Page 1

{PreventiveMaint}{Production}{Health Group}{Restricted}

Publication No. PM4366-1

07MAR08

Restricted

PREVENTIVE MAINTENANCE

for the

Kodak DirectView CR 500 SYSTEM

Service Code: 4366

Important

• Qualified service personnel must do these procedures.

• When doing the procedures in this document, you must use safe work practices and wear

the correct Personal Protective Equipment (for example: SAFETY EYEWEAR) according

to your Company’s Standard Operating Procedures.

H195_0016BC

© CARESTREAM HEALTH, INC.

Page 2

PREVENTIVE MAINTENANCE

07MAR08

PM4366-1

Page

2 of 31

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to t he subject

matter gained by Carestream Health, Inc. prior to publication.

No patent license is granted by this information.

Carestream Health, Inc. reserves the right to chang e this information withou t notice, and ma kes no

warranty, express or implied, with respect to this infor mation. Carestr eam Health shall not be liable

for any loss or damage, including consequ ential o r special damages, resulting fr om any use of this

information, even if loss or damage is caused by Carestream Health’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Table of Contents

Description Page

Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Necessary Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Maintenance Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Cleaning the CR 500 SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cleaning the SLOW SCAN AY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cleaning the ERASE AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning the PHOSPHOR SCREENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Checking the Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Page 3

07MAR08

PM4366-1

Page

3 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

Section 1: Preventive Maintenance

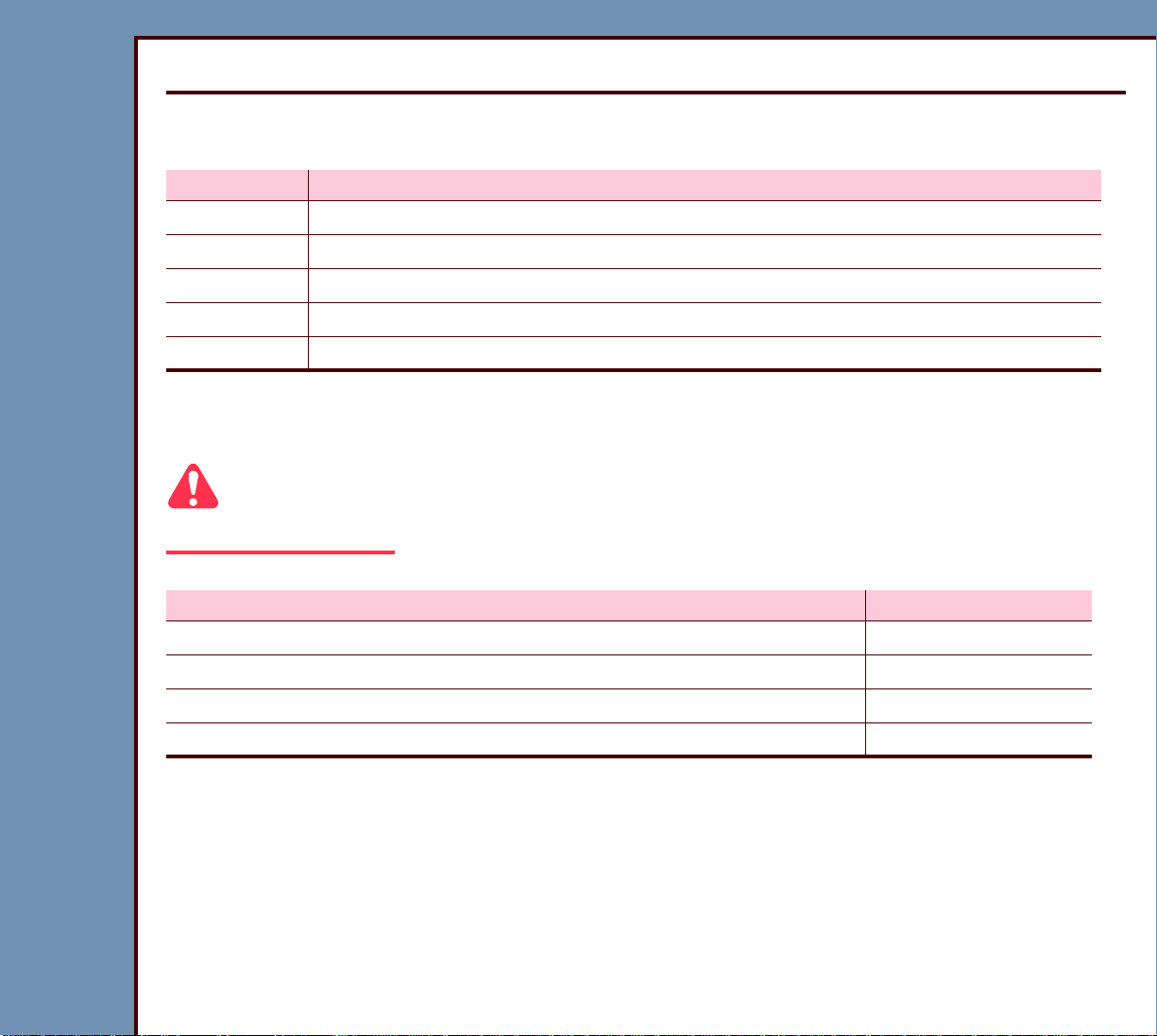

Necessary Materials

Par t N o. Description

TL845 4977 Kodak SCREEN CLEANER

- - - LINT-FREE CLOTHS

- - - ESD-SAFE VACUUM CLEANER with DUST BRUSH ATTACHMENT

- - - LENS WIPES

1C8068 LENS CLEANER

Maintenance Plan

Caution

Only qualified service personnel must do the procedure Cleaning the SLOW SCAN AY.

