Page 1

© EASTMAN KODAK COMPANY, 2006 HEALTH GROUP

Confidential

Restricted

Information

{Adjust/Replace}{Production}{Health Group}{ExternalAndInternal}

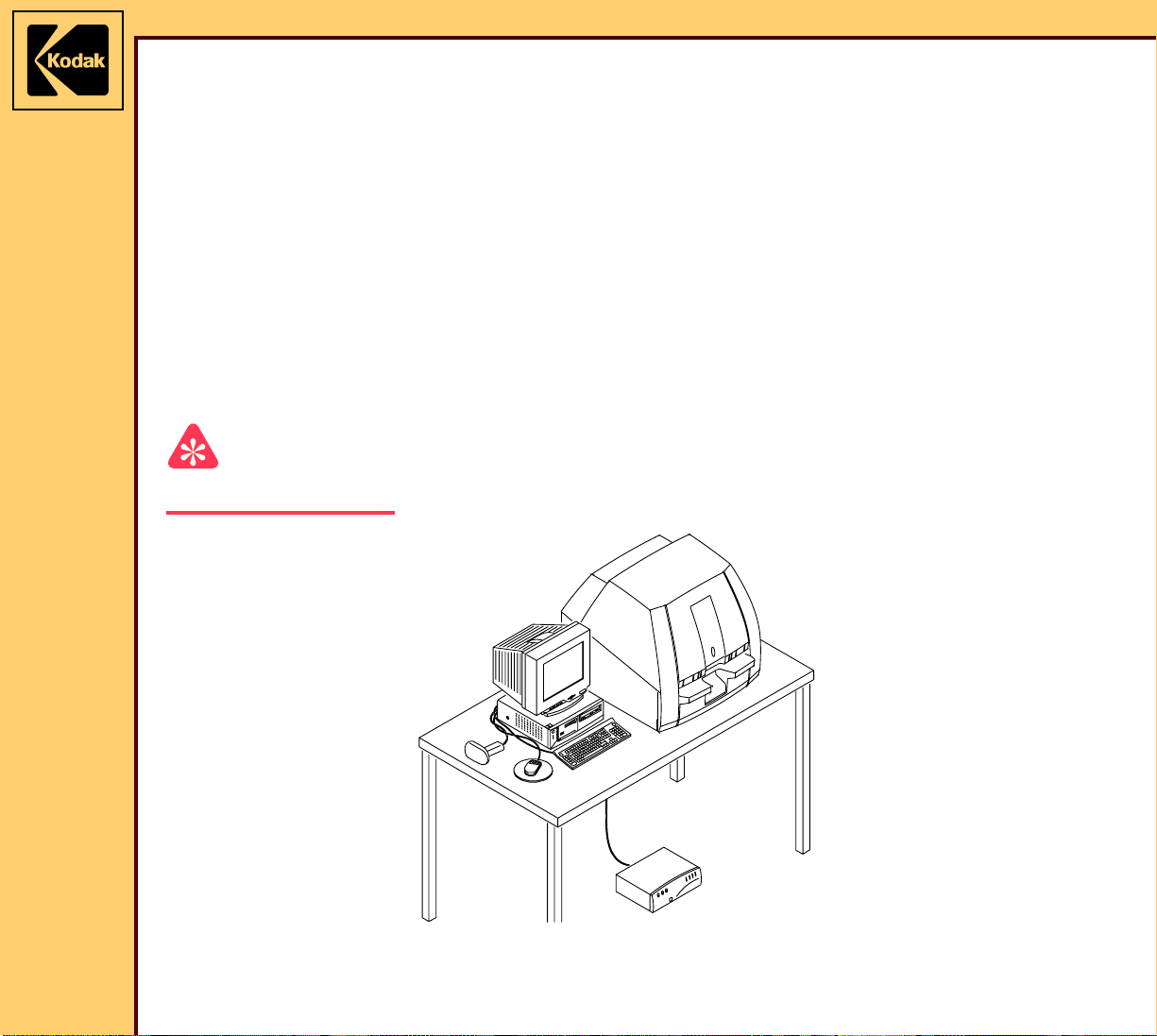

ADJUSTMENTS AND REPLACEMENTS

for the

Kodak DirectView CR 500 SYSTEM

Service Code: 4366

Important

Qualified service personnel must do these procedures.

Publication No. AR4366-1

06DEC05

Supersedes AR4366-1

29NOV04

H195_0016BCH195_0016BC

Page 2

ADJUSTMENTS AND REPLACEMENTS

06DEC05

AR4366-1

Page

2 of 219

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be

liable for any loss or damage, including consequential or special damages, resulting from any

use of this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Table of Contents

Description Page

Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

GALVO AY - Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FOLD MIRROR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

COLLECTOR AY - Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

GALVO BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

EXTRACTION PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SCREEN - Skew. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Replacements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

FRONT COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

TOP COVER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

HARD DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

EXTRACTION PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

S1/S4 and S12/S13 SENSOR BOARDS - DETECTOR . . . . . . . . . . . . . . . . . . . . . 68

S1/S4 and S12/S13 SENSOR BOARDS - EMITTER . . . . . . . . . . . . . . . . . . . . . . . 70

CASSETTE INTERFACE AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

GUIDE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

M9 LEFT CASSETTE CLAMP MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

M3 FEED DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

LEFT CARRIAGE AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

LEFT CASSETTE CLAMP DRIVE BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

M2 PIN EXTRACT MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

M10 RIGHT CLAMP MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

RIGHT CARRIAGE AY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

S5 FEED SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Page 3

ADJUSTMENTS AND REPLACEMENTS

06DEC05

AR4366-1

Page

3 of 219

S14 PIN EXTRACTION SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

RP 1 PRESSURE ROLLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

RP 1 DRIVE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

RP 2 PRESSURE ROLLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

RP 2 DRIVE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

RP 1 ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

RP 2 ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

RP 1 and RP 2 DRIVE BELTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

DRIVE BELT TENSIONER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

RP 1 and RP 2 CAM MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

SENSORS S10 and S11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

RP 1 and RP 2 CAM POSITION SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

SLOW SCAN DRIVER BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

ERASE AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

ERASE LAMP HOUSING AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

RP 3 DRIVE MOTOR BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

RP 3 CAM DRIVE BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

RP 3 CAM DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

AC POWER MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

POWER SUPPLY 1 and POWER SUPPLY 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

S8 SCREEN ERASE SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

S9 ERASE CAM SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

M6 ERASE DRIVE MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

ERASE LAMP RELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

RP 3 DRIVE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

RP 3 PRESSURE ROLLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

ERASE LAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

SCREEN GUIDE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

PMT BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

SLOW SCAN AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

SLOW SCAN MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

MECHANISM SYSTEM CONTROLLER (MSC) BOARD . . . . . . . . . . . . . . . . . . . . 177

COLLECTOR AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

FOLD MIRROR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

GALVO BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

MASTER CENTRAL PROCESSING UNIT (MCPU)/DIGITIZER BOARD. . . . . . . . 189

LASER PREREGULATOR BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

MINI FAST SCAN AY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Additional Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Checking the PHOSPHOR SCREEN for “Curl” and “Flatness” . . . . . . . . . . . . 198

Doing a Calibration of the LASER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Setting the Laser Calibration Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Page 4

ADJUSTMENTS AND REPLACEMENTS

06DEC05

AR4366-1

Page

4 of 219

Setting the Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Page 5

06DEC05

AR4366-1

Page

5 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

Section 1: Adjustments

GALVO AY - Center

Adjustment Specification

Purpose: To set the correct position of the laser beam.

Specification: The laser beam is aligned with the TAB on the FOLD MIRROR.

Special Tools: LASER SAFETY GOGGLES TL-5693

Prerequisites:

None

To Check:

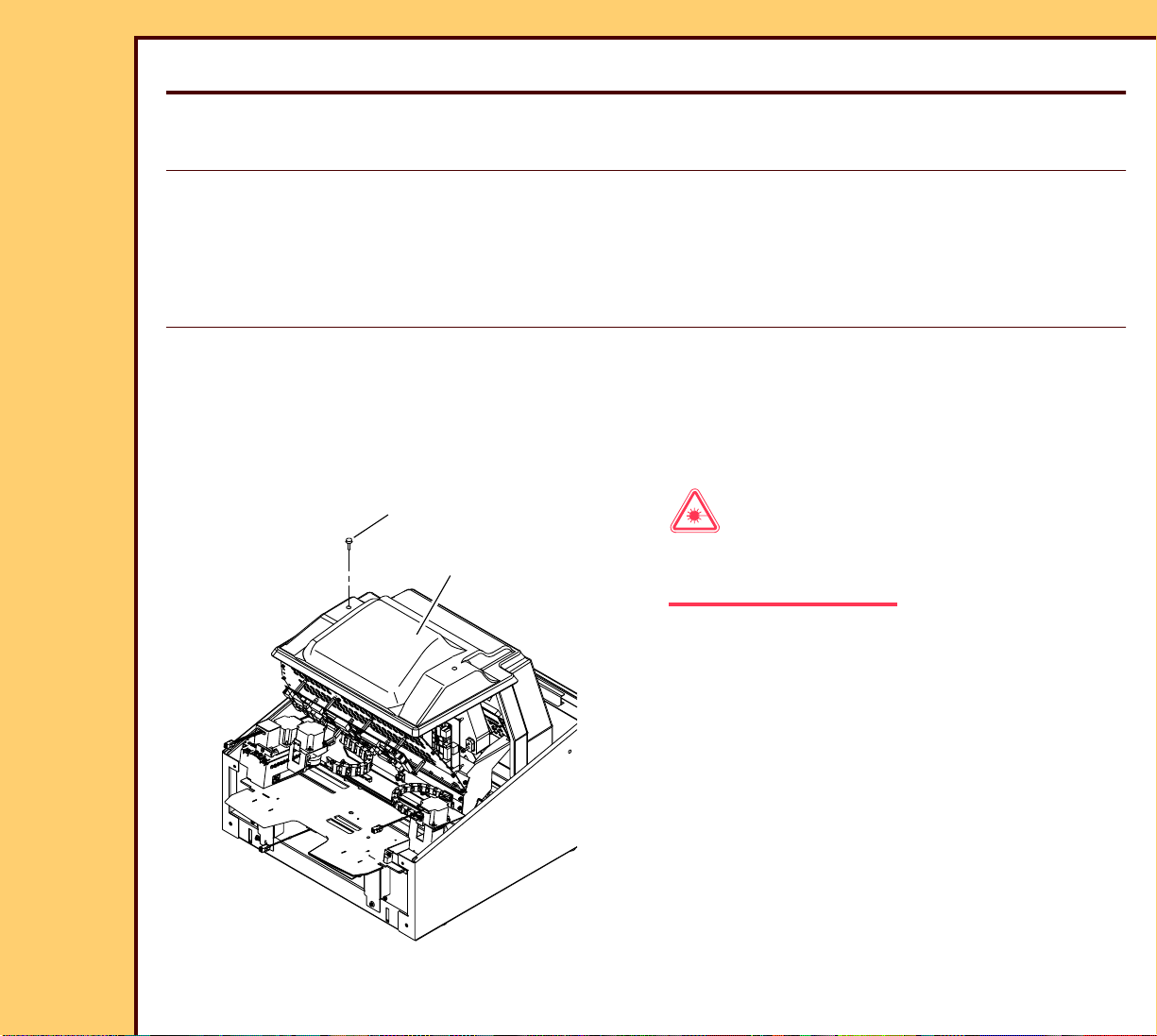

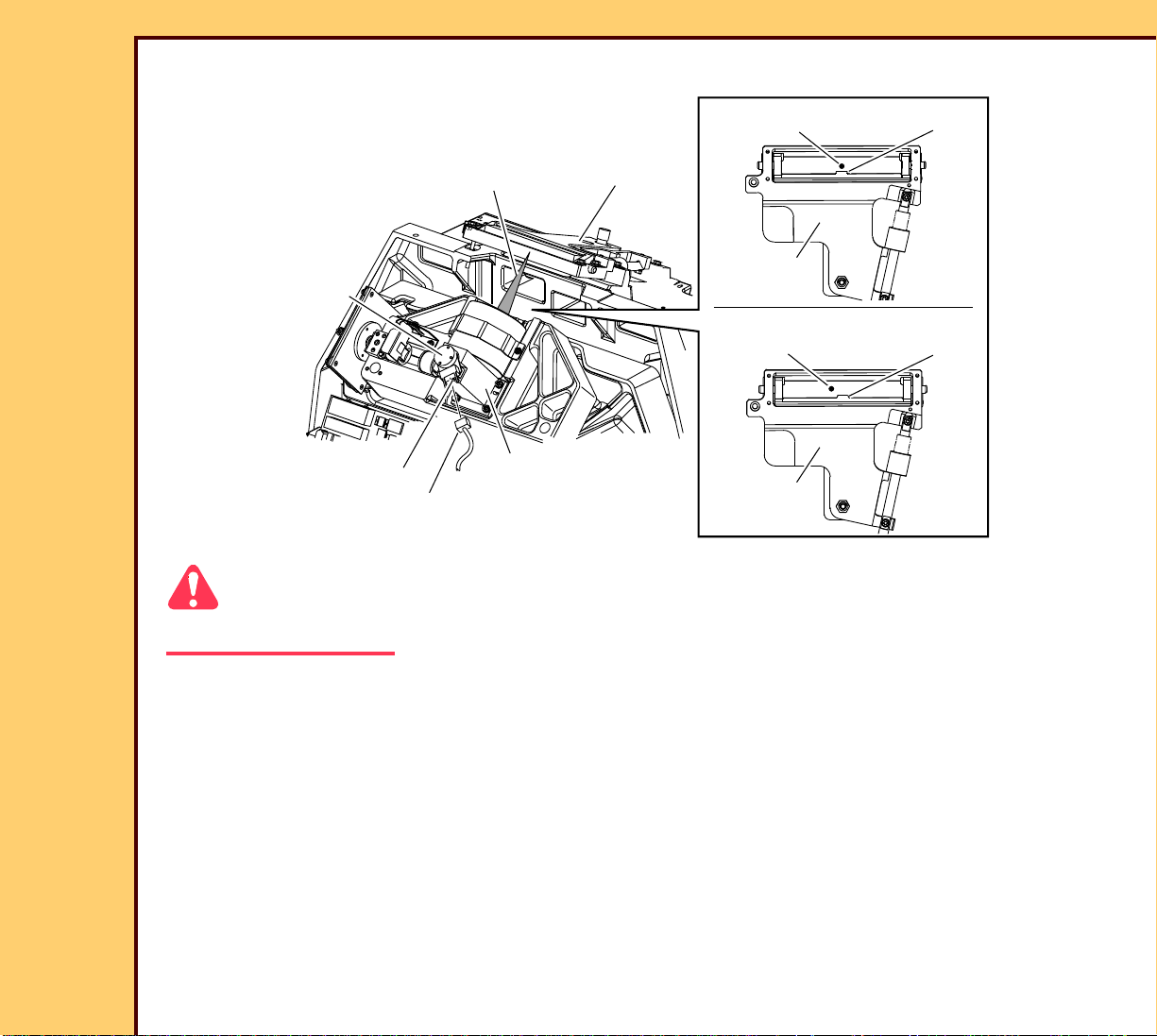

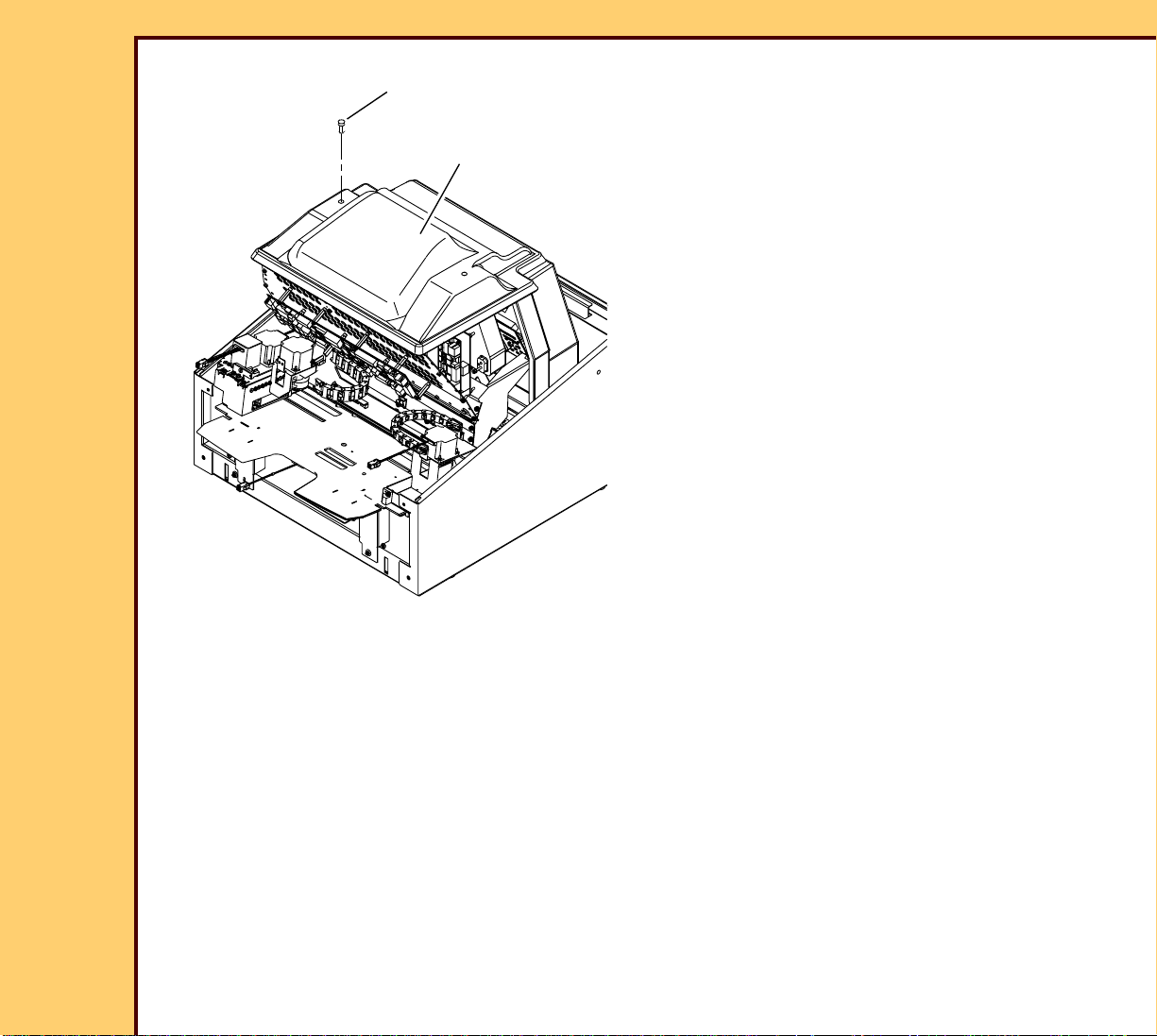

2 SCREWS

Laser Warning

LASER SAFETY

COVER

This equipment uses a visible red laser.

