Page 1

Micrographic Quality

D-31

Storage and

Preservation

of Microfilms

Page 2

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Electronic Imaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Record Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Storage Hazards and Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fire Protectio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Storage Vaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cabinets and Safes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Effects of High Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Water Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Effects of High and Low Relative Humidities . . . . . . . . . . . . . . . . . . 5

High Humidit y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Low Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Molecular Sieves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Humidity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Air Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Moisture-Tight Containers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Humidification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fungus Growth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Microscopic Blemishes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Toning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chemical Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Composition of Enclosure Materials . . . . . . . . . . . . . . . . . . . . . . . 10

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Plastic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Metal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adhesive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Printing Inks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Theft Protec tio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Processing for Permanence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Silver-Gel a tin F ilms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fixing Baths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Squeegees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Washing Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Residual Hypo Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Residual Silver Compound Test . . . . . . . . . . . . . . . . . . . . . . . . 12

Protective Coatings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

D-31 June 2002 i

Page 3

Processing of Other Film Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Thermally Processed Silver (TPS) . . . . . . . . . . . . . . . . . . . . . . . . 13

Diazo Films . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Vesicular Films . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Special Storage and Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Underground Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Effects of Nuclear Ex p lo s io n s . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Time-Capsule S torage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Handling and F iling Film Records . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Interfiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 1: Applicable Standards for Microfilm . . . . . . . . . . . . . . . . . 15

Table 2: Storage Life of Microfilms . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 3: Storage Temperature and Relative Humidity . . . . . . . . . . 17

Summary of Requirements for Storage and

Preservation of Records on Kodak Microfilm . . . . . . . . . . . . . . . . . 17

Storage Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

References and Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ii D-31 June 2002

Page 4

Introduction

Definitions

Photographic film remains an important

documentary material. The increasing quantity

and value of microfilm records used in financial

institutions, libraries, government offi ces, and

industrial firms have focused attention on the

care of such records to make certain that they

last as long as possible.

The distinction between phot ographic film recor ds

intended for storage and those intended for use

has not always been clear. Use or work copies

are the predominant photographic records found

in libraries or record centers and are subject

to much handling due to their value as quick

references. However, because of this handling,

they are subject to dirt, abrasion, fingerprints,

contamination with foreign materials, and

exposure to excessive light, temperatures, and

harmful atmospheric pollutants. As a result, these

copies in daily use cannot be considered suitable

for long-term preservation. For lo ng-t erm stor age,

it is imperative to prepare duplicate copies that

meet certain criteria, such as proper filming,

duplicating, processing, minimum handling,

controlled environment, and storage.

In general, the care needed for storing

photographic records is similar to that for

storing written paper records, although there

are some requirements peculiar to the storage

of photographic film.

The permanence of photographic records

depends on the chemical stability of the film,

how the film is processed, and the conditions

under which the processed film records are

stored. The stability of the film layers is

determined in manufacture and processing, while

storage is controlled by the user. This pamphlet

discusses the composition and properties of

black-and-white silver-gelatin, thermally

processed silver (TPS), diazo, and vesicular films

as they relate to film permanence. It also

describes the essential requirements of good

processing and storage practices.

NOTE:Refer to the latest revision of each ANSI or

ISO Standard specified.

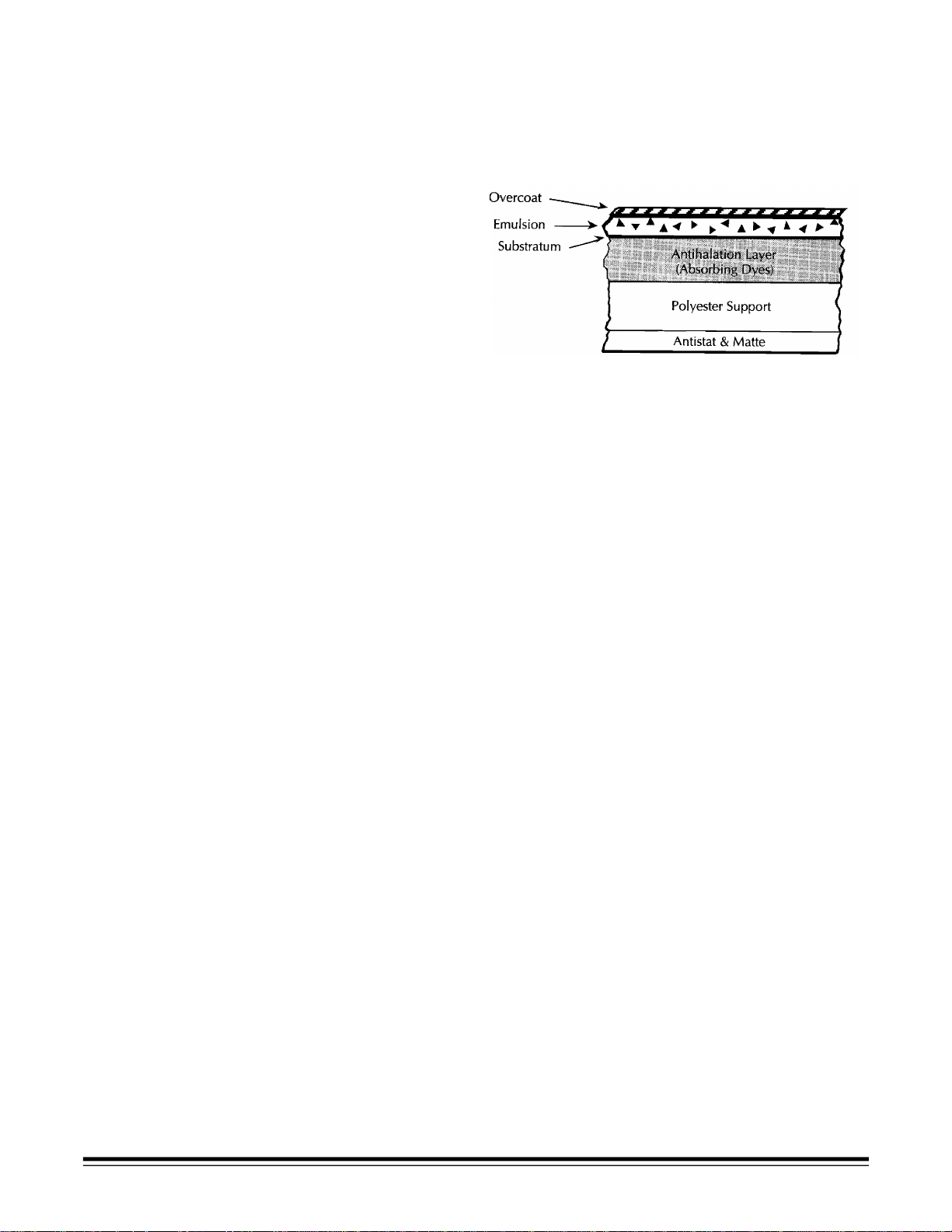

To help understand storage requirements,

the composition and structure of microfilm are

described and definitions of commonly used

1

terms are given.

Structure of a typical black-and-white negative film.

Acetate film—(acetate base) safety film with a

base composed principally of cellulose acetate

or triacetate.

Antihalation undercoat—separate layer of

light-absorbing dye located between the film

emulsion and the base to suppress li ght reflection.

During processing of this film, the dye layer

becomes transparent.

Base or support—a flexible plastic material tha t

is coated with a thin, light-sensitive, imageforming layer. The thickness of the base varies

with different film types.

Dimensional stability—ability of photographic

materials to maintain their origina l size and shape

during and after processing and also under

various conditions of temperature and humidit y.