Procedure Do:

Cleaning the CR 500 SYSTEM When necessary

Cleaning the SLOW SCAN AY When necessary

Cleaning the ERASE AY When necessary

Cleaning the PHOSPHOR SCREENS At each service call

Page 4

PREVENTIVE MAINTENANCE Preventive Maintenance

07MAR08

PM4366-1

Page

4 of 31

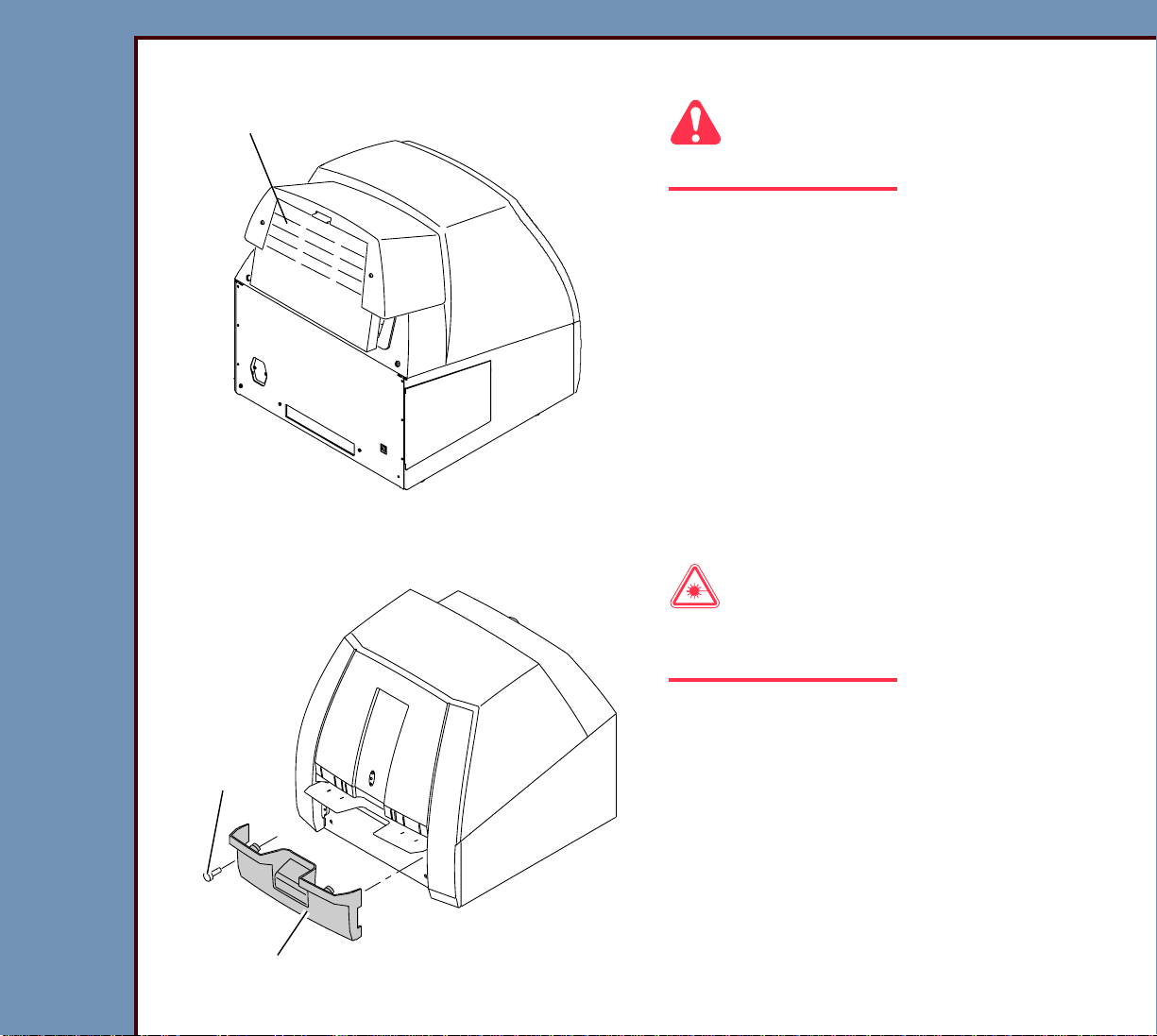

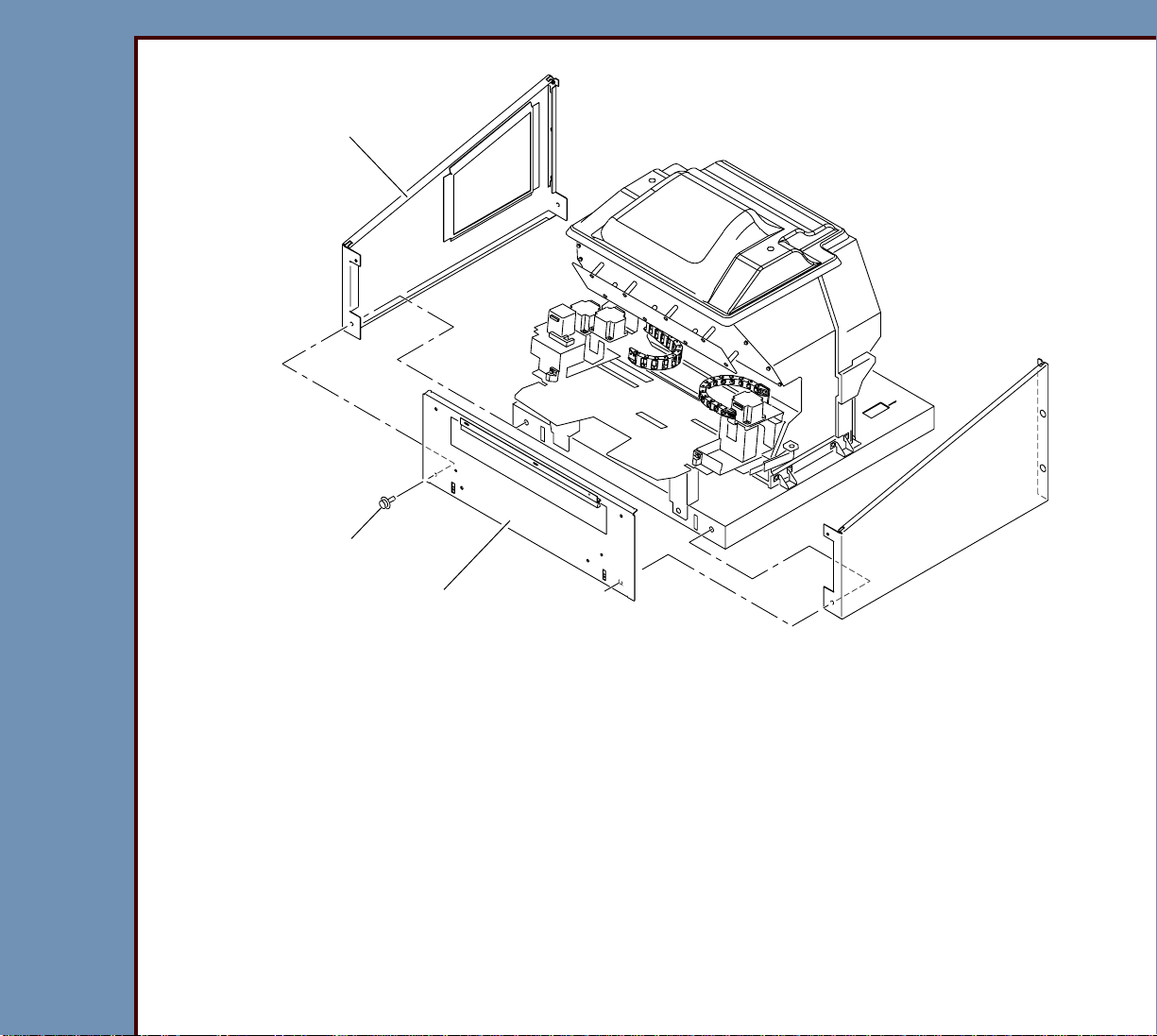

Cleaning the CR 500 SYSTEM

