Page 1

Large Format 4800 Series Inkjet Printers

Reference

Guide

Page 2

WARRANTY

United States

Kodak warrants its printers (“PRODUCT”) to be free from defects in workmanship and materials for

a period of one year from the date of purchase.

Kodak reserves the right to make changes or improvements to Products, without incurring any

obligation to similarly alter Products previously purchased.

Buyer’s sole and exclusive rights pursuant to this Warranty shall be for the repair or replacement of

defective Product. Kodak specifically disclaims any and all other warranties, expressed or implied,

including but not limited to, implied warranties of merchantability and fitness for a particular

purpose. In no event shall Kodak be liable for any loss of profit or other commercial damages,

special, incidental or consequential damages, or any other damages or claims, whatsoever.

This Warranty gives Buyer specific legal rights, and Buyer may also have other rights that vary

from state to state.

Reference Guide

This Warranty applies only to printers purchased from Kodak, or authorized Kodak distributors or

dealers. The intent of this Warranty is to repair or replace defective Products subjected to normal

wear and tear, when operated according to Kodak instructions.

This warranty does not cover damage to the Product resulting from the following:

· Accident or negligence.

· Unauthorized modification of the Product.

· Adverse environmental conditions.

· Service of the Product by other than a Kodak authorized service provider.

· Unauthorized or improper use, including but not limited to:

- Use in applications for which the Product was not designed.

- Using cartridges, ink, or media other than Kodak products.

- Lubricating any part of the printer.

Internationally: Contact your dealer or distributor for warranty information.

i

Page 3

FCC Statement (U.S.A.)

The United States Federal Communications Commission has specified that the following

notice be brought to the attention of users of the KODAK printers.

FEDERAL COMMUNICATIONS COMMISSION RADIO AND TELEVISION

INTERFERENCE FOR CLASS A DEVICE

Statement

NOTE: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Reference Guide

ii

Page 4

VDE statement

Hiermit wird bescheinigt, daß der Drucker in Übereinstimmung mit den Bestimmungen

der BMPT-AmstbIVfg 234/1991 funkentstört ist. Der vorschriftsmäßige Betrieb

mancher Geräte (z.B. Meßsender) kann allerdings gewissen Einschränkungen

unterliegen. Beachten Sie deshalb die Hinweise in der Bedienungsanleitung.

Dem Zentralamt für Zulassungen im Fernmeldewesen würde den Inverkehrbringen dieses

Gerätes angezeigt und die Berechtigung zur Überprüfung der Serie auf die Einhaltung der

Bestimmungen eingeräumt.

Industry Canada

This Class A digital apparatus meets all requirements of the Canadian InterferenceCausing Equipment Regulations.

Cet apparell numérique de la classe A respecte toutes les exigences du Réglement sur le

matériel brouilleur du Canada.

Reference Guide

VCCI Japan

This is a Class A product based on the standard of the Voluntary Control Council for

Interference by Information Technology Equipment (VCCI). If this equipment is used in

a domestic environment, radio disturbance may arise. When such trouble occurs, the user

may be required to take corrective actions.

iii

Page 5

Material safety data sheet

To obtain information on the proper use, handling, and disposal of Kodak inks, consult the

material safety data sheet (MSDS) which should have shipped with your first ink order.

MSDSs can also be obtained from the Kodak Environmental Services web page (http://

www.kodak.com/go/kes) by using the product name or catalog number. MSDSs can also

be obtained by calling the Kodak Information Center (KIC) at 1-800-23KODAK.

The disposal of any product is typically municipality dependent. There should be enough

information on the MSDS to provide enough guidance for proper disposal. If you are

unsure, contact your local municipality or the Kodak Environmental Services group at

(716) 477-3194.

Printer Disposal

This product contains a small amount of lead. Disposal of this product may be regulated

due to environmental considerations. For disposal or recycling, please contact your local

authorities.

Reference Guide

General operating safety

The use of a <HAR> cord set (rated 10A, 250VAC) with the proper plug configuration

for the country where the device will be used, is required for continued safety compliance.

Ein harmonisiertes (<HAR>) Netzkabel (min. 10A, 250V~) mit dem vorgeschriebenen

Netzstecker für das entsprechende Land in dem das Gerät installiert wird, ist unbedingt

notwendig für die elektrische Sicherheit.

El uso de cable poder <marcado HAR> (capacidad de 10A, 250V~), con el enchufe

apropiado para el país donde se use el producto, es requerido para acatamiento de

seguridad eléctrica.

L' emploi d' un cordon surmoulé <HAR> (estimé 10A, 250V CA) avec la configuration

de la fiche convenable pour le pays où l' appareil sera utilisé, est exigé pour la conformité

à la sécurité continuée.

iv

Page 6

Dryer safety

CAUTION: Never open the dryer. There are no user serviceable parts

inside. Refer servicing to qualified service personnel only.

CAUTION: This assembly heat by radiation.

CAUTION: Once the dryer is plugged in, there is continuous power to the

dryer,

Manual conventions

Reference Guide

even when the printer is turned off.

DISCONNECT POWER CORD BEFORE SERVICING!

ê

Indicates a procedure for you to follow in order to perform a specific function.

Read the accompanying explanatory text before following the step-by-step

procedure.

! Indicates a warning. Ignoring the warning can damage the printer or result in an

unsatisfactorily printed image.

3

Other reference materials

In addition to this guide, the following additional documentation is included with your

printer:

Quick Start Guide - Tells you how to assemble and install the printer's hardware.

System CD-ROM - the system CD-ROM contains:

Indicates a tip or suggestion that can make using the printer easier or improve

your printed images.

• Maintenance Guide, instructions for maintaining your 4800 printer; and

• print server software.

v

Page 7

Reference Guide

Contents

Introduction ....................................................................................................1-1

Printing with 4800 Series printers ....................................................................................1-1

Obtaining quality results ..................................................................................................1-2

Use the Correct Inks and Media ...................................................................................... 1-2

Caring for Media ..............................................................................................................1-2

Caring for your ink and cartridges ....................................................................................1-3

Nine Factors that Affect Print Quality ..............................................................................1-5

Printer options ............................................................................................... 2-1

Cartridge set ...................................................................................................................2-1

Choosing print mode options ........................................................................................... 2-2

Color mode ......................................................................................................................2-3

Quality modes .................................................................................................................2-3

Dots per inch................................................................................................................... 2-4

Print passes.................................................................................................................... 2-5

Carriage speed ................................................................................................................ 2-5

Print direction .................................................................................................................. 2-6

Choosing feed media options........................................................................................... 2-6

End of media ................................................................................................................... 2-6

Media counter .................................................................................................................2-7

Choosing paper options ...................................................................................................2-8

Supply Type ....................................................................................................................2-9

Media standard ...............................................................................................................2-9

Margins .........................................................................................................................2-12

Auto-Load Delay ............................................................................................................2-13

Auto-Cut........................................................................................................................2-13

Auto-Cut Delay ..............................................................................................................2-14

Delay Status ................................................................................................................. 2-14

Save Media ...................................................................................................................2-15

Defining user setup........................................................................................................ 2-15

Choosing a language ..................................................................................................... 2-16

Choosing ink options ..................................................................................................... 2-16

LCD Contrast ................................................................................................................ 2-18

Printing the settings ...................................................................................................... 2-19

Returning to the default settings .................................................................................... 2-19

Printer Default Settings ................................................................................................. 2-20

vi

Page 8

Reference Guide

HP-GL/2 options............................................................................................. 3-1

Printing vector data.......................................................................................................... 3-1

Accessing HP-GL/2 features ........................................................................................... 3-1

Palette select .................................................................................................................. 3-2

Control ............................................................................................................................3-2

Rotation ..........................................................................................................................3-3

Reprints ..........................................................................................................................3-3

Nesting ........................................................................................................................... 3-4

Nest wait time .................................................................................................................3-5

Ink limit ...........................................................................................................................3-6

HP-GL/2 Test File ............................................................................................................3-6

Installing additional memory ...................................................................... A-1

Acceptable DIMM sizes ................................................................................................. A-1

DIMM installation ........................................................................................................... A-1

Technical information .................................................................................. B-1

Menu tree........................................................................................................ C-1

Main menu at a glance ................................................................................................... C-1

Main menu ..................................................................................................................... C-2

Feed media menu .......................................................................................................... C-3

Setup menu at a glance ................................................................................................. C-4

Setup menu.................................................................................................................... C-5

Utility menu at a glance................................................................................................ C-11

Utility menu .................................................................................................................. C-12

Error messages ............................................................................................. D-1

Error Messages .............................................................................................................. D-1

Cartridge Errors .............................................................................................................. D-1

Troubleshooting ............................................................................................ E-1

Troubleshooting quick list ............................................................................................... E-1

Isolating problems .......................................................................................................... E-1

Printer Health ................................................................................................................. E-2

Data Transfer ................................................................................................................ E-12

Application Software ..................................................................................................... E-14

Calling for Help ............................................................................................................. E-15

Customer Technical Support ......................................................................................... E-15

vii

Page 9

Introduction 1

Y

This Reference Guide describes the KODAK PROFESSIONAL Large Format 4800

Series Printer inkjet printer.

