Knight Equipment KLE 150GT Installation Manual

'LVKPDFKLQH

./(*7

INSTRUCTION

AND

PART MANUAL

CONTENTS

INSTRUCTION MANUAL

INTRODUCTION Page 1

INSTALLATION Page 1

INITIAL OPERATION Page 2

TIME SETTINGS Page 3

JUMPER SETTINGS Page 4

CIRCUIT BOARD BUTTONS Page 4

NORMAL OPERATION Page 4

PROOF OF FLOW Page 5

PROOF OF FLOW Page 6

MAINTENANCE SCHEDULE Page 7

TROUBLESHOOTING Page 8

ELECTRICAL DIAGRAM Page 9

WARRANTY Page 10

PARTS MANUAL

ELECTRICAL BOX Page 12

DOOR Page 13

CABINET Page 14

SPRAY ARM Page 15

PLUMBING Page 16

DRAIN Page 17

Page 11

Headquarters: 20531 Crescent Bay Drive, Lake Forest, CA 92630 U.S.A. (949) 595-4800

Toronto, Ontario, Canada: 2283 Argentia Road, Unit 3, Mississauga, Ontario, Canada L5N 5Z2 (905) 542-2333

London England: Unit 15 Brunel Centre, Newton Road, Crawley, West Sussex, U.K. RH102UB (44) 1293-615570

Sydney, Australia: Unit 28, 317-321 Woodpark Road, Smithfield N.S.W., 2164 Australia (61)29.725.2588

Netherlands: 68 Marssteden, 7547 TD Enschede Holland 31.53.4285800

(8/01) Revision A EO 3986 Part No. 9641612

READ ALL INSTRUCTION BEFORE INSTALLATION

INTRODUCTION

The KLE 150 GT dishwasher is designed to provide years of excellent warewash results under many types of

conditions. This unit is configured as a push button start dishwasher. The dishwasher includes a three product

chemical dispenser which dispenses liquid detergent, rinse product, and a chemical sanitizer suitable for low

temperature (recommended 140 deg. F applications.) Options and additional features are also available. Contact

your nearest Knight representative for more details.