Emulsion—the image-forming layer. For

unprocessed black-and-white silver-gelatin films,

it is composed primarily of minute silver halide

crystals suspended in gelatin. Exposure to

light in a camera or printer causes no visible

effect, but there is an invisible change which

produces a “latent image.” To obtain a visible,

usable image, the exposed material must be

chemically processed.

For diazo and vesicular films, the sens itized layers

are composed of light-sensitive diazonium salts.

To obtain a visible, usable image with these films,

the exposed material is heat-processed. Diazo

films are typically heat-processed in the presence

of ammonia.

For TPS films, the image-forming la yer is ty pic all y

silver halide and silver salts suspended in a

polymeric binding.

D-31 June 2002 1

Page 5

Emulsion layer(s)—image or image-forming

layer(s) of photographic films, papers, and plates.

Film base—the plastic support for the emuls ion

and backing layers.

Halation—halo or ghost around the desired

image on a photographic emulsion. (This is

caused by the reflection of rays of light fr om th e

base to the emulsion or by internal scattering of

light within the film.)

Nitrate film—a photographic film with a base

consisting of cellulose nitrate. Nitrate-base films

decompose with age and are not suitable for

permanent records. The manufacture of nitrate

film by Eastman Kodak Company in the United

States of America was discontinued in 1951, but

older nitrate motion-picture fil ms are often found in

storage. It is not always possible to determi ne by

visual examination if a film has a nitrate base.

However , neither KODAK nor RECORDAK

Microfilms in any width were ever made on

nitrate base.

Non-curl backing layer—a layer, usually made

of gelatin, applied to the side of the film base

opposite to that of the emulsion layer, for the

purpose of preventing curl.

NOTE:It is comparable to the emulsion layer

in thickness and is not removed in

processing. (Antihalation or other

layers removed in processing are

excluded from this definition.)

Polyester film—a photographic film having a

polyester base. This type of base manufactured

by Eastman Kodak Company is called Estar Base.

It is exceptionally tough and strong and has

excellent dimensional stability. Microfilm

emulsions on Estar Base are currently supplied

for many purposes. Kodak currently manufact ures

only microfilms on Estar Base.

Safety photographic film—photographi c film

which passes the ignition time test and burning

time test as specified in ANSI and ISO Standards.

Safety poly(ethylene terephthalate ) base—

a polyester film base for recording materials

composed mainly of a polymer of ethylene

glycol and terephthalic acid. All safety films

(both acetate and polyester) manufactured

by Eastman Kodak Company meet these

requirements. This means that they are

difficult to ignite and are slow burning.

All silver-gelatin Kodak Microfi lms on Estar Base,

when processed as recommended by Kodak,

meet the current specific ations established by the

American National Standards Institute, Inc.,

(ANSI) for films intended for use as LE 500.

Substratum (subbing or precoat)—the layer

that bonds the emulsion to the base.

Electronic Imaging

With the coming of electronic digit al imaging

systems, the need for continuing the quality

concepts already est ablished i n the micrograph ics

arena has evolved. Following are a few

key concepts.

Digitization—use of a scanner to convert

documents (on paper or microforms) to

digitally coded electronic images suitable

for electronic storage.

Digital—the use of binary code to record

information. “Information” can be text in a binary

code (e.g., ASCII), images in bitmapped form,

or sound in a sampled digital form or video.

NOTE:Information is recorded digitally for

accuracy in storage and transmission.

Some types of data manipulation are

easier in digi tal form.

Scanning—1.) In electronic imaging, scanning is

the operation which precedes digitization, where

the surface of a document is divided into pixels

and analog values are collected representing the

optical density (brightness and possibly color)

of each pixel.

2.) In electronic imaging, OCR scanning is the

conversion of marks that represent symbols into

symbols for use in a data processing system.

The paper or microfilm with the human-readable

marks is first scanned as an image, then is

analyzed to recognize the intended symbol.

The result is the set of symbolic information,

in a machine-readable code such as ASCII

(also known as handprint character recognition,

intelligent character recognition, and optical

character recognition).

3.) In micrographics, sca nning is the movement of

an image on a reader screen in a direction

perpendicular to the direction of r oll-fil m transport.

4.) Scanning is the systematic examination of

data (ISO).

2 D-31 June 2002

Page 6

Scanner—a device that electro-optically conver t s

a document into a series of pixels by detecting

and measuring the intensity of light reflected or

transmitted. When initially captured, each pixel is

a level of brightness (gray or color), initially an

analog quantity, but potentially digitized.

NOTE:For many applications, total information

about each pixel is not needed and would

represent a burdensome amount of output

from the scanner. Therefore, most

scanners digitize the value of each pixel

and reduce the amount of data output to

only that which is required. For example,

output might be limited to one bit per pixel

for “black-and-white” scanning.

Scanner threshold—the brightness level above

which a pixel is considered pure white and

below which the pixel is considered pure black

(sometimes set manually [lighter/darker

setting], or set automatically based on the

average brightness of the document).

Record Classification

On the basis of required retention, photographic

records can be classified broadly as requiring

medium-term storage and long-term storage.

Archival medium—recording material tha t can

be expected to retain information forever, so

that such information can be retrieved without

significant loss when properly stored. However,

there is no such material and it is not a term to be

used in American National Standard material or

system specifications.

Life expectancy (LE)—the length of time that

information is predicted to be retrievable in a

system at 21°C and 50% RH.

LE designation—the rating for the “life

expectancy” of recording materials and

associated retrieval systems.

NOTE:The number following the LE symbol is a

prediction of the minimum life expectancy,

in years, for which information can be

retrieved without significant loss when

stored at 21°C and 50% RH.

Extended-term storage conditions—storage

conditions suitab le for the preservation of

recorded information on the majority of freshly

processed photographic films for 500 years .

Medium-term storage conditions—storage

conditions suitab le for the preservation of

recorded information for a minimum of 10 years.

Methylene blue—a chemical dye formed

during the testing of permanence of processed

microimages using the methylene-blue

method. Also called residual thiosulfate ion

and silver densitometric method.

Storage Hazards and Protection

There are a number of hazards to the sat isfactory

storage of photographic film that apply to records

intended for medium-term, long-term, or

extended-term storage. In fact, it is not always

possible to predict the desired life of recor ds at the

time they are made.

While films of medium-term, long-term, or

extended-term interest are subject to the same

hazards, the storage protection provided for

them will differ in degree because of a number

of factors. These include the cost of providing

storage facilities, desired record life, frequency

of record use, value of the records, etc. See

ANSI/PIMA IT9.11-1993

5

and ANSI IT9.2-1991.

Fire Protection

All Kodak Microfilms are slow-burning films as

defined by the American National Standards

Institute, Inc.

will burn considerably slower than paper, the

same precautions against damage by fire

should be taken for them as for paper records

of comparable value.

Depending on the importance of the records,

fire protection provided can vary from the full

protection described on the following pages for

valuable records to that provided by ordinary

office storage.

3

Even though photographic records

6

For example, LE-100 indicates that

information can be retrieved for at least

100 years of storage. Silver-gelatin films

have an LE of 500; thermally processed

silver (TPS) have an LE of 100 years.

D-31 June 2002 3

Page 7

Storage Vaults

The highest degree of protection for a large

number of records is afforded by a fireproof

storage vault or record room. It should be located

and constructed in accordance with the local

building code, Fire Underwriters ’ Regulations, and

the requirements of the National Fire Protection

Association (NFPA)

room, except that an approved, controlled,

air-conditioning unit shoul d be installed. While

NFPA discourages air conditioning such an

installation, the fire hazard introduced by

openings for air-conditioning ducts can be

overcome by the use of automatic, fire-control

dampers approved by Underwriters’ Laborato ries,

Inc. These can be installed in the ducts in

accordance with recommendations of NFPA.

Sufficient insulati on should be provided in the

vault to permit satisfactory temperature control at

all seasons of the year and to prevent moisture

condensation from forming on the walls.

