Page 1

MAXI-SHOT

INSTRUCTION SHEET

INTRODUCTION

The MAXI-SHOT Hand Pump is a wall-mount positive displacement pump that can be easily configured to dispense

different portions of product. The MAXI-SHOT Hand Pump can be configured to dispense either 1 oz. or 1.7 oz. of

product (actual volume may be as high as 2 oz. per shot depending on viscosity and location of concentrate).

INSTALLATION

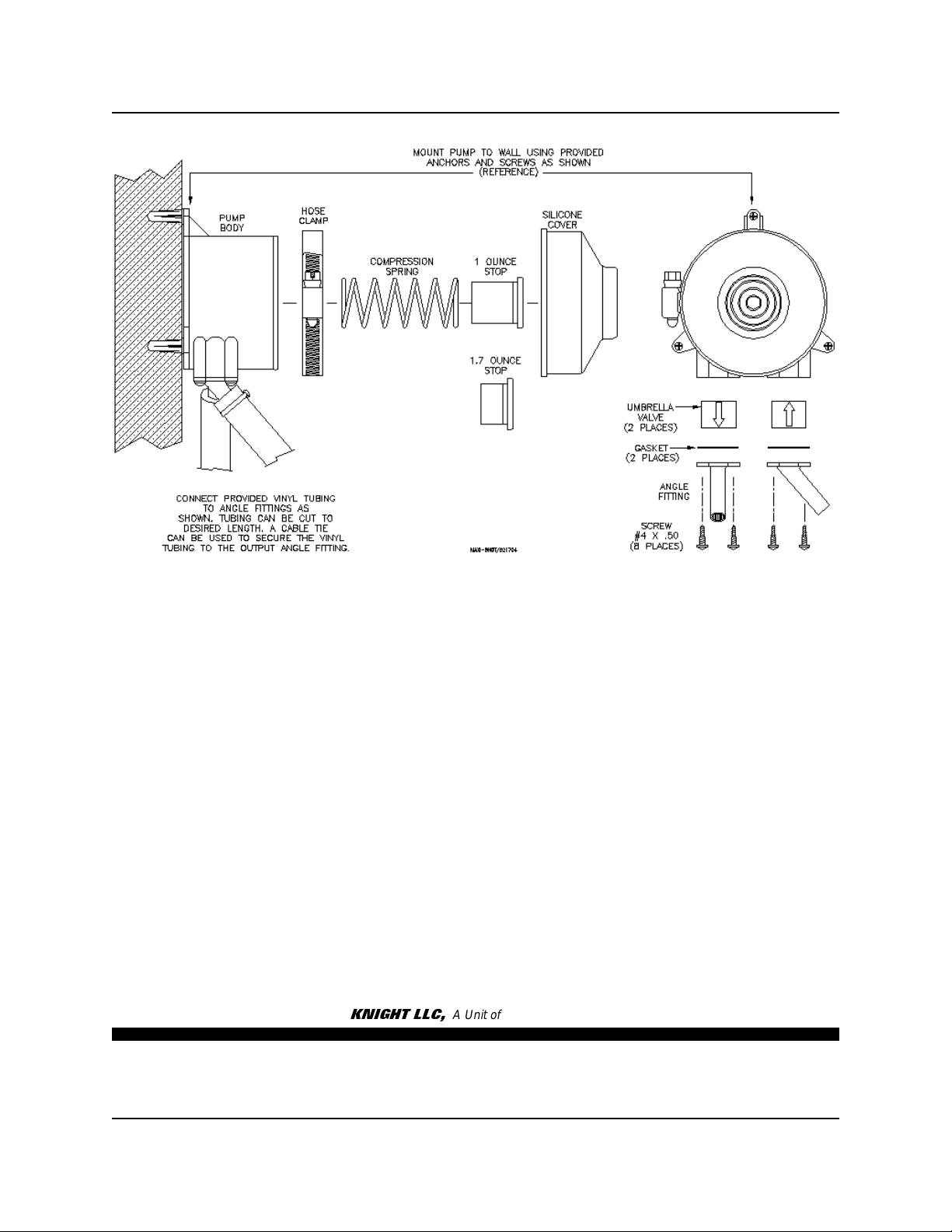

(1) Locate a suitable location on the wall to mount the pump. Mount the pump on the wall using the mounting

hardware provided. Refer to the drawing on the back page. The pump should not be mounted more than 20"

below, or 20" above the product to be dispensed.