Prevent direct exposure to the laser beam.

H195_1020GCA

H195_1020GC

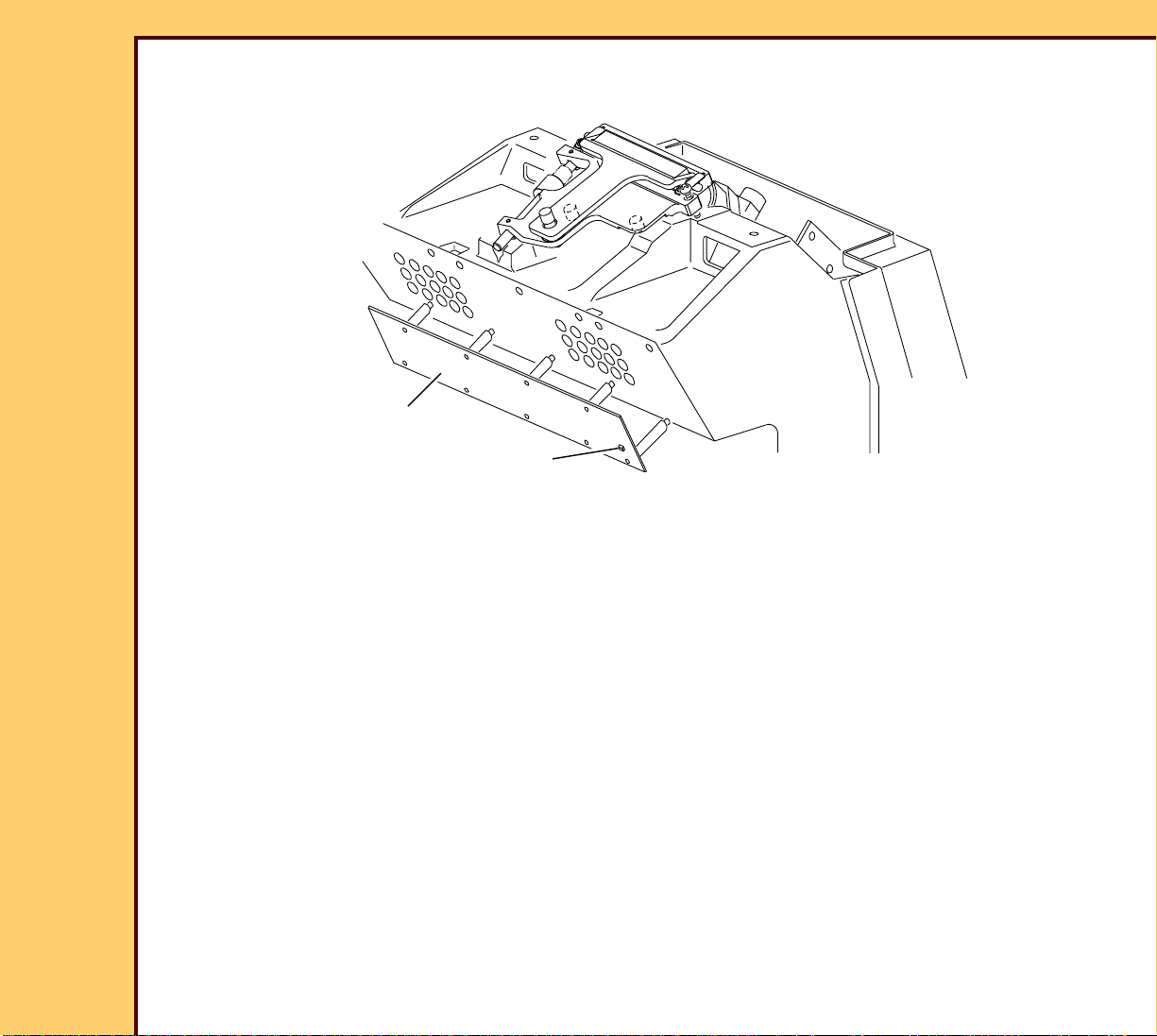

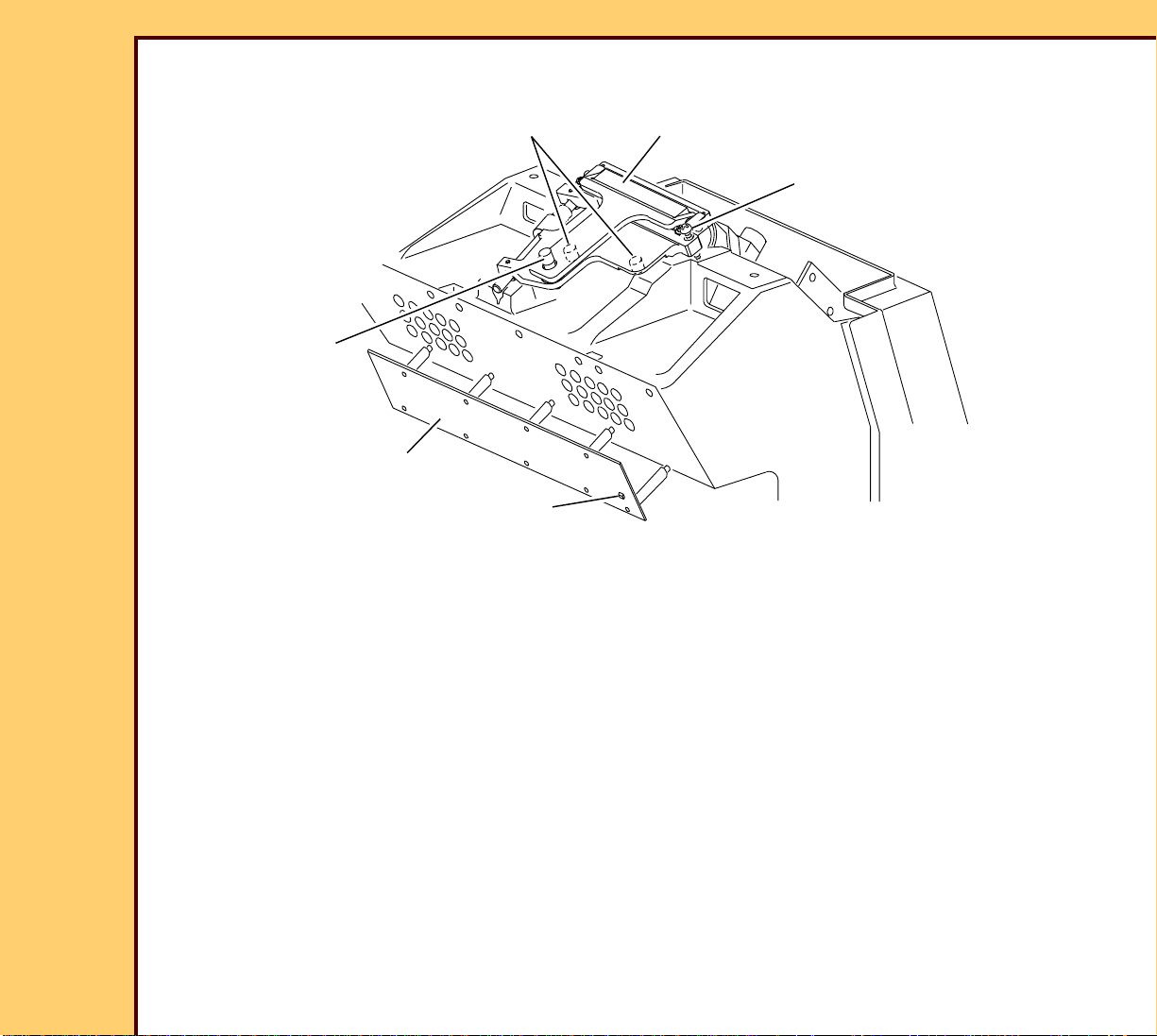

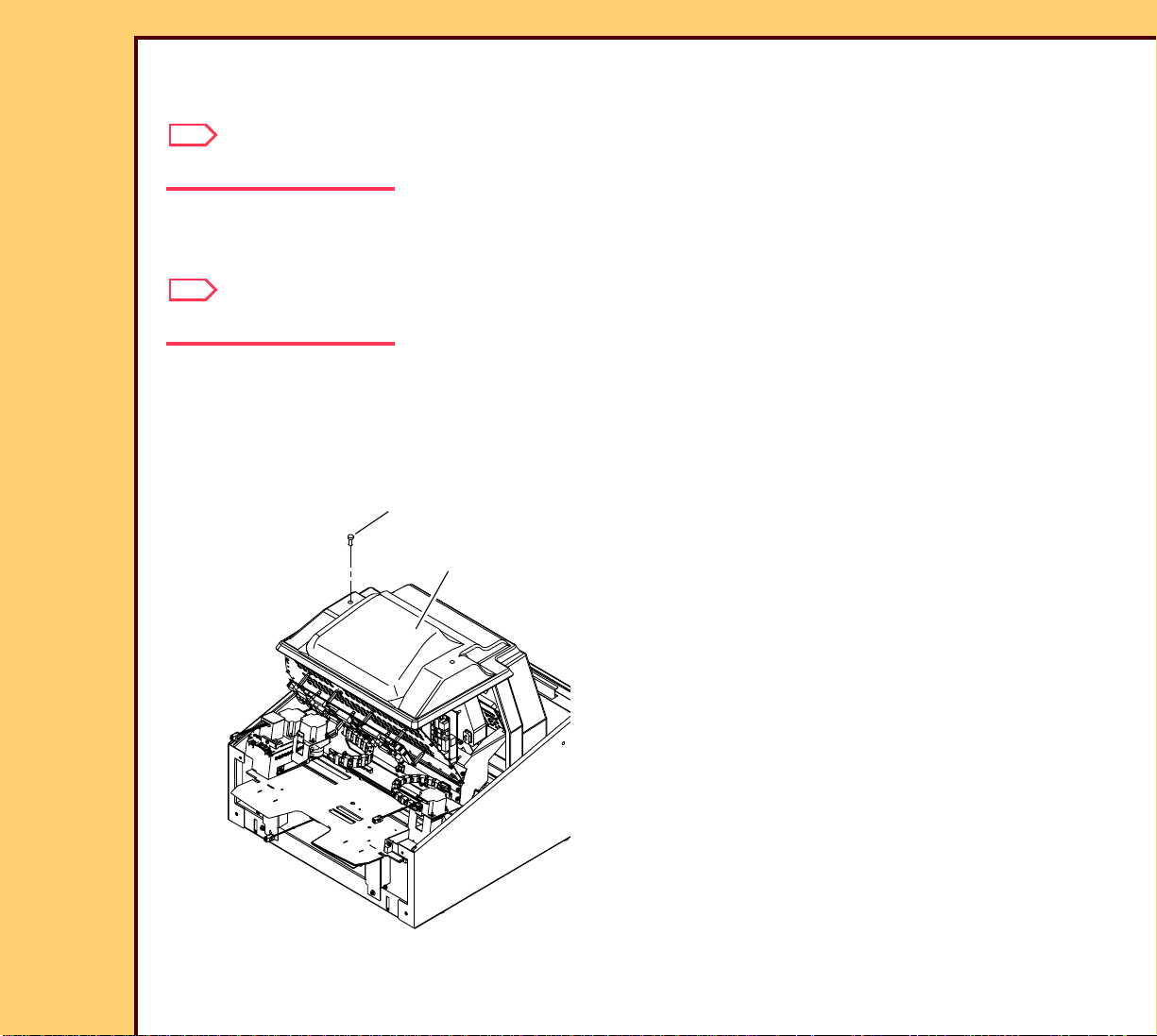

1 Remove:

• FRONT COVER

• TOP COVER

• 2 SCREWS

• LASER SAFETY COVER

Page 6

06DEC05

AR4366-1

Page

6 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

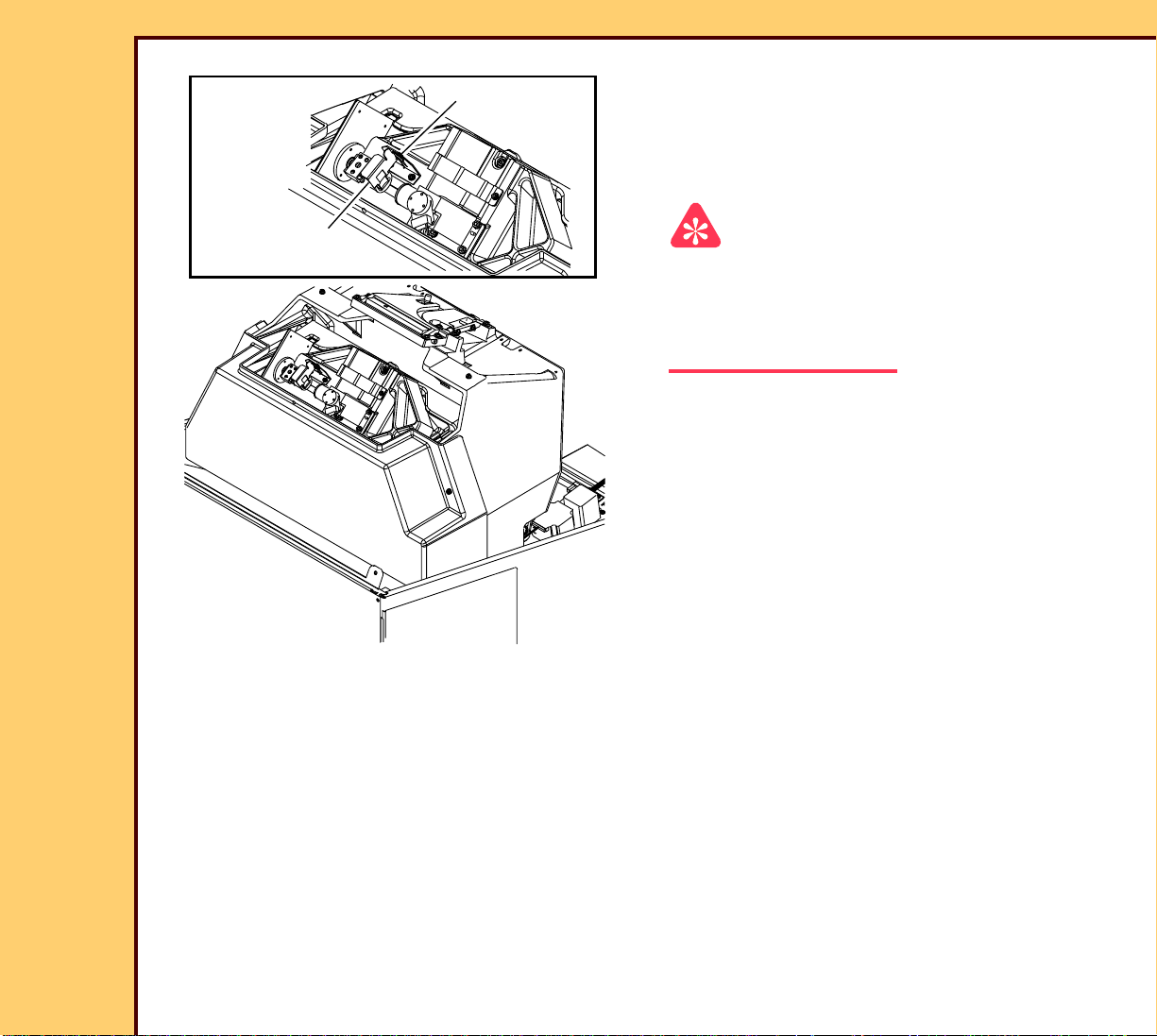

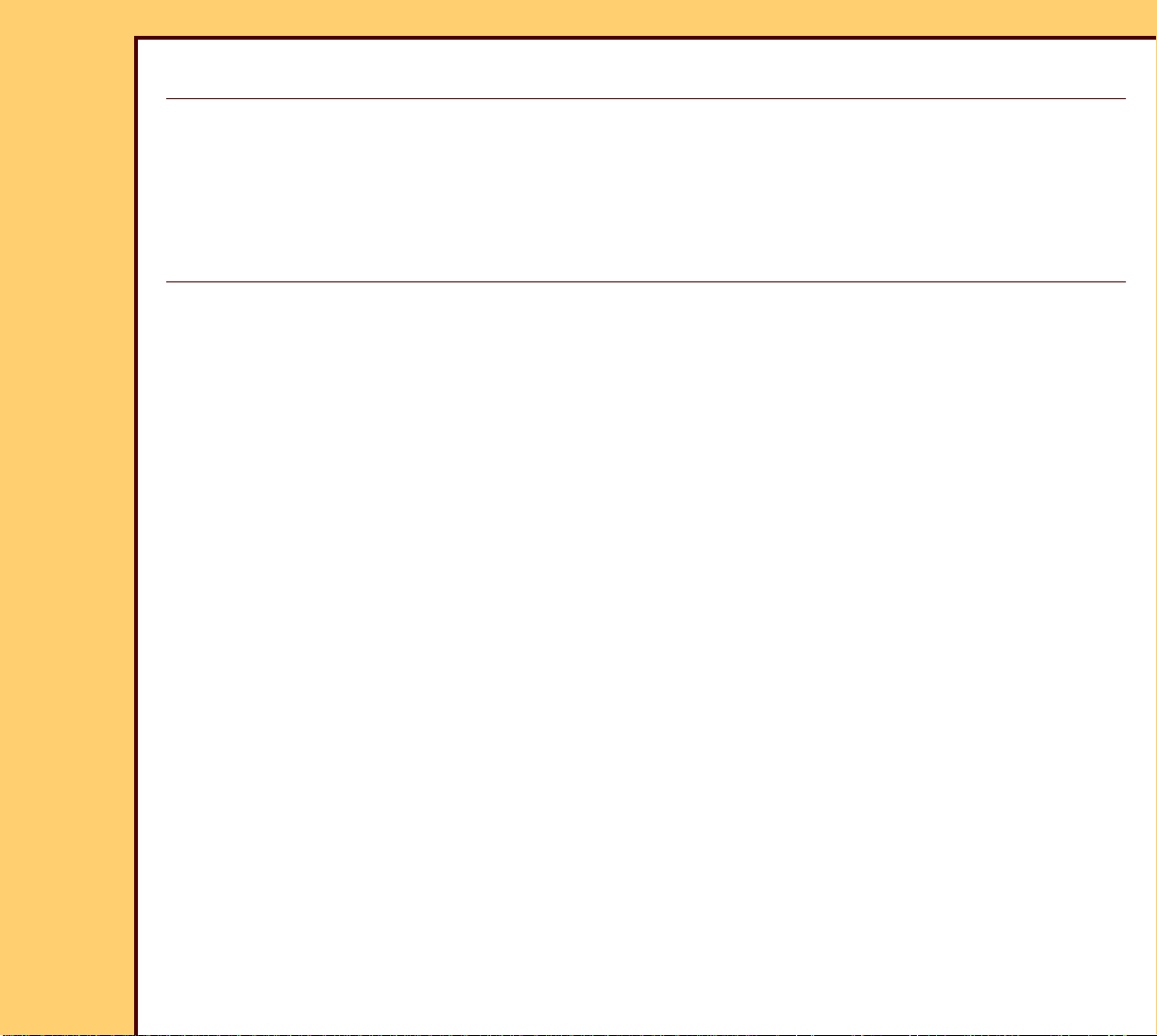

2 Loosen the THUMBSCREW.

THUMBSCREW

3 Move the LASER SAFETY FILTER into

the laser beam.

