Page 1

Workshop Manual

Werkplaatshandboek

Manuel D’Atelier

Werkstatthandbuch

Manuale D’Officina

Manual De Taller

Manual de Oficina

Page 2

Page 3

AMENDMENT INSTRUCTION SHEET

MINI WORKSHOP MANUAL

Publication Number RCL 0193ENG - 2nd Edition

Amendment Number: XN-001/97ENG Date: 12/96

To ensure that this manual is kept up to date and that a record of amendments to this manual is available, an

Amendment Instruction Sheet will be issued with each set of revised pages.

• The Title page of the Manual is re-issued, and the Part No. has been raised to the next edition. Except for the

Contents pages, all revised and new pages have the issue date at the foot of each page, together with an

indication of whether the pages are revised or new.

• This Amendment Instruction Sheet must be inserted at the front of the manual to indicate that the amendment

has been incorporated. Do not discard previous Amendment Instruction sheets.

• Your manual is only complete to this issue providing all prior Amendments are included.

• The filing instructions give section and page numbers affected. Additional pages or complete new sections may

be issued, insert the pages as instructed.

FILING INSTRUCTIONS

Section Discard Existing

Introduction Title Page Title Page Introduction of new sections. Part number

Information Contents Page Contents Page Corrections to existing information and

Engine Contents Page Contents Page Corrections to existing information and

Emission Control Description and

Engine Management

System - MEMS

Fuel Delivery System Contents Page Contents Page Corrections to existing information and

Pages

General data,1 General data,1

Torque wrench

settings, 1&3

Repairs, 33-37 Repairs, 33-41

operation, 1

Repairs, 1 Repairs,1

Contents Page Contents Page Corrections to existing information.

Description and

operation, 1-11

- Adjustments

Repairs, 1 Repairs,1

Insert New Pages Reason for Amendment

raised to next edition.

addition of new torque figures.

Torque wrench

settings, 1-5

addition of new repair procedures.

Description and

operation, 1

Description and

operation, 1-11

Corrections to existing information.

introduction of Adjustments section.

Cooling System Repairs, 3 Repairs,3 Corrections to existing information.

Manifold & Exhaust

Systems

Clutch Contents page Contents Page Corrections to existing information and

Description and

operation, 3

Adjustments, 1 Adjustments, 1

Repairs, 1-7 Repairs,1-11

Description and

operation, 3

Corrections to existing information.

addition of new repair procedures.

Continued.....

Page 4

Section Discard Existing

Pages

Insert New Pages Reason for Amendment

Manual Gearbox Contents page Contents Page Corrections to existing information and

Adjustments, 1 Adjustments, 1

- Repairs, 1-5

Drive shafts - Contents Page NewSection

- Repairs, 1-5

Steering Contents page Contents Page Corrections to existing information and

- Adjustments, 1

Repairs, 1 Repairs, 1-11

Suspension - Contents Page New Section.

- Adjustments, 1

- Repairs, 1&3

Brakes Contents Page Contents Page Corrections to existing information and

Adjustments, 1 Adjustments, 1

Repairs, 1&3 Repairs, 1-17

Restraint Systems Description and

operation, 3

Repairs, 3&5 Repairs, 3&5

Body Contents Page Contents Page Corrections to existing information and

Exterior fittings,

1&3

Interior trim

components, 1

Screens, 1 Screens, 1

- Seats and seat

Description and

operation, 3

Exterior fittings,

1-7

Interior trim

components, 1-7

belts, 1&3

addition of new repair procedures.

addition of new repair procedures.

addition of new repair procedures.

Corrections to existing information.

addition of new repair procedures.

Heating & Ventilation - Contents Page New Section.

- Repairs, 1-7

Wipers & Washers Contents Page Contents page Addition of new repair procedures

Repairs, 1 Repairs, 1-7

Electrical Contents Page Contents Page Corrections to existing information and

Description and

operation, 1

Adjustments, 1 Adjustments, 1

Repairs, 1-19 Repairs, 1-27

Instruments Repairs, 7 Repairs, 7 Corrections to existing information.

Description and

operation, 1

addition of new repair procedures.

Page 5

AMENDMENT INSTRUCTION SHEET

MINI WORKSHOP MANUAL

Publication Number RCL0193ENG (3rd Edition)

Amendment Number: XN003.98ENG Date: 11/98

To ensure that this manual is kept up to date and that a record of amendments to this manual is available, an

Amendment Instruction Sheet will be issued with each set of revised pages.

• The Title page of the Manual is re-issued, and the Part No. has been raised to the next edition. Except for the

Contents pages, all revised and new pages have the issue date at the foot of each page, together with an

indication of whether the pages are revised or new.

• This Amendment Instruction Sheet must be inserted at the front of the manual to indicate that the amendment

has been incorporated. Do not discard previous Amendment Instruction sheets.

• Your manual is only complete to this issue providing all prior Amendments are included.

• The filing instructions give section and page numbers affected. Additional pages or complete new sections may

be issued, insert the pages as instructed.

FILING INSTRUCTIONS

Section Discard Existing

Pages

TITLE PAGE Title page Title page Part number raised to 4th Edition and year

INSTRUMENTS Contents page Contents page Additional jobs added

INSTRUMENTS Page 9 Pages 9 and 11 Speedometer cable upper and lower added

Insert New Pages Reason for Amendment

of copyright amended.

Page 6

AMENDMENT INSTRUCTION SHEET

MINI WORKSHOP MANUAL

Publication Number RCL0193ENG (4th Edition)

Amendment Number: XN002.99ENG Date: 06/99

To ensure that this manual is kept up to date and that a record of amendments to this manual is available, an

Amendment Instruction Sheet will be issued with each set of revised pages.

• The Title page of the Manual is re-issued, and the Part No. has been raised to the next edition. Except for the

Contents pages, all revised and new pages have the issue date at the foot of each page, together with an

indication of whether the pages are revised or new.

• This Amendment Instruction Sheet must be inserted at the front of the manual to indicate that the amendment

has been incorporated. Do not discard previous Amendment Instruction sheets.

• Your manual is only complete to this issue providing all prior Amendments are included.

• The filing instructions give section and page numbers affected. Additional pages or complete new sections may

be issued, insert the pages as instructed.

FILING INSTRUCTIONS

Section Discard Existing

Pages

TITLE PAGE Title Page Title Page Part number raised to 5th Edition.

ELECTRICAL Contents page Contents page Contents changed.

Adjustments pages

1&2

Repairs pages 1 &2Repairs pages 1 &2Auxiliary Drive Belt - Remove and Refit -

Repairs page 27 Repairs pages 27

Insert New Pages Reason for Amendment

Adjustments pages

1&2

&28

Auxiliary Drive Belt - Check and Adjust Caution regarding drive belt adjusting bolt

added.

Cautions regarding drive belt adjusting bolt

added.

CD Player - Remove and Refit - New

operation issued herewith.

Page 7

WORKSHOP

INTRODUCTION

GENERAL INFORMATION

INFORMATION

ENGINE

EMISSION CONTROL

ENGINE MANAGEMENT SYSTEM

FUEL DELIVERY SYSTEM

COOLING SYSTEM

MANUAL

This manual covers changes to Mini models

manufactured from VIN SAXXNNAZEBD 134455

and should be used in conjunction with the following

manuals.

AKM 7169 Mini Repair Manual

RCL 0194 Mini Electrical Circuit Diagrams

MANIFOLD & EXHAUST SYSTEMS

CLUTCH

MANUAL GEARBOX

DRIVE SHAFTS

STEERING

SUSPENSION

BRAKES

Publication Part No. RCL 0193ENG (5th Edition)

Published by Rover Technical Communication

1998 Rover Group Limited

RESTRAINT SYSTEMS

BODY

HEATING & VENTILATION

WIPERS & WASHERS

ELECTRICAL

INSTRUMENTS

Page 8

Page 9

INTRODUCTION

CONTENTS

INTRODUCTION

INTRODUCTION 1......................................................................................................

REPAIRS AND REPLACEMENTS 2...........................................................................

SPECIFICATION 2......................................................................................................

ABBREVIATIONS AND SYMBOLS 3..........................................................................

Page

Page 10

Page 11

INTRODUCTION

INTRODUCTION

How to use this Manual

To assist in the use of this Manual the section title is

given at the top and the relevant sub-section is given

at the bottom each page.

Each major section starts with a contents page,

listing the information contained in the relevant

sub-sections. To assist filing of revised information

each sub-section is numbered from page 1.

The individual items comprising repair operations

are to be followed in the sequence in which they

appear. Items numbers in the illustration are referred

to in the text.

Adjustment and repair operations include reference

to Service tool numbers and the associated

illustration depicts the tool. Where usage is not

obvious the tool is shown in use. Adjustment and

repair operations also include reference to wear

limits, relevant data, torque figures, and specialist

information and useful assembly details. Each

adjustment or repair operation is given its Repair

Operation Time number. WARNINGS, CAUTIONS

and NOTES have the following meanings:

References

References to the LH or RH side given in this

Manual are made when viewing the vehicle from the

rear. With the engine and gearbox assembly

removed, the crankshaft pulley end of the engine is

referred to as the front.

Operations covered in this Manual do not include

reference to testing the vehicle after repair. It is

essential that work is inspected and tested after

completion and if necessary a road test of the

vehicle is carried out particularly where safety

related items are concerned.

Dimensions

The dimensions quoted are to design engineering

specification with Service limits where applicable.

WARNING: Procedures which must be

followed precisely to avoid the possibility

of injury.

CAUTION: Calls attention to procedures

which must be followed to avoid damage

to components.

NOTE: Gives helpful information.

INTRODUCTION 1

Page 12

INTRODUCTION

REPAIRS AND REPLACEMENTS

When replacement parts are required it is essential

that only Rover recommended parts are used.

Attention is particularly drawn to the following points

concerning repairs and the fitting of replacement

parts and accessories.

Safety features and corrosion prevention treatments

embodied in the car may be impaired if other than

Rover recommended parts are fitted. In certain

territories, legislation prohibits the fitting of parts not

to the manufacturer’s specification. Torque wrench

setting figures given in this Manual must be used.

Locking devices, where specified, must be fitted. If

the efficiency of a locking device is impaired during

removal it must be renewed.