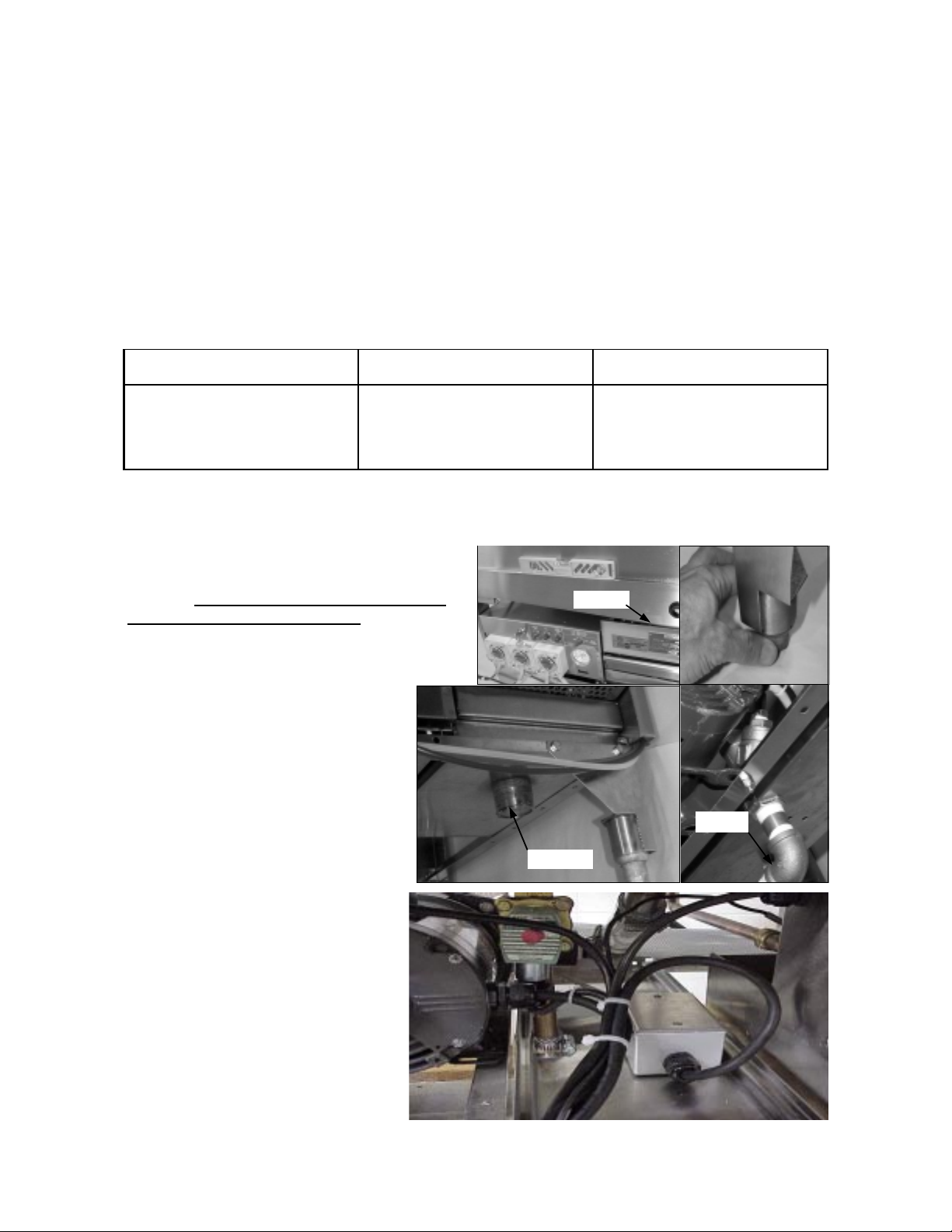

INSTALLATION - Caution –

1. Inspect the dishwasher upon initial receipt. Open the door and locate the accessory package inside the

dishwasher. Note that it includes a spray arm and other equipment required for installation.

2. Examine the spot where the dishwasher is to be operated. Insure that all electrical and plumbing connections have been considered for installation Parameters:

Electrical Water line Drain line

Access into electrical enclosure must be performed by authorized personnel.

- 120V 20 AMP circuit or

- 240V 10 AMP circuit (not field

convertible) connection box on

the tray stand.

20 psi flow pressure 140 deg. F

3/4” FPT lower left side 4 inches

above floor.

1-1/2” MPT on scrap accumulator

Lower right side, 6 inches above

floor.

3. Install detergent, sanitizer, and rinse tubing to the inlet side of the peristaltic pumps. Use the provided hose

clamp ties to secure tubing to squeeze tubing. If machine is ordered with Chem. alarm option, see page 6 for

instructions.

4. Place the dishwasher at the spot desired for normal

operation. Level the dishwasher using adjustable

Name plate

bullet feet at the bottom of the legs. Install spray

arm included in the accessory box.

5. Connect hot water supply line to the 3/4

FPT elbow at bottom-left of machine. Insure that water pressure is sufficient for fill

(approx. 10 GPM flow @ 20 psi.). Connect

drain to 1-1/2” MPT nipple on scrap accumulator to the lower right.

6. Make electrical connections (refer to

data plate for voltage and current ratings)

to the stationary conduit box located on the

1-1/2 MPT

3/4 FPT

stand tray behind electrical box. Remove

cover from stationary conduit box and

make connections (use appropriate wire

size) . Run all electri cal wire through suitable conduit and insure all connections are

made in accordance with local wiring

codes. It is recommended that the circuit

breaker carrying the dishwasher load have

NO OTHER ELECTRICAL DEVICES

and dishwasher is directly connected to

the circuit breaker.

