Keyence BL-700 Series, BL-701, BL-740, BL-741, BL-780 User Manual

...

96M1126

Safety Precautions

This instruction manual describes the operation and function of the BL-700. Read

this manual carefully to ensure safe use and maximum performance from your BL-

700. The BL-700 series uses a semiconductor laser as light source. Before using

the product, see "Laser Safety Precautions" on page 1 to learn the safe and correct

method of using the BL-700 series.

Symbols

The following symbols alert you to important messages. Be sure to read these

messages carefully.

Failure to follow instruction may lead to injury. (electric

shock, burn, etc.)

Failure to follow instructions may lead to product damage.

Provides additional information on proper operation.

General Precautions

• At startup and during operation, be sure to monitor the functions and performance of the BL-700.

• We recommend that you take substantial safety measures to avoid any damage

in the event a problem occurs.

• Do not open or modify the BL-700 or use it in any way other than described in

the specifications.

• When the BL-700 is used in combination with other instruments, functions and

performance may be degraded, depending on operating conditions and the

surrounding environment.

• Do not use the BL-700 for the purpose of protecting the human body.

WARNING

CAUTION

Note:

i

ii

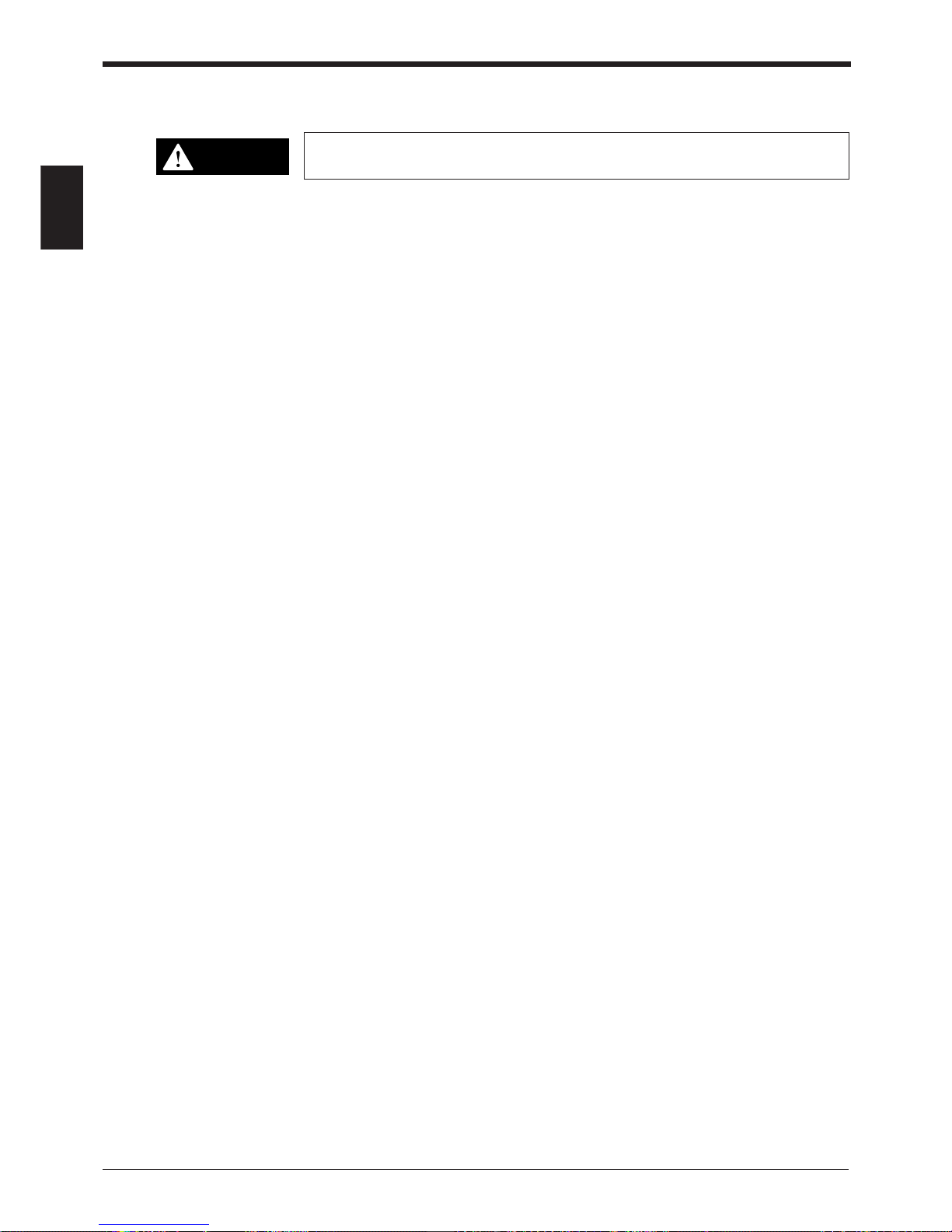

Warnings and Cautions Specific to the BL-700

• The BL-700 uses a 5 VDC power supply. Using a different voltage level

may damage the unit.

When using the KEYENCE power supply unit BL-U1, BL-U2, N-42 or N-48,

select the voltage level which can be supplied by the power supply unit. If

a nonconforming power supply is connected, the BL-700 may be damaged.

• The BL-700 is a precision instrument. If the unit is dropped or shocked, it

may be damaged. Take due consideration when transporting or installing

the unit.

• Do not hold the cables when carrying the units. The units may hit each

other and become damaged.

• Before installing the BL-700, read “2.4 Installation” of this manual carefully to

select a suitable installation site.

• You cannot perform any operation for 5 seconds after turning ON the BL-700.

During this time, the motor rotation stabilizes. Wait for a while after turning ON

the BL-700, then start reading or another operation.

• At shipment, the protective seals are affixed to the transmitter and receiver to

avoid fingerprints when mounting the unit. Be sure to remove the seals before

use.

• Do not allow water, oil or dust to adhere to the transmitter and receiver. Adhesion of these materials may cause a reading error. If the surface is contaminated, gently wipe it with a soft cloth moistened with alcohol.

CAUTION

Incorrect

Incorrect

96M1126

iii

Package Contents List

The package contains the following components. Be sure to check the package

contents against the checklist before use.

■ BL-700 package

• BL-700 unit ................................................................................................ 1

• Mounting bracket ......................................................................................1

• Mounting screw ......................................................................................... 2

• Insulating spacer ....................................................................................... 4

• Washer ...................................................................................................... 4

• Laser warning label (Japanese/English/German) ............................... 1 set

■ BL-U1 package

• BL-U1 unit .................................................................................................1

■ BL-U2 package

• BL-U2 unit .................................................................................................1

• D-sub 9-pin connector, connector case .................................................... 1

• Instruction manual ..................................................................................... 1

■ N-42 package

• N-42 unit ...................................................................................................1

• Instruction manual ..................................................................................... 1

■ Setup software, user’s manual (BL-H1WE)

• Setup software (3.5-inch, 1.44 MB) ..........................................................1

• User’s manual (this manual) ..................................................................... 1

iv

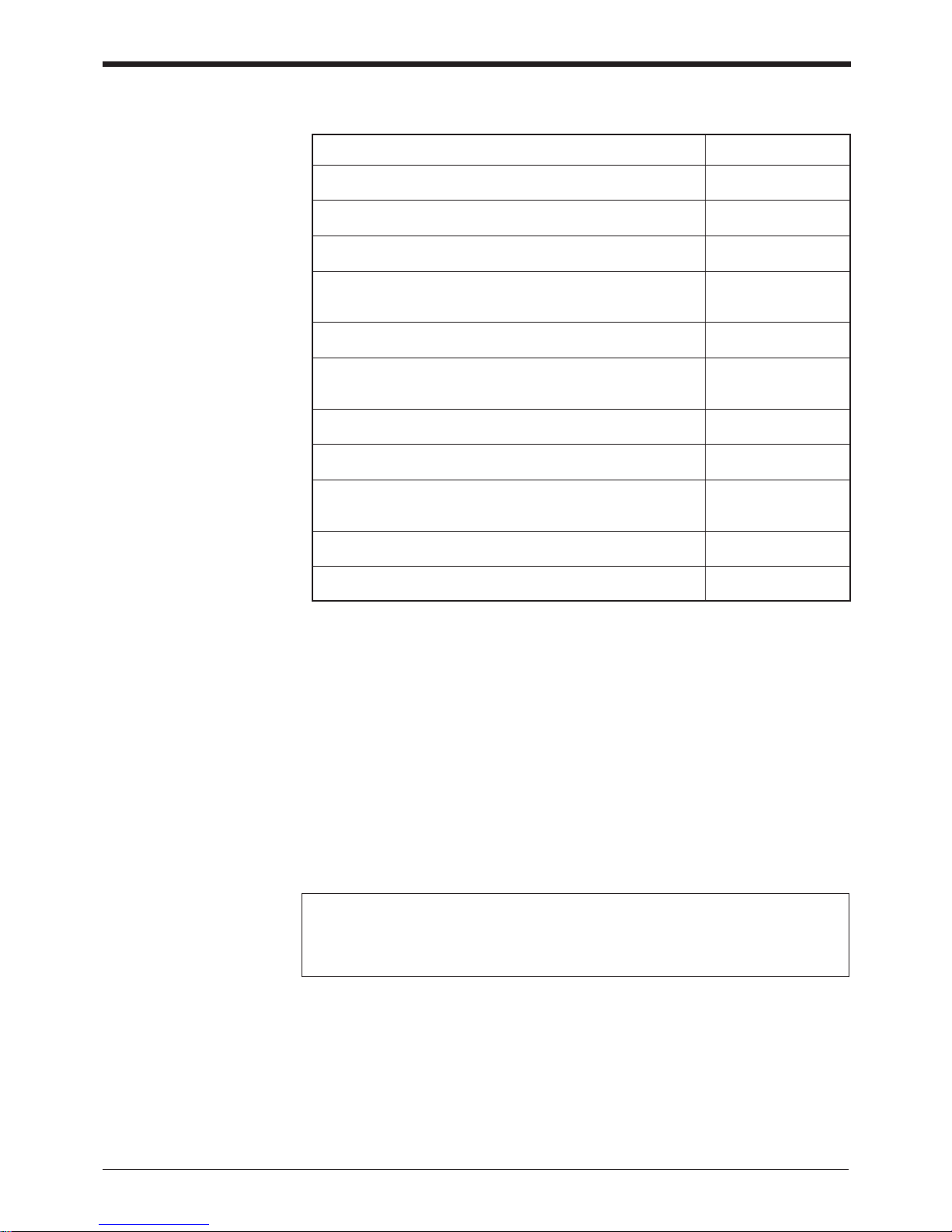

BL Series Lineup

■ Laser bar code reader

■ Power supply

■ Other options

• N-400: Multi-drop controller

Used as the master unit when multi-drop linking with the BL series.

• BL-P1E: Handheld programmer specially designed for the BL series.

Used when changing the BL-series or N-400 settings.

• OP-22149 : D-sub 25-pin (male) — D-sub 25-pin (male) RS-232C cross cable

Connects the BL-U1 to the PC (use with OP-25057).

• OP-25057 : D-sub 25-pin — D-sub 9-pin conversion connector

Used in conjunction with OP-22149 when connecting the BL-U1 to

the DOS PC.

• OP-27937: D-sub 9-pin — D-sub 9-pin RS-232C cross cable

Connects the BL-U2 to the DOS PC.

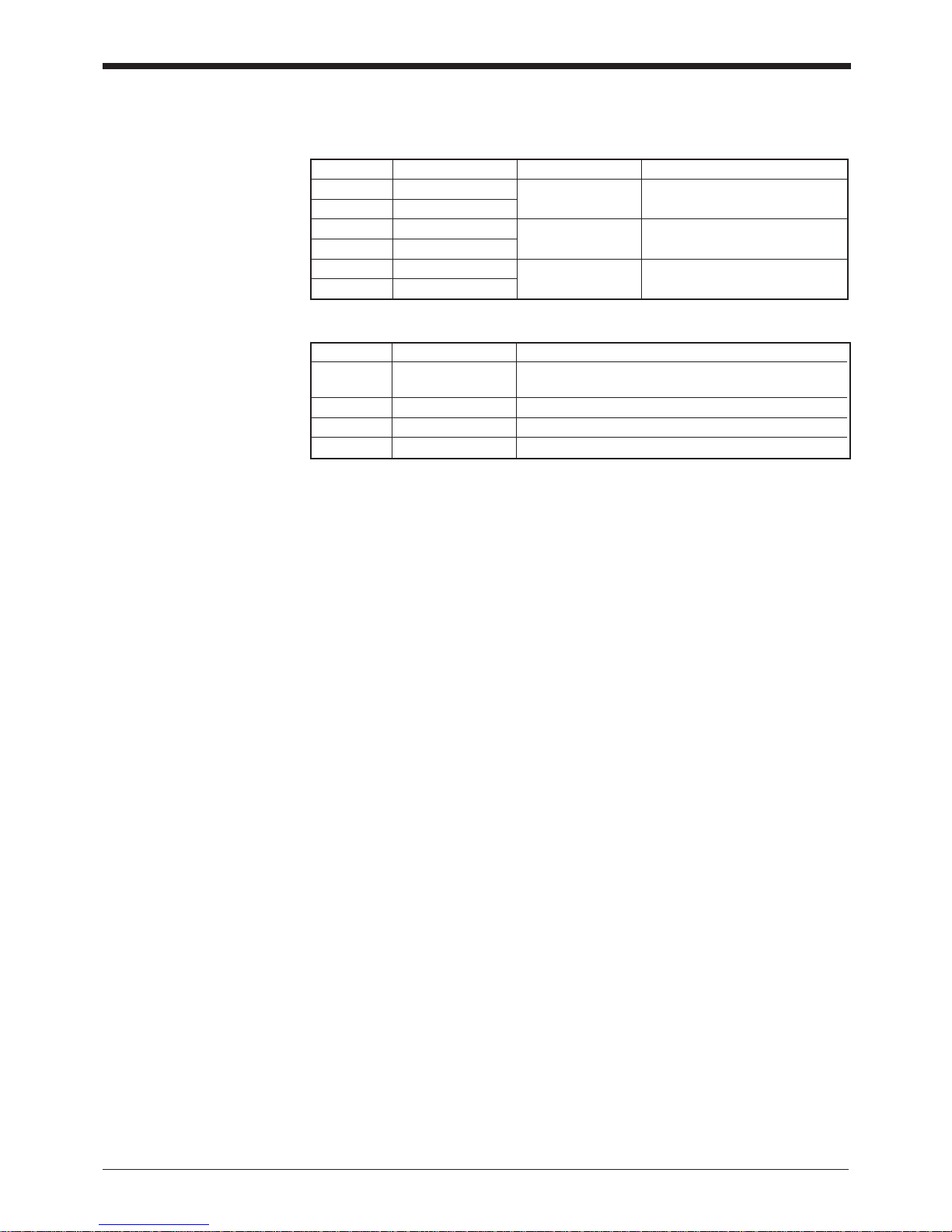

Model Scanning method Readable bar width Reading distance

BL-700 Single 0.15 to 1.0 mm 160 to 370 mm

BL-701 Raster (When narrow width is 0.5 mm)

BL-740 Single 0.25 to 2.0 mm 150 to 750 mm

BL-741 Raster (When narrow width is 1.0 mm)

BL-780 Single 0.32 to 2.0 mm 200 to 1200 mm

BL-781 Raster (When narrow width is 2.0 mm)

Model Supply voltage Interface

BL-U1 100 to 240 VAC RS-232C, RS-422A, RS-485 multi-drop

* Select one of these.