These printers give you professional-quality output with all the brilliance and gloss of liquid

ink. For signmakers, service bureaus, photographic services, creative and business

professionals, our printers let you experience the value of exceptional graphics quality.

These printers cut hours of production time, while giving you the dramatic impact of high

fidelity images. These printers are being used for many types of printing needs:

• Posters • Banners • Exhibits

• Signs • Packaging prototypes • POP Displays

• Imposition proofing • Point of purchase • Fine art

Printing with 4800 Series printers

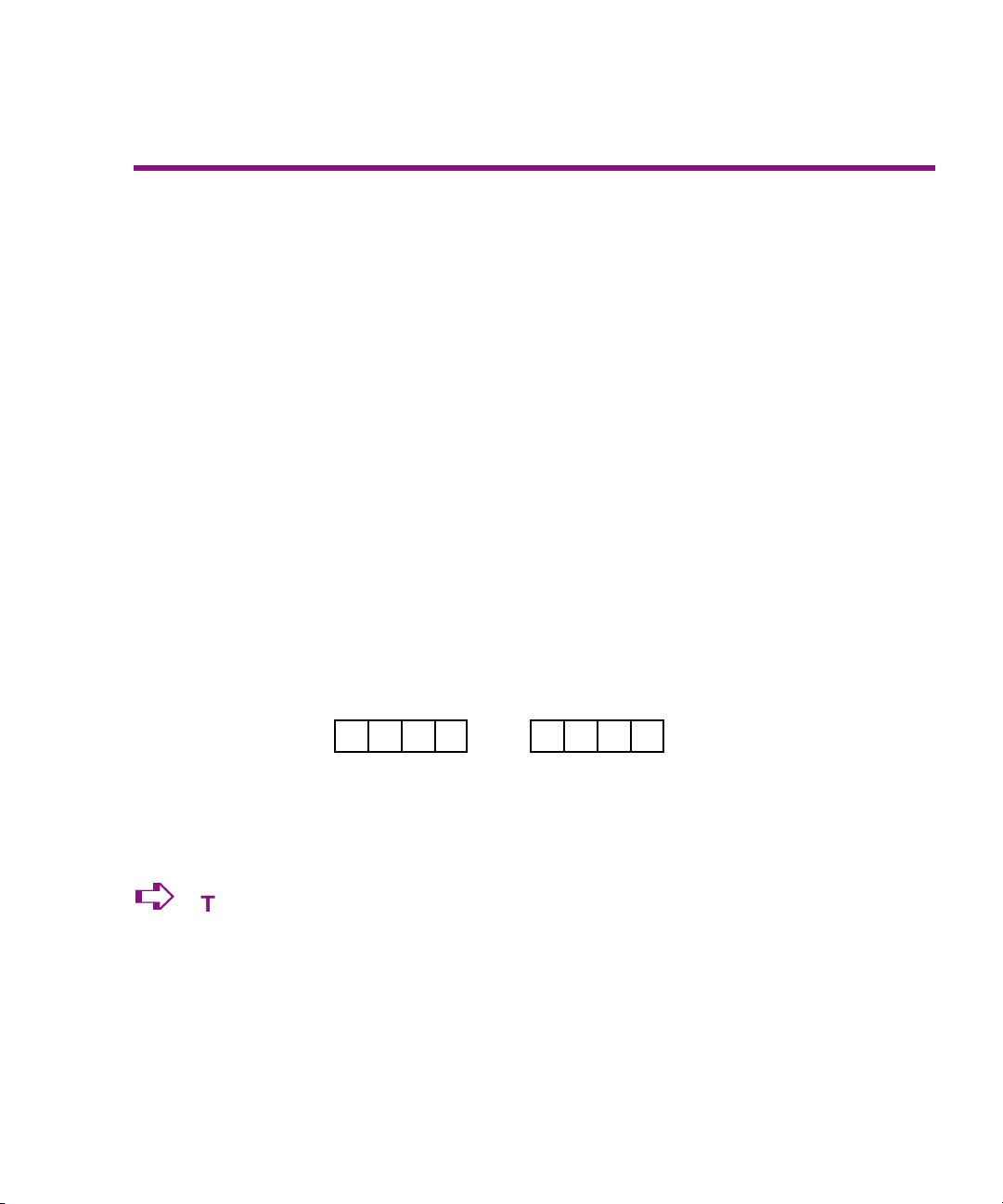

This printer is an 8-head inkjet printer. You can print with the left four cartridges, the right

four cartridges or all eight cartridges. Facing the printer, the left four cartridges are

designated as 1 x 4 Left cartridge set, the right four cartridges are designated as 1 x 4

Right cartridge set and when using all cartridges they are designated as 2 x 4 cartridge

set. The following illustration will help you identify each one of the stalls or slots on the

carriage where the cartridges are installed.

1 X 4 Left 1 X 4 Right

4321

MCK

2 x 4

Page 10

Featuring a continuous-feeding ink system which uses 500ml reservoirs for each color,

you never have to worry about running out of ink halfway through a big print job. Before

starting a print job, just look at the transparent plastic reservoirs to check the ink supply.

When the ink supply is low, just open the cap and refill. In addition, the printer features

dual ink lines on the 1 x 4 Left cartridge set, which makes fast work of switching from

one type of ink to another.

These printers accept raster-oriented data in the form of HP RTL format. In this mode,

printing begins immediately after the first complete line of HP RTL data is received.

Depending on the software used, millions of colors are possible, yielding superb results for

continuous-tone images or 3D renderings.

If your applications do not support HP RTL, there are several software utilities available

to convert various raster file formats (TIFF, GIF, BMP, etc.) into HP RTL. There are also

more than 50 Raster Image Processors (RIPs) which convert Postscript or CGM to HP

RTL. When choosing a RIP or a file format converter for output to the printer, make sure

it has the features you need. (Contact your reseller for an up-to-date listing.)

Obtaining quality results

You have probably seen a demonstration of your printer's capabilities or sample output. If

so, you are aware of the superb color graphics which can be obtained, and the variety of

papers and films you can use. Note, however, that to obtain high-quality results, you must

consider several factors. Follow the simple guidelines in the sections that follow to obtain

excellent results.

Reference Guide

Use the Correct Inks and Media

KODAK has inks and media for your job regardless of what output you want to print

with your large format 4800 printers. KODAK’s image scientists, color scientists, ink

formulators, and media formulators work together to produce a line of supplies that are

scientifically matched with this printer. Refer to KODAK’s Ink and Media Data Sheets

for details on KODAK’s line of inks and media that are compatible with these printers.

Caring for Media

Storage

Store inkjet media in the original box at 65 to 75° F (18 to 24° C) at 45 to 55% relative

humidity. Extreme temperatures and variations in humidity could adversely affect

product performance.

Introduction 1-2

Page 11

Operating Environment

These media work best in an environment ranging from 68 to 82° F (20 to 28° C) at 30 to

70% relative humidity. Image drying time depends on the humidity, temperature, and

amount of ink coverage. Inks dry more slowly when relative humidity is high. When

relative humidity is too low, inks may not spread enough to obscure scan lines resulting in

banding which is usually first observed in areas of solid colors.

Handling

KODAK PROFESSIONAL inkjet media are wound ink-receiving side out The inkreceiving side has a slightly rougher surface compared to the surface on the back side.

Avoid getting fingerprints on the image area of the ink-receiving side. Wear clean cotton

or latex gloves, and handle rolls only by the edges. Also, keep the material free from

moisture at all times.

Caring for your ink and cartridges

! Handle cartridges only on the plastic areas. Touching the copper electrical interconnect

or the inkjets can damage the cartridge.

• Be sure the ink in the cartridges matches the ink in the reservoirs.

Reference Guide

• Do not mix inks.

• Do not shake ink refill containers.

• Store ink and cartridges in the same environment as the printer whenever possible.

• Removing cartridges may result in loss of negative pressure and cause the cartridge to

leak through the jet plate. If you remove a cartridge from the printer, leave the tube

needle attached to the cartridge. This will help maintain negative pressure within the

cartridge. Do not leave cartridges exposed to the air for an extended periods because

the jets may clog. Replace the original tape on the jet plate. Place the cartridge in a

cartridge garage or sealed plastic bag and store it in a closed area at room temperature.

Keep it out of direct sunlight.

• Open new cartridges only when you are ready to install them.

• Use only KODAK PROFESSIONAL-brand ink refills and cartridges.

• Be sure to connect cartridges to reservoirs which contain the same color and type of ink

originally in the cartridge.

• Drawings containing both black and color elements require alignment of the cartridges

to each other. See the Quick Start Guide for details.