7

for a valuable record

8

moisture, which will expand under heat and, under

some conditions, might generate slight press ure.

However , such intense heat would be requi red on

the outside of the fire-resistant cabinet that the

cabinet would be seriously damaged from the fire

before appreciable pressure developed.

Effects of High Temperatures

In addition to complete l oss by fire , damage to film

records can also oc cur i f the y ar e exposed t o v ery

high temperatures. Excessive heat causes fil m to

buckle because of shrinkage at the edges. When

severe, this distortion affects the ease with which

the information can be taken from microfilms,

either by projection (for reading) or by printing

onto another film.

Silver-gelatin films that have been conditioned at

a relative humidity of 50% or lower will withstand

121°C (250°F) for 24 hours without significant

loss in readability or printability. At 149°C (300°F),

severe distortion can occur in a few hours.

Cabinets and Safes

For smaller quantities of records , a fi re-resistant

cabinet or safe of the type described by NFPA

will provide considerable protection. Such a safe

should protect records against a severe fire for at

least four hours.

Many fire-resistant safes and cabi nets use a type

of insulation that when heated releases moisture

and thus fills the interior of the safe with steam

during a fire. This can cause melting or stripping

of the film emulsion layer and loss of the image.

For protection, films stored in such a safe should

be placed in moisture-tight cans, as descri bed

under “Humidity Control” in this publ ication.

It is preferable to use fire-resi stant safes that are

available with an inner chamber sealed against

moisture. These are classified by Underwriters’

Laboratories, Inc., as Class 150 Record

Containers.

9

Film damage caused by steam

is not a problem with these safes.

The question is sometimes raised as to whether

microfilm stored in drawers or cabinets designed

to resist fire for several hours might, in case of a

fire, generate enough pressure to damage or

explode the cabinet. There is practically no

danger of an explosion from the storage of either

Estar Base or acetate base safety film under

these conditions. There are small amounts of

organic materials in acetate film base, as well as

7

Films that have been conditioned at a relative

humidity above 50% may show objectionable

distortion in somewhat shorter times or at lower

temperatures. Higher humidities, however , are

undesirable for other reasons, as explained later.

Thermally processed silver films will build

up background densities fairly rapidly at

temperatures of 93°C (200°F) and above.

At these temperatures, even a few hours will

produce significant loss in readability or

printability. At 149°C (300°F) or above, severe

distortion can occur in a few hours.

Diazo films, while quite stable, cont ain dye images

that can fade and/or discolor as a result of high

temperatures. Kodak Diazo Microfilms can

withstand a week at 93°C (200°F) without image

loss. At 149°C (300°F) or above, severe distor tion

can occur in a few hours.

High temperature is the greatest enemy of

vesicular film. Although Kodak Thermal Print

Films can withstand 71°C (160°F) for several

hours, high temperatures can cause a complete

loss of images if care is not taken with regard to

temperature control.

4 D-31 June 2002

Page 8

Water Protection

Film records should be protected from possible

water damage, such as from leaks, fire-sprinkler

discharge, and flooding. If possible, storage

facilities should be located above basement

levels. Storage cabinets should be raised so that

the lowest shelf or drawer is at least 15.2 cm

(6 in.) off the floor and should be constructed so

that water cannot splash through ventilating

louvers onto the records. Drains provided should

have adequate capacity to keep water from a

sprinkler discharge from reachi ng a depth of

7.6 cm (3 in.).

If the record-storage area s hould become flooded,

prompt steps should be taken to reclai m any

immersed records. Allowing microfilm records

to dry, even partially, will cause the layers to

stick together. If there are no local facilities for

rewashing and drying the films immediately,

promptly place the films in a wat er-filled container

and send them to a laboratory where they can be

washed and dried properly.

10

High Humidity

Stor age in moist air, such as that frequently found

in basement rooms, and storage humid ities above

50% should be avoided; relative humidities of

40% or less are recommended for minimizing the

possibility of growth of microscopic blemishes.

At humidities above 60%, there is the additional

danger of fungus growth.

Effects of High and Low

Relative Humidities

The choice of humidity level for storage depends

on the type of photographic film and the humidity

of the work area. In order to minimize subsequent

moisture conditioning in stora ge, the humidity of

the work area should not be markedly different

from that of the storage area. Very large humidity

differences may lead to some physical distortion.

The best relative humidity for storage is the

lowest that can be achieved practically and

controlled reliably, within the limits specified

in ANSI/PIMA IT9.11-1998 and ISO 18911

their latest revisions.

5

or

These curves show the relationship between relative

humidity and the moisture content of a typical emulsion,

triacetate filmbase, Estar Base, and a complete film at

equilibrium of various relative humidities at 21°C (70°F).

Low Humidity

At low humidities, problems of brittleness or

static might arise if the films are to be handled

frequently. However, in the case of inactive

films (regardless of their intended permanence),

the increased protection that low humidity gives

against microscopic blemishes might be

desirable. The recommended humidity is

30% for silver-gelatin polyester-base film and

15% for silver-gelatin acetate-b ase film and all

other silver and non-silver films.

5

D-31 June 2002 5

Page 9

Very low humidities have, in the past, caused film

to be brittle. However, film of current manufacture

has not been found to exhibit brittleness or

breaking tendencies under normal handling,

even at relative humidities as low as 15%. Old fil m

that is found to be brittle at low humidity should

be reconditioned to a higher humidity before

use. One day’s storage is usually sufficient for

conditioning a dry 16 mm roll halfway to a higher

ambient relative humidity; to bring i t to full

equilibrium requires about a week. In each case,

both sides of the roll should be exposed to the air.

Molecular Sieves

Molecular sieves are capable of absorbing most

of the potential film degradation agents such as

moisture, oxidants, solvents, and others when

kept in close proximity with the films under

confined storage.

Company recommends the use of molecular

sieves with triaceta te and polyest er-based f ilms to

reduce the physical aging of films and incre ase

the longevity of black-and-white images under

confined storage. It also prevent s ferrotyping

(mold/fungal growth on films), as it reduces the

moisture content of film.

Tests have shown that molecular sieves prevent

vinegar syndrome associated with acetate-based

films and micro-blemishes, and arrests the

oxidation of silver images due to peroxides and

ozone in the atmosphere. Using molecular sieves

slows the rate of these degradation reacti ons

under confined storage and thus extends the

keeping and longevity of older film collections.

24

Therefore, Eastman Kodak

Rate of conditioning a typical safety film from 20% to 50%

relative humidity at 21°C (70°F).

Low humidity affects the curl of silver-gelatin film,

causing a slight contraction of the emulsion layer

and resulting in a slight curl toward that side.

This is generally believed to be an advantage

because the concave emulsion surface is better

protected against abrasion. However, excessive

curl may cause difficult y in focusing images in

some microfilm readers. This can be avoided

by conditioning the film to a relative humidity of

30-50% before use. The curl of diazo, TPS, and

vesicular films is virtually unaffected by humidity.

Film handled at very low humidities may also

develop a static charge as it passes through a

reader or rewinder. This static charge will attract

dust particles that can damage the emulsion by

chemical action or physical abrasi on. Therefore,

it is important that any film handling area be kept

clean. If film is kept in a dry storage area, it may

be necessary to use the film in an office area of

higher humidity to minimize static problems.

However , as previously noted, large humidity

differences may lead to conditioning problems.

A single molecular sieve packet inserted into the

existing flip-top boxes containing microfilm will

last for five to seven years, under recommended

storage conditions. Microfilm should be inspected

periodically to off e r an opportunity to replace

the molecular sieves.

