Page 1

Computer Output

Microfilm Data Sheet

KODAK IMAGELINK DL 1000 Microfilm / 2482

Description

Kodak Imagelink DL 1000 Microfilm 2482 is a

rapid-access, thermally processed (dry) silver

computer output microfilm. This film is designed

to be exposed by a red (helium neon) laser.

When developed, a positive appearing image is

formed (dark characters on a light background).

Kodak Imagelink DL 1000 Microfilm is an

extremely fine-grain, high-contrast microfilm

which offers the highest quality thermally

processed microimage available. When

DL 1000 is used with Kodak Premium 1000

Thermal Print Film 1323, a very high-quality

duplicate is achieved at optimum equipment

throughput speeds.

Product Applications

Kodak Imagelink DL 1000 Microfilm is designed

to generate positive-appearing camera originals

in fiche format from helium-neon lasers used

in dry computer output microfilmers (COM)

equipment such as the Kodak Komstar 100/200/

300 Microimage Processors, Kodak Komstar

Microimage Processor IV, Kodak Optistar

Datawriter, Kodak Optistar V Processor,

Kodak Komstar Processor V, and the Kodak

Optistar Image Writer. This film can be handled

in room light and the equipment it is used with

does not require any special plumbing, venting,

or dark rooms.

Imagelink DL 1000 Microfilm is primarily used to

make masters for generating negative-appearing

distribution copies (clear characters with dark

background) on thermal print film. Positive- or

negative-appearing copies can also be made on

diazo or silver films, depending on customer

preference. This film is not intended to be used

as the primary working copy or for frequent use

in reader printers.

D-45

Page 2

Features and Benefits

Physical Properties (before-process)

High contrast

Extremely fine granularity

Ultra-high resolving power

Very slow speed

Optimum sensitization for helium-neon

lasers (633 nm) for character exposure and

filtered tungsten source for forms overlay

Blue-tinted 4 mil Estar Base of 0.1 nominal

visual density

The sensitized layer of this film contains

an organic silver compound and an

incorporated developing agent

When properly handled and stored,

information on this film can be retrieved

for at least 100 years

Meets requirements of ANSI/NAPM

IT9.19-1994 for thermally processed

silver microfilms

Reformulated emulsion layer

Improved image tone, resulting in blacker

characters; reduces post-process print-up;

improves raw stock keeping, resulting in

invariant speed; improves halation protection

New conductive antistat layer and

copolymer backing

Reduces dirt attraction, resulting in cleaner

dupes; improves transport and handling;

lowers duplicator exposure time, increasing

productivity; reduces Newton's Rings on

dupes; patented technology

Improved overcoat

Improves overcoat adhesion on processed

fiche; patented technology

Nominal Thickness Data

Unprocessed Film

Base 4.0 mil

Emulsion 0.5 mil*

Total 4.5 mil

*blue-tinted, Estar Base; backing: antistat layer and

copolymer topcoatnegligible

Handling

Film not in cartridges should be handled in total

darkness. Unexposed film in its cartridge can be

handled in room light.

Storage

Store unopened packages of film at 21°C (70°F).

If storage for longer than three months is

needed, 13°C (55°F) or lower is recommended.

Keep the film at 50% relative humidity or below,

and protected from radiation and X-rays. To

avoid moisture condensation on the film, cold

or frozen film should be warmed throughout to

approximate room temperature before the

package is opened, six hours if refrigerated, or

overnight if frozen. Once a package is opened,

do not refrigerate or freeze the film. If the Kodak

Komstar Microimage Processor will be shut

down for four hours or more, unthread the film

from the film transport.

Image Structure

Resolving power: (based on recommended

process)

Test-Object Contrast 1000:1 (ISO-RP)

1000 lines/mm

These values were determined by a method

similar to the one described in ISO Standard

6328-1982 PhotographyPhotographic

MaterialsDetermination of ISO Resolving

Power.

Diffuse RMS granularity: 15

Read at a net diffuse density of 1.00 (with a

Kodak Wratten Gelatin Filter No. 47B) using a

48-micrometer aperture.