Introduction 1-3

Page 12

Choose the right media

You can rely on KODAK PROFESSIONAL media for rich, vivid images across the

entire color spectrum. They are specially formulated to demanding specifications, strict

performance criteria, and uncompromising quality controls. This assures superb interaction

with KODAK PROFESSIONAL Ink and flawless performance with the printer.

KODAK offers a wide range of sheet and roll media and is always adding new products.

Check with your authorized KODAK PROFESSIONAL supplies dealer for the latest

offerings.

Caring for your media

Store media in its original packaging in a cool, dry area until you are ready to use it. The

environment should be stable; i.e., no extremes of heat and cold, and non-condensing

humidity. If conditions are outside the operating ranges recommended for the printer, allow

the media to acclimate in the operating environment for at least 48 hours before using it.

If you remove a roll of media from the printer, be sure to store it in a manner which keeps

it clean and dust-free. Ideally, you should return it to its original packaging for storage.

Print on the correct side! Roll media is wound with the coated side out.

Reference Guide

Handle with care! Handle your media carefully to avoid creases, scrapes, and tears.

Avoid crushing or damaging roll media edges.

Wear cotton gloves! Film-based and photographic paper-based media are susceptible to

absorbing skin oils. Fingerprints on the media prior to printing may result in visible

fingerprints after ink is applied.

Choose the correct printing mode

There are four printing modes, giving you freedom to trade off drawing output quality and

speed. When printing heavier renderings, maps or art graphics, choose one of the enhanced printing modes (Photo or Enhanced).

Use the right software

The quality of the software driver or the RIP (Raster Image Processor) can be very

important, especially when printing continuous tone images or 3D renderings. Error

diffusion or stochastic screening algorithms can yield photo-like images, even when these

images are scaled to full size. Software without advanced imaging features may produce

images which are grainy when enlarged.

Introduction 1-4

Page 13

Nine Factors that Affect Print Quality

Understanding all the factors that contribute to print quality is the only way to ensure

perfect printing each and every time. This section details nine important factors; by

controlling them, you can achieve the very best print quality possible.

1. Use the highest quality type of image possible.

2. Check to make sure the image is in focus and exposed properly.

3. Scan it with the best scanner possible.

4. Scan it at the proper resolution.

5. Color correct and sharpen the image with software.

6. Ensure your color profile accurately reflects the exact ink and media you are using.

7. Use the best diffusion pattern available in your RIP.

8. Use only the best possible ink and media combinations.

9. Make sure your cartridges are aligned and firing properly.

1. Original Image Type

The type of original image will determine the quality of your final inkjet print. The best

image type is an original transparency (not a duplicate). They are extremely crisp with

superb edge definition. Print film photos are not as good as they are already one generation removed from the original film. Also, because of the emulsion process of photo

prints, edge definitions tend to be lost. Color prints can be used, but they have to be of

very good quality to produce acceptable scaled prints. Digital photo files are the newest

image type. Many are unacceptable for large-format printing as they contain only a

small fraction of the information contained in a film transparency.

Reference Guide

For example, many digital cameras can only create a 1 MB file. This is not enough

information for large inkjet prints. A file must be at least 10 - 12 MB for a fair print and

30 - 50 MB for a good E-size print (see scanning section). Only the best commercial

digital cameras can achieve these files sizes. Digital files from other sources such as

CD stock photography are usually created from scanned transparencies, so they may be

suitable for inkjet printing. Check with the manufacturer to ensure that the images are at

least 10 - 12 MB and were created from high-quality drum-scanned transparencies.

The better CDs have images of 28MB or more stored in a TIFF format. These are

preferable for great quality prints. If you use a file stored in PhotoCD format, make sure

you use the highest resolution available. Images stored in compressed files such as

JPEG, LZW, GIF, etc. can lose valuable data during the compression process. Avoid

images stored this way if possible. If you have to use a compression file format for

whatever reason, use JPEG. It is closer to a “lossless” compression.

Introduction 1-5

Page 14

2. Original Image Clarity and Color

The quality of the original photograph, transparency, or digital file plays a key role in final

print quality as this is where the clarity and color of the image is created. If the original

photographer took a picture that was not in focus, or was fuzzy for any reason, sharpening

or after-effects cannot correct it and a poor inkjet print will result. Differences in film,

speed, grain, or developing process can also affect quality of prints. If the image was too

dark or too light, color correction cannot correct it and a poor inkjet print will result. The

axiom of “garbage in, garbage out” applies to all printing, including inkjet printing. Companies that utilize a lot of photography for large-format inkjet printing should check for focus

by using a loupe. If you have a good, in-focus original, you can maintain the image quality

throughout the entire process.

3. Scanner Type

How you get the original image into the computer is important to the overall printing

process as scanner quality varies greatly. Using a scanner that meets the requirement of

the overall print quality is essential to have enough color fidelity and edge clarity. An

image scanned with a low end scanner will lose detail, clarity, and color. It is important

that you understand what type of image quality is required for your print and use the right

scanner to achieve it.

Reference Guide

Traditionally, drum scanners are ideal for retaining the best edge definition and color

depth. If the original image is poor, an expensive drum scan may be a waste of money.

Almost all service bureaus use drum scanners.

Flatbed scanners require an optional transparency adapter to scan transparencies.

4. Scan Resolution

Scanning the original at low resolution will degrade the large-format inkjet print quality.

Scanning at a resolution which is too high slows down the RIP and adds no quality to the

image. Consequently, choosing the right resolution for the output print size (and thus, the

amount of scaling needed after scanning) will determine what the optimum resolution

should be for each image.

The quality of the image you would like to produce is determined by the final output size

and the file size. For example, if you want output a 36" x 36" image, the file size will be

approximately 24MB for a fair-to-good quality image (75dpi), 43MB for a good-very

good quality (100 dpi) and 97MB for an excellent quality (150 dpi) print.

Your service bureau can help you determine the optimum resolution to scan your image

based on the size and quality of the image you would like to print.

Introduction 1-6

Page 15

DO NOT USE INTERPOLATED RESOLUTION OF YOUR SCANNER TO COMPUTE IMAGE SIZE

Most 300 dpi scanners can interpolate or “imitate” 600 dpi scanning. This is really not

really scanning at 600 dpi and will degrade the image quality. When scanning, ensure that

you are using the scanner's true optical resolution, not its interpolated resolution. Scanning at the highest optical resolution (300 dpi) is better than scanning at the scanner's

highest interpolated resolution (600 dpi).

5. Post Scanning Color Correction and Sharpening

All scanned images, even those scanned on expensive drum scanners, must be color

corrected and sharpened before using them for a large-format inkjet print. If you are

using a service bureau for scanning images, their scanner operator will usually do this as

part of the scanning fee. However, you should always check the image before using it.

Although the process of color correction and sharpening is more detailed than can be

explained within this document, the following outline will give you a good grasp of what

is required:

Color Correction - all scanners give the image a slight color cast during the scanning

process. This happens because all light sensing devices have a slight bias. The easiest

way to correct most of this color cast is to use a function such as Auto Levels in

PhotoShop. This function finds the whitest pixel and the darkest pixel in an image and

distributes all colors in-between. This works well on 75% of all images that are properly

exposed. In very dark night scenes or in very white snow background scenes, Auto

Levels does not work properly and the correction must be made manually using histogram adjustments.

Reference Guide

Sharpening using UnSharp Mask - all scanned images, even images scanned on the

most expensive drum scanners, need to be sharpened. The best digital tool to do this with

is a function called an unsharp mask (available in programs such as PhotoShop). An

unsharp mask basically redefines the edges of images by adding a mask. Most unsharp

mask tools allow you to set the pixel width of the mask and the amount of sharpening. A

good start is to use a pixel width of 3 - 5, with an amount of 75%. Too much unsharp

mask will give the whole image a hard, pixelated look. A little more unsharp mask can be

used with inkjet images as they are somewhat diffused in the printing process, hiding any

small amounts of oversharpening.

Introduction 1-7

Page 16

6. RIP Color Profile

The engine that converts your image into a series of C, M, Y, K dots is called the Raster

Image Processor or RIP. Before it can actually create these dot patterns, it must first

adjust for the colors of the inks, color of the media, dot volume of the cartridges on a

particular machine, and the humidity/temperature of the environment on the day of

printing (as this affects how far the ink will spread or dot gain). Most RIPs include what

is commonly referred to as a color profile or color link. Usually, this profile is automatically used when you choose the media and ink within the software. However, color

profiles are created in the factory with new cartridges in a clean and average environment. If you have older cartridges, media that was stored in sunlight for 6 months, and the

humidity is 88%, the standard color profile may not give the best result. In this case, a

new color profile may need to be created. Most professional RIPs today have this as an

optional process. If your RIP cannot make a change, you can use an image editing

program such as PhotoShop and re-RIP the image. Make sure your color profile delivers

the colors and quality you need.

