Page 1

© EASTMAN KODAK COMPANY, 2005 HEALTH GROUP

Confidential

Restricted

Information

{Adjust/Replace}{Production}{Health Group}{ExternalAndInternal}

ADJUSTMENTS AND REPLACEMENTS

for the

Kodak DirectView CR 825/850 SYSTEMS

Service Codes: 5634, 4825

Important

Qualified service personnel must do these procedures.

Publication No. AR4825-1

10DEC05

Supersedes AR4825-1

21JUL04

H177_0500AC

Page 2

ADJUSTMENTS AND REPLACEMENTS

10DEC05

AR4825-1

Page

2 of 160

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be

liable for any loss or damage, including consequential or special damages, resulting from any

use of this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Table of Contents

Description Page

Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INTERLOCK SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

TOP COVER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

GALVO BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

GALVO ROTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

FOLD MIRROR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

COLLECTOR AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

INTERMEDIATE PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

CAM SENSOR BOARD A8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

CAM MOTOR AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

SLED CAM FOLLOWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

CLAMP BAR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

CASSETTE END STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

REAR CASSETTE SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

EXTRACTION BAR HOME POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

PLATE POSITIONING AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

RIGHT and LEFT PLUSH AY - Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

LEFT PLUSH AY - Vertical Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

INTERNAL BAR CODE READER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

CASSETTE LOAD CRADLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Replacements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

GALVO and BLOCK AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

OPTICS MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

PMT/DAS BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

PMTs and COLLECTOR AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Page 3

ADJUSTMENTS AND REPLACEMENTS

10DEC05

AR4825-1

Page

3 of 160

FOLD MIRROR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

CASSETTE HANDLING AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

CAM MOTOR AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

HOOK YOKE AY and HOOK YOKE BEARING. . . . . . . . . . . . . . . . . . . . . . . . . . . 103

IDLER ROLLER AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

CASSETTE DRIVE AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

CASSETTE DRIVE ROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

CASSETTE DRIVE MOTOR AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

LEFT PLUSH AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

RIGHT PLUSH AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

EXTRACTION BAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

SLOW SCAN AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

EXTRACTION BAR REFERENCE SENSOR S9 . . . . . . . . . . . . . . . . . . . . . . . . . . 119

PLATE PRESENT SENSOR S5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

COIL BOARD A7, ENCODER and SLOW SCAN ROTOR . . . . . . . . . . . . . . . . . . 122

PLATE POSITIONING AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

ERASE LAMP AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

HARD DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Additional Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Opening and Removing COVERS and PANELS . . . . . . . . . . . . . . . . . . . . . . . . . 139

Restoring the Purchased Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Restoring the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Setting the Laser Calibration Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Calibration for the CR 825/850 SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Page 4

10DEC05

AR4825-1

Page

4 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

Section 1: Adjustments

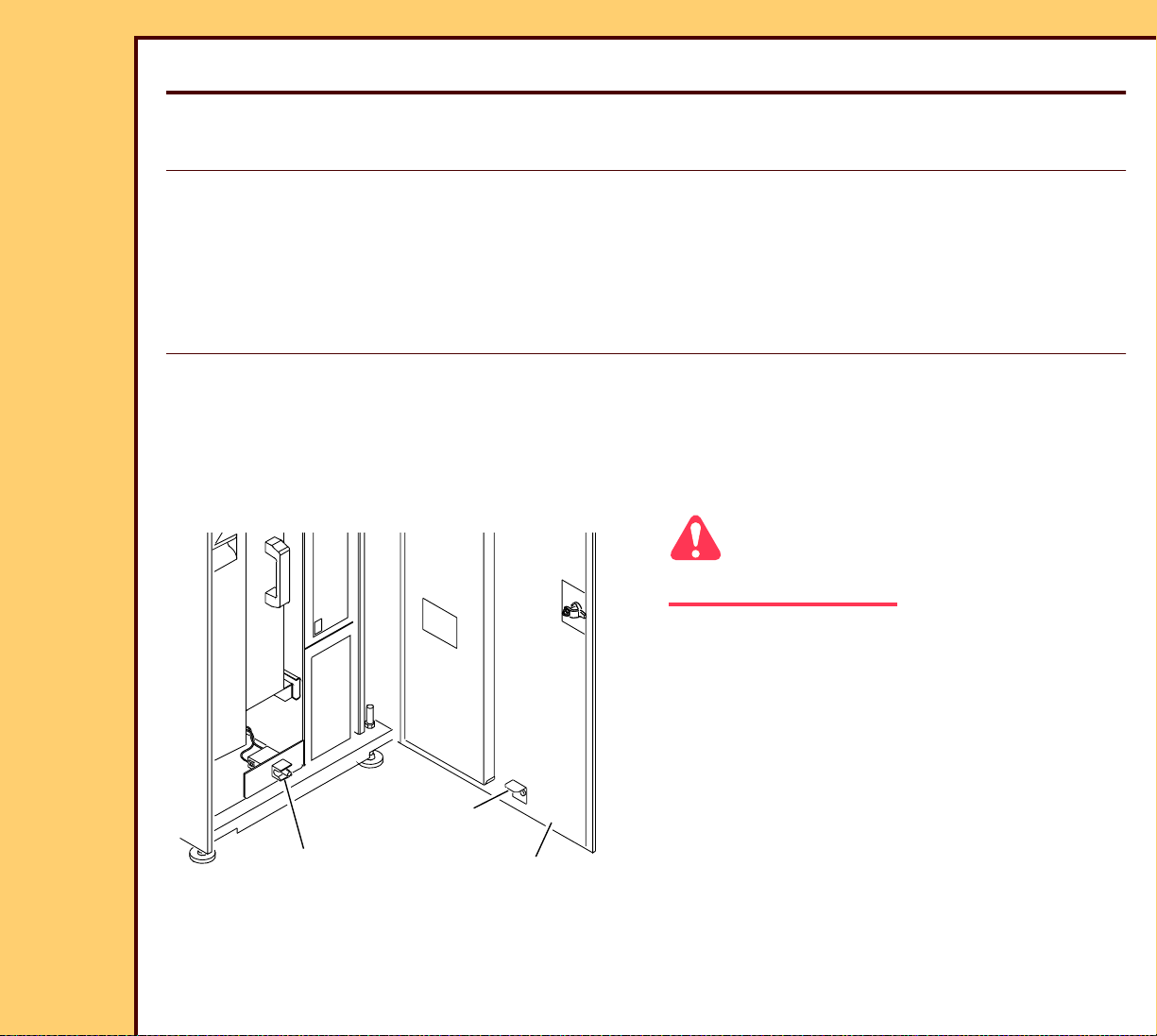

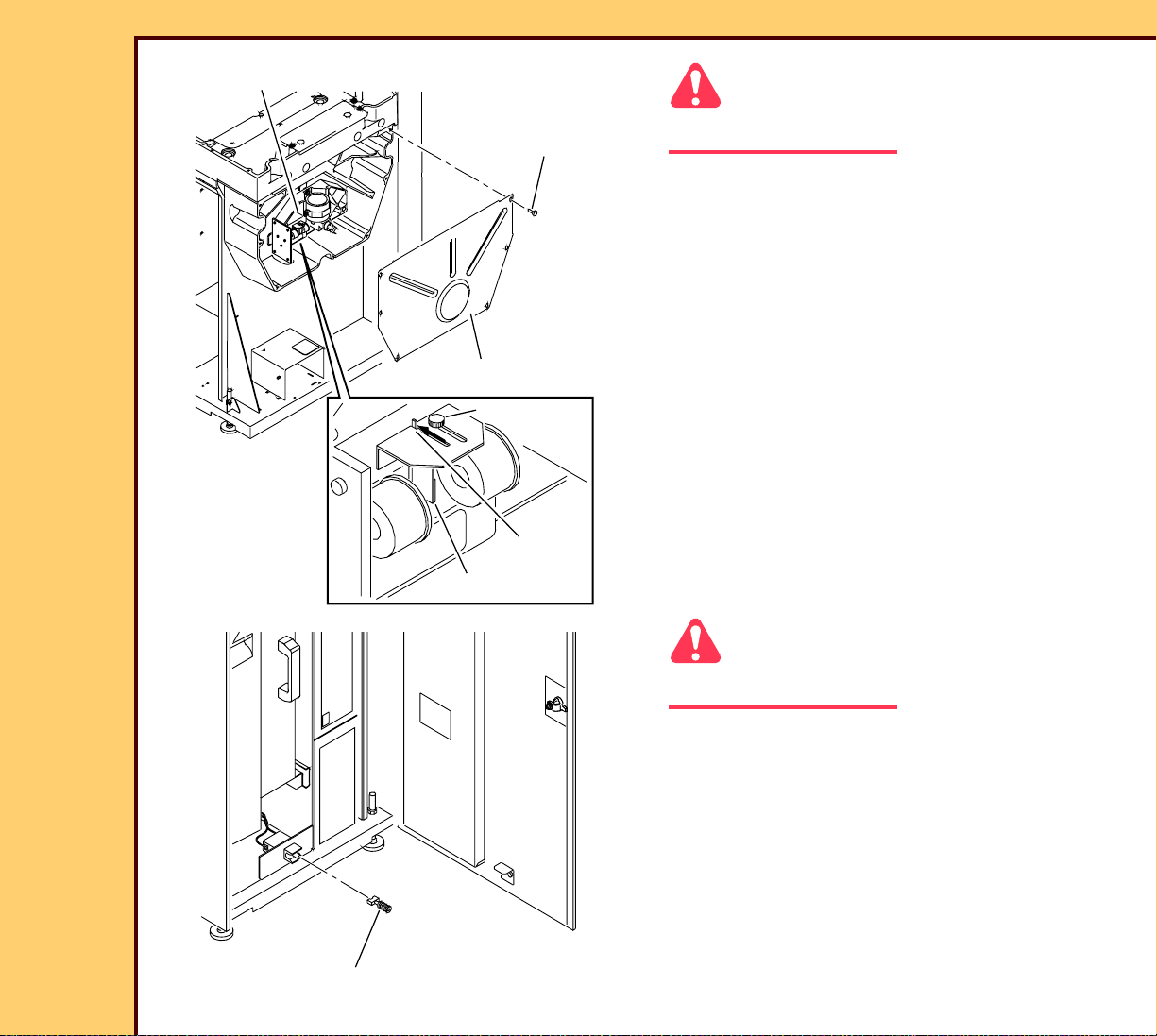

INTERLOCK SWITCH

Adjustment Specification

Purpose: To place the INTERLOCK ACTUATOR in the correct position.

Specification: The INTERLOCK ACTUATOR enters the center of the INTERLOCK

SWITCH when you close the FRONT DOOR.

Special Tools: None

Prerequisites:

None

To Check:

Caution

Dangerous Voltage

INTERLOCK

SWITCH

INTERLOCK

ACTUATOR

FRONT DOOR

H194_0043ACA

H194_0043AC

1 Open the FRONT DOOR.

2 Close the FRONT DOOR and observe

the INTERLOCK ACTUATOR entering

the INTERLOCK SWITCH.

3 Check that the INTERLOCK

ACTUATOR enters the center of the

INTERLOCK SWITCH.

Page 5

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

5 of 160

To Ad j u st :

INTERLOCK

ACTUATOR

Postrequisites:

2 SCREWS

FRONT DOOR

H194_0043ACB

H194_0043AC

1 Open the FRONT DOOR.

2 Loosen the 2 SCREWS.

3 Move the INTERLOCK ACTUATOR up

or down to the correct position.

