Page 1

Restricted

{Diagnostics}{Production}{Carestream Health Inc.}{Restricted}

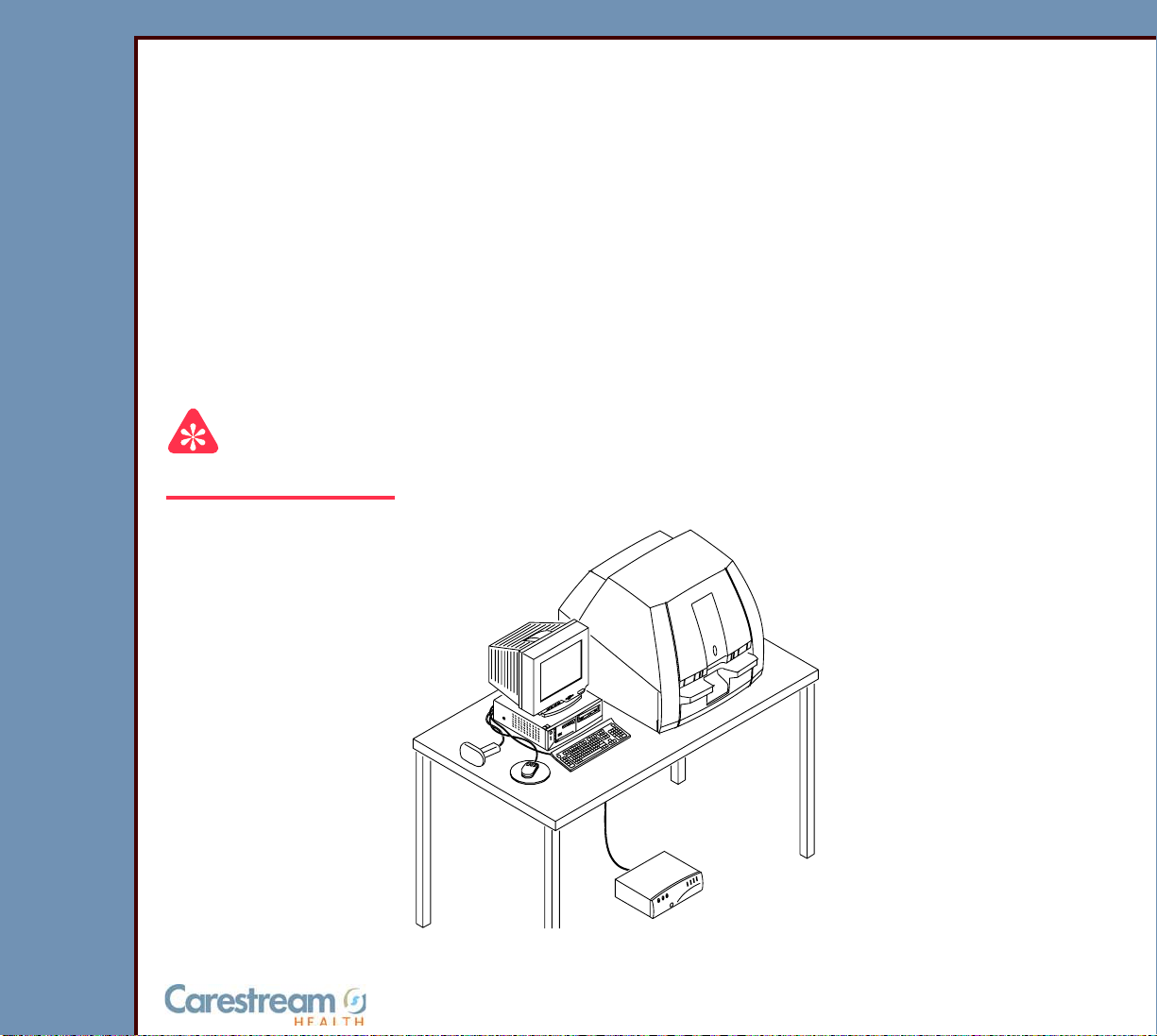

DIAGNOSTICS

for the

Kodak DirectView CR 500 SYSTEM

Service Code: 4366

Important

Qualified service personnel must repair this equipment.

Publication No. DG4366-1

09OCT07

Supersedes DG4366-1

22NOV04

H195_0016BC

© CARESTREAM HEALTH, INC.

Page 2

DIAGNOSTICS

09OCT07

DG4366-1

Page

2 of 211

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to t he subject

matter gained by Carestream Health, Inc. prior to publication.

No patent license is granted by this information.

Carestream Health, Inc. reserves the right to chang e this information withou t notice, and ma kes no

warranty, express or implied, with respect to this infor mation. Carestr eam Health shall not be liable

for any loss or damage, including consequ ential o r special damages, resulting fr om any use of this

information, even if loss or damage is caused by Carestream Health’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Table of Contents

Description Page

Using the Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

“System Service Diagnostic” Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Functions of the “System Service Diagnostic” Screen . . . . . . . . . . . . . . . . . . . 20

Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Individual Component Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Component Control: Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Light Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Slow Scan Current and Velocity Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Laser Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

GALVO Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

GALVO PLOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

AUTOLOOPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

System Self Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Diagnostic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Checking the Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Checking the Error Frequency Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Checking the Actuation Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Storing the Error Logs on a Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Clearing the Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Displaying the Software Versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Downloading Software to the BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

CASSETTE LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Page 3

DIAGNOSTICS

09OCT07

DG4366-1

Page

3 of 211

940 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

941 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

942 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

950 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

951 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

952 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

953 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

954 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

955 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

956 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

957 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

958 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

959 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

960 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

961 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

962 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

963 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

994 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

995 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

996 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

997 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

998 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

999 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

1000 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

1001 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10021 - MSC BOARD A1: Software malfunction . . . . . . . . . . . . . . . . . . . . . 76

10022 - MSC BOARD A1: Software malfunction . . . . . . . . . . . . . . . . . . . . . 77

10024 - MSC BOARD A1: Software malfunction . . . . . . . . . . . . . . . . . . . . . 77

10030 - READER did not read the CASSETTE BAR CODE . . . . . . . . . . . . 78

10031 - Cannot home cassette guides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10032 - Cannot activate cassette load switch. . . . . . . . . . . . . . . . . . . . . . . 79

10033 - Cannot clamp the cassette correctly . . . . . . . . . . . . . . . . . . . . . . . 79

10034 - Unable to retract cassette feed pin . . . . . . . . . . . . . . . . . . . . . . . . . 79

10035 - Cannot home the feed motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10036 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10037 - Retrying clamp cassette with guides . . . . . . . . . . . . . . . . . . . . . . . 80

10038 - Retrying extract screen from cassette . . . . . . . . . . . . . . . . . . . . . . 80

10039 - BAR CODE read failure occurred . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10040 - MSC BOARD A1: Software malfunction - RTXC timer

allocation failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10999 - MSC BOARD A1: Software malfunction . . . . . . . . . . . . . . . . . . . . . 82

CASSETTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Page 4

DIAGNOSTICS

09OCT07

DG4366-1

Page

4 of 211

Screen Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

SLOW SCAN AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

12009 - Caution! SLOW SCAN MOTOR drawing too much power . . . . . . 83

12012 - SLOW SCAN AY: Timeout Error . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

12013 - SLOW SCAN AY: Timeout error . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

12014 - MSC BOARD A1: Software Error for SLOW SCAN . . . . . . . . . . . . 83

12100 - SLOW SCAN CONTROLLER BOARD A6: Software Error . . . . . . 84

12101 - SLOW SCAN frequency locked range error while scanning . . . . 84

12102 - SLOW SCAN stopped, position error while scanning . . . . . . . . . 85

12103 - SLOW SCAN stopped, frequency lock motion stalled error

while scanning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

12107 - SLOW SCAN: +24 V DC malfunction during scan. . . . . . . . . . . . . 86

12108 - SLOW SCAN stopped during scan . . . . . . . . . . . . . . . . . . . . . . . . . 86

12109 - SLOW SCAN stopped during scan . . . . . . . . . . . . . . . . . . . . . . . . . 87

12110 - SLOW SCAN did not communicate with the

MOTION SYSTEM CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12111 - SLOW SCAN did not move. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12112 - SLOW SCAN did not move. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12113 - SLOW SCAN CONTROLLER BOARD A6: NVRAM malfunctioned 87

12115 - SLOW SCAN CONTROLLER BOARD A6: Software Error . . . . . . 88

12116 - SLOW SCAN CONTROLLER BOARD A6 did not communicate

with MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12120 - SLOW SCAN did not move. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12121 - SLOW SCAN did not move. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12122 - SLOW SCAN COIL BOARD A7 malfunctioned. . . . . . . . . . . . . . . . 89

12123 - SLOW SCAN CONTROLLER BOARD A6: Software Error . . . . . . 89

12124 - SLOW SCAN CONTROLLER BOARD A6: Software Error . . . . . . 89

12125 - SLOW SCAN COIL BOARD A7 malfunctioned. . . . . . . . . . . . . . . . 89

12126 - Caution! SLOW SCAN MOTOR is overheated . . . . . . . . . . . . . . . . 89

12130 - SLOW SCAN CONTROLLER BOARD A6: Software Error . . . . . . 90

12131 - SLOW SCAN CONTROLLER BOARD A6 did not communicate

with MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12132 - SLOW SCAN CONTROLLER BOARD A6 did not communicate

with MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12201 - SLOW SCAN CONTROLLER BOARD A6: Programming Error . . 90

12202 to 12260 - SLOW SCAN CONTROLLER BOARD A6: “Memory

Command” Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

12261 - Roller Pair 1 Cam Motor Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . 93

12262 - Roller Pair 2 Cam Motor Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . 95

12263 - Roller Pair 3 Cam Motor Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . 97

12264 - Screen start sensor blocked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

12265 - Screen start timeout. Screen did not enter reader . . . . . . . . . . . . 99

Page 5

DIAGNOSTICS

09OCT07

DG4366-1

Page

5 of 211

12266 - Screen did not fully enter the erase assembly . . . . . . . . . . . . . . . 102

12267 - Screen did not return to cassette . . . . . . . . . . . . . . . . . . . . . . . . . . 103

12301 - Slow Scan frequency locked range error while not scanning. . . 103

12302 - SLOW SCAN stopped, position error while not scanning. . . . . . 104

12303 - SLOW SCAN stopped, frequency lock motion stalled error

while not scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

12307 - SLOW SCAN: +24 V DC malfunction during SCREEN transport. 107

12896 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Reset . . . 107

12900 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 107

12901 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 107

12902 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 108

12903 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 108

12904 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 109

12905 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 109

12906 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 109

12907 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 109

12908 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 110

12909 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 110

12910 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 110

12911 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 110

12913 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 110

12914 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 111

12915 - SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . 111

12930 - SLOW SCAN: Unexpected Retry during Current Test . . . . . . . . . 111

12931 - SLOW SCAN: Unexpected Retry during Velocity Test. . . . . . . . . 112

12941 - SLOW SCAN: Unexpected Retry during Communication to

MSC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

ERASE LAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

13009 - All ERASE LAMPS malfunctioned . . . . . . . . . . . . . . . . . . . . . . . . . . 112

13010 - Erase time exceeds maximum allowed. . . . . . . . . . . . . . . . . . . . . . 114

13011 - Command to Erase did not occur . . . . . . . . . . . . . . . . . . . . . . . . . . 114

13012 - MSC BOARD A1: Invalid Command for ERASE LAMPS . . . . . . . 114

13013 - MSC BOARD A1: Software failure during erase . . . . . . . . . . . . . . 114

13899 - General Erase Error.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

14001 - SLOW SCAN: Malfunction of 24 V Power . . . . . . . . . . . . . . . . . . . 115

14002 - STEPPER: Malfunction of 24 V Power . . . . . . . . . . . . . . . . . . . . . . 115

14008 - SLOW SCAN: Initialization Error. . . . . . . . . . . . . . . . . . . . . . . . . . . 115

14010 - Slow Scan Async Reset Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

14015 - MSC initialization failed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

14016 - MSC initialization succeeded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

14017 - MSC initialization started

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Page 6

DIAGNOSTICS

09OCT07

DG4366-1

Page

6 of 211

14018 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

14019 - The MSC BOARD A1 has reported a model number that is

not consistent with the current version of embedded MCPU software 116

14020 - SCREEN eject failed. The SCREEN may or may not still be

inside of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

DATA PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

15001 - MCPU BOARD A2: Fatal Error in Software . . . . . . . . . . . . . . . . . . 117

15002 - MCPU BOARD A2: Fatal Error in Software . . . . . . . . . . . . . . . . . . 117

15003 - MCPU BOARD A2: Communications Error in Software . . . . . . . . 118

15005 - LASER: Reference Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

15006 - Communications Error between MCPU BD A2 and

GALVO BD A4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

15007 - Communications Error between MCPU BD A2 and

GALVO BD A4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

15008 - Start of Scan Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

15011 - LASER: Power is below the lower limit . . . . . . . . . . . . . . . . . . . . . 120

15012 - Communications Error between MCPU BOARD A2 and the PC . 120

15013 - Image Quality Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

15014 - LASER power not calibrated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

15015 - SCREEN not calibrated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

15016 - The LASER reference voltage is too high . . . . . . . . . . . . . . . . . . . 121

15017 - SCREEN not calibrated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

15018 - There was an error reading or writing to the PCMCIA card.. . . . 122

15040 - Communications Error Between MCPU and the PC . . . . . . . . . . . 122

15800 - Image resent at NT reboot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

15900 - NT rejected image at end of scan. Retransmission being

attempted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

16001 - Calibration Error: Did not find START OF SCAN position . . . . . . 124

16002 - Calibration Error: Did not find Offset . . . . . . . . . . . . . . . . . . . . . . . 124

16003 - Calibration Error: Did not find Amplitude . . . . . . . . . . . . . . . . . . . 125

16005 - Calibration Error: Routine did not receive image in the

time allowed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

16006 - Calibration Error: Did not acquire image . . . . . . . . . . . . . . . . . . . . 125

16010 - Possible Light Leak. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

16011 - Imaging System Error occurred during Initialization . . . . . . . . . . 126

16012 - PMT/DAS BOARD A5: Calculation Error occurred during

Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

16013 - Imaging System contains out-of-range noise . . . . . . . . . . . . . . . . 127

16014 - Imaging System did not zero or PMT did not calibrate . . . . . . . . 127

16016 - Malfunctioning PMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Page 7