The sieves must be replaced at some interval,

depending on storage conditions. The use of

molecular sieves is cited by the American Natio nal

Standards Institute (ANSI) as another proc edure

to reduce redox blemishes caused by high

humidity conditions and oxidants in the air. For

more information or to obtain molecular sieves

(listed below), call Multisorb at 1-800-445-9890.

Molecular Sieves

Part No. Film Format Content

41 ag 43 16 mm 3.5 grams 400

41 ag 47 35 mm 7.0 grams 200

41 ag 51 105 mm 12.5 grams 125

With or without molecular sieves, it is very

important to foll ow current ind ustry r ecommended

practices for film storage, such as keeping film

under proper temperature and relative humidity

conditions. However, placing recommended

amounts of molecular sieves inside flip-top

boxes will extend the life of the films significantly.

This adds additional protection by slowing the

deterioration process.

6 D-31 June 2002

Page 10

Humidity Control

Control of relative humidity is required for

preservation of permanent records.

Air Conditioning

Properly controlled air conditioning of the storage

area is definitely recommended for the optimum

long-term preservation of permanent records.

The air should be filtered to remove dust,

cleansed of gaseous contaminants, if present,

and controlled to the desired relative humidity and

temperature. Slightly positive air pressure should

be maintained within the storage room or vault .

Film should be conditioned to this environment

and then placed in containers.

Where air conditioning is not available and hi gh

humidities are likely to be present, the humid ity

of the storage area can be lowered by electrical

refrigeration-type dehumidif iers. These are readily

available and inexpensive. The storage space

should first be vapor-sealed by covering the walls

with asphalt or aluminum paint or, better yet,

paper-laminated aluminum foil or other watervapor barriers. Painting the sto rage area is

suggested, but follow the painting precautions.

A humidistat set at the desired level of humidity

should be used to control the dehumidifier. The

humidity level should be check ed frequently with a

reliable hygrometer , such as a sling psychromete r .

For added protection against short-term moisture

effects, such as dehumidifier failure, tape the

containers as described in the following section,

“Moisture-Tight Containers.”

Dehumidifiers using desiccants should be used

with caution. They may create a danger of fine

dust particles getting on the film and causing

abrasion when the film is used. Also, when some

chemical-desiccant particles are trapped in rolls

of microfilm, they may form bleached spots.

Therefore, inert desiccates should be used, and

it is essential that the system be designed so

that particulate material cannot enter the storage

area. The use of molecular sieve packets is

recommended, as this is an efficient desiccant.

Chemically pure silica gel may also be used as

a desiccant, provided that filtration is used to

remove particle layers larger than 0.3 micron.

See ANSI/PIMA IT9.11-1998 and ISO 18911-

5

1998

or their latest revisions.

Moisture-Tight Containers

If humidity control of the storage area is not

possible, the storage of film in moisture-tight

containers is required to maintain the film’s

humidity limits. The film must be condi tioned to

the required humidity before being sealed in the

container. This requires the temporary use of an

air-conditioned cabinet or room, or an electrical

dehumidifier. Smaller quantities of film can be

conditioned for two or three weeks in a desi ccator

containing activated silica gel, and then removed

and quickly sealed.

Only properly sealed metal or glass containers

are considered moisture- and gas-proof. They

are preferred when long-term air conditioning is

not practical, when gaseous impurities may

regularly be present, or when low-temperature

storage is used.

Plastic boxes, such as Kodak Microfilm Plastic

Storage Cartons (CAT No. 108-6867—16 mm;

CAT No. 841-8741—35 mm), can be used as

protective containers in controlled areas. They

provide satisfactory protec tion against short-term

problems of moisture or gaseous impurities,

such as might occur with floods, dehumidifier

failures, sm o k e from a fire, or m o is t ure released

by insulation (upon exposure to heat) in certain

fire-resistant safes and cabinets.

With both metal and plastic containers, all

materials (including any gaskets and protective

paints or lacquers) must be non-corroding and

free of peroxides, reactive fumes, and exudations

during storage. Closed containers with frictiontype or threaded twist-on l ids may require no other

seal, but should be tested for imperviousness.

If the container is in an area having the prescribed

humidity and known to be free of harmful gases,

taping is not required. If these condi tions are not

met, taping will provide satis fact o ry protection.

Plastic boxes or cans are preferable, as they

provide more insulation in case of fire.

D-31 June 2002 7

Page 11

Humidification

Humidification is not necessary or desirable

unless the prevailing relative humidity is under

15%—under 30% for polyester-base films—for

long periods of time and unless the film is used

frequently and physical troubles are encountered.

Neither water trays nor saturated chemical

solutions should be used for humidification of

storage cabinets because of the more serious

danger of overhumidification. Even humidification

controlled by instrumentation is risky unless

“fail-safe” devices are installed.

Fungus Growth

Fungus spores are found in the air everywhere.

They germinate and grow under favorable

conditions. When silv er-gelatin f ilms are store d for

any length of time in an atmosphere having a

relative humidity of above 60%, fungus (often

called mold or mildew) has a tendency to grow on

the emulsion surface, the back of the film, or on

the film reel. The higher the relative humid ity, the

greater the chance of fungus attack and the more

abundant its growth. The only real protection

against fungus growth is to make certain that

conditions are unfavorable fo r its growth.

If fungus growth progresses far enough, it can

cause serious and permanent damage to film.

This takes the form of distortion of the emulsion

and eventually causes chemical breakdown so

that the gelatin becomes sticky and readily sol uble

in water. Water or water solutions should not be

used for the removal of fungus growth because

either may lead to disintegration of the image.

Clean affected film by wiping it with a soft plush

or cotton pad moistened with an approved

film-cleaning liquid, such as isopropyl alcohol.

This procedure is described in detail in a separate

Kodak Pamphlet.

Fungus can grow on most surfaces, including

diazo and vesicular films; however, these films are

more resistant to fungu s growth than sil ver-gelatin

films. If necessary, clean these film types by

wiping with a soft, plush or cotton pad, moistened

with water. Do not use solvents on diazo,

vesicular, or thermally processed silver films.

10

Microscopic Blemishes

Some processed silver-gelatin microfilms in

storage for two to twenty years have developed

microscopically small colored spots or blemishes.

The fogged leader at the outside of the roll i s most

frequently affected by the blemishes, which are

generally red or yel low i n c olor a nd s maller i n size

than the image characters (e.g., a typewri tten

letter reduced 20X) on the microfi lm. On occasion,

these spots progress further into the roll and

appear in image areas. A more detailed

description of the blemishes and of the techniques

used in inspecting microfilm is giv en in National

Bureau of Stan dards Handbook 96.

The spots are caused by local oxidation of image

silver , resulting in the formation of minute deposi ts

of yellow- or red-colored colloidal silver.

Possible oxidizing agents entering from outside

the roll of microfilm are aerial oxygen, whose

action on the film is strongly accelerated by

moisture, and atmospheric contaminants such

as peroxides, ozone, sulfur dioxide, hydrogen

sulfide, and nitrogen oxides, which all occur in

industrial atmospheres.

Assuming that your microfilm was processed to

established qualit y control s tan dards, micros copic

blemishes (redox) may occur due to the oxidation

of the metallic silver image by the presence of

oxidants in the storage area: peroxides, ozone,

nitrogen oxides, oil-based paint fumes, organic

solvents, floor-cl eaning agents, cardboard

cartons, excessive temperature and humidity,

or a variety of other materials that generate

peroxides which attack silver microfilms.

The use of low concentrations of potassium

iodide in the fixing bath (0.2 g/L) has been

recommended and has been found to provide

a good degree of protection against these

blemishes.

13

Kodak Microfilm and Prostar Fix

Solutions contain this stability-enhanci ng iodide.

Once the deterioration of the microfilm occurs,

it cannot be reversed. Silver film duplication,

Kodak Brown Toner, and the use of molecular

sieves can be used to stabilize the reaction.