(8/01) Revision A EO3986 Part No. 9641612

Page No. 1

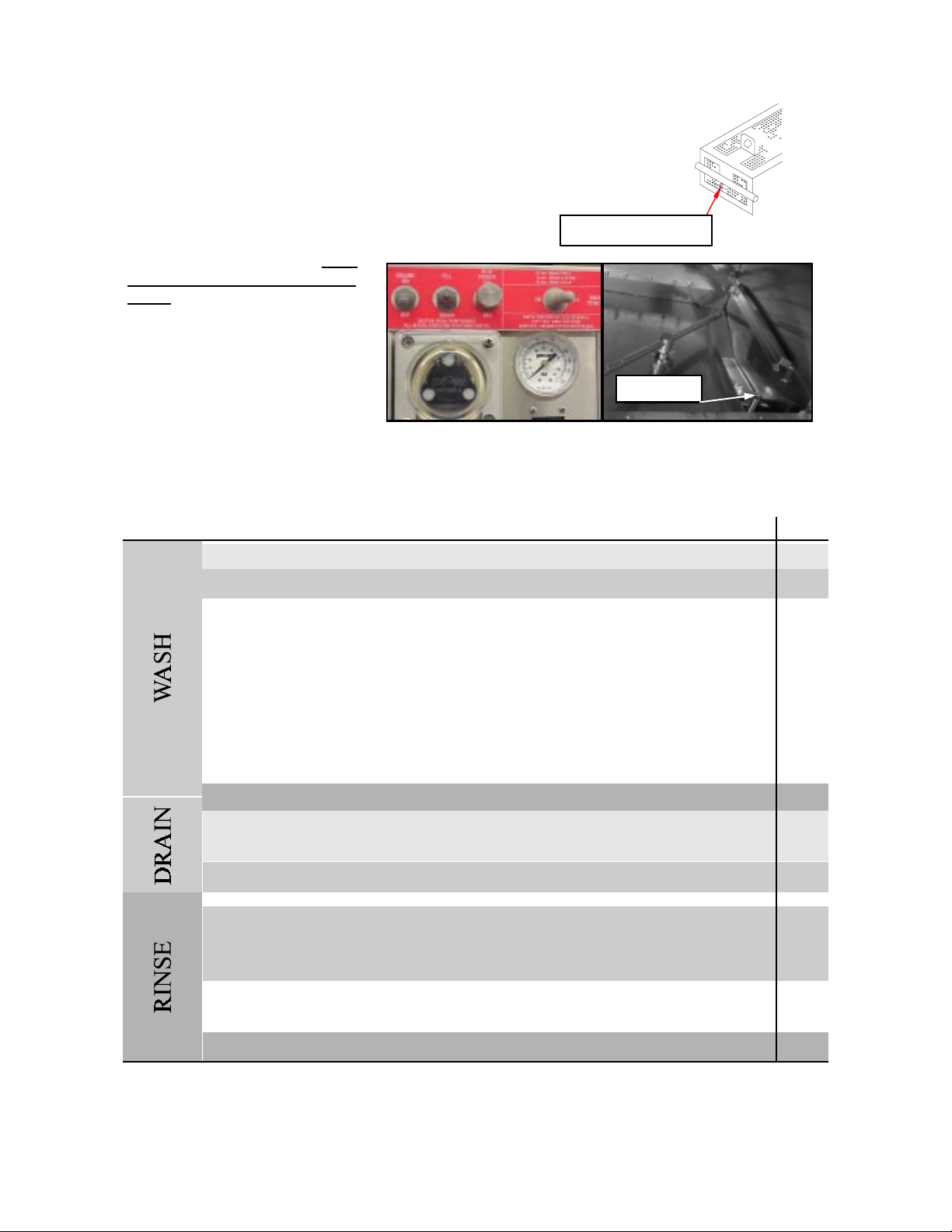

INITIAL OPERATION

1. Check pump intake screen for proper installation.

2. Start with all switches in the OFF position.

Hook tab under rod

3. Turn on main power switch. Open

and close door to reset the control

board. With door closed, flip up the fill

button to fill the dishwasher with fresh

140 deg. F water (120 deg. F min). Fill

until level with top of drain ball stem

(over flow point).

