Page 1

Electronic Metering Pumps

Series E PLUS

Key Features

Automatic Control,

•

external pacing, with stop function.

Manual Control

•

stroke length.

Agency approved

•

applications.

Auto-Off-Manual

•

Highly Reliable

•

Circuit Protection

•

Panel Mounted Fuse.

•

Solenoid Protection

•

Water Resistant,

•

Indicator Lights,

•

Guided Ball Check Valve Systems,

•

and enhance outstanding priming characteristics.

Safe & Easy Priming

•

assembly (standard).

Complete Economical Selection

Nineteen distinct models are available, having pressure

capabilities to 300 PSIG @ 3 GPD, and flow capacities to

504 GPD @ 20PSIG, with a turndown ratio of 100:1. Metering

performance is reproducible to within ± 2% of maximum

capacity.

Please refer to the reverse side for Series E PLUS specifications.

available with 4-20 mADC direct or

by on-line adjustable stroke rate and

for demanding

switch.

timing circuit.

against voltage and current upsets.

by thermal overload with auto-reset.

for outdoor and indoor applications.

panel mounted.

with durable leak-free bleed valve

OUTDOOR

to reduce back flow

and indoor

A Unit of IDEX Corporation

System Compatibility

A wide variety of chemicals can be pumped.

Liquid end materials include glass-filled polypropylene

(GFPPL), PVC, styrene-acrylonitrile (SAN), Polyvinylidene

Fluoride (PVDF), PTFE, Hypalon, Viton, ceramic, alloys

and 316SS.

Immediate installation and start-up.

Included as standard accessories with all models are an

injection/back pressure valve assembly and a foot valve/

strainer assembly*, including discharge and suction tubing

(*not avail. with high viscosity connections for >3000 CPS).

Safe and easy priming and valve maintenance.

Included as a standard accessory is a bleed valve

assembly, including return tubing (available

only on those models with tubing

connections and < 240 GPD).

Quick and economical liquid end

maintenance.

Available for every model is a unique

KOPkit®, a convenient, economically

priced, package containing

new cartridge

check valves

and other

important

spare parts.

Operating Benefits

Reliable metering performance. Our guided check valves,

with their state-of-the-art seat and ball designs, provide

precise seating, and excellent priming and suction lift

characteristics. Our timing circuit is highly reliable and, by

design, virtually unaffected by temperature, EMI and other

electrical disturbances.

Rated “hot” for continuous duty. Series E PLUS pumps

continue to meet their specifications for pressure and

capacity even during extended use. That’s because of

our high quality solenoid and special enclosure that

effectively dissipates heat.

High viscosity capability. A straight flow path and ample

clearance between the diaphragm and head enable standard

PULSAtron pumps to handle viscous chemicals up to a

viscosity of 3000 CPS. For higher vicosity applications,

larger, spring-loaded connections are available.

Leak-free, sealless, liquid end. Our diaphragms are of

superior construction—PTFE-faced, bonded to a composite

of Hypalon and fabric layers, and reinforced with a metal

insert for optimum flexibility and durability.

For additional information about PULSAtron’s full-featured Series MP refer to Technical Sheet

No. EMP-027, about the mid-range Series E, Series D & Series A

No. EMP-022, EMP-023 & EMP-025. For information about the economical Series C

Series C, refer to Technical Sheet No. EM P-026 & EMP-024.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