4 Tighten the THUMBSCREW.

LASER SAFETY

FILTER

H195_1023GCA

H195_1023GC

Important

For systems with software version ≥ 4.1, you

must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

5 At the main menu, click:

• [Service Functions]

• [Diagnostics]

• [Galvo Test]

Page 7

06DEC05

AR4366-1

Page

7 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

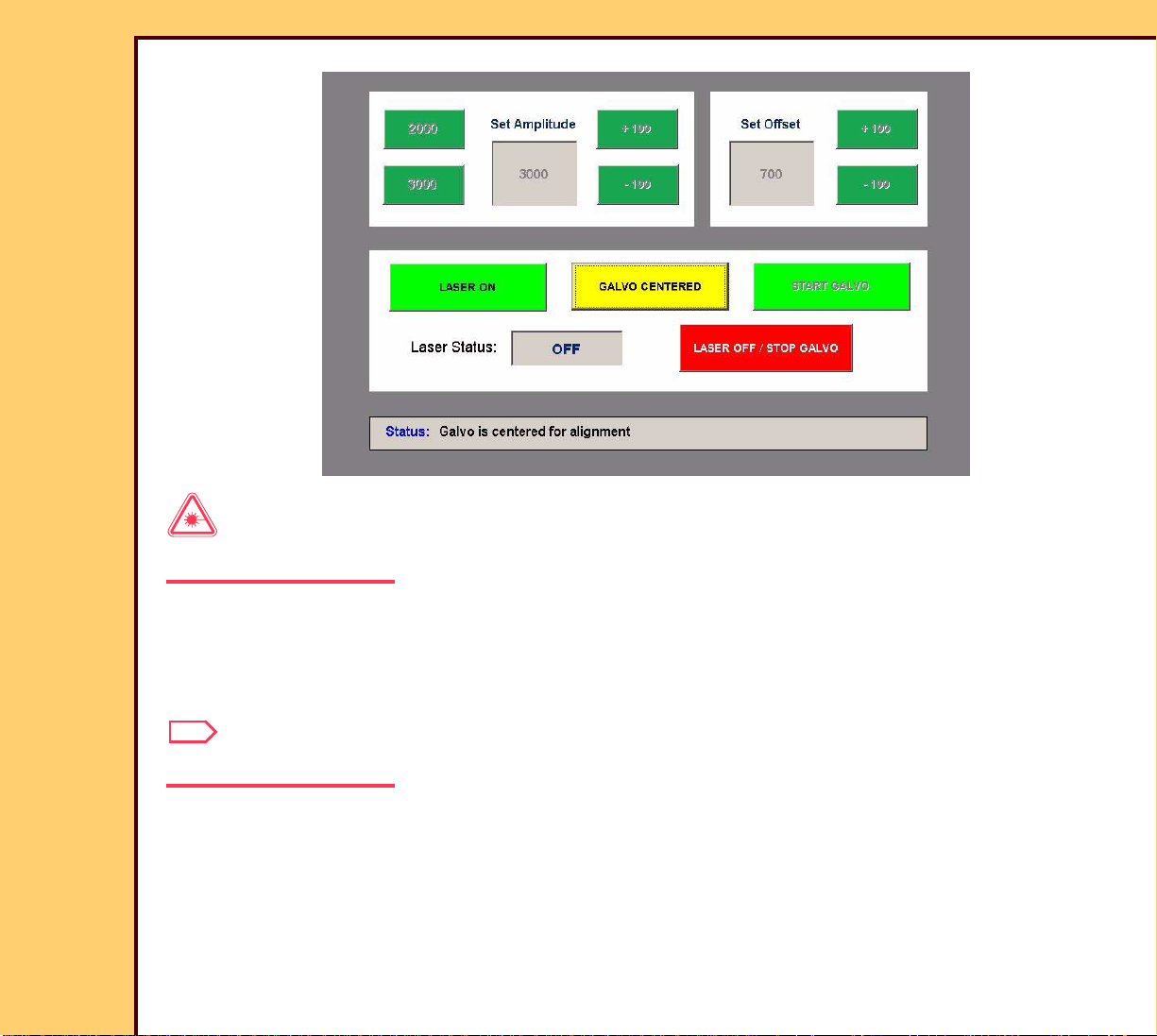

Laser Warning

This equipment uses a visible red laser. Prevent direct exposure to the laser beam.

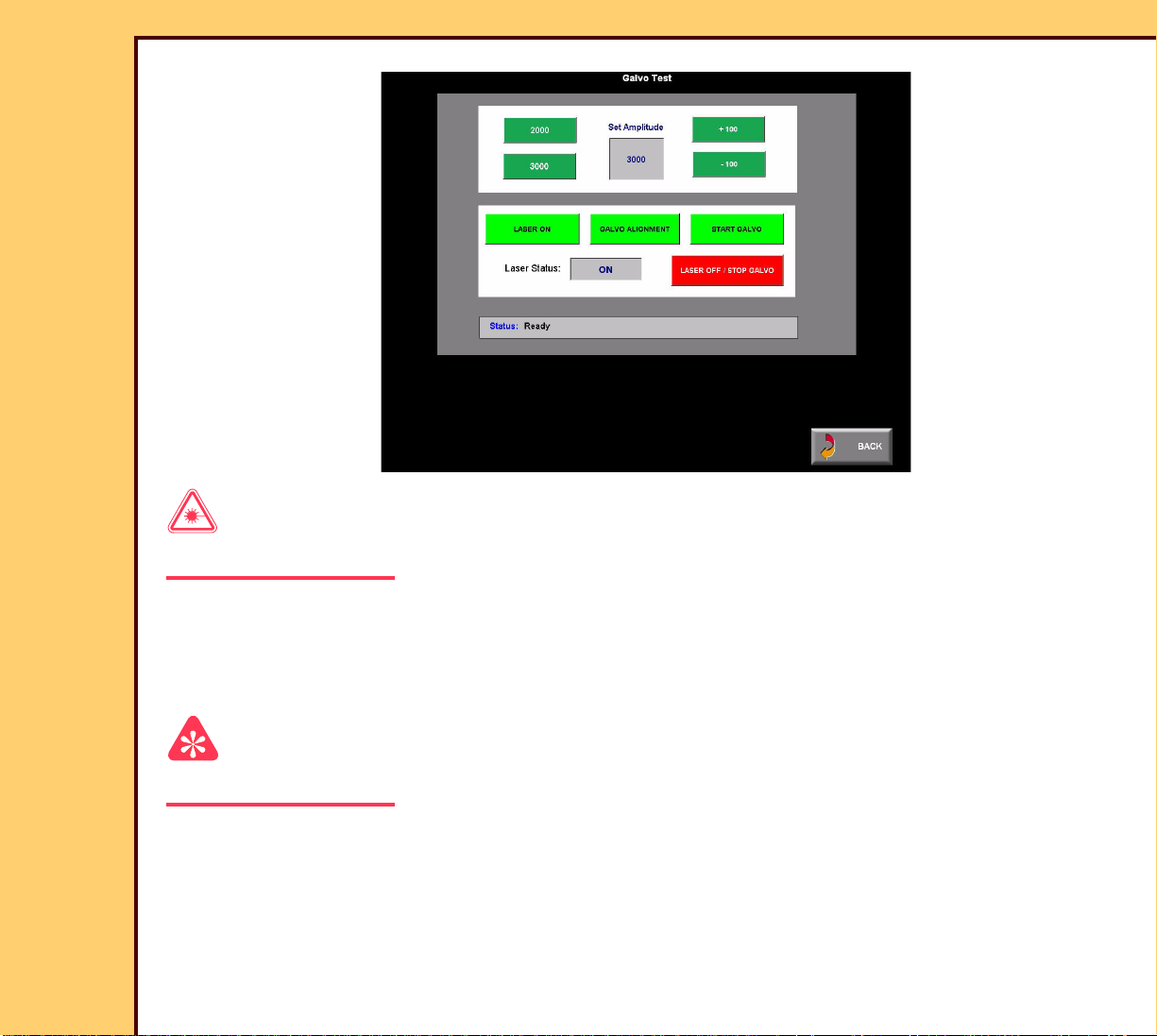

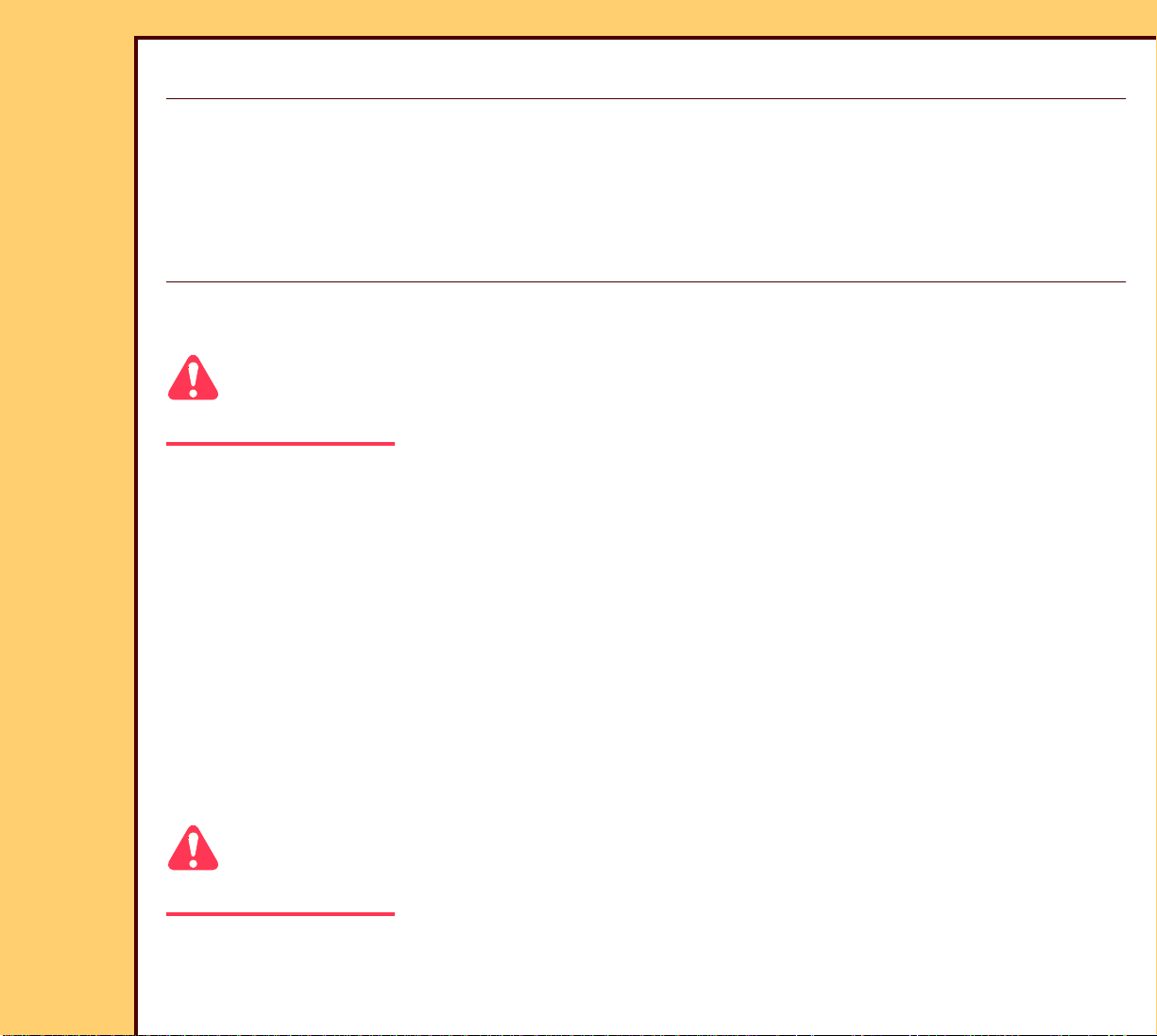

6 At the “Galvo Test” screen, click:

• [GALVO ALIGNMENT]

• [LASER ON]

Note

The [Galvo Alignment] BUTTON changes to [Galvo Centered].

Page 8

06DEC05

AR4366-1

Page

8 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

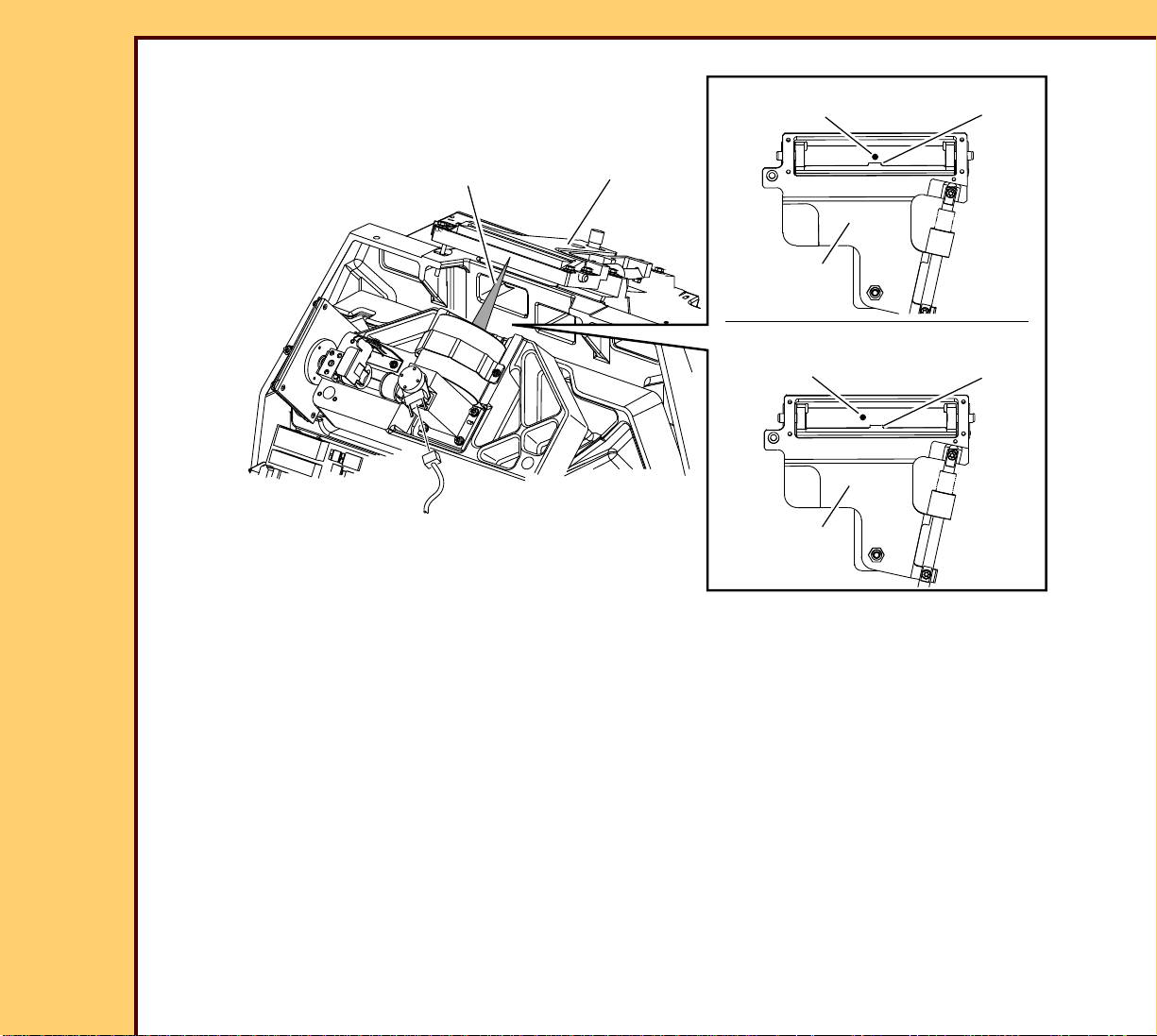

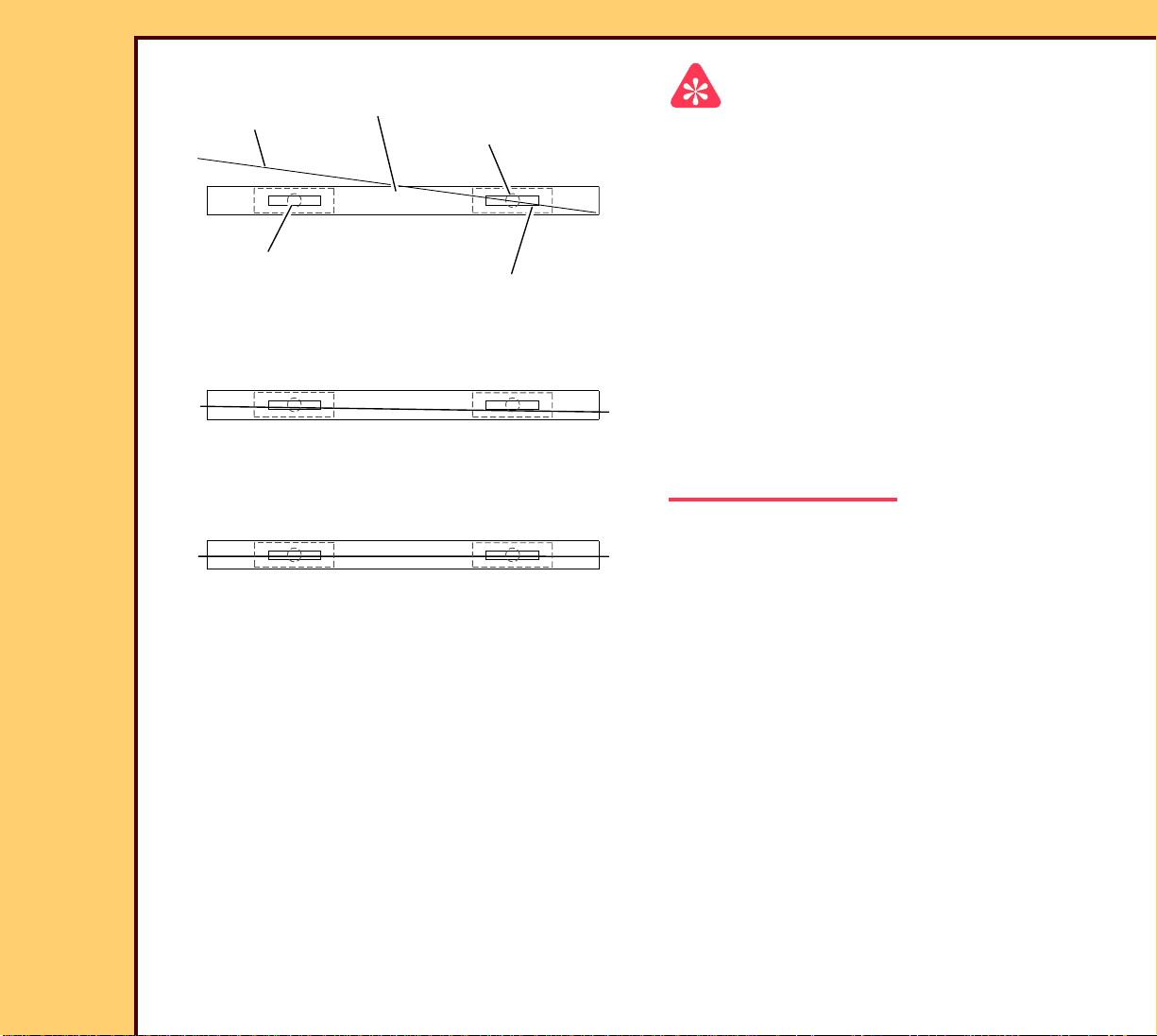

correct

laser beam

TAB

laser beam

FOLD MIRROR

FOLD MIRROR

not correct

laser beam

FOLD MIRROR

H195_1163HCB

H195_1163HC

7 Check that the laser beam is aligned with the TAB on the FOLD MIRROR.

TAB

Page 9

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

9 of 219

To Ad j u st :