DIAGNOSTICS

09OCT07

DG4366-1

Page

7 of 211

16019 - Calibration could not find offset, rotate GALVO

counterclockwise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

16020 - Calibration could not find offset, rotate GALVO clockwise . . . . . 127

16021 - Malfunctioning PMT1: Gain out of range . . . . . . . . . . . . . . . . . . . . 128

16022 - Malfunctioning PMT2: Gain out of range . . . . . . . . . . . . . . . . . . . . 128

16026 - The laser diode is not calibrated. . . . . . . . . . . . . . . . . . . . . . . . . . . 129

16027 - The laser diode calibration data is out of range . . . . . . . . . . . . . . 129

16028 - The galvo is out of range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

“Self Test” for the MASTER CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . 130

19001 - Check GALVO COMMUNICATIONS CABLE . . . . . . . . . . . . . . . . . . 130

19002 - Check PMT BOARD CABLE and power . . . . . . . . . . . . . . . . . . . . . 130

19003 - Check the power to the GALVO BOARD . . . . . . . . . . . . . . . . . . . . 130

19004 - GALVO AGC reference is too high. Suggest check if GALVO

connected and/or ad just AGC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

19005 - Check the GALVO reference (too low) . . . . . . . . . . . . . . . . . . . . . . 131

19006 - Memory self test failed. Replace the MCPU BOARD . . . . . . . . . . 131

19009 - The LASER diode off power is too high. . . . . . . . . . . . . . . . . . . . . 131

19010 - The LASER diode on power is too low . . . . . . . . . . . . . . . . . . . . . 131

19011 - PMT BOARD ramp test failed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

19012 - Galvo sweep error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

MECHANISM SYSTEM CONTROL BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

22000 - MSC BOARD A1: Fatal Software Error . . . . . . . . . . . . . . . . . . . . . . 132

22001 - MSC BOARD A1: Memory did not

erase during Download . . . . . 132

22002 - MSC BOARD A1: Error during download of MSC Software. . . . . 133

22003 - MSC BOARD A1: Checksum of Main Application failed . . . . . . . 133

22004 - MSC BOARD A1: RAM Test failed . . . . . . . . . . . . . . . . . . . . . . . . . . 133

22005 - MSC BOARD A1: Error during download of MSC Software. . . . . 134

22006 - MSC BOARD A1: Error during download of MSC Software. . . . . 134

22007 - MSC BOARD A1: Error during download of MSC Software. . . . . 134

22008 - MSC BOARD A1: Error during download of MSC Software. . . . . 134

22009 - MSC BOARD A1: Error during download of MSC Software. . . . . 135

22010 - MSC BOARD A1: Error during download of MSC Software. . . . . 136

22011 - MSC BOARD A1: Error during download of MSC Software. . . . . 136

MECHANISM SYSTEM CONTROL BOARD RTXC . . . . . . . . . . . . . . . . . . . . . . . . 137

29001 - 29008 - MSC BOARD A1: Software malfunctioned . . . . . . . . . . . . 137

MECHANISM SYSTEM CONTROL BOARD SYSTEM . . . . . . . . . . . . . . . . . . . . . . 138

30002 - 30033 - MSC BOARD A1: Software malfunctioned . . . . . . . . . . . . 138

30041 - Cassette task did not respond to a command . . . . . . . . . . . . . . . 138

30042 - Did not receive a Load SCREEN command . . . . . . . . . . . . . . . . . . 138

30043 - MSC is in Fatal Error state. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

30044 - General MSC Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

30045 - Interlock switch is open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Page 8

DIAGNOSTICS

09OCT07

DG4366-1

Page

8 of 211

30046 - 24 V supply error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

30047 - Interlock switch closed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

30048 - Transient 24 V loss. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Communications for the MECHANISM SYSTEM CONTROL BOARD . . . . . . . . 139

32001 - Communications malfunctioned between MCPU and

SSC BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

32002 - MSC BOARD A1: Internal Communications Error. . . . . . . . . . . . . 140

32003 - MSC BOARD A1: Internal Communications Error. . . . . . . . . . . . . 140

32004 - Communications Error between MCPU and SSC BOARDS. . . . . 140

32005 - Communications Error between MCPU and SSC BOARDS. . . . . 141

32006 - Synchronization lost. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

SHUTDOWN MANAGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

47001 - Communications to MCPU BD failed during Shut Down . . . . . . . 141

47002 - Internal communications failure . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

47003 - Internal communications to UPS failed . . . . . . . . . . . . . . . . . . . . . 142

47500 - 47504 - Internal communications to UPS failed . . . . . . . . . . . . . . 142

47510 - 47511 - Internal communications failure to UPS1 . . . . . . . . . . . . . 142

47520 - 47522 - Internal communications failure to UPS1 . . . . . . . . . . . . . 142

47550 - The BATTERY in UPS1 is too low. System will be shutdown

in 1 minute. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

47551 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

47900 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

47950 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

47951 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

47952 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

47960 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

47961 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

47962 - Display only, no Log Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

DISK MANAGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

49000 - HARD DISK is full. DISK MANAGER not able to

remove images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

49001 - Image Files have been deleted . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Service Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

54001 - Entered Service Diagnostic mode . . . . . . . . . . . . . . . . . . . . . . . . . . 145

54002 - Exited Service Diagnostic mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

54003 - Unable to enter Service Diagnostic mode . . . . . . . . . . . . . . . . . . . 145

54004 - Unable to exit Service Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 146

54010 - MCPU application software download complete . . . . . . . . . . . . . . 146

54011 - MSC application software download complete . . . . . . . . . . . . . . . 146

54012 - Slowscan boot and app software download complete . . . . . . . . . 146

54013 - Slowscan application software download complete. . . . . . . . . . . 146

54014 - Slowscan parameters download complete. . . . . . . . . . . . . . . . . . . 147

Page 9

DIAGNOSTICS

09OCT07

DG4366-1

Page

9 of 211

54020 - Failed FTP software transfer from PC to MCPU . . . . . . . . . . . . . . 147

54021 - Failed MSC application software download. . . . . . . . . . . . . . . . . . 147

54022 - Failed SLOWSCAN boot and application software download. . . 14 8

54023 - Failed SLOWSCAN application software download . . . . . . . . . . . 148

54024 - Failed SLOWSCAN parameters download . . . . . . . . . . . . . . . . . . . 149

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

55100 - Error on the Options Diskette or this is not a valid Options

Diskette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

55101 - Could not open files on the Options Diskette. Try another

Options Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

55102 - Pentium III identification not enabled on this Pentium III

class machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

55103 - Could not open files on the Options Diskette. . . . . . . . . . . . . . . . 150

55104 - Error updating the options on the CR 500 SYSTEM. . . . . . . . . . . 150

55105 - Could not allocate essential memory . . . . . . . . . . . . . . . . . . . . . . . 150

55106 - The Options on this diskette are already enabled on this

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

55107 - This Options Diskette has been used on another device . . . . . . 150

55109 - Error occurred while trying to update the Options on the

UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

CD/DVD SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

59001 - Warning: Disk Space getting low on DVD/CD-RW . . . . . . . . . . . . 151

59002 - SYSTEM - Unable to load Settings . . . . . . . . . . . . . . . . . . . . . . . . . 151

59003 - SYSTEM - Start FAILURE, Invalid command line . . . . . . . . . . . . . 151

59004 - DICOM - Unable to create Directory . . . . . . . . . . . . . . . . . . . . . . . . 151

59005 - DICOM - Incoming Store Request Rejected, Low Resource -

Import Disk Space. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

59006 - DICOM - Storing Incoming Image FAILED - Missing Image

Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

59007 - DICOM - Unable to generate unique file name . . . . . . . . . . . . . . . 152

59008 - DICOM - Unable to save DicomDir File. . . . . . . . . . . . . . . . . . . . . . 152

59009 - DICOM - Unable to get Peer Name . . . . . . . . . . . . . . . . . . . . . . . . . 152

59010 - DICOM - Unable to delete File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

59011 - Create process failed - error = error number . . . . . . . . . . . . . . . . 153

59012 - DICOM - Copying Image to bad directory . . . . . . . . . . . . . . . . . . . 153

59013 - DICOM - Copying Image to bad directory . . . . . . . . . . . . . . . . . . . 154

59014 - DICOM - Negotiating Association FAILED - Unknown Calling

AE Title “%s” at “%s” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

59015 - DICOM - Negotiating Association FAILED - Provider Congestion 154

59016 - DICOM - Negotiation Association FAILED. Missing

implementation UID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Page 10

DIAGNOSTICS

09OCT07

DG4366-1

Page

10 of 211

59017 - DICOM - Negotiating Association FAILED - Missing

Application Context . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

59018 - DICOM - Negotiating Association FAILED - Invalid Protocol

Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

59019 - DICOM - Negotiating Association FAILED - Invalid Called

AE Title . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

59020 - DICOM - Negotiating Association FAILED - No Presentation

Items Given or DICOM - Negotiating Association FAILED -

No Presentation Context . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

59021 - DICOM - Unable to Decode File . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

59022 - DICOM - Incoming Retrieve Request FAILED -

Send Association FAILED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

59023 - DVD-RW drive is not ready . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

59024 - Error creating DICOM_DIR file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

59801 - Error during Create Process or waiting for the DLA

command to complete. Advise rebooting the system . . . . . . . . . . . . . . 156

59802 - S/W programmer error - invalid argument supplied to a

dvdcntrl method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

59803 - Format of media failed. Either the media is the wrong type

or is unusable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

59804 - Status of media failed. Either the media is the wrong type

or is unusable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

59805 - No media was detected. Either the media was not inserted,

or is the wrong type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

59806 - DLA command timed out. Either the media is the wrong type

or is unusable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

59807 - DVD/CD writer is still busy. Either the media is corrupted

or a h/w problems exists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Security Audit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

60000 - Component verification failed for one or more files.

Would you like to startup in unsafe mode? . . . . . . . . . . . . . . . . . . . . . . 158

61001 - The Security Log database is approaching the high watermark.

When the high watermark is exceeded old entries will be deleted. . . . 159

61002 - The Security Log database has exceed the high watermark.

Old entries will be deleted to reach the low watermark . . . . . . . . . . . . . 159

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Initialization Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

“Power-On Self-Test” (POST) Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Software Loading Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Loading of CASSETTE Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Application Software Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Dark CRT or FLAT PANEL DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Page 11

DIAGNOSTICS

09OCT07

DG4366-1

Page

11 of 211

Image Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Malfunctions of SCREENS and CASSETTES. . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Checkout Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

BOARDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

MECHANISM SYSTEM CONTROL BOARD A1. . . . . . . . . . . . . . . . . . . . . . . 165

MASTER CENTRAL PROCESSING UNIT BOARD A2 . . . . . . . . . . . . . . . . . 166

DIGITIZER BOARD A3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

GALVO BOARD A4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

PMT/DAS BOARD A5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

SLOW SCAN CONTROLLER BOARD A6 and COIL BOARD A7 . . . . . . . . 174

LASER DRIVER BOARD A17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

POWER SUPPLY PS1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

POWER SUPPLY PS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

ISOLATION TRANSFORMER T1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

UNINTERRUPTED POWER SUPPLY (UPS1) . . . . . . . . . . . . . . . . . . . . . . . . 185

System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Test Points and LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

MECHANISM SYSTEM CONTROL BOARD A1. . . . . . . . . . . . . . . . . . . . . . . 194

MASTER CENTRAL PROCESSING UNIT BOARD A2 . . . . . . . . . . . . . . . . . 197

DIGITIZER BOARD A3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

GALVO BOARD A4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

PMT/DAS BOARD A5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

LASER DRIVER BOARD A17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

SLOW SCAN CONTROLLER BOARD A6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