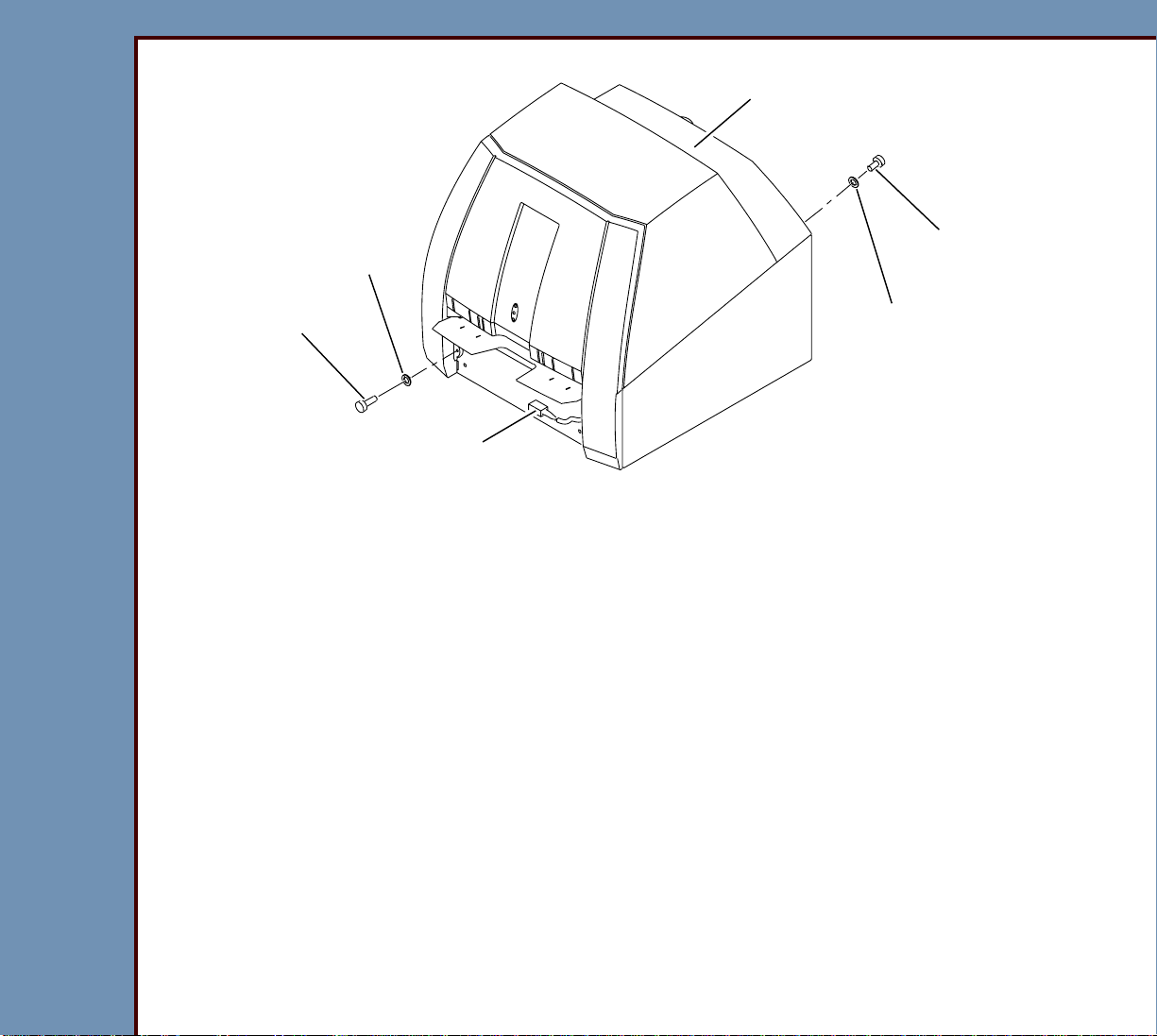

BACK DOOR AY

H195_1189ACA

H195_1189AC

Caution

Dangerous Voltage

1 De-energize and disconnect the Kodak

DirectView CR 500 SYSTEM from the

main power.

2 If necessary, remove the BACK DOOR

AY.

2 SCREWS

FRONT COVER

H195_1017ACA

H195_1017AC

Laser Warning

This equipment uses a visible red laser.

Prevent direct exposure to the laser beam.