GALVO

SCREW

GALVO CONNECTOR

H195_1163HCA

H195_1163HC

laser beam

GALVO

MOUNTING BRACKET

FOLD MIRROR

laser beam

FOLD MIRROR

laser beam

FOLD MIRROR

correct

TAB

not correct

TAB

Caution

electrical connections are exposed. Do not touch the GALVO CONNECTOR on the GALVO.

1 Loosen the SCREW on the GALVO MOUNTING BRACKET.

2 Rotate the GALVO until the laser beam is aligned with the center TAB on the FOLD

MIRROR.

3 Tighten the SCREW.

4 Click:

• “Stop Galvo”

• “LASER OFF”

Postrequisites:

1 Adjust the FOLD MIRROR.

Page 10

06DEC05

AR4366-1

Page

10 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

FOLD MIRROR

Adjustment Specification

Purpose: To align the laser beam with the PHOTODIODES on the PLATEN.

Specification: The LED DS3 on the MECHANISM SYSTEM CONTROLLER (MSC)

BOARD illuminates amber.

Special Tools: LASER SAFETY GOGGLES TL-5693

Prerequisites:

1 Do the adjustment for the GALVO AY - Center.

Page 11

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

11 of 219

To Check:

2 SCREWS

LASER SAFETY

COVER

Laser Warning

This equipment uses a visible red laser.

Prevent direct exposure to the laser beam.

1 Remove:

• If necessary, FRONT COVER

• If necessary, TOP COVER

• 2 SCREWS

• LASER SAFETY COVER

H195_1020GCA

H195_1020GC

Page 12

06DEC05

AR4366-1

Page

12 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

2 Loosen the THUMBSCREW.

THUMBSCREW

3 Move the LASER SAFETY FILTER into

the laser beam.

4 Tighten the THUMBSCREW.

LASER SAFETY

FILTER

H195_1023GCA

H195_1023GC

Important

For systems with software version ≥ 4.1, you must have a “Session ID” for access to “Service

Functions” and “Diagnostics”. See SERVICE BULLETIN 843.

5 At the main menu, click:

• “Service Functions”

• “Diagnostics”

• “Galvo Test”

Page 13

06DEC05

AR4366-1

Page

13 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

Laser Warning

This equipment uses a visible red laser. Prevent direct exposure to the laser beam.

6 Click:

• [LASER ON]

• [START GALVO]

Important

The Error Code 16028 might occur. Do not acknowledge this Error Code.

7 Increase the “Set Amplitude” to “3900”.

Page 14

06DEC05

AR4366-1

Page

14 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

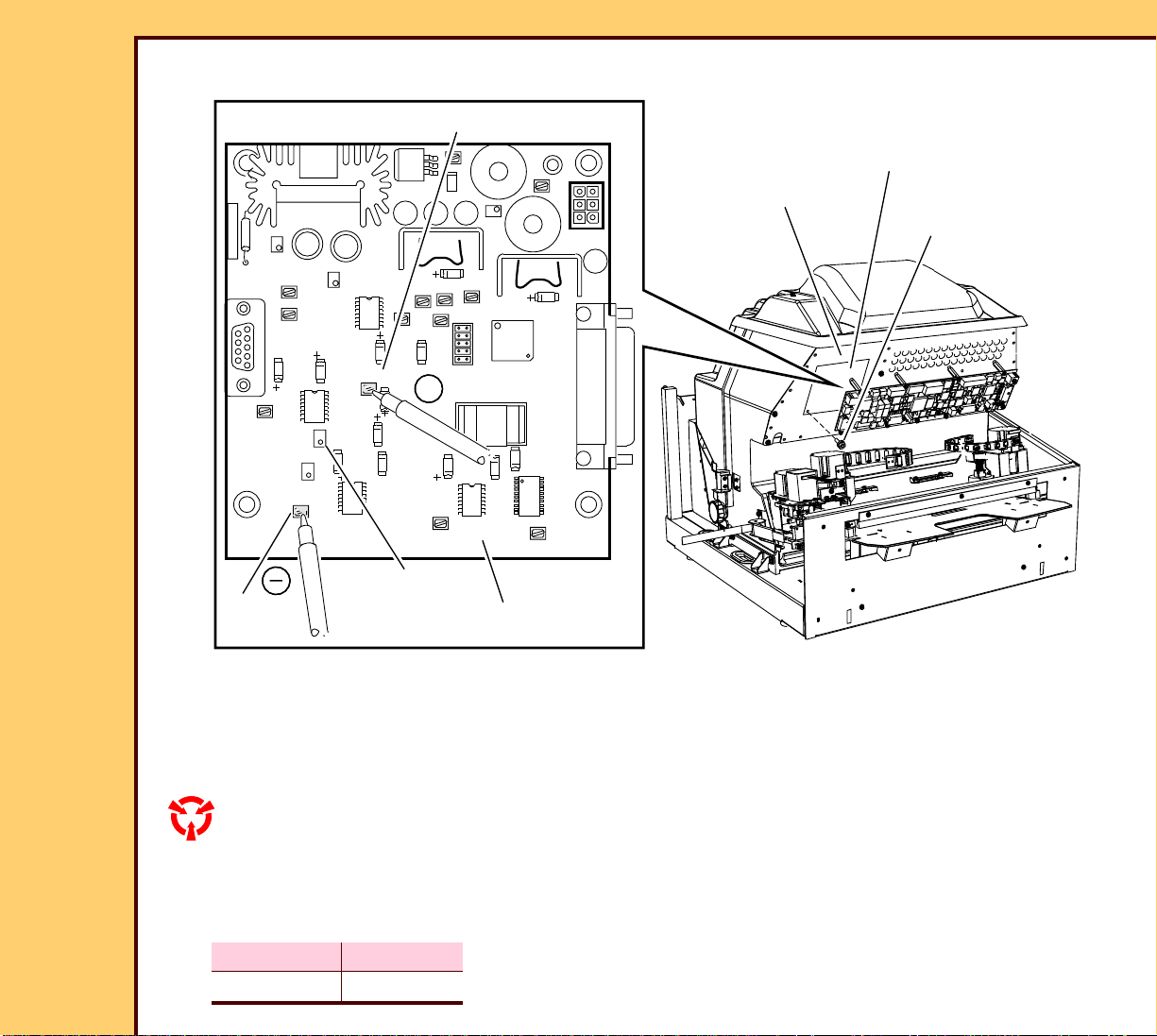

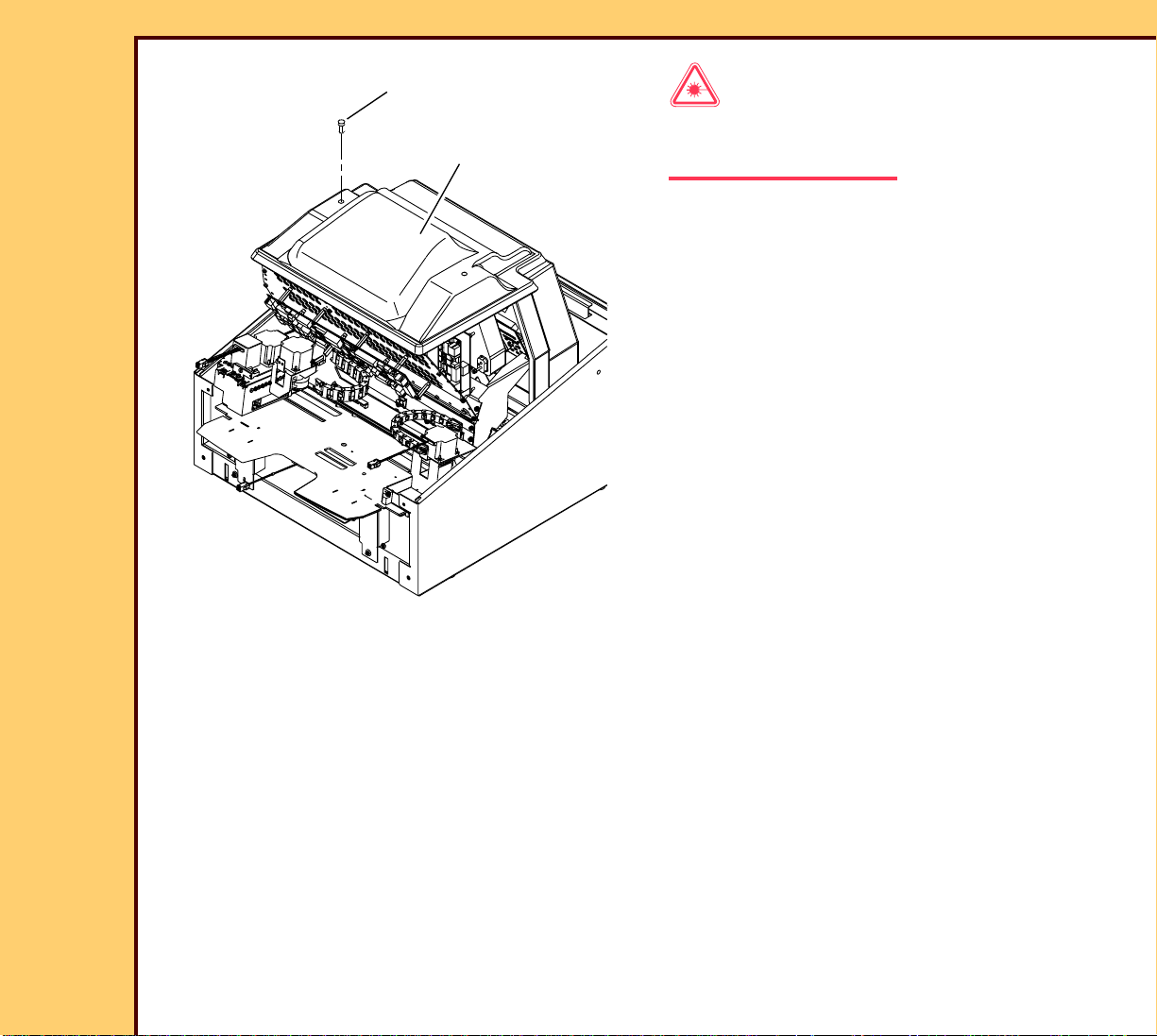

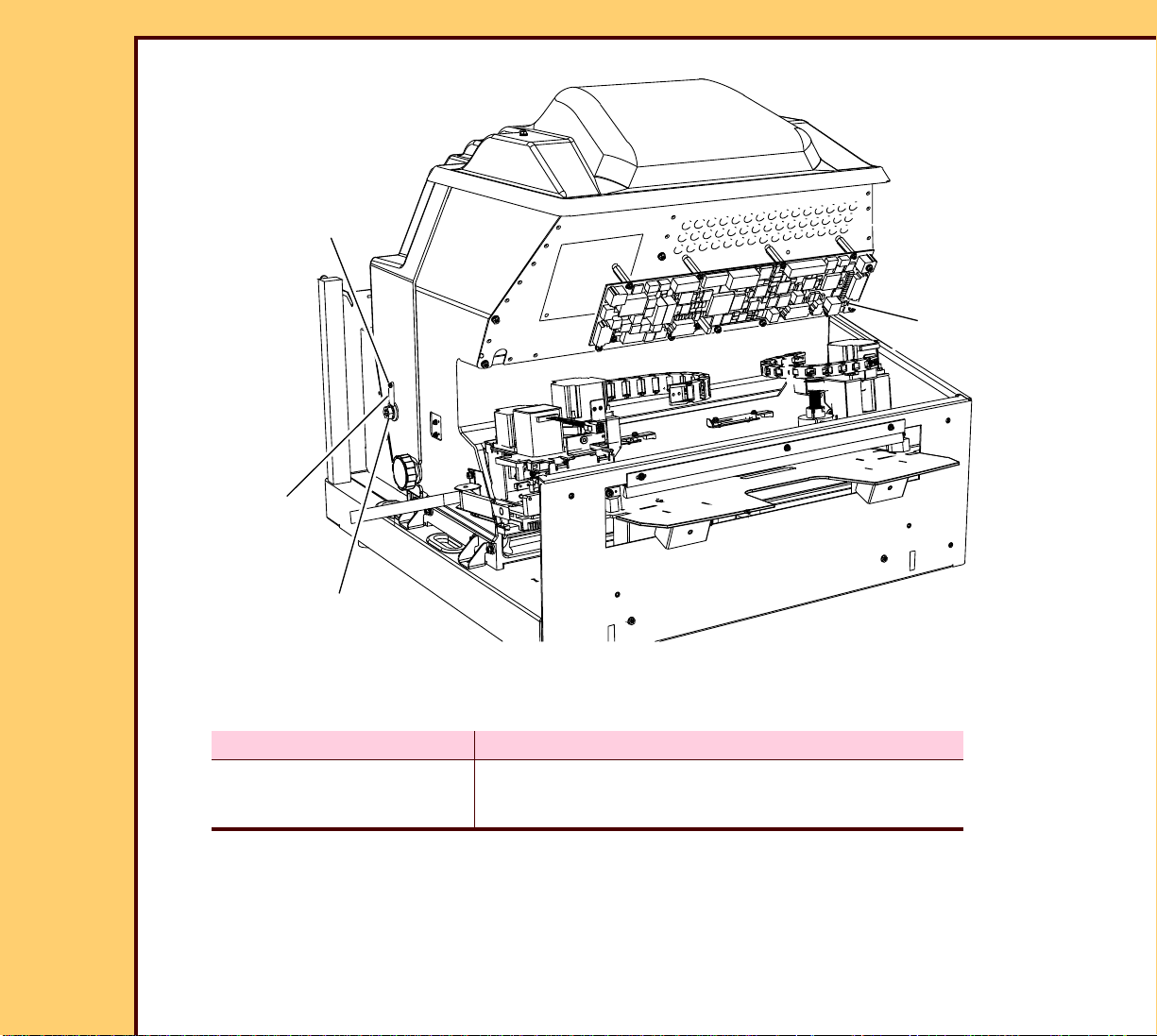

MSC BOARD

H195_1061BCB

LED DS3

H195_1061BC

8 Check that the LED DS3 on the MSC BOARD illuminates amber.

Page 15

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

15 of 219

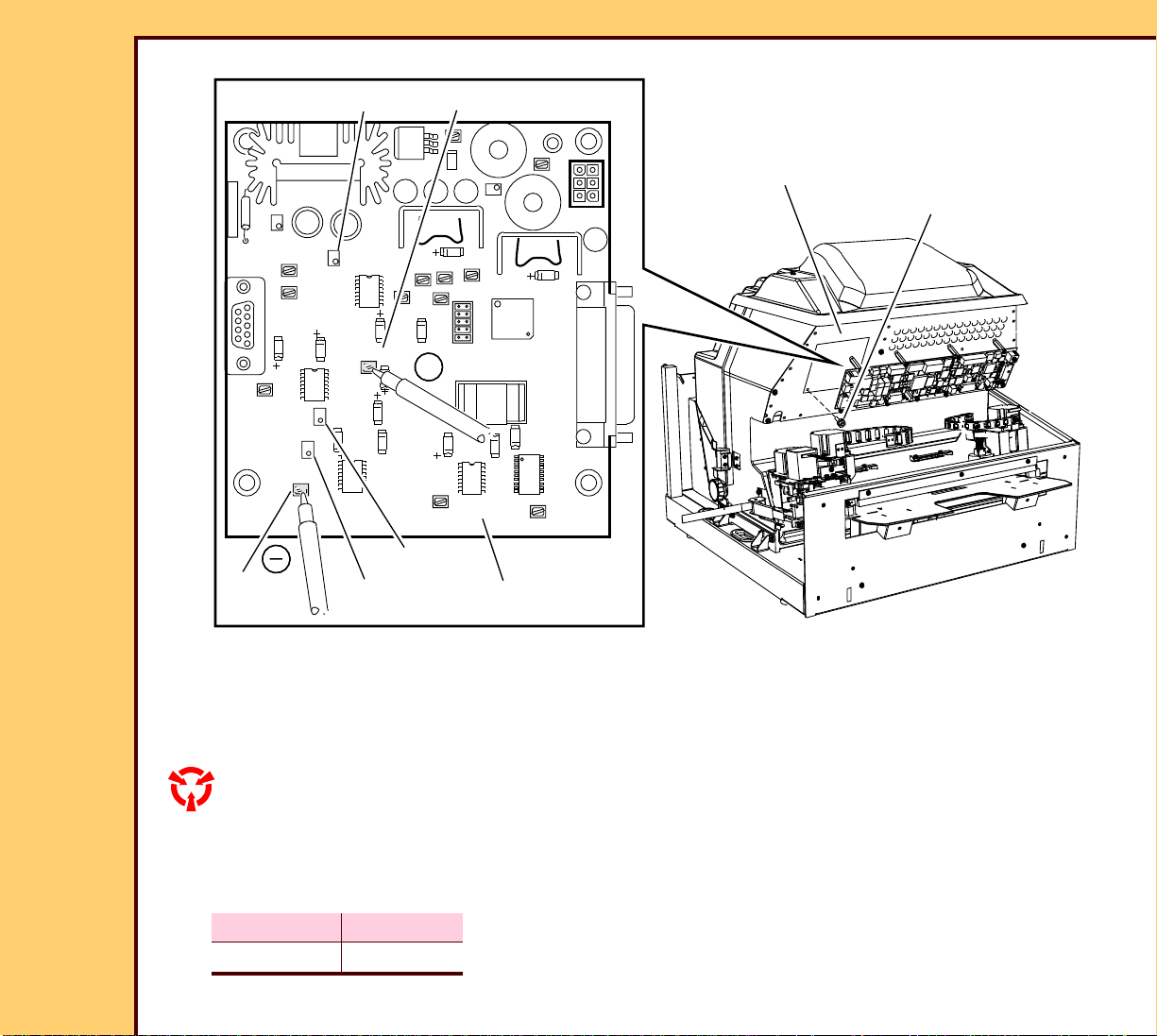

To Ad j u st :

GALVO BD

TP11

TP4

TP10

TP1 (-)

TP1

TP13 (+)

GALVO BOARD ACCESS PANEL

EMI BRACKET PANEL

6 SCREWS

+

TP15

TP12

U9

TP5

U4

TP16

U6

TP9

TP14

TP13

U8

U7

TP17

R2

GALVO BOARD

H195_1026HCC

H195_1026HC

1 Loosen the 6 SCREWS.

2 Remove the GALVO BOARD ACCESS PANEL.

3 Set the VOLTMETER to “DC”.

ESD

Possible damage from electrostatic discharge.