4 Tighten the 2 SCREWS.

None

Page 6

10DEC05

AR4825-1

Page

6 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

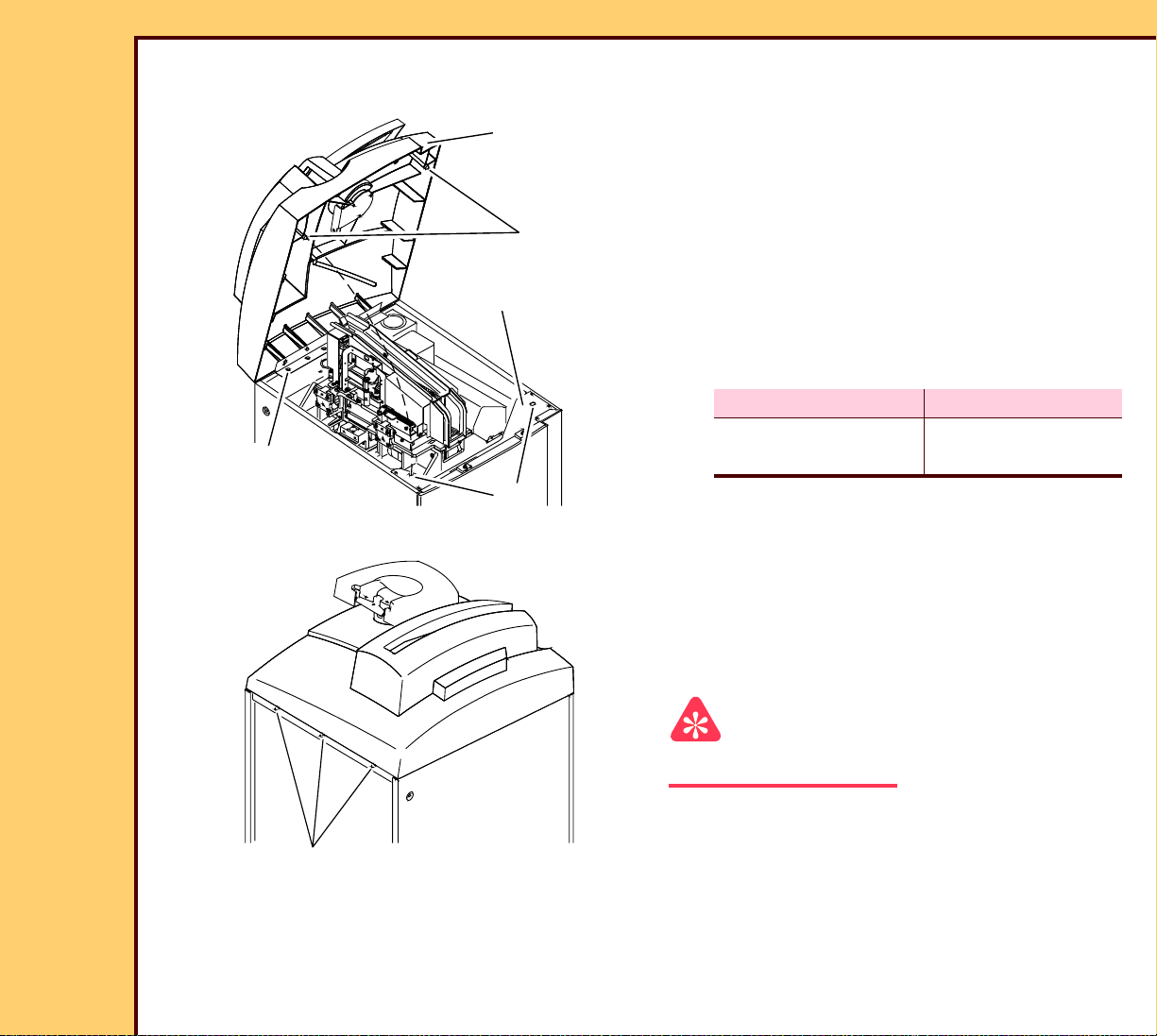

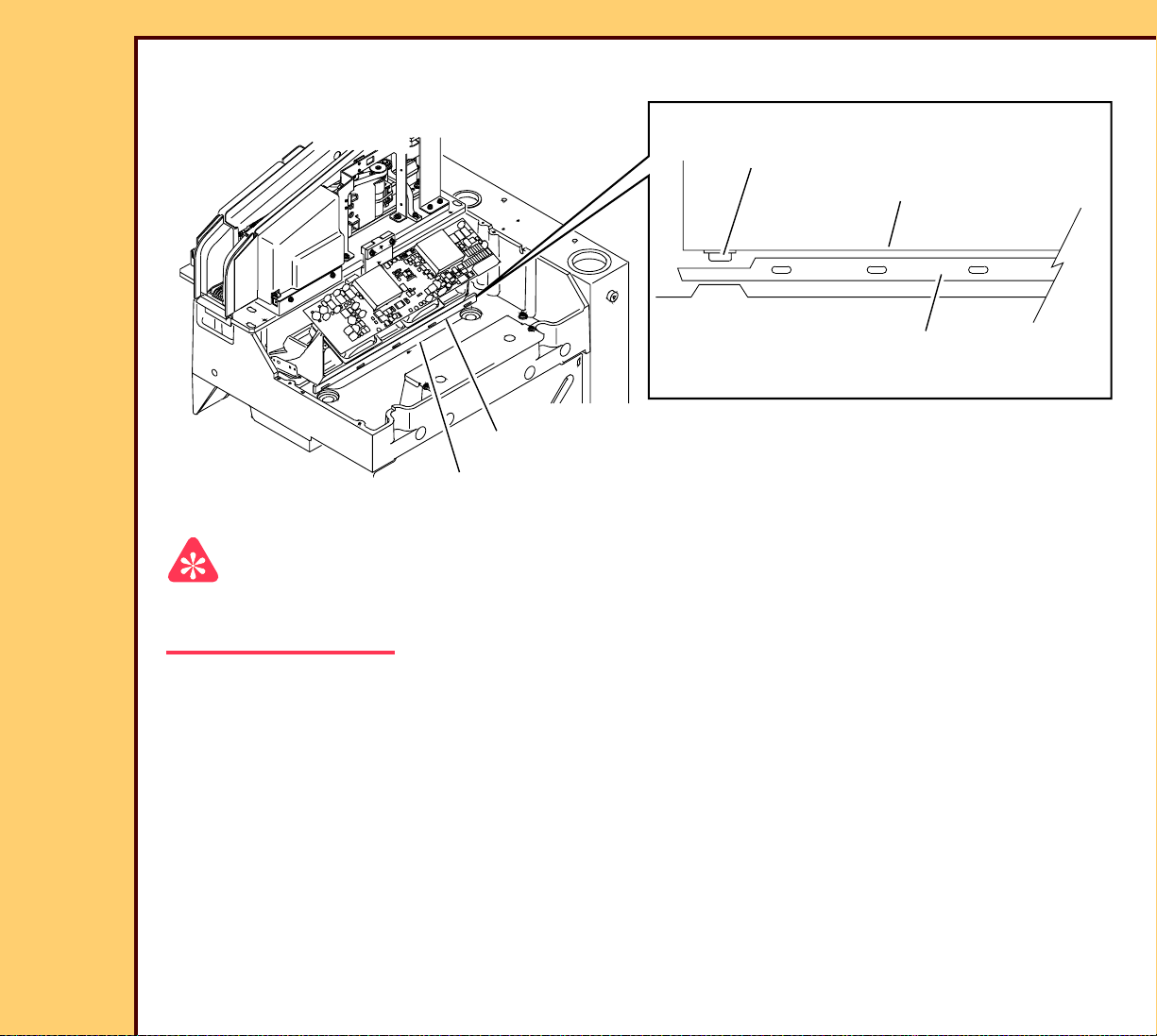

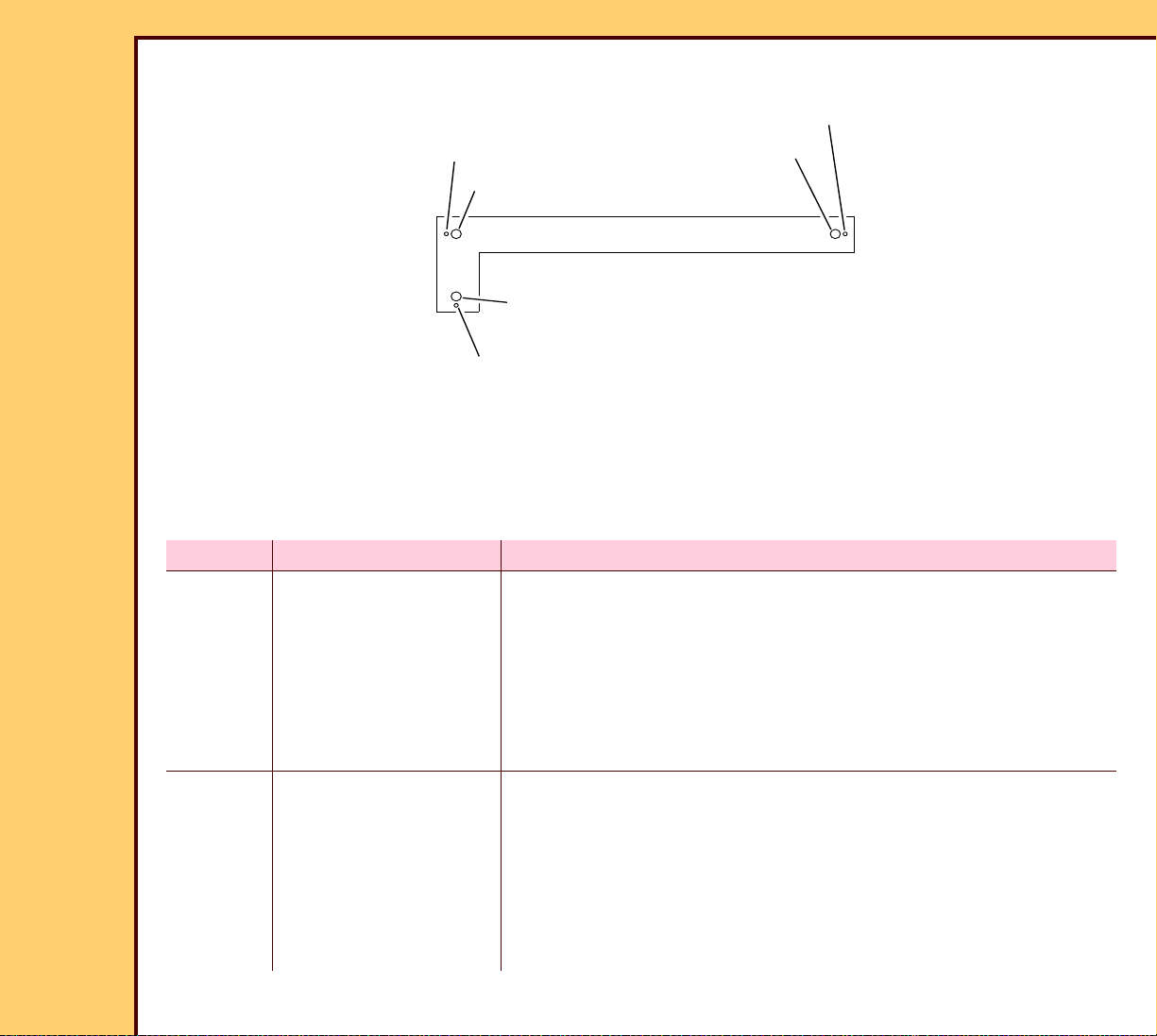

TOP COVER

Adjustment Specification

Purpose: To place the TOP COVER in the correct position.

Specification: When the TOP COVER is closed, the 2 PINS seat into the center of the

holes in the CROSSBRACE.

Special Tools: None

Prerequisites:

1 Adjust the INTERLOCK SWITCH.

To Check:

1 Open the FRONT DOOR.

TOP COVER

2 PINS

2 Open the TOP COVER.

3 Close the TOP COVER slowly and

observe the 2 PINS entering the holes

in the CROSSBRACE.

H194_0044ACA

H194_0044AC

CROSSBRACE

holes

4 Check that the 2 PINS seat into the

center of the holes in the

CROSSBRACE.

Page 7

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

7 of 160

To Ad j u st :

5 LOWER SCREWS

H194_0044ACB

H194_0044AC

TOP COVER

2 PINS

CROSSBRACE

holes

1 Open the TOP COVER.

2 Loosen the 5 LOWER SCREWS until

the TOP COVER can be moved with a

small force.

3 Close the TOP COVER.

4 Move the TOP COVER left or right until

the 2 PINS seat into the center of the

holes of the CROSSBRACE.

5 Can you make the adjustment?

No Yes

Continue with

Step 6.

Advance to

Step 10.

6 Remove the REAR PANEL.

7 Loosen the 3 SCREWS.

8 Move the TOP COVER left or right until

the 2 PINS seat into the center of the

holes of the CROSSBRACE.

3 SCREWS

Postrequisites:

None

H194_0051ACA

H194_0051AC

9 Tighten the 3 SCREWS.

Important

Do not move the TOP COVER left or right

10 Carefully lift the TOP COVER.

11 Tighten the 5 LOWER SCREWS.

Page 8

10DEC05

AR4825-1

Page

8 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

GALVO BOARD

Adjustment Specification

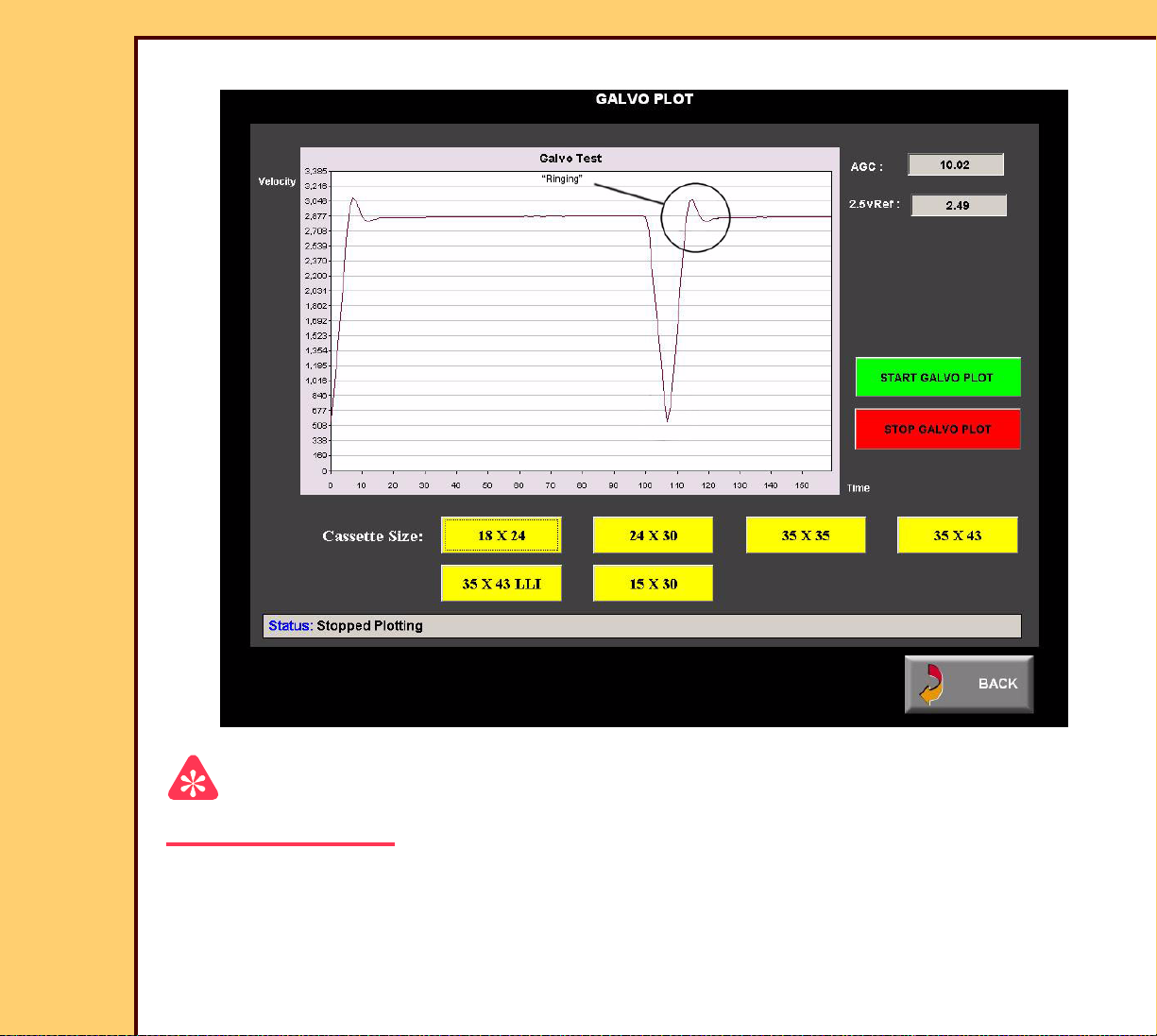

Purpose: To set the AUTOMATIC GAIN CONTROL (AGC), and the “Velocity Profile”.

Specification: • The AGC voltage on the “Galvo Plot” screen is 8.2 V DC - 11.9 V DC

with the correct “Velocity Profile”.

• No “Ringin g” in the “Wave Form”.

Special Tools: • TOOL TL-5726

• DIGITAL VOLTAGE METER (DVM) TL-3386

Prerequisites:

1 Do Setting the Laser Calibration Voltage.

To Check:

Caution

Dangerous Voltage

1 Energize the system.

Important

You must have a “Session ID” for access to “Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

