Page 1

KNIGHT

Uniflow 1/2"

Bolted Plastic Pumps

Operating Instructions

Model Part Description

KAP-50SK 1600979 PVDF/Santoprene

KAP-50SP 1600968 Poly/Santoprene

KAP-50TP 1600945 Poly/TF

KAP-50TK 1600986 PVDF/TF

Rev: A (05/07)

Page 2

Read these instructions completely before installation and

start-up. It is the responsibility of the purchaser to retain

this manual for reference. Failure to comply with the recommendations stated in this manual could result in death,

serious bodily injury and/or property damage including

damage to the pump and/or voiding the factory warranty.

Correct pump selection is crucial to the pump operation.

Please assure pressure, temperature and chemical

compatibility before installation. Please consult Knight

Equipment, Engineering Specifications, Chemical Compatibility

Chart, or your distributor if in doubt about any application.

Operating Limitations for Various Elastomers

Neoprene 0°F (-18°C) to 200°F (93°C)

Buna-N 10°F (-12°C) to180°F (82°C)

Nordel -60°F (-51°C) to 280°F (138°C)

Viton -40°F (-40°C) to 350°F (176°C)

Polyurethane 10°F (-12°C) to 170°F (77°C)

XL TPE (Santoprene) -20°F ( -29°C) to 300°F (149°C)

FDA Hytrel -20°F ( -29°C) to 220°F (104°C)

Operating Limitations for Plastic Pumps

Kynar (PVDF) 10°F (-12°C) to 225°F (107°C)

Polypropylene 32°F (0°C) to 175°F (79°C)

Maximum temperature limits are based upon mechanical

stress only. Certain chemicals and environment conditions

significantly reduce maximum safe temperature limits.

Before pump operation, inspect all gasketed fasteners for

looseness caused by gasket creep. Re-torque all loose

fasteners to prevent leakage. Follow recommended torques

stated in this manual. Failure of the sealing components

creates the possibility of jetting or forceful discharge of

pumped material at a potentially harmful velocity.

Be certain that approved eye protection and protective

clothing are always worn during installation, service, mainte-

nance or when in the vicinity of the pump. Failure to follow

these recommendations may result in serious injury or death.

Never allow the piping system to be supported by the pump

manifolds or valve housing. The manifolds and valve housing

are not designed to support any structural weight and failure

of the pump may result.

Take action to prevent static sparking. Fire or explosion

can result, especially when handling flammable liquids. The

pump, piping, valves, containers, or other miscellaneous

equipment must be grounded.

Noise levels can exceed 85 dBA. Take precautions to prevent

personal injury due to excessive pump noise.

Do not exceed pump maximum operating pressure (found

on label and/or operating manual.)

Before doing any maintenance or repair on this pump,

be certain all pressure is completely vented for the pump,

suction, discharge, piping, and all other openings.

In the event of a diaphragm rupture, pumped material

may enter the air end of the pump and be discharged into

the atmosphere. If pumping a product that is hazardous

or toxic, the air exhaust must be piped to an appropriate

area for safe disposition.

SAFETY WARNINGS

40°F (4°C) to 220°F (105°C)

Page 2

Rev: A (05/07)