7. RIP Diffusion/Dither Patterns

Images that are going to be printed on an inkjet printer are eventually divided into C, M, Y,

K and rasterized into dots using patterns that cause the eye to see a continuous tone

image. These patterns are called many things, such as frequency modulated screening,

diffusion patterns, dither patterns, screen patterns, etc. There are various types of screening that are better for photographic images. Stochastic screening was developed specifically for the CMYK process to avoid the problem of visually perceptible banding that

occurs with other pattern types. It does this by pseudo-random placement of dots. Variations of the stochastic strategy have evolved into even better patterns. Each RIP manufacturer uses different names to describe its particular variation on the stochastic theme. To

get the best print quality, make sure you are using the best possible diffusion pattern

available from the RIP software you are using. Also remember that a different diffusion

pattern should be used for spot color objects (such as filled vector objects). If you are

printing an image that contains both photographs and spot color objects, use the diffusion

pattern designed for photos.

Reference Guide

Introduction 1-8

Page 17

8. Ink and Media

Using the right ink and media is a much bigger factor in print quality than most inkjet users

realize. Then and only then can they fully appreciate what quality materials and inks can

do. Inks must be developed specifically for a particular head, otherwise, cartridge reliability will be severely reduced. KODAK inks are specifically developed for KODAK

cartridges, printers, and media. These inks create the perfect ink drop shape, trajectory,

and landing shape when used with KODAK cartridges. The media controls the color, dot

gain, and durability of the final print. As the ink must chemically interact with the media,

only media developed specifically for a particular ink can achieve the perfect dot shape

that leads to improved image quality. Additionally, the chemical bond created through codeveloped inks and media is much better than independently developed inks and media.

Although many people will not be able to visually perceive differences in quality inks and

media initially (poor inks and media show more pronounced visual defects), a less-thanoptimal image quality, image color, or image durability will likely develop over time.

Chemical compatibility between inks (made for a specific head technology) and media is a

key, and often overlooked ingredient to print quality.

9. Cartridge Preparation and Alignment

The single most overlooked factor in image color accuracy and quality is cartridge alignment. Even if you carefully control factors 1 though 8, a printer with poor cartridge

alignment or unmaintained heads can severely deteriorate image quality. Cartridge

maintenance and alignment are key to producing images that exhibit the best of what a

printer is capable of. Printer wiping stations must be kept clean so that heads stay clean.

Cartridges need to be aligned and checked to be sure that all nozzles are working properly. Use a loupe to evaluate the registration of test patterns to achieve the best possible

accuracy. Whenever you adjust, move, or replace a cartridge, take the time to realign the

cartridges. Alignment errors of a single pixel (or single digit in the alignment process)

affect perceived color and image quality.

Reference Guide

Introduction 1-9

Page 18

Printer options 2

You can define printer options through your application software or by choosing settings

from the printer's control panel. The following printer options are described in this

chapter:

• Cartridge set

• Print mode

• Paper Options

• User Setup

• Initialize (return to printer default settings)

Cartridge set

Your printer is an eight-head inkjet printer. The eight cartridges are grouped into two sets

of four cartridges. You can print with the left set of cartridges (1x4 Left), the right set of

cartridges (1x4 Right) or all eight cartridges (2x4). You should be familiar with the four

cartridge designations of YMCK. To identify the other four cartridges, we have added

4321. Facing the front of the printer, the cartridge sets and cartridges are identified in the

following illustration.

ê

1x4 Left 1x4 Right

YMCK4321

2x4

Note: You must always determine the cartridge set prior to setting the other Print Mode

options, even when selecting one of the pre-defined quality modes.

To choose the cartridge set

1 Press Setup Menu/Print Mode Menu/Cartridge Set.

2 Choose 1x4 Right, 1x4 Left or 2x4.

3 Press OK.

Page 19

Choosing print mode options

Your printer offers four quality modes, three of them pre-defined, which let you make

tradeoffs between speed and quality.

The quality mode you use depends on various factors, such as your software application, whether you’re printing in color or monochrome, and the type of media you’re

using. Each quality mode directly affects the printing speed and quality of the image

you print, so you should understand the differences.

Each of the quality modes attempts to strike a balance between speed and quality.

The default quality mode, Photo, provides quality images at a reasonable printing

speed for most users. Whenever you choose a print mode other than Photo, you will

choose to emphasize either speed or quality.

The quality modes include the following print mode options:

• Color mode

• DPI

• Print passes

• Carriage speed

• Print direction

Selecting the User quality mode will allow you to set each of the print mode options

individually. Quality modes are summarized in the table which follows. It is not

necessary to set all the parameters, unless you want to create a user-defined print

mode. Note: Make sure you choose the cartridge set before selecting a

quality mode.

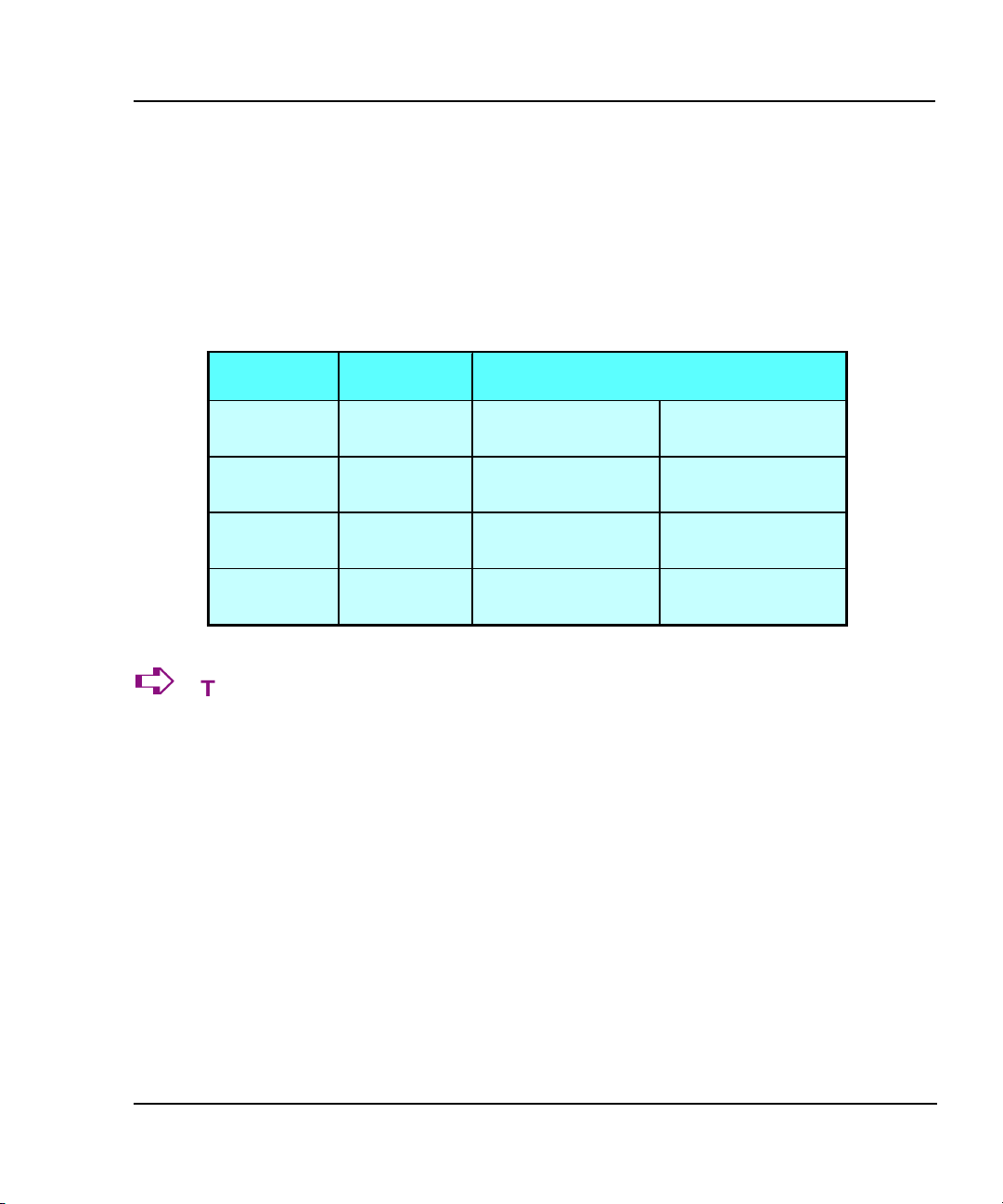

Quality Modes for 1x4 Right and 1x4 Left Cartridge Sets

Quality

Mode

Production Color 600 2 10 Bi

Photo Color 600 4 10 Bi

Enhanced Color 600 6 10 Bi

User User Defined

Color

Mode

per Inch

Dots

Print

Passes

Carriage

Speed

Reference Guide

Print

Direction

Quality Modes for 2x4 Cartridge Set

Quality

Mode

Production Color 600 2 10 Bi

Photo Color 600 3 10 Bi

Enhanced Color 600 4 10 Bi

User User Defined

Color

Mode

Dots

per Inch

Print

Passes

Carriage

Speed

Print

Direction

Printer Options 2-2

Page 20

Color mode

Color mode refers to whether you are printing in color or monochrome.

