Knight Equipment KTM-600 Installation Manual

KTM-

INSTRUCTION SHEET

600 CIRCUIT BOARD

PRIMING

(1) Locate the dip-switch pack on the circuit board and

setswitch#6toRELAY.

(2) Press and hold the Start button until the chemical

line is fully primed, then release the button.

(3) Set switch #6 to SIGNAL (unless you intend to use

relay mode).

PROGRAMMING

Pump Run Time:

(1) Locate the dip-switch pack on the circuit board. Set

switch #6 to SIGNAL, set switch #7 to RUN TIME

andsetswitch#8toPROGRAMMODE.

(2) Using a measuring cup or flask, press Start switch

and release when pump starts. Let the pump run

until desired amount of chemical is dispensed then

press Start switch again to stop. The run time is

now programmed.

(3) Set mode switch #8 to RUN MODE.

Delay Time:

(1) Locate the dip-switch pack on the circuit board. Set

switch #6 to SIGNAL, set switch #7 to DELAY TIME

andsetswitch#8toPROGRAMMODE.

(2) Press Start switch and release when the LED

begins flashing. When the desired delay time has

passed, press the Start switch again. The One Shot

delay time is now programmed. Repeat step if new

delay time is required.

(max run time: 12 min and 42 sec)

(max delay time: 12 min and 42 sec)

OPERATION

Manual activation:

or on the remote switch box for 1 full second. The KTM600 will begin counting down the delay time (if used)

and will then run the pump for the amount of time

programmed. Once the lock-out time expires the pump

will be ready to restart.

Signal activation:

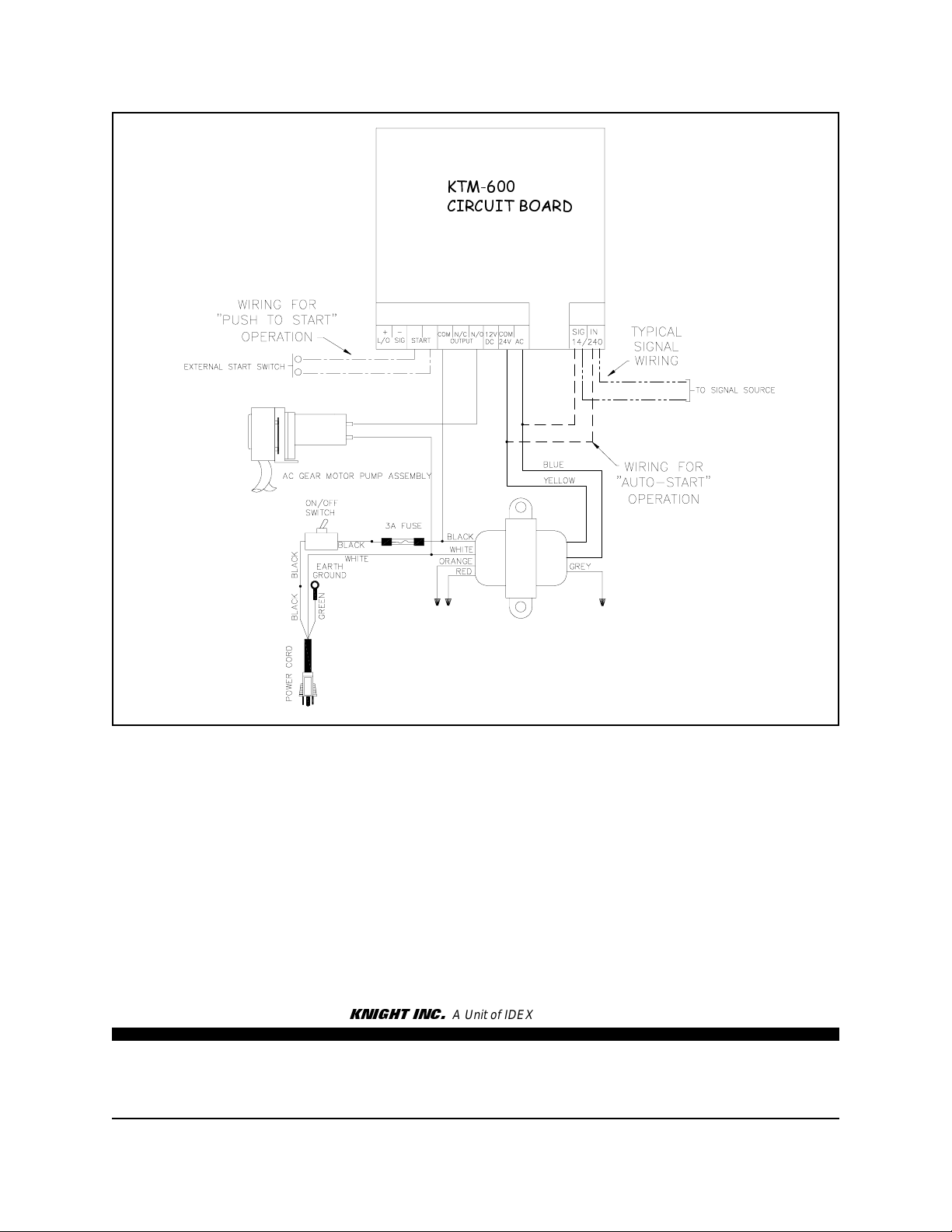

board (wiring diagram on back page) receives a 14-240

VAC trigger signal for at least 5 full seconds, the delay

time (if used) will begin counting down. Then the pump

will run for the amount of time programmed. Once the

lock-out time expires the pump will be ready to restart.

Relay Mode:

activate for as long as an external trigger signal is

present, or for as long as the manual button is

depressed. All other board functions (such as delay

time and lock-out time) are by-passed in relay mode.

Press the Start button on the cover

When the signal input on the circuit

Setswitch#6toRELAY.Thepumpwill

DISABLING THE START BUTTON

There is a jumper marked “JP1” on the circuit board that

can be used to prevent manual activation in certain

applications, or to allow manual activation by remote

push-button only. This jumper only affects the on-board

start button. A remote start button, or trigger signal, can

always be used to activate the pump.

• Jumper ON:the on-board start button is functional.

• Jumper OFF: the on-board start button is disabled.

(3) Set mode switch #8 to RUN MODE.

Lock-Out Time:

This feature defeats consecutive dispensing of product

for a pre-determined interval.Select a combination of

switches1–5toprogramtotallock-outtime.

Example: For 10 minute lock-out, set switches #2 and

#4 to ON with all other switches OFF.

(max lock-out time is 31 minutes)

• For maximumlock-out (31 min) set all switches ON.

• For no lock-out, set all switches OFF.

0906969 Rev: REL (07/02)

KTM-600

CIRCUIT BOARD

DISCLAIMER

Knight Inc. does not accept responsibility for the mishandling, misuse, or non-performance of the described items

when used for purposes other than those specified in the instructions. For hazardous materials information consult

label, MSDS, or Knight Inc.

WARRANTY

All Knight controls and pump systems are warranted against defects in material and workmanship for a period of

ONE year. All electronic control boards have a TWO year warranty. Warranty applies only to the replacement or

repair of such parts when returned to factory with a Knight Return Authorization (KRA) number, freight prepaid, and

found to be defective upon factory authorized inspection. Bearings and pump seals or rubber and synthetic rubber

parts such as “O” rings, diaphragms, squeeze tubing, and gaskets are considered expendable and are not covered

under warranty. Warranty does not cover liability resulting from performance of this equipment nor the labor to

replace this equipment. Product abuse or misuse voids warranty.

KNIGHT INC.

World Headquarters: 20531 Crescent Bay Drive, LakeForest, CA92630-8825 (USA) TEL: 949-595-4800, FAX:949-595-4801, www.knightequip.com

Atlanta Branch:

415 GeesMill Business

Court NE, Suite 200

Conyers, GA 30013 USA

TEL: 770-760-8777

FAX: 770-761-0199

Toronto Branch:

2880 Argentia Road, Unit 6

Mississauga, Ontario

L5N 7X8 Canada

TEL: 905-542-2333

FAX: 905-542-1536

London Branch:

#15 Brunel Centre

Newton Road, Crawley

West Sussex UK RH10 9TU

TEL: 44-1293-615570

FAX: 44-1293-615585

0906969 Rev: REL (07/02)

A Unit of IDEX Corporation

Sydney Branch:

Unit 28,317-321

Woodpark Rd., Smithfield

NSW Australia 2164

TEL: 61-29-725-2588

FAX: 61-29-725-2025

AmsterdamBranch:

Marssteden 68

7547 TDEnschede

The Netherlands

TEL: 31-53-428-58-00

FAX: 31-53-428-58-09

Spain Branch:

Port Ginesta, Local 210

08860 Sitges

Barcelona Spain

TEL: 34-936-342-130

FAX: 34-936-643-477

Loading...

Loading...