BL-U2 24 VDC RS-232C

N-42 24 VDC RS-422A

N-48 24 VDC RS-485 multi-drop

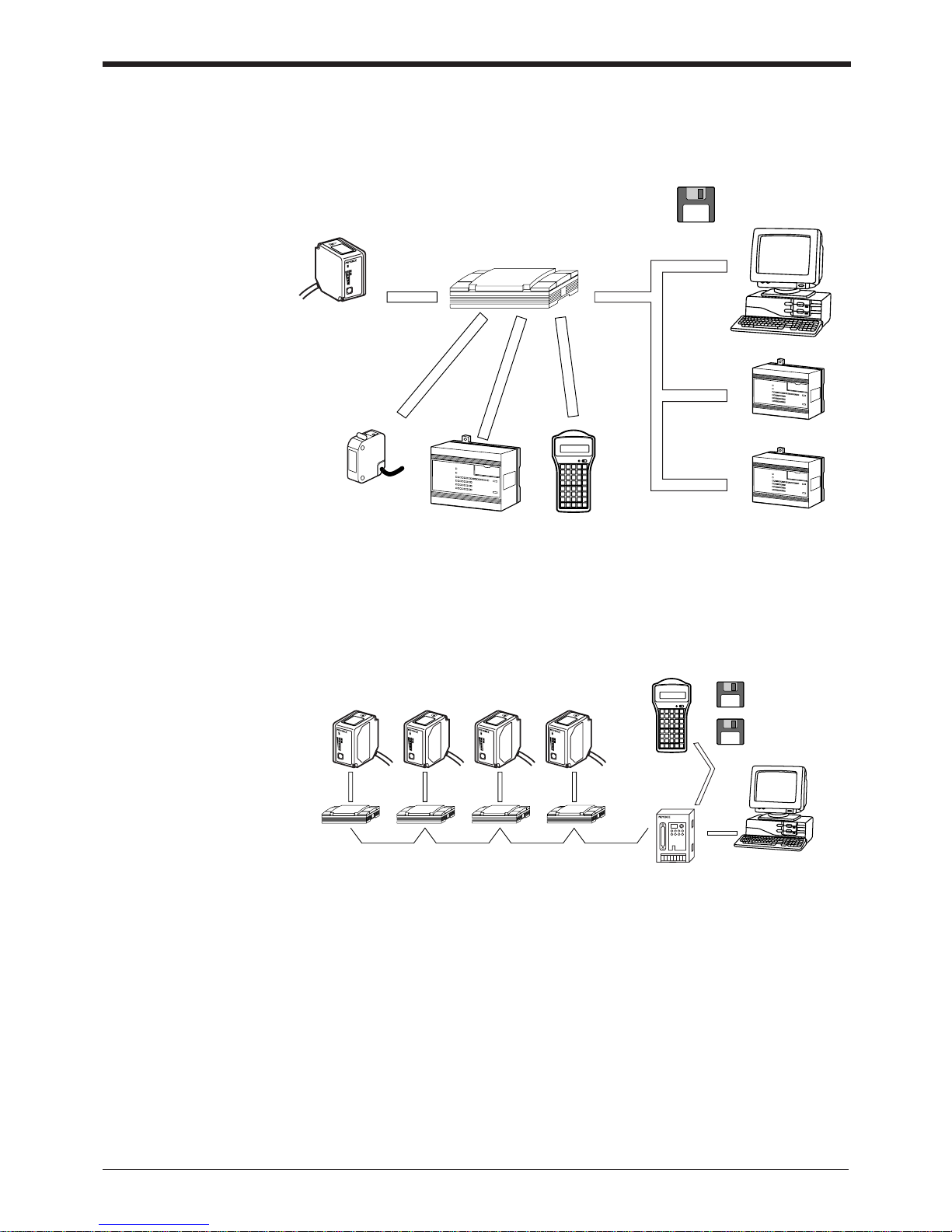

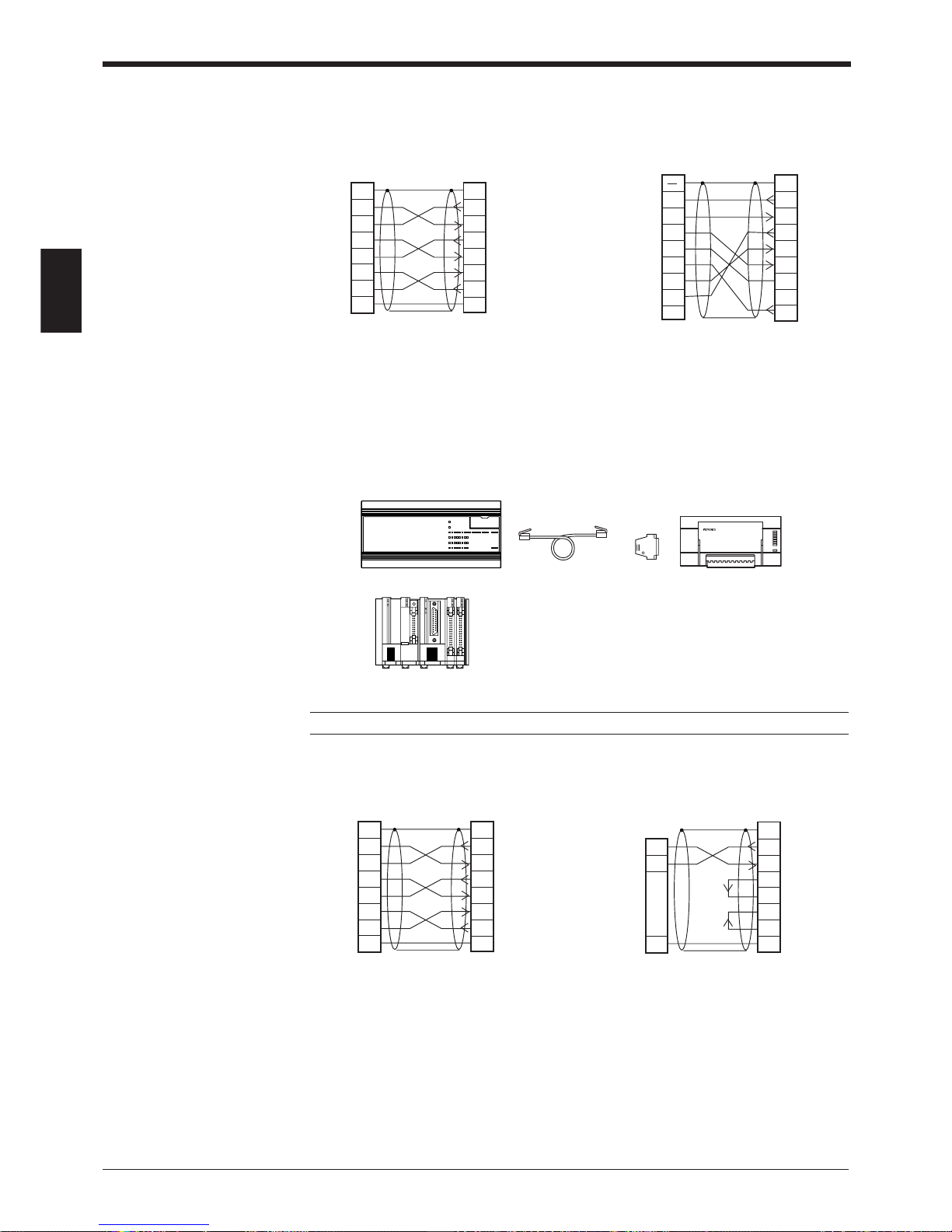

System Configuration

■ When using RS-232C or RS-422A

BL-700

RS-232C

Serial

communication

Serial

communication

BL-U1, BL-U2, N-42

Power supply unit

RS-422A

OK/NG

output

IBM PC/AT

or compatible

Setup software

for BL series

(BL-H1WE)

Windows version

Trigger input

PLC etc. Handheld

programmer BL-P1E

PLC (Link unit)

PLC (RS-232C/422A unit)

PLC link

Timing sensor

LASER ON

STB

OK/NG

TIMING

TEST

BL-700

* Use the BL setup software or the handheld programmer BL-P1E to set the BL

series.

BL-700

Power supply unit

BL-U1, N-48

RS-485

Multi-drop

controller N-400

Handheld programmer

BL-P1E

BL setup software

Windows version

N-400 setup software

Windows version

RS-232C

PC

LASER ON

STB

OK/NG

TIMING

TEST

B

L-70

0

LASER ON

STB

OK/NG

TIMING

TEST

B

L-70

0

LASER ON

STB

OK/NG

TIMING

TEST

B

L-70

0

LASER ON

STB

OK/NG

TIMING

TEST

B

L-70

0

■ When using the RS-485 multi-drop link

* Use the N-400 setup software or handheld programmer BL-P1E to set the multi-

drop controller N-400.

* For system configuration for the multi-drop link, see the “N-400 User’s Manual”.

Also, for connection and operation of the multi-drop link controller, see the “N400 User’s Manual”. The BL-700 User’s Manual does not cover these subjects.