4 Connect the VOLTMETER on the GALVO BOARD to:

+ -

TP 13 TP 1

Page 16

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

16 of 219

5 Click:

• [START GALVO PLOT]

• [35 x 43 F]

6 On the GALVO BOARD, rotate the POTENTIOMETER R2 until the VOLTMETER displays

9.0 ± 0.10 V DC.

7 Remove the VOLTMETER.

8 Install the GALVO BOARD ACCESS PANEL.

9 Tighten the 6 SCREWS.

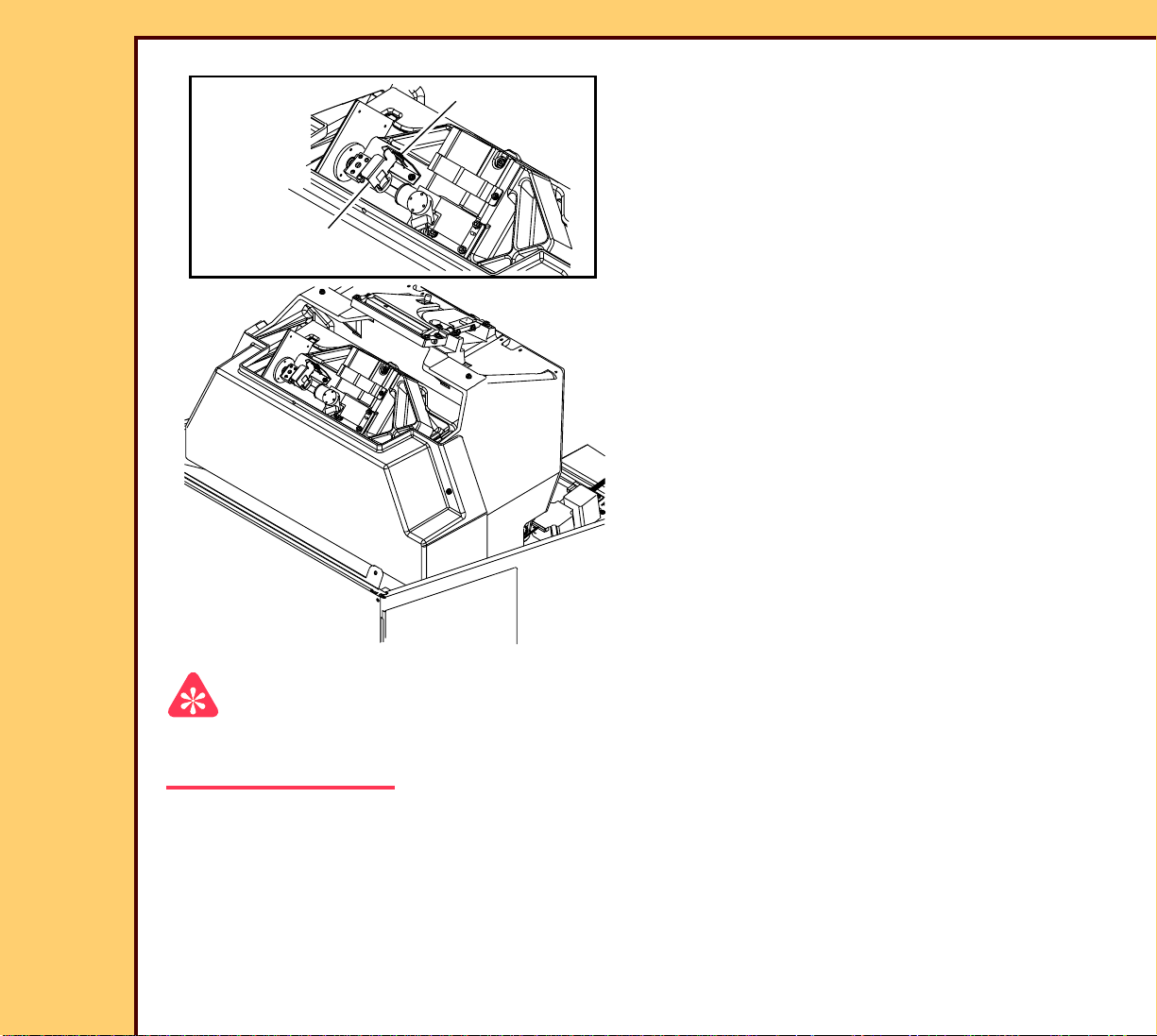

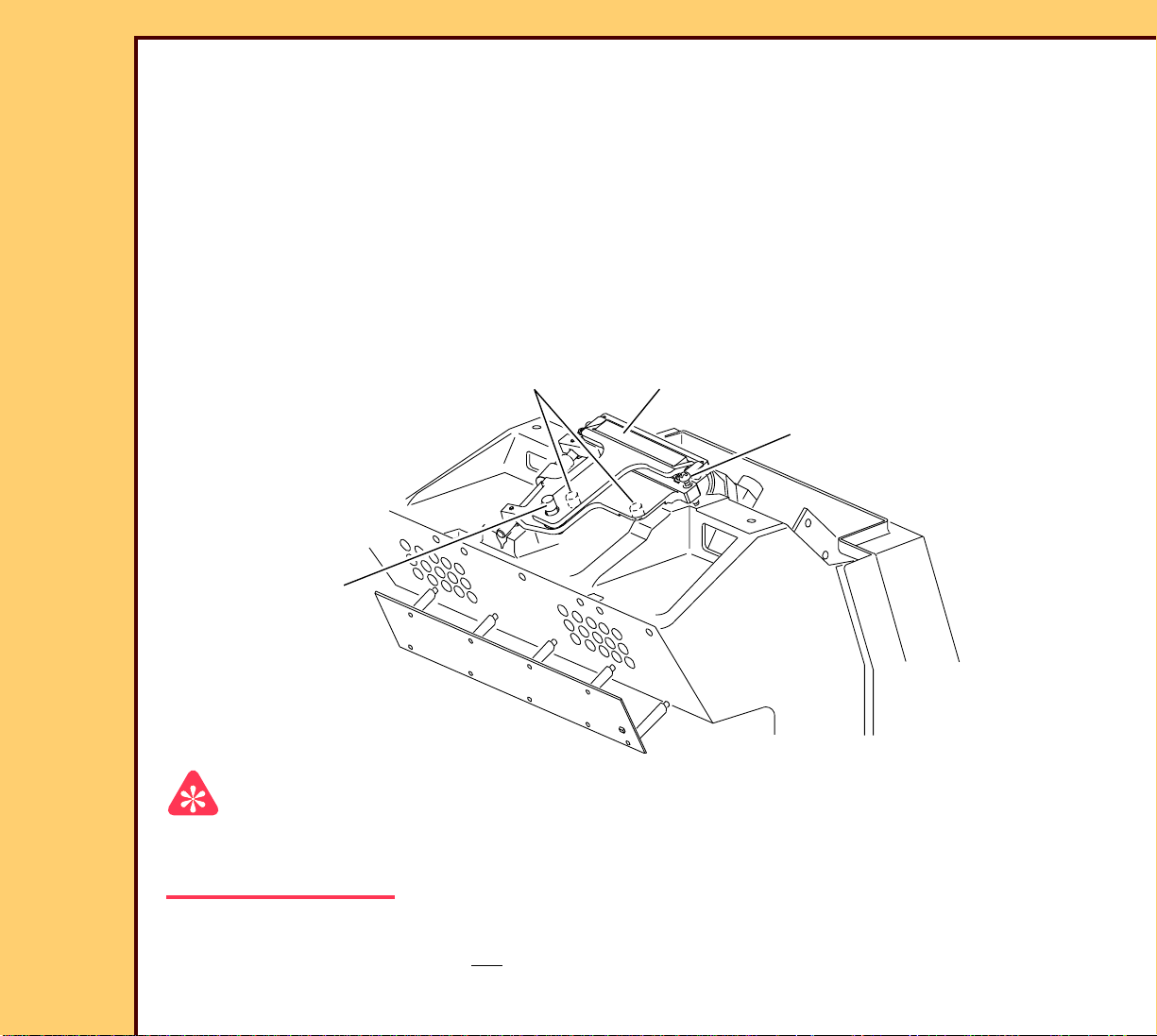

2 SPRINGS

THUMBSCREW

FOLD MIRROR

ADJUSTING

SCREW

H195_1061BCE

H195_1061BC

Important

• The THUMBSCREW adjusts the parallel position of the laser beam.

• The ADJUSTING SCREW adjusts the tilt of the beam

10 On the FOLD MIRROR, rotate both the THUMBSCREW and the ADJUSTING SCREW

until the 2 SPRINGS are not compressed.

Page 17

06DEC05

AR4366-1

Page

17 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

2 SPRINGS

FOLD MIRROR

ADJUSTING

SCREW

THUMBSCREW

MSC BOARD

H195_1061BCA

LED DS3

H195_1061BC

Page 18

06DEC05

AR4366-1

Page

18 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

beam

PLATEN

S11

Important

• The graphic is an example of the laser

beam from the FOLD MIRROR inside

the system.

a

• The beam is not visible for this

procedure.

• When the beam covers:

– S10 SENSOR, the LED DS3

illuminates red

– S11 SENSOR, the LED DS3

illuminates green

– S10 and S11 SENSORS, the LED

DS3 illuminates amber

11 Do:

a. Tighten the THUMBSCREW until the

LED DS3 on the MSC BOARD

illuminates green.

b. Using the THUMBSCREW to keep

the LED DS3 illuminated green,

rotate the ADJUSTING SCREW until

the LED DS3 illuminates amber.

b

c

H195_1161GCA

H195_1161GC

S10

2 SLOTS

c. With the LED DS3 illuminated

amber, rotate both the

THUMBSCREW and the

ADJUSTING SCREW to place the

beam in the center position of the

SLOT in the PLATEN.

Page 19

06DEC05

AR4366-1

Page

19 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

2 SCREWS

Laser Warning

LASER SAFETY

COVER

This equipment uses a visible red laser.

Prevent direct exposure to the laser beam.

12 Click:

• [STOP GALVO]

• [LASER OFF]

13 Remove:

• 2 SCREWS

• LASER SAFETY COVER

H195_1020GCA

H195_1020GC

Page 20

06DEC05

AR4366-1

Page

20 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

14 Loosen the THUMBSCREW.

THUMBSCREW

15 Move the LASER SAFETY FILTER from

the laser beam.

16 Tighten the THUMBSCREW.

LASER SAFETY

FILTER

H195_1023GCA

H195_1023GC

Page 21

06DEC05

AR4366-1

Page

21 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

2 SCREWS

17 Install:

• LASER SAFETY COVER

LASER SAFETY

COVER

• 2 SCREWS

H195_1020GCA

H195_1020GC

Postrequisites:

1 Do the adjustment for the COLLECTOR AY - Tilt.

Page 22

06DEC05

AR4366-1

Page

22 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

COLLECTOR AY - Tilt

Adjustment Specification

Purpose: To set the position of the COLLECTOR AY.

Specification: The LEDs Illuminate amber when the COLLECTOR AY is moved to the

center position using the “Scan Line Bow Magnitude”.

Special Tools: None

Prerequisites:

Caution

You must have the LASER SAFETY FILTER moved into the laser beam.

1 Adjust:

• GALVO AY - Center

• FOLD MIRROR

To Check:

You cannot check this adjustment.

To Ad j u st :

1 Remove:

• FRONT COVER

• TOP COVER

Caution

Dangerous Voltage

2 Energize the system.

Page 23

06DEC05

AR4366-1

Page

23 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

Important

For systems with software version ≥ 4.1, you must have a “Session ID” for access to “Service

Functions” and “Diagnostics”. See SERVICE BULLETIN 843.

3 At the main menu, click:

• [Service Functions]

• [Diagnostics]

• [Galvo Test]

• [START GALVO]

• [LASER ON]

Important

The Error Code 16028 might occur, disregard the Error Code.