Water level

4. Press the RUN POWER switch and with door in closed position the machine will start to wash. Allow machine to run through one cycle and watch machine seque nce thro ugh the follo wing wash cycle: (90 seco nd cycle evaluated). 120 second cycle consists of 50 second wash, 15 second drain and 55 second rinse. See pages

3,4 and 9 for more details on 72, and 120 cycles.

TIME

1 second – wash pump motor turns on

3 seconds – detergent pump runs for adjusted period of time.

0

10

20

30

40

45 seconds – drain opens and machine drains for 15 seconds.

Adjustable 48 to 60 seconds – fresh water valve opens and rinses inside of dishwasher

(drain is still open)

50

60 seconds – drain closes and fill remains open for period of time to fill dish machine.

60

70 seconds – sanitizer and rinse pumps run for an adjustable period of time.

70

70 seconds – wash pump motor stops for three seconds then starts to “burp” the

machine.

80

90 seconds – machine will stop. This is the end of the wash cycle.

90

5. Machine is factory adjusted but may need to be adjusted to your location water pressure to operate

properly.

(8/01) Revision A EO 3986 Part No. 9641612

Page No. 2

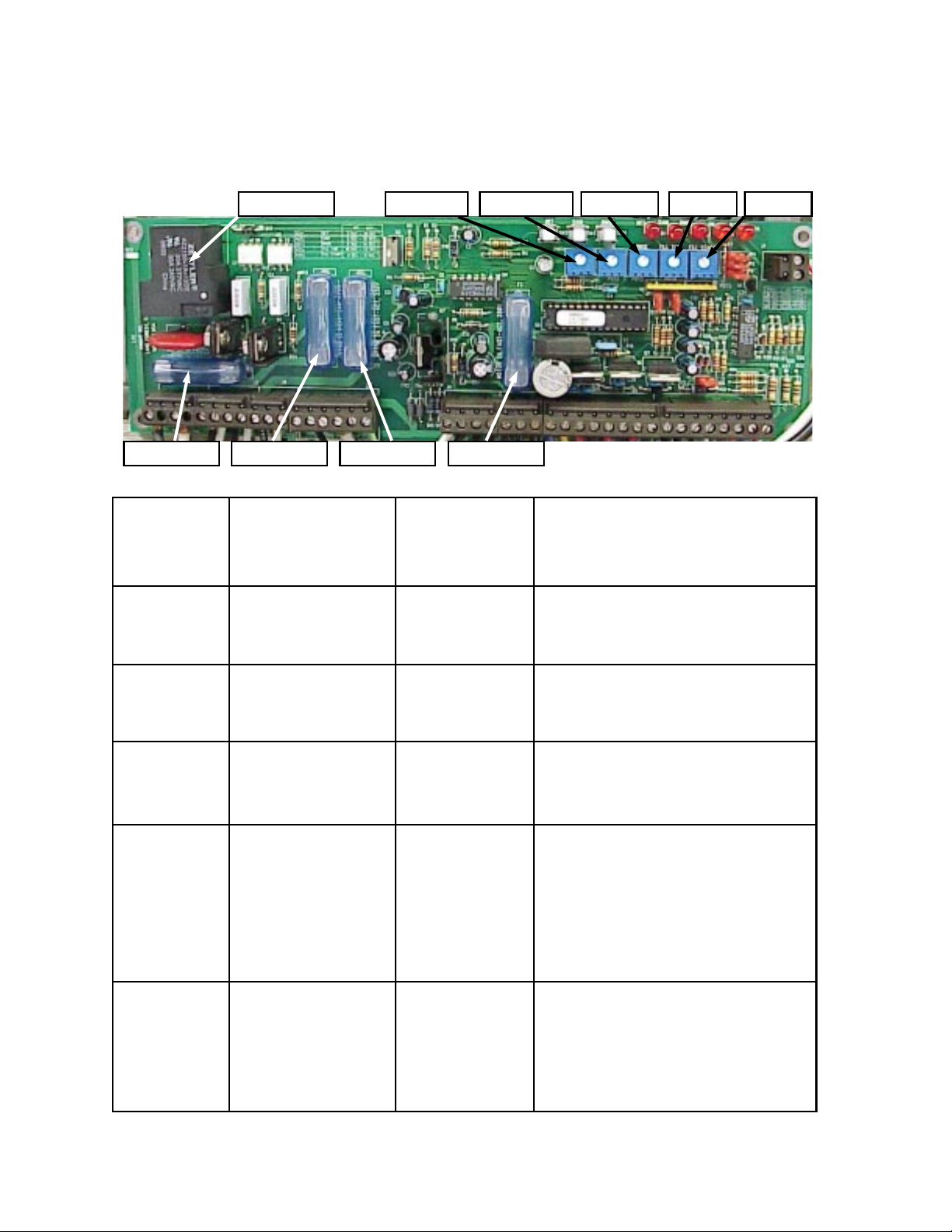

TIME SETTINGS

Time settings will need to be done by authorized personnel only. The time settings for detergent pump, fresh

water fill, sanitizer pump, and rinse pump are done inside the control box using the single turn pots. T he pots

control the time duration of each of the listed components. Use the chart below to make settings.

POT

CONTROL

Detergent Pump

Pump motor relay sanitizer pump pot rinse pump pot Fill time pot Fill start pot