Reference Guide

ê

Quality modes

ê

To choose the color mode

1 Press Setup Menu/Print Mode Menu/Color Mode.

2 Choose Color, Mono or Gray.

3 Press OK.

There are four print quality modes:

Production - This setting is useful for fast, better than average quality printing on paper

media.

Photo - For high quality continuous tone images where quality is more important than

printing speed. (Default)

Enhanced - This is our best pre-defined quality mode.

User defined - Allows you to set each one of the print mode options individually to meet

your unique requirements.

To choose print quality

1 Press Setup Menu/Print Mode Menu/Quality Mode.

2 Choose the desired quality.

3 Press OK.

Printer Options 2-3

Page 21

Dots per inch

For best results, be sure the printer dpi setting matches the image resolution in the file you

are printing.

The printer always prints at 600 dpi, even when the dpi setting in the Print Mode menu is

set to 300 dpi. The dpi setting refers to the resolution at which your image is created, not

the resolution at which it is printed.

The resolution at which you save your image file affects the size of the printed image as

shown in the following table:

Reference Guide

ê

Image (file)

resolution

300 dpi 300 dpi 1 input pixel prints as 4

300 dpi 600 dpi 1 input pixel prints as 1

600 dpi 300 dpi 1 input pixel prints as 4

600 dpi 600 dpi 1 input pixel prints as 1

Printer dpi

setting

Affect on printed output

output pixels.

output pixel.

output pixel.

output pixel.

The printed image is the

same size as the

original.

The printed image is 1/2

the length and width of

the original.

The printed image is

twice the width and

length of the original.

The printed image is the

same size as the

original.

To choose dpi

1 Press Setup menu/Print mode menu/Dots per inch.

2 Choose 300 or 600 as the resolution.

3 Press OK.

Printer Options 2-4

Page 22

Print passes

The number of passes indicates how many times the cartridges must fire to lay down the

ink for a complete scan line. You may select multiple passes, so that on a single pass, the

jets fire only a fraction of the dots. If you're printing an image with heavy fill or shading,

setting the print mode to an option that lays down less ink can help prevent running and

bleeding. Note: When using the 2 x 4 cartridge set, a single pass fires ink from two

cartridges for each color.

Reference Guide

3

ê

Carriage speed

ê

To change the number of passes

1 Choose Setup Menu/Print Mode Menu/Print Passes.

2 Choose Single, Two, Three, Four, Six, Eight or Ten for 1x4 cartridge sets

3 Press OK.

Carriage speed lets you determine the number of dots per second that are laid down as

the carriage moves over the media.

To set the carriage speed

1 Press Setup Menu/Print Mode Menu/Carriage Speed.

2 Choose 1, 2, 3, 4, 5, 6, 7, 8, 9 or 10. (10 is the fastest.)

3 Press OK.

Single pass is not recommended for graphic arts printing.

or Single, Two, Three, Four or Five for 2x4 cartridge set.

Printer Options 2-5

Page 23

Print direction

Print direction specifies whether the inkjets fire on both passes of the carriage over the

print area (bidirectional), or just on the return pass (unidirectional). If you’re printing an

image with heavy fill or shading, unidirectional can reduce running and ink bleeding. If

you’re more concerned with printer speed, bidirectional firing can decrease your printing

time.

Reference Guide

ê

To change the print direction

1 Press Setup Menu/Print Mode Menu/Print Direction.

2 Choose Unidirectional or Bidirectional.

3 Press OK.

Choosing feed media options

Feed media options allow you to:

• define End of Media

• display/enter Media Counter values

Note: Media feeding and loading are described in the Quick Start Guide.

End of media

There are circumstances where the media does not fully detach from the feeder roll or

the media gets stuck and does not fully advance through the printer. In either case, the

carriage board sensor detects the presence of media and the printer continues to print.

This creates a mess as the printer continues to lay down ink on the same portion of

media.

If the End of Media feature is set to FEEDER STOP, the printer will look for an abnormally long absence of the loop of media that occurs between the feeder roll and the

platen. After 20 seconds, the printer enters pause mode just as if you had pressed

PAUSE from the main menu. The printer will remain in pause mode until you press

PAUSE (which toggles to the resume state) or you press RESET. Pressing PAUSE

allows you to continue the current print at your discretion.

Printer Options 2-6

Page 24

Reference Guide

A few rules regarding the End of Media feature:

• will not work with Cut Sheet selected as supply type.

• setting is remembered across power cycles.

• setting is not stored as a user parameter.

• setting cannot be changed once a plot begins to print.

• if you press PAUSE to resume the print, detection is disabled for the remainder of

the print.

• if enabled, detection is reinstated at the beginning of each print.

• when the printer is in pause mode due to End of Media, the printer will beep 3

times every 20 seconds until the PAUSE or RESET buttons are pressed.

ê

To set end of media

1 Press Feed Media Menu/End of Media.

2 Choose Feeder Stop or Normal.

3 Press OK.

Media counter

Media Counter gives you a means of estimating the amount of media left on a roll.

When a new roll of media, or a used roll where the remaining length is known, is installed

on the printer, you can enter the length of the roll into the printer's front panel display. As

the printer prints, this amount is decremented. You can view the estimated amount of

media remaining on the printer's front panel display. When you are ready to remove the

roll, you can print the estimated amount of media remaining on the roll. When you reload

this media, you can use this figure to enter into the printer's front panel display. The

media counter can be reset to 0 to avoid confusion if the media counter is not being used.

The media counter will not decrement below 0. The current value of the media counter

is maintained across power cycles. The current value is not stored as a user parameter.

ê

To enter a media length value

1 Press Feed Media Menu/Media Counter.

2 Set the media length.

3 Press OK.

Printer Options 2-7

Page 25

Reference Guide

ê

ê

ê

Choosing paper options

To display the current value

1 Press Feed Media Menu/Display Counter.

2 View the current value.

3 Press EXIT.

To print the current value

1 Press Feed Media Menu/Display Counter.

2 Press Print Counter.

3 Press EXIT.

To reset the media counter 0

1 Press Feed Media Menu/Media Counter.

2 Press Reset Counter.

3 Press OK.

Paper options let you define the following:

• Supply Type • Media Standard

• Margins • Auto-Load Delay

• Auto-Cut • Save Media

• Auto-Cut Delay

Note: Media feeding and loading are described in the Quick Start Guide.

Printer Options 2-8

Page 26

Supply Type

This setting allows you to select your supply options. The available options are sheet, roll,

roll2 or takeup. Select sheet if you intend to use cut sheet stock. Select roll if you are

going to use roll paper on the upper roll feeder. (No takeup available with this option.)

Select roll2 if you are going to use roll paper with the lower roll feeder. (No takeup

available with this option.) Select takeup if you intend to use roll paper with the optional

takeup system.

Reference Guide

ê

Media standard

ê

To choose supply type

1 Press Setup Menu/Paper Option Menu/Supply Type.

2 Choose the supply type.

3 Press OK.

When you create an image, you determine its size at the computer. It's important that you

know the size of the image and load the appropriate size media because the printer

automatically defines the print area based on the loaded media's width. Be sure that the

media you load is wide enough to accommodate the image. If extra length is required, use

roll media. If the media is smaller than the image, the image may be truncated. Minimum

media width is 11".

To choose the media standard

1 Press Setup Menu/Paper Option Menu/Media Standard.

2 Choose the size of media you are loading.

3 Press OK.

Printer Options 2-9

Page 27

Reference Guide

The tables which follow provide details on the media sizes and maximum printing areas for

rollfeed and sheet media.

Media Sizes and Maximum Printing Areas for Rollfeed Media

Paper Size Normal Print Area Expanded Print Area

GRAPHICS (U.S. OFFSET)

19.0" x 25.0" 17.8" x 23.8" 18.6" x 24.6"

20.0" x 28.0" 18.8" x 26.8" 19.6" x 27.6"

22.0" x 26.0" 20.8" x 24.8" 21.6" x 25.6"

23.0" x 35.0" 21.8' x 33.8" 22.6" x 34.6"

24.0" x 29.0" 22.8" x 27.8" 23.6" x 28.6"

25.0" x 38.0" 23.8" x 36.8" 24.6" x 37.6"

26.0' x 38.0 24.8" x 35.8" 25.6" x 37.6"

27.0" x 39.0 25.8" x 37.8" 26.6" x 38.6"

30.0" x 42.0" 28.8" x 40.8" 29.6" x 41.6"

32.0" x 44.0" 30.8" x 42.8" 31.6" x 43.6"

35.0" x 45.0" 33.8" x 43.8" 34.6" x 44.6"

36.0" x 45.0" 34.8" x 43.8" 35.6" x 44.6"

40.0" x 50.0" 38.8" x 48.8" 39.6" x 49.6"

42.0" x 65.0" 40.8" x 63.8" 41.6 x 64.6"

48.0" x 65.0" 46.8" x 63.8" 47.6" x 64.6"