PLUS refer to Technical Sheet

PLUS &

technology

innovation

diversity

e x cellence

Page 2

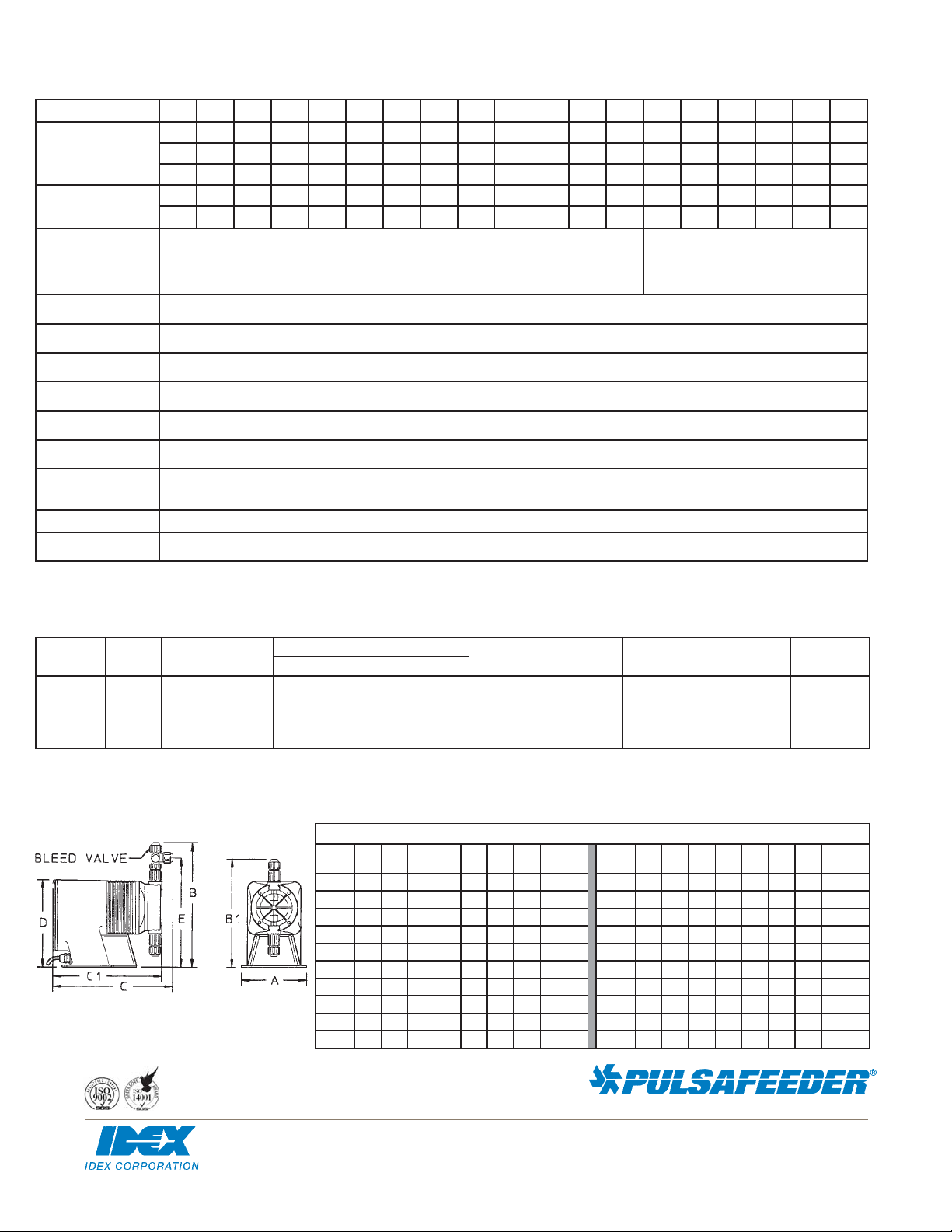

PULSAtron Series E PLUS Specifications

Pressure and Flow Rate Capacity

LEDOM2KPL2BPL2APL3DPL3BPL3APL3KPL4FPL4DPL4BPL4HPL4GPL4EPL5KPL5HPL6HPL7KPL7HPL8HPL

yticapaCHPG31.012.052.005.005.005.006.058.009.000.