11

12,13

The Kodak Disaster Recovery Laboratory

offers no charge evaluation of suspect microfilm

and can be reached at 1-800-EKC-TEST

(1-800-352-8378) or 1-585-253-3907.

8 D-31 June 2002

Page 12

The conditions under which microfilm is stored

have been found to play an important role in

the development of microscopic blemishes.

Stor age in cool, dry air that is free of oxidizing

gases or vapors is an effective means for

arresting their formation and growth. Stor age

in sealed, metal cans is a sound preventive

measure, if this is practical and consistent with

the humidity requirements.

Additional protection can be obtai ned by adding

molecular sieves to the storage containers

or toning the film with toners such as Kodak

Brown Toner (CAT No. 146-4452—8 oz.;

CAT No. 140-0928—1 gal.). For information

about the use of brown toner as a treatment

to extend the life of microfilm, order Kodak

Publication A-1671.

26

Toning

The life expectancy of your microfil m, processed

to established quality control standards and stor ed

under ideal environmental conditions, can be

many years. However, we do not have control of

environmental surroundings at all times.

Therefore, you should consider taking the extra

precaution of toning your films against oxidative

attack. Toning can be accomplished by use of

sulfide toning agent s such as Kodak Brown Toner.

Other types of toners, such as selenium or gol d,

are also accepted but not commonly used.

ANSI/PIMA IT 9.1-1998 (ISO 18901) now

recognizes that films toned with toners like

this can still be considered to meet the standards

for records of permanent or long-term value.

Brown toning is a service offered by the

Kodak Disaster Recovery Laboratory.

The lab can be reached at 1-800-EKC-TEST

(1-800-352-8378) or 1-585-253-3907.

Chemical Contamination

Air contaminants may add an oxidizing or

reducing effect to the atmospher e. This in turn

may cause deterioration of the film base and a

gradual fading of the photographic image, as

well as the formation of the microscopic blemishes

mentioned above. Typical contaminants are

paint fumes, peroxides, nitrogen oxides,

hydrogen sulfide, sulfur dioxide, and similar

gases. If an area is to be painted, any films st or ed

there should be removed beforehand and should

not be returned to the area for three months.

The removal of contaminating gases from the

air requires special consideration.

Contaminants can come from illuminating gas,

coal gas, automobile exhaust, and certain

chemical plants. They are present in harmful

concentrations in most in dustrial and ur ban areas.

Other contamination can come from ozone and

ammonia produced by certain photocopying

devices. For this reaso n, a long-term storage v ault

should be located as far as possible from such

areas. When a contaminated atmosphere cannot

be avoided, steps should be taken either to

eliminate the fumes by air conditioning the

storage area or to protect the film from contact

with the atmosphere by sealing it in containers.

In addition to atmospheric contaminants, care

should be taken about other materials kept or

used in the storage area. It has already been

mentioned that nitrate-base films should never be

used for permanent-record films . Furthermore,

such films should never be stored with safety-f il m

records (either in the same room or in rooms

connected by ventilating ducts in the same

building) because the gases given off by

decomposing nitrate film will damage or destroy

images on safety-film records.

5,14,15,16,17

Films not of the silver-gelatin t ype (e.g., di azo and

vesicular) should not be wound on the same rolls,

stored in the same containers, or be in physical

contact with silver-gelatin films. In addition, some

older vesicular films have been known to give of f

acidic fumes and require a separate storage

housing with a separate circulating air system.

4

Avoid using rubber bands around rolls of film,

since residual sulfur from rubber vulcanization

promotes the growth of microscopic blemishes.

Adhesive tapes, tap e splices, bleached papers,

and printing inks also cause undesirable effects.

D-31 June 2002 9

Page 13

Composition of Enclosure Materials

Paper

Paper should be made from rag, bleached sulfite

or bleached kraft pulp with an alpha-cellulose

content greater than 87%. It should be free from

highly lignified fibres, such as ground wood, as

determined by the phloroglucinol spot test .

For paper in direct contact with black-and-white

photographic material, the pH should be between

7.5 and 9.5. The pH should be close to 7.0 when

in direct contac t with colo r or diazo mat erial. There

should be an alkali reserve of at least 2% (m/m).

The alkali reserve should be obtained by the

incorporation of an alkaline earth carbonate.

Neutral or alkaline-sizing chemic als should be

employed and the material should be essentially

free from particle s of m e tal. Glassine envelopes

should not be used.

Adhesive

Some photographic images can be damaged

by adhesives incorporating impurities such as

sulfur, iron, copper, or other ingredients that

might react with image silver or gelatin. Pressuresensitive adhesives and ether-li nked products

should be avoided.

Rubber-based products such as rubber cement

should not be used. Not only might they contain

harmful solvents or plast icizers, but they might be

compounded with photographically damaging

sulfur, usually as a vulcanizer, accelerator, or

stabilizer. Even some “low-desensitizing” or

“sulfur-free” rubbers contain sulfur.

Photographic-quality gelatin and many polyvinyl

acetate and cellulose ester adhes ives are

suitable for use with paper enclosures. Heat

sealing and mechanical sealing should be used

when possible.

Plastic

Suitable plastic enclosure materials are

photographic film support materials such as

uncoated polyester (polyethylene terephthalate)

polypropylene and polyethylene. Chlo rinated

or nitrated sheeting should not be used and

cellulose nitrate, in particular, should be avoided.

Metal

Metal enclosures should be noncorrosive

materials such as anodized alumi num or st ainles s

steel. The use of steel is permissible, provided

that the surface is well protected by lacquer,

enamel, tinning, plating, or some othe r corrosionresistant finish. Lacquer, which might give off

reactive fumes, peroxides, or exudations during

storage should not be used.

Printing Inks

Printing inks are known to cause microscopic

spots in fine-grain silver microfilm; consequently,

there should be no printed matter on the inside of

the filing enclosure. The ink used for imp rinting

the outside of filing enclosures should not bleed,

spread, or transfer, and it should not be a source

of products that attack the photograph or the

enclosure itse lf.

For additional specifications, see ANSI/PIMA

IT9.11-1998

IT9.2-1991

5

(ISO 18911) and ANSI/PIMA

6

(ISO 18903).

Theft Protection

Safes provide good protection against the theft of

valuable records. Where such records are lar ge in

number , vaults of burglar-proof construction may

be required. Theft of important records involves

double peril—that of classified films falling into

unauthorized hands and the complete loss of

valuable information. Protect ion against the latter

can, of course, be provided by storing duplicate

records in another location.

10 D-31 June 2002

Page 14

Processing for Permanence

Silver-Gelatin Films

Processing is one of the most important

factors affecting the potential permanence of

photographic records. The removal of residual

processing chemicals, the exclusion of dirt

contamination, and uniform drying are factors

normally controlled by proper processing.

Processed film, for long-term storage or

permanent records, must meet the requirements

of ANSI/PIMA IT9.1-1992 (R1996) or ISO 189 01.

The ability to meet most of these requirements is

controlled in film manufacture, but films must be

fixed and washed adequately, whether given

conventional or full-r eversal processing, to meet

residual thiosulfate requirements. Films

processed without fixation, such as in halidereversal processes and certain reversal

processes with only redevelopment, may give a

“visible, usable image,” but do not come under the

scope of the long-term storage standards.

If fixing and washing are inadequate, thiosul fates

or silver salts, or both, will be retained by the film.

These can break down, especially under poor

storage conditions, to produce yellow stain in

clear areas and fading in areas containing

image silver.