v

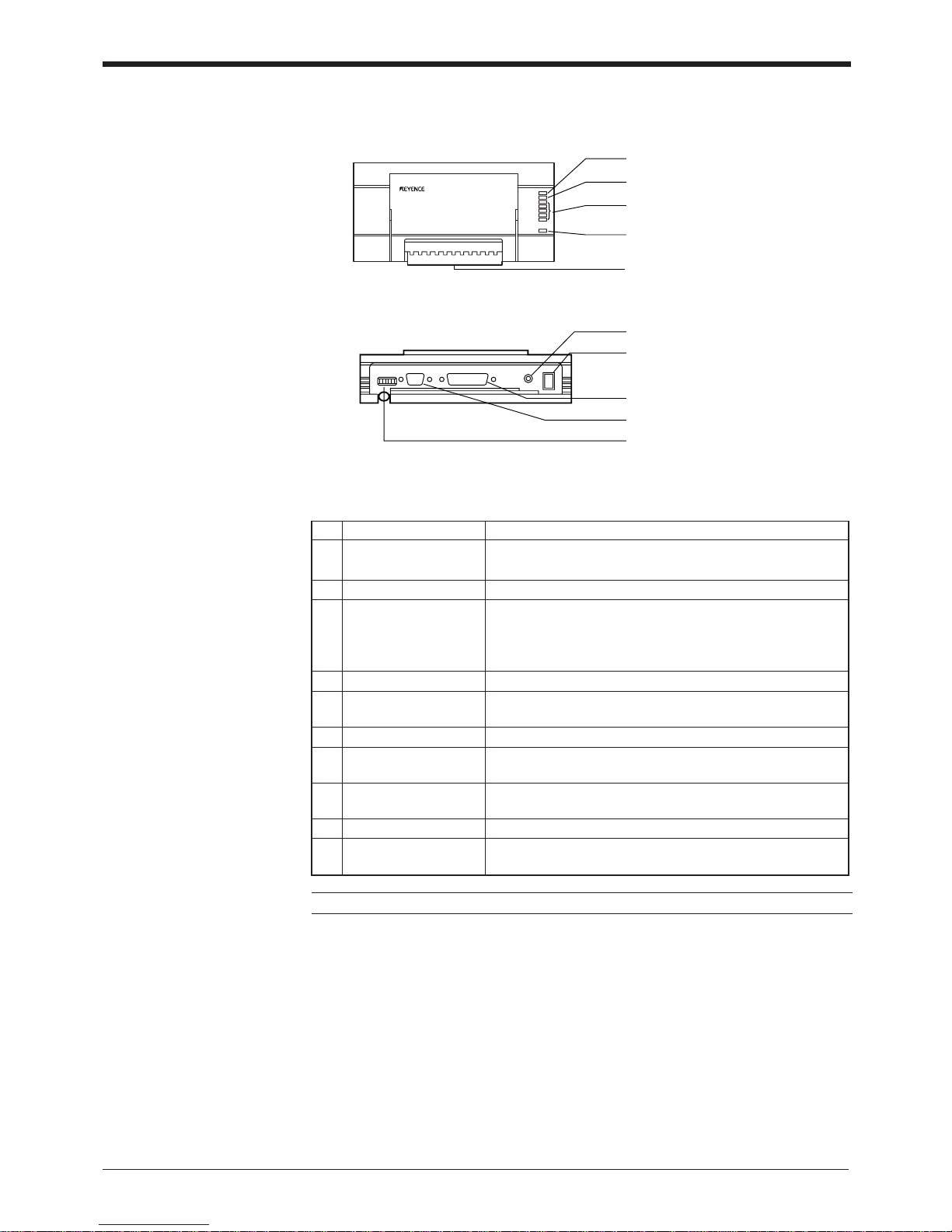

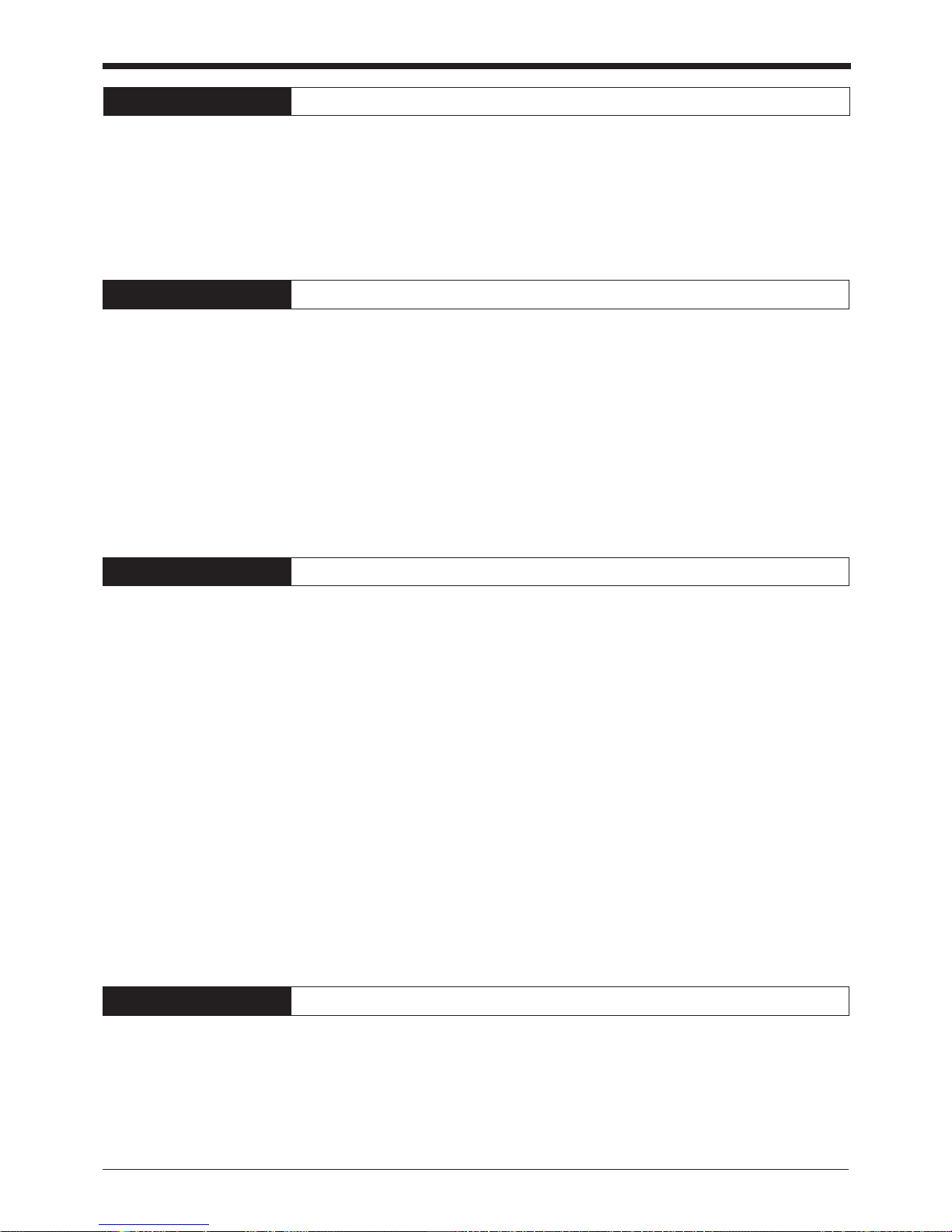

Parts and Functions

BL-700

LASER ON

STB

OK/NG

TIMING

TEST

BL-700

1LASER ON LED

2STABILITY LED

3OK/NG LED

4TIMING LED

5TEST switch

6Transmitter/receiver

7 Cable

No. Name Function

1 LASER ON LED Lit when laser beams are emitted.

2 STABILITY LED Displays the reading stability and the BL-700 operating status.

➮

See P. 64 to P. 65

3 OK/NG LED • When OK output is ON: The green LED lights.

• When NG output is ON: The red LED lights.

4 TIMING LED Lit when trigger input is ON.

5 TEST SWITCH This switch allows the following operations:

• Start the test mode.

• Pressing the switch once reads the bar code once.

• Sets the communication protocol to the initial values when

sending the settings.

➮

See P.75

• Reset the error status.

➮

See P.45

6 Transmitter/receiver Window to emit laser beams and receive reflected lights.

7 Cable Cable length is 1.8 m.

vi

No. Name Function

1 OK/NG LED • When OK output is ON: The green LED lights.

• When NG output is ON: The red LED lights.

2 TIMING LED Lit when trigger input is ON.

3 • Allows you to monitor the communication status of the

RS-232C port.

• The SD, RD, RS and CS indicators are provided in this

order from the top.

4 POWER LED Lit when power is ON.

5 I/O terminal block Includes the trigger input terminal, OK/NG output terminals,

RS-422A terminal and RS-485 terminal.

6 Power switch Turns the power ON/OFF.

7 Use a 100 to 240 VAC (50/60 Hz) power supply.

8 RS-232C port Connect a personal computer to this port. This port is

unused in multi-drop link mode.

9 READER port Connect the BL series to this port.

0 DIP switches Switches the communication port, and turns the terminator

ON/OFF.

Communication status

indicator LEDs

Power supply cable

(2 m)

BL-U1

1 OK/NG LED

2 TIMING LED

3 Communication status indicator

LEDs

4 POWER LED

5 I/O terminal block

6 Power switch

7 Power supply cable (2 m)

8 RS-232C port

9 READER port

0 DIP switches

vii

Note: This product does not comply with EC directives.

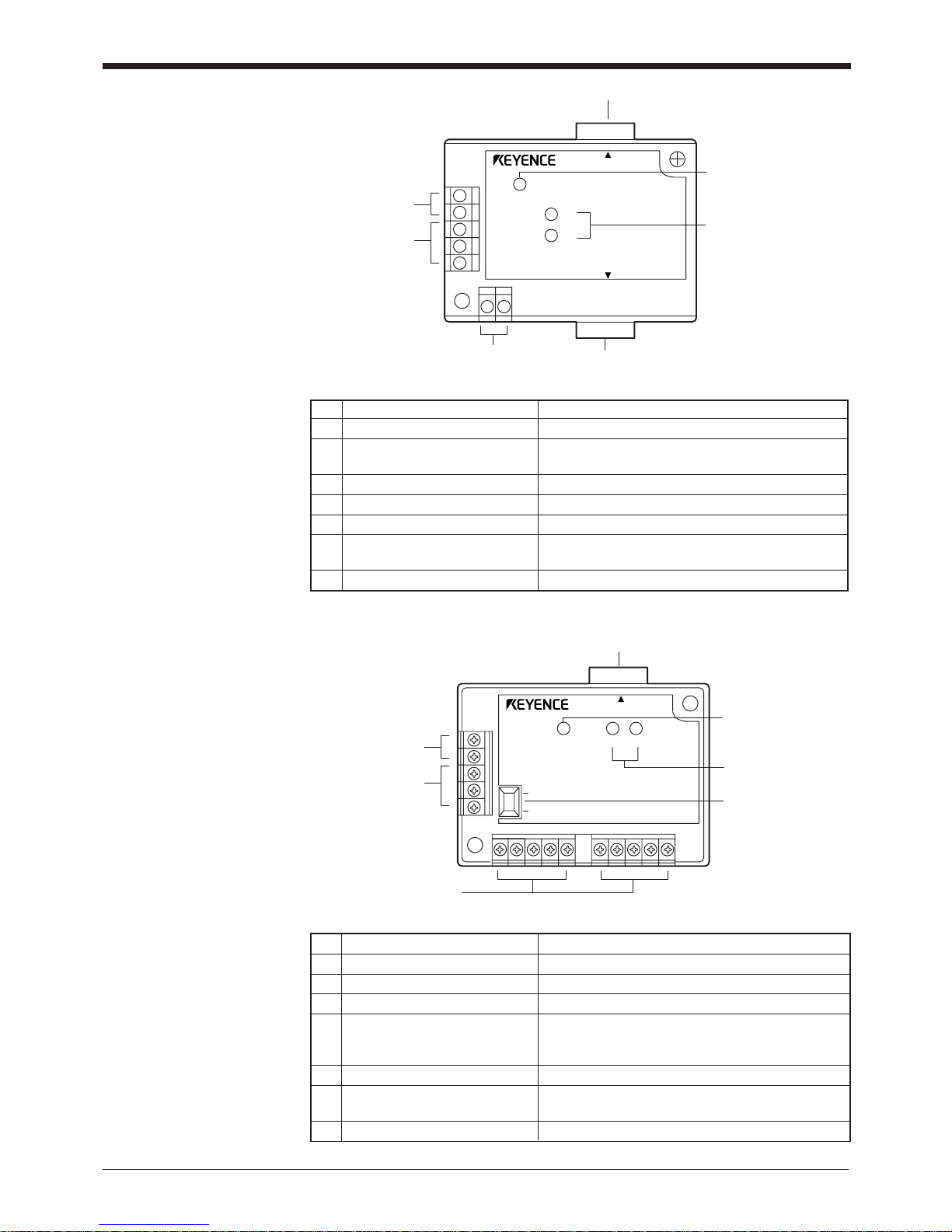

BL-U2

POWER

SD

RD

BL-U2

RS-232C

READER

7 RS-232C port

1 READER port

2 TRIGGER input

terminals

3 OK/NG output

terminals

4 Power supply

terminals

5 POWER LED

6 Communication

status indicator LEDs

5 Terminator switch

1 READER port

4 Power supply terminals

7 POWER LED

6 Communication

status indicator

LEDs

ON

OFF

2 TRIGGER input

terminals

3 OK/NG output

terminals

POWER SD RD

READER

N-42

No. Name Function

1 READER port Connects to a BL series or RS-232C equipment.

2 TRIGGER input terminals Connect to a sensor for trigger input.

3 OK/NG output terminals Output OK/NG signals.

4 Power supply/ interface The 24 VDC power supply terminal and communi-

terminal block cation interface (RS-422A or RS-485) terminal are

provided.

5 Terminator switch Turns ON/OFF the terminator resistor: 100 ).

6 Communication status Indicates the RS-422A or RS-485 communication

status.

7 POWER LED Lights when the power is turned ON

No. Name Function

1 READER port Connects to a BL series bar code reader.

2 TRIGGER Connect to a sensor for input terminals

trigger input.

3 OK/NG output terminals Output OK/NG signals.

4 Power supply terminals Connect to a 24 VDC power supply.

5 POWER LED Turns on when the power is on.

6 Communication status Indicate the communication status of the RS-232C.

indicator LEDs

7 RS-232C port Connects to a personal computer, etc.

viii

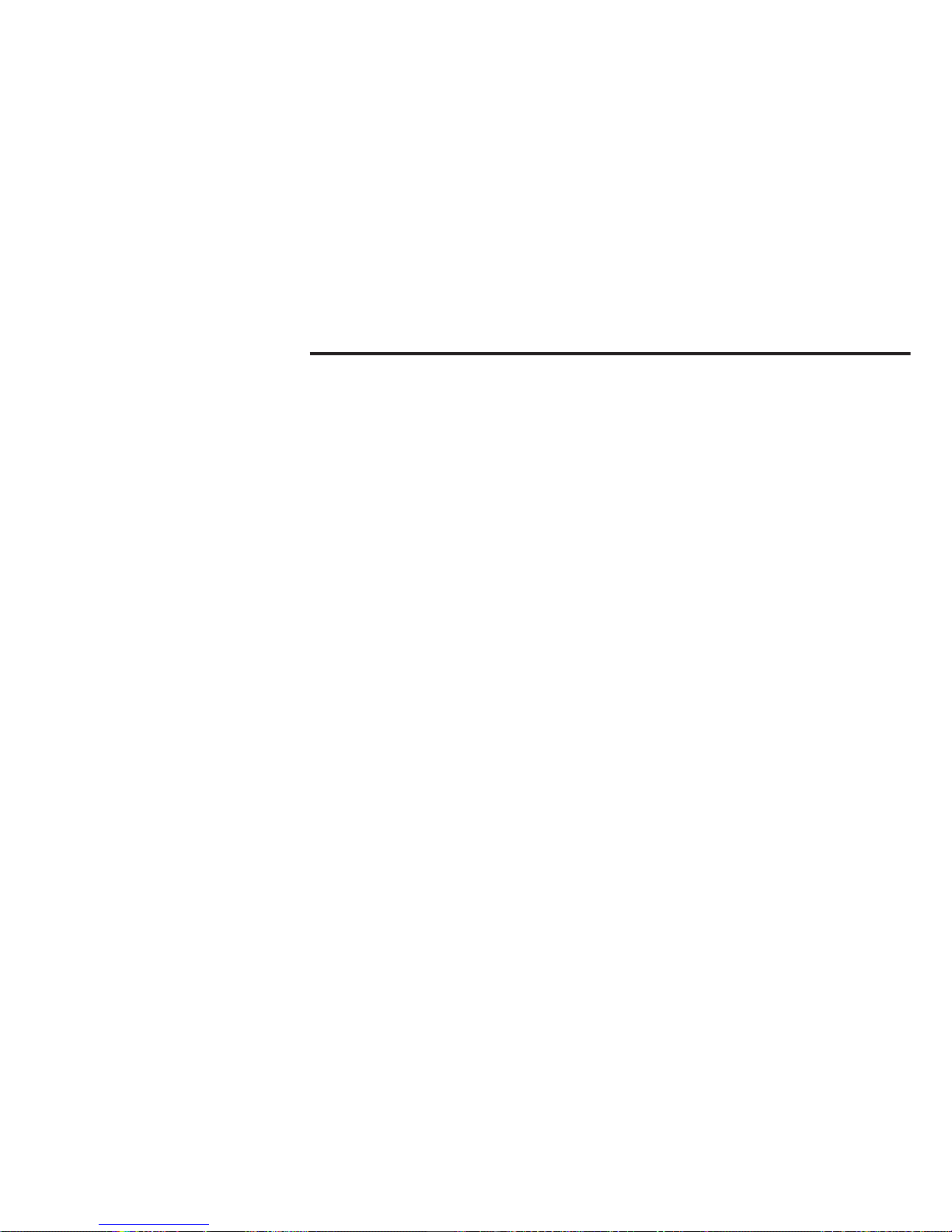

Using the Manual

* This manual uses the expression “BL-700” for the BL-700/701/740/741/780/781

unless otherwise specified.