lanimonDPG 356 212121410222421424440667021291042006

).xam(HPL5.08.09.09.19.19.13.22.34.38.34.66.60.75.99.119.813

erusserPGISP003052051052051001001052051001052051001051051001055303

).xam(RAB127101710177710177101701017 3.34.22

:snoitcennoCgnibuT

gnipiP

ytilibicudorpeR

yticapac.xamta

SPCxaMytisocsiV .ezisllab/noitcennocenimretedlliwetarwolF.lairetamll

ycneuqerFekortS

MPSxaM

oitaRnwoD

htgneLekortS

tupnIrewoP

:CAV511@

-nruTycneuqerFekortS

oitaRnwoD-nruT

warDtnerruCegarevA

spmA

spmA:CAV032@

sttaWrewoPtupnIkaeP 003

rewoPtupnIegarevA

sttaW:MPSxam@

DO"8/3XDI"4/1

DO"2/1XDI"8/3

DO"61/5XDI"61/3

TPNF"4/1

Important: Series E PLUS - 19 model selections. Digit 1 and 2 (LP) signify product class, digit 3 and 4 signify pressure/flow.

For full model selection information refer to Price Schedule EMP-PS LP.

107.157.158.105.251.300.500.800.0100.52

.039.736.49

DO"2/1XDI"8/3

)YLNO8HPL(DO"4/3xDI"2/1

TPNF"4/1

TPNF"2/1

%2-/+

abSS613htiwCroB,4,3ezisnoitcennoctceles,SPC0003otpuytisocsivroF

skcehcllabdedaolgnirpseriuqerSPC0003nahtretaerG

521

:01

1

1:01

hp1/ZH06-05/CAV511

hp1/ZH06-05/CAV032

0.1

5.0

031

.noitcennocreporprofediuGnoitceleSeeS.

Liquid End Materials

Series

E PLUS

Pump

Head

GFPPL

PVC

SAN

PVDF

316 SS

Diaphragm

PTFE-faced

Hypalon-backed

Seats/ O-Rings Balls

Important: Material Code— GFPPL = Glass-filled Polypropylene, PVC = Polyvinyl Chloride, SAN = Styrene-Acrylonitrile, PE = Polyethylene,

PVDF = Polyvinylidene Fluoride. Hypalon and Viton are registered trademarks of E.I. DuPont Company. PVC wetted end

recommended for sodium hypochlorite.

Dimensions

Check Valves

PTFE,

Hypalon,

Viton

ledoM

.oNAB1BC 1CDE

2APL4.53.01- 8.01-5.79.831

3APL4.56.01- 7.01-5.72.931

2BPL4.53.01- 8.01-5.79.831

3BPL4.56.01- 7.01-5.72.931

4BPL4.56.01- 7.01-5.72.931

3DPL4.56.01- 2.11-5.72.951

4DPL4.56.01- 2.11-5.72.951

4EPL4.56.01- 2.11-5.72.951

4FPL4.56.01- 7.11-5.72.981

4GPL4.56.01-7.11-5.72.981

NOTE: Inches X 2.54 = cm

* the LPH8 is designed without a bleed valve available.

Ceramic,

PTFE,

316SS,

Alloy C

Fittings Bleed Valve

GFPPL

PVDF

PVC

Same as fitting

and check

valve selected,

except 316SS

gnippihS

thgieW

Injection Valve Assembly

Foot Valve Assembly

Same as fitting and

check valve selected

)sehcni(snoisnemiDsulPEseireS

ledoM

.oNAB1BC 1CDE

4HPL2.69.01-2.11-2.85.912

5HPL2.63.11-2.11-2.89.912

6HPL2.63.11-9.11-2.89.912

7HPL1.67.11-9.11-2.83.0112

*8HPL1.6- 9.01-3.112.8- 62

2KPL4.53.01- 8.01-5.79.831

3KPL4.56.01- 7.01-5.72.931

5KPL4.59.01- 7.11-5.75.981

7KPL1.67.11- 2.11-2.83.0112

Tubing

Clear PVC

White PE

gnippihS

thgieW

An ISO Certified Company

A Unit of IDEX Corporation

Standard Product Operations

27101 Airport Road • Punta Gorda, Florida 33982

TEL (941) 575-3800 • TEL 800-333-6677

FAX (941) 575-4085 • FAX 800-456-4085

spotech@pulsa.com •

www.pulsa.com

Brochure No. EMP-021

Printed in the USA 04/04

Loading...

Loading...