Fixing Baths

In the fixing step, undeveloped silv er-halide

crystals in the emulsion are converted to soluble

silver compounds which c an be washed away wi th

water. The chemicals most commonly used for

fixing are sodium or ammonium thiosulfate

(commonly called “hypo”). The fixing bath may

also contain other chemicals to maintain a

desirable pH, provide hardening, stabilize the

solution, protect the image from microscopic

blemishes, etc.

For maximum washing efficiency, a non-hardening

fixer followed by a non-oxidizing washing aid,

such as Microfilm Clearing Bath and Replenisher

should be used. (Call Solutek at 1-617-445-5335

to order CAT No. 414-24). Hypo eliminators

containing oxidizing agents, such as peroxide,

should be avoided. Oxid izing agents may promote

image deterioration.

To make sure that there is enough time for the

fixing reaction to be completed, specific

recommendations for each type of film should

be followed. Undeveloped silver halides are

dissolved by the fixer as complex ions of silver

and thiosulfate. As the silver content of the fixer

increases with processing, the silver -thiosulfate

complex becomes increasingly dif ficult to wash

from the film. This can be avoided by frequent

replacement or proper replenishment of the fixing

bath or by in-line recirc ulating electrol ytic recovery

of silver from the fixer.

2

Recovery of silver from fixer is advisable for

reasons of economics, conservation and ecology.

There are three principal methods of silver

recovery:

and sulfide precipitation. For additional

information, refer to Kodak Publication J-212.

18

metallic replacement, elec trolytic

Washing

Adequate washing is essential to the p ermanence

of silver-gelatin microfilm. After all undeveloped

silver halide is converted, the emulsion is still

saturated with fixing bath and some dissolv ed

silver compounds. If these are not removed by

washing, they will slowly decompose and attack

the image, causing discoloration and fading.

The effect is accelerated greatly by high humidity

and temperature. The smaller the grain size of

the image, the greater this reaction is. Microfilms,

being very fine grained, are very sensitive to

this effect.

For good washing, a rapid flow of fresh water

should be used. The water should be filtered to

remove dirt particles. To improve washing,

countercurrent and spray systems are frequently

used in processing-machine constructi on.

Washing efficiency decreases rapidly wit h

decreased temperature and is very low

at temperatures below 16°C (60°F). High

wash-water temperatures produce the most

efficient washing, but emulsion reticulation can

result if the wash-water temperature is too high

and not kept close to that of the other processing

solutions. In some cases, extremely soft water

can also cause reticulation. In the case of

contained chemical kits such as the Kodak

Miniprocessor, the manufacturer's recommended

film processing capacity should not be exceeded.

23

D-31 June 2002 11

Page 15

Squeegees

It is important to use an adequate squeegee

where the film leaves the water wash and enters

the drying section. Otherwise, res idual water

droplets will dry and form visible sur face defects

and, in some cases, caus e physical stick ing of t he

film laps. In wound-up rolls, these spots may

provide places where microscopic blemishes can

form. Inspect squeegees regularly (particularly

blade and roller types) to make sure that they do

not cause film scratches.

Drying

Drying should be uniform. The drying air should

be filtered so that airborne particles of dirt or

potentially harmful chemical dust s, often present

in processing laboratories, will not become

imbedded in the emulsion while it is t acky.

In machine processing, the recommendations of

both the equipment and film manufacturer for

operating conditions and processing chemicals

should be followed.

In other modes of processing, the following factors

are involved.

Washi n g Ai ds

Using a washing aid, such as Kodak Hypo

Clearing Agent (CAT No. 146-4254—5 gal.) or

Kodak Microfilm Clearing Bath and Replenisher,

greatly increases both the rate and thoroughness

of hypo removal during the washing step.

After fixing, the film is first rinsed to remove the

major portion of hypo; nex t, the film is treated in a

Kodak Microfilm Clearing Bath and Replenisher;

then it is given a final wash.

Residual Hypo Test

The accepted criterion for adequate washing is

the methylene blue method described in ANSI/

PIMA IT9.17-1998.

the silver densitometric method, which has been

suggested by the Association for Information and

Image Management (AIIM) as a simpler and less

expensive alternative. If the silver densitometric

density difference is 0.02 or less, AIIM considers

that the methylene blue requirements for

extended-term storage record films have been

met. In both methods, a clear area of the film is

tested and residual hypo tests may be run up to

two weeks after processing. A simpler, but less

sensitive, method is the use of the Kodak Hypo

Test Kit (CAT No. 196-5847). This test gives an

indication of residual hypo, but it should not be

used as a measurement for meeting the

requirements of the ANSI specification.

NOTE:For satisfactory residual hypo levels in

films, both fixing and washing must be

acceptable—inadequacies in one cannot

be compensated by the other.

19

IT9.17-1998 also describes

Residual Silver Compound Test

ANSI/PIMA IT 9.17-199819 and ISO 18917-1999

contain a test designed to indicate residual silver

salts in the film. Such salts are an import ant cause

of image layer degradation in aged-processed

photographic films.

Protective Coatings

It should be recognized that while lacquers and

other coatings have advant ages for working pri nts

receiving hard use, they are not within the scope

of the ANSI long-term storage specifications.

NOTE:The use of hypo eliminators, such as

Kodak Hypo Eliminator HE-1, is not

recommended for microfilm because

some hypo eliminators contain oxidizing

agents that can contribute to the

formation of emulsion blisters and

microscopic blemishes.

12 D-31 June 2002

Page 16

Processing of Other Film Types

Special Storage and Hazards

Thermally Processed Silver (TPS)

This film should be processed in accordan ce

with the manufacturers’ recommendations for

optimum image stability. ANSI/PIMA IT9.19-1994

and ISO-18919-1999

stability of TPS films.

24

give specifications for

Diazo Films

The proper processing of diazo films can also

affect keeping qualities. In the diazo process,

the film should be processed to completion for

maximum storage stability. ANSI/PIMA IT9.5-

4

1992

and ISO 18905-1999 give specific details

for methods and measurements for proper

development for image stabil ity.

Also, as with conventional silver films, if

processing equipment utilizes squeegees and

dryer chambers, regular inspections should be

made to make sure that the process is scratchfree and free from airborne dirt and chemicals.

Vesicular Films

The only variables in processing thermal or

vesicular films are the proce ssing temperature

and time. Insufficient processing can increase

the possibility of fading in the heat of the reader

and potentially shorten keeping life. Processing

within manufacturers’ reco mmend ations should

maximize keeping qualities. In addition to

monitoring process temperature and time,

regular checks should be made to make

sure that scratch-free film is being produced.

ANSI/PIMA IT9.12-1995 and ISO 18912-1999,

“Specifications for S t ability of Processed Vesicular

Film,” discuss the criteria for proper development.

21

Underground Storage

Most large industrial organizations and

government agencies have developed methods

for safeguarding vit al r ecords i n the event of a war

or a natural catastrophe. Many keep their vital

records in underground reposi tories l ocated many

miles from large metropolitan areas. When

microfilm is kept underground in caves, mines,

tunnels, subbasements, or similar locations,

special care should be taken to make certain that

there is adequate control of the relative humidity.

Film should not be stored where the relative

humidity exceeds the limits recommended for

storage. See Table 1 of ANSI/PIMA IT9.11-1998

or ISO 18911-1999.

controlled sa tisfactorily, film must be dri e d (a s

described under “Air Conditioning”), then placed

in a moisture-proof container. The film must also

be protected, as in other types of storage, again st

airborne dirt or chemical contamination.

In underground situations, proper film-storage

conditions can often be achieved by simply

heating the cool, moist air that is present.

For example, conditions in a typical mine may be

10°C (50°F) and 85% relative humidity; by heat ing

the storage area to 21°C (70°F), the relative

humidity is reduced to 40%. Where it is not

practical to lower the relative humidity adequately

by this means, supplementary dehumidification

may be required.