LASER DRIVER PRE-REGULATOR BOARD A18. . . . . . . . . . . . . . . . . . . . . 210

Page 12

09OCT07

DG4366-1

Page

12 of 211

DIAGNOSTICS Using the Diagnostics

Section 1: Using the Diagnostics

“System Service Diagnostic” Screen

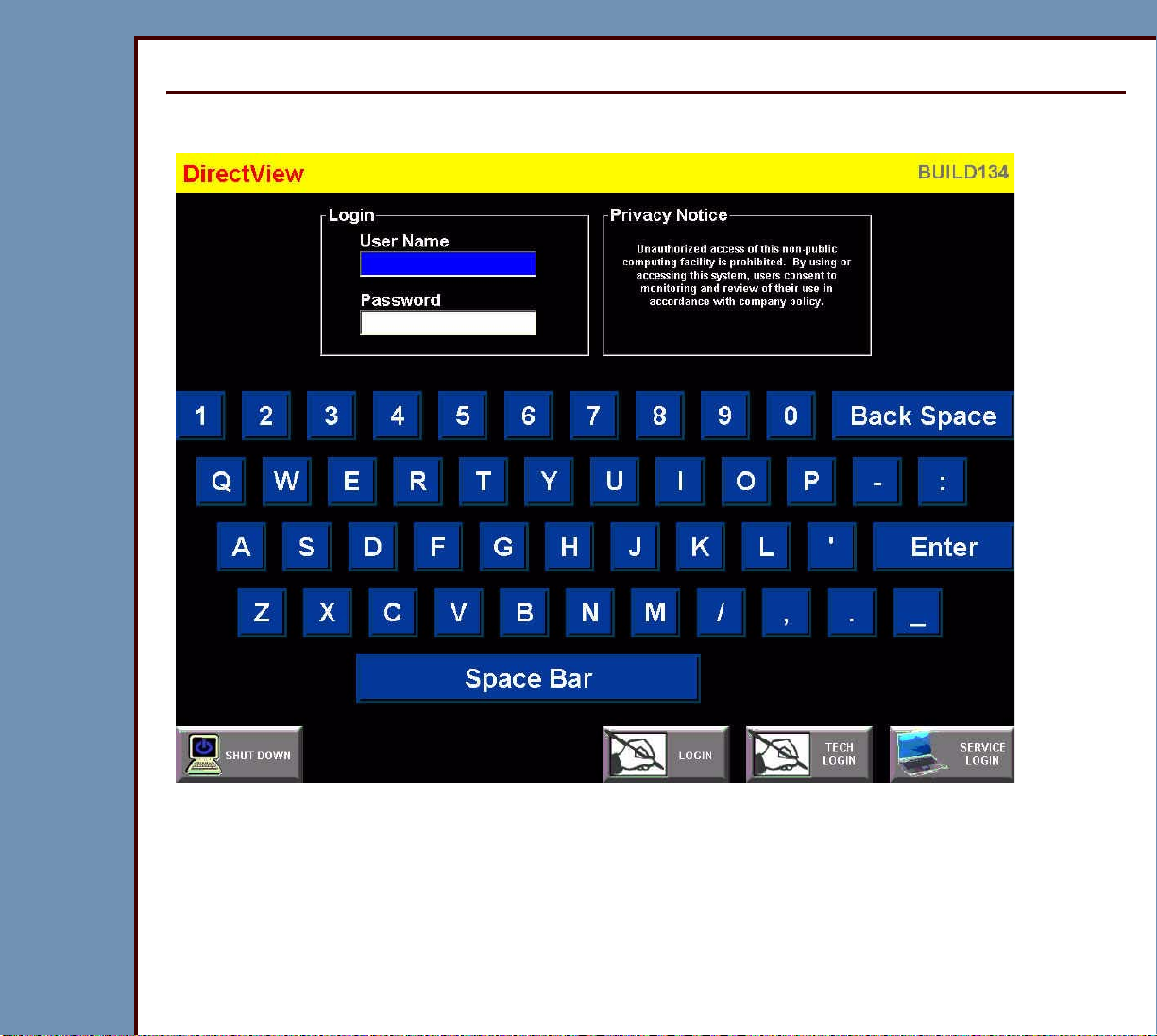

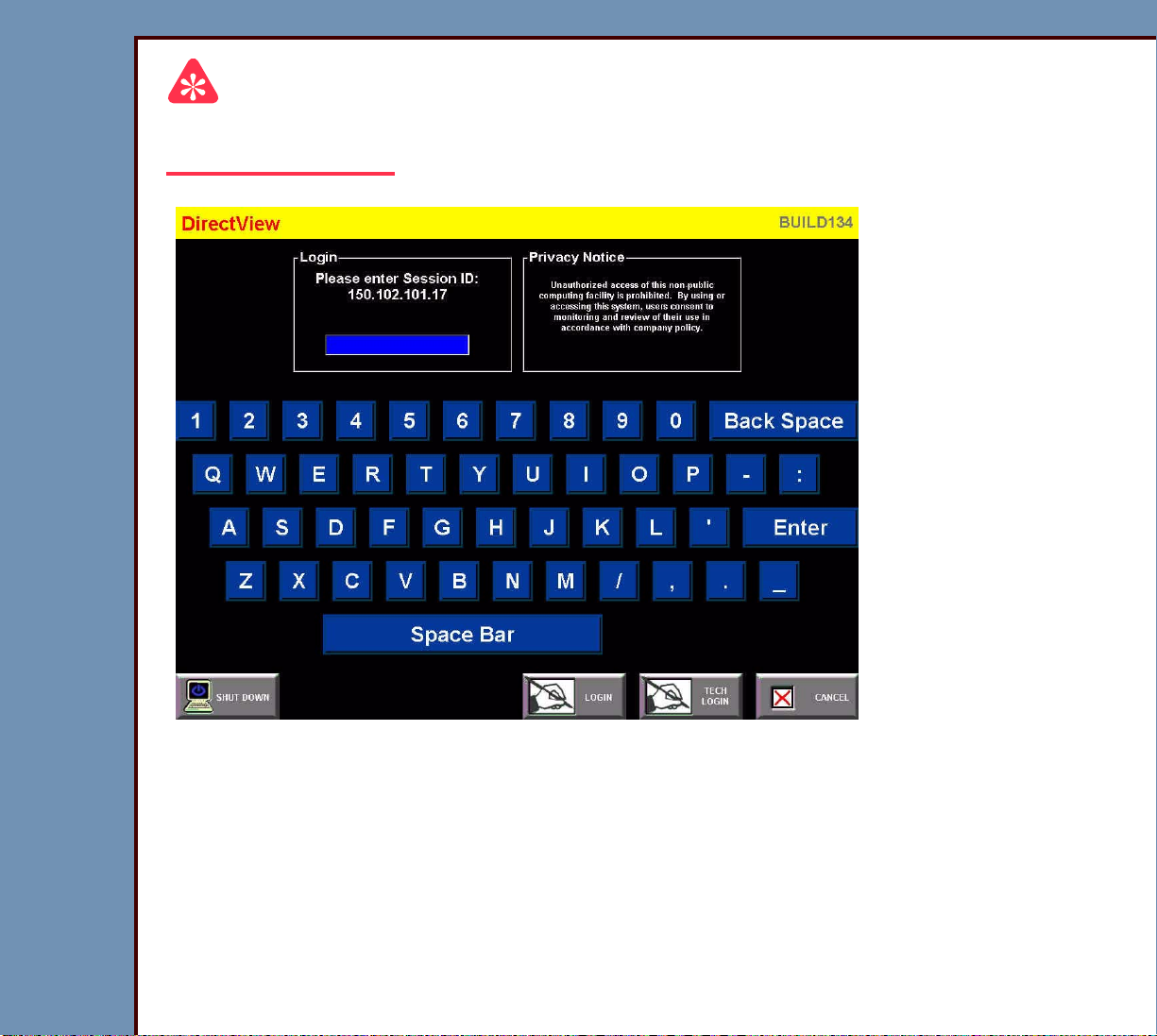

1 At the “Login” screen, type the correct information for:

• “User Name”

• “Password”

Page 13

09OCT07

DG4366-1

Page

13 of 211

DIAGNOSTICS Using the Diagnostics

Important

For systems with Software Version ≥ 4.1, you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See SERVICE BULLETIN 843.

2 If necessar y, at the “Service Logon” screen, type your “Session ID”.

3 At the main menu, click:

• [Service Functions]

• [Diagnostics]

Page 14

09OCT07

DG4366-1

Page

14 of 211

DIAGNOSTICS Using the Diagnostics

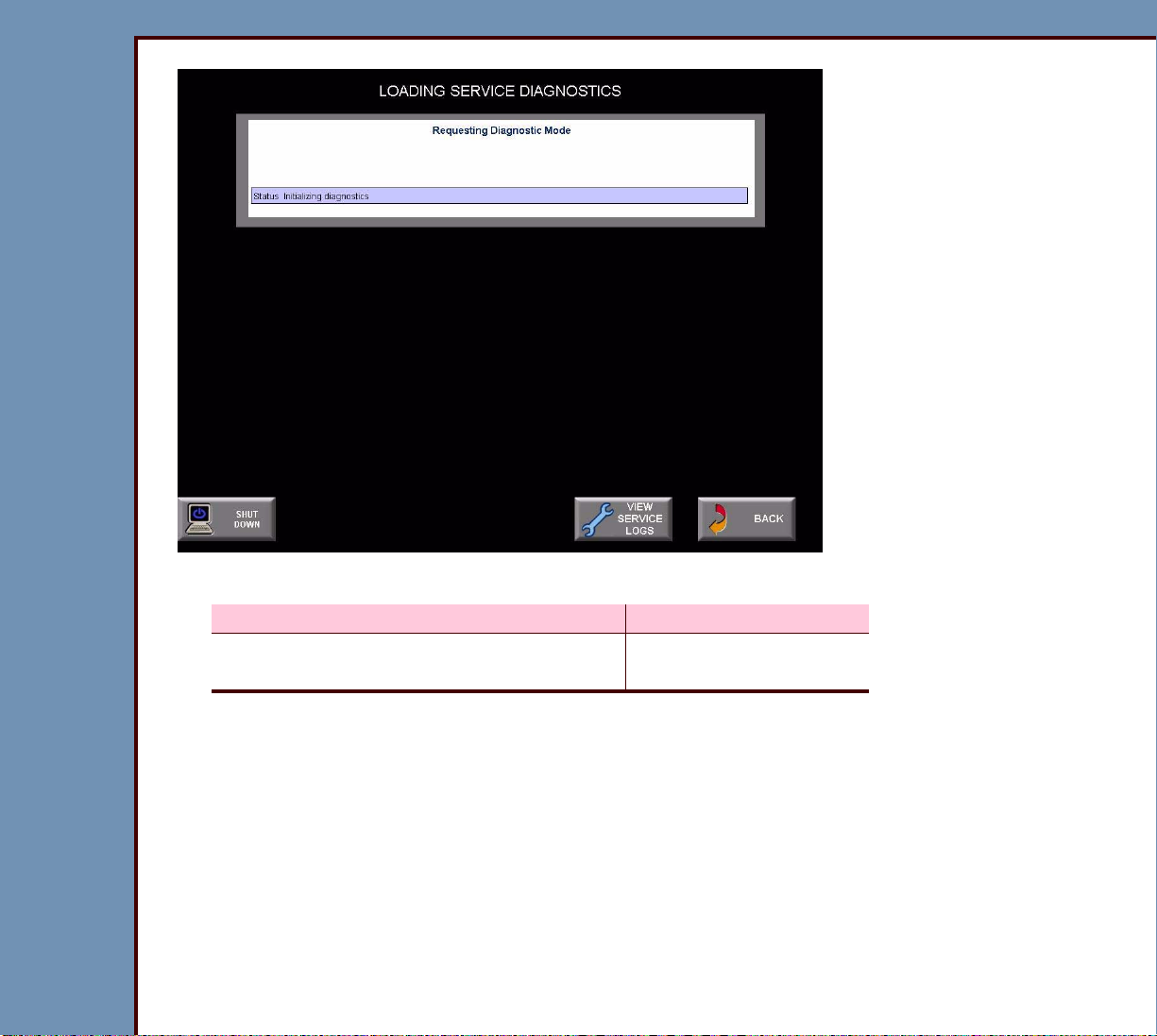

4 Does the “LOADING SERVICE DIAGNOSTICS” screen display?

Yes No

Advance to Functions of the “System

Continue with Step 5.

Service Diagnostic” Screen.

5 Check that the TX and RX LEDs are blinking on the MASTER CENTRAL PROCESSING

UNIT BOARD A2 and on the NETWORK CARD in the computer.

Page 15

09OCT07

DG4366-1

Page

15 of 211

DIAGNOSTICS Using the Diagnostics

6 Does the “CR model 0 not recognized” screen display?

Yes No

a. Check that the TX and RX LEDs are blinking on

Continue with Step 7.

the MASTER CENTRAL PROCESSING UNIT

BOARD A2 and on the NETWORK CARD in the

computer.

b. Advance to Step 9.

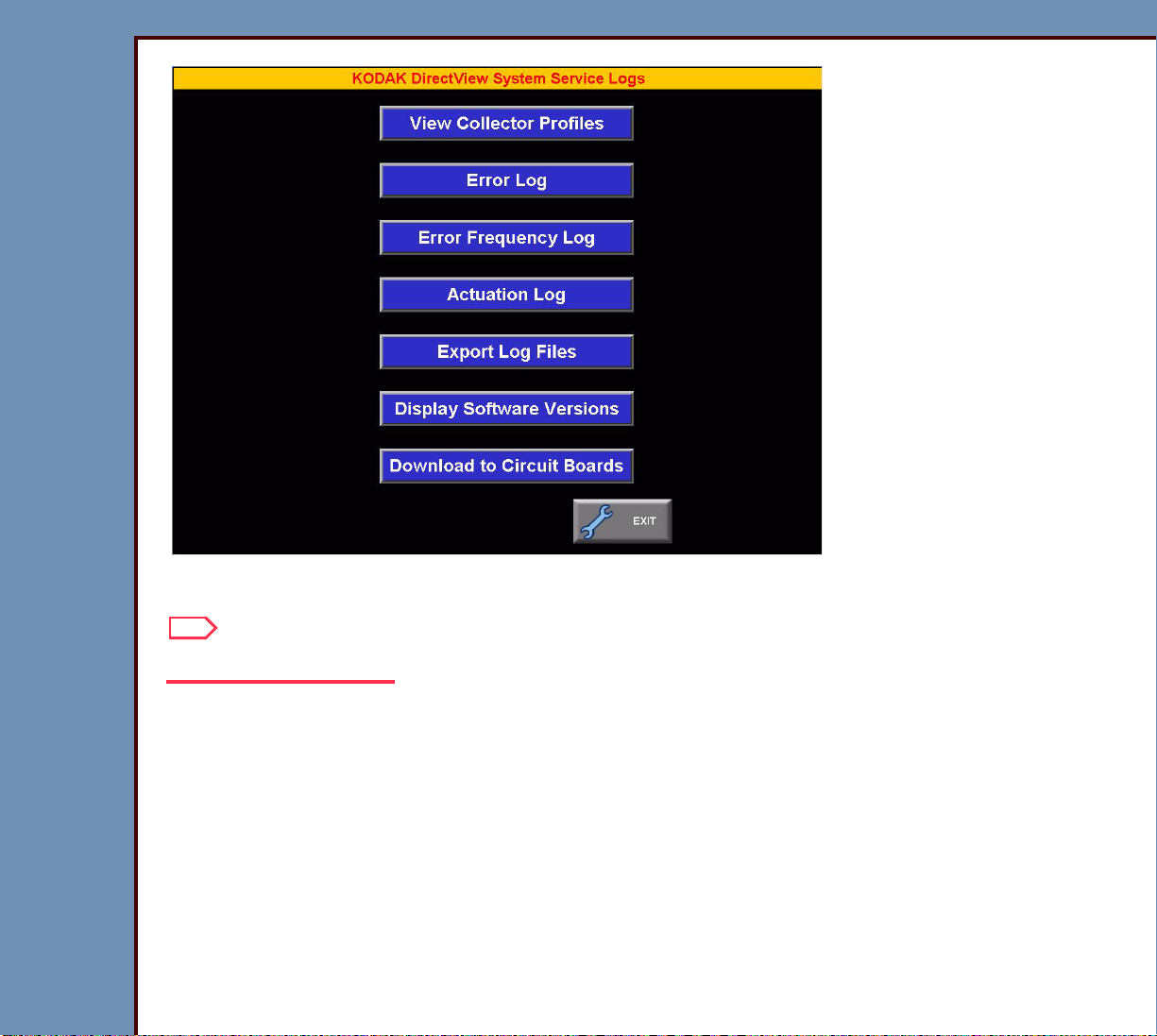

7 Select [VIEW SERVICE LOGS / SOFTWARE DOWNLOAD].

Page 16

09OCT07

DG4366-1

Page

16 of 211

DIAGNOSTICS Using the Diagnostics

8 Select [EXIT].

Note

Wait for the application to begin.