PTFE

Page 3

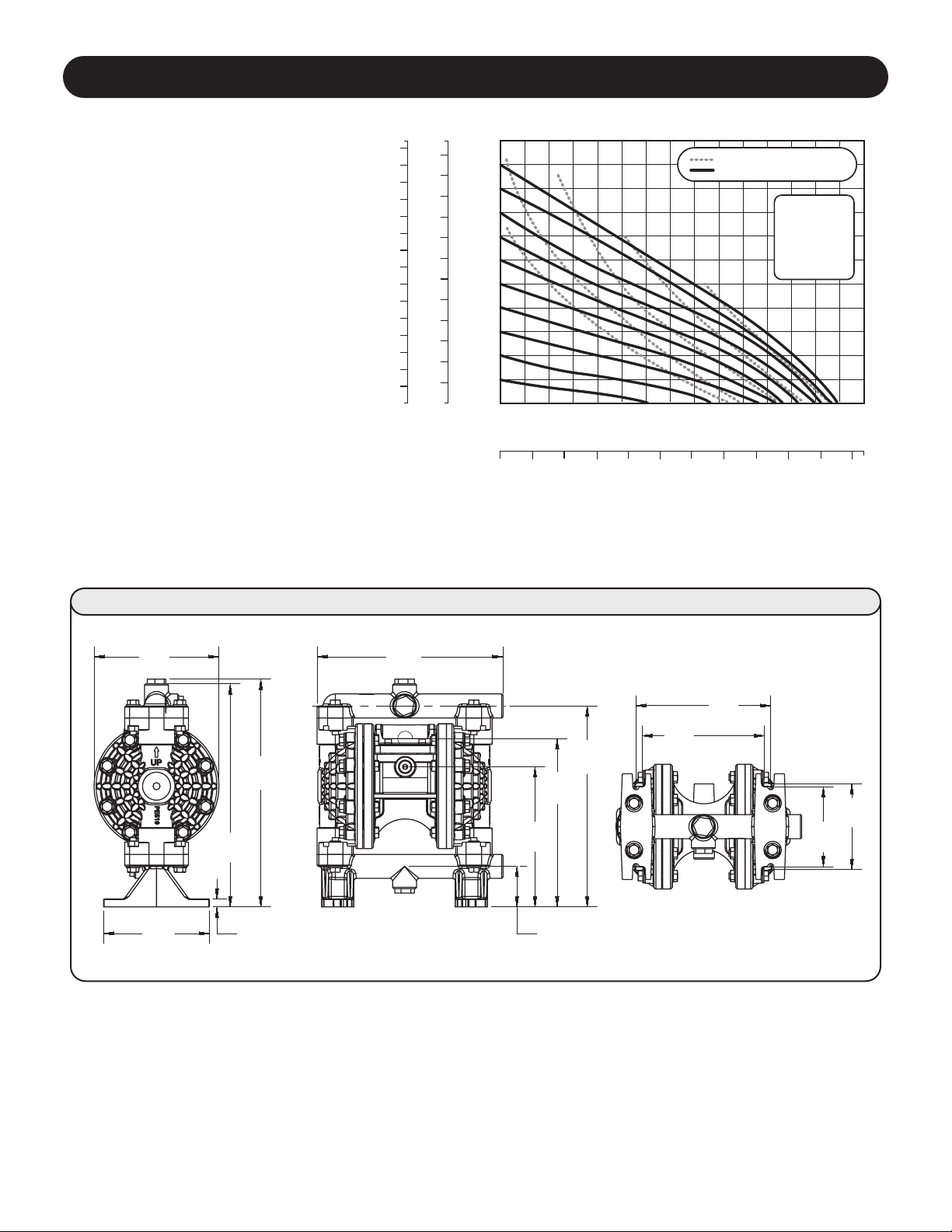

SPECIFICATIONS AND PERFORMANCE

Knight Uniflow

1/2" Bolted Plastic Pump

Flow Rate

Adjustable to . . . . . . . . 0-14 gpm (56 lpm)

Port Size

Suction . . . . . . . . . . . . . . . . . . . .50" NPTF

Discharge . . . . . . . . . . . . . . . . . .50" NPTF

Air Inlet. . . . . . . . . . . . . . . . . . 0.375" NPT

Air Exhaust . . . . . . . . . . . . . . 0.375" NPT

Suction Lift

Rubber . . . . . . . . . . . . . . 20' (6.09 m) Dry

Max. Particle Size (Diameter)

. . . . . . . . . . . . . . . . . . . 0.0625" (1.66 mm)

dB(A) Reading . . . . . . . . . . . . . 67.1 dB(A)

Shipping Weights

Polypropylene . . . . . . . . . . 6.8 lbs (3.1 kg)

Kynar. . . . . . . . . . . . . . . . . . 10 lbs (4.5 kg)

Acetal . . . . . . . . . . . . . . . . . 10 lbs (4.5 kg)

CCaauuttiioonn:: ddoo nnoott eexxcceeeedd 110000 ppssiigg

((66..99 bbaarr)) lliiqquuiidd oorr aaiirr ssuuppppllyy pprreessssuurree..