Owners purchasing accessories while travelling

abroad should ensure that the accessory and its

fitted location on the car conform to legal

requirements.

The Terms of the vehicle Warranty may be

invalidated by the fitting of other than Rover

recommended parts.

SPECIFICATION

Rover are constantly seeking to improve the

specification, design and production of their vehicles

and alterations take place accordingly. While every

effort has been made to ensure the accuracy of this

Manual, it should not be regarded as an infallible

guide to current specifications of any particular

vehicle.

This Manual does not constitute an offer for sale of

any particular vehicle. Rover Dealers are not agents

of Rover and have no authority to bind the

manufacturer by any expressed or implied

undertaking or representation.

All Rover recommended parts have the full backing

of the vehicle Warranty.

Rover Dealers are obliged to supply only Rover

recommended parts.

2

INTRODUCTION

Page 13

ABBREVIATIONS AND SYMBOLS

INTRODUCTION

After Bottom Dead Centre ABDC

After Top Dead Centre ATDC

Air conditioning A/C

Air fuel ratio AFR

Alternating current ac

Amperes A

Anti-lock brake system ABS

Automatic temperature control ATC

Before Bottom Dead Centre BBDC

Before Top Dead Centre BTDC

Bottom Dead Centre BDC

British Standards BS

Camshaft Position CMP

Carbon monoxide CO

Celcius (Centigrade) C

Centimetre cm

Chlorofluorocarbons CFC’s

Cubic centimetres cm

Crankshaft position CKP

Degree (angle) deg. or °

Degree (temperature) deg. or °

Dial test indicator DTI

Diameter dia.

Direct current dc

Electronic Control Unit ECU

Exhaust gas recirculation EGR

Engine Control Module ECM

Engine coolant temperature ECT

Fuel Injection Pump FIP

Manifold absolute pressure MAP

Mass air flow MAF

Maximum max.

Mercury Hg

Metre m

Metric unit of horse power PS

Miles per hour mph

Millimetre mm

Minimum min

Minus (of tolerance) Minute (angle) ’

Model Year MY

Multi-point injection MPi

Negative (electrical) (-)

Newton metre Nm

Number No.

3

Outside diameter o.dia.

Percentage %

Plus or minus ±

Plus (tolerance) +

Positive (electrical) +

Positive crankcase ventilation PCV

Radius r

Ratio :

Reference ref

Revolutions per minute rev/min

Right-hand RH

Right-hand drive RHD

Rover Engineering Standards RES

Gramme (mass) g

High compression hc

High Tension h.t.

Hour h

Idle Air Control Valve IACV

Inertia Fuel Shut-off IFS

Intake air temperature IAT

Internal diameter i.dia.

International Organisation for

ISO

Standardization

Kilometre km

Kilogramme kg

Left-hand LH

Left-hand drive LHD

Light emitting diode LED

Litre l

Low Compression lc

Second (angle) "

Single overhead camshaft SOHC

Specific gravity sp.gr

Square centimetres cm

Standard std.

Supplementary Restraint System SRS

Synchronizer/synchromesh synchro

Thousand k

Top dead centre TDC

Throttle position TP

United Kingdom UK

United States US

Variable induction system VIS

Vehicle identification number VIN

Volt V

Watt W

2

INTRODUCTION 3

Page 14

Page 15

GENERAL INFORMATION

CONTENTS

VEHICLE IDENTIFICATION NUMBER

VEHICLE IDENTIFICATION NUMBER 1....................................................................

IDENTIFICATION NUMBER LOCATIONS 1...............................................................

GENERAL PRECAUTIONS AND FITTING INSTRUCTIONS

GENERAL PRECAUTIONS AND FITTING INSTRUCTIONS 1..................................

Dangerous substances 1.............................................................................................

Engine oils 1................................................................................................................

Health Protection Precautions 1..................................................................................

Environmental Protection Precautions 1......................................................................

SAFETY INSTRUCTIONS 2........................................................................................

FUEL HANDLING PRECAUTIONS

FUEL HANDLING PRECAUTIONS 1..........................................................................

ELECTRICAL PRECAUTIONS

ELECTRICAL PRECAUTIONS 1.................................................................................

Page

Page 16

Page 17

GENERAL INFORMATION

VEHICLE IDENTIFICATION NUMBER

Location

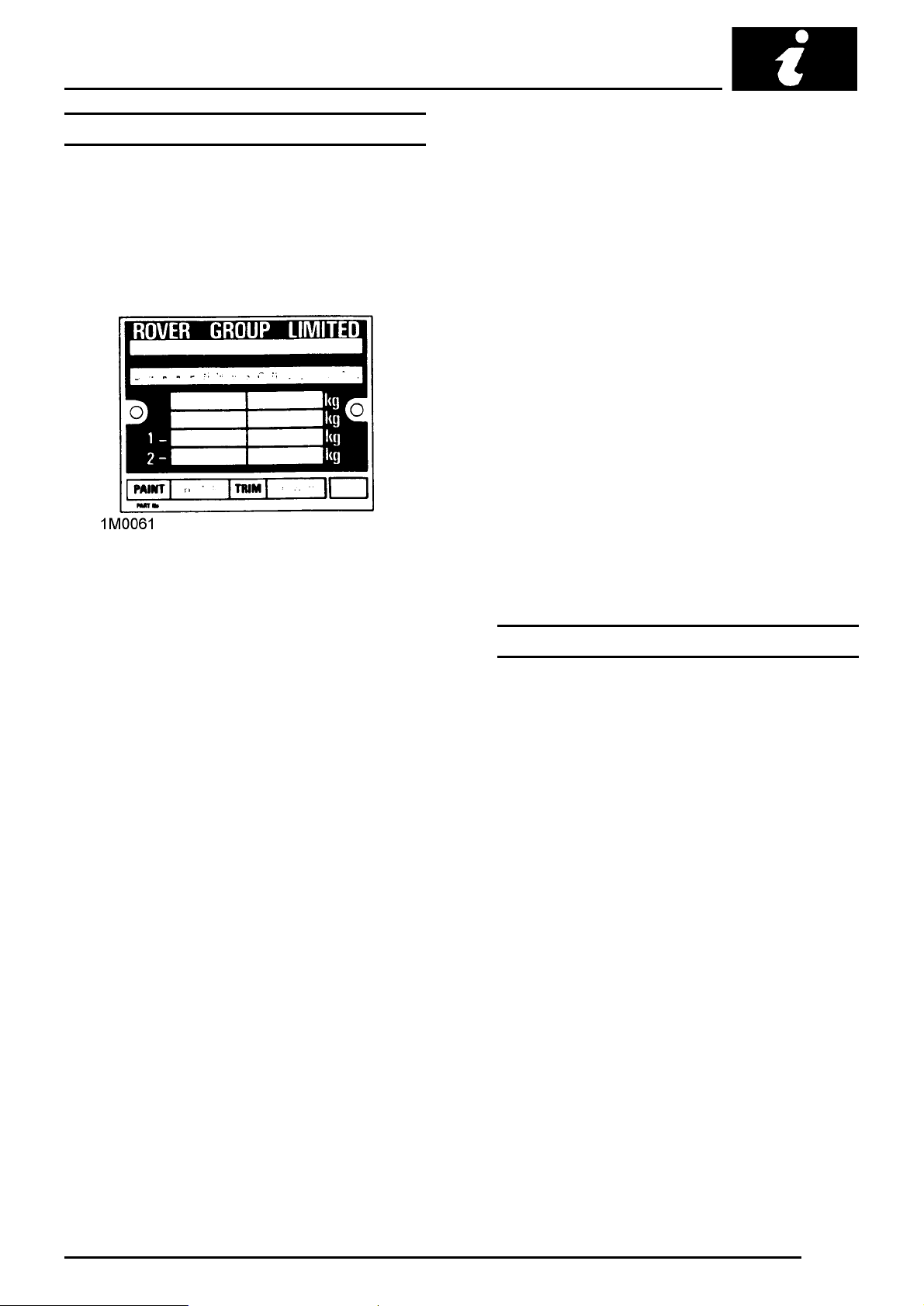

The Vehicle Identification Number (VIN) plate is

attached to the RH inner wing valance.

The VIN is also etched into the lower LH corners of

the windscreen and rear window.

Paint and Trim colour codes

3-letter codes identifying the original Paint and Trim

colours are stamped on the VIN plate.

Paint

Example: H A M

H= Basic colour

A= Mark identifier

M= Colour/Shade name

Trim

Example: L P R

L= Basic colour

P= Mark identifier

R= Colour/Shade name

Vehicle identification number

Example: SAXXNNAZEBD134455

S= Geographic area

A= Country

X= Manufacturer

XN= Marque/Model

N= Class

A= Body

Z= Engine

E= Transmission and Steering

B= Model change

D= Assembly plant

6 figures= Serial number

IDENTIFICATION NUMBER LOCATIONS

Engine number

Stamped on the front face of the cylinder block

adjacent to the alternator.

Gearbox number

Shown on a label attached to the upper face of the

final drive housing.

Body number

The body number is stamped on a plate fixed to the

bonnet locking platform.

VEHICLE IDENTIFICATION NUMBER 1

Page 18

Page 19

GENERAL INFORMATION

GENERAL PRECAUTIONS AND FITTING INSTRUCTIONS

Ignition system safety precautions

WARNING: Before commencing work on

an ignition system, all high tension

terminals, adapters and diagnostic

equipment for testing should be inspected to

ensure that they are adequately insulated and

shielded to prevent accidental personal contacts

and minimise the risk of shock. Wearers of

surgically implanted pacemaker devices should

not be in close proximity to ignition circuits or

diagnostic equipment.

Dangerous substances

WARNING: Many liquids and other

substances used in motor vehicles are

poisonous and should under no

circumstances be consumed and should, as far

as possible, be kept from contact with the skin.

These substances among others include acid,

anti- freeze, asbestos, brake fluid, fuel,

windscreen washer additives, lubricants,

refrigerant and various adhesives.

Always read carefully the instructions printed on

labels or stamped on components and obey

them implicitly. Such instructions are included

for reasons of your health and personal safety.

Never disregard them.

