Page 1

INSTRUCTION MANUAL

INTRODUCTION

Foam cleaning is recognized as an effective method for removing oil and heavy soils from all types of surfaces. It is

used for cleaning throughout the food processing, dairy, transportation, industrial and agricultural industry. Due to it’s

characteristics, cleaning with foam is safe and cost effective. Foam can adhere to irregular surfaces and provide

better coverage than liquid cleaning chemicals. Foam stays in place longer to actively lift dirt and oil from surfaces

until it is rinsed off.

Knight’s Foam Clean system dispenses a rich lather of foam up to 65 GPM with a distance of up to 35 feet. With a

built-in 6.8 GPM (23 ltr/min) air operated pump, you’ll get consistent foaming quality for clean results. Simply turn a

knob and you can adjust the dryness or wetness of the foam for different cleaning applications.

APPLICATIONS

Food Processing Plants: Process Food, Beverage, Dairy, Baking, Poultry, Smoke Houses, Seafood.

Transportation:

Industrial:

Agricultural:

SPECIFICATIONS

Trucking, Aviation, Transit, Automotive, Military, Ships, Construction Equipment.

General Cleaning, Machinery Degreasing, Paint Manufacturers, Paper Mills.

Dairy, Poultry, Farm Equipment, Hog.

Foam Output 65 gal/min (246 ltr/min)

Foaming Distance 35 feet (10 meters)

Chemical Compatibility PTFE: All acids, corrosives, and petroleum products

Air Operated Pump Materials Polypropylene Body w/ PTFE Seals and Diaphragm

Air Consumption 60-80 psi, 5-10 scfm

Hose Portable: 25 feet (7.6 meters) reinforced hose, 3/4” ID with wand

EPDM: Alkalines, soaps, mild acids, sodium hypochlorite

Polypropylene Body w/ EPDM Seals and Diaphragm

Kynar Body w/ EPDM Seals and Diaphragm

REQUIREMENTS

•

Minimum 60 PSI clean, dry air at 5 – 10 CFM during operation of the foamer.

•

Chemical requirement: Most foam cleaning dilution rates operate at 3 to 5 oz/gal (24 to 39 ml/ltr) — consult your

chemical supplier for the proper foaming product and mixing ratio to use.

CAUTION: Wear protective clothing and

eyewear when dispensing chemicals or

other materials. Observe safety handling

instructions (MSDS) of chemical mfrs.

CAUTION: When installing any equipment,

ensure that all national and local safety,

electrical, and plumbing codes are met.

0901154 Rev: REL (09/08) Page 1 of 8

Page 2

SAFETY PRECAUTIONS

•

Before pump operation, inspect all gasketed fasteners

for looseness caused by gasket creep. Re-torque all

loose fasteners to recommended specs (shown to right)

to prevent leakage. Failure of the sealing components

creates the possibility of jetting or forceful discharge of

pumped material at a potentially harmful velocity.

16X 40in-lbs

•

Read and understand the MSDS sheets for the cleaning chemicals that will be used — consult your chemical

supplier if you have any questions.

•

Always wear safety goggles and protective gloves while operating the foam unit.

•

Avoid contact of cleaning agents with skin and eyes. If contact occurs, rinse affected area with water for 15

minutes, and seek medical attention, if needed.

•

Drain fluid contents of unit and flush out tank if using different types of chemicals from operation to operation.

•

Never point the Discharge Foam Wand at anyone.

•

Be sure to flush unit with fresh water when switching from alkaline to acid, or acid to alkaline product.

•

Never leave unit unattended while discharge hose is under pressure.

•

Never foam directly into an uncovered electrical outlet or electrical panel.

4X 25 in-lbs

•

Stand far enough away from surface being foamed to prevent foam from splashing on you.

AFTER-USE

(1) Fill the tank with fresh water and rinse thoroughly. With discharge valve “open”, allow pump to run until all

chemical has been pumped through discharge hose, and air has been purged.

(2) Close the Air Inlet Valve and relieve all remaining pressure on the unit by opening the valve on the discharge

hose and leave in the “open” position.

(3) Open the drain plug on the bottom of the tank to remove any remaining liquid from the tank. The drain plug is 1”

NPT with a 1.375” hex head.

MAINTENANCE

•

Periodically check the air pump for leaks or evidence of wear/breakdown.

•

Periodically replace filter media in filter/dryer.

•

Periodically check the pickup tube for blockage, and flush to clean.