D-45 2

Page 3

Processing

Kodak Komstar Microimage Processors contain

a heated metal drum which processes this film

at 1.8 meters (6 feet) per minute. Starting point

recommendations are 119 ± ½°C (246 ±1½°F)

for five (5) seconds.

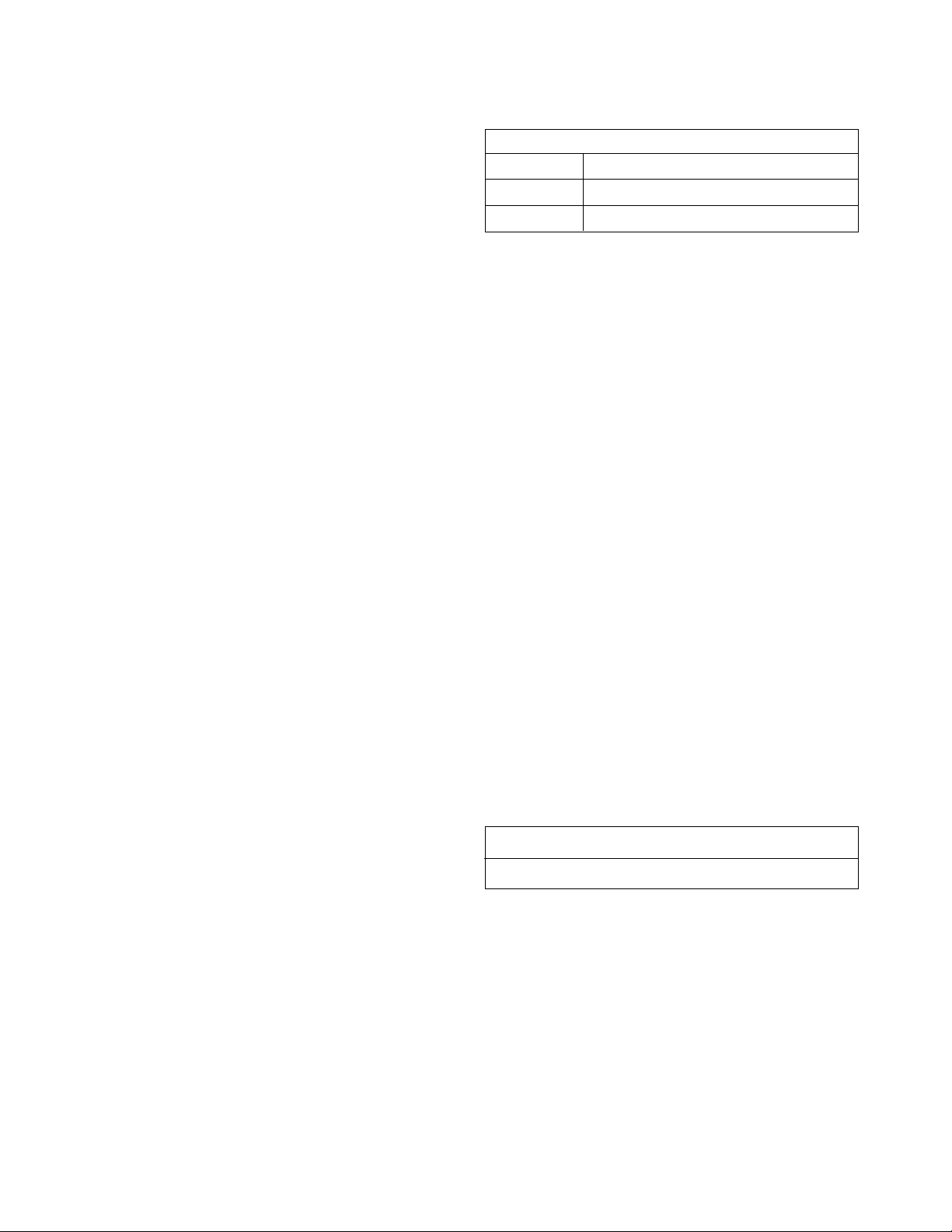

Duplicating Masters

Print film density aims recommended when

printing from Kodak Imagelink DL 1000 Microfilm

/ 2482 Microfilm masters onto Kodak Premium

1000 Thermal Print Film 1323:

1. Produce a processed BLANK master fiche

from the COM.