50.0" x 65.0" 48.8" x 63.8" 49.6" x 64.6"

54.0" x 65.0" 52.8" x 63.8" 53.6" x 64.6"

60.0" x 65.0" 58.8" x 63.8" 59.6" x 64.6"

A 9.0" x 12.0" 7.8" x 10.8" 8.6" x 11.6"

B 12.0" x 18.0" 10.8" x 16.8" 11.6" x 17.6"

C 18.0" x 24.0" 16.8" x 22.8" 17.6" x 23.6"

D 24.0" x 36.0" 22.8" x 34.8" 23.6" x 35.6"

E 36.0" x 48.0" 34.8" x 46.8" 35.6" x 47.6"

B 11.0" x 17.0" 9.8" x 15.8" 11.6" x 16.6"

C 17.0" x 22.0" 15.8" x 20.8" 16.6" x 21.6"

D 22.0" x 34.0" 20.8" x 32.8" 21.6" x 33.6"

E 34.0" x 44.0" 32.8" x 42.8" 33.6" x 43.6"

A3 297 x 420 mm 267 x 390 mm 287 x 410 mm

A2 420 x 594 mm 390 x 564 mm 410 x 584 mm

A1 594 x 840 mm 564 x 811 mm 584 x 831 mm

625 x 880 mm 595 x 850 mm 615 x 870 mm

A0 841 x 1189 mm 811 x 1159 mm 831 x 1179 mm

A3 337 x 460 mm 307 x 430 mm 327 x 450 mm

A2 460 x 634 mm 430 x 604 mm 450 x 624 mm

610 x 860 mm 580 x 830 mm 600 x 850 mm

A1 634 x 881 mm 604 x 851 mm 624 x 871 mm

860 x 1220 mm 830 x 1190 mm 850 x 1200 mm

A0 881 x 1129 mm 851 x 1199 mm 871 x 1219 mm

1000 x 1414 mm 970 x 1384 mm 990 x 1404 mm

1189 x 1682 mm 1159 x 1652 mm 1179 x 1672 mm

B4 250 x 353 mm 220 x 323 mm 240 x 343 mm

B3 353 x 500 mm 323 x 470 mm 343 x 490 mm

B2 500 x 707 mm 470 x 677 mm 490 x 697 mm

B1 707 x 1000 mm 677 x 970 mm 697 x 990 mm

U.S. ARCHITECTURAL

U.S. ENGINEERING

ISO-A

METRIC-DIN

ISO-B

Printer Options 2-10

Page 28

Media Sizes and Maximum Printing Areas for Sheet Media

Paper Size Normal Print Area Expanded Print Area

GRAPHICS (U.S. OFFSET)

19.0" x 25.0" 17.8" x 22.4" 18.6" x 22.8"

20.0" x 28.0" 18.8" x 25.4" 19.6" x 25.8"

22.0" x 26.0" 20.8" x 23.4" 21.6" x 23.8"

23.0" x 35.0" 21.8" x 32.4" 22.6" x 32.8"

24.0" x 29.0" 22.8" x 26.4" 23.6" x 26.8"

25.0" x 38.0" 23.8" x 35.4" 24.6" x 35.8"

26.0" x 38.0" 24.8" x 35.4" 25.6" x 35.8"

27.0" x 39.0" 25.8" x 36.4" 26.6" x 36.8"

30.0" x 42.0" 28.8" x 49.4" 29.6" x 39.8"

32.0" x 44.0" 30.8" x 41.4" 31.6" x 41.8"

35.0" x 45.0" 33.8" x 42.4" 34.6" x 42.8"

36.0" x 45.0" 34.8" x 42.4" 35.6" x 42.8"

40.0" x 50.0" 38.8" x 47.4" 39.6" x 47.8"

42.0" x 65.0" 40.8" x 62.4" 41.6 x 62.8"

48.0" x 65.0" 46.8" x 62.4" 47.6" x 62.8"

50.0" x 65.0" 48.8" x 62.4" 49.6" x 62.8"

54.0" x 65.0" 52.8" x 62.4" 53.6" x 62.8"

60.0" x 65.0" 58.8" x 62.4" 59.6" x 62.8"

U.S. ARCHITECTURAL

A 9.0" x 12.0" 7.8" x 9.4" 8.6" x 9.8"

B 12.0" x 18.0" 10.8" x 15.4" 11.6" x 15.8"

C 18.0" x 24.0" 16.8" x 21.4" 17.6" x 21.8"

D 24.0" x 36.0" 22.8" x 33.4" 23.6" x 33.8"

E 36.0" x 48.0" 34.8" x 44.0" 35.6" x 44.4"

U.S. ENGINEERING

A 8.5" x 11.0" 7.3" x 8.4" 8.1" x 8.8"

B 11.0" x 17.0" 9.8" x 14.4" 10.6" x 14.8"

C 17.0" x 22.0" 15.8" x 19.4" 16.6" x 19.8"

D 22.0" x 34.0" 20.8" x 31.4" 21.6" x 31.8"

E 34.0" x 44.0" 32.8" x 40.0" 33.6" x 40.4"

ISO-A

A4 210 x 297 mm 180 x 232 mm 200 x 242 mm

A3 297 x 420 mm 267 x 355 mm 287 x 365 mm

A2 420 x 594 mm 390 x 529 mm 410 x 539 mm

A1 594 x 840 mm 564 x 775 mm 584 x 785 mm

625 x 880 mm 595 x 815 mm 615 x 825 mm

A0 841 x 1189 mm 811 x 1124 mm 831 x 1134 mm

METRIC-DIN

A4 250 x 337 mm 220 x 272 mm 240 x 282 mm

A3 337 x 460 mm 307 x 395 mm 327 x 405 mm

A2 460 x 634 mm 430 x 567 mm 450 x 579 mm

610 x 860 mm 580 x 795 mm 600 x 805 mm

A1 634 x 881 mm 804 x 816 mm 624 x 826 mm

860 x 1220 mm 830 x 1155 mm 850 x 1165 mm

A0 881 x 1229 mm 851 x 1164 mm 871 x 1174 mm

1000 x 1414 mm 970 x 1349 mm 990 x 1359 mm

1189 x 1682 mm 1158 x 1617 mm 1179 x 1627 mm

ISO-B

B4 250 x 353 mm 220 x 288 mm 240 x 298 mm

B3 353 x 500 mm 323 x 435 mm 343 x 445 mm

B2 500 x 707 mm 470 x 642 mm 490 x 652 mm

B1 707 x 1000 mm 677 x 935 mm 697 x 945 mm

Reference Guide

Printer Options 2-11

Page 29

Margins

Margins can be set to Normal or Expanded. The Expanded setting expands the print area

and decreases the margins.

Any part of the image that extends into the margin will be clipped. When the Margins

option is set to Expanded, make sure that you align the media accurately using the guide

on the right of the platen so that the ink doesn’t exceed the edge of the media.

Cut sheet maximum printing area

Normal: 0.59" (15 mm) margin on each of three sides and 1.38"

(35 mm) margin on the fourth side.

Expanded: 0.197" (5 mm) margin on each of three sides and a 1.38"

(35 mm) margin on the fourth side.

Reference Guide

Rollfeed maximum printing area

Normal: 0.59" (15 mm) margin on all sides.

Expanded: 0.197" (5 mm) margin on all sides.

Printer Options 2-12

Page 30

Reference Guide

ê

Auto-Load Delay

ê

Auto-Cut

To set margins

1 Press Setup Menu/Paper Option Menu/Margins.

2 Choose Normal or Expanded.

3 Press OK.

Auto-Load Delay lets you set the time between when the printer senses the media and

when printing starts. This lets you manually reposition the media, if necessary. The

default is 6 seconds, selectable from a range of 1-12 seconds.

To set auto-load delay

1 Press Setup Menu/Paper Option Menu/Auto-Load Delay.

2 Choose the delay time.

3 Press OK.

When the Auto-Cut option is set to On, the printer automatically cuts the media when the

image is complete. To be sure the image is dry before cutting, turn on the dryer and/or

specify an auto-cut delay time. See “Auto-Cut Delay” in this chapter for the procedure.

You can select Cut from the control panel at any time to cut the media.

ê

Note: Automatic cutting is disabled when the paper feed option is set to TAKEUP.

To set auto-cut

1 Press Setup Menu/Paper Option Menu/Auto-Cut Menu/Auto-Cut.

2 Choose On or Off.

3 Press OK.

Printer Options 2-13

Page 31

Auto-Cut Delay

Auto-Cut Delay allows you to set a delay time before the printer automatically performs

the Auto-cut function. This provides additional time for unattended prints to dry. In

addition, you may want to delay auto-cut depending on the media you are using, the

ambient temperature and the humidity. Auto-Cut Delay values range from 0 to 55

seconds in five second intervals and 1 to 60 minutes in one minute intervals. When the

delay time has expired, the printer rolls or cuts the image and begins printing the next

image in the buffer. Auto-Cut Delay is ignored when Auto-cut is set to Off.

