature malfunction occurs, one of the THERMAL

Page 62

THEORY GUIDE THERMAL PROCESSOR

30JUL07

8F2924

Page

62 of 72

CUTOFFS in the FLATBED opens. This interrupts 120 V AC power to all

HEATERS in the FLATBED and DRUM.

COOLING SECTION

Film is cooled by contact with “hollow” ROLLERS in the COOLING SECTION. The

TEMPERATURE MICROPROCESSOR controls 2 FANS that blow cooling air

through the “hollow” ROLLERS to remove the heat. Temperature is controlled by

changing the speed of the 2 FANS.

PROCESSOR CONTROL BOARD

The PROCESSOR CONTROL BOARD (PCB) provides:

• Power and temperature control for the 3 HEATER zones on the DRUM.

• Power and temperature control for the 6 HEATER zones in the FLATBED

PLATE.

• Power and temperature control for the 2 HEATER zones in the FLATBED

COVER.

• Power and control for the 2 STEPPER MOTORS.

• Power and control for 2 COOLING FAN MOTORS.

• Power and control for 4 DC FAN MOTORS: the MAKEUP AIR FAN, the HEAT

EXCHANGER FAN, and 2 FILTER FANS.

• Power for a DC FAN that runs to cool the PROCESSOR CONTROL BOARD.

The PCB has 2 MICROPROCESSORS. The TEMPERATURE

MICROPROCESSOR controls the temperatures of the 11 heat zones and also

controls 6 FANS in the PROCESSOR. The main application software runs in this

MICROPROCESSOR. The software for the 2 TRANSPORT MOTORS is in the

MOTOR MICROPROCESSOR. Both MICROPROCESSORS are connected to the

I2C bus and to a shared NVRAM, also on the I2C bus. The

MICROPROCESSORS communicate with each other on the I2C bus and through

the shared NVRAM.

Each heat zone has a RESISTANCE TEMPERATURE DEVICE (RTD) and 1 or

more HEATER ELEMENTS “bonded” to an “aluminum substrate”. The RTD senses

Page 63

THEORY GUIDE THERMAL PROCESSOR

30JUL07

8F2924

Page

63 of 72

the temperature of the “aluminum base” by changing the electrical resistance. The

resistance is measured by switching a “known” current through the RTD and

measuring the voltage across it.

A MULTIPLEXER on the PCB connects the RTDs for the 11 heat zones to the

MICROPROCESSOR. Through the MULTIPLEXER, the MICROPROCESSOR

scans the RTD voltages. An ANALOG-TO-DIGITAL CONVERTER on the BOARD

converts each analog voltage to a digital temperature value. The application

software compares the temperature value for each zone with the temperature

“setpoint” for that zone, stored in NVRAM. The application then switches the

corresponding HEATERS ON or OFF in response to the differences between the

measured temperatures and temperature “setpoints”. SOLID STATE RELAYS

(SSRs) on the BOARD, controlled by the MICROPROCESSOR, switch 120 V AC

current to the HEATERS.

An additional RTD at the entrance of the DRUM senses a decrease in temperature

caused by heat transfer to the film during periods of high usage. In response, the

application software adjusts temperature “setpoints” for the DRUM upward to offset

for the heat loss.

Page 64

THEORY GUIDE THERMAL PROCESSOR

SOLID STATE RELAYS (SSRs)

SSR

CONTROL

LINES

COOLING

SECTION

FLATBED

DRUM and

SLIP RING

AY

Power to 8

HEATERS

Power to 3

HEATERS

Analog to

Digital Converter

Cooling

Zone RTD

Flatbed

RTDs (8)

DRUM

RTDs (3)

MULTIPLEXER

Analog

Voltage

(Temperature)

Digital

Voltage

(Temperature)

Scans RTDs

DRUM

STEPPER MOTOR

M13

MOTOR

DRIVER

FLATBED/

COOLING SECTION

STEPPER MOTOR

M14

MOTOR

DRIVER

NVRAM

Stores

Parameters

I2C Bus

COOLING SECTION

FAN PWM DRIVER

FAN ON/OFF

CONTROL

FAN

FAN

120 VAC Input

Power

MICROPROCESSOR

Temperature

MICROPROCESSOR

Transport

COOLING FANS

FAN

FAN

FAN

FAN

PROCESSOR CONTROL BOARD

I2C - To/From

DATAPATH BOARD

30JUL07

8F2924

Page

64 of 72

Figure 25 PROCESSOR CONTROL BOARD

The TEMPERATURE MICROPROCESSOR controls the HEATERS and 6 of the 7

FANS in the COOLING SECTION. See AIRFLOW in the PROCESSOR.

.

Page 65

THEORY GUIDE THERMAL PROCESSOR

30JUL07

8F2924

Page

65 of 72

The second MICROPROCESSOR controls the 2 transport MOTORS in the

PROCESSOR.

There are a number of LED INDICATORS on the BOARD that show the status of

the THERMAL CUTOUTS, status of HEATERS and a number of other conditions.

See the 6800 FUNCTIONAL DIAGRAMS for a description of the LEDs

AIRFLOW in the PROCESSOR

The graphic on Page 66 shows the 7 FANS that move air through the

PROCESSOR. All of these FANS, except the CIRCUIT BOARD FAN, are

controlled by the TEMPERATURE MICROPROCESSOR.

The 2 FILTER FANS and the MAKE-UP AIR FAN provide air flow through the

DRUM and FLATBED areas to remove vapors released when film is heated. The

vapors are condensed and collected in the PREVENTATIVE MAINTENANCE

MODULE (PMM). The FILTER FANS also pull air that has a low level of