Used engine oils: Prolonged exposure to used

engine oils can cause serious skin disorders,

avoid excessive skin contact and always adhere

to the following recommendations:

Engine oils

Prolonged and repeated contact with mineral oil will

result in the removal of natural fats from the skin,

leading to dryness, irritation and dermatitis. In

addition, used engine oil contains potentially harmful

contaminants which may cause skin cancer.

Adequate means of skin protection and washing

facilities must be provided.

Health Protection Precautions

• Avoid prolonged and repeated contact with oils,

particularly used engine oils.

• Wear protective clothing, including impervious

gloves where practicable.

• Do not put oily rags in pockets.

• Avoid contaminating clothes, particularly

underpants, with oil.

• Overalls must be cleaned regularly. Discard

heavily soiled clothing and oil impregnated

footwear.

• First aid treatment should be obtained

immediately for open cuts and wounds.

• Use barrier creams, applying before each work

period, to help the removal of oil from the skin.

• Wash with soap and water to ensure all oil is

removed (skin cleansers and nail brushes will

help). Preparations containing lanolin replace the

natural skin oils which have been removed.

• Do not use petrol, kerosene, diesel fuel, gas oil,

thinners or solvents for cleaning skin.

• If skin disorders develop, obtain medical advice

without delay.

• Where practicable, degrease components prior

to handling.

• Where there is a risk of eye contact, eye

protection should be worn, for example, chemical

goggles or face shields; in addition an eye wash

facility should be provided.

Environmental Protection Precautions

It is illegal to pour used oil on to the ground, down

sewers or drains, or into water courses.

Burning of used engine oil in small space heaters or

boilers can be recommended only for units of

approved design. The heating system must meet the

regulatory standards of HMIP for small burners of

less than 0.4 MV. If in doubt check with the

appropriate local authority and/or manufacturer of

approved appliance.

Dispose of used oil and used filters through

authorised waste disposal contractors to licensed

waste disposal sites, or to the waste oil reclamation

trade. If in doubt, contact the Local Authority for

advice on disposal facilities.

GENERAL PRECAUTIONS AND FITTING INSTRUCTIONS 1

Page 20

GENERAL INFORMATION

SAFETY INSTRUCTIONS

Jacking

The recommended jacking points are given in

LIFTING AND TOWING, always ensure that any

lifting apparatus has adequate load and safety

capacity for the weight to be lifted. Ensure the

vehicle is standing on level ground prior to lifting or

jacking. Apply the handbrake and chock the wheels.

Never rely on a jack as the sole means of support

when working beneath the vehicle. Use additional

safety supports beneath the vehicle.

Do not leave tools, lifting equipment, spilt oil, etc.

around or on the work bench area.

Precautions against damage

Always fit wing and seat covers before commencing

work. Avoid spilling brake fluid or battery acid on

paintwork. Wash off with water immediately if this

occurs.

Disconnect the battery earth lead before starting

work, see ELECTRICAL PRECAUTIONS.

Always use the recommended service tool or a

satisfactory equivalent where specified.

Protect exposed bearing and sealing surfaces and

screw threads from damage.

Brake shoes and pads

WARNING: Always fit the correct grade

and specification of brake linings and

renew brake pads and brake shoes in axle

sets only.

Brake hydraulics

WARNING: It is imperative that the correct

brake fittings are used and that threads of

components are compatible.

Always use two spanners when slackening or

tightening brake pipe or hose connections. Ensure

that hoses run in a natural curve and are not kinked

or twisted. Fit brake pipes securely in their retaining

clips and ensure that the pipe run cannot contact a

potential chafing point.

Containers used for hydraulic fluid must be kept

absolutely clean. Do not store hydraulic fluid in an

unsealed container, it will absorb water and in this

condition would be dangerous to use. Do not allow

hydraulic fluid to be contaminated with mineral oil, or

use a container which has previously contained

mineral oil. Do not re-use fluid from the system.

Always use clean brake fluid or a recommended

alternative to clean hydraulic components. Fit a

blanking cap to an hydraulic union and a plug to its

socket after removal to prevent the ingress of dirt.

Absolute cleanliness must be observed with

hydraulic components.

Engine coolant caps and plugs

Extreme care is necessary when removing engine

coolant caps and plugs when the engine is hot and

especially if it is overheated. To avoid the possibility

of scalding allow the engine to cool before

attempting coolant cap or plug removal.

Cleaning components

Always use the recommended cleaning agent or

equivalent.

Do not use degreasing equipment for components

containing items which could be damaged by the

use of this process. Whenever possible clean

components and the area surrounding them before

removal. Always observe scrupulous cleanliness

when cleaning dismantled components.

2

GENERAL PRECAUTIONS AND FITTING INSTRUCTIONS

Page 21

GENERAL INFORMATION

Joints and joint faces

Fit joints dry unless otherwise specified in this

Manual.

If gaskets and/or jointing compound is

recommended for use; remove all traces of old

jointing material prior to reassembly. Do not use a

tool which will damage the joint faces and smooth

out any scratches or burrs on the joint faces using

an oil stone. Do not allow dirt or jointing material to

enter any tapped holes.

Prior to reassembly, blow through any pipes,

channels or crevices with compressed air.

Screw threads

Both UNF and metric threads to ISO standards are

used.

Damaged nuts, bolts and screws must always be

discarded.

Cleaning up damaged threads with a die or tap

impairs the strength and closeness of fit of the

threads and is not recommended.