ACTIVE TIME

IN 90 SECONDS

at time = 3 seconds

Det. Pump pot

SPAN OF POT

ADJUSTMENT

2-30 seconds

FUSE 2A, 250V FUSE 2A, 250 V FUSE 1A, 250V FUSE 1 A, 250 V

TIME

COMMENTS

pot turns from 7 o'clock to 5 o'clock or 10 division.

Each division is 2.7 seconds. Pump flow is approximately 1.3 ml/sec.

Sani Pump

Rinse Pump

Fill Start

Fill Time

at time = 70 seconds

at time = 70 seconds

at time = 48 to 59

seconds

determined by fill start

0-15 seconds

0-15 seconds

0-11 seconds

10-42 seconds

pot turns 7 o'clock to 5 o'clock or 10 divisions. Each

division is 1.5 seconds. Pump flow is approximately

1.3 ml/sec.

pot turns 7 o'clock to 5 o'clock or 10 divisions. Each

division is 1.5 seconds. Pump flow is approximately

1.3 ml/sec.

fill start is activated during the fixed drain cycle (45

to 60 seconds) at the 7 o'clock setting time is 0 and

will start fill at 48 seconds in cycle. At the 5 o'clock

setting time is 11 seconds and will start fill at 59

seconds in cycle. Fill start is set according to water

pressure and the required time to rinse debris down

the drain. Normal setting at 20 psi flow pressure is 12

o'clock or 5.5 seconds.

begins at the setting of the fill start. Once fill start is

set the fill time determines the duration of time fresh

water solenoid valve remains open. 7 o'clock setting

time is 10 seconds, 5 o'clock setting time is 42 seconds. Adjust according to water pressure. Normal

setting at 20 psi flow pressure is 11 o'clock

or 15 seconds.

(8/01) Revision A EO3986 Part No. 9641612

Page No. 3

detergent

push button

sanitizer

push button

rinse push

button

JP4, JP5 JP6

ALARM CONN.