2. Run an exposure series on the duplicator.

Request 11 copies in the semiautomatic or

manual mode.

Set the exposure to 1.0.

Using the fresh Kodak Imagelink DL 1000

fiche, start the copy cycle.

After each exposure, increase the exposure

setting by 0.1.

Kodak Premium 1000 Thermal Print Film 1323

Optimum background density 2.20

Preferred background density range 1.90 to 2.25

Minimum background density 1.80

Kodak Imagelink DL 1000 Microfilm / 2482 Microfilm

Densitometry = Diffuse Status M Blue

Kodak Thermal Print Film 1353/1323 Film

Densitometry = f/4.5 Visual Projection

See Kodak Publication D-49 for a description of

Kodak Thermal Print Films.

Photographic Properties

The following data are based on development in

the Kodak Komstar Microimage Processor as

recommended.

Exposure

Kodak Imagelink DL 1000 Microfilm / 2482 is

exposed inside a computer output microfilmer

using a helium-neon laser for characters and

a tungsten light or helium-neon laser exposure

for the forms slide.

The optimum exposure intensity setting is

determined by selecting from a complete

intensity series produced according to

procedures as indicated under Exposure

Optimization below.

There should be 11 fiche produced, with

increasing background densities.

3. Using either a densitometer or the Kodak

Thermal Print Density Comparator, select

the fiche which has a density of 2.2 or

close to, but not darker than, the Upper

Limit patch on the Kodak Comparator.

This will become the background onto which

the Komstar characters will be printed.

4. Produce an exposure series of Komstar

data onto Kodak Imagelink DL 1000

Microfilm such that it can be duplicated

onto a fiche with the proper background

density.

Depending on the Komstar being used, this

can be done in several ways.

Kodak Optistar Image Writer

Note the current intensity settings.

Run either a test job or the Quality Monitor

Test from the Optistar Systems Console.

Run the job several times and vary the

intensity up or down (in increments of 10)

each time.

Komstar 100/200/300 Microimage

Processors, Komstar Microimage

Processor IV, and Optistar Processor V

Spectral Sensitivity

Optimum sensitizing for helium-neon lasers

(633 nm).

Exposure Optimization

To determine the proper COM and duplicator

exposure settings, perform the following

procedure:

Run either a test job or the Quality Monitor

Test from the Optistar Systems Console.

As the Komstar is running and starts a new

column of data (determined by either counting

frames or listening for the camera to change

directions), increase the Data Intensity

setting by one. This should produce a fiche

with eight columns of data at eight different

settings.

D-453

Page 4

5. After you have produced a master fiche

with varying densities, the next step is to

duplicate that data at the duplicator

exposure setting which you determined

yielded the proper background density.

Make three copies, use the second, and

observe it in a viewer starting with the lowest

exposure. Look for the Komstar setting which

yields the brightest and most defined

character. If necessary, make paper prints to

determine optimum settings.

6. Once the Komstar data and forms intensity

settings are determined, produce a master

and duplicate fiche at those settings for

future reference.

After-Processing Information

Handling

As with all photographic products, exercise care

to avoid scratches, abrasions, and fingerprints.

It is recommended that camera originals be

handled as little as possible and with lint-free

nylon or cotton gloves.

Keeping (Life Expectancy)

For optimum storage life, store processed film

in the dark at 70°F (21°C), 50% relative humidity

or below, with other conditions as specified in

American National Standard ANSI/NAPM

IT9.11-1993, Imaging MediaProcessed Safety

Photographic FilmsStorage. The useful life of

Kodak Imagelink DL 1000 Microfilm can only be

estimated from incubation tests at accelerated

conditions, since the film has not been

manufactured long enough to have experienced

practical losses of the image. Extrapolation of

high temperature keeping behavior to room

temperature storage is always subject to some

uncertainties. On the basis of work done at

Eastman Kodak Company and by the ANSI/

NAPM IT9-4 subcommittee, this film is estimated

to maintain a usable image for at least 100 years

when processed as recommended, and handled

and stored as described in ANSI/NAPM IT9.11-

1993. Storage at low temperature provides

greater assurance of satisfactory image stability.