Purpose Reference page

Turn on the trigger timing or wire the RS-232C cable. P.6 to 24

Mount the bar code reader. P.25 to 29

Perform the simple read test. P.40

Check the test mode reading rate or readout count on the P.81

PC screen.

Change the BL-700 settings using the setup software. P.51 –

Change the BL-700 settings through the handheld programmer See the BL-P1E

BL-P1E. User’s Manual.

Communicate with a PC. P.105 –

Control the BL-700 with the PLC link. P.121 –

Use the BL-700 with the multi-drop link. See the N-400

User’s Manual.

Troubleshooting P.136

PLC link communication setup. P.118

Notice

• No part of this instruction manual may be reprinted or reproduced without the

prior written permission of KEYENCE CORPORATION.

• KEYENCE assumes no responsibility for the contents of this manual. No liability

is assumed for damages resulting from a program created by customers.

• The contents of this manual are subject to change without notice.

• “MS”, “Windows” and “Windows95” are registered trademarks of Microsoft,

U.S.A.

• Other company names and product names are registered or nonregistered

trademarks of respective companies.

ix

Contents

Chapter 1 Laser Safety Precautions

1.1 Classification ..........................................................................................2

1.2 Warning Labels ......................................................................................2

1.3 Label Location ........................................................................................3

1.4 Safety Consideration ............................................................................. 4

1.5 Safety Features Provided with the BL-700 Series .............................. 4

Chapter 2 Connection and Installation

2.1 BL-700 connections ............................................................................... 6

2.1.1 Connector pin assignment ........................................................................6

2.1.2 Power supply connections ........................................................................6

2.1.3 Wiring I/O .................................................................................................. 7

2.1.4 RS-232C connection................................................................................. 7

2.2 Connecting BL-U1 and wiring ...............................................................8

2.2.1 Connecting the power supply.................................................................... 8

2.2.2 Connecting the BL-700 .............................................................................8

2.2.3 Setting BL-U1 DIP switches...................................................................... 9

2.2.4 Terminals of I/O terminal block and wiring.............................................. 10

2.2.5 Connecting RS-232C .............................................................................. 11

2.2.6 Wiring the RS-422A ................................................................................14

2.3 Wiring the KEYENCE power supply unit BL-U2/N-42 ....................... 16

2.3.1 Connecting the power supply.................................................................. 16

2.3.2 Connecting the BL-700 to BL-U2/N-42 ...................................................16

2.3.3 Terminals of I/O terminal block and connections .................................... 17

2.3.4 Terminal .................................................................................................. 18

2.3.5 Connecting RS-232C (BL-U2) ................................................................ 18

2.3.6 Connecting the N-42 to RS-422A ........................................................... 21

2.4 Installation ............................................................................................ 23

2.4.1 Operating environment precautions........................................................ 23

2.4.2 Installing the BL-700 Series .................................................................... 25

2.4.3 Installing the BL-U1................................................................................. 27

2.4.4 Installing the BL-U2, N-42....................................................................... 27

x

Chapter 3 Functions for Reading Operation

3.1 Read Operation .................................................................................... 30

3.1.1 Scanning method .................................................................................... 30

3.1.2 Data-send mode ..................................................................................... 32

3.2 Read Modes ..........................................................................................33

3.2.1 Single label read mode ...........................................................................33

3.2.2 Multi-label read mode 1 (Multi 1) ............................................................ 33

3.2.3 Multi-label read mode 2 (Multi 2) ............................................................ 34

3.2.4 Multi-label read mode 3 (Multi 3) ............................................................ 35

3.3 Label Orientation Mode........................................................................... 37

3.4 Test Mode ............................................................................................. 38

3.4.1 Reading rate check mode ....................................................................... 38

3.4.2 Tact check mode..................................................................................... 39

3.4.3 Online test mode..................................................................................... 41

3.5 STABILITY LEDs .................................................................................. 42

3.6 Preset Function (Compare with:) .......................................................44

3.6.1 What is the preset function? ................................................................... 44

3.6.2 Wildcard Symbols (“!” and “?”) ...............................................................45

3.7 Additional Information ......................................................................... 46

3.8 Max. Code Length (Designated Digit ) Output Function .................. 48

Chapter 4 Setup Software

4.1 Installing the Setup Software .............................................................. 50

4.1.1 Installing setup software ......................................................................... 50

4.1.2 Installation procedure.............................................................................. 50

4. 2 Setup Software Operating Procedure ................................................ 52

4.2.1 Operating procedure ............................................................................... 52

4.2.2 Description on each setup screen........................................................... 53

4.2.3 Outline of operation................................................................................. 54

4.3 Details of Setup ....................................................................................56

4.3.1 Setup procedure ..................................................................................... 56

4.3.2 Reading/Saving/Printing File................................................................... 69

4.4 Sending/Receiving Settings ................................................................ 73

4.5 Using Monitor .......................................................................................77

4.6 List of Error Messages ........................................................................ 80

4.7 Example of Printing from the Setup Software ................................... 81

xi

Chapter 5 Serial Communication

5.1 Serial Communication ......................................................................... 84

5.2 Details on Data Communication ......................................................... 85

5.3 Command Communication .................................................................88

5.3.1 Setup of Direct Control Commands ........................................................88

5.3.2 Details on Parameter Setting Commands............................................... 92

Chapter 6 PLC Link

6.1 PLC Link ............................................................................................. 104

6.1.1 List of PLCs used for PLC link ..............................................................104

6.1.2 Devices used for PLC link..................................................................... 105

6.2 Setting the BL-700 and PLC .............................................................. 106

6.2.1 Setting the BL-700 series...................................................................... 106

6.2.2 Setting the PLC..................................................................................... 106

6.3 Device Assignment ............................................................................ 109

6.4 PLC Link Error ....................................................................................116

6.5 Communication Time ........................................................................ 117

Appendices

Appendix A Specifications .......................................................................120

Appendix A.1 Specifications ..........................................................................120

Appendix A.2 Reading range characteristics (Typical) .................................. 122

Appendix A.3 Angular characteristics (Typical) .............................................125

Appendix B. BL-U1 Specifications ............................................................126

Appendix C. BL-U2, N-42 Specifications .................................................. 127

Appendix D. Dimensions ...........................................................................128

Appendix E. Example Program for Serial Communication .................... 131

Appendix F. Sample Program for the PLC Link ......................................132

Appendix G. Troubleshooting ................................................................... 135

Appendix H. CODE93 Specifications ........................................................ 137

Appendix I. CODE128 Specifications ...................................................... 138

Appendix J. Checksum Calculation Method ........................................... 139

Appendix K. ASCII Code Table ..................................................................141

Appendix L. Setup Parameter List ............................................................142

Appendix M. Default Setting List ............................................................... 145

Chapter 7 Warranty

Warranty ..................................................................................................147