Page 9

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

9 of 160

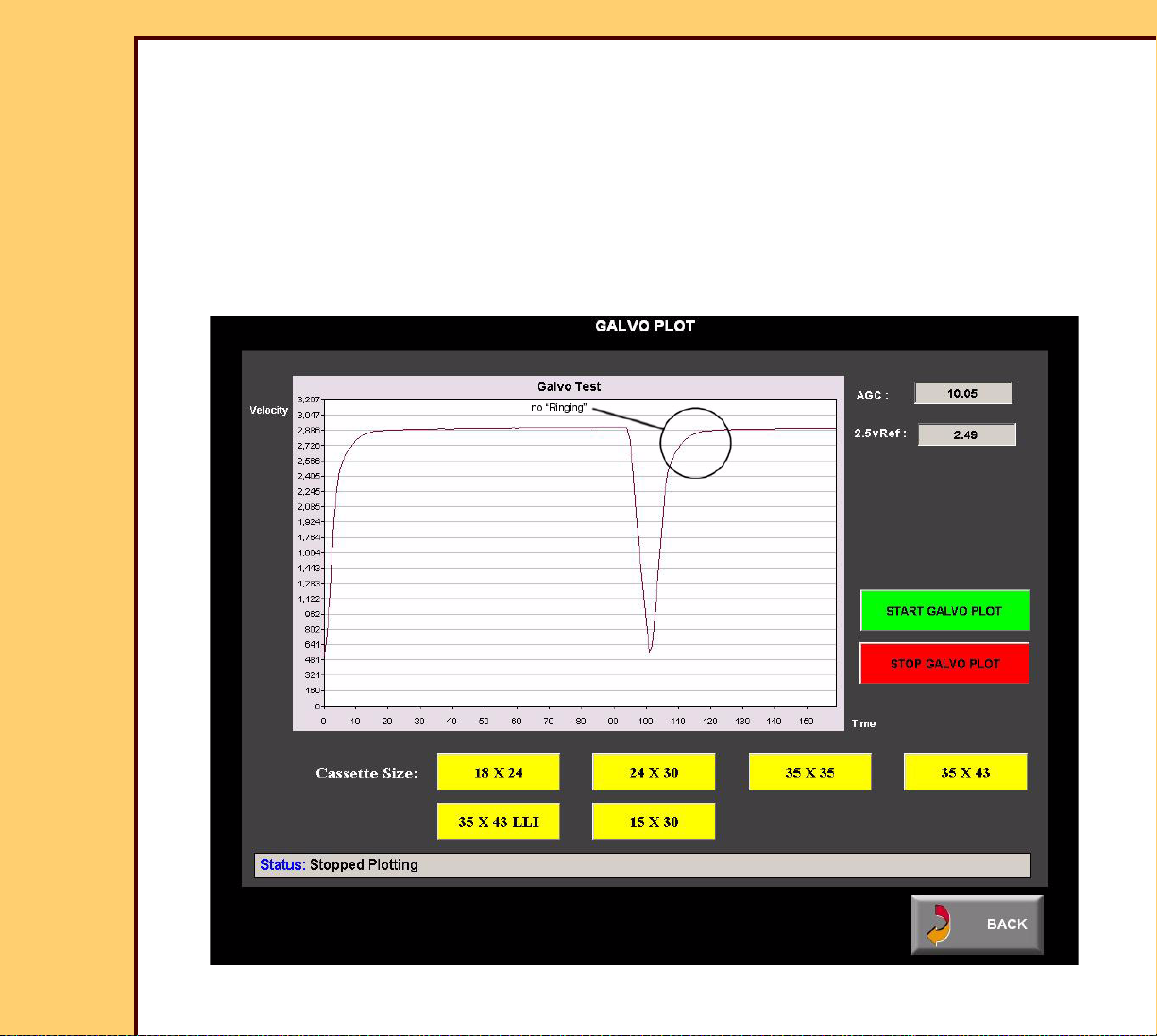

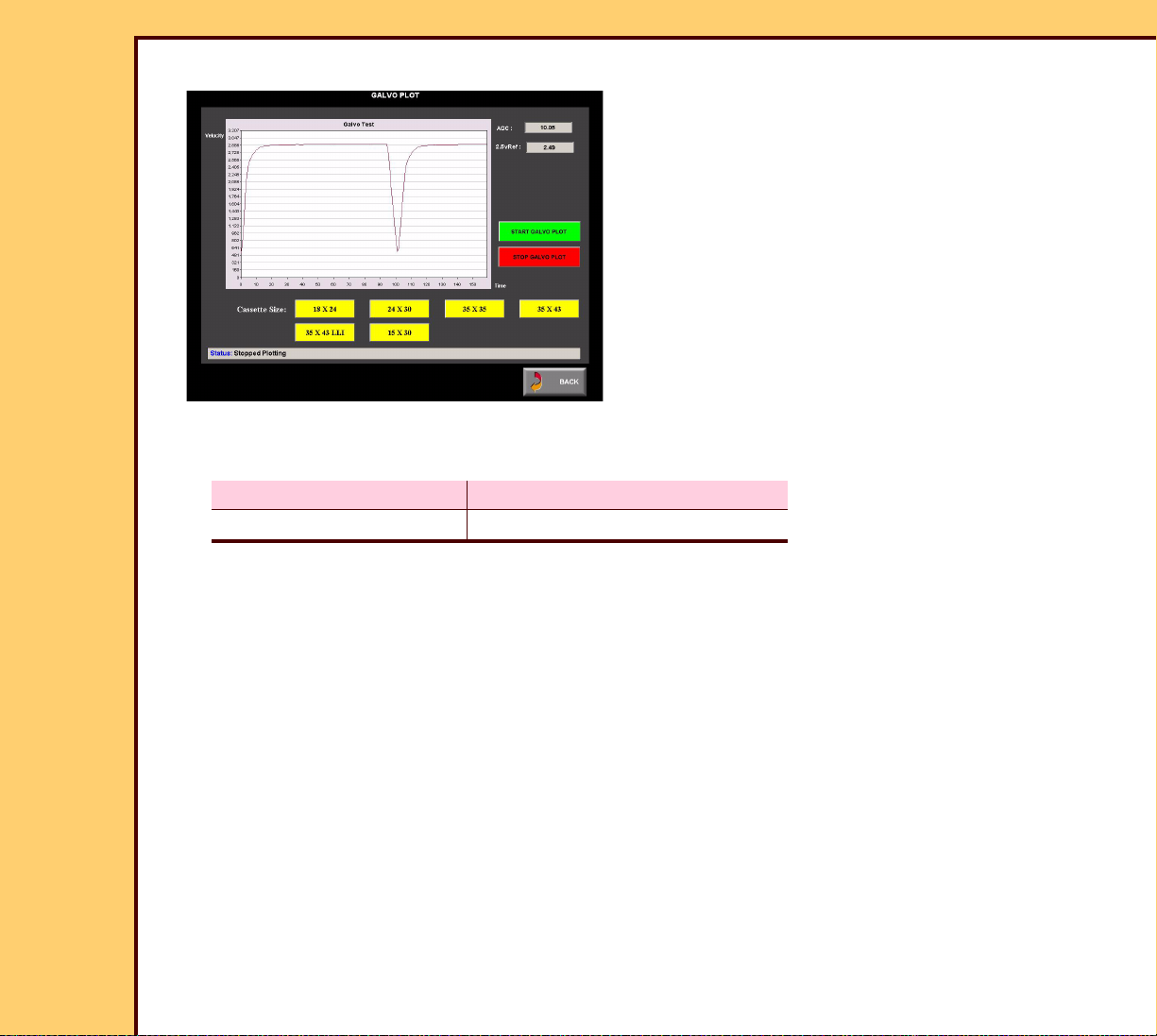

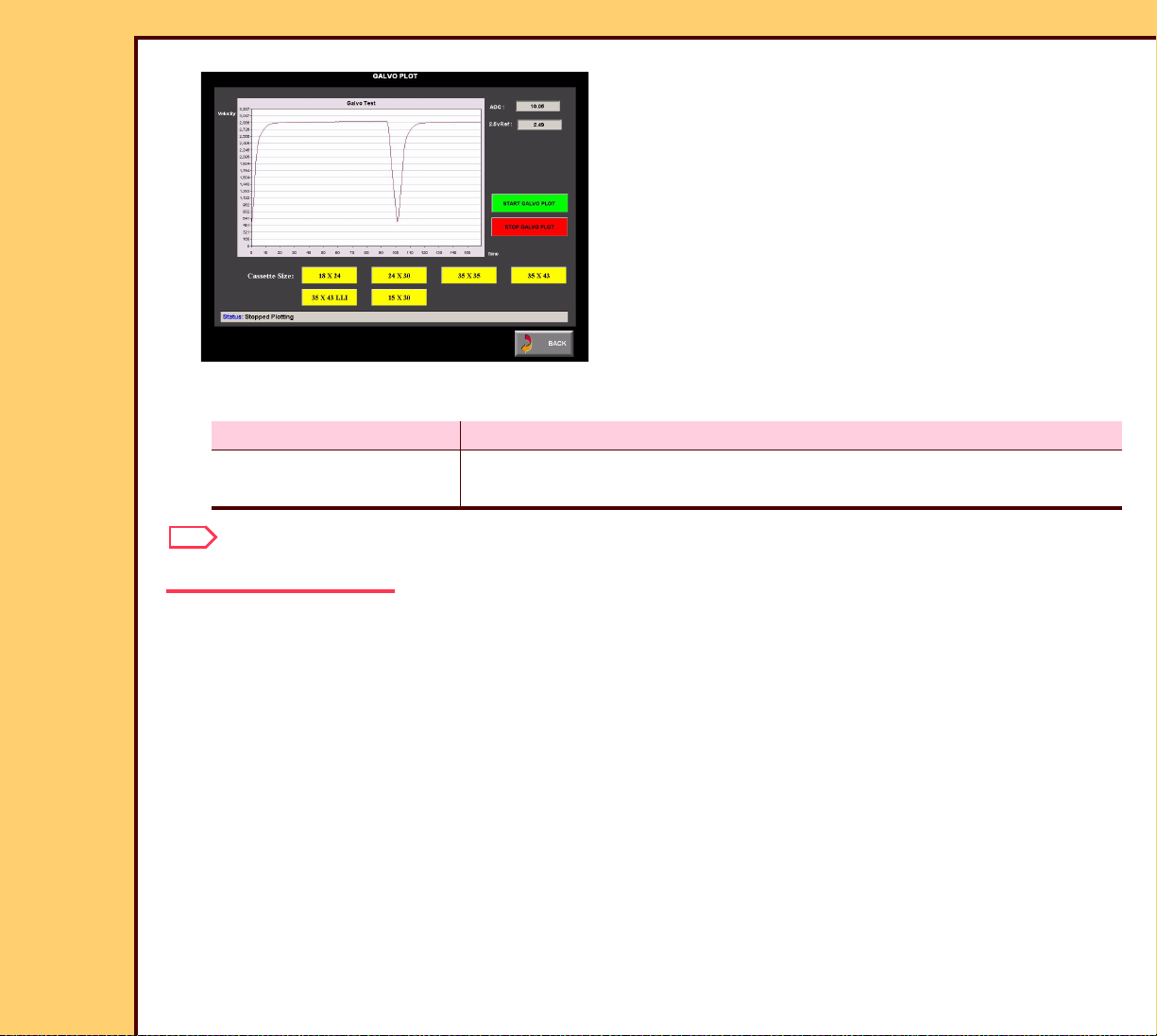

2 At the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

• [Galvo Plot]

• [Star t Galvo Plot]

• [35 x 43]

Correct

Page 10

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

10 of 160

Not Correct

Important

The GALVO stops after 500 cycles. If necessary to start again, select “Star t Galvo Plot”.

3 Check:

• no “Ringing” in the “Wave Form”

• “AGC” is at 8.2 V DC - 11.9 V DC

Page 11

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

11 of 160

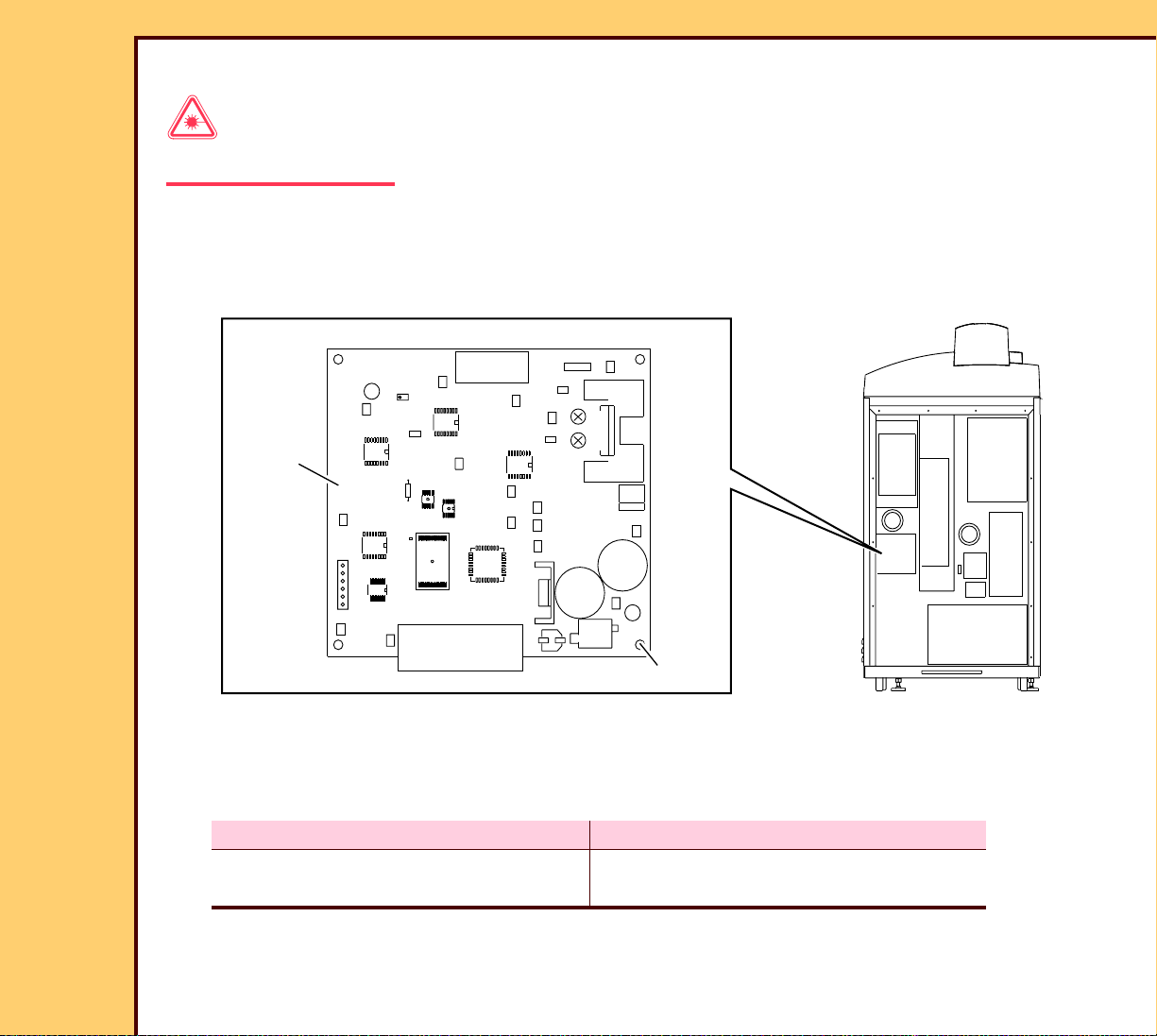

To Ad j u st :

Laser Warning

This equipment uses a visible red laser. Prevent direct exposure to the beam from the laser.

1 Do Step 1 - Step 8 of the GALVO ROTATION procedure.

2 Remove the REAR PANEL.

TP7

R112

TP6

TP3

GALVO

BOARD

TP10

R112

TP1

R2

TP13

C55

TP17

61

TP2

TP16

TP4

TP11 R1

TP14

TP9

TP15

TP12

TP5

H194_1408BCB

H194_1408BC

4 SCREWS

3 On the GALVO BOARD, use the DVM TL-3386 set to V DC and connect the (+) end of

the DVM to TP13 and the (-) end of the DVM to TP1.

4 Is the GALVO BOARD new?

Yes No

Adjust R2 until the voltage on the

DVM is 10 ± 0.02 V DC.

Check that the voltage on the DVM is

between 8.2 V DC and 11.9 V DC.

Page 12

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

12 of 160

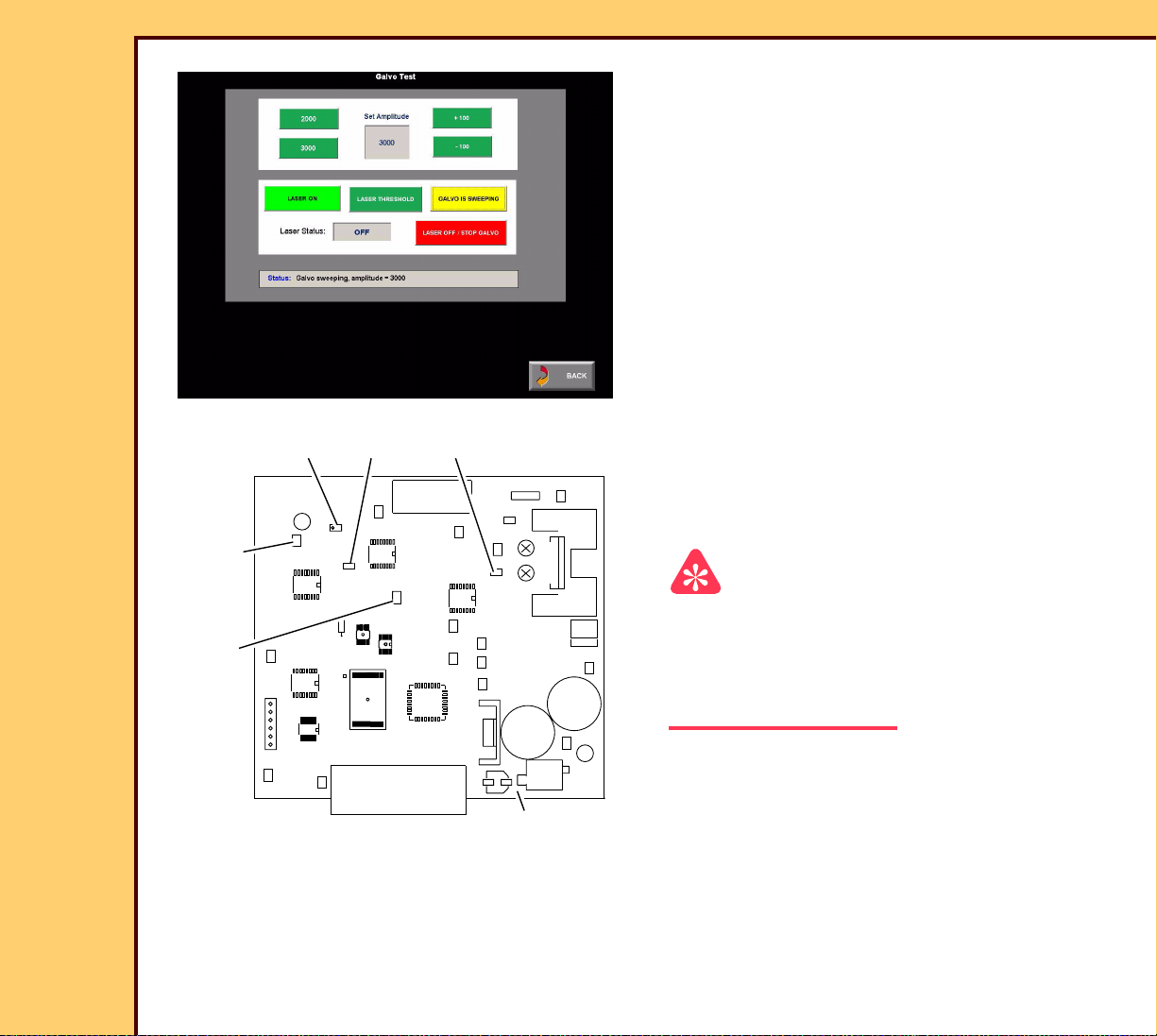

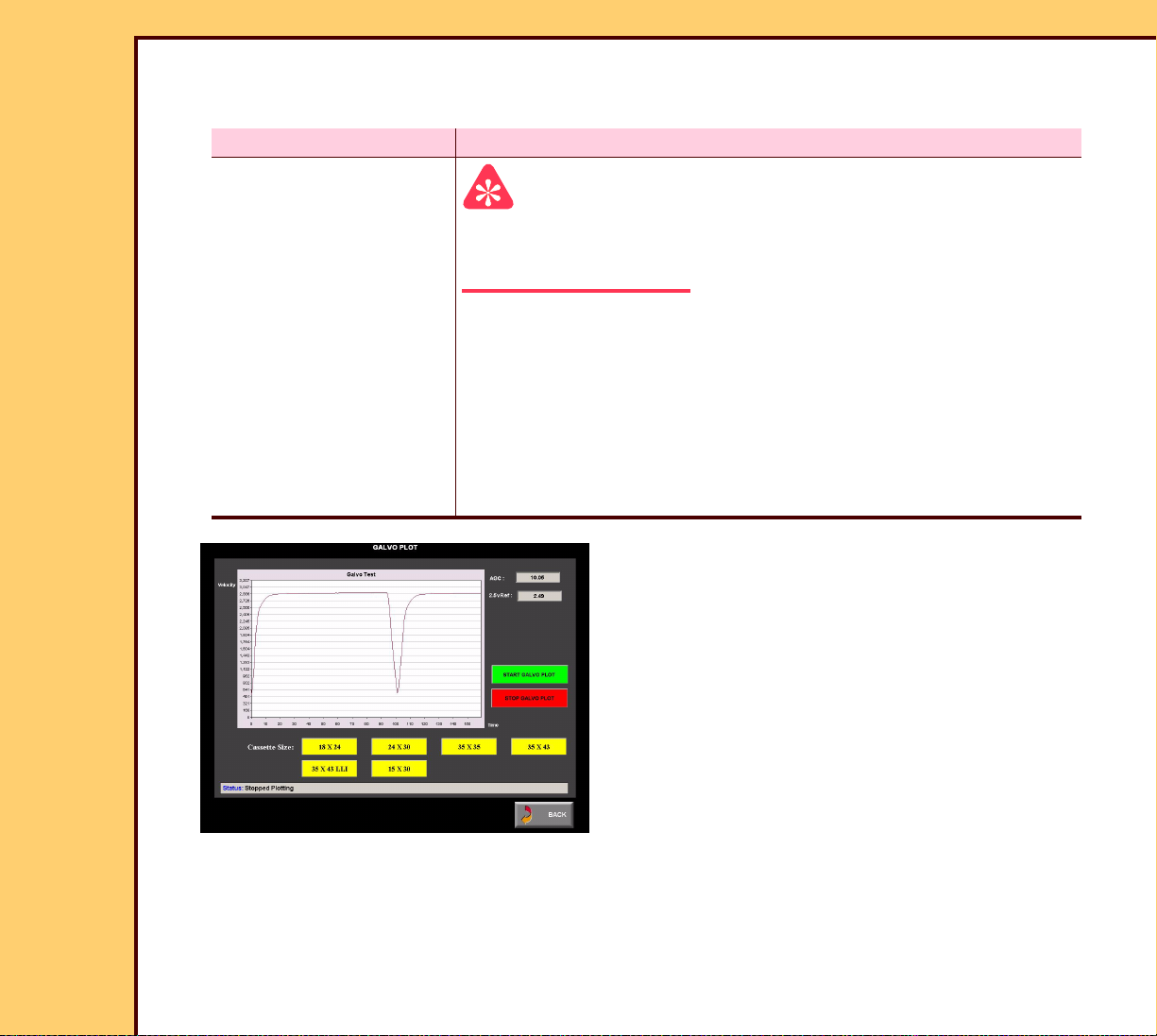

5 Touch:

• [Star t Galvo Plot]

• [35 x 43]

6 Adjust R1 until the “hook” or “ringing” is just visible on the GALVO SWEEP PROFILE.

7 Adjust R1 until the “hook” or “ringing” just disappears on the GALVO SWEEP PROFILE.

8 Touch:

• [Back]

• [Galvo Test]

• [Star t Galvo Plot]

• [35 x 43]

9 Is the “Wave Form” correct?

Yes No

Advance to Step 16. Continue with Step 10.

