Knight Equipment KLE 175GT Installation Manual

'LVKPDFKLQH

./(*7

Three Door Configuration

INSTRUCTION MANUAL

and

PART S MANUAL

CONTENTS

INSTRUCTION MANUAL

INTRODUCTION Page 1

INSTALLATION Page 1

INITIAL OPERATION Page 2

TIME SETTINGS Page 3

JUMPER SETTINGS Page 4

CIRCUIT BOARD BUTTONS Page 4

NORMAL OPERATION Page 4

DOOR CONVERSION Page 5

SCRAP TRAP CONVERSION Page 7

MAINTENANCE SCHEDULE Page 8

TROUBLESHOOTING Page 9

ELECTRICAL DIAGRAM Page 10

WARRANTY Page 11

PARTS MANUAL

ELECTRICAL BOX Page 13

PLUMBING Page 14

WRAPPER Page 15

PAN Page 16

PUMP Page 17

STAND Page 18

ACCESSORY KIT Page 19

Page 12

Headquarters: 20531 Crescent Bay Drive, Lake Forest, CA 92630 U.S.A. (949) 595-4800

Atlanta Branch: 8111 Technology Dr. NE Covington, GA 30014 USA TEL: 770-787-9400

Toronto Branch: 2880 Argentia Road, Unit 6 Mississauga, Ontario L5N 7X8 Canada TEL: 905-542-2333

London Branch: #15 Brunel Centre Newton Road, Crawley West Sussex UK RH10 9TU TEL: 44-1293-615570

Sydney Branch: Unit 28, 317-321 Woodpark Rd., Smithfield NSW Australia 2164 TEL: 61-29-725-2588

Amsterdam Branch: Marssteden 68 7547 TD Enschede The Netherlands TEL: 31-53-428-58-00

Spain Branch: Port Ginesta, Local 210 08860 Sitges Barcelona Spain TEL: 34-936-342-130

(11/10/01) Revision F, EO 4109 Part No. 9641606

INTRODUCTION

The KLE 175 GT dishwasher is designed to provide years of excellent warewash results under many types of

conditions. Each unit is configured as an automatic start dishwasher, meaning that the dishwasher starts when

the doors are closed. The dishwasher includes a three product chemical dispenser located on top of the dishwasher which dispenses liquid detergent, rinse product, and a chemical sanitizer suitable for low temperature

(recommended 140 deg. F applications.) Options and additional features are also available. Contact your nearest Knight representative for more details.

INSTALLATION - Caution –

Access into electrical enclosure must be performed by authorized personnel.

1. Inspect the dishwasher upon initial receipt. Lift the door arm and open the accessory package located inside

the dishwasher. Note that it includes spray arms and other equipment required for installation.

2. Examine the spot where the dishwasher is to be operated. Insure that all electrical and plumbing connections,

as well as dish table placement have been considered for installation. Parameters:

Electrical Water line Drain line

- 120V 20 AMP circuit or

- 240V 10 AMP circuit (not field

20 psi flow pressure 140 deg. F

3/4” FPT on machine

1-1/2” MPT on scrap accumulator

convertible)