9 At the main menu, select:

• [SERVICE UTILITIES]

• [EXIT TO DESKTOP]

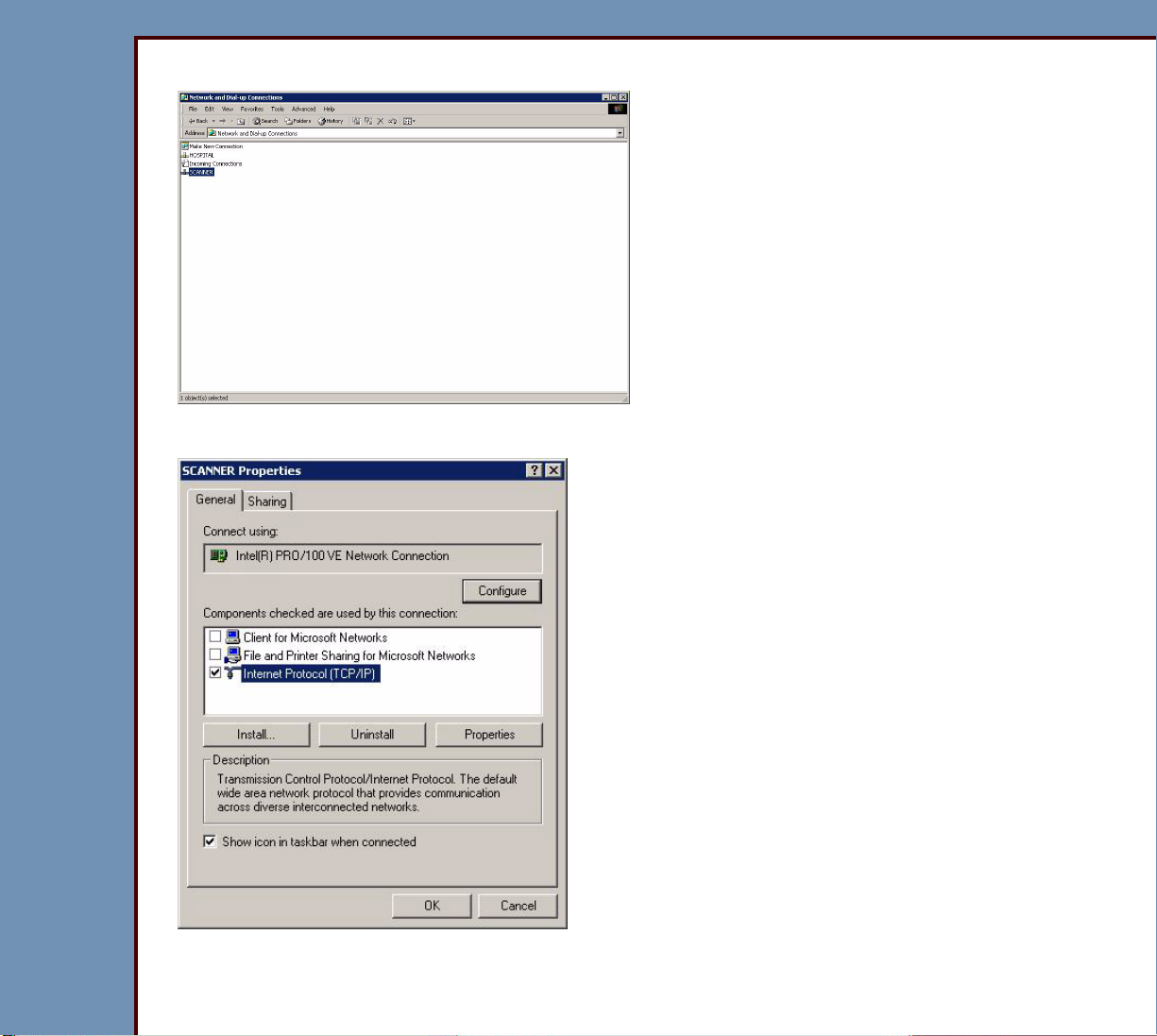

10 Double-click:

• “My Computer”

• “Control Panel”

• “Network and Dial-up Connections”

Page 17

09OCT07

DG4366-1

Page

17 of 211

DIAGNOSTICS Using the Diagnostics

11 Right-click “SCANNER”.

12 Click “Properties”.

13 Double-click “Internet Protocol (TCP/IP)”.

Page 18

09OCT07

DG4366-1

Page

18 of 211

DIAGNOSTICS Using the Diagnostics

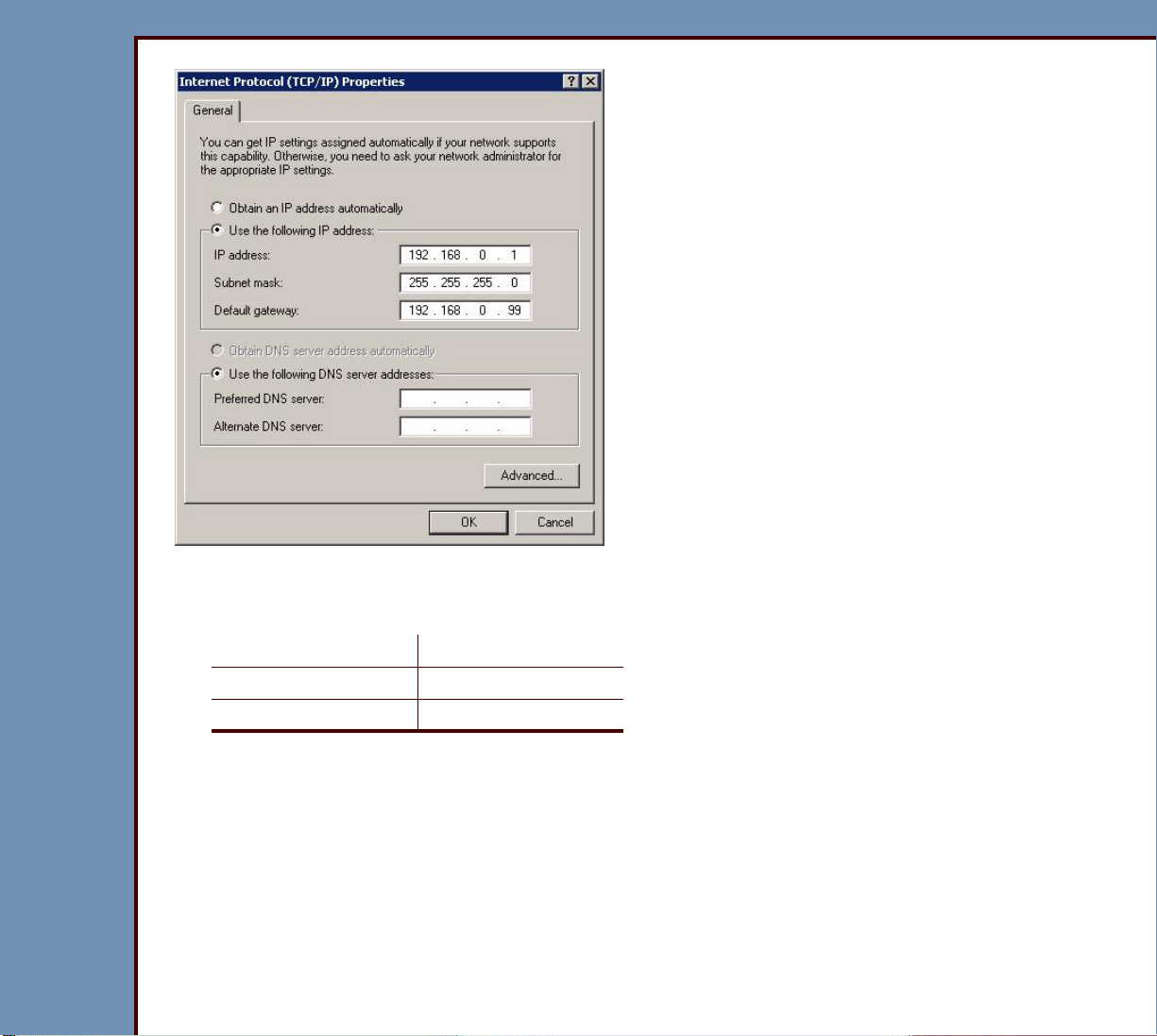

14 Click “Use the following IP address:”.

15 Check the values for the internal addresses:

“IP Address” 192.168.0.1

“Subnet Mask” 255.255.255.0

“Default Gateway” 192.168.0.99

Page 19

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

19 of 211

16 Are the values correct?

Yes No

a. Select:

• [OK]

• [OK]

• [Close all windows]

b. Select Start>Shutdown.

c. Wait for the CR 500 SYSTEM to de-

energize.

d. Energize the CR 500 SYSTEM.

e. At the main menu screen, click:

• [Service Functions]

• [Diagnostics]

a. Enter the correct values from Step 15.

b. Select:

• [OK]

• [OK]

• [Close]

c. Select Start>Shutdown

d. Wait for the CR 500 SYSTEM to de-

energize.

e. Energize the CR 500 SYSTEM.

f. At the main menu, select:

• [Service Functions]

• [Diagnostics]

Page 20

09OCT07

DG4366-1

Page

20 of 211

DIAGNOSTICS Using the Diagnostics

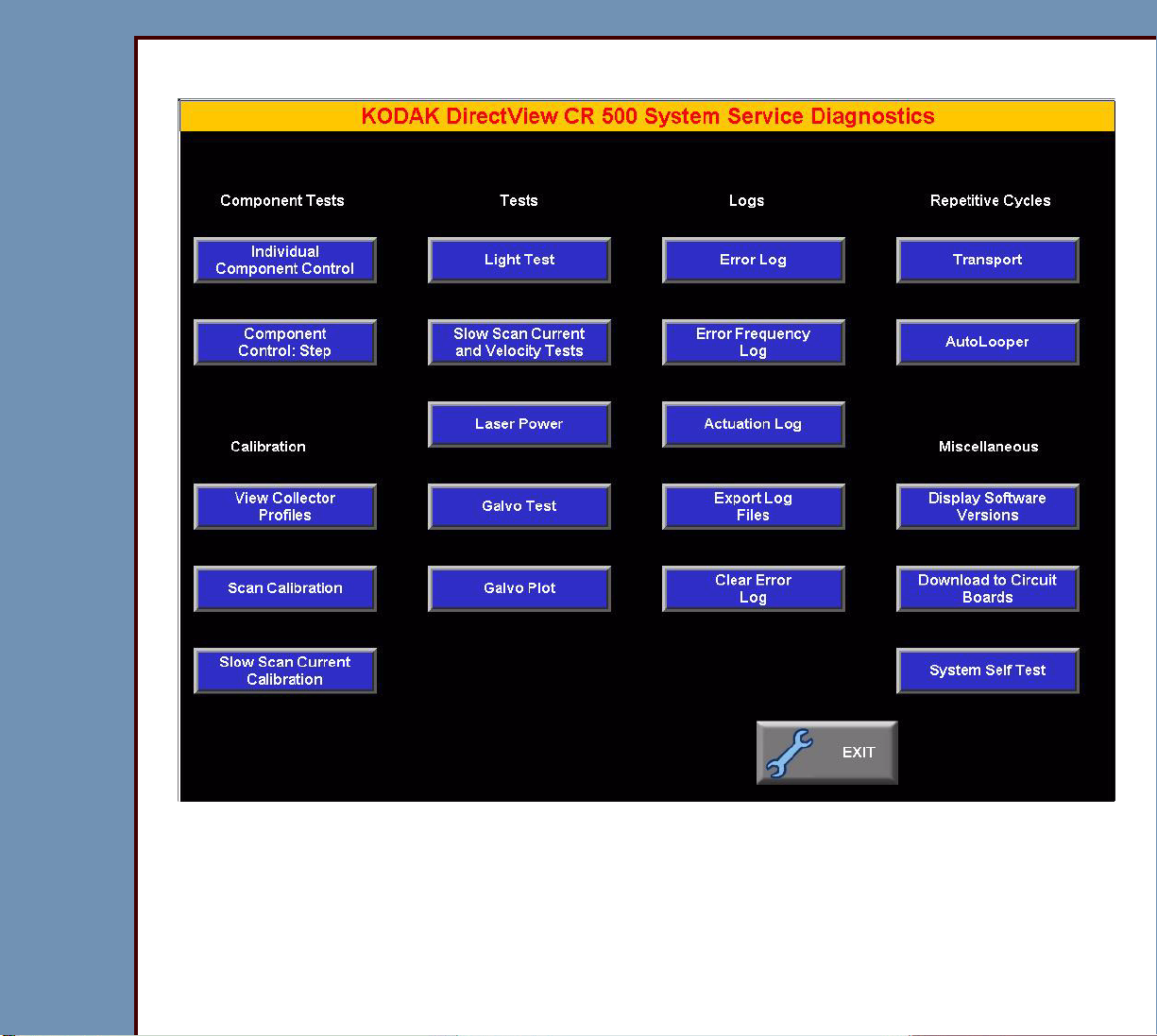

Functions of the “System Service Diagnostic” Screen

Page 21

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

21 of 211

Table 1 Component Tests

BUTTON Description

[Individual Component Control]

Important

For the procedure, see the Individual Component Control

test.

Allows you to actuate and check the status of:

• MOTORS, CAMS

– FEED MOTOR

– GUIDE MOTOR

– RP1 CAM

– RP2 CAM

– ERASE CAM

– SIDE ACTUATOR

– PIN EXTRACTOR

• SCANNER

– CASSETTE COMMANDS

– SLOW SCAN CONTROLLER

– ERASE MOTOR

– SCREEN START SENSOR

– ERASE LAMPS

Page 22

09OCT07

DG4366-1

Page

22 of 211

DIAGNOSTICS Using the Diagnostics

BUTTON Description

[Component Control: Step]

Important

For the procedure, see the Component Control: Step

test.

Allows you to:

• check the status of the components by executing the

following steps:

1. clamping the CASSETTE

2. removing, scanning, and erasing the SCREEN

3. returning the SCREEN to the CASSETTE

4. latching the CASSETTE

5. releasing the CASSETTE

• repair jams

• read the CASSETTE ID

Page 23

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

23 of 211

Table 2 Calibration

BUTTON Description

[View Collector Profiles]

Important

For the procedure, see “Setting the Calibration” in the

ADJUSTMENTS and REPLACEMENTS for the Kodak DirectView

CR 500 SYSTEM, AR4366-1.

Displays the COLLECTOR PROFILE for each size of CASSETTE:

• “OFFSET” - Number of pixels from “START” or left side of the

screen to the diagnostic image.

• “Amplitude” - Number of pixels from “OFFSET” to the last pixel

of the diagnostic image or right side of the screen.

