Knight Equipment KAP-50TK Installation Manual

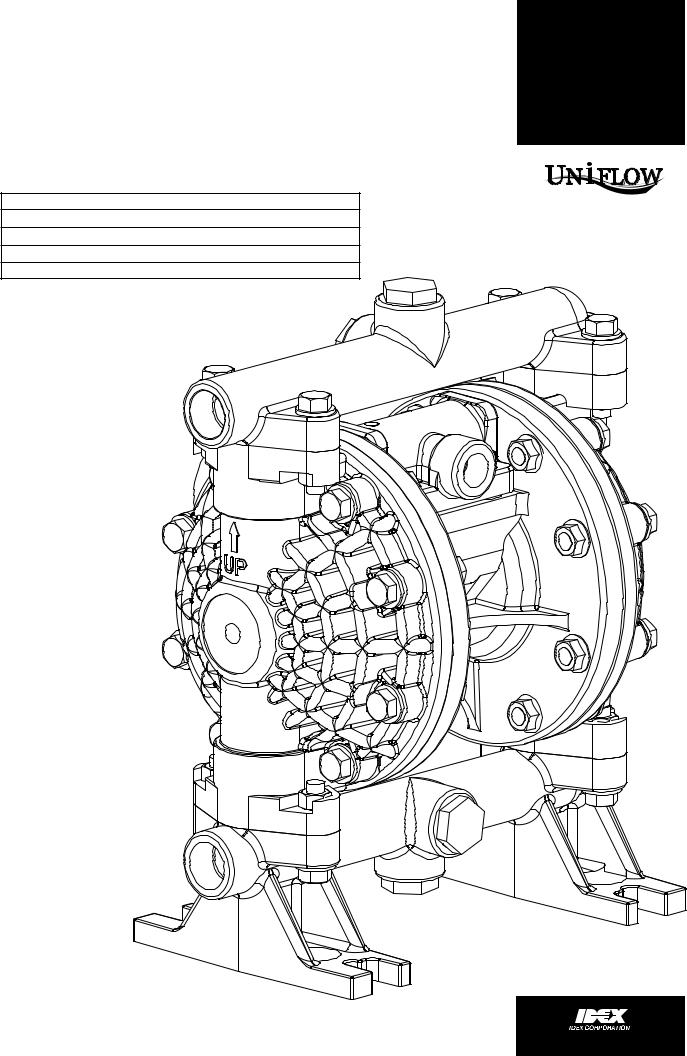

Uniflow 1/2" |

|

KNIGHT |

|

Bolted Plastic Pumps |

|||

Operating Instructions |

|

||

Model |

Part |

Description |

|

KAP-50SK |

1600979 |

PVDF/Santoprene |

|

KAP-50SP |

1600968 |

Poly/Santoprene |

|

KAP-50TP |

1600945 |

Poly/TF |

|

KAP-50TK |

1600986 |

PVDF/TF |

|

Rev: A (05/07)

SAFETY WARNINGS

Read these instructions completely before installation and start-up. It is the responsibility of the purchaser to retain this manual for reference. Failure to comply with the recommendations stated in this manual could result in death, serious bodily injury and/or property damage including damage to the pump and/or voiding the factory warranty.

Correct pump selection is crucial to the pump operation. Please assure pressure, temperature and chemical compatibility before installation. Please consult Knight Equipment, Engineering Specifications, Chemical Compatibility Chart, or your distributor if in doubt about any application.

Operating Limitations for Various Elastomers

Neoprene |

0°F (-18°C) to 200°F (93°C) |

|

Buna-N |

10°F (-12°C) to180°F (82°C) |

|

Nordel |

-60°F (-51°C) to 280°F (138°C) |

|

Viton |

-40°F (-40°C) to 350°F (176°C) |

|

PTFE |

40°F (4°C) to 220°F (105°C) |

|

Polyurethane |

10°F (-12°C) to 170°F (77°C) |

|

XL TPE (Santoprene) |

-20°F ( -29°C) to 300°F (149°C) |

|

FDA Hytrel |

-20°F ( -29°C) to 220°F (104°C) |

|

Operating Limitations for Plastic Pumps

Kynar (PVDF) |

10°F (-12°C) to 225°F (107°C) |

Polypropylene |

32°F (0°C) to 175°F (79°C) |

Maximum temperature limits are based upon mechanical stress only. Certain chemicals and environment conditions significantly reduce maximum safe temperature limits.

Before pump operation, inspect all gasketed fasteners for looseness caused by gasket creep. Re-torque all loose fasteners to prevent leakage. Follow recommended torques

stated in this manual. Failure of the sealing components creates the possibility of jetting or forceful discharge of pumped material at a potentially harmful velocity.

Be certain that approved eye protection and protective clothing are always worn during installation, service, maintenance or when in the vicinity of the pump. Failure to follow these recommendations may result in serious injury or death.

Never allow the piping system to be supported by the pump manifolds or valve housing. The manifolds and valve housing are not designed to support any structural weight and failure of the pump may result.