3 Remove:

• 2 SCREWS

• FRONT COVER

Page 5

07MAR08

PM4366-1

Page

5 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

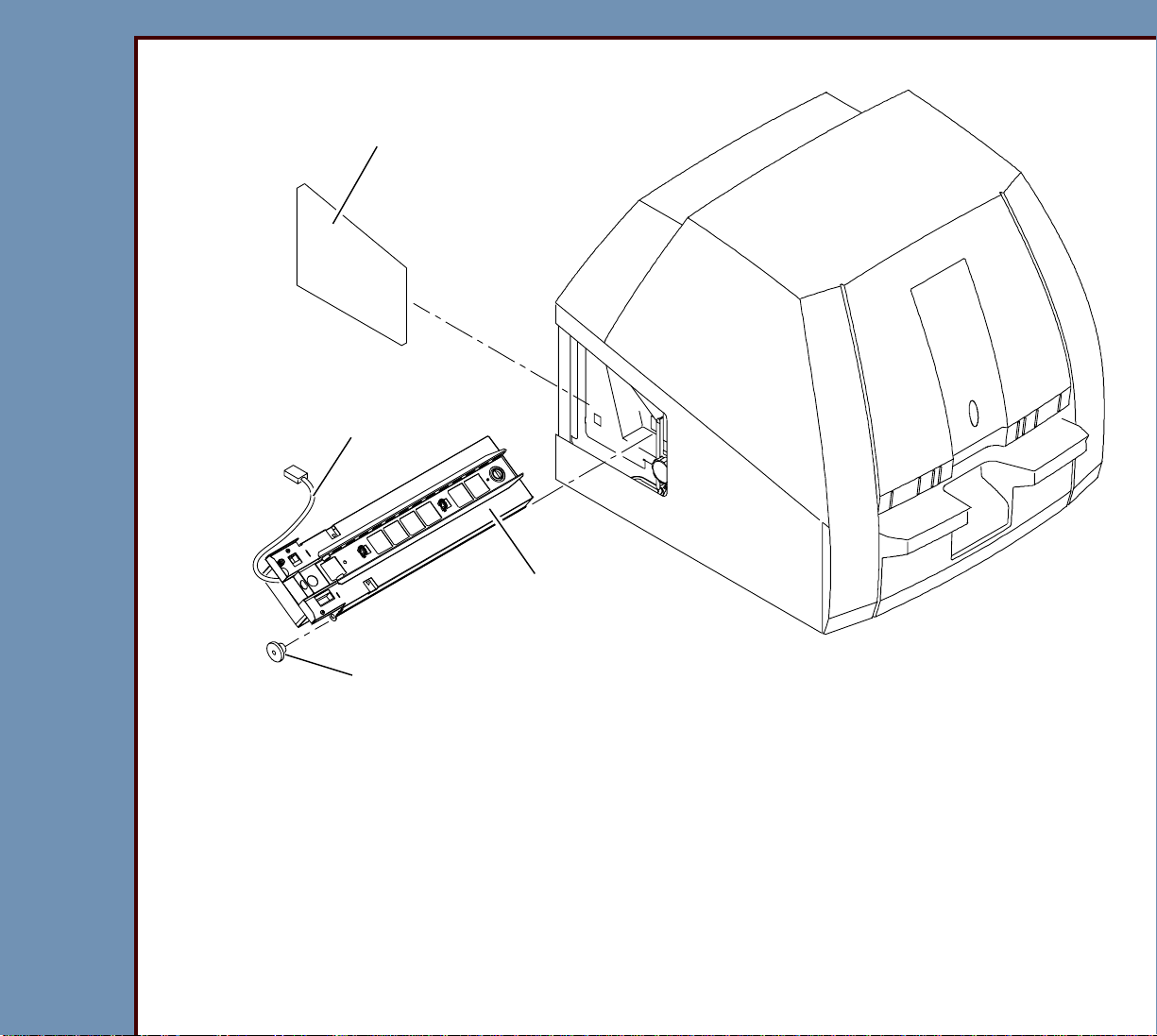

TOP COVER

2 WASHERS

2 front SCREWS

OPERATOR INTERFACE

CABLE CONNECTOR J101

2 WASHERS

4 Disconnect the OPERATOR INTERFACE CABLE CONNECTOR J101.

5 Remove:

• 2 front SCREWS

• 2 WASHERS

• 2 back SCREWS

• 2 WASHERS

• TOP COVER

2 back SCREWS

H195_1021BCA

H195_1021BC

Page 6

07MAR08

PM4366-1

Page

6 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

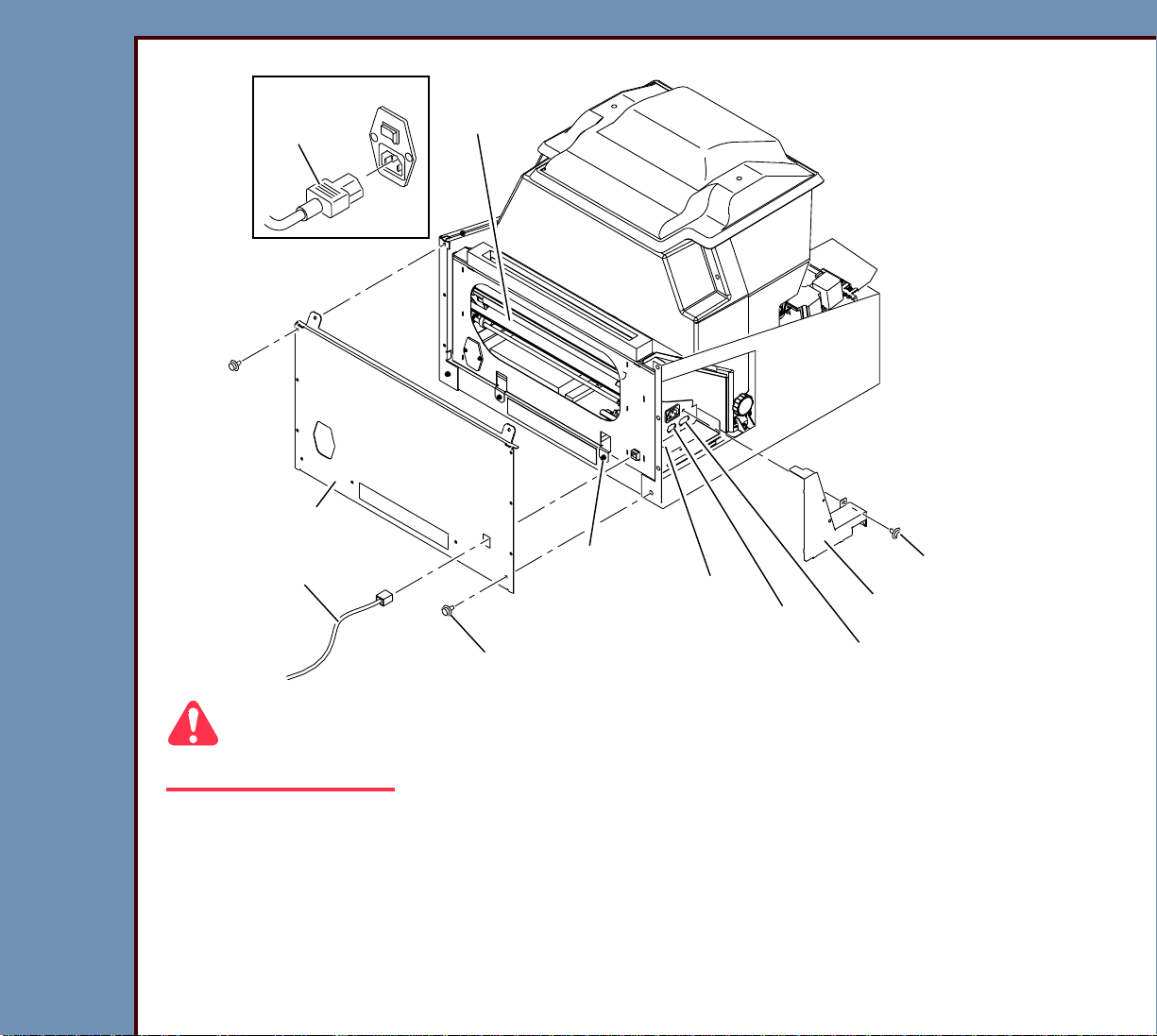

LEFT SIDE

ACCESS PANEL

ERASE AY

POWER CORD

ERASE LAMP

HOUSING AY

THUMBSCREW

6 Remove the LEFT SIDE ACCESS PANEL.

7 Disconnect the ERASE AY POWER CORD.

8 Remove:

• THUMBSCREW

• ERASE LAMP HOUSING AY

H195_1090HCA

H195_1090HC

Page 7

07MAR08

PM4366-1

Page

7 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

110 V

POWER

CORD

BACK COVER

ERASE AY

NETWORK

CABLE

Caution

Dangerous Voltage

9 Disconnect:

• 110 V POWER CORD

• NETWORK CABLE

8 SCREWS

2 SCREWS

CONNECTOR RJ45

CONNECTOR A9P1

DRIVE BELT COVER

CONNECTOR A9J2

2 SCREWS

H195_1216HCA

H195_1216HC

Page 8

PREVENTIVE MAINTENANCE Preventive Maintenance

07MAR08

PM4366-1

Page

8 of 31

10 Remove:

• 8 SCREWS

• BACK COVER

• 2 SCREWS

• DRIVE BELT COVER

11 Disconnect the CONNECTORS:

• RJ45

• A9P1

• A9J2

Caution

Be careful. Do not allow the ERASE AY to fall.