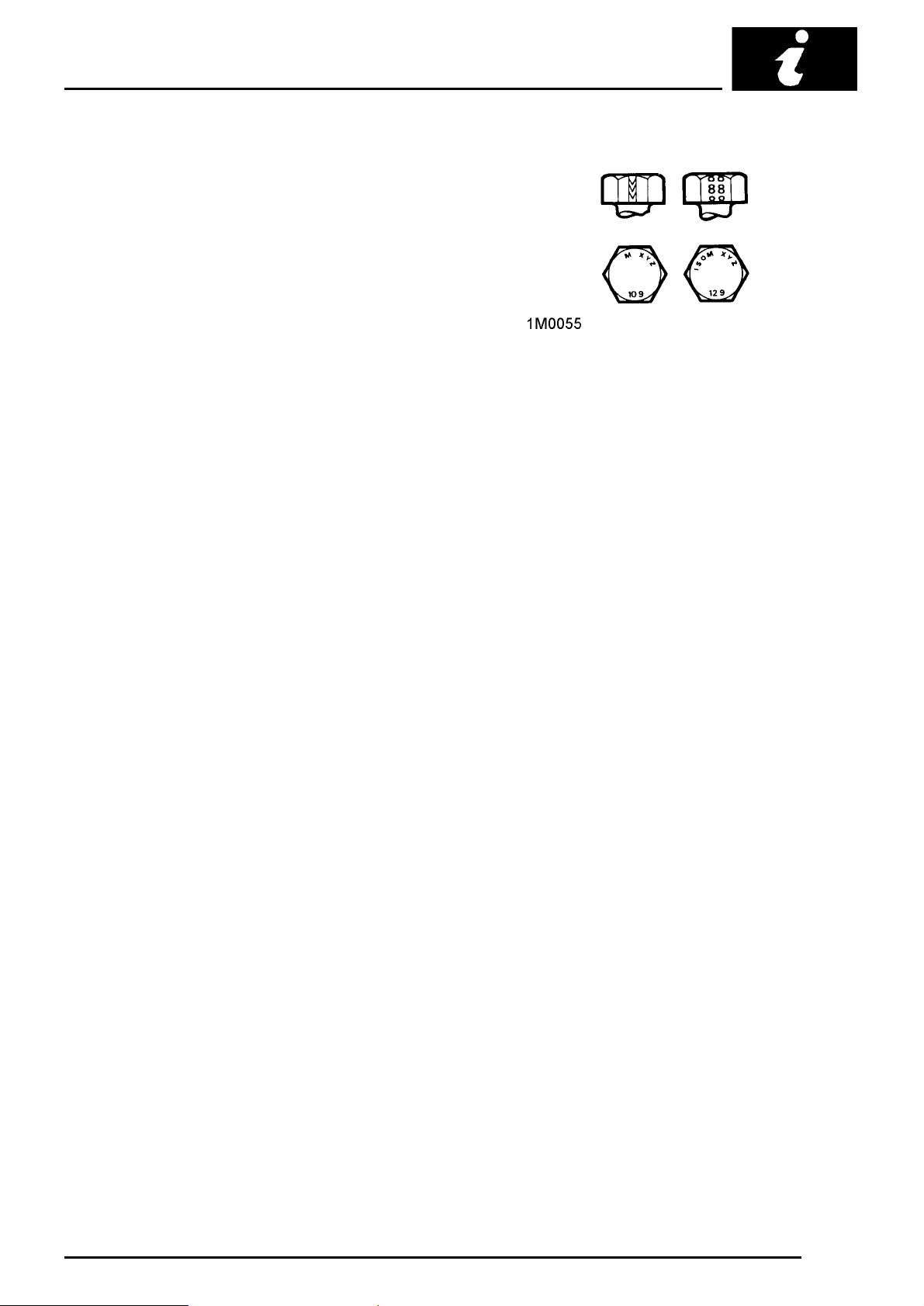

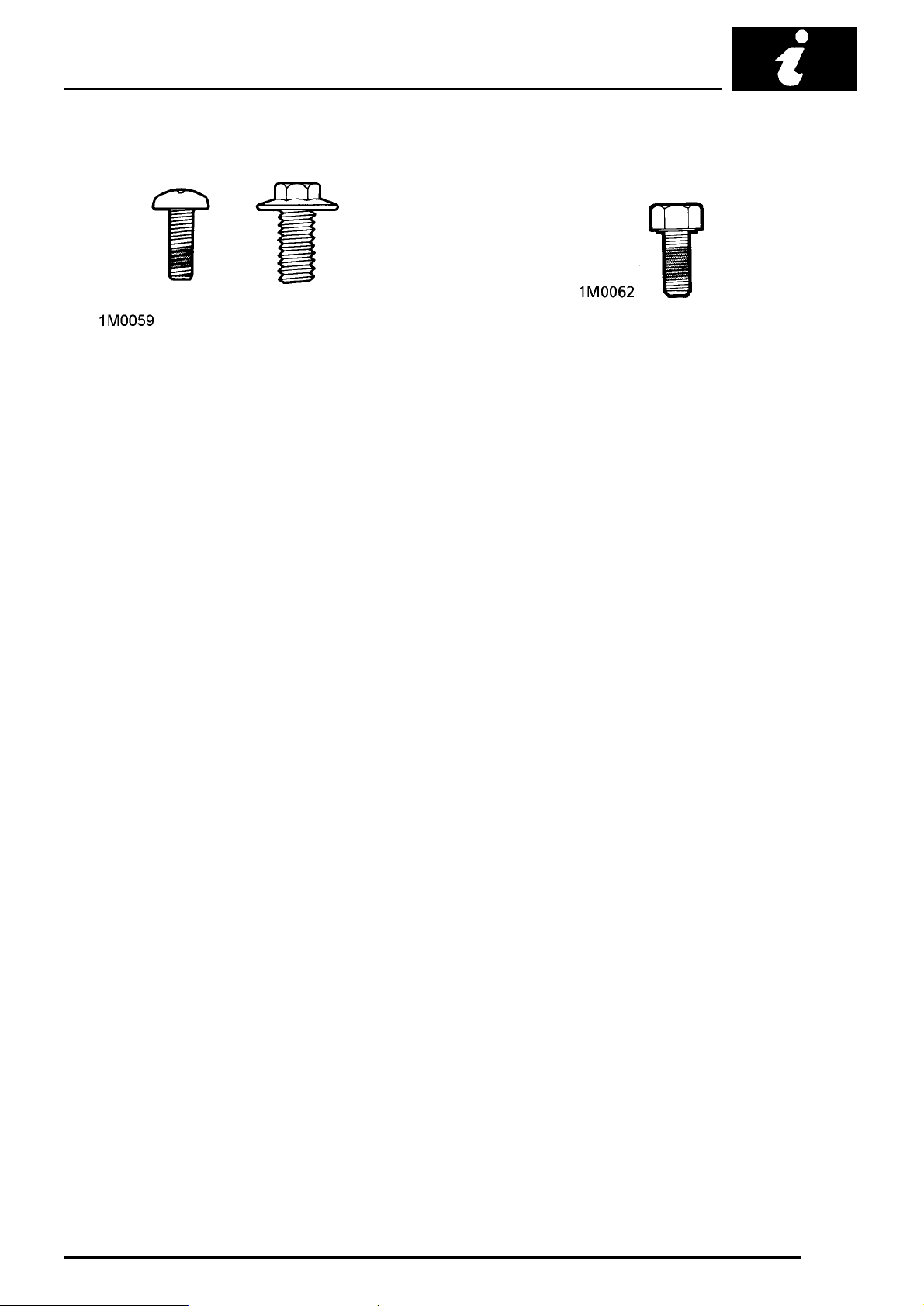

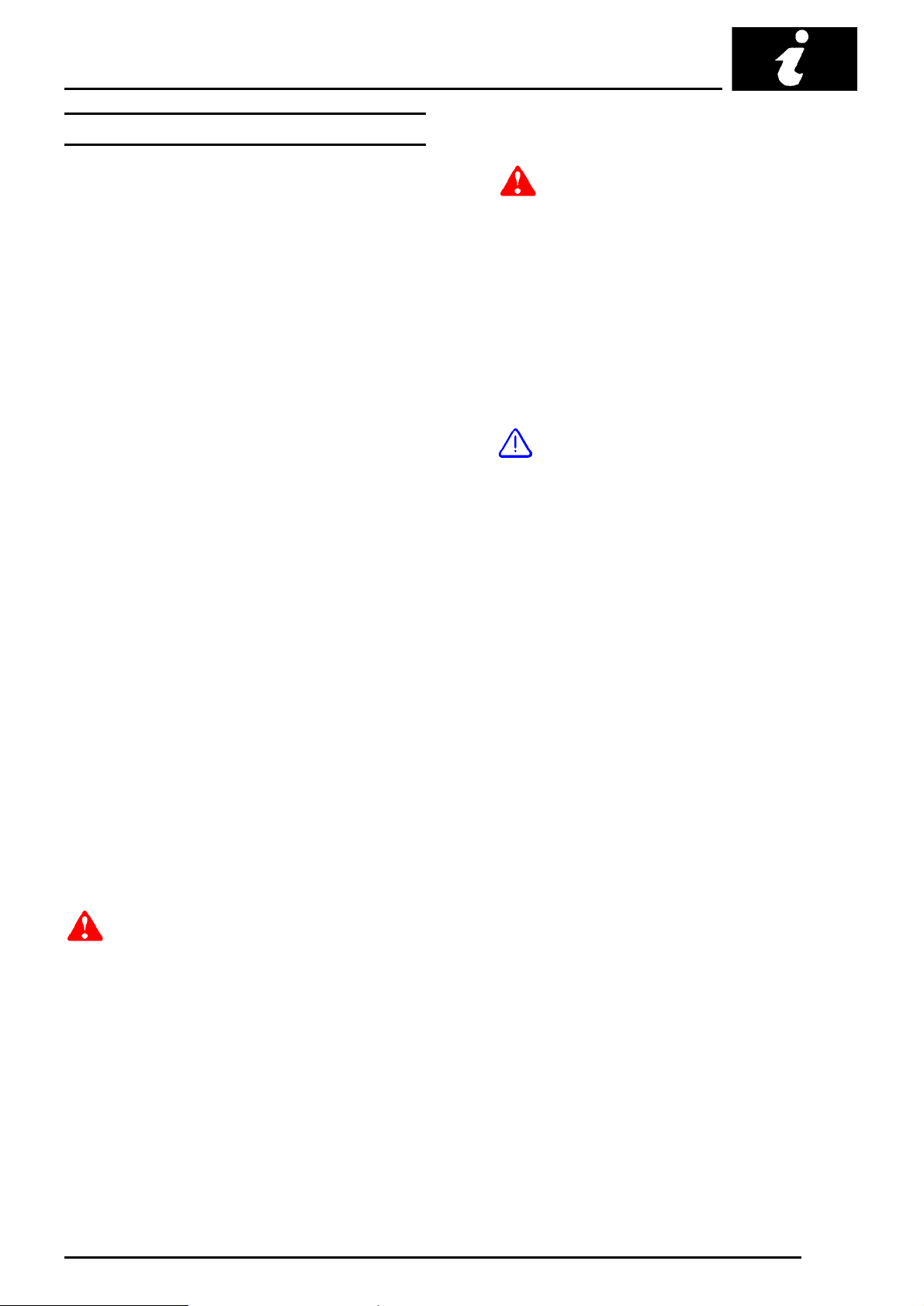

Bolt identification

An ISO metric bolt or screw made of steel and larger

than 6 mm in diameter can be identified by either of

the symbols ISO M or M embossed or indented on

top of the head.

In addition to marks to identify the manufacturer, the

head is also marked with symbols to indicate the

strength grade, e.g. 8.8; 10.9; 12.9; 14.9. As an

alternative, some bolts and screws have the M and

strength grade symbol on the flats of the hexagon.

Castellated nuts must not be slackened back to

accept a split-pin, except in those recommended

cases when this forms part of an adjustment.

Do not allow oil or grease to enter blind threaded

holes. The hydraulic action on screwing in the bolt or

stud could split the housing.

Always tighten a nut or bolt to the recommended

torque figure. Damaged or corroded threads can

affect the torque reading.

To check or re-tighten a bolt or screw to a specified

torque figure, first slacken a quarter of a turn, then

retighten to the correct torque figure.