4 Set the “Galvo Amplitude” to 3900

Page 24

06DEC05

AR4366-1

Page

24 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

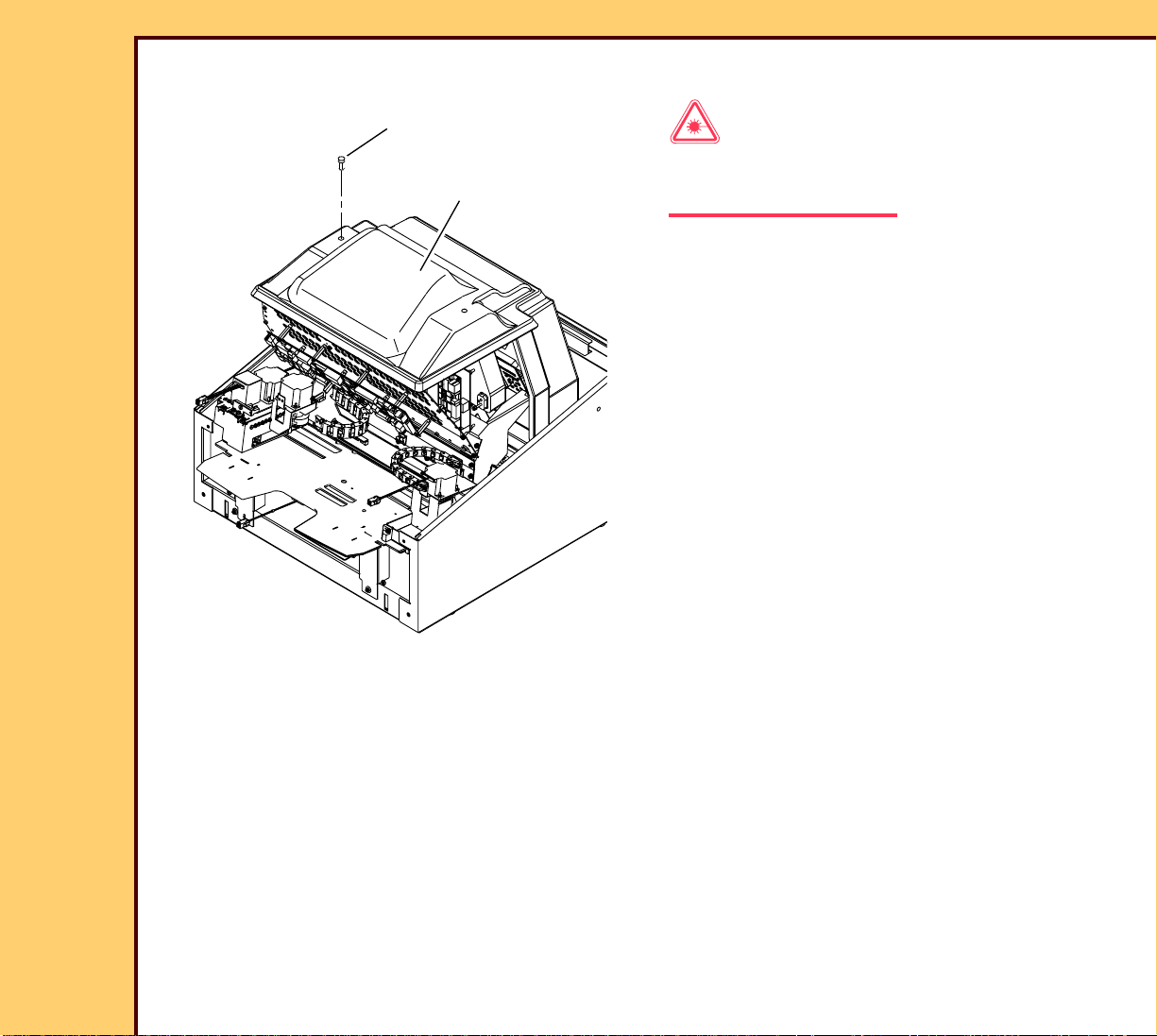

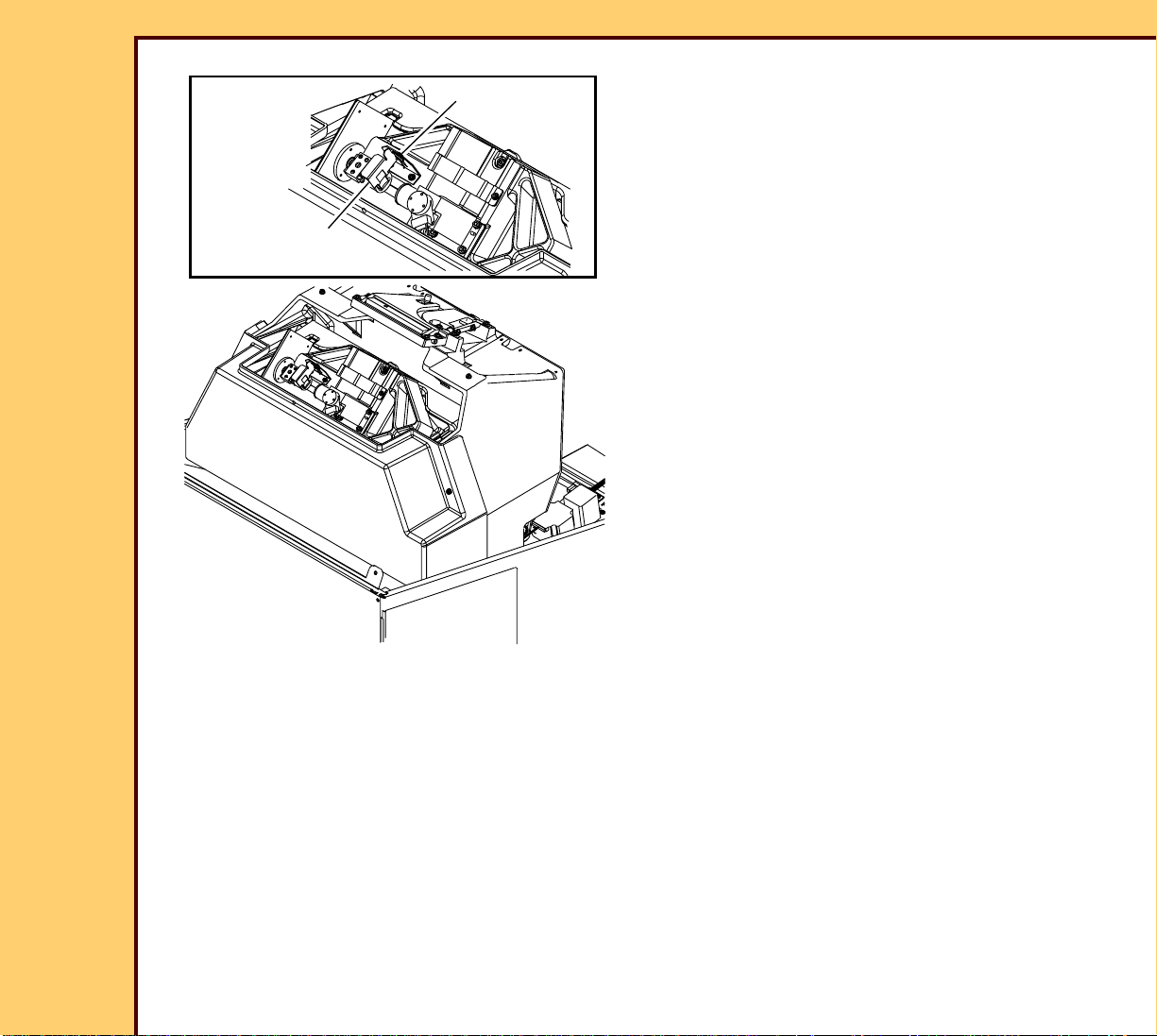

COLLECTOR TILT

ADJUSTING NUT

LEDs

LOCKING

TAB

COLLECTOR

TILT SCREW

H195_1104HCA

H195_1104HC

5 Check that the LEDs illuminate amber.

6 Did the LEDs illuminate amber?

Yes No

Continue with Step 7. a. Do the adjustment for the FOLD MIRROR.

b. Do Steps 2 - 6 again.

7 Loosen the LOCKING TAB on the COLLECTOR TILT ADJUSTING NUT.

8 Rotate the COLLECTOR TILT SCREW clockwise 30 - 40 rotations until the LEDs

illuminate red, green or no color.

Page 25

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

25 of 219

9 Rotate the COLLECTOR TILT SCREW counterclockwise until the LEDs illuminate amber

again.

Note

The COLLECTOR AY is at the end position.

10 Rotate the COLLECTOR TILT SCREW counterclockwise and record the number of

rotations until the LEDs change from amber to red, green or no color.

Note

The number of rotations is approximately 70 - 100.

11 To obtain the center position of the COLLECTOR AY, do the following formula:

number of rotations from Step 10 ÷ 2

example: 74 rotations ÷ 2 = 37

2 SCREWS

LASER SAFETY

COVER

12 Remove:

• 2 SCREWS

• LASER SAFETY COVER

H195_1020GCA

H195_1020GC

Page 26

06DEC05

H195_1105BC

Power High

Voltage High

Datecode

Scan Line Bow

Voltage Low

Power Low

Magnitude (+/-)

mW

V

mW

V

microns

H195_1105BCA

FASTSCAN

SCAN LINE BOW STICKER

AR4366-1

Page

26 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

2 SCREWS

LASER SAFETY

COVER

H195_1020GCA

H195_1020GC

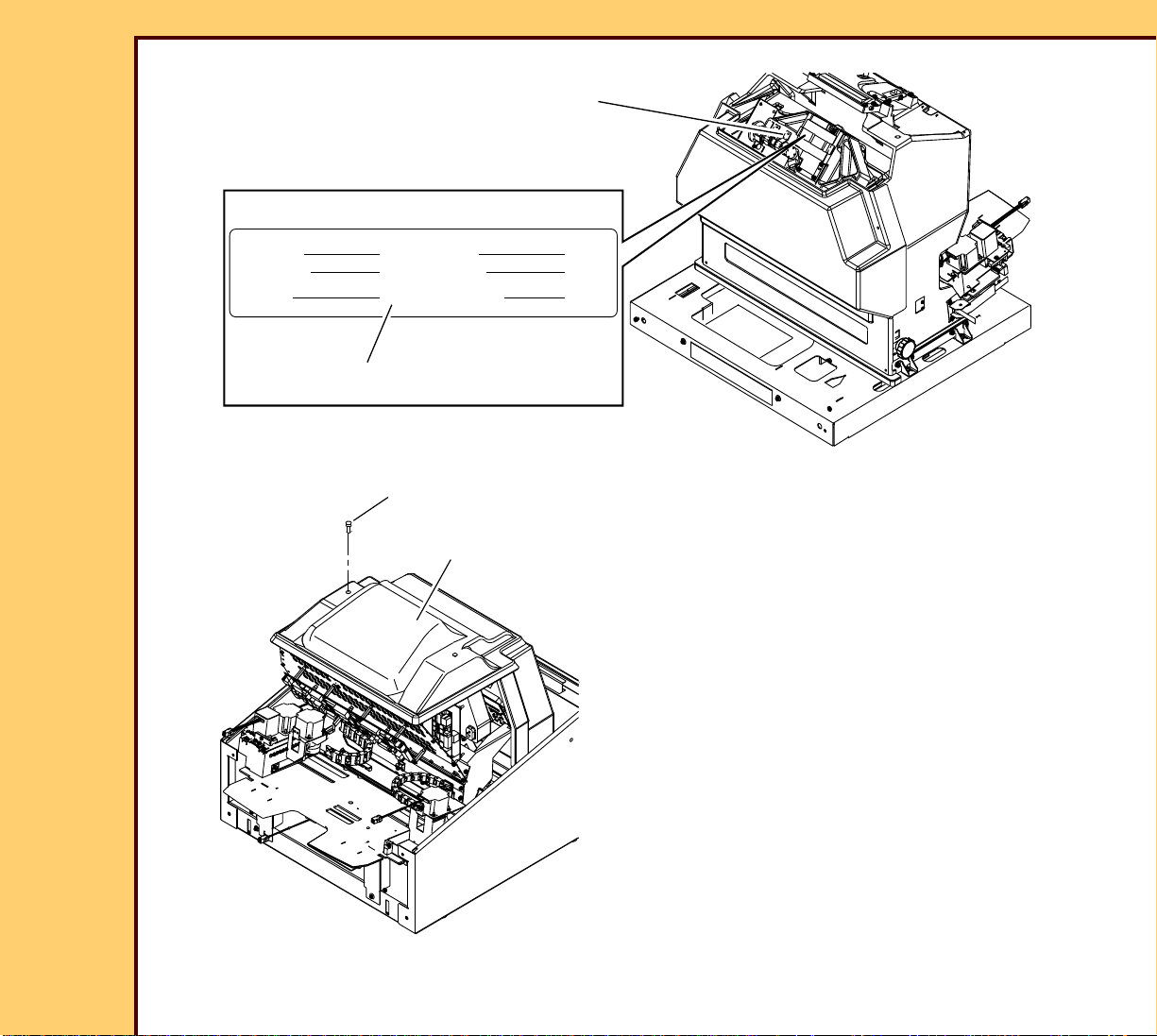

13 See the SCAN LINE BOW STICKER on

the FASTSCAN and record the “Scan

Line Bow Magnitude” from the

STICKER.

14 Install:

• LASER SAFETY COVER

• 2 SCREWS

Page 27

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

27 of 219

15 Do the following formula:

“Scan Line Bow Magnitude” ÷ 40 = number of rotations for “Scan Line Bow”

Important

If the number of rotations for “Scan Line Bow” is:

• positive - you must add the number of rotations to the center position determined in

Step 11

• negative - you must subtract the number of rotations from the center position determined

in Step 11

16 Determine the new number of rotations for the COLLECTOR TILT SCREW, see the

examples:

Example 1:

• number of rotations = 74 ÷ 2 = 37

• number of rotations for “Scan Line Bow Magnitude” = -120 ÷ 40 = -3

• new number of rotations = 37 - 3 = 34 rotations

Example 2:

If you rotated the COLLECTOR TILT SCREW 74 rotations and the“Scan Line Bow

Magnitude” is -120 um, rotate the COLLECTOR TILT SCREW clockwise until the

LEDs illuminate amber then continue clockwise for 34 rotations to center the

“scanline” in the COLLECTOR.

17 Rotate the COLLECTOR TILT SCREW clockwise the new number of rotations obtained

in Step 16.

18 Tighten the LOCKING TAB.

19 Click:

• [STOP GALVO]

• [LASER OFF]

Page 28

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

28 of 219

Postrequisites:

Do Setting the Calibration.

GALVO BOARD

Adjustment Specification

Purpose: To obtain the correct “Amplitude” of the “Collector Profile Screen”.

Specification: • The “Amplitude” of the “Collector Profile Screen” for the 35 x 43 F size

SCREEN is 3000

• The leading edge “Peak” on the GALVO PLOT CURVE is correct. See

the graphic on page 31.

Special Tools: VOLTMETER TL-3424

Prerequisites:

1 Do the adjustment procedure for the:

• GALVO AY - Center

± 100.

• FOLD MIRROR

• COLLECTOR AY - Tilt

To Check:

1 You cannot check this adjustment.

To Ad j u st :

Laser Warning

This equipment uses a visible red laser. Prevent direct exposure to the laser beam.

Page 29

06DEC05

AR4366-1

Page

29 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

R1

TP13 (+)

EMI BRACKET PANEL

6 SCREWS

GALVO BD

TP10

TP11

TP4

TP1

U6

TP9

TP14

TP13

U8

U7

TP17

+

TP15

TP12

U9

TP5

U4

TP16

R2

TP1 (-)

R112

GALVO BOARD

H195_1026HCB

H195_1026HC

1 Loosen the 6 SCREWS.

2 Remove the GALVO BOARD ACCESS PANEL.

3 Set the VOLTMETER to “DC”.

ESD

Possible damage from electrostatic discharge.

4 Connect the VOLTMETER on the GALVO BOARD to:

+ -

TP 13 TP 1

Page 30

06DEC05

AR4366-1

Page

30 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

Important

For systems with software version ≥ 4.1, you must have a “Session ID” for access to “Service

Functions” and “Diagnostics”. See SERVICE BULLETIN 843.

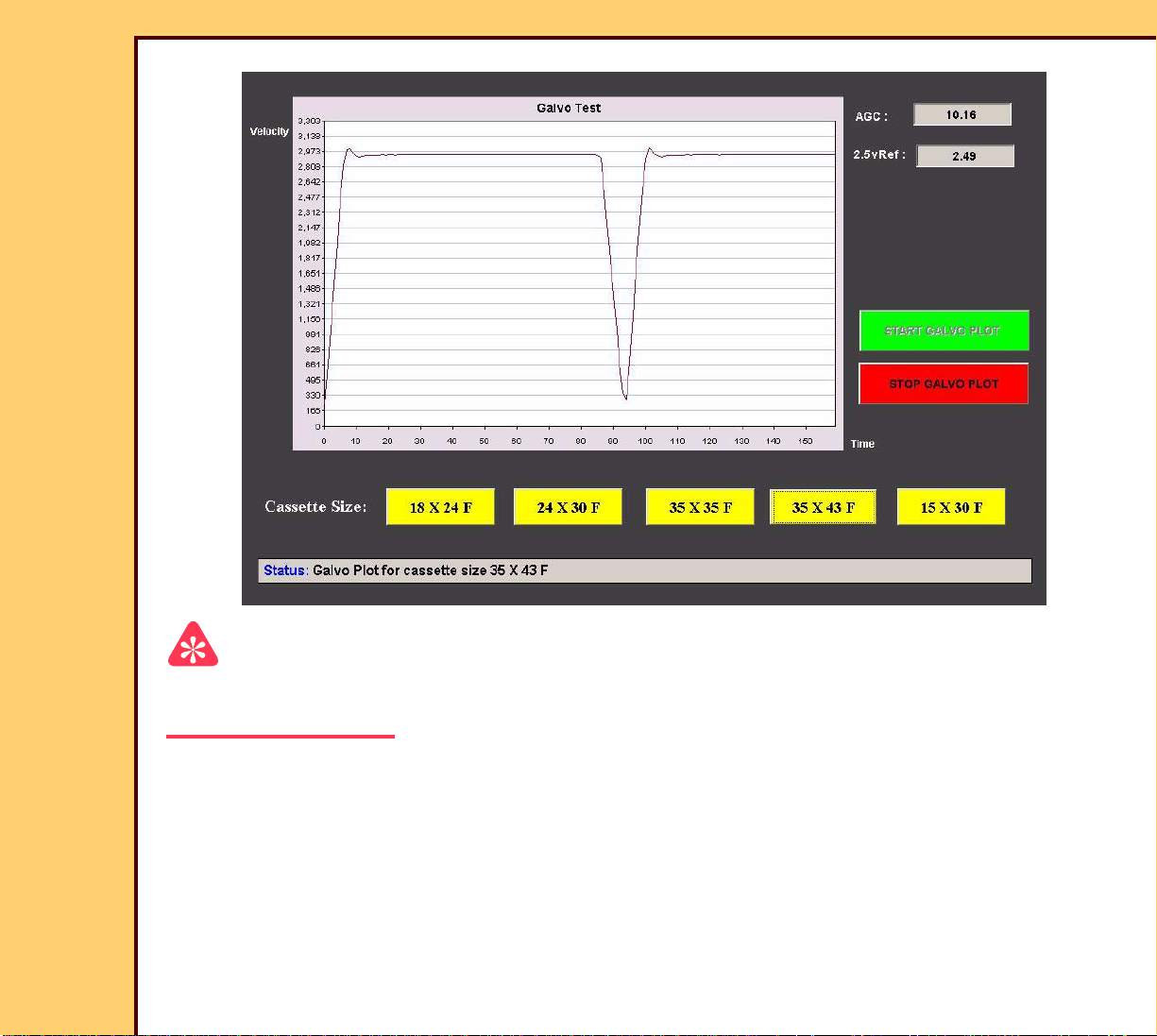

5 At the main menu, click:

• [Service Functions]

• [Diagnostics]

• [Galvo Plot]

• [Start Galvo Plot]

• [35 x 43 F]

Page 31

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

31 of 219

GALVO PLOT CURVE

Not Correct

Peak

Velocity

H195_0064BCA

H195_0064BC

3.195

3.035

2.876

2.716

2.556

2.396

2.236

2.077

1.917

Velocity

horizontal level

3.195

3.035

2.876

2.716

2.556

2.396

2.236

2.077

1.917

Velocity

6 Is the leading edge “Peak” on the GALVO PLOT CURVE correct?

Yes No

Advance to Step 8. Continue with Step 7.

Not CorrectCorrect

3.195

3.035

2.876

2.716

2.556

2.396

2.236

2.077

1.917

7 Rotate the POTENTIOMETER R1:

• until the leading edge “Peak” of the GALVO PLOT CURVE extends above the

horizontal level.

• back until the leading edge “Peak” on the GALVO PLOT CURVE matches the

horizontal level.

8 Click:

• [BACK]

• [Galvo Test]

• [Start Galvo]

9 Set the VOLTMETER to “AC”.

Page 32

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

32 of 219

10 On the GALVO BOARD, rotate the POTENTIOMETER R112 until the minimum AC

voltage is

obtained.

Note

This is the lowest value.

11 Click:

• [BACK]

• [Galvo Plot]

• [START GALVO PLOT]

• [35 x 43 F]

Velocity

Peak

3.195

3.035

2.876

2.716

2.556

2.396

2.236

2.077

1.917

Velocity

Not Correct

3.195

3.035

2.876

2.716

2.556

2.396

2.236

2.077

1.917

Velocity

Not CorrectCorrect

3.195

3.035

2.876

2.716

2.556

2.396

2.236

2.077

1.917

H195_0064BCA

H195_0064BC

horizontal level

12 Is the leading edge “Peak” on the GALVO PLOT CURVE correct?

Yes No

Continue with Step 13. Do Steps 7 - 12 again.

Page 33

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

33 of 219

13 Using the 35 x 43 cm CASSETTE, do the following:

• Preparing the CASSETTES

• Preparing the Room

• Preparing the Equipment

• Cleaning the PHOSPHOR SCREEN

• Exposing the CASSETTE

• Doing a Calibration for the Scan

14 Click:

• [GET COLLECTOR PROFILES]

• [35 x 43 F]

Page 34

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

34 of 219

15 Is the “amplitude” 3000 ± 100 counts?

Yes No

a. Click [BACK].

Continue with Step 16.

b. Advance to Step 18.

16 Is the “amplitude”?

Too Low To o H i g h

a. Set the VOLTMETER to “DC”.

b. Rotate R2 to increase the DC voltage

by 150 mV for every 100 counts.

c. Do Steps 5 - 15 again.