Reference Guide

ê

Delay Status

ê

To set Auto-Cut Delay

1 Press Setup Menu/Ink OptionMenu/Auto-Cut Menu/Auto-Cut Delay.

2 Choose a time.

3 Press OK.

Delay Status allows users to view the time remaining before Auto-Cut and cancel the

remaining delay time, if desired. A countdown timer displays time left before Auto-Cut in

minutes and seconds. Reset Counter forces the count to zero and the printer initiates the

Auto-Cut immediately.

To reset counter to zero and initiate Auto-Cut

1 Press Setup Menu/Ink OptionMenu/Auto-Cut Menu/Delay Status.

2 Choose Reset Counter.

3 Press OK.

Printer Options 2-14

Page 32

Save Media

When the Save Media is On (the default), the media advances only as far as needed to

print the image. With the Save Media option turned off, the printer advances the full print

area of the loaded media. For example, if a 36 inch roll is loaded, the printer advances the

length of the print area for a standard 36 x 48" sheet even if the printed image is only 30

inches long.

Reference Guide

ê

To turn off Save Media

1 Press Setup Menu/Paper Option Menu/Save Media.

2 Choose Off.

3 Press OK.

Defining user setup

You can save the options you use most frequently so you don’t have to reconfigure the

printer each time you print an image. You can define up to eight different combinations of

options and save them with a user number ranging from 1-8. Select the user number you

want to use before sending an image to the printer. If your printer driver has hostcontrolled settings, the user setup may be overridden. If possible, disable the driver

control settings.

You can save settings for the following options:

• Cut On or Off • Auto-Wipe On or Off • Normal or Expanded Margins

• Media Standard • Monochrome or Color • Save Media On or Off

• Auto-Cut Delay • Quality Mode • Dryer Auto/Off

• Cartridge Set • Print Mode

ê

To save user setup

1 Press Setup Menu/User Setup Menu/Save User.

2 Scroll to the number for the user settings.

3 Press OK.

Printer Options 2-15

Page 33

Reference Guide

ê

To use a previously saved user setting

1 Press Setup Menu/User Setup Menu/Select User.

2 Scroll to the number for the user settings (i.e. user 1, user 2, etc.) to use.

3 Press OK.

Choosing a language

Printer menus and options can be displayed in the following languages: English, German,

French, Italian, Portuguese, Spanish, simplified and traditional Chinese, Japanese, and

Korean.

ê

To choose a language

1 Press Setup Menu/User Setup Menu/Language.

2 Choose the language to display.

3 Press OK.

Choosing ink options

Ink Preheat

Cartridge heat settings are optimized for KODAK PROFESSIONAL media being

printed in a standard office environment. If you are experiencing banding, poor fills, or

over dot gain, and you have tried all other means to correct these conditions, you may

want to experiment with the ink preheat settings. These will vary depending on the

ambient temperature where the printer is located and the media and ink used.

Defaults for the heater setting are determined by the ink type in use. The printer determines this by reading the chip on the back of each cartridge. When you adjust the ink

settings, you are increasing or decreasing the heat from the default temperature. Pressing the Previous and Next buttons increases or decreases the temperature. When you

have reached the limits of the temperature range, the panel will display either MAX or

OFF. These settings are saved in the printer. If you change to a different type of ink, you

may need to change the heater settings to accommodate the new ink type.

If you are working in a cold or dry environment, try turning the heat up for a larger dot

size. If the heat is turned up too far, the ink may run or sputter. If you are working in a

humid or hot environment, turn the heat down for a smaller dot size.

Printer Options 2-16

Page 34

Reference Guide

You can set preheat values for each cartridge in the Left and Right cartridge sets. The

following example sets the preheat value for cartridge 4 of the Left cartridge set.

ê

ê

Auto-Wipe

To set the ink preheat value for cartridge 4 of the left cartridge

set

1 Press Setup Menu/Ink Option Menu/Ink Preheat Menu/Left/4 Preheat.

2 Choose a preheat value.

3 Press OK.

The following example sets the preheat value for cartridge Y of the Right cartridge set.

To set the ink preheat value for cartridge Y of the right

cartridge set

1 Press Setup Menu/Ink Option Menu/Ink Preheat Menu/Right/Y Preheat.

2 Choose a preheat value.

3 Press OK.

When set to On, the cartridge jet plates are periodically wiped during printing. This

eliminates dripping during heavy continuous usage. However, if you are having problems

with banding, you can sometimes solve the problem by setting the wiper to Off (the

default).

ê

To turn on the wiper

1 Press Setup Menu/Paper Option Menu/Auto-Wipe.

2 Choose On.

3 Press OK.

Printer Options 2-17

Page 35

Dryer

Reference Guide

The dryer helps to dry ink. When set to Auto, the dryer automatically turns on, samples

the ambient temperature/humidity and calculates the required dryer output temperature.

When set to On, the dryer is at maximum dryer output. Ambient temperature and

humidity are ignored and the dryer is at maximum output for every print job. Choices are

Off, On and Auto. Note: When using the dryer, Auto is the recommended setting. It

reduces energy consumption and reduces the amount of heat generated by the dryer.

CAUTION: Never open the dryer. There are no user serviceable

parts inside. Refer servicing to qualified service personnel only.

CAUTION: This assembly emits heat by radiation.

CAUTION: Once the dryer is plugged in, there is continuous power

to the dryer,

even when the printer is turned off.

DISCONNECT POWER CORD BEFORE SERVICING!

ê

To set the dryer

1 Press Setup Menu/Ink Option Menu/Dryer.

2 Choose Auto.

3 Press OK.

LCD Contrast

The LCD Contrast function lets you adjust the brightness of the control panel. The range

is 1-8, where 1 is less contrast. The default is 4. Note that if brightness is set too high,

you may not be able to see the text displayed on the control panel.

ê

To set LCD contrast

1 Press Setup Menu/User Setup Menu/LCD Contrast.

2 Choose the contrast value.

3 Press OK.

Printer Options 2-18

Page 36

Printing the settings

Pressing the SetupMenu/User Setup Menu/Print Settings buttons causes the printer

to print a listing of its current settings. Be sure to have paper loaded before you start.

Returning to the default settings

Pressing the SetupMenu/User Setup Menu/Init Settings buttons returns all printer

options to the factory defaults. All saved user settings are lost. The following table

shows the printer defaults.

Reference Guide

Printer Options 2-19

Page 37

Printer Default Settings

USER SETTINGS DEFAULT OTHER OPTIONS

COLOR MODE COLOR MONO, GRAY

CARTRIDGE SET 2x4 1x4 RIGHT, 1x4 LEFT

QUALITY MODE PHOTO PRODUCTION, ENHANCED, USER

DOTS PER INCH 600 300

PRINT PASSES 4 (1x4)

CARRIAGE SPEED 10 1-10

PRINT DIRECTION BI UNI

AUTO-LOAD DELAY 6 1-12 SEC.

MEDIA STANDARD ALL US ENGR, US ARCH, ISO A, MET ALL, US ALL,

MARGINS NORMAL EXPANDED

AUTO CUT ON OFF

AUTO-CUT DELAY 0 0:10, 0:20, … 60:00

SAVE MEDIA ON OFF

CALIB XY ON OFF

SELECT USER 1 1 TO 8

SAVE USER 1 1 TO 8

UNITS SELECT ENGLISH METRIC

LANGUAGE ENGLISH GERMAN, FRENCH, ITALIAN, SPANISH,

DRYER OFF AUTO, ON

AUTO WIPE OFF ON

SYSTEM SETTINGS DEFAULT OTHER OPTIONS

SUPPLY TYPE TAKE-UP SHEET, ROLL, ROLL2

LCD CONTRAST 4 1-8

END OF MEDIA FEEDER STOP NORMAL

MEDIA COUNTER 0 1-500 FT.

CALIBRATION SETTINGS DEFAULT OTHER OPTIONS

DEADBAND (KCMY1234) 44 0…196

SLOW DEADBAND 0 -2…+2

VERTICAL (4321YMC) 0 -9…+9

HORIZONTAL (4321YMC) 0 -9…+9

PAPER AXIS 33.00 32-34

3 (2x4)

Reference Guide

1, 2, 3, 4, 6, 8, 10 (1x4)

1, 2, 3, 4, 5 (2x4)

GRAPHICS, MET OVER A, ISO B, SPECIAL

PORTUGUESE, JAPANESE. CHINESE, KOREAN

Printer Options 2-20

Page 38

HP-GL/2 options 3

This chapter describes the setting of printing parameters generally used with vectorbased files, including palette selection, printer control, rotation, reprints, nesting, ink

reduction and ink limiting.

KODAK's implementation of HP-GL/2 supports vector/raster merge and conforms to

"The HP-GL/2 and HP RTL Reference Guide, Third Edition" by Hewlett-Packard

Company (Addison-Wesley, 1997, ISBN 0-201-31014-7). Please refer to this guide for

detail on HP-GL/2 commands.