Meters Feet

Discharge Head in PSI

2106

0

100

90

80

70

60

50

40

30

20

10

0

240

220

200

180

160

140

120

100

80

60

40

20

0

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

128414

40

0

5 101520253035 455055

Capacity in Liters Per Minute

Capacity in U.S. Gallons Per Minute

Displacement Per Stroke, 0.03 Gal. (0.11 L)

4

8

12

16

2

AIR CONSUMPTION IN SCFM

AIR PRESSURE IN PSI

SCFM M3/HR

2 3.4

4 6.8

8 13.6

12 20.4

16 27.2

5.30

[134.6]

6.25

[158.8]

11.40

[289.6]

11.17

[283.7]

.40

[10.2]

2.03

[51.6]

8.43

[214]

10.06

[255.5]

7.01

[178.2]

9.30

[236.1]

6.75

[171.5]

6.12

[155.4]

4.30

[109.2]

4.00

[101.6]

Inches [mm]

Uniflow 1/2" Bolted Plastic Pump

Page 3

Rev: A (05/07)

.. ...........

PTFE.

(3.4 m) Dry

Page 4

Installation

The pump should be mounted in a vertical position.

In permanent installations, the pump should be

attached to plant piping using a flexible coupling on

both the intake and discharge connections to reduce

vibration to the pump and piping. To further reduce

vibration, a surge suppressor next to the pump may

be used.

Suction pipe size should be at least the same

diameter as the inlet connection size, even larger if

highly viscous fluid is to be pumped. If suction hose

is used, it must be of a non-collapsible reinforced

type. Discharge piping should be of at least the same

diameter as the discharge connection. It is critical,

especially on the suction side of the pump, that all

fittings and connections are air tight or pumping

efficiency will be reduced and priming will be difficult.

Make certain the air supply line and connections

and compressor are capable of supplying the

required pressure and volume of air to operate

the pump at the desired flow rate. The quality of the

compressed air source should be considered.

Air that is contaminated with moisture and dirt may

result in erratic pump performance and increased

maintenance cost as well as frequent process “down

time” when the pump fails to operate properly.

Pump Operation

The pump is powered by compressed air.

Compressed air is directed to the pump air chamber

by the main air valve. The compressed air is

separated from the fluid by a membrane called a

diaphragm. The diaphragm in turn applies pressure

on the fluid and forces it out of the pump discharge.

While this is occurring, the opposite air chamber

is de-pressurized and exhausted to atmosphere and

fluid is drawn into the pump suction. The cycle again

repeats, thus creating a constant reciprocating action

which maintains flow through the pump. The flow

is always in through the bottom suction connection

and out through the top discharge connection. Since

the air pressure acts directly on the diaphragms, the

pressure applied to the fluid roughly approximates

the air supply pressure supplied to the main air valve.

Manifold Bolts 35 in-lbs (4.0 N-m)

Water Chamber Bolts 60 in-lbs (6.8 N-m)

Diaphragm Plates — Rubber 75 in-lbs (8.5 N-m)

Air Valve Cap Screws 30 in-lbs (3.4 N-m)

Pump Size

Minimum Air Minimum Suction

Line Size Line Size

1/2" 1/2" 1/2"

INSTALLATION, OPERATION AND MAINTENANCE

Recommended Piping Connections

Torque Settings

DISCHARGE PIPING

AODD PUMP

SUCTION PIPING

AIR INLET PIPING

Shut Off

Valve

Shut Off

Valve

Flexible

Connection

Filter

Lubricator

Regulator

Air Exhaust

Muffler

Fluid

Inlet

Fluid

Discharge

Flexible

Connection

Shut Off

Valve

Union or Pipe Flange

Connection

Union or Pipe Flange

Connection

Flexible

Connection

Discharge

Pressure

Gauge

Suction

Pressure

Gauge

Page 4

Rev: A (05/07)

Diaphragm Plates ---PTFE 60-lbs (6.8 N-m)

Page 5

Mounting

Bolts

Fluid

Suction

Fluid

Discharge

Air

Supply

Surge

Suppresser

Shut Off

Valve

Pressure

Gauge

Flexible

Connection

Union or

Pipe Flange

Connection

Filter

Regulator

Air Exhaust

Muffler

Shut Off

Valve

Shut Off

Valve

Suggested Installation

In suction lift installations the pump datum is above the fluid

line. IMPORTANT: each pump has different lift capabilities.