xii

xiii

Chapter 1

Laser Safety Precautions

1.1 Classification ........................................................................ 2

1.2 Warning Labels ..................................................................... 2

1.3 Label Location ...................................................................... 3

1.4 Safety Consideration ............................................................4

1.5 Safety Features Provided with the BL-700 Series .............4

Chapter 1 Laser Safety Precautions

1

2

1.1 Classification

Model BL-700/701 BL-740/741 BL-780/781

FDA (CDRH) Class II

IEC/EN 60825-1: 1993 + A2: 2001 Class 2

DIN EN 60825-1 2001 Klasse 2

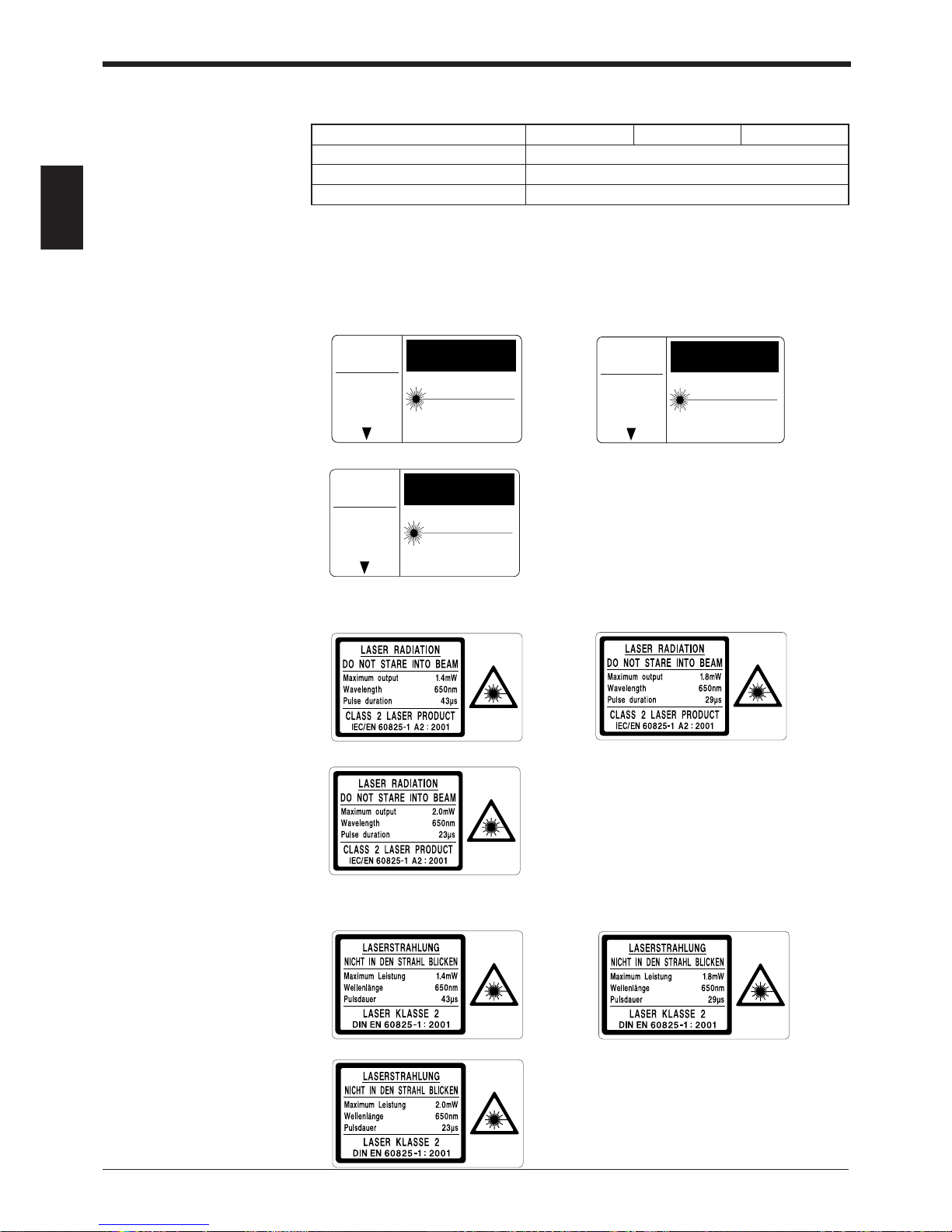

1.2 Warning Labels

1) Warning labels

■ FDA

BL-700/701 BL-740/741

BL-780/781

■ IEC

BL-700/701 BL-740/741

BL-780/781

■ DIN

BL-700/701 BL-740/741

BL-780/781

LASER RADIATIONDO NOT STARE INTO BEAM

SEMICONDUCTOR LASER 650nm

MAXIMUM OUTPUT 1.4mW

PULSED RADIATION 91 µm

CLASS II LASER PRODUCT

CAUTION

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

LASER RADIATIONDO NOT STARE INTO BEAM

SEMICONDUCTOR LASER 650nm

MAXIMUM OUTPUT 2.0mW

PULSED RADIATION 91 µm

CLASS II LASER PRODUCT

CAUTION

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

LASER RADIATIONDO NOT STARE INTO BEAM

SEMICONDUCTOR LASER 650nm

MAXIMUM OUTPUT 1.8mW

PULSED RADIATION 50 µm

CLASS II LASER PRODUCT

CAUTION

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

Chapter 1 Laser Safety Precautions

1

3

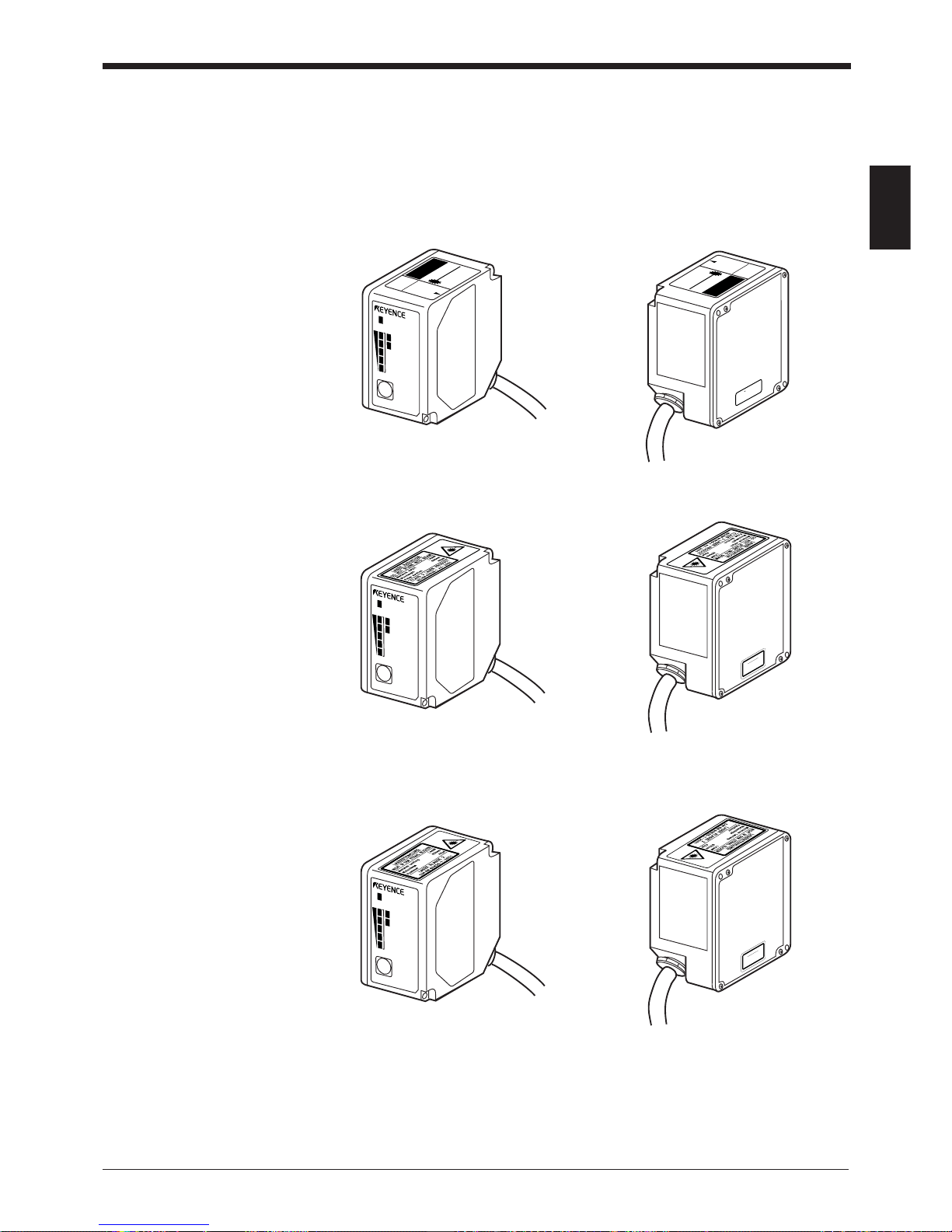

1.3 Labels Location

FDA Warning labels are attached to the sensor head as shown below.

The IEC/DIN Warning labels are packaged with the BL-700 Series. Affix the Warning labels on the sensor head as shown below.

■ FDA

■ IEC

■ DIN

LASER RADIATION-

DO NOT STARE INTO BEAM

SEMICONDUCTOR LASER 650nm

MAXIMUM OUTPUT 1.4mW

PULSED RADIATION 91 µm

CLASS II LASER PRODUCT

CAUTION

AVOID EXPOSURE

LASER RADIATION

IS EM

ITTED FROM

THIS APERTURE.

LASER ON

STB

OK/NG

TIMING

TEST

BL-700

CAUTION LASER RADIATION

WHEN OPEN.

DO NOT

STARE INTO BEAM.

LASER RADIATION-

DO NOT STARE INTO BEAM

SE

M

IC

O

N

D

U

C

T

O

R

LA

S

ER

6

50

nm

M

A

XIM

U

M

O

U

TP

U

T

1.4m

W

P

U

LS

E

D

R

AD

IA

T

IO

N

91

µm

C

LA

SS

II LA

S

E

R

P

R

O

D

U

C

T

CAUTIONCAUTION

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

LASER ON

STB

OK/NG

TIMING

TEST

BL-700

CAUTION

Laser radiation when

open. Do not stare

into beam.

LASER ON

STB

OK/NG

TIMING

TEST

BL-700

VORSICHT

Laserstrahlung wenn

Abdeckung geöffnet.

Nicht in den strahl blicken.

Chapter 1 Laser Safety Precautions

1

4

1.4 Safety Consideration

Use of controls or adjustment or the performance of procedures other than those

specified herein may result in hazardous radiation exposure.

The laser beam is not harmful to the skin. There is, therefore, no danger in exposing arms or hands to the beam. The only possible health hazard is in exposing the

eyes to the laser beam. Damage to the eyes can occur if the operator stares

directly into the beam.

Follow the safety precautions below to ensure operator safety:

• Operate the BL-700 Series only according to the procedures described in

this instruction manual.

Otherwise, injury may occur due to exposure to the laser beam.

• Do not disassemble the sensor head.

Laser emission from the BL-700 Series is not automatically stopped if the

sensor head is disassembled. If you disassemble the sensor head for inspection

or repair, you may be exposed to the laser beam. If the BL-700 Series malfunctions, contact KEYENCE immediately.

• Do not look directly at the laser beam.

Looking directly at the laser beam may result in serious eye injury.

• Protective enclosure

We recommend that you install a protective enclosure around the sensor head

to prevent any person from getting near the sensor head during operation.

• Protective goggles

We recommend that you wear protective goggles when using the BL-700

Series.

• Stop laser emissions before cleaning the laser emission port.

Failure to stop the laser emission may expose eyes or skin to the laser beam.

• Check the laser beam path.

To prevent exposure to the laser beam due to specular or diffuse reflection,

install a screen which offers the appropriate reflectance and temperature

characteristics to interrupt the reflected laser beam. Do not install the BL-700

Series in such a way that the laser beam passes at eye height.

1.5 Safety Features Provided with the BL-700 Series

The BL-700 Series is provided with the following safety features. Make sure these

features function correctly before operating.

• Laser emission caution LED (LASER ON LED)

During laser emission, the LASER ON LED illuminates. The LED ON status can be

checked through the laser protective glasses.

• Laser forced OFF command

Sending the laser forced OFF command (LOCK, see P.92) to the BL-700 can

inhibit emission of laser beams. When working near the laser transmitter, be sure

to use the laser forced OFF command to avoid looking into the laser beams.

When this command is selected, the bottom STABILITY LED flashes.

CAUTION

Chapter 2

Connection and Installation

2.1 BL-700 connections .............................................................. 6

2.1.1 Connector pin assignment .......................................................6

2.1.2 Power supply connections .......................................................6

2.1.3 Wiring I/O ................................................................................. 7

2.1.4 RS-232C connection................................................................ 7

2.2 Connecting BL-U1 and wiring ............................................. 8

2.2.1 Connecting the power supply .................................................. 8

2.2.2 Connecting the BL-700 ............................................................8

2.2.3 Setting BL-U1 DIP switches..................................................... 9

2.2.4 Terminals of I/O terminal block and wiring............................. 10

2.2.5 Connecting RS-232C ............................................................. 11

2.2.6 Wiring the RS-422A ...............................................................14

2.3 Wiring the KEYENCE power supply unit BL-U2/N-42 ...... 16

2.3.1 Connecting the power supply ................................................ 16

2.3.2 Connecting the BL-700 to BL-U2/N-42 ..................................16

2.3.3 Terminals of I/O terminal block and connections ................... 17

2.3.4 Terminal ................................................................................. 18

2.3.5 Connecting RS-232C (BL-U2) ............................................... 18

2.3.6 Connecting the N-42 to RS-422A .......................................... 21

2.4 Installation ...........................................................................23

2.4.1 Operating environment precautions....................................... 23

2.4.2 Installing the BL-700 Series ................................................... 25

2.4.3 Installing the BL-U1 ............................................................... 27

2.4.4 Installing the BL-U2, N-42...................................................... 27

Chapter 2 Connection and Installation

2

6

2.1 BL-700 Connections

This section describes connections when a KEYENCE power supply unit is not

used.

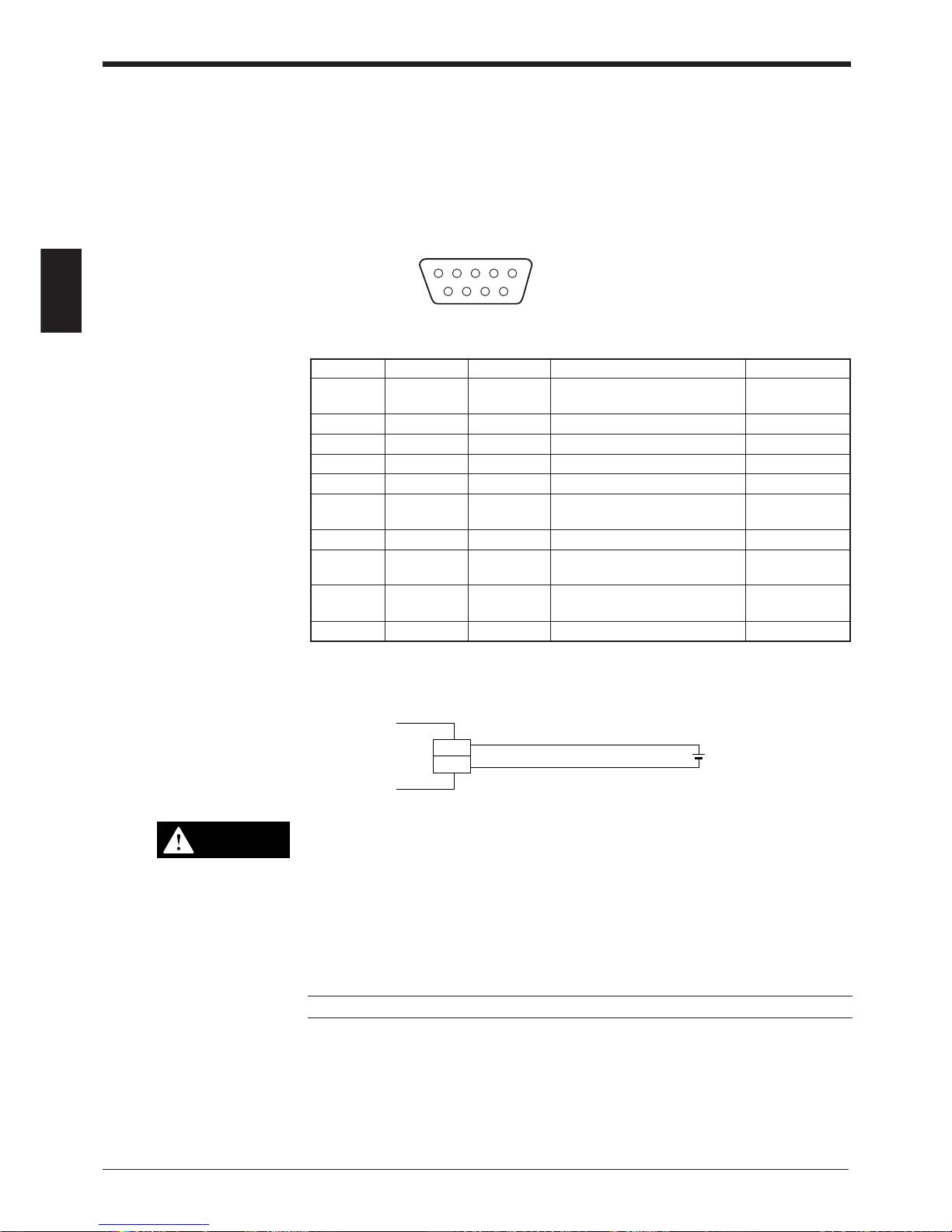

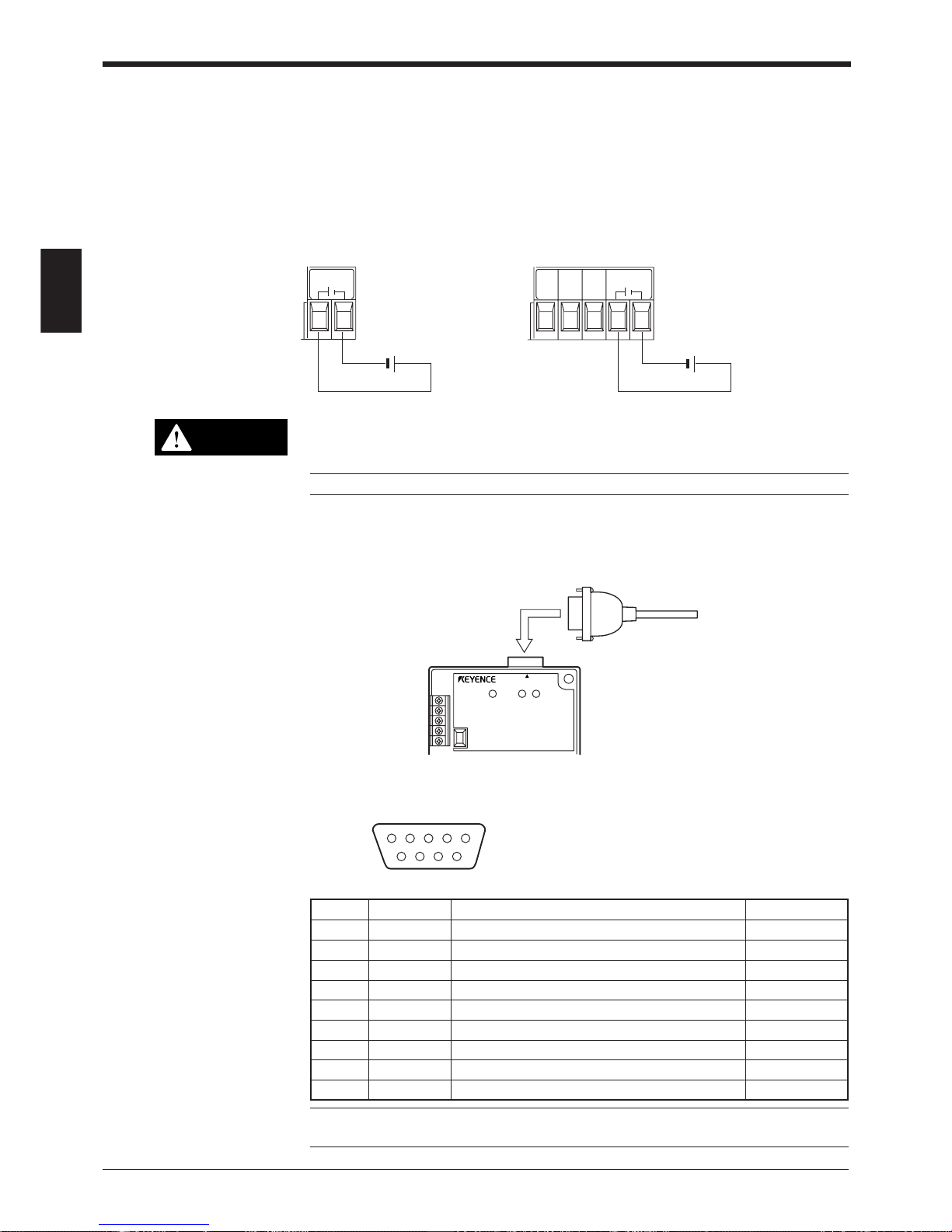

2.1.1 Connector pin assignment

The BL-700 connector has the following pin assignment.