Printing vector data

When printing vector data, you can control certain options from your software application, or you can assign control to the printer and set its options. Whether you assign

control to the software (the default) or the printer depends on your personal preferences.

You might choose to override software control because the software is not providing the

features you want.

Accessing HP-GL/2 features

The following functions are available from the HP-GL/2 menu: palette select, printer vs.

software control, rotation, reprints, nesting, ink reduction and ink limit.

ê

To access HP-GL/2 features

1 Press Setup Menu/HP-GL/2 Menu.

The HP-GL/2 menu displays with further options.

Palette Select Nesting Menu

l

Control Reprints

l

Rotation Ink Limit

l

Ink Reduction Exit

l

l

l

l

l

Page 39

Palette select

Palette select lets you choose either the HP-GL/2 or AutoCAD palette. Both palettes

allow 256 active colors with eight colors predefined. The predefined colors for each

palette are shown in the following table.

Pen 0 White White

Pen 1 Black Red

Pen 2 Red Yellow

Pen 3 Green Green

Pen 4 Yellow Cyan

Pen 5 Blue Blue

Pen 6 Magenta Magenta

Pen 7 Cyan Black

Reference Guide

HP-GL/2 Au toCAD

ê

To choose a palette type

1 Press Setup Menu/HP-GL/2 menu/Palette Select.

2 Choose either AutoCAD or HP-GL/2.

3 Press OK.

Control

Control determines whether certain printing parameters are set in the software application or overridden by the printer's front panel. Control overrides the following parameters of the HP-GL/2 header file: repeat plot (RP) and enable auto cutter (EC).

Repeat Plot: With Control set to Printer, the printer will ignore RP commands in the

plot file and only print one plot. From the printer's front panel you can specify additional copies using the Reprints menu.

Enable Auto Cutter: With Control set to Printer, the printer will ignore EC commands

in the plot file and will not automatically cut after each plot. From the printer's front

panel, you can enable automatic cutting or initiate a command for a single cut.

3

Do not override software control when sending merged raster/vector data to the printer.

HP-GL/2 options 3-2

Page 40

Reference Guide

ê

Rotation

ê

To set control

1 Press Setup Menu/HP-GL/2 menu/Control.

2 Choose either Software or Printer.

3 Press OK.

The printer automatically prints an image with the long side on the paper axis. To better

fit images and save media, you can use the Rotation option to turn vector files counterclockwise 90 degrees at a time. If the rotation specified won't fit on the media or contains raster images, it will not be rotated. When the Rotate value is set to AUTO, the

algorithm will automatically rotate the plot if it determines that the rotation will save

media (regardless of whether Nesting is enabled). If Rotate is set to 0, the plot will not

be rotated. The Control function does not override the RO command in the plot file.

Note: Rotation is supported for HP-GL/2 files only. It is not supported for RTL files.

To rotate the image

1 Press Setup Menu/HP-GL/2 menu/Rotation.

2 Choose the rotation angle (0, 90, 180, 270, auto).

3 Press OK.

Reprints

You can print up to 99 copies of a specific vector file. When Reprint is set to 0, only one

image is printed.

ê

To make multiple prints

1 Press Setup Menu/HP-GL/2 menu/Reprints.

2 Enter the number of reprints (0 to 99).

3 Press OK.

HP-GL/2 options 3-3

Page 41

Ink reduction

Ink reduction lets you reduce the percentage of ink laid down by the printer. This feature

applies only to HPGL/2 format images (vector-based images) and has no effect on

continuous tone images. It is especially useful for images with large amounts of printed

area and helps to avoid bleeding or oversaturating the media. It does, however, change

the appearance of colors, so you may want to run a small test print.

Reference Guide

ê

Nesting

To set ink reduction

1 Press Setup Menu/HP-GL/2 Menu/Ink Reduction.

2 Choose a reduction percentage - 0%,12.5, 25%, 37.5, or 50%.

3 Press OK.

Nesting allows the user to save media by printing multiple plots along the horizontal

width of the media. This feature makes the most efficient use of consumables and

reduces the time required to print multiple plots.

When nesting is active, HP-GL/2 plots will be stored within the printer, accumulating in

a nest. Printing will only begin when a nest becomes full, when a nesting timeout

occurs, if printer memory is exhausted, or when a plot that is incompatible with the

current nest is received.

A nest is full when the printer determines that no further jobs can fit across the page.

Nest timeouts are governed by the Nest Time parameter, which is set via the printer’s

front panel.

If the printer runs out of memory, the current nest will be printed immediately, so that

memory may be reclaimed for use by new plots.

An incompatible plot is either a non-HP-GL/2 plot or an HP-GL/2 plot which has

different job characteristics than the current nest, such as quality, dpi, or margins. If any

of the following plot parameters are different between one plot and the next, the last plot

will be incompatible with the current nest, causing the nest to begin printing immediately.

HP-GL/2 options 3-4

Page 42

Parameters which are monitored for Nest compatibility:

• Print quality;

• Number of passes;

• Print direction;

• Speed;

• Color mode;

• DPI;

• Dry time;

• Margins;

• Wipe on/off; and

• Media Save.

The following parameters will not affect nesting:

• Ink limiting;

• Replots;

• If Auto Rotation is enabled, then the nesting algorithm is free to rotate

the plot if it determines that doing so will save media. Plots are sequentially fitted across the page from right to left; and

• The HP-GL/2 EC command can be used to control cutting. If any plot in

a nest has the cutter enabled, the plotter will cut after the nest.

Reference Guide

ê

To enable nesting

1 Press Setup Menu/HP-GL/2 menu/Nesting Menu/Nest Enable.

2 Choose Nest On or Off.

3 Press OK.

Nest wait time

Nesting Wait Time is the amount of time the printer waits for the next plot to fill the

current nest.

The printer will begin printing whenever the printer has been idle for the specified time

interval. The time is reset whenever a print job is received.

HP-GL/2 options 3-5

Page 43

Reference Guide

ê

Ink limit

ê

To define nesting wait time

The printer can assign an ink limit to polygon fills and wide vectors. This helps prevent

bleeding when printing on inexpensive inkjet media. The default for this option is On. If

you are using high quality media, this option may not be needed and can be turned off.

To enable the ink limit

1 Press Setup Menu/HP-GL/2 menu/Nesting Menu.

2 Choose Nest Enable/On.

3 Press OK.

4 On the Nesting menu, choose Nest Time.

5 Choose the Nest Time (30 seconds, 1 minute, 2 minutes).

6 Press OK.

1 Press Setup Menu/HP-GL/2 menu/Ink Limit.

2 Choose On.

3 Press OK.

HP-GL/2 Test File

To assist in diagnosing potential problems with your printer, we have placed an HP-GL/2

test file in the printers ROM memory. The colors that print on the test file are the RGB

values for those colors as defined in AutoCAD. Settings for Ink Reduction and Ink

Limiting have no effect on this file. All other printer options such as Number of Passes

and Carriage Speed are available.

ê

To print the test file

1 Press Utility Menu/Service Menu/Test Print.

HP-GL/2 options 3-6

Page 44

Installing additional memory A

The 4800 Series inkjet printers ship with 64 MB of RAM and are upgradable to a maximum of 256 MB. Additional memory helps to free the host computer more quickly.

Acceptable DIMM sizes

Printer memory may be upgraded by installing PC133 (or faster) 168-pin DIMMs (Dual

In-line Memory Modules). The printer will accept 64 MB, 128 MB or 256MB DIMMs.

DIMM installation

The DIMM is located on the MPCB (Main Printed Circuit Board) inside the right cover.

The MPCB comes with one DIMM slot that has a 64 MB RAM DIMM installed on the

board. The following procedures describe how to remove the right cover, remove the

currently installed DIMM, install a new DIMM and replace the cover. You will need a #2

Phillips screwdriver to complete the procedures.

! ALWAYS UNPLUG THE POWER CORD BEFORE BEGINNING.

! To avoid static damage to the printer, never touch the circuit board or its components

without first touching the bright metal portions of the printer. Static damage is more

likely when the relative humidity is low. If possible, wear a grounding strap when

touching the circuit board.

ê

To remove the right cover

1 Disconnect the power and the interface cables.

2 Remove the printer's top cover.

3 Remove the three screws under the right side of the printer which attach the

right side cover and the two screws which attach the cover to the right plate.

4 Slide back the pin that holds the right cover to the rear cover.

5 Move the right cover, being careful to clear the parallel port on the back of

the unit.

6 Carefully disconnect the ribbon cable from the connector on the PC board

and the other cable that goes to the cover.

Page 45

Reference Guide

ê

ê

To remove the DIMM

1 Facing the top of the DIMM, push the side clips gently away from the

DIMM.

DIMM Slot

2 The DIMM should pop up. Pull the DIMM straight up out of the slot.

To install the new DIMM

1 With the large label on the DIMM facing the away from the board,

insert into the slots on the side clips and push straight down. Next