The recent specifications for Thermally

Processed Silver MicrofilmSpecifications for

Stability are listed in ANSI/NAPM IT9.19-1994.

Print-up

Because this is a heat-processed film with

incorporated developers, extreme heat or an

intense light source (i.e., readers and printers),

can cause further development of the

background area. Darkening of the background

is called print-up. Print-up is cosmetic in nature

and does not duplicate onto the second

generation copy. Kodak Imagelink DL 1000

Microfilm has properties which reduce print-up.

Viewing and Printing

Readers and viewers are a source of heat and

light at the film plane and can possibly cause

print-up. A reader whose gate temperature does

not exceed 65°C (150°F)* will, even after the

film has been viewed for several hours, maintain

sharp and easily read images. Readers and

viewers can be a source of scratches and

abrasions. For these reasons, it is recommended

that, whenever possible, only test fiche be used

in a reader.

NOTE: Refer to the latest revision of each

ANSI or ISO Standard specified.

*If the heat at the film plane is kept at 65°C (150°F) or lower

when measured as specified in ANSI/NAPM IT9.19-1994,

this print-up has no practical effect when viewing on a

reader or in making duplicates on a printer.

D-45 4

Page 5

Characteristic Curve

Kodak Imagelink DL Microfilm / 2482

HeNe Laser; Heat Processed, 5 sec at 119°C (246°F); Status M Blue

4

3

2

1

0

-2.00 -1.00 0.00 1.00 2.00 3.00 4.00

Log Exposure (lux seconds)

Modulation Transfer Function Curve

Kodak Imagelink DL Microfilm / 2482

Heat Processed, 5 sec at 119°C (246°F); Status M Blue

1000

100

10

1

1 10 100 1000

SPATIAL FREQUENCY (cycles/mm)

Spectral Sensitivity Curve

Kodak Imagelink DL Microfilm / 2482

HeNe Laser; Heat Processed, 5 sec at 119°C (246°F);

Status M Blue

0

-1

-2

-3

-4

250 300 350 400 450 500 550 600 650 700 750

Wavelength (nm)

D=1.0>D-min

D=0.3>D-min

NOTE: These photographic modulation-transfer values were determined by using a method similar to the one described in

ANSI/NAPM PH2.39-1977(R1990) Photographic Modulation Transfer Function of Continuous-Tone Black-and-White

Photographic Films, Method of Measuring. The film was exposed with the specified illuminant to spatially varying

sinusoidal test patterns having an aerial image modulation of a nominal 35% at the image plane, with processing as

indicated. In most cases, the photographic modulation-transfer values are influenced by development-adjacency

effects and are not equivalent to the true optical modulation-transfer curve of the emulsion layer in the particular

photographic product.