• PMT 1 - 2: Correction value of each PMT for gain adjustment

• graphic of the values

[Scan Calibration]

Caution

• All COVERS must be installed when using this option.

• For the procedure, see “Setting the Calibration” in the

ADJUSTMENTS and REPLACEMENTS for the Kodak

DirectView CR 500 SYSTEM, AR4366-1.

• Completes the calibration of:

– GALVO AY

– PMT 1

– PMT 2

• Displays a COLLECTOR PROFILE for the 5 sizes of

STORAGE PHOSPHOR SCREENS.

• Allows calibration of the SCREENS exposed at 20 mR.

• Displays the date and time of the last successful calibration.

Page 24

09OCT07

DG4366-1

Page

24 of 211

DIAGNOSTICS Using the Diagnostics

BUTTON Description

[Slow Scan Current Calibration]

Important

For the procedure, see “Setting the Calibration” in the

ADJUSTMENTS and REPLACEMENTS for the Kodak

DirectView CR 500 SYSTEM, AR4366-1.

Completes the calibration of the SLOW SCAN AY for the

correct current at all 3 phases of the MOTOR.

Page 25

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

25 of 211

Ta b l e 3 Te s ts

BUTTON Description

[Light Test]

[Slow Scan Current and

Velocity Tests]

Important

For the test procedure, see Light Test.

• Checks for excessive light to the PMTs during the

loading of a CASSETTE.

• Allows you to:

– actuate or deactuate the high voltage of the PMTs

– “AUTO-ZERO” the PMTs

• Tests the signal for noise.

Caution

• An increase in current might indicate that a bind is

occurring in the SLOW SCAN AY.

• For the test procedure, see Slow Scan Current and

Velocity Tests.

• Drives the SLOW SCAN AY to the limits in both

directions.

• Displays for the SLOW SCAN AY:

– speed variation

– current

Page 26

09OCT07

DG4366-1

Page

26 of 211

DIAGNOSTICS Using the Diagnostics

BUTTON Description

[Laser Power]

Laser Warning

• Prevent direct exposure to the laser beam.

• For the test procedure, see Laser Power.

Allows you to:

• check the power of the LASER DIODE

• set the power values for a new LASER DIODE

• store the calibration values for the LASER DIODE

[Galvo Test]

Important

For the test procedure, see GALVO Test.

Allows you to:

• set the “Amplitude” of the GALVO AY

[Galvo Plot]

• check the response of the LASER DIODE

• start and stop the GALVO AY

Important

For the procedure, see the GALVO PLOT test.

Allows you to:

• check:

– response of the GALVO AY

– linearity of the GALVO AY

– automatic gain control - AGC

• set the GALVO AY without an OSCILLOSCOPE

Page 27

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

27 of 211

Table 4 Logs

BUTTON Description

[Error Log]

Important

For the procedure, see Checking the Error Logs.

Allows you to:

• check:

– error code and description

– date and time

– CASSETTE ID

– scan count

• collate the error codes by:

– number

– date

– CASSETTE ID

Page 28

09OCT07

DG4366-1

Page

28 of 211

DIAGNOSTICS Using the Diagnostics

BUTTON Description

[Error Frequency Log]

Important

For the procedure, see Checking the Error Frequency

Log.

Allows you to:

• check:

– frequency of each error code

– date and time of last error

• collate error codes by:

– date

– error number

– frequency

[Actuation Log]

Important

For the procedure, you must see Checking the Actuation

Logs.

Allows you to check:

• “SCAN CYCLES” - This value cannot be reset

• “BATCH ERASE CYCLES” - The number of times that

the “Batch Erase” function was used

• “TOTAL POWER-ON HOURS”

• “LASER DIODE SCAN CYCLES”

• “LASER HOURS (hours and minutes)”

• “LASER HOURS LAST CLEARED”

Page 29

09OCT07

DG4366-1

Page

29 of 211

DIAGNOSTICS Using the Diagnostics

BUTTON Description

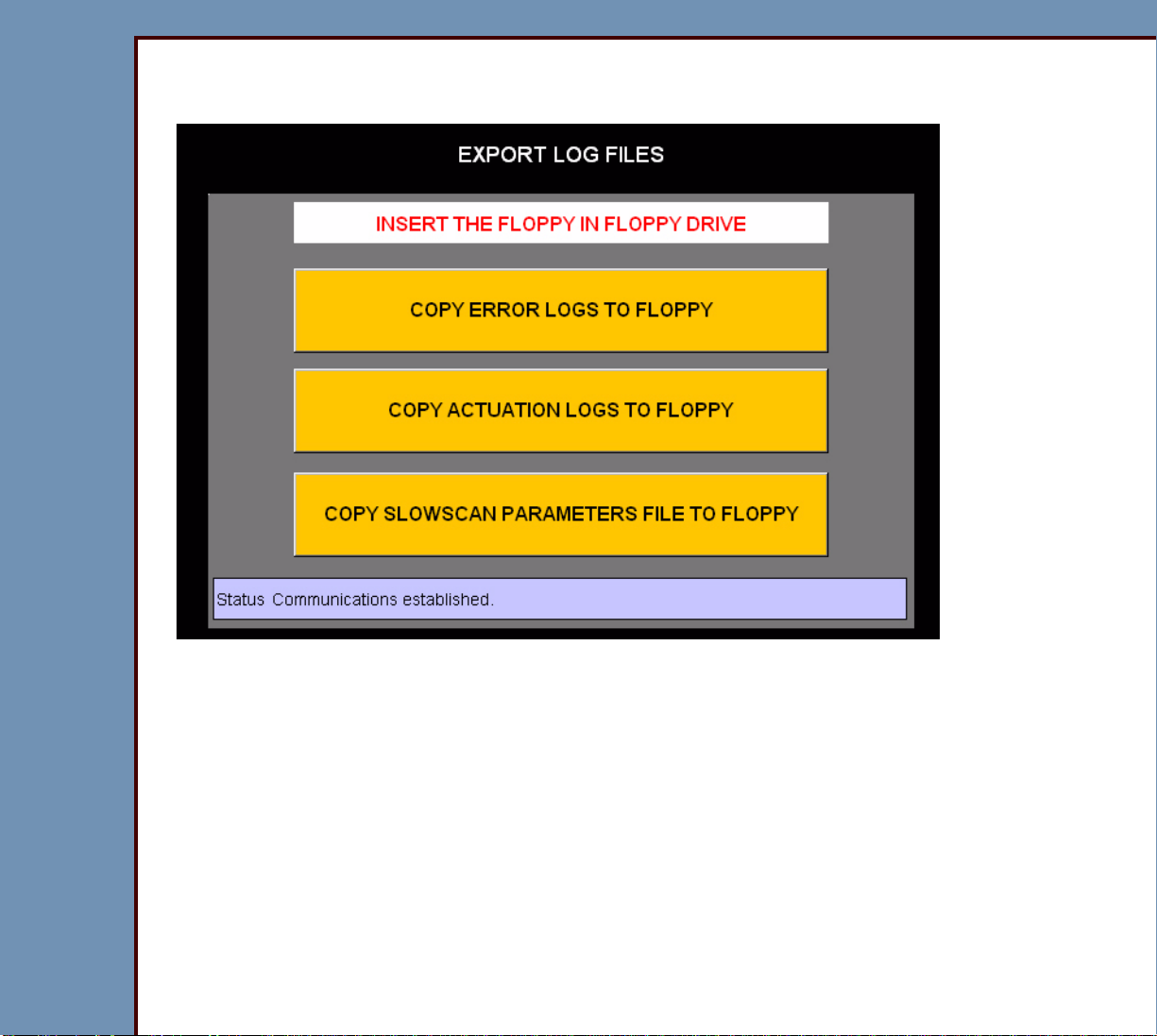

[Export Log Files]

Important

For the procedure, see Storing the Error Logs on a Disk.

Records onto a FLOPPY DISKETTE:

• “Actuation Logs”

• error logs

• parameters of the SLOW SCAN

[Clear Error Log]

Important

For the procedure, see Clearing the Error Logs.

• Clears all the errors from the error logs.

• Displays the date when the error logs were last cleared.

Page 30

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

30 of 211

Table 5 “Repetitive Cycles”

BUTTON Description

[AutoLooper]

Important

• You must have:

– SLOW SCAN AY COVER installed

– LASER SAFETY COVER installed

– “Light Leak Test” enabled.

• For the procedure, see the AUTOLOOPER test.

• Errors will occur if panels are removed during the

“AutoLooper Test”.

• Automatically processes the CASSETTE to check if

it is reliable.

• Completes a test cycle including scanning and

erasing.

• Displays status screens for the SENSORS.

[Transport]

Important

• The “Light Leak Test” is disabled to allow removal of

the PANELS during the “Transport Test”.

• For the procedure, see the Transport test.

• Uses a CASSETTE to test the operation of loading.

• Displays the status of the SENSORS at each step.

Page 31

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

31 of 211

Table 6 Miscellaneous

BUTTON Description

[Download to Circuit

Boards]

[Display Software Versions]

Important

For the procedure, you must see Downloading Software to

the BOARDS.

Allows you to download the necessary software to all the

BOARDS from the HARD DRIVE.

Important

For the procedure, you must see Displaying the Software

Versions.

Displays the software version number for:

• CR 500 SYSTEM

• MASTER CENTRAL PROCESSING UNIT BOARD (MCPU)

A2

• MECHANISM SYSTEM CONTROL BOARD BOOT

• MECHANISM SYSTEM CONTROL BOARD A1

• SLOW SCAN CONTROLLER BOARD BOOT

• SLOW SCAN CONTROLLER BOARD FIXED APPLICATION

• SLOW SCAN CONTROLLER BOARD PRODUCT

APPLICATION

• DIGITIZER BOARD A3

• MEDICAL IMAGE MANAGER

• DIAGNOSTICS

Page 32

09OCT07

DG4366-1

Page

32 of 211

DIAGNOSTICS Using the Diagnostics

[System Self Test]

Important

For the test procedure, you must see System Self Tests.

Completes the following diagnostic tests:

• “GALVO BOARD COMMUNICATION” - Checks the

connection of the CABLE between:

– GALVO BOARD A4

– MCPU BOARD A2

• “GALVO REFERENCE” - Reads the GALVO AGC

CHANNEL connected to the reference voltage of the

GALVO.

• “GALVO MOTOR” - Reads the voltage of the GALVO

AGC to check for problems with the GALVO AY.

• “GALVO SWEEP” - Checks the functions of reading and

writing of the REGISTERS on the GALVO BOARD A4.

• “LASER OFFSET”

• “PMT BOARD TEST” - Checks the connection of the

CABLE between:

– MCPU BOARD A2

– PMT/DAS BOARD A5

• “MCPU BOARD MEMORY TEST” - Checks for errors in

the reading and writing of data to each of the image

buffers.

Page 33

09OCT07

DG4366-1

Page

33 of 211

DIAGNOSTICS Using the Diagnostics

Diagnostic Tests

Individual Component Control

1 At the “Ser vice System Diagnostic” screen, select [Individual Component Control].

Important

• If you actuate any of the components, you must select [RESET] before returning to the

diagnostics main menu.

• An “ x ” in the check box indicates a SENSOR is blocked.

• If RP1 and RP2:

– are open, an “x” is displayed in the check box

– are closed, the check box is clear

2 Select [MOTORS, CAMS] tab.

Page 34

09OCT07

DG4366-1

Page

34 of 211

DIAGNOSTICS Using the Diagnostics

3 Use the BUTTONS to actuate:

• GUIDE MOTOR

• RP 1 CAM

• RP 2 CAM

• SIDE ACTUATOR

• PIN EXTRACTION

• ERASE CAM

• FEED MOTOR

4 Select [SCANNER].

Important

You must click [LED ON] to energize the “SCREEN START SENSOR”.

Page 35

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

35 of 211

5 Use the BUTTONS to actuate the:

• CASSETTE COMMANDS

• SLOW SCAN CONTROLLER

• ERASE MOTOR

• SCREEN START SENSOR

• ERASE LAMPS

Important

You must select [RESET] after selecting BUTTONS.

6 Select [RESET].

Page 36

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

36 of 211

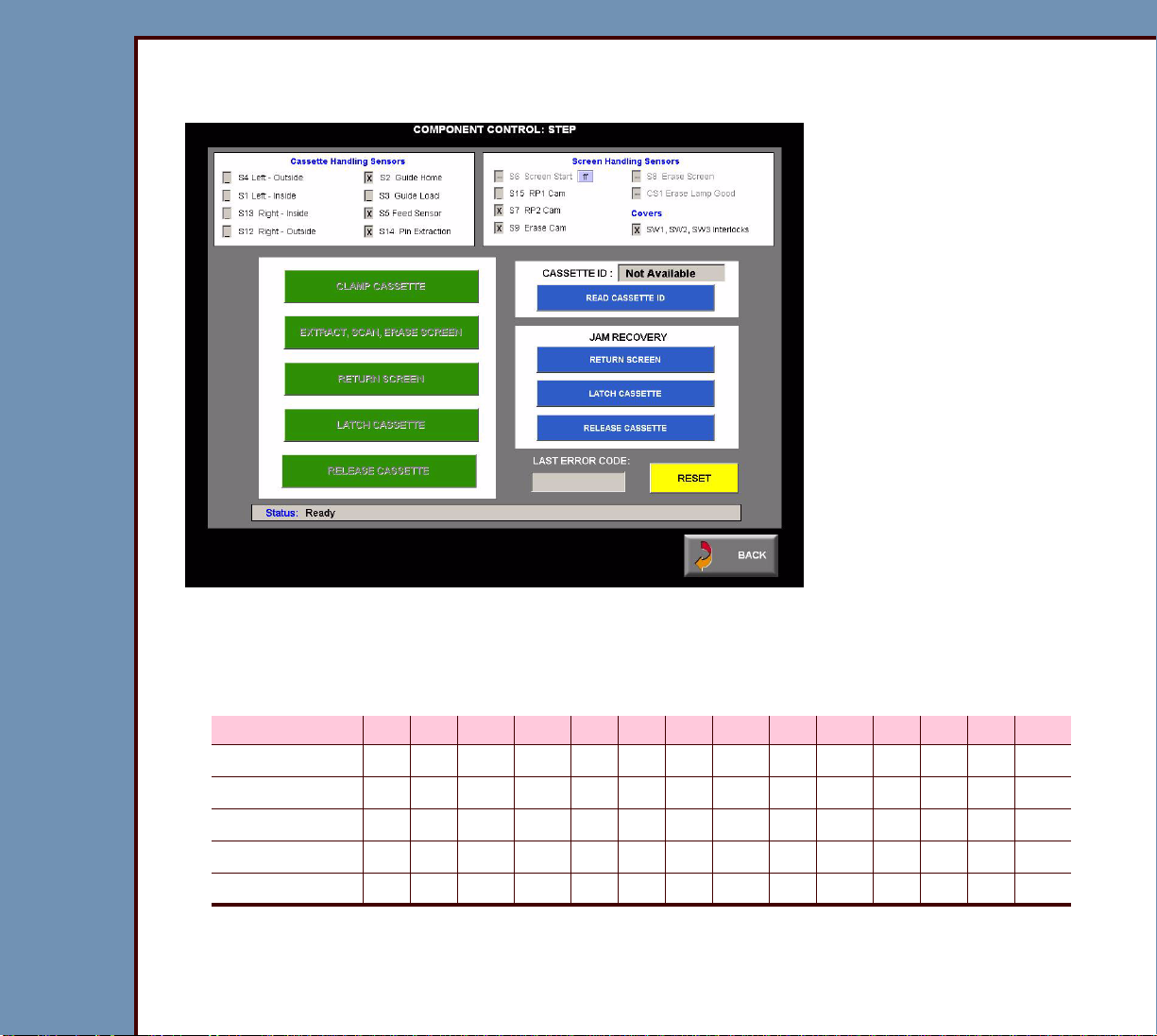

Component Control: Step

1 On the “System Ser vice Diagnostic” screen, select [Component Control: Step].

2 Inser t the CASSETTE into the CR 500 SYSTEM.

3 Check that the status of the SENSORS on the screen matches the table for the correct

size of CASSETTE.