GENERAL PRECAUTIONS AND FITTING INSTRUCTIONS 3

Page 22

GENERAL INFORMATION

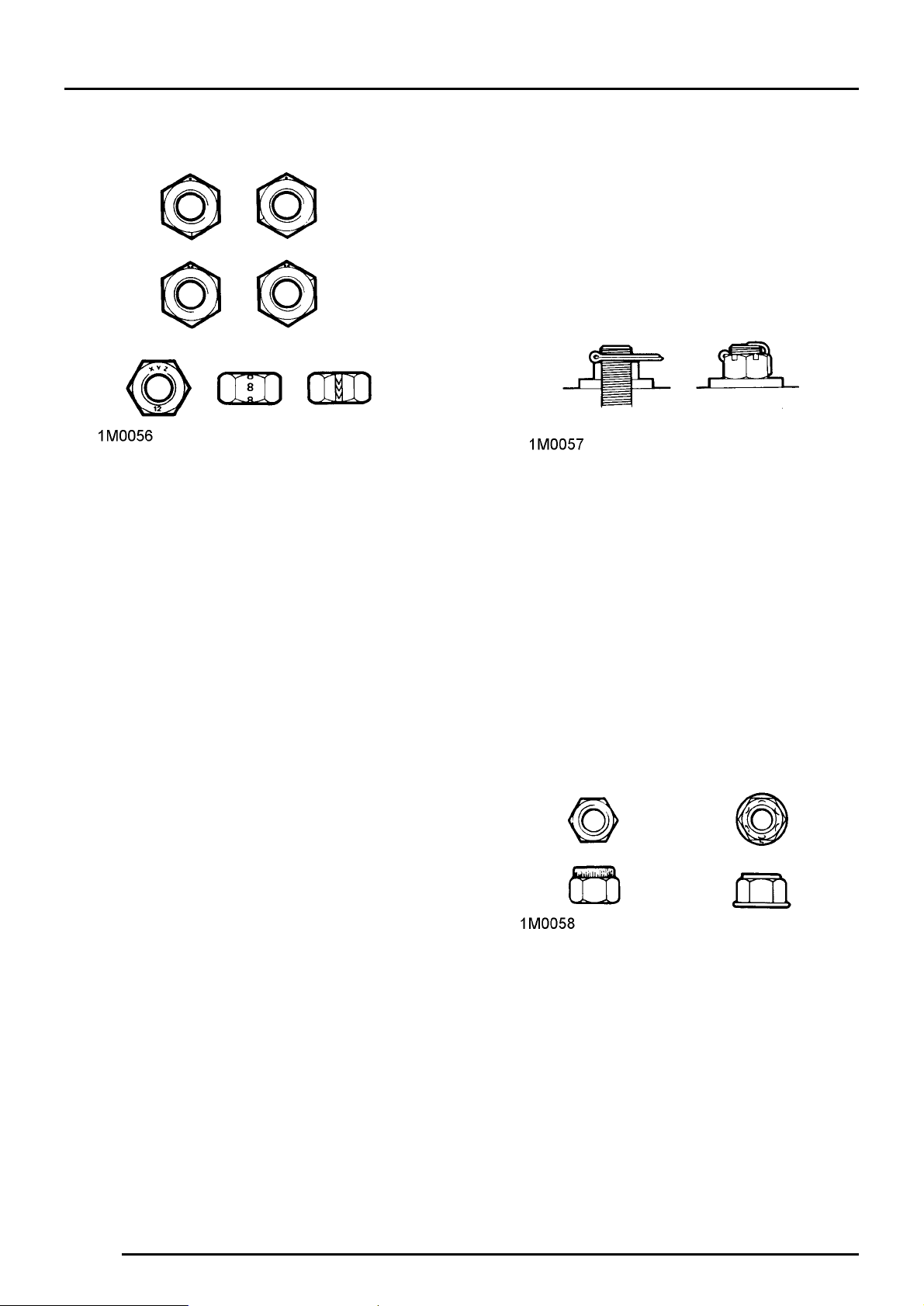

Nut identification

A nut with an ISO metric thread is marked on one

face or on one of the flats of the hexagon with the

strength grade symbol 8, 12, or 14. Some nuts with

a strength grade 4, 5 or 6 are also marked and some

have the metric symbol M on the flat opposite the

strength grade marking.

A clock face system is used as an alternative

method of indicating the strength grade. The

external chambers or a face of the nut is marked in a

position relative to the appropriate hour mark on a

clock face to indicate the strength grade.

A dot is used to locate the 12 o’clock position and a

dash to indicate the strength grade. If the grade is

above 12, two dots identify the 12 o’clock position.

Locking devices

Always release locking tabs and fit new locking

washers, do not re-use locking tabs. Always use a

backing spanner when slackening or tightening

brake and fuel pipe unions.

Fitting a split pin

Always fit new split-pins of the correct size for the

hole in the bolt or stud. Do not slacken back nut to

enter split-pin.

Always fit new roll pins of an interference fit in the

hole.

Always fit new circlips of the correct size for the

groove.

Self-locking nuts

Self-locking nuts, i.e. nylon insert or metal stiff nuts

can be re-used providing resistance can be felt

when the locking portion of the nut passes over the

thread of the bolt or stud.

4

GENERAL PRECAUTIONS AND FITTING INSTRUCTIONS

Page 23

GENERAL INFORMATION

Self-locking bolts and screws

Self-locking bolts and screws, i.e. nylon patched or

trilobular thread can be re-used providing resistance

can be felt when the locking portion enters the

female thread.

Nylon patched bolts and screws have a locking

agent pre-applied to the threads. They are identified

by the presence of a coloured section of thread

which extends for up to 180° around the thread.

Trilobular i.e. Powerlok bolts have a special thread

form which creates a slight interference in the

tapped hole or threads of the nut into which it is

screwed.

DO NOT re-use self-locking fasteners in critical

locations eg engine bearings flywheel. Always use

the correct replacement self-locking nut, bolt or

screw.

DO NOT fit non self-locking fasteners in applications

where a self-locking nut, bolt or screw is specified.

Encapsulated bolts and screws

Encapsulated bolts and screws have a

micro-encapsulated locking agent pre-applied to the

thread. They are identified by the presence of a

coloured section of thread which extends completely

around the thread - 360°. The locking agent is

released and activated by the assembly process and

is then chemically cured to provide the locking

action.

Unless a specific repair procedure states otherwise,

encapsulated bolts may be re-used providing the

threads are undamaged and the following procedure

is adopted.

Remove loose adhesive from the bolt and housing

threads, ensure threads are clean and free of oil and

grease. Apply an approved adhesive.

Fit a new encapsulated bolt, or if not available a bolt

of equivalent specification treated with an approved

adhesive.

GENERAL PRECAUTIONS AND FITTING INSTRUCTIONS 5

Page 24

GENERAL INFORMATION

Oil seals

Always renew oil seals which have been removed

from their working location either as an individual

component or as part of an assembly.

Ensure the surface on which the new seal is to run is

free of burrs or scratches. Renew the component if

the original sealing surface cannot be completely

restored.

Protect the seal from any surface which it has to

pass when being fitted. Use a protective sleeve or

tape to cover the relevant surface.

Lubricate the sealing lips with a recommended

lubricant before use to prevent damage in initial use.

On dual lipped seals, smear the area between the

lips with grease.

Use the recommended service tool to fit an oil seal.

If the correct service tool is not available, use a

suitable tube approximately 0.4 mm smaller than the

outside diameter of the seal.

Body repairs

Any damage found, that would affect the corrosion

resistance of the vehicle during the Warranty period

must be rectified by an authorised Rover Dealer to

the standards, and by the methods, detailed in the

Body Repair Manual.

Replacement body panels

Body panels are supplied coated in cathodic

electrocoat primer.

Synthetic rubber

Many ’O’ rings, seals, hoses, flexible pipes and other

similar items which appear to be natural rubber, are

in fact, made of synthetic materials called

Fluoroelastomers. Under normal operating

conditions this material is safe and does not present

a health hazard. However, if the material is

damaged by fire or excessive heating, it can break

down and produce highly corrosive Hydrofluoric acid

which can cause serious burns on contact with skin.

If skin contact does occur:

Press or drift the seal in to the depth of its housing,

with the sealing lip facing the lubricant to be retained

if the housing is shouldered, or flush with the face of

the housing where no shoulder is provided.

Service tools and garage equipment

Special service tools have been developed to

facilitate removal, dismantling and assembly of

mechanical components in a cost effective and

practical manner without causing damage. Some

operations in this Manual cannot be carried out

without the aid of the relevant service tools.

TestBook

TestBook is a computerised workshop tool which

provides your dealership with instant access to the

very latest Technical Information from ROVER,

allowing for accurate and effective fault diagnosis

and repair of all Rover Vehicles.

Where specific garage equipment is required for

diagnosis and repair, reference should be made to

the Service Tools and Equipment Programme where

details of the equipment recommended by Rover

Service may be found.

• Remove any contaminated clothing immediately.

• Irrigate effected area with a copious amount of

cold water or limewater for 15 to 60 minutes.

• Obtain medical assistance immediately

Should the material be in a burnt or over-heated

condition handle only with seamless industrial

gloves. Decontaminate and dispose of loves

immediately after use.

6

GENERAL PRECAUTIONS AND FITTING INSTRUCTIONS

Page 25

GENERAL INFORMATION

FUEL HANDLING PRECAUTIONS

General

The following information provides basic precautions

which must be observed if petrol (gasoline) is to be

handled safely. It also outlines other areas of risk

which must not be ignored. This information is

issued for basic guidance only, and if in doubt

appropriate enquiries should be made of your local

Fire Officer.

Petrol - Gasoline

Petrol/gasoline vapour is highly flammable and in

confined spaces is also explosive and toxic.

When petrol/gasoline evaporates it produces 150

times its own volume in vapour which when diluted

with air becomes a readily ignitable mixture. The

vapour is heavier than air and will always fall to the

lowest level. It can readily be distributed throughout

a workshop by air currents; consequently, even a

small spillage of petrol/ gasoline is potentially very

dangerous.

Always have a fire extinguisher containing FOAM,

CO2, GAS or POWDER close at hand when

handling or draining fuel or when dismantling fuel

systems and in other areas where fuel containers

are stored.

Always disconnect the vehicle battery before

carrying out dismantling or draining work on a fuel

system.

Fuel tank drainage

WARNING: Petrol/gasoline must not be

extracted or drained from any vehicle

whilst it is standing over a pit.

Draining or extraction of petrol/gasoline from a

vehicle fuel tank must be carried out in a well

ventilated area.

The receptacle used to contain the

petrol/gasoline must be more than adequate for

the full amount of fuel to be extracted or drained.

The receptacle should be clearly marked with its

contents, and placed in a safe storage area

which meets the requirements of local authority

regulations.

CAUTION: When petrol/gasoline has been

extracted or drained from a fuel tank the

precautions governing naked lights and

ignition sources should be maintained.

Fuel tank removal

When the fuel line is secured to the fuel tank outlet

by a spring steel clip, the clip must be released

before the fuel line is disconnected or the fuel tank is

removed. This procedure will avoid the possibility of

residual petrol fumes in the fuel tank being ignited

when the clip is released.

As an added precaution fuel tanks should have a

’PETROL (GASOLINE) VAPOUR’ warning label

attached to them as soon as they are removed from

the vehicle.

Whenever petrol/gasoline is being handled, drained

or stored or when fuel systems are being

dismantled, all forms of ignition must be

extinguished or removed; any leadlamps must be

flameproof and kept clear of spillage.

WARNING: No one should be permitted to

repair components associated with

petrol/gasoline without first having

specialist training.

FUEL HANDLING PRECAUTIONS 1

Page 26

GENERAL INFORMATION

Fuel tank repairs

Under no circumstances should a repair to any fuel

tank involving heat treatment be carried out without

first rendering the tank SAFE, by using one of the

following methods:

a. STEAMING: With the filler cap and tank unit

removed, empty the tank. Steam the tank for at least

two hours with low pressure steam. Position the tank

so that condensation can drain away freely, ensuring

that any sediment and sludge not volatized by the

steam is washed out during the steaming process.

b. BOILING: With the filler cap and tank unit

removed, empty the tank. Immerse the tank

completely in boiling water containing an effective

alkaline degreasing agent or a detergent, with the

water filling and also surrounding the tank for at least

two hours.

After steaming or boiling, a signed and dated label to

this effect should be attached to the tank.

Body and chassis repairs

When a body or chassis repairs involve the use of

heat, all fuel pipes which run in the vicinity of the

repair area must be removed, and the tank outlet

plugged, BEFORE HEAT IS APPLIED. If the repair

is in the vicinity of the fuel tank, the tank must be

removed.