JP1 JP2

JP3

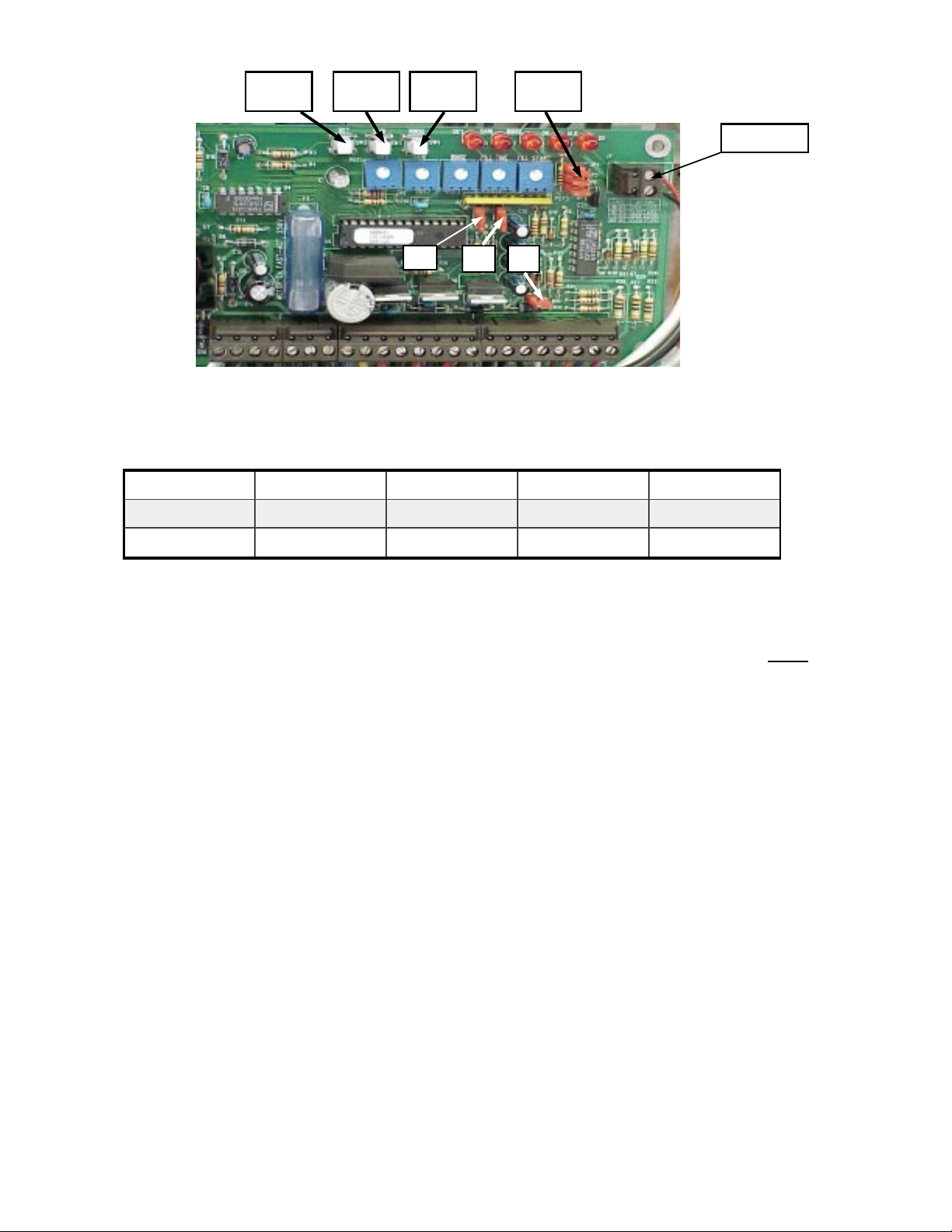

JUMPER SETTINGS

Jumper settings will need to be done by authorized personnel only. JP1 and JP2 control the wash cycle time.