D-sub 9-pin (female)

DTE specification (defined as terminal)

#4-40 screw (male)

12 3 45

6789

2.1.2 Power supply connections

• Be sure to match the polarities of the power supply when soldering the

connections. Reversing the polarities will damage the unit.

• Make sure that the power supply provides a stable 5 VDC ± 5%. If the

power supply does not function in the above range, it can damage the unit.

• Do not extend the power cable. A long power cable can cause a voltage

drop, preventing the BL-700 from starting properly.

Note: If the power supply is UL rated, it must provide Class 2 output.

Pin No. Cable color Symbol Description Signal direction

Connector Shield FG Frame ground —

case

1 Yellow TIM Trigger input Input

2 Brown RD (RXD) Receives RS-232C data Input

3 Purple SD (TXD) Sends RS-232C data Output

4 White OK OK output Output

5 Black GND (SG) Ground (common ground for —

respective signals)

6 Gray NG NG output Output

7 Pink RS (RTS) Request to send RS-232C data Output

(always ON)

8 Blue CS (CTS) Enable to send data through Input

RS-232C

9 Red +5 V +5 V DC power supply Input

5 VDC

BL-700

+5V

9

GND

5

+

CAUTION

Chapter 2 Connection and Installation

2

7

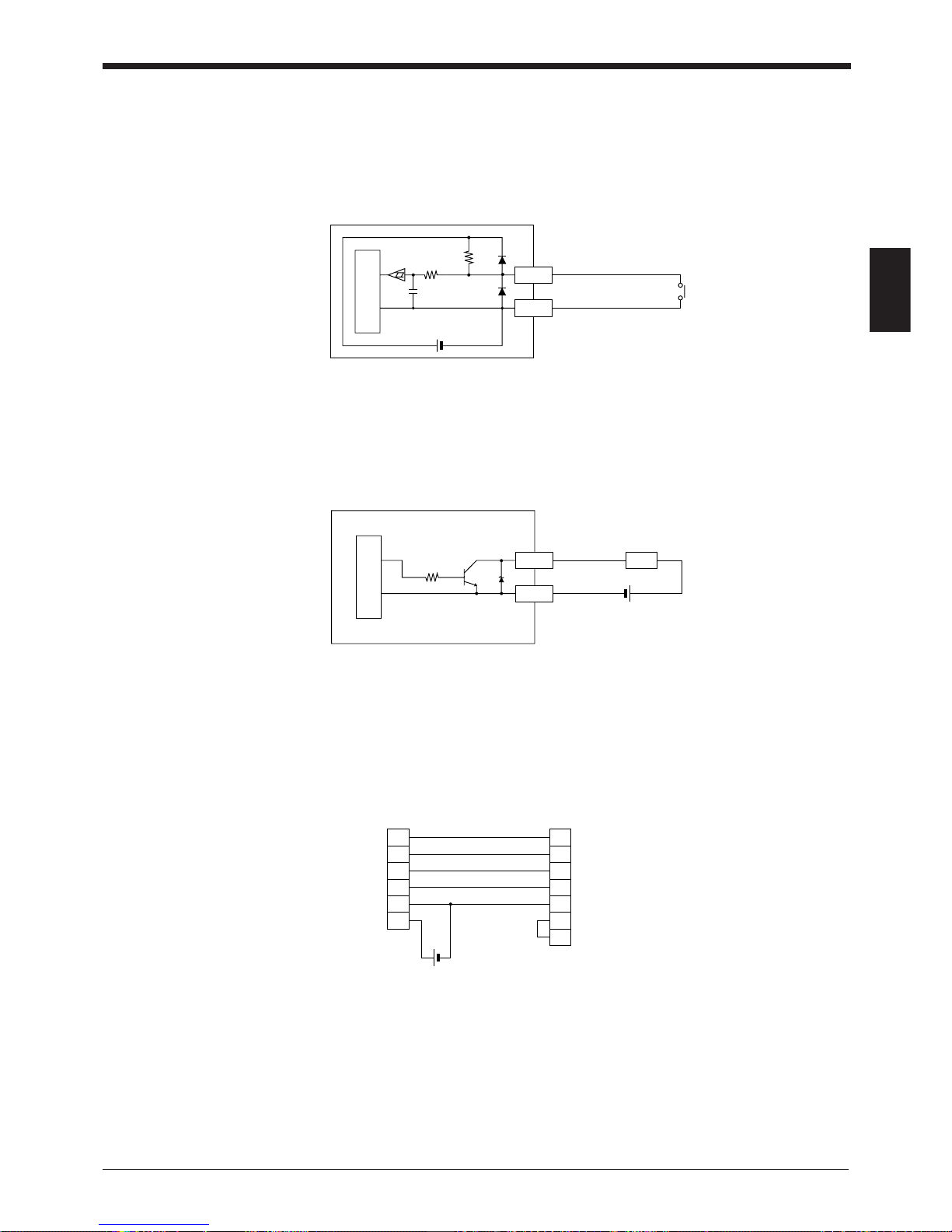

2.1.3 Wiring I/O

■ Trigger input

The trigger input is used to signal the BL-700 to start reading (start laser emission).

The trigger input is a non-voltage input (TTL input is also available with negative

logic).

■ OK/NG output

This output signals whether the readout data is the same as the preset data. When

no preset data has been entered, the signal indicates bar code read status. It is an

NPN open-collector output.

➮

See P. 44

2.1.4 RS-232C connection

Wire the RS-232C as indicated below when connecting the BL-700 to a PC.

■ Connecting the computer with 25-pin

GND

TIM

1

5

5 VDC

10 kΩ

4.7

kΩ

Internal circuit

BL-700

Contact or

solid-state

3

2

8

7

5

9

BL-700

SD

CS

RS

GND

+5V

PC

2

3

4

7

6

5

20

SDRD

RD

RS

CS

SG

DR

ER

D-sub 25-pin (male)

M2.6 screw

D-sub 9-pin (male)

# 4-40 screw

GND

OK/NG

4/6

5

Load

BL-700

10 kΩ

* Rated load: 24 VDC

(30 mA) max.

+

Internal circuit

Chapter 2 Connection and Installation

2

8

2.2 Connecting BL-U1 and Wiring

Note: This product does not comply with EC directives.

To use the BL-U1 AC power supply, connect it as described below.

2.2.1 Connecting the power supply

Plug the BL-U1 power cable into an outlet.

Use a power supply with 100 to 240 VAC ± 10% (50/60 Hz).

2.2.2 Connecting the BL-700

Connect the BL-700 to the READER port of the BL-U1.

The BL-U1 READER port pin assignment is as described below.

■ BL-U1 READER port pin assignment

FG line

CAUTION

Pin No. Symbol Function Signal direction

1 TIM Trigger input Output

2 RD (RXD) Receives RS-232C data. Output

3 SD (TXD) Sends RS-232C data. Input

4OKOK Input

5 GND (SG) Ground (Common ground for respective —

signal)

6NGNG Input

7 RS (RTS) Ready to send RS-232C data. Input

8 CS (CTS) Request to send RS-232C data. Output

(Control method can be selected with the DIP

switches.)

➮

See p. 9.

9 +5 V +5 V power supply Output

D-sub 9-pin (male)

DCE specification (defined as terminal)

#4-40 screw (female)

12 3 45

6789

Note: Do not extend a power cable. A long power cable can cause a voltage drop,

preventing the BL-700 from starting properly.

Note: This product does not comply with EC directives.

Chapter 2 Connection and Installation

2

9

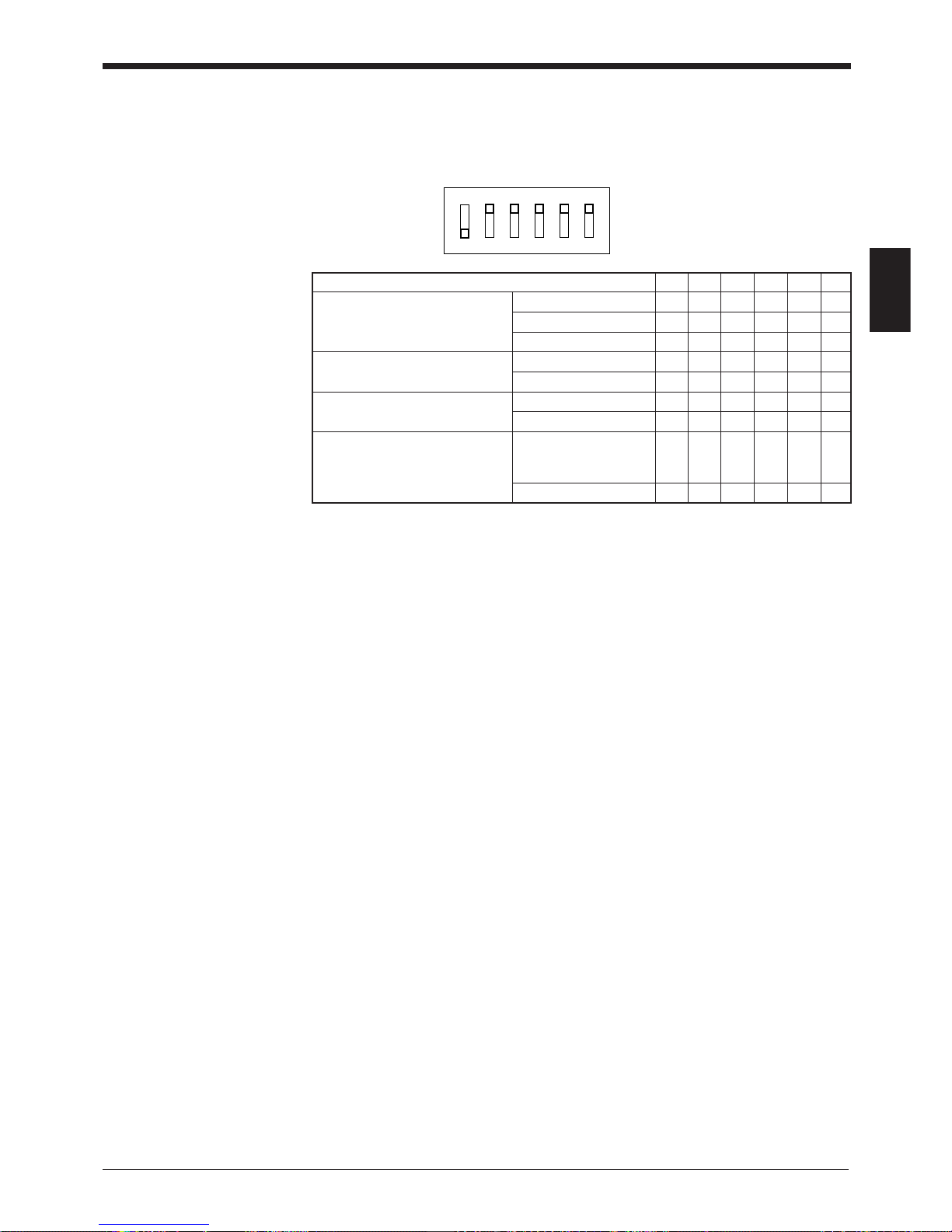

2.2.3 Setting BL-U1 DIP switches

Change the DIP switch settings depending on the selected interface and trigger

input method.

DIP Switch No. 1 2 3 4 5 6

Interface selection RS-232C ON OFF OFF

RS-422A OFF ON OFF

RS-485 multidrop OFF OFF ON

RS-422A terminator OFF OFF

(Termination resistance: 100 ) ON ON

RS-485 terminator OFF OFF

(Termination resistance: 100 ) ON ON

Selection of READER port ON or OFF according

CS control method to the RS-232C port OFF

CS signal status.

Normally ON ON

OFF

ON

123456

* The figure on the left shows the

default settings.