5

If humidity cannot be

Effects of Nuclear Explosio ns

The protection of vital microfilm records against

the effects of nuclear explosions is mostly a

matter of providing sufficient blast and fire

protection. Processed microfilm is essentially

unaffected by radiation, even of the intensity

encountered in the vicinity of a nuclear explosion.

Best protection from blast and fire is afforded

by removing security files from potential target

areas. Storage in underground vault s, with

duplicate copies in dif ferent locations, provides

the greatest security.

D-31 June 2002 13

Page 17

Time-Capsule Storage

Only silver-gelatin fil ms conformi ng to ANSI/ PIMA

IT9.1-1998

2

or ISO 18901-1999 should be used

for time capsules or sealed in cornerstones of

buildings. Film intended for thi s kind of storage

should be conditioned to a low relative humidity

(20-30% is recommended for acetate-base films)

in a conditioning room or chamber. During

conditioning, air should be cir culated against

both roll surfaces. Conditioning times should be at

least two weeks for 16 mm film and f our weeks for

35 mm film. This conforms to ANSI/PIMA IT9.11-

1998 and ISO 18911-1999.

5

During conditioning, the film should be in t he form

intended for final storage (wound on itself or a

glass rod, not on a conventional core or reel)

because the possibility of rapid moisture change

makes it inadvisable to rewind the film after

conditioning. The cap sule should b e loaded in the

conditioning chamber, if possible; if not, the film

should be transferred immediately to t he capsule

and sealed tightly.

The capsule should be a stainless steel cylinder

gasketed cover. When there is more than one roll

of film, it is a good idea to separate rolls with

stainless steel disks of the same inside diameter

as that of the capsule. Cores, reels, or wrapp ing of

any kind should not be included; only the film it self

should be put into the capsule.

Handling and Filing

Film Records

Well-planned filing systems and proper handling

of film records are important in the storage of

records. The custodian should set up safeguards

against loss or misplacement of valuable records

and also make sure that the methods of filing and

handling do not add unnecessary wear to the

records. When films must be used, duplicates

should be made and originals retained in storage.

Interfiling

Microfilm may be subject to interactions when

stored with films of different generic types

(e.g., diazo and silver-gelatin). Do not wind

different generic fil m types on the same rol l or

store them in the same container. Diazo and

silver-gelatin microfil ms should be stored

separately before and after processing.

Diazonium salt gases emitted from Diazo

microfilm (pre- and post-process) can be

detrimental to silver-gelatin microfilm.

Continual handling of film, even under favorable

conditions, causes some wear, but wear can be

accelerated greatly by certain factors which can

be controlled. Scratching occurs when film is dirty

or equipment is poorly maintained or wrongly

used. “Cinching” causes scratches and occurs

when film is made to slide layer on layer

(e.g., when the end of a loose roll of film is pul led).

Tearing and fingerprinting occur when equipment

and handling methods are not suitable.

Remove dirt from film by wiping with a lintless

fabric pad moistened with fil m cleaner or its

equivalent. Carry out cleaning operati ons in an

atmosphere of about 50% relative humidity to

minimize the possibility that the film will become

electrostatically charged and attract dust particles.

Another proven method for removing foreign

matter from film is the use of Particle Transfer

Roller (PTR) technology. These rollers are a

polyurethane material whose tackiness and

cushiness pick up dust, hair, and other unwanted

material from a continuous moving film surface.

These rollers can be mounted in-line with most

film operations. They can be cleaned easily with

warm water and mild soap. For more information

about Particle Transfer Roller technology call

FPC, Inc., (an Eastman Kodak Company)

at 1-323-468-5774 or contact your local

Kodak Representative.

Cleanliness of the work space is essent ial to

success in these operations. Static discharge

devices are available for use when handling fi lm

which has been in dry storage. Alternatively, film

can be conditioned to a higher relative humidity

before cleaning and then reconditioned to the

original low relative humidity. Other suggestions

for improving handling operations can be found in

Eastman Professional Motion Picture Films

The Book of Film Care.

22

20

and

14 D-31 June 2002

Page 18

Inspection

The potential life of photographic records depends

largely on atmospheric conditions—temp erature,

humidity, cleanliness—and the manner in which

the film is used. If storage conditi ons are kept

within the limits suggested in Table 3, inspection

of an adequate number of properly selected lot

samples should be made at two-year intervals.

While extended-term records should definitely be

kept under the recommended storage conditions,

film records of medium-term value may have

more leeway in terms of storage humidity and

temperature. Where humidity is not controll ed

closely, film should be inspected more frequently

than at two-year intervals; the inter vals between

inspection should not initially exceed six months

and then, if no deterioration is noted, can be

extended but should not exceed one year.

12

Sometimes film inspection is considered too

laborious and costly and is neglected for many

years—occasionally with unfortunate results.

If it is not always possible to open every film

can or rewind every roll at the recommended

frequency, select a few rolls at random from

the film collection each month for examination.

This approach provides some protection at a

relatively small cost. If there is any indication

that film records are not keeping properly,

storage conditions should be improved and other

protective treatments given the film. Make copies

of films that show signs of deterioration because

deterioratio n , o nc e in itiated, is an irre v e rs ib l e

process that may be restrained, but not

terminated, by improving storage conditions.

Therefore, extensive and frequent inspections

should be made.

ANSI/AIIM standards and technical reports are

available related to the inspection of silver gelatin

microforms. An example can be found in

American National Standard: “Imaging Materials–

Processed Silver-Gelatin Type–Black and White

Film–Specifications for Stability.”

2

Table 1: Applicable Standards for Microfilm

*LE is for polyester-based

**LE is for acetate-based

“Safety Film Specifications” IT9.6/

“Specifications for Microfilms on

Polyester Base”

and

“... on Acetate Base”

“Methylene Blue Method ...” IT9.17/

“Specifications for Thermally

Processed Silver Microfilms”

“Specifications for Stability of

Diazo Films ...”

“Specifications for Stability of

Vesicular Films”

“Practice for Storage of

Photographic Film”

Silver-Gelatin

Long Term

LE 500*

LE 100**

ISO 18906

IT9.1/

ISO 18901

ISO 18917

IT9.11/

ISO 18911

Thermally

Processed Silver

(TPS)

Long Term

LE 100*

IT9.6/

ISO 18906

IT9.19/

ISO 18919

IT9.11/

ISO 18911

Diazo Vesicular

Medium, Long

LE 100*

IT9.6/

ISO 18906

IT9.5/

ISO 18905

IT9.11/

ISO 18911

Medium, Long

LE 100*

IT9.6/

ISO 18906

IT9.12/

ISO 18912

IT9.11/

ISO 18911

D-31 June 2002 15

Page 19

Film/Type/Parameter

Table 2: Storage Life of Microfilms

Anticipated Storage Life

Medium Term

(Minimum of 10 Years)

Extended Term

(Minimum of 100 Years)

Long Term

(Indefinitely)

Silver-Gelatin Films

Residual Hypo

Residual Silver Salts

All Films—

Storage Conditions

Temperature and

Relative Humidity

Air Conditioning Not necessary

unless film records

are subjected to

frequent or sustained

high humidity (3)

Air Purification Normal Must be free from airborne gases, dirt particles,

Enclosures Not necessary with

moisture control

and/or air conditioning

NOTES:

(1), (2)

—

Not above 0.030 grams

per square meter (1)

No more than perceptible tint by spot stain test.

See Table 3

Essential—including slightly positive air pressure.

and other contaminants.

If proper humidity control is prov ided, plastic or

metal, unsealed, can be used.

If adequate humidity control is not avai lable, only

metal or glass sealed containers are acceptable.

Not above 0.014 grams

per square meter (1)

(1) Expressed as thiosulfate ion.

(2) Specific limits have not been set—the recommended washing should be satisfactory.