12 Remove:

• 2 SCREWS

• ERASE AY

13 Place the ERASE AY on a flat surface.

Page 9

07MAR08

PM4366-1

Page

9 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

2 SIDE PANELS

6 SCREWS

14 Remove:

• 6 SCREWS

• FRONT PANEL

• 2 SIDE PANELS

FRONT PANEL

H195_1217HCA

H195_1217HC

Page 10

07MAR08

PM4366-1

Page

10 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

2 CASSETTE

GUIDES

CASSETTE

INTERFACE AY

center

position

H195_1234HCA

H195_1234HC

15 Use the ESD-SAFE VACUUM CLEANER to carefully remove all dust and debris from the

CASSETTE INTERFACE AY.

16 Move the 2 CASSETTE GUIDES to the outside, and continue cleaning the CASSETTE

INTERFACE AY.

17 If any dust or debris remains on the CASSETTE INTERFACE AY, carefully use a damp,

LINT-FREE CLOTH to remove it.

18 Move the 2 CASSETTE GUIDES to the center position of the CASSETTE INTERFACE

AY.

Page 11

07MAR08

PM4366-1

Page

11 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

2 SCREWS

LASER SAFETY

COVER

4 SCREWS

BACK LIGHT

LOCK COVER

19 Remove:

• 2 SCREWS

• LASER SAFETY COVER

• 4 SCREWS

• BACK LIGHT LOCK COVER

H195_1034HCA

H195_1034HC

Page 12

07MAR08

PM4366-1

Page

12 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

CONNECTOR A5J1

CONNECTOR

A5J2

H195_1167HCA

H195_1167HC

20 Disconnect from the PMT BOARD:

• CONNECTOR A5J2

• CONNECTOR A5J1

ESD

Possible damage from electrostatic discharge.

PMT BOARD

Page 13

07MAR08

PM4366-1

Page

13 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

2 SCREWS

CONNECTOR

A11P2

2 top SCREWS

2 bottom SCREWS

ENCODER CABLE

SLOW SCAN COLLECTOR BOARD

CONTROLLER BOARD

CONNECTOR A7J1

Important

The PMT BOARD is not displayed in the graphic.

21 Loosen the 2 SCREWS for the CONNECTOR A11P2.

22 Disconnect:

• CONNECTOR A11P2

• CONNECTOR A7J1 from the SLOW SCAN CONTROLLER BOARD

• ENCODER CABLE from the SLOW SCAN CONTROLLER BOARD

SLOW SCAN AY

FRAME CHANNEL

H195_1164HCA

H195_1164HC

Page 14

PREVENTIVE MAINTENANCE Preventive Maintenance

07MAR08

PM4366-1

Page

14 of 31

23 Remove from the FRAME CHANNEL:

• ENCODER CABLE

• CONNECTOR A7J1

24 Remove from the SLOW SCAN AY:

• 2 bottom SCREWS

• 2 top SCREWS

Caution

The weight of the SLOW SCAN AY is 13 kg (45 lb).