10 Touch:

• [Back]

• [Galvo Test]

• [Star t Galvo]

Page 13

10DEC05

AR4825-1

Page

13 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

11 Set the “Amplitude” to “3000”.

TP1

TP13

H194_0045ACA

H194_0045AC

R112

TP1

TP17

16

TP2

TP16

R2

R1

12 Use the DVM TL-3386 set to V AC and

connect the (+) end of the DVM to

TP10

R112

R2

TP13

C55

TP4

R1TP11

TP14

TP9

TP15

TP12

TP5

TP7

R112

TP6

TP13 and the (-) end of the DVM to

TP1.

Important

• The GALVO must be “sweeping” when

you adjust R112.

• The lowest value is normally 10 - 25 mV

AC.

TP3

13 Adjust R112 until the voltage on the

DVM is at the lowest value.

GALVO BOARD

Page 14

10DEC05

AR4825-1

Page

14 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

14 Touch:

• [Stop Galvo]

• [Back]

• [Galvo Plot]

• [Star t Galvo Plot]

• [35 x 43]

15 Is the “Wave Form” correct?

Yes No

Continue with Step 16.Do Step 3 - Step 15 again.

Page 15

10DEC05

AR4825-1

Page

15 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

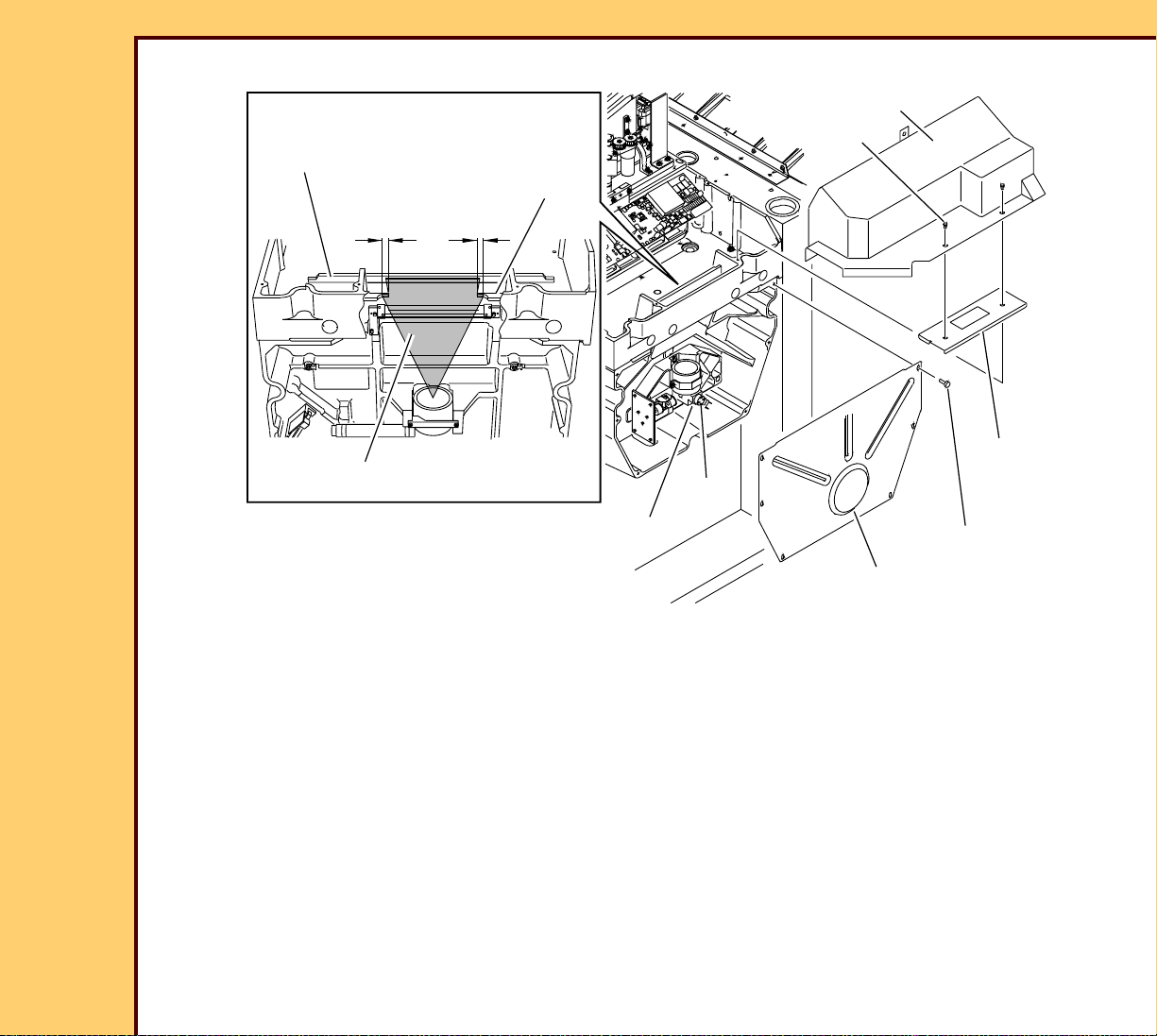

PMT COVER

5 SCREWS

TOOL TL-5726

3.17 mm

(0.125 in.)

laser beam

2 BEAM

CLIPPERS

n

e

h

w

.

n

d

e

io

t

t

a

ia

e

d

f

a

e

.

r

d

r

m

s

e

a

k

s

e

c

a

b

L

lo

o

r

t

e

B

t

e

3

r

in

s

u

s

d

s

a

n

o

l

a

p

C

x

n

e

e

p

id

o

o

v

A

GALVO

FOLD

MIRROR

COVER

H194_1418HCA

H194_1418HC

16 Lift the TOP COVER.

17 Remove:

• 5 SCREWS

• PMT COVER

• FOLD MIRROR COVER

• 6 SCREWS

• COVER

18 Install the TOOL TL-5726.

SCREW

6 SCREWS

COVER

Page 16

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

16 of 160

19 Touch [Laser On].

20 Is the laser beam 3.17 mm (.125 in.) on the 2 BEAM CLIPPERS?

Yes No

Continue with

Step 21.

Important

• Rotating the GALVO centers the laser beam.

• Adjusting R2 makes the laser beam shor ter or longer.

a. Loosen the SCREW.

b. Rotate the GALVO until the laser beam is in the center.

c. Tighten the SCREW.

d. Adjust R2 on the GALVO BOARD until the laser beam is

3.17 mm (.125 in.) on the 2 BEAM CLIPPERS.

e. Continue with Step 21.

21 Touch:

• [Stop Galvo]

• [Back]

• [Galvo Plot]

• [Star t Galvo Plot]

22 Check that the “Velocity Profile” is

correct for all sizes of CASSETTE.

Page 17

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

17 of 160

23 Is the “Velocity Profile” correct?

Yes No

Continue with

Step 25.

a. Adjust R1 until the “Velocity Profile” is

correct.

b. Do Step 19 - Step 23, or use

diagnostics to solve the problem.

24 Do GALVO ROTATION.

25 Install:

• REAR PANEL

• FOLD MIRROR COVER

• PMT COVER

• 5 SCREWS

• COVER

• 6 SCREWS

Postrequisites:

1 Adjust the FOLD MIRROR.

Page 18

10DEC05

AR4825-1

Page

18 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

GALVO ROTATION

Adjustment Specification

Purpose: To set the GALVO home position.

Specification: The laser beam displays on the wide RING of the F-THETA LENS.

Special Tools: None

Prerequisites:

1 Do Setting the Laser Calibration Voltage.

2 Adjust the GALVO BOARD.

To Check:

Press the Escape key to dismiss the video after viewing.

Laser Warning

• This equipment uses a visible red laser. Prevent direct exposure to the beam from the

laser.

• Dangerous Voltage

1 De-energize the system.

2 Remove the FRONT DOOR and RIGHT PANEL.

Page 19

10DEC05

AR4825-1

Page

19 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

OPTICAL AY

Caution

Do not cause damage to the OPTICAL AY.

6 SCREWS

3 Remove:

• 6 SCREWS

hen

.

ted

tion w

dia

efea

m.

s d

ea

ck

aser ra

b

L

rlo

to

te

3B

re

d in

posu

an

Class

pen

id ex

o

vo

A

• COVER

4 Loosen the THUMBSCREW.

5 Move the LASER FILTER into the

service position.

H194_1412GCA

H194_1412GC

Class 3B

open and interlocks defeated.

void exposure to beam

A

INTERLOCK KEY

Laser radiation w

COVER

THUMBSCREW

hen

.

service

position

LASER FILTER

H194_0049ACA

H194_0049AC

6 Tighten the THUMBSCREW.

Caution

Dangerous Voltage

7 Energize the system.

8 Install the INTERLOCK KEY.

Important

You must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

9 At the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

• [Galvo Test]

• [Laser on]

Page 20

10DEC05

AR4825-1

Page

20 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

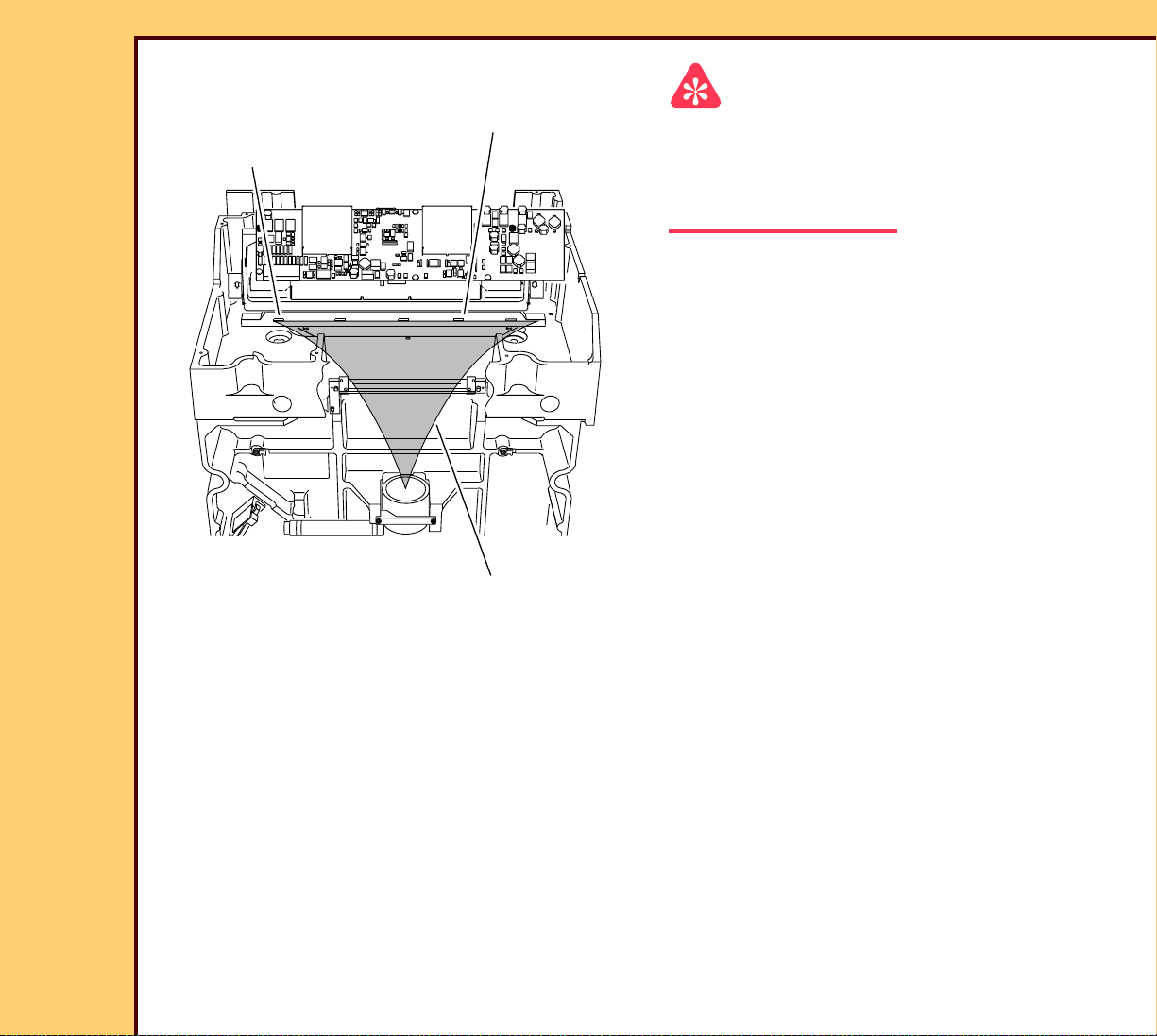

10 Check that the laser beam displays on

F-THETA LENS

laser

beam

the wide RING of the F-THETA LENS

and the reflected light just touches the

upper RING of the F-THETA LENS.

wide

CORRECT NOT CORRECT

RING

H196_2700GCA

H196_2700GC

F-THETA LENS

To Ad j u st :

Press the Escape key to dismiss the video after viewing.

laser

beam

WALL

Class 3B Laser radiation when

open and interlocks defeated.

Avoid exposure to beam.

Page 21

10DEC05

AR4825-1

Page

21 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

wide RING

F-THETA LENS

OPTICAL AY

laser

beam

GALVO

Caution

• Do not cause damage to the OPTICAL

AY.

• If the laser beam is adjusted below the

wide RING, the error code 1602 occurs

during the Calibration for the Scan

procedure.

n

e

h

w

.

n

d

te

tio

a

ia

d

fe

e

.

d

r ra

m

s

e

a

k

s

e

c

a

b

L

rlo

to

B

te

3

re

in

s

u

s

d

la

a

C

n

e

p

id

o

o

v

A

s

n

o

p

x

e

CLAMP

1 Loosen the SETSCREW in the CLAMP.

2 Rotate the GALVO in the CLAMP until

the laser beam is on the wide RING of

H194_1415ACA

H194_1415AC

SETSCREW

the F-THETA LENS and the reflected

light just touches the upper RING of the

F-THETA LENS.

Note

It may be helpful to place a piece of PAPER

on top of the F-THETA LENS. Rotate the

GALVO until the laser creates a bright spot

on the right side, then rotate the GALVO in

the opposite direction until the bright spot

just disappears.

3 Tighten the SETSCREW in the CLAMP.

4 Do Step 16 - Step 23 of the adjustment procedure for the GALVO BOARD again.

Page 22

10DEC05

AR4825-1

Page

22 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

5 Touch:

• [Stop Galvo]

• [Back]

• [Galvo Plot]

• [Star t Galvo Plot]

• [35 x 43]

6 Is the “Wave Form” correct?

Yes No

Continue with Step 7. Do the adjustment for the GALVO BOARD again or use

diagnostics to solve the problem.

Note

It may take 3 cycles of the adjustments to correctly position the GALVO.

Page 23

10DEC05

AR4825-1

Page

23 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

7 Loosen the THUMBSCREW.

8 Move the LASER FILTER into the

operation position.

H194_1413GCA

H194_1413GC

6 SCREWS

9 Tighten the THUMBSCREW.

10 Install:

n

e

h

w

.

n

d

io

te

t

a

ia

e

d

f

a

e

.

r

d

r

m

s

e

a

k

s

e

c

a

b

o

L

l

o

r

t

e

B

t

e

3

r

in

s

u

s

d

s

n

o

la

p

a

C

x

n

e

e

p

id

o

o

v

A

• COVER

• 6 SCREWS

COVER

THUMBSCREW

operation

Class 3B Laser radiation when

open and interlocks defeated.

Avoid exposure to beam.

LASER FILTER

position

Postrequisites:

1 Do the adjustments:

• FOLD MIRROR

• GALVO BOARD

2 Do:

• Calibration for the CR 825/850 SYSTEM

• Kodak DirectView TOTAL QUALITY TOOL for CR SYSTEMS

Page 24

10DEC05

AR4825-1

Page

24 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

FOLD MIRROR

Adjustment Specification

Purpose: To align the laser beam.

Specification: The laser beam is in the center of each of the SLOTS on the

TOOL TL-5726.

Special Tools: TOOL TL-5726

Prerequisites:

None

To Check:

Press the Escape key to dismiss the video after viewing.

Laser Warning

• This equipment uses a visible red laser. Prevent direct exposure to the beam from the

laser.

• Dangerous Voltage

Page 25

10DEC05

AR4825-1

Page

25 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

1 De-energize the system.

4 SCREWS

2 Open the TOP COVER.

PMT COVER

3 Remove:

• FRONT DOOR and RIGHT PANEL

• 4 SCREWS

• PMT COVER

H194_1406GCB

H194_1406GC

Page 26

10DEC05

AR4825-1

Page

26 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

OPTICAL AY

Caution

6 SCREWS

Do not cause damage to the OPTICAL AY.

4 Remove:

H194_1412GCA

H194_1412GC

n

e

h

w

.

n

d

o

e

i

t

t

a

a

i

e

d

f

a

e

.

r

d

r

m

s

e

a

k

s

e

c

a

b

o

L

l

o

r

t

e

B

t

e

3

n

r

i

s

u

s

d

s

a

n

o

l

a

p

C

x

n

e

e

d

p

i

o

o

v

A

• 6 SCREWS

• COVER

5 Loosen the THUMBSCREW.

6 Move the LASER FILTER into the

service position.

7 Tighten the THUMBSCREW.

Caution

Class 3B Laser radiation when

open and interlocks defeated.

Avoid exposure to beam.