(2) Vinyl tubing is provided with the MAXI-SHOT. Slide an end of the vinyl tubing over the input angle fitting. The

input fitting is the angle fitting that extends lateral to the pump body. Place the other end of the vinyl tubing in a

container of the product to be dispensed. The vinyl tubing can be cut to any desired length. A cable tie may be

required to secure the vinyl tubing to the input angle fitting.

(3) Slide an end of the vinyl tubing over the output angle fitting. Secure the vinyl tubing to the output angle fitting with

the cable tie provided. Run the vinyl tubing to the product dispensing location.

(4) The orientation of the angle fittings can be adjusted by removing the screws that secure that angle fittings to the

pump body, rotating the angle fittings to the desired direction, and securing the angle fittings to the pump body.

OPERATION

Product is dispensed by pressing and releasing the silicone cover. The amount of product to be dispensed can be

changed. To change the amount of product to be dispensed, do the following:

(1) Loosen the hose clamp that secures the silicone rubber cover to the pump body. Remove the silicone cover from

the pump body.

(2) A plastic 1 oz. stop is located in the spring. A 1.7 oz. stop is also provided with the pump. The 1.7 oz. stop has

shorter sides than the 1 oz. stop. Replace the stop currently in the spring with the desired stop and reattach the

silicone cover to the pump body.

The check valves are located in the input and output sides of the pump body to prevent accidental flow of product

through the pump body.

CAUTION: Wear protective clothing and eyewear when dispensing chemicals or

other materials. Observe safety handling instructions (MSDS) of chemical mfrs.

CAUTION: When installing any equipment, ensure that all national and local

safety, electrical, and plumbing codes are met.

0900971 Rev: E (02/04)

Page 2

DISCLAIMER

Knight LLC does not accept responsibility for the mishandling, misuse, or non-performance of the described items

when used for purposes other than those specified in the instructions. For hazardous materials information consult

label, MSDS, or Knight LLC. Knight products are not for use in potentially explosive environments. Any use of our

equipment in such an environment is at the risk of the user, Knight does not accept any liability in such

circumstances.

WARRANTY

All Knight controls and pump systems are warranted against defects in material and workmanship for a period of

ONE year. All electronic control boards have a TWO year warranty. Warranty applies only to the replacement or

repair of such parts when returned to factory with a Knight Return Authorization (KRA) number, freight prepaid, and

found to be defective upon factory authorized inspection. Bearings and pump seals or rubber and synthetic rubber

parts such as “O” rings, diaphragms, squeeze tubing, and gaskets are considered expendable and are not covered

under warranty. Warranty does not cover liability resulting from performance of this equipment nor the labor to

replace this equipment. Product abuse or misuse voids warranty.

KNIGHT LLC,

World Headquarters: 20531 Crescent Bay Drive, Lake Forest, CA 92630-8825 (USA) TEL: 949-595-4800, FAX: 949-595-4801, www.knightequip.com

Atlanta Branch:

415 Gees Mill Business Court NE,

Suite 200

Conyers, GA 30013 USA

TEL: 770-760-8777

FAX: 770-761-0199

Toronto Branch:

2880 Argentia Road, Unit 6

Mississauga, Ontario

L5N 7X8 Canada

TEL: 905-542-2333

FAX: 905-542-1536

A Unit of IDEX Corporation

London Branch:

#15 Brunel Centre

Newton Road, Crawley

West Sussex UK RH10 9TU

TEL: 44-1293-615570

FAX: 44-1293-615585

Sydney Branch:

Unit 28, 317-321

Woodpark Rd., Smithfield

NSW Australia 2164

TEL: 61-29-725-2588

FAX: 61-29-725-2025

0900971 Rev: E (02/04)

Amsterdam Branch:

Marssteden 68

7547 TD Enschede

The Netherlands

TEL: 31-53-428-58-00

FAX: 31-53-428-58-09

Loading...

Loading...