Chapter 2 Connection and Installation

2

10

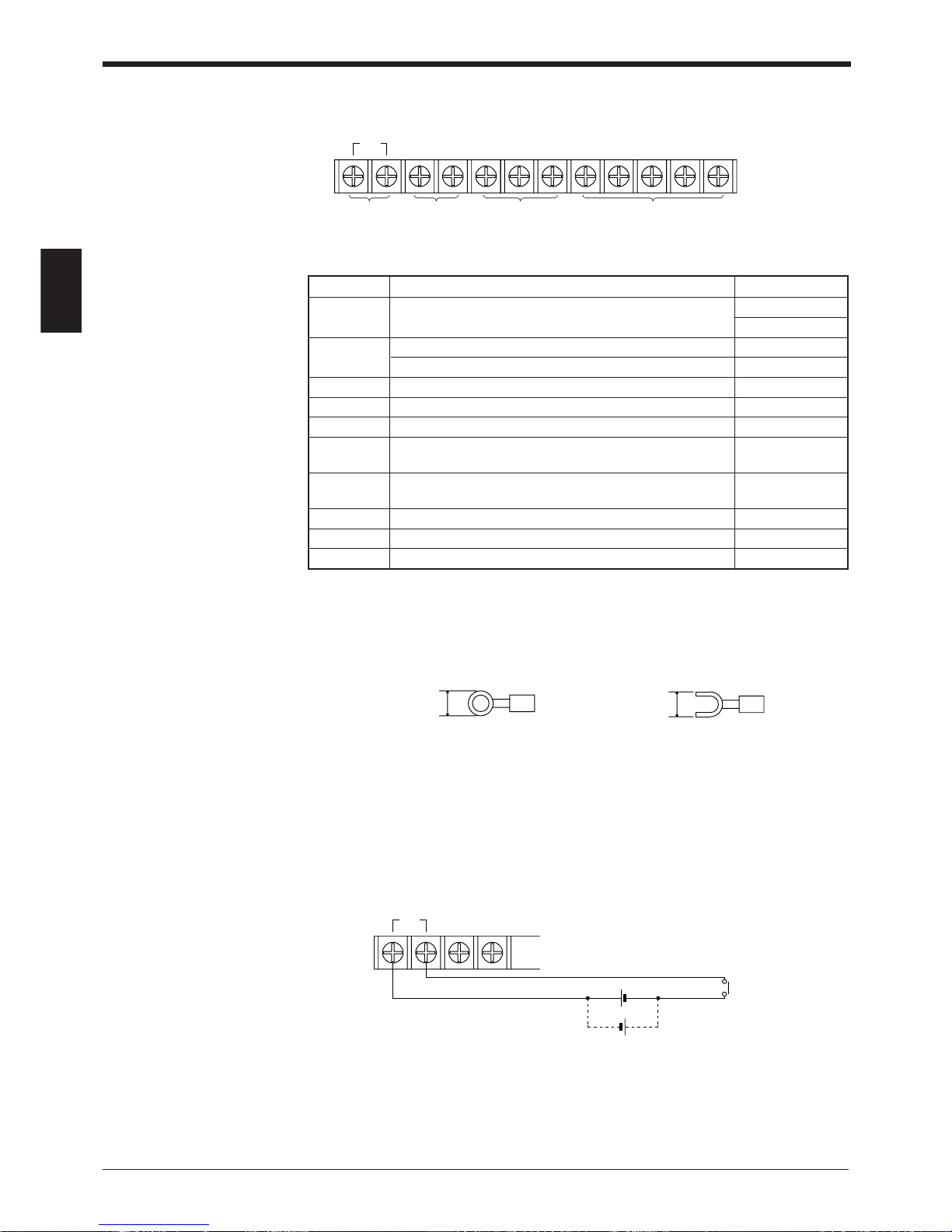

2.2.4 Terminals of I/O terminal block and wiring

* Viewed from the left of the terminal block

• M3.0 screws are used for the terminal block.

• Use the following crimp terminals for connections.

■ Connecting trigger input

The trigger input allows the BL-700 series to start reading bar codes (turn on the

laser beam).

The trigger input is turned ON when 8.5 to 30 VDC input is activated between the

trigger input terminals.

The BL-U1 power supply for the sensor can be used as the input power supply.

Symbol Description Signal direction

TIM Trigger input Input

Input

+12 V OUT- + terminal of power supply for sensor (12 VDC, 300 mA) Output

– terminal of power supply for sensor (0 V) Output

COM Common terminal for OK/NG output —

OK OK output Output

NG NG output Output

SDA + terminal for RS-422A data transmission/ Output,

RS-485 + terminal Input/Output

SDB – terminal for RS-422A data transmission/ Output,

RS-485 - terminal Input/Output

SG Signal ground —

RDA + terminal for RS-422A data reception Input

RDB – terminal for RS-422A data reception Input

TIM +12V OUT– COM OK NG SDA SDB SG RDA RDB

Trigger

input

Power supply

for sensors

(12 VDC, 300 mA)

OK/NG output RS-422A/RS-485

6.0 mm or

less

Round-shape

6.0 mm or

less

Fork-shape

TIM +12V OUT–

8.5 to 30 VDC

+

+

Contact or

solid-state

Chapter 2 Connection and Installation

2

11

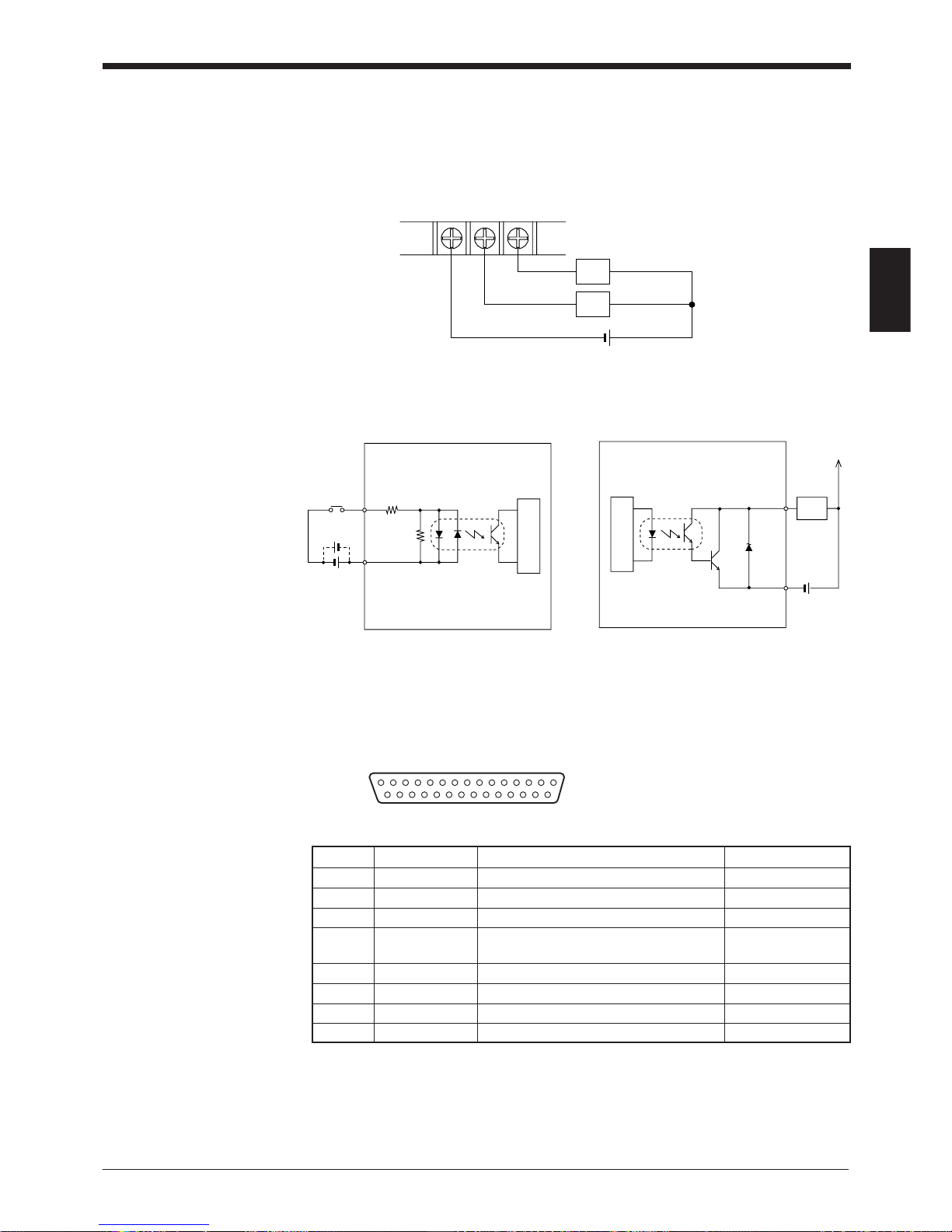

■ Connecting OK/NG output

The OK/NG output is used to differentiate between acceptable and unacceptable

results based on the comparison with the preset data, and to indicate whether or

not the BL-700 series successfully read bar codes.

➮

See P.44.

The OK/NG output is an open-collector output.

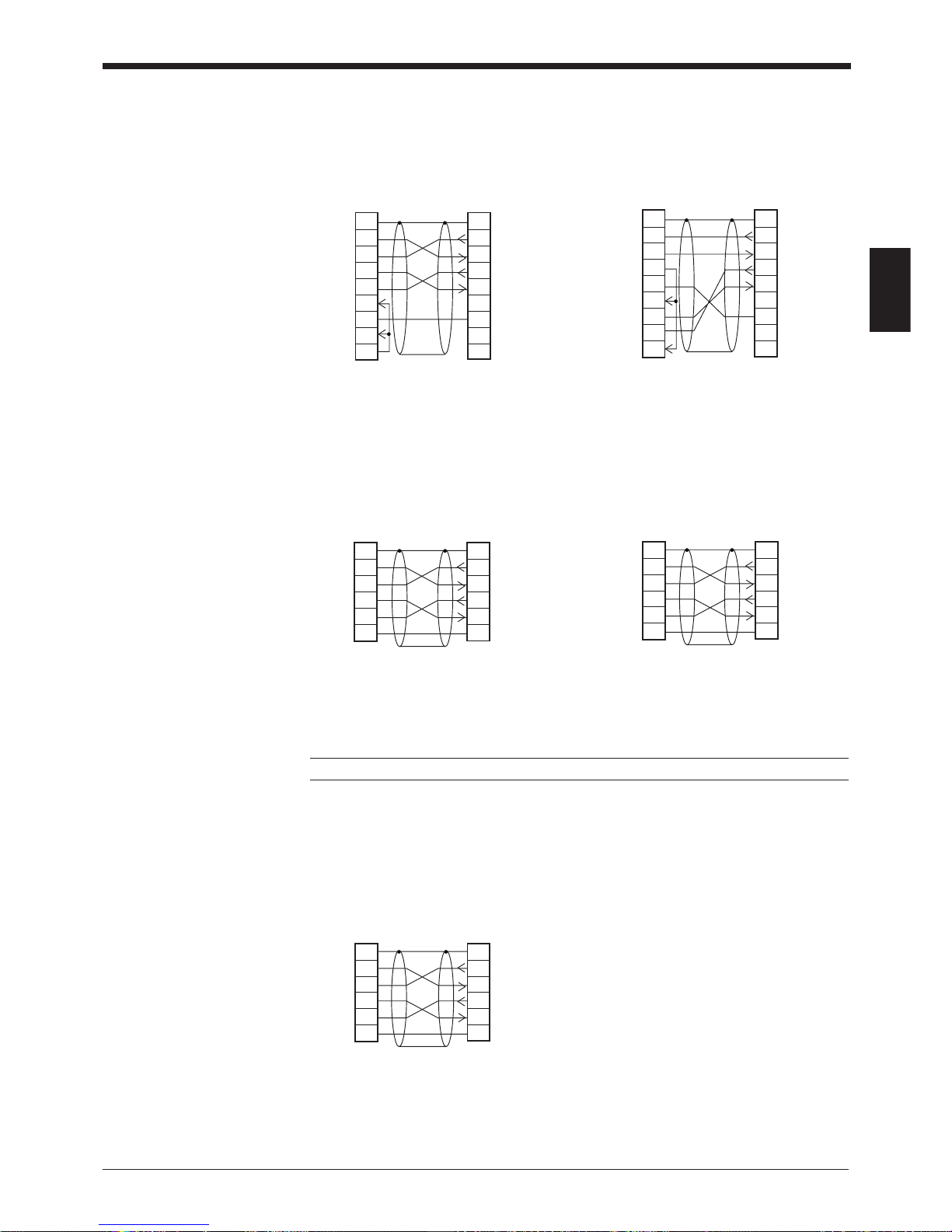

■ I/O circuit diagram

• Input circuit diagram • Output circuit diagram

2.2.5 Connecting RS-232C

Pin assignment

COM OK NG

Load

Load

+

*Rated load: 30 V max. (100 mA)

TIM

2.4

kΩ

3.3 kΩ

Internal circuit

Load

OK/NG

COM

+

Internal circuit

13 1

25 14

D-sub 25-pin (female)

DCE specification (defined as terminal)

M2.6 screw (female)

Pin No. Symbol Function Signal direction

1FG Frame ground —

2 SD (TXD) Sends RS-232C data Output

3 RD (RXD) Receives RS-232C data Input

4 RS (RTS) Ready to send RS-232C data Output

(always ON)

5 CS (CTS) Request to send RS-232C data Input

6 DR (DSR) Connected to pin No. 20 inside. Input

7 GND (SG) Signal ground —

20 ER (DTR) Connected to pin No. 6 inside. Output

Chapter 2 Connection and Installation

2

12

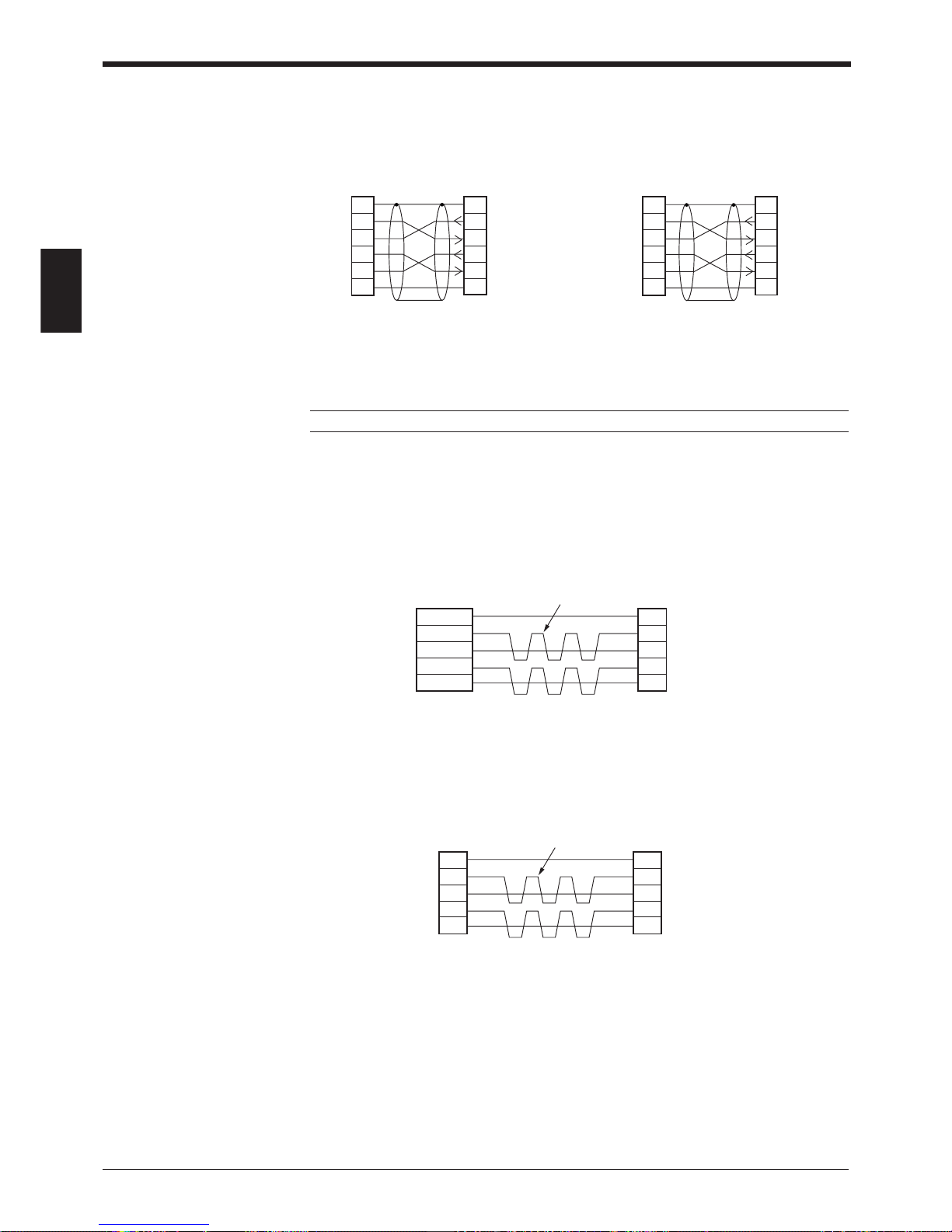

Wiring the RS-232C cable

■ Connecting a PC

25-pin serial port 9-pin serial port

■ Connecting KV series/Handheld programmer port

Use the optional cable manufactured by KEYENCE.