Machine is factory set at 90 second cycle . Use table below to activate other wash cycles. Turn OFF main power

switch to change cycle times. Adjust pots for proper operation.

JUMPER 72 SEC 90 SEC 120 SEC 360 SEC

JP1

OPEN OPEN CLOSED CLOSED

JP2

NOTE:

JP3 MUST BE OPEN FOR PROPER OPERATION OF KLE 150GT.

CLOSED OPEN OPEN CLOSED

JP4,

JP3 MUST BE CLOSED FOR PROPER OPERATION OF KLE 175GT.

JP5 and JP6 control proof of detergent, sanitizer and rinse aid delivery respectively. They should be closed

if

proof of chemical delivery kit (P/N 7501318, optional) is not installed. Machine can be ordered with proof of

chemical delivery kit or kit can be ordered separately.

PRIME CHEMICAL PUMP S

Each chemical pump can be primed simply by turning the delime switch to “ON” position during run time of

pump in wash cycle. This feature elements opening the control box lid and holding chemical push button

switches to prime.

CIRCUIT BOARD PUSH BUTTONS

Circuit board control done by authorized personnel only.

Detergent Push Button- Activities detergent pump any time during wash cycle or delime cycle. Active when

main power switch is on. Can be used to prime detergent pump.

Sanitizer Push Button- Same as detergent

Rinse Push Button- Same as detergent

NORMAL OPERATION

1. Manually remove food debris from dishes, glasses, cups, etc. The better the pre-rinse the better the wash.

2. Place dishes, glasses, cups, etc. in dish rack. Do not stack dishes. Insure glasses and cups are placed upside

down.

3. With the main power switch ON, close dish machine door (door must be open and closed after each cycle to

reset the system) and press the run power switch, machine will start. The wash cycle will take 90 seconds (72 or

120 seconds).

(8/01) Revision A EO 3986 Part No. 9641612

Page No. 4

PROOF OF DELIVERY SYSTEM

(OPTION)

PUMP Page 18

DRAIN SYSTEM Page 13

Introduction:

PUMP Page 14

Proof of delivery system is designed to alert the dish washer operator of

Interruptions in flow of liquid chemicals (detergent sanitizer rinse aid).

This option can be ordered with your dishmachine orders or separately

using part number 7501318.