Page 2 of 8 0901154 Rev: REL (09/08)

Page 3

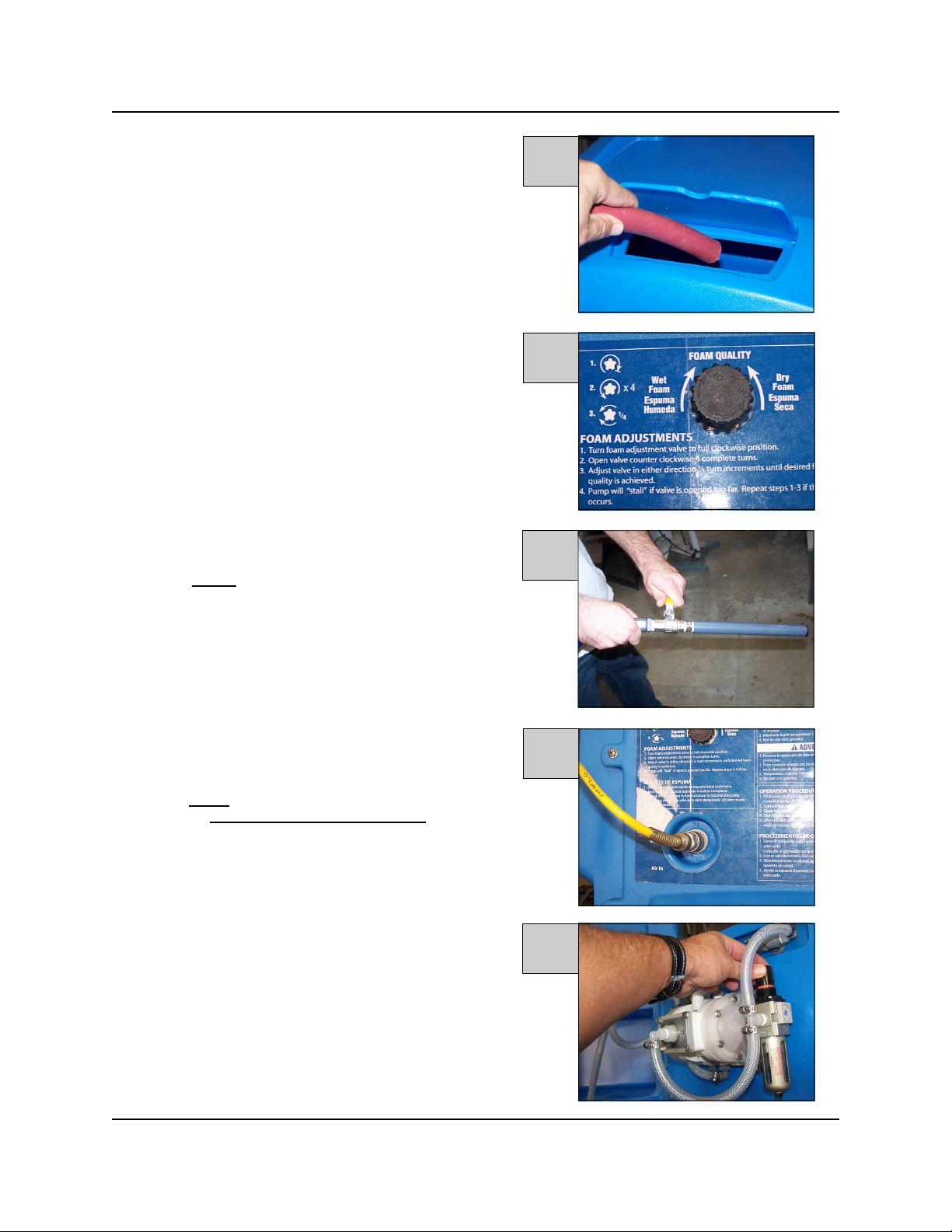

OPERATION

(1) [Fig. A] Fill the foamer tank with a combination of

water and foaming chemical — consult your chemical

supplier for proper dilutions. Do not overfill tank.

(2) [Fig. B] Close Wet Foam/Dry Foam Valve completely

— turn clockwise until it stops.

Figure

A

Figure

B

(3) [Fig. C] Make sure the ball valve on the discharge

hose is closed

(4) [Fig. D] Connect a clean, dry, air supply to the

5/16” quick connect fitting on the unit. Note: Unit

will operate when air supply is on.

(5) [Fig. C] Slowly

hose while holding foam wand away from you.

Closing the ball valve will turn pump off.

(5) [Fig. E] Adjust air pressure regulator to achieve

desired pump flow rate (between 60—80 PSI for

optimum results).

!

open the ball valve on the discharge

Figure

C

Figure

D

Figure

E

(6) [Fig. B] Open Wet Foam/Dry Foam Valve in the

counter-clockwise direction four complete turns.

(7) [Fig. B] Continue to open the Wet Foam-Dry Foam

Valve in ¼ turn increments, allowing a few seconds

between adjustments, until the proper consistency

(dryness) of foam is achieved.

0901154 Rev: REL (09/08) Page 3 of 8

Page 4

TROUBLESHOOTING

PROBLEM SOLUTION

(1) Unit will not operate.

(2) Unit will not make foam.

(3) Wet Foam-Dry Foam Valve is opened too far

pump will not cycle properly due to lack of air

pressure.