COVER

THUMBSCREW

service

position

LASER FILTER

Dangerous Voltage

8 Energize the system.

INTERLOCK KEY

H194_0049ACA

H194_0049AC

9 Install the INTERLOCK KEY.

Page 27

10DEC05

AR4825-1

Page

27 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

SCREW HEAD

FRAME

TOOL TL-5726

TOOL TL-5726

H194_1406BCA

FRAME

H194_1406BC

Important

The small SLOTS of the TOOL TL-5726 are toward the laser beam. TOOL TL-5726 must be

positioned correctly under the SCREW HEAD.

10 Place the TOOL TL-5726:

• against the FRAME

• under the SCREW HEAD

Page 28

10DEC05

AR4825-1

Page

28 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

TOOL

Important

For systems with Software Version ≥ 4.1,

SLOTS

you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

11 At the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

• [Galvo Test]

• [Treshold]

• [Star t Galvo]

12 Set the “Amplitude” to “3000”.

13 Check that the laser beam is in the

center of the small SLOTS in the TOOL

TL-5726.

H194_0046GCA

H194_0046GC

laser beam

Page 29

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

29 of 160

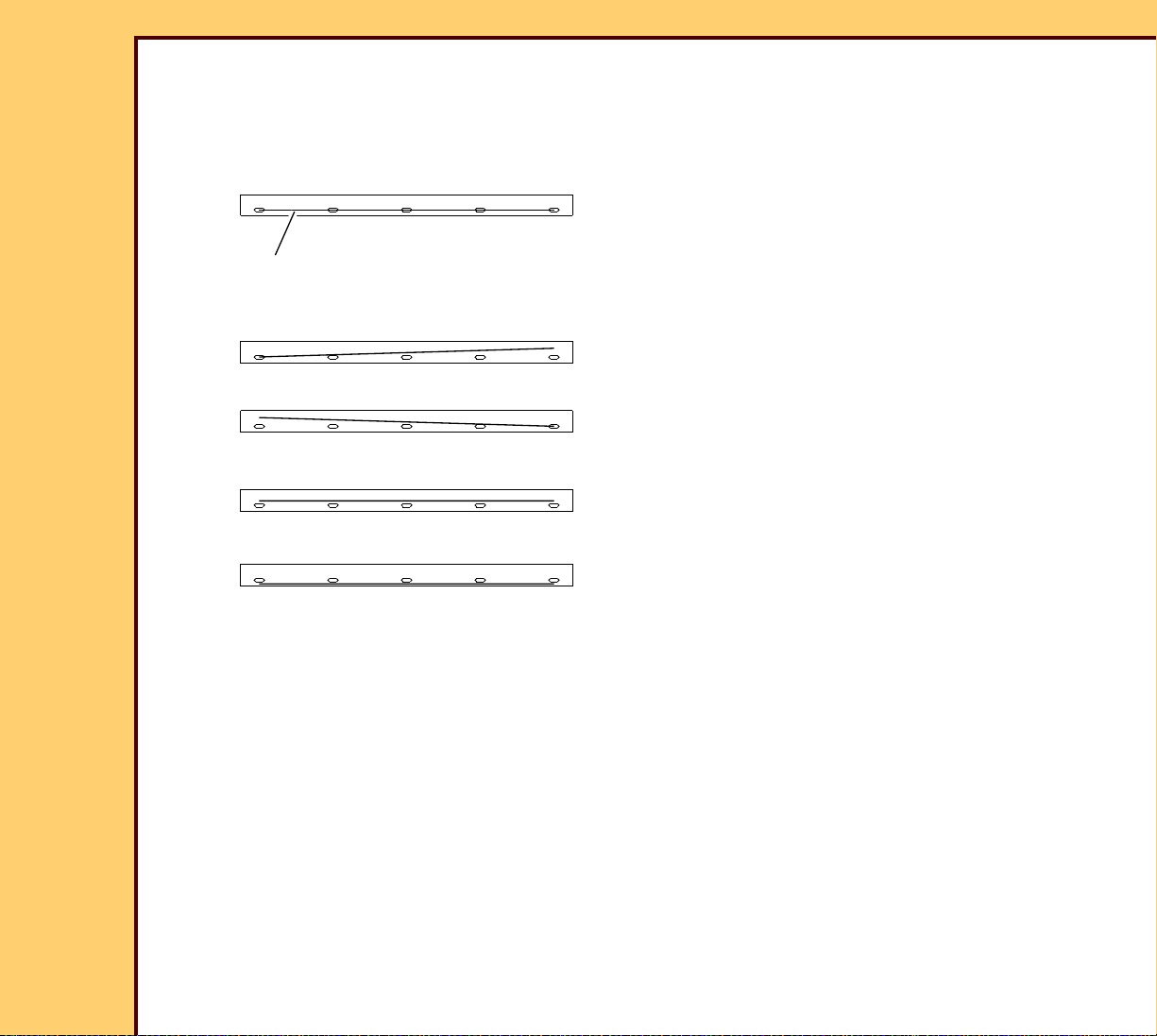

To Ad j u st :

laser beam

A

B

C

D

correct

not correct

1 Deter mine the position of the laser

beam. See the graphic for the

differences.

H194_1407GCA

H194_1407GC

Page 30

10DEC05

AR4825-1

Page

30 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

ADJUSTING SCREW B

ADJUSTING SCREW A

SCREW A

SCREW C

ADJUSTING SCREW C

H194_0047ACA

H194_0047AC

SCREW B

2 To adjust the laser beam to the center of the SLOTS in the TOOL TL-5726:

Item Laser Beam Do:

A Left end tilted up or

down

a. Loosen the SCREW A.

b. Rotate the ADJUSTING SCREW A counterclockwise to

move the left end of the laser beam down.

c. Rotate the ADJUSTING SCREW A clockwise to move

the left end of the laser beam up.

B Right end tilted up

or down

d. Tighten the SCREW A.

a. Loosen the SCREW B.

b. Rotate the ADJUSTING SCREW B counterclockwise to

move the right end of the laser beam down.

c. Rotate the ADJUSTING SCREW B clockwise to move

the right end of the laser beam up.

d. Tighten the SCREW B.

Page 31

10DEC05

AR4825-1

Page

31 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

Item Laser Beam Do:

CAbove the SLOTSa. Loosen the SCREW C.

b. Rotate the ADJUSTING SCREW C clockwise to move

the laser beam up.

c. Tighten the SCREW C.

D Below the SLOTS a. Loosen the SCREW C.

b. Rotate the ADJUSTING SCREW C counterclockwise to

move the laser beam down.

c. Tighten the SCREW C.

3 Touch:

• [Stop Galvo]

• [Laser “OFF”]

Page 32

10DEC05

AR4825-1

Page

32 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

4 Loosen the THUMBSCREW.

5 Move the LASER FILTER into the

6 SCREWS

operation position.

6 Tighten the THUMBSCREW.

7 Install:

n

e

h

w

.

n

d

io

te

t

a

ia

e

d

f

a

e

.

r

d

r

m

s

e

a

k

s

e

c

a

b

o

L

rl

to

e

B

t

e

3

r

in

s

u

s

d

s

n

o

la

a

p

C

x

n

e

e

d

p

i

o

o

v

A

• COVER

• 6 SCREWS

COVER

THUMBSCREW

H194_1413GCA

H194_1413GC

Postrequisite:

1 Do:

• Calibration for the Scan

• Kodak DirectView TOTAL QUALITY TOOL for CR SYSTEMS

Class 3B Laser radiation when

open and interlocks defeated.

Avoid exposure to beam.

operation

position

LASER FILTER

Page 33

10DEC05

AR4825-1

Page

33 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

COLLECTOR AY

Adjustment Specification

Purpose: To check that the space between the COLLECTOR AY and the

EXTRACTION BAR is correct.

Specification: The COLLECTOR touches the TOOL TL-5727.

Special Tools: TOOL TL-5727

Prerequisites:

None

To Check:

CR850 Serial No. below 8500

CR825 Serial No. below 100

CR850 Serial No. above 8500

CR825 Serial No. above 100

You cannot check this adjustment. COLLECTOR AY is against the

STOP BLOCKS

To Ad j u st :

Press the Escape key to dismiss the video after viewing.

Page 34

10DEC05

AR4825-1

Page

34 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

4 SCREWS

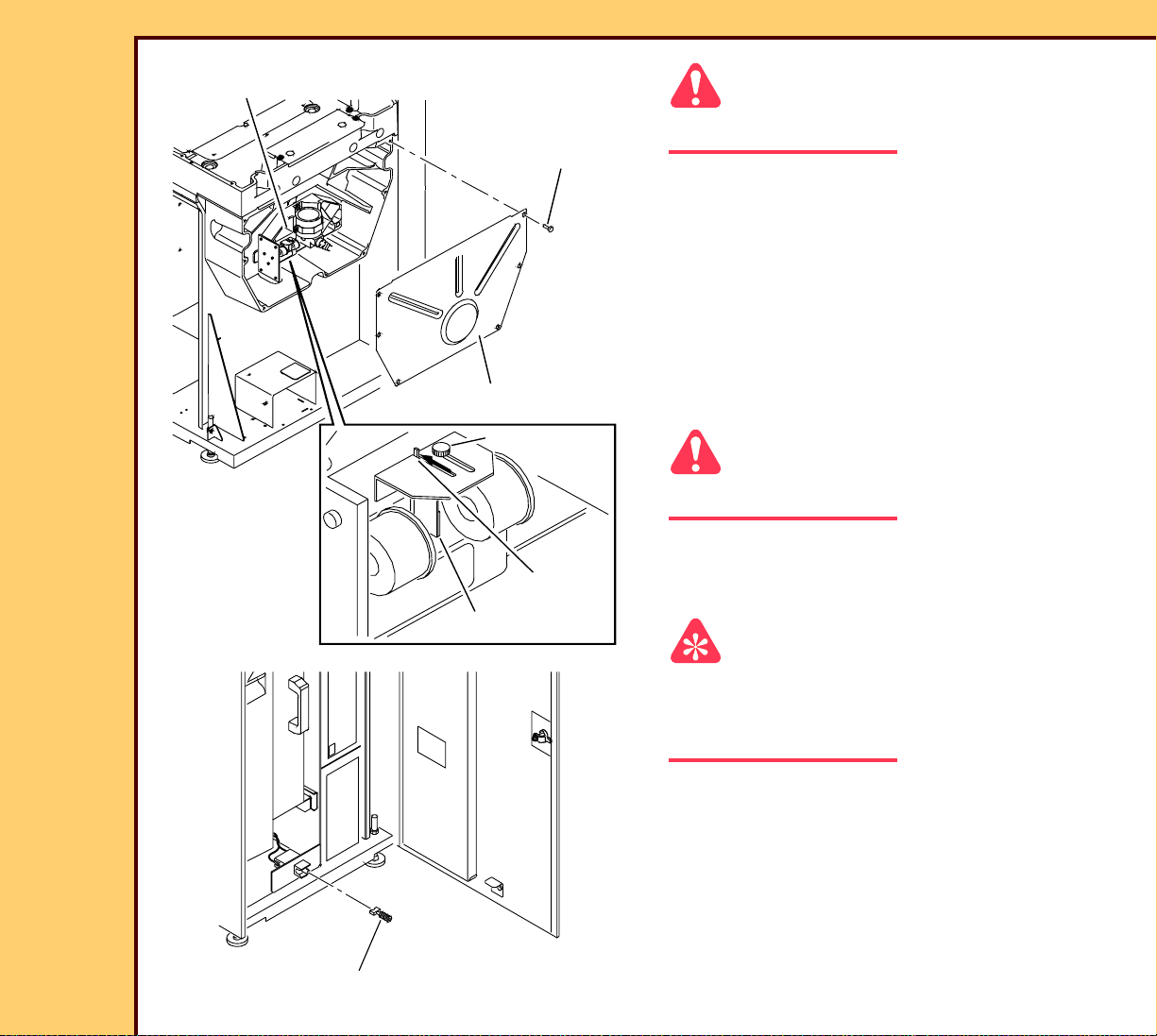

Caution

PMT COVER

• Dangerous Voltage

• The PMT/DAS BOARD may be damaged

if POWER CONNECTOR J1 is not

removed before energizing.

CASSETTE

LOAD CRADLE

2 SCREWS

Caution

Dangerous Voltage

4 Energize the system.

H194_1416GCA

H194_1416GC

1 De-energize the system.

2 Open the TOP COVER.

3 Remove:

• 4 SCREWS

• PMT COVER

• 2 SCREWS

• CASSETTE LOAD CRADLE

• POWER CONNECTOR J1 from the

PMT/DAS BOARD

Important

For systems with Software Version ≥ 4.1, you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See SERVICE BULLETIN 843.

Page 35

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

35 of 160

5 At the main menu, to uch:

• [Ser vice Functions]

• [Diagnostics]

• [Extraction Bar Position]

• [Locate Extraction Bar Home]

EXTRACTION

BAR

CLAMP

SPRING TENSIONER

EXTRACTION

BAR

TOOL

TL-5727

long end

TOOL

TL-5727

6 Loosen the 2 SCREWS on the

COLLECTOR AY.

7 Move the COLLECTOR AY away from

the EXTRACTION BAR.

8 Touch [Collector adjustment position].

9 Place the TOOL TL-5727 on the

EXTRACTION BAR with the long end

toward the COLLECTOR AY.

10 Move the COLLECTOR AY toward the

TOOL TL-5727.

11 Tighten the 2 SCREWS.

2 SCREWS

COLLECTOR AY

H194_0048GCA

H194_0048GC

12 Remove the TOOL TL-5727.

13 Touch [Return To Home].

14 De-energize the system.

Page 36

10DEC05

AR4825-1

Page

36 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

4 SCREWS

15 Install:

• POWER CONNECTOR J1 from the

PMT COVER

PMT/DAS Board

• 4 SCREWS

• PMT COVER

• 2 SCREWS

CASSETTE

LOAD CRADLE

2 SCREWS

H194_1416GCA

H194_1416GC

Postrequisites:

1 Adjust the CASSETTE LOAD CRADLE.

2 Do:

• Calibration for the Scan

• CASSETTE LOAD CRADLE

• Kodak DirectView TOTAL QUALITY TOOL for CR SYSTEMS

Page 37

10DEC05

AR4825-1

Page

37 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

INTERMEDIATE PLATE

Adjustment Specification

Purpose: To check that the position of the CASSETTE is aligned with the

EXTRACTION BAR.

Specification: The clearance is correct between the EXTRACTION BAR and the SLED.

Special Tools: TOOL TL-5728

Prerequisites:

None

To Check:

You cannot check this adjustment.

To Ad j u st :

Press the Escape key to dismiss the video after viewing.

Page 38

10DEC05

AR4825-1

Page

38 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

1 Open the TOP COVER.

LEFT CASSETTE GUIDE

RIGHT CASSETTE GUIDE

2 Remove:

• 2 COVERS

• 4 SCREWS

• LEFT CASSETTE GUIDE

4 SCREWS

2 COVERS

• RIGHT CASSETTE GUIDE

• 2 SCREWS

• CASSETTE LOAD CRADLE

Important

For systems with Software Version ≥ 4.1,

you must have a “Session ID” for access to

2 SCREWS

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

H194_1062GCA

H194_1062GC

CASSETTE

LOAD CRADLE

3 At the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

• [Extraction Bar Position]

• [Locate Extraction Bar Home]

• [Back]

• [Cam Position Actuation]

• [Unlatch Position]

Page 39

10DEC05

AR4825-1

Page

39 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

4 Loosen the 7 SCREWS on the

INTERMEDIATE PLATE.

H194_1046ACA

H194_1046AC

INTERMEDIATE PLATE

7 SCREWS

CASSETTE

END STOP

LEFT

PANEL

EXTRACTION

BAR

CLAMP SPRING

TENSIONER

H194_1036GCA

H194_1036GC

RIGHT PANEL

TOOL TL-5728

SLED

INTERMEDIATE PLATE

COLLECTOR AY

RIGHT

PLUSH AY

FRONT

LIGHT SEAL

5 Open the CLAMP SPRING

TENSIONER.

6 Move the INTERMEDIATE PLATE

toward the COLLECTOR AY.

7 Manually open and hold the RIGHT

PLUSH AY and the FRONT LIGHT

SEAL.

8 Inser t the TOOL TL-5728 on the

EXTRACTION BAR with the thin end

toward the COLLECTOR AY.

Note

The TOOL TL-5728 should touch the

CASSETTE END STOP.

9 Close the CLAMP SPRING

TENSIONER.

Page 40

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

40 of 160

10 Move the INTERMEDIATE PLATE toward the LEFT PANEL until the INTERMEDIATE

PLATE stops.

11 Tighten the 7 SCREWS.

12 To safely remove the TOOL TL-5728, touch:

• [Back]

• [Extraction Bar Position]

• [Erase]

13 Open the CLAMP SPRING TENSIONER.

14 Remove the TOOL TL-5728.

15 Close the CLAMP SPRING TENSIONER.

16 Touch:

• [Retur n To Home]

• [Back]

• [Cam Actuation Position]

• [Ho me Cam]

Postrequisites:

1 Adjust the CASSETTE LOAD CRADLE.

Page 41

10DEC05

AR4825-1

Page

41 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

CAM SENSOR BOARD A8

Adjustment Specification

Purpose: To check that the DUPLEX CAM home position is correct.

Specification: The height at “A” and “B” from the SLED to the TOOL TL-5724, on the

DUPLEX CAM, is within 1.5 mm (0.060 in.) of each other.

Special Tools: • TOOL TL-5724

• 6-in. SCALE TL-2762

Prerequisites:

None

To Check:

Press the Escape key to dismiss the video after viewing.

Caution

Dangerous Voltage

1 Energize the system.

2 Open the TOP COVER.

Page 42

10DEC05

AR4825-1

Page

42 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

Important

For systems with Software Version ≥ 4.1,

you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See

TOOL

TL-5724

SERVICE BULLETIN 843.