Plastic fuel pipes are particularly susceptible to heat,

even at relatively low temperature, and can be

melted by heat conducted from some distance away.

Fuel lines or tanks must not be removed whilst the

vehicle is over an inspection pit.

2

FUEL HANDLING PRECAUTIONS

Page 27

GENERAL INFORMATION

ELECTRICAL PRECAUTIONS

General

The following guidelines are intended to ensure the

safety of the operator whilst preventing damage to

the electrical and electronic components fitted to the

vehicle. Where necessary specific precautions are

detailed in the relevant sections of this Manual which

should be referred to prior to commencing repair

operations.

Equipment - Prior to commencing any test

procedure on the vehicle ensure that the relevant

test equipment is working correctly and any harness

or connectors are in good condition, this particularly

applies to mains lead and plugs.

WARNING: Before commencing work on

an ignition system all high tension

terminals, adapters and diagnostic

equipment for testing should be inspected to

ensure that they are adequately insulated and

shielded to prevent accidental personal contacts

and minimise the risk of shock. Wearers of

surgically implanted pacemaker devices should

not be in close proximity to ignition circuits or

diagnostic equipment.

Polarity - Never reverse connect the vehicle battery

and always observe the correct polarity when

connecting test equipment.

High Voltage Circuits - Whenever disconnecting live

ht circuits always use insulated pliers and never

allow the open end of the ht lead to come into

contact with other components particularly ECU’s.

Exercise caution when measuring the voltage on the

coil terminals while the engine is running, high

voltage spikes can occur on these terminals.

Having confirmed a component to be faulty switch

off the ignition and disconnect the battery. Remove

the component and support the disconnected

harness. When replacing the component keep oily

hands away from electrical connection areas and

push connectors home until any locking tabs fully

engage.

Battery disconnection

Before disconnecting the battery, switch off all

electrical equipment. If the radio is to be serviced,

ensure the security code has been deactivated.

CAUTION: To prevent damage to electrical

components ALWAYS disconnect the

battery when working on the vehicle

electrical system. The earth lead must be

disconnected first and reconnected last.

Always ensure that battery leads are routed

correctly and are not close to any potential

chafing points.

Battery charging

Recharge the battery out of the vehicle and keep the

top well ventilated. While being charged or

discharged, and for approximately fifteen minutes

afterwards, batteries emit hydrogen gas. This gas is

inflammable.

Always ensure any battery charging area is well

ventilated and that every precautions is taken to

avoid naked flames and sparks.

Connectors and Harness - The engine compartment

of a vehicle is a particularly hostile environment for

electrical components and connectors. Always

ensure these items are dry and oil free before

disconnecting and connecting test equipment. Never

force connectors apart either by using tools or by

pulling on the wiring harness. Always ensure locking

tabs are disengaged before removal and not

orientation to enable correct reconnection. Ensure

that any protective covers and substances are

replaced if disturbed.

ELECTRICAL PRECAUTIONS 1

Page 28

GENERAL INFORMATION

Disciplines

Switch off ignition prior to making any connection or

disconnection in the system as electrical surge

caused by disconnecting ’live’ connections can

damage electronic components.

Ensure hands and work surfaces are clean and free

of grease, swarf, etc. as grease collects dirt which

can cause tracking or high-resistance contacts.

When handling printed circuit boards, treat them as

you would a disc - hold by the edges only; note that

some electronic components are susceptible to body

static.

Connectors should never be subjected to forced

removal or refit, especially inter-board connectors,

damaged contacts will cause short- circuit and

open-circuit conditions.

Prior to commencing test, and periodically during

test, touch a good earth, i.e. cigar lighter socket, to

discharge body static as some electronic

components are vulnerable to static electricity.

Grease for electrical connectors

All under bonnet and under body connectors are

protected against corrosion by the application of a

special grease on production. Should connectors be

disturbed in service or repaired or replaced, a

grease of this type, available in 150 gm tubes under

Part No. BAU 5811, should again be applied.

NOTE: The use of other greases must be

avoided as they can migrate into relays,

switches etc. contaminating the contacts

and leading to intermittent operation or failure.

2

ELECTRICAL PRECAUTIONS

Page 29

INFORMATION

CONTENTS

LIFTING AND TOWING

JACKING, SUPPORTING AND TOWING 1................................................................

WORKSHOP JACK 2..................................................................................................

WHEEL-FREE LIFT 2..................................................................................................

TOWING 2...................................................................................................................

GENERAL DATA

ENGINE 1....................................................................................................................

FUEL SYSTEM 1.........................................................................................................

COOLING SYSTEM 1..................................................................................................

CLUTCH 2...................................................................................................................

MANUAL GEARBOX 2................................................................................................

AUTOMATIC GEARBOX 2..........................................................................................

FINAL DRIVE 2............................................................................................................

WHEELS 3...................................................................................................................

TYRE SIZE 3...............................................................................................................

TYRE PRESSURES 3.................................................................................................

ELECTRICAL 3............................................................................................................

DIMENSIONS 4...........................................................................................................

WEIGHTS 4.................................................................................................................

Page

ENGINE TUNING DATA

Model: SPi with manual gearbox 1..............................................................................

Model: SPi with automatic gearbox 2...........................................................................

Model: MPi 3................................................................................................................

TORQUE WRENCH SETTINGS

GENERAL 1.................................................................................................................

ENGINE 1....................................................................................................................

EMISSION CONTROL 2..............................................................................................

ENGINE MANAGEMENT SYSTEM 2..........................................................................

FUEL SYSTEM 2.........................................................................................................

COOLING 2.................................................................................................................

MANIFOLD AND EXHAUST 3.....................................................................................

CLUTCH 3...................................................................................................................

MANUAL GEARBOX 3................................................................................................

STEERING 3...............................................................................................................

SUSPENSION 4..........................................................................................................

BRAKES 4...................................................................................................................

RESTRAINT SYSTEMS 4...........................................................................................

BODY 5........................................................................................................................

HEATING AND VENTILATION 5.................................................................................

WIPERS AND WASHERS 5........................................................................................

ELECTRICAL 5............................................................................................................

INSTRUMENTS 5........................................................................................................

CAPACITIES, FLUIDS AND LUBRICANTS

CAPACITIES 1.............................................................................................................

FLUIDS 1.....................................................................................................................

LUBRICATION 2..........................................................................................................

Page 30

Page 31

JACKING, SUPPORTING AND TOWING

INFORMATION

Jacking and support points

1. Lashing/towing eye - front

2. LH floor front reinforcement

3. RH floor front reinforcement

4. Sill reinforced brackets - front

5. LH subframe longitudinal - front

WARNING: In accordance with normal

workshop practice and to avoid the

possibility of damage or personal injury,

work must not be carried out on or under a

vehicle when it is supported solely on a jack.

Place safety supports under the sill reinforced

brackets (4 and 7).

6. RH subframe longitudinal - front

7. Sill reinforced brackets - rear

8. RH subframe longitudinal - rear

9. LH subframe longitudinal - rear

10. Lashing eye - rear

WARNING: Do not position a jack, jack

stand or wheel free support under the

subframe transverse members.

CAUTION: Use suitable hardwood or

rubber pads when jacking and supporting

the vehicle.

LIFTING AND TOWING 1

Page 32

INFORMATION

WORKSHOP JACK

Front

Locate the jack head under the front subframe

longitudinal (5 or 6) towards the rear directly below

the drive shaft.

Position a safety support under the appropriate floor

front reinforcement (2 or 3).

Side

Locate the jack head under the appropriate front sill

reinforced bracket (4).

Position a safety support under the nearest floor

front reinforcement (2 or 3).

CAUTION: The side jacking points are

designed to accommodate the vehicle jack

only.

Rear

Locate the jack head under the triangular depression

on the appropriate rear subframe longitudinal (8 or

9).

Position a safety support under the adjacent rear sill

reinforcement (7).

WHEEL-FREE LIFT

TOWING

It is recommended that a recovery trailer or two

wheel car ambulance be used. When a recovery

trailer, the car should be secured using the front

lashing/towing eye (1) and the rear lashing points on

the subframe (10). No other attachment points may

be used for this purpose. In an emergency, the car

may be towed on its own wheels using the front

lashing/towing eye.

CAUTION: Do not use the car for towing

another light vehicle, or a trailer, as it not

suitable for this purpose.

Suspended tow

A front wheel lift should be used with a cross beam

and body protection.

Before towing commences release the handbrake,

place the gear lever in neutral and the ignition switch

at ’I’. Do not tow at a speed greater than 30 mph, 50

km/h.

CAUTION: On no account should the car

be towed with the front wheels on the

ground if the transmission is faulty, the

transmission fluid level is low, or the towing

distance exceeds 30 miles, 50 km.

Two-post lift and crossbeams: Locate the pads

under the floor front reinforcements (2, 3), and under

the rear sill reinforcements (5, 7).

Longitudinal beams: Locate the beams under the

front and rear subframe longitudinals (5, 6) and (8,

9). Raise the lift a few inches and ensure the car is

firmly supported. Raise the lift to full height and

inspect the lifting points for security.

2

LIFTING AND TOWING

Page 33

Manual gearbox models

Use the front lashing/towing eye (1) for towing the

car on all four wheels from the front.

WARNING: To ensure that the steering

does not lock when the car is being towed,

it is essential that the starter key is turned

to position ’I’, and remains there while the car is

moving.

Ensure the following precautions are observed:

Do not tow if the gearbox or a drive shaft is

faulty.

Do not tow if a wheel or drive shafts are touching

the body or frame.

Ensure the gear lever is in neutral and the

handbrake is released.

Remember that greater effort than normal will be

necessary to apply the brakes if the car is being

towed without the engine running.

Automatic gearbox models

When a car with an automatic gearbox is to be

towed, a suspended tow must be used because the

gearbox is not adequately lubricated without the

engine running. The following precautions must be

observed:

INFORMATION

The selector must be at ’N’.

CAUTION: A rear suspended tow must not

be attempted as serious damage will be

caused to the automatic transmission.

NOTE: A vehicle fitted with an automatic

gearbox cannot be started by towing or

pushing.

LIFTING AND TOWING 3

Page 34

Page 35

ENGINE

Type 8 valve OHV......................................

Cylinder arrangement 4 in line - transverse........................