D-455

Page 6

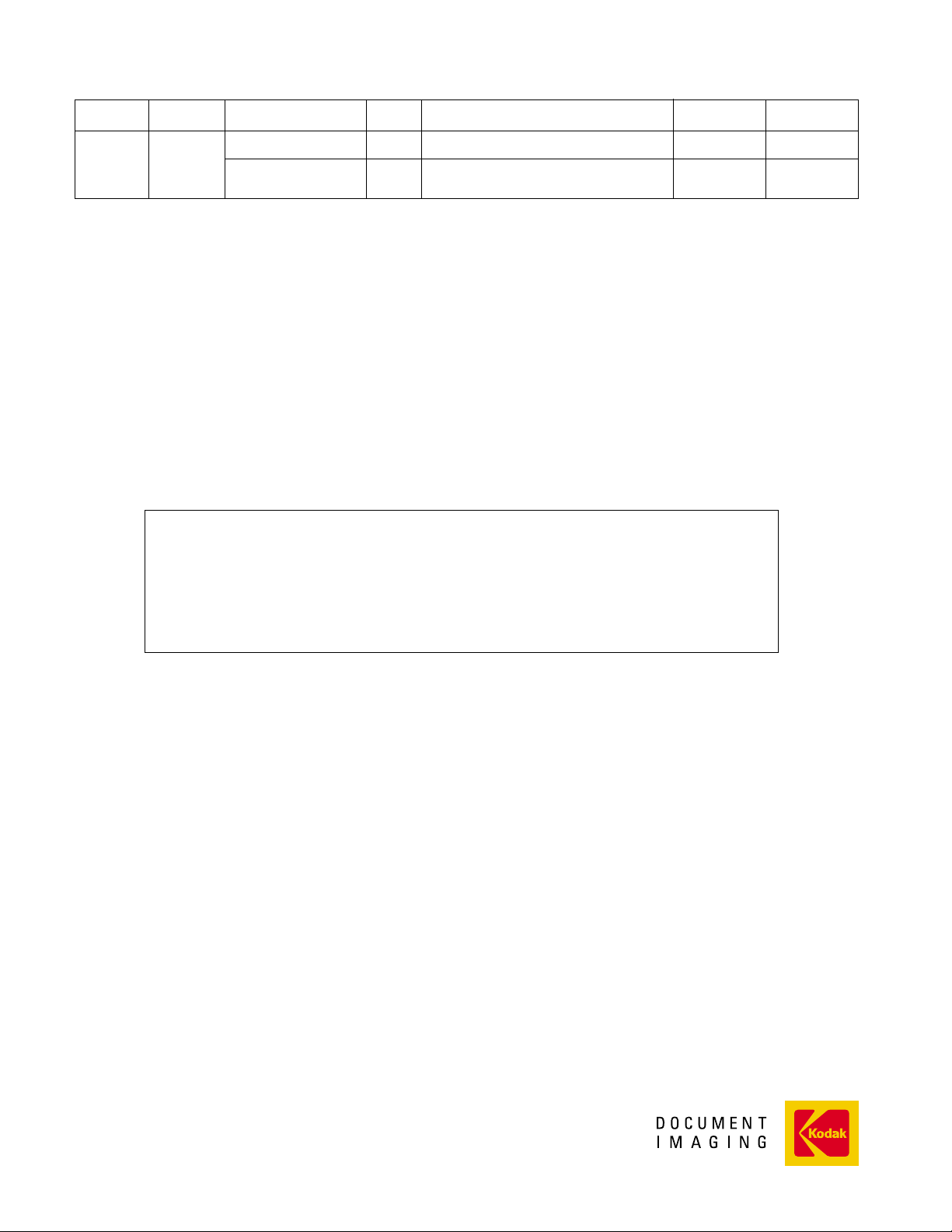

Ordering Information: Imagelink DL 1000 Microfilm

Code Mil Format Spec Description # / Case Cat. No.

2482 4.0 105 mm x 125 m 987 Imagelink DL 1000 Microfilm 4 190 6718

105 mm x 200 m 929K Imagelink DL 1000 Microfilm 2 820 0024

READ THIS NOTICE: The sensitometric curves and data in this publication represent

product tested under the conditions of exposure and processing specified. They are

representative of production coatings and, therefore, do not apply directly to a

particular box or roll of photographic material. They do not represent standards or

specifications which must be met by Eastman Kodak Company. The company

reserves the right to change and improve product characteristics at any time.

EASTMAN KODAK COMPANY

Document Imaging

Rochester, New York 14650

Kodak, Imagelink, Optistar, Estar,

Komstar, and Wratten are trademarks

of Eastman Kodak Company.

Kodak Imagelink DL 1000 Microfilm

Kodak Publication No. D-45

CAT No. 810 3244 7/2001

Printed in U.S.A.

© Eastman Kodak Company, 2001

www.kodak.com/go/docimaging

Loading...

Loading...