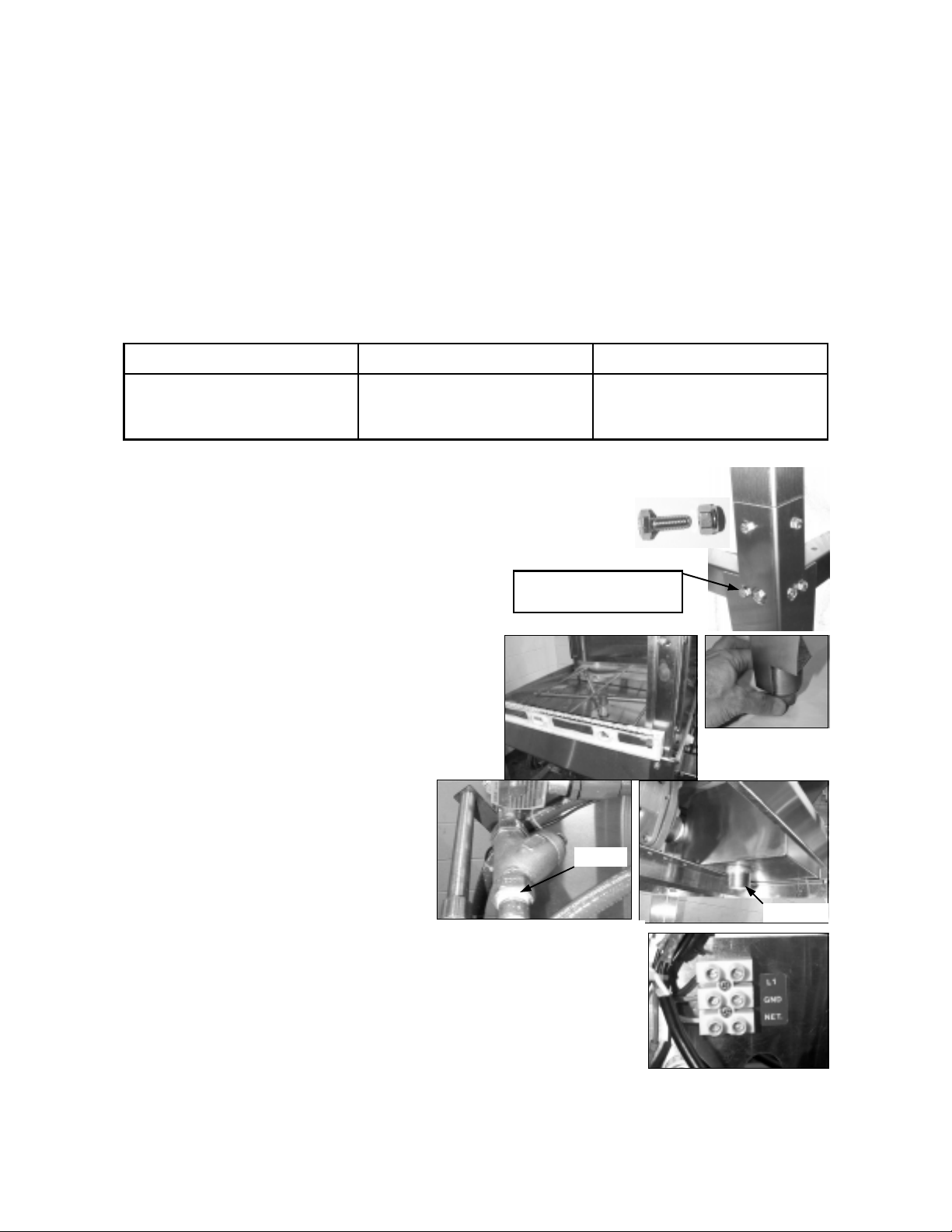

3. Install leg extensions. Each leg requires 4 bolt assemblies, 1/4-20x1/2” long, to secure legs to dish machine. Bolts are located in the accessory kit envelope and on

stand. This job requires two people. Lean the machine back and install two leg

extensions, lean the machine in the other direction and install the other two legs.

4. Install detergent, sanitizer, and rinse tubing to the peristaltic pumps. Use the provided hose clamp ties to secure

delivery tubing to squeeze tubing. Feed outlet tubing to 70

Attached to stand, remove and

reinstall to attach legs

deg. elbow on side of pan directly over the sump. Tubing

installation is easier if done before tabling installation.

5. Place the dishwasher at the spot desired for

normal operation. Level the dishwasher using

adjustable bullet feet at the bottom of the legs.

Install spray arms included in the accessory box.

6. Connect hot water supply line to the 3/4 FPT

line strainer at rear of machine. Ensure that water pressure is sufficient for fill (approx. 10

3/4 FPT

GPM flow @ 20 psi.). Connect drain to 1-1/2”

MPT nipple on scrap accumulator.

7. Make electrical connections (refer to data plate for voltage and current ratings)

to the labeled barrier provided at the inside back of the control box. Run all electrical wire through suitable conduit and insure all connections are made in accordance with local wiring codes. It is recommended that the circuit breaker carrying

the dishwasher load have NO OTHER ELECTRICAL DEVICES connected.

1-1/2 MPT

8. Attach prewash and drying tables to the dishwasher, insuring that sufficient

space is provided for the dishwasher operator. Insure that adjustable legs on

prewash and drying tables have been adjusted for proper drainage of water.