Bore 70.61 mm......................................

Stroke 81.28 mm....................................

Capacity 1275 cm

Firing order 1 - 3 - 4 - 2................................

Rotation Clockwise, viewed from front of engine...................................

Compression ratio 10.0: 1...........................

Valve timing

Inlet:

Opens 9°BTDC...................................

Closes 41°ABDC...................................

Exhaust:

Opens 55°BBDC...................................

Closes 17°ATDC...................................

Lubrication

System type Wet sump, crankshaft driven eccentric rotor pump................................

Relief valve opening pressure 2.0 bar..................

Pressure at idle 0.5 bar.............................

Oil pressure warning light switch opens 0.2 to 0.3 bar..........

Oil filter Full flow with disposable canister...................................

...................................

INFORMATION

3

FUEL SYSTEM

Electronic fuel injection data See Engine Tuning Data...................

Fuel Pump:

Type Electric immersible.....................................

Pump maximum pressure at 16V 2.7 bar..............

Regulated injection pressure range 1.0 to 3.0 bar ± 0.2 bar.............

COOLING SYSTEM

Pressure cap opens 0.5 bar..........................

Thermostat starts to open 88°C ± 2°.....................

Thermostat fully open 100°C ± 2°........................

Cooling fan operation:

On 105°C......................................

Off 98°C......................................

GENERAL DATA 1REVISED: 12/96

Page 36

INFORMATION

CLUTCH

Type Diaphragm spring, hydraulically operated......................................

Clutch plate diameter 180 mm.........................

MANUAL GEARBOX

Gear ratios:

Fourth 1.000 : 1...................................

Third 1.425 : 1....................................

Second 2.185 : 1..................................

First 3.647 : 1.....................................

Reverse 3.667 : 1..................................

AUTOMATIC GEARBOX

Type 3-speed, torque converter......................................

Gear ratios:

Drive 1.000 : 1....................................

Third 1.460 : 1....................................

Second 1.845 : 1..................................

First 2.690 : 1.....................................

Reverse 2.690 : 1..................................

FINAL DRIVE

Manual gearbox:

Ratio 3.213 : 1....................................

Road speed at 1000 rev/min:

Fourth 28.6 km/h................................... 17.8 mph

Third 20.1 km/h.................................... 12.5 mph

Second 13.1 km/h.................................. 8.2mph

First 7.9 km/h..................................... 4.9mph

Automatic gearbox:

Ratio 2.690 : 1....................................

Road speed at 1000 rev/min:

Drive 29.3 km/h.................................... 18.2 mph

Third 20.1 km/h.................................... 12.5 mph

Second 15.9 km/h.................................. 9.9mph

First 10.1 km/h..................................... 6.8mph

2

GENERAL DATA

Page 37

WHEELS

Wheel size and type:

Steel wheel (spare only) 4«J x 12.....................

Standard alloy wheel 4«J x 12........................

Optional alloy wheel 6J x 13........................

TYRE SIZE

Steel spare wheel 145/70-SR 12...........................

Standard alloy wheel 145/70-SR 12.........................

Optional alloy wheel 175/50-VR 13.........................

TYRE PRESSURES

Pressures (cold):

INFORMATION

Loading conditions bar lbf/in

All load conditions

145/70-SR 12

Front 2.0 28

Rear 2.0 28

175/50-VR 13

Front 2.0 28

Rear 1.8 26

ELECTRICAL

System 12 volt, negative earth....................................

Battery

Cold crank 265 amps.................................

Reserve capacity 45 minutes............................

Alternator

Type A115l - 65......................................

Maximum output 65 Amps............................

Regulator 21TR..................................

Starter motor

Type M79......................................

Power 0.8 kW....................................

GENERAL DATA 3

Page 38

INFORMATION

DIMENSIONS

Overall length 3.05 m..............................

Overall width (including mirrors) 1.58 m................

Overall height * 1.34 m.............................

Ground clearance * 163 mm..........................

Wheelbase 2.04 m.................................

Turning circle (kerb to kerb):

145/70 SR-12 tyres 8.60 m.........................

175/VR-13 tyres 8.80 m............................

* At unladen weight

WEIGHTS

Unladen (fuel tank full, excluding optional fittings) 715 kg...

Maximum gross vehicle weight 1050 kg.................

Maximum roof rack load (distributed) 50 kg............

CAUTION: Do not use the vehicle for towing a trailer, as it is not suitable for this purpose.

4

GENERAL DATA

Page 39

Model: SPi with manual gearbox

INFORMATION

Engine

Type / Capacity 12A2EK71/1275 cm

Firing order 1 - 3 - 4 - 2................................

Compression ratio 10.0: 1...........................

Idle speed, controlled by the ECM * 900 æ 50 rev/min.............

Exhaust gas CO content at idle less than 0.4% hot.................

Ignition timing at idle speed ¸c15°BTDC (nominal)..................

Valve rocker clearance (cold) 0.27 to 0.33 mm..................

Ignition Coil

Type Quad type dry......................................

Part No. NEC 1000710...................................

Primary resistance at 20°C 0.41 to 0.61 ohm....................

Secondary resistance at 20°C 6200 to 6700 ohm..................

Consumption at engine idle speed 4.7 to 6.7 amps..............

Spark Plugs

Type NGK BPR6E......................................

Plug gap 0.80 to 0.90 mm..................................

Engine Management System

Type Single point throttle body injection......................................

MEMS ECM MNE 101350................................

Fuel pump module WFX 10047...........................

Injector/fuel pressure regulator JZX 3300................

Fuel pressure 1.0 æ 0.2 bar constant..............................

Throttle position (TP) sensor MJC 10020...................

Intake air temperature (IAT) sensor NNK 10001..............

Crankshaft position (CKP) sensor ADU 7340...............

Engine coolant temperature (ECT) sensor ADU 7161........

Heated oxygen sensor (HO2S) MHK 10004.................

Lost motion gap at engine idle speed Equal either side of lever............

TP sensor voltage:

Throttle closed 0 to 1v.............................

Throttle open 90° 4to5v...........................

Throttle open 65° 3to4v...........................

Fuel grade 95 RON minimum - UNLEADED fuel.................................

.............................

3

CAUTION: Do not use LEADED fuel as it will damage the catalyst. Serious damage to the engine may

occur if a lower octane number fuel than that recommended is used.

* No electrical load present

¸c Crankshaft degrees and rev/min

ENGINE TUNING DATA 1

Page 40

INFORMATION

Model: SPi with automatic gearbox

Engine

Type / Capacity 12A2EK72/1275 cm

Firing order 1 - 3 - 4 - 2................................

Compression ratio 9.4: 1...........................

Idle speed, controlled by the ECM * 900 æ 50 rev/min.............

Exhaust gas CO content at idle less than 0.4% hot.................

Ignition timing at idle speed ¸c15°BTDC (nominal)..................

Valve rocker clearance (cold) 0.27 to 0.33 mm..................

Ignition Coil

Type Quad type dry......................................

Part No. NEC 1000710...................................

Primary resistance at 20°C 0.41 to 0.61 ohm....................

Secondary resistance at 20°C 6200 to 6700 ohm..................

Consumption at engine idle speed 4.7 to 6.7 amps..............

Spark Plugs

Type NGK BPR6E......................................

Plug gap 0.80 to 0.90 mm..................................

Engine Management System

Type Single point throttle body injection......................................

MEMS ECM MNE 101350................................

Fuel pump module WFX 10047...........................

Injector/fuel pressure regulator JZX 3300................

Fuel pressure 1.0 æ 0.2 bar constant..............................

Throttle position (TP) sensor MJC 10020...................

Intake air temperature (IAT) sensor NNK 10001..............

Crankshaft position (CKP) sensor ADU 7340...............

Engine coolant temperature (ECT) sensor ADU 7161........

Heated oxygen sensor (HO2S) MHK 10004.................

Lost motion gap at engine idle speed Equal either side of lever............

TP sensor voltage:

Throttle closed 0 to 1v.............................

Throttle open 90° 4to5v...........................

Throttle open 65° 3to4v...........................

Fuel grade 95 RON minimum - UNLEADED fuel.................................

.............................

3

CAUTION: Do not use LEADED fuel as it will damage the catalyst. Serious damage to the engine may

occur if a lower octane number fuel than that recommended is used.

* No electrical load present

¸c Crankshaft degrees and rev/min

2

ENGINE TUNING DATA

Page 41

Model: MPi

INFORMATION

Engine

Type / Capacity 12A2LK70/1275 cm

Firing order 1 - 3 - 4 - 2................................

Compression ratio 10.0: 1...........................

Idle speed, controlled by the ECM * 900 æ 50 rev/min.............

Exhaust gas CO content at idle less than 0.4% hot.................

Ignition timing at idle speed ¸c12°BTDC (nominal)..................

Valve rocker clearance (cold) 0.27 to 0.33 mm..................

Ignition Coil

Type Quad type dry......................................

Part No. NEC 1000710...................................

Primary resistance at 20°C 0.41 to 0.61 ohm....................

Secondary resistance at 20°C 6200 to 6700 ohm..................

Consumption at engine idle speed 4.7 to 6.7 amps..............

Spark Plugs

Type NGK BPR6E......................................

Plug gap 0.80 to 0.90 mm..................................

Engine Management System

Type Two point injection......................................

MEMS ECM MNE 104290................................

Fuel pump module WFX 100810...........................

Injector/fuel pressure regulator MKW 10016................

Fuel pressure 3.0 æ 0.2 bar constant..............................

Throttle position (TP) sensor MJC 10020...................

Intake air temperature (IAT) sensor NNK 10001..............

Crankshaft position (CKP) sensor ADU 7340...............

Camshaft position (CMP) sensor NSC100390................

Engine coolant temperature (ECT) sensor MEK 100060........

Heated oxygen sensor (HO2S) MHK 10004.................

TP sensor voltage:

Throttle closed 0 to 1v.............................

Throttle open 90° 4to5v...........................

Throttle open 65° 3to4v...........................

Fuel grade 95 RON minimum - UNLEADED fuel.................................

.............................

3

CAUTION: Do not use LEADED fuel as it will damage the catalyst. Serious damage to the engine may

occur if a lower octane number fuel than that recommended is used.