Take action to prevent static sparking. Fire or explosion can result, especially when handling flammable liquids. The pump, piping, valves, containers, or other miscellaneous equipment must be grounded.

Noise levels can exceed 85 dBA. Take precautions to prevent personal injury due to excessive pump noise.

Do not exceed pump maximum operating pressure (found on label and/or operating manual.)

Before doing any maintenance or repair on this pump, be certain all pressure is completely vented for the pump, suction, discharge, piping, and all other openings.

In the event of a diaphragm rupture, pumped material may enter the air end of the pump and be discharged into the atmosphere. If pumping a product that is hazardous or toxic, the air exhaust must be piped to an appropriate area for safe disposition.

Page 2 |

Rev: A (05/07) |

SPECIFICATIONS AND PERFORMANCE

Knight Uniflow

1/2" Bolted Plastic Pump

Flow Rate

Adjustable to . . . . . . . . 0-14 gpm (56 lpm)

Port Size

Suction . . . . . . . . . . . . . . . . . . . .50" NPTF Discharge . . . . . . . . . . . . . . . . . .50" NPTF Air Inlet. . . . . . . . . . . . . . . . . . 0.375" NPT Air Exhaust . . . . . . . . . . . . . . 0.375" NPT

Suction Lift

Rubber . |

. . . . . . . . . . . . . 20' (6.09 m) Dry |

PTFE. . . |

. . . . . . . . . . . (3.4 m) Dry |

Max. Particle Size (Diameter)

. . . . . . . . . . . . . . . . . . . 0.0625" (1.66 mm) dB(A) Reading . . . . . . . . . . . . . 67.1 dB(A)

Shipping Weights

Polypropylene . . . . . . . . . . 6.8 lbs (3.1 kg) Kynar. . . . . . . . . . . . . . . . . . 10 lbs (4.5 kg) Acetal . . . . . . . . . . . . . . . . . 10 lbs (4.5 kg)

Caution: do not exceed 100 psig (6.9 bar) liquid or air supply pressure.

75 |

|

|

240 |

|

|

|

|

|

|

||

70 |

|

|

|

|

|

|

|

220 |

|

|

|

65 |

|

|

|

|

|

|

|

200 |

|

|

|

60 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

||

55 |

|

|

180 |

|

|

|

|

|

|

||

50 |

|

|

160 |

|

|

|

|

|

|

||

45 |

|

|

|

|

|

|

|

140 |

|

|

|

|

|

|

|

||

40 |

|

|

|

|

|

|

|

120 |

|

|

|

35 |

|

|

|

|

|

|

|

|

|

||

|

|

100 |

|

|

|

30 |

|

|

|

|

|

|

|

|

|

||

25 |

|

|

80 |

|

|

|

|

|

|

||

|

|

|

|||

20 |

|

|

60 |

|

|

|

|

|

|

||

15 |

|

|

|

|

|

|

|

40 |

|

|

|

|

|

|

|

||

10 |

|

|

|

|

|

|

|

|

|

||

|

|

20 |

|

|

|

5 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

||

0 |

|

|

0 |

|

|

|

|

||||

Meters |

Feet |

||||

Displacement Per Stroke, 0.03 Gal. (0.11 L)

|

100 |

4 |

|

AIR CONSUMPTION IN SCFM |

|

|

|

8 |

|||

|

90 |

|

AIR PRESSURE IN PSI |

|

|

|

|

|

|

|

|

PSIin |

80 |

2 |

12 |

SCFM |

M3/HR |

70 |

4 |

6.8 |

|||

|

|

|

|

2 |

3.4 |

Head |

60 |

|

|

8 |

13.6 |

|

|

16 |

27.2 |

||

|

|

|

|

12 |

20.4 |

Discharge |

50 |

|

|

16 |

|

|

|

|

|

||

30 |

|

|

|

|

|

|

40 |

|

|

|

|

|

20 |

|

|

|

|

|

10 |

|

|

|

|

|

0 |

|

|

|

|

0 |

|

|

2 |

|

4 |

|

|

6 |

|

8 |

|

|

10 |

|

12 |

|

|

14 |

|

||||

|

|

|

|

|

|

Capacity in U.S. Gallons Per Minute |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

||||||||||||

|

|

|

|

|

|

|

Capacity in Liters Per Minute |

|

|

|

|

|

|

||||||||||

|

Uniflow 1/2" Bolted Plastic Pump |

|

|

6.25 |

9.30 |

|

|

[158.8] |

[236.1] |

|

|

|

|

6.75 |

|

|

|

[171.5] |

|

|

|

6.12 |

|

|

10.06 |

[155.4] |

|

11.40 |

[255.5] |

|

|

[289.6] |

8.43 |

|

|

|

[214] |

4.30 |

|

|

|

||

|

7.01 |

[109.2] |

|

11.17 |

4.00 |

||

[178.2] |

[101.6] |

||

[283.7] |

|||

|

|

5.30 |

.40 |

2.03 |

Inches [mm] |

[134.6] |

[10.2] |

[51.6] |

|

Page 3

Rev: A (05/07)

Loading...

Loading...