Page No. 1

(11/10/01) Revision F, EO 4109 Part No. 9641606

INITIAL OPERATION

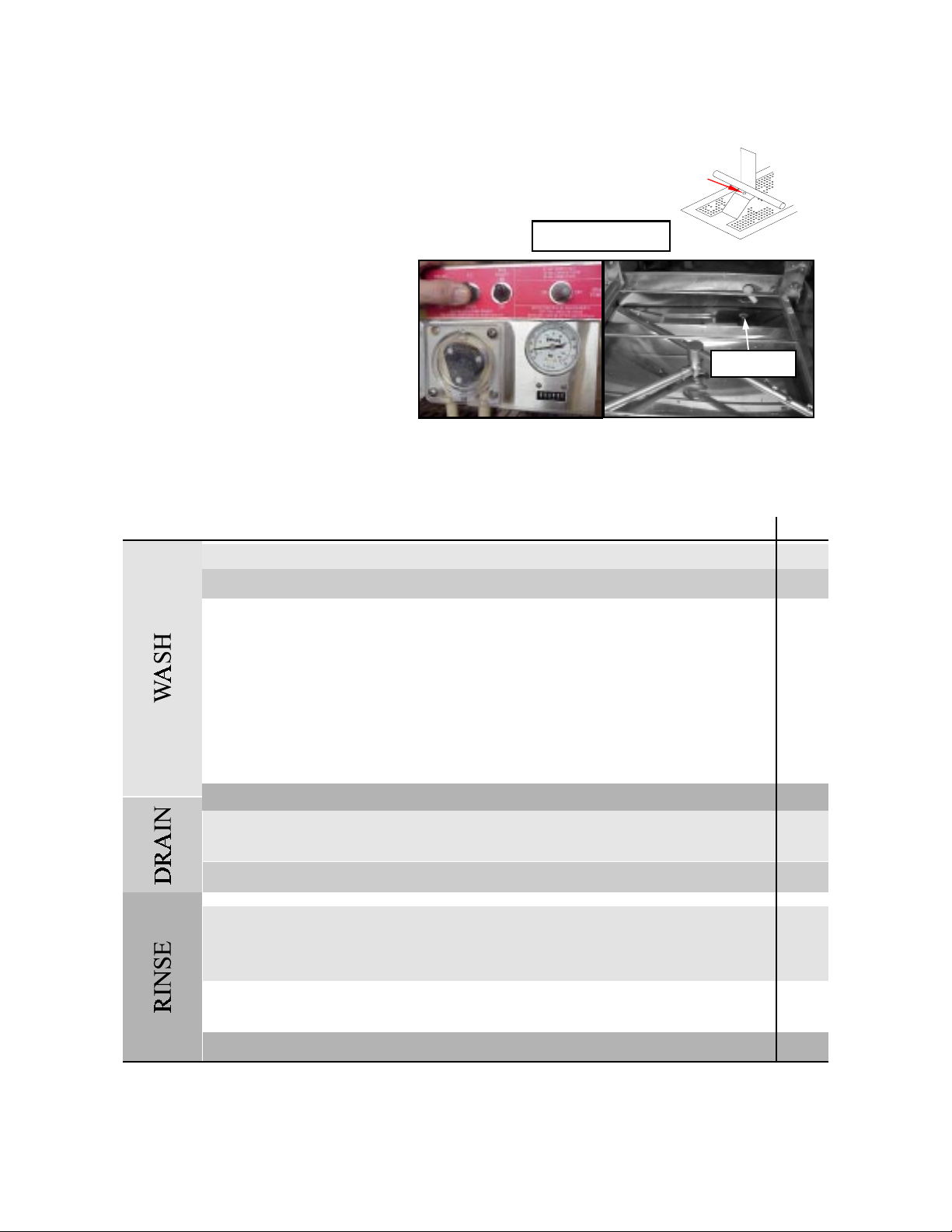

1. Check pump intake screen for proper installation.

2. Start with all switches in the OFF position

Hook tab under rod

3. Turn on main power switch. With

doors closed, flip-up the fill button to

fill the dishwasher with fresh 140 deg.

F water (120 F min.). Fill until level

with top of drain ball tube.

Water level

4. Turn ON the RUN POWER switch and with doors in closed position the machine will start to wash. Allow

machine to run through one cycle and watch machine sequence through the follo wing wash cycle: (90 second

cycle evaluated ). Machine can be adjusted to 120, 90 or 72 second cycles. See below and page 4 for more details. (Cycle adjustments will need to be done by authorized personnel only.

TIME

1 second – wash pump motor turns on

3 seconds – detergent pump runs for adjusted period of time.