17 Remove the VOLTMETER.

18 Install:

• EMI BRACKET PANEL

• 6 SCREWS

• FRONT COVER

a. Set the VOLTMETER to “DC”.

b. Rotate R2 to decrease the DC voltage

by 150 mV for every 100 counts.

c. Do Steps 5 - 15 again.

• TOP COVER

Postrequisites:

1 None

Page 35

06DEC05

AR4366-1

Page

35 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

EXTRACTION PIN

Adjustment Specification

Purpose: To set the correct position of the EXTRACTION PIN.

Specification: The distance between the MECH PLATE and the surface outside of the

FEED PIN is 143 ± 0.25 mm (5.667 ± 0.010 in.).

Special Tools: None

Prerequisites:

1 Remove:

• FRONT COVER

• TOP COVER

To Check:

Important

For systems with software version ≥ 4.1, you

must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See

SERVICE BULLETIN 843.

1 At the Main Menu, click:

• [Service Functions]

• [Diagnostics]

• [Individual Component Control]

• [EXTEND]

2 Under “PIN EXTRACTION”, click

[EXTEND]

Page 36

06DEC05

AR4366-1

Page

36 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

3 Place the RULER against the MECH

FEED MOTOR HOME

SENSOR FLAG

PLATE.

4 Check that the distance between the

ADJUSTING

SCREW

MECH PLATE and the center of the

FEED PIN is 143 ± 0.25 mm

(5.667 ± 0.010 in.).

LOCKING

SCREW

MOUNTING

SCREW

+

_

0.25 mm

FEED PIN

143

(5.667

+

_

0.010 in.)

MECH PLATE

RULER

H195_1018GCA

H195_1018GC

To Ad j u st :

1 Loosen the LOCKING SCREW on the FEED MOTOR HOME SENSOR FLAG.

2 Rotate the ADJUSTING SCREW clockwise or counterclockwise.

3 Under “FEED MOTOR”, click:

• [EXTRACT]

• [HOME]

4 Click [RESET].

5 Wait until the “RESET” is completed.

Page 37

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

37 of 219

6 Check that the distance between the MECH PLATE and the center of the FEED PIN is

143 ± 0.25 mm (5.667 ± 0.010 in.).

7 Is the distance correct?

Yes No

Continue with Step 8. Do Steps 2 - 7 again.

8 Tighten the LOCKING SCREW

9 Click:

• [BACK]

• [TRANSPORT]

10 Install the CASSETTE into the FEED

TRAY.

FEED

TRAY

35 x 43 CM

CASSETTE

TUBE SIDE

H195_1019GCA

H195_1019GC

Page 38

06DEC05

AR4366-1

Page

38 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

11 Click:

• [+] or [-] until “1” displays

• [Cycle given number of times]

12 Did the system complete the cycle?

Yes No

Continue with Step 13. Do Steps 1 - 7 again.

13 Remove the CASSETTE.

Page 39

06DEC05

AR4366-1

Page

39 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

CR 500 SYSTEM CASSETTE

open close

T U B E S I D E

CASSETTE DOOR

H195_1193BCA

H195_1193BC

14 Is the CASSETTE DOOR and LATCH closed?

Yes No

Continue with Step 15. a. Do Steps 1 - 7 again.

b. Use Diagnostics to correct the problem.

15 Do Steps 11 - 12 for all size CASSETTES.

Postrequisites:

None

LATCH

Page 40

06DEC05

AR4366-1

Page

40 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

SCREEN - Skew

Adjustment Specification

Purpose: To remove the skew from the SCREEN during EXTRACTION

and RETURN.

Specification: Both sides of the SCREEN must be the same distance from the

FLANGE within 3.0 mm (0.12 in.) during EXTRACTION.

Special Tools: 15 in. RULER

Prerequisites:

None

To Check:

Important

• For systems with software version ≥ 4.1, you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See SERVICE BULLETIN 843.

• Some other indications that the SCREEN has excessive skew are:

– white marks at the entrance to the CASSETTE

– damaged corners on the trail edge of the SCREEN

– debris in the CASSETTE

– excessive error codes 12302

– excessive error codes 12267

1 Remove:

• FRONT COVER

• TOP COVER

• 10 SCREWS

• BACK COVER

Page 41

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

41 of 219

2 At the Main Menu, click:

• [Service Functions]

• [Diagnostics]

• [Component Control: Step]

3 Insert a 35 x 43 CASSETTE into the CR 500 SYSTEM.

4 Click:

• [Clamp Cassette]

• [Extract, Scan, Erase Screen]

5 Wait for the SCREEN to stop in the ERASE position.

Important

NON-ACCESS

DOOR SIDE

SCREEN

RULER

The distance from the FLANGE to the top of

the SCREEN is approximately 290 - 310

mm (11.4 - 12.2 in.).

6 Use the RULER to measure the

distance from the FLANGE to the top of

SCREEN on each side of the SCREEN.

RULER

H195_1206GCA

H195_1206GC

FLANGE

ACCESS DOOR

SIDE

7 Record the measurement for each side

of the SCREEN:

• ACCESS DOOR SIDE

• NON-ACCESS DOOR SIDE

8 Click:

• [Return Screen]

• [Latch Cassette]

• [Release Cassette]

Page 42

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

42 of 219

9 Do Step 4 - Step 8 again 2 more times.

10 Remove the CASSETTE.

11 Compare the measurements recorded in Step 7.

12 Is the difference in the measurement between the 2 sides of the SCREEN

≥ 3.0 mm (0.12 in.) for any of the 3 times?

Yes No

Continue with Step 13. Advance to Step 6.

Note

The SCREEN does not have skew.

13 Remove:

4 SCREWS

• 4 SCREWS

CASSETTE TOP

• CASSETTE TOP

14 Insert the CASSETTE into the CR 500

SYSTEM.

T U B E S I D E

H195_1197ACB

H195_1197AC

Page 43

06DEC05

AR4366-1

Page

43 of 219

ADJUSTMENTS AND REPLACEMENTS Adjustments

15 Click:

• [Clamp Cassette]

• [Extract, Scan, Erase Screen]

16 Wait for the SCREEN to stop in the

ERASE position.

17 Click [Return Screen].

Important

SCREEN

If the corner of the SCREEN hits the RAIL,

the SCREEN has excessive skew.

CASSETTE

H195_1207GCA

H195_1207GC

corner

18 Observe the SCREEN returning to the

CASSETTE.

19 Click:

• [Latch Cassette]

• [Release Cassette]

20 If necessary, do Step 15 - Step 19 to

check the skew again.

RAIL

Page 44

ADJUSTMENTS AND REPLACEMENTS Adjustments

A

06DEC05

AR4366-1

Page

44 of 219

To Ad j u st :

CCESS

DOOR

SIDE

ERASE AY

TAB

TAB

SPRING

SPRING

1 Remove:

• ERASE LAMP HOUSING AY

• ERASE AY

• 2 SCREWS

• ERASE AY TOP COVER

2 Determine which side of the screen is

the lowest in measurement from Step 7:

• ACCESS DOOR SIDE

• NON-ACCESS DOOR SIDE

3 On the side lowest in measurement,

bend the TAB approximately 1.6 mm

(0.06 in.) to increase the tension in the

SPRING.

4 Install:

• ERASE AY TOP COVER

• 2 SCREWS

H195_1208GCA

H195_1208GC

NON-ACCESS

DOOR SIDE

• ERASE LAMP HOUSING AY

5 Do the procedure To Ch e c k : again to deter mine if the skew is repaired.

6 Install:

• BACK COVER

• 10 SCREWS

• TOP COVER

• FRONT COVER

• ERASE AY

Page 45

ADJUSTMENTS AND REPLACEMENTS Adjustments

06DEC05

AR4366-1

Page

45 of 219

Postrequisites:

None

Page 46

06DEC05

AR4366-1

Page

46 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

Section 2: Replacements

FRONT COVER

Prerequisites:

None

To Remove:

Laser Warning

This equipment uses a visible red laser.

Prevent direct exposure to the laser beam.

2 SCREWS

• 2 SCREWS

• FRONT COVER

1 Remove:

H195_1017ACA

FRONT COVER

H195_1017AC

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 47

06DEC05

AR4366-1

Page

47 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

TOP COVER

Prerequisites:

1 Remove the FRONT COVER.

To Remove:

TOP COVER

2 WASHERS

2 front SCREWS

OPERATOR INTERFACE

CABLE CONNECTOR J101

2 back SCREWS

2 WASHERS

1 Disconnect the OPERATOR INTERFACE CABLE CONNECTOR J101.

Laser Warning

This equipment uses a visible red laser. Prevent direct exposure to the laser beam.

2 Remove:

• 2 front SCREWS

• 2 WASHERS

H195_1021BCA

H195_1021BC

Page 48

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

48 of 219

• 2 back SCREWS

• 2 WASHERS

• TOP COVER

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 49

06DEC05

AR4366-1

Page

49 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

CPU

Prerequisites:

To Remove:

1 None.

Important

For systems with software version ≥ 4.1, you must have a “Session ID” for access to “Service

Functions” and “Diagnostics”. See SERVICE BULLETIN 843.

2 At the main menu, click:

• [Service Functions]

• [Diagnostics]

• [Display Software Versions]

Page 50

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

50 of 219

3 Record:

• “CR 500 SYSTEM” __________________________________________

• “MCPU” ______________________________________________

• “MSC Board Boot” _____________________________________________

• “MSC Board” ______________________________________

• “SSC Boot” ______________________________________

• “SSC Board Fixed Application” ______________________________________

• “SSC Product Application” ______________________________________

• “D-Board” ______________________________________

• “MIM” ______________________________________

• “Inbox Build” ______________________________________

• “Diagnostics” ______________________________________

4 At the main menu, click:

• [Service Functions]

• [Network Configuration]

Page 51

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

51 of 219

5 Record:

• “Local IP Address” __________________________________________

• “Computer Station Name” ______________________________________________

• “Subnet Mask” _____________________________________________

• “Default Gateway” ______________________________________

• “RAS IP Address Range” ______________________________________

• “Network Speed/Duplex” ______________________________________

6 Click [MAIN MENU].

7 If necessary, for access to the HOSPITAL INFORMATION SYSTEM (HIS) REMOTE

INFORMATION SYSTEM (RIS) information, click:

• [Key Operator Functions]

• [System Configuration]

• [HIS/RIS - Broker Configuration]

• [Polling Configuration]

8 Record the HIS/RIS information:

• “PACS Broker AE Title”

• “PACS Broker IP Address”

• “PACS Broker Port”

• “PACS Broker Modality”

• “Station Name/AE Title(s)”

9 Record the selected parameters check boxes.

Page 52

06DEC05

AR4366-1

Page

52 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

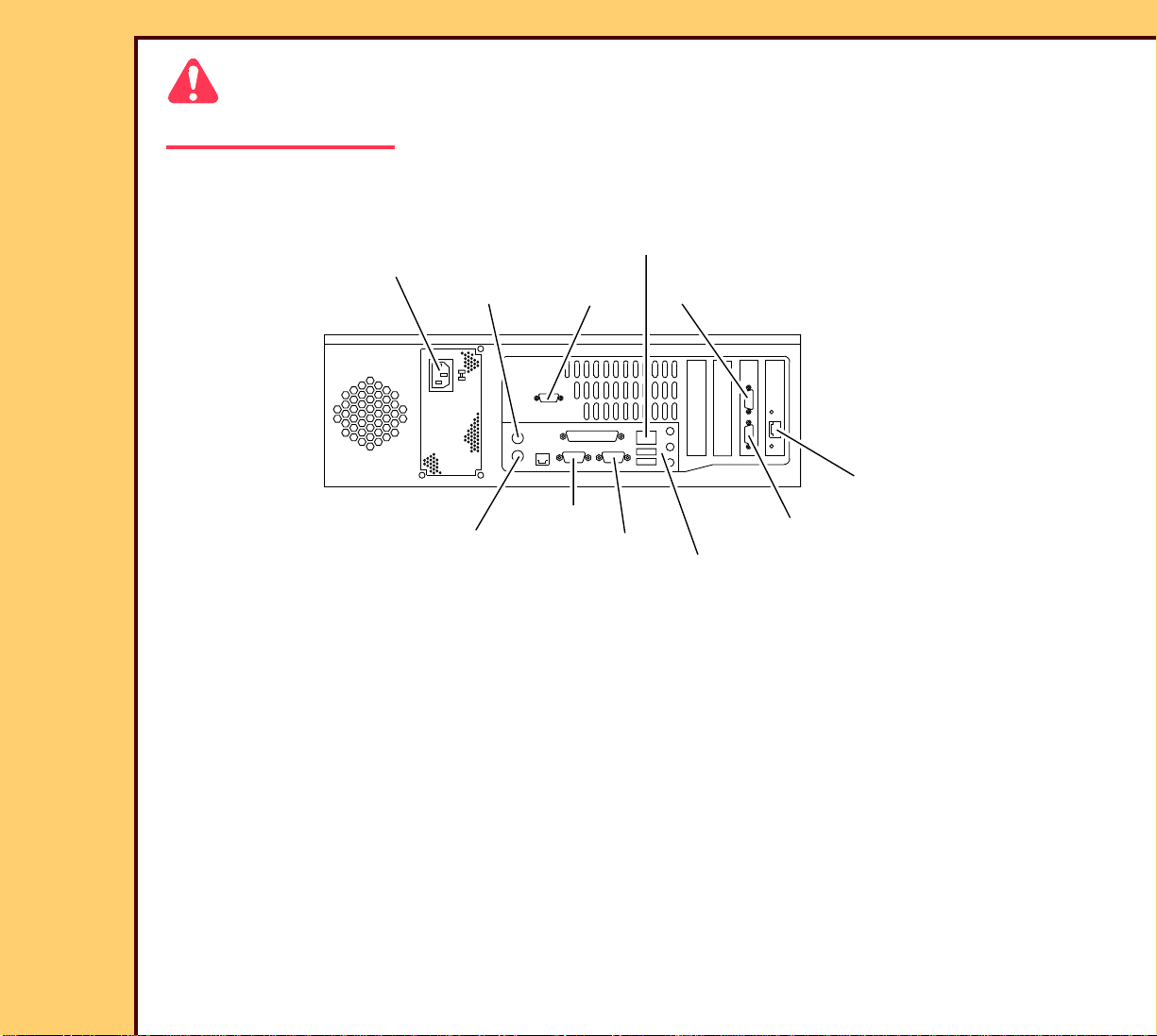

Caution

Dangerous Voltage

10 De-energize the CR 500 SYSTEM.

INTERNAL

NETWORK

POWER

MOUSE

COM 2

COM 3

CUSTOMER NETWORK

KEYBOARD

COM 1

MONITOR

MOTHER BOARD

COM 4

H195_1195BCA

H195_1195BC

Page 53

06DEC05

AR4366-1

Page

53 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

Important

On computers with 2 COM PORTS on the MOTHER BOARD, COM 1 is next to the

MONITOR CONNECTOR.

11 Label and then disconnect the following CABLES:

CABLE From 2.4 GHz Computer From 3.0 GHz Computer

UPS CABLE COM 1 COM 1

HOSPITAL NETWORK CABLE CUSTOMER NETWORK CUSTOMER NETWORK

INTERNAL NETWORK CABLE INTERNAL NETWORK INTERNAL NETWORK

MONITOR CABLE MONITOR MONITOR

MOUSE CABLE MOUSE MOUSE

KEYBOARD CABLE KEYBOARD KEYBOARD

POWER POWER POWER

MODEM - optional COM 2 COM 4

BAR CODE READER - optional KEYBOARD

COM 3

KEYBOARD

COM 3

Page 54

06DEC05

AR4366-1

Page

54 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

CPU

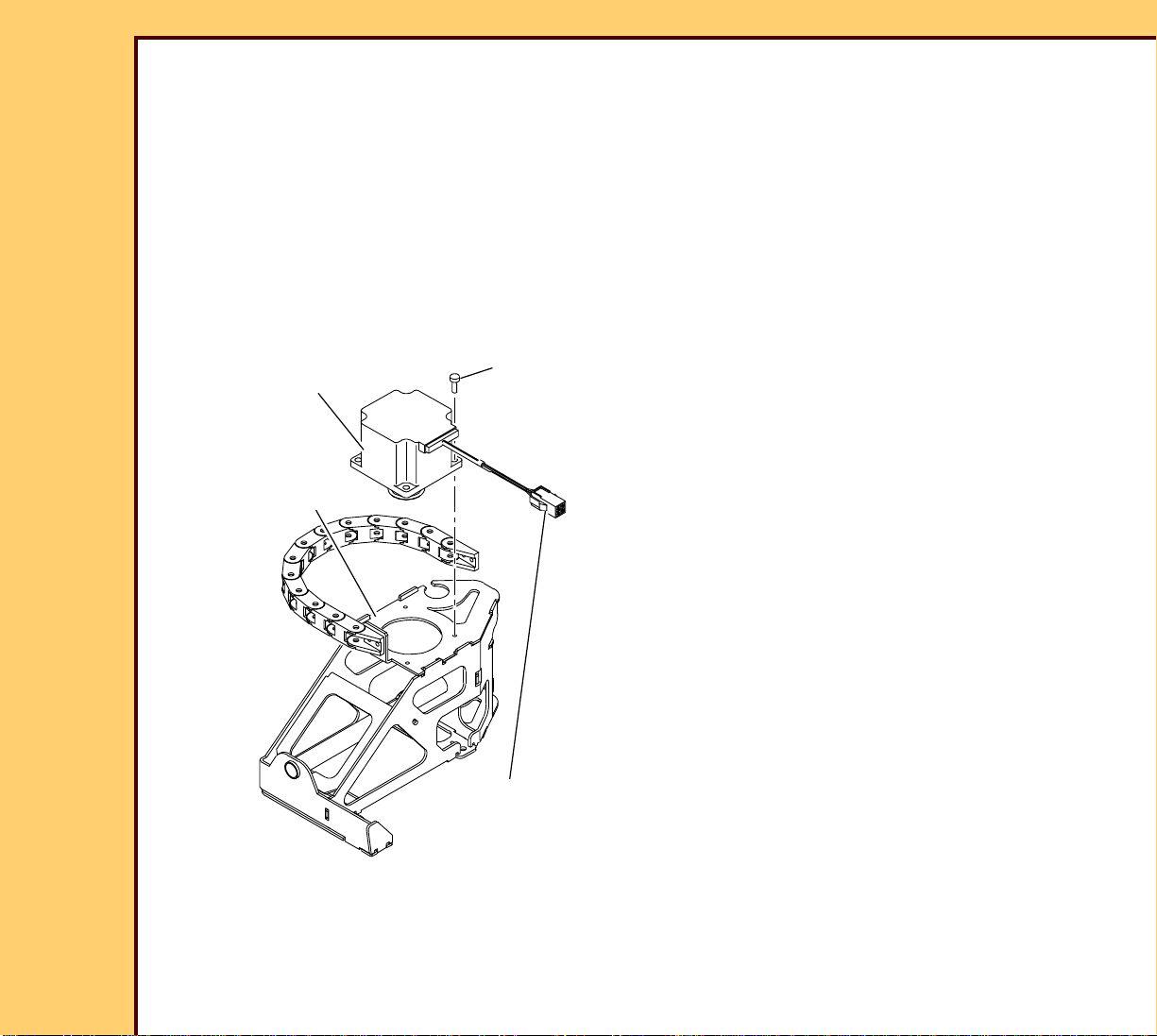

H195_0016BCA

H195_0016BC

12 Remove the CPU.

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Page 55

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

55 of 219

Postrequisites:

1 Restore all customer configurations. See:

Publication Procedure

• For system software version 4.10 - SOFTWARE

INSTRUCTIONS for the RECOVERY KIT V4 .1

SI3519-8

• For system software version 3.6 - SOFTWARE

INSTRUCTIONS for the RECOVERY KIT V3 .6

SI4366-1

Restoring the Parameters

Page 56

06DEC05

AR4366-1

Page

56 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

HARD DRIVE

Prerequisites:

1 None.

To Remove:

1 Indicate to the customer that all images will be erased.

Important

For systems with software version ≥ 4.1, you must have a “Session ID” for access to “Service

Functions” and “Diagnostics”. See SERVICE BULLETIN 843.