3 At the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

• [Cam Position Actuation]

• [Home Cam]

DUPLEX CAM

A

DUPLEX CAM

TOOL TL-5724

SLED

H194_1017ACA

H194_1017AC

B

H194_1037ACA

H194_1037AC

4 Install the TOOL TL-5724 on the

DUPLEX CAM.

5 Hold the TOOL in position.

6 Check that the height at “A” and “B”

from the SLED to the TOOL TL-5724,

on the DUPLEX CAM, is within 1.5 mm

(0.060 in.) of each other.

Page 43

10DEC05

AR4825-1

Page

43 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

To Ad j u st :

Press the Escape key to dismiss the video after viewing.

Caution

TOOL

You must remove the TOOL to prevent

damage to the DUPLEX CAM and the

TOOL.

1 Remove the TOOL from the DUPLEX

CAM.

2 Loosen the 2 SCREWS.

DUPLEX CAM

CAM SENSOR BOARD A8

Postrequisites:

None

2 SCREWS

H194_1017ACB

H194_1017AC

3 Move the CAM SENSOR BOARD A8:

• up, if “A” is more than “B”

• down, if “A” is less than “B”

4 Tighten the 2 SCREWS.

5 Touch [Home Cam].

6 Is the adjustment correct?

Yes No

Continue with the

adjustment for the

CAM MOTOR AY.

Do Step 2 -

Step 5 until the

adjustment is

correct.

Page 44

10DEC05

AR4825-1

Page

44 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

CAM MOTOR AY

Adjustment Specification

Purpose: To adjust the height of the CAM MOTOR AY to enable the correct timing of

the CAM.

Specification: When the CAM is in the home position, TOOL TL-5722 makes contact with

the SLED CAM FOLLOWER.

Special Tools: TOOL TL-5722

Prerequisites:

1 Adjust the CAM SENSOR BOARD A8.

To Check:

You cannot check this adjustment.

To Ad j u st :

Press the Escape key to dismiss the video after viewing.

Caution

Dangerous Voltage

1 Energize the system.

2 Open the TOP COVER.

3 Remove the LEFT PANEL.

Page 45

10DEC05

AR4825-1

Page

45 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

4 Install the INTERLOCK KEY.

Important

For systems with Software Version ≥ 4.1,

you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

5 A the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

INTERLOCK KEY

H194_0049AC

• [Cam Position Actuation]

H194_0049ACA

• [Home Cam]

Page 46

10DEC05

AR4825-1

Page

46 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

6 Loosen:

• 6 SCREWS o n the CAM MOTOR

SLED CAM

FOLLOWER

TOOL TL-5722

BRACKET

• 2 SCREWS o n the ADJUSTMENT

HOLD BRACKET

CAM MOTOR AY

ADJUSTMENT

HOLD BRACKET

H194_1020GCA

H194_1020GC

6 SCREWS

Postrequisites:

1 Adjust:

CAM MOTOR

BRACKET

2 SCREWS

7 Install the TOOL TL-5722.

8 Hold the TOOL in position and press

down on the CAM MOTOR AY until the

TOOL makes contact with the SLED

CAM FOLLOWER.

9 Hold the CAM MOTOR AY down and

tighten the 6 SCREWS on the CAM

MOTOR BRACKET.

10 Move the ADJUSTMENT HOLD

BRACKET down until it reaches the

limit.

11 Tighten the 2 SCREWS on the

ADJUSTMENT HOLD BRACKET.

• SLED CAM FOL LOWER

• CASSETTE END STOP

• REAR CASSETTE SENSOR

Page 47

10DEC05

AR4825-1

Page

47 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

SLED CAM FOLLOWER

Adjustment Specification

Purpose: To adjust the front to back position of the SLED to the EXTRACTION BAR.

Specification: The LEFT IDLER ROLLER BRACKET is parallel to the DUPLEX CAM when

the SLED is in the home position.

Special Tools: None

Prerequisites:

1 Adjust:

• CAM SENSOR BOARD A8

• CAM MOTOR AY

To Check:

Press the Escape key to dismiss the video after viewing.

Page 48

10DEC05

AR4825-1

Page

48 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

1 Open the TOP COVER.

LEFT CASSETTE GUIDE

RIGHT CASSETTE GUIDE

2 Remove:

• 2 COVERS

• 4 SCREWS

• LEFT CASSETTE GUIDE

4 SCREWS

2 COVERS

• RIGHT CASSETTE GUIDE

• 2 SCREWS

• CASSETTE LOAD CRADLE

2 SCREWS

H194_1062GCA

H194_1062GC

CASSETTE

LOAD CRADLE

Page 49

10DEC05

AR4825-1

Page

49 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

IDLER

ROLLER

BRACKET

not correctcorrect

IDLER

ROLLER

BRACKET

For systems with Software Version ≥ 4.1,

you must have a “Session ID” for access to

Important

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

3 A the main menu, touch:

• [Ser vice Functions]

DUPLEX CAM

DUPLEX CAM

• [Diagnostics]

• [Extraction Bar Positions]

• [Locate Extraction Bar Home]

• [Back]

• [Cam Position Actuation]

• [Home Cam]

H194_1064GCA

H194_1064GC

To Ad j u st :

Press the Escape key to dismiss the video after viewing.

1 Open the TOP COVER.

4 Check that the LEFT IDLER ROLLER

BRACKET is parallel to the DUPLEX

CAM.

Page 50

10DEC05

AR4825-1

Page

50 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

2 Open the CLAMP SPRING

TENSIONER.

CLAMP SPRING TENSIONER

H194_1058ACA

H194_1058AC

3 Loosen the 2 SCREWS on the SLED

2 SCREWS

CAM FOLLOWER.

H194_1066ACA

H194_1066AC

SLED CAM

FOLLOWER

Page 51

10DEC05

AR4825-1

Page

51 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

4 Move the SLED backward and forward

not correctcorrect

until the LEFT IDLER ROLLER

BRACKET is parallel to the DUPLEX

CAM.

5 Hold the SLED.

6 Tighten the 2 SCREWS on the SLED

CAM FOLLOWER.

7 Close the CLAMP SPRING

TENSIONER.

8 Check that the adjustment is correct.

H194_1064GC

Postrequisites:

1 Adjust:

• CLAMP BAR

• CASSETTE END STOP

• REAR CASSETTE SENSOR

Page 52

10DEC05

AR4825-1

Page

52 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

CLAMP BAR

Adjustment Specification

Purpose: To set the front and back space of the CLAMP BAR.

Specification: • The front space is a minimum of 17.25 mm (0.680 in.).

• The back space is a minimum of 16.25 mm (0.640 in.).

• The difference between the back and front measurement is 0.508 - 1.5

mm (0.020 - 0.060 in.) when the SLED is in the home position.

Special Tools: CALIPER TL-1727 or 15 cm (6 in.) SCALE TL-2762 or equivalent

Prerequisites:

1 Adjust the SLED CAM FOLLOWER.

To Check:

Press the Escape key to dismiss the video after viewing.

Page 53

10DEC05

AR4825-1

Page

53 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

LEFT CASSETTE GUIDE

RIGHT CASSETTE GUIDE

Dangerous Voltage

Caution

1 Energize the system.

2 Open the TOP COVER.

4 SCREWS

2 COVERS

3 Remove:

• 2 COVERS

• 4 SCREWS

• LEFT CASSETTE GUIDE

• RIGHT CASSETTE GUIDE

• 2 SCREWS

H194_1062GCA

H194_1062GC

CASSETTE

LOAD CRADLE

2 SCREWS

• CASSETTE LOAD CRADLE

Important

For systems with Software Version ≥ 4.1,

you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

4 At the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

• [Cam Position Actuation]

• [Home Cam]

Page 54

10DEC05

AR4825-1

Page

54 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

5 Use the CALIPER TL-1727 to measure

the front space of the CLAMP BAR.

CALIPER

TL-1727

front

space

6 Is the measurement a minimum of

17.25 mm (0.680 in.) or more?

Yes No

Continue with

Step 7.

Advance to Step 3

of the adjustment

procedure.

SCREW

To Ad j u st :

back space

CLAMP BAR

H194_1040GCA

H194_1040GC

7 Use the CALIPER TL-1727 to measure

the back space of the CLAMP BAR.

8 Is the measurement a minimum of

16.25 mm (0.640 in.) and not more than

the front measurement?

Yes No

Continue with

Step 9.

Advance to Step 2

of the adjustment

procedure.

9 Is the difference between the back and

front measurement 0.508 - 1.5 mm

(0.020 - 0.060 in.)?

Yes No

Checkout

procedure is

complete.

Advance to Step 1

of the adjustment

procedure.

Press the Escape key to dismiss the video after viewing.

Page 55

10DEC05

AR4825-1

Page

55 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

Important

Excessive wear or loose parts will cause the front and back space measurement to be wrong.

1 Use the CALIPER TL-1727 to measure

the back space of the CLAMP BAR.

CALIPER

TL-1727

2 Adjust the SCREW until the

measurement is a minimum of 16.25

mm (0.640 in.).

3 Check that the front space

front

space

CLAMP BAR

back space

measurement is a minimum of 17.25

mm (0.680 in.).

4 Is the difference between the back and

front measurement 0.508 - 1.5 mm

(0.020 - 0.060 in.)?

Yes No

Adjustment

procedure is

Do Step 1 -

Step 4 again.

complete.

H194_1040GCA

SCREW

H194_1040GC

Postrequisites:

1 Adjust the RIGHT and LEFT PLUSH AY - Alignment.

Page 56

10DEC05

AR4825-1

Page

56 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

CASSETTE END STOP

Adjustment Specification

Purpose: To adjust the position of the CASSETTE END STOP.

Specification: The TOOL TL-5729 touches the EXTRACTION BAR HOOK and CASSETTE

END STOP at the same time.

Special Tools: • TOOL TL-5729

• TOOL TL-5582

Prerequisites:

1 Adjust the SLED CAM FOLLOWER.

To Check:

You cannot check this adjustment.

To Ad j u st :

Press the Escape key to dismiss the video after viewing.

Caution

Dangerous Voltage

1 Energize the system.

2 Open the TOP COVER.

Page 57

10DEC05

AR4825-1

Page

57 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

CASSETTE

END STOP

TOOL TL-5582

TOOL TL-5729

For systems with Software Version ≥ 4.1,

Important

you must have a “Session ID” for access to

back HOOK

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

SCREW

EXTRACTION BAR

TOOL TL-5582

TOOL TL-5729

YOKE

SCREW

CASSETTE END STOP

H194_1041GCA

H194_1041GC

Postrequisites:

1 Adjust the REAR CASSETTE SENSOR.

3 At the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

• [Extraction Bar Positions]

• [Locate Extraction Bar Home]

4 Rotate the SCREW counterclockwise 2

rotations.

5 Manually move the YOKE down.

6 Place the TOOL TL-5729 between the

CASSETTE END STOP and the back

HOOK on the EXTRACTION BAR.

7 Adjust the SCREW until the

TOOL TL-5729 touches the HOOK and

CASSETTE END STOP.

Page 58

10DEC05

AR4825-1

Page

58 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

REAR CASSETTE SENSOR

Adjustment Specification

Purpose: To adjust the position of the REAR CASSETTE SENSOR.

Specification: The SENSOR BRACKET is at the front limit position of the CASSETTE.

Special Tools: • FEELER GAUGE TL-2372

• 35 x 43 cm CASSETTE

Prerequisites:

1 Adjust:

• SLED CAM FOL LOWER

• CASSETTE END STOP

To Check:

1 See the table in Step 17 of the adjustment procedure.

To Ad j u st :

Press the Escape key to dismiss the video after viewing.

Caution

Dangerous Voltage

1 Energize the system.

2 Open the TOP COVER.

Page 59

10DEC05

AR4825-1

Page

59 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

Important

For systems with Software Version ≥ 4.1,

you must have a “Session ID” for access to

35 x 43 cm CASSETTE

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

SENSOR

BRACKET

3 At the main menu, touch:

2 SCREWS

CASSETTE

END STOP

1.0 mm (0.040 in.)

FEELER GAUGE

H194_1043GCA

H194_1043GC

• [Ser vice Functions]

• [Diagnostics]

• [Individual Component Control]

4 Remove the 1.0 mm (0.040 in.)

FEELER GAUGE from the FEELER

GAUGE TOOL TL-2372.

5 Install the 1.0 mm (0.040 in.) FEELER

GAUGE on to the 35 x 43 cm

CASSETTE.

6 Load the 35 x 43 cm CASSETTE until

the FEELER GAUGE touches the

CASSETTE END STOP.

7 Obser ve the check box next to the [S3]

CASSETTE REAR SENSOR.

8 Is the “x” displayed in the check box?

Yes No

Advance to

Step 12.

Continue with

Step 9.

9 Loosen the 2 SCREWS on the SENSOR BRACKET.

10 Move the SENSOR BRACKET until the “x” is displayed in the check box.

11 Tighten the 2 SCREWS.

Page 60

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

60 of 160

12 Remove:

• 35 x 43 cm CASSETTE

• 1.0 mm (0.040 in.) FEELER GAUGE from the 35 x 43 cm CASSETTE

13 Remove the 1.5 mm (0.060 in.) FEELER GAUGE from the FEELER GAUGE TOOL TL-

2372.

14 Install the 1.5 mm (0.060 in.) FEELER GAUGE on to the 35 x 43 cm CASSETTE.

15 Load the 35 x 43 cm CASSETTE until the FEELER GAUGE touches the CASSETTE

END STOP.

16 Obser ve the check box next to the [S3] CASSETTE REAR SENSOR.

17 Is the “x” displayed in the check box?

Yes No

Do Step 9 - Step 17 until the [S3] CASSETTE

Adjustment procedure is complete.

REAR SENSOR is made with the 1.0 mm

(0.040 in.) FEELER GAUGE installed and not

made with the 1.5 mm (0.060 in.) FEELER

GAUGE installed.

Postrequisites:

None

Page 61

10DEC05

AR4825-1

Page

61 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

EXTRACTION BAR HOME POSITION

Adjustment Specification

Purpose: To adjust the home position of the EXTRACTION BAR.

Specification: The TOOL TL-5723 is under the EXTRACTION BAR HOOKS with no end

vertical play.

Special Tools: TOOL TL-5723

Prerequisites:

None

To Check:

Press the Escape key to dismiss the video after viewing.

Page 62

10DEC05

AR4825-1

Page

62 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

LEFT CASSETTE GUIDE

RIGHT CASSETTE GUIDE

Dangerous Voltage

Caution

1 Energize the system.

4 SCREWS

2 COVERS

H194_1063GCA

H194_1063GC

2 Remove:

• 2 COVERS

• 4 SCREWS

• LEFT CASSETTE GUIDE

• RIGHT CASSETTE GUIDE

Important

For systems with Software Version ≥ 4.1,

you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

3 At the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

• [Set Extraction Bar Home]

• [Verify Position]

Page 63

10DEC05

AR4825-1

Page

63 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

4 Wait until the EXTRACTION BAR has

TOOL

TL-5723

stopped moving.

5 Touch [Hooks Up].

EXTRACTION

HOOK

H194_1044GCA

H194_1044GC

EXTRACTION BAR

EXTRACTION BAR

6 Place the TOOL TL-5723 under the

EXTRACTION BAR HOOKS on the

EXTRACTION BAR until the end of

both EXTRACTION BAR HOOKS are in

line with the mark on the

TOOL TL-5723.

7 Is the TOOL TL-5723 is under the

EXTRACTION BAR HOOKS with no

vertical play?

Yes No

Checkout

procedure is

complete.

Advance to Step 1

of the adjustment

procedure.

To Ad j u st :

Press the Escape key to dismiss the video after viewing.

1 Remove the TOOL TL-5723.

Page 64

10DEC05

AR4825-1

Page

64 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

Important

After “Set Position” is selected, the value will return to 0.0 (+ 5.0 or - 1991).

2 Touch:

• [Ho oks Down]

• [Set Position]

Note

The minimal “up position” is with the top of the EXTRACTION BAR even with the CASSETTE

HANDLING AY.

3 To adjust the height of the HOOK, touch:

• [Fine Nudge Up]

• [Coarse Nudge Up]

• [Fine Nudge Down]

• [Coarse Nudge Down]

4 Touch [Hooks Up].

5 Install TOOL TL-5723.

6 Is the adjustment correct?

Yes No

Continue with Step 7. a. Remove TOOL TL-5723.

b. Touch [Hooks Down].

c. Do Step 3 - Step 6 again.

Important

Do not touch [Save] until the HOOKS are in the correct position.

7 Remove the TOOL TL-5723.

Page 65

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

65 of 160

8 Touch:

• [HOOKS DOWN]

• [Save]

Postrequisites:

1 Do Calibration for the Scan.

Page 66

10DEC05

AR4825-1

Page

66 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

PLATE POSITIONING AY

Adjustment Specification

Purpose: To adjust the position of the LOWER ARM and the position of the UPPER

ARM.

Specification: • The LOWER ARM touches the TOOL TL-5595.

• The UPPER ARM touches the TOOL TL-5725.

Special Tools: • 2 TOOL TL-5595

• TOOL TL-5725

• LOWER TOOL 9F6387A

Prerequisites:

None

To Check:

Press the Escape key to dismiss the video after viewing.

Page 67

10DEC05

AR4825-1

Page

67 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

LEFT CASSETTE GUIDE

RIGHT CASSETTE GUIDE

Dangerous Voltage

Caution

1 Energize the system.

4 SCREWS

2 COVERS

2 Open the TOP COVER.

3 Remove:

• LEF T PANEL

• ERASE LAMP AY

4 Remove:

• 2 COVERS

• 4 SCREWS

• LEFT CASSETTE GUIDE

H194_1063GCA

H194_1063GC

• RIGHT CASSETTE GUIDE

Important

For systems with Software Version ≥ 4.1,

you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

5 At the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

• [Extraction Bar Positions]

• [Lower Plate Guide Roller Position]

Page 68

10DEC05

AR4825-1

Page

68 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

back PLATE

POSITIONING AY

Important

Do not force the TOOL TL-5595 into

front PLATE

POSITIONING AY

position.