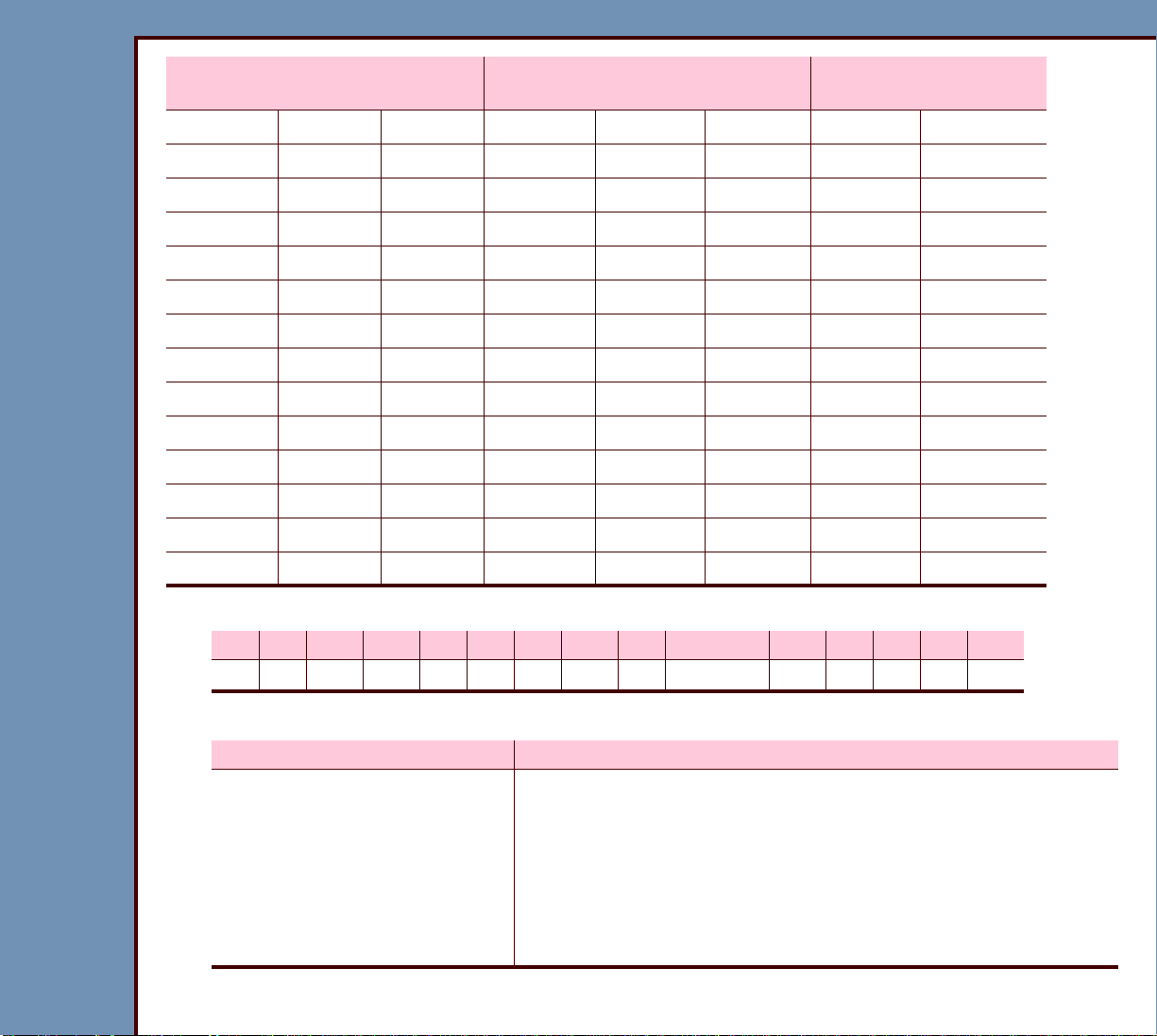

CASSETTE S4 S1 S13 S12 S2 S3 S5 S14 S6 S15 S7 S9 S8 CS1

18 x 24 cm X X X X X - X X X - 15 x 30 cm X X X X X - X X X - 24 x 30 cm X X X X X X X - X X X - 35 x 35 cm X X X X X X X - X X X - 35 x 43 cm X X X X X X X - X X X - -

4 Select [CLAMP CASSETTE]

Page 37

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

37 of 211

5 Check that the status of the SENSORS on the screen matches the table.

S4 S1 S13 S12 S2 S3 S5 S14 S6 S15 S7 S9 S8 CS1

XXX X XX XX- -

6 Does the status of the SENSORS match the table?

Yes No

Continue with Step 7. 1. Check the “Status” on the screen for messages or

error codes.

2. Check the error logs. See Checking the Error Logs.

3. See the Error Codes to determine the possible cause

and action for the problem.

4. Continue with Step 7.

7 Select [EXTRACT, SCAN, ERASE SCREEN].

8 Wait approximately 10 seconds for the cycle to complete.

9 Check that the status of the SENSORS on the screen matches the table.

S4 S1 S13 S12 S2 S3 S5 S14 S6 S15 S7 S9 S8 CS1

XXXXXX-X X

10 Does the status of the SENSORS match?

Yes No

Continue with Step 11. 1. Check the “Status” on the screen for messages or

error codes.

2. Check the error logs. See Checking the Error Logs.

3. See the Error Codes to determine the possible cause

and action for the problem.

4. Continue with Step 11.

11 Select [RETURN SCREEN].

12 Wait approximately 5 seconds for the SCREEN to be inserted into the CASSETTE.

Page 38

09OCT07

DG4366-1

Page

38 of 211

DIAGNOSTICS Using the Diagnostics

Important

The S6 SCREEN START SENSOR displays a HEXIDECIMAL VALUE of:

• 00 - 60 when a screen is blocking the sensor

• C0 - FF when a screen is not blocking the sensor

13 The following table lists the HEXIDECIMAL VALUE for the S6 SENSOR.

0 - 5F = A SCREEN is under the

S6 SENSOR

60 - BF = S6 is in a Transitional

State

CO - FF = No SCREEN

under the S6 SENSOR

020406080A0C0E0

121416181A1C1E1

222426282A2C2E2

323436383A3C3E3

424446484A4C4E4

525456585A5C5E5

626466686A6C6E6

727476787A7C7E7

828486888A8C8E8

929496989A9C9E9

0A 2A 4A 6A 8A AA CA EA

0B 2B 4B 6B 8B AB CB EB

0C 2C 4C 6C 8C AC CC EC

0D 2D 4D 6D 8D AD CD ED

0E 2E 4E 6E 8E AE CE EE

0F 2F 4F 6F 8F AF CF EF

10 30 50 70 90 B0 D0 F0

11 31 51 71 91 B1 D1 F1

12 32 52 72 92 B2 D2 F2

Page 39

09OCT07

DG4366-1

Page

39 of 211

DIAGNOSTICS Using the Diagnostics

0 - 5F = A SCREEN is under the

S6 SENSOR

60 - BF = S6 is in a Transitional

State

CO - FF = No SCREEN

under the S6 SENSOR

13 33 53 73 93 B3 D3 F3

14 34 54 74 94 B4 D4 F4

15 35 55 75 95 B5 D5 F5

16 36 56 76 96 B6 D6 F6

17 37 57 77 97 B7 D7 F7

18 38 58 78 98 B8 D8 F8

19 39 59 79 99 B9 D9 F9

1A 3A 5A 7A 9A BA DA FA

1B 3B 5B 7B 9B BB DB FB

1C 3C 5C 7C 9C BC DC FC

1D 3D 5D 7D 9D BD DD FD

1E 3E 5E 7E 9E BE DE FE

1F 3F 5F 7F 9F BF DF FF

020406080A0C0E0

14 Check that the status of the SENSORS on the screen matches the table.

S4 S1 S13 S12 S2 S3 S5 S14 S6 S6 S15 S7 S9 S8 CS1

X X X X __ X __ X __ C0 - FF __ __ __ -- --

15 Does the status of the SENSORS match?

Yes No

Continue with Step 16. 1. Check the “Status” on the screen for messages or

error codes.

2. Check the error logs. See Checking the Error Logs.

3. See the Error Codes to determine the possible cause

and action for the problem.

4. Continue with Step 16.

16 Select [LATCH CASSETTE].

Page 40

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

40 of 211

17 Check that the status of the SENSORS on the screen matches the table.

S4 S1 S13 S12 S2 S3 S5 S14 S6 S6 S15 S7 S9 S8 CS1

XXXXX__XX-- FFXXX----

18 Does the status of the SENSORS match?

Yes No

Continue with Step 19. 1. Check the “Status” on the screen for messages or

error codes.

2. Check the error logs. See Checking the Error Logs.

3. See the Error Codes to determine the possible cause

and action for the problem.

4. Continue with Step 19.

19 Select [RELEASE CASSETTE].

20 Check that the status of the SENSORS on the screen matches the table.

S4 S1 S13 S12 S2 S3 S5 S14 S6 S6 S15 S7 S9 S8 CS1

XXXXX__XX-- FFXXX----

21 Does the status of the SENSORS match?

Yes No

Continue with Step 22. 1. Check the “Status” on the screen for messages or

error codes.

2. Check the error logs. See Checking the Error Logs.

3. See the Error Codes to determine the possible cause

and action for the problem.

4. Continue with Step 22.

22 Remove the CASSETTE.

Page 41

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

41 of 211

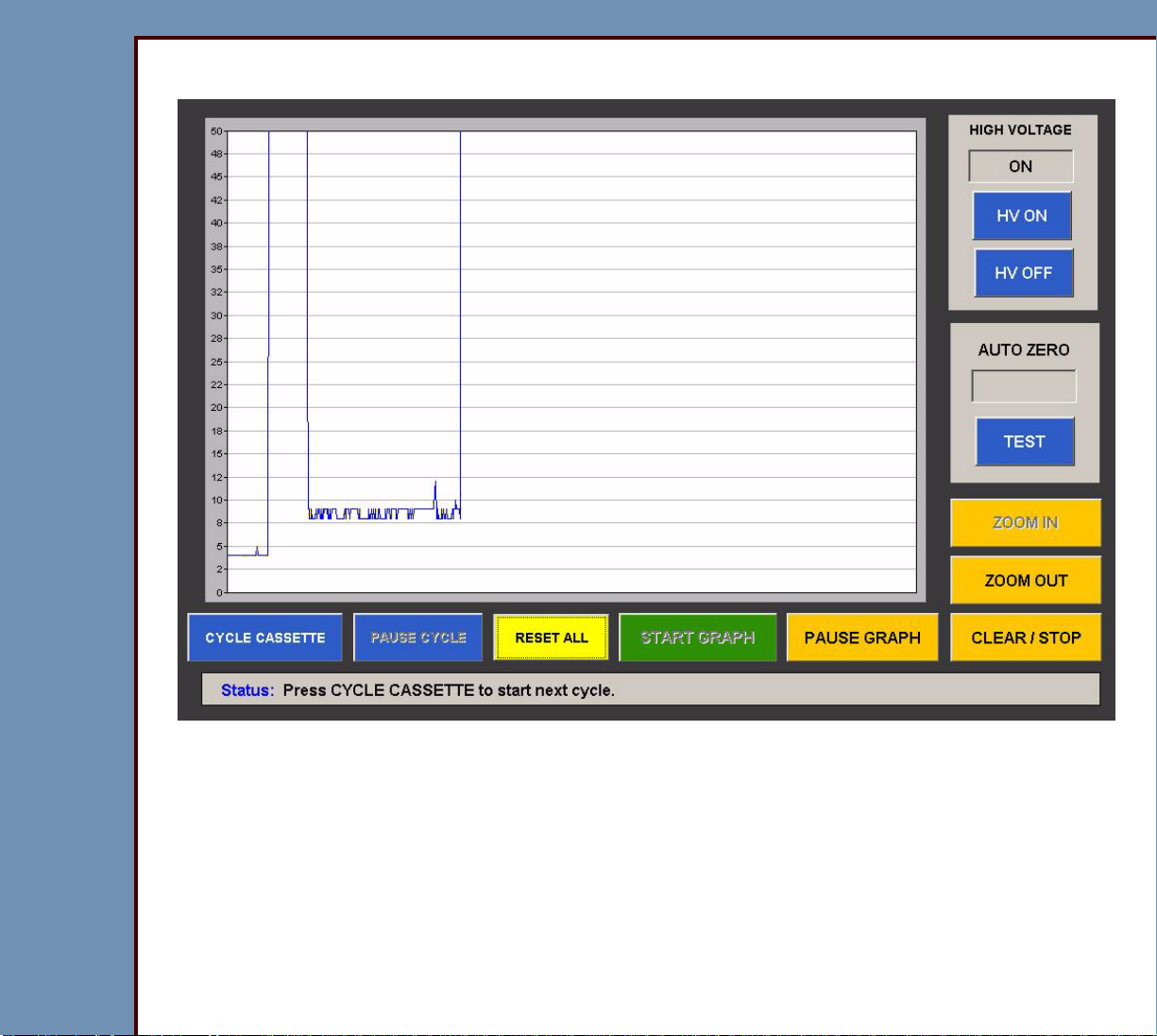

Light Test

1 On the “System Ser vice Diagnostic” screen, select [Light Test].

2 Select:

• [HV OFF]

• [TEST]

3 Wait for the test to complete.

4 Check that “PASS” displays in the “AUTO-ZERO” field.

5 Select [START GRAPH].

Page 42

09OCT07

DG4366-1

Page

42 of 211

DIAGNOSTICS Using the Diagnostics

6 Check that the value is between 4 and 5.

7 Select [HV ON].

8 The graphic displays a large “spike”.

9 Inser t a CASSETTE into the CR 500 SYSTEM.

10 Select [CYCLE CASSETTE].

Page 43

09OCT07

DG4366-1

Page

43 of 211

DIAGNOSTICS Using the Diagnostics

11 Check that the value is between 7 and 8.

12 Select [ZOOM IN].

13 When the CASSETTE is in cycle, select [HV ON].

Page 44

09OCT07

DG4366-1

Page

44 of 211

DIAGNOSTICS Using the Diagnostics

14 Check that the value:

• increases to approximately 50 - 51

• decreases to <10

15 If the value does not decrease to <10:

a. check the TAPE on the CASSETTE INTERFACE AY

b. check the COVERS and PANELS

c. do the checkout for the PMT/DAS BOARD A5

d. scan an ERASED PLATE

16 Select [CLEAR / STOP].

17 Remove the CASSETTE.

Page 45

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

45 of 211

Slow Scan Current and Velocity Tests

1 On the “System Ser vice Diagnostic” screen, select [Slow Scan Current and Velocity

Tests].