Be sure to verify the lift capability of a particular pump before

installing it into a system.

A flooded suction installation has the pump datum line

below the fluid level. IMPORTANT: in flooded suction

installations the pressure at the fluid inlet of the pump

should never exceed 69 kPa (10 psi).

In a submerged application, the air exhaust port of the

pump must be ported above the fluid line. Be certain that the

fluid being pumped is compatible with the materials on both

the airside and the wetted side of the pump before the pump

is submerged.

A typical installation showing all the components that are

recommended in a system, including valves, pressure gauges,

air regulators, filters, and surge suppressors.

Flooded Suction Installation

Pump Datum

Fluid Discharge

Air Exhaust

Air Inlet

Suggested Submerged Installation

Suction Lift Installation

Pump Datum

Use of an air operated anti-siphon check valve for closed

system installations such as pressurized pipe is

recommended.

To maintain prime use a suction check valve inserted in

suction tube/pipe.

Drum

Check Valve

Air Operat ed

2 Way Valve

TYPICAL INSTALLATIONS

Page 5

Rev: A (05/07)

Page 6

EXPLODED VIEWS

55

54

64

63

48

52

50

49

65

38

40

45

46

47

35

37

25

34

22

48

33

18

20

19

6

8

21

53

9

2

3

5

4

7

1

11

Exploded View shows Rugged Diaphragm

35

37

4140

38

Description Kit Contents Part Number

Santoprene Diaphragms (2), Balls (4), Seat O-rings (4) 7600821

Main Diaphragms (2), Back-up Diaphragms (4), Balls (4), Seat O-rings (4) 7600822

REPAIR & MAINTENANCE KITS

PTFE DiaphragmsPTFE Diaphragms

Page 6

Rev: A (05/07)

Wet End Kit

PTFE, Buna

PTFE, Poly

Wet End Kit

Page 7

PARTS LIST

AIR VALVE ASSEMBLY

Item Description Quantity

Air Valve Assembly (Includes items 1-10)

1 Valve Body 1

2 Valve Spool 1

3 Valve Spool U-Cup 2

4 End Cap 2

5 End Cap O-Ring 2

6 Staple 2

7 Air Diverter 1

8 Valve Insert 1

9 Valve Gasket 1

10 Valve Screw 4

AIR END ASSEMBLY

Item Description Quantity

11 Center Section 1

18 Pilot Shaft 1

19 Pilot Shaft Spacer 5

20 Pilot Shaft O-Ring 6

21 Pilot Shaft Snap Ring 2

22 Shaft Retainer 2

25 Shaft Retainer Screw 4

33 Muffler 1

DIAPHRAGM ASSEMBLY

Item Description Quantity

34 Main Shaft O-Ring 2

35 Main Shaft 1

37 Inner Diaphragm Plate 2

38 Outer Diaphragm Plate 2

40 Diaphragm 2

41 Back-Up Diaphragm 2

WET END ASSEMBLY

Item Description Quantity

44 Water Chamber 2

45 Water Chamber Bolt 16

46 Water Chamber Washer 16

47 Water Chamber Nut 16

48 Valve Ball Cage 4

49 Valve Seat O-ring 4

50 Valve Seat 4

52 Valve Ball 4

53 Discharge Manifold 1

54 Inlet Manifold 1

55 Manifold Plugs 4

63 Manifold Bolts 8

64 Manifold Washers 8

65 Manifold Nuts 8

Page 7

Rev: A (05/07)

Page 8

©2007 IDEX Corporation KAP50-0307

20531 Crescent Bay Drive

Lake Forest, CA 92630

(949) 595-4800 • (800) 854-3764

Fax: (949) 595-4801

www.knightequip.com

Kynar® is a registered trademark of Penwalt Corp. Geolast® is a registered trademark of AES.

Distributed by:

Page 8

Rev: A (05/07)

Loading...

Loading...