6 Place the 2 TOOLS TL-5595 on the

EXTRACTION BAR in the vertical

position, in parallel with both of the

LOWER ARMS of the PLATE

POSITIONING AYs.

7 Do the 2 TOOLS fit between the

LOWER ARMS and the EXTRACTION

BRACKET

BAR?

LOWER ARM

EXTRACTION

BAR

2 TOOLS

TL-5595

H194_1029GCA

H194_1029GC

Yes No

Continue with

Step 8.

Advance to Step 1

of the adjustment

procedure.

8 Check that the 2 TOOLS TL-5595 touch

the LOWER ARMS.

Yes No

Continue with

Step 9.

Advance to Step 1

of the adjustment

procedure.

9 Remove the 2 TOOLS TL-5595 from

the EXTRACTION BAR.

Page 69

10DEC05

AR4825-1

Page

69 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

10 Touch:

• [Retur nTo Home]

• [Back]

• [Cam Position Actuation]

TOOL TL-5725

CLAMP SPRING

TENSIONER

LEVER

2 SCREWS

H194_1045GCA

H194_1045GC

• [Unlatch Position]

• [Back]

• [Extraction Bar Positions]

• [Lower Plate Guide Roller Position]

11 Open the CLAMP SPRING

TENSIONER.

12 Install the TOOL TL-5725 with the thin

end toward the right side and the back

against the CASSETTE END STOP.

13 Close the CLAMP SPRING

TENSIONER.

Page 70

10DEC05

AR4825-1

Page

70 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

TOOL TL-5725

TOOL

CLAMP SPRING

TENSIONER

TL-5725

UPPER ARM

ADJUSTMENT

BRACKET

UPPER ARM

BRACKET

LEVER

2 SCREWS

H194_1075HCA

H194_1075HC

Important

• The CLAMP SPRING T ENSIONER must be closed.

• Damage to the PLATE POSITIONING AY might cause the UPPER ARM BRACKET to

touch the ADJUSTMENT BRACKET.

14 Check that the TOOL TL-5725 touches both of the UPPER ARMS.

Yes No

The checkout

procedure is

complete and

Advance to Step 9

of the adjustment

procedure.

adjustment is not

necessary.

15 Open the CLAMP SPRING TENSIONER.

Page 71

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

71 of 160

16 Remove the TOOL TL-5725.

To Ad j u st :

Press the Escape key to dismiss the video after viewing.

2 PLATE

POSITIONING AYS

SCREW

BRACKET

H194_1028ACA

H194_1028AC

1 Loosen the SCREW on the BRACKET

of both PLATE POSITIONING AYs.

2 Move both of the BRACKETS until both

of the LOWER ARMS touch the 2

TOOLS TL-5595.

3 Tighten the SCREW on the BRACKET

of both PLATE POSITIONING AYs.

4 Remove the 2 TOOLS TL-5595.

5 Touch:

• [Retur n To Home]

• [Back]

• [Cam Position Actuation]

• [Unlatch Position]

• [Back]

• [Extraction Bar Positions]

• [Lower Plate Guide Roller Position]

Page 72

10DEC05

AR4825-1

Page

72 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

6 Open the CLAMP SPRING

TOOL TL-5725

TENSIONER.

7 Install the TOOL TL-5725 with the thin

CLAMP SPRING

TENSIONER

end toward the right side and the back

against the CASSETTE END STOP.

8 Close the CLAMP SPRING

TENSIONER.

9 Loosen the 2 SCREWS on both of the

PLATE POSITIONING AYS.

10 Move the LEVER down then up until it

stops.

11 Tighten the 2 SCREWS on both of the

PLATE POSITIONING AYS.

12 Open the CLAMP SPRING

TENSIONER.

13 Remove the TOOL TL-5725.

LEVER

2 SCREWS

Postrequisites:

None

H194_1045GCA

H194_1045GC

14 Close the CLAMP SPRING

TENSIONER.

15 Touch:

• [Retur n To Home]

• [Back]

• [Cam Position Actuation]

• [Home Cam]

Page 73

10DEC05

AR4825-1

Page

73 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

RIGHT and LEFT PLUSH AY - Alignment

Adjustment Specification

Purpose: To align the RIGHT and LEFT PLUSH AY.

Specification: With the RIGHT PLUSH AY adjusted to 7 - 8 mm (0.25 - 0.30 in.) from the

end of the 18 x 24 cm CASSETTE, the LEFT PLUSH AY SHUTTERS must

not touch the RIGHT PLUSH AY.

Special Tools: 6-in. SCALE TL-2762

Prerequisites:

1 Adjust:

• SLED CAM FOL LOWER

• CLAMP BAR

To Check:

Press the Escape key to dismiss the video after viewing.

Page 74

10DEC05

AR4825-1

Page

74 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

1 Open the TOP COVER.

LEFT CASSETTE GUIDE

2 Remove:

RIGHT CASSETTE GUIDE

• 2 COVERS

• 4 SCREWS

4 SCREWS

2 COVERS

H194_1063GCA

H194_1063GC

• LEFT CASSETTE GUIDE

• RIGHT CASSETTE GUIDE

Caution

Dangerous Voltage

3 Energize the system.

Important

For systems with Software Version ≥ 4.1,

you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

4 At the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

• [Cam Position Actuation]

• [Load Cassette]

Page 75

10DEC05

AR4825-1

Page

75 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

5 Load the 18 x 24 cm CASSETTE.

CASSETTE

CASSETTE

6 Check for a 7 - 8 mm (0.25 - 0.30 in.)

clearance from the end of the

CASSETTE to the PLUSH BRACKET.

Yes No

7-8 mm

(0.25 -

0.30 in.)

PLUSH BRACKET

Continue with

Step 7.

Advance to Step 1

of the adjustment

procedure.

H194_1048ACA

H194_1048AC

2 SCREWS

LEFT

PLUSH AY

SHUTTER

.76 mm

(0.030 in.)

PLUSH

BRACKET

RIGHT

PLUSH AY

H194_1067ACA

H194_1067AC

7 Check that the left PLUSH AY

SHUTTERS are 0.76 mm (0.030 in.)

from the RIGHT PLUSH AY.

Yes No

The checkout

procedure is

complete.

Advance to Step 4

of the adjustment

procedure.

8 Touch [Eject Cassette].

Page 76

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

76 of 160

To Ad j u st :

Press the Escape key to dismiss the video after viewing.

CASSETTE

RIGHT PLUSH AY

2 SCREWS

2 SCREWS

H194_1051ACA

H194_1051AC

1 Loosen the 2 SCREWS.

2 Move the right PLUSH AY into the

correct position.

3 Tighten the 2 SCREWS.

4 Loosen the 2 SCREWS on the LEFT

PLUSH AY.

LEFT

PLUSH AY

SHUTTER

Postrequisites:

None

.76 mm

(0.030 in.)

RIGHT

PLUSH AY

H194_1067ACA

H194_1067AC

5 Align the left PLUSH AY SHUTTERS to

be 0.76 mm (0.030 in) from the RIGHT

PLUSH AY.

6 Tighten the 2 SCREWS.

7 Eject the CASSETTE.

Page 77

10DEC05

AR4825-1

Page

77 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

LEFT PLUSH AY - Vertical Position

Adjustment Specification

Purpose: To adjust the vertical position of the LEFT PLUSH AY.

Specification: The LEFT PLUSH ARM is vertical to the LEFT PLUSH AY BRACKET.

Special Tools: None

Prerequisites:

1 Adjust:

• SLED CAM FOL LOWER

• CLAMP BAR

Page 78

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

78 of 160

To Check:

4 SCREWS

H194_1062GCA

H194_1062GC

LEFT CASSETTE GUIDE

RIGHT CASSETTE GUIDE

2 COVERS

2 SCREWS

CASSETTE

LOAD CRADLE

1 Open the TOP COVER.

2 Remove:

• 2 COVERS

• 4 SCREWS

• LEFT CASSETTE GUIDE

• RIGHT CASSETTE GUIDE

• 2 SCREWS

• CASSETTE LOAD CRADLE

Caution

Dangerous Voltage

3 Energize the system.

Important

For systems with Software Version ≥ 4.1,

you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

4 At the main menu, touch:

• [Ser vice Functions]

• [Diagnostics]

• [Cam Position Actuation]

• [Home Cam]

Page 79

10DEC05

C

A

AR4825-1

Page

79 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

5 Check that the left PLUSH ARM AY is

vertical to the left PLUSH AY

PLUSH

ARM AY

PLUSH AY

BRACKET

SPRING

BRACKET

BRACKET.

2 SCREWS

H194_1069GC

H194_1069G

Page 80

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

80 of 160

To Ad j u st :

PLUSH

ARM AY

PLUSH AY

BRACKET

1 Loosen the 2 SCREWS.

2 Move the SPRING BRACKET until the

left PLUSH ARM AY is ver tical to the

left PLUSH AY BRACKET.

3 Tighten the 2 SCREWS.

SPRING

BRACKET

2 SCREWS

Postrequisites:

1 Adjust:

• SLED CAM FOL LOWER

• CLAMP BAR

• CASSETTE END STOP

• REAR CASSETTE SENSOR

H194_1069GCA

H194_1069GC

Page 81

10DEC05

AR4825-1

Page

81 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

INTERNAL BAR CODE READER

Adjustment Specification

Purpose: To check the alignment of the INTERNAL BAR CODE READER.

Specification: When you install the BAR CODE ALIGNMENT TOOL TL-5600 and touch

[READ CASSETTE ID] the MONITOR displays “x222222222”.

Special Tools: BAR CODE ALIGNMENT TOOL TL-5600

Prerequisites:

None

To Check:

Caution

Dangerous Voltage

1 Energize the system.

2 Open the TOP COVER.

3 Close the FRONT DOOR.

HANDLE

4 PINS

BAR CODE

ALIGNMENT

TOOL TL-5600

WINDOW

H194_1024ACA

H194_1024AC

4 Seat the 4 PINS of the BAR CODE

ALIGNMENT TOOL TL-5600 in the

WINDOW of the EXTRACTION BAR.

5 Hold the HANDLE vertically.

Page 82

10DEC05

AR4825-1

Page

82 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

Important

For systems with Software Version ≥ 4.1, you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See SERVICE BULLETIN 843.

6 At the main menu, to uch:

• [Ser vice Functions]

• [Diagnostics]

• [Component Control: Step]

• [READ CASSETTE ID]

Important

The “Status” might read “The bar code is backwards”, this is normal.

7 Check that the CASSETTE ID “x222222222” is displayed.

To Ad j u st :

1 Remove the LEFT PANEL.

Page 83

10DEC05

AR4825-1

Page

83 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

2 Loosen the 2 SCREWS.

2 SCREWS

BRACKET

H194_1025ACA

H194_1025AC

3 If the displayed value is:

“x333333333” “x111111111” “Error”

a. Move the BRACKET

up a minimum

distance.

b. Tighten the

2 SCREWS.

a. Move the BRACKET

down a minimum

distance.

b. Tighten the 2 SCREWS.

a. Move the BRACKET a

minimum distance in either

direction until numbers

display.

b. Tighten the 2 SCREWS.

4 Touch [READ CASSETTE ID] again.

Page 84

10DEC05

AR4825-1

Page

84 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

BAR CODE ALIGNMENT

TOOL

bar code 9111111111

Important

If the reading at either edge of the bar code

is “x222222222”, the adjustment will not

hold.

5 Check that the BAR CODE READER is

bar code 9333333333

bar code 9222222222

Correct

reading at the center of the bar code

“x222222222”.

a Make a mark on the BRACKET for

the position of the SCREW.

b Move the BRACKET in the same

direction that you did during Step 3

Not Correct

H177_2483ACA

H177_2483AC

until “x333333333” or “x111111111”

displays on the MONITOR.

H194_1026ACA

H194_1026AC

mark

BRACKET

2 SCREWS

c Tighten the 2 SCREWS.

d Make another mark on the

BRACKET for the new position of

the SCREW.

e Move the BRACKET until the

SCREW is in the center of the 2

marks.

f Tighten the 2 SCREWS.

g Check that “x222222222” displays

on the MONITOR.

Page 85

10DEC05

AR4825-1

Page

85 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

Important

The BRACKET must be at a 31-degree

BRACKET

angle.

31 degree

angle

H177_2481ACA

H177_2481AC

9 Is the angle of the BRACKET correct?

Yes No

The INTERNAL BAR

CODE READER

adjustment procedure is

a. Install a new BRACKET.

b. Continue with Step 10.

complete.

10 Do Step 2 - Step 3 again.

6 If “x2222222222” does not display on

the MONITOR, remove the BRACKET.

7 Compare the angle of the BRACKET

with the BRACKET in the graphic.

8 Hold the BRACKET against the image

on the screen of your computer.

Postrequisites:

None

Page 86

10DEC05

AR4825-1

Page

86 of 160

ADJUSTMENTS AND REPLACEMENTS Adjustments

CASSETTE LOAD CRADLE

Adjustment Specification

Purpose: To make the CASSETTE LOAD CRADLE align with the CASSETTE.

Specification: The CASSETTE LOAD CRADLE is aligned with the CASSETTE, the

CASSETTE GUIDES and the EXTRACTION BAR.

Special Tools: 18 x 24 cm CASSETTE

Prerequisites:

None

To Check:

You cannot check this adjustment.

To Ad j u st :

1 Open the TOP COVER.

2 Energize the system.

Important

For systems with Software Version ≥ 4.1, you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See SERVICE BULLETIN 843.

3 Touch:

• [Ser vice Functions]

• [Diagnostics]

• [Extraction Bar Position]

• [Home Position]

• [Back]

• [Cam Position Actuation]

Page 87

ADJUSTMENTS AND REPLACEMENTS Adjustments

10DEC05

AR4825-1

Page

87 of 160

• [Ho me Cam]

CASSETTE

CASSETTE

GUIDES

CASSETTE

LOAD

CRADLE

CASSETTE

LOAD CRADLE

1 - 2 mm

(0.04 - 0.08 in.)

EXTRACTION

BAR

CASSETTE

TONGUE

4 Loosen the 2 SCREWS.

5 Position a 18 x 24 cm CASSETTE.

6 Move:

• CASSETTE LOAD CRADLE until the

vertical clearance between the

CASSETTE and the TONGUE is

1 - 2 mm (0.04 - 0.08 in.)

• CASSETTE LOAD CRADLE in the

center from side to side with the

CASSETTE GUIDES

Note

If you touch the CASSETTE at the front, it

should move down and up.

7 Hold the CASSETTE LOAD CRADLE

and tighten the 2 SCREWS.

CASSETTE

2 SCREWS

Postrequisites:

None

CASSETTE

LOAD CRADLE

H194_1042GCA

H194_1042GC

8 Check that the adjustment is correct.

9 Remove the CASSETTE.

Page 88

10DEC05

AR4825-1

Page

88 of 160

ADJUSTMENTS AND REPLACEMENTS Replacements

Section 2: Replacements

GALVO and BLOCK AY

Prerequisites:

None

To Remove:

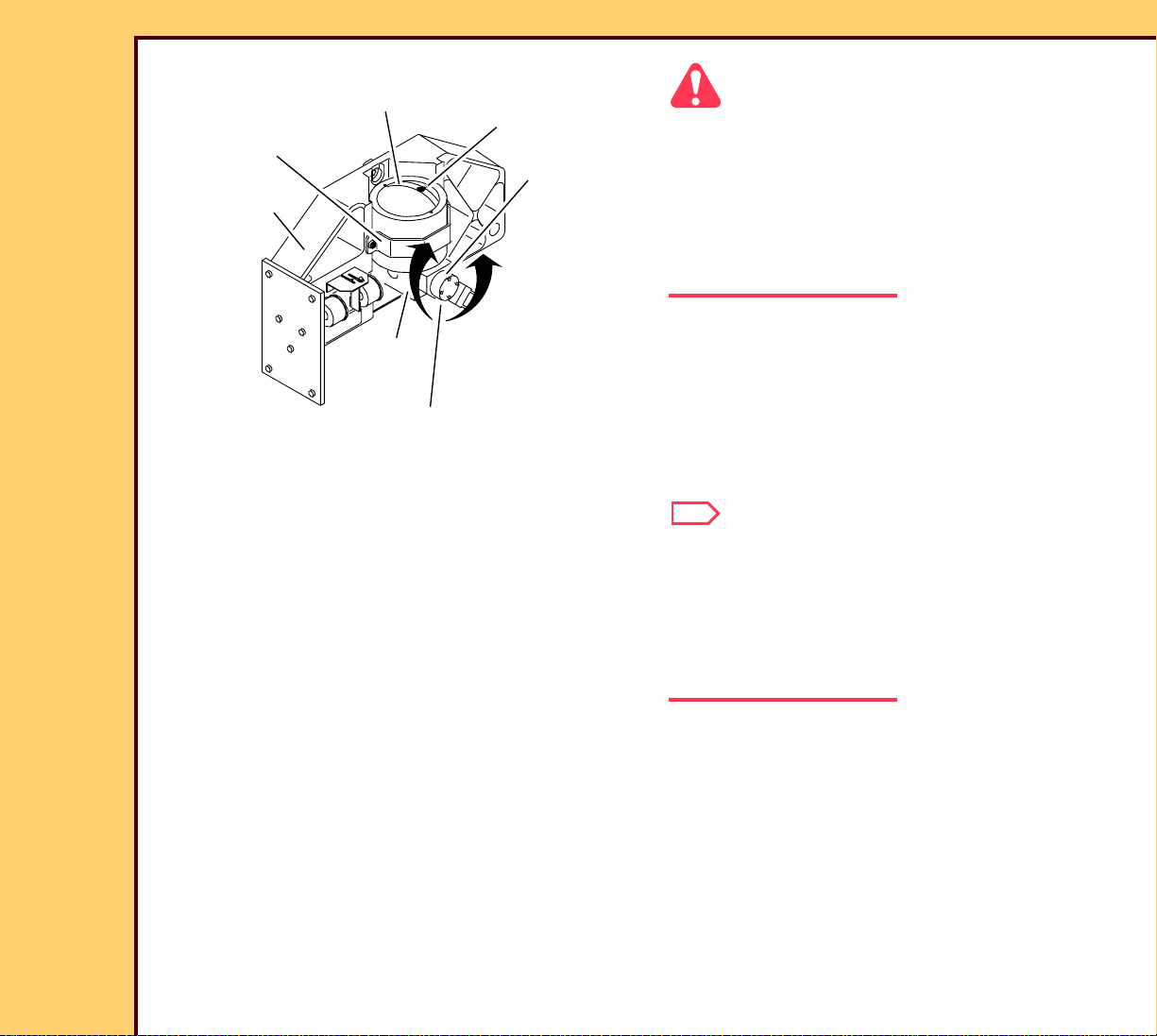

Caution

Dangerous Voltage

1 De-energize the system.

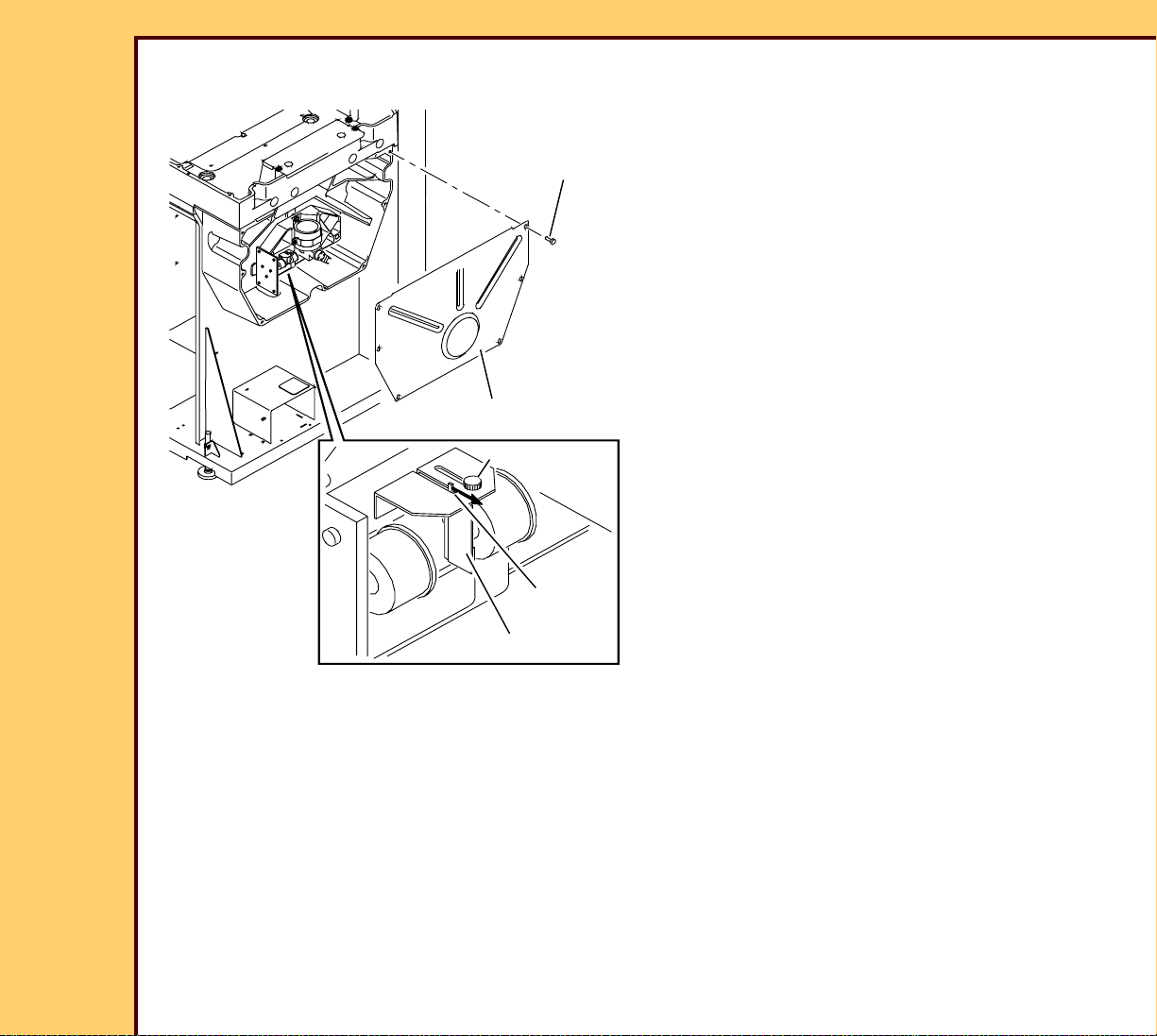

2 Remove the FRONT DOOR and RIGHT PANEL.

Caution

Do not cause damage to the OPTICAL AY.

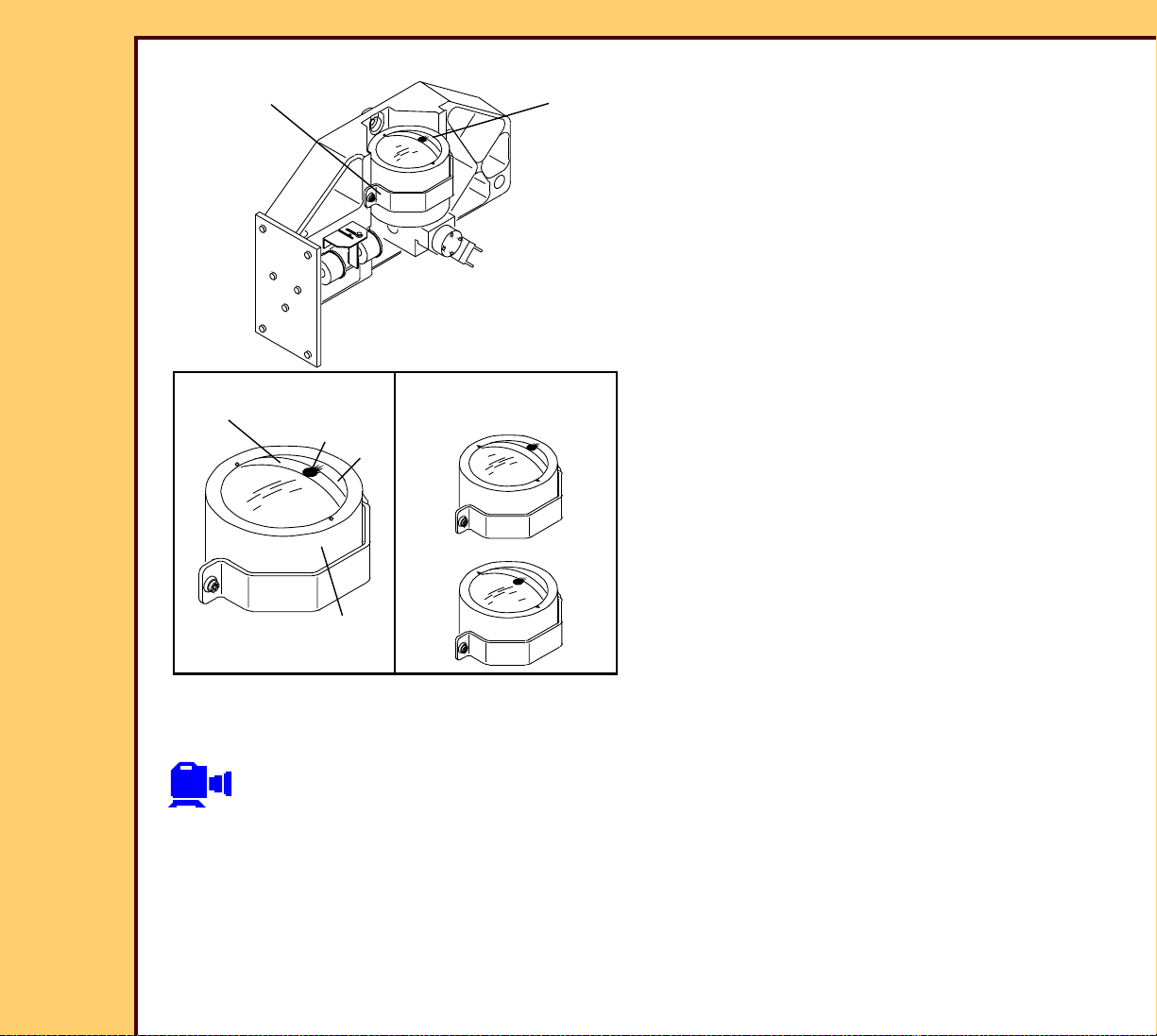

SHOCK WATCH

H194_1400ACA

H194_1400AC

3 Remove:

• 6 SCREWS

• COVER

Page 89

10DEC05

AR4825-1

Page

89 of 160

ADJUSTMENTS AND REPLACEMENTS Replacements

4 Disconnect the CONNECTOR.

5 Loosen the SCREW.

6 Remove the GALVO.

n

e

h

w

.

n

d

te

tio

a

ia

d

fe

e

.

d

r ra

m

s

e

a

k

s

e

c

a

b

L

rlo

to

B

te

3

re

in

s

u

s

d

s

n

o

la

a

C

xp

n

e

e

p

id

o

o

v

A

CONNECTOR

H194_1417ACA

H194_1417AC

SCREW

GALVO

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

1 Adjust:

• GALVO BOARD

• GALVO ROTATION

• FOLD MIRROR

2 Do the Calibration for the CR 825/850 SYSTEM.

Page 90

10DEC05

AR4825-1

Page

90 of 160

ADJUSTMENTS AND REPLACEMENTS Replacements

OPTICS MODULE

Prerequisites:

None

To Remove:

Press the Escape key to dismiss the video after viewing.

Caution

Dangerous Voltage

H194_1402GCA

H194_1402GC

lass 3B Laser radiatio

C

open and

void

A

CONNECTOR J2

ground wire

hen

n w

d.

te

efea

.

eam

rlocks d

inte

sure to b

xpo

e

OPTICS

MODULE

3 SCREWS

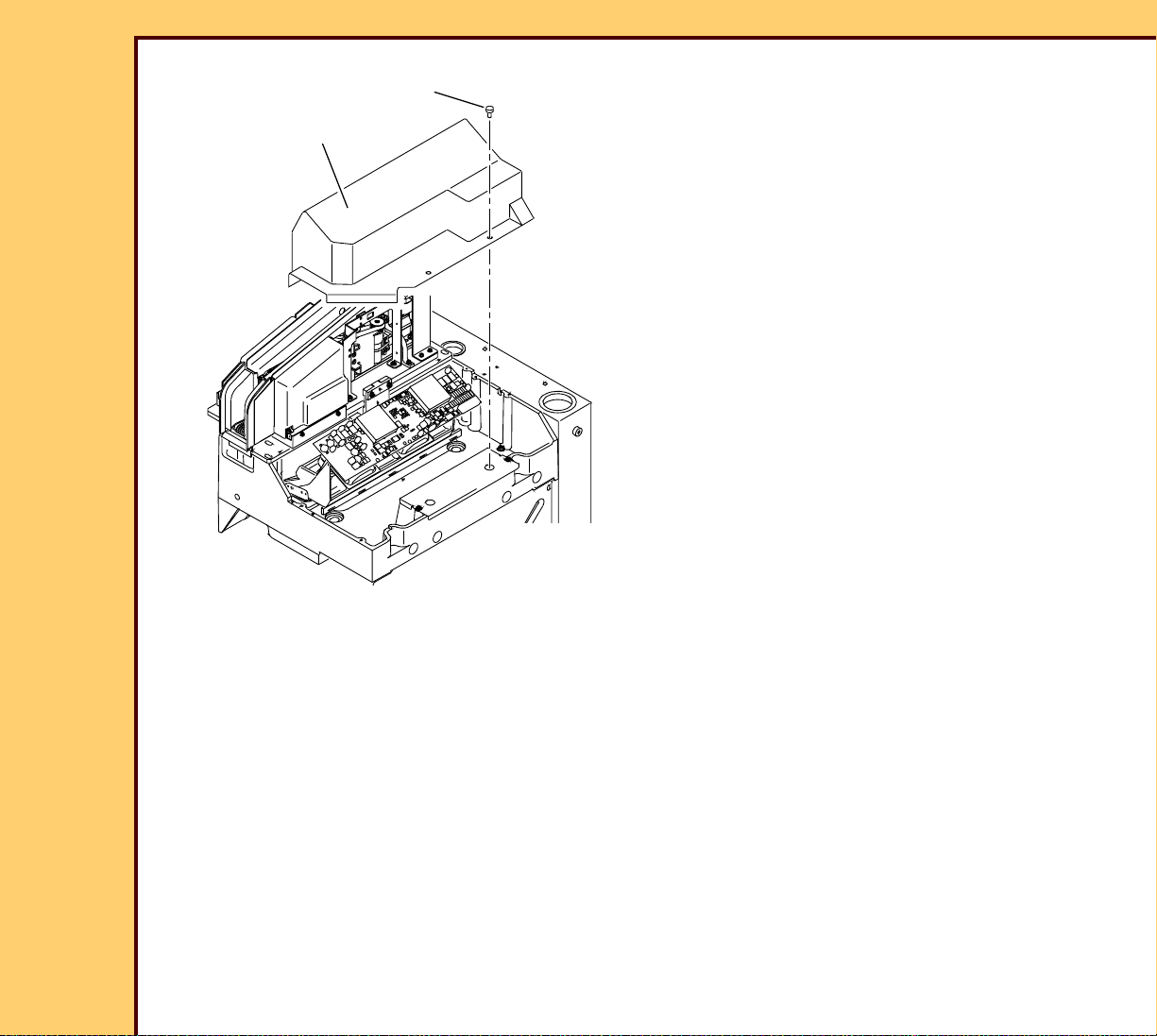

1 De-energize the system.

2 Remove the FRONT DOOR and RIGHT

PANEL.

ESD

Possible damage from electrostatic discharge.

3 Disconnect:

• CONNECTOR J2

• GROUND wire

• 3 SCREWS

• OPTICS MODUL E

Page 91

ADJUSTMENTS AND REPLACEMENTS Replacements

10DEC05

AR4825-1

Page

91 of 160

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

1 Do Setting the Laser Calibration Voltage.

2 Adjust:

• GALVO ROTATION

• GALVO BOARD

• FOLD MIRROR

3 Do the Calibration for the Scan.

Page 92

10DEC05

AR4825-1

Page

92 of 160

ADJUSTMENTS AND REPLACEMENTS Replacements

PMT/DAS BOARD

Prerequisites:

None

To Remove:

4 SCREWS

PMT COVER

2 SCREWS

Dangerous Voltage

Possible damage from electrostatic discharge.

Caution

1 De-energize the system.

2 Open the TOP COVER.

ESD

3 Remove:

CONNECTOR

J2

CONNECTOR J1

PMT/DAS BOARD

H194_0021GCA

H194_0021GC

SCREW

GROUND STRAP

To Install:

1 Reverse the steps in the removal procedure.

• 5 SCREWS

• PMT COVER

• CONNECTOR J1

• CONNECTOR J2

• SCREW

• ground STRAP

• 2 SCREWS

• PMT/DAS BOARD

Page 93

ADJUSTMENTS AND REPLACEMENTS Replacements

10DEC05

AR4825-1

Page

93 of 160

Postrequisites:

1 Do the Calibration for the CR 825/850 SYSTEM.

Page 94

10DEC05

AR4825-1

Page

94 of 160

ADJUSTMENTS AND REPLACEMENTS Replacements

PMTs and COLLECTOR AY

Prerequisites:

None

To Remove:

2 SCREWS

COVER

2 PMTs

COLLECTOR AY

2 SCREWS

Caution

Dangerous Voltage

1 De-energize the system.

FOAM

2 Open the TOP COVER.

3 Remove the PMT/DAS BOARD.

ESD

Possible damage from electrostatic discharge.

4 Remove:

• 2 SCREWS

• COLLECTOR AY

• 2 SCREWS

• COVER

• FOAM

H194_0022GCA

H194_0022GC

• 2 PMTs

Page 95

ADJUSTMENTS AND REPLACEMENTS Replacements

10DEC05

AR4825-1

Page

95 of 160

To Install:

Caution

Do not damage the PMT.

1 Reverse the steps in the removal procedure.

Postrequisites:

1 Adjust the COLLECTOR AY.

2 Do the “Calibration for the CR 825/850 SYSTEM.

Page 96

10DEC05

AR4825-1

Page

96 of 160

ADJUSTMENTS AND REPLACEMENTS Replacements

FOLD MIRROR

Prerequisites:

None

To Remove:

PMT COVER

FOLD MIRROR

COVER

H194_0050GCA

H194_0050GC

5 SCREWS

2 PLUGS

FOLD

MIRROR

3 SCREWS

Caution

Dangerous Voltage

1 De-energize the system.

2 Remove the FRONT DOOR and RIGHT

PANEL.

3 Remove:

• 5 SCREWS

• PMT COVER

• FOLD MIRROR COVER

• 2 PLUGS

• 3 SCREWS

• FOLD MIRROR

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

1 Adjust the FOLD MIRROR.

2 Do the Calibration for the Scan.

Page 97

10DEC05

AR4825-1

Page

97 of 160

ADJUSTMENTS AND REPLACEMENTS Replacements