2 At the main menu, click:

• [Service Functions]

• [Network Configuration]

Page 57

06DEC05

AR4366-1

Page

57 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

Page 58

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

58 of 219

3 Record:

• “Local IP Address” __________________________________________

• “Computer Station Name” ______________________________________________

• “Subnet Mask” _____________________________________________

• “Default Gateway” ______________________________________

• “RAS IP Address Range” ______________________________________

• “Network Speed/Duplex” ______________________________________

4 Click [MAIN MENU].

5 If necessary, for access to the HIS/RIS information, click:

• [Key Operator Functions]

• [System Configuration]

• [HIS/RIS - Broker Configuration]

• [Polling Configuration]

6 Record the HIS/RIS information:

• “PACS Broker AE Title”

• “PACS Broker IP Address”

• “PACS Broker Port”

• “PACS Broker Modality”

• “Station Name/AE Title(s)”

7 Record the selected parameters check boxes.

8 Insert the USER PREFERENCE DISKETTE stored at the customer site.

9 At the main menu, click:

• [Key Operator Functions]

• [System Configuration]

Page 59

06DEC05

AR4366-1

Page

59 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

10 Click [SAVE ALL CONFIGS].

11 Remove the USER PREFERENCE DISKETTE.

12 Click [MAIN MENU].

Caution

Dangerous Voltage

13 De-energize the CR 500 SYSTEM.

14 Remove the CPU.

Page 60

06DEC05

AR4366-1

Page

60 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

2 BUTTONS

2 BUTTONS

CPU COVER

ESD

Possible damage from electrostatic discharge.

CPU COVER

15 Press the 2 BUTTONS on the CPU

COVER and remove it.

H195_1092ACA

H195_1092ACA

H195_1092AC

CPU

CPU

H195_1092AC

Page 61

06DEC05

AR4366-1

Page

61 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

4 SCREWS

HARD DRIVE

2 SCREWS

CPU

16 Remove:

• 2 SCREWS

• HARD DRIVE BRACKET

17 Disconnect:

HARD DRIVE

BRACKET

POWER

CABLE

RIBBON

CABLE

H177_0704HCA

H177_0704HC

• RIBBON CABLE

• POWER CABLE

18 Remove:

• 4 SCREWS - keep

• HARD DRIVE - discard

Page 62

06DEC05

AR4366-1

Page

62 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

CONNECTOR J26

H177_0708HCA

H177_0708HC

19 Check that the CONNECTOR J26 is seated correctly.

Note

If CONNECTOR J26 is not seated correctly, you might receive the following message: “1962

No operating system found”. “Press F1 to start boot sequence”.

Page 63

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

63 of 219

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

4 SCREWS

2 SCREWS

HARD DRIVE

BRACKET

CPU

POWER

CABLE

RIBBON

CABLE

HARD DRIVE

1 Install the new HARD DRIVE with the existing 4 SCREWS.

H177_0704HCA

H177_0704HC

Page 64

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

64 of 219

2 Install:

• RIBBON CABLE

• POWER CABLE

• HARD DRIVE BRACKET

• 2 SCREWS

3 Install:

• CPU COVER

CPU COVER

• CPU

CPU

H195_1092ACB

H195_1092AC

Caution

Dangerous Voltage

4 Energize the CR 500 SYSTEM.

5 Wait until the main menu displays.

6 Insert the USER PREFERENCES DISK stored at the customer site.

Page 65

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

65 of 219

Postrequisites:

1 Restore all customer configurations. See:

Publication Procedure

• For system software version 4.10 - SOFTWARE

INSTRUCTIONS for the RECOVERY KIT V4 .1

SI3519-8

• For system software version 3.6 - SOFTWARE

INSTRUCTIONS for the RECOVERY KIT V3 .6

SI4366-1

Restoring the Parameters

Page 66

06DEC05

AR4366-1

Page

66 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

EXTRACTION PIN

Prerequisites:

1 Remove:

• FRONT COVER

• TOP COVER

To Remove:

Caution

Dangerous Voltage

1 Remove:

LEFT SIDE

PANEL

FRONT PANEL

4 SCREWS

6 SCREWS

H195_1022ACB

H195_1022AC

• 6 SCREWS

• FRONT PANEL

• 4 SCREWS

• LEFT SIDE PANEL

Page 67

06DEC05

H195_1025BC

SPRING

EXTRACTION PIN

H195_1025BCA

EXTRACTION PIN

SPRING

H195_1025BC

SPRING

EXTRACTION PIN

H195_1025BCA

EXTRACTION PIN

SPRING

AR4366-1

Page

67 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

Important

Do not allow the SPRING to fall.

2 Disengage the SPRING.

3 Remove the EXTRACTION PIN.

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 68

06DEC05

AR4366-1

Page

68 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

S1/S4 and S12/S13 SENSOR BOARDS - DETECTOR

Prerequisites:

1 Remove:

• FRONT COVER

• TOP COVER

To Remove:

1 Disconnect the CONNECTOR.

2 Remove:

• 2 SCREWS

S1/S4 LEFT

DETECTOR

SENSOR BD

S12/S13 RIGHT

DETECTOR

SENSOR BD

CONNECTOR

CONNECTOR

2 SCREWS

2 SCREWS

H195_1062HCA

H195_1062HC

• if necessary, S1/S4 LEFT DETECTOR SENSOR BOARD

• if necessary, S12/S13 RIGHT DETECTOR SENSOR BOARD

Page 69

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

69 of 219

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 70

06DEC05

AR4366-1

Page

70 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

S1/S4 and S12/S13 SENSOR BOARDS - EMITTER

Prerequisites:

1 Remove the CASSETTE INTERFACE AY:

To Remove:

Caution

The weight of the CASSETTE INTERFACE

CASSETTE

INTERFACE AY

AY is 13 kg (29 lb).

1 Place the CASSETTE INTERFACE AY

on a flat surface.

2 Disconnect the CONNECTOR.

3 Remove:

• 2 SCREWS

• if necessary, S1/S4 LEFT EMITTER

SENSOR BOARD

S12/S13 RIGHT

EMITTER SENSOR

BOARD

2 SCREWS

S1/S4 LEFT

H195_1027GCA

H195_1027GC

EMITTER SENSOR

BOARD

CONNECTOR

• if necessary, S12/S13 RIGHT

EMITTER SENSOR BOARD

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

Page 71

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

71 of 219

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 72

06DEC05

AR4366-1

Page

72 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

CASSETTE INTERFACE AY

Prerequisites:

1 Remove:

• FRONT COVER

• TOP COVER

To Remove:

Caution

Dangerous Voltage

1 De-energize the system.

NETWORK CABLE

2 Remove:

• 6 SCREWS

• FRONT PANEL

FRONT PANEL

6 SCREWS

POWER

CABLE

H195_1110HCA

H195_1110HC

Page 73

06DEC05

AR4366-1

Page

73 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

2 CASSETTE

GUIDES

Important

You must move the 2 CASSETTE GUIDES

to the center position to prevent damage to

center

position

LIGHT

LOCK

SEALS

the LIGHT LOCK SEALS.

3 Move the 2 CASSETTE GUIDES to the

center position of the CASSETTE

INTERFACE AY.

4 Fasten the WIRE TIE to the 2

CASSETTE GUIDES.

CASSETTE

INTERFACE AY

center

position

WIRE TIE

H195_1118ACB

H195_1118AC

CLIP

CONNECTOR A1J10

CONNECTOR A1P2

CONNECTOR A1P1

CASSETTE

INTERFACE AY

SCREW

CASSETTE

GUIDES

2 SCREWS

LIGHT LOCK

SEALS

H195_1109HCA

H195_1109HC

Page 74

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

74 of 219

5 Disconnect the CONNECTORS:

• A1P1

• A1P2

• A1J10

6 Remove:

• SCREW

• CLIP

Caution

• The weight of the CASSETTE INTERFACE AY is 13 kg (29 lb).

• Prevent damage to the LIGHT LOCK SEALS.

• The CASSETTE GUIDES must be in the center position

7 Remove:

• 2 SCREWS

• CASSETTE INTERFACE AY

8 Place the CASSETTE INTERFACE AY on a flat surface.

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 75

06DEC05

AR4366-1

Page

75 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

GUIDE MOTOR

Prerequisites:

1 Remove the CASSETTE INTERFACE AY.

To Remove:

Important

You might have to cut the WIRE TIE to install the TOOL 6F9611.

CASSETTE

INTERFACE AY

C-CLAMP

TOOL

CASSETTE

GUIDES

WIRE TIE

H195_1174ACA

1 If necessary, cut the WIRE TIE.

2 Install:

• TOOL 6F9611 on to the CASSETTE

GUIDES

• C-CLAMP on to the TOOL and the

CASSETTE INTERFACE AY

H195_1174AC

Page 76

06DEC05

AR4366-1

Page

76 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

4 NUTS

GUIDE MOTOR

3 Remove the 4 NUTS.

4 Disconnect:

CONNECTOR

ground wire

H195_1028GCA

H195_1028GC

To Install:

• CONNECTOR

• ground wire

5 Remove the GUIDE MOTOR.

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 77

06DEC05

AR4366-1

Page

77 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

M9 LEFT CASSETTE CLAMP MOTOR

Prerequisites:

1 Remove:

• FRONT COVER

• TOP COVER

• CASSETTE INTERFACE AY

To Remove:

Important

The CASSETTE GUIDES must be:

• moved to the center of the CASSETTE INTERFACE AY

• fastened with WIRE TIES

Page 78

06DEC05

AR4366-1

Page

78 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

4 SCREWS

CONNECTOR M9J1

LEFT CASSETTE

CLAMP MOTOR

ground wire

1 Disconnect:

• CONNECTOR M9J1

• ground wire

2 Remove the 4 SCREWS.

3 Remove the LEFT CASSETTE CLAMP MOTOR.

H195_1063HCD

H195_1063HC

Page 79

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

79 of 219

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 80

06DEC05

AR4366-1

Page

80 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

M3 FEED DRIVE MOTOR

Prerequisites:

1 Remove the CASSETTE INTERFACE AY.

To Remove:

Important

The CASSETTE GUIDES must be:

• moved to the center of the CASSETTE INTERFACE AY

• fastened with WIRE TIES

Page 81

06DEC05

AR4366-1

Page

81 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

4 SCREWS

CONNECTOR M3J1

FEED DRIVE

MOTOR

1 Disconnect the CONNECTOR M3J1.

2 Remove:

• 4 SCREWS

• FEED DRIVE MOTOR

H195_1063HCE

H195_1063HC

Page 82

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

82 of 219

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 83

06DEC05

AR4366-1

Page

83 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

LEFT CARRIAGE AY

Prerequisites:

1 Remove the M3 FEED DRIVE MOTOR.

To Remove:

RIGHT CARRIAGE AY

2 SCREWS

CASSETTE

INTERFACE AY

1 Remove:

• 2 SCREWS

• RIGHT CARRIAGE AY

H195_1182GCA

H195_1182GC

Page 84

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

84 of 219

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 85

06DEC05

H195_1117HC

BRACKET

SHAFT

DRIVE BELT

LEFT CASSETTE

BEARING

CLAMP AY

E-RING

H195_1117HCA

WASHER

AR4366-1

Page

85 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

LEFT CASSETTE CLAMP DRIVE BELT

Prerequisites:

1 Remove:

• M9 LEFT CASSETTE CLAMP MOTOR

• M3 FEED DRIVE MOTOR

• LEFT CARRIAGE AY

To Remove:

1 Move the BEARING down the SHAFT from the BRACKET.

Page 86

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

86 of 219

2 Remove:

• E-RING

• WASHER

• CLAMP AY

• LEFT CASSETTE CLAMP DRIVE BELT

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 87

06DEC05

AR4366-1

Page

87 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

M2 PIN EXTRACT MOTOR

Prerequisites:

1 Remove:

• FRONT COVER

• TOP COVER

• LEFT CARRIAGE AY

To Remove:

1 Disconnect the CONNECTOR M2J1.

4 SCREWS

2 Remove:

• SPRING

• 4 SCREWS

• M2 PIN EXTRACT MOTOR

ground wire

CONNECTOR M2J1

H195_1065GCA

H195_1065GC

SPRING

M2 PIN

EXTRACTION

MOTOR

Page 88

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

88 of 219

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 89

06DEC05

AR4366-1

Page

89 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

M10 RIGHT CLAMP MOTOR

Prerequisites:

1 Remove:

• FRONT COVER

• TOP COVER

• CASSETTE INTERFACE AY

To Remove:

M10 PIN

EXTRACTION MOTOR

RIGHT CARRIAGE AY

4 SCREWS

CONNECTOR M10J1

H195_1183GCA

H195_1183GC

1 Disconnect the CONNECTOR M10J1.

2 Remove from the RIGHT CARRIAGE

AY:

• 4 SCREWS

• M10 PIN EXTRACT MOTOR

Page 90

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

90 of 219

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 91

06DEC05

AR4366-1

Page

91 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

RIGHT CARRIAGE AY

Prerequisites:

1 Remove:

• FRONT COVER

• TOP COVER

• CASSETTE INTERFACE AY

To Remove:

RIGHT CARRIAGE AY

2 SCREWS

CASSETTE

INTERFACE AY

H195_1181GCA

H195_1181GC

1 Remove:

• 2 SCREWS

• RIGHT CARRIAGE AY

Page 92

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

92 of 219

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

None

Page 93

06DEC05

AR4366-1

Page

93 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

S5 FEED SENSOR

Prerequisites:

1 Remove:

• FRONT COVER

• TOP COVER

To Remove:

1 Disconnect the CONNECTOR S5/J1.

SCREW

S5 FEED

SENSOR

2 Remove:

• SCREW

• S5 FEED SENSOR

CONNECTOR

S5/J1

H195_1114GCA

H195_1114GC

Page 94

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

94 of 219

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 Reverse the steps in the removal procedure.

Postrequisites:

1 Do the adjustment procedure for the EXTRACTION PIN.

Page 95

06DEC05

AR4366-1

Page

95 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

S14 PIN EXTRACTION SENSOR

Prerequisites:

1 Remove:

• FRONT COVER

• TOP COVER

• CASSETTE INTERFACE AY

To Remove:

1 Cut the WIRE TIE.

WIRE TIE

H195_1118ACD

H195_1118AC

Page 96

06DEC05

AR4366-1

Page

96 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

2 Disconnect the CONNECTOR S14/J1.

3 Remove:

• SCREW

• S14 PIN EXTRACTION SENSOR

CONNECTOR

S14/J1

S14 PIN

EXTRACTION

SENSOR

SCREW

H195_1115GCA

H195_1115GC

Page 97

06DEC05

AR4366-1

Page

97 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

4 Move the 2 CASSETTE GUIDES to the

2 CASSETTE

GUIDES

center position of the CASSETTE

INTERFACE AY.

center

position

CASSETTE

INTERFACE AY

center

position

WIRE TIE

H195_1118ACC

H195_1118AC

CASSETTE GUIDES.

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

5 Fasten the WIRE TIE to the 2

1 Install:

• S14 PIN EXTRACTION SENSOR

• SCREW

2 Tighten the SCREW to 21 in./lb.

3 Connect the CONNECTOR S14/J1.

Postrequisites:

1 Do the adjustment procedure for the EXTRACTION PIN.

Page 98

06DEC05

AR4366-1

Page

98 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

RP 1 PRESSURE ROLLER

Prerequisites:

1 Remove the SLOW SCAN AY.

To Remove:

RP 1 CAM

DRIVE BELT

2 BEARINGS

2 C-RINGS

1 Remove:

• RP 1 CAM DRIVE BELT

• TENSION SPRING

• 2 CABLES

• 2 C-RINGS

• 2 BEARINGS

• RP 1 IDLER ROLLER

RP 1 IDLER ROLLER

2 CABLES

TENSION SPRING

H195_1155HCA

H195_1155HC

Page 99

ADJUSTMENTS AND REPLACEMENTS Replacements

06DEC05

AR4366-1

Page

99 of 219

To Install:

Important

You must use a TORQUE WRENCH TL-1537 to tighten all Torx SCREWS to:

• 12 in./lb for T-10 size Torx SCREWS

• 21 in./lb for T- 20 size Torx SCREWS

1 If necessary, use EMERY CLOTH to remove any debris from the ends of the new RP 1

IDLER SHAFT.

2 Reverse the steps in the removal procedure.

Postrequisites:

1 Adjust:

• FOLD MIRROR

• COLLECTOR AY - Tilt

2 Do Setting the Calibration.

Page 100

06DEC05

AR4366-1

Page

100 of 219

ADJUSTMENTS AND REPLACEMENTS Replacements

RP 1 DRIVE ROLLER

Prerequisites:

1 Remove:

• ERASE AY

• SLOW SCAN AY

To Remove:

BELT

E-RING

H195_1157BCA

H195_1157BC

1 Remove:

• BELT

• E-RING

• TENSION SPRING

• 2 CABLES

2 CABLES

TENSION

SPRING

Loading...

Loading...