(3) Dehumidification may be necessary even though automatic air conditioning is not pract ical.

16 D-31 June 2002

Page 20

Summary of Requirements for

Storage and Preservation of

Records on Kodak Microfilm

Storage Facilities

The type of storage vault, safe, cabinet, or area

selected must be based on the value of the film

records and their intended storage li fe. In gener al,

one roll per container is recommended.

Containers should be stored in metal cabinets.

Cabinets should be spaced in the room so there

are no stagnant air pockets or localized areas

where temperature and humidity may reach

higher levels than the general condition. If

humidity is not controlled, sealed metal or glass

containers are required.

Table 3: Storage Temperature and Relative Humidity

Extended and Long Term Medium Term

Although the same general storage principles

apply to medium-term and long-term storage

records, much greater care must be taken to

obtain maximum protection for long-term storage

records; makeshift or temporary arrangements

should not be considered.

In summary, Table 3 indicates the conditions that

are considered suitable for black-and-white silvergelatin, thermally processed si lver, diazo, and

vesicular Kodak Microfilms.

Film Type Base

Silver-Gelatin Cellulose ester

(Acetate)

Silver-Gelatin Polyester 30–40% 21 69.8 20–60% 25 77

Thermally Processed Silver Polyester 15–30% 21 69.8 20–60% 25 77

Diazo Polyester 20–50%

Vesicular Polyester 15–50% 20 70 20–60% 25 77

Electro-Photographic Polyester 15–50% 20 70 20–60% 25 77

Photo-Plastic Polyester 15–50% 20 70 20–60% 25 77

Color Cellulose ester

(Acetate)

Color Polyester 25–30% 2 35.6 20–60% 25 77

Relative

Humidity

20–50%

20–40%

20–30%

20–50%

20–50%

20-30%

20–40%

Temperature

(Max.)

°C °F °C °F

2

5

7

-10

-3

2

-10

-3

35.6

41.0

44.6

14

26.6

35.6

14

26.6

Relative

Humidity

20–60% 25 77

20–60% 25 77

20–60%

20–60%

Temperature

(Max.)

25

25

77

77

NOTE:If the storage temperature is sufficien tl y low or if the air where the film is to be handled is quite

moist, leave the film in its closed container until it warms up to approximate room temperature.

Otherwise, condensation of moisture will occur on the cold film surfaces.

D-31 June 2002 17

Page 21

References and Bibliography

1. American National Standard: “Technical Report—

Glossary of Document Technologies,” ANSI/AIIM

TR2-1998.

2. American National Standard: “Imaging Materials—

Processed Silver-Gelatin Type Black and White

Film—Specifications for Stability,” ANSI/PIMAIT9.11996 or ISO 18901.

3. American National Standard: “Imaging Materials—

Photographic Films - Specifications for Safety Film,”

ANSI IT9.6-1991 (R1996) or ISO 18906.

4. American National Standard: “Imaging Materials—

Ammonia-Processed Diazo Photographic Film—

Specifications for Stability,” ANSI/PIMAIT9.5-1996 or

ISO 18905.

5. American National Standard: “Imaging Media—

Processed Safety Photographic Film—Storage,”

ANSI/PIMA IT9.11-1998 or ISO 18911.

6. American National Standard: “Imaging Media—

Photographic Processed Films, Plates, and Papers—

Filing Enclosures and Storage Containers,”

ANSI IT9.2-1991.

7. American National Standard: “Protection of Records,”

ANSI/NFPA 232-1995.

8. American National Standard: “Installation of Air

Conditioning and Ventilating Systems,” ANSI/NFPA

90A-1996.

9. American National Standard: “Tests for Fire

Resistance of Record Protection Equipment,”

ANSI/UL 72-1990.

10. “Prevention and Removal of Fungus on Prints and

Films,” Eastman Kodak Company, Kodak Pamphlet

No. AE-22.

11. “Inspection of Processed Photographic Record Films

for Aging Blemishes,” C. S. McCamy , National Bureau

of Standards Handbook 96, January 24, 1964.

12. “Microscopic Spots—A Progress Report,” D. G. Wiest

and R. W. Henn, National Micro-News, 70, 249257,

June 1964.

13. “Microscopic Spots in Processed Microfilm—Their

Nature and Prevention,” D. G. Wiest and R. W. Henn,

Photographic Science and Engineering, 7 (5),

253-261 (1963).

14. “Microscopic Spots in Processed Micr ofilm: The Effect

of lodide,” R. W. Henn, D. G. Wiest, and B. D. Mack,

Photographic Science and Engineering, 9 (3),

167-173 (1965).

15. Fundamentals, ASHRAE Handbook, New York:

American Society of Heating, Refrigerating and Air-

Conditioning Engineers, 1993.

16. HVAC Systems and Equipment, ASHRAE Handbook,

New York: American Society of Heating, Refrigerating

and Air-Conditioning Engineers, 1992.

†

†

17. HVAC Applications, ASHRAE Handbook, New York:

American Society of Heating, Refrigerating and Air-

Conditioning Engineers, 1991.

†

18. Refrigeration, ASHRAE Handbook, New York:

American Society of Heating, Refrigerating and

Air-Conditioning Engineers, 1994.

†

19. “Recovering Silver from Photographic Materials,”

Eastman Kodak Company, Kodak Publication

No. J-10A.

20. American National Standard: “Photography—

Determination of Residual Thiosulfate and Other

Related Chemicals in Processed Photographic

Materials—Methods Using Iodine-Amylose,

Methylene Blue and Silver Sulfide,” ANSI/PIMA

IT9.17-1993 or ISO 18918.

21. “Eastman Professional Motion Picture Films,”

Eastman Kodak Company, Kodak Publication

No. H-1.

22. American National Standard: “Imaging Material—

Processed Vesicular Photographic Film—

Specifications for Stability,” ANSI/PIMA IT9.12-1995

or ISO 18912.

23. “The Book of Film Care,” Eastman Kodak Company,

Kodak Publication No. H-23.

24. “The Technology of Silver Recovery for Photographic

Processing Facilities,” Eastman Kodak Company,

Kodak Publication No. J-212.

25. American National Standard: “Imaging Media (Film)—

Thermally Processed Silver Microfilm—Specifications

for Stability,” ANSI/NAPM IT9.19-1994 or ISO/DIS

14806-1996.

26. “The Effects and Prevention of the Vinegar

Syndrome,” A. Tulsi Ram, David F. Koperl,

Richard C. Sehlin, Stephanie Masaryk-Morris,

James L. Vincent, and Paige Miller, Journal of

Imaging Science and Technology, Vol. 38, No. 3,

249-261, May/June 1994.

27. “Use of Kodak Brown Toner to Extend the Life of

Microfilm,” Eastman Kodak Company, Kodak

Publication No. A-1671.

†

Available from the American Society of Heating,

Refrigerating and Air-Conditioning Engineers,

1791 Tullie Circle NE, Atlanta, GA 30329-2305.

All ANSI Specifications are available from American

National Standards Institute, Inc., 11 W. 42nd St.,

New York, NY 10036 or http://www.ansi.org.

All AIIM Standards are available from Association for

Information and Image Management, 1100 Wayne

Avenue, Suite 1100, Silver Spring, MD 20910 or

http://www.aiim.org.

Kodak Publications are available by calling

1-888-247-1234.

18 D-31 June 2002

Page 22

KODAK Publication No. D-31

CAT No. 811-6386 6/2002

©Eastman Kodak Company, 2002

Printed in U.S.A.

EASTMAN KODAK COMPANY

Document Imaging

Rochester, New York 14650

www.kodak.com/go/docimaging

Kodak, Eastman, Estar, and Prostar are

trademarks of Eastman Kodak Company.

Loading...

Loading...