■ Connecting KV-L2*

Port 1 Port 2

2

PC

SD

RD

RS

CS

DR

ER

SG

3

4

5

6

2

11

BL-U1

SD

FGFG

RD

RS

CS

DR

ER

SG

3

4

5

6

20

7

20

7

D-sub 25-pin (male)

M2.6 screw

D-sub 25-pin (male)

M2.6 screw

* KEYENCE option OP-22149 (1.5 m)

or commercially available cross cable

can be used.

* KEYENCE option OP-22149 (1.5 m)

and OP-25057 (conversion connector) can be used.

2

PC

SD

CD

RD

RS

CS

DR

SG

ER

3

4

5

6

2

1

BL-U1

SD

FG

RD

SG

RS

CS

DR

ER

3

4

5

6

7

8

7

8

201

D-sub 25-pin (male)

M2.6 screw

Connector case

D-sub 9-pin (female)

#4-40 screw

OP-96369

BL-U1*

OP-96368 (2.5 m)

KV-10, 16, 24

KV-40, 80

KV-300*

2

KV-L2

SD

RD

RS

CS

DR

ER

SG

3

4

5

6

2

11

BL-U1*

SD

FGFG

RD

RS

CS

DR

ER

SG

3

4

5

6

20

7

20

7

D-sub 25-pin (male)

M2.6 screw

D-sub 25-pin (male)

M2.6 screw

3

KZ-L2

SD

RD

SG

5

2

1

BL-U1*

SD

FG

RD

RS

CS

DR

ER

SG

3

4

5

6

20

71

D-sub 25-pin (male)

M2.6 screw

Terminal block

* KEYENCE option OP-22149 (1.5 m) or

commercially available cross cable can be

used.

Note: KV-300 and BL-U1 are not available in Europe.

Chapter 2 Connection and Installation

2

13

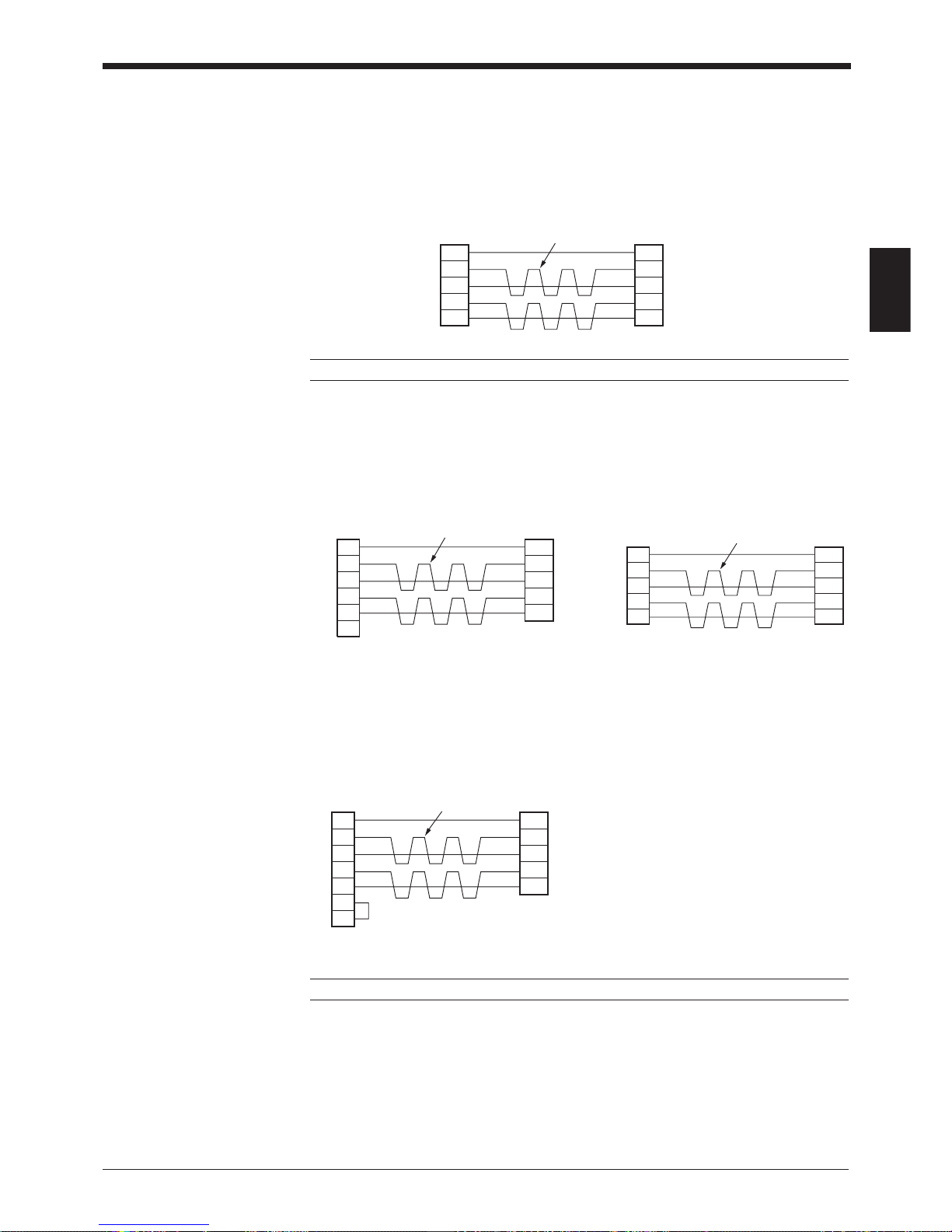

■ Connecting MELSEC-A series

Connection with AJ71C24,

AL71C24-S■■,

A0J2-C214-S1,

AJ71UC24

■ SYSMAC-C series

Connection with C-200H-LK201(-V1),

C-500-LK203,

C-500-LK201-V1,

C120-LK201-V1

Note: KV-L2 and BL-U1 are not available in Europe.

Connection with C-200HS(CPU21/23/31/33),

CQM1(CPU21/41/42/43/44),

C-200HE(CPU42),

C200HG(CPU43/63),

C200HX(CPU44/64),

C200HW-COM02/COM04/COM05/COM06

2

Link unit

SD

RD

RS

CS

DR

SG

ER

3

4

5

6

2

11

BL-U1*

SD

FGFG

RD

RS

CS

DR

SG

ER

3

4

5

6

7

20

7

20

CD

88

D-sub 25-pin (male)

M2.6 screw

D-sub 25-pin (male)

M2.6 screw

2

Link unit

RD

SD

ER

SG

DR

RS

CD

3

4

5

6

2

1–

BL-U1*

SD

FGConnector case

RD

RS

CS

DR

SG

ER

3

4

5

6

7

20

7

1

CS

88

D-sub 25-pin (male)

M2.6 screw

D-sub 9-pin (male)

M2.6 screw

Connection with A1SJ71(U)C24-R2/PRF,

A2CCPUC24,

A2CCPUC24-PRF

Connection with C-20H,

C-28H,

C-40H,

C-60H

* KEYENCE option OP-22149 (1.5 m) or

commercially available cross cable can be

used.

2

Link unit

SD

RD

RS

CS

SG

3

4

5

7

2

11

BL-U1*

SD

FGFG

RD

RS

CS

SG

3

4

5

7

D-sub 25-pin (male)

M2.6 screw

D-sub 25-pin (male)

M2.6 screw

2

PLC

SD

RD

RS

CS

SG

3

4

5

7

2

11

BL-U1*

SD

FGFG

RD

RS

CS

SG

3

4

5

7

D-sub 25-pin (male)

M2.6 screw

D-sub 9-pin (male)

M2.6 screw

2

PLC

SD

RD

RS

CS

SG

3

4

5

9

2

11

BL-U1*

SD

FGFG

RD

RS

CS

SG

3

4

5

7

D-sub 25-pin (male)

M2.6 screw

D-sub 9-pin (male)

M2.6 screw

Chapter 2 Connection and Installation

2

14

■ SYSMAC-CV series

Connection with CV500-LK201

(Port 1)

Note: BL-U1 is not available in Europe.

2.2.6 Wiring the RS-422A

Wire the RS-422A as indicated below.

■ Connecting a general RS-422A unit

Use the same wiring when connecting the BL-U1 to the BL-U1*.

• Turn ON the terminators (BL-U1/external unit terminal resistance: 100 ).

➮

See P.35

.

• The cable can be extended to within 1.2 km.

■ Connecting KV-L2*

Connecting the unit to RS-422A port 2

SDA

SG

BL-U1*

SDB

RDA

RDB

RD + (RDA)

SG

External unit

BL-U1*

RD – (RDB)

SD + (SDA)

SD – (SDB)

Twisted pair cable

SDA

SG

BL-U1*

SDB

RDA

RDB

RDB

SG

Link Unit

RDA

SDB

SDA

Twisted pair cable

Connection with CV500-LK201 (Port 2),

CV500,

CV1000,

CVM1

* KEYENCE option OP-22149 (1.5 m) or

commercially available cross cable can be

used.

2

Link unit

SD

RD

RS

CS

SG

3

4

5

7

2

11

BL-U1*

SD

FGFG

RD

RS

CS

SG

3

4

5

7

D-sub 25-pin (male)

M2.6 screw

D-sub 25-pin (male)

M2.6 screw

2

PLC

SD

RD

RS

CS

SG

3

4

5

9

2

11

BL-U1*

SD

FGFG

RD

RS

CS

SG

3

4

5

7

D-sub 25-pin (male)

M2.6 screw

D-sub 9-pin (male)

M2.6 screw

Chapter 2 Connection and Installation

2

15

■ Connecting the MELSEC-A series

Connecting with AJ71C24,

AJ71C24-S■■,

AJ71UC24,

A0J2-C214-S1,

A1SJ71(U)C24-R4

Note: BL-U1 and KV-L2 are not available in Europe.

■ Connecting SYSMAC-C series

Connecting with C200H-LK202 (-V1), Connecting with C200HW-COM03/

C500-LK201-V1, COM06

C500-LK203,

C120-LK202-V1

■ Connecting SYSMAC-CV series

Connecting with CV-500-LK201,

CV500,

CV1000,

CVM1

Note: BL-U1 is not available in Europe.

SDA

SG

BL-U1*

SDB

RDA

RDB

RDA

SG

Link unit

RDB

SDA

SDB

Twisted pair cable

SDA

SG

BL-U1*

SDB

RDA

RDB

Link unit

1RDB

RDA

SDB

SDA

FG

6

5

9

7

3

SG

D-sub 9-pin (male)

M2.6 screw

Twisted pair cable

SDA

SG

BL-U1*

SDB

RDA

RDB

8RDB

RDA

SDB

SDA

6

2

1

9

SG

D-sub 9-pin (male)

M2.6 screw

Twisted pair cable

Communication

board

SDA

SG

BL-U1*

SDB

RDA

RDB

PLC

8RDB

RDA

SDB

SDA

RS

CS

6

2

1

4

9

SG

5

D-sub 9-pin (male)

M2.6 screw

Twisted pair cable

Chapter 2 Connection and Installation

2

16

24 VDC

+

+–

24V DC IN

24 VDC

+

+–

24V DC IN

N.C. N.C. N.C.

CAUTION

D-sub 9-pin (male)

DCE specification (defined as terminal)

#4-40 screw (female)

12 3 45

6789

POWER SD RD

READER

2.3 Wiring the KEYENCE Power Supply Unit BL-U2/N-42

To use the BL-U2/N-42, connect as indicated below.

2.3.1 Connecting the power supply

Connect BL-U2/N-42 to a 24 VDC power supply.

BL-U2 N-42

Make sure that the power supply provides 24 VDC. If the power supply output

is not 24 VDC, it can damage the unit.

Note: If the power supply is UL rated, it must provide Class 2 output.

2.3.2 Connecting the BL-700 to BL-U2/N-42

Connect the BL-700 to the READER port of the BL-U2/N-42.

■ READER port pin assignment

Note: Do not extend a power cable. A long power cable can cause a voltage drop,

preventing the BL-700 from starting properly.

Pin No. Symbol Function Signal direction

1 TIM Trigger input Output

2 RD (RXD) Receives RS-232C data Output

3 SD (TXD) Sends RS-232C data Input

4OK OK signal Input

5 GND (SG) Ground (Common ground for respective signal) —

6NG NG signal Input

7 RS (RTS) Ready to send RS-232C data Input

8 CS (CTS) Request to send RS-232C data Output

9 +5 V 5 V power supply output Output

Loading...

Loading...