25 Tilt the SLOW SCAN AY backward to remove.

26 Place the SLOW SCAN AY on a flat surface.

Page 15

07MAR08

PM4366-1

Page

15 of 31

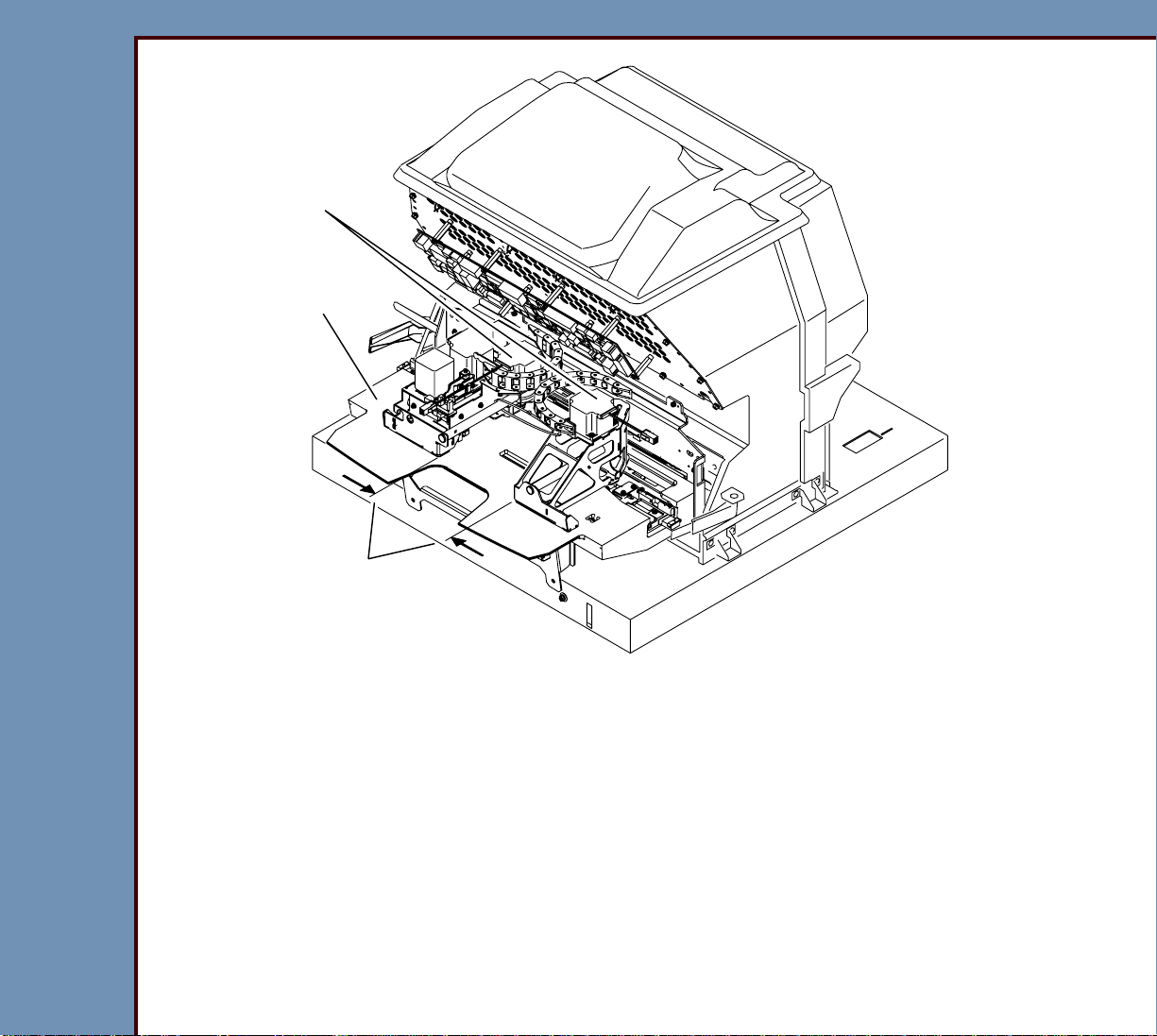

PREVENTIVE MAINTENANCE Preventive Maintenance

F-THETA LENS

MINI-FAST SCAN BOARD - do not touch or clean

MSC

BOARD

BASE FRAME

OPTICAL FRAME

OPTICAL CAVITY

H195_1235HCA

H195_1235HC

SLOW SCAN BOARD

ESD

Possible damage from electrostatic discharge.

27 Connect your ESD WRIST STRAP to the ground on the CR 500 SYSTEM.

Caution

Do not clean or touch the MINI-FAST SCAN BOARD.

Page 16

PREVENTIVE MAINTENANCE Preventive Maintenance

07MAR08

PM4366-1

Page

16 of 31

28 Use the ESD-SAFE VACUUM CLEANER to remove all dust and debris from:

• OPTICAL CAVITY

• OPTICAL FRAME

• SLOW SCAN BOARD

• BASE FRAME

• MSC BOARD

29 If any dust or debris remains on the CR 500 SYSTEM, carefully use a damp, LINT-FREE

CLOTH to remove it.

30 Carefully clean any dust and debris from the F-THETA LENS. Use:

• LENS WIPES, or

• LINT-FREE CLOTH

• LENS CLEANER 1C8068

Page 17

PREVENTIVE MAINTENANCE Preventive Maintenance

07MAR08

PM4366-1

Page

17 of 31

Cleaning the SLOW SCAN AY

Important

• You must:

RP 1 DRIVE ROLLER

RP 1 PRESSURE ROLLER

H195_1214BCA

H195_1214BC

– rotate the ROLLERS to clean all sides

– clean the ROLLERS until the cloth has no black debris

• If necessary, use more than one LINT-FREE CLOTH.

1 Use water and a LINT-FREE CLOTH to clean:

• RP 1 PRESSURE ROLLER

• RP 1 DRIVE ROLLER

2 Allow the ROLLERS to dry.

Page 18

PREVENTIVE MAINTENANCE Preventive Maintenance

07MAR08

PM4366-1

Page

18 of 31

3 Check that the ROLLERS are:

• clean

• dry

• free of debris

2 SCREWS

CONNECTOR

A11P2

2 top SCREWS

2 bottom SCREWS

ENCODER CABLE

SLOW SCAN COLLECTOR BOARD

CONTROLLER BOARD

CONNECTOR A7J1

SLOW SCAN AY

FRAME CHANNEL

H195_1164HCA

H195_1164HC

Page 19

07MAR08

PM4366-1

Page

19 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

Caution

• The weight of the SLOW SCAN AY is 13 kg (45 lb).

• The PMT BOARD is not displayed in the graphic.

4 Tilt the SLOW SCAN AY backward to install.

5 Install:

• 2 bottom SCREWS

• 2 top SCREWS

6 Insert into the FRAME CHANNEL:

• ENCODER CABLE

• CONNECTOR A7J1

7 Connect:

• CONNECTOR A11P2

• CONNECTOR A7J1 to the SLOW SCAN CONTROLLER BOARD

• ENCODER CABLE to the SLOW SCAN CONTROLLER BOARD

8 Tighten the 2 SCREWS for the CONNECTOR A11P2.

Page 20

07MAR08

PM4366-1

Page

20 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

CONNECTOR A5J1

CONNECTOR

A5J2

H195_1167HCA

H195_1167HC

ESD

Possible damage from electrostatic discharge.

9 Connect to the PMT BOARD:

• CONNECTOR A5J1

• CONNECTOR A5J2

PMT BOARD

Page 21

07MAR08

H195_1034HC

LOCK COVER

BACK LIGHT

4 SCREWS

COVER

LASER SAFETY

2 SCREWS

H195_1034HCA

PM4366-1

Page

21 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

10 Use the ESD-SAFE VACUUM CLEANER to remove the dust and debris from both sides

of:

• BACK LIGHT LOCK COVER

• LASER SAFETY COVER

11 Install:

• BACK LIGHT LOCK COVER

• 4 SCREWS

• LASER SAFETY COVER

• 2 SCREWS

Page 22

07MAR08

PM4366-1

Page

22 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

2 SIDE PANELS

6 SCREWS

FRONT PANEL

12 Use the ESD-SAFE VACUUM CLEANER to carefully clean:

• FRONT PANEL

• 2 SIDE PANELS

• BACK COVER

13 Install:

• 2 SIDE PANELS

• FRONT PANEL

• 6 SCREWS

H195_1217HCA

H195_1217HC

Page 23

PREVENTIVE MAINTENANCE Preventive Maintenance

07MAR08

PM4366-1

Page

23 of 31

Cleaning the ERASE AY

ERASE AY

SCREEN GUIDE

2 SCREWS

ERASE AY

TOP COVER

H195_1236HCA

H195_1236HC

1 Remove:

• 2 SCREWS

• ERASE AY TOP COVER

• 2 SCREWS

• ERASE AY SCREEN GUIDE

2 SCREWS

Page 24

07MAR08

PM4366-1

Page

24 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

ESD

Possible damage from electrostatic discharge.