(4) Air passes through the pump without cycling.

Check for proper air pressure (60 PSI or more into

unit). 60 PSI on Air Gauge.

Check Air Regulator Filter for obstruction such as

water, oil, or debris.

Check for plugged strainer and replace Air

Regulator Filter Assembly, if necessary.

Make sure the correct foaming chemicals and

concentrations are being used.

Checkvalve is installed backwards.

Packing is contaminated or degraded. See item #8

for details on how to service the packing.

If this occurs, close valve and follow the instruction

in Steps 7 and 8 under “Operation” (page 3).

Repair or replace the pump.

(5) Foam Solution backs up into the air filter.

(6) Pump cycles but no liquid is discharged.

If all of the above check out okay.

Page 4 of 8 0901154 Rev: REL (09/08)

Checkvalve needs replacing.

Check to see if pump is primed.

Check footvalve/strainer orientation. Arrow must

point toward pump suction port.

Suction line leak.

Pump fittings loose or broken.

Suction line not submerged down into liquid.

Repair or replace the pump.

Page 5

PROBLEM

(7) Foam comes out wet regardless of where the Wet

Foam-Dry Foam is set.

(8) Unit foams at reduced pressure.

If both of the above check out okay, the S.S.

packing could be plugged. Remove and clean it

per the instructions to the right:

(i) Be sure to turn off air to unit and open the cut-off

SOLUTION

Checkvalve may be plugged and needs replacing.

Ball valve may not be open all the way on foam

wand. This may happen if the operator is standing

too close to a wall and closing the ball valve slightly

to reduce splash of foam.

Check the air supply into the unit. If air pressure is

low, turn unit off until air supply can bring pressure

back up.

If you know the air supply is 60 PSI or higher, check

the internal air gauge which should read near 60 PSI

or higher. Adjust Pressure Regulator to required

minimum 60 PSI.

valve on the discharge hose to remove backpressure on the unit.

(ii) Remove the hose barb from the Discharge Tee.

(iii) Remove the screen retainer and packing from inside

the tee.

(iv) Clean any particles from the packing and the screen

retainer.

(v) Replace the packing and screen retainer into the tee

and replace the hose barb fitting. Use a pipe thread

sealant to prevent leaks.

(9) Pump does not stop with ball valve (wand) turned

off.

Chemical lines not primed and/or air leaks in the

pump tubing.

0901154 Rev: REL (09/08) Page 5 of 8

Page 6

MOBILE CART & DISCHARGE HOSE

Page 6 of 8 0901154 Rev: REL (09/08)

Page 7

PUMP & PLUMBING

0901154 Rev: REL (09/08) Page 7 of 8

Page 8

DISCLAIMER

Knight LLC does not accept responsibility for the mishandling, misuse, or non-performance of the described items

when used for purposes other than those specified in the instructions. For hazardous materials information consult

label, MSDS, or Knight LLC. Knight products are not for use in potentially explosive environments. Any use of our

equipment in such an environment is at the risk of the user, Knight does not accept any liability in such

circumstances.

WARRANTY

All Knight controls and pump systems are warranted against defects in material and workmanship for a period of

ONE year. All electronic control boards have a TWO year warranty. Foam Clean 25-95 Air Pump warranty is two

years for defects in material and workmanship. Warranty applies only to the replacement or repair of such parts when

returned to factory with a Knight Return Authorization (KRA) number, freight prepaid, and found to be defective upon

factory authorized inspection. Bearings and pump seals or rubber and synthetic rubber parts such as “O” rings,

diaphragms, squeeze tubing, and gaskets are considered expendable and are not covered under warranty. Warranty

does not cover liability resulting from performance of this equipment nor the labor to replace this equipment. Product

abuse or misuse voids warranty.

FOOTNOTE

The information and specifications included in this publication were in effect at the time of approval for printing.

Knight, LLC reserves the right, however, to discontinue or change specifications or design at any time without notice

and without incurring any obligation whatsoever.

KNIGHT LLC,

Knight Headquarters

Tel: 949.595.4800

Fax: 949.595.4801

USA Toll Free

Tel: 800.854.3764

Fax: 800.752.9518

KNIGHT LLC,

KNIGHT LLC, KNIGHT LLC,

Tel: 905.542.2333

Fax: 905.542.1536

A Unit of IDEX Corporation (www.knightequip.com)

Knight Canada

Knight Europe

Tel: 44.1293.615.570

Fax: 44.1293.615.585

Knight Australia

Tel: 61.2.9725.2588

Fax: 61.2.9725.2025

Knight N. Asia

Tel: 82.2.3481.6683

Fax: 82.2.3482.5742

Knight S. Asia

Tel: 65.6763.6633

Fax: 65.6764.4020

Page 8 of 8 0901154 Rev: REL (09/08)

Loading...

Loading...