2 Inser t a CASSETTE into the CR 500 SYSTEM.

3 Select [Star t CURRENT TEST].

4 Wait for the test to complete.

Page 46

09OCT07

DG4366-1

Page

46 of 211

DIAGNOSTICS Using the Diagnostics

5 Check that the results are below 300.

6 If the results are not correct, check the error logs. See Checking the Error Logs.

7 Select [Star t VELOCITY TEST].

8 Wait for the test to complete.

Page 47

09OCT07

DG4366-1

Page

47 of 211

DIAGNOSTICS Using the Diagnostics

9 Check that the results are below 210.

10 If the results are not correct, check the error logs. See Checking the Error Logs.

11 Remove the CASSETTE.

Page 48

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

48 of 211

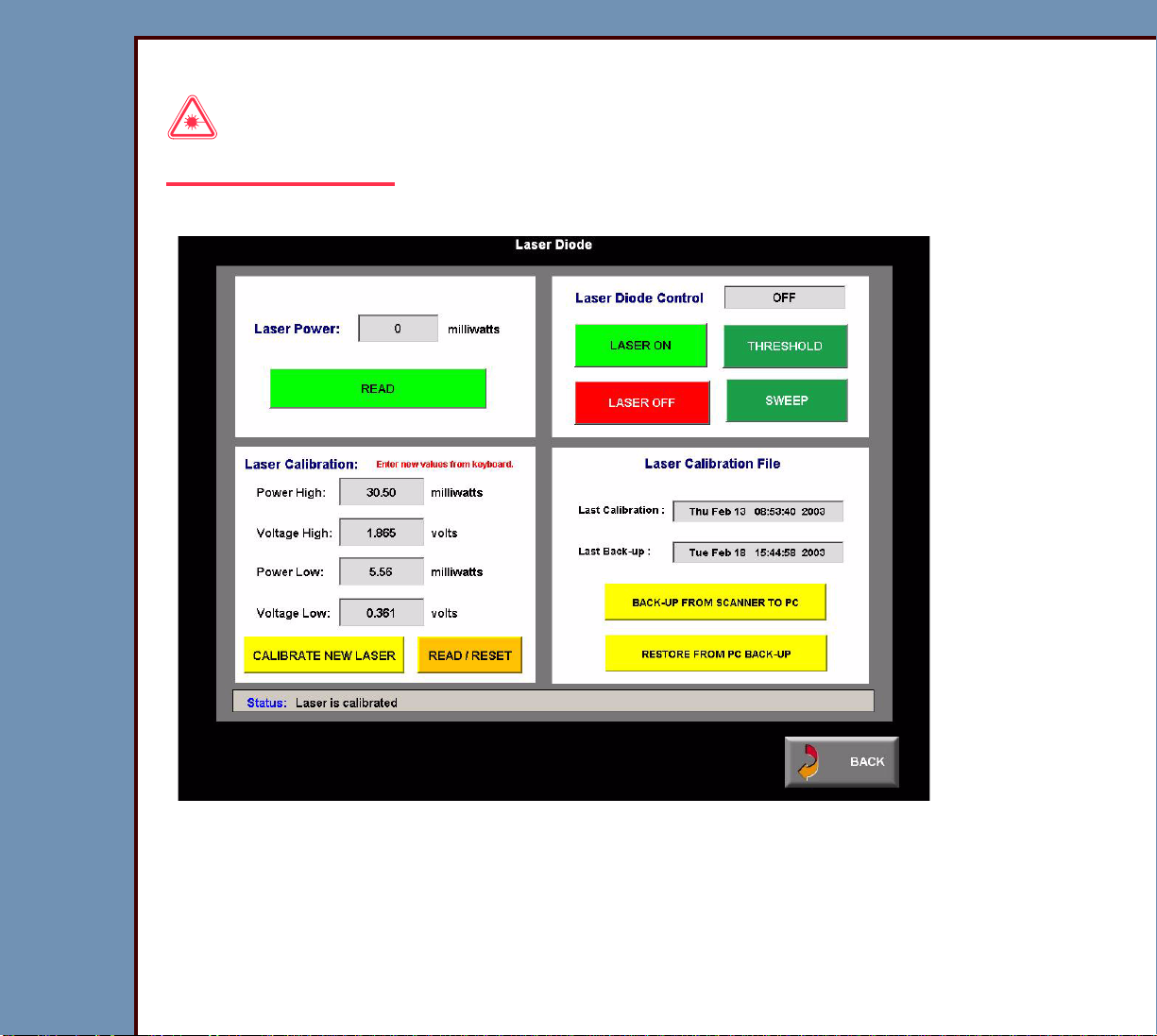

Laser Power

Laser Warning

Prevent direct exposure to the laser beam.

1 On the “System Ser vice Diagnostic” screen, select [Laser Power].

2 Select:

• [LASER ON]

• [READ]

3 Check that the “Laser Power” is 28 - 32 mW.

Page 49

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

49 of 211

4 Is the “Laser Power” value correct?

Yes No

Continue with the next test. 1. Check the connections to the

LASER DRIVER BOARD A17.

2. Install a new LASER DRIVER

BOARD.

5 Select [LASER OFF].

GALVO Test

1 On the “System Ser vice Diagnostic” screen, select [Galvo Test].

Laser Warning

Prevent direct exposure to the laser beam.

2 Select:

• [START GALVO]

• [LASER ON]

Page 50

09OCT07

DG4366-1

Page

50 of 211

DIAGNOSTICS Using the Diagnostics

3 Remove the PANELS.

FOLD MIRROR

laser beam

4 Inser t one sheet of paper into the CR

500 SYSTEM between:

• FOLD MIRROR

paper

• COLLECTOR

5 Obser ve the laser beam on the sheet of

paper.

CR 500 SYSTEM

COLLECTOR

H195_0051GCA

H195_0051GC

Page 51

09OCT07

DG4366-1

Page

51 of 211

DIAGNOSTICS Using the Diagnostics

6 Select [-100] or [+100] until:

• “Set Offset” value is 700

• “Set Amplitude” value is 1000

7 Obser ve the laser beam on the sheet of paper.

8 Select [+100] until the “Set Amplitude” value is 3000.

9 Obser ve the laser beam on the sheet of paper.

“Set Amplitude” Laser Beam

400 short

3900 long

Page 52

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

52 of 211

10 If the laser beam does not change size correctly, do the action in the table:

Description Action

The laser does not scan. The beam

illuminates in a point.

Check:

1. POWER SUPPLY PS1

2. POWER SUPPLY PS2

3. connections between:

• GALVO AY

• GALVO BOARD A4

4. GALVO AY

5. GALVO BOARD A4

The laser beam on the paper does

not change size.

Do the checkout for the GALVO

BOARD A4.

The LASER is not operating. Check:

1. POWER SUPPLY PS1

2. POWER SUPPLY PS2

3. GALVO BOARD A4

4. LASER DRIVER BOARD A17

Page 53

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

53 of 211

GALVO PLOT

1 On the “System Ser vice Diagnostic” screen, select [GALVO PLOT].

2 Select:

• [START GALVO PLOT]

• [35 X 43 F]

Page 54

09OCT07

DG4366-1

Page

54 of 211

DIAGNOSTICS Using the Diagnostics

3 Obser ve the GALVO PLOT.

Page 55

09OCT07

DG4366-1

Page

55 of 211

DIAGNOSTICS Using the Diagnostics

Not Correct

Not CorrectCorrect

Peak

Velocity

H195_0064BCA

H195_0064BC

3.195

3.035

2.876

2.716

2.556

2.396

2.236

2.077

1.917

horizontal level

Velocity

4 Check the values:

• GALVO PLOT is correct

• AGC = 8.0 V to 10.0 V

• 2.5 vRef = 2.5 ± 0.1

• PEAK matches the HORIZONTAL LEVEL

5 Are the values correct?

Yes No

Continue with the next

test.

Adjust the GALVO BOARD until the GALVO PLOT is

normal. See the adjustment procedure GALVO BOARD in

the ADJUSTMENTS and REPLACEMENTS for the Kodak

DirectView CR 500 SYSTEM, AR4366-1

3.195

3.035

2.876

2.716

2.556

2.396

2.236

2.077

1.917

Velocity

3.195

3.035

2.876

2.716

2.556

2.396

2.236

2.077

1.917

Page 56

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

56 of 211

Transport

1 On the “System Ser vice Diagnostic” screen, select [Transport].

2 Inser t a CASSETTE into the CR 500 SYSTEM.

3 Use the [+] or [-] to set the “Cycle given number of times” to 10.

4 Select either :

• [Cycle given number of times], or

• [Cycle continuously]

Page 57

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

57 of 211

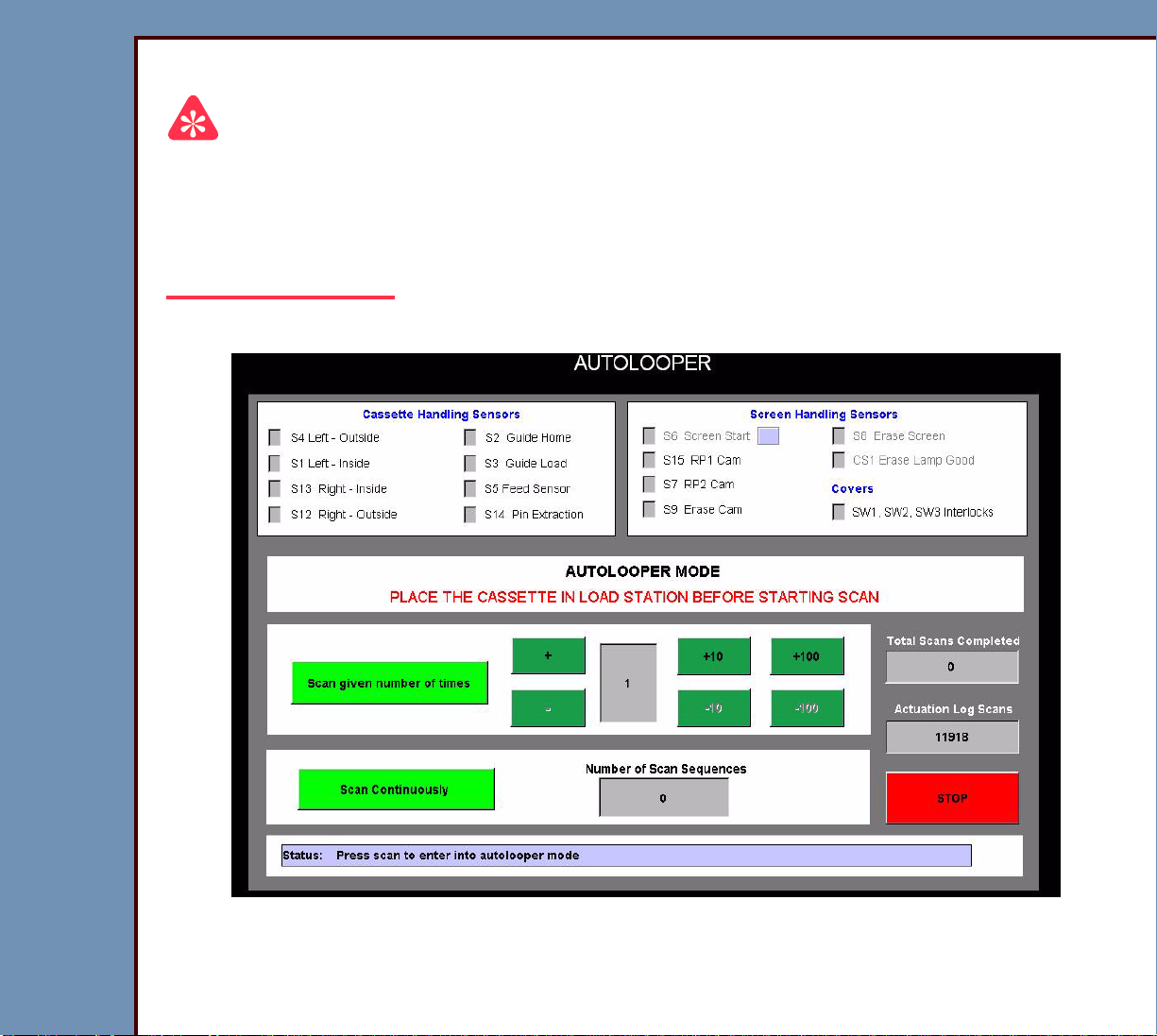

AUTOLOOPER

Important

You must have:

• LIGHT TEST set to enabled

• SLOW SCAN COVER installed

• LASER SAFETY COVER installed

1 On the “System Ser vice Diagnostic” screen, select [AutoLooper].

2 Inser t a CASSETTE into the CR 500 SYSTEM.

3 Use the [+] or [-] to set the “Number of Cycles” to 10.

Page 58

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

58 of 211

4 Select either :

• [Scan given number of times], or

• [Scan Continuously]

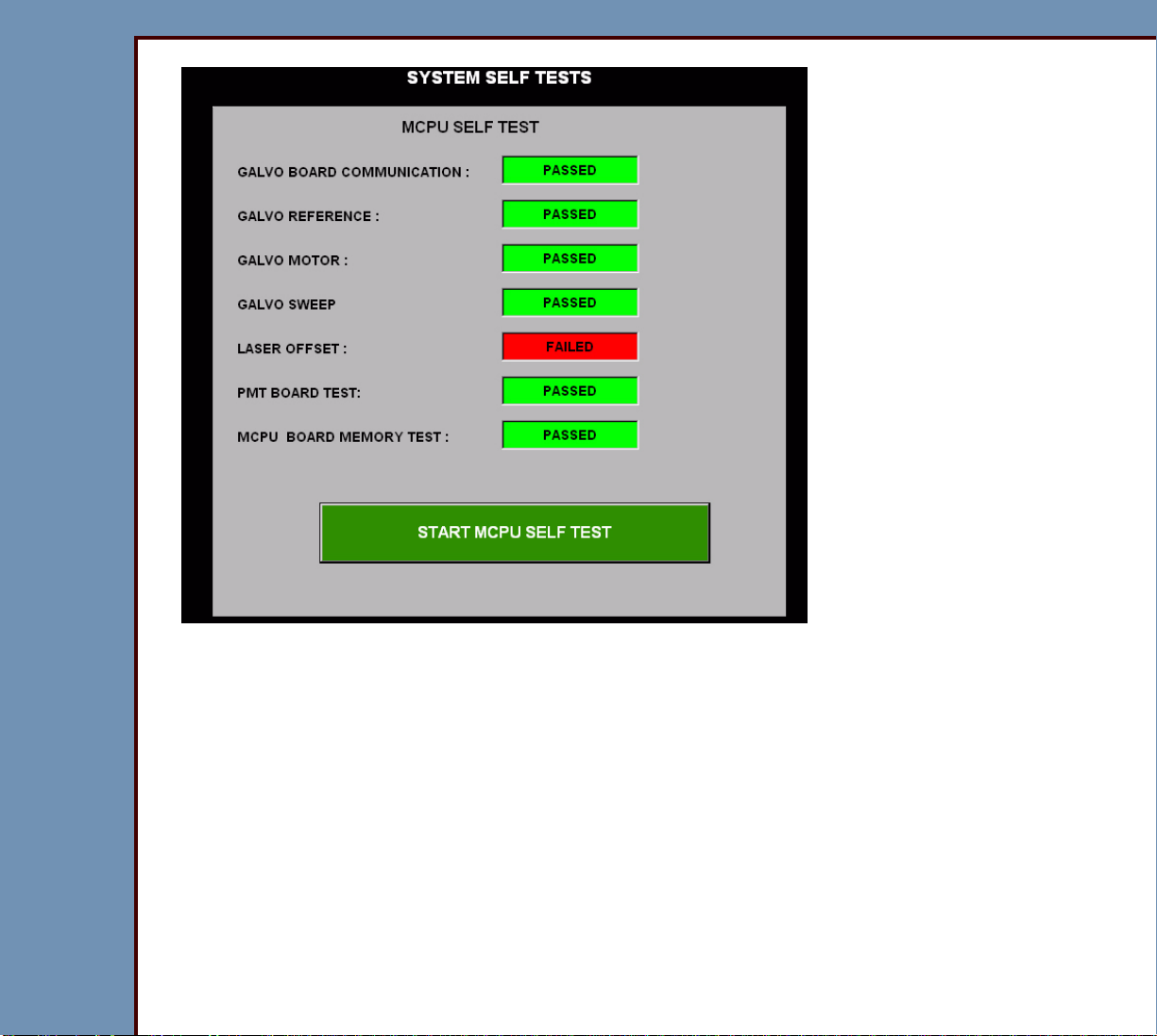

System Self Tests

1 On the “System Ser vice Diagnostic” screen, select [System Self Test].

2 Select [START MCPU SELF TEST].

3 Wait approximately 20 seconds for the test to complete.

Page 59

09OCT07

DG4366-1

Page

59 of 211

DIAGNOSTICS Using the Diagnostics

4 Obser ve the results for each test.

5 If any of the tests display “FAILED”, check the error logs. See Checking the Error Logs.

6 See the Error Codes to determine the possible cause and action for the problem.

Page 60

09OCT07

DG4366-1

Page

60 of 211

DIAGNOSTICS Using the Diagnostics

Diagnostic Procedures

Checking the Error Logs

1 On the “System Ser vice Diagnostic” screen, select [Error Log].

2 Select either :

• [Sort By Date],

• [Sort By ErrorCode], o r

• [Sort By CassetteID]

Page 61

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

61 of 211

Checking the Error Frequency Log

1 On the “System Ser vice Diagnostic” screen, select [Error Frequency Log].

2 Select either :

• [Sort By Date],

• [Sort By ErrorCode], o r

• [Sort ErrorFrequency]

Page 62

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

62 of 211

Checking the Actuation Logs

1 On the “System Ser vice Diagnostic” screen, select [Actuation Logs].

Page 63

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

63 of 211

Storing the Error Logs on a Disk

1 On the “System Ser vice Diagnostic” screen, select [Export Log Files].

2 Inser t a disk into the DRIVE.

3 Select either :

• [COPY ERROR LOGS TO FLOPPY],

• [COPY ACTUATION LOGS TO FLOPPY], or

• [COPY SLOWSCAN PARAMETERS FILE TO FLOPPY]

Page 64

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

64 of 211

Clearing the Error Logs

1 On the “System Ser vice Diagnostic” screen, select [Clear Error Log].

2 Select [CLEAR ERROR LOG].

Page 65

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

65 of 211

Displaying the Software Versions

1 On the “System Ser vice Diagnostic” screen, select [Display Software Versions].

Page 66

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

66 of 211

2 Check that each BOARD has the correct communication:

Message Description Action

The version number

is in the field.

All fields are blank. The diagnostics is not

The BOARD is

“Responding”.

operating.

Check that the newest and correct

version of the software is installed.

1. Do a shutdown of the computer.

2. De-energize the CR 500

3. Energize the CR 500 SYSTEM.

“Not Responding”

Important

The message is normal

1. Check the connections to the

2. Download the software to the

during initialization.

Failure of communications

3. If you cannot successfully

to the BOARD.

“Not Repor ting” The BOARD has a failure of

1. Check the BOARD that is “Not

communication because

another BOARD is “Not

Responding”.

2. Do the test again.

SYSTEM.

BOARD.

BOARD.

download the software to the

BOARD, install a new BOARD.

Responding”.

Page 67

DIAGNOSTICS Using the Diagnostics

09OCT07

DG4366-1

Page

67 of 211

Downloading Software to the BOARDS

1 On the “System Ser vice Diagnostic” screen, select [Download to Circuit Boards].

Caution

Downloading the “SSC BOOT” can cause damage to the SLOW SCAN CONTROLLER

BOARD A6. Only download the “SSC BOOT” if necessar y.

2 Select either :

• [DOWNLOAD MSC APPLICATION],

• [DOWNLOAD SSC BOOT AND APPLICATIONS],

• [DOWNLOAD MCPU APPLICATION],

• [DOWNLOAD SSC APPLICATIONS], or

• [DOWNLOAD SSC PARAMET ERS]

Page 68

09OCT07

DG4366-1

Page

68 of 211

DIAGNOSTICS Error Codes

Section 2: Error Codes

Overview

The first 2 digits of the error code identify the subsystem or component with the error.

Example: 10003

The “1” and the “0” indicate that the error occurred in the subsystem CASSETTE LOAD.

1 Use Table 7 to help identify the component with the error.

2 Advance to the error code to diagnose the error.

Table 7 Subsystem

ID No. Subsystem

10 CASSETTE LOAD

12 SLOW SCAN AY

13 ERASE LAMPS

14 POWER SUPPLY

15 DATA PAT H

16 Calibration

19 “Self Test” for the MASTER CENTRAL PROCESSING UNIT

22 MECHANISM SYSTEM CONTROL BOARD

29 MECHANISM SYSTEM CONTROL BOARD RTXC

30 MECHANISM SYSTEM CONTROL BOARD SYSTEM

32 Communications for the MECHANISM SYSTEM CONTROL BOARD

Windows 2000 SUBSYSTEM

47 SHUTDOWN MANAGER

49 DISK MANAGER

54 Service Diagnostics

55 Installation

Page 69

09OCT07

DG4366-1

Page

69 of 211

DIAGNOSTICS Error Codes

ID No. Subsystem

59 CD/DVD SYSTEM

60 Security Audit

Page 70

09OCT07

DG4366-1

Page

70 of 211

DIAGNOSTICS Error Codes

CASSETTE LOAD

940 - Display only, no Log Message

Description: The SCANNER is energizing. Do not scan CASSETTES at this time.

Cause: The CR 500 SYSTEM is not fully energized.

Action: Wait for the CR 500 SYSTEM to fully energize.

941 - Display only, no Log Message

Description: The communications between the MASTER CENTRAL PROCESSING

UNIT BOARD A2 and the MOTION CONTROL SYSTEM BOARD A1

malfunctioned.

Cause: The CABLE between the MASTER CENTRAL PROCESSING UNIT BOARD A2

and the MOTION CONTROL SYSTEM BOARD A1 malfunctioned.

Action: 1. Check the CABLE.

2. If this error continues, call the Technical Service Center.

942 - Display only, no Log Message

Description: The bar code could not be read.

Cause: The BAR CODE READER could not read the bar code.

Action: 1. Insert the CASSETTE again.

2. Insert another CASSETTE.

950 - Display only, no Log Message

Description: The CR 500 SYSTEM malfunctioned.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. De-energize the CR 500 SYSTEM.

2. Energize the CR 500 SYSTEM.

3. If this error continues, call the Technical Service Center.

Page 71

09OCT07

DG4366-1

Page

71 of 211

DIAGNOSTICS Error Codes

951 - Display only, no Log Message

Description: The CASSETTE did not load.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. Select “Continue” to eject the CASSETTE.

2. Insert the CASSETTE again.

3. If this error continues, call the Technical Service Center.

952 - Display only, no Log Message

Description: The CASSETTE did not load.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. Select “Continue” to eject the CASSETTE.

2. Insert the CASSETTE again.

3. If this error continues, call the Technical Service Center.

953 - Display only, no Log Message

Description: The CASSETTE did not scan.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. Select “Continue” to erase the CASSETTE.

2. Insert a new CASSETTE.

3. If this error continues, call the Technical Service Center.

Page 72

09OCT07

DG4366-1

Page

72 of 211

DIAGNOSTICS Error Codes

954 - Display only, no Log Message

Description: The CASSETTE did not erase.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. Select “Continue” to eject the CASSETTE.

2. Insert the CASSETTE again.

3. Erase the CASSETTE.

4. If this error continues, call the Technical Service Center.

955 - Display only, no Log Message

Description: The CASSETTE did not eject.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. Select “Continue” to eject the CASSETTE.

2. Insert the CASSETTE again.

3. If this error continues, call the Technical Service Center.

956 - Display only, no Log Message

Description: The CASSETTE did not scan.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. Select “Continue” to eject the CASSETTE.

2. Insert the CASSETTE again.

3. If this error continues, de-energize the CR 500 SYSTEM.

4. Energize the CR 500 SYSTEM.

Page 73

09OCT07

DG4366-1

Page

73 of 211

DIAGNOSTICS Error Codes

957 - Display only, no Log Message

Description: The CASSETTE could not be scanned because the memor y is full.

Cause: The disk is full.

Action: Call the Technical Service Center.

958 - Display only, no Log Message

Description: The CR 500 SYSTEM is in recovery from a malfunction.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. Eject the CASSETTE.

2. Insert the CASSETTE again.

959 - Display only, no Log Message

Description: The CR 500 SYSTEM malfunctioned.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. De-energize the CR 500 SYSTEM.

2. Energize the CR 500 SYSTEM.

3. If this error continues, call the Technical Service Center.

960 - Display only, no Log Message

Description: The communications of the CR 500 SYSTEM malfunctioned.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. De-energize the CR 500 SYSTEM.

2. Energize the CR 500 SYSTEM.

3. If this error continues, call the Technical Service Center.

Page 74

09OCT07

DG4366-1

Page

74 of 211

DIAGNOSTICS Error Codes

961 - Display only, no Log Message

Description: The CR 500 SYSTEM is not able to load the SCREEN.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. Select “Continue” to release the CASSETTE.

2. Remove the CASSETTE.

3. Insert the CASSETTE again.

4. If this error continues, call the Technical Service Center.

962 - Display only, no Log Message

Description: The CR 500 SYSTEM is not able to scan the CASSETTE.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. Select “Continue” to eject the SCREEN.

2. Remove the CASSETTE.

3. Insert the CASSETTE again.

4. If this error continues, contact the Technical Service Center.

963 - Display only, no Log Message

Description: The CR 500 SYSTEM is not able to eject the SCREEN.

Cause: More than one cause is possibl e. See the error codes displayed.

Action: 1. Select “Retry” to eject the SCREEN.

2. If the SCREEN does not eject, select “Cancel” to release the CASSETTE.

3. Remove the SCREEN manually.

4. Insert another CASSETTE.

5. If this error continues, call the Technical Service Center.

Page 75

DIAGNOSTICS Error Codes

09OCT07

DG4366-1

Page

75 of 211

994 - Display only, no Log Message

Description: The CASSETTE was not loaded correctly into the CR 500 SYSTEM.

Cause: The CASSETTE was not inserted correctly.

Action: 1. Remove the CASSETTE.

2. Insert the CASSETTE again.

995 - Display only, no Log Message

Description: The CASSETTE was not scanned.

Cause: The CASSETTE was not scanned.

Action: 1. Remove the CASSETTE.

2. Insert the CASSETTE again.

996 - Display only, no Log Message

Description: The CASSETTE was not erased.

Cause: The CASSETTE was not erased.

Action: 1. Remove the CASSETTE.

2. Insert the CASSETTE again.

3. Erase the CASSETTE.

997 - Display only, no Log Message