2 Use the ESD-SAFE VACUUM CLEANER to carefully remove dust and debris from the

POWER SUPPLY.

3 Use a damp, LINT-FREE CLOTH to carefully clean:

• ERASE AY

• ERASE TOP COVER

• ERASE LAMP AY

• DRIVE BELT COVER

4 Install:

• ERASE AY SCREEN GUIDE

• 2 SCREWS

• ERASE AY TOP COVER

• 2 SCREWS

Page 25

07MAR08

PM4366-1

Page

25 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

110 V

110 V

POWER

POWER

CORD

CORD

BACK COVER

BACK COVER

NETWORK

NETWORK

CABLE

CABLE

ERASE AY

ERASE AY

2 SCREWS

2 SCREWS

8 SCREWS

8 SCREWS

CONNECTOR RJ45

CONNECTOR A9P1

CONNECTOR A9J2

2 SCREWS

2 SCREWS

DRIVE BELT COVER

DRIVE BELT COVER

H195_1142HCA

H195_1142HCA

H195_1142HC

Caution

Be careful. Do not allow the ERASE AY to fall.

5 Install:

• ERASE AY

• 2 SCREWS

Page 26

PREVENTIVE MAINTENANCE Preventive Maintenance

07MAR08

PM4366-1

Page

26 of 31

6 Connect the CONNECTORS:

• A9P1

• A9J2

• RJ45

7 Install:

• DRIVE BELT COVER

• 2 SCREWS

• BACK COVER

• 8 SCREWS

Caution

Dangerous Voltage

8 Connect:

• 110 V POWER CORD

• NETWORK CABLE

9 Install:

• TOP COVER

• 4 WASHERS

• 4 SCREWS

• FRONT COVER

• 2 SCREWS

Page 27

07MAR08

PM4366-1

Page

27 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

10 Remove the FOAM.

FOAM

11 Use water and mild detergent to clean

the FOAM.

12 Rinse the FOAM.

13 Squeeze the FOAM to remove all the

water.

14 Install the FOAM.

H195_1237ACA

H195_1237AC

Page 28

PREVENTIVE MAINTENANCE Preventive Maintenance

07MAR08

PM4366-1

Page

28 of 31

Cleaning the PHOSPHOR SCREENS

Caution

• Do not cause damage to the PHOSPHOR SCREENS.

• The PHOSPHOR SCREENS are sensitive to water.

• Do not use excessive force to clean the surface of the PHOSPHOR SCREENS.

• You must clean both sides of the PHOSPHOR SCREENS.

• Before starting to clean the PHOSPHOR SCREENS, you must:

– wash your hands with mild soap and water

– use Nitrile or equivalent powder-free GLOVES

– prepare a flat, clean, horizontal surface

• You must do these procedures for all the CASSETTES at the site.

Page 29

07MAR08

PM4366-1

Page

29 of 31

PREVENTIVE MAINTENANCE Preventive Maintenance

1 Move the LATCH to the left to open the

FLEXIBLE PHOSPHOR SCREEN.

FLEXIBLE

PHOSPHOR

SCREEN

CASSETTE

2 Remove the PHOSPHOR SCREEN

from the CASSETTE.

3 Apply the Kodak SCREEN CLEANER

TL845 4977 to a LINT-FREE CLOTH.

E

B E S I D

T U

KC

VM

D

SFIFJO

LZX

Important

• Do not pour the SCREEN CLEANER

directly on the PHOSPHOR SCREEN.

hole

• You must wipe the PHOSPHOR

SCREEN in only one direction.

4 Carefully wipe the PHOSPHOR

SCREEN until all dust and debris are

removed. If necessary, use a new LINT-

To

Open

LATCH

H195_1103GCA

H195_1103GC

FREE CLOTH.

5 Check that no debris remains on the

PHOSPHOR SCREEN.

Important

Do not leave the PHOSPHOR SCREEN to

dry in the air.

6 Use a LINT-FREE CLOTH to wipe the

PHOSPHOR SCREEN until it is dry.

7 Did the SCREEN CLEANER clean the PHOSPHOR SCREEN?

Yes No

Insert the PHOS PHOR SCREEN into the

Call the Technical Service Center.

CASSETTE.

Page 30

PREVENTIVE MAINTENANCE Preventive Maintenance

07MAR08

PM4366-1

Page

30 of 31

Checking the Operation

Caution

Dangerous Voltage

1 Connect the main power.

2 Check that the equipment is operating correctly.

Page 31

PREVENTIVE MAINTENANCE Preventive Maintenance

07MAR08

PM4366-1

Page

31 of 31

Table 1 Publication History

Publication

Date

Publication

No.

ECO No.

Changed

Pages

File Name Notes

07MAR08 PM4366-1 ----- --- pm4366_1.fm New Publication

Printed in U.S.A. • pm4366_1.fm

Carestream Health, Inc.

150 Verona Street

Rochester, NY 14608

DirectView is a trademark of Carestream Health.

Kodak is a trademark of Kodak used under license.

Loading...

Loading...