* No electrical load present

¸c Crankshaft degrees and rev/min

ENGINE TUNING DATA 3

Page 42

Page 43

Refer to the appropriate section heading for component torque figures, e.g.

Road wheel nuts - refer to SUSPENSION,

Exhaust front pipe to manifold - refer to MANIFOLD AND EXHAUST

GENERAL

Bolt M6 10 Nm...................................

Bolt M8 25 Nm...................................

Bolt M10 45 Nm..................................

Bolt M12 80 Nm..................................

1/4 UNC/UNF 9 Nm..............................

5/16 UNC/UNF 25 Nm.............................

3/8 UNC/UNF 40 Nm..............................

7/16 UNC/UNF 75 Nm.............................

1/2 UNC/UNF 90 Nm..............................

5/8 UNC/UNF 135 Nm..............................

INFORMATION

ENGINE

Timing gear cover bolts 16 Nm.......................

Timing gear nuts 90 Nm............................

Timing chain tensioner bolts 22 Nm...................

Cylinder head nuts 34 Nm then a further 34 Nm...........................

Front cover plate bolts 11 Nm........................

Rocker shaft nuts 25 Nm............................

Camshaft thrust plate screws 11 Nm..................

Rocker cover bolts 5 Nm...........................

Crankshaft pulley bolt 150 Nm........................

Engine LH mounting:

Mounting to subframe - nuts 25 Nm..................

Mounting to engine - bolts 25 Nm....................

Engine RH mounting:

Mounting to flywheel housing cover - bolts 18 Nm.......

Mounting to subframe - nuts 22 Nm..................

Engine steady bar upper bolts 22 Nm..................

Engine steady bar lower:

Bar to subframe bolt 40 Nm........................

Bar to flywheel housing bolt 40 Nm...................

Oil pressure gauge sensor 60 Nm....................

Oil pressure relief valve cap 60 Nm...................

Oil pressure switch 25 Nm..........................

Oil pump to engine - bolts 11 Nm.....................

Flywheel housing to engine/gearbox - bolts 25 Nm.......

Earth lead to engine - bolt 10 Nm.....................

Engine to gearbox - nuts and bolts 8 Nm..............

Flywheel to crankshaft - bolt 150 Nm...................

Flywheel housing cover - bolts 10 Nm.................

Engine mounting adaptor plate to engine - bolts 25 Nm....

TORQUE WRENCH SETTINGS 1REVISED: 12/96

Page 44

INFORMATION

EMISSION CONTROL

Oil breather/separator to flywheel housing 18 Nm........

Catalytic converter to tail pipe nuts 9 Nm..............

Catalytic converter to front pipe nuts 45 Nm.............

Emission canister purge valve to body - bolts 9 Nm......

ENGINE MANAGEMENT SYSTEM

ECT sensor to thermostat housing 15 Nm..............

MAP sensor to inlet manifold 6 Nm...................

IAT sensor to inlet manifold 7 Nm....................

TP sensor to throttle body screws 1.5 Nm...............

Throttle housing to inlet mainifold - bolts 8 Nm..........

Throttle pedal nuts 25 Nm...........................

Spark plugs 25 Nm................................

Ignition coil to bracket - bolts 10 Nm...................

HO2S to exhaust manifold 55 Nm.....................

Air cleaner to inlet manifold 7 Nm....................

ECM to mounting bracket 10 Nm.....................

ECM mounting bracket to body 10 Nm.................

IACV to inlet manifold - bolts 7 Nm...................

CMP sensor to engine - bolt 10 Nm...................

CKP sensor to flywheel housing - bolts 6 Nm...........

CKP sensor multiplug to flywheel housing - bolt 3 Nm....

FUEL SYSTEM

Fuel breather valve nut 9 Nm.......................

Fuel pump to fuel tank nuts 9 Nm....................

IFS to bulkhead - screws 2 Nm......................

Fuel filter mounting bracket to body 9 Nm..............

Fuel pipe unions to fuel filter 30 Nm...................

Fuel feed/return pipes to fuel rail 5 Nm................

Fuel rail to inlet manifold - bolts 10 Nm.................

COOLING

Radiator brackets to bonnet platform 9 Nm.............

Thermostat housing bolts 11 Nm.....................

Coolant pump bolts 22 Nm..........................

Coolant pump pulley bolts 10 Nm.....................

Expansion tank to mounting bracket 10 Nm.............

Expansion tank mounting bracket to body 10 Nm.........

2

TORQUE WRENCH SETTINGS REVISED:12/96

Page 45

MANIFOLD AND EXHAUST

Front pipe to manifold nuts 22 Nm....................

Front pipe to differential housing 22 Nm................

Inlet and exhaust manifold nuts 22 Nm.................

Catalytic converter to tail pipe nuts 9 Nm..............

Catalytic converter to front pipe nuts 45 Nm.............

CLUTCH

Flywheel centre bolt 150 Nm..........................

Pressure plate to flywheel bolts 25 Nm.................

Flywheel housing to engine block bolts 25 Nm...........

Slave cylinder to mounting bracket 37 Nm..............

Slave cylinder mounting bracket to flywheel

housing:

M8 bolts 37 Nm..................................

M5 bolt 7 Nm...................................

Pipe union to master cylinder 14 Nm..................

Pipe union to slave cylinder 14 Nm....................

INFORMATION

MANUAL GEARBOX

Gearbox to engine bolts 28 Nm......................

Third motion shaft bearing retaining bolts 18 Nm.........

First motion shaft gear nut 200 Nm.....................

Speedometer drive housing to gearbox - bolts 25 Nm.....

Speedometer drive housing cover - bolts 8 Nm.........

Speedometer drive pinion clamping plate - bolt 8 Nm.....

STEERING

Steering wheel nut 49 Nm...........................

Drivers air bag module Torx screws 9 Nm.............

Steering column upper mounting to fascia rail bolt 25 Nm..

Inner column to steering rack pinion clamp bolt 16 Nm....

Track rod ball joint to steering arm nut 30 Nm...........

Steering rack U-bolts 15 Nm.........................

Steering rack pinion cover bolts 15 Nm.................

Steering arm to front hub bolts 45 Nm.................

Steering column to pinion - bolt 15 Nm.................

TORQUE WRENCH SETTINGS 3REVISED: 12/96

Page 46

INFORMATION

SUSPENSION

Wheel nuts:

Alloy wheels 50 Nm...............................

Steel wheels 60 Nm..............................

Upper arm to front hub 52 Nm.......................

Lower arm to front hub 52 Nm.......................

Front hub to drive shaft - nut 260 Nm...................

Front subframe turret bolts 67 Nm....................

Front damper to body bracket - nut 37 Nm..............

Front damper to upper arm - nut 48 Nm................

Front subframe to body - nuts and bolts 25 Nm..........

Rear damper to body 25 Nm.........................

Rear damper to suspension arm 25 Nm................

BRAKES

Bleed screw to caliper 9 Nm........................

Brake master cylinder nuts 25 Nm....................

Brake servo banjo bolt 50 Nm........................

Brake servo to bracket nuts 25 Nm....................

Brake servo bracket nuts and bolts to body 25 Nm........

Brake caliper to swivel hub bolts 52Nm................

Brake disc to drive flange bolts 57 Nm.................

Brake drum back plate to radius arm bolts 28 Nm........

Pressure limiting valve to body bolt 17 Nm..............

Brake pipe to master cylinder - union 14 Nm............

Brake drum to hub - screw 7 Nm....................

Brake pipe union to pressure reducing valve 14 Nm.......

Pressure reducing valve to body - bolt 17Nm...........

Brake pedal pivot bolt - nut 15 Nm....................

Brake light switch bracket to pedal box 5 Nm...........

Brake hose union to caliper 15 Nm....................

Brake pipe unon to wheel cylinder 14 Nm...............

RESTRAINT SYSTEMS

Rotary coupler bolts 15 Nm..........................

Diagnostic unit 9 Nm..............................

Airbag module screws 7 Nm........................

Diagnostic harness earth lead bolt 10 Nm..............

Front seat belt stalk bolt 32 Nm......................

Front seat belt upper mounting bolt 32 Nm..............

Front seat belt lower mounting bolt 30 Nm..............

Front seat belt upper mounting bolt 30 Nm..............

Seat belt pre-tensioner reel bolt 30 Nm.................

Seat belt pre-tensioner tube nut 6 Nm................

Seat belt pre-tensioner tube screw 1.2 Nm..............

Rear seat belt buckle to body - bolt 30 Nm..............

Rear seat belt reel to body - bolt 30 Nm................

Rear seat belt lower mounting bolt 30 Nm..............

Rear seat belt upper mounting bolt 30 Nm..............

4

TORQUE WRENCH SETTINGS REVISED:12/96

Page 47

BODY

Bonnet hinge nuts 9 Nm...........................

Front/Rear bumper to body - nuts 10 Nm...............

Door striker to body - screws 18 Nm...................

Bonnet latch to body - bolts 9 Nm....................

Wheel arch extension to body - nuts 9 Nm.............

Fascia top rail to body - nuts 9 Nm...................

Front seat to body - nut and bolt 25 Nm................

HEATING AND VENTILATION

Heater to bulkhead - nut 9 Nm......................

INFORMATION

WIPERS AND WASHERS

Wiper wheel boxes to body - nut 10 Nm................

ELECTRICAL

Alternator pulley nut 25 Nm..........................

Auxiliary drive belt tensioner pulley nut 25 Nm...........

Auxiliary drive belt tensioner to engine 22 Nm...........

Starter motor to flywheel housing bolts 37 Nm...........

Starter solenoid terminal nuts 4 Nm..................

Horn mounting bracket to body 9 Nm.................

Horn to mounting bracket 10 Nm.....................

INSTRUMENTS

Oil temperature gauge sensor 60 Nm..................

TORQUE WRENCH SETTINGS 5ISSUED: 12/96

Page 48

Page 49

CAPACITIES

Fuel tank 34.0 litres..................................

Engine/gearbox oil refill and filter change 4.8 litres.........

Automatic gearbox 5.1 litres...........................

Cooling system refill 4.0 litres.........................

Windscreen washer reservoir 2.3 litres..................

FLUIDS

Fuel