0

10

20

30

40

45 seconds – drain opens and machine drains for 15 seconds.

Adjustable 48 to 60 seconds – fresh water valve opens and rinses inside of dishwasher

(drain is still open)

50

60 seconds – drain closes and fill remains open for period of time to fill dish machine.

60

70 seconds – sanitizer and rinse pumps run for an adjustable period of time.

70

70 seconds – wash pump motor stops for three seconds then starts to “burp” the

machine.

80

90 seconds – machine will stop. This is the end of the wash cycle.

90

5. Machine is factory adjusted but may need to be adjusted to local water pressure to operate properly.

Page No. 2

(11/10/01) Revision F, EO 4109 Part No. 9641606

TIME SETTINGS

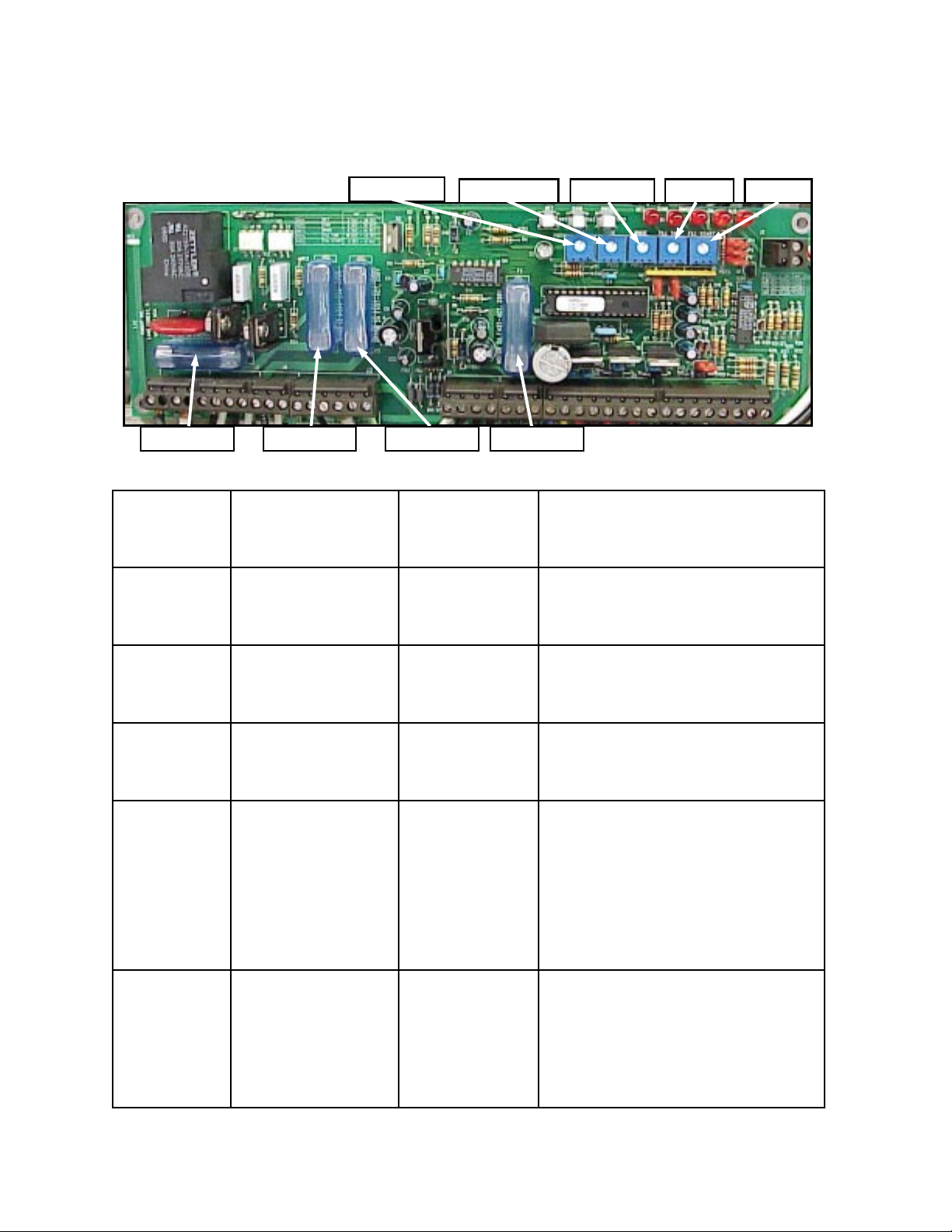

Time settings will need to be done by authorized personnel only. The time settings for detergent pump, fresh water fill,

sanitizer pump, and rinse pump are done inside the control box using the single turn pots. The pots control the time duration of each of the listed components. Use the chart below to make settings.

Det. Pump pot.

Fuse 1 Amp 250V Fuse 1 Amp 250V Fuse 3 Amp 250V Fuse 2 Amp 250V

POT

CONTROL

ACTIVE TIME

IN 90 SECONDS

sanitizer pump pot. rinse pump pot. Fill time pot. Fill start pot.

SPAN OF POT

TIME

ADJUSTMENT

Detergent Pump

at time = 3 seconds

2-30 seconds

COMMENTS

pot turns from 7 o'clock to 5 o'clock or 10 division. Each division is 2.7 seconds. Pump flow is

approximately 1.3 ml/sec.

Sani Pump

Rinse Pump

Fill Start

Fill Time

at time = 70 seconds

0-15 seconds

pot turns 7 o'clock to 5 o'clock or 10 divisions.

Each division is 1.5 seconds. Pump flow is approximately 1.3 ml/sec.

at time = 70 seconds

0-15 seconds

pot turns 7 o'clock to 5 o'clock or 10 divisions.

Each division is 1.5 seconds. Pump flow is approximately 1.3 ml/sec.

at time = 48 to 59

seconds

0-11 seconds

fill start is activated during the fixed drain cycle

(45 to 60 seconds) at the 7 o'clock setting time

is 0 and will start fill at 48 seconds in cycle. At

the 5 o'clock setting time is 11 seconds and will

start fill at 59 seconds in cycle. Fill start is set

according to water pressure and the required

time to rinse debris down the drain. Normal

setting at 20 psi flow pressure is 12 o'clock or

determined by fill start

10-42 seconds

5.5 seconds.

begins at the setting of the fill start. Once fill

start is set the fill time determines the duration

of time fresh water solenoid valve remains open.

7 o'clock setting time is 10 seconds, 5 o'clock

setting time is 42 seconds. Adjust according to

water pressure. Normal setting at 20 psi flow

pressure is 11 o'clock or 15 seconds.

Page No. 3

(11/10/01) Revision F, EO 4109 Part No. 9641606

detergent

push button

sanitizer

push button

rinse push

button

JP4, JP5,

JP6

Buzzer

Conn.

JP1 JP2

JP3

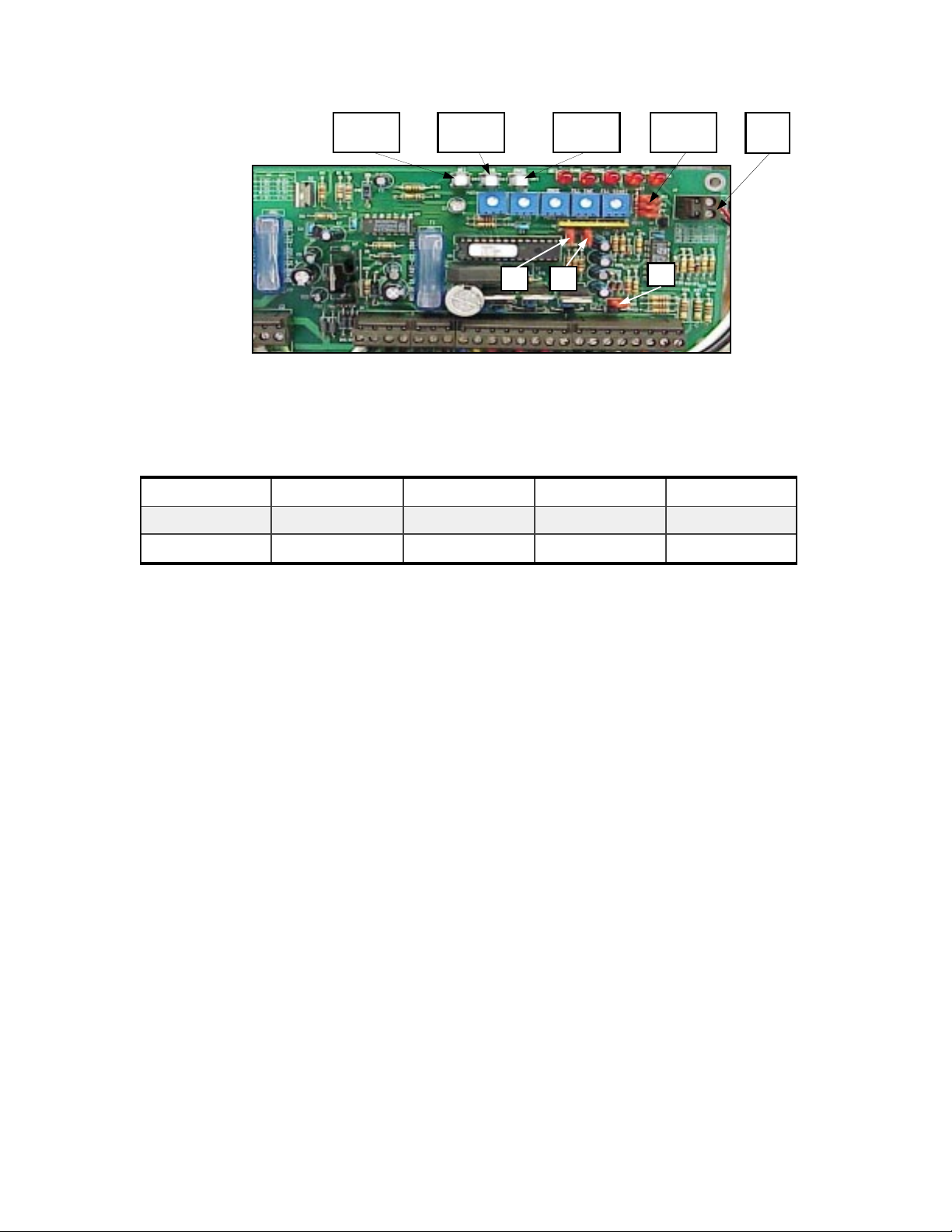

JUMPER SETTINGS

Jumper settings will need to be done by authorized p ersonnel only. JP1 and JP2 control the wash cycle time.

Machine is factory set at 90 second wash cycle. Use table below to activate other wash cycles. Turn OFF main

power switch to change cycle times. Adjust Fill time, Fill start and other Pot's for proper operation.

JUMPER 72 SEC 90 SEC 120 SEC 360 SEC

JP1

JP2

OPEN OPEN CLOSED CLOSED

CLOSED OPEN OPEN CLOSED

NOTE: JP3 MUST BE CLOSED FOR PROPER OPERATION OF KLE 175GT.

JP3 MUST BE OPEN FOR PROPER OPERATION OF KLE 150GT.

JP4, JP5 and JP6 control proof of chemical delivery. They should be closed if proof of chemical delivery kit (P/

N 7501318 optional) is not installed. Machine can be ordered with proof of chemical delivery kit or kit can be

ordered separately.

PRIME CHEMICAL PUMP S

Each chemical pump can be primed simply by turning the delime switch to “ON” position during run time of

pump in wash cycle. This feature eliminates opening the control box lid to prime pumps using push button

prime switches.

CIRCUIT BOARD PUSH BUTTONS

Circuit board control done by authorized personnel only.

Detergent Push Button- Activities detergent pump if the main power switch is ON.

Sanitizer Push Button- Same as detergent

Rinse Push Button- Same as detergent

NORMAL OPERATION

1. Manually remove food debris from dishes, glasses, cups, etc. The better the pre-rinse the better the wash.

2. Place dishes, glasses, cups, etc. in dish rack. Do not stack dishes. Ensure glasses and cups are placed upside

down.

3. With the run power switch ON, close dish machine doors and machine will start. The wash cycle will take 90

seconds (120 or 72 seconds).

Page No. 4

(11/1001) Revision F, EO 4109 Part No. 9641606

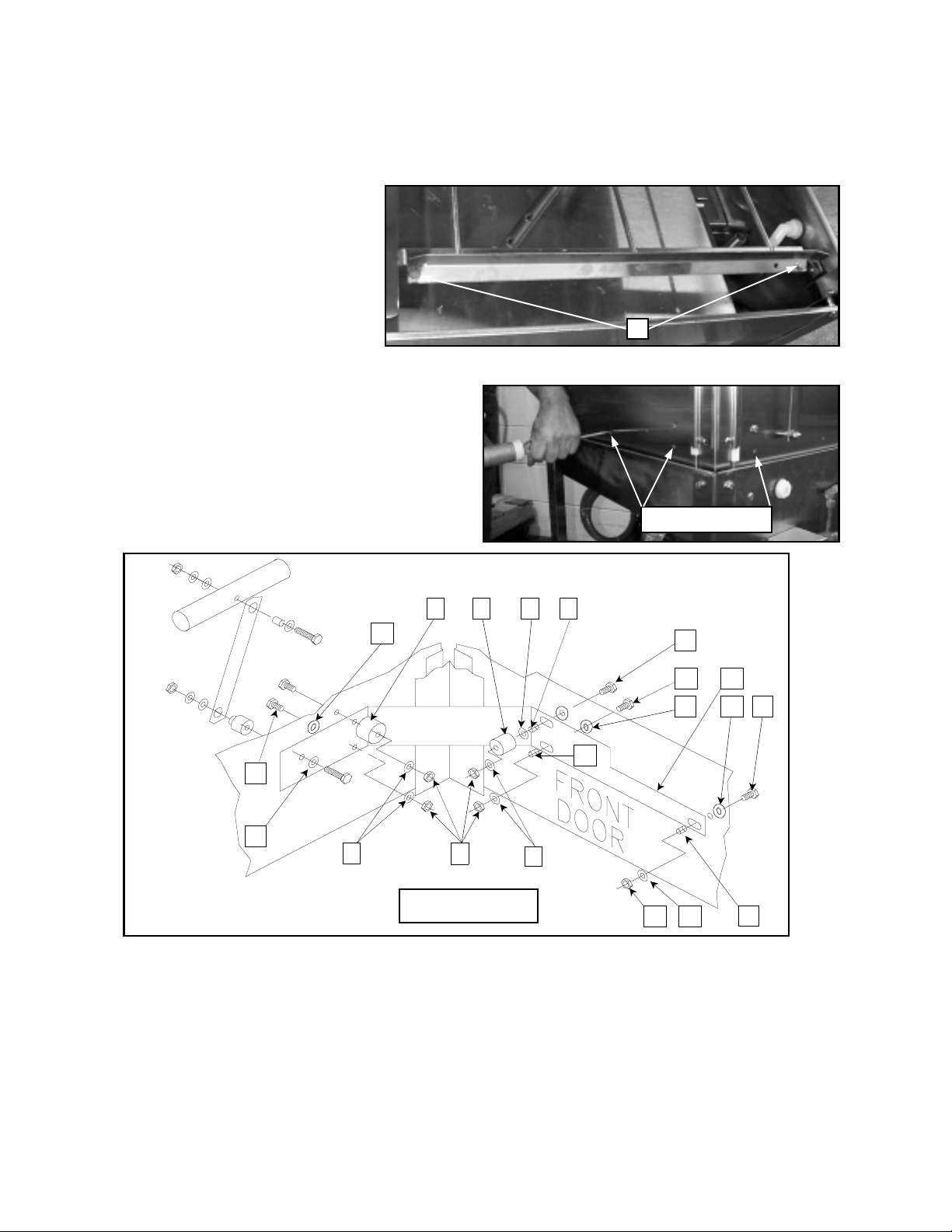

INLINE OR CORNER DOOR CONVERSION

Conversion from inline to corner can be done by changing the location o f the tray stop on the tray rails and installing door conversion bracket and screws in the accessory kit. Two 7/16 wrenches will be needed to make the conversion.

Conversion of the machine is easier

if done before tabling is attached.

Machines are factory set in the

inline configuration.

1. Remove the two (A) bolts/nuts

securing the tray rail stop located

on the tray rail and reposition to

A

desired configuration.

2. Make sure sump screen is in place over the pump

intake tube so no parts fall in to the pump! Remove

the two knockouts on the front door. One is located in

the center and the other is directly below the right

side door stop bumper. Remove one knockout directly

below bumper on right side door.

remove knockouts

9

9

1

5

1

2

INSIDE

4

VIEW

2

8

3

7

3

1

1

6

2

4 6 2

6

3. The accessory kit supplied with the dish machine contains the door strap and fasteners required to convert

the machine. Table below describes part provided for conversion in this kit.

Page No. 5

(11/01) Revision F, EO 4109 Part No. 9641606

Loading...

Loading...