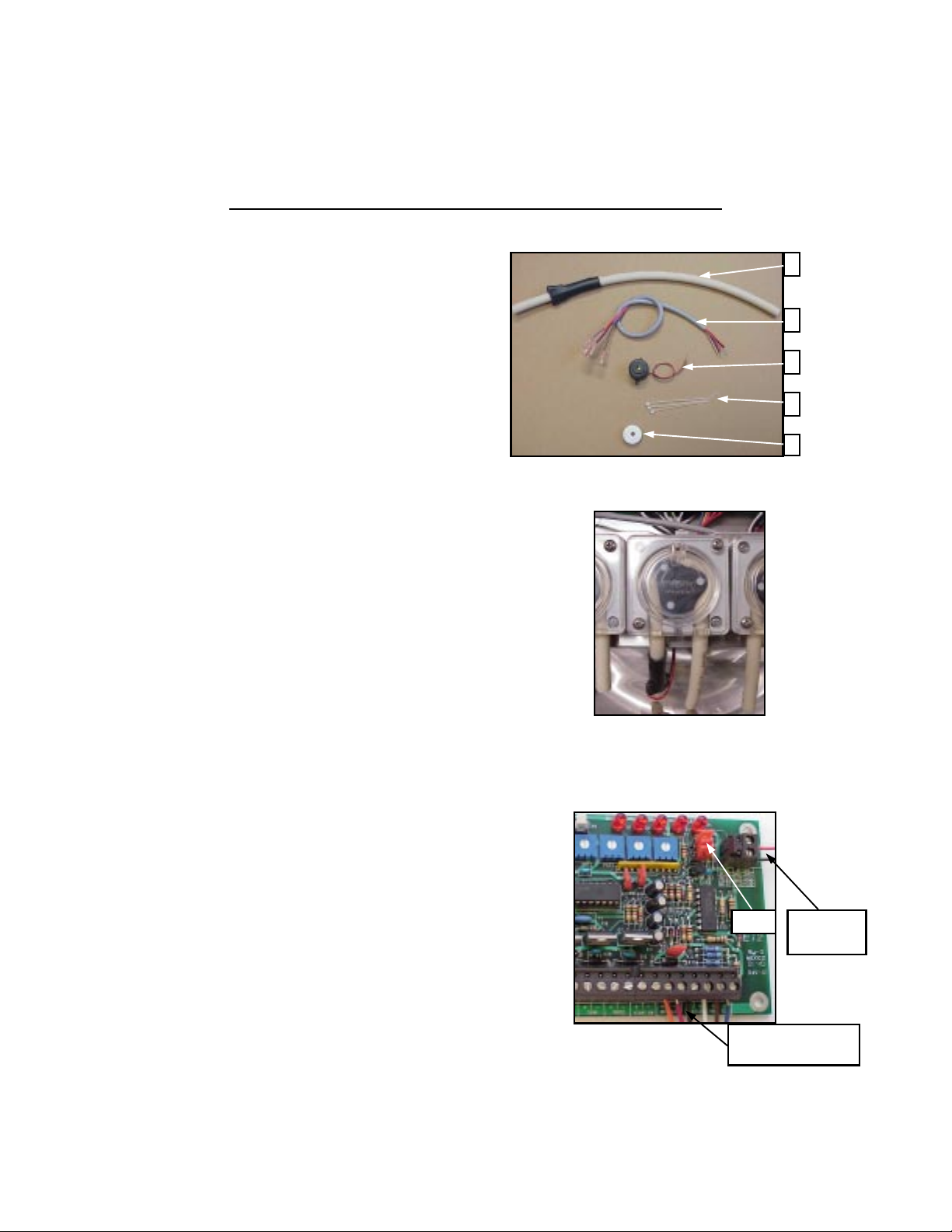

Parts included in this kit:

A- P/N 9640943, Tube probe assembly. (3)

B– P/N 9600027, Cable set assembly. (1)

C– P/N 1900598-1, Buzzer, piezzo, w/ 1 5” lead. (1)

D– P/N 0300121, Cable tie 3.5”. (3)

E– P/N 0300420, Hole plug. (1)

Fig. 1

Installation:

1- Turn main power switch and wall breaker to “OFF” position.

2– Plug all probe tube assembly connectors (A) in cable set

assembly (B) Spade connectors in the following wire color sequences:

Red/orange, white/ black and blue/brown for detergent , sani and

Rinse aid respectively.

3– Replace your pump’s existing squeeze tube with the tube probe assembly

as shown in Fig. 2.

Insert other end of cable set assembly in hole plug (E) and pass through the

Hole on the bottom of control box.

4– Make all chemical wire connections as shown .

Wire color sequences must be followed as in section 3.

Red /orange, detergent connections

White/ black, sanitizer connections.

Blue/ brown, rinse aid connections.

Jumpers JP4 (detergent), JP5 (sanitizer) and JP6 (rinse aid)

must be opened at this time to enable the alarm for each

Chemical.

Note: These jumpers are only opened if you are alarming

Chemicals. If you are alarming one chemical, only

The corresponding Jumper must be opned.

PROOF OF DELIVERY INSTALLATION INSTRUCTIONS

P/N 7501318

Fig. 2

JP4,5&6

Det, Sani and Rinse aid

alarm wire connections

Fig. 3

A

B

C

D

E

Buzzer conn.

JP4,5&6

.

(8/01) Revision A EC 3986 Part No. 9641612